Page 1

Mounting and Service

Instructions

Room controller

Logamatic EMS

RC35 user interface

6 720 618 477-00.1RS

For trained and

certified installers

Read carefully prior

to installation and

maintenance.

6 720 640 227 - 05/2009 US/CA

Page 2

Contents

Contents

1 Explanation of symbols and safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Correct use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Package contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Applicability of these instructions for function modules (accessories) . . . . . . . . . . . . . . 9

2.6 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Choosing the right installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.1 Installation in reference room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.2 Installation on boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Types of installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Installation and connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 User interface: attaching or removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Operating basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Overview of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Introduction to the Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Overview of the Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 General commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Checklist: important parameters for commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Quick commissioning (Quick operation menu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4 Detailed commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.5 System commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.6 Shut-down/switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.7 Operating tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Logamatic EMS RC35 user interface - Subject to technical modifications.2

Page 3

Contents

6 Entering system settings (Service menu – Settings) . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1 System data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.1 Type of building (“damping” of outdoor temperature) . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1.2 Minimum outdoor temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2 Boiler data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3 Heating zone data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3.1 Assignment of user interface/remote control unit in the software . . . . . . . . . . . . . . . . . . 32

6.3.2 Control mode (outdoor temperature controlled/room influence) . . . . . . . . . . . . . . . . . . 32

6.3.3 Characteristic heating curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.3.4 Reduction modes (night setback) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.5 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4 Domestic hot water (DHW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.5 Solar data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.6 RC35 calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.7 Contact data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1 Function test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2 Monitor value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.3 Error message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.4 Characteristic heating curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.5 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11 Service menu RC35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Logamatic EMS RC35 user interface - Subject to technical modifications. 3

Page 4

1

Explanation of symbols and safety instructions

1 Explanation of symbols and safety instructions

1.1 Explanation of symbols

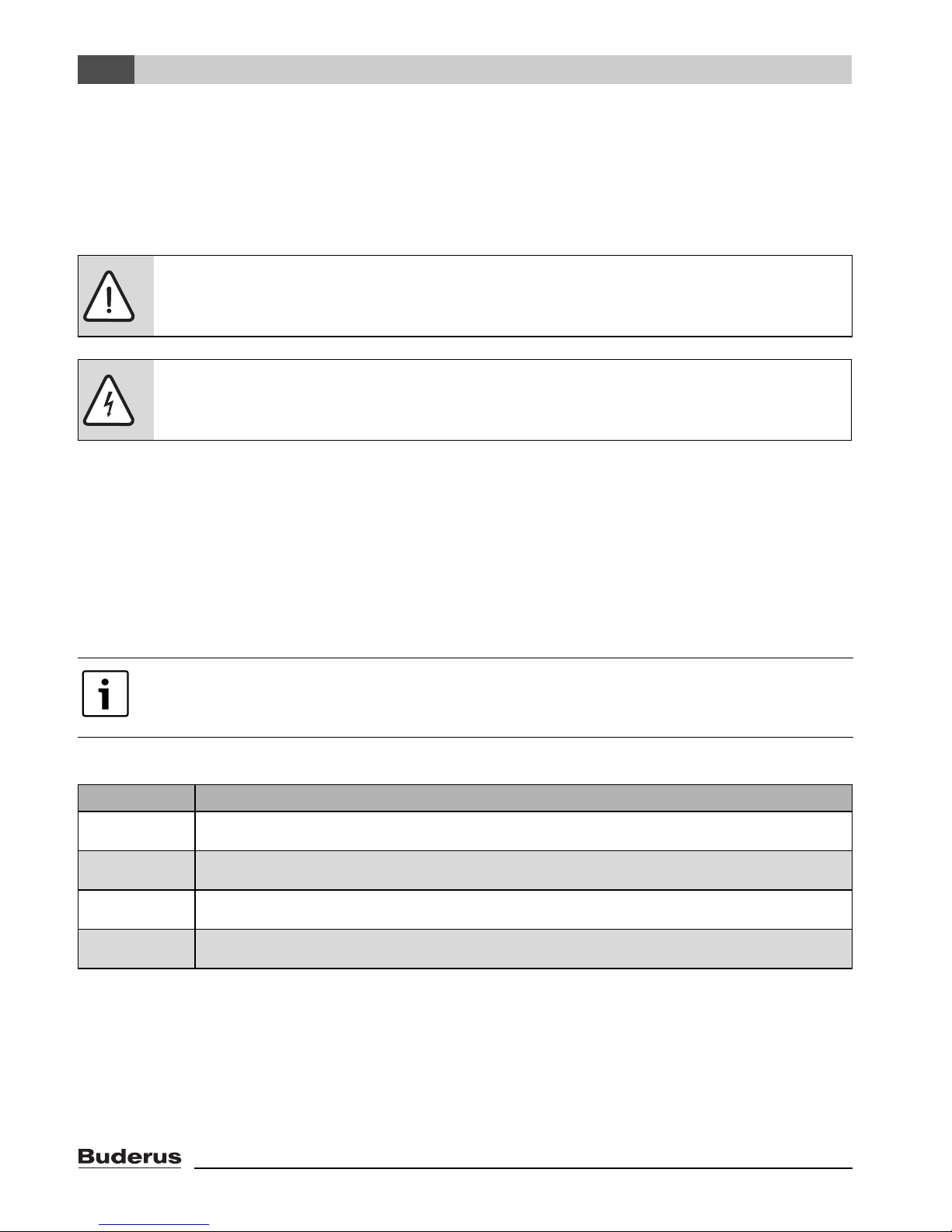

Warnings

Warnings in the text are indicated by a warning triangle with a gray background in a

framed box.

In case of danger due to current, the exclamation point on the warning triangle is

replaced with a lightning symbol.

Signal words at the beginning of a warning are used to indicate the type and seriousness of the

ensuing risk if measures for minimizing damage are not taken.

• NOTE indicates that damage to property may occur.

• CAUTION indicates possible minor to medium personal injury.

• WARNING indicates possible severe personal injury.

• DANGER indicates that severe personal injury may occur.

Important Information

Important information that presents no risk to people or property is indicated with this

symbol. They are separated by lines above and below the text.

Additional symbols

Symbol Explanation

B Sequence of steps

Æ Cross-reference to other points in this document or to other documents

• Listing/list entry

– Listing/list entry (2nd level)

Tab. 1

Logamatic EMS RC35 user interface - Subject to technical modifications.4

Page 5

Explanation of symbols and safety instructions

1

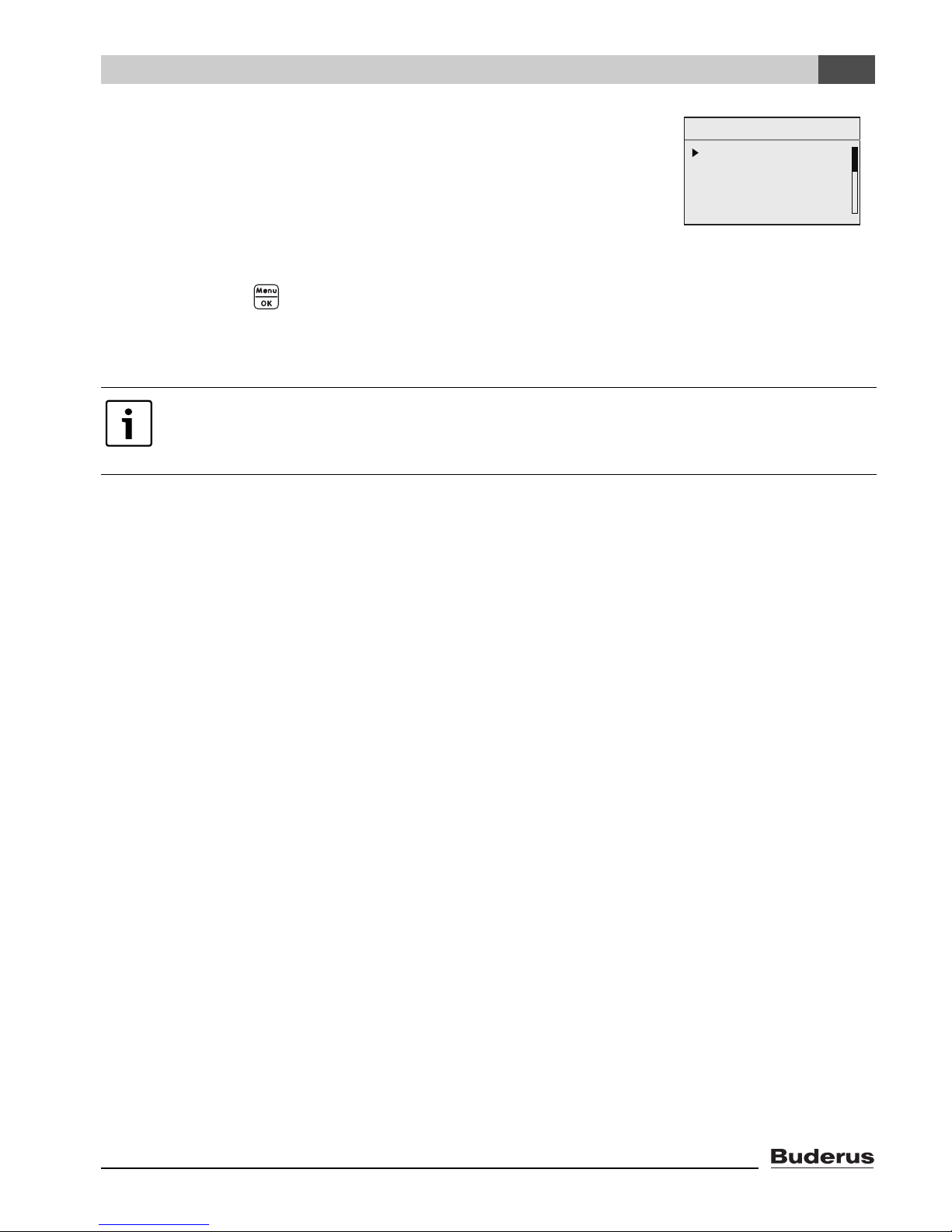

Display text: Words appearing on the display are shown in bold

in the text.

Example: USER MENU

USER MENU

standard display

modes of operation

program

WWSD temperature

Action sequences: Sequences of steps are marked with a triangle with its point towards the text.

Example: Press .

If action sequences have more than two steps and the order of the steps is important,

they are numbered (1., 2., ...).

Note on using this manual: Section 4.2 "Introduction to the Service menu" explains

in detail the steps needed for programming all the settings in the Service menu. In the

sections which come after it, programming is only exexplained in outline.

Logamatic EMS RC35 user interface - Subject to technical modifications. 5

Page 6

1

Explanation of symbols and safety instructions

1.2 Safety instructions

Installation and commissioning

B Observe all instructions to ensure satisfactory operation.

B Read and observe the safety information and codes of conduct.

B Installation and commissioning must only be carried out by qualified and trained system installers.

Use

B Always use this device correctly and in conjunction with the stated control systems.

B Observe all regulations, standards, and codes applicable to installation and operation of the

system in your country.

Risk of death from electric shock

B The electrical supply must be connected by a qualified electrician. The terminal diagram must be

followed.

B Before installation: isolate all poles of the power supply (120 V AC).

B Do not install this device in rooms with high moisture exposure (e.g. bathrooms, saunas).

B Never directly connect this device to the 120 V AC power mains.

Risk of scalding at the taps

B Make sure that a thermostatic mixing valve is installed and that it is set to temperatures below

122 °F (50 °C).

Warning: frost

The heating system can freeze up in cold weather, if switched OFF or locked out.

B Leave the heating system permanently switched ON.

B Enable frost protection.

B In the event of a fault: remedy the fault immediately.

Warning: device damage

The RC35 has no field serviceable parts inside. Attempt to open the housing will cause internal

damage, render the device inoperable, and void the manufacturer's warranty.

B In case of system irregularities please consult the 7 "Diagnosis" and 10 "Troubleshooting"

sections of this manual.

Logamatic EMS RC35 user interface - Subject to technical modifications.6

Page 7

Product description

2

2 Product description

2.1 Correct use

The RC35 control unit is intended for the operation and control of Buderus heating systems in single

and multi-family houses.

The boiler must be equipped with EMS (energy management system).

The user interface must not be used in conjunction with Logamatic 2000/4000 control units.

We recommend that the heating system is always operated with a user interface (only emergency

operation is possible without a user interface).

These instructions describe all the possible functions of the RC35. Some of these functions may

not be available, depending on which boiler (burner control unit) is used. For more information, refer

to the relevant chapter.

For information on the burner control units used, refer to the DIAGNOSIS\VERSIONS menu

(Æ page 45).

2.2 Certifications

This product has been tested and is certified for both the US and Canadian markets,

and meets all applicable US and Canadian standards.

2.3 Package contents

• RC35 user interface

• Operating instructions

• Mounting and maintenance instructions

• Wall bracket, attachment kit

Logamatic EMS RC35 user interface - Subject to technical modifications. 7

Page 8

2

Product description

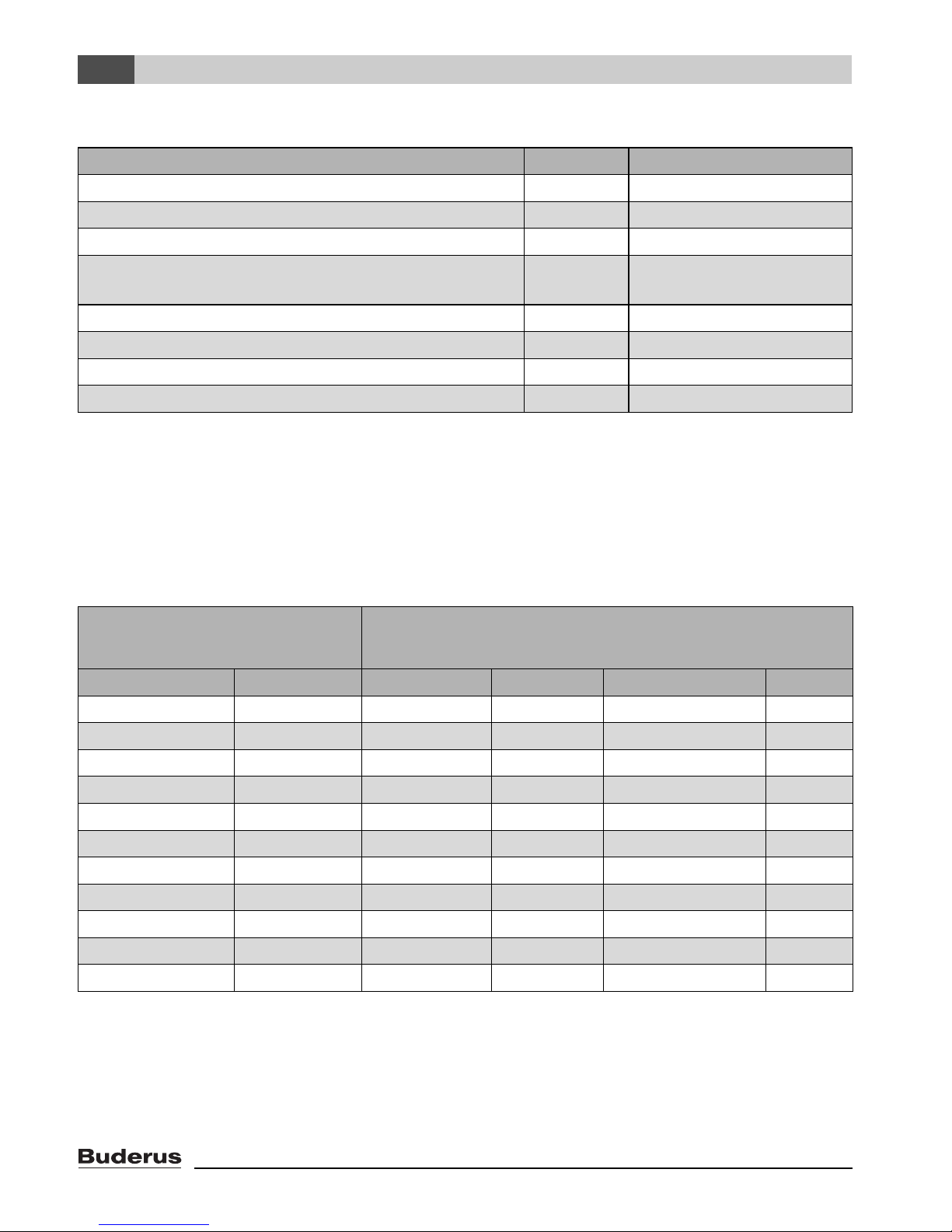

2.4 Technical specifications

Unit RC35

Power supply via bus system V 16 V DC

Power consumption W 0.3

Power consumption with backlight W 0.6

Dimensions (width/height/depth) inches

(mm)

6"/3-1/2"/1-1/2"

(150/90/32)

Weight ounces (g) 8.2 (233)

Operating temperature °F (°C) 32 – 122 (0 – 50)

Storage temperature °F (°C) 32 – 158 (0 – 70)

Relative humidity % 0– 90

Tab. 2 Specifications for the RC35 user interface

Temperature sensor characteristics

When measuring the resistance of temperature sensors, observe the following requirements:

• Isolate from the system before measuring.

• Measure the resistance at the cable ends.

• The resistances represent mean values and are subject to tolerances.

Supply temperature sensor

Outdoor temperature sensor

DHW temperature sensor

°F (°C) k Ω °C k Ω °C k Ω

–4 °F (–20 °C) 96.358 50 °F (10 °C) 19.872 140 °F (60 °C) 2.490

5°F(–15°C) 72.510 59 °F (15 °C) 15.699 149 °F (65 °C) 2.084

14 °F (–10 °C) 55.054 68 °F (20 °C) 12.488 158 °F (70 °C) 1.753

23 °F (–5 °C) 42.162 77 °F (25 °C) 10.001 167 °F (75 °C) 1.481

32 °F (0 °C) 32.556 86 °F (30 °C) 8.060 176 °F (80 °C) 1.256

41 °F (5 °C) 25.339 95 °F (35 °C) 6.535 185 °F (85 °C) 1.070

50 °F (10 °C) 19.872 104 °F (40 °C) 5.331 194 °F (90 °C) 0.915

59 °F (15 °C) 15.699 113 °F (45 °C) 4.372 203 °F (95 °C) 0.786

68 °F (20 °C) 12.488 122 °F (50 °C) 3.606 212 °F (100 °C) 0.677

77 °F (25 °C) 10.001 131 °F (55 °C) 2.989

86 °F (30 °C) 8.060

Tab. 3 Resistances of the 10 kΩ temperature sensors, for EMS only

Logamatic EMS RC35 user interface - Subject to technical modifications.8

Page 9

Product description

2

2.5 Applicability of these instructions for function modules

(accessories)

These instructions also apply to the user interface when used in conjunction with the MM10 mixing

module and the WM10 low loss header module.

If the heating system is equipped with other function modules (e.g. SM10 solar module), additional

settings and menus become available. Please see the instructions included with the module for

details.

2.6 Accessories

For detailed information on suitable accessories, refer to the catalogue.

• MM10 mixing module for controlling a 3-way mixing valve

• WM10 low loss header module

• Solar module and other EMS modules

• Outdoor temperature sensor, separate room temperature sensor

Logamatic EMS RC35 user interface - Subject to technical modifications. 9

Page 10

3

Installation

3 Installation

3.1 Choosing the right installation location

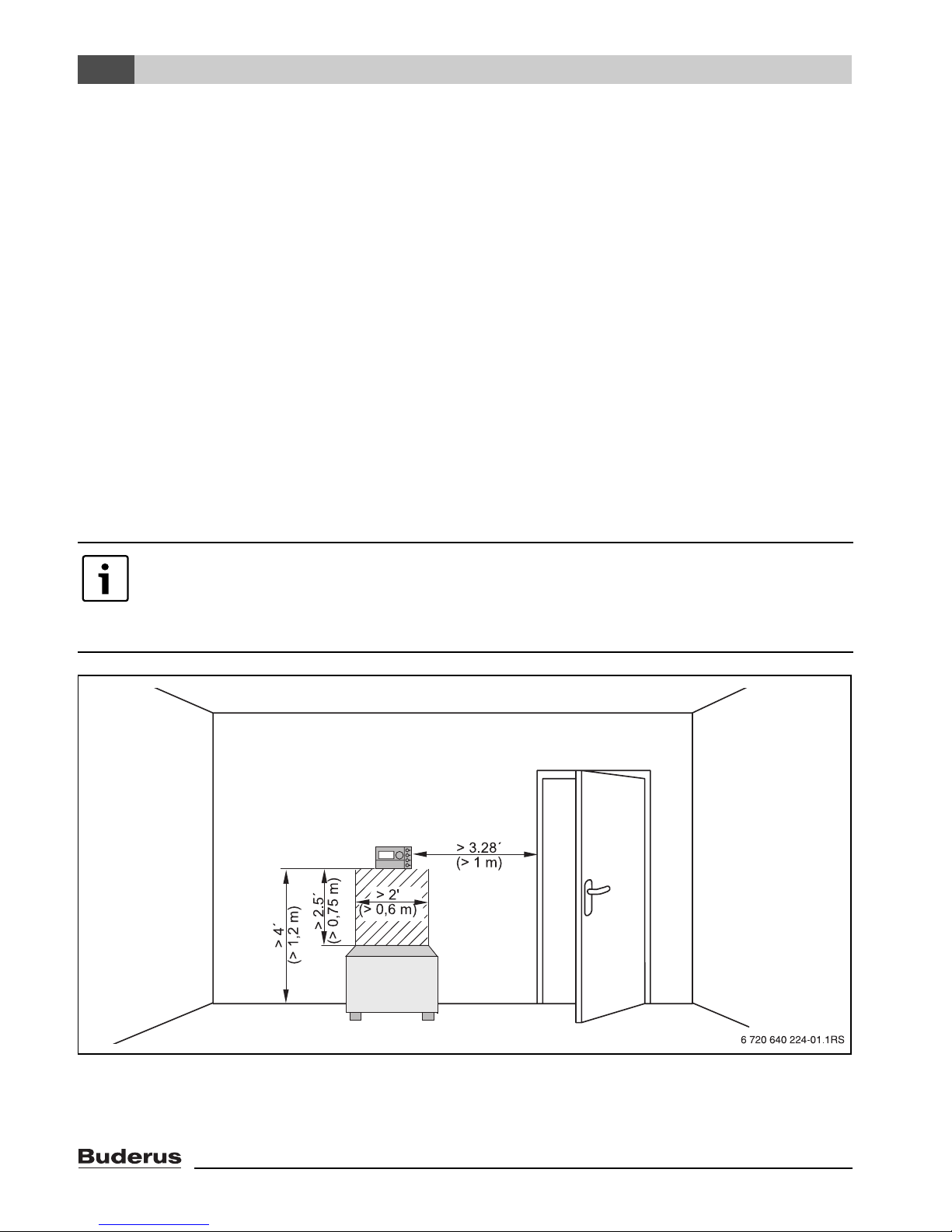

3.1.1 Installation in reference room

If the system is room-temperature controlled, the following requirements must be met:

• Installation on an internal wall (Æ Fig. 1).

• Maintain the specified distance from door(s) (to avoid drafts).

• Allow clearance below the user interface (Æ Fig. 1, shaded area) (to ensure correct temperature

measurement).

• The reference room (= installation room) must be as representative as possible of the entire home

(or zone) if possible. External heat sources in the reference room (like sunlight or an open

fireplace) affect the control's function. This means it may be too cold in rooms without those

external heat sources.

• The thermostatic valves on the radiators (if installed) in the reference room must always stay fully

open so that the two temperature controls do not affect one another.

If there is no suitable reference room, we recommend setting the system to outdoor

temperature control instead (this requires an outdoor sensor). Alternatively, you could

install an external room temperature sensor in the room with the greatest heating

requirements (e.g. living room).

Fig. 1 Minimum clearances for mounting in a reference room

Logamatic EMS RC35 user interface - Subject to technical modifications.10

Page 11

Installation

3

3.1.2 Installation on boiler

The unit can be installed directly on boilers equipped with EMS.

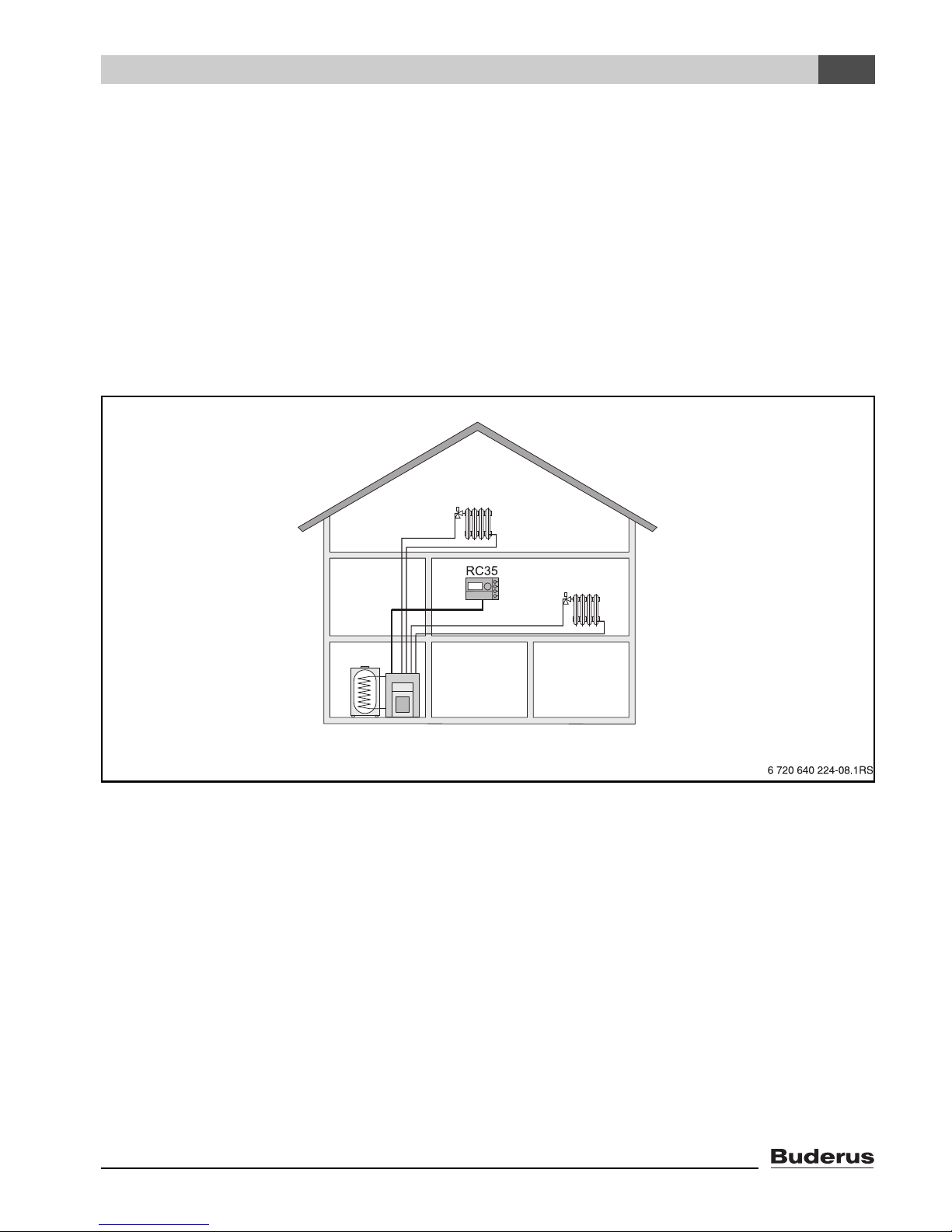

3.2 Types of installation

The user interface can be installed in three different ways:

• As the only user interface in the system (factory setting): the RC35 user interface is mounted in

a room in the home (the reference room) or on the boiler.

Example: single-family house with one heating zone.

• As the only user interface in a heating system with two or more heating zones (Æ Fig. 2).

Examples: radiant floor heating on one story, radiators in the other.

HZ1

HZ2

Fig. 2 Options for a heating system with two heating zones

Logamatic EMS RC35 user interface - Subject to technical modifications. 11

Page 12

3

Installation

3.3 Installation and connection

Please use only the wall bracket with screw terminals.

B If a wall bracket without screw terminals is already installed, replace it.

The wall bracket can be attached directly to the wall.

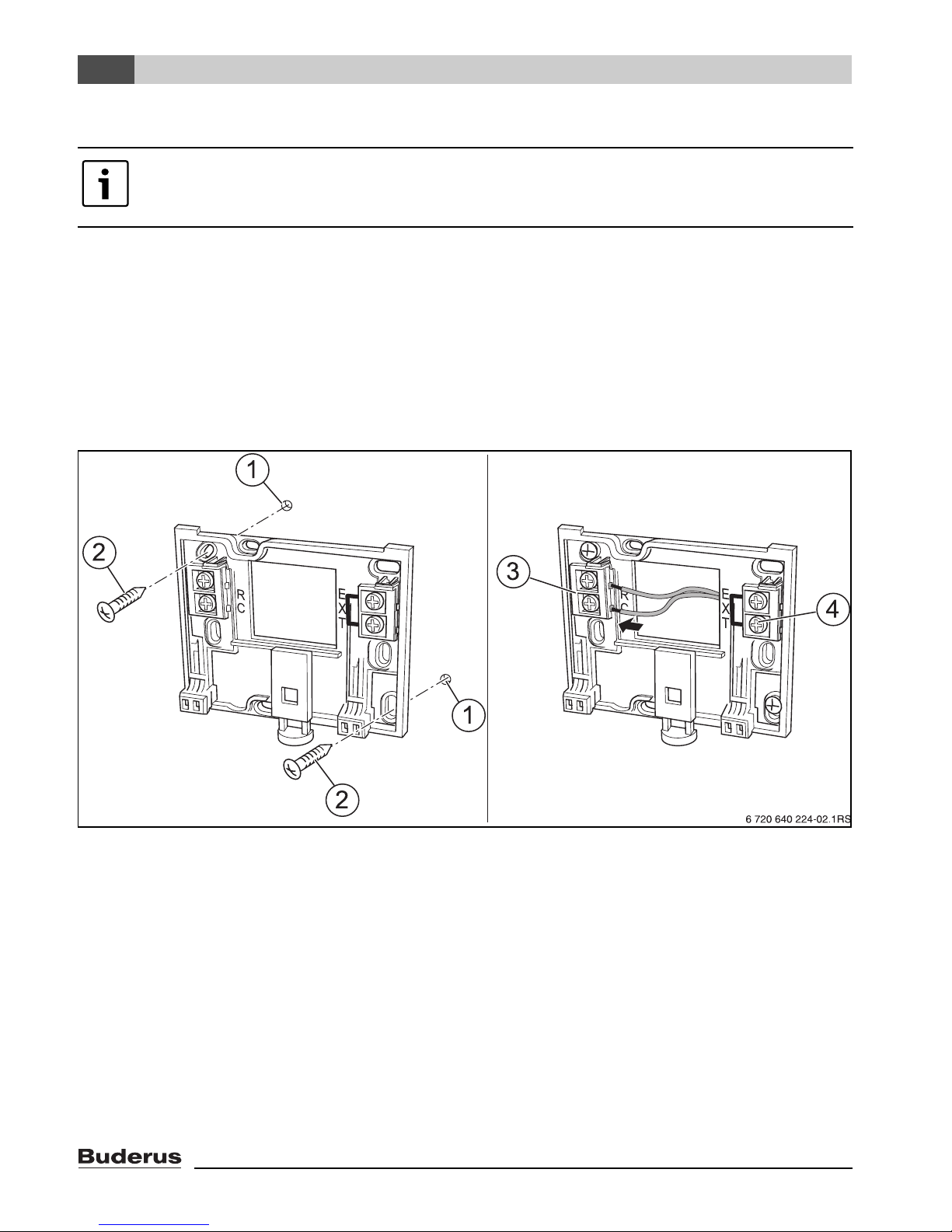

B Mount the wall bracket (Æ Fig. 3, left).

B Connect the two-wire bus cable from the Energy Management System (EMS) to the “RC” cable

terminals (Æ Fig. 3, [3]).

2

– Cable type: AWG18 (8 ft

– The two wires are not polarity sensitive.

– Never route the cables next to power cables.

(0.75 mm2)), length max. 330 ft. (100 m)

Fig. 3 Mounting the wall bracket (left) and connecting the wires (right)

1 Hole drilled in the wall

2 Screws (included with the unit) for surface-mounting on the wall

3 “RC” terminals for EMS (boiler)

4 “EXT” terminals for external room temperature sensor or for jumper

B If the RC35 is operated without an external room sensor, a jumper is needed on the “EXT”

terminals (Æ Fig. 3, [4]) (the jumper is factory-installed).

B If the RC35 is operated with an external room temperature sensor (optional), the factory-installed

jumper on “EXT” must be removed and the external room temperature sensor must be connected

there instead.

Logamatic EMS RC35 user interface - Subject to technical modifications.12

Page 13

Installation

3

3.4 User interface: attaching or removing

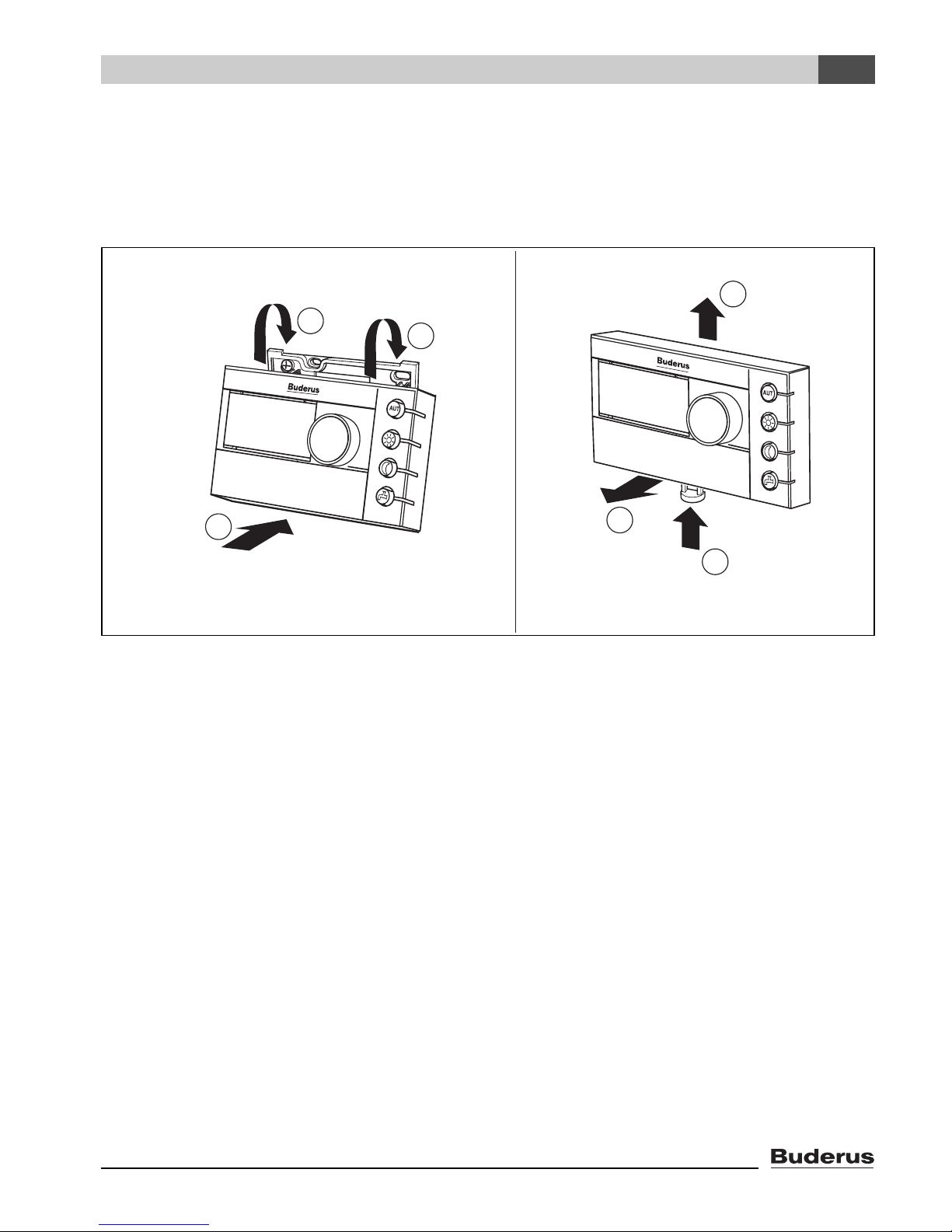

Attaching the user interface

1. Hook the user interface at the top into the mounting plate in the direction of the arrow.

2. Push the user interface at the bottom against the mounting plate, until it snaps into place.

AB

3

1

1

2

2

1

Fig. 4 Attaching the user interface (left) or removing it (right)

Removing the user interface

1. Press the button underneath the mounting plate in the direction of the arrow.

2. At the same time pull the user interface forwards.

3. Remove the user interface by lifting upward.

Logamatic EMS RC35 user interface - Subject to technical modifications. 13

Page 14

4

Operating basics

4 Operating basics

4.1 Overview of operation

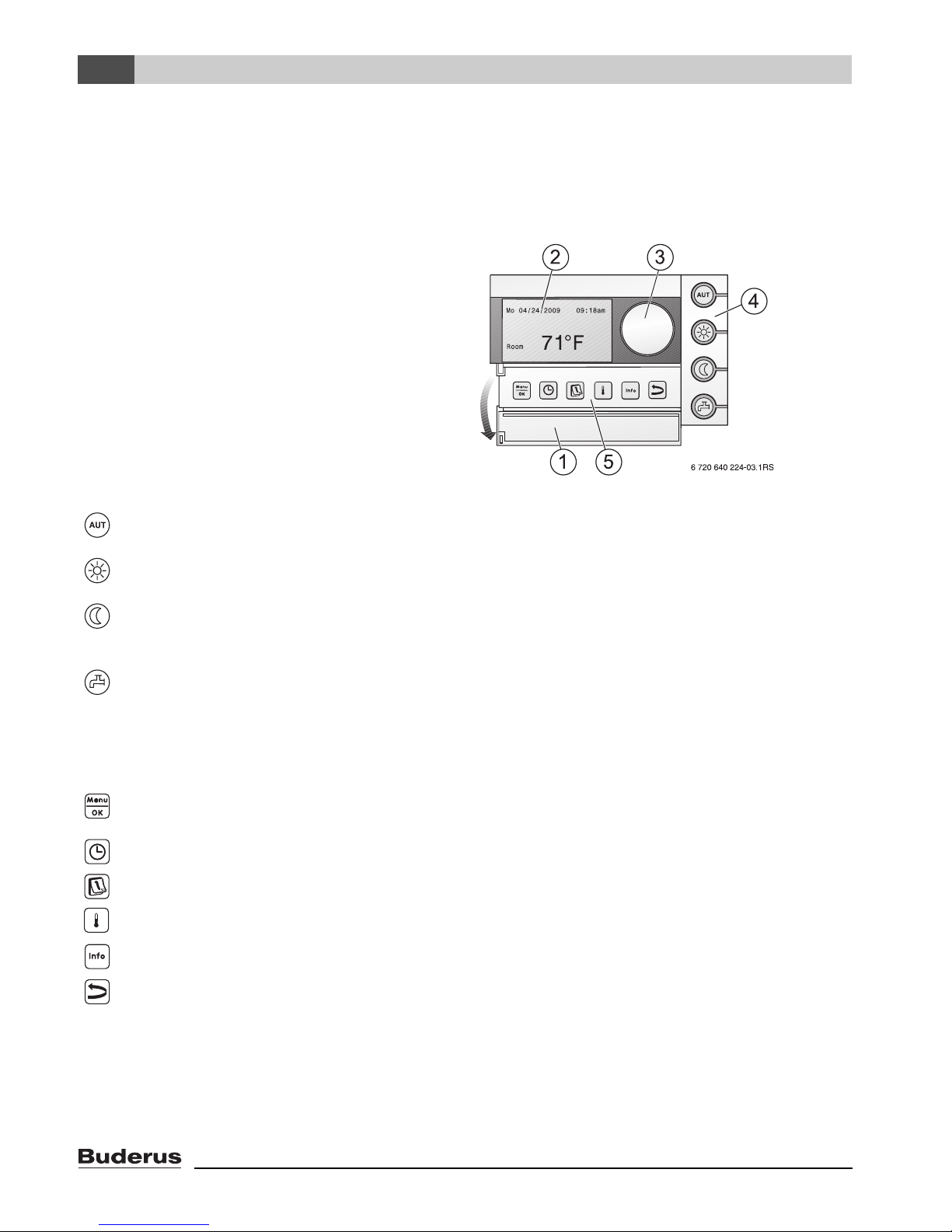

Legend for figure:

1 Cover: Pull the recessed grip on the

left to open

2 Display

3 Dial for changing values and

temperatures or for navigating

through the menus

4 Buttons for basic functions: When the LED lights up ...

“AUT” (automatic) • ... the program is active (automatic switchover between day and

night room temperatures).

“Day mode” (manual) • ... the heating system operates at the set day room temperature.

DHW heating is switched on (factory setting).

“Night mode” (manual) • ... the heating system operates at the set night setback room

temperature. Frost protection is active. DHW heating is

switched OFF (factory setting).

“DHW” (domestic hot water) • ... the DHW temperature has fallen below its set value while in

setback mode. The DHW can be heated up again (single

change) by pressing the button (the LED will then flash).

5 Buttons for

additional functions:

“Menu/OK” Open the user menu and confirm the current selection.

“Time” Set the time.

“Date” Set the date.

“Temperature” Set the room temperature.

“Info” Open the Info menu (to view values).

Function:

Turning the dial while pressing the button will change the value.

“Back” Go back one step or one menu item.

In Automatic mode, an additional LED lights up with the “AUT” LED to indicate which operating status is

currently active (“day mode” or “night mode”). The “domestic hot water” LED can also be disabled.

Logamatic EMS RC35 user interface - Subject to technical modifications.14

Page 15

Operating basics

4

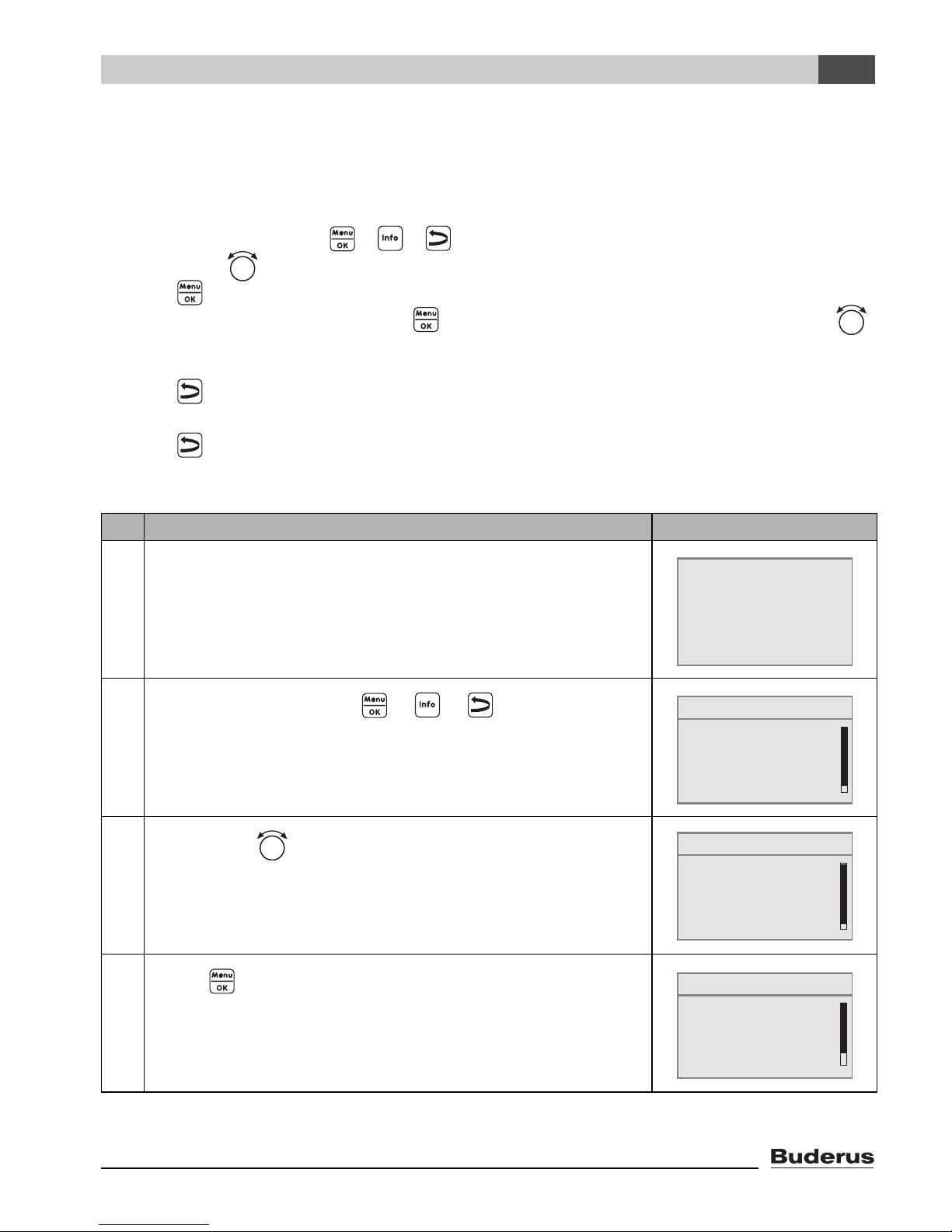

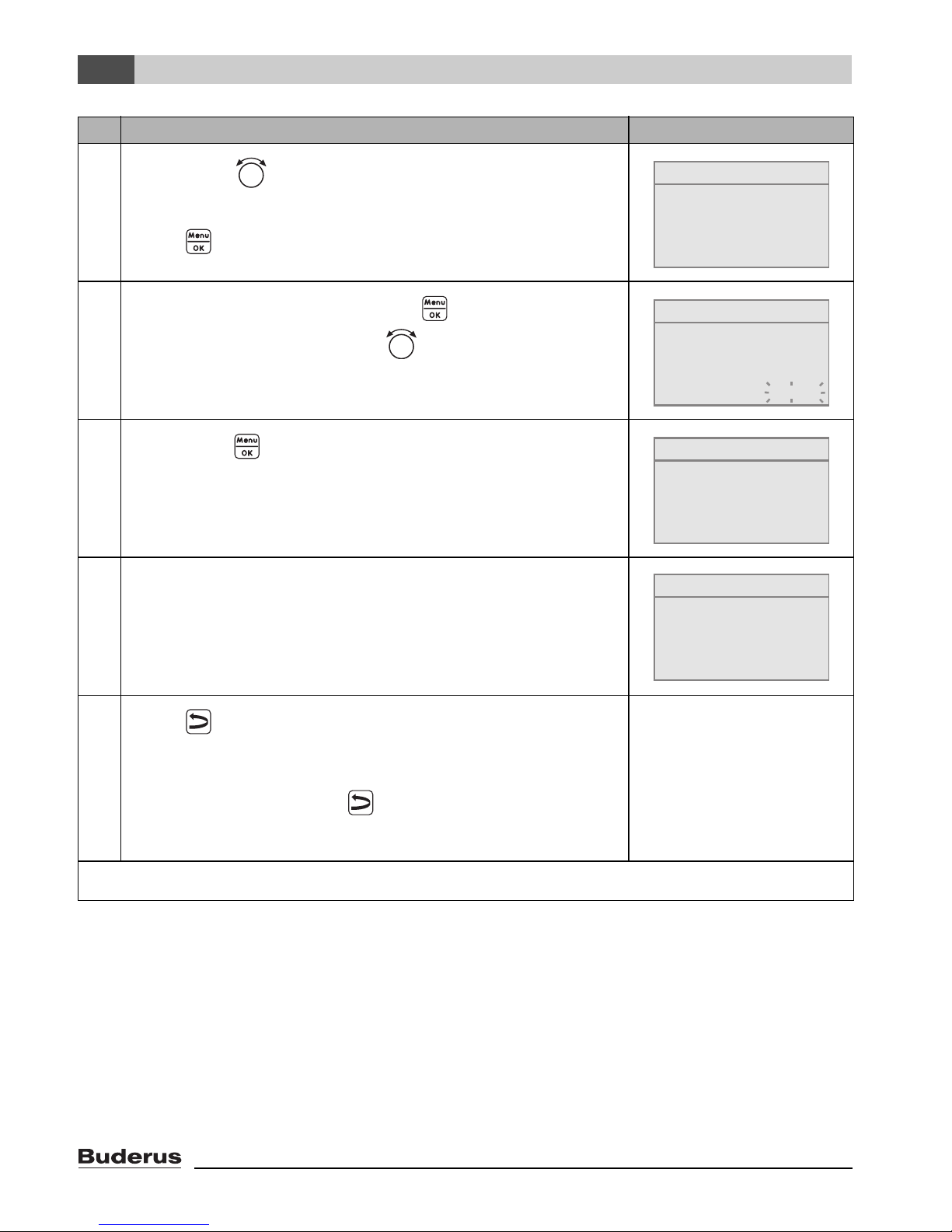

4.2 Introduction to the Service menu

The SERVICE MENU sets the system parameters. The Service menu also contains fault diagnosis,

for maintenance purposes, and performing a reset. The procedure for operation is always the same:

1. Open the cover (by pulling the recessed grip on the left).

2. Simultaneously press the + + buttons to open the SERVICE MENU.

3. Turn the dial to change the selected item (marked with).

4. Press to make your selection.

5. To change the value, hold down the button (the value starts flashing) and turn the dial

at the same time.

Release the button: the changed value is saved.

6. Press to go back one step.

-or-

7. Press several times or shut the cover to return to the default display.

Example: Setting the type of building (“delay” time)

Operating Instructions Result

1. Open the cover (by pulling the recessed grip on the left).

2.

Simultaneously press the + + buttons to open

the SERVICE MENU.

3.

Turn the dial counter-clockwise until settings is selected

(marked with).

4.

Press to confirm the selection.

The SERVICE\SETTINGS menu is opened.

Fr 12/02/2009 10:20am

outdoor tmp. 30°F

71 ˚F

SERVICE MENU

B

quick operation

settings

diagnosis

servicing

SERVICE MENU

quick operation

B

settings

diagnosis

servicing

SERVICE\SETTINGS

B

system data

boiler data

domestic hot water

heating zone 1

Tab. 4 How to use the Service menu (example)

Logamatic EMS RC35 user interface - Subject to technical modifications. 15

Page 16

4

Operating basics

Operating Instructions Result

5.

Turn the dial counter-clockwise until system data is

selected (marked with).

SETTINGS\BOILER

What type of building

do you have?

Press to select system data.

6.

To change the value, hold down the button (the value

starts flashing) and turn the dial at the same time.

7.

Release the button.

The value stops flashing. The modified value is saved.

8. If you have carried out this example as practice only, make

sure that the original setting is retained.

To do so, repeat steps 6 and 7 if necessary.

medium

SETTINGS\BOILER

What type of building

do you have?

medium

SETTINGS\BOILER

What type of building

do you have?

light

SETTINGS\BOILER

What type of building

do you have?

medium

9.

Press to go back one step.

-or-

To finish entering settings, shut the cover.

The standard display re-appears.

You can enter all settings in the SERVICE MENU using this procedure.

Tab. 4 How to use the Service menu (example)

Logamatic EMS RC35 user interface - Subject to technical modifications.16

Page 17

Operating basics

4.3 Overview of the Service menu

The SERVICE MENU is divided into the following menus and submenus:

Menu Submenu Contents/function Page

4

quick

operation

settings

(all

parameters)

diagnosis

The most important parameters from the

“settings” menu for configuration of the

heating system

system data

1)

Parameters: language, number of heating

zones, installed modules, building type,

minimum outdoor temperature

boiler data

1)2)

Parameters: pump after-run time and

modulation

heating zone data

1)

domestic hot water (DHW)

solar data

2)

Parameters of the installed heating zones 28

1)

Parameters for domestic hot water 37

If solar is installed: see documentation

for the solar module

RC35 calibration Parameters: calibration of the displayed

room temperature

contact data Entering the heating contractor's name

and telephone number

functional test

1)2)

Activating individual components for test

purposes

20

24

27

39

40

41

42

monitor value Viewing target values and actual values 43

error message

1)

Viewing fault messages 44

heating curve Viewing the set heating characteristics

in the form of a graph

versions Viewing software versions 45

servicing

1)2)

service interval Setting times for maintenance, by number

of operating hours or by date

current messages Viewing service messages 46

RESET service Resetting service messages 46

RESET

1)

factory default set Reset all parameters 47

fault list 47

service message 47

run time 47

Tab. 5 Service menu navigator

1) Subject to restrictions depending on which boiler is used.

2) Not possible or not available, depending on the boiler used.

45

46

Logamatic EMS RC35 user interface - Subject to technical modifications. 17

Page 18

5

Commissioning

5 Commissioning

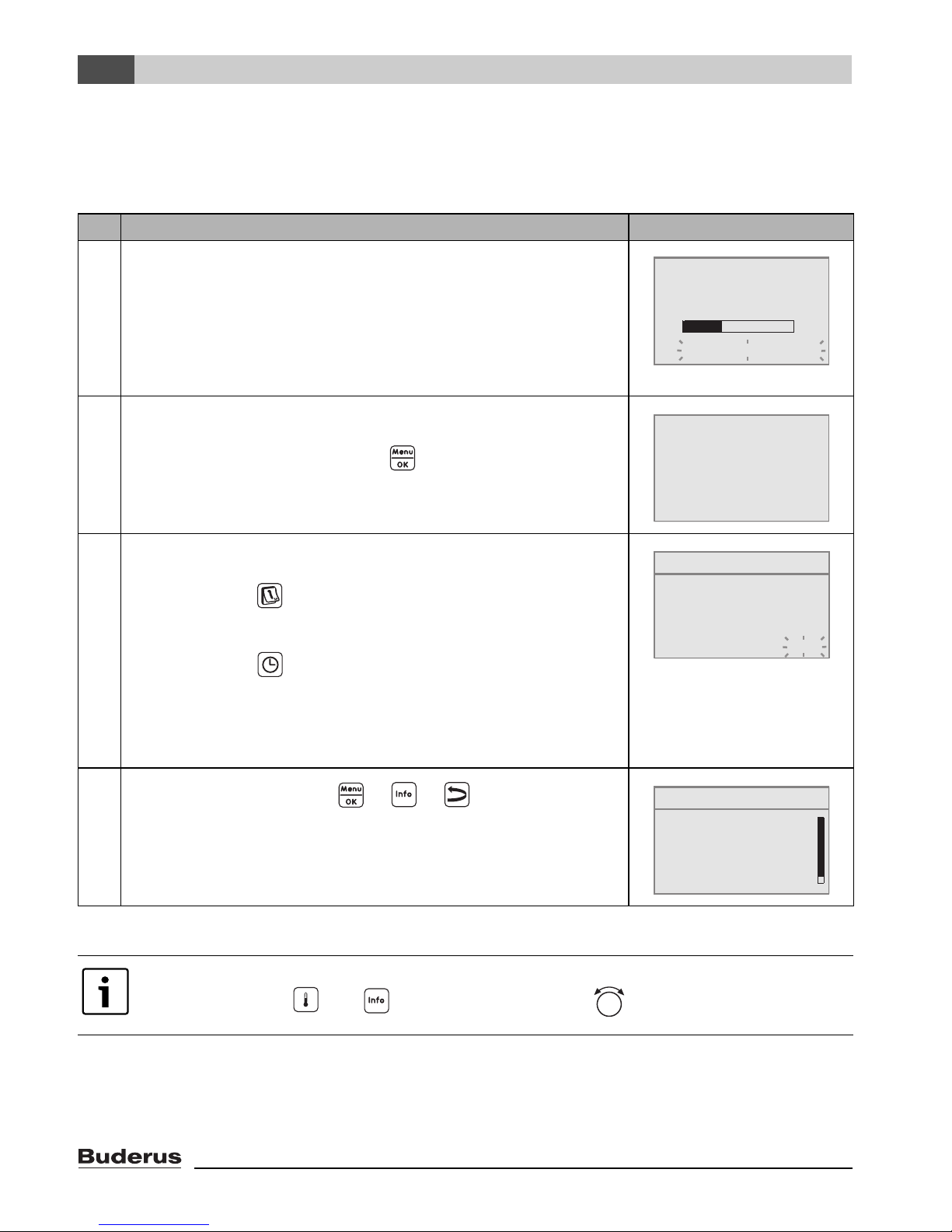

5.1 General commissioning

Operation Result

1. Switch on the heating system.

While setting up the connection between the RC35 and EMS

the display shows the message on the right.

If the display shows a different message, look it up in

section 10, page 48.

2. Set the language:

Open the cover. Hold down the button and use the dial

to set the language.

3. Set the date and time:

Hold down the button and use the dial to set the values

that are flashing. Release the button.

Hold down the button and use the dial to set the values

that are flashing. Release the button.

RC35 version:

connect to:

connecting ...

please wait

Open cover to set

language using

OK key.

language set:

American

SET DATE

set year

01/01/2000

In the event of a power failure, the date and time are retained

for up to 8 hours. All other settings are retained permanently.

4.

Simultaneously press the + + buttons to open

the SERVICE MENU.

Tab. 6 General commissioning

If necessary, you can change the contrast on the display:

B Hold down the and buttons and turn the dial at the same time.

SERVICE MENU

B

quick operation

settings

diagnosis

servicing

Logamatic EMS RC35 user interface - Subject to technical modifications.18

Page 19

Commissioning

5

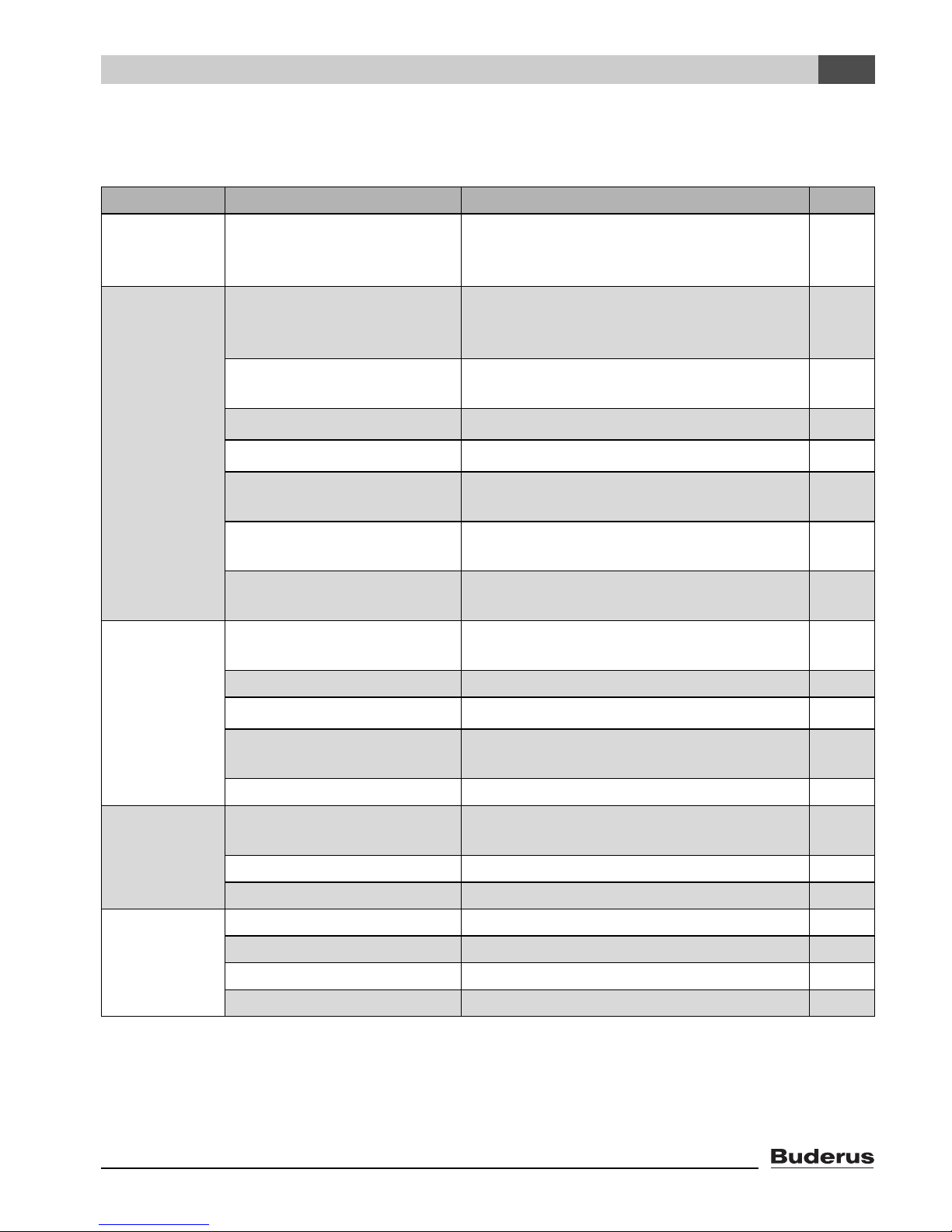

5.2 Checklist: important parameters for commissioning

When putting the device into service, ensure that the heating system settings meets the customer's

needs and expectations. In our experience, the following parameters are very important for the

satisfaction of the system owner.

B Find out the system owner's requirements and preferences regarding ...

Service menu\

Input range Factory setting

Settings\

... the desired setback

mode (night setback)

... the desired control

mode

... the correct heating

characteristics

... the correct type of

building (“delayed”

response to outdoor

temperature)

... the switch-on

frequency of the

DHW circulation pump

Outdoor setback mode

Room setback mode

setback mode

shutdown operation

outdoor reset control

room reset control

By means of the

following parameters:

standard temperature,

minimum outdoor

temperature, offset, and

target room temperature

light

medium

heavy

Permanent, 1 x, 2 x, 3 x,

4 x, 5 x, 6 x per hour for

3 min each time

Outdoor setback

mode

outdoor reset

control

heating zone x,

page 29

heating zone x,

page 32

heating zone x,

page 28

medium system data,

page 25

2 x domestic hot

water,

page 38

... DHW Priority yes

... program

(times)

Tab. 7 Checklist: important parameters for commissioning

Logamatic EMS RC35 user interface - Subject to technical modifications. 19

no

Standard program

e.g. family,

custom program

yes heating zone x,

page 30

family heating zone x,

page 31

Page 20

5

Commissioning

5.3 Quick commissioning (Quick operation menu)

B Press to open the quick operation menu.

SHORTCUT Menu item Input range

BASIC SETUP Which language should

be used?

American,

French,

Spanish

LOW LOSS

HEADER

UNMIXED HZ Is heating zone 1

Did you install a low

loss header module?

yes, no no In connection with

yes, no yes

installed (unmixed

heating zone)?

# OF MIX

VALVES

How many mixed

heating zones are

0 to 3 0 Set the address on the

installed?

SERVICE MENU

B

quick operation

settings

diagnosis

servicing

Factory

setting Other information

American

MCM10 the setting is

set automatically to

“yes”; the screen

disappears.

dial on the MM10 mixing

module

(factory setting: HZ2).

HEATING

ZONE 1

(and other heating

zones)

Which user interface is

assigned to heating

zone 1?

How should heating

zone 1 be controlled?

Which heating system

does heating zone 1

have?

Tab. 8 Quick operation menu navigator

RC20, RC35

none

outdoor reset,

room reset

panel radiator,

convector,

floor

RC35 To assign user interface

to heating zone

(Æ page 32).

outdoor

reset

General heating zone

data (Æ page 28).

Set any other heating

zones in the same way

as for heating zone 1.

panel

radiator

Heating characteristic

curve (Æ page 33)

Logamatic EMS RC35 user interface - Subject to technical modifications.20

Page 21

Commissioning

SHORTCUT Menu item Input range

5

Factory

setting Other information

DHW Is a DHW tank

installed?

What should be used

for domestic hot water

heating?

Please select the

domestic hot water

temperature.

SOLAR MODULE Has a solar module

been installed?

Tab. 8 Quick operation menu navigator

Use the checklist on page 19 to check whether more settings are needed.

yes, no no

low loss

header,

low loss

header

tank charging

pump

90 to 176 °F 140 °F To allow the hot water

temperature to be

changed, set the hot

water dial on the boiler

controller to Aut.

yes, no

5.4 Detailed commissioning

B Check whether the factory settings in the SERVICE\SETTINGS menu are suitable for the

customer's heating system.

B Write down modified settings for future reference in the Set Up Log.

5.5 System commissioning

B Make sure that both dials on the BC10 boiler controller are set to “Aut”, so that DHW

temperature and supply temperature are controlled by the RC35.

B Explain to the customer how the device works and how to operate it.

B Inform the customer of the settings chosen.

We recommend giving these installation and servicing instructions to the customer so

they can be kept close to the heating system.

Logamatic EMS RC35 user interface - Subject to technical modifications. 21

Page 22

5

Commissioning

5.6 Shut-down/switching off

The RC35 controls is supplied with power via the heating system and is permanently switched on.

It is only switched off if the heating system is switched off, such as for maintenance purposes.

B To switch the heating system on or off: set the ON/OFF switch on the boiler to position 1 (ON)

or 0 (OFF).

After switching the unit OFF or in the event of a power failure, the date and time are

retained for up to 8 hours. All other settings are permanently memorized.

Logamatic EMS RC35 user interface - Subject to technical modifications.22

Page 23

Commissioning

5

5.7 Operating tips

Devices on the EMS bus

In a bus system, only one device can carry out the calculations for a heating zone. Therefore only

one RC35 can be installed in a heating system. If additional room controllers are needed, they are

installed as remote control units with a designated heating zone (Æ page 28).

Thermostatic radiator valves in the reference room

With room temperature control, thermostat valves do not need to be installed on the radiators in the

1)

reference room

. If there are thermostatic radiator valves in the reference room, they must be fully

open at all times.

Pump anti-seize Feature

In all operating modes, all heating zone pumps are switched on for 10 seconds every Wednesday

at 12 noon to prevent pump damage. The mixing valves are then set to “OPEN” for 10 seconds and

then to “CLOSE”. After 10 seconds, all pumps and mixing valves then return to their normal,

regulated operation.

1) Room in which an RC35 is installed.

Logamatic EMS RC35 user interface - Subject to technical modifications. 23

Page 24

6

Entering system settings (Service menu – Settings)

6 Entering system settings (Service menu –

Settings)

B Simultaneously press the + + buttons to open the

SERVICE MENU.

B Turn the dial counter-clockwise until settings is selected

(marked with).

B Press to open the SERVICE\SETTINGS menu.

Note that the menu items shown will vary depending on the heating system.

6.1 System data

B Press to select system data.

The SETTINGS\SYSTEM menu opens.

Factory

Menu item Input range

setting Other information

SERVICE MENU

quick operation

B

settings

diagnosis

servicing

SERVICE\SETTINGS

B

system data

boiler data

domestic hot water

heating zone 1

Which language should be

used?

American,

French,

American

Spanish

Choose units of

measurement.

US customary units °F,

metric °C/bar

Choose time format: am/pm 24h

Choose date format: MM/DD/YYYY DD/MM/YYYY

Did you install a low loss

header module?

yes, no no In connection with MCM10 the

setting is set automatically to

“yes”; the screen disappears.

Is heating zone 1 installed

yes, no yes

(unmixed heating zone)?

How many mixed heating

zones are installed?

0 to 3 0 Set the address on the dial on the

MM10 mixing module

(factory setting: HZ2).

Has a solar module been

yes, no no

installed?

Tab. 9 Navigator for Service menu SETTINGS\SYSTEM

Logamatic EMS RC35 user interface - Subject to technical modifications.24

Page 25

Entering system settings (Service menu – Settings)

Menu item Input range

6

Factory

setting Other information

Confirm disabling the use of

the calculated outdoor

yes, no no If “yes”, the following parameter

(building type) is not shown.

temperature.

What type of building do you

have?

light,

medium,

medium For type of building (heat storage

capacity) (Æ page 25).

heavy

What is the design day

temperature in your region?

–40 °F – 32 °F

(–40 °C – 0 °C)

–14 °F (Æ page 26)

Tab. 9 Navigator for Service menu SETTINGS\SYSTEM

6.1.1 Type of building (“damping” of outdoor temperature)

A building's heat storage capacity and its characteristic resistance to heat transfer will delay the

effect of outdoor temperature variation on the rooms inside. As a consequence, it is not the current

outdoor temperature that is crucial to the heat demand of rooms, but the so-called “adjusted outdoor

temperature”.

The building type parameter can be used to set the level of delay with which variations in outdoor

temperature are registered. This allows the heating system control adapt to the characteristic

behavior of the building.

The controlls calculates the time constant for the delay in response to the outdoor temperature

Parameter:

building type Type of construction

light Buildings with small heat storage capacity and low to medium levels of

insulation, e.g. 2x4 wood frame or prefabricated construction with typical

insulation.

medium Buildings with medium heat storage capacity and high levels of insulation,

e.g. 2x6 wood frame or cinder block construction with above average insulation

(factory default).

heavy Massive buildings with high heat storage capacity and high levels of insulation,

e.g. poured concrete, heavy brick or heavy cinder block construction with

excellent insulation.

Tab. 10 Calculating the damping time constant

Logamatic EMS RC35 user interface - Subject to technical modifications. 25

Page 26

6

Example:

Entering system settings (Service menu – Settings)

Fig. 5 This greatly simplified example shows how the delayed response to outdoor temperature

follows the outdoor temperature, but does not reach its extreme values.

1 Current outdoor temperature

2 Adjusted outdoor temperature

With the factory setting, changes in the outdoor temperature will affect the calculations

for outdoor-temperature-based control after a delay of no more than three hours

(30 x 6 minutes = 180 minutes).

B To monitor the calculated, delayed response to outdoor temperature and the

currently recorded outdoor temperature:

open the menu Diagnosis\Monitor\boiler/burner.

6.1.2 Minimum outdoor temperature

The “minimum outdoor temperature” is the mean of all the coldest outdoor temperatures of recent

years, and helps to determine the heating characteristics. The value can be taken from the heat

requirement calculation that should be done for every building, or from the climatic zone chart of your

region.

Logamatic EMS RC35 user interface - Subject to technical modifications.26

Page 27

Entering system settings (Service menu – Settings)

6.2 Boiler data

6

B Turn the dial counter-clockwise until boiler data is selected

(marked with).

B Press to select boiler data.

The SETTINGS\BOILER menu opens.

Factory

Menu item Input range

Set boiler pump post

purge after burner stops?

deactivated,

1 to 60 min,

setting

5 min Setting only possible with boilers with

Other information

internal boiler pump.

24 hours

Please adjust modulating

pump settings.

0 to 8 2 Characteristics of the boiler pump

depend on the boiler installed

• 0: if a hydraulic low loss header has

been installed

• 1 – 8: see boiler documentation

Tab. 11 Navigator for Service menu SETTINGS\BOILER

SERVICE\SETTINGS

system data

B

boiler data

domestic hot water

heating zone 1

1)

1) system-dependent

Logamatic EMS RC35 user interface - Subject to technical modifications. 27

Page 28

6

Entering system settings (Service menu – Settings)

6.3 Heating zone data

This section explains the settings for all heating zones: using heating zone 1 as an example.

B Turn the dial counter-clockwise until

heating zone 1 is selected (marked with).

B Press to select heating zone 1.

The SETTINGS\HTG. ZONE 1 menu opens.

Menu item Input range

Should heating zone 1

yes, no yes

be activated?

Which user interface is

none, RC20, RC35 RC35 (Æ page 33)

assigned to heating

zone 1?

How should heating

zone 1 be controlled?

outdoor reset,

room reset

SERVICE\SETTINGS

system data

boiler data

domestic hot water

B

heating zone 1

Factory

setting

Other information

If none is selected, the control

mode is changed to outdoor reset

and will not be shown.

outdoor reset Room reset can only be set if an

RC20 or RC35 has been

assigned to the heating zone.

If there is one unmixed zone on a

system with a modulating burner,

the boiler power will used to

directly control the room

temperature; in all other cases the

supply temperature will be

controlled.

Which heating system

does heating zone 1

have?

panel radiator,

convector,

floor

panel radiator With HZ1, only use the floor

Heating curve

Design tmp

14 °F (-10 °C)

84 °F to 194 °F

(30 °C – 90 °C)

167 °F (75 °C)

(panel radiator,

convector)

113 °F (45 °C)

(floor)

Tab. 12 Navigator for Service menu SETTINGS\HTG. ZONE 1

Logamatic EMS RC35 user interface - Subject to technical modifications.28

setting if the boiler is a gas

condensing boiler. Additional

heating zones can then be

installed.

A safety thermostat must be used

with radiant floor heating

regardless.

Setting entered only if the control

mode has been set to outdoor

reset (Æ page 33).

Page 29

Entering system settings (Service menu – Settings)

Factory

Menu item Input range

setting Other information

6

max.supply temp. panel radiator,

convector:

86 °F – 194 °F

Enter the maximum

supply

temperature:

(30 °C – 90 °C)

floor:

86 °F – 140 °F

(30 °C – 60 °C)

min.supply temp. 41°F– 158°F

(5 °C – 70 °C)

Enter the minimum

supply

temperature:

room tmp.offset –9 °F – +9 °F

(–5 °C – +5 °C)

Enter the maximum

room influence:

0°F– 18°F

(0 °C – 10 °C)

panel radiator,

convector:

167°F (75°C)

floor:

122 °F (50 °C)

Setting entered only if the control

mode has been set to outdoor

reset (Æ page 32)

Setting entered only if the control

mode has been set to room temp.

controlled (Æ page 32).

41 °F (5 °C) Setting entered only if the control

mode has been set to outdoor

reset (Æ page 32)

Setting entered only if the control

mode has been set to room temp.

controlled (Æ page 32).

0 °F (0 °C) Parallel shifting of characteristic

heating curve.

Setting entered only if the control

mode has been set to outdoor

reset (Æ page 32)

0 °F (0 °C) Setting entered only if the control

mode has been set to outdoor

reset (Æ page 32)

Select the type of

setback:

Outdoor setback

mode, setback

Outdoor

setback mode

operation, Room

setback mode (only if

RC35 or RC20 has

been assigned to the

heating zone)

What outdoor temp.

should be used for

–4 °F – +50 °F

(–20 °C – +10 °C)

41 °F (5 °C) Temperature threshold for outdoor

setback operation?

Frost protection

Set temperature for

frost protection.

outdoor temperature

no frost protection

outdoor

temperature

room temperature

Tab. 12 Navigator for Service menu SETTINGS\HTG. ZONE 1

Night setback (Æ page 34)

setback mode (Æ page 34).

Setting entered only if the

reduction mode has been set to

outdoor setback mode.

Room temperature can only be set

if RC20 or RC35 has been

assigned to the heating zone

(Æ page 35).

Logamatic EMS RC35 user interface - Subject to technical modifications. 29

Page 30

6

Entering system settings (Service menu – Settings)

Menu item Input range

Factory

setting Other information

Set temperature for

frost protection.

At what outdoor

temp. should the

setback be

–4 °F – +50 °F

(–20 °C – +10 °C)

OFF,

–22 °F – 50 °F

(–30 °C – +10 °C)

canceled?

Confirm activating

yes, no no

DHW priority.

Mixing valve

Is a mixing valve

yes, no yes Can only be set for heating

installed?

What is the run

10 – 600 seconds 120 seconds

time of the mixing

valve?

What increase

should be used for

0°F– 36°F

(0 °C – 20 °C)

the boiler?

Drying floor radiant slab

Confirm running a

yes, no no Can only be set if radiant floor

slab drying cycle.

41 °F (5 °C) Refers to outdoor temperature

(Æ page 35).

OFF

zones 2 and up.

10 °F (5 °C)

heating has been entered as the

heating system. DHW heating is

disabled while slab is drying.

Set the frequency

for raising the

every day, every 2nd

day to every 5th day

daily

supply

temperature.

Set the supply

temperature

0°F– 72°F

(0 K – 40 K)

9°F (5°C)

increase.

Set the maximum

supply

77 °F – 140 °F

(25 °C – 60 °C)

113 °F (45 °C)

temperature.

For how many days

0 – 20 days 4 days

should max. supply

temp. be

maintained?

Tab. 12 Navigator for Service menu SETTINGS\HTG. ZONE 1

Logamatic EMS RC35 user interface - Subject to technical modifications.30

Page 31

Entering system settings (Service menu – Settings)

Factory

Menu item Input range

setting Other information

6

Set the frequency

for reducing the

supply

temperature.

Set the supply

temperature

decrease.

Confirm changing the

program?

Should the program be

optimized?

What setback mode

should be used for

vacation / absence?

direct normal operat.,

every day

every day,

every 2nd day to

every 5th day

0°F– 36°F

(0 °C to 20 °C)

9 °F (5 °C) Can only be set if direct normal

operat. has not been entered for

supply temperature reduction.

yes, no no Selecting “yes” takes you to the

program for the heating zone.

yes, no no Switch-on and switch-off times

are automatically adjusted

according to the outdoor

temperature, room temperature

and building type (heat storage

capacity).

Outdoor setback

mode

Room setback mode

setback mode

shut-down mode

Outdoor

setback mode

Æ page 34.

Room setback mode can only be

set if a remote control unit

(e.g. RC20) has been assigned to

the heating zone.

What outdoor temp.

should be used in

–4 °F – +50 °F

(–20 °C – +10 °C)

41 °F (5 °C) Temperature threshold for outdoor

vacation mode?

Tab. 12 Navigator for Service menu SETTINGS\HTG. ZONE 1

If setback mode is selected the

normal night temperature is used.

setback mode (Æ page 34).

Setting entered only if the reduction mode for vacation has been

set to Outdoor setback mode.

Logamatic EMS RC35 user interface - Subject to technical modifications. 31

Page 32

6

Entering system settings (Service menu – Settings)

6.3.1 Assignment of user interface/remote control unit in the software

Example: heating system with heating zone 1 and heating zone 2 (Æ page 11)

Alternative Setting: Which remote control is

Effect

assigned to the heating zone?

A HZ 1 = RC35, HZ 2 = RC35

Same room temperatures for HZ 1 and HZ 2

(Æ Fig. 2, [1], page 11)

B HZ 1 = RC35, HZ 2 = none

(Æ Fig. 2, [1], page 11)

Room temperatures for HZ 1 and HZ 2 can

be set separately

Tab. 13 Settings for room temperature depending on user interface

6.3.2 Control mode (outdoor temperature controlled/room influence)

The temperature of the heating water in the boiler is defined by the heating characteristics

determined in the Logamatic controls. A selection can be made whether these heating

characteristics will be influenced solely by the outdoor temperature, or by a combination of outdoor

temperature and room temperature.

• Outdoor temperature controlled: The boiler temperature calculated in the controls will be

controlled by variation in the “delayed” response to outdoor temperature in combination with

selected settings for target room temperature, offset, standard temperature and minimum

outdoor temperature. This temperature is then delivered to the radiators or radiant floor heating

by means of permanent operation of the heating zone pump. The only situations in which this

setting could result in shut-down of the heating zone pump are summer operation, night setback

(depending on the reduction mode selected) or DHW mode (only with domestic hot water

priority).

• Outdoor temperature controlled, influenced by room temperature (factory default):

this form of control works in exactly the same way as pure outdoor temperature control, except

that you can use the maximum room influence parameter to determine whether and to what

extent the room temperature should influence the heating characteristics.

The remote control unit must be installed in a reference room, so that a representative room

temperature is recorded.

The greater the parameter set, the greater the influence of the room temperature on the heating

characteristics (factory setting: 0 °F (0 °C)). This applies when the room temperature exceeds or

falls below the target room temperature. If the maximum room influence parameter is set to 0,

the heating characteristics will be controlled solely by outdoor temperature.

Logamatic EMS RC35 user interface - Subject to technical modifications.32

Page 33

Entering system settings (Service menu – Settings)

6

6.3.3 Characteristic heating curve

Parameters: Standard temperature, maximum and minimum supply temperature and room

temperature offset (parallel shifting of characteristic heating curve)

The characteristic heating curve forms the basis for economical and easy operation of the heating

system with outdoor reset. To calculate the characteristic heating curve, the Logamatic control uses

a number of parameters.

This calculation takes into account the “delayed” response to outdoor temperature changes and the

room temperature. The room temperature is internally calculated, based on target room temperature

and the room influence factor.

This allows the user to influence the heating characteristics directly by modifying the target room

temperature.

The heating characteristic curve (Æ Fig. 6, page 34) is determined by the base point and end point.

The base point is located at 14 °F (–10 °C) supply temperature at a room temperature of 68 °F

(20 °C). The end point of the heating characteristic curve must be set in accordance with the design

temperature of the heating system.

The gradient of the heating characteristic curve (the shape of the curve) is determined by the parameters minimum outdoor temperature (the lowest outdoor temperature expected in a particular

region, Æ page 26) and the standard temperature (the supply temperature which should be

reached when the outdoor temperature is at minimum) (Æ Fig. 6, left).

The x-axis of the heating characteristic curve shown on the display covers the range

from +68 °F to –4 °F (+20 °C to –20 °C). With the parameter std. tmp., the minimum

outdoor temperature is represented by a circle. However, the diagram will not be quite

correct if a minimum outdoor temperature below –4 °F (–20 °C) is entered (the circle

will no longer be on the heating characteristic curve).

The minimum supply temperature parameter can be used to define a minimum target value

(Æ Fig. 6, [4]). If the temperature falls below this value, the burner is fired.

The characteristic heating curve can be shifted, up or down, in parallel to the original curve, by

adjusting the room temperature offset parameter and/or the set room temperature

(Æ Fig. 6, right). This feature should be used if, for example, the room temperature measured with

a thermometer differs from the set target value.

Logamatic EMS RC35 user interface - Subject to technical modifications. 33

Page 34

6

Entering system settings (Service menu – Settings)

Fig. 6 Setting the characteristic heating curve

Left: setting the gradient by means of standard temperature and design day temperature

Right: parallel shift possible by means of offset or target room temperature

T

T

1 Setting: design temperature 167 °F (75 °C), minimum outdoor temperature 14 °F (–10 °C) (base curve)

2 Adjustment: Design temperature 167 °F (75 °C), minimum outdoor temperature 4 °F (–20 °C)

3 Adjustment: Design temperature 122 °F (50 °C), minimum outdoor temperature 14 °F (–10 °C)

4 Setting: minimum supply temperature 95 °F (35 °C)

5 Setting: design temperature 167 °F (75 °C), minimum outdoor temperature 14 °F (–10 °C) (base curve)

6 Parallel shifting of base curve by changing the offset +6 °F (+3 °C) or by increasing the target room

7 Parallel shifting of base curve by changing the offset –6 °F (–3 °C) or by reducing the target room

Minimum outdoor temperature

minA

Standard temperature (i.e. the design temperature – the supply temperature to be reached at design day

A

temperature)

temperature

temperature

6.3.4 Reduction modes (night setback)

There are a number of different reduction modes available, which allow night setback to be adjusted

to suit the differing needs of the user:

• setback mode: The rooms are maintained at a reasonable temperature by constant heating

operation (the heating zone pump runs constantly). A target room temperature for nighttime can

be set. This must be at least 2 °F (1 °C) lower than the daytime target room temperature. The

heating characteristics will be calculated in accordance with this setting.This setting is

recommended for radiant floor heating.

Logamatic EMS RC35 user interface - Subject to technical modifications.34

Page 35

Entering system settings (Service menu – Settings)

6

• shut-down mode: The boiler and the heating zone pump are switched off, and frost protection

is activated. The heating zone pump runs only for purposes of frost protection. Not recommended

if there is a risk that the building could cool down too much.

• Room setback mode: If the room temperature falls below the set night temperature (the target

value), the heating system will operate in the same way as for reduced heating operation (as

described under reduction mode “setback mode”). If the room temperature exceeds the target

night temperature by more than 2 °F (1 °C), the boiler and the heating zone pump are switched

off (as described under reduction mode “shut-down mode”). This reduction mode is only possible

if a remote control unit has been installed in a representative room (the reference room) or if the

room temperature is recorded using an external room sensor.

• Outdoor setback mode: If the “delayed” response to outdoor temperature falls below a user-

defined threshold, the heating system will operate in the same way as for reduced heating

operation (as described under “setback mode”). Above this threshold, the heating system will be

switched off (as described under reduction mode “shut-down mode”). This reduction mode is

suitable for heating zones that do not have their own remote control unit, and protects the rooms

from cooling down too much once a certain outdoor temperature is reached.

6.3.5 Frost protection

The frost protection function comprises the following options:

• no frost protection (frost protection is switched off)

• outdoor temperature (outdoor temperature sensor required) If the outdoor temperature falls

below the adjustable frost protection temperature threshold, the heating zone pump is switched

on automatically.

• room temperature (room temperature sensor in the RC35 or RC20) If the room temperature

falls below the fixed value of 41 °F (5 °C), the heating zone pump is switched on automatically. If

the room temperature rises above 44 °F (7 °C), the heating zone pump is switched off

automatically.

CAUTION: Risk of system damage due to freezing. The settings no frost protection

and room temperature provide either no frost protection or inadequate frost

protection. When these settings are selected, the display shows a message indicating

the risk of freezing.

B For reliable frost protection, use the outdoor temperature setting.

The room temperature setting does not provide absolute frost protection because

pipes laid in external walls (for example) could freeze even though the temperature in

the reference room might be clearly above 41 °F (5 °C) due to external heat sources

(fireplace etc.).

Logamatic EMS RC35 user interface - Subject to technical modifications. 35

Page 36

6

Entering system settings (Service menu – Settings)

At what outdoor temperature should setback be cancelled?

In the parameter At what outdoor temp. should the setback be canceled?, you can set an

outdoor temperature threshold (this threshold applies to the “delayed” response to outdoor

temperature; Æ page 25).

Fig. 7 shows how the frost protection function works, without this parameter activated and with it

activated. Settings selected: frost protection by outdoor temperature; frost protection

temperature 41 °F (5 °C).

Fig. 7 Effects of the parameter “At what outdoor temperature should reduction be interrupted?”

Left: parameter is set to “OFF” (factory setting)

Right: parameter is set to 5 °F (–15 °C)

T

T

1 Shutdown operation

2 Reduced operation (at set nighttime room temperature)

3 Heating operation (at set daytime room temperature)

Outdoor temperature

A

Supply temperature

V

If the outdoor temperature falls below the set value of 6 °F (–15 °C), heating switches from reduced

operation to heating operation (Æ Fig. 7, [3]). This allows smaller heating surfaces to be utilized.

Logamatic EMS RC35 user interface - Subject to technical modifications.36

Page 37

Entering system settings (Service menu – Settings)

6.4 Domestic hot water (DHW)

WARNING: Risk of scalding at the taps.

There is a risk of scalding at the taps whenever domestic hot water temperatures can

be set to more than 122 °F (50 °C), and also during thermal disinfection.

B Make sure that a thermostatic mixing valve is installed and that it is set to

temperatures below 122 °F (50 °C).

6

B Turn the dial counter-clockwise until domestic hot water

is selected (marked with).

B Press to select domestic hot water.

The SETTINGS\DHW menu opens.

Factory

Menu item Input range

setting Other information

Is a DHW tank installed? yes, no no

Set maximum DHW

temperature:

Please select the domestic

hot water temperature.

What should be used for

domestic hot water heating?

140°F– 176°F

(60 °C – 80 °C)

86 °F to 176 °F

(30 °C – 80 °C)

Selection of 3-way

switching valve vs

140 °F (60 °C) Depending on the boiler,

140 °F (60 °C) If the limit is set to

3-way valve

tank primary pump

SERVICE\SETTINGS

system data

boiler data

domestic hot water

B

heating zone 1

the max. possible DHW

target temperature is

limited to 140 °F (60 °C).

> 140 °F (> 60 °C), it will

be possible to set

temperatures of that level

in the User menu as well.

Confirm changing the DHW

program.

Recirculation

Is a recirculation pump

installed?

Tab. 14 Navigator for Service menu SETTINGS\DHW

Logamatic EMS RC35 user interface - Subject to technical modifications. 37

yes, no no Selecting “yes” takes you

to the program for

domestic hot water.

yes, no no

Page 38

6

Entering system settings (Service menu – Settings)

Menu item Input range

Factory

setting Other information

Specify the frequency of

the recirculation pump

per hour.

once for 3 minutes,

twice for 3 minutes,

3 times for 3 minutes,

twice for

3 minutes

4 times for 3 minutes,

5 times for 3 minutes,

6 times for 3 minutes,

permanent operation

run recirc pump Graphical display of

number of times the pump

is switched on per hour.

Confirm changing the

recirculation program.

yes, no no Selecting “yes” takes you

to the program for hot

water circulation.

Thermal disinfection

Confirm performing a

yes, no no

thermal disinfection.

Set thermal disinfection

temperature.

140°F– 176°F

(60 °C – 80 °C)

1)

158 °F (70 °C) At temperatures above

122°F (50°C) there is a

risk of scalding at the taps

during and after thermal

disinfection.

Set the day of the thermal

disinfection.

Monday, Tuesday,

Wednesday,

Tuesday

Thursday, Friday,

Saturday, Sunday,

daily

Set the time of day of the

thermal disinfection.

12:00 am – 11:00 pm 1:00 am Times entered must

be whole hours only

(no minutes).

Should the LED of the single

charge key be activated?

yes, no yes The single charge function

(for one-off heating of

hot water) still works but

is no longer indicated by

an LED.

Tab. 14 Navigator for Service menu SETTINGS\DHW

1) Depending on the boiler, a fixed temperature is defined and it cannot be changed.

Logamatic EMS RC35 user interface - Subject to technical modifications.38

Page 39

Entering system settings (Service menu – Settings)

6.5 Solar data

In order for the solar menu to become available, under SETTINGS\SYSTEM the

question: “Has a solar module been installed?” must be answered with “yes”.

6

B Turn the dial counter-clockwise until solar data is selected

(marked with).

B Press to select solar data.

The SETTINGS\SOLAR menu opens.

SERVICE\SETTINGS

boiler data

domestic hot water

heating zone 1

B

solar data

Menu item Input range Factory setting

Set the maximum solar tank

temperature.

Set the minimum solar tank

temperature.

86 °F – 194 °F

(30 °C – 90 °C)

86 °F – 130 °F

(30 °C – 54 °C)

140 °F

OFF

OFF

What is the minimum pump rating? 20 % – 100 % 30 %

Tab. 15 Navigator for Service menu SETTINGS\SOLAR

For explanations of the settings, see the documentation for the SM10 solar module.

Other

information

Logamatic EMS RC35 user interface - Subject to technical modifications. 39

Page 40

6

Entering system settings (Service menu – Settings)

6.6 RC35 calibration

B Turn the dial counter-clockwise until RC35 calibration is

selected (marked with).

B Press to select RC35 calibration.

The SETTINGS\CALIB. RC35 menu is opened.

SERVICE\SETTINGS

domestic hot water

heating zone 1

solar data

B

RC35 calibration

Menu item Input range Factory setting Other information

Calibration of the room

temperature

–9.0 °F – +9.0 °F

(–5.0 °C – +5.0 °C)

0.0 °F (0.0 °C)

Tab. 16 Navigator for Service menu SETTINGS\CALIB. RC35

Calibration of the displayed room temperature

If there is a separate thermometer near the controls, it may show a different room temperature to that

shown on the RC35. This function can be used to adjust the RC35 to match the thermometer

(i.e. “calibrate”).

Before calibrating the room temperature, consider the following:

• Is the thermometer more accurate than the RC35?

• Is the thermometer located close to the unit so that they are both subject to the same heat

influences (e.g. sunlight, fireplace)?

Other thermometers may show temperature changes more slowly or more quickly than

the RC35.

B Never calibrate the controls when your heating system is in the process of cooling

down or heating up, but only in steady state conditions.

Example: if the thermometer is showing a temperature 2 °F (1 °C) higher than the controls, enter

“+2 °F (+1 °C)” as the calibration value.

Logamatic EMS RC35 user interface - Subject to technical modifications.40

Page 41

Entering system settings (Service menu – Settings)

6

6.7 Contact data

The details entered in “Contact data” are automatically displayed to the customer in the event of a

fault. Use this feature to alert the homeowner to call your 24 hour service hotline.

B Turn the dial counter-clockwise until contact data is selected

(marked with).

B Press to select contact data.

The menu SETTING\CONTACT is opened.

SERVICE\SETTINGS

heating zone 1

solar data

RC35 calibration

B

contact data

Menu item Input range Other information

Name and phone # of

heating contractor:

_ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _

Tab. 17 Navigator for Service menu SETTING\CONTACT

Entering company name and telephone number

Two rows are available, each with 21 characters (capital letters, numbers and some other symbols).

The current cursor position will flash (marked by).

1. Hold down the button and turn the dial simultaneously to select another character.

Release the button: the modified character is saved.

2. Turn the dial counter-clockwise or clockwise to move the cursor.

3. To delete a character, enter a space.

4. Press to save your entries and leave the menu.

Logamatic EMS RC35 user interface - Subject to technical modifications. 41

Page 42

7

Diagnosis

7 Diagnosis

The Diagnosis service menu contains a number of diagnostic tools:

• Function test

• Monitor value

• Error message

• Characteristic heating curve

• Version information

B Simultaneously press the + + buttons to open the

SERVICE MENU.

B Turn the dial counter-clockwise to select Diagnosis

(indicated by).

SERVICE MENU

quick operation

settings

B

diagnosis

servicing

B Press to open the SERVICE\DIAGNOSIS menu.

Note that the menu items shown will vary depending on the heating system.

7.1 Function test

Use this menu to activate separate EMS components individually in order to test their functions.

The available functions and the possible settings vary depending on the system installed.

B Hold down the button and turn the dial at the same time to

change the setting: e.g. BURNER OFF to BURNER ON.

The change takes effect when you release the button.

FUNCT. TEST\BOILER

valve 1 clsed 2 clsed

ignition OFF

flame OFF

flame current 0.0μA

B

BURNER ON

B Turn the dial to switch between different displays (for function

tests).

Be mindful of the information which appears on the display when you switch to menus

or when you enter settings. Press any of the buttons or turn the dial to confirm the

information.

FUNCT. TEST\BOILER

act. boilertmp. 140°F

air temperature 90°F

flue gas temp. 172°F

flame OFF

B

BURNER OFF

Logamatic EMS RC35 user interface - Subject to technical modifications.42

Page 43

Diagnosis

7

No settings are available that might result in damage to the components. This is why

some settings may not be accepted.

7.2 Monitor value

Use the monitor value menu to view the target and actual values for the heating system. The target

value will be displayed first and then the actual value. The values displayed for monitoring purposes

vary depending on the system installed.

If the values to be displayed do not all fit on the screen, they are displayed as a list. Scroll

down the list by turning the dial.

DIAGNOSIS\MONITOR Other information

boiler/burner

MCMC10/cascade Only in conjunction with a MCM10 burner

(in position “boiler/burner”)

boiler

1)

Only in conjunction with a MCM10 burner

(in position “boiler/burner”)

low loss header

domestic hot water

heating zone 1 Values for other heating zones are displayed if such zones are

installed.

solar

bus users

Tab. 18 Navigator for the monitor value menu

1) The monitor values are displayed per boiler on an individual screen. By turning the dial, the monitor values

for the next boiler are called up.

Symbol present = corresponding function is active. Key to symbols Æ Tab. 19, page 44.

Logamatic EMS RC35 user interface - Subject to technical modifications. 43

Page 44

7

Diagnosis

Burner on

Heat demand

DHW demand

Flue gas test

service due / error

Tab. 19 Key to symbols for footnote 1), page 43

7.3 Error message

The most recent fault from the fault memory can be displayed using the error message

(e.g. to investigate a fault).

The faults are divided into the following categories:

• Current faults are all unresolved faults currently present in the system. These can be one of the

following types: locking, blocking or system error.

• Locking faults: When the fault is remedied, the heating system needs to be unlocked manually.

To do so, press the Reset button on the boiler.

• Blocking type faults: With blocking faults, the heating system resumes operation automatically as

soon as the fault has been rectified.

• System faults in the heating system are logged in the RC35, with the exception of faults in the

boiler or the burner, which are either “locking” faults or “blocking” faults errors. The heating

system continues to run – where possible – during the fault state; no reset is necessary.

For a list of the locking and blocking faults, which vary depending on the boiler, see the

installation and maintenance instructions of the boiler.

B Turn the dial to show the next message.

Logamatic EMS RC35 user interface - Subject to technical modifications.44

Page 45

Diagnosis

7

7.4 Characteristic heating curve

Use the heating curve menu to view the characteristics of each heating zone in the form of a graph.

B If the system has more than one heating zone: turn the dial to

view the characteristic heating curve for the next zone.

DIAG.\HEATG.CURVE HZ2

194

70

targ.supply tmp 135°F

7.5 Versions

You can use the INFO\VERSIONS menu to view the software versions for heating system

components.

B If the information cannot be displayed in one screen: turn the dial to

display the next screen.

INFO\VERSIONS

RC35 1.02

UBA3.5 1.21

Logamatic EMS RC35 user interface - Subject to technical modifications. 45

Page 46

8

Service

8 Service

The servicing menu is used to set a service interval and to view and reset current service messages.

The interval can be set to expire either after a given number of operating hours or when a given date

is reached. The RC35 will then show a message so that the customer can notify the heating

contractor to arrange an appointment.

Service messages are indicated by an Hxx code, e.g. H07.

SERVICE MENU\

SERVICE Menu item Input range

service interval How should

servicing

messages be

no messages,

by run time,

by date

triggered?

Factory

setting

no

messages

Other

information

Selecting “run time”

or “date” takes you

automatically to the

corresponding

setting.

For “by date”:

Annual servicing,

starting on:

01/01/2009 01/01/2009 To set the date:

hold down and

turn the dial at the

same time.

For “by operation

hours”:

Boiler operation

1000 h – 6000 h 6000 h Number of hours of

operation with burner

switched on

hours until next

servicing message

current messages Message/code To view further

messages: turn the

dial.

RESET service Confirm resetting

the service

messages.

Tab. 20 Navigator for the Servicing menu

no, yes no If you select “yes” the

servicing messages

will be reset.

Observe information

in display.

Logamatic EMS RC35 user interface - Subject to technical modifications.46

Page 47

Reset

9 Reset

The SERVICE MENU\RESET resets the following:

• All parameters back to their factory settings

• Fault list

• Service messages

• The run time.

After resetting parameters to the factory setting, the parameters may need to be

adjusted again to suit the system configuration.

B Turn the dial to select a menu, e.g. fault list. Press to go to the relevant screen, e.g.

Confirm resetting the list of faults. Press and turn the dial to set the display to yes.

When the button is released, the reset is carried out.

During this process, a corresponding message appears, which disappears again automatically.

9

B Once reset is complete: confirm by pressing any of the buttons.

Logamatic EMS RC35 user interface - Subject to technical modifications. 47

Page 48

10

Troubleshooting

10 Troubleshooting

This fault table lists possible “system errors”, i.e. faults of heating system components. The heating

system keeps operating as much as possible in the event of a system error; in other words, heating

of the home can continue as long as it is safe.

Use only original Buderus parts. Losses caused by the use of parts not supplied by

Buderus are excluded from the Buderus warranty.

The faults displayed will vary depending on the specific type of boiler in use.

Abbreviations used:

SC = Service code; x = heating zone with the number x, e.g. A23 for heating zone 3

FC = Fault code

HZx = Heating zone with the number x

Fault

SC FC

message

A01 800 Outdoor

sensor

defective.

Effect on control

characteristics Possible cause Remedy

The minimum outdoor

temperature is used

instead of the actual

outdoor temperature.

Tab. 21 Fault table