Page 1

Operating instructions

Control unit

Logamatic 4211

7 747 016 927 - 03/2008 GB/IE

For users

Read carefully before use

Page 2

Contents

Logamatic 4211 - Subject to technical modifications.

2

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 What you should know about your heating system. . . . . . . . . . . . . . . . . . 5

3 Tips on energy-efficient heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 About these instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Correct use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Standards and guidelines/directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 Symbol key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5 Please observe these notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.6 Cleaning the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Controls and MEC2 programming unit . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Control unit controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 MEC2 programming unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Switching on the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 Switching off the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Standard functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1 Simple operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Permanent display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.3 Selecting the operating mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.4 Setting the room temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.5 Heating DHW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 Extended functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.1 Keys for extended functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2 Controlling the extended functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.3 Displaying operating values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.4 Changing the permanent display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.5 Setting the date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.6 Selecting a heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.7 Adjusting the room temperature for another heating circuit. . . . . . . . . . . . . . . . . 31

7.8 Heating circuits with MEC2 programming unit. . . . . . . . . . . . . . . . . . . . . . . . . 33

7.9 Selecting and modifying a heating program . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.10 Selecting a standard program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.11 Summary of standard programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.12 Modifying the standard program by moving switching points . . . . . . . . . . . . . . . 38

7.13 Setting the summer/winter time adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.14 Setting the DHW operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.15 Setting the operating mode for DHW circulation . . . . . . . . . . . . . . . . . . . . . . . 43

7.16 Setting the holiday function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Page 3

Contents

Logamatic 4211 - Subject to technical modifications.

3

7.17 Interrupting and continuing the holiday function . . . . . . . . . . . . . . . . . . . . . . . . 46

7.18 Setting the party function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.19 Setting the pause function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.20 Room temperature matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.21 Automatic maintenance message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8 Additional programming options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1 Modifying the standard program by inserting/deleting switching points . . . . . . . . . . 50

8.2 Creating a new heating program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.3 Creating a new DHW program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.4 Creating a new DHW circulation pump program . . . . . . . . . . . . . . . . . . . . . . . . 63

9 Modules and their functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.1 ZM422 central module (standard equipment level) . . . . . . . . . . . . . . . . . . . . . . 65

9.2 FM442 function module (accessory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10 Boiler flue gas test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11.1 Simple troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

11.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

12 Operation in the event of a fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

12.1 Emergency mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

12.2 Heating with manual override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

13 Setup report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

14 Keyword index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Page 4

Introduction

1

Logamatic 4211 - Subject to technical modifications.

4

1 Introduction

With your purchase of this Logamatic control unit you

have acquired a product that promises you easy control

over your heating system. It offers you optimum heating

convenience and minimum energy consumption.

The control unit enables you to operate your heating

system to be able to combine your economical and

ecological aspirations. Of course, your personal comfort

is always priority.

The control unit, which is regulated by the MEC2

programming unit, is set up at the factory for immediate

use. Naturally, you or your heating contractor can modify

these default settings and adapt them to your individual

requirements.

The MEC2 programming unit is the central control unit.

Some functions which you may need are located behind

a flap. The keys behind this flap enable you to make

various adjustments.

The control concept is:

"Push and turn"

"This control unit speaks your language."

Your heating system offers a wealth of other useful

functions. Some examples of these are:

– Automatic summer/winter time adjustment

– Party/pause function

– Holiday function

– DHW heating at the touch of a button

Page 5

What you should know about your heating system

2

Logamatic 4211 - Subject to technical modifications.

5

2 What you should know about your heating system

Why should you become more familiar with your

heating system?

Modern heating systems offer many functions for saving

energy without sacrificing comfort. Getting to know this

heating technology may appear daunting at first, but

after a short while you will recognise the advantages you

can gain from a heating system that is set up to meet

your personal requirements. The more you are aware of

the options offered by your heating system, the greater

the benefit you will be able to draw from it.

How does your heating system work?

Your heating system comprises the boiler with burner,

heating control unit, pipework and radiators. A DHW

cylinder or an instantaneous water heater heats the

water required for a shower, bath or washing your

hands. Subject to the way your heating system has been

installed, it can operate either purely as a central heating

system or together with a DHW cylinder. The important

thing is that the various components match each other.

The burner combusts fuel (e.g. gas or oil) and heats the

water inside the boiler. Using pumps, this hot water is

transported through the pipework to the consumers

(radiators, underfloor heating system, etc).

Page 6

What you should know about your heating system

2

Logamatic 4211 - Subject to technical modifications.

6

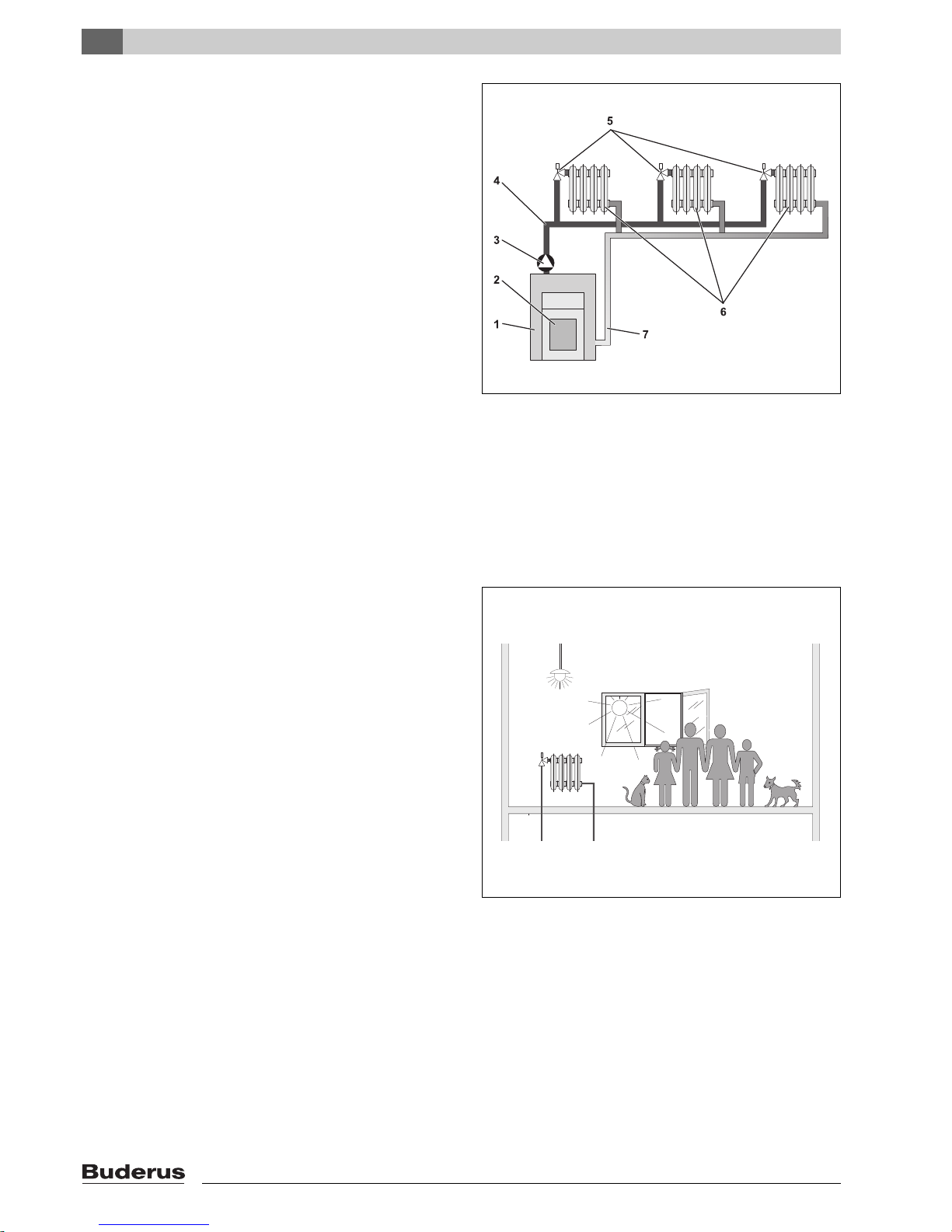

Fig. 1 shows the heating circuit of a pumped central

heating system: The burner [2] heats the water inside

the boiler [1]. This heating water is transported by the

pump [3] through the flow line [4] to the radiators [6]. The

heating water flows through the radiators, and in doing

so, gives off some of its heat. The heating water flows

back to the boiler via the return line [7], where the cycle

starts again.

The room temperature can be adjusted to your personal

requirements using the thermostatic radiator valves [5].

All radiators are supplied with the same flow

temperature. The heat transferred to the room depends

on the radiator surface and the heating water

throughput. Therefore, the heat transfer can be

manipulated via the thermostatic radiator valves.

What determines the heat demand of a room?

The heat demand of a room largely depends on the

following factors:

– Outside temperature

– Required room temperature

– Type of construction/insulation of the building

– Wind chill factor

– Solar radiant energy

– Internal heat sources (open fireplace, occupants,

lamps, etc.)

– Closed or open windows

Take these factors into consideration to achieve

a comfortable room temperature.

Fig. 1 Pumped central heating design

1 Boiler

2 Burner

3 Pump

4 Flow line

5 Thermostatic radiator valves

6 Radiators

7 Return line

Fig. 2 Influences on the room climate

Page 7

What you should know about your heating system

2

Logamatic 4211 - Subject to technical modifications.

7

Why do you need a heating control unit?

The heating control unit ensures convenient heat and

economical consumption of fuel and electrical energy.

It starts the heat source (boiler and burner) and pumps

when warm rooms or DHW are required. In doing so, it

utilises the components of your heating system at the

correct time.

Furthermore, your heating control unit records different

variables that influence the room temperature and

compensates for these.

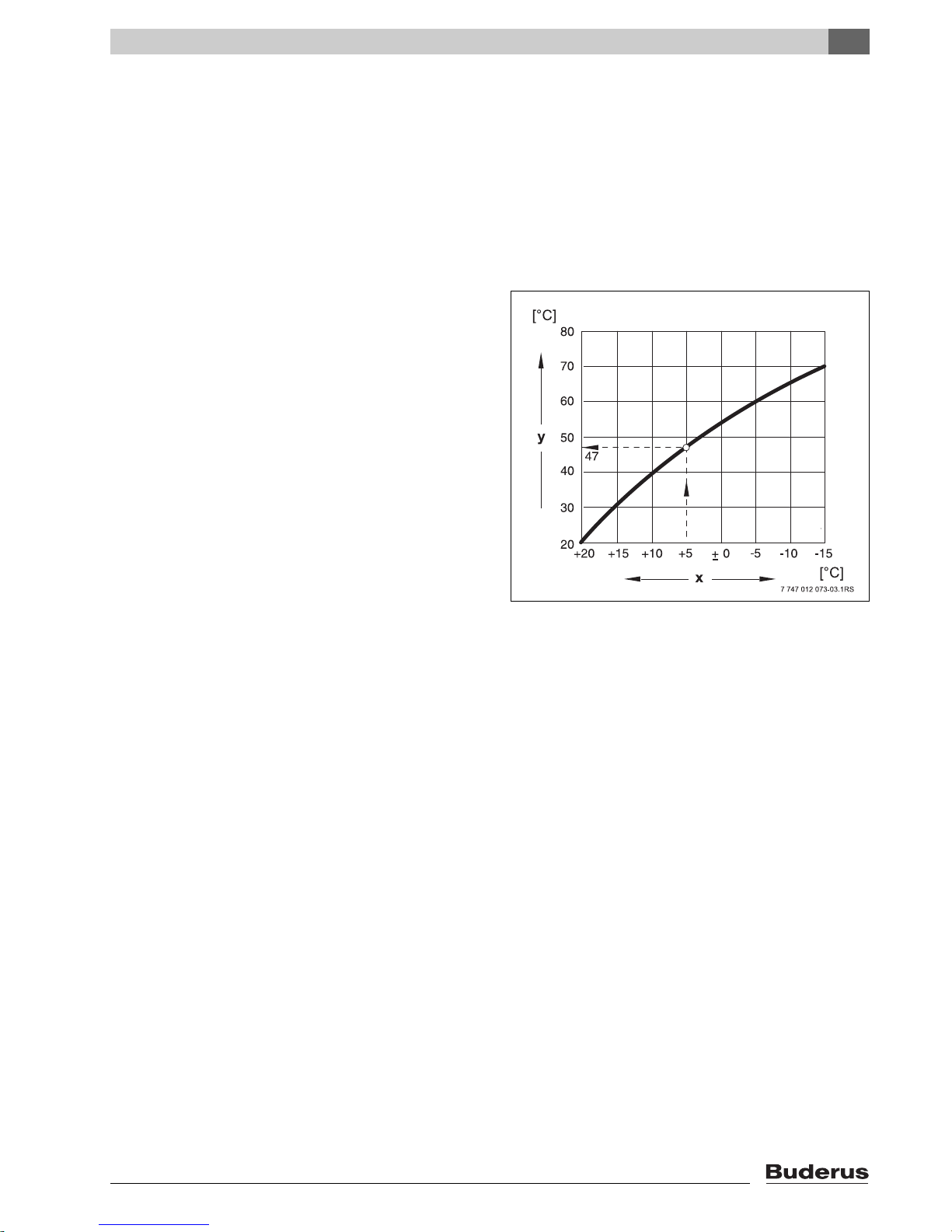

What does the control unit calculate?

Advanced control units calculate the temperature

required within the boiler (the so-called flow

temperature) subject to the outside temperature. The

relationship between the outside temperature and the

flow temperature is described as the heating curve.

The lower the outside temperature, the higher the flow

temperature must be.

The control unit can operate in three control modes:

– Weather-compensated control

– Room temperature-dependent control

– Weather-compensated control with room

temperature hook-up

Fig. 3 Heating circuit curve (example)

x Outside temperature

y Flow temperature

Page 8

What you should know about your heating system

2

Logamatic 4211 - Subject to technical modifications.

8

Weather-compensated control

With weather-compensated control, only the outside

temperature captured by the outside temperature

sensor is decisive for the flow temperature level. Room

temperature fluctuations through solar radiant energy,

occupants, open fireplaces or similar external heat

sources are then ignored.

If you utilise this type of control, adjust the thermostatic

radiator valves so that the required room temperature is

achieved in the different rooms.

Room temperature-dependent control

Another possible heating control method is room

temperature-dependent control. The control unit

calculates the flow temperature based on the set and

actual room temperatures.

To be able to utilise room temperature-dependent

control, you need a room that is representative of your

whole home. All factors influencing the temperature in

this "reference room" – where the programming unit is

located – will also apply to all other rooms. Not every

home has a room that meets these requirements. Pure

room temperature-dependent control has, in such

cases, certain limitations.

Should you, for example, open a window in the room

where the room temperature is measured, the control

unit will "think" that you have opened the windows in

every room in your house and will begin to heat

vigorously.

Or the reverse might apply: You measure the

temperature in a south-facing room with different heat

sources (solar or other heat sources, e.g. an open

fireplace). Now the control unit "thinks" that it is as hot in

every room as in the reference room; consequently the

boiler output will be severely reduced so that, for

example, the north-facing rooms will become too cold.

With this kind of control you always need to keep all

thermostatic radiator valves in the reference room fully

open.

Weather-compensated control with room

temperature hook-up

Weather-compensated control with room temperature

hook-up combines the advantages of the other two

control modes. The required flow temperature, which is

mainly subject to the outside temperature, can be

adjusted by the room temperature only to a limited

degree. This achieves improved maintenance of the

room temperature within the room containing the

programming unit, without completely ignoring the

other rooms.

With this kind of control you will also need to keep all

thermostatic radiator valves in the reference room fully

open.

Why do the thermostatic valves have to stay fully

open?

If, for example, you want to reduce the room

temperature in the reference room, and you therefore

close the thermostatic valve further, the flow rate

through the radiator is reduced and, therefore, less heat

is transferred to the room. This reduces the room

temperature. The control unit will endeavour to

counteract the drop in room temperature by raising the

flow temperature. However, raising the flow

temperature does not raise the room temperature, as

the thermostatic valve continues to limit the room

temperature.

An excessive flow temperature results in unnecessary

heat losses from the boiler and pipework. At the same

time, the temperature in all rooms without thermostatic

valves increases due to the higher boiler water

temperature.

Page 9

What you should know about your heating system

2

Logamatic 4211 - Subject to technical modifications.

9

Why do I need a time switch?

Advanced heating systems are equipped with a time

switch to save energy. With a time switch you can set up

an automatic changeover between two different room

temperatures, subject to time. This enables you to set a

reduced room temperature at night, or other times when

a reduced temperature is sufficient, whilst operating

your heating system with the standard room

temperature during the day.

You have four options for reducing the room

temperature via the control unit. Upon request, your

heating contractor will select and set up one of these

options:

– Total shutdown (no room temperature regulation)

– Reduced room temperature (a reduced room

temperature will be regulated)

– Change between total shutdown and reduced

heating subject to room temperature

– Change between total shutdown and reduced

heating subject to outside temperature

With total shutdown of the heating system, no pumps

or other system components are controlled. Heating

only recommences if the heating system is subject to

a risk of frost.

Heating with reduced room temperature (night mode)

only differs from standard heating mode (day mode)

through a lower flow temperature.

When changing from total shutdown to reduced

heating, total shutdown is activated subject to room

temperature when the actual room temperature

exceeds the set room temperature. This function is only

possible if a room temperature is being monitored.

When changing from total shutdown to reduced

heating, total shutdown is activated subject to outside

temperature when the actual outside temperature

exceeds the set outside temperature.

What are heating circuits?

A heating circuit describes the circuit taken by the

heating water from the boiler via the radiators and back

again (Æ Fig. 1, page 6). A simple heating circuit

comprises a heat source, a flow line, a radiator and

a return line. A pump installed in the flow line circulates

the heating water.

Several heating circuits may be connected to one

boiler, for example, one heating circuit for supplying

radiators and a further circuit for supplying an

underfloor heating system. In this case, the radiators

are supplied at a higher flow temperature than the

underfloor heating system.

The supply of different flow temperatures to different

heating circuits can be achieved by e.g. installing a

three-way valve between the boiler and the underfloor

heating system.

Using an additional temperature sensor in the flow of

the heating circuit to be supplied, sufficient cold return

water is mixed via a three-way valve into the hot flow

water, to achieve the required lower temperature. It is

important to note that heating circuits with three-way

valves require an additional pump. This pump enables

the second heating circuit to be operated independently

of the first heating circuit.

Page 10

Tips on energy-efficient heating

3

Logamatic 4211 - Subject to technical modifications.

10

3 Tips on energy-efficient heating

Here are a few tips on how to heat economically, without

sacrificing convenience:

z Only heat if you need warmth. Utilise the preset

heating programs (standard programs) in the control

unit, or those that have been tailored to your

individual requirements.

z Air rooms correctly during the heating season: Open

windows fully three to four times a day for

approximately 5 minutes. Having the window slightly

open all the time does not provide an air change and

wastes valuable energy.

z Close the thermostatic valves whilst ventilating.

z Windows and doors are places where a lot of heat is

lost. Therefore, check whether the doors and

windows are correctly sealed. Shut your roller

shutters (if installed) at night.

z Never position large objects such as a sofa or a desk

immediately in front of the radiators, (minimum

clearance 50 cm). Otherwise, the heated air cannot

circulate and heat the room adequately.

z In rooms you occupy during the day, you can, for

example, set a room temperature of 21°C, whilst

17 °C may be sufficient at night. To achieve this, use

standard heating mode (day mode) and setback

mode (night mode) (Æ Chapter 6).

z Never overheat rooms; overheated rooms are

unhealthy, plus they waste money and energy. If you

reduce the day room temperature, for example from

21 °C to 20 °C, you can save approximately six

percent of your heating bill.

z Also heat in an energy-conscious manner in spring

and autumn, and utilise the summer/winter time

adjustment (Æ Chapter 7).

z A pleasant room climate not only depends on the

room temperature, but also on the relative humidity.

The drier the air, the cooler a room feels. You can

optimise the relative humidity with house plants.

z You can also save money when heating DHW: Only

operate the DHW circulation pump via a time switch.

Research has shown that it is generally sufficient to

run the DHW circulation pump for only three minutes

every half hour.

z Arrange for your heating contractor to service your

heating system annually.

Page 11

Safety

4

Logamatic 4211 - Subject to technical modifications.

11

4 Safety

4.1 About these instructions

These operating instructions contain important

information regarding the safe and correct operation of

the Logamatic 4211 control unit.

4.2 Correct use

The Logamatic 4211 control unit is designed to control

heating systems in detached houses, apartment

buildings, residential complexes and other buildings.

4.3 Standards and guidelines/directives

4.4 Symbol key

Two levels of danger are identified and signified by the

following terms:

4.5 Please observe these notes

z Only operate the control unit as intended and if it is in

perfect working order.

z Let your heating contractor instruct you thoroughly in

the operation of this system.

z Read these operating instructions carefully.

z Only enter or change the operating values detailed in

these instructions. Other entries alter the control

programs of the heating system and can lead to

incorrect system functions.

z Maintenance and repairs as well as troubleshooting

should only be carried out by authorised and

qualified personnel.

The design and operation of this product

conform to European Directives and the

supplementary national requirements.

Its conformity is demonstrated by the CE

designation.

You can view the Declaration of Conformity

on the internet at www.buderus.de/konfo or

request a copy from your local Buderus

sales office.

WARNING!

RISK TO LIFE

Identifies possible risks associated with a

product that might lead to serious injury or

death if appropriate care is not taken.

CAUTION!

RISK OF INJURY/

SYSTEM DAMAGE

Indicates a potentially dangerous situation

which could lead to minor or moderately

serious injuries or to damage to property.

USER INFORMATION

User tips for the optimum utilisation and

setting of the appliance plus useful

information.

WARNING!

RISK TO LIFE

from electric shock.

z Never open the control unit.

z In an emergency, switch off the control

unit (e.g. with the heating system

emergency stop switch) or isolate the

heating system from the mains supply

by removing the main fuse.

z Arrange for your heating contractor to

rectify any heating system faults

immediately.

CAUTION!

RISK OF INJURY/

SYSTEM DAMAGE

from operator error.

Operator errors can result in injury and/or

damage to property.

z Ensure that children never operate the

appliance unsupervised or play with it.

z Ensure that only personnel able to

operate the appliance correctly have

access to it.

Page 12

Safety

4

Logamatic 4211 - Subject to technical modifications.

12

4.6 Cleaning the control unit

z Only clean the control unit with a damp cloth.

4.7 Disposal

z Dispose of the control unit packaging in an

environmentally responsible manner.

z The lithium battery in the CM431 module may only be

replaced by your heating contractor.

WARNING!

RISK OF SCALDING

For thermal disinfection, the entire DHW

system is set at the factory to heat up to

70 °C (start: Tuesday night at 01:00).

z If required (e.g. shift work), your

heating contractor can alter the start

time.

z During this time, never open any hot

water tap without mixing in cold water if

the DHW circuit of your heating system

is not equipped with a thermostatic

mixer.

z As there is a risk of scalding at

temperatures above approximately

60 °C, ask your heating contractor

about the set DHW temperatures.

CAUTION!

SYSTEM DAMAGE

from frost.

When the heating system is switched off,

it can suffer damage from frost.

z Protect your heating system against

frost damage by draining it and the

DHW pipework at the lowest possible

point.

Page 13

Controls and MEC2 programming unit

5

Logamatic 4211 - Subject to technical modifications.

13

5 Controls and MEC2 programming unit

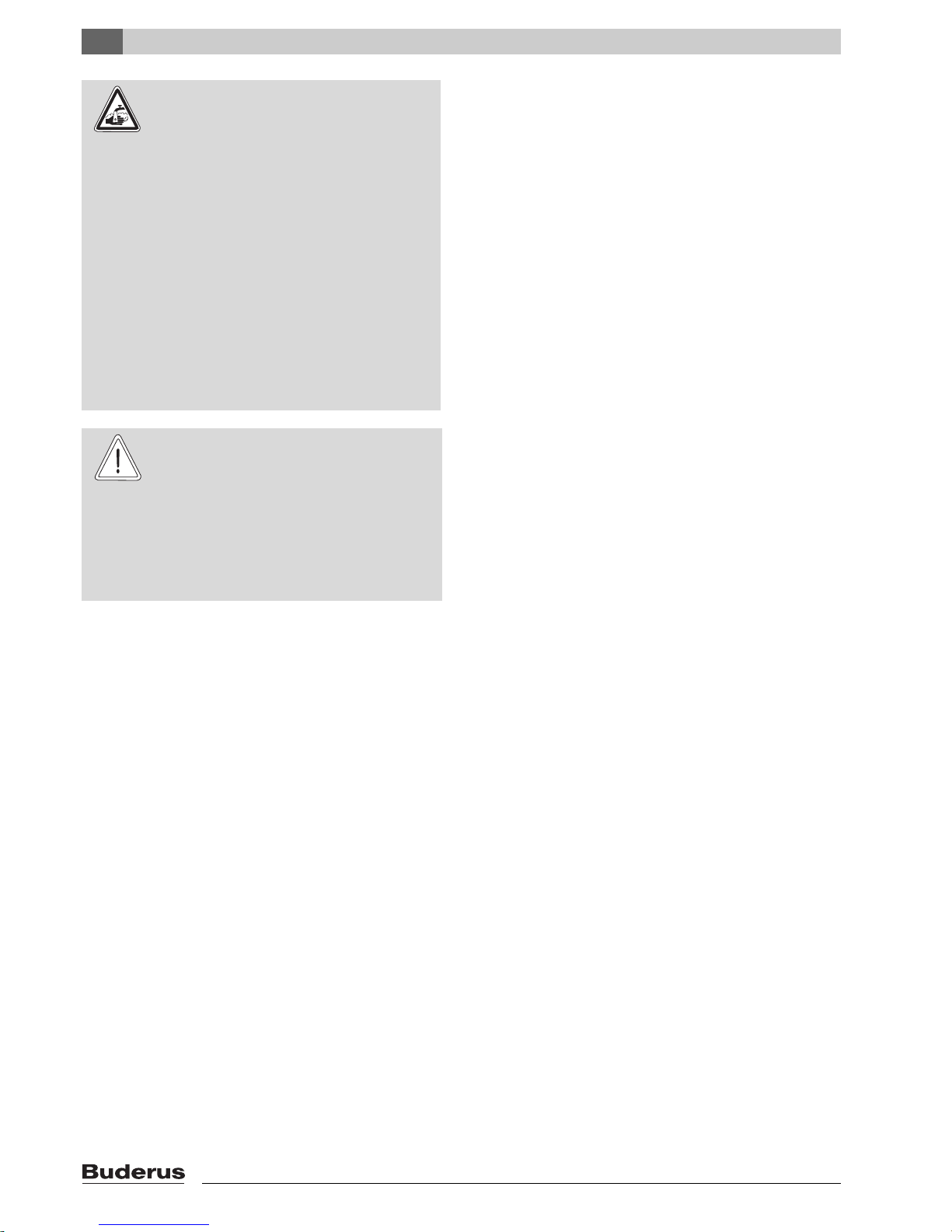

5.1 Control unit controls

Fig. 4 Logamatic 4211 control unit - controls (delivered condition)

1 High limit safety cut-out

2 Boiler water thermostat

3 Fuse F1

4 Connection for external service equipment and MEC2

5 Burner emergency operation switch

6 ON/OFF switch

Fig. 5 Fitted modules

1 Slot 1: e.g. FM442 – heating circuit 1, heating circuit 2

A Slot A: ZM422 – heating circuit 0 / boiler / DHW

B Slot B: MEC2 (CM431) – MEC2 programming unit

2 Slot 2: e.g. FM442 – heating circuit 3, heating circuit 4

Page 14

Controls and MEC2 programming unit

5

Logamatic 4211 - Subject to technical modifications.

14

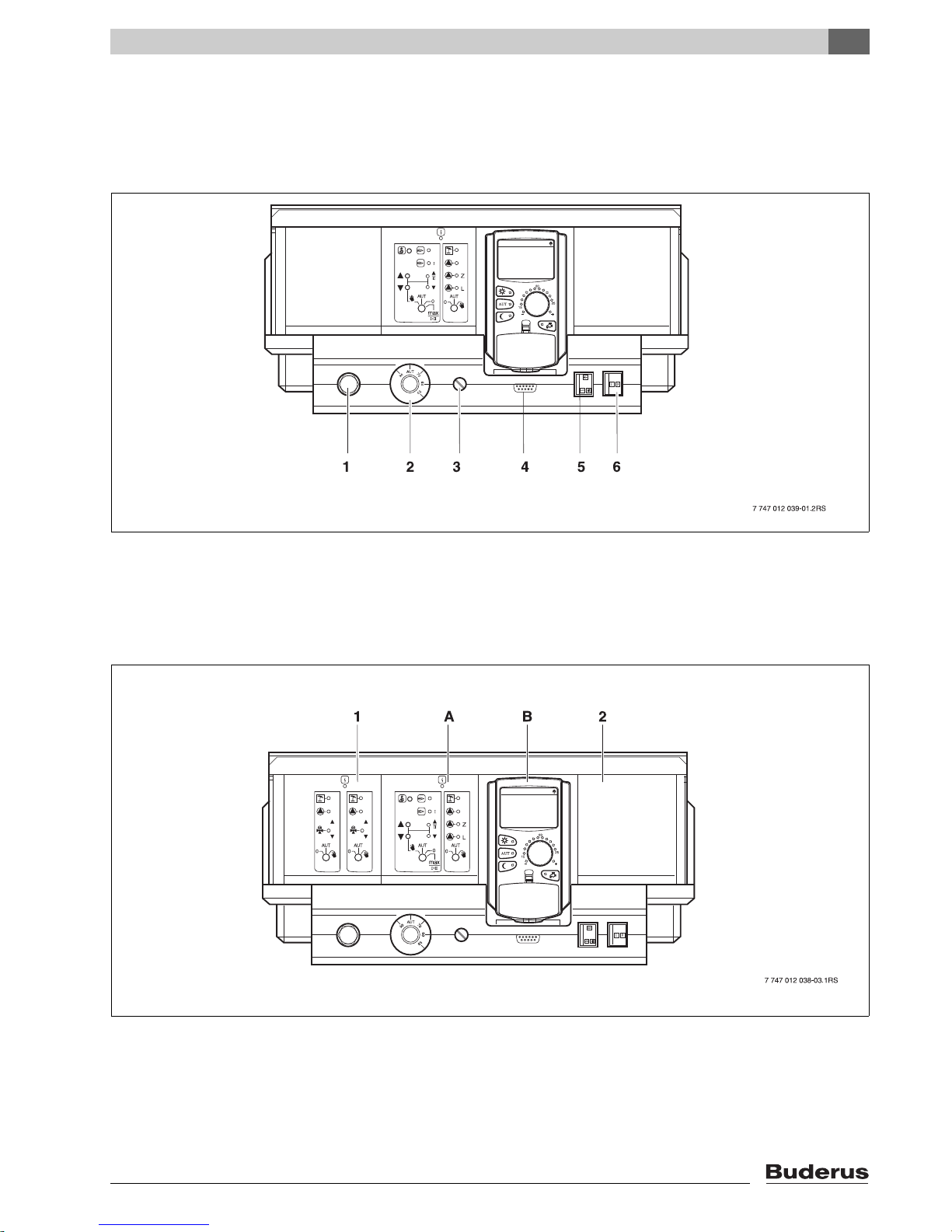

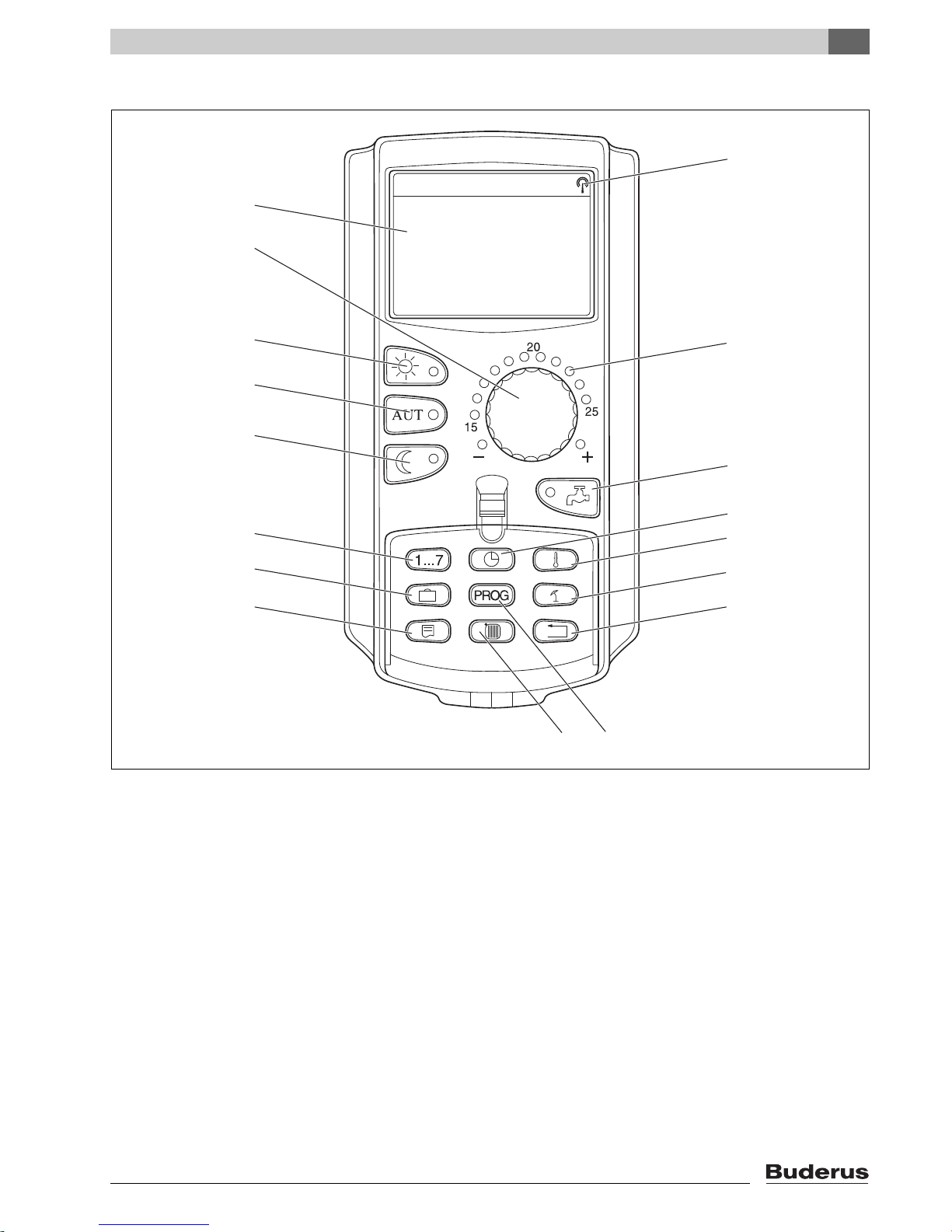

5.2 MEC2 programming unit

The MEC2 programming unit is the central element with

which you operate your Logamatic 4211 control unit.

Display

The display (Æ Fig. 6, [4]) indicates functions and

operating values, e.g. the actual room temperature.

Rotary selector

The rotary selector (Æ Fig. 6, [5]) is used to set new

values and scroll through the menus.

Keys

You control the functions via the keys, and the relevant

indications appear on the display. If you push a key and

hold it down, you can change a value using the rotary

selector.

The new value will be accepted and saved after you

release the key.

You can reach certain functions, such as day room

temperature, night room temperature, and possibly the

DHW temperature or automatic heating mode, directly

via the corresponding keys (Æ Fig. 6, [1] to [3] and [6]).

Behind a flap (Æ Fig. 6, [7]), further keys are available

for additional settings, e.g. for the entry of weekdays or

setting the time.

The unit automatically returns to the standard display if

no entry is detected for some time.

Fig. 6 MEC2 programming unit

1 Constant setback mode

2 Automatic heating mode in acc. with a time switch

3 Constant heating mode

4 Display

5 Rotary selector

6 Enter DHW temperature/reheating

7 Flap for the keypad of control level 2

Tag Zeit Temp

Urlaub Auswahl So/Wi

Anzeige Heizkreis Zurück

AUT

1

2

3

6

4

5

7

Page 15

Controls and MEC2 programming unit

5

Logamatic 4211 - Subject to technical modifications.

15

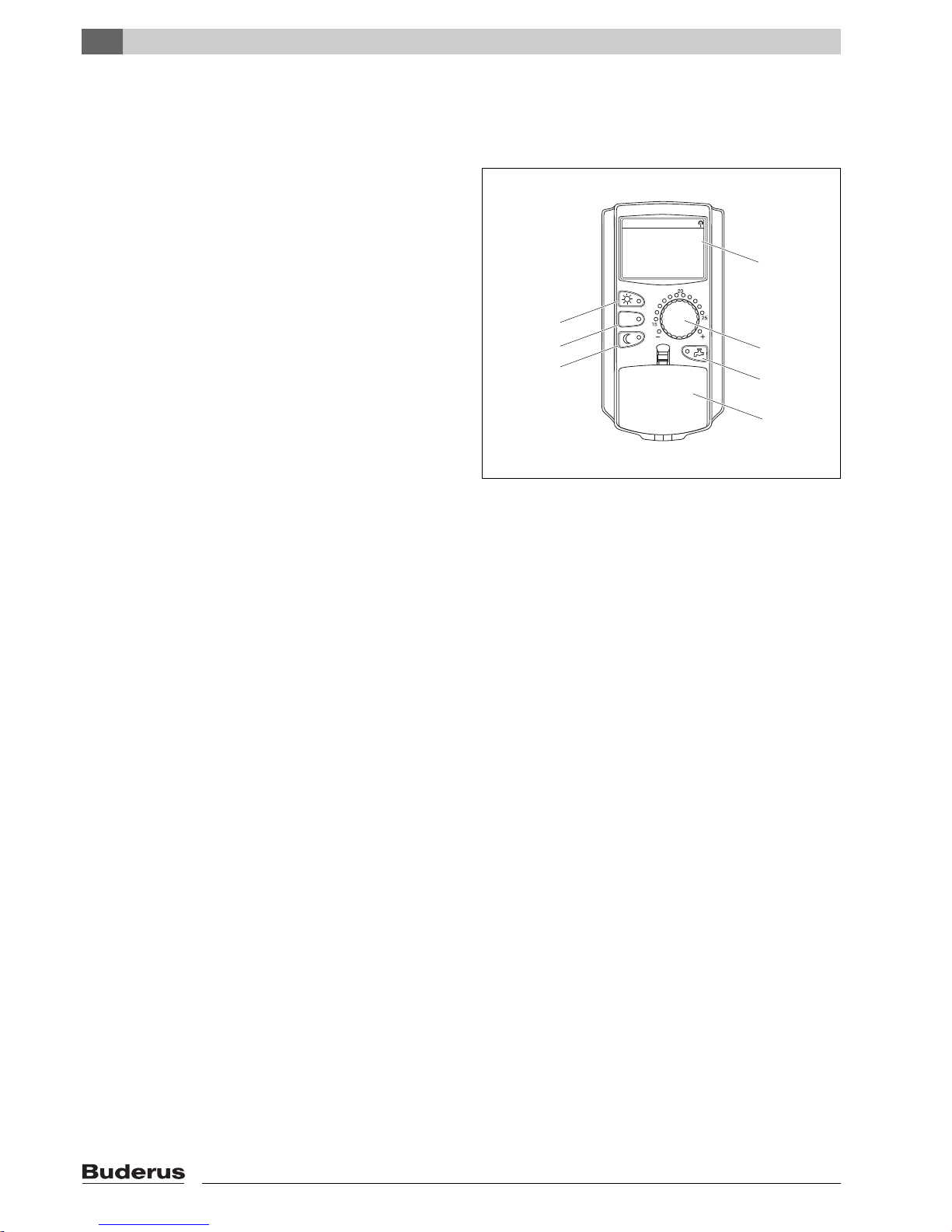

MEC2 programming unit

Fig. 7 MEC2 programming unit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

7 747 012 074-01.1RS

1 Display

2 Rotary selector

3 Constant heating mode

4 Automatic heating mode in acc. with a time switch

5 Constant setback mode

6 Enter the day of the week

7 Enter holidays

8 Select standard display

9 Radio clock signal (only within Germany)

10 Display for set room temperature

11 Enter DHW temperature/reheating

12 Set the time

13 Change temperature values

14 Summer/winter time adjustment

15 Back to the standard display

16 Select a time switch program

17 Select heating circuits/DHW circuit

Page 16

Controls and MEC2 programming unit

5

Logamatic 4211 - Subject to technical modifications.

16

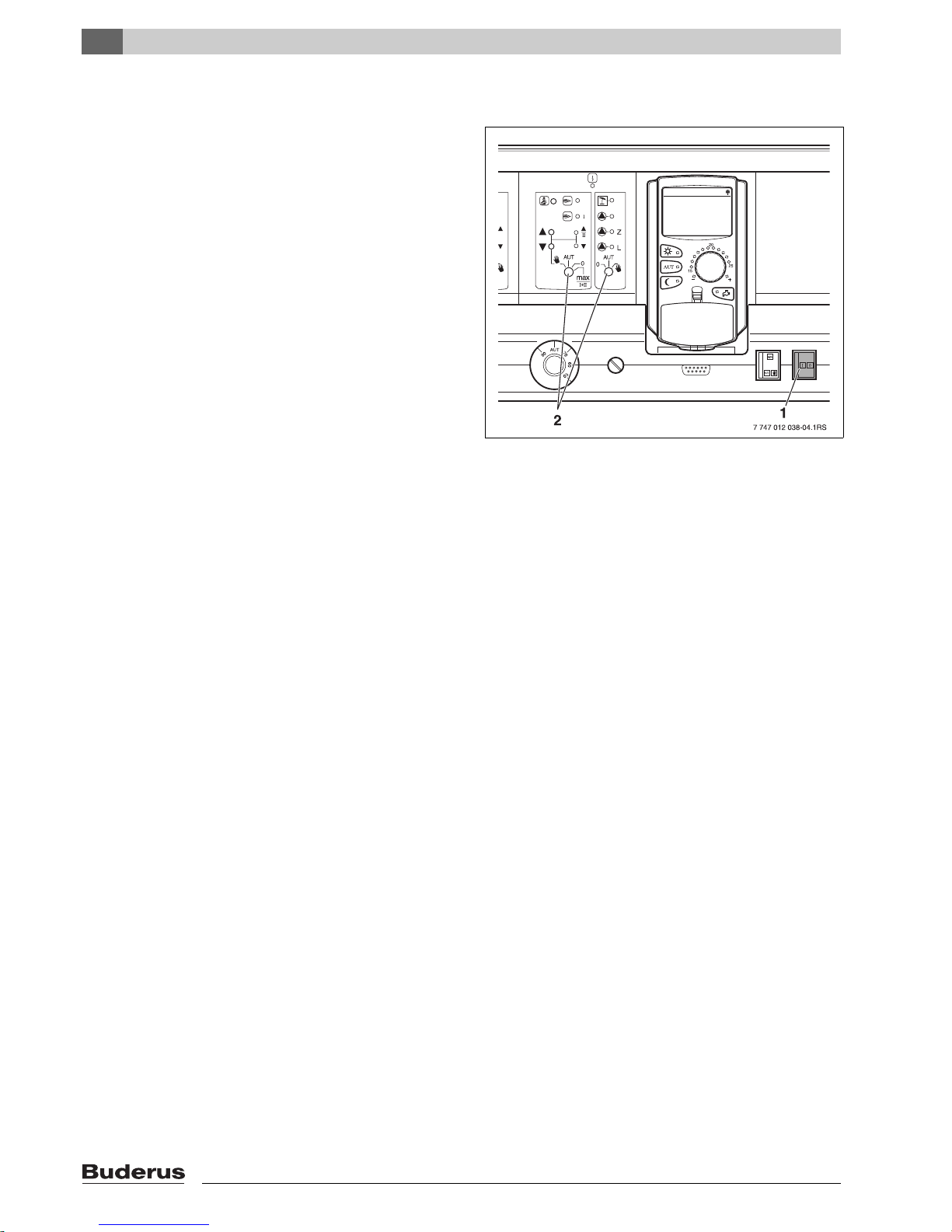

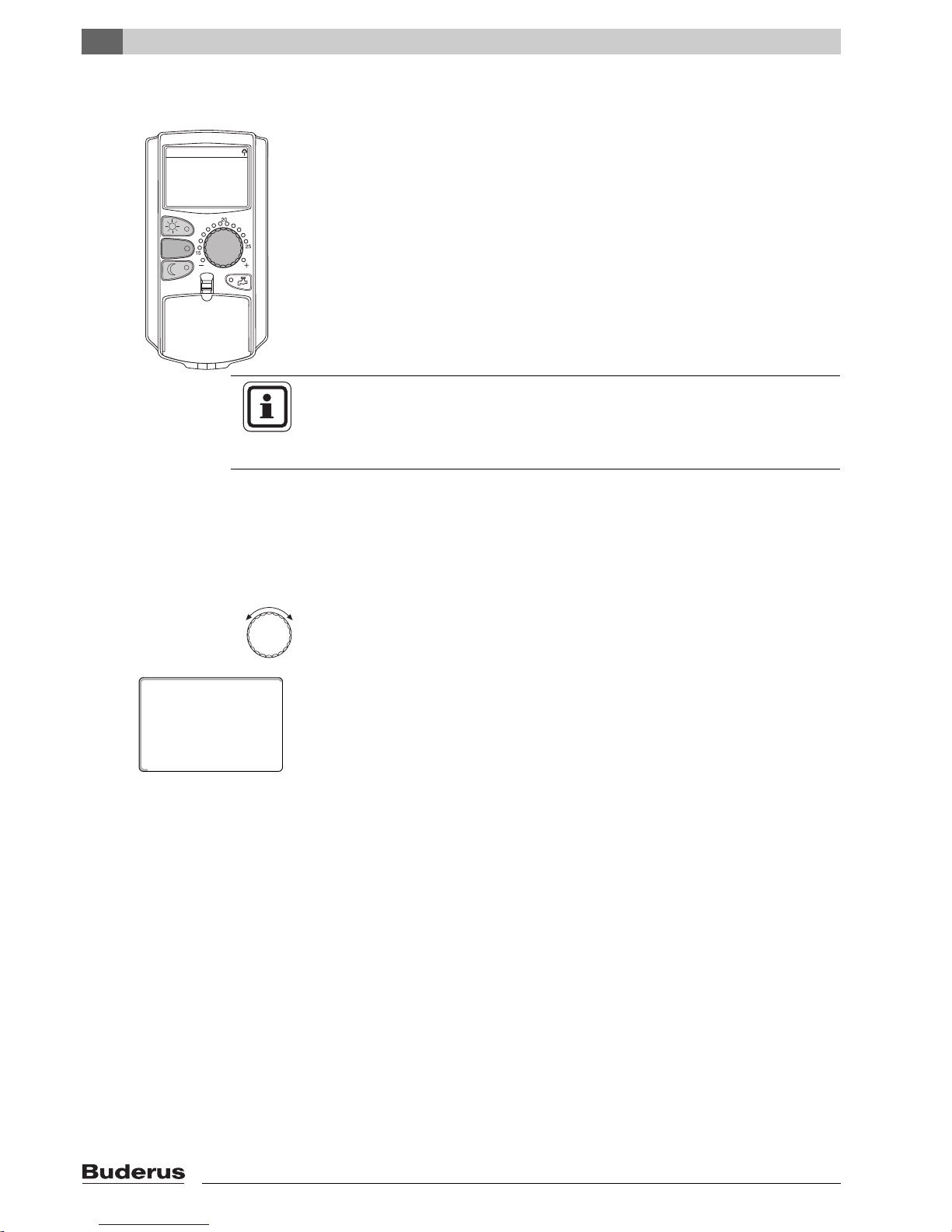

5.3 Switching on the control unit

z Check that the control unit ON/OFF switch

(Æ Fig. 8, [1]) and the switches on the fitted modules

(Æ Fig. 8, [2]) are set to "I" and "AUT".

z Switch the control unit ON by setting the ON/OFF

switch to "I" (Æ Fig. 8, [1]).

After approximately 2 minutes all modules fitted to the

control unit are recognised, and the standard display is

shown.

5.4 Switching off the control unit

z Switch the control unit OFF by setting the ON/OFF

switch to "0" (Æ Fig. 8, [1]).

z When there is a risk: Isolate the heating system from

the mains supply with the emergency stop switch

upstream of the boiler room, or by removing the main

fuse.

Fig. 8 ON/OFF switch

1 ON/OFF switch

2 Switch on the module

Page 17

Standard functions

6

Logamatic 4211 - Subject to technical modifications.

17

6 Standard functions

In this chapter you will find information about the standard functions of the MEC2

programming unit and their use. The standard functions are:

– Selecting the operating mode

– Setting the room temperature

– Setting the DHW temperature

– Heating DHW once

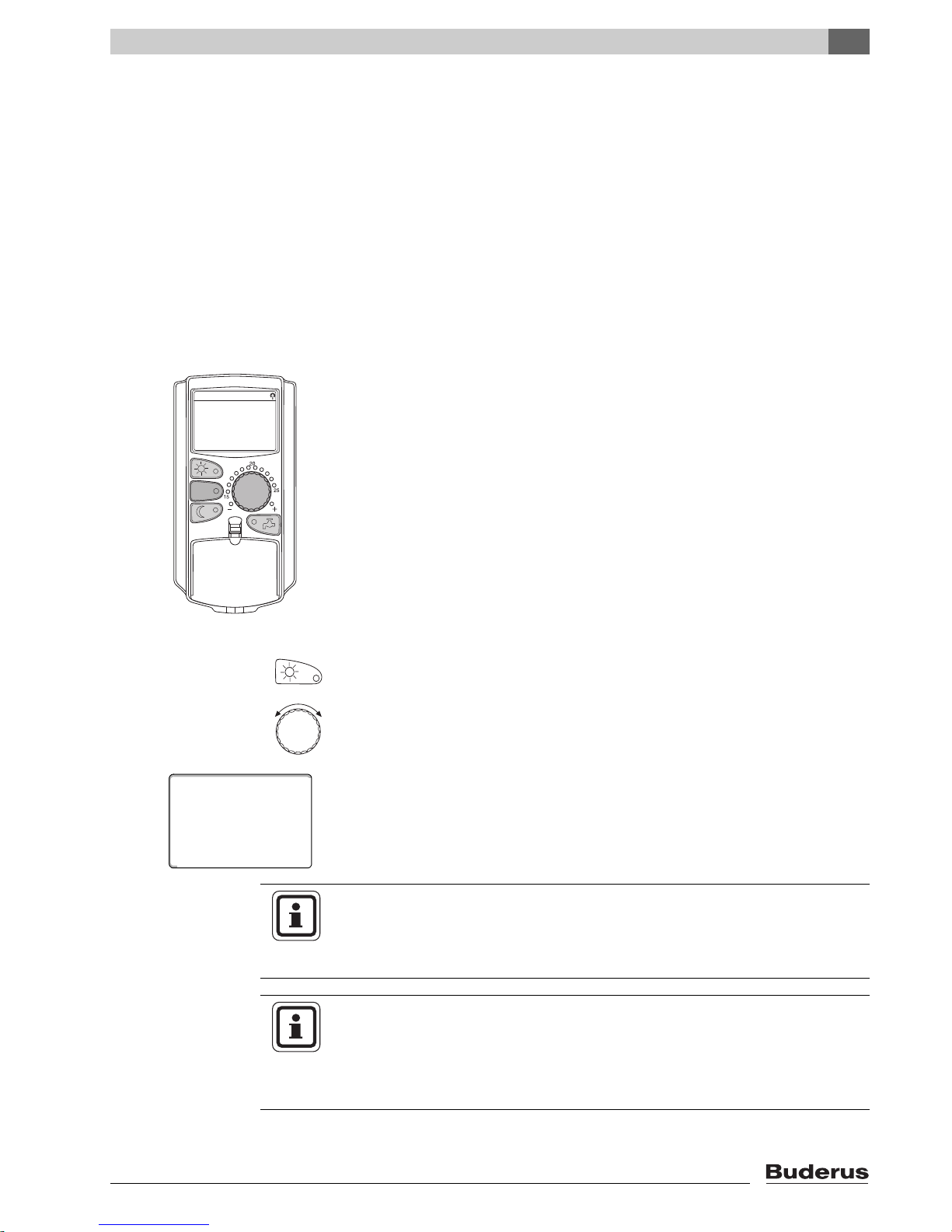

6.1 Simple operation

The standard functions are controlled by pressing one of the keys on the

"Standard function" keypad or by turning the rotary selector.

Example: Adjusting the room temperature for day mode

Press "Day mode" to select the standard heating mode (day mode). The LED of

the "Day mode" key illuminates; day mode is enabled.

Set the required room temperature by turning the rotary selector. (Condition: For

this, the programming unit flap must be closed.)

The display shows the set value.

Tag Zeit Temp

Urlaub Auswahl So/Wi

Anzeige Heizkreis Zurück

AUT

AUT

Set room

Constant day

21°C

USER INFORMATION

If your heating system is equipped with several heating circuits, first select the

correct heating circuit (Æ Chapter 7.6). Only then can you select the operating

mode and room temperature.

USER INFORMATION

The following MEC2 displays only describe the possible displays:

– of the ZM422 module (standard equipment level)

– of the most frequently used FM442 module (accessory)

Page 18

Standard functions

6

Logamatic 4211 - Subject to technical modifications.

18

Subject to the way your heating contractor has configured your system, one or

more MEC2 displays may not appear, although the above modules are fitted in

your control unit.

Detailed descriptions of MEC2 displays for other modules are included in the

corresponding module documentation.

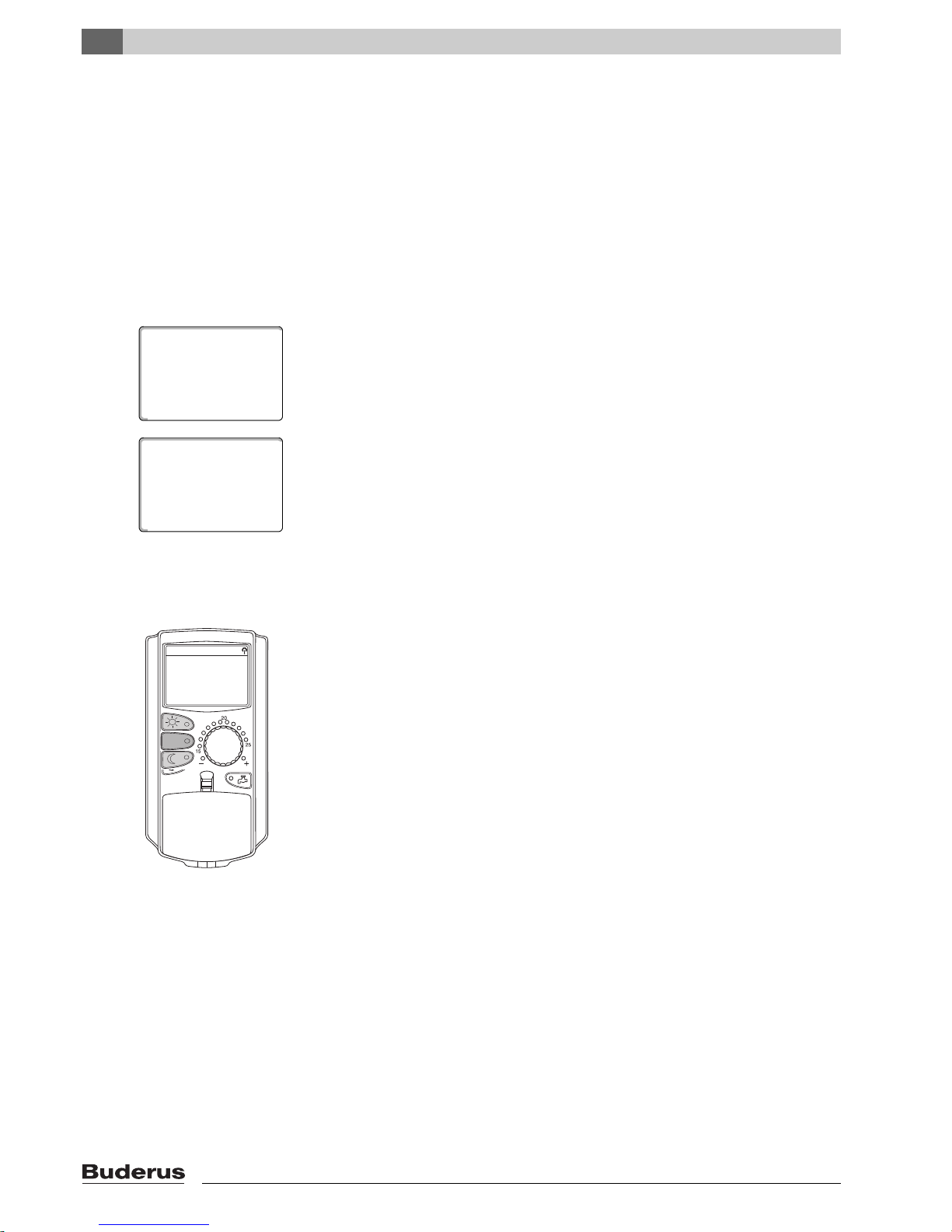

6.2 Permanent display

There are two different permanent displays. Either one of the factory-set

permanent displays is shown, subject to whether the MEC2 is fitted in the control

unit or is installed as a wall mounted unit.

Factory-set permanent display, if the MEC2 is fitted in the control unit.

Factory-set permanent display, if the MEC2 is installed as a wall mounted unit.

6.3 Selecting the operating mode

You can operate the MEC2 programming unit in two ways:

– In automatic mode

– In manual mode

Automatic mode

Generally, homes are heated less at night than during the day. With the MEC2

programming unit you don't need to adjust the thermostatic radiator valves

before bedtime or in the morning. The automatic changeover of the MEC2

programming unit does this for you. It changes over between day mode

(standard mode) and night mode (setback mode).

The times at which your heating system changes from day to night mode – and

vice-versa – are factory-set via standard programs (Æ Chapter 7.10). However,

you or your heating contractor can modify these settings (Æ Chapter 7.12).

Manual mode

For example, if you want to heat longer in the evening or not quite as early in the

morning, you can also select day and night mode manually (Æ Chapter 6.3.2).

You can also use manual mode to heat on cooler days when the system

operates in summer mode.

Common flow

Outside temp.

21°C

45°C

Actual room

Outside temp.

0°C

19.5°C

Tag Zeit Temp

Urlaub Auswahl So/Wi

Anzeige Heizkreis Zurück

AUT

AUT

Page 19

Standard functions

6

Logamatic 4211 - Subject to technical modifications.

19

6.3.1 Selecting automatic mode

In automatic mode your heating system will operate with the time switch

program, i.e. central and DHW heating at preset times.

Example: Enabling automatic mode

Press "AUT".

The "AUT" LED illuminates; automatic mode is enabled.

In addition, either the "Day mode" or "Night mode" LED will illuminate. This is

subject to the set times for day and night mode.

Automatic day and night mode

At fixed times, central heating is provided or the room temperature is set back.

6.3.2 Selecting manual mode

Press either "Day mode" or "Night mode" to change to manual mode.

Press "Day mode".

The "Day mode" LED illuminates. Now your heating system is in constant day

mode (standard mode).

Press "Night mode".

The "Night mode" LED illuminates. Your heating system is now in constant night

mode (setback mode), and operates at a lower room temperature.

AUT

Set room

Automatic day

21°C

Fig. 9 Changeover from day and night mode at fixed times (example)

1 Day mode

2 Night mode

7 747 012 053-18.1RS

1

2

05:30

22:00

21 °C

17 °C

Set room

Constant day

21°C

Set room

Constant night

17°C

USER INFORMATION

If you have selected manual mode, other automatic controls will also be

switched off, e.g. the summer/winter time adjustment (Æ Chapter 7.13).

Page 20

Standard functions

6

Logamatic 4211 - Subject to technical modifications.

20

6.4 Setting the room temperature

With the flap closed you can adjust the room temperature with the rotary

selector. With the flap open, also press "Day mode" or "Night mode".

With the rotary selector, you can select the room temperature in degree steps

between 11 °C (day), or 2°C (night), and 30 °C. The set temperature is displayed

via an LED next to the rotary selector. For temperatures below 15 °C or above

25 °C, the "–" or "+" LED illuminates.

The factory setting for the day room temperature is 21 °C.

The factory setting for the night room temperature is 17 °C.

Any adjustment applies to all heating circuits assigned to the MEC2

programming unit (Æ Chapter 7.7).

6.4.1 For the current operating mode

You are currently in automatic "Day mode" and would like to alter the room

temperature.

(Condition: For this, the programming unit flap must be closed.)

Turn the rotary selector to the required day room temperature (here: "23°C").

The day room temperature is now adjusted to 23 °C. The selected permanent

display will then appear again.

Tag Zeit Temp

Urlaub Auswahl So/Wi

Anzeige Heizkreis Zurück

AUT

AUT

USER INFORMATION

The set room temperature applies to the currently enabled heating mode,

i.e. day or night mode. You can recognise the currently enabled heating mode

because the green LED illuminates.

Set room

Automatic day

23°C

Page 21

Standard functions

6

Logamatic 4211 - Subject to technical modifications.

21

6.4.2 For the operating mode not currently enabled

You may also adjust the room temperature for an operating mode that is not

currently enabled.

For example, you are currently in automatic "Day mode" and would like to alter

the set night temperature.

Hold down "Night mode", and select the required night room temperature with

the rotary selector (here: "16°C").

Release "Night mode" key.

The night setback temperature is now adjusted to 16°C. The selected

permanent display will then appear again.

Press "AUT".

The "AUT" LED illuminates; automatic mode is re-enabled.

+

Set room

Constant night

16°C

AUT

USER INFORMATION

If you are currently in automatic "Night mode", and you wish to adjust the day

mode, proceed as described above, but instead hold down the "Day mode"

key.

Page 22

Standard functions

6

Logamatic 4211 - Subject to technical modifications.

22

6.5 Heating DHW

The programming unit also offers you the option of heating DHW in an energyconscious manner. For this purpose, DHW heating can be selected via a time

switch. You can select between the set values for DHW and "OFF", to stop DHW

heating.

To save energy, DHW heating will be stopped outside the programmed times,

i.e. DHW is not heated in night mode.

DHW heating is factory-set to 60 °C in automatic mode.

We recommend heating the DHW cylinder once in the morning, before central

heating begins, and reheating once in the evening if necessary (see Æ Fig. 10).

Tag Zeit Temp

Urlaub Auswahl So/Wi

Anzeige Heizkreis Zurück

AUT

Fig. 10 Example: DHW heating

1 Day mode

2 Night mode

3 OFF

7 747 012 053-17.1RS

1

2

05:30

21:00

09:00

18:00

60 °C

3

USER INFORMATION

The DHW temperature will have fallen below the set value if the green "DHW"

LED illuminates.

Page 23

Standard functions

6

Logamatic 4211 - Subject to technical modifications.

23

6.5.1 Setting the DHW temperature

You can change the DHW temperature as follows:

Hold down the "DHW" key, and select the required DHW temperature within the

rotary selector.

Release "DHW" key. The newly selected DHW temperature is saved in

approximately 2 seconds. The permanent display will then appear again.

WARNING!

RISK OF SCALDING

from hot water.

The DHW cylinder temperature is preset to 60 °C. There is a risk of scalding

from hot water if your heating contractor has set the DHW temperature higher,

or has enabled the "Therm. disinfect" function, and the heating water circuit of

your heating system is not equipped with a thermostatically controlled mixer.

Please note that fittings can also get very hot.

z In such cases, only ever draw off mixed water (hot and cold).

+

DHW

60°C

set

USER INFORMATION

For thermal disinfection, the DHW will be heated to at least 60 °C once or twice

per week to kill off possible bacteria (e.g. legionella).

Page 24

Standard functions

6

Logamatic 4211 - Subject to technical modifications.

24

6.5.2 Heating DHW once

If the "DHW" LED illuminates, only a limited amount of hot water remains in the

cylinder. Should you require a larger amount of DHW, proceed as follows:

Press "DHW".

The "DHW" LED flashes, and heating DHW once commences.

Subject to the size of the DHW cylinder and the boiler output, DHW will be

available after approximately 10 to 30 minutes. With instantaneous water

heaters or combination boilers, DHW is available almost immediately.

DHW

Reheating

actual 55°C

Page 25

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

25

7 Extended functions

The extended functions are explained in this chapter. You need the extended

functions to be able to change the factory settings of your heating system. You

can use the following functions:

– Display the current operating values of your heating system

– Set the time

– Set the date

– Set heating circuits

– Select a heating program

– Set the room temperature for additional heating circuits

The keys for the extended functions are located behind the flap of the MEC2

programming unit.

7.1 Keys for extended functions

Fig. 11 Keys for the extended functions

1 Enter the day of the week

2 Enter holidays

3 Select standard display

4 Set the time

5 Change temperature values

6 Summer/winter time adjustment

7 Return to the standard display

8 Select a time switch program

9 Select heating circuits/DHW circuit

1

2

3

4

5

6

7

8

9

7 747 012 073-01.1RS

Page 26

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

26

7.2 Controlling the extended functions

The extended functions provide access to a further control level. At this level,

proceed according to the "Push and turn" principle. The control procedure is

always similar:

z Open flap.

Hold the required key down, e.g. the "Time" key, and simultaneously turn the

rotary selector.

By turning the rotary selector you modify the values that flash on the display.

Release key. Modified values are saved.

7.3 Displaying operating values

You can display and control the various operating values of the boiler, the

selected heating circuit and the system.

Only the operating values of the selected heating circuit, e.g. heating circuit 0,

are displayed (Æ Chapter 7.6).

z Open flap.

Turn the rotary selector clockwise without pressing any other key.

Subject to the modules, various of the following operating displays can be called

up:

– Burner and Hours run

– Actual heating circuit room temperature

– Set heating circuit room temperature

– Heating circuit operating state

– Actual heating circuit flow temperature

– Actual DHW temperature*

– Set DHW temperature*

– DHW operating mode*

– Operating state – DHW circulation pump and cylinder primary pump*

* Only if a DHW module has been installed.

+

"Back" key = Exit menu.

AUT

Heating circ. 0

20°C

Set room

Page 27

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

27

7.4 Changing the permanent display

You can determine the permanent display of the programming unit.

The following permanent displays are available:

– Common flow (if MEC2 is installed as a wall mounted unit)

– Outside temp.

– DHW*

– Time

– Date

* Only if DHW is installed.

Hold the "Display" key down, and select the required permanent display with the

rotary selector (here: "Date").

Release "Display" key. The selected permanent display has now been saved.

AUT

+

Common flow

Date

20.08.2001

45°C

Page 28

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

28

7.5 Setting the date and time

The MEC2 contains a radio receiver that under normal reception conditions

constantly monitors and corrects the control unit time switch.

When using the MEC2 programming unit, the reception of the radio clock

signal depends on location and position.

Reception of the radio clock signal is indicated by symbol

on the display.

Normally, reception is possible within a radius of 1500 kilometers around

Frankfurt/Main [Germany].

In case of reception problems, please observe the following:

– The radio reception is weaker in rooms surrounded by steel-reinforced walls,

cellars, high-rise buildings etc.

– The distance from sources of interference, such as computer monitors and

TV sets, should be at least 1.5 m.

– The radio reception tends to be better at night than during the day.

You can manually adjust the date and time on the MEC2 if the radio clock signal

is not available in your area.

USER INFORMATION

Date and time are preset at the factory.

This function is safeguarded through battery backup, i.e. independent of the

mains power supply.

USER INFORMATION

We recommend leaving the radio clock receiver disabled outside Germany

to prevent the reception of false signals (incorrect time setting).

AUT

/

USER INFORMATION

Well screened boiler rooms may impede the reception of the radio signal. If the

radio clock signal reception is impaired or non-existent, retain the automatic

factory setting according to calendar for summer/winter time adjustment.

Page 29

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

29

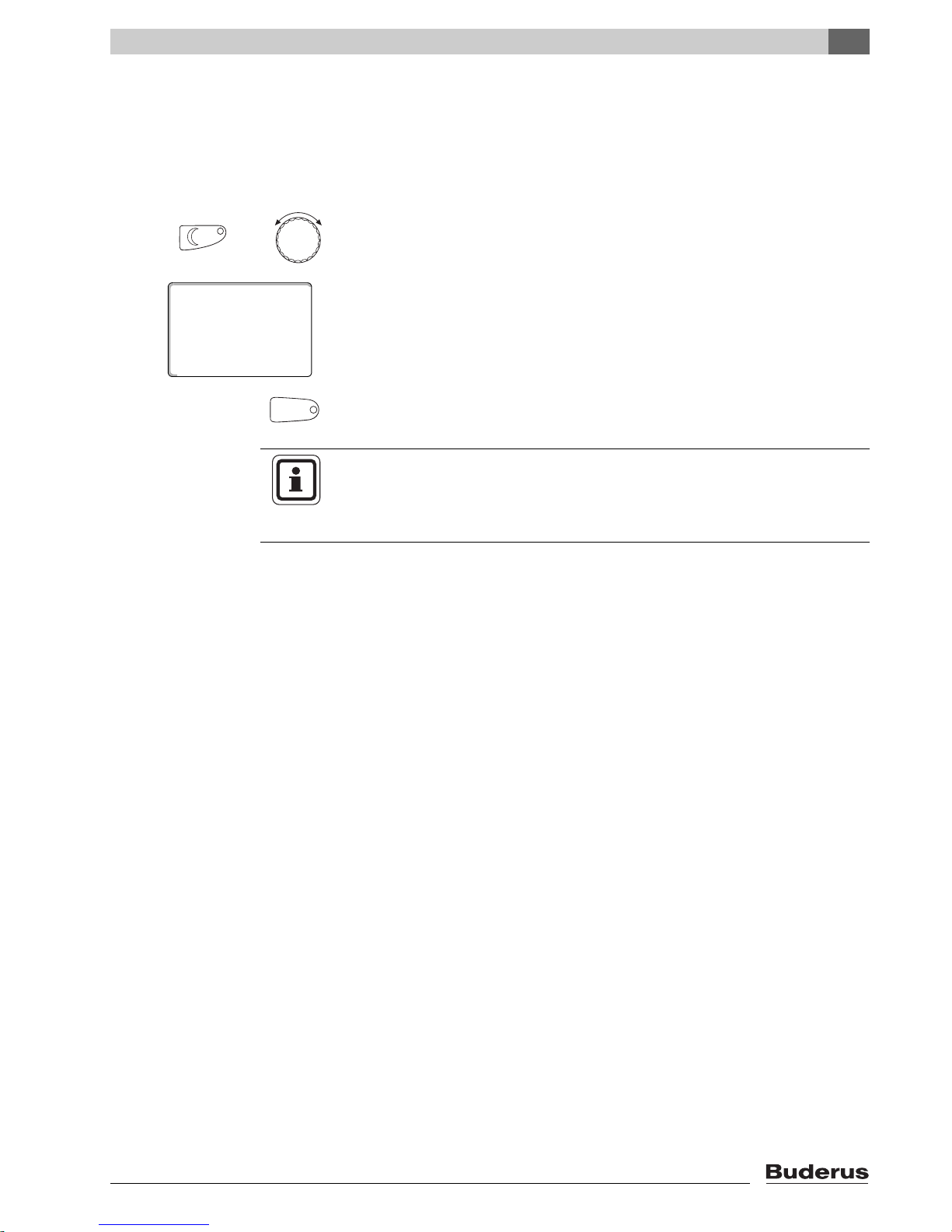

Setting the date

Hold "Weekday" down, and select the required date with the rotary selector

(here: "20").

The name of the day automatically changes (here: "Monday") if you set the date

for the day using the rotary selector (here: "20").

Release "Weekday" to save your input.

Press "Weekday" again to re-enter the month.

Press "Weekday" again to enter the year.

The item flashing can be modified with the rotary selector.

Setting the time

Hold down "Time", and select the required time with the rotary selector.

The time is set in one-minute steps.

Release "Time" to save your input.

+

Set date

Monday

20.08.2001

+

Set time

15:52:58

Page 30

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

30

7.6 Selecting a heating circuit

Your heating system may be equipped with several heating circuits. If you want

to change a setting, e.g. the heating program, first select the heating circuit

whose setting you want to change.

Subject to the equipment level of your heating system, the following heating

circuits can be selected:

– MEC2 heating circuits (all heating circuits assigned to the MEC2,

Æ Chapter 7.8)

– Heating circuit 0 – 8

– DHW

– DHW circulation

z Open flap.

Hold down "Heating circuit" and select the required heating circuit with the rotary

selector (here: "Heating circ. 2").

Release "Heating circuit" key. The displayed heating circuit is now selected.

As soon as the heating circuit has been selected, the display returns to the

permanent display.

AUT

+

Heat. circ. sel.

Heating circ. 2

Page 31

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

31

7.7 Adjusting the room temperature for another heating circuit

Your heating system may be equipped with several heating circuits. If you want

to change the room temperature for a different heating circuit than the one last

selected, first select the required heating circuit.

Subject to the equipment level of your heating system, the following heating

circuits can be selected:

– MEC2 heating circuits (all heating circuits assigned to the MEC2,

Æ Chapter 7.8)

– Heating circuit 0 – 8

If several heating circuits are assigned to the MEC2, the temperature for these

heating circuits can only be adjusted for all. Otherwise a fault message

"Setting Not possible. MEC heat. circ. select" will appear. In such cases select

"MEC heat. circ.".

z Open flap.

Hold down "Heating circuit" and select the required heating circuit with the rotary

selector (here: "Heating circ. 2").

Release "Heating circuit" key. The displayed heating circuit is now selected.

As soon as the heating circuit has been selected, the display returns to the

permanent display.

AUT

AUT

+

Heat. circ. sel.

Heating circ. 2

Actual room

Outside temp.

0°C

19.5°C

Page 32

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

32

Press and hold down "Temperature". First, the heating circuit whose

temperature you want to adjust is displayed. After approximately 2 seconds, the

display will show the currently selected temperature and operating mode.

Adjust the temperature with the rotary selector (here: "21°C") for the heating

circuit.

Release the key to save your input.

The day room temperature is now adjusted to 21 °C. The selected permanent

display will then appear again.

+

Set room

Automatic day

21°C

USER INFORMATION

If you want to adjust the temperature for an operating mode that is not the

current mode, first select the corresponding operating mode (e.g. with the

"Night mode" key). After modifying the temperature, reset the operating mode

to the previous setting.

USER INFORMATION

For heating circuits with individual remote control units (e.g. BFU), you can

adjust the room temperature only via this remote control (Æ see the

instructions for that remote control unit).

Page 33

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

33

7.8 Heating circuits with MEC2 programming unit

During installation, your heating contractor will determine which heating circuits

are to be controlled by the MEC2 programming unit. These heating circuits will

be designated "MEC heat. circ.".

MEC heat. circ.

The following adjustments made at the MEC2 apply all to "MEC heat. circ."

simultaneously:

– Setting the room temperature

– Setting the summer/winter time adjustment

– Selecting the operating mode

– Setting the holiday function

– Setting the party or pause function

If you have selected an individual heating circuit that is assigned to the MEC2,

and you want to make one of the above adjustments, the fault message "Setting

Not possible. MEC heat. circ. select" will appear.

Select "MEC heat. circ." to program these settings (Æ Chapter 7.6).

Individual heating circuits

The following adjustments can only be implemented for each individual heating

circuit separately:

– Selecting the standard program

– Modifying the standard program by moving switching points

– Inserting or deleting switching points

– Deleting or connecting heating phases

– Creating a heating, DHW or DHW circulation pump program

If you have selected "MEC heat. circ.", and you want to make one of the above

adjustments, the fault message "Time switch Not possible. Single heat circ

select" will appear.

Enter these settings for each heating circuit separately (Æ Chapter 7.6).

Setting

select

MEC heat. circ.

Not possible

Time switch

select

Single heat circ

Not possible

Page 34

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

34

7.9 Selecting and modifying a heating program

7.9.1 What is a heating program?

A heating program provides automatic changeover between operating modes

(day and night mode) at fixed times. This automatic changeover is effected via

a time switch.

Before you utilise this option, consider the following:

– At what time in the morning should your home be warm? Is this time also

subject to the day of the week?

– Are there days when you don't want to heat?

– From what time in the evening do you no longer need to heat? This may also

depend on the day of the week.

The length of time your heating system takes to heat up individual rooms may

vary. This will be subject to the outside temperature, the building insulation and

the room temperature setback.

The "Optimisation" function of the programming unit calculates the various heatup times. Ask your heating contractor whether this function has been enabled. If

so, all you need to do is enter the times at which your home should be warm.

With the programming unit, Buderus offers eight different, preset heating

programs as standard programs.

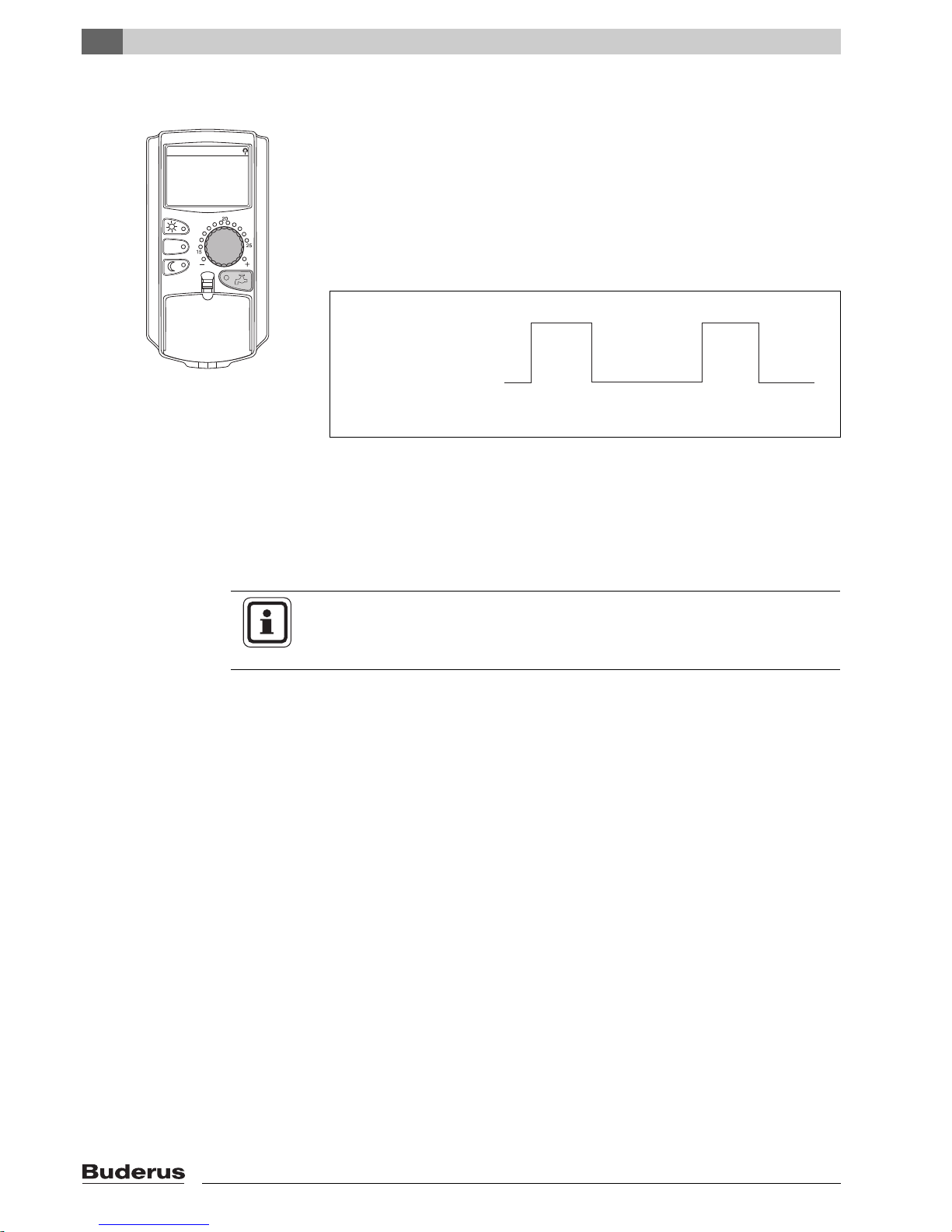

Fig. 12 Example for a standard program (here: "Family program" from Monday to

Thursday)

1 Day mode

2 Night mode

7 747 012 053-16.1RS

1

2

05:30

22:00

USER INFORMATION

After commissioning, check whether the selected heating program suits your

lifestyle. If not, several options are available for matching the heating program

to your individual requirements.

Page 35

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

35

7.9.2 Time switch program for DHW

You may enter your own heating program for DHW heating. This saves you

energy.

Determine the time points so that DHW is only available when one heating circuit

is in standard heating mode (day mode). In this case, DHW is heated 30 minutes

prior to the start of day mode of the first heating circuit so it is available at the

selected time.

If you require additional hot water, you may, at short notice, heat DHW with the

"DHW heating once" function (Æ Chapter 6.5.2).

Fig. 13 DHW heating begins 30 minutes before day mode of the first heating circuit, and

ends with the beginning of night mode of the last heating circuit.

A Heating circ. 1

B Heating circ. 2

C DHW

1 Day mode

2 Night mode

7 747 012 053-19.1RS

1

2

06:30 23:00

1

2

06:00

A

B

1

2

05:30

23:00

C

30 min

22:00

USER INFORMATION

DHW will not be subject to a temperature setback if you operate one heating

circuit in "Constant day" mode, and DHW is being heated "by heat. circs".

USER INFORMATION

DHW will not be heated if you are operating all heating circuits in the "Constant

night" mode and DHW is heated "by heat. circs.".

Page 36

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

36

7.10 Selecting a standard program

The MEC2 programming unit is equipped with eight different, preset heating

programs that act as standard programs. See the following page for a summary

of the preset times of the standard programs.

Please check which standard program best meets your requirements. First

check the number of switching points, and then the times. The "Family" program

is preset at the factory.

z Open flap.

z Select a heating circuit (Æ Chapter 7.6).

Hold down "PROG". Initially the heating circuit is displayed for which you want

to select a standard program. Approximately 2 seconds later the designation of

the currently selected standard program will appear.

Select the required standard program with the rotary selector (here: "Seniors").

Release "PROG" key. The displayed program is now selected.

The display shows the program designation and the first switching point for the

selected heating program (here: "Senior program").

Press "Back" to return to the permanent display.

AUT

+

Time switch

Program select.

Seniors

Senior program

Monday

21°C

at 05:30

USER INFORMATION

Switching programs are only effective in automatic mode (Æ Chapter 6.3.1).

Page 37

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

37

7.11 Summary of standard programs

Program designation Weekday ON OFF ON OFF ON OFF

"Family"

(factory setting)

Mo–Th

Fr

Sa

Su

05:30

05:30

06:30

07:00

22:00

23:00

23:30

22:00

"Early morning"

Early shift

Mo–Th

Fr

Sa

Su

04:30

04:30

06:30

07:00

22:00

23:00

23:30

22:00

"Late evening"

Late shift

Mo – Fr

Sa

Su

06:30

06:30

07:00

23:00

23:30

23:00

"Morning"

Part-time work in the

morning

Mo–Th

Fr

Sa

Su

05:30

05:30

06:30

07:00

08:30

08:30

23:30

22:00

12:00

12:00

22:00

23:00

"Afternoon"

Part-time work in the

afternoon

Mo–Th

Fr

Sa

Su

06:00

06:00

06:30

07:00

11:30

11:30

23:30

22:00

16:00

15:00

22:00

23:00

"Noon"

Noon at home

Mo–Th

Fr

Sa

Su

06:00

06:00

06:00

07:00

08:00

08:00

23:00

22:00

11:30

11:30

13:00

23:00

17:00 22:00

"Single"

Mo–Th

Fr

Sa

Su

06:00

06:00

07:00

08:00

08:00

08:00

23:30

22:00

16:00

15:00

22:00

23:00

"Seniors" Mo–Su 05:30 22:00

"New"

You can enter your own individual program here:

"Own 1"

If none of the standard programs suit you, you may alter them, have them changed by your heating

contractor, or enter a new heating program (Æ Chapter 8.2). This will be saved under "Own" and the

number of the heating circuit.

Tab. 1 Standard programs ("ON" = day mode, "OFF" = night mode)

Page 38

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

38

7.12 Modifying the standard program by moving switching points

If the switching points, i.e. the times of a standard program at which the system

changes over between day and night mode, only partially suit you, you may

change them, or ask your heating contractor to change them for you. The

modified standard program is saved under "Own" and the number of the heating

circuit. The heating program memory is available for this.

The following example shows how the switching points of the standard program

"Family" can be changed for the days Monday to Thursday.

z Open flap.

z Select a heating circuit (here: "Heating circ. 2", Æ Chapter 7.6).

Hold down "PROG" and select the required standard program with the rotary

selector.

Release "PROG" key.

The first switching point (Monday, 05:30) appears.

Hold down "Time", and select the required time with the rotary selector.

Example: "06:30".

AUT

Fig. 14 Changing the switching points from 05:30 to 06:30 and from 22:00 to 23:00

(example)

A "Family program"

B New program "Own program 2"

1 Day mode

2 Night mode

A

B

7 747 012 053-15.1RS

1

2

1

2

05:30

22:00

05:30 06:30

22:00

23:00

+

Time switch

Program select.

Family

Family program

Monday

21°C

at 05:30

+

Page 39

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

39

Release "Time" key. The newly adjusted time for the "ON" switching point is now

saved.

The modified switching point will be saved under the "Own" program and the

number of the heating circuit (here: "2").

Continue to turn the rotary selector until the next switching point that you want

to change is displayed.

The "OFF" switching point for Monday appears. Now you can modify the time for

the "OFF" switching point.

Hold down "Time", and select the required time with the rotary selector.

Example: "23:00".

Release "Time" key. The newly adjusted time for the "OFF" switching point is

saved.

Next switching point

Continue to turn the rotary selector until the next switching point is displayed.

The next switching point (Tuesday, 05:30) appears.

Also change the following switching points to 06:30 and 23:00. The system will

now heat from 06:30 to 23:00 Monday to Thursday.

Press "Back" to return to the permanent display.

The modified standard program is saved under "Own" and the number of the

heating circuit.

Own program 2

Monday

21°C

at 06:30

+

USER INFORMATION

You can change the weekday if you press "Weekday" instead of "Time".

You can change the switching state ("ON"/"OFF") by pressing "Display"

instead of "Weekday" or "Time". The operating mode determines the switching

state: "ON" = day mode, "OFF" = night mode.

z Ensure that an stop point is associated with every start point.

Page 40

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

40

7.13 Setting the summer/winter time adjustment

In addition to the outside temperature, your control unit considers the ability of

the building to store heat and its thermal insulation (creating from these the

"Adjusted outside temperature" Æ Fig. 15). After a delay, it automatically

changes over between summer and winter mode.

Summer mode

Heating operation is switched off if the "Adjusted outdoor temperature" exceeds

the factory-set changeover threshold of 17 °C.

Summer mode is indicated on the display with symbol .

DHW heating remains operational.

Press "Day mode" if you want to heat at short notice in summer mode.

The heating system returns to automatic summer mode if you press "AUT".

Winter mode

DHW and central heating are operational if the "Adjusted outside temperature"

falls below the factory-set changeover threshold of 17°C.

Setting the automatic summer/winter time adjustment

Select the required heating circuit before calling up the summer/winter time

adjustment. You may select either an individual heating circuit or all circuits

assigned to the MEC2.

z Select a heating circuit (Æ Chapter 7.6).

Example: Heating circ. 2

AUT

AUT

Fig. 15 Actual and adjusted outside temperatures compared

1 Current outside temperature

2 Adjusted outside temperature

x Time

y Outside temperature

AUT

Page 41

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

41

Setting the changeover temperature

Hold down "Su/Wi". The display briefly shows the heating circuit. Then turn the

rotary selector to the required changeover temperature, below which you want

to heat (here: "18°C").

The display shows the set changeover temperature.

Release "Su/Wi" key to save your input.

Setting up constant summer mode

z Select a heating circuit (Æ Chapter 7.6).

Example: Heating circ. 2

Hold down "Su/Wi". The display briefly shows the heating circuit. Then turn the

rotary selector to a changeover temperature below 10 °C.

The display shows "Constant summer".

Release "Su/Wi" key to save your input.

Your heating system will constantly operate in summer mode.

Setting up constant winter mode

z Select a heating circuit (Æ Chapter 7.6).

Example: Heating circ. 2

Hold down "Su/Wi". The display briefly shows the heating circuit. Then turn the

rotary selector to a changeover temperature above 30 °C.

The display shows "Constant winter".

Release "Su/Wi" key to save your input.

Your heating system will constantly operate in winter mode.

+

Summer / Winter

Summer from

18°C

+

Summer / Winter

Constant summer

+

Summer / Winter

Constant winter

Page 42

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

42

7.14 Setting the DHW operating mode

This allows you to change the DHW temperature in the DHW cylinder.

z Open flap.

Hold down "Heating circ." and select "DHW" with the rotary selector.

Release "Heating circuit" key.

The permanent display will then appear again.

Select one of the following operating modes for DHW:

– "Const. operation"

The water inside the DHW cylinder is constantly maintained at the set

temperature.

Press "Day mode" to select constant operation. After approximately three

seconds, the permanent display will appear again.

– "Automatic"

30 minutes before the first heating circuit is started, the boiler heats the

DHW cylinder to the set temperature, and stops when the last heating circuit

is switched off (factory setting). Alternatively, you can enter your own DHW

program (Æ Chapter 8.3).

Press "Automatic" to select automatic mode. After approximately three seconds,

the permanent display will appear again.

– "DHW OFF"

DHW heating is switched off. By pressing "DHW", you will switch heating on

for the duration of "DHW heating once".

Press "Night mode" to stop DHW heating. After approximately three seconds,

the permanent display will appear again.

AUT

AUT

+

Heat. circ. sel.

DHW

Actual room

Outside temp.

0°C

19.5°C

AUT

Page 43

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

43

7.15 Setting the operating mode for DHW circulation

The DHW circulation pump provides an almost instantaneous supply of DHW to

the draw-off points. For this, the DHW is circulated by a separate DHW

circulation pump twice per hour for three minutes. Your heating contractor can

match this interval to requirements at the service level.

You can modify the operating mode of DHW circulation as follows:

z Open flap.

Hold down "Heating circ." and select "DHW circulation" with the rotary selector.

Release "Heating circuit" key.

The permanent display will then appear again.

Select one of the following operating modes for the DHW circulation pump:

– "Const. operation"

The DHW circulation pump will operate at the set interval, i.e. independently

of the heating circuits.

Press "Day mode" to select constant operation. After approximately three

seconds, the permanent display will appear again.

– "Automatic"

30 minutes before the first heating circuit is started, the DHW circulation

pump starts to run at the set interval, and stops when the last heating circuit

is switched off (factory setting). Alternatively, you can enter your own DHW

circulation pump program (Æ Chapter 8.4).

Press "Automatic" to select automatic mode. After approximately three seconds,

the permanent display will appear again.

– "DHW circ. OFF"

The DHW circulation pump will not be controlled. Pressing "DHW" switches

the DHW circulation pump on for the duration of heating DHW once.

Press "Night mode" to switch off DHW circulation. After approximately three

seconds, the permanent display will appear again.

AUT

AUT

+

Heat. circ. sel.

DHW circulation

Actual room

Outside temp.

0°C

19.5°C

AUT

Page 44

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

44

7.16 Setting the holiday function

Using the holiday function, you can heat at a lower room temperature if you are

away for a prolonged period.

Example:

If you are on holiday for the next five days and want to heat less during that time,

e.g. heating circ. 2 with a reduced room temperature of 12 °C.

z Select a heating circuit (Æ Chapter 7.6).

Example: Heating circ. 2

Enter holiday function:

Hold "Holiday" down, and select the required number of days with the rotary

selector (here: "5").

The display shows "5".

Release "Holiday" key to save your input.

Hold "Temp" down, and select the required temperature with the rotary selector

(here: "12°C").

The display shows 12 °C.

Release "Temp" key to save your input.

The holiday function is enabled immediately after entry.

USER NOTE

As the holiday function is enabled immediately after completing your entry, you

should only enter this function on the day of your departure.

AUT

+

Holiday days

Set room

17°C

5

USER INFORMATION

The "Set room" display only appears if the "Hold room temp" holiday reduction

type or "Reduced" has been set by the heating contractor.

+

Holiday days

Set room

12°C

5

Page 45

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

45

You can cancel the holiday function any time by calling it up, as described

above, and by setting the number of holiday days to "0".

USER INFORMATION

DHW heating and DHW circulation will be switched off automatically if DHW

is heated subject to the heating circuits ("Program select. by heat. circs",

Æ Chapter 8.3), and all heating circuits are set to holiday mode. You cannot

enter a separate DHW holiday function.

USER INFORMATION

A separate DHW holiday function can be entered if DHW is produced

according to a separate time program ("Program select. own DHW",

Æ Chapter 8.3). The DHW circulation pump is switched off automatically

during the DHW holiday function.

Page 46

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

46

7.17 Interrupting and continuing the holiday function

You may interrupt your holiday program at any time and provide heat according

to the set day and night temperatures.

Only the "AUT" LED illuminates if a heating circuit is in holiday mode.

Interrupting the holiday function

Press "Day mode".

The display shows "Constant day".

You may interrupt the holiday function any time by pressing "Day mode". In this

case the system heats according to the set room temperature (Æ Chapter 6.4).

Continuing the holiday function

Press "AUT" to continue the interrupted holiday function.

Interrupting the holiday function

Press "Night mode".

The display shows "Constant night".

You may interrupt the holiday function at any time by pressing "Night mode".

In this case the system heats according to the set night temperature

(Æ Chapter 6.4).

Continuing the holiday function

Press "AUT" to continue the interrupted holiday function.

AUT

AUT

Set room

Constant day

21°C

AUT

Set room

Constant night

17°C

AUT

Page 47

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

47

7.18 Setting the party function

This function only applies to heating circuits to which the MEC2 has been

assigned as a remote control unit ("MEC heat. circ.") All heating circuits without

an MEC2 continue to operate normally.

Enter the length of time the system should only heat to the preset room

temperature.

Example:

You have a party and want to heat for the next four hours to the preset room

temperature.

Hold down "Day mode", and simultaneously open the flap of the MEC2.

"Party function" is enabled. Hold "Day mode" down, and turn the rotary selector

until the required number of hours is displayed (here: "4").

The display shows the party function together with the set number of hours.

Release "Day mode" key.

The party function starts immediately. After the set time has expired, the heating

system returns to automatic heating mode.

If you want to cancel the party function, call up party function as described above

and turn the rotary selector to "0".

7.19 Setting the pause function

This function only applies to heating circuits to which the MEC2 has been

assigned as a remote control unit ("MEC heat. circ."). All heating circuits without

an MEC2 continue to operate normally.

Enter the length of time the system should heat to the preset room temperature.

Example:

You are about to leave your home for three hours and would like to heat less

whilst you are away.

Hold down "Night mode", and simultaneously open the flap of the MEC2. The

pause function is enabled. Continue to hold down "Night mode", and turn the

rotary selector until the required number of hours is displayed (here: "3").

The display shows the pause function together with the set number of hours.

Release "Night mode" key.

The pause function starts immediately. After the set time has expired, the

heating system returns to automatic heating mode.

If you want to cancel the pause function, call up pause function as described

above and turn the rotary selector to "0".

+

Party function

4 hours

+

Pause function

3 hours

Page 48

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

48

7.20 Room temperature matching

The factory setting is 0 °C. The possible correction range is between +5 °C and

–5 °C.

Example:

Displayed room temperature 22°C, actual room temperature 22.5 °C

z Open flap

Simultaneously press and then release "Display" and "Temp".

The display shows "Calibration MEC".

Hold down "Temp" and turn the rotary selector to the required value

(here: "0.5°C").

The display shows the set value.

Release "Temp" key to save your input.

Press "Back" to return to the permanent display.

The display shows the corrected temperature (22.5°C).

USER INFORMATION

This function is only available if the MEC2 is fitted within the living space.

If the room temperature shown on the display varies from the actual

temperature measured with a thermometer, the display value can be adjusted

using "Calibration MEC".

+

Calibration MEC

Correction

Room temperature

0.0°C

+

Calibration MEC

Correction

Room temperature

0.5°C

Page 49

Extended functions

7

Logamatic 4211 - Subject to technical modifications.

49

7.21 Automatic maintenance message

If your heating contractor has (with your agreement) enabled the "automatic

maintenance message", the maintenance message "Note maint. message" is

displayed at a predetermined time (on a particular date or after so many hours

run).

z Open flap.

Turn the rotary selector.

You will see either "maint. after Date required" or "maint. after Hours run

required".

z Notify your heating contractor to schedule the inspection and maintenance

work.

Where fitted, the Logamatic telecontrol system enables the maintenance

message to be transmitted automatically to your mobile, PC or fax machine.

Note

Maint. message

Note

maint. message

maint. after

required

Date

maint. after

required

Hours run

USER INFORMATION

The automatic maintenance message remains active until it is reset by your

heating contractor.

Page 50

Additional programming options

8

Logamatic 4211 - Subject to technical modifications.

50

8 Additional programming options

This chapter is intended to provide more detailed information to those of our

customers who would like to familiarise themselves further with the functions of