Buderus Logamatic LON-Gateway Technical Information

Technical Information

Interface with DDC

6 720 642 841-00.1RS

Logamatic LON-Gateway

6 720 643 554 (01/2010) US/CA

For heating contractors

during project planning.

Contents

Contents

1 Explanation of symbols and safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Guideline to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Correct use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Specified communication objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Logamatic LON-Gateway firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6.1 Firmware when delivered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6.2 Procedure for updating firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Network interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Overview of the SNVTs for variant 2 boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Description of the SNVTs for variant 2 boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.2 Heating zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.3 DHW heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2.4 Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.5 Floor-standing boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2.6 Solar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3 Overview of the SNVTs for variant 4 boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4 Description of the SNVTs for variant 4 boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4.2 Heating zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4.3 DHW heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4.4 Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.5 Boiler 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.4.6 Boiler 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.4.7 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4 Operating basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

Contents

5 Incorporation of Logamatic 4000 in LON networks via Logamatic LON-Gateway . 39

5.1 Structure of the hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2 Creating LON networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.1 Commissioning LON networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.2 Decommissioning LON networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6 The LON-Gateway as LonMark object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.1 Variant 2 boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2 Variant 4 boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7 Error list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

3

Explanation of symbols and safety instructions

1

1 Explanation of symbols and safety instructions

1.1 Guideline to symbols

Warnings

Warnings are indicated in the text by a warning triangle and a gray background.

In case of danger from electric shock, the exclamation point on the warning triangle is

replaced with a lightning symbol.

Signal words at the beginning of a warning are used to indicate the type and seriousness of the

ensuing risk if measures for minimizing damage are not taken.

• NOTE indicates that minor damage to property may occur.

• CAUTION indicates possible minor to medium personal injury.

• WARNING indicates possible severe personal injury.

• DANGER indicates that severe personal injury may occur.

Important information

Important information that presents no risk to people or property is indicated with this

symbol. It is separated by horizontal lines above and below the text.

Additional symbols

Symbol Meaning

B Sequence of steps

Æ Cross-reference to other points in this document or to other documents

• Listing/list entry

– Listing/list entry (2nd level)

Tab. 1

4

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

Explanation of symbols and safety instructions

1

WARNING: Only transformers with following specification are permitted:

6 V AC; 400 mA. The transformer is not part of the product! Please take care to use a

reliable product which meets our requirements shown above. Do not mount the

transformer internally!

Buderus does not accept responsibility for systems which contravene the Installation

instruction or addition documentation in scope of delivery.

The transformer must be mounted in a separate enclosure which is rated for this purpose.

1.2 Safety instructions

Installation and commissioning

The Logamatic LON-Gateway interface module has been designed and built in accordance with

currently recognized standards and safety requirements.

However, dangers or property damage may arise if it is used improperly.

B Observe these instructions to ensure satisfactory operation.

B The appliance may only be installed and started up by a trained installer.

B All changes and adjustments made via superior control systems must meet the heating system

requirements.

Risk of death from electric shock

B The power supply must be connected by a qualified electrician.

B The terminal diagram must be followed.

B Before opening the appliance, isolate all poles of the mains power supply and secure against

unintentional reconnection.

B Never install this appliance in wet rooms.

B Ensure that a circuit breaker is available to disconnect all poles from the mains power supply.

If there is no circuit breaker, you will need to install one.

Risk of damage from operator error

Operator errors can cause injury and damage to property.

B Ensure that children never operate this appliance unsupervised or play with it.

B Ensure that only individuals who can operate this appliance correctly have access to it.

Device damage from electrostatic discharge (ESD)

B Before unpacking the module, touch a radiator or a grounded metal water pipe to discharge any

electrostatic charge in your body.

Damage from incorrect spare parts

B Only use original Buderus spare parts. Damage caused by the use of spare parts not supplied

by Buderus are excluded from the Buderus warranty.

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

5

Product description

2

2 Product description

2.1 Correct use

The Logamatic LON-Gateway may only be used to connect Buderus boilers with control panel from

the Buderus Logamatic 4000 control series to superior control and/or building control systems via

LON-BUS.

2.2 Disposal

B Electronic components do not belong in household waste.

Dispose of defunct modules correctly through an authorized disposal site.

6

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

Product description

2

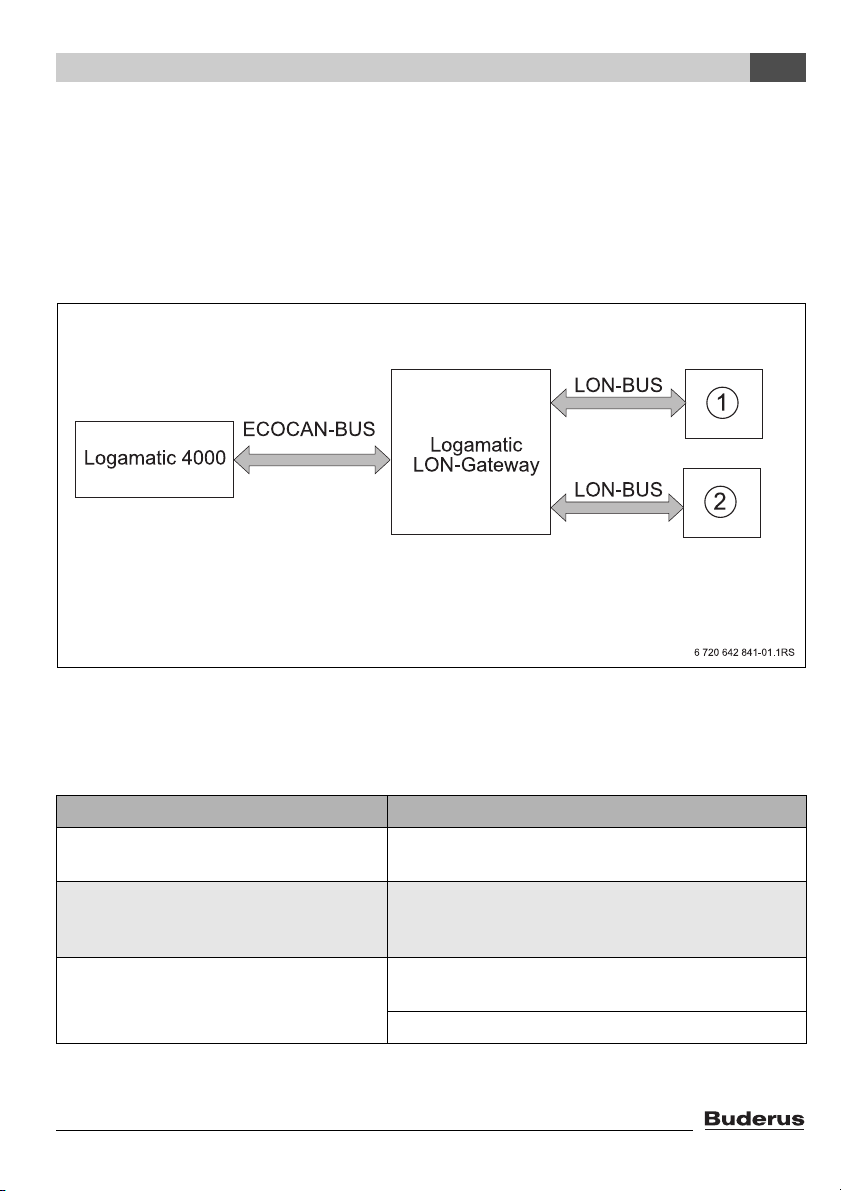

2.3 Product description

The Logamatic LON-Gateway is incorporated into a LON network via a twisted pair cable (twisted

2-wire line). The twisted pair cable is protected against reverse polarity.

Defined data of the Buderus control panel is implemented with the Logamatic LON-Gateway

interface on standard network variable types (SNVTs) for the LON data bus. The communication

includes forwarding of error messages, operating messages, and actual values, as well as changing

of set points and operating modes for boilers and consumers.

Fig. 1 Block diagram

1 Superior control system (building control system)

2 LON Gateway

Making the electrical connections

Logamatic LON-Gateway

Connection of the Logamatic LON-Gateway

with Logamatic 4000

Connection of Logamatic LON-Gateway to

LON networks

Maximum cable length for FTT 10 depending

on the cable types used (see Echelon documentation).

ECOCAN-BUS interface (BUS communication),

3000 ft (1000 m) shielded cable

FTT-10A transceiver for incorporation via 2-wire cable

(twisted pair) to standardized LON BUS network; line or

free BUS topology possible

JY(ST)Y 2x2 x 0,8: max. 1050 ft (320 m) for node to node,

1640 ft (500 m) total

Cat5: max. 820 ft (250 m) for node to node 1480 t (450 m)

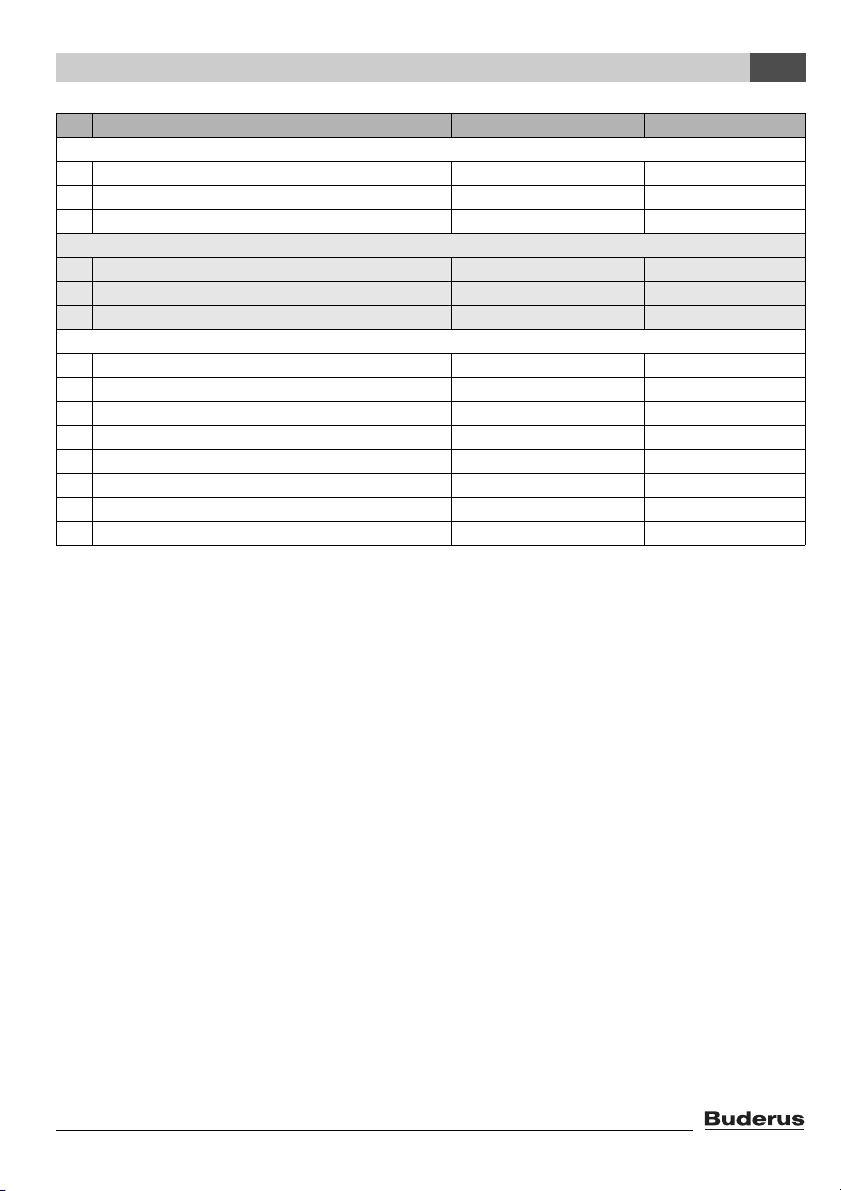

Tab. 2 Electrical connections on the LON-Gateway

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

7

Product description

2

Product features of the LON-Gateway

• Can be used with all digital Logamatic 4000 control panels

• Interface can be equipped after the fact for the superior control system or for LON thermostats,

integration into existing building control technology/direct digital control (GLT/DDC)

• Interoperability through use of the standard network variable types (SNVT) assured according to

LonMark®

• Provision of the SNVT data for systems consisting of:

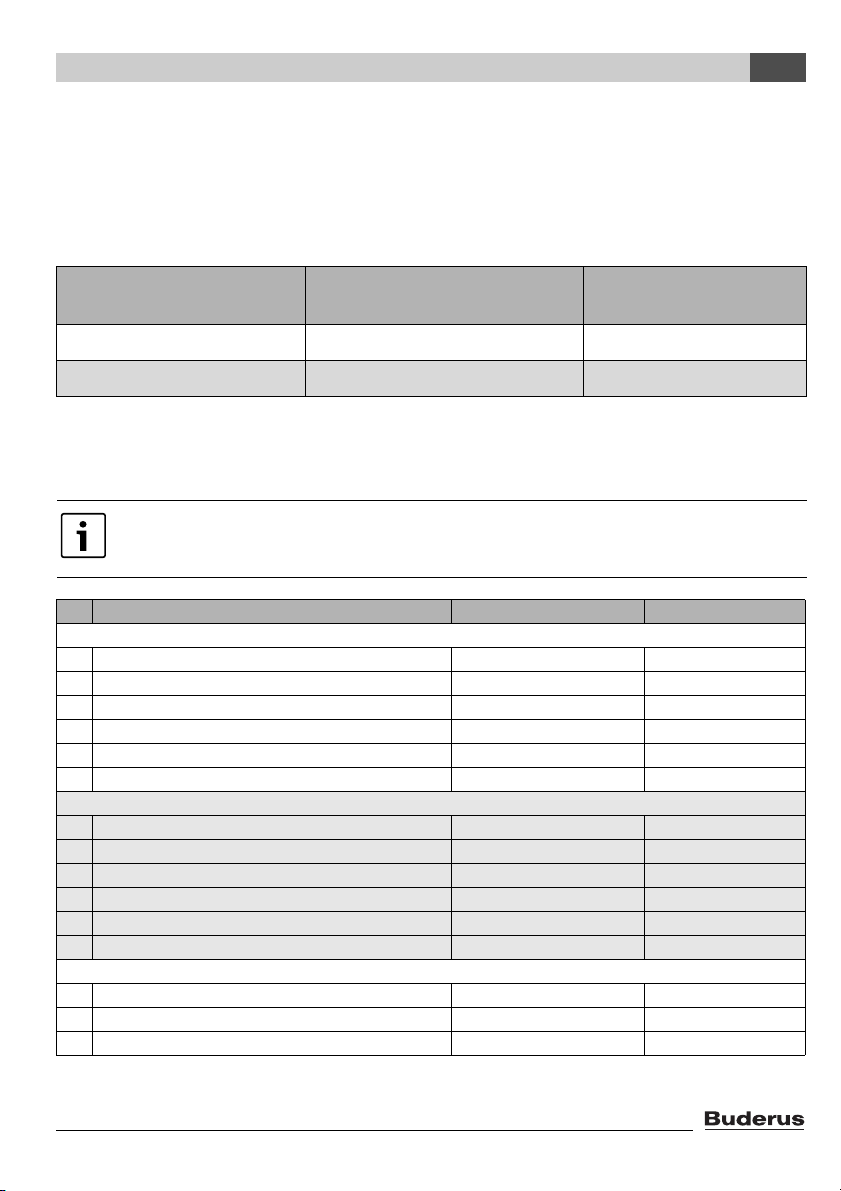

Communication objects Variant 2 boiler Variant 4 boiler

Boiler 2 4

Heating zones 5 1

DHW zone with tank charging pump and

11

recirculation pump

Solar thermal system for DHW heating 1 -

Tab. 3 Variants

2.4 Specifications

Unit Logamatic LON-Gateway

Power supply L 6 V AC, 400 mA

Frequency Hz 50/60 Hz

Power consumption VA 1.5

Dimensions (width/height/depth) inches (mm) 5-1/8" / 5-1/2" / 9/16"

(130/140/40)

Weight oz (g) 14 (400)

Operating temperature °F (°C) 40 to 122 (5 to 50)

Protection level IP40

Tab. 4 Specifications

2.5 Specified communication objects

With the LON-Gateway, selected data from up to four Logamatic 4000 control panels can be

exchanged via LON data bus with third-party control systems.

In addition to the communication objects for the first boilers, which are a component of the control

panel, additional functions in the form of modules for multi-boiler systems, heating zones, DHW, and

solar can be added.

If heating zones are served via LON, no other remote controls, e.g. Buderus remote

control BFU, may be connected to this heating zone.

8

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

Product description

2

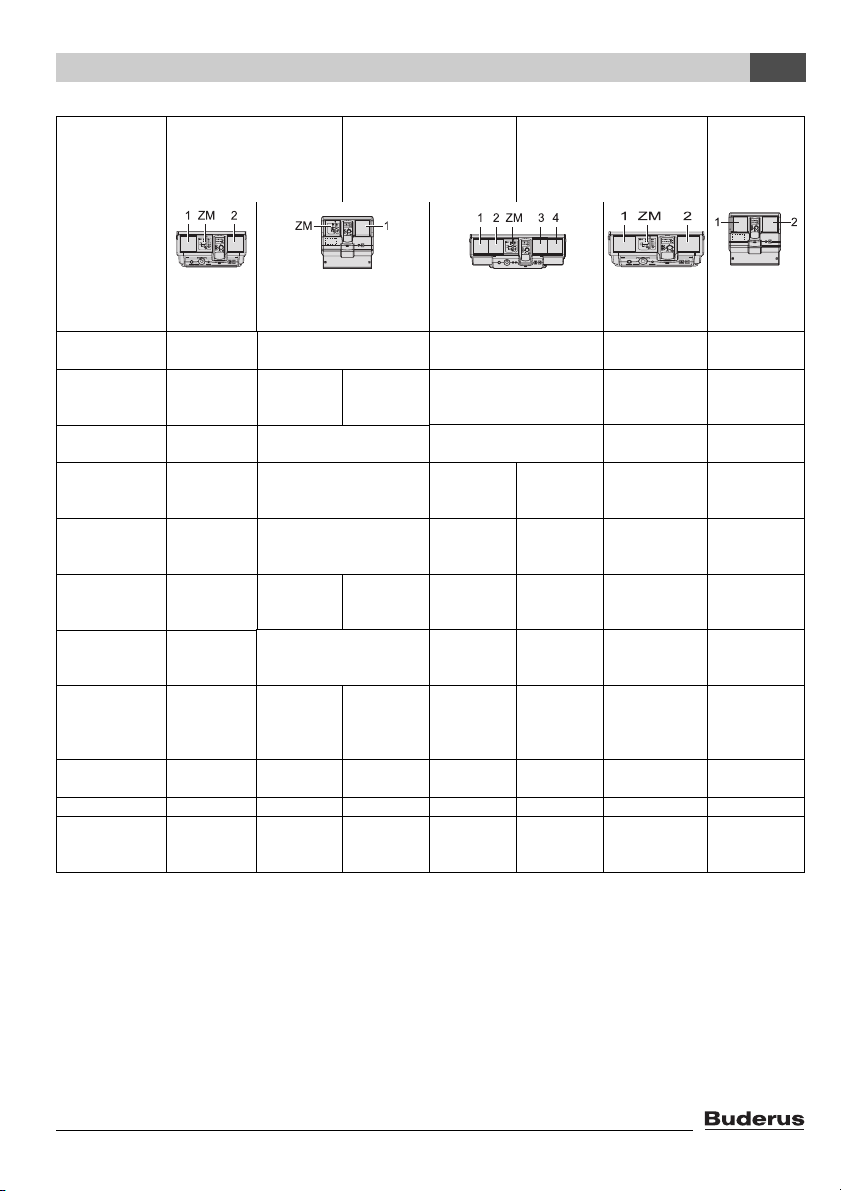

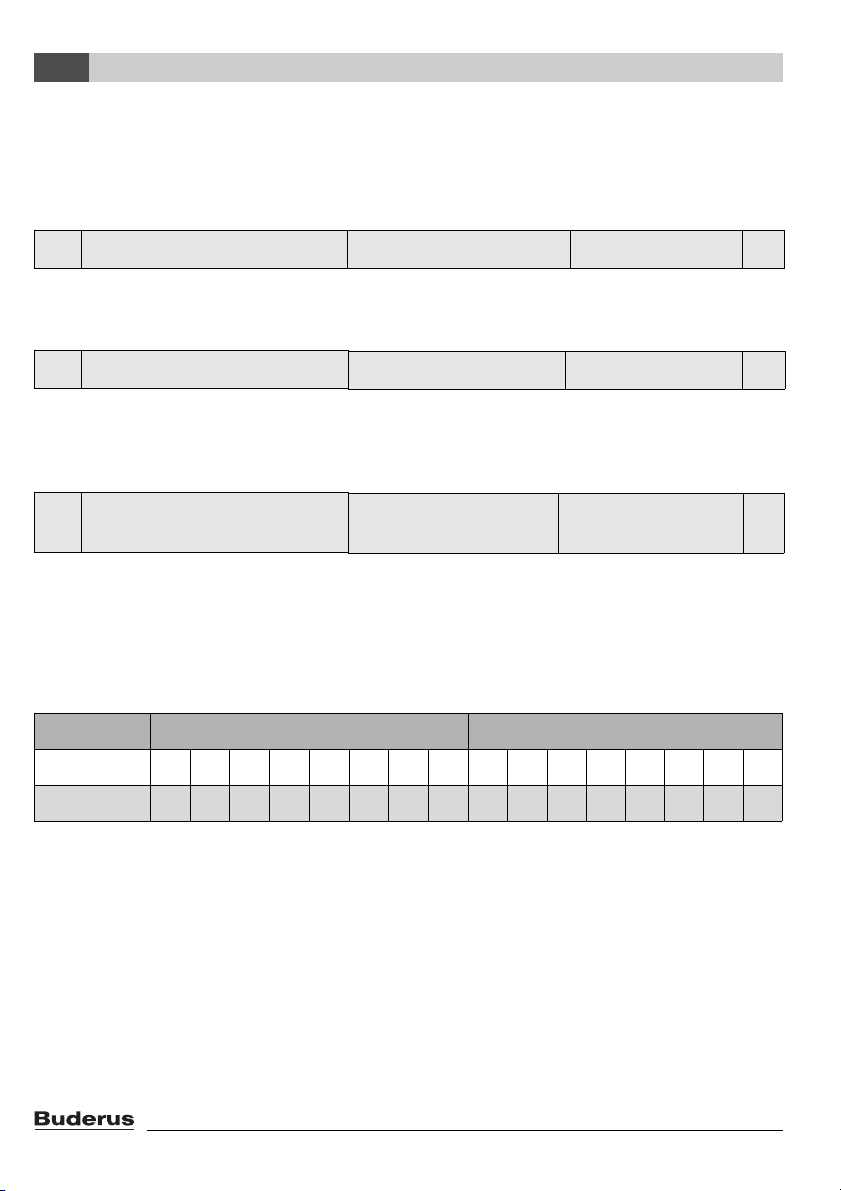

Requirement

5 heating zones

Logamatic

4211

Boiler with

Logamatic 4000y(ZM422)

Boiler with

– y

Logamatic EMS

1 boiler

1 DHW

1 solar

Logamatic

4121

–o

(ZM424)o(FM456 in

2 boiler

5 heating zones

1 DHW

1 solar

Logamatic

4321

2)

(FM458)

2)

o

(FM458)

4 boilers

1 heating zone

1 DHW

Logamatic

4323

(FM458)

(FM458)

Expansion

for heating

zones 3, 4

Logamatic

4122

2)

o

2)

o

–

–

slot 2)

DHW heating y

(ZM422)

LON HK 1 o

(FM442 in

slot 1)

LON HK 2 o

(FM442 in

slot 1)

LON HK 5 y

(ZM422)

y

(ZM424)

y

(ZM424)

(FM442 in

o

(FM441 in slot 2)o(FM441 in slot 1)

o

(FM441 in

slot 1)

y

(ZM424)

o

(FM442 in

slot 1)

––o

(FM442 in

–

o

o

–

(FM441 in slot 1)

slot 1)

–– –

–– –

slot 3)

Solar DHW

heating

LON HK 3

LON HK 4

o

(FM443 in

slot 2)

1)

o

o

(FM443 in slot 2)

1)

o

o

o

(FM443 in

1)

slot 2)

o

(4322 with

FM442 in

–– –

–– o

(FM442 in

slot 2)

slot 2)

LON flasher

version

XIF file version LON_2B_00 LON_2B_00 LON_2B_00 LON_2B_00 LON_4B_00 LON_4B_00

Address of

LON Flasher

2B_00

LON Flasher

2B_E_00

LON Flasher

2B_E_00

LON Flasher

2B_00

1111

3)

LON Flasher

4B_00

3)

1

LON Flasher

4B_00

12

Logamatic

control panel

Tab. 5 Overview of LON-Gateway and Logamatic control system

1) Logamatic 4122 required if LON heating zones 3 and 4 are required in one and two-boiler systems.

2) Function module FM458 combines boiler with the Logamatic 4000 and Logamatic EMS control system.

3) ECOCAN-BUS address of the Logamatic 4321 control panel on the first boiler; additional boilers with

Logamatic 4321 control panel of the 4322 are assigned ECOCAN-BUS addresses 2 to 4.

1)

y = Basic equipment

o = Optional (required accessories in parentheses)

– = Not required

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

9

Product description

2

2.6 Logamatic LON-Gateway firmware

2.6.1 Firmware when delivered

When delivered, the firmware version LON_Flasher_2B_00 is preinstalled. This version is for a

heating system with floor-standing boilers with Logamatic 4321. If you need another firmware variant

(e.g. LON_Flasher_4B_00) for your installation, it is easy to update the firmware. (see procedure for

updating firmware)

The firmware version of your LON-Gateway is displayed via the Logamatic ECO-SOFT

4000/EMS service software (Start communication -> Select COM port settings ->

Direct connection).

You can find the correct COM port under: Windows XP from the device manager

(Control panel -> System -> Hardware -> Device manager -> COM port).

Procedure for Windows Visa and Windows 7: Control panel -> Hardware and Sound > Device manager -> COM port.

2.6.2 Procedure for updating firmware

First the LON-Gateway must be connected to the power supply and connected on-site to your

computer via the RS232 interface or USB converter.

B Obtain the desired firmware from Buderus and, start the LONFlasher*******.exe.

B Select the COM port.

B Start the update with the Flash button.

A display informs you about the current progress. The update is only complete when a message

"...successful!" appears.

B When a message "...successful!" appears, confirm with OK.

The update is complete.

After the successful update, disconnect the LON-Gateway from the line voltage for approx.

2 minutes to perform a reset. This completes the firmware update.

10

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

Network interface

3

3 Network interface

3.1 Overview of the SNVTs for variant 2 boilers

The prerequisite for the proper function is that the firmware on the LON-Gateway interface has at

least the version number indicated below and the following application file is used:

Buderus

Alternative

2 boilers with Logamatic EMS LON_Flasher_2B_E_00 LON_2B_00

2 boilers with Logamatic 4000 LON_Flasher_2B_00 LON_2B_00

(alternative of the LON-Flasher)

LON application file

(XIF file)

Tab. 6

Communication via the Logamatic LON-Gateway takes place using standard network variable types

(SNVT). Standard configuration parameter types (SCPTs) are not used.

Set the system up for repeated reading of SNVTs, which ensure data exchange

between the network participants.

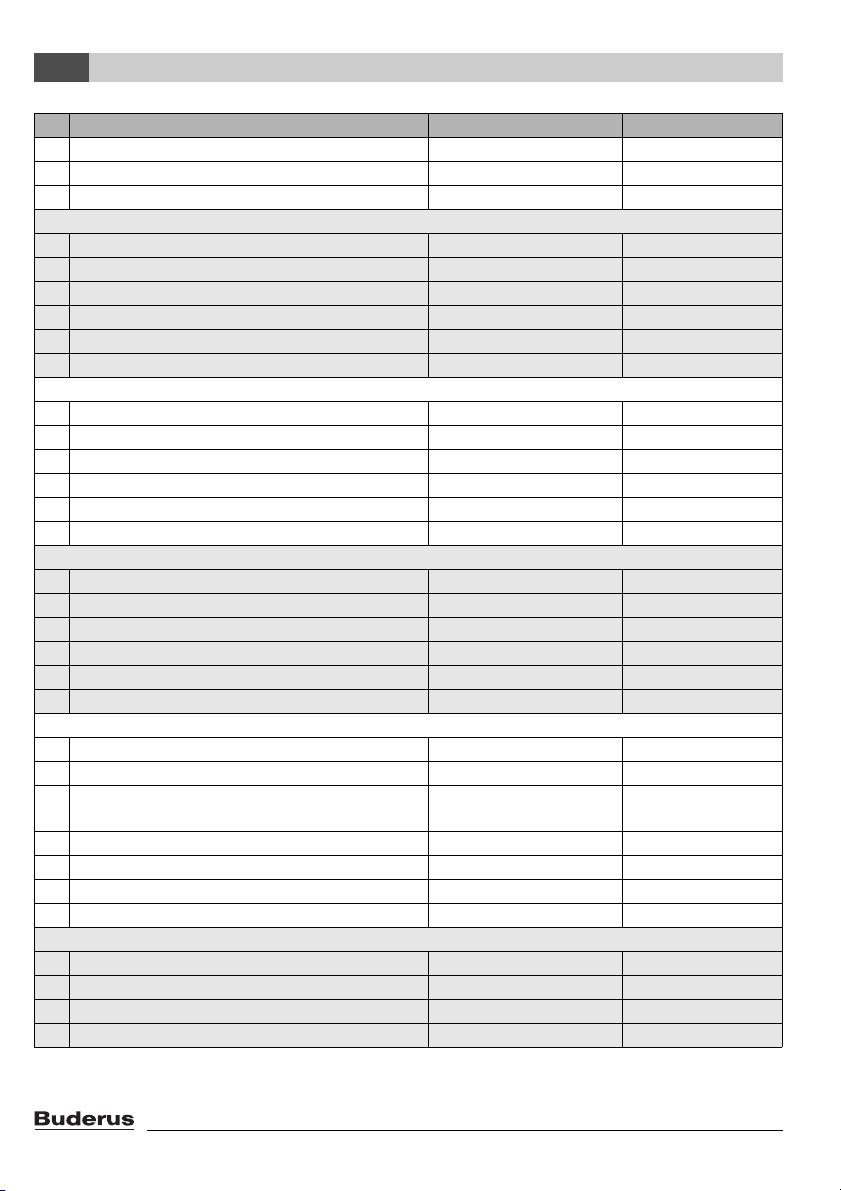

No. Meaning SNVT type SNVT name

General

0 Time SNVT_time_ stamp(84) nviUhrzeit

1 Outdoor temperature SNVT_temp_p(105) nvoAussen_Tp

2 Error message 1 control unit addresses 1 + 2 SNVT_state(83) nvoFehler1

3 Error message 2 control unit addresses 1 + 2 SNVT_state(83) nvoFehler2

4 Error message 3 control unit addresses 1 + 2 SNVT_state(83) nvoFehler3

5 Error message 4 control unit addresses 1 + 2 SNVT_state(83) nvoFehler4

Heating zone 1

6 Change operating mode (D/N/A) SNVT_hvac_mode(108) nviHK1TgNtAt

7 Change room set point night temperature SNVT_temp_p(105) nviHK1RaumSNt_Tp

8 Change room set point day temperature SNVT_temp_p(105) nviHK1RaumSTg_Tp

9 Display room set point temperature SNVT_temp_p(105) nvoHK1Raum_S_Tp

10 Display operating mode (D/N/A) SNVT_hvac_mode(108) nvoHK1Betrieb

11 Display heating zone supply actual temperature SNVT_temp_p(105) nvoHK1VLIst_Tp

Heating zone 2

12 Change operating mode (D/N/A) SNVT_hvac_mode(108) nviHK2TgNtAt

13 Change room set point night temperature SNVT_temp_p(105) nviHK2RaumSNt_Tp

14 Change room set point day temperature SNVT_temp_p(105) nviHK2RaumSTg_Tp

Tab. 7 Service menu navigator

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

11

Network interface

3

No. Meaning SNVT type SNVT name

15 Display room set point temperature SNVT_temp_p(105) nvoHK2Raum_S_Tp

16 Display operating mode (D/N/A) SNVT_hvac_mode(108) nvoHK2Betrieb

17 Display heating zone supply actual temperature SNVT_temp_p(105) nvoHK2VLIst_Tp

Heating zone 3

18 Change operating mode (D/N/A) SNVT_hvac_mode(108) nviHK3TgNtAt

19 Change room set point night temperature SNVT_temp_p(105) nviHK3RaumSNt_Tp

20 Change room set point day temperature SNVT_temp_p(105) nviHK3RaumSTg_Tp

21 Display room set point temperature SNVT_temp_p(105) nvoHK3Raum_S_Tp

22 Display operating mode (D/N/A) SNVT_hvac_mode(108) nvoHK3Betrieb

23 Display heating zone supply actual temperature SNVT_temp_p(105) nvoHK3VLIst_Tp

Heating zone 4

24 Change operating mode (D/N/A) SNVT_hvac_mode(108) nviHK4TgNtAt

25 Change room set point night temperature SNVT_temp_p(105) nviHK4RaumSNt_Tp

26 Change room set point day temperature SNVT_temp_p(105) nviHK4RaumSTg_Tp

27 Display room set point temperature SNVT_temp_p(105) nvoHK4Raum_S_Tp

28 Display operating mode (D/N/A) SNVT_hvac_mode (108) nvoHK4Betrieb

29 Display heating zone supply actual temperature SNVT_temp_p(105) nvoHK4VLIst_Tp

Heating zone 5

30 Change operating mode (D/N/A) SNVT_hvac_mode (108) nviHK5TgNtAt

31 Change room set point night temperature SNVT_temp_p(105) nviHK5RaumSNt_Tp

32 Change room set point day temperature SNVT_temp_p(105) nviHK5RaumSTg_Tp

33 Display room set point temperature SNVT_temp_p(105) nvoHK5Raum_S_Tp

34 Display operating mode (D/N/A) SNVT_hvac_mode (108) nvoHK5Betrieb

35 Display heating zone supply actual temperature SNVT_temp_p(105) nvoHK5VLIst_Tp

DHW

36 Change operating mode (D/N/A) SNVT_hvac_mode (108) nviHK1TgNtAt

37 Change DHW set point temperature SNVT_temp_p(105) nviWW_Set_Tp

38 Change recirculation pump operating mode

SNVT_hvac_mode (108) nviZP_TgNtAt

(D/N/A)

39 Display operating mode (D/N/A) SNVT_hvac_mode (108) nvoWW_Betrieb

40 Display DHW set point temperature SNVT_temp_p(105) nvoWW_S_Tp

41 Display DHW actual temperature SNVT_temp_p(105) nvoWW_Ist_Tp

42 Display recirculation pump operating mode (D/N/A) SNVT_hvac_mode (108) nvoZP_Betrieb

Strategy

43 Change system operating mode (D/N/A) SNVT_hvac_mode (108) nviAnlTgNtAt

44 Change system supply set point temperature SNVT_temp_p(105) nviAnlVorgabe_Tp

45 Display system supply actual temperature SNVT_temp_p(105) nvoAnlVLIst_Tp

46 Display system return actual temperature SNVT_temp_p(105) nvoAnlRLIst_Tp

Tab. 7 Service menu navigator

12

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

Network interface

No. Meaning SNVT type SNVT name

Boiler 1

47 Status of burner boiler 1

1)

SNVT_state(83) nvoKS1Br1Stufe1

48 Status burner boiler 1 SNVT_state(83) nvoKS1Br1Stufe2

49 Display boiler actual temperature SNVT_temp_p(105) nvoKS1VLIst_Tp

Boiler 2

50 Status burner boiler 2

1)

SNVT_state(83) nvoKS2Br1Stufe1

51 Status burner boiler 2 SNVT_state(83) nvoKS2Br1Stufe2

52 Display boiler actual temperature SNVT_temp_p(105) nvoKS2VLIst_Tp

Solar thermal system

53 Change operating mode (D/N/A) SNVT_hvac_mode (108) nviSLTgNtAt

54 Display operating mode (D/N/A) SNVT_hvac_mode (108) nvoSLBetrieb

55 Display collector actual temperature (FSK) SNVT_temp_p(105) nvoSLKoll_Tp

56 Display solar tank actual temperature (FSS1) SNVT_temp_p(105) nvoSLSP1Unten_Tp

57 Display solar yield (heat quantity) SNVT_elec_kwh_l (146) nvoSLWMZ_Ertrag

58 SNVT_file_pos(90) nviParameter

59 SNVT_file_pos(90) nviAdresse

60 SNVT_file_pos(90) nvoMonitoring

Tab. 7 Service menu navigator

1) Display of the output for boilers with Logamatic EMS

3

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

13

Network interface

3

3.2 Description of the SNVTs for variant 2 boilers

Note:

The right column indicates the number of bytes.

3.2.1 General

0 Time SNVT_time_ stamp(84) nviUhrzeit 7

Tab. 8 Value for comparison of the time in the Buderus control system with the LON network

Format: YYYY/MM/DD hh:mm:ss

1 Outdoor temperature SNVT_temp_p(105) nvoAussen_Tp 2

Tab. 9 Display of the current outdoor temperature

Note:

230 °F (110 °C) is an invalid value (e.g. no temperature sensor connected, sensor defective, etc.)

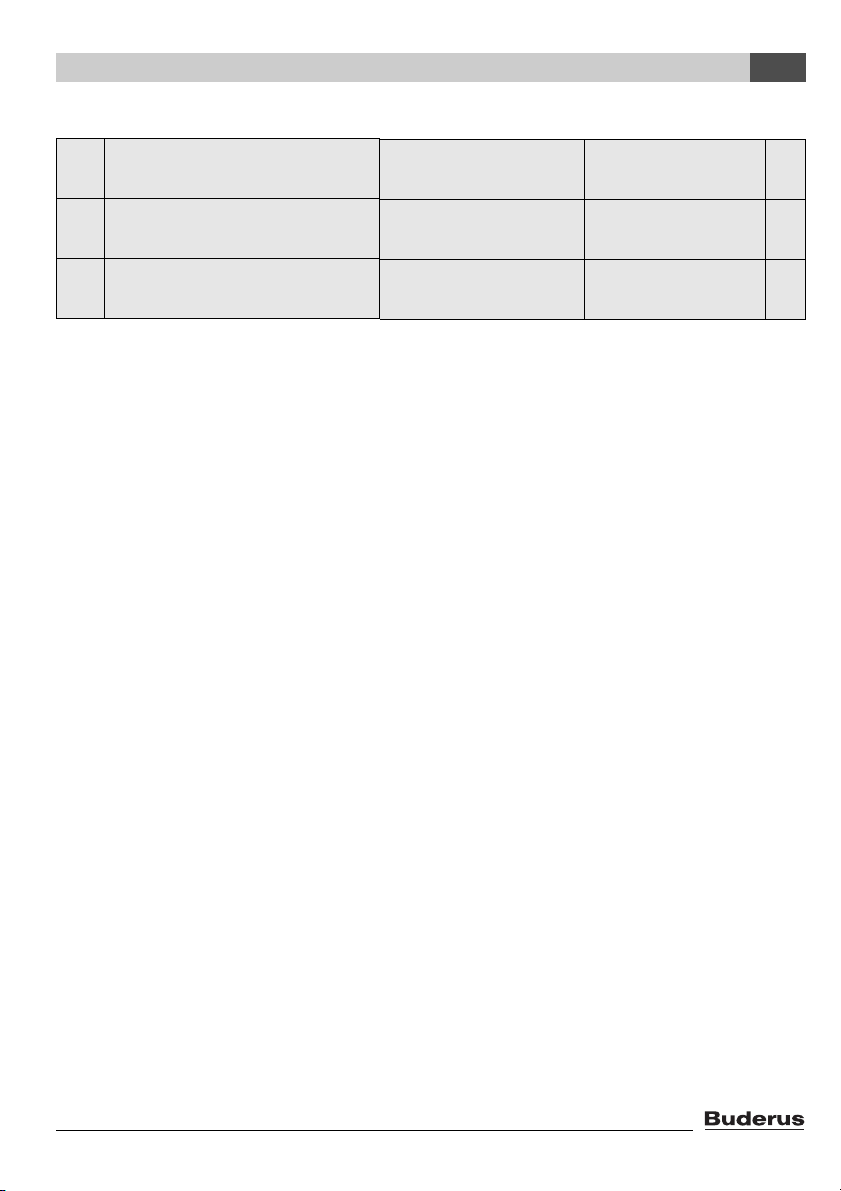

2 Error message 1 control

SNVT_state(83) nvoFehler1 2

panel address 1 + 2

Tab. 10 Output for error messages: error 1 of control panel 1 and 2

For the error list, see Chapter 7, page 43.

Error messages are displayed as 2-byte values (2 x 8 bits). The first byte (the first 8 bits seen from

the left) is the interpretation of the error message of control panel address 2. The second byte (the

remaining 8 bits) is the interpretation of the error message of control panel address 1:

First byte - error boiler 2 Second byte - error boiler 1

Display 0000000000000000

Interpretation 2021222324252627202122232425262

7

Tab. 11

Errors are displayed as binary values and must be converted to decimal values. By comparing with

the error list (see Chapter 7, page 43), the associated texts are assigned to the error numbers.

Example: see page 27

14

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

Network interface

Example:

3

3 Error message 2 control

SNVT_state(83) nvoFehler1 2

panel address 1 + 2

4 Error message 3 control

SNVT_state(83) nvoFehler1 2

panel address 1 + 2

5 Error message 4 control

SNVT_state(83) nvoFehler1 2

panel address 1 + 2

Tab. 12 Outputs for error messages

Second, third, and fourth current errors in the control panel in question. List of the error list, see

Chapter 7, page 43.

Interpretation as described for error message 1.

Technical Information Logamatic LON-Gateway - Subject to modifications resulting from technical improvements!

15

Loading...

Loading...