Page 1

5644258 -

8/95

GB

Service instructions

Control panel HS 2102

Save these instructions !

Buderus

HEIZTECHNIK

Service instructions 24.10

Page 2

Attention

The settings described in

this

manual

must

be

performed

by

a qualified heating

company.

All adjustments made which

do

not

correspond

to

the settings and changes described here for-

feit

the warranty.

Switch the current

off

before opening

the

con-

trol

panel (emergency switch outside the heating

room).

2

Page 3

Contents

II

II

El

II

II

II

II

II

II

m

Ill

m

m

Page

Checking the safety temperature limit st

at

. . . . . . . . . . . . . . . . 4

Program overv i

ew

.

5

Key code

.....

6

Installation entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 14

Installation entries f

or

special functio ns . . . . . . . . . . . . . . . . . 15 - 17

Re

lay test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

LCD tes

t.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Heating curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

Version

numb

er

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Re

set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

Sensor cur

ve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22, 23

In

dex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24

Settin

gs

record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3

Page 4

II

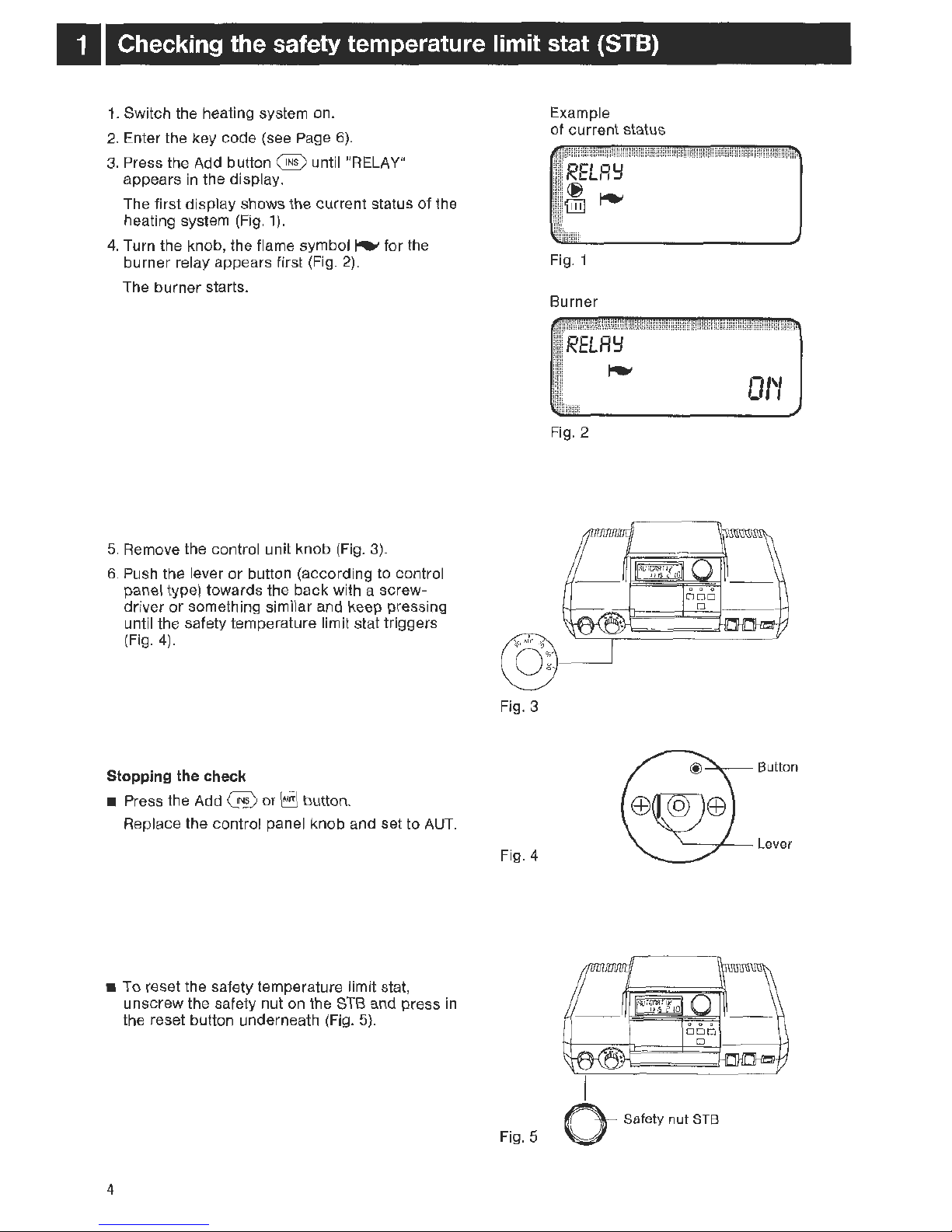

Checking the safety temperature limit stat (STB)

1.

Switch the heating system on.

2.

Enter the key code (see Page

6).

3.

Press the Add

button@

until "RELAY"

appears in the displ

ay.

The first display shows the current status of the

heating system

(Fig.

1).

4.

Turn the knob, the flame symbol ~ for the

burner relay appears first (Fig.

2).

The burner starts.

5.

Remove the control unit knob

(Fi

g.

3).

6.

Push the lever or button (accordi

ng

to

control

panel type) towards the back with a screwdriver

or

something similar and keep pressing

until the safety temperature limit stat

tr

iggers

(

Fig.

4).

Stopping the check

• Press the Add @ or

EJ

button.

Replace

th

e contro l panel knob and set to

AUT.

• To reset the safety temperature limit stat,

unscrew the safety nut

on the

STB

and press

in

the reset button underneath

(Fig.

5).

4

Fig. 3

Fig. 4

Fig. 5

Example

of current stat us

RELR':I

~

'iilll~

Fig. 1

Burner

RELR':I

~

Fig.

2

0 Safety

nut

STB

0/'/

Page 5

Program overview

Possible settings for the 2nd

operating level

1.

Selecting the language

- Factory setting: German

Other languages: French, Italian,

Turki

sh, Polish, Czech

2. Selecting the unit of temperature

- Factory setting:

oc

Possible selection: °Fahrenheit

3.

Nominal setting for heating circuit =

Boiler water temperature .

- Factory setting: 75 °C

4.

Frost protection temperature

- Factory setting: + 1 °C

5.

Remote contro l ON/OFF

- Factory setting:

OFF.

6.

Compensation temperature

(only wi

th

remote control)

- Factory setting: + 3

oc

7.

Setba

ck

mode: Outdoor control

Reduced

Room control (only

with remote control)

Switch-off

- Factory setting: Outdoor control

8.

Minimum switch-on burner temperature

- Factory setting: 10°C

9.

Maximum switch-off burner temperature

- Factory setting: 85°C

10. Flue gas = specificati

on

of a flue gas

temperature

- Factory setting:

OFF

11. Clock = recalibration

- Factory setting: 0 sec

I day

12. Offset = room temperature display

comparison

- Factory setting: 0.0°C

13. Relay test

14.

LCD

test

15. Heating curve

16. Version number

FJ

5

Page 6

II

Key Code

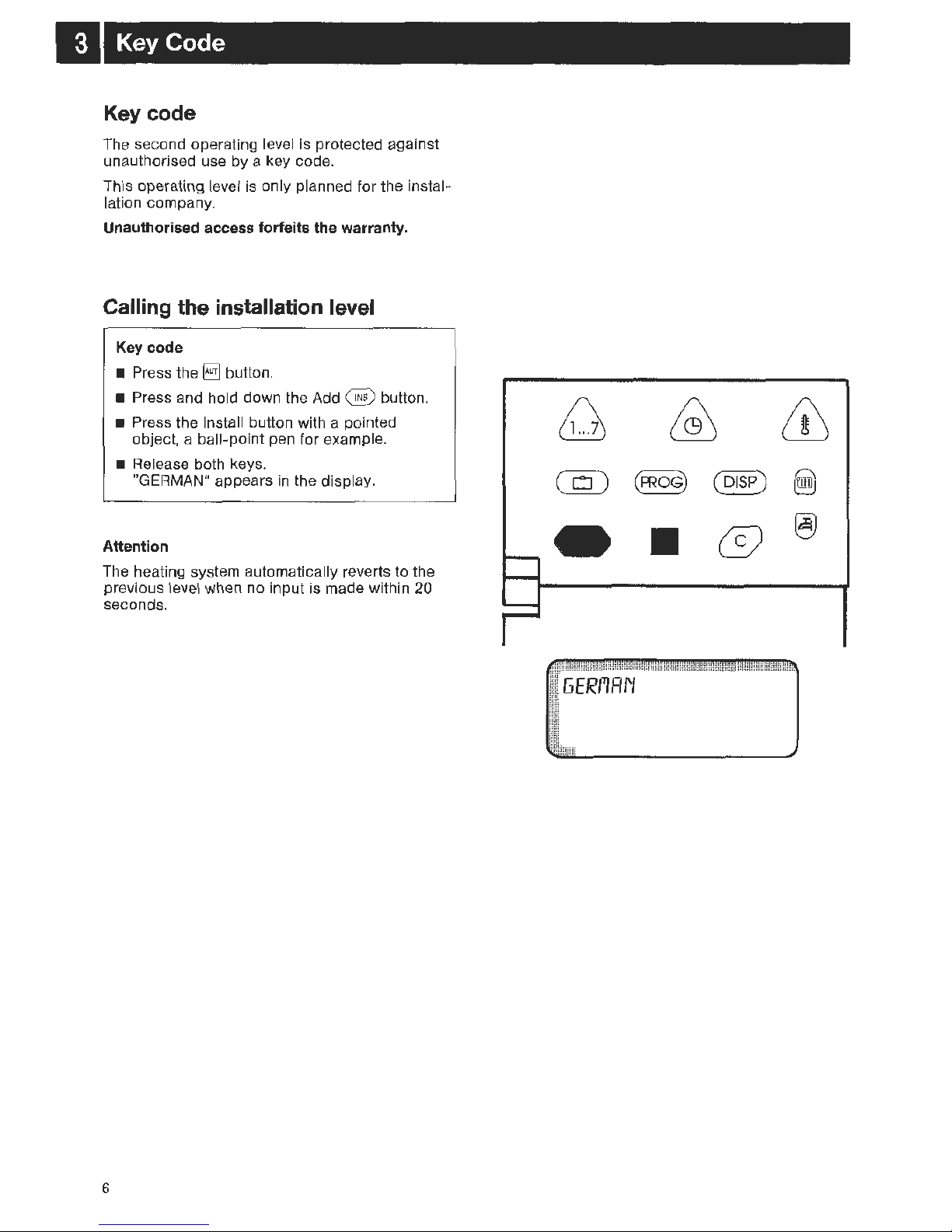

Key code

The second operating level is protected against

unauthorised use by a key code.

This operating level is only planned for the instal-

lation company.

Unauthorised access forfeits the warranty.

Calling the installation level

Key code

• Press the

§]

button.

• Press and hold down the Add @ button.

• Press the Install button with a pointed

object, a ball-point pen for examp l

e.

• Release both keys.

"GERMAN" a

ppears

in the display.

Attention

The heating system automatically reverts to the

previous level when no input is made within 20

seconds.

6

II

@

Page 7

I

Installation entries

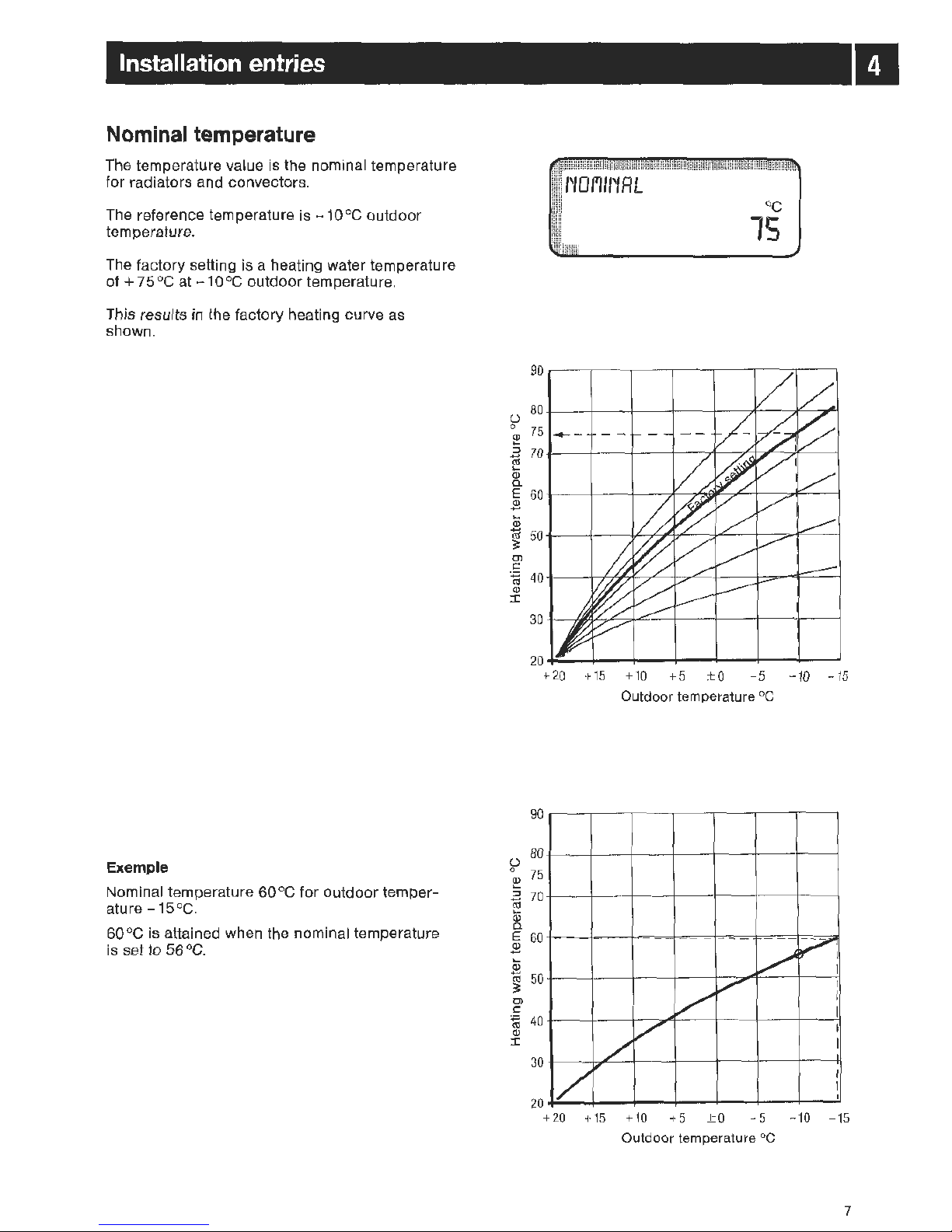

Nominal temperature

The temperature value is the nominal temperature

for radiators and

co

nvectors.

Th

e reference temperature is

-10

°C outdoor

temperature.

The factory setting is a heating water temperature

of+

75°C at -10°C

outdoor temperature.

This results in the factory heating curve as

shown.

Example

Nominal temperature 60 °C for outdoor temper-

atu

re

-15°

C.

60

°C is attained when the nominal temperature

is set to 56

°C.

f'

fOI"'trtR

L

oc

15

~

80~

--+---4-

--~

---r--~--

~~

~

Q)

75 ---

...

2

70~

--+---4---~--

~~~~~

~~

I.U

...

Q)

a.

E

60~

--+---4---~-T.

~~~

--

~~

~

$

...

~

50

+-

--4-

--~~~~~~-+~

~~~

Ol

c:

~ 40+---47~~

~~~-+--

-t

~~

=-~

Q)

I

20~--4---~--~--~---+--~--~

+

20

+ 15 +

10

+ 5 ± 0 - 5 -

10

-15

Outdoor temperature °C

90

(.)

80

0

75

Q)

...

::::1

70

-

I.U

...

Q)

a.

E

60

Q)

-

...

Q)

-

50

I.U

==

Ol

c:

~

40

Q)

I

30

--

v

?,

I

v

I

/

I

I

/

I

/

I

1/

I

I

I

20

+20 +15

+10

+5

± 0

-5

- 10 -15

Outdoor temperature oc

7

II

Page 8

II

Installation entries

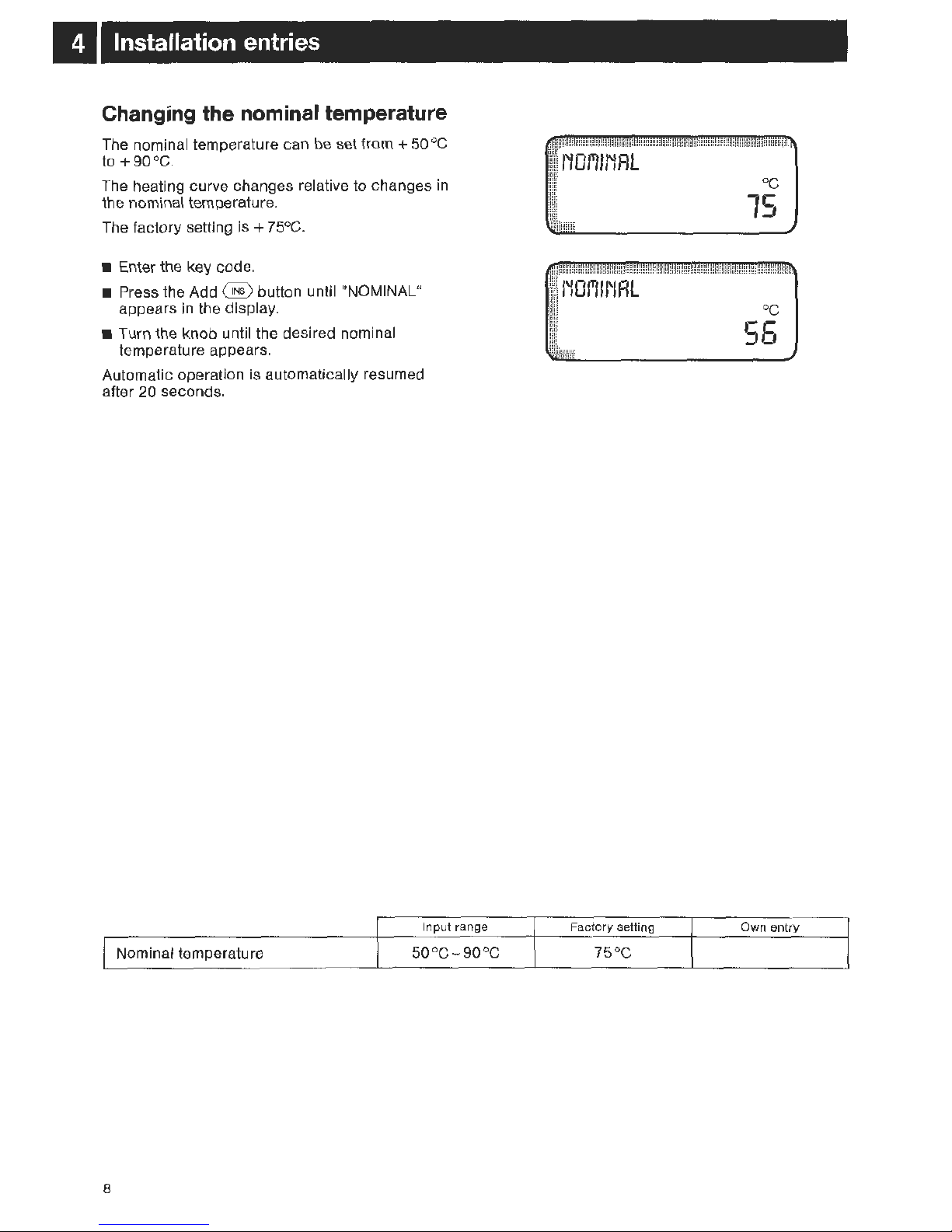

Changing the nominal temperature

The nominal temperature can be set from

+50

oc

to +90°C.

The heating curve changes relative to changes

in

the nominal temperature.

The factory setting i

s+ 75°C.

• Enter the key cod

e.

• Press the Add @ button until "NOMINAL"

appears

in

the display.

• Turn the knob until the desired nominal

temperature appears.

Automatic operation is automatically res

um

ed

after 20 seconds.

Input range

I Nominal temperature 50°C

-9

0°C

8

rt0/'11/~RL

oc

15

N 0

1'111'1

R L

oc

56

Factory setting

Own

entry

75°C

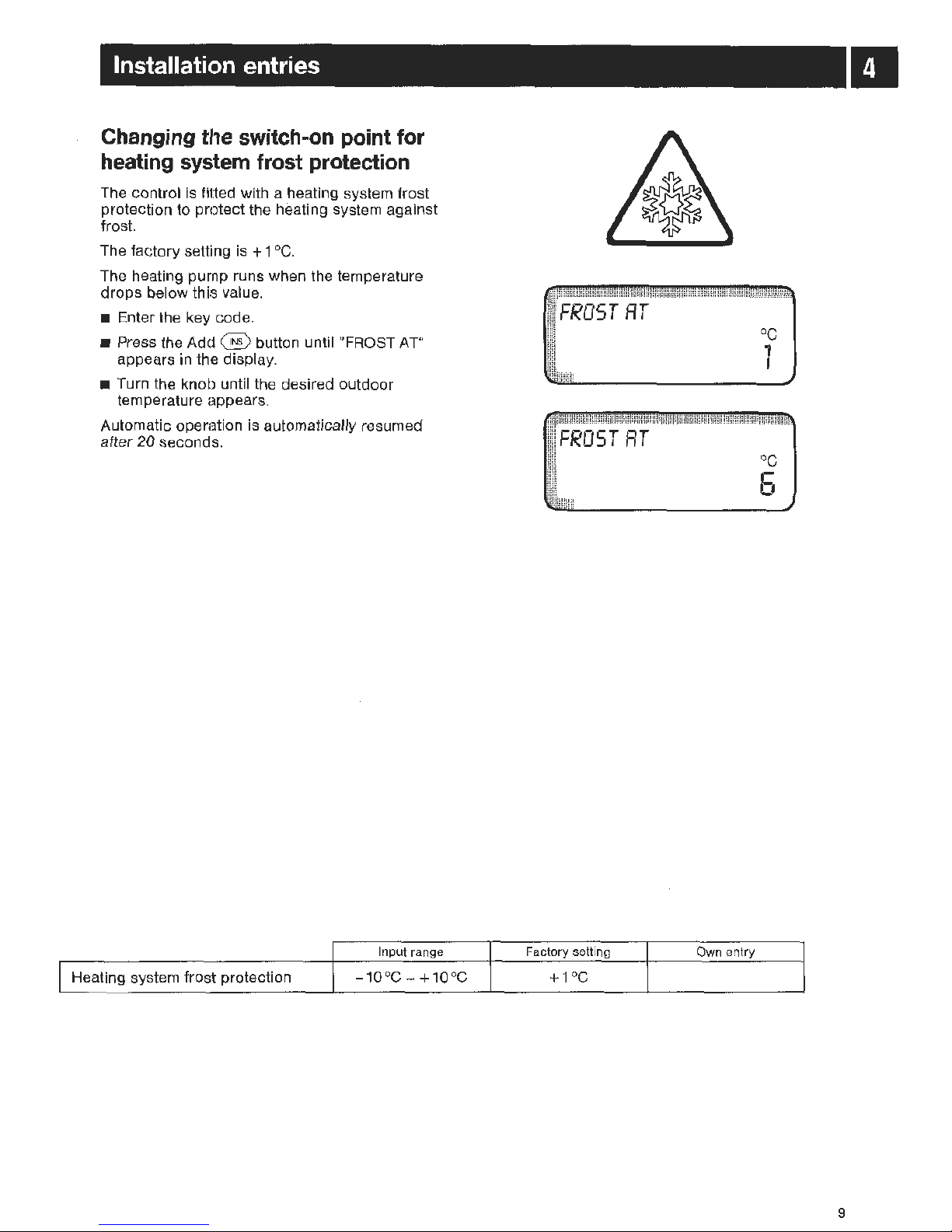

Page 9

Installation entries

Changing

the

switch-on

point

for

heating

system

frost

protection

The control is fitted wi

th

a heating system frost

protection to protect the heating system against

fros

t.

The factory setti

ng

is + 1 °C.

The heating purnp runs when the temperatur e

drops below this value.

• Enter the key code.

• Press the Add @ button until "FROST

AT

"

appears

in

the displa

y.

• Turn the knob until the desired outdoor

temperature appears.

Automatic operation is

au

tomatically resumed

after 20 second

s.

Input range

I Heating system frost protection - 1 0 °C - + 1 0 °C

•

FROST

RT

oc

6

Factory setting Own entry

+ 1°C

9

Page 10

•

Installation entries

Remote control Yes I No

The remote control must be activated when the

control is fitted with a

BFC

remote control.

• Enter the key code.

• Press the Add

@ button until "REMCONT

OFF" appears in the display.

• Turn the knob until

,.ON"

appear

s.

Automatic operati

on

Is automatica lly resum

ed

after 20 second

s.

Once the remote control has been activ ated, it is

no longer possible

to adjust the pl

an

day and

night temperatures

on

the control panel; they can

o

nl

y be adjusted using the remote control.

"REMCONT" a,ppears in

th

e display when the

Temp button

m is pressed.

I Remote

co

ntrol

10

Inpu t range

OFF/O

N

REI'ICOI'IT

REI'ICOI~T

Factory setting

OFF

-cr:

o,

,-

01'1

Own entry

Page 11

Installation entries

Compensation temperature

The compensation temperature can only be

entered after the remote

co

ntrol has been

activated. The compensation temperature limits

the influence of the room temperature on the

heating water temperature

(h

eating curve).

The factory setting

is

3 °C.

Attention: The influence of the room temperature

on the heating wat

er

temperature (heating curve)

is not active when you enter "OFF

".

• Enter the key code.

• Press the Add

@ button until "COM

PEN

SAT"

appears

in

the display.

• Turn the knob until

,.

OFF"

or

th e des ired com-

pensation temperature appears.

Automatic operation is automatically resumed

after 20 seconds.

Input range

I Compensation temperature

OFF

I 1 - 10°C

•

COI'IPENSRT

oc

ll!iillll!l

3

COI'IPEriSRT

OFF

Factory setting Own entry

3°C

11

Page 12

II

Installation entries

Setback mode

You can choose between tour setback modes:

1.

Outdoor control (factory settin

g)

2. Reduced

3.

Switch-off

4.

Room contro l (only wi

th

remote control)

Sel

ect

ing

the se

tba

ck

mod

e

Outdoor

control:

Reduced:

Swi

tc

h-off:

Rom

control:

Either switch-off or r

ed

uced mode

is set dependi

ng

on the outdoor

temperatur

e.

The threshold is the frost protection temperatur

e.

Adjustment to a lower pl

an

room

temperature . The heating circuit

ci

rc

ulati

on

pump con tinues to run.

Th

e heating circuit

is

completely

switched-off, apart from fr ost pro tection, during setback time

s.

The room t

el"!)pe

rature set with

slide switch

(S,

is maintained.

You can only select the room con trol setback mode when a remote

control is available and ,

REM

-

CO

NT

ON" has been set under

"Remote

co

ntrol

Yes/No".

• Recommended settings:

Heating circuit with

remote contro

l:

Heating circuit without

re

mote con tro

l:

Floor heating:

Heating circuit sw

it

ched oft

for setback:

• Enter the key code.

Room control

Outdoor

co

ntrol

R

ed

uced

Switch-off

•

Pr

ess the Add @ button until "OUTDOOR"

appears

in

the display.

• Turn the knob until the desired setba

ck

mode

appears.

Automatic ope ration Is automati

ca

lly resumed

after 20 seconds.

Input range

Setback mode Outdoor, Reduced,

Switch-off, Room

12

OUTDOOR

REDUCED

SI.JITCH-OFF

Factory setting

Own e

nt

ry

Ou

tdoor

Page 13

Installation entries

Minimum switch-on temperature

This is the boiler temperature at which the burner

is switched

on

at the latest when

heati

ng

is

required.

The

factory setting is 10

°C.

• Enter the key code.

• Press the Add @ button until

"M

IN

ON"

appears in the displ

ay.

• Tu

rn

the knob until the desired minimum

switch-

on

temperature appears.

Automatic operation is automatically resum

ed

after 20 seconds.

Input range

J Min. switch

-o

n temp. 10

°C-40°C

Minimum switch-off temperature

This is the heating water temperature at which the

burner is switched off at the earliest.

The factory setting is 45

°C.

Th

is value cannot

be

set at the installation level

and is not shown in the disp l

ay.

II

!lili!!ill§i!~

!:~~;~§

~lgj~~;HIIWii!tsa::Ei~

lflEEE

~ii!iltii

l;

f'l/1

'/ 0 /'/

oc

10

oc

20

Fa

ctory setting Own entry

10

°C

13

Page 14

I

Installation entries

Maximum switch-off temperature

Th

is is the nominal temperature whi ch should not

be exceeded

in

the boiler.

The factory setting is

85 °

C.

• Enter the key code.

• Press the

Add@

button until "MAX

OFF"

ap

pears in the display.

• Turn the knob until the desired maximum

switch-off temperature appea r

s.

Automatic operation is automatically resumed

after 20 seconds.

I

Max.

switch-off temp.

14

Input range

65°C-

90°C

f'lRX

01'

1

oc

85

llilililll

l

f'lRX

OFF

oc

15

Factory setting

Own entry

85°C

Page 15

Installation entries for special functions

Flue gas

The flue gas temperature can only be measured

wi

th the additional module

KM

202 and a flue gas

sensor.

A service message

is

output using the

ECO-KOM

modem (when installed) when the flue gas

temperature set is exceeded.

The boiler must then be serviced.

The factory setting is

OFF.

Flue gas measuring must be activated when the

additional module and the fl

ue

gas sensor are

installed.

• Enter the key code.

• Press the Add @ button until "FLUE GAS"

appears in the display.

• Turn the knob until the desired maximum flue

gas temperature appears.

Automatic operation is automatically resumed

after 20 seconds.

The flue gas temperatur

e,

and all other

temperatures, can be inquired using the

display on the operating level.

Input range

I Flue gas temperature

OFF

I

50°C-

250°C

FLUE

GAS

FLUE

GAS

Facto

ry

setting

OFF

0

.-.

,-,-

oc

785

Own entry

15

Page 16

El

Installation entries for special functions

Clock

You

can set the clock to a second.

The factory setting is 0 seconds/day.

Determine the deviation.

• Enter the key code.

• Press the Add @ button until "CLOCK"

appears

in

the disp lay.

• Turn the knob until the determined deviati

on

appears

in

the display.

For exampl

e,

set

-10

sec/day when the clock

runs 1 0

sec/

day too fast.

Automatic operati

on

is automatically resumed

after 20 seconds.

Input range

I Cl

ock

-

59

to +

59

sec/

day

16

CLOCK

0

I

H!illlll

'

CLOCK

-10

Factory setting Own entry

0

Page 17

Installation entries for special functions

Offset

"OFFSET" can be used for adjustments when the

nominal room temperature shown in the display

deviates from the actual room temperature

measured with a thermometer.

The factory setting

is

0.0°C.

For exampl

e,

displayed nominal room

temperature 22

oc

actual room temperature 24 °C

• Enter the key code.

• Press the Add @ button until "OFFSET"

appears in the displ

ay.

• Turn the knob until - 2.0°C appears in the

display.

Automatic operation is automatical

ly

resumed

after 20 second

s.

Input range

I Offset

-5.0°C-

+5.0

°C

OFFSET

oc

0.0

OFFSET

oc

-2

.0

Factory setting Own entry

0.0°C

17

Page 18

I

Relay test

You

can use the relay test to test the switch

relays

in

the control pan

el.

The following relays

can be called up:

- burner

- domestic water loading pump

- heating circuit circu lation pump.

• Enter the key code.

• Press the

Add@

button until "RELAY"

appears in the displ

ay.

The actual heating system status is shown

in

the first display.

• Turn the knob. The flame symbol

~

for the

burner appears firs

t.

"RELAY ON" is sent

to

the control panel when

the burner function is correct.

"ON" does not appear when a malfunction is

detected.

• Turn the knob furth

er.

The symbols for

domestic water and heating cir

cuit

circu lation

pump relays appear sequentially.

The pump function can be checked when the

pump symbo l appears in the displ

ay.

The relay test has no time limit.

Stopping or leaving the relay test:

• Press the Add @ or

§]

button.

18

An

example of the actual heating

system status.

i!

iiii!H

H

Burner

RELAY

~

Domestic water

01'1

Heating circuit circul ation pump

RELAY

~

'iilll

Page 19

LCD test

You can use the

LCD

test to check whether a

ll

digits and symbols are shown correctly in the

display.

• Enter the key code.

• Press the

Add@

button until "LCD-TEST"

appears

in

the display.

• Turn the knob. All digits and symbols must

appear correctly

in

the display.

The display is defective

wh

en it is not complete.

The unit must th

en

be replaced.

All other displays under "LCD-TEST" are for inter-

nal factory use only.

Automatic operation is automatically resumed

after 20 seconds.

LCD-

TEST

I I I

III [(I

OJ

JJJ

III

CO

Ill

ITI

$

185

''"'I'M~'

~ll.l.l

00 lXI

~I ~I

0

f°C

~~~

.---

@)~e.:

oc1.0D£

_I

Lf

Ll

1234567 OLf"CICJ pm

Ll

LI.O

I

19

Page 20

El

Heating curve

You ca n u

se

the heating curve test to display the

heating water temperature for the nominal day

room temperature which is effective for outdoor

te

mp

eratures of

+10

°C,

± 0°C and - 10°C.

•

En

ter the key code.

• Press the

Add@

button until

"HE

ATCURV

E"

appears

in

the display .

• Turn the knob.

The

first display shows the

heating water temperature for +

10°C,

the

second for ± 0

°C

and the third for - 10°

C.

Automatic operation is automatically resumed

after 20 seconds.

20

HERTCURIJE

oc

Y7

10

HERTCURf)E

oc

S6 0

HERTCURIJE

oc

66 - 7 0

Page 21

Version

number

The

version number is a key number and represents the manufactured status of the control

panel.

The

version number must

be

specifi

ed

for recla-

mations or control panel

ex

tensions.

• Enter the key code.

• Press the Add @ button until

"VERS

ION"

appears in the di

splay.

Automatic operation is automatically resumed

after 20 seconds.

RESET

RESET

• Press and hold down the

Time~

.

Add @

an

d Cance l @ buttons at the same

time until

"RESET" appears in

th

e displ

ay.

• Hold all three buttons down until a

ll

digits/

characters have disappeared from the display.

RESET

sets a

ll settings back to the factory

settings, language to

GER

MAN

and unit of

temperature to

°C.

Switching points,

time and day of the week

remain set.

VERS/0

1'1

706

Ll

I

Version

number~

RESET

Factory set version number

o@

8888

888

21

Page 22

m

Sensor curves

Ge

neral

Switch

off

the current before measuring.

Measure the resistance at the

cab

le ends.

Outdoor temperature sens

or

80

""

60

a

~

~

'

~

(\)

0

The comparative temperature (room, flow, outdoor

and flue gas temperatures) must be measu-

red close to the sensor.

The

cur

ves show mean values and are subject

to

tolerances.

c

11:1

40

~

"""

Ui

·w

(\)

a:

~

r---.-.

20

~

r-----._

-

0

- 15

- 10

- 5 ± 0

+5

+1

0

+1

5

Out

door

temperature (

0

C}

Boiler, flow, warm water temperature sensors

14

12

10

a

~

8

(\)

0

c

11:1

-

C/)

6

·w

(\)

a:

4

2

·"'

""

"'

"'

"'

~

"""'

..........

r--.......

r--...

r--

0

20

30

40

50

60 70

80

90

Heating wat

er

temperature (

0

C)

22

Page 23

Sensor curves

Ill

Room temperature sensor

22

20

18

a

~

16

Q)

()

c:

tU

-

C/l

14

'(i)

Q)

a:

12

10

8

""

"

""

"""

"'

......

"'

~

.........

""'

~

~

~

5 10 15 20 25

30

Room temperature (°C)

Flue gas temperature sensor

350

300

250

a

~

200

Q)

()

c:

tU

-

C/l

150

'iii

Q)

a:

100

50

~

\

\

\

~

~

~

~

r---_

0

I

0

20 40

60

80

100

1

20

140

160 180 200

Flue gas temperature (

0

C}

23

Page 24

Index

c

Checking the safety temperature limit stat

C

lock

Compensation temperature

F

Flue

gas

temperature

Frost prot

ect

ion

H

Heating curve

Heating syst

em

frost protection

Heating water temperature

K

Key

code

L

LCD test

N

Nominal temperature

0

Offset

p

Program overview

R

Relay test

Remote co ntrol

24

4

16

11

15

9

20

9

7,8

6

19

7,8

17

5

18

10

s

Saf

ety

temperature limit stat

Sen

sor

curv

es

Setback mod e Outdoor contro l

Reduced

Room control

Switch -off

Switch-off te

mperature,

maximum

Switch

-o

ff temperature, minimum

Switch

-on

temperature

T

Time-switch

v

Version number

4

22

,23

12

14

13

13

16

21

Page 25

Protocollo delle tarature

Operating values on the 1st operating level

Input range

Factory

Own entry

setting

Factory program

1-8,

EMPTY

1 Family

Domestic water

OFF

1 40°C to 60°C

OFF

Domestic water temperature

40°C to 60°C

Summer/winter changeover

10°C

to 30°C

Day room temperature

10°C

to

30°C

Night room temperature

10°C

to 30°C

Operating values on the 2nd operating level

Unit

of

temperature °C I °F

oc

Language German

Nominal temperature

50°C to

90°C

85°C

Heating system frost protection

- 10

oc

to + 1 0

oc

+1 °C

Remote control

OFF I ON

OFF

Compensation temperature

OFF

I 1- 10°C

3°C

Setback mode Outdoor control Outdoor control

Reduced

Room control

Switch-off

Minimum switch-on temperature

10°Cto40°C

10°C

Maximum switch-off temperature

65°C

to

90°C 85°C

Flue gas temperature

OFF

I 50 °C to 250 °C

OFF

Cl

ock

- 59 to

+59

sec/day

0

Offset - 5.0°C

to+

5.0°C 0.0°C

25

Page 26

Page 27

Page 28

Subject

to

change without notice!

Loading...

Loading...