Bryant 704B User Manual

User Information Manual

704B

SINGLE-PACKAGED ELECTRIC COOLING UNIT

WITH PURON® (R-410A) REFRIGERANT

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualified personnel should install, repair, or service

air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of

cleaning coils and filters. All other operations should be performed

by trained service personnel. When working on air-conditioning

equipment, observe precautions in the literature, tags, and labels

attached to the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for unbrazing operations. Have fire extinguisher

available for all brazing operations.

Recognize safety information. This is the safety-alert symbol .

When you see this symbol on the product or in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words — DANGER, WARNING, CAUTION, and NOTE. Danger identifies the most serious hazards,

which will result in severe personal injury or death. Warning

indicatesacondition that could cause serious personal injury or

death. Caution is used to identify unsafe practices, which would

result in minor personal injury or product and property damage.

NOTEis used to highlight suggestions which will result in

enhanced installation, reliability, or operation.

Note to Installer: This manual should be left with the equipment

user.

WARNING: Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of this or any

other appliance. Failure to follow this warning could

result in fire, serious injury, or death.

WARNING: Do not use this unit if any part has been

under water. Immediately callaqualified service technician to inspect the unit and to replace any part of the

control system which has been under water. Failure to

follow this warning could result in electrical shock, fire,

serious injury, or death.

WARNING: Before performing recommended maintenance, be sure the main power switch to unit is turned off.

Electric shock could cause serious injury or death.

STARTINGORSHUTTING UNITOFF

1. To start the unit:

a. Turn on the electrical power supply to unit.

Cancels: New OM01–61

6–03

C99064

Fig. 1—Unit 704B

b. Select temperature and set SYSTEM switch or MODE

control to desired mode.

2. To shut unit off:

NOTE: If the unit is being shut down because ofamalfunction,

call your dealer as soon as possible.

a. Set system SWITCH or MODE control to OFF.

b. Turn off the electrical power supply to unit.

OPERATINGYOUR PACKAGEDCOOLING UNIT

The operation of your packaged cooling system is controlled by

the indoor thermostat. You simply adjust the thermostat and it

maintains the indoor temperature at the level you select. Most

thermostats of cooling systems have3controls:atemperature

control selector,aFAN control, andaSYSTEM or MODE control.

Refer to your thermostat owner’s manual for more information.

To better protect your investment and to eliminate unnecessary

service calls, familiarize yourself with the following facts:

I. COOLING MODE

With the SYSTEM or MODE control set to COOL, your unit will

run in cooling mode until the indoor temperature is lowered to the

level you have selected. On extremely hot days, your system will

run for longer periods atatime and have shorter “off” periods than

on moderate days.

II. HEATING MODE (IF INSTALLED WITH OPTIONAL

ELECTRIC HEAT)

Your system may also be equipped with an electric heating source.

On cold days and nights, place your MODE control to HEAT and

your system will automatically turn on the supplemental heat in

order to maintain the level of comfort you have selected.

—1—

MAINTENANCE AND SERVICE

This section discusses maintenance that should be performed by

your dealer and care you, as the owner, may wish to handle for

your new system.

A. Routine Maintenance

All routine maintenance should be handled by skilled, experienced

personnel. Your dealer can help you establish a standard procedure.

For your safety, keep the unit area clear and free of combustible

materials, gasoline, and other flammable liquids and vapors.

To assure proper functioning of the unit, flow of condenser air

must not be obstructed from reaching the unit. Clearance from the

top of the unit is 48 in. Clearance of at least 36 in. is required on

sides except the power entry side (42 in. clearance) and the duct

side (12 in. minimum clearance).

B. Maintenance and Care for the Equipment Owner

Before proceeding with those things you might want to maintain

yourself, please carefully consider the following:

WARNING: 1. TURN OFF ELECTRICAL POWER

TO YOUR UNIT BEFORE SERVICING OR PERFORMING MAINTENANCE. ELECTRIC SHOCK COULD

CAUSE SERIOUS INJURY OR

DEATH.

2. When removing access panels or performing maintenance functions inside your unit, be aware of sharp

sheet metal parts and screws. Although special care is

taken to keep sharp edges to a minimum, be extremely

careful when handling parts or reaching into the unit.

AIR FILTERS

The air filter(s) should be checked at least every 3 or 4 weeks and

changed or cleaned whenever it becomes dirty. Dirty filters

produce excessive stress on the blower motor and can cause the

motor to overheat and shut down.

This unit must have air filters in place before it can be operated.

These filters can be located in one of at least two places. In many

applications the installer will provide return air filter grilles

mounted on the wall or ceiling of the conditioned structure. In the

instance of filter grilles, the filters can simply be removed from the

grille and replaced.

The other typical application is an accessory filter rack installed

inside the unit itself. The following information is given to assist

in changing filters used in these internal filter racks.

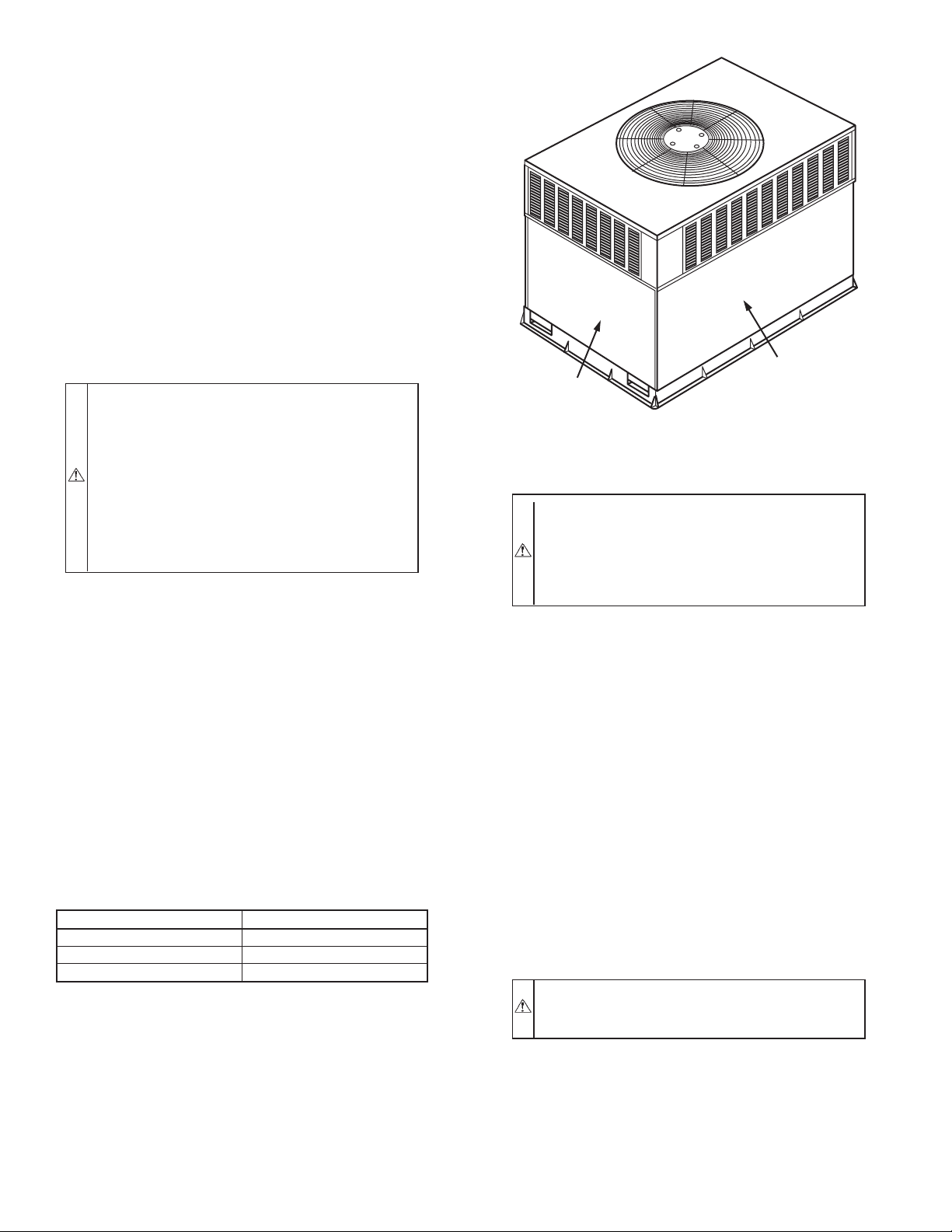

Table 1 indicates the correct filter size for your unit. Refer to Fig.

2 to access filters installed in the accessory filter rack.

TABLE 1—INDOOR-AIR FILTER DATA

UNIT SIZE FILTER SIZE

704B024-030 20x20x1

704B036 20x24x1

704B042-060 24x30x1

To replace or inspect filters in accessory filter rack (See Fig. 2):

1. Remove the filter access panel using a 5/16-in. nut driver.

2. Remove the filter(s) by pulling it out of the unit. If the

filter(s) is dirty, clean or replace with a new one.

When installing the new filter(s), note the direction of the airflow

arrows on the filter frame.

If you have difficulty locating your air filter(s) or have questions

concerning proper filter maintenance, contact your dealer for

instructions. When replacing filters, always use the same size and

type of filter that was supplied, originally, by the installer.

ACCESS PANEL

FILTER ACCESS

PANEL*

*For accessory filter rack.

C99094

Fig. 2—Accessory Filter Rack Access Panel

CAUTION: Never operate your unit without the filter(s)

in place. Failure to heed this warning may result in

damage to the blower motor and/or compressor. An

accumulation of dust and lint on internal parts of your

unit can cause loss of efficiency and , in some cases, a

fire.

FANS AND FAN MOTOR

Periodically, check the condition of fan wheels and housings and

fan-motor shaft bearings. Contact your dealer for the required

annual maintenance.

INDOOR AND OUTDOOR COILS

Cleaning of the coils should only be done by qualified service

personnel. Contact your dealer for the required annual maintenance.

CONDENSATE DRAIN

The drain pan and condensate drain line should be checked and

cleaned at the same time the cooling coils are checked by your

dealer.

COMPRESSOR

All compressors are factory-shipped with a normal charge of the

correct type refrigeration grade oil. A compressor should rarely

require additional oil.

CONDENSER FAN

CAUTION: Do not poke sticks, screwdrivers, or any

other objects into revolving fan blades. Injury or equipment damage may result.

The fan must be kept free of all obstructions to ensure proper

cooling. Contact your dealer for any required service.

ELECTRICAL CONTROLS AND WIRING

Electrical controls are difficult to check without proper instrumentations. If there are any discrepancies in the operating cycle,

contact your dealer and request service.

—2—

Loading...

Loading...