Buderus Logalux LT135/2, Logalux LT300/2, Logalux LT160/2, Logalux LT200/2 Installation And Maintenance Manual

Page 1

6302 4827 – 05/2003 US For Installers

Read these Instructions Carefully for Assembly and Maintenance

Installation and Maintenance

Manual

Indirect-fired Water Heaters

Logalux LT135/2 – 300/2

Page 2

Foreword

2

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Technical Changes!

Buderus Hydronic Systems, Inc. reserves the right to

make changes due to continued technological and

engineering improvements.

Updating Technical Information

Please contact us if you have suggestions for improving

this manual or when you have noticed incorrect

information.

To these instructions

This Installation and Maintenance manual contains

important information regarding proper installation,

operation and maintenance of the indirect fired domestic

hot water tank series LT135/2 - 300/2 (DHW storage

tank).

The installation and maintenance instructions are

directed at a licensed installing contractor with

knowledge of accepted industry practices for the

installation and maintenance of the equipment and

various applications of the equipment involved.

Please inform the owner regarding proper use of the

equipment and point out the safety components and

features of the equipment.

Please hand over after finalizing the installation

these technical documents to the end user.

Page 3

Table of Contents

3

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.1 Standards and Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 Tools, Materials and Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Safety Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 Application Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Guideline of Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.3 Observe the following Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.4 Waste Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4 Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.1 Dimensions and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.2 Safety Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

5 Transport and Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

5.1 Moving the Tank on a Pallet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

5.2 Moving the Tank Unpackaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

6 Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 Placement of the Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2 Installation of Water Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3 Installation of Temperature Sensor/Aquastat . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.4 Checking Magnesium Anode Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7 Putting the Tank in Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.1 Putting Tank in Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.2 Operating Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.3 Taking out Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.1 Preparing the Tank for Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.2 Cleaning of the Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.3 Checking Anode Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.4 Changing out the Anode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.5 Placing the Tank back in Operation after Cleaning . . . . . . . . . . . . . . . . . . . . . . 19

Page 4

4

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

General Information1

1 General Information

1.1 Standards and Guidelines

1.2 Tools, Materials and Test Equipment

Standard tools and equipment from the HVAC industry

are required for the installation.

Other useful components:

– Dolly with strap

– Transport aids: 3 pipes with ¾“ NPT or 1“ NPT (see

page 9)

– Dry vac for cleaning

– Electrical test equipment to check anode operation

Caution!

Please observe the local and state

requirements regarding equipment

installation!

NOTICE

When installing the tank in the state of

Massachusetts the installation must by

done by a Massachusetts licensed

plumber or contractor.

Page 5

Safety Considerations 2

5

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

2 Safety Considerations

2.1 Application Purpose

The LT135/2 - 300/2 are designed to be used for heating

of domestic hot water.

The tanks can only be heated using heating water and

can only be used in closed systems.

2.2 Guideline of Notices

Two levels of danger are identified by the following

warning labels:

The following symbols are used to denote danger and

other notices:

2.3 Observe the following Notices

2.4 Waste Disposal

Dispose of the packaging components in an

environmental friendly manner.

The old replaced DHW tank, if present, shall be

disposed off properly.

WARN ING!

HEALTH DANGER

Denotes a possible severely dangerous

situation where, without proper caution,

bodily injury or loss of life may result.

CAUTION!

DANGER OF INJURY/SYSTEM

DAMAGE

Denotes a possible dangerous situation

that can lead to mild to moderate bodily

injury or physical damage.

WARN ING!

DANGER

Due to electricity.

APPLICATION NOTICE

Application comment for optimum use of

equipment and adjustment as well as

useful information.

WARNING!

HEALTH DANGER

Due to improper cleaning the domestic hot

water can be contaminated.

CAUTION!

TANK DAMAGE

Due to improper cleaning and maintenance.

A bi-annual cleaning is recommended.

Please correct any issue immediately,

to avoid further damage.

APPLICATION NOTICE

Use only original Buderus parts for service

and replacement. We are not responsible

for damage caused by non-Buderus parts.

Page 6

6

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Product Description3

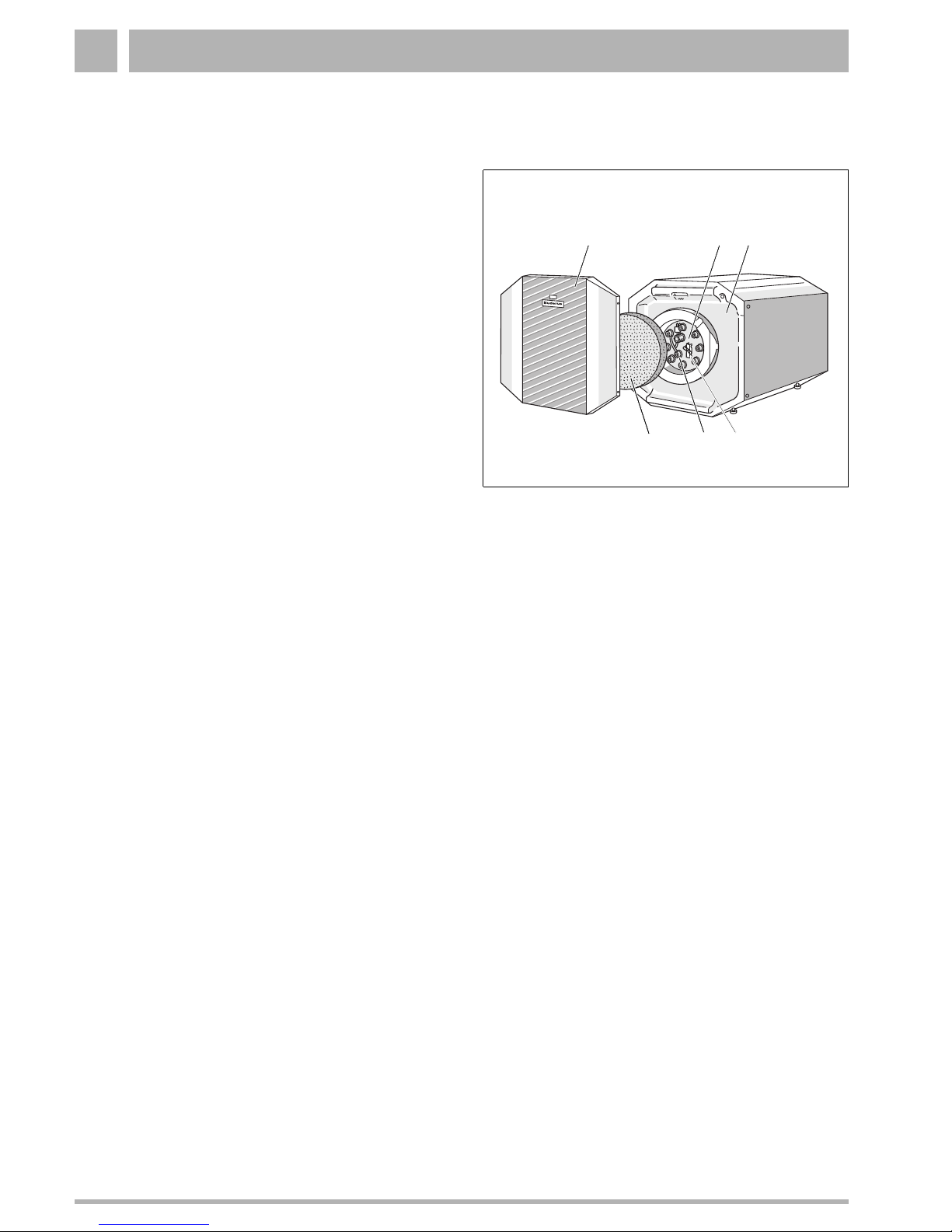

3 Product Description

The LT135/2 - 300/2 indirect fired domestic hot water

tanks are factory assembled with exception of screw-on

feet (packaged with the boiler) and piping accessories

(packaged in envelope with tank) to be installed in the

field.

The major components of the tank are:

– Tank vessel with corrosion protection

Corrosion protection is provided by hygienic Buderus

Thermoglaze "DUOCLEAN" as well as additional

cathodic protection using a magnesium anode rod

(Fig. 1, Item. 5), which is accessible by means of the

clean-out cover (Fig. 1, Item. 2).

– Clean-out cover (Fig. 1, Item. 2) for maintenance

and service access.

– Insulation (Fig. 1, Item. 3)

The insulation consists of high density polyurethane

directly attached to the tank vessel. An insulating

ring (Fig. 1, Item. 6) reduces heat loss from the

clean-out cover.

– Domestic water temperature sensor bracket (when

using Buderus Logamatic control) (Fig. 1, Item. 4)

The sensor is strapped under the clip on the cleanout cover for temperature control when using a

Buderus Logamatic control. When using a

Honeywell aquastat (not furnished), the coupling and

immersion well supplied are connected to the EZ

connection on the back of the tank.

– Smooth surface heat exchanger

A smooth surface heat exchanger inside the tank

vessel transfers the energy from the boiler water to

the domestic water. The temperature in the tank will

be evenly distributed.

Fig. 1 Logalux LT135/2 – 300/2

Item. 1: Front cover

Item. 2: Clean-out cover

Item. 3: Insulation

Item. 4: Sensor bracket

Item. 5: Magnesium anode rod

Item. 6: Insulation clean out

1

56

2 3

4

Page 7

Technical Information 4

7

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

4 Technical Information

4.1 Dimensions and Connections

Table. 1 Dimensions and Connections

1

without water, incl. packaging.

4.2 Safety Standards

Fig. 2 Dimensions and Connections

M

25 ¾ in.

25¾ in.

0.6 – 1 in.

M: Strap-on location for Logamatic/SP30D sensor

AW: DHW Outlet EZ: DHW recirc connection/well for Honeywell aquastat

VS: Boiler Water Supply EK: DHW Inlet

RS: Boiler Water Return EL: Tank Drain

Type

Tank content

VS/RS/AW EK/EL EZ

Length L Weight

1

Gal. In. Lbs.

LT135/2 36

NPT 1 NPT 1¼ NPT ¾

32 190

LT160/2 42 36¼ 220

LT200/2 53 42¼ 247

LT300/2 79 57¾ 364

Maximum Value Tempe-

rature

Operating

pressure

Test

pressure

2

°C (°F) bar (psi) bar (psi)

Boiler water 100 (212) 16 (232)

1

k.A.

1

Domestic water 95 (203) 10 (1453) 10 (1453)

Table. 2 Limiting Values for DHW Tanks

1

Depending on relief valve and expansion tank settings.

2

Operating and Test Pressures are gauge pressures.

3

Maximum 100 psi for Massachussetts.

CAUTION!

TANK DAMAGE

Due to exceeding critical values.

Please observe the maximium listed

safety values.

Page 8

8

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Transportation and Placement5

5 Transportation and Placement

5.1 Moving the Tank on the Pallet

Use suitable cart/dolly to move the tank. Secure the

tank from tipping over.

Remove plastic wrapping across from the side of the

tank labelled "Kessel -Speicherbefestigung" (Fig. 3).

Remove only this cut-out section.

Screw in the 4 tank feet (Fig. 3, Item. 2) (packaged

with boiler in plastic bag) about ½" into the bottom of

the tank.

Remove the two wooden corner posts (Fig. 3,

Item. 1) from the bottom side of the tank.

Tip the tank horizontally using the pallet as support

(Fig. 4).

Remove rest of plastic wrapping, packaging material

and pallet by lifting the tank carefully.

NOTICE

The storage tank can be moved in its

original packaging. This will protect the

tank against possible damage.

Fig. 3 Cut out of plastic wrapping and screwing in of feet

Item. 1: Wooden corner posts

Item. 2: Screw-in feet

Item. 3: Back side of tank

Item. 4: Front side of tank

Fig. 4 Placement of tank

1

2

4

3

NOTICE

The tank can also be moved using a overhead crane. Cut out a portion from the top

insulation and put hook through the lifting

eye at the tank top.

Page 9

Transportation and Placement 5

9

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

5.2 Moving the Tank Unpackaged

You can easily move the tank when you attach three carrying pipe stubs (not supplied) to the tank.

Remove the 4 front panel screws (Fig. 5).

Remove front panel. Pull the front and bottom of the

panel back.

Remove insulating ring.

One carrying pipe stub ( ¾ NPT) for the front of the

tank

Screw a ¾“ coupling on a pipe end (Fig. 6, Item. 1).

Tread coupling on front clean-out cover.

Two carrying pipe stubs (1“ NPT) on rear side of

tank

Screw two 1“ coupling on two pipe ends (Fig. 7,

Item. 1).

Screw carrying pipe stubs on boiler coil connections.

Fig. 5 Remove front cover

Fig. 6 Assembly of front carrying pipe stub

1

NPT¾

Fig. 7 Assembly of rear carrying pipe stubs

1

VS/RSRS/VS

Page 10

1

0

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Tank Installation6

6 Tank Installation

6.1 Placement of the Tank

The tank is designed for horizontal installation and can

serve as base for a Buderus boiler.

For placement of the tank, observe the recommended

clearance dimensions for proper access and service.

(Fig. 8). Buderus requires maintaining a minimum

clearance of 2" between hot water piping and

combustible surfaces.

Make sure that the floor is level and sufficiently strong.

The tank can be installed on combustible flooring as

long as the screw-in feet are used.

Level the tank using the adjustable feet (Fig 9).

Fig. 8 Placement of tank (Recommended clearances)

min.

26 in.

min.

16 in.

CAUTION!

TANK DAMAGE

Due to frost.

Make sure that the boiler room is dry

and frost free.

Fig. 9 Leveling of the tank using a level

NOTICE

The screw-in feet have rubber feet that

allows you to slide the tank in its final

location.

Page 11

Tank Installation 6

11

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

6.2 Installation of Water Piping

Please observe the following warnings before piping the

indirect tank. Follow these warnings carefully to ensure

trouble free operation. The installation of the indirectfired hot water tank and all associated piping must be in

accordance with all applicable codes and regulations.

All work must be done by a licensed contractor.

Fig. 10 Installation Diagram

Item. 1: Indirect-fired hot water tank

Item. 2: Service valve

Item. 3: P and T relief valve

Item. 4: Flow check

Item. 5: Tank charging pump

Item. 6: Optional DHW recirc pump

Item. 7: Air purge valve

Item. 8: Drain valve

Item. 9: Back flow preventer

Item. 10:Thermal expansion tank

AW: DHW outlet

EZ: DHW recirc tapping

VS Boiler supply

RS Boiler return

EK/EL: DHW inlet/drain

Install furnished brass tees on AW and EK/EL

connections. Install supplied P and T valve on ¾"

connection of brass tee at the AW connection; install

tank drain on ¾" connection of brass tee at the

EK/EL connection.

If using a Logamatic control or Goldline SP30D

control, plug EZ connection, or use it for DHW recirc.

If using a Honeywell aquastat for tank water

sensing, use furnished ¾" coupling and long shank

immersion well on EZ connection to mount

Honeywell aquastat on.

CAUTION!

TANK DAMAGE

In the domestic water connections AW, EZ

and EK you will find protective inserts.

These inserts provide additional protection

to the coated interior pipe surfaces.

Keep these inserts in place during

piping.

WARN ING!

HEALTH DANGER

The domestic water can be contaminated

if the assembly process is done in a

unclean fashion.

Install all domestic water piping in a

hygienic fashion and clean all joints

thoroughly.

CAREFUL!

SYSTEM DAMAGE

Due to unprofessional installation.

Observe all local codes and regulations

as well as common industry standards

during installation and operation of the

tank.

NOTICE

When a backflow preventer is present or

required, a domestic expansion tank must

be used.

CAREFUL!

SYSTEM DAMAGE

Due to leaking connections.

Install all piping connections without

tension.

When using flexible connections, make

sure they are not kinked or twisted.

NOTICE

If boiler output exceeds 100,000 Btu/hr,

change the P and T relief valve to match or

exceed the boiler rating.

Page 12

12

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Tank Installation6

Install all domestic water piping according to local

code and regulations.

Do not install elbows in the tank drain piping to

ensure easy flushing of the tank.

6.3 Installation of Temperature Sensor/Aquastat

6.3.1 Logamatic or Goldline SP30D control

When using a Buderus Logamatic control or Goldline

SP30D control, the temperature sensor must be

strapped to the front of the tank. Remove the front cover

from the tank. (see Chapter 5.2, page 9).

Follow the Installation Manual for the control regarding

the proper electrical connections:

Guide the sensor wiring (Fig. 11, Item. 1) into the

raceway from the rear of the tank (Fig. 11, Item. 2).

Make sure to lengthen the wiring for the LT300/2

model by splicing in 18 gauge wire.

Pull the sensor wiring out of the raceway on the front

of the tank.

Guide the sensor wiring through the knock-out in the

tank insulation (Fig. 12, Item. 4) to the clean-out

cover.

Slide the sensor under the strap-on clip (Fig. 12,

Item. 3) on the clean-out cover and tighten this clip.

6.3.2 Honeywell Aquastat

When using a Honeywell aquastat (not supplied),

install as follows:

Install ¾" brass coupling and long shank immersion

well (furnished with tank) on the EZ connection.

Slide Honeywell capillary fully into immersion well

and secure aquastat to well.

6.4 Checking the Magnesium Anode

Connection

Make sure that the ground cable (Fig. 12, Item. 2) of

the magnesium anode rod (Fig. 12, Item. 1) is

securely tightened to one of the clean-out cover

bolts.

Fig. 11 Installation of temperature sensor

Item. 1: Temperature sensor

Item. 2: Cable raceway

1

2

Fig. 12 Testing the Magnesium anode rod

Item. 1: Magnesium anode

Item. 2: Ground cable

Item. 3: Sensor fastening clip

Item. 4: Knock-out in insulation

Item. 5: Clean-out cover

2

1

3

4

5

Page 13

Putting the Tank in/out of Operation 7

1

3

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

7 Putting the Tank in/out of Operation

7.1 Putting the Tank in Operation

Prior to putting the tank in operation, check for leaks and

correct immediately.

Open the highest tap location, to vent the domestic

water system.

Open the cold feed to the tank (Fig. 13, Item. 1) to fill

the tank.

Prior to heating the tank, check to make sure that the

boiler, tank and water lines are filled with water.

Open a hot water faucet at the highest location for

this purpose. Close faucet afterwards.

Check all connections, water lines and clean-out

cover for leaks.

7.1.1 Installation of Insulation and Front Cover

Place insulation ring (Fig. 14, Item. 2) on clean-out

cover.

Install front cover (Fig. 14, Item. 1) and secure with

4 screws.

Fig. 13 Installation diagram

Item. 1: Shut-off valve for cold feed

Item. 2: Pressure/temperature (P and T) relief piping

AW: DHW outlet

EK: Cold feed

EZ: DHW recirc

2

1

NOTICE

Check for leaks on the tank using

strictly domestic water. Maximum

DHW test pressure can not exceed the

pressure relief valve rating.

Fig. 14 Installation of insulation and front cover

Pos. 1: Front cover

Pos. 2: Insulation ring

21

Page 14

14

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Putting the Tank in/out of Operation7

7.2 Operating Notice

Notify the end-user/owner of the following points:

– Make sure to always keep P and T relief piping open

and unobstructed (Fig. 13, page 13).

– Periodically to check the operation of the P and T

valve by manually opening the valve.

– To contact a qualified service company or contractor

if the manual reset trips regularly on the boiler (if

required by local code).

7.3 Taking out of Operation

In case the tank is not used for a long time, we

recommend the following:

Keep the tank in operation.

Set the control to the vacation function (Logamatic),

or set the tank to its minimum setting.

When the tank has been taken out of operation, observe

local code and regulations regarding placing the tank

back in operation and possibly rinsing the domestic

water lines.

CAUTION!

TANK DAMAGE

When the pressure/temperature relief

valve is blocked or damaged, potential

damage may occur to the tank and a very

dangerous situation can develop.

Make sure that the P and T relief

piping Fig. 13, page 13) is NEVER

blocked.

NOTICE

Information regarding operation of the

sensor/aquastat can be obtained from the

documentation furnished with the control.

CAUTION!

TANK DAMAGE

When the tank is kept empty for several

days, localized corrosion can take place

due to residual moisture.

Dry out the tank interior using warm air

and keep the access port open.

Page 15

Maintenance 8

1

5

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

8 Maintenance

It is recommended that a licensed contractor or service

company checks and cleans the tank at least once every

two years.

For unfavorable water conditions, (hard or very hard),

extreme high usage and/or high temperature, more

frequent inspections and cleanings are recommended.

8.1 Preparing the Tank for Maintenance

Disconnect electricity to the heating system.

Remove front cover and insulation ring from the tank

(see Chapter 5.2 „Moving the Tank Unpackaged“,

page 9).

Drain tank. Shut off the cold feed (EK) and open tank

drain (Fig. 10, page 11). Open the highest faucet for

venting.

Remove hex head bolts (Fig. 15, Item. 4) from the

clean-out cover (Fig. 15, Item. 3).

Remove clean-out cover together with Magnesium

anode (Fig. 15, Item. 1) and gasket (Fig. 15,

Item. 2).

CAUTION!

TANK DAMAGE

Due to improper maintenance and

cleaning.

Perform the inspection and cleaning at

least every two years.

Correct any problems immediately.

Fig. 15 Removal of clean-out cover

Item. 1: Magnesium anode

Item. 2: Clean-out cover gasket

Item. 3: Clean-out cover

Item. 4: Hex head bolts

3

2

4

1

Page 16

1

6

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Maintenance8

8.2 Cleaning the Tank

Check the tank interior for lime deposits.

Follow the procedure below to properly clean the tank

interior:

Spray the interior surfaces with a high pressure cold

water stream (ca. 58 –

72 psi) (Fig. 16).

You can increase the effectiveness by circulating

heated boiler water through the coil. The thermal

shock will cause the deposits to break off the smooth

surface heat exchanger. Use a wet vac to remove

the deposits from the bottom of the tank.

When large quantities of lime and deposits are found in

the tank, it is advisable to remove these using a

chemical treatment. We recommend to have the

chemical cleaning performed by a professional service

company.

8.3 Checking Anode Operation

The Magnesium anode rod is a sacrificial rod that will be

consumed during use. You must verify the status and

diameter of the anode rod at least once every two years.

In addition, we recommend to perform an annual check

of the electrical protective current.

Benefits of the current measurement are:

– You do not need to shut down the heating system.

– You do not need to access or remove the anode rod.

Fig. 16 Spraying of tank interior

1

2

CAUTION!

SYSTEM DAMAGE

Due to damaged tank surface scratching.

Do NOT use sharp objects to clean the

tank interior.

Page 17

Maintenance 8

17

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

8.3.1 Visual Inspection of Anode Rod

Check magnesium anode (Fig. 18, Item. 1) for

decay. Replace anode rod, if the diameter is reduced

to ½" to ¾".

8.3.2 Check the Magnesium anode with multimeter

Follow the outlined procedure:

Remove one side of the grounding lead (Fig. 17,

Item. 3) on the tank.

Set multi-meter (MM) to DcmA (milli amps)

Connect black wire (Fig. 17, Item. 6) of MM to

grounding cable or bolt (Fig. 17, Item. 7).

Connect red cable (Fig. 17, Item. 5) of MM to the

anode.

Ensure clean metallic surfaces for terminal

connections.

The tank must be filled with water during the test.

A reading between .3 mA and 10 mA on the MM is

good.

Record readings each year in the Table. 3.

Record the test date and sign off in the table below:

Properly reconnect the grounding cable after each

test.

NOTICE

Do not contaminate the surface of the rod

with oil or grease. Keep the rod clean.

Fig. 17 Testing the anode with an multi-meter

Item. 1: Magnesium anode

Item. 2: M8-bolt

Item. 3: Ground cable

Item. 4: Clean-out cover

Item. 5: Red cable from multi-meter

Item. 6: Black cable from multi-meter

Item. 7: Hex head bolt from tank

Item. 8: Digital multi-meter

2

1

3

4

6

7

5

8

Date mA Reading Service Company/Signature

Table. 3 Service records

Page 18

1

8

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Maintenance8

8.4 Changing out the Anode

Remove the M8 nut (Fig. 18, Item. 10) to remove the

ground cable (Fig. 18, Item. 8).

Remove M8 nut (Fig. 18, Item. 7).

Separate clean-out cover (Fig. 18, Item. 3) from the

Magnesium anode rod (Fig. 18, Item. 1).

Replace Magnesium anode rod.

Install new rod including the small parts, as shown in

Fig. 18.

Fig. 18 Changing out of the Magnesium anode rod

Item. 1: Magnesium anode

Item. 2: Gasket

Item. 3: Clean-out cover

Item. 4: Insulation piece

Item. 5: Flat washer

Item. 6: Lock washer

Item. 7: M8 nut

Item. 8: Ground cable tab

Item. 9: Lock washer

Item. 10:M8 nut

1

2

3

4

5

6

7

8

9

10

Page 19

Maintenance 8

1

9

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Manual Logalux LT135/2 – 300/2 • Issue 05/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

8.5 Placing the Tank Back in Operation after Cleaning

Install the clean-out cover together with magnesium

anode (Fig. 19, Item. 1) back in the tank. Observe

the orientation of the tank gasket. The word

"Deckelseite" must be facing the clean-out cover.

Tighten hex head bolts (Fig. 19, Item. 4) by hand.

Tighten the hex head bolts for the clean-out cover

with a ¾ turn using a wrench (Fig. 19, Item. 4).

Fill the tank and turn on the heating system.

Check all connections and clean-out cover for leaks.

Put back the insulation ring (Fig. 20, Item. 2).

Put the front cover (Fig. 20, Item. 1) back and secure

with 4 screws.

Fig. 19 Installing a new anode rod

Item. 1: Magnesium anode

Item. 2: Clean-out cover gasket

Item. 3: Clean-out cover

Item. 4: Hex head bolt

Item. 5: Ground cable tap

3

2

4

1

5

CAUTION!

SYSTEM DAMAGE

Due to defective gasket.

We recommend using a new gasket

(Fig. 19, Item. 2) when changing out

the Magnesium anode to avoid a

leakage at the tank.

CAUTION!

SYSTEM DAMAGE

Due to corrosion.

Make sure to securely tighten the

ground cable (Fig. 19, Item 5) with a

wrench to the clean-out cover to ensure

a good electrical connection.

Fig. 20 Installing insulation and front cover

Item. 1: Front cover

Item. 2: Insulation Ring

21

Page 20

BBT North America Corporation

50 Wentworth Avenue

Londonderry, NH 03053

Tel: 603-552-1100 ● Fax: 603-584-1681

www.buderus.net

BBT North America Corporation reserves the right to make changes without notice

due to continuing engineering and technological advances.

Heating Contractor:

PRODUCTS MANUFACTURED BY

BBT Thermotechnik GmbH

35573 Wetzlar

www.buderus.de

Loading...

Loading...