Buderus Logamax plus Installation Instructions Manual

Installation instructions

CAUTION!

Before putting the boiler into operation read this manual carefully.

WARNING!

Improper installation, adjustment, alteration, service or maintenance can cause

injury, loss of life or property damage. Refer to this manual. For assistance or additional information consult a qualified installer, service agency or the gas supplier.

CAUTION!

The operating manual is part of the documentation that is delivered to the installation's operator. Go through the information in this manual with the owner/operator

and make sure that he or she is familiar with all the necessary operating instructions.

NOTICE!

In the Commonwealth of Massachusetts this boiler must be installed by a licensed

Plumber or Gas Fitter.

Warning: If the information in these instructions is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

– Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

– What to do if you smell gas

• Do not try to light any boiler.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

– Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

Condensing gas boiler

7 746 800 103 (09/2009) US/CA

Notice:

• This manual is available in the English and French language.

• This manual must be retained for future reference.

Logamax plus

GB162-80 kW/100 kW

For the registered installer

Please read these

instructions carefully

before starting the

operation

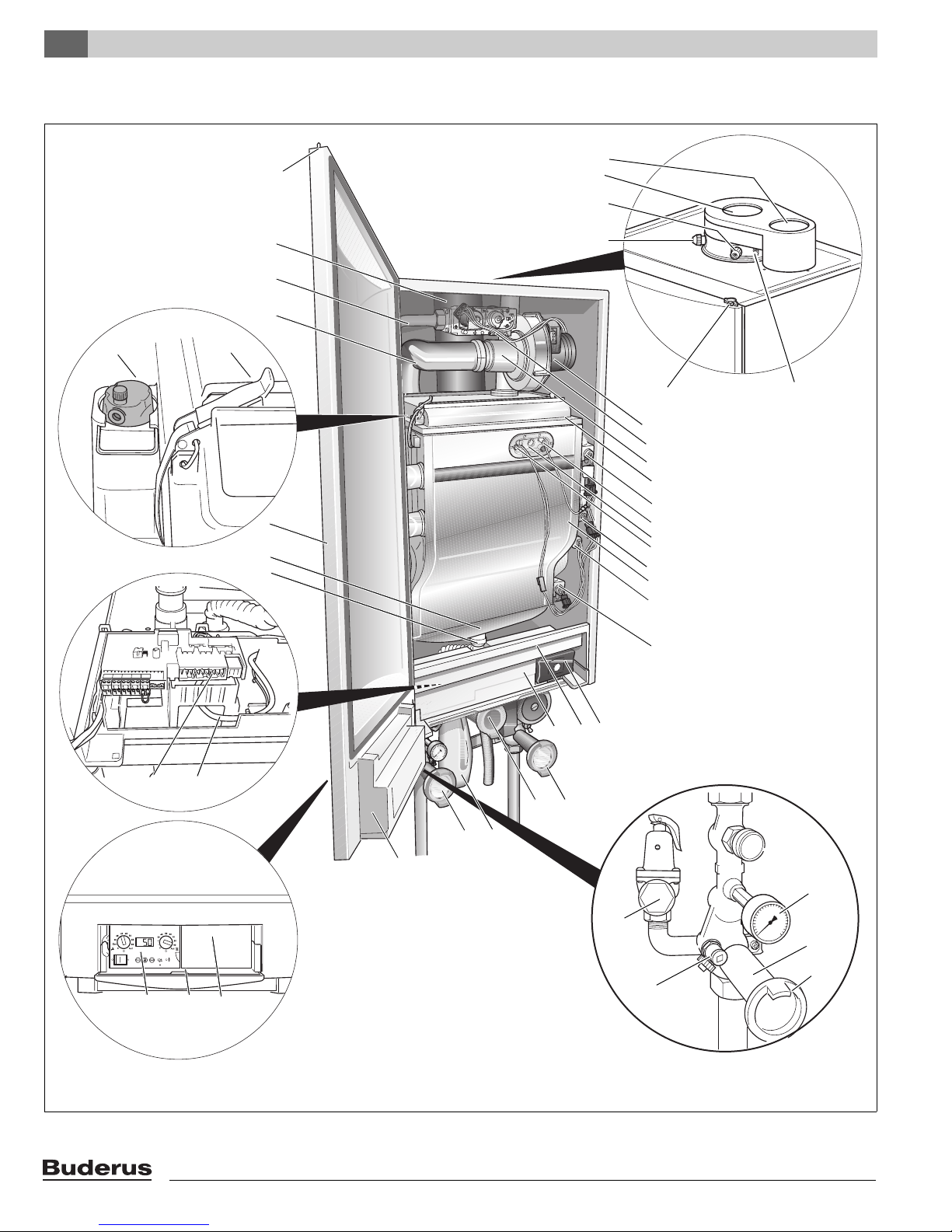

Product description

Product description

15

20

19

18

10

11

14

13

12

8

7

17

15

21

22

23

24

25

269

27

28

29

30

31

32

16

5

6

34 2

Fig. 1 Logamax plus GB162 with pump group

33

34

35

3738

3639

1

40

44

41

42

43

2

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!

Product description

1: BC10 basic controller receptacle

2: Installation option for room controller, e.g. RC35

3: Cover with user manual compartment

4: BC10 basic controller, can be expanded e.g. by the RC35 room controller

5: Connection box (low-voltage and 120 VAC connections)

6: Fan harness and mains lead of the pump

7: Condensate drain outlet

8: Condensate collector

9: Boiler front door

10: Automatic air vent

11: Retaining clips

12: Air intake for the fan

13: Gas pipe

14: Flue gas pipe

15: Door lock

16: Flue gas sensor

17: Flue measuring point

18: Measuring point for air intake

19: Flue gas connection

20: Air intake connection

21: Fan

22: Gas valve

23: Venturi

24: Burner cover

25: Flow temperature sensor

26: Ionization electrode

27: Sighting glass

28: Glow ignitor

29: Safety temperature sensor

30: Heat exchanger

31: Pressure sensor

32: Return temperature sensor

33: Universal Burner Automatic Version 3 (UBA 3)

34: Draw with function module integration options

35: Cover shield

36: Condensate trap

Pump group (scope of delivery):

37: Isolating valve, blue (CH boiler return) with pump, drain cock, check valve and thermometer

38: Manual gas shutoff valve, yellow (GAS)

39: Isolating valve, red (CH boiler flow) with drain cock, pressure gauge and thermometer

40: Pressure gauge

41: Isolating valve

42: Thermometer (optional accessory)

43: Drain valve

44: Safety valve 30 psi (2 bar) (or 50 psi [3.45 bar] = optional)

The pump group also includes an insulation cover (see also pump group installation instructions).

Low loss header (scope of delivery, single appliance only):

45: Low loss header (not illustrated)

3

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!

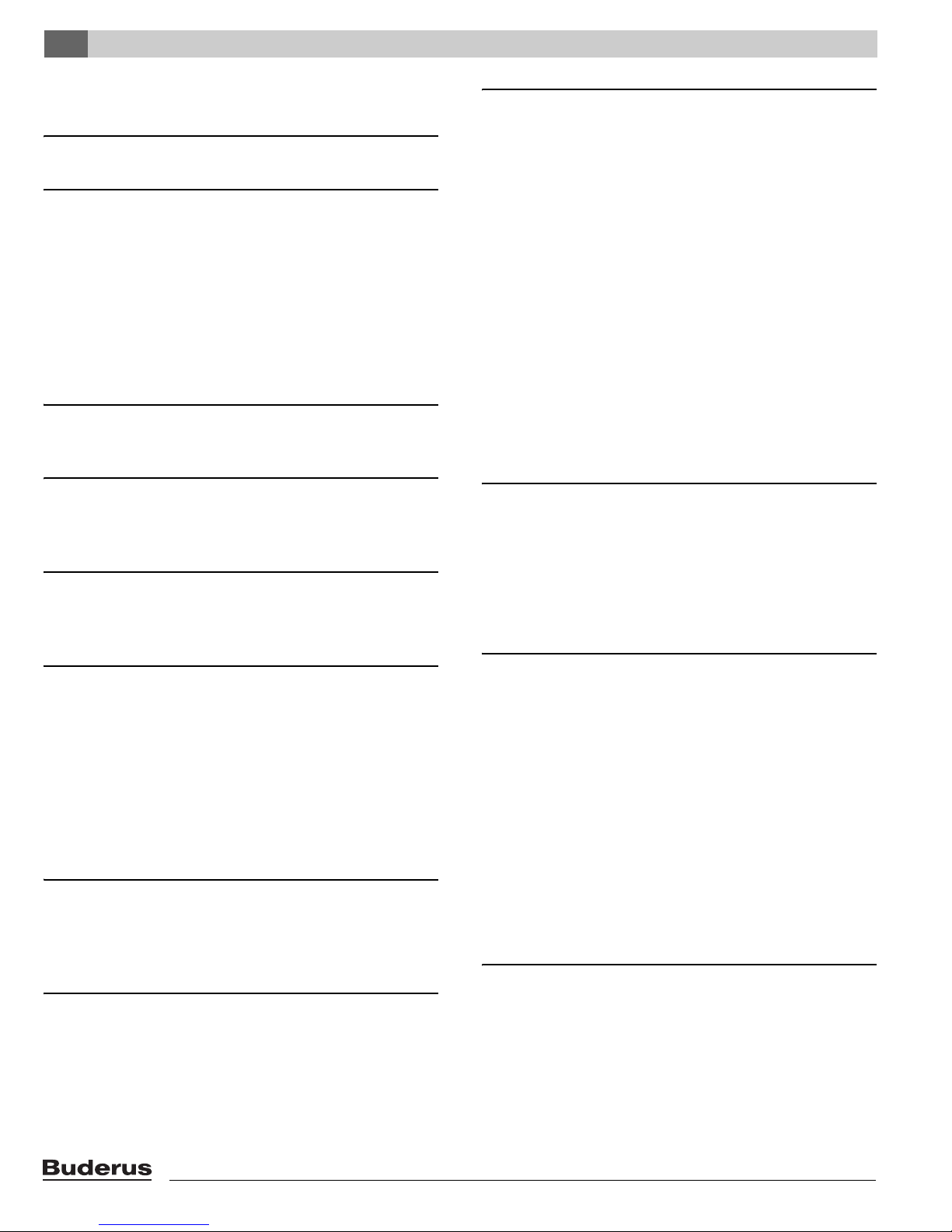

Contents

Contents

1 General information . . . . . . . . . . . . . . . . . . . . . . . .6

2 Safety and general instructions . . . . . . . . . . . . . .7

2.1 Designated use . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Hazard definitions . . . . . . . . . . . . . . . . . . . . .7

2.3 The following instructions must be observed.7

2.4 Heating system water quality . . . . . . . . . . . . .8

2.5 Pump test. . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.6 Freeze protection . . . . . . . . . . . . . . . . . . . . . .8

2.7 Tools, materials and further equipment . . . . .8

2.8 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3 Regulations and guidelines . . . . . . . . . . . . . . . . .9

3.1 Massachusetts Installations Only: . . . . . . . . .9

4 Dimensions and connections . . . . . . . . . . . . . . .11

4.1 Without pump group. . . . . . . . . . . . . . . . . . .11

4.2 With pump group . . . . . . . . . . . . . . . . . . . . .12

5 Packaging and transportation . . . . . . . . . . . . . .13

5.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . .13

5.2 Transporting the boiler . . . . . . . . . . . . . . . . .13

9 Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . 45

9.1 Check for gas leaks . . . . . . . . . . . . . . . . . . 46

9.2 Fill the heating system . . . . . . . . . . . . . . . . 47

9.3 Fill the condensate trap with water . . . . . . . 48

9.4 Bleed the gas supply valve. . . . . . . . . . . . . 49

9.5 Check the air/flue gas connection . . . . . . . 49

9.6 Checking the appliance configuration . . . . 50

9.7 Measure the gas inlet pressure

(working pressure) . . . . . . . . . . . . . . . . . . . 50

9.8 Check and adjust the gas/air ratio . . . . . . . 52

9.9 Carry out a leakage test in operating

conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.10 Measure the flue gases CO emissions. . . . 55

9.11 Carry out a function test . . . . . . . . . . . . . . . 56

9.12 Measure the ionization current . . . . . . . . . . 56

9.13 Test the Ignition Safety shut off device . . . 57

9.14 Boiler settings. . . . . . . . . . . . . . . . . . . . . . . 58

9.15 Final activities. . . . . . . . . . . . . . . . . . . . . . . 60

10 Shutting down the system. . . . . . . . . . . . . . . . . 61

10.1 Shut down the heating system using

the basic controller . . . . . . . . . . . . . . . . . . . 61

10.2 Shutting down the heating system if there

is a risk of freezing (interruption of use) . . . 61

10.3 Shutting down the heating system in

the event of an emergency. . . . . . . . . . . . . 61

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.1 Requirements for the installation room . . . .15

6.2 Installing the boiler . . . . . . . . . . . . . . . . . . . .15

6.3 Water and Gas connection . . . . . . . . . . . . .17

6.4 Connecting the condensate drain pipe . . . .21

6.5 Combustion Air and Ventilation Openings . .22

6.6 Flue gas adapter . . . . . . . . . . . . . . . . . . . . .24

6.7 Installation of the Exhaust and Air Intake

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7 Electrical connections . . . . . . . . . . . . . . . . . . . . .30

7.1 External connection board connections . . . .30

7.2 Installing function modules (accessories) . .33

7.3 Electrical wiring diagram . . . . . . . . . . . . . . .37

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

8.1 BC10 basic controller. . . . . . . . . . . . . . . . . .39

8.2 BC10 operating instructions. . . . . . . . . . . . .41

11 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11.1 Prepare the heating system for inspection . 62

11.2 Carry out a visual check for general

signs of corrosion . . . . . . . . . . . . . . . . . . . . 63

11.3 Gas valve leakage test . . . . . . . . . . . . . . . . 63

11.4 Measure the ionization current . . . . . . . . . . 63

11.5 Measure the gas inlet pressure

(working pressure) . . . . . . . . . . . . . . . . . . . 64

11.6 Check and adjust the gas/air ratio . . . . . . . 64

11.7 Carry out a leakage test in operating

conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.8 Measure the flue gases CO emissions. . . . 64

11.9 Fill the heating system . . . . . . . . . . . . . . . . 64

11.10 Check the air/flue gas connection . . . . . . . 64

12 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

12.1 Prepare the heating system for

maintenance. . . . . . . . . . . . . . . . . . . . . . . . 65

12.2 Remove the boiler door . . . . . . . . . . . . . . . 65

12.3 Clean the heat exchanger, burner and

condensate trap . . . . . . . . . . . . . . . . . . . . . 66

12.4 Check and adjust the gas/air ratio . . . . . . . 71

12.5 Function check . . . . . . . . . . . . . . . . . . . . . . 71

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!4

13 Display information . . . . . . . . . . . . . . . . . . . . . . 72

13.1 Removing the control panel . . . . . . . . . . . . 72

13.2 Replacing the control panel . . . . . . . . . . . . 73

13.3 BC10 Display readings . . . . . . . . . . . . . . . . 73

13.4 BC10 Display settings. . . . . . . . . . . . . . . . . 73

13.5 BC10 Display codes . . . . . . . . . . . . . . . . . . 74

14 Technical specifications . . . . . . . . . . . . . . . . . . 81

14.1 Technical specifications of GB162-boilers

at sea level (0-4,000 ft) . . . . . . . . . . . . . . . . 81

14.2 Technical specifications of GB162-boilers

at high altitude (4,000-10,000 ft). . . . . . . . . 82

15 Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

15.1 Start-up report. . . . . . . . . . . . . . . . . . . . . . . 85

15.2 Inspection report . . . . . . . . . . . . . . . . . . . . . 86

15.3 Service report . . . . . . . . . . . . . . . . . . . . . . . 87

Contents

16 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

17 Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 5

General information1

1 General information

About these instructions

These Installation Instructions contain important information

for the safe and professional installation, start-up and maintenance of the boiler with boiler input rating of 80 kW and

100 kW.

These Installation Instructions are intended for professional

installers, who have the necessary training and experience

for working on heating and gas systems.

Cascade installation

Special cascade units (accessories) have been developed

to enable this boiler to be installed in a cascade system.

Every cascade unit includes an installation frame, horizontal

headers, connection pipes for the boiler, main gas pipe and

a vertical low loss header.

Cascade units are available for installing the boilers inline or

back-to-back. These cascade units make installing a

cascade system easier and less labor intensive.

Please contact Buderus for further information about

cascade systems.

Updating of documentation

The following technical documentation is available for the

Logamax plus GB162-80 kW/100 kW:

– Installation instructions

– User’s manual

– Service manual.

Please contact us if you have any suggestions for improvement or corrections.

GB162 Natural Gas Propane Gas

80 kW 290,000 btu/hr 270,000 btu/hr

100 kW 333,000 btu/hr 315,000 btu/hr

Table 1 max. input rate

Subject to technical modifications

Slight changes may be made without prior notice to the illustrations, process steps and technical data as a result of our

policy of continuous improvement.

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!6

2 Safety and general instructions

Safety and general instructions 2

Please observe these instructions in the interest of your

own safety.

2.1 Designated use

The boiler was designed for heating water for a central

heating system and generating domestic hot water.

The boiler is suitable for connection to fully pumped,

sealed water systems ONLY.

The boiler can be installed either as a single system or as

part of a multiple system (cascade system) with a

maximum of 8 boilers connected together.

2.2 Hazard definitions

The following defined terms are used throughout the documentation to bring attention to the presence of hazards of

various risk levels. Notices give important information

concerning the operation of the product.

DANGER

Indicates the presence of hazards that will

cause severe personal injury, death or

substantial property damage.

WARNING

Indicates the presence of hazards that can

cause severe personal injury, death or

substantial property damage.

CAUTION

Indicates presence of hazards that will or

cause minor personal injury or property

damage.

CAUTION

Risk of electric shock.

Indicates presence of hazards due to electric

shock.

NOTICE

Indicates special instructions on installation,

operation or maintenance that are important

but not related to personal injury or property

damage.

2.3 The following instructions must be

observed

– The boiler must only be used for its designated

purpose, observing the Installation Instructions.

– Only use the boiler in the combinations and with the

accessories and spares listed.

– Maintenance and repairs must only be carried out by

trained professionals.

– You are only permitted to operate the condensing gas

boiler with the combustion air/flue gas system that has

been specifically designed and approved for this type of

boiler.

– Please note that local approval of the flue system and

the condensate connection to the public sewer system

may be required.

– If boiler installation is provided as replacement heater,

DO NOT connect new boiler venting to an existing vent

system, if it is shared with other appliances.

You must also observe:

– The local building regulations stipulating the installation

rules at the time of installation.

– The local building regulations concerning the air intake

and outlet systems and the chimney connection.

– The regulations for the power supply connection.

– The technical rules laid down by the gas utility company

concerning the connection of the gas burner fitting to

the local gas main.

– The instructions and standards concerning the safety

equipment for the water/space heating system.

– The Installation Instructions for building heating

systems.

– The boiler must be located in an area where leakage of

the tank or connections will not result in damage to the

area adjacent to the boiler or to lower floors of the

structure. When such locations cannot be avoided, it is

recommended that a suitable drain pan, adequately

drained, be installed under the boiler. The pan must not

restrict combustion air flow.

– The boiler must be installed such that the gas ignition

system components are protected from water (dripping,

spraying, rain etc.) during boiler operation and service.

– The boiler must not be installed on carpeting.

– Do not restrict or seal any air intake or outlet openings.

– If you find any defects, you must inform the owner of the

system of the defect and the associated hazard in

writing.

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 7

Safety and general instructions2

DANGER

if flammable gas explodes.

Beware if you smell gas: there may be an

explosion hazard!

Warning: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

z Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of

this or any other boiler.

What to do if you smell gas

z Do not try to light any boiler.

z Do not touch any electrical switch; do not

use any phone in your building.

z Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

z If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

WARNING

Danger of fatal accident from explosive

fumes.

z Only carry out work on gas pipes and

fittings if you are properly registered.

– The low loss header and boiler connection set must be

installed (supplied with the boiler).

– When using oxygen-permeable pipes (plastic), e.g. for

floor heating systems, you must separate the system

using secondary heat exchangers.

2.5 Heating system water quality

The quality of the system water is very important. Poor

water quality can damage heating systems due to scale

formation and corrosion. For further details, please see

the accompanying "Water quality requirements for

Logamax plus GB162-80 kW/100 kW" manual.

CAUTION

Risk of system damage due to unsuitable

heating system water.

z If oxygen-permeable pipes are used, e.g.

for underfloor heating systems, the

systems must be separated from one

another by plate heat exchangers.

Unsuitable heating system water

promotes sludge and corrosion formation. This can result in heat exchanger

malfunction and damage.

2.6 Pump test

If the boiler has not been operational for approx. 4 weeks,

the pump will automatically run for 10 seconds every

24 hours. This pump test is first carried out 24 hours after

the main power has been connected to the boiler.

2.7 Freeze protection

WARNING

Dangerous flue gas can escape if the air

supply is insufficient.

z Make sure that air vents are not reduced

in size or obstructed.

z The boiler may only be operated after the

defect has been remedied.

z Warn the user of the system of the defect

verbally and in writing.

2.4 Heating system requirements

– Installing a dirt trap like a y-strainer and a desludging

device is required. This must be installed in the heating

system in the immediate vicinity of the boiler, in an

easily accessible position between the boiler and the

lowest point in the return of the system.

– Clean the dirt trap at every annual service.

– Never use salt bedding type exchangers (ion

exchangers) to soften the water.

The boiler has integrated freeze protection that switches

the boiler ON at a space heating (CH) water temperature

of 45 °F (7 °C) and switches it OFF at a CH flow temperature of 59 °F (15 °C).

This feature does not protect the central heating system

from freezing. If there is a risk of radiators or pipe sections

freezing up, we recommend setting the pump run-over

time to 24 hours. See paragraph 13.4 on page 73.

2.8 Tools, materials and further equipment

For the installation and maintenance of the boiler you will

need the standard tools for space heating, gas and water

fitting. In addition, a handtruck with a fastening belt is

useful.

2.9 Disposal

– Dispose of the boiler packaging in an environmentally

sound manner.

– Dispose of components of the heating system (e. g.

boiler or control device), that must be replaced in an

environmentally responsible manner.

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!8

3 Regulations and guidelines

Regulations and guidelines 3

The installation must conform to the requirements of the

authority having jurisdiction or, in the absence of such

requirements, to the latest edition of the National Fuel Gas

Code, ANSI Z223.1./NFPA 54. In Canada, installation

must be in accordance with the requirements of

CAN/CSA B149.1, Natural Gas and Propane Installation

Code.

Where required by the authority having jurisdiction, the

installation must conform to the Standard for Controls and

Safety Devices for Automatically Fired Boilers,

ANSI/ASME CSD-1.

Install CO detectors per local regulations. Boiler requires

yearly maintenance, see chapter 12 "Maintenance",

page 65.

Operating Limits of the boiler:

Max. boiler temperature: 230 °F (110 °C)

Max. operating pressure: 30

– with optional pressure relief valve 50 psi (3.45 bar)

The hot water distribution system must comply with all

applicable codes and regulations. When replacing an

existing boiler, it is important to check the condition of the

entire hot water distribution system to ensure safe operation.

psi (2.6 bar)

3.1 Massachusetts Installations Only:

(a) For all side wall side horizontally vented gas fueled

equipment installed in every dwelling, building or structure

used in whole or in part for residential purposes, including

those owned or operated by the Commonwealth and

where the side wall exhaust vent termination is less than

seven (7) feet above finished grade in the area of the

venting, including but not limited to decks and porches, the

following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS. At the time of installation of the side

wall horizontal vented gas fueled equipment, the

installing plumber or gasfitter shall observe that a hard

wired carbon monoxide detector with an alarm and

battery back-up is installed on the floor level where the

gas equipment is to be installed. In addition, the

installing plumber or gasfitter shall observe that a

battery operated or hard wired carbon monoxide

detector with an alarm is installed on each additional

level of the dwelling, buiding or structure served by the

side wall horizontal vented gas fueled equipment. It

shall be the responsibility of the property owner to

secure the services of qualified licensed professionals

for the installation of hard wired carbon monoxide

detectors.

a. In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space

or an attic, the hard wired carbon monoxide

detector with alarm and battery back-up may be

installed on the next adjacent floor level.

b. In the event that the requirements of this

subdivision can not be met at the time of

completion of installation, the owner shall have a

period of thirty (30) days to comply with the above

requirements; provided, however, that during said

thirty (30) day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS.

Each carbon monoxide detector as required in

accordance with the above provisions shall comply

with NPA 720 and be ANSI/UL 2034 listed and

IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall

be permanently mounted to the exterior of the building

at a minimum height of eight (8) feet above grade

directly in line with the exhaust vent terminal for the

horizontally vented gas fueled heating appliance or

equipment. The sign shall read, in print size no less

than one-half (½) inch in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the

side wall horizontally vented gas fueled equipment

shall not approve the installation unless, upon

inspections, the inspector observes carbon monoxide

detectors and signage installed in accordance with the

provisions of 248 CRM 5.08(2)(a)1 through 4.

(b) EXEMPTIONS: The following equipment is exempt

from 248 CRM 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled

“Equipment Not Required To Be Vented” in the

most currect edition of NFPA 54 as adopted by the

board: and

2. Product Approved side wall horizontally vented gas

fueled equipment installed in a room or structure

separate from the dwelling, building or structure

used in whole or in part for residential puposes.

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 9

Regulations and guidelines3

(c) MANUFACTURERS REQUIREMENTS - GAS EQUIP-

MENT VENTING SYSTEM REQUIRED.

When the manufacturer of Product Approved side wall

horizontally mounted gas equipment provides a venting

system design or venting system components with the

equipment, the instructions provided by the manufacturer

for the installation of the equipment and venting shall

include:

1. Detailed instructions for the installation of the

venting system or the venting system components:

and

2. A complete parts list for the venting system design

or venting system.

(d) MANUFACTURERS REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of Product Approved side wall

horizontally vented gas fueled equipment does not provide

the parts for the venting of flue gases, but identifies

“special venting systems”, the following requirements shall

be satisfied by the manufacturer:

1. The referenced “special venting systems” shall be

included with the appliance or equipment

installation instructions: and

2. The “special venting systems” shall be Product

Approved by the Board, and the instructions for

that system shall include a parts list and detailed

installation instructions.

(e) A copy of all instructions for all Product Approved side

wall horizontally vented gas fueled equipment, all venting

instructions, all parts lists for venting instructions, and/or

venting design instructions shall remain with the appliance

or equipment at the completion of the installation.

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!10

4 Dimensions and connections

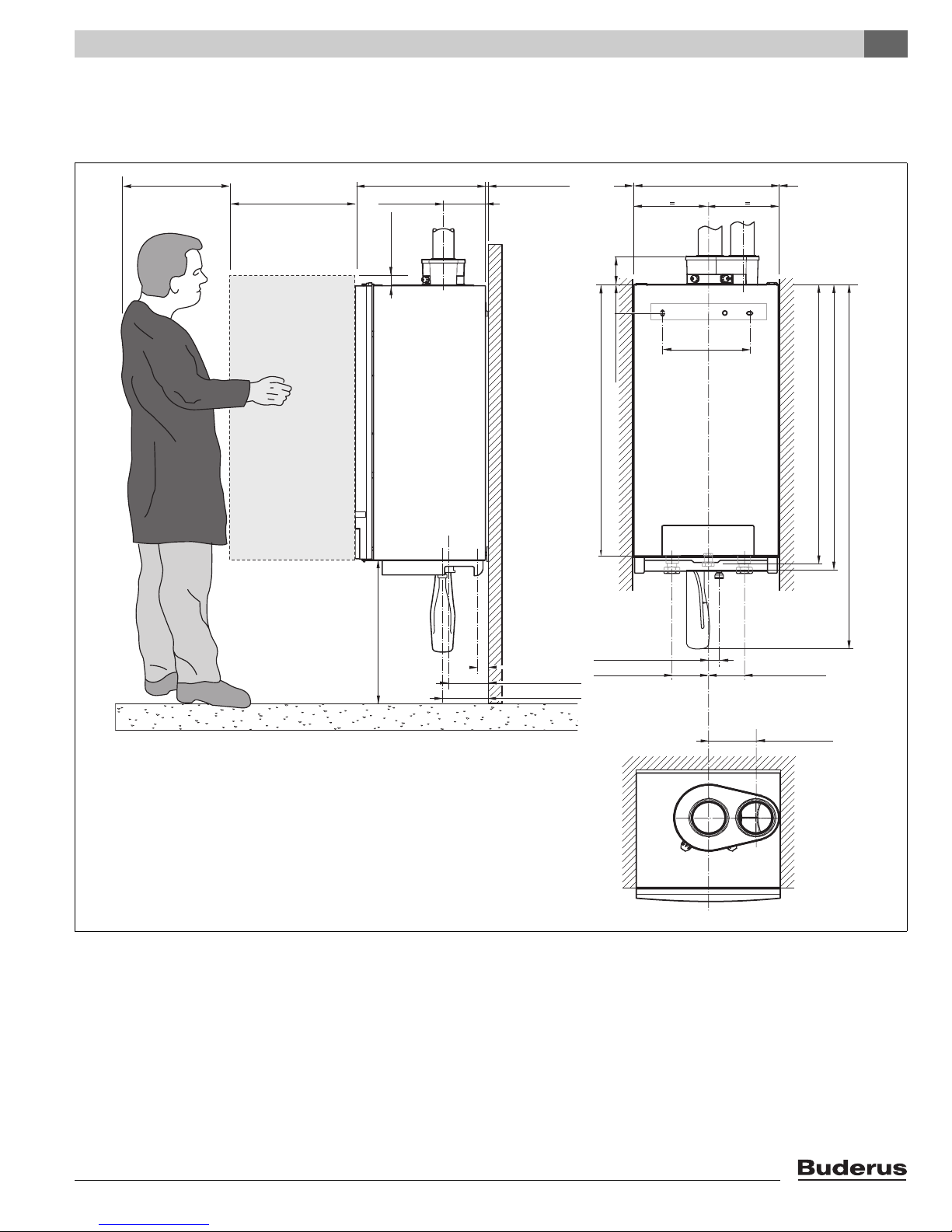

4.1 Without pump group

Dimensions and connections 4

16.5" (420 mm)

20.5" (520 mm)

18.3” (465 mm)

6” (152 mm)

A/B

1.2” (30 mm)

G

D/F

E

0.25” (6 mm)

4.1” (103.5 mm)

0 020.5” (520 mm)

C

16” (406 mm)

5.3” (135 mm)

38.58” (980 mm)

DFE

AB

G

39.5” (1003 mm)

40,55” (1030 mm)

51.6” (1310 mm)

24.8” (630 mm)

1.4” (35 mm)

5.4” (138 mm)

6.4” (162 mm)

The required permanent clearances (closet) are:

in front: 1” (25 mm)

right side: 0

left side: 0

above: 6” (152 mm)

The position selected for installation MUST allow adequate space for servicing in

front of the boiler of at least 16.5” + 20.5” = 37” (940 mm).

Maintain an installation clearance from combustible construction from hot water

piping of at least 1" (25 mm).

Fig. 2 Dimensions and connections without pump group

A (LA) = Flue gas connection;

E (GAS) = Gas connection to boiler;

inside diameter 4” (100 mm)

B (AA) = Air intake connection;

F (RK) = Return;

inside diameter 4” (100 mm)

C (WB) = Wall Bracket (not shown)

G (AKO) = Condensate outlet;

D (VK) = Supply;

G1½’’ union nut with female thread

1.54” (39 mm)

5.1” (130 mm)

5.1” (130 mm)

5.5” (140 mm)

Rp1’’ female thread

G1½’’ union nut with female thread

Ø 32 mm (1¼”) O/D

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 11

Dimensions and connections4

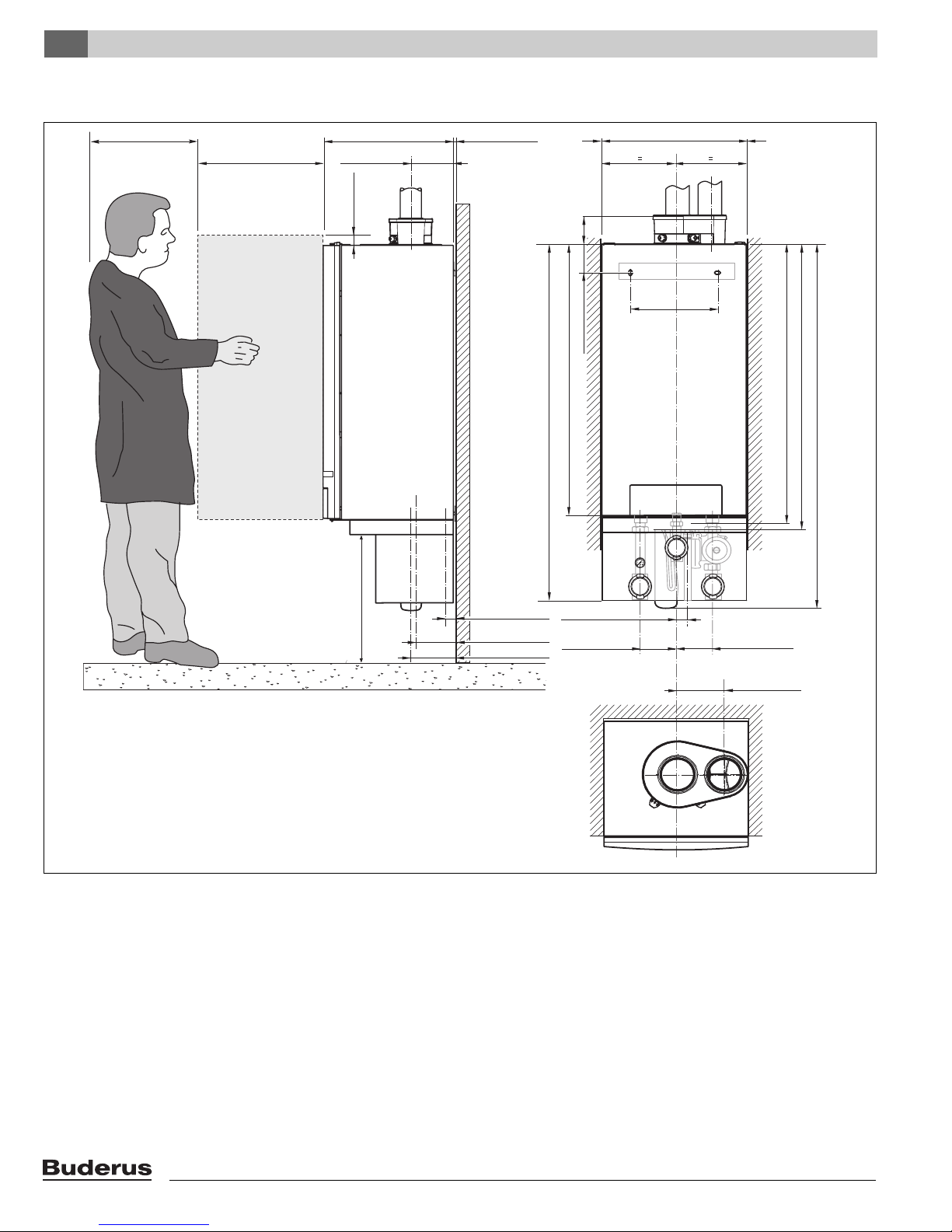

4.2 With pump group

16.5" (420 mm)

20.5" (520 mm)

18.3” (465 mm) 0.25” (6 mm)

6” (152 mm)

A/B

1.2” (30 mm)

4.1” (103.5 mm)

D/F

G

E

0 020.5” (520 mm)

5.3” (135 mm)

38.58” (980 mm)

50.4” (1280 mm)

AB

C

16” (406 mm)

DFE

39.5” (1003 mm)

40,55” (1030 mm)

51.6” (1310 mm)

G

24.8” (630 mm)

H/J

5.4” (138 mm)

6.4” (162 mm)

The required permanent clearances (closet) are:

in front: 1” (25 mm)

right side: 0

left side: 0

above: 6” (152 mm)

The position selected for installation MUST allow adequate space for servicing

in front of the boiler of at least 16.5” + 20.5” = 37” (940 mm).

Maintain an installation clearance from combustible construction from hot water

piping of at least 1" (25 mm).

Fig. 3 Dimensions and connections with pump group

1

The pump group is an accessory.

A (LA) = Flue gas connection;

inside diameter 4” (100 mm)

B (AA) = Air intake connection;

inside diameter 4” (100 mm)

C (WB) = Wall Bracket (not shown)

D (VK) = Supply;

G1½’’ union nut with female thread

E (GAS) = Gas connection to boiler;

Rp1’’ female thread

1.4” (35 mm)

1.54” (39 mm)

5.1” (130 mm)

HI

G

J

5.1” (130 mm)

5.5” (140 mm)

F (RK) = Return;

G1½’’ union nut with female thread

G (AKO) = Condensate outlet;

Ø 32 mm (1¼”) O/D

H (PF) = Pump group supply;

G1½’’ male thread, flat seal

I = Gas connection to pump group;

1” NPT female thread

J (PR) = Pump group return;

G1½’’ male thread, flat seal

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!12

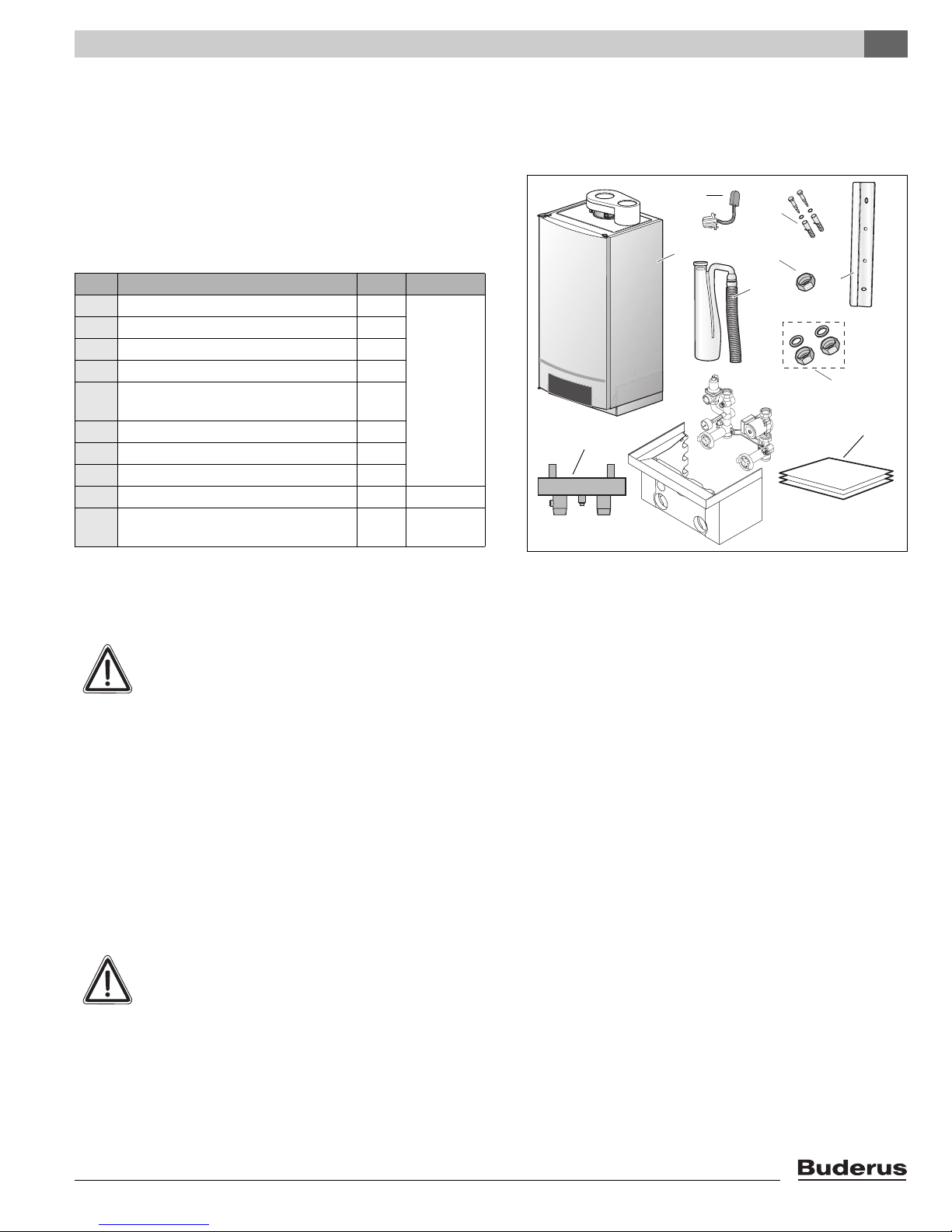

5 Packaging and transportation

5.1 Scope of delivery

Packaging and transportation 5

The boiler is delivered factory-assembled.

z When receiving the delivery, check if the packaging is

intact.

z Check that all items are included in the delivery (fig. 4).

Pos. Parts Qty Packaging

1 Boiler with casing 1 1 box

2 Wall bracket 1

3 Condensate trap with hose 1

4 Technical documents set 1

5 Supply and return union nuts with

sealing rings

6 Screws and plugs for wall bracket 2

7 Union nut for gas connection 1

8 DHW sensor 1

9 Pump group 1 1 box

10 Low loss header

(single installation only)

Table 2 Items supplied with GB162-80 kW/100 kW

2

1 1 box

5.2 Transporting the boiler

8

1

2

1

3

0

4

10

9

Fig. 4 Items supplied with unit

6

7

3

2

5

4

CAUTION

The boiler may be damaged when it is improperly secured.

z Only transport the boiler using the right

transportation equipment, such as a

handtruck with a fastening belt or special

equipment for manuevering steps.

z During transportation the boiler must be

secured on the transportation equipment to

prevent it from falling off.

z Protect all parts against impacts if they are to

be transported.

z Observe the transportation markings on the

packaging.

CAUTION

The unpacked boiler may be damaged when

not protected against contamination.

z Leave the protective covers on the connec-

tions.

z Cover the flue gas connections at the top of

the boiler with plastic film.

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 13

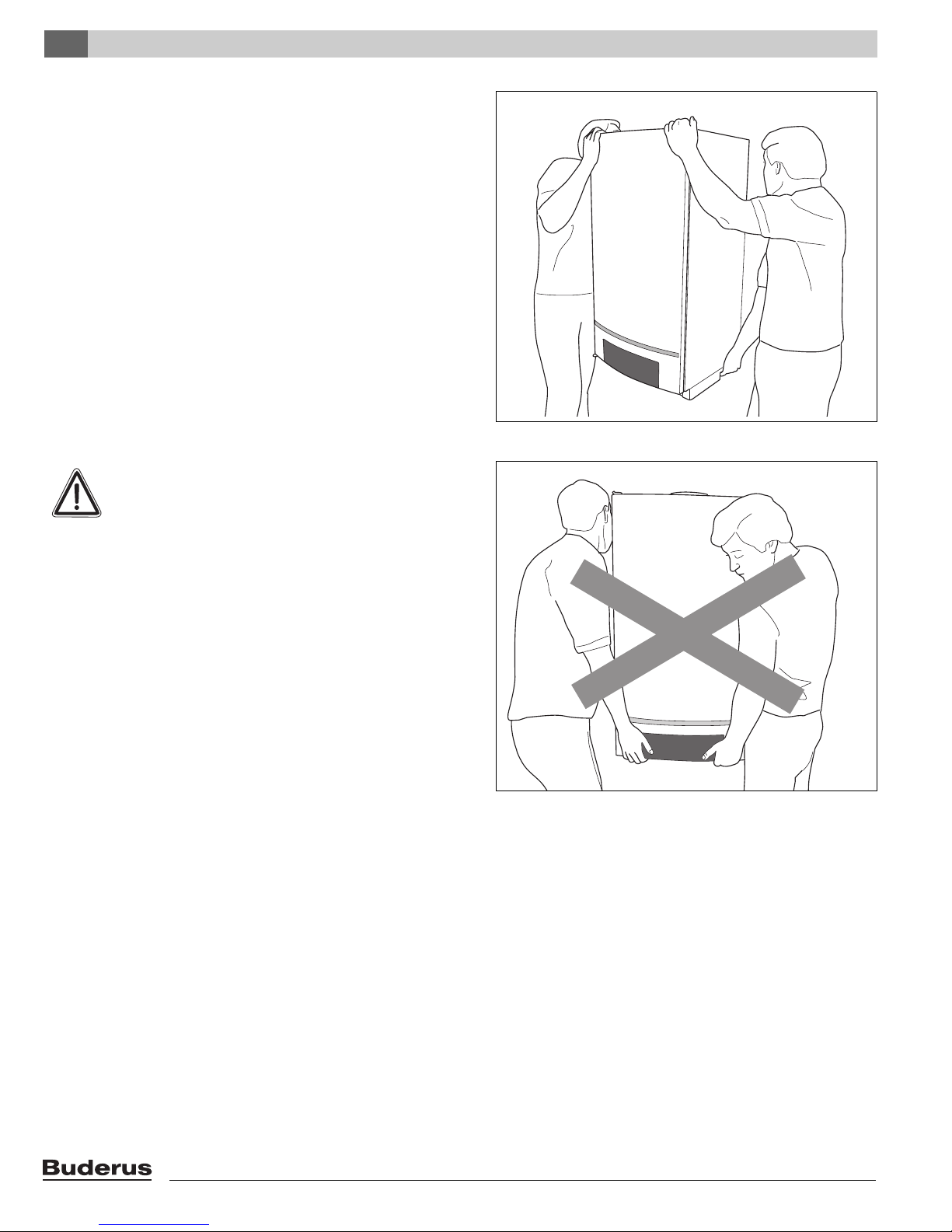

Packaging and transportation5

z Always lift and carry the boiler with two people as shown

in fig. 5, or use a handtruck or special equipment.

CAUTION

Damage to the unit by lifting or carrying incorrectly.

z Do not hold the boiler by the door covering

the control panel (fig. 6).

Fig. 5 Lift and carry the boiler correctly

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!14

Fig. 6 Incorrect way of lifting and carrying the boiler

6 Installation

6.1 Requirements for the installation room

DANGER

z Install the heating system in a frost-free

room.

z If the boiler is operated dependent on room

air, the installation room must have the

required air vents. DO NOT obstruct these

vents. The air vents must always be free.

z When installed in a room with thin walls or a

thin floor, resonating noise may occur. Install

noise reducing parts if required.

z Do not store any flammable materials or

liquids in the immediate vicinity of the boiler.

z Never use any chlorinated detergents or

halogenated hydrocarbons (e. g. in spray

cans, solvents and detergents, paints,

adhesives).

z Do not allow too much dust to collect on the

boiler.

Installation 6

6.2 Installing the boiler

Observe the installation distances of the combustion air/flue

gas system.

z Before starting installation check that the carrying

capacity of the wall is sufficient for the boiler weight.

NOTICE

z To protect the connection orifice you must

not remove the styrofoam bottom panel.

z Do not lift the boiler by the door covering the

control panel, see paragraph 5.2, page 13.

z Protect the boiler and the combustion

air/flue gas orifice against pollution during

installation.

z Remove the packaging and dispose of it in an environ-

mentally manner.

z Measure the installation height (see chapter 4 "Dimen-

sions and connections", page 11).

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 15

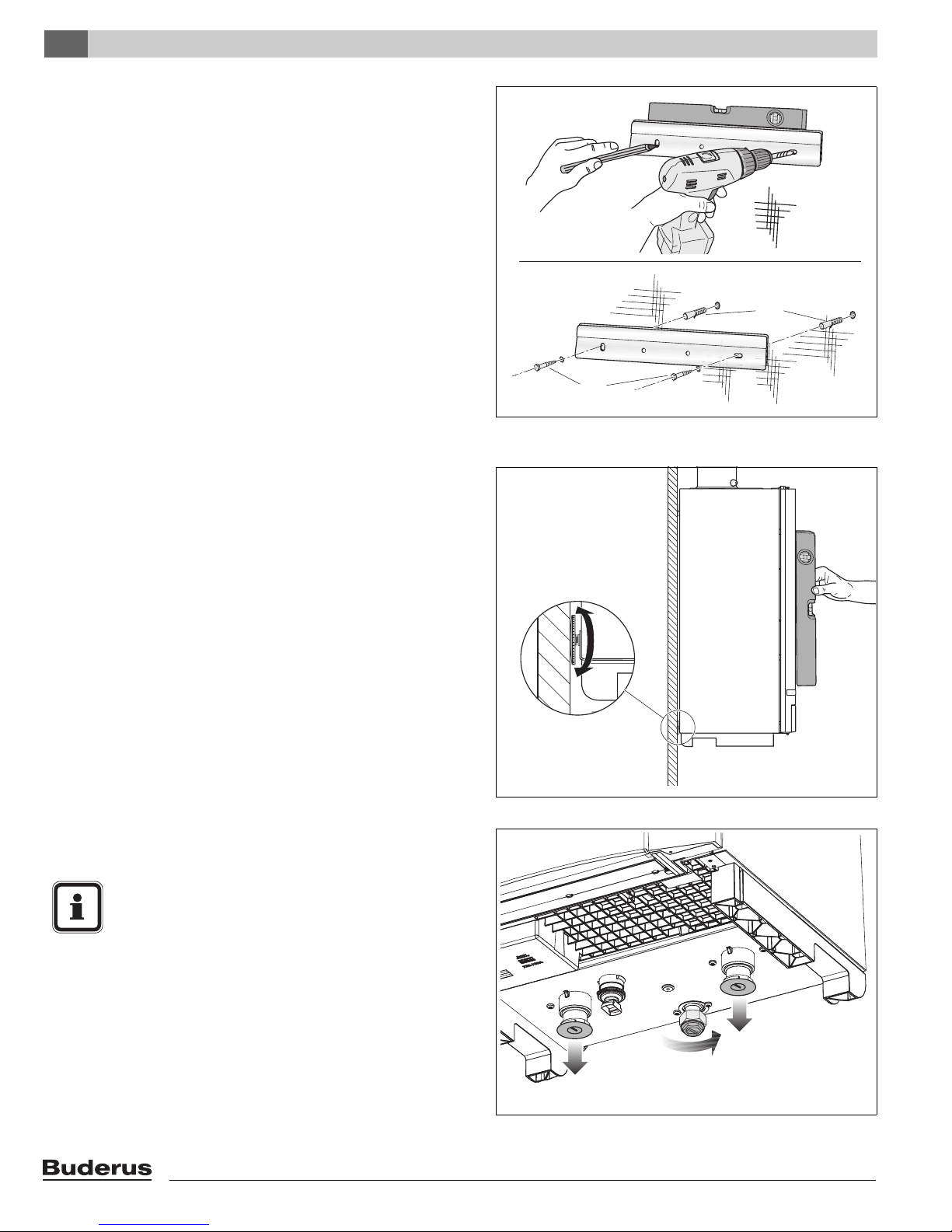

Installation6

z Mark both holes with the wall bracket (fig. 7) using a spirit

level.

z Install the wall bracket with 2 screws (fig. 7).

z With two people, lift the boiler by holding it by its back and

by the transport rail at its bottom and install it on the wall

bracket (fig. 5, page 14).

z The boiler can be moved sideways to get the correct

position.

z Level the boiler with the set screw and a spirit level

(fig. 8).

A

B

C

D

Fig. 7 Installing the wall bracket

z Remove the protective covers from the bottom of the

boiler (fig. 9).

NOTICE

Some residual water from final testing may

leak away.

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!16

Fig. 8 Aligning the boiler with the set screw

Fig. 9 Removing the covers – boiler bottom

Installation 6

6.3 Water and Gas connection

6.3.1 General

The water and gas connections to the boiler are made using

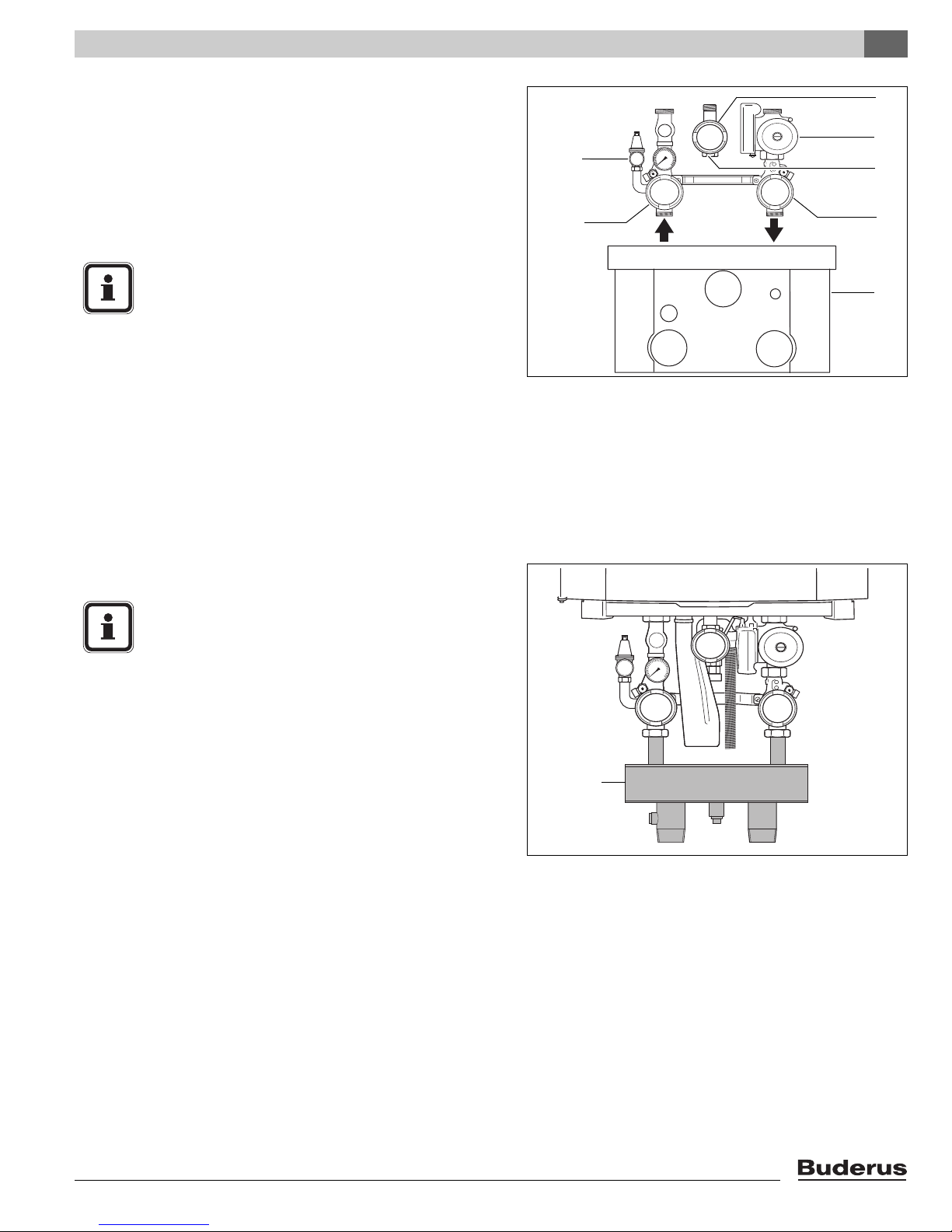

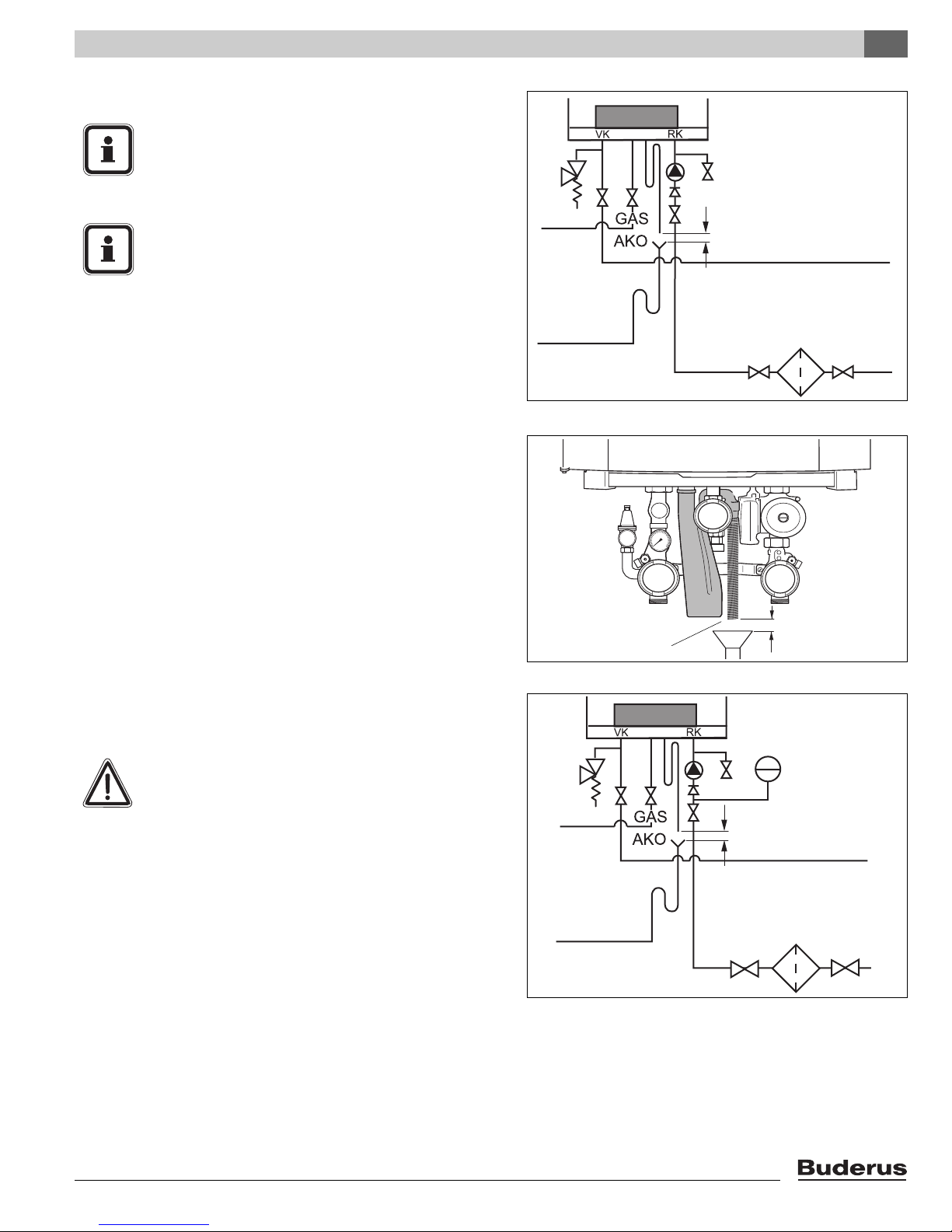

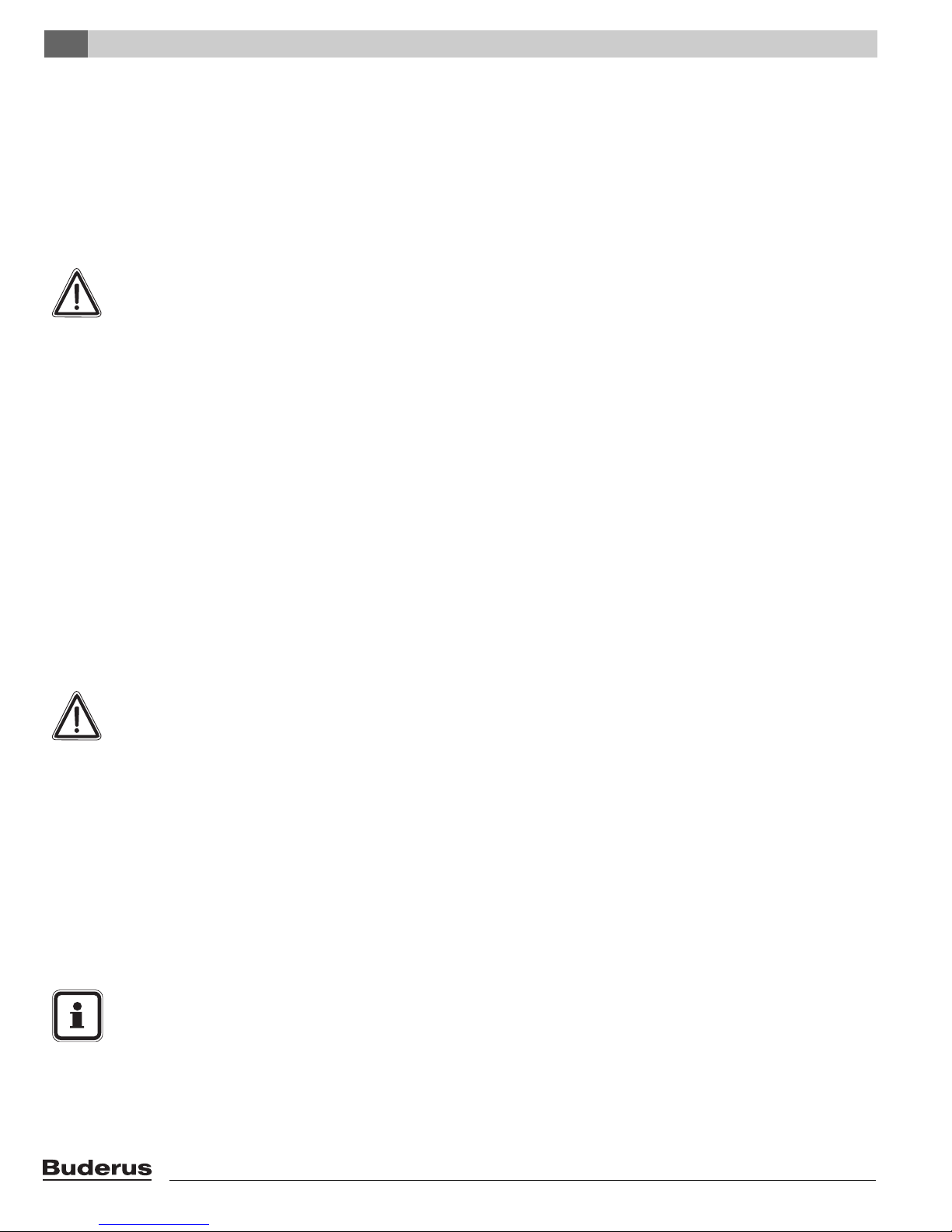

the pump group, see fig. 10 (scope of delivery). This pump

group includes the circulation pump and a pressure relief

valve.

NOTICE

If you do not use the included pump group, you

have to install a separate circulation pump

under the boiler. This pump must be selected so

that the volume flow through the boiler is sufficient to handle the maximum boiler input rating.

See paragraph 6.3.5 "Installing the pump",

page 19.

z Install the pump group on the boiler in accordance with

the pump group installation instructions.

A single boiler must be installed with the included low loss

header to regulate the flow.

1

2

Fig. 10 Pump group

pos. 1: pressure relief valve

pos. 2: supply water valve

pos. 3: manual gas shutoff valve

pos. 4: circulation pump

pos. 5: gas inlet

pos. 6: return water valve

pos. 7: Pump group cover

3

4

5

6

7

z Install the low loss header (fig. 11, pos. 1).

NOTICE

Avoid installing the boiler above radiation levels.

If the boiler is installed above radiation sections,

a low water cutoff shall be installed and wired to

the boiler. Follow local code or in case of use of

a low water cutoff, be aware to use an air vent,

in order to prevent the boiler from shutting down

unnecessarily.

6.3.2 Connecting the pressure relief valve (PRV)

The pressure relief valve is a part of the supplied pump

group, see fig. 10. A listed ASME pressure relief valve

supplied with the boiler must be installed at the time of installation. No valve is to be placed between the PRV and the

boiler.

No reducing coupling or other restriction may be installed in

the discharge line. The discharge line must be a minimum of

4” (100 mm) above a drain and installed such that it allows

complete drainage of both the PRV and the line. The location of the PRV must be readily accessible for servicing or

replacement and be mounted as close to the boiler as

possible. To install the PRV, a suitable fitting connected to

an extension on a “T” fitting can be sweated to the hot water

line. Support all piping.

Maintain an installation clearance from combustible

construction of at least 1” (25 mm) from the hot water piping.

1

Fig. 11 Low loss header

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 17

Installation6

6.3.3 Making the gas connection

DANGER

Only carry out work on gas lines if you are a

qualified gas fitter.

z The manual gas shutoff valve is part of the pump group,

and is installed in accordance with the pump group installation instructions.

z Determine proper size gas pipe for the installation using

table 3 and table 4. Do not forget the pipe fitting losses

and observe proper size of the fittings.

z Connect the gas supply pipe to the manual gas shutoff

valve, so that it is free from any strain.

NOTICE

When installing the gas supply connection, it

must comply with local regulations or, if such

regulations do not exist, with the National Fuel

Gas Code, ANSI Z 223.1./NFPA 54.

In Canada, the gas supply connection must

comply with local regulations or, if such regulations do not exist, with CAN/CSA B149.1,

Natural Gas and Propane Installation Code.

A sediment trap must be provided upstream of the manual

gas shutoff valve, but downstream of the appliance gas

valve.

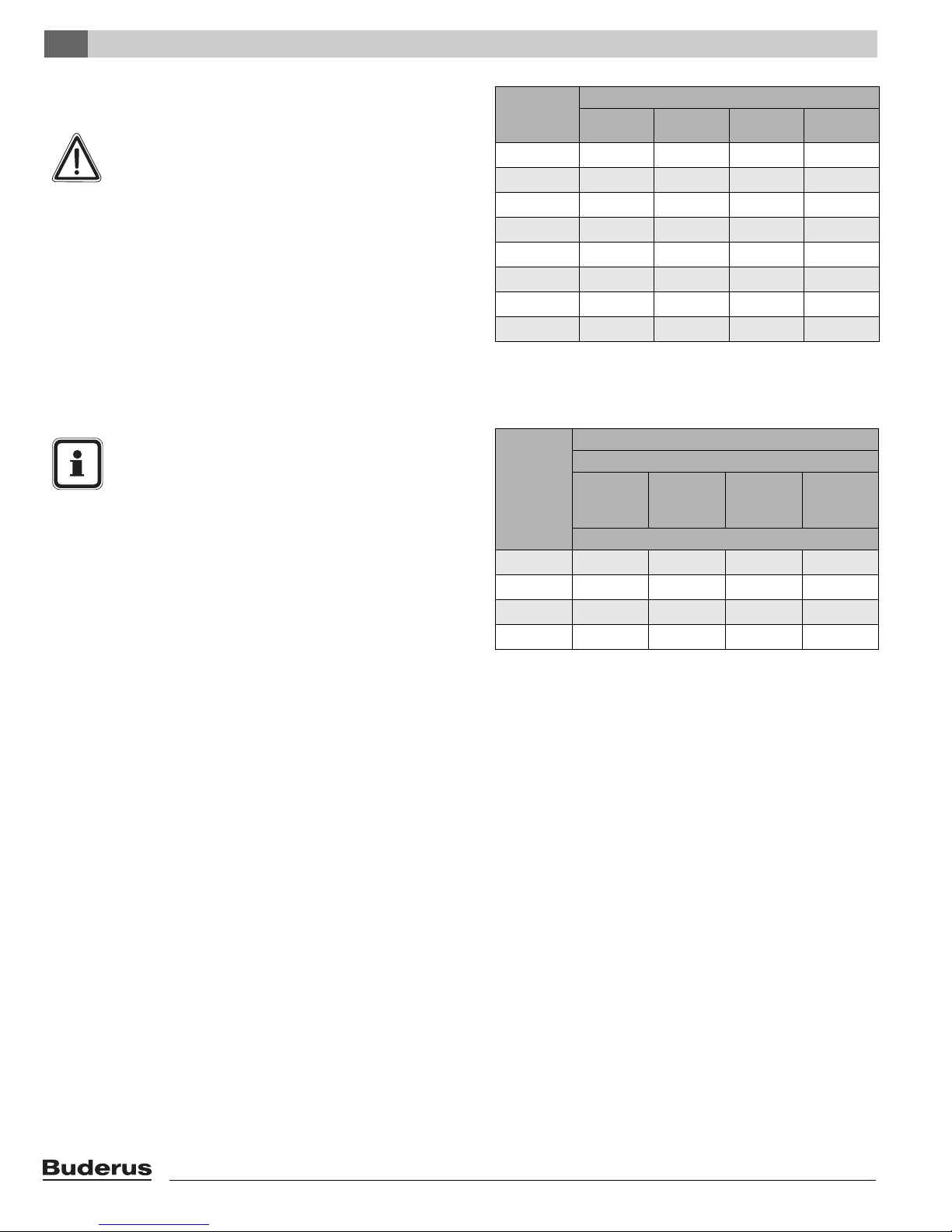

Length of

pipe in feet

(m)

10 (3.05) 278 520 1,060 1,600

20 (6.1) 190 350 730 1,100

30 (9.15) 152 285 590 890

40 (12.2) 130 245 500 760

50 (15.25) 115 215 440 670

75 (22.88) 93 175 360 545

100 (30.5) 79 160 305 480

150 (47.25) 64 120 250 380

Table 3 Gas Pipe Capacity for different pipe sizes

1 Maximum pipe capacity in ft3/hr, based on a specific gravity of

.60 (42 mbar) and a inlet gas pressure of 14 inches W.C.

(35 mbar) or less and a pressure drop of .3 inches W.C. (20 mbar)

Steel pipe

diameter

in inches

(mm)

¾ (19) 2.1 (0.64) 4.1 (1.25) 0.5 (0.15) 1.25 (0.38)

1 (25) 2.6 (0.79) 5.2 (1.59) 0.6 (0.18) 1.60 (0.49)

1 ¼ (32) 3.5 (1.07) 6.9 (2.11) 0.8 (0.24) 2.15 (0.66)

1 ½ (38) 4.0 (1.22) 8.0 (2.44) 0.9 (0.27) 2.50 (0.76)

Table 4 Equivalent length for pipe fittings in feet

Gas Volume Capacity in ft3 / hr

¾" 1" 1 ¼" 1 ½"

Equivalent length for Pipe Fittings in feet (m)

Type of pipe fitting

90°-Elbow Tee

(flow thru

branch)

Equivalent length in feet (m)

Gate valve Gas cocks

1

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!18

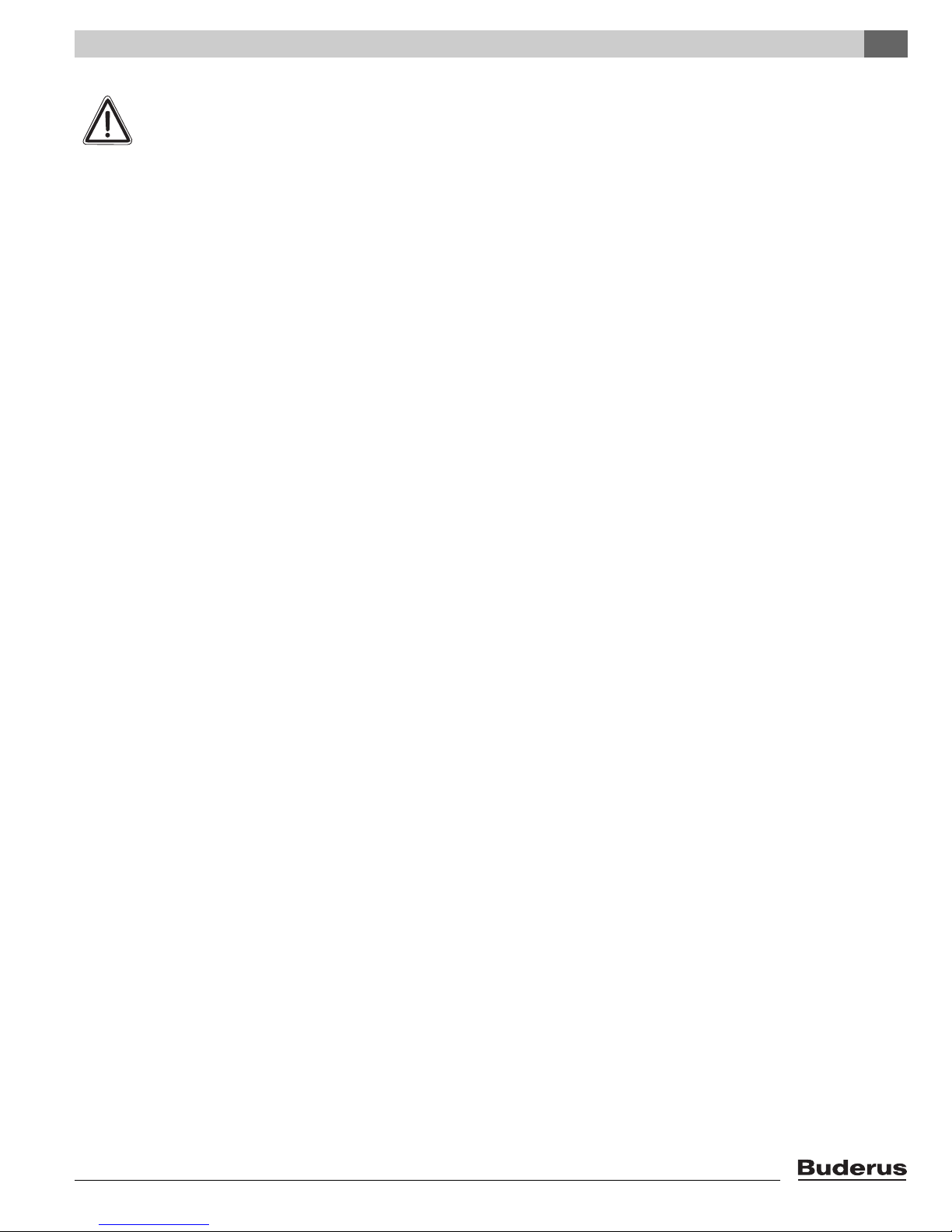

6.3.4 Installing the heating supply and return pipe

NOTICE

When using plastic pipes, observe the supplier’s

instructions - especially those referring to

recommended jointing techniques and the

notes relating to the heating system water on

page 8.

NOTICE

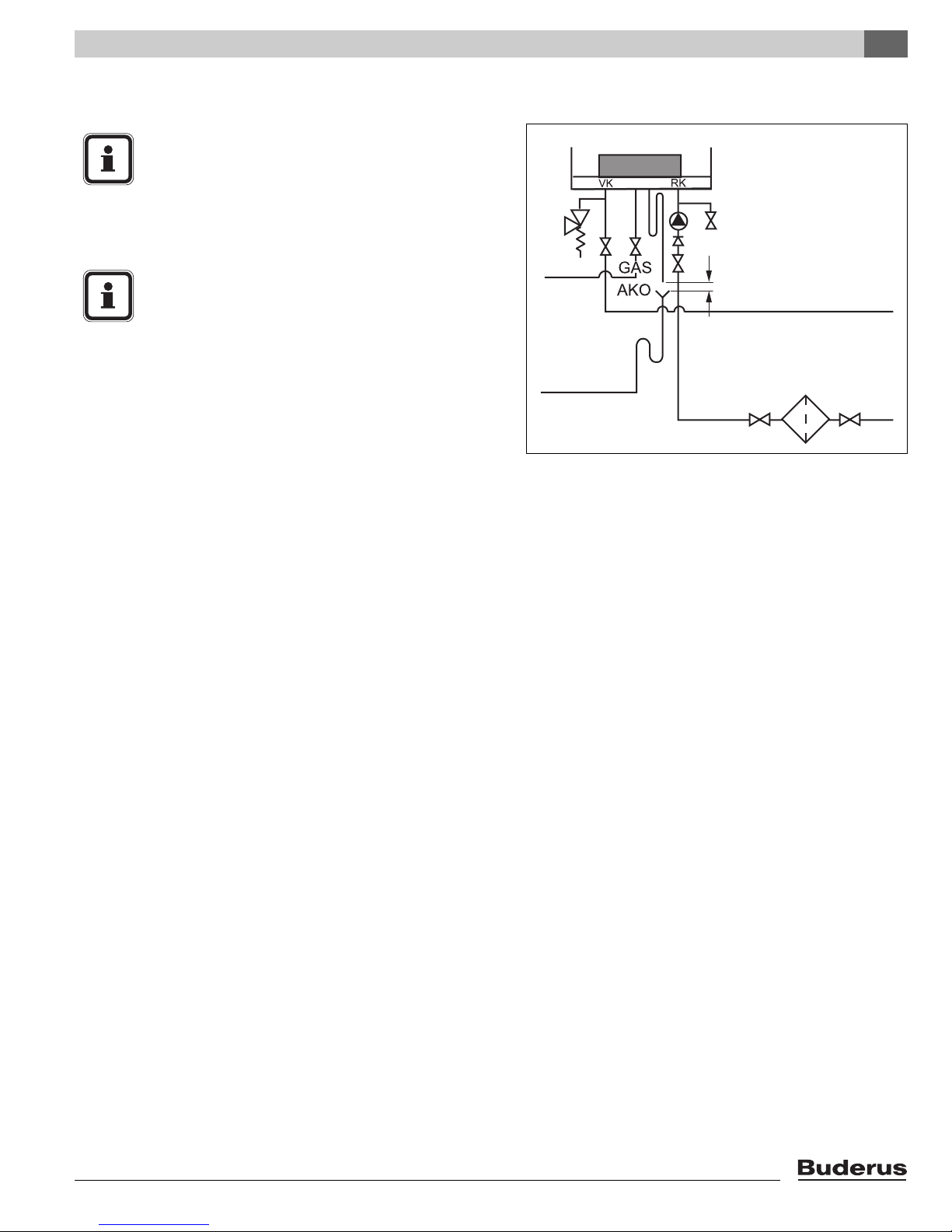

To prevent contamination in the heating system

we recommend you integrate a dirt filter (fig. 12,

pos. 10) in the return pipe, near the boiler. In an

old system it is a requirement to install a dirt

filter. Also install shutoff valves to enable filter

cleaning immediately upstream and downstream of the dirt filter (scale cartridge or

y-strainer).

z Connect the supply pipe with a flat rubber seal installed

to the Supply connection (fig. 12, pos. 1) making sure it

is not under stress. Use a supply pipe with a minimum

diameter of 1½" (38 mm).

z Connect the return pipe with a flat rubber seal installed to

the Return connection (fig. 12, pos. 2) making sure it is

not under stress. Use a return pipe with a minimum

diameter of 1½" (38 mm).

Installation 6

1

6

35

Fig. 12 Connecting the boiler supply and return

pos. 1: Supply

pos. 2: Return

pos. 3: Isolating valves

pos. 4: Drain cock

pos. 5: Gas valve

pos. 6: Pressure relief valve

pos. 7: Condensate trap

pos. 8: Pump

pos. 9: Non-return valve

pos. 10: Dirt filter (for example scale cartridge or y-strainer)

2

48

9

>1” (2.54 cm)

3

7

10

3

3

6.3.5 Installing the pump

Always use the supplied Buderus pump group and the low

loss header when installing a single boiler so correct flows

are guaranteed. It is not necessary to install a low loss

header for cascade systems.

z Install the pump (fig. 12, pos. 8) in the return circuit

(fig. 12, pos. 2).

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 19

Installation6

6.3.6 Installing the condensate trap

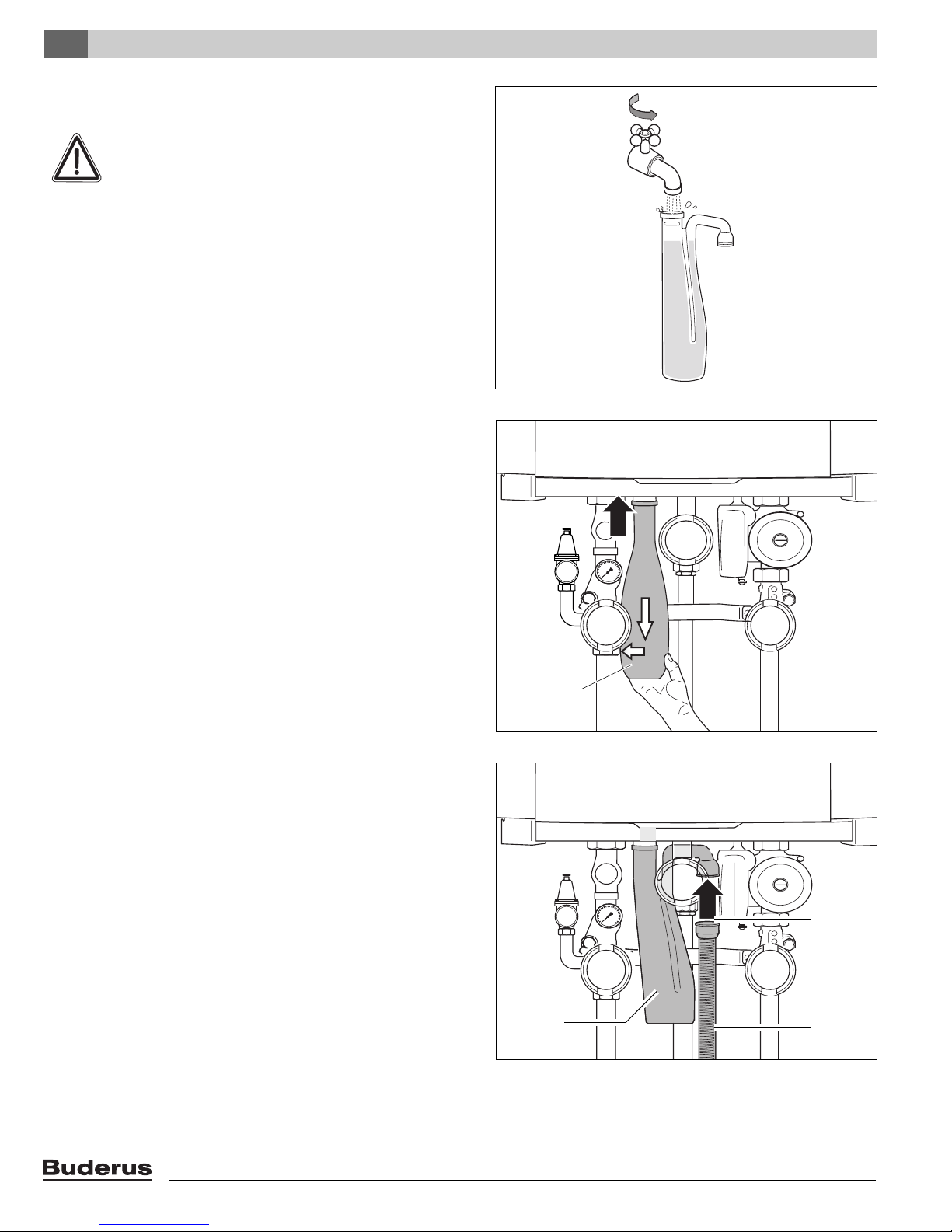

WARNING

Danger of fatal accident due to poisoning.

z If the condensate trap is not filled with water,

flue gas can escape and put people's lives at

risk.

High temperature applications:

z Fill the condensate trap (supplied with the boiler) with

water (fig. 13). Use mineral oil in case of high temperature systems and non-condensing applications.

z Connect the condensate trap (fig. 14, pos. 1) to the

condensate outlet. The condensate trap has a bayonet

connector, insert and turn ¼ rotation clockwise to click

into position.

Fig. 13 Filling the condensate trap with water

z Connect the condensate trap hose (fig. 15, pos. 3) and

the rubber sleeve (fig. 15, pos. 2) to the condensate trap

(fig. 15, pos. 1).

1

Fig. 14 Installing the condensate trap

1

Fig. 15 Installing the condensate trap hose

2

3

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!20

6.4 Connecting the condensate drain pipe

NOTICE

The condensate must be drained from the boiler

in accordance with local, state or federal rules

and regulations.

NOTICE

Use materials approved by the authority having

jurisdiction. In the absence of such authority,

PVC and CPVC pipe must comply with ASTM

D1785, F441 or D2665. Cement and primer

must comply with ASTM D2564 or F493.

For Canada, use ULC certified PVC or CPVC

pipe, fittings and cement.

z Install the condensate drain pipe taking the following into

account:

– An air gap of at least 1” (2.54 cm) must be maintained

between the boiler condensate trap hose and the

condensate pipework, see fig. 16 and fig. 17.

– If the condensate outlet of the boiler is lower than the

drain, a condensate pump must be used.

– The condensate produced by the boiler has a pH value

between 3 and 4.

z Install a neutralization unit if required by the local code.

Installation 6

>1” (2.54 cm)

1

Fig. 16 Connecting the condensate trap

6.4.1 Connecting the expansion vessel in a singleboiler system

CAUTION

Damage to the installation due to faulty pressure

relief valve.

z The expansion vessel must be of sufficient

capacity.

z Connect the expansion tank to the boiler return. If a

check valve is available: connect the expansion vessel to

the CH-side of the check valve in the return circuit

(fig. 18, pos. 1).

1

Fig. 17 Condensate drainage pipe

> 1” (2.54 cm)

1

>1” (2.54 cm)

Fig. 18 Connecting the expansion vessel in a single-boiler

system

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 21

Installation6

6.5 Combustion Air and Ventilation

Openings

Provisions for combustion and ventilation air must be made

in accordance with section 5.3, Air for Combustion and

Ventilation, of the National Flue Gas Code,

ANSI Z223.1/NFPA 54, or Sections 7.2, 7.3 or 7.4 of

CAN/CGA B149, Installation Codes, or applicable provisions of the local building codes.

CAUTION

BOILER DAMAGE AND OPERATIONAL

FAILURES !

Due to insufficient or improper openings for

combustion air and/or ventilation of the boiler

room.

Provisions for combustion air and ventilation are

always required, regardless whether the

combustion air is taken from the outside (sealed

combustion) or inside (room air for combustion).

Insufficient ventilation of the boiler room can

lead to high air temperatures. This can result in

boiler damage.

– Make sure that intake and exhaust openings

are sufficiently sized and no reduction or

closure of openings takes place.

– When the problem is not resolved, do not

operate the boiler.

– Please note these restrictions and its

dangers to the operator of the boiler.

WARNING

BOILER DAMAGE !

Due to contaminated air.

– Boiler must be clear and free from

combustible materials, gasoline and other

flammable vapors and liquids, and corrosive

liquids and vapors.

Never use chlorine and hydrocarbon

containing chemicals (such as spray

chemicals, solution and cleaning agents,

paints, glues etc) in the vicinity of the boiler.

– Do not store and use these chemicals in the

boiler room.

– Avoid excessive dust formation and build-up.

NOTICE

When one expects contaminated combustion

air (near swimming pools, chemical cleaning

operations and hair salons), sealed combustion

operation is recommended.

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!22

DANGER

Fire danger due to flammable materials or

liquids.

– Do not store flammable materials and

liquids in the immediate vicinity of the

boiler.

All Air from Inside the Building (room air)

The closet shall be provided with two permanent openings

communicating directly with an additional room(s). The total

input of all gas utilization equipment installed in the

combined space shall be considered in making this determination. Each opening shall have a minimum free area of

1 square inch per 1,000 Btu per hour of total input rating of

all gas utilization equipment in the confined space, but no

less than 100 square inches. One opening shall commence

within 12 inches (305 mm) of the top, and one opening shall

commence within 12 inches (305 mm) of the bottom of the

enclosure. The minimum dimension of air openings shall be

not less than 4 inches (101.6 mm).

Installation 6

All Air from Outdoor (sealed combustion)

The closet shall be provided with two permanent openings,

one commencing within 12 inches (305 mm) from the top,

and one commencing within 12 inches (305 mm) from the

bottom of the enclosure. The openings shall communicate

directly, or by ducts, with the outdoors or spaces (crawl or

attic) that freely communicate with the outdoors.

The minimum dimension of air openings shall be no less

than 4 inches (101.6 mm).

1. Where directly communicating with the outdoors, each

opening shall have a minimum free area of 1 square

inch per 4,000 Btu/hr of total input rating of all

equipment in the enclosure.

2. Where communicating with the outdoors through

vertical ducts, each opening shall have a minimum free

area of 1 square inch per 4,000 Btu/hr of total input

rating of all equipment in the enclosure.

3. Where communicating with the outdoors through

horizontal ducts, each opening shall have a minimum

free area of 1 square inch per 2,000 Btu/hr of total input

rating of all equipment in the enclosure.

4. Where ducts are used, they shall be of the same crosssectional area as the free area of the opening to which

they connect.

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 23

Installation6

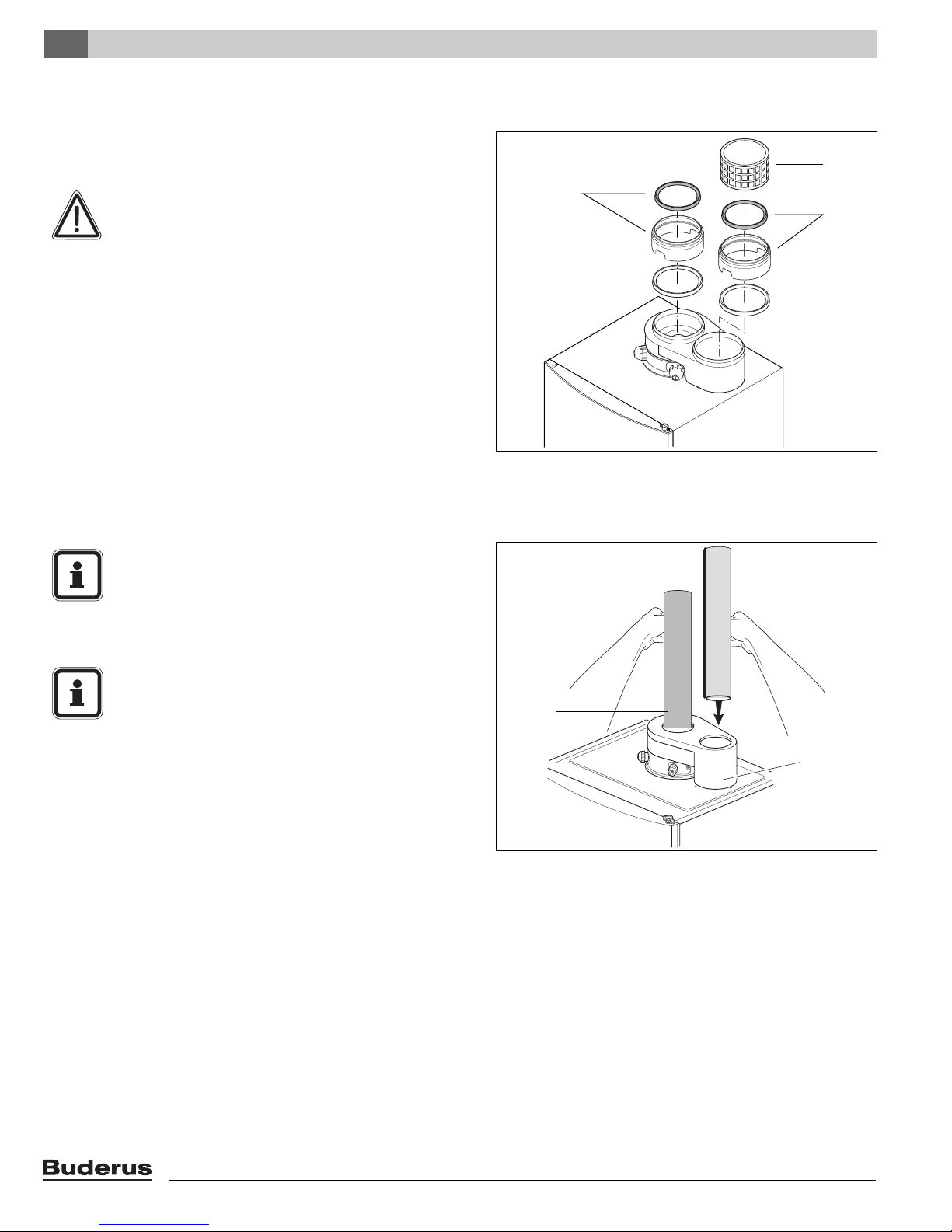

6.6 Flue gas adapter

z When installing PVC vent pipes remove the upper lip ring

and insert (fig. 19, pos. 1).

CAUTION

DO NOT use lubricants to avoid degradation of

the lip rings.

z In case of open venting, use basket (fig. 19, pos. 2) on

the air intake.

6.7 Installation of the Exhaust and Air Intake

system

2

1

1

Fig. 19 Connecting the flue gas adapter (parallel)

NOTICE

Consult local and state codes pertaining to

special building code and fire department

requirements. Adhere to national code requirements.

NOTICE

Observe the listed maximum lengths of vent

system, which are boiler model dependent.

The maximum permissible lengths are listed in

table 5, page 28.

Optional vent kits are:

– horizontal, two-pipe, parallel wall terminal fields.

The termination shall be at least 4 ft (1,220 mm) for the U.S.

and 6 ft (1,830 mm) for Canada away from a gas utility

meter, service regulator or the like (for room air applications

only).

The termination shall terminate at least 4 ft (1,220 mm)

below, 4 ft (1,220 mm) horizontally from, or 1 ft (305 mm)

above any door, window, or gravity air inlet into any building.

2

1

Fig. 20 Vent pipes

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!24

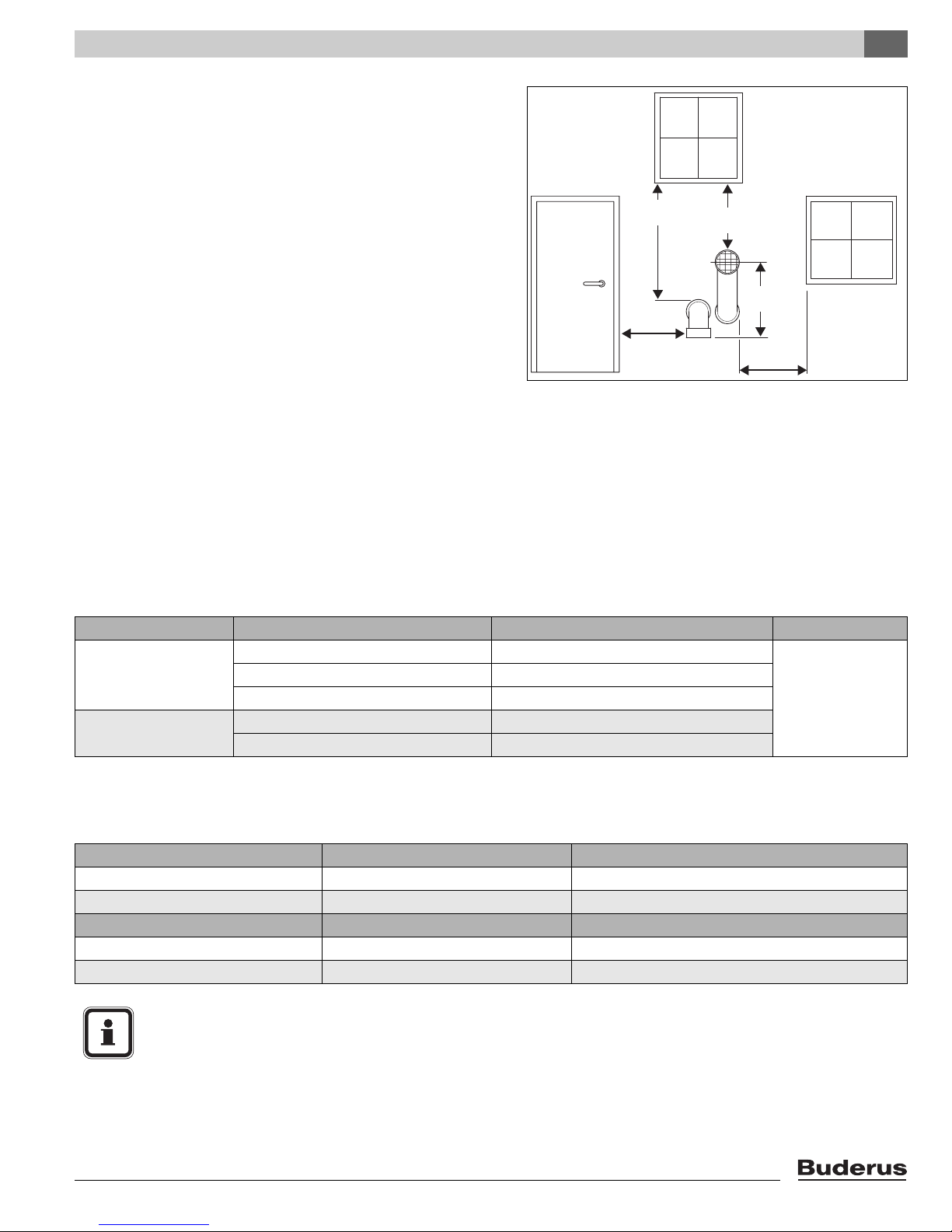

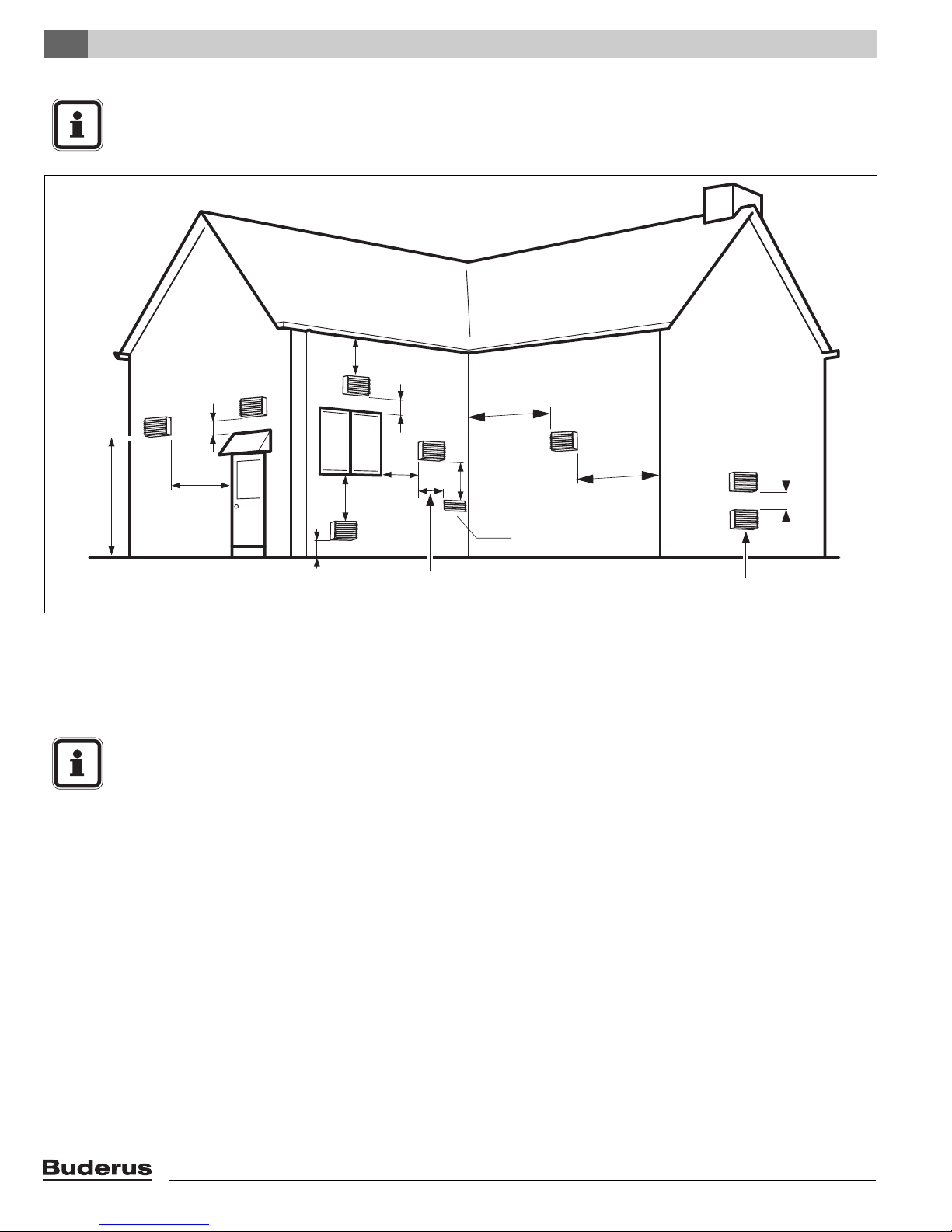

Vent must be at least 12 inches (305 mm) above grade,

anticipated snow line or roof surface (Canada 18” (457 mm)

minimum) (see fig. 21).

Vent termination must be at least 7 ft (2,135 mm) above

a public walkway (see fig. 22).

Vent must be 3 ft (915 mm) above any forced air intake

within 10 ft (3,050 mm) (see fig. 22).

Do not extend exposed vent pipe outside the building

beyond recommended distance. Condensate could freeze

and block vent pipe.

Vent should terminate at least 3 ft (915 mm) away from adjacent walls, inside corners and 5 ft (1525 mm) below roof

overhang (see fig. 22).

It is not recommended to terminate vent above any door or

window, condensate can freeze causing ice formations.

Do not use chimney as a raceway if another boiler or fireplace is vented into or through chimney.

All non-steel vent pipes must be glued, except for the flue

gas adapter. Installed you can slide the pipe onto the

adapter, properly supported and the exhaust pipe must be

pitched a minimum of a ¼ inch (6.35 mm) per foot back to

the boiler. This allows the condensate to drain away.

All non-steel combustion air and vent pipe materials and

fittings must comply with the following and must be UL

approved venting material:

Installation 6

12" (305 mm)

minimum

12" (305 mm)

minimum

Fig. 21 Vent and air pipe position (1) of a sealed combustion

system

12" (305 mm)

minimum

EXHAUST

INTAKE

12" (305 mm)

minimum

12" (305 mm)

minimum

Item Material United states Canada

4” (100 mm) Vent or air

pipe and fitting

Pipe

cement/ primer

* Components of the certified vent systems must not be interchanged with other vent systems or unlisted pipe fittings Plastic components, and specified

primers and glues of the certified vent system must be from a single system manufacturer and not intermixed with other system manufacturer's vent

system parts.

PVC schedule 40, 80 ANSI/ASTM D1785

PVC-DWV ANSI/ASTM D2665

CPVC schedule 40, 80 ANSI/ASTM F441

PVC ANSI/ASTM D2564

CPVC ANSI/ASTM F493

BH Gas venting

systems,

ULC S636 *

Approved flue material are from:

Roof terminals Flue System (trade name) Supplier

4”/6" (100/150 mm) concentric PVC IPEX

4” (100 mm) parallel stainless steel Flex-L

Wall terminals Flue System (trade name) Supplier

4” (100 mm) parallel stainless steel Flex-L

90°-elbow with inlet screen PVC/stainless steel Z-Flex/Heat Fab

NOTICE

- DO NOT use cellular core pipe.

- DO NOT use PVC when using anti-freeze in the primary circuit of the boiler. Use CPVC or stainless steel only!

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 25

Installation6

NOTICE

A minimum clearance of 4 ft (1,220 mm) horizontally from and in no case above and below, unless a 4-foot

(1,220 mm) horizontal distance is maintained, from electric meters, gas meters, regulators and relief equipment

(1525 mm)

5'

1'

1'

(305 mm)

4'

7'

(2135 mm)

Fig. 22 Vent and air pipe position (2) of a system with combustion air supply from the room (non-room sealed)

(1220 mm)

at least 1 ft (305 mm)

above grade and snow line

4'

(1220 mm)

(1220 mm)

(305 mm)

4'

3'

Exhaust terminal must be at least 3 ft (915 mm)

above forced air inlet within 10 ft (3,050 mm)

3'

(915 mm)

(1220 mm)

3'

(915 mm)

Forced

Air Inlet

Gravity Air Inlet

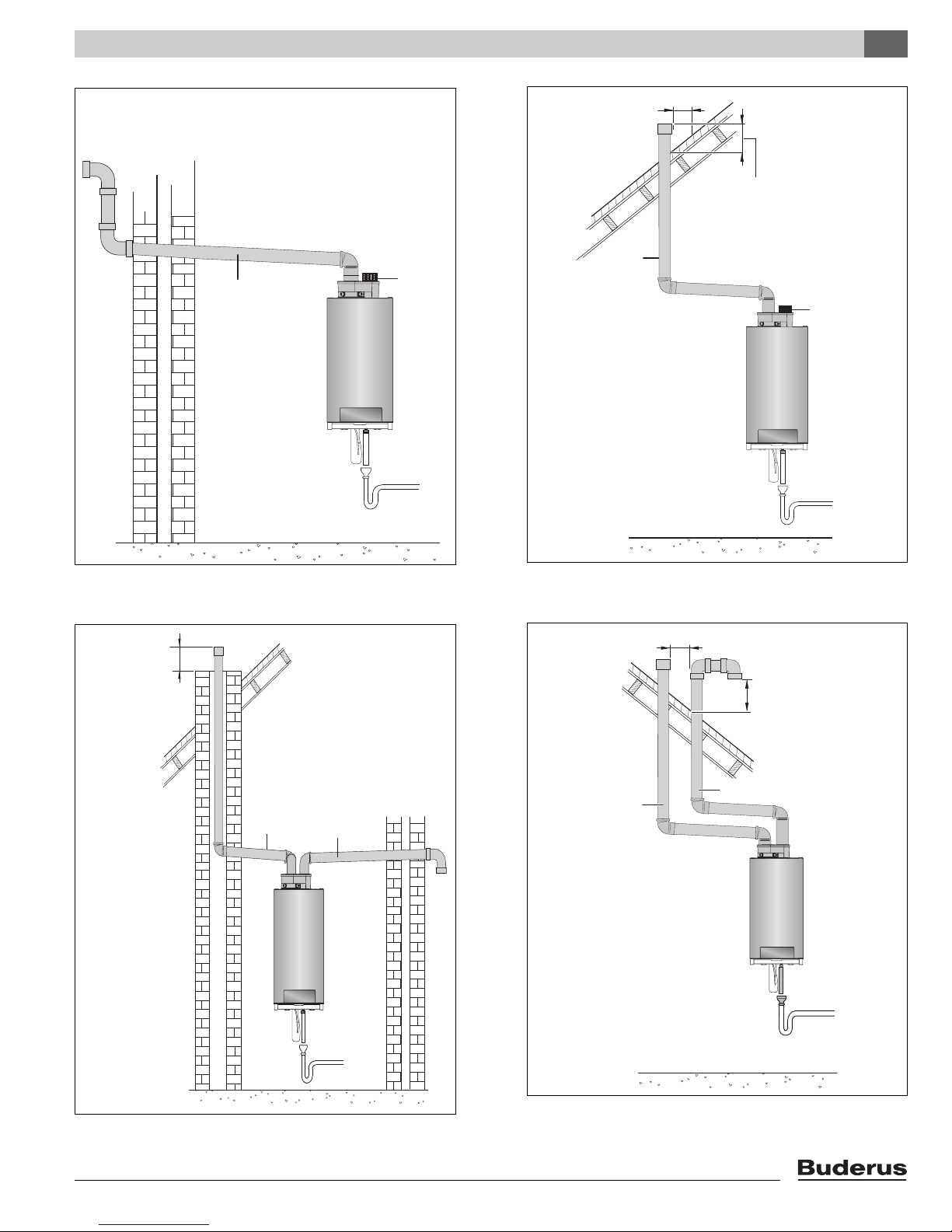

Below are approved examples of vertical and horizontal

venting installation

NOTICE

z Place pipe supports every 5 feet (1,525 mm)

of horizontal and vertical run, beginning with

support near boiler.

z The condensate must be drained in accor-

dance with the applicable rules.

See paragraph 6.4: "Connecting the

condensate drain pipe" on page 21.

z Periodic cleaning of the vent terminal and

air-intake screens is mandatory.

z Avoid locating vent terminals near equip-

ment or construction which can be subject to

degradation from exhaust gases.

1'

(305 mm)

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!26

EXHAUST

INTAKE

EXHAUST

10"- 0" MIN

(250 mm - 0 mm MIN)

Installation 6

12” (300 mm) over maximum

snow level or 24” (600 mm)

whichever is greater

INTAKE

Fig. 24 Horizontal venting system (room air only) -

Situation 1

12” (300 mm) over maximum

snow level or 24” (600 mm)

whichever is greater

Exhaust

Intake

Fig. 23 Vertical venting system (room air only)

10"- 0" MIN

(250 mm - 0 mm MIN)

12" (300 mm) OVER

MAXIMUM SNOW LEVEL

OR 24" (600 mm)

WHICHEVER IS

GREATER

EXHAUST

INTAKE

4" (102 mm)

4" (102 mm)

Fig. 26 Vertical venting system (sealed combustion)

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements! 27

Fig. 25 Vertical parallel venting system (sealed

combustion) - Situation 1

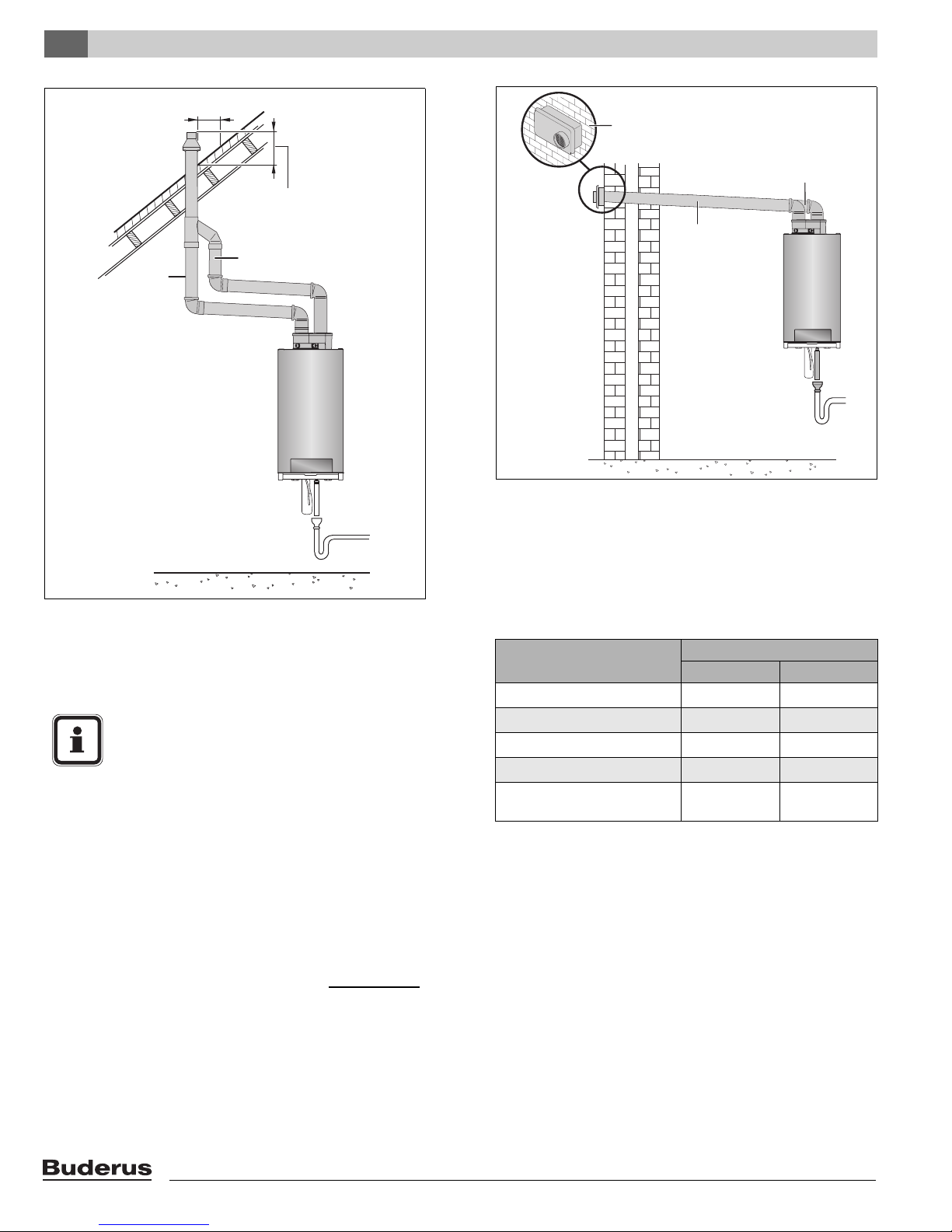

Installation6

10”-0“ MIN

(250 mm - 0 mm MIN)

WALL TERMINATION

INTAKE (BEHIND)

Exhaust

12” (300 mm) over maximum

snow level or 24” (600 mm)

whichever is greater

Intake

EXHAUST

Fig. 27 Horizontal venting system (sealed combustion) -

Situation 2 (PVC only)

4" (102 mm)

Fig. 28 Vertical venting system (sealed combustion)

Do not exceed the total equivalent venting length of 100 feet

(30,480 mm) maximum requirement each for the intake and

exhaust piping.

NOTICE

Appliance input rates are based on minimum

vent length operation. Longer vent lengths

(up to maximum) will reduce the input proportionally.

See table 5 for the Friction Loss Equivalent in piping and

fittings.

Example:

When you end up using 3 x 45°-elbows and the concentric

roof terminal, then the total venting length may not exceed

68 feet (20.72 m).

3 x 45°-elbow = 3 x 4 ft (1.22 m) = 12 ft (3.66 m)

concentric roof terminal 4"/6" = 20 ft (6.10 m)

Total friction loss equivalent = 32 ft (9.76 m)

Total venting length for this example is:

GB162-80 kW/100 kW = 100 ft (30.48 m) - 32 ft (9.76 m) =

68 ft (20.72 m) each for the intake and exhaust piping.

Fittings or Piping Equivalent

feet m

45 degree elbow

90 degree elbow

plastic pipe per foot

parallel vent kit

concentric roof terminal

41.22

7 2.13

10.30

2 0.61

20 6.10

4"/6" (100/150 mm)

Table 5 Friction Loss Equivalent in piping and fittings

Logamax plus GB162-80 kW/100 kW - Subject to modifications resulting from technical improvements!28

Loading...

Loading...