Buderus Logamax Plus GB142-24, Logamax Plus GB142-30, Logamax Plus GB142-45, Logamax Plus GB142-60 Installation Instructions Manual

Installation instructions

CAUTION!

Before putting the boiler into operation read this manual carefully.

WARNING!

Improper installation, adjustment, alteration, service or maintenance can

cause injury, loss of life or property damage. Refer to this manual. For

assistance or additional information consult a qualified installer, service

agency or the gas supplier.

CAUTION!

The operating manual is part of the documentation that is delivered to the

installation's operator. Go through the information in this manual with the

owner/operator and make sure that he or she is familiar with all the necessary operating instructions.

NOTICE!

In the Commonwealth of Massachusetts this boiler must be installed by a

licensed Plumber or Gas Fitter.

– Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other boiler.

– What to do if you smell gas

• Do not try to light any boiler.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

–

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

Warning: If the information in these instructions is not

followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life.

Condensing gas boiler

Logamax plus

GB142-24/30/45/60

For registered installers

Please read thoroughly

before installing servicing

7215 0200 (11/2012) US/CA

Preface

About these instructions

These Installation Instructions contain important information for the safe and professional installation, start-up and

maintenance of the boiler with boiler capacities 24, 30, 45

and 60 kW.

These Installation Instructions are intended for professional installers, who have the necessary training and

experience for working on heating and gas systems.

Subject to technical changes!

Slight changes may be made to the illustrations, process

steps and technical data as a result of our policy of

continuous improvement.

Updating of documentation

Please contact us if you have any suggestions for

improvements or corrections.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!2

1 Safety and general instructions 5

1.1 Designated use 5

1.2 Hazard definitions 5

1.3 The following instructions must be observed 5

1.4 Observe these instructions for space heating

water 6

1.5 Tools, materials and additional equipment 6

1.6 Disposal 6

2 Regulations and guidelines 7

3 Product description 9

4 Dimensions and connections 10

5 Packaging and transportation 12

5.1 Scope of delivery 12

5.2 Transporting the boiler 12

Contents

8.13 Testing the Ignition Safety shut off device 38

8.14 Installing the casing 38

8.15 Informing the owner, handing over the technical

documents 38

9 BC10 basic controller 39

9.1 Operating the BC10 basic controller 39

9.1.1 Switching the heating system on and off 39

9.1.2 Displaying the operating conditions of the burner

and resetting the burner or resetting burner

faults 39

9.1.3 Displaying the heating system status and/or

faults 40

9.2 Carrying out additional tasks 42

9.2.1 Carrying out a flue gas test 42

9.2.2 Selecting partial load operation (e. g. during

flue gas testing) 42

9.2.3 Switching the heating system to manual mode 42

9.3 Configuring the boiler 43

9.3.1 Adjusting the heating capacity 43

9.3.2 Setting the DHW temperature value 44

9.3.3 Entering the space heating water temperature 44

9.3.4 Setting the pump post-purge period 45

6 Installation 13

6.1 Requirements for the installation room 13

6.2 Fitting the boiler 13

6.3 Making the gas connection 14

6.4 Fitting the heating circuit supply and return pipes 15

6.5 Combustion Air and Ventilation Openings 18

6.6 Installation of the flue gas adapter (included in

the scope of delivery) 20

6.7 Installation of the Exhaust and Air Intake system 21

6.8 Conversion to Propane 26

7 Electrical connections 27

7.1 External connection board connections 27

8 Start-up procedure 30

8.1 Testing for gas leaks 31

8.2 Filling the boiler 31

8.3 Filling the condensate trap 32

8.4 Bleeding the gas supply valve 32

8.5 Checking the combustion air/flue gas connection 32

8.6 Checking the orifices 33

8.7 Inlet gas pressure 33

8.8 Checking and adjusting the gas/air ratio 34

8.9 Carrying out a leak test in operating conditions 36

8.10 Measuring the carbon monoxide content (CO) 36

8.11 Function testing 36

8.12 Measuring the ionization current 37

10 Shutting down the system 46

10.1 Shut down the heating system using the

control unit 46

10.2 Shutting down the heating system in the event

of an emergency 46

11 Inspection 47

11.1 Preparing the boiler for inspection 47

11.2 Visual inspection for general signs of corrosion 47

11.3 Internal leak testing 48

11.4 Measuring the ionization current 48

11.5 Measuring the inlet gas pressure 48

11.6 Checking and adjusting the gas/air ratio 48

11.7 Carrying out a gas leak test in operating

conditions 48

11.8 Measuring the carbon monoxide content (CO) 48

11.9 Carrying out a pressure test of the heating

system 48

11.10 Checking the functioning and the safety of

the air intake and flue gas conduit 48

11.11 Checking venting systems 48

12 Maintenance 49

12.1 Cleaning the heat exchanger, burner and

condensate trap 49

12.2 Checking and adjusting the gas/air-ratio 51

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 3

Contents

13 Appendix 52

13.1 Operating messages 52

13.2 Error messages 53

13.3 Technical specifications 54

14 Reports 56

14.1 Start-up report 56

14.2 Inspection report 57

14.3 Maintenance report 58

15 Spare parts 59

16 Index 63

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!4

1 Safety and general instructions

Safety and general instructions 1

Please observe these instructions in the interest of your

own safety.

1.1 Designated use

The boiler was designed for heating water for a central

heating system and generating domestic hot water.

The boiler is delivered with a BC10 basic controller and the

"Universal Automatic Burner Control Unit 3" (UBA 3)

pre-installed.

The boiler can be fitted with a modulating outdoor reset

control AM10 (scope of delivery), a room controller RC10

(optional), or an On/Off thermostat or relay panel end

switch (accessories).

1.2 Hazard definitions

The following defined terms are used throughout the documentation to bring attention to the presence of hazards of

various risk levels. Notices give important information

concerning the operation of the product.

DANGER:

Indicates the presence of hazards that will

cause severe personal injury, death or

substantial property damage.

WARNING:

Indicates the presence of hazards that can

cause severe personal injury, death or

substantial property damage.

CAUTION:

Indicates presence of hazards that will or

cause minor personal injury or property

damage.

CAUTION:

Risk of electric shock.

Indicates presence of hazards due to electric

shock.

NOTICE:

Indicates special instructions on installation,

operation or maintenance that are important

but not related to personal injury or property

damage.

1.3 The following instructions must be

observed

– The boiler must only be used for its designated

purpose, observing the Installation Instructions.

– Only use the boiler in the combinations and with the

accessories and spares listed.

– Other combinations, accessories and consumables

must only be used if they are specifically designed for

the intended application and do not affect the system

performance and the safety requirements.

– Maintenance and repairs must only be carried out by

trained professionals.

– You must report the installation of a condensing gas

boiler to the relevant gas utility company and have it

approved.

– You are only allowed to operate the condensing gas

boiler with the combustion air/flue gas system that has

been specifically designed and approved for this type of

boiler.

– Please note that local permission for the flue system

and the condensate water connection to the public

sewer system may be required.

You must also observe:

– the local building regulations stipulating the installation

rules.

– the local building regulations concerning the air intake

and outlet systems and the chimney connection.

– the regulations for the power supply connection.

– the technical rules laid down by the gas utility company

concerning the connection of the gas burner fitting to

the local gas main.

– the instructions and standards concerning the safety

equipment for the water/space heating system.

– the Installation Instructions for building heating

systems.

– The boiler must be located in an area where leakage of

the tank or connections will not result in damage to the

area adjacent to the boiler or to lower floors of the

structure. When such locations cannot be avoided, it is

recommended that a suitable drain pan, adequately

drained, be installed under the boiler. The pan must not

restrict combustion air flow.

– The boiler must be installed such that the gas ignition

system components are protected from water (dripping,

spraying, rain etc.) during boiler operation and service.

– The boiler must not be installed on carpeting.

– Do not restrict or seal any air intake or outlet openings.

– If you find any defects, you must inform the owner of the

system of the defect and the associated hazard in

writing.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 5

Safety and general instructions1

DANGER

if flammable gas explodes.

Beware if you smell gas: there may be an

explosion hazard!

Warning: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of

this or any other boiler.

What to do if you smell gas

Do not try to light any boiler.

Do not touch any electrical switch; do not

use any phone in your building.

Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

1.4 Observe these instructions for space

heating water

Unsuitable heating system water can promote the formation of scale or sludge, which affects system efficiency.

It can also cause corrosion and reduce life of the heat

exchanger.

– You must follow Buderus guidelines for boiler water

quality.

– Thoroughly flush the system prior to filling.

– Use of a Buderus approved boiler cleaner is

recommended.

– Never use salt bedding exchangers to soften the water.

– Do not use inhibitors or other additives unless approved

by Buderus for that purpose!

– When frost protection of the heating system is desired,

only use Buderus-approved Aluminum-safe antifreeze.

– When using oxygen-permeable pipes, e. g. for floor

heating systems, you must separate the system using

heat exchangers.

– The maximum permissible flow rate of the

GB142-24/30 this is 11 GPM (gal./min.)(= 42 l/min.), for

the GB142-45 is 15 GPM (= 57 l/min.) and for the

GB142-60 is 20 GPM (= 76 l/min.).

1.5 Tools, materials and additional

equipment

For the installation and maintenance of the boiler you will

need the standard tools for space heating, gas and water

fitting.

In addition, a handtruck with a fastening belt is useful.

1.6 Disposal

– Dispose of the boiler packaging in an environmentally

sound manner.

– Dispose of components of the heating system (e. g.

boiler or control device), that must be replaced in an

environmentally responsible manner.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!6

2 Regulations and guidelines

Regulations and guidelines 2

The installation must conform to the requirements of the

authority having jurisdiction or, in the absence of such

requirements, to the latest edition of the National Fuel Gas

Code, ANSI Z223.1. In Canada, installation must be in

accordance with the requirements of CAN/CSA B149.1,

Natural Gas and Propane Installation Code.

Where required by the authority having jurisdiction, the

installation must conform to the Standard for Controls and

Safety Devices for Automatically Fired Boilers, ANSI/

ASME CSD-1.

Install CO detectors per local regulations. Boiler requires

yearly maintenance, see maintenance section see

chapter 12 "Maintenance", page 49.

Operating Limits of the boiler:

Max. boiler temperature: 230 °F (110 °C)

Max. operating pressure: 44

The hot water distribution system must comply with all

applicable codes and regulations. When replacing an

existing boiler, it is important to check the condition of the

entire hot water distribution system to ensure safe operation.

Massachusetts Installations Only:

(a) For all side wall side horizontally vented gas fueled

equipment installed in every dwelling, building or structure

used in whole or in part for residential purposes, including

those owned or operated by the Commonwealth and

where the side wall exhaust vent termination is less than

seven (7) feet above finished grade in the area of the

venting, including but not limited to decks and porches, the

following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS. At the time of installation of the side

wall horizontal vented gas fueled equipment, the

installing plumber or gasfitter shall observe that a hard

wired carbon monoxide detector with an alarm and

battery back-up is installed on the floor level where the

gas equipment is to be installed. In addition, the

installing plumber or gasfitter shall observe that a

battery operated or hard wired carbon monoxide

detector with an alarm is installed on each additional

level of the dwelling, buiding or structure served by the

side wall horizontal vented gas fueled equipment. It

shall be the responsibility of the property owner to

secure the services of qualified licensed proffesionals

for the installation of hard wired carbon monoxide

detectors.

psi (3 bar)

a. In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space

or an attic, the hard wired carbon monoxide

detector with alarm and battery back-up may be

installed on the next adjacent floor level.

b. In the event that the requirements of this

subdivision can not be met at the time of

completion of installation, the owner shall have a

period of thirty (30) days to comply with the above

requirements; provided, however, that during said

thirty (30) day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS.

Each carbon monoxide detector as required in

accordance with the above provisions shall comply

with NPA 720 and be ANSI/UL 2034 listed and

IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall

be permanently mounted to the exterior of the building

at a minimum height of eight (8) feet above grade

directly in line with the exhaust vent terminal for the

horizontally vented gas fueled heating appliance or

equipment. the sign shall read, in print size no less

than one-half (½) inch in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the

side wall horizontally vented gas fueled equipment

shall not approve the installation unless, upon

inspections, the inspector observes carbon monoxide

detectors and signage installed in accordance with the

provisions of 248 CRM 5.08(2)(a)1 through 4.

(b) EXEMPTIONS: The following equipment is exempt

from 248 CRM 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled

“Equipment Not Required To Be Vented” in the

most currect edition of NFPA 54 as adopted by the

board: and

2. Product Approved side wall horizontally vented gas

fueled equipment installed in a room or structure

separate from the dwelling, building or structure

used in whole or in part for residential puposes.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 7

Regulations and guidelines2

(c) MANUFACTURERS REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM REQUIRED.

When the manufacturer of Product Approved side wall horizontally mounted gas equipment provides a venting system

design or venting system components with the equipment,

the instructions provided by the manufacturer for the installation of the equipment and venting shall include:

1. Detailed instructions for the installation of the venting

system or the venting system components: and

2. A complete parts list for the venting system design or

venting system.

(d) MANUFACTURERS REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of Product Approved side wall horizontally vented gas fueled equipment does not provide the

parts for the venting of flue gases, but identifies “special

venting systems”, the following requirements shall be satisfied by the manufacturer:

1. The referenced “special venting systems” shall be

included with the appliance or equipment installation

instructions: and

2. The “special venting systems” shall be Product

Approved by the Board, and the instructions for that

system shall include a parts list and detaild

installation instructions.

(e) A copy of all instructions for all Product Approved side

wall horizontally vented gas fueled equipment, all venting

instructions, all parts lists for venting instructions, and/or

venting design instructions shall remain with the appliance

or equipment at the completion of the installation.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!8

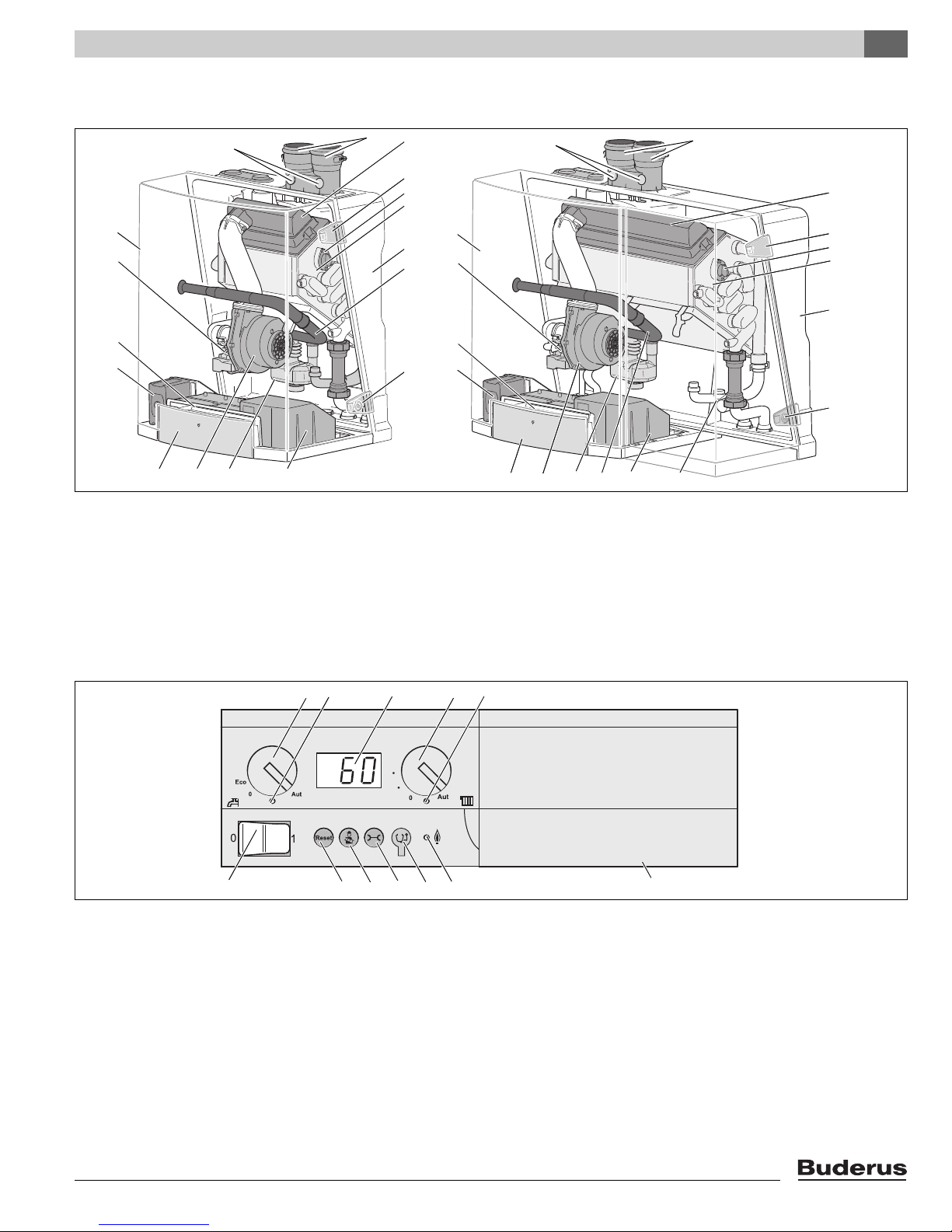

3 Product description

1

2

3

9

11

13

14

9

16

15

5

8

1

4

10

12

13

14

2

3

5

4

6

7

9

11

9

8

10

12

16

15

17

7

6

190

170

150

130

90

110

140

130

120

90

100

110

4

7

2

1

5

812

1011

3 6

9

Product description 3

Fig. 1 Logamax plus GB142-24/30 (left) and GB142-45/60 (right)

pos. 1: Drawer with control unit

2: Universal Burner Automat (UBA3)

3: Control unit BC10

4: Gas valve

5: Cover

6: Flue measuring points

7: Parallel flue

8: Burner

Fig. 2 Basic Controller Logamatic BC10

pos. 1: Main switch

2: DHW temperature knob

3: LED "DHW status"

4: Display

5: Space heating water temperature knob

6: LED "Heating system status"

1) ECO mode means that the temperature inside the hot water tank is 140 °F (60 °C), with a hysteresis (T) of 18 °F (10 °C) instead of 9 °F (5 °C)

1)

7: Under the cover a RC system controller can be installed

8: LED "Burner Operation"

9: Service Tool connector

10: "Service"

11: "Chimney sweep"

12: "Reset"

9: Latches of which two have locks

10: Sighting glass

11: Heat exchanger

12: Back cover

13: Air intake for the fan

14: Fan

15: Condensate trap and internal condensate drain flue gas pipe

16: External Connection Board (under the cover)

17: Pressure sensor

e button

d button

c button

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 9

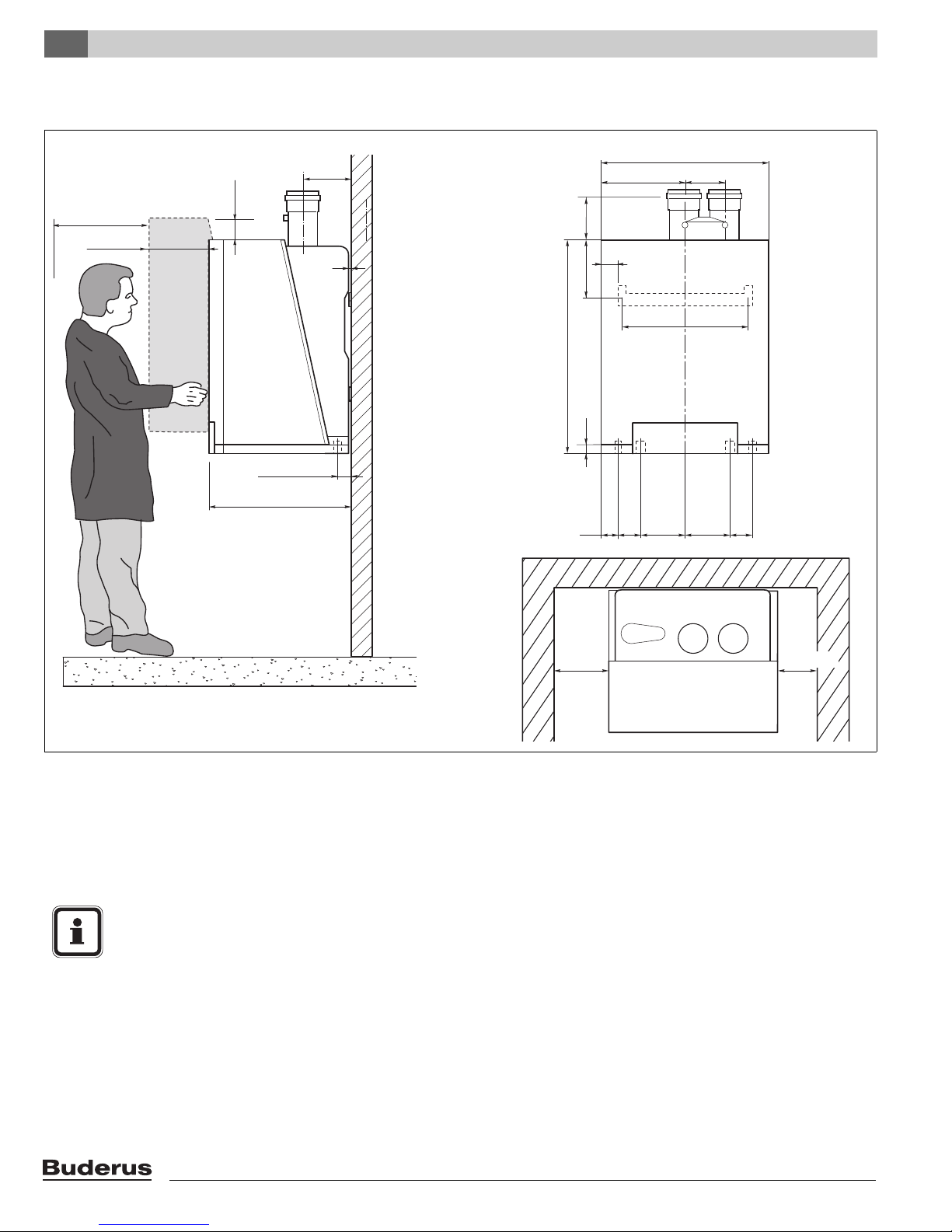

Dimensions and connections4

4" (100 mm)

12" (300 mm)

20" (500 mm)

6.2"

(158 mm)

0.25"

(6 mm)

1.8" (46 mm)

18.7" (475 mm)

> 6"

(150 mm)

2.2" (55 mm)

3" (75 mm)

3" (75 mm)

6" (150 mm)

1.2" (30 mm)

16" (420 mm)

7.5" (190 mm)

28" (712 mm)

5.5" (239 mm)

4.3" (110 mm)13.2" (335 mm)

22" (560 mm)

3" (75 mm)

> 4"

(100 mm)

6" (150 mm)

DE FG

AB

C

4 Dimensions and connections

Fig. 3 Dimensions and connections for boiler GB142-24/30 (dimensions in inches)

Flue gas connection (inside diameter 3'')

AA (A)

AKO (E)

GAS (D)

=

Condensate water outlet, Ø 1.3” (Ø 32 mm) outside

=

diameter

=

Gas connection, ¾” NPT

1

One Ø 1.0” (Ø 25.4 mm) inside x 1'' NPT threaded compression fitting is delivered enclosed with boiler packaging

NOTICE

Observe the lateral minimum distances of the

boiler (12” = 300 mm) and the necessary

distances (24” (600 mm) at the front and

LA (B)

RK (G)

VK (F)

WB (C)

=

=

=

=

Air intake (inside diameter 3'')

Return, Ø 1.0”

Supply, Ø 1.0”

Wall bracket

4” (100 mm) at the top) for removing the casing

and for servicing.

Closet clearances are:

4” (100 mm) to the right, 4” (100 mm) at the top

and 6” (150 mm) to the left.

1

(Ø 25.4 mm)

1

(Ø 25.4 mm)

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!10

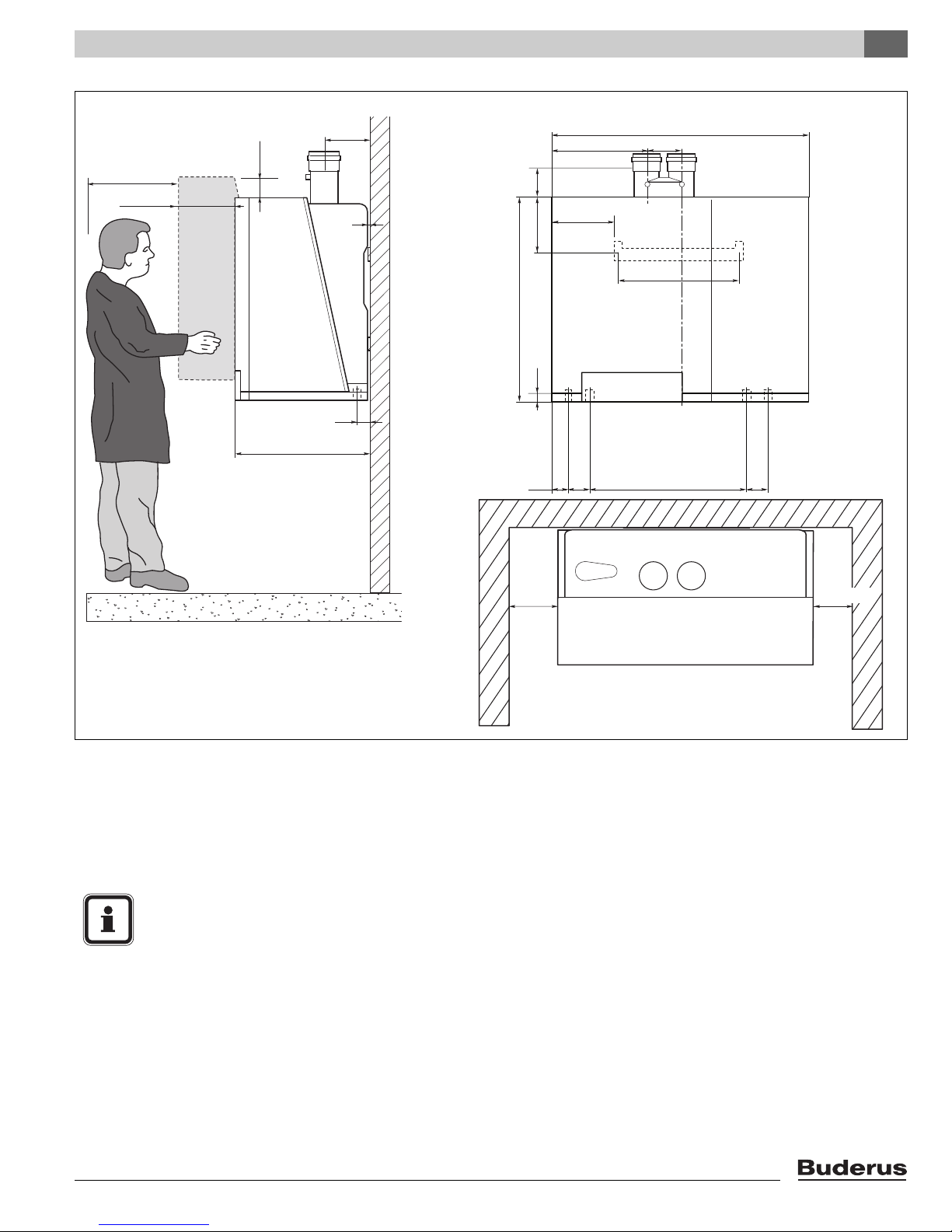

Dimensions and connections 4

20.7" (526 mm)

1.2" (30 mm)

16" (420 mm)

7.5" (190 mm)

28" (712 mm)

5.5" (239 mm)

4.3" (110 mm)

13.2" (335 mm)

35.4" (900 mm)

9.7" (246 mm)

6.2"

(158 mm)

0.25"

(6 mm)

1.8" (46 mm)

18.7" (475 mm)

> 6"

(150 mm)

> 4"

(100 mm)

2.2" (55 mm)

3" (75 mm)

3" (75 mm)

DE F G

AB

C

4" (100 mm)

12" (300 mm)

20" (500 mm)

Fig. 4 Dimensions and connections for boiler GB142-45/60 (dimensions in inches)

Combustion air

AA (A)

AKO (E)

GAS (D)

1

One Ø 1.0” (Ø 25.4 mm) inside x 1'' NPT threaded compression fitting is delivered enclosed.

=

Condensate water outlet, Ø 1.3” (Ø 32 mm)

=

Gas connection, ¾” NPT

=

LA (B)

RK (G)

VK (F)

WB (C)

=

=

=

=

NOTICE

Observe the lateral minimum distances of the

boiler (12” = 300 mm) and the necessary

distances (24” (600 mm) at the front and

4” (100 mm) at the top) for removing the casing

and for servicing.

Closet clearances are:

4” (100 mm) to the right, 4” (100 mm) at the top

and 6” (150 mm) to the left.

Air intake

Return, Ø 1.0”

Supply, Ø 1.0”

Wall bracket

1

(Ø 25.4 mm)

1

(Ø 25.4 mm)

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 11

Packaging and transportation5

1

2

6

8

4

3

7

9

5

5 Packaging and transportation

5.1 Scope of delivery

The boiler is delivered fully assembled.

When receiving the delivery, check if the packaging is

intact.

Check that all the items listed in see table 1 are included

in the delivery.

5.2 Transporting the boiler

CAUTION

The boiler may be damaged when it is improperly secured.

– Only transport the boiler using the right

transportation equipment, such as a

handtruck with a fastening belt or special

equipment for manoeuvering steps.

– During transportation the boiler must be

secured on the transportation equipment to

prevent it from falling off.

– Protect all parts against impacts if they are to

be transported.

– Observe the transportation markings on the

packaging.

Packaged boilers must always be lifted and carried to

their destination by two people, or you must use a

handtruck or special equipment to transport them to their

destination.

Transport the boiler to the room where it is to be installed.

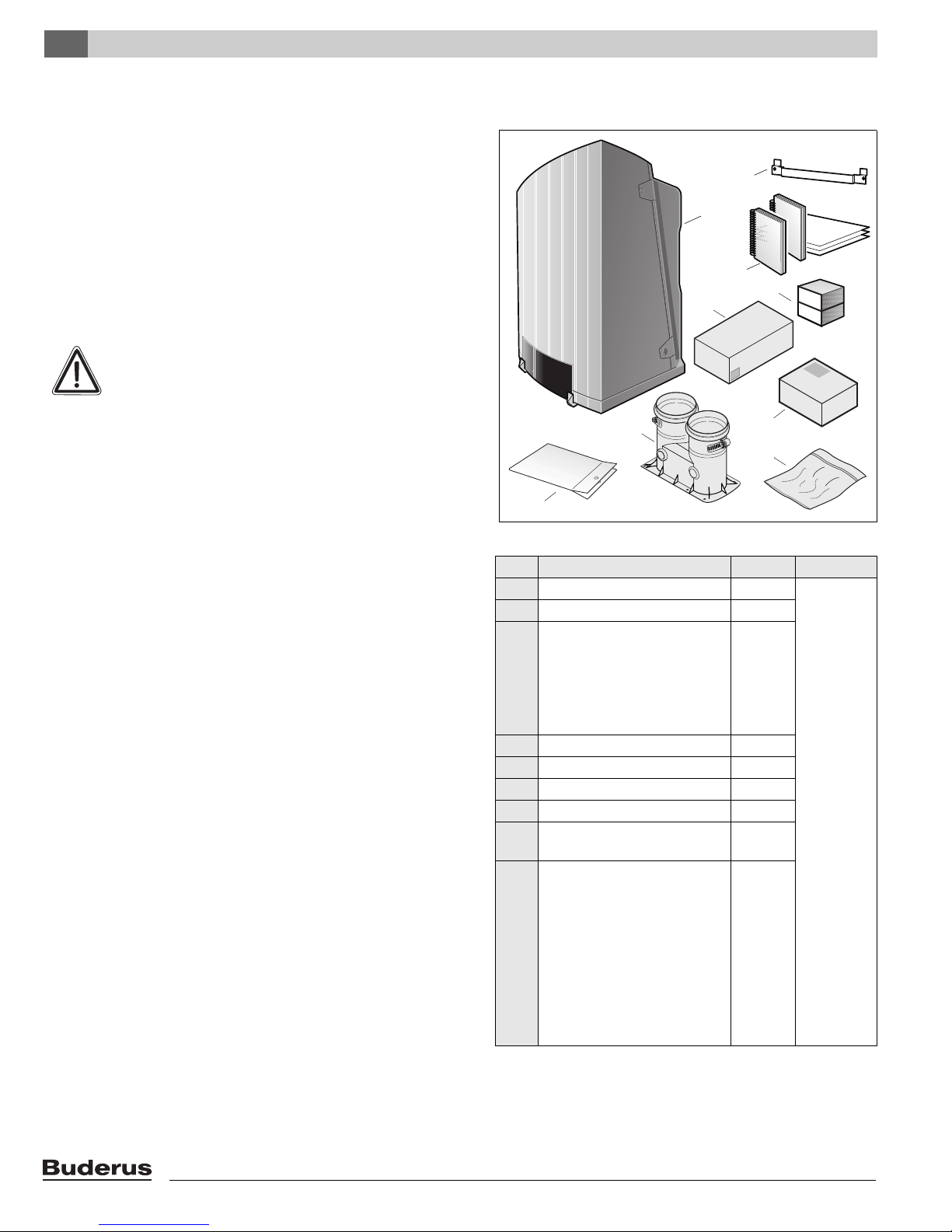

Fig. 5 Items supplied with unit

Pos. Parts Quantity Packaging

1 Boiler with casing 1 1 box

2 Wall bracket 1

3 Technical documents

including:

- User's Instructions

- Installation Instructions

- wall mounting template

- Servicing Instructions

4 Compression fittings 2

5 AM10 with outdoor sensor 1

6 Flue gas adapter 1

7 Propane conversion kit 1

8 Boiler connection kit,

including the DHW sensor

9 GB142 Boiler manifold

including:

- low loss header

- pressure relief valve

- tridicator

- DHW connections

- Grundfos 15-58 3-speed

boiler circulator

- supply and return shutoff ball

valves

Table 1 Items supplied with unit

1

The user’s instructions (in a special format) is located in the boiler

drawer

1

3

1

1

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!12

6 Installation

6.1 Requirements for the installation room

DANGER

– Install the heating system in a frost-free

room.

– Do not store any flammable materials or

liquids in the immediate vicinity of the boiler.

– Never use any chlorinated detergents or

halogenated hydrocarbons (e. g. in

spraycans, solvents and detergents, paints,

adhesives).

– Do not allow too much dust to collect on the

boiler.

6.2 Fitting the boiler

Observe the installation clearances of the combustion air/

flue gas system.

Installation 6

NOTICE

– To protect the connection orifice you must

not remove the styrofoam bottom panel.

– Do not lift the boiler by the drawer.

– Do not remove the transport safety clamps

(see fig. 6) from the drawer at this time.

– Protect the boiler and the combustion

air/flue gas orifice against pollution during

installation.

Remove the packaging materials and dispose of them.

Use the mounting template to mark the drill holes.

Install the wall bracket taking into account the necessary

service clearances.

Remove the transport safety clamps (fig. 6).

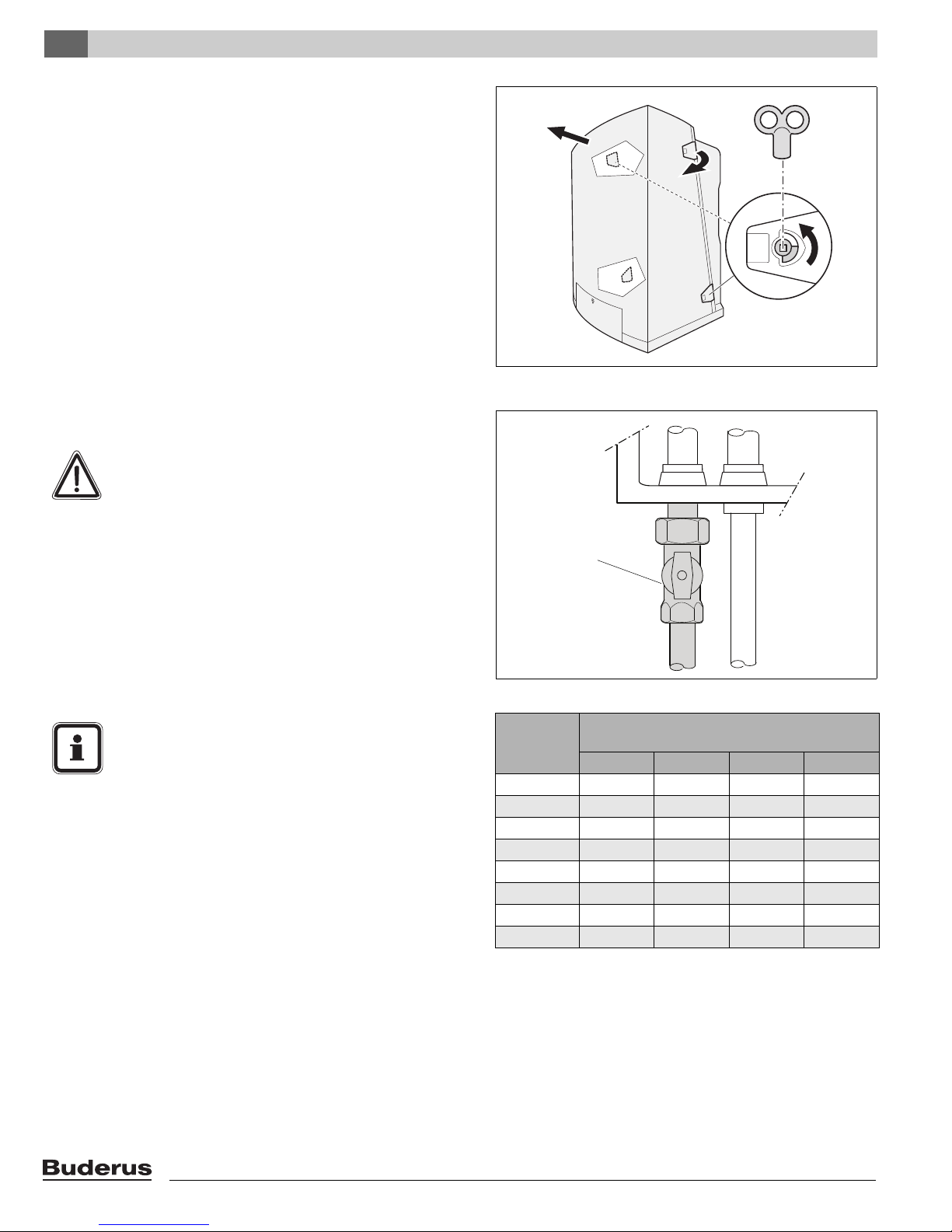

Fig. 6 Removing the transport safety clamps

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 13

Installation6

1

2

2

2

2

3

1

Use the radiator key to unlock the two latches a quarter

turn (fig. 7, pos. 1).

Open the latches (fig. 7, pos. 2).

Remove the casing by lifting it upwards and then pulling

it forwards (fig. 7, pos. 3); do not hold the casing by the

latches.

Hold the boiler by the rear boiler casing and place it on

the wall bracket.

Level out the boiler.

6.3 Making the gas connection

DANGER

Only carry out work on gas lines if you are

licensed for such work.

Fig. 7 Removing the casing

Determine proper size gas pipe for the installation using

see table 2 and see table 3. Do not forget the pipe fitting

losses and observe proper size of the fittings.

Install the furnished ¾” gas cock on the gas connection.

Connect the gas pipe to the gas cock (fig. 8, pos. 1) so

that it is free from any strain.

NOTICE

When installing the gas supply connection, it

must comply with local regulations or, if such

regulations do not exist, with the National Fuel

Gas Code, ANSI Z 223.1.

In Canada, the gas supply connection must

comply with local regulations or, if such regulations do not exist, with CAN/CSA B149.1,

Natural Gas and Propane Installation Code.

A sediment trap must be provided upstream of the gas

controls.

Fig. 8 Making the gas connection

Length of

pipe (feet)

¾" 1" 1 ¼" 1 ½"

10 278 520 1,060 1,600

20 190 350 730 1,100

30 152 285 590 890

40 130 245 500 760

50 115 215 440 670

75 93 175 360 545

100 79 160 305 480

150 64 120 250 380

Table 2 Gas Pipe Capacity for different pipe sizes

1 Maximum pipe capacity in ft3/hr, based on a specific gravity of

.60 (42 mbar) and a inlet gas pressure of 14 inches W.C.

(35 mbar) or less and a pressure drop of .3 inches W.C. (20 mbar)

Gas Volume Capacity

(ft3 / hr)

1

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!14

Installation 6

6.4 Fitting the heating circuit supply and

return pipes

NOTICE

– To protect the entire heating system we

require installing a WYE strainer in the return

circuit. When retrofitting the boiler to an

existing heating system this filter is required.

– Install shut-off valves immediately before and

after the dirt particle filter to allow the filter to

be cleaned.

Steel pipe

diameter

in inches

¾ 2.1 4.1 0.5 1.25

1 2.6 5.2 0.6 1.60

1 ¼ 3.5 6.9 0.8 2.15

1 ½ 4.0 8.0 0.9 2.50

Table 3 Equivalent length for pipe fittings in feet

Equivalent length for Pipe Fittings in feet

Type of pipe fitting

90°-Elbow Tee

(flow thru

branch)

Equivalent length in feet

Gate valve Gas cocks

1

11

3

2

11

4

Fit a filling and drain cock in the heating system supply

pipe if required.

Also fit an adequately sized safety valve in the system

that meets all applicable codes and regulations.

NOTICE

When using oxygen-permeable pipes, e. g. for

radiant floor heating systems, you must separate the system using heat exchangers.

Buderus recommends hydraulically isolating

snowmelt systems using heat exchangers.

Thoroughly flush all pipes and radiators. Use of a

Buderus approved boiler cleaner is recommended.

Refer to the installation template for the pipe connection

dimensions.

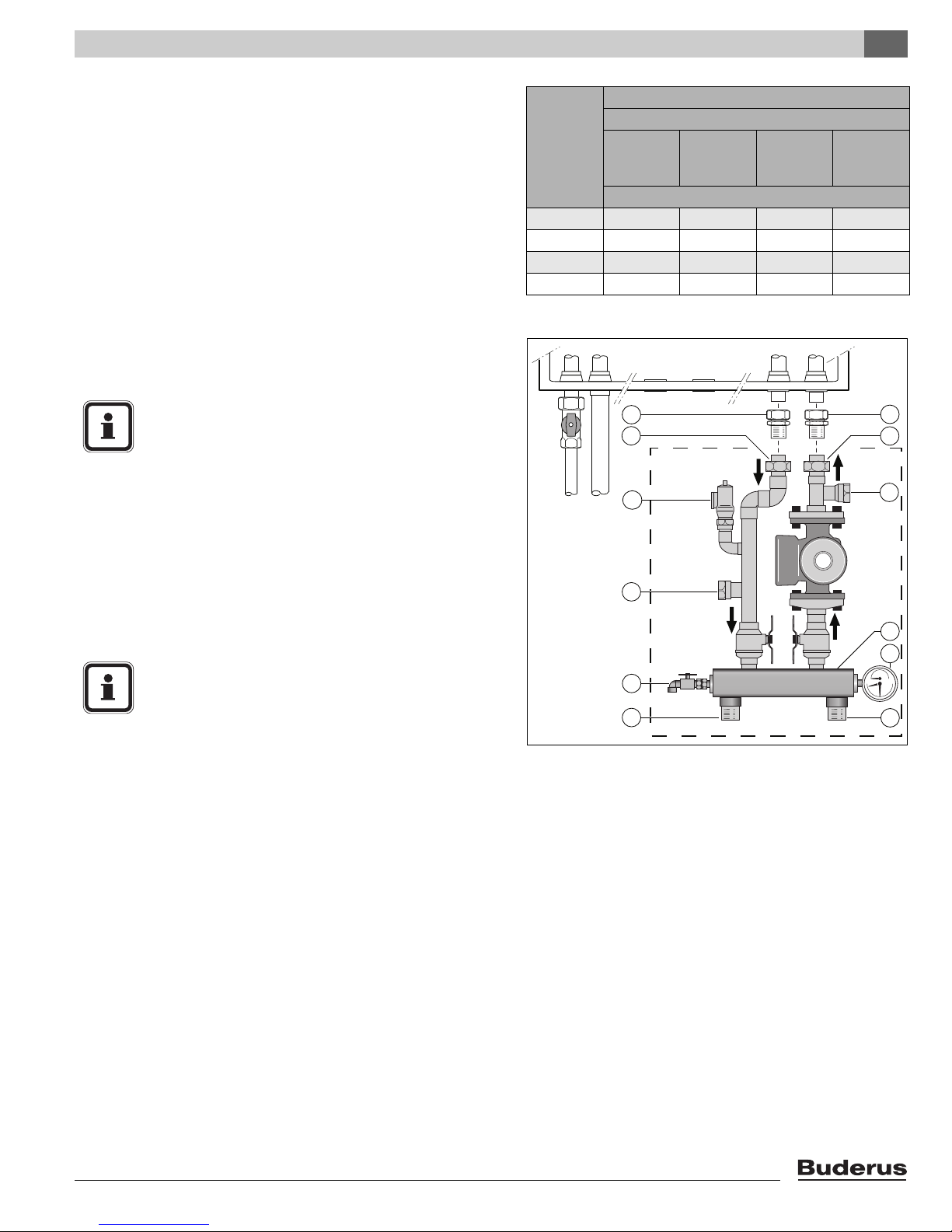

Fit the compression fittings (fig. 9, pos. 1 and 2) first to

the Hydronic set (see fig. 10, 11 and 12) and then to the

boiler.

Connect the expansion tank to the system.

Connect the pipes so that they are free from strain.

Connecting boiler with DHW tank

Connect the external hot-water tank according to the

Installation instructions of the hot-water tank and fittings

concerned.

5

8

9

Fig. 9 Pump manifold installation

pos. 1: Compression fitting (heating system supply pipe)

2: Compression fitting (heating system return pipe)

3: Relief valve

4: DHW return 1“FPT

5: DHW supply 1“FPT

6: Low loss header

7: System return 1½ MPT

8: Drain valve

9: System supply 1½ MPT

10: Tridicator

11: Di electric union

6

10

7

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 15

Installation6

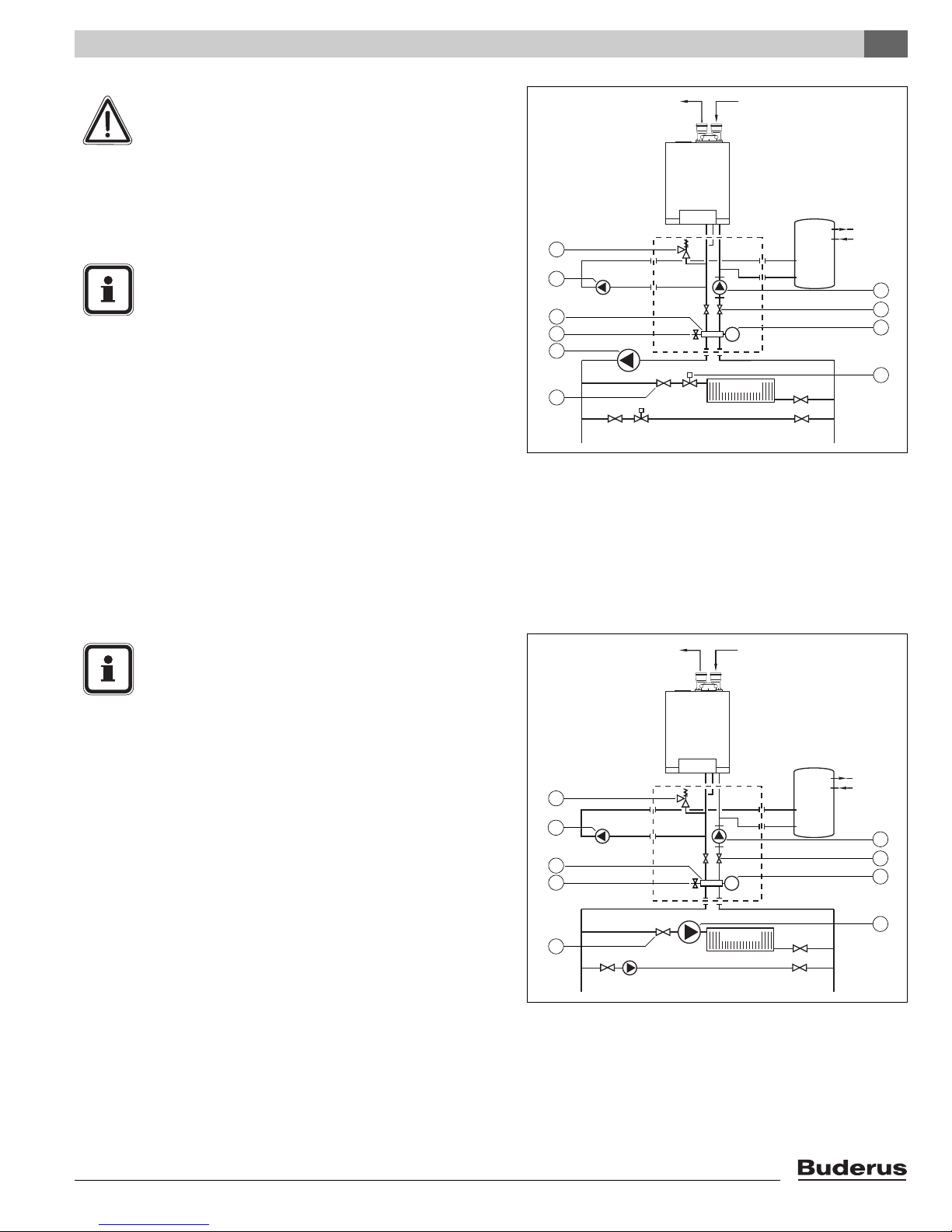

Piping examples

The following illustrations are two Installation examples.

NOTICE

The following illustrations are simplified conceptual illustrations only.

FLUE GAS AIR INTAKE

Piping and field components must be field verified.

A hot water boiler installed above radiation level or as

required by the Authority having jurisdiction, must be

provided with a low water cutoff device either as a part of

the boiler or at the time of boiler installation.

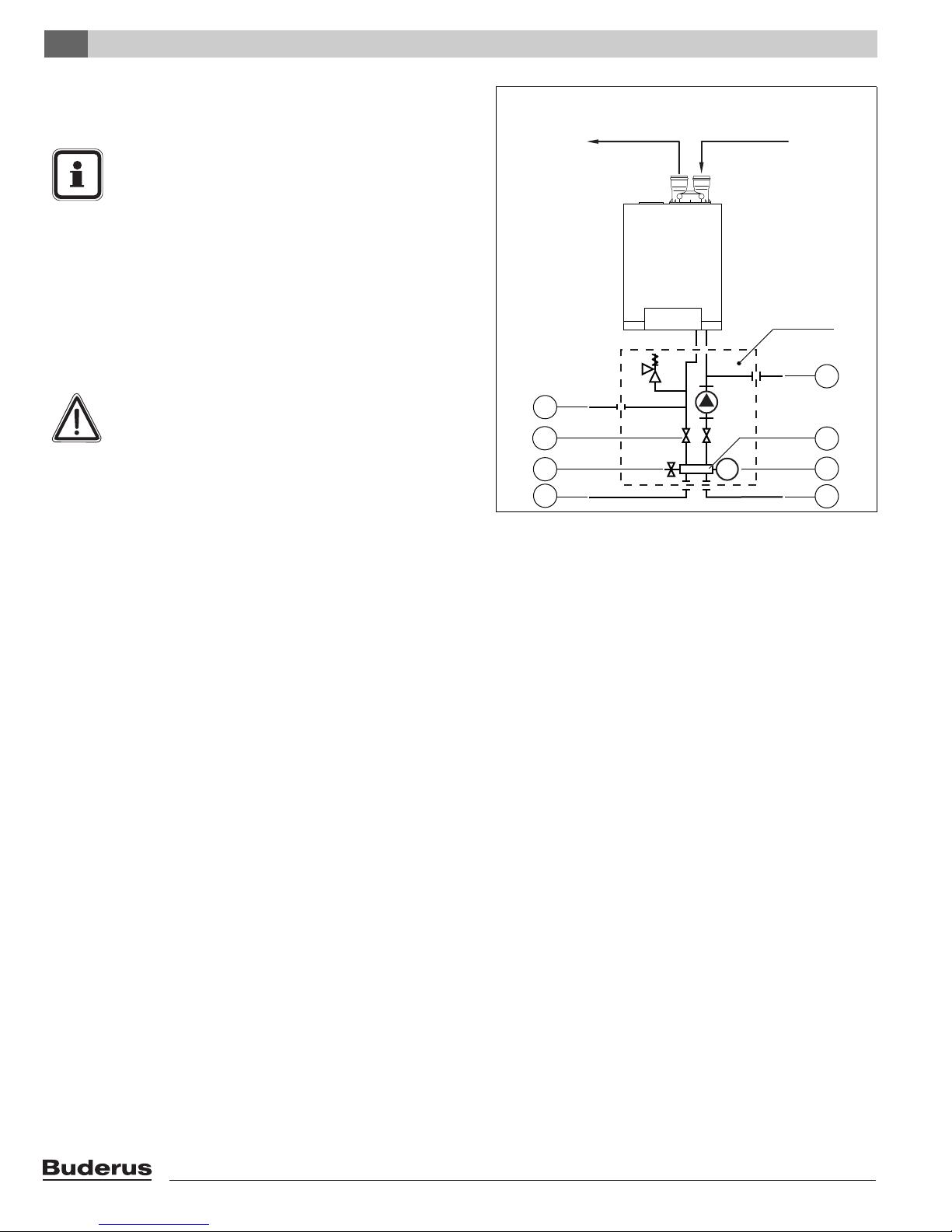

Fig. 10 is a schematic representation of fig. 9.

NOTICE

If this boiler is installed in a closed water supply

system with an external indirect DHW tank,

such as one having a backflow preventer in the

cold water supply line, means shall be provided

to control thermal expansion. Contact the water

supplier or local plumbing inspector on how to

control this situation.

Relief valve

The indirect DHW tank must have a temperature and pressure relief valve installed. The

relief valve shall comply with the Standard for

Relief Valves and Automatic Gas Shutoff

Devices for Hot Water Supply Systems, ANSI

Z21.22-CSA 4.4.

Install the relief valve according fig. 10.

The relief valve must comply with following

specifications:

– dimensions: height 2¼ inch (57.15 mm),

width 2 inch (50.8 mm).

– 30 Psi (2 bar) discharge pressure.

– discharge is ¾ inch (19.1 mm) female in

diameter.

GB142GB142

pump manifold

2

1

3

5

PT

7

Fig. 10 Schematic representation of the boiler with the hydronic set

pos. 1: DHW supply 1“FPT

2: DHW return 1“FPT

3: pump manifold shut-off valve

4: Low loss header

5: drain valve

6: PT gauge (pressure and temperature gauge)

7: System supply 1½ MPT

8: System return 1½ MPT

4

6

8

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!16

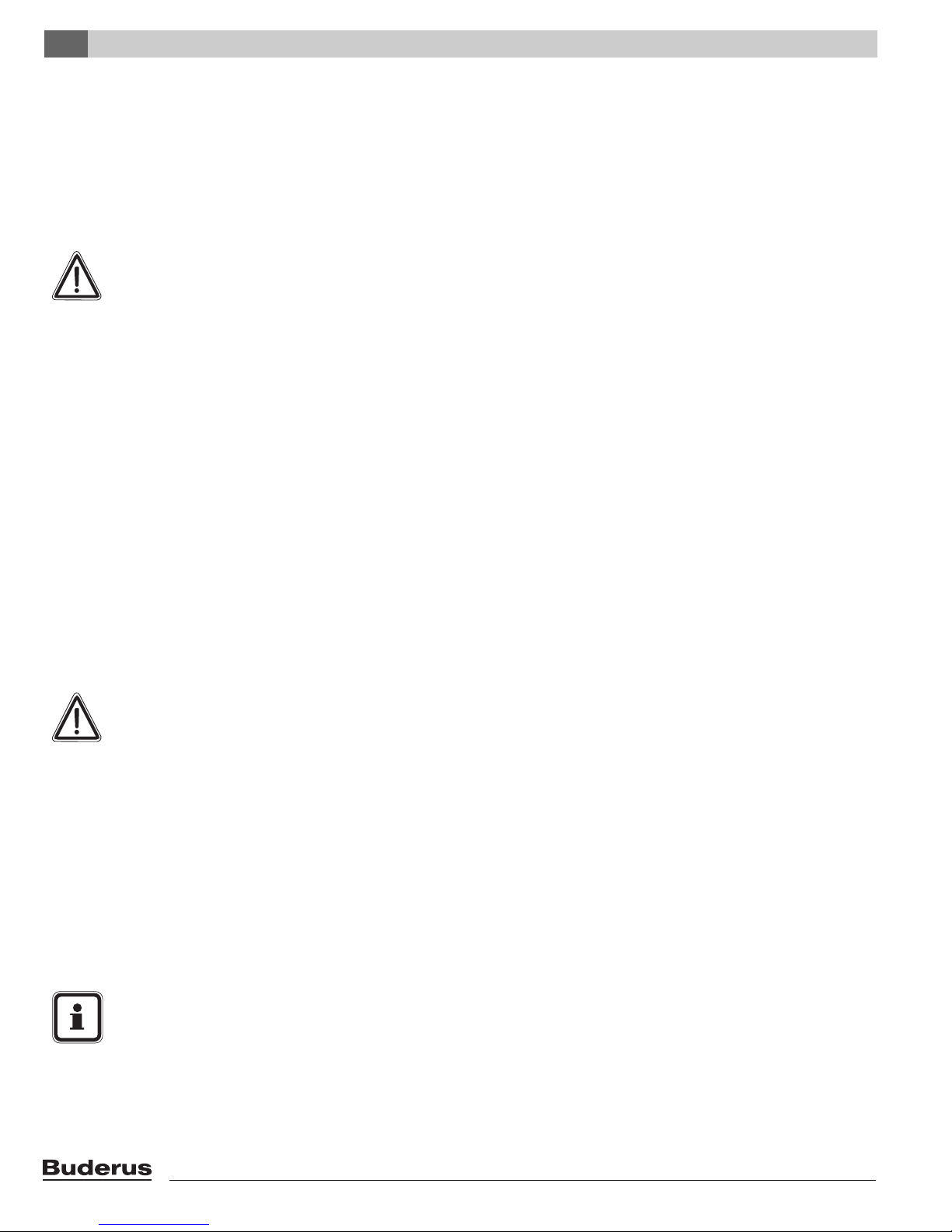

Installation 6

WARNING

No valve is to be placed between the relief valve

and the tank. Discharge of the relief valve must

be conducted to a suitable place for disposal

when relief occurs and no reducing coupling or

other restriction may be installed in the

discharge line.

NOTICE

For the maximum permissible flow rate of the

DHW pump see §1.4 (page 6)

FLUE GAS

GB142GB142

1

3

5

7

AIR INTAKE

PT

Optional

Additional

DHW

DHW

Tank

Tank

2

4

6

9

8

10

zones

Radiant

Aditional zones

Fig. 11 Schematic representation of the boiler with the hydraulic set

connected to an optional hot water tank with one or multiple

zones including one pump and zone valves

1: pressure relief valve

2: primary pump

3: DHW pump

4: Shut-off valve

7: drain valve

8: zone valve

9: secondary pump

10: shut-off valve

5: Low los header

6: PT gauge (pressure and

temperature gauge)

NOTICE

Primary boiler pump must have an internal

check valve.

FLUE GAS

GB142GB142

1

AIR INTAKE

Optional

Additional

DHW

DHW

Tank

Tank

3

5

7

zones

9

Aditional zones

PT

Radiant

Fig. 12 Schematic representation of the boiler with the

Hydronic set connected to an optional hot water tank

with one or multiple zones and zone pumps

1: pressure relief valve

2: primary pump

3: DHW pump

4: shut-off valve

5: Low loss header

6: PT gauge (pressure and

temperature gauge)

7: drain valve

8: zone pump

9: shut-off valve

2

4

6

8

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 17

Installation6

6.5 Combustion Air and Ventilation

Openings

Provisions for combustion and ventilation air must be made

in accordance with section 5.3, Air for Combustion and

Ventilation, of the National Flue Gas Code, ANSI Z223.1, or

Sections 7.2, 7.3 or 7.4 of CAN/CGA B149, Installation

Codes, or applicable provisions of the local building codes.

CAUTION:

BOILER DAMAGE AND OPERATIONAL

FAILURES !

Due to insufficient or lacking openings for

combustion air and/or ventilation of the boiler

room.

Provisions for combustion air and ventilation are

always required, regardless whether the

combustion air is taken from the outside (sealed

combustion) or inside (non sealed combustion

for combustion).

Insufficient ventilation of the boiler room can

lead to high air temperatures. This can result in

boiler damage.

– Make sure that intake and exhaust openings

are sufficiently sized and no reduction or

closure of openings takes place.

– When the problem is not resolved, do not

operate the boiler.

– Please note these restrictions and its

dangers to the operator of the boiler.

WARNING:

BOILER DAMAGE !

due to contaminated air.

– Boiler must be clear and free from

combustible materials, gasoline and other

flammable vapors and liquids, and corrosive

liquids and vapors.

Never use chlorine and hydrocarbon

containing chemicals (such as spray

chemicals, solution and cleaning agents,

paints, glues etc) in the vicinity of the boiler.

– Do not store and use these chemicals in the

boiler room.

– Avoid excessive dust formation and build-up.

NOTICE

When one expects contaminated combustion

air (near swimming pools, chemical cleaning

operations and hair salons), sealed combustion

operation is recommended.

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!18

DANGER:

FIRE DANGER !

due to flammable materials or liquids.

– Do not store flammable materials and liquids

in the immediate vicinity of the boiler.

All Air from Inside the Building (non sealed combustion)

The closet shall be provided with two permanent openings

communicating directly with an additional room(s). The total

input of all gas utilization equipment installed in the

combined space shall be considered in making this determination. Each opening shall have a minimum free area of

1 square inch per 1,000 Btu per hour of total input rating of

all gas utilization equipment in the confined space, but no

less than 100 square inches. One opening shall commence

within 12 inches (305 mm) of the top, and one opening shall

commence within 12 inches (305 mm) of the bottom of the

enclosure. The minimum dimension of air openings shall be

not less than 3 inches (75 mm).

1. Where directly communicating with the outdoors, each

opening shall have a minimum free area of 1 square

inch per 4,000 Btu/hr of total input rating of all

equipment in the enclosure.

2. Where communicating with the outdoors through

vertical ducts, each opening shall have a minimum free

area of 1 square inch per 4,000 Btu/hr of total input

rating of all equipment in the enclosure.

3. Where communicating with the outdoors through

horizontal ducts, each opening shall have a minimum

free area of 1 square inch per 2,000 Btu/hr of total input

rating of all equipment in the enclosure.

4. Where ducts are used, they shall be of the same crosssectional area as the free area of the opening to which

they connect.

Installation 6

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications! 19

Installation6

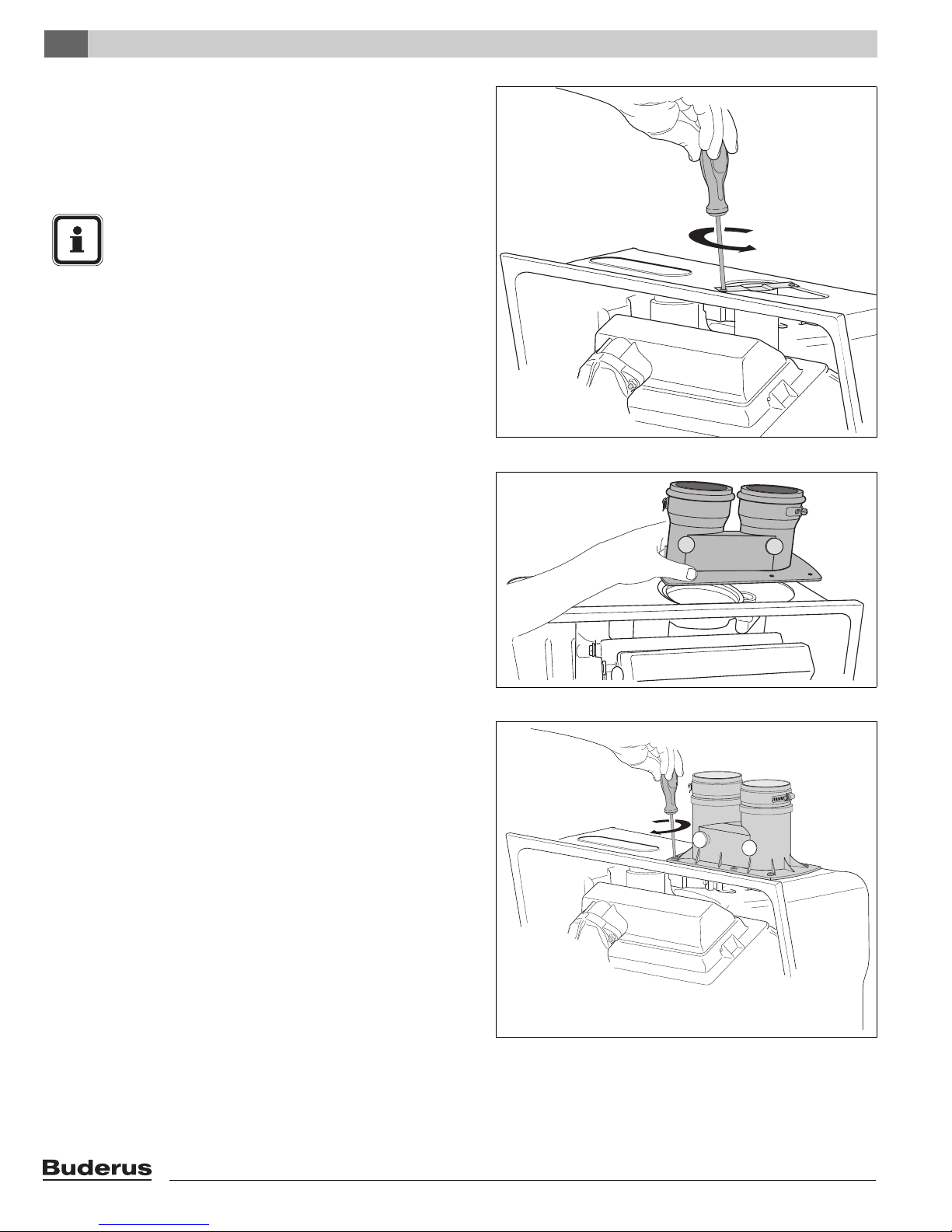

6.6 Installation of the flue gas adapter

(included in the scope of delivery)

Before installing the exhaust and air intake system, it is

necessary to remove the transport safety device and to

install the flue gas adapter.

NOTICE

The transport safety device has been installed

to prevent unwanted movement of the heat

exchanger during transport.

Remove the transport safety device with the two screws

(see fig. 13).

Remove the protective cap from the internal condens

bypass pipe. Place the flue gas adapter and connect the

internal condens bypass pipe (see fig. 14).

Fig. 13 Removing the transport safety device

Screw on the flue gas adapter using six screws (see

fig. 15).

Fig. 14 Placing the flue gas adapter

Fig. 15 Connecting the flue gas adapter

Logamax plus GB142-24/30/45/60 - We reserve the right to make any changes due to technical modifications!20

Loading...

Loading...