Buderus Logalux SM300/1, Logalux SM400/1 Installation And Maintenance Manual

Installation and

Maintenance Manual

Solar and High Capacity Domestic Hot Water

Logalux SM300/1

Logalux SM400/1

6 720 615 190 - 02/2008 US

Documentation for the contractor

Please read carefully prior

to installation and maintenance

When the anode rod is not professionally and annually maintained, the

tank will lose its warranty. Annual

service records must be maintained

and shown in case of a warranty

claim along with an original proof of

purchase. Refer to page 23 to 27 for

annual maintenance instructions to

maintain tank warranty.

In the Commonwealth of Massachusetts this tank must be installed by a

licensed plumber.

Index

Index

1 Safety Precautions and symbol clarification 3

1.1 Placement, remodeling 3

1.2 Symbol Clarification 3

2 Product Description 4

2.1 Applications 4

2.2 Intended Use 4

2.3 Guidelines for Installations 4

2.4 Product Disposal 4

2.5 Product Packaging 5

2.6 Dimensions and Connections 7

2.7 Technical Specifications 9

3 Transportation 10

3.1 Transportation Means 10

3.1.1 Transportation with dolly 10

3.1.2 Transportation with overhead crane 11

3.2 Product Placement 11

4 Tank Assembly 12

4.1 SM300/1 Placement and Installation 12

4.1.1 Installation of tank feet 12

4.1.2 Installation of tank aquastat or temperature

sensor 12

4.2 SM400/1 Placement and Installation 15

4.2.1 Installation of M2 - M5 temperature sensors 15

4.2.2 Installation of Tank Insulation

for SM400/1 Tank 16

4.3 Water side Piping Connections for both

Tank Models 17

4.4 Connections for Solar station KS 19

4.5 Connections for High Output Indirect Fired

Tank Piping 20

4.5.1 Serial Connections of the bottom and

top coils 20

4.5.2 Parallel Connections of bottom and top coils 20

6 Maintenance 23

6.1 Preparation of cleaning of solar water tank 23

6.2 Cleaning of solar hot water tank 24

6.3 Checking of magnesium anode rod 25

6.4 Placing solar tank back in operation after

cleaning 27

7 Replacement Parts 28

7.1 Replacement parts for SM300/1 - 300/1W 28

7.2 Access cover and anode rod assembly

for SM300/1 - 300/1W 30

7.3 Replacement parts for SM400/1 31

7.4 Tank access cover and anode rod assembly

for SM400/1 33

7.5 Tank Jacket System for SM400/1 Tank 35

5 Start-up and Shut-down of Tank 21

5.1 Start-up Operations 21

5.1.1 Operational information from contractor 21

5.1.2 System start-up 22

5.2 Decommissioning of the system 22

5.2.1 Shutdown of solar hot water tank 22

5.2.2 Shutdown of heating system in cold

weather conditions 22

5.2.3 Environmental protection 22

2

Logalux SM300/1 - SM400/1 - Technical specifications are subject to change without prior notice.

Safety Precautions and symbol clarification

1 Safety Precautions and symbol clarification

1

1.1 Placement, remodeling

Placement, remodeling

V Fire danger!

Solder and welding operations can result in fire, as the

insulation is combustible.

V The solar tank can only be installed or renovated by

technical specialists.

Installation and Start-up Procedure

V In the Commonwealth of Massachusetts this tank must

be installed by a licensed plumber.

V Any electrical wiring must be installed by a licensed

electrician.

V Do not assemble the equipment in a damp environ-

ment.

Function

V Follow these directions for trouble free operation for

installation and maintenance.

V Danger of Scalding!

(> 140 °F) during operation of the tank as part of a

solar system. Please install tempering valve on domestic hot outlet connection of tank, which is supplied with

solar pumping station

Maintenance

V Recommendation for end customer: Please sign

up for an annual service and maintenance contract with

your installer. Make sure to have annual maintenance

performed on your boiler and solar system.

V Use only original replacement parts.

1.2 Symbol Clarification

Safety warnings are designated in the text

with a triangular warning label and grey coloring.

Signal words are describing the gravity of each danger

when safety precautions are not followed.

– Careful indicates possibility of light property damage.

– Warning indicates light personal injury or severe prop-

erty damage.

– Danger indicates possible severe personal injury with

potential loss of life.

Guidelines in the text are designated with

shown symbol. The text is bracketed between

two horizontal lines.

Guidelines contain important information in these cases

to avoid or reduce danger to people and equipment.

In case the solar storage tank will be installed in Massachusetts, it must be installed by an installer or dealer who

is registered in that state.

We reserve the right to change and improve technical

information without notice.

It is expected that the installer is a licensed heating contractor with the knowledge of accepted industry practices

for the installation and maintenance of the equipment and

various applications of the equipment involved.

Logalux SM300/1 - SM400/1 - Technical specifications are subject to change without prior notice.

3

2

Product Description

2 Product Description

2.1 Applications

The solar tanks SM300/1 and SM400/1 are designed for

the heating and storage of domestic hot water. Applicable

guidelines for domestic hot water must be followed.

2.2 Intended Use

The domestic hot water can be heating by a solar system

with a boiler as a back-up system, or by a boiler in general

for high output hot water heating. (Operate the 2 coils

either in series or in parallel). In case of solar heating, the

solar system must be filled with a solar fluid to prevent

accidental freezing. The tank can only be used in a closed

system.

Any other application voids the warranty of the tank.

2.3 Guidelines for Installations

Follow all specific state and local codes regarding the installation and operation of the

equipment.

All electrical components must be approved

for the US.

2.4 Product Disposal

V Dispose of packaging of the solar tank in an environ-

mental friendly fashion.

V A solar hot water heater that is being replaced must be

disposed of in a suitable fashion.

4

Logalux SM300/1 - SM400/1 - Technical specifications are subject to change without prior notice.

2.5 Product Packaging

Solar hot water tank consists of:

– Tank shell [6] with corrosion protection and magne-

sium anode rodes.

– Tank insulation [1] made from non FCKW insulation

material.

– SM300/1: direct attached to tank shell.

– SM400/1: Insulation must separately be installed.

– 2 Smooth high output heat transfer coils [11]

– The smooth surface coil transfers the energy from

the solar and/or heating system to the domestic

water inside the tank shell. The water volume is

evenly heated with the coil areas.

– Dry well M1 [12] for installation of DHW tank tempera-

ture sensor or aquastat.

–

Dry well

– The solar control is controlled by the tank tempera-

– Hand hole [3] cover for service and maintenance

access

– Dual magnesium anodes [5; 10]

– Jacket cover [8]

–B-Kit (US) (Æ Fig. 2, page 6)

[14]

for installation of tank temperature sensor.

ture sensor (lower port) which operates the solar

system based on collector sensor.

Product Description

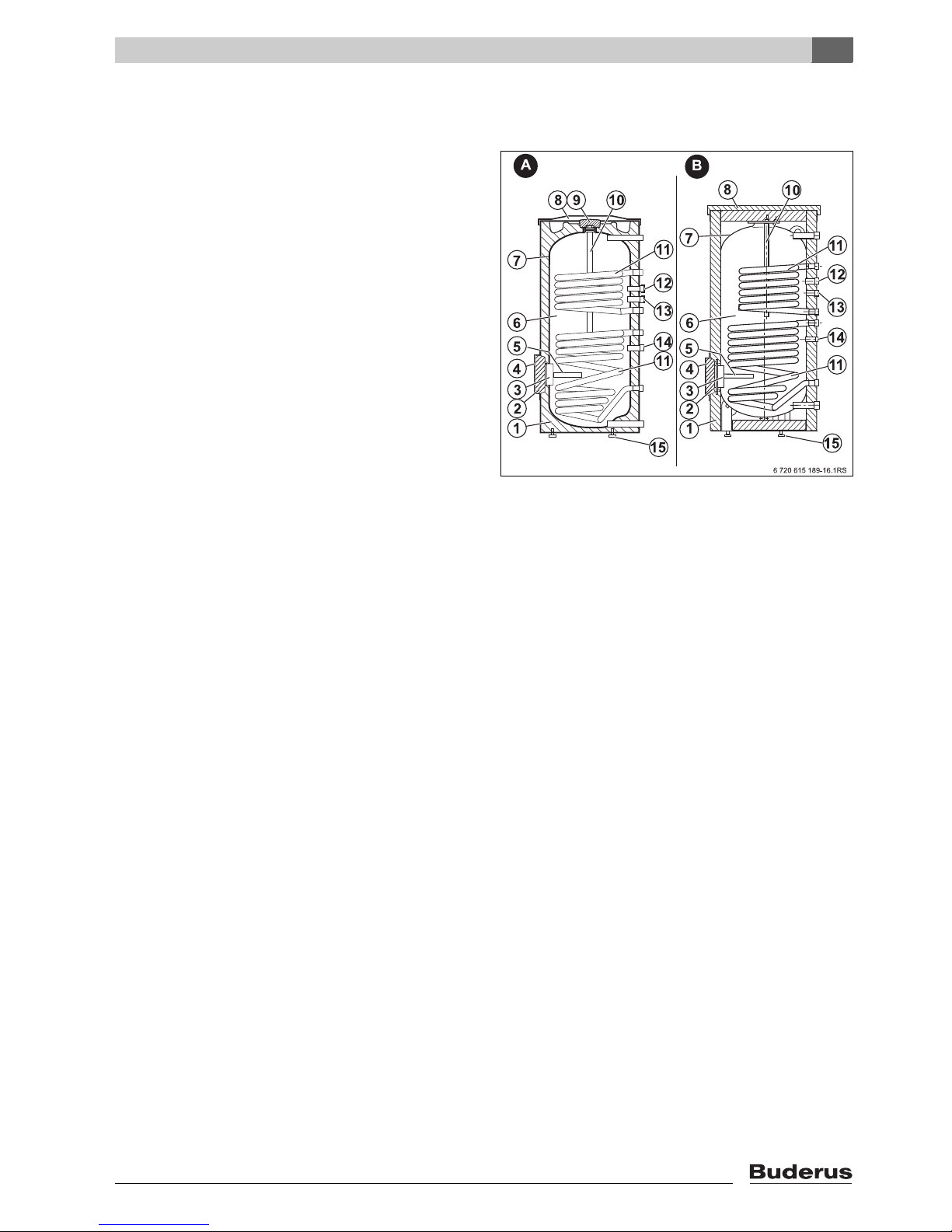

Fig. 1 A: SM300/1

B: SM400/1

1 Insulation

2 Clean-out cover insulation

3 Inspection opening

4 Inspection opening cover

5 Magnesium anode rod

6 Tank shell

7 Thermoglaze Duo Clean

8 Top tank cover

9 Insulation disc for SM300/1 tank

10 Magnesium anode rod

11 Smooth coil heat exchangers

12 Dry well sensing port for heating system control

13 DHW recirculation connection

14 Dry well sensing port for solar

15 Tank feet

2

Logalux SM300/1 - SM400/1 - Technical specifications are subject to change without prior notice.

5

2

Product Description

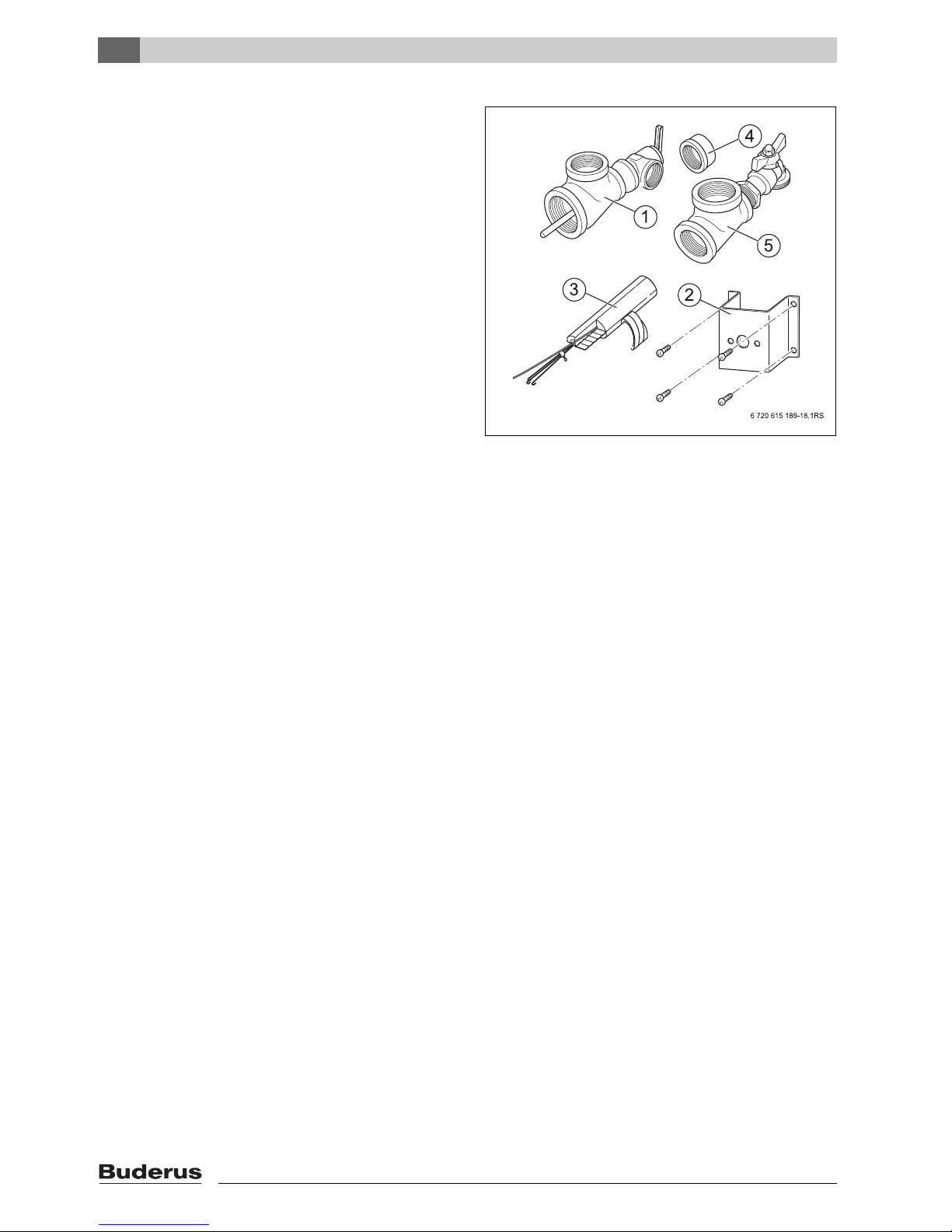

B-Kit Komponenten

Fig. 2 Tank kit fittings

1 Tee piece with P & T relief valve

2 Bracket for mounting of aquastat

3 Spacer set for securing DHW tank sensor

4 Cover cap for DHW recirc connection (EZ)

5 Tee piece with tank drain valve

6

Logalux SM300/1 - SM400/1 - Technical specifications are subject to change without prior notice.

2.6 Dimensions and Connections

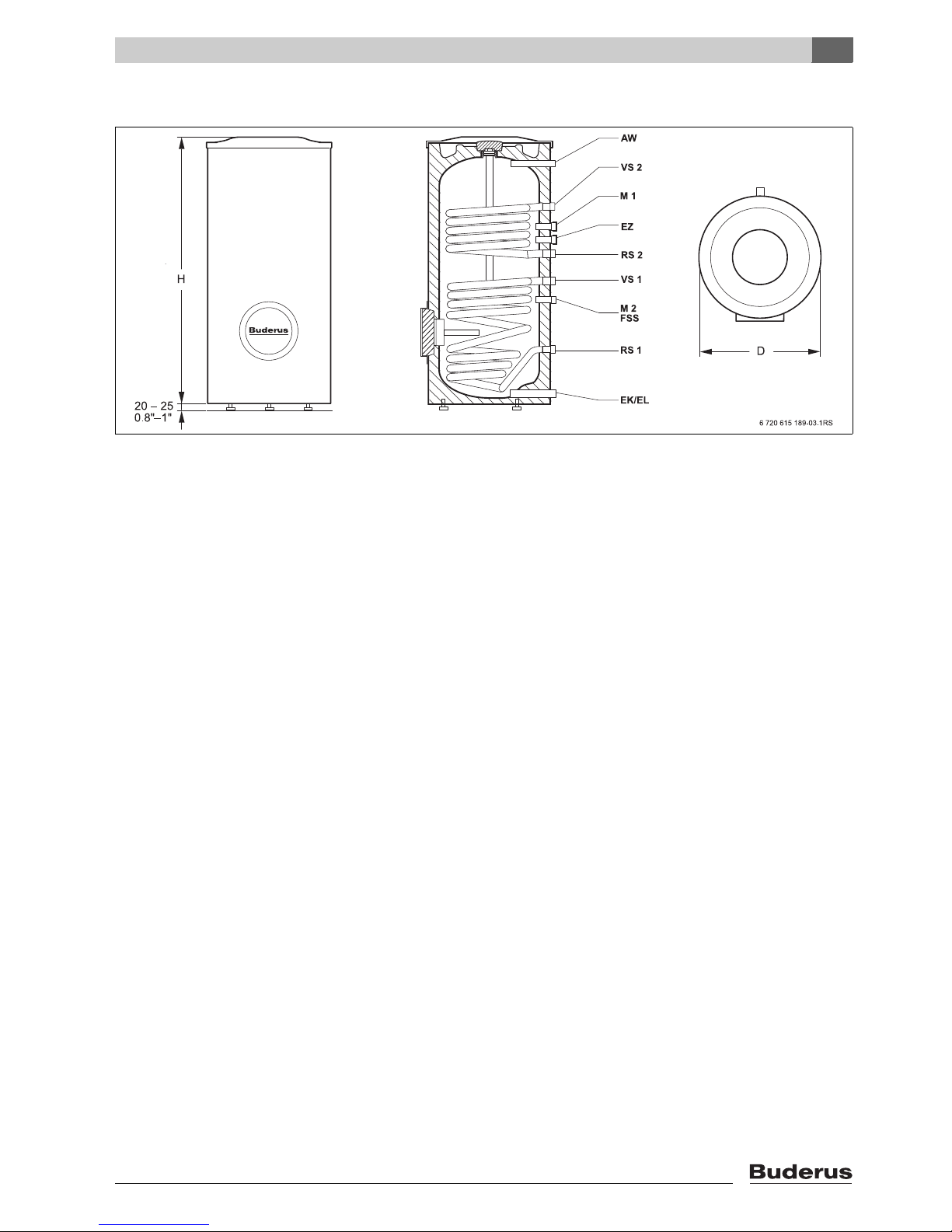

Fig. 3 SM300/1 Dimensions and connections

AW DHW outlet

VS1 Solar coil supply

VS2 Boiler coil supply

RS1 Solar coil return

RS2 Boiler coil return

M1 Temperature measuring point for DHW temperature sensor (FB) or aquastat

M2 Temperature measuring point for solar DHW sensor (FSS)

EK Cold water feed

EL Tank drain

EZ DHW recirc tapping

Product Description

2

Logalux SM300/1 - SM400/1 - Technical specifications are subject to change without prior notice.

7

2

4

0.8

Product Description

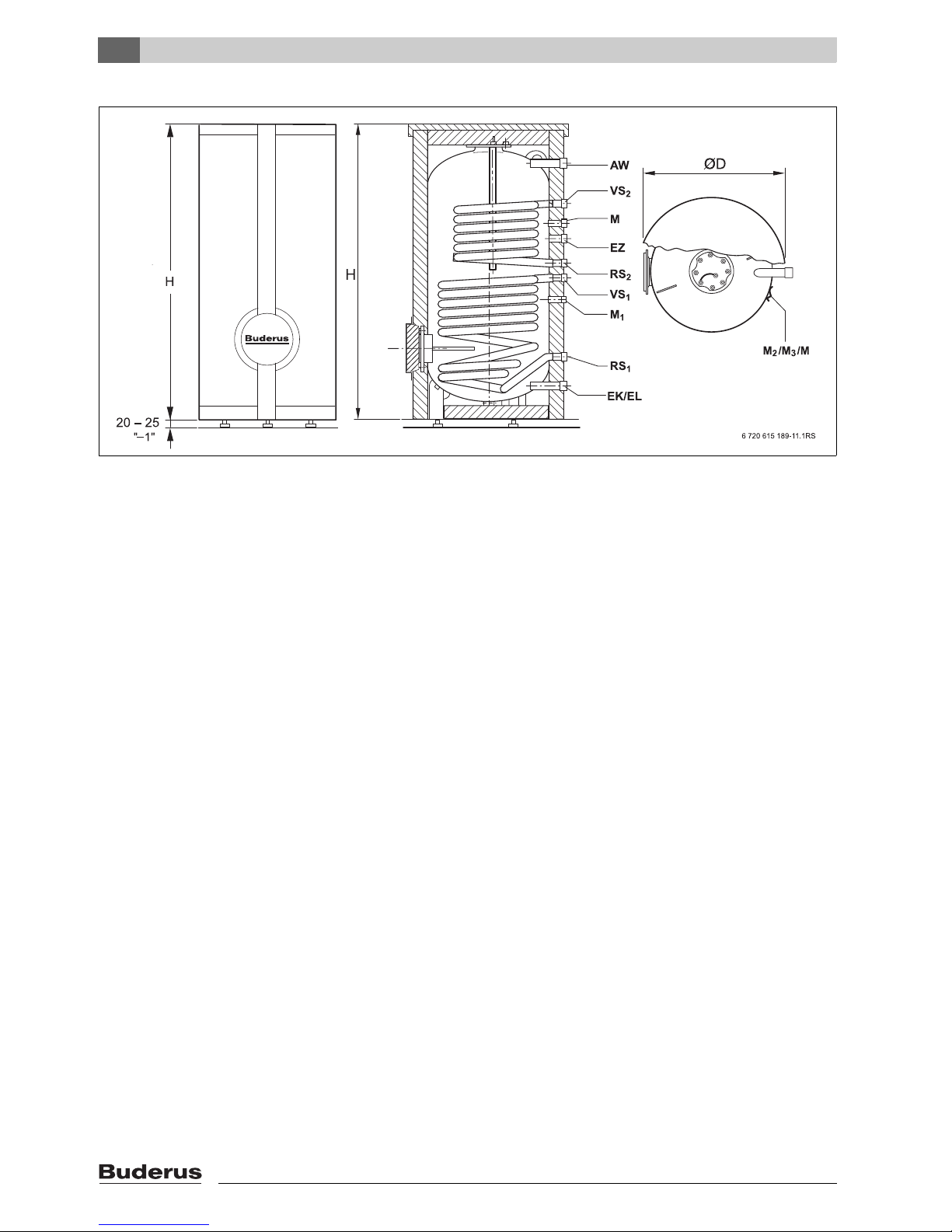

Fig. 4 SM400/1 Dimensions and connections

AW DHW outlet

VS1 Solar coil supply

VS2 Boiler coil supply

RS1 Solar coil return

RS2 Boiler coil return

M Temperature measuring point for DHW temperature sensor (FB) or aquastat

M1 Temperature measuring point #1 for solar DHW sensor (FSS) or temperature sensor solid fuel boiler (FPM)

M2 Alternative location for DHW temperature sensor (FB) or shut-off sensor for loading by solid fuel boiler (FPU)

M3 Solid fuel boiler on temperature

M4 Temperature measuring point #2 for solar DHW sensor (FSS)

EK Cold water feed

EL Tank drain

EZ DHW recirc tapping

8

Logalux SM300/1 - SM400/1 - Technical specifications are subject to change without prior notice.

Product Description

2.7 Technical Specifications

Tank Model SM300/1 SM400/1

Tank volume gal 77 103

Liter 290 390

Volume of solar heat exchanger gal 2 2.5

Liter 8 9.5

Diameter inch 27 34

mm 670 850

1)

Height H

Height H (Installation site)

AW - Domestic outlet connection NPT 1 NPT 1

VS - Coil supply connection NPT 1 NPT 1

RS - Coil return connection NPT 1 NPT 1

EK/EL - tank drain/cold feed NPT 1¼ NPT 1¼

EZ - DHW recirculation connection NPT ¾ NPT ¾

Dry weight

Maximum Operating Values

Solar system fluid temperature °F 320 320

DHW temperature °F 203 203

Operating pressure solar fluid system

Operating pressure DHW

3)

2)

4)

5)

Tab. 1 Technical Specifications

1) Included top cover, without tank feet.

2) Minimum height required for removal of anode rod.

3) Without water, includes packaging.

4) Every installation requires the use of a thermal expansion tank and pressure/temperature relief valve in the heating system and solar system.

5) In the Commonwealth of Massachusetts the operating pressure is limited to 100 psi. Install a 100 psi relief valve.

inch 59 62

mm 1465 1550

inch 86 74

mm 2150 1880

lb. 342 445

kg 155 202

°C 160 160

°C 95 95

psi 232 232

bar 16 16

psi 145 145

bar 10 10

2

Logalux SM300/1 - SM400/1 - Technical specifications are subject to change without prior notice.

9

3

Transportation

3 Transportation

3.1 Transportation Means

One can move the solar water heater tank SM300/1 with

a hand dolly and the SM400/1 also with a lifting crane or

device.

Danger: Potential danger due to falling over

of tank.

V Use only transport devices that are in safe

operating condition

V Place the lifting hook only in the designat-

ed location.

Danger: Potential for injury due to carrying

of heavy loads.

V Also move and lift the tank with at least

two people.

Caution: Potential damage due to improper

securing of tank for transport.

V Use suitable tools and strapping materials

when securing and moving the tank with a

transport aid.

Bring in the entire tank in its original packaging to the final installation location. This will

protect the tank better during transport.

A Buderus dolly (kuli cart) can be purchased

through your local wholesaler.

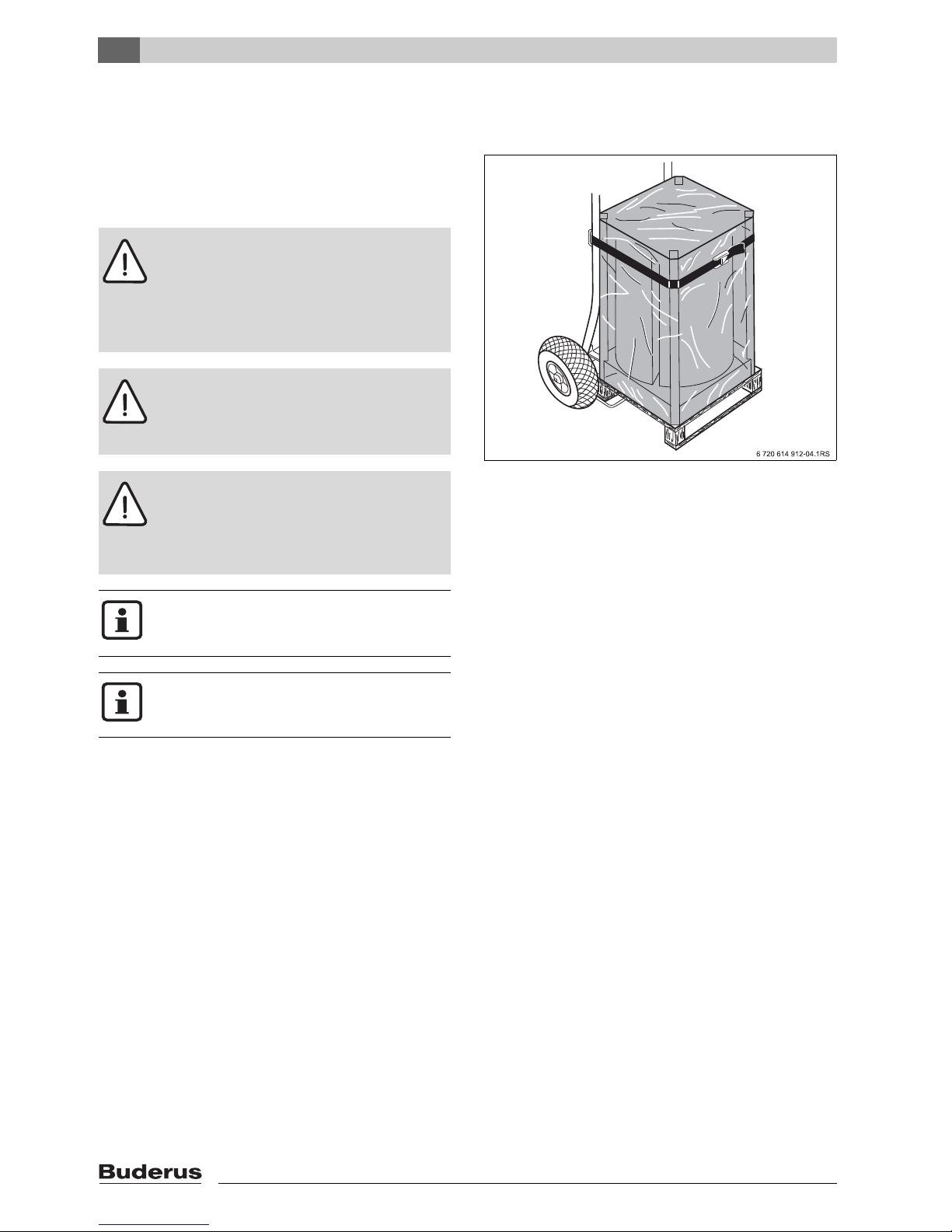

3.1.1 Transportation with dolly

V Place the hand dolly at the backside of the packaged

tank.

V Strap the tank to the hand dolly.

V Move the tank to its final location.

V Remove only the tank packaging at the final installation

site.

Fig. 5 Transportation with kuli cart

10

Logalux SM300/1 - SM400/1 - Technical specifications are subject to change without prior notice.

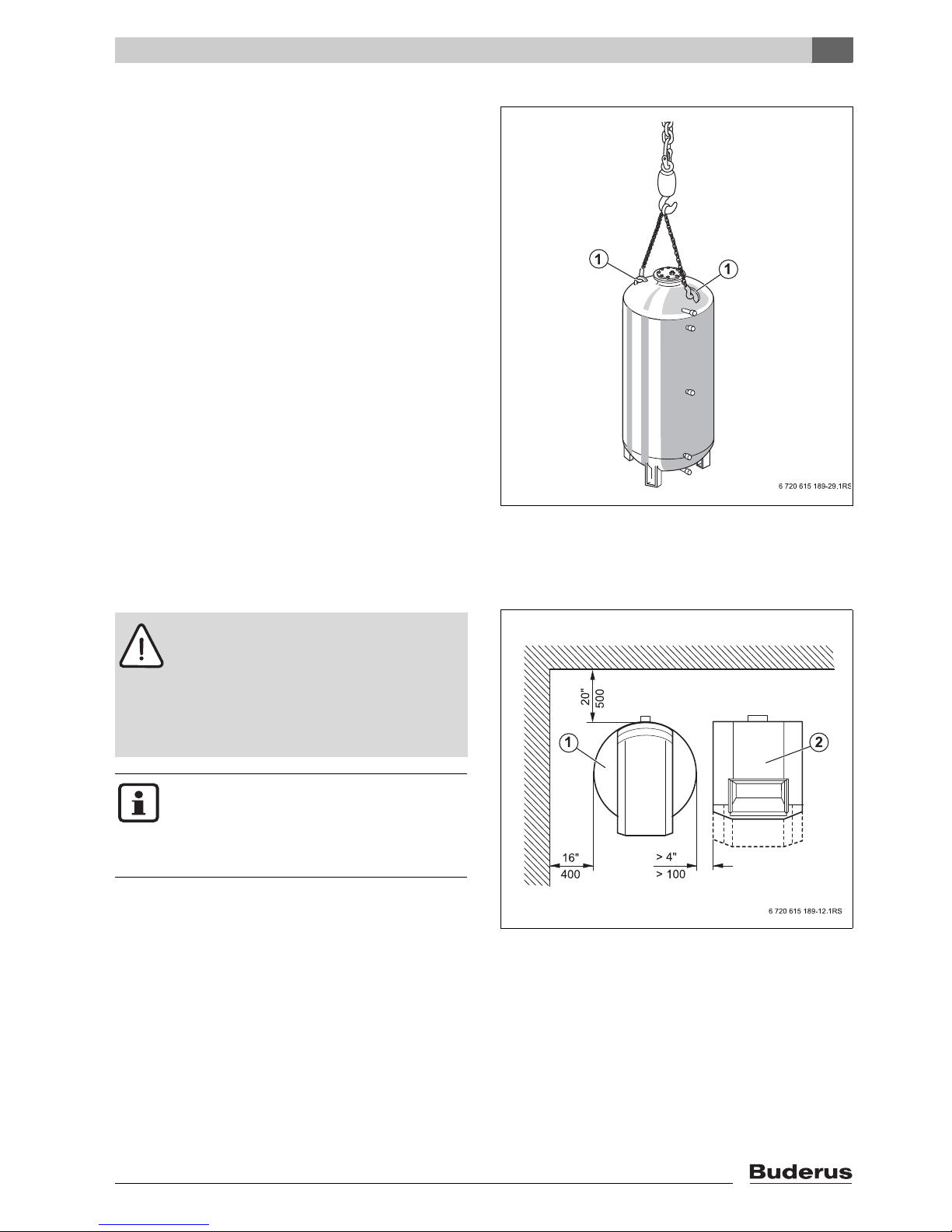

3.1.2 Transportation with overhead crane

V Place the two lifting hooks of the chain into the desig-

nated lifting rings on top of the tank [1].

V Hook the crane chain into the lifting chain.

V Protect the tank from falling and lift the tank to its final

installation location.

V Lower the tank carefully to the floor; do not drop down

onto the floor!

One can move the tank inside the building also in a horizontal manner due to possible height restrictions.

V Remove only the tank packaging at the final installation

site.

Transportation

3

3.2 Product Placement

Caution: Damage due to internal stresses

and corrosion!

V Place the tank in a frost free room.

V Use the solar water heater ONLY in

closed loop applications.

V Open expansion tanks can NOT be used

with these solar water heater tanks.

Minimum 12" overhead space is required for

the removal of the magnesium anode rod as

well as some side clearance.

V Verify for suitable clearance dimensions by

referencing (Æ Tab. 1, page 9 und Fig. 7).

V Maintain suggested service access dimensions

(Æ Fig. 7).

V Maintain 2" clearance from heated pipes to

combustible surfaces.

V Place tank on a level and sufficiently strong floor.

V Remove plastic and packaging materials.

Fig. 6 Transportation with lifting crane (SM400/1)

1 Lifting eyes

Clearance to wall

Fig. 7 Recommended minimum clearances

(in inch/mm)

1 Solar hot water heater

2 Boiler

Logalux SM300/1 - SM400/1 - Technical specifications are subject to change without prior notice.

11

4

Tank Assembly

4 Tank Assembly

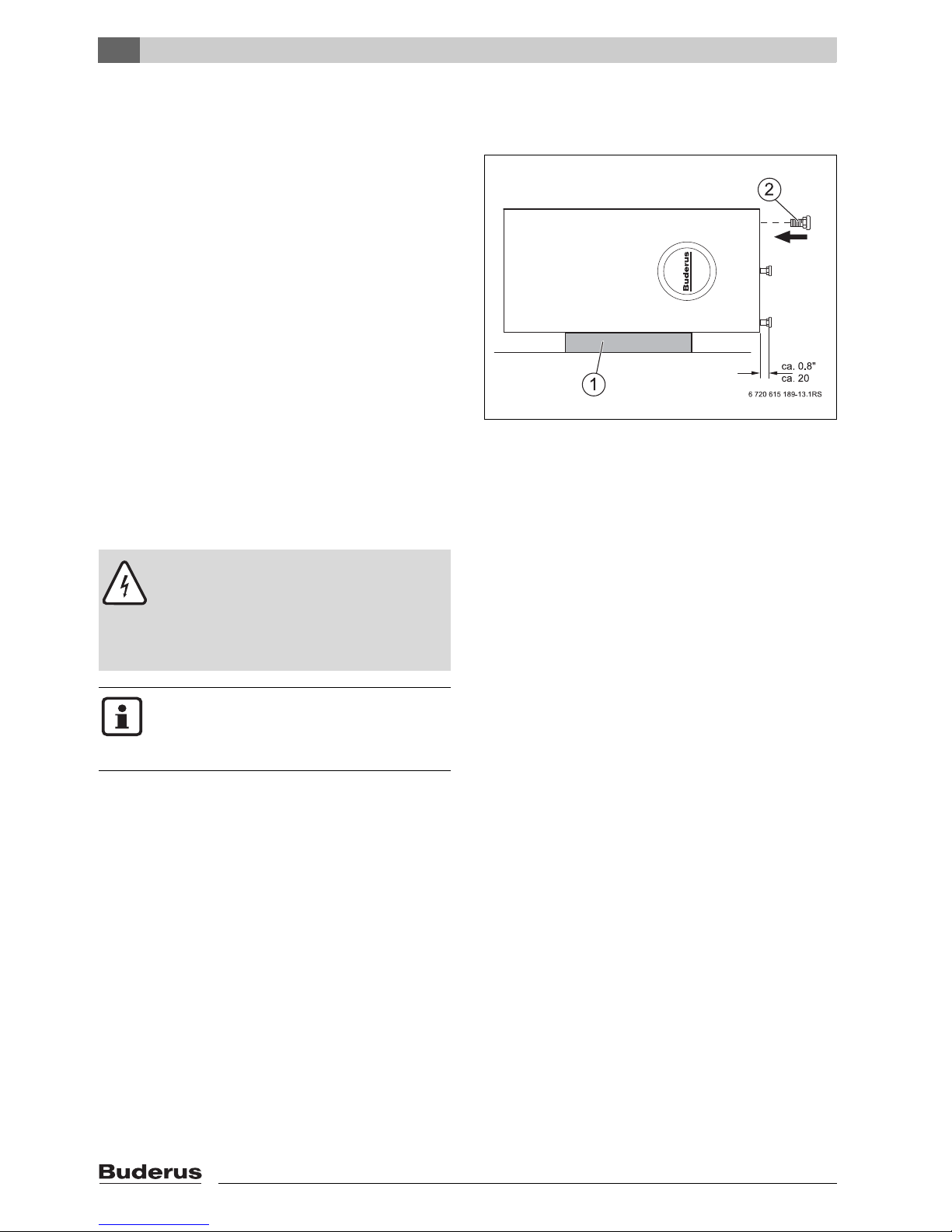

4.1 SM300/1 Placement and Installation

4.1.1 Installation of tank feet

V Place top foam material on the floor [1].

V Carefully place the solar tank on its side on top of the

foam material.

V Remove the tank support bolts M10x30 from the Styro-

foam packaging and screw into the bottom of the tank

[2].

V Put solar tank straight-up and level by adjusting the

tank bolts [2].

Fig. 8 Installation of tank bolts

1 Foam packaging material

2 Tank bolts

4.1.2 Installation of tank aquastat or temperature

sensor

Danger: Risk of fatal injury from electric

shock.

V Electrically disconnect the system.

For DHW temperature control, one can

use an aquastat or tank sensor depending

on the selected control strategy.

Follow the directions supplied by the manufacturer of the aquastat or tank sensor regarding electrical wiring connections and

temperature adjustments.

V To measure and secure the DHW water temperature

an installed temperature sensor or aquastat on the

DHW tank is reqiured.

12

Logalux SM300/1 - SM400/1 - Technical specifications are subject to change without prior notice.

Loading...

Loading...