Page 1

Bryant

Air Conditioning

SINGLE PACKAGE

GAS HEATING/

ELECTRIC COOLING UNITS

DESCRIPTION

All 588Amodelsfeatureonepiece,compactdesignandarefully

self-contained units that are prewired, prepiped, and precharged for minimum installation expense. Unit is designed for

easy use in either downflow (vertical) or horizontal applications.

STANDARD FEATURES

FACTORY-ASSEMBLED PACKAGE is a compact, fully self-

contained, gas heating/electric cooling unit that is prewired, prepiped, and precharged for minimum installation expense.

588A units are lightweight and available in a variety of standard

heating and cooling sizes with voltage options to meet residential and light commercial requirements. Unit installs easily on a

rooftop or a ground-level pad.

CONVERTIBLE DUCT CONFIGURATION on the 588A is designed for easy use in either downflow or horizontal discharge

applications.

HIGH-EFFICIENCY DESIGN with SEERs (Seasonal Energy Efficiency Ratios) of 10.0.

DURABLE, DEPENDABLE COMPRESSORS are designed for

high efficiency. Each compressor is hermetically sealed against

contamination to help promote longer life and dependable operation. Each compressor also has vibration isolation to provide

quiet operation. Rotary, reciprocating, or scroll compressors are

used. Compressors have internal high-pressure and overcurrent protection.

DIRECT-DRIVE MULTISPEED, PSC (permanent split capacitor) BLOWER MOTOR is standard on all models.

DIRECT-DRIVE, PSC CONDENSER-FAN MOTORS are de-

signed to help reduce energy consumption and provide for cooling operation down to 40 F.

Model 588A

Sizes 018-060

11⁄2to 5 Tons

REFRIGERANT SYSTEM is designed to provide dependability.

Liquid refrigerant strainers are used to promote clean, unrestricted operation. Each unit leaves the factory with a full refrigerant charge. Refrigerant service connections make checking

operating pressures easier.

EVAPORATOR AND CONDENSER COILS are computerdesigned for optimum heat transfer and cooling efficiency. Condenser coil is fabricated of copper tube and aluminum fins and

is located inside the unit for protection against damage and for

long life and reliable operation. The condenser coil is internally

mounted and protected by a composite grille.

Copper fin coils for condenser coil are also available by special

order. These coils are recommended in applications where aluminum fins are likely to be damaged due to corrosion. Copper

fin coils are ideal for seacoast applications.

MONOPORT INSHOT BURNERS produce precise air-to-gas

mixture, which provides for clean and efficient combustion. The

large monoport on the inshot (or injection type) burners seldom,

if ever, needs cleaning.

WEATHERIZED CABINETS are constructed of heavy-duty,

phosphated, zinc-coated prepainted steel capable of withstanding 500 hours in salt spray. Interior surfaces of the evaporator

compartment are insulated with foil-faced fiberglass to help

keep the conditioned air from being affected by the outdoor ambient temperature and provide improved air quality.Conforms to

American Society of Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE) No. 62P. Sloped condensate pan permits

an external drain.

LOW SOUND RATINGS ensure a quiet indoor and outdoor environment with sound ratings as low as 7.4 bels.

EASY TO SERVICE CABINETS provide easy accessibility to

serviceable components during maintenance and installation.

Rounded corners are an important safety feature, and a highquality finish ensures an attractive appearance.

LOW AND HIGH VOLTAGE ELECTRICAL ENTRIES allow low

and high voltage to be brought in either through the duct panel

or rear flue panel.

INTEGRATED GAS CONTROL BOARD provides safe and efficient control of heating and simplifies troubleshooting through

its built-in diagnostic function.

OPTIONAL BASE RAILS provide holes for rigging and handling as well as an elevated mounting frame that provides structural support for horizontal installations.

DOWNFLOW OPTIONS is converted for downflow at factory for

easy vertical ductwork connections.

Form No. PDS 588A.18.4B

Page 2

FACTORY-INSTALLED OPTIONS DESCRIPTION AND USAGE

Unit With Base Rail — Unit has rigging holes and an elevated

mounting frame.

SUGGESTED USE:

• Rigging holes to provide greater ease in handling. Frame to

provide elevation and structural support for horizontal

applications.

FIELD-INSTALLED ACCESSORY DESCRIPTION AND USAGE

Downflow Option — Unit is shipped from factory configured for

downflow application. Unit is equipped with base rail.

SUGGESTED USE:

• To provide easy vertical ductwork connections.

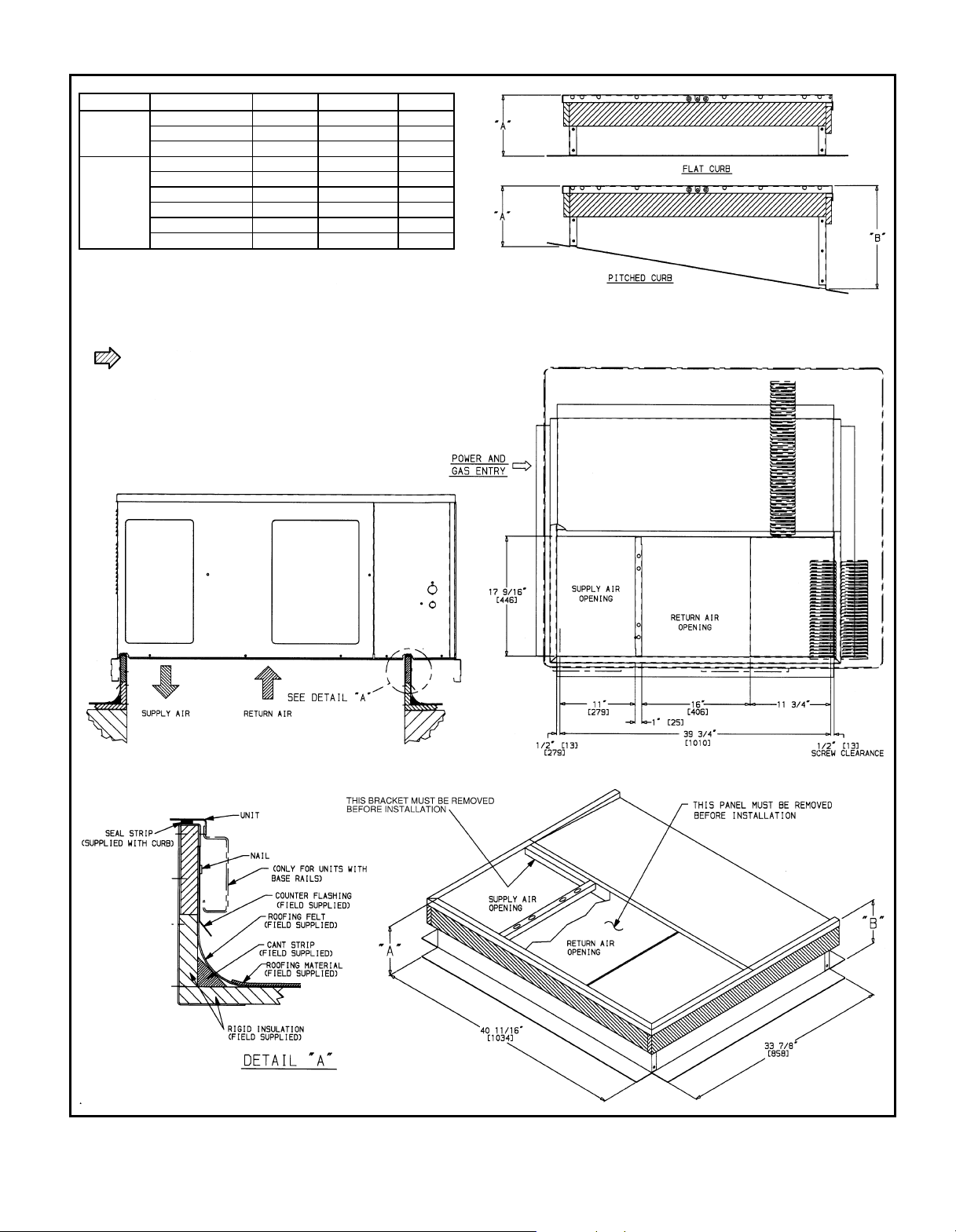

Flat Roof Curb — Consists of galvanized steel support frame in

8-, 11-, and 14-in. high designs. Provides wood nailer to attach

roof counter flashing. Insulated basepans in curbs are provided

to prevent condensation. Ductwork attaches to rails provided in

the roof curb. A gasket is provided to form an airtight and watertight seal between unit and curb. The roof curb design meets

the standards of the NRCA (National Roofing Contractors’

Association).

SUGGESTED USE:

• Slab-mounted applications when elevation of the unit above

the slab is necessary.

• Rooftop application for downflow discharge.

• Curbs are preassembled and are available for flat or pitched

roofs.

Pitched Roof Curb — Provided in ratios of 1, 2, 3, 4, 5, and 6

to 12 for use on pitched roof applications.

SUGGESTED USE:

• For when a roof curb is needed on a pitched roof.

Modulating Economizer — Economizer is available for downflow or horizontal applications, and is designed for easy installation. Economizer reduces energy costs and extends

equipment life by allowing the use of outdoor air to supply ‘‘free’’

cooling when conditions are favorable.

Constant ventilation is recommended for light commercial applications when the conditioned space is occupied.

The economizer is shipped complete with a damper motor and

linkage, enthalpy control, low-voltage wiring harness, and a

rainhood. Adequate wire lengths are provided (additional fieldsupplied wires are not required). Horizontal economizers are

also furnished with a 2-in. disposable air filter and gasket

material.

Modulating economizer package consists of low-leakage dampers with controls. The economizer will allow a fixed percentage

of outdoor ventilation air into the unit whenever the evaporator

fan is running.

SUGGESTED USE:

• Allows outdoor air to be used for ‘‘free’’ cooling whenever the

outdoor air is below the enthalpy control setting.

• To reduce energy usage. Use whenever the hours of operation at temperatures below 40 F are significant.

Two-Position Damper — In the two-position dampers, the enthalpy control detects when outdoor air is suitable for ‘‘free’’

cooling by measuring the outdoor-air dry bulb temperature and

humidity. Whenever the outdoor-air quality is acceptable for

‘‘free’’ cooling, the outdoor-air damper opens fully and the

return-air damper closes, allowing outdoor air to enter the

building.

SUGGESTED USE:

• Allows use of outdoor air to cool building without using compressor. Damper closes when evaporator fan is off to prevent

cold backdraft, and wasted energy.

Manual Outdoor-Air Damper — Package consists of a manually adjustable damper and includes a rainhood and birdscreen.

SUGGESTED USE:

• Toallow a fixed percentage of outdoor air for ventilation under

all conditions.

• The damper may be used on either downflow or horizontal airflow applications.

Thermostat and Subbase — These accessories provide cooling control for unit. Autochangeover and manual changeover

types are available.

SUGGESTED USE:

• To operate and control unit, and to maintain desired building

temperature.

The 0° F Low Ambient Kit — Kit permits operation down to

0° F.

SUGGESTED USE:

• When mechanical cooling is required when outdoor-air temperature is between 40 F and 0° F.

Natural-to-Propane Conversion Kit — Kit consists of gas orifices and other hardware required to convert the unit for use

with LP (liquid propane) gas.

SUGGESTED USE:

• When natural gas cannot be obtained and liquid propane is

used as fuel.

Filter Rack — Rack features easy installation and serviceability.

The filter rack housing is constructed of heavy-gage steel and is

fully insulated. Both sides of the filter rack are flanged for easy

installation.

SUGGESTED USE:

• Kit provides ability to locate filters inside the unit.

Flexible Duct Kit — Consists of 2 flexible UL-listed (Underwriters’ Laboratories) ducts. The duct construction includes vapor

barrier and 1-in. fiberglass insulation. The ‘‘K’’ factor is 0.23.

Each duct has a square-to-round snap adapter for attachment

to the accessory roof curb on one end, and a round clamp collar

for attachment to the concentric diffuser box on the other end.

SUGGESTED USE:

• For use with accessory roof curb and concentric box to provide an easily-installed concentric system.

Concentric Diffuser Box — Is aerodynamically designed and

equipped with a combination 4-way supply and a center return

diffuser. Aspecial core is provided within the diffuser box to provide even 4-way distribution.

SUGGESTED USE:

• For use with accessory roof curb and concentric box to provide an easily-installed concentric system.

Crankcase Heater — Warms crankcase oil to reduce refrigerant migration and ensure proper compressor lubrication.

SUGGESTED USE:

• For use in applications where crankcase is subjected to low

outside temperatures. Recommended on 208/230-v, singlephase, 024-042 units only.

Solid-State ComprotecT Device — Package consists of a control to be field-wired into the unit controls, and provides a

5-minute delay in compressor operation between cooling

cycles.

SUGGESTED USE:

• Prevents compressor short cycling when rapid compressor

cycles may be a problem.

2

Page 3

FIELD-INSTALLED ACCESSORY DESCRIPTION AND

USAGE (cont)

Lifting Bracket Kit — Provides attachment point for rigging

straps.

SUGGESTED USE:

• When unit needs to be lifted or moved. The kit is not required

when unit is equipped with optional base rail or downflow

application.

High- and Low-Pressure Switches — Protect the unit from

running at unsuitable pressures.

SUGGESTED USE:

• Provides additional safety features when needed.

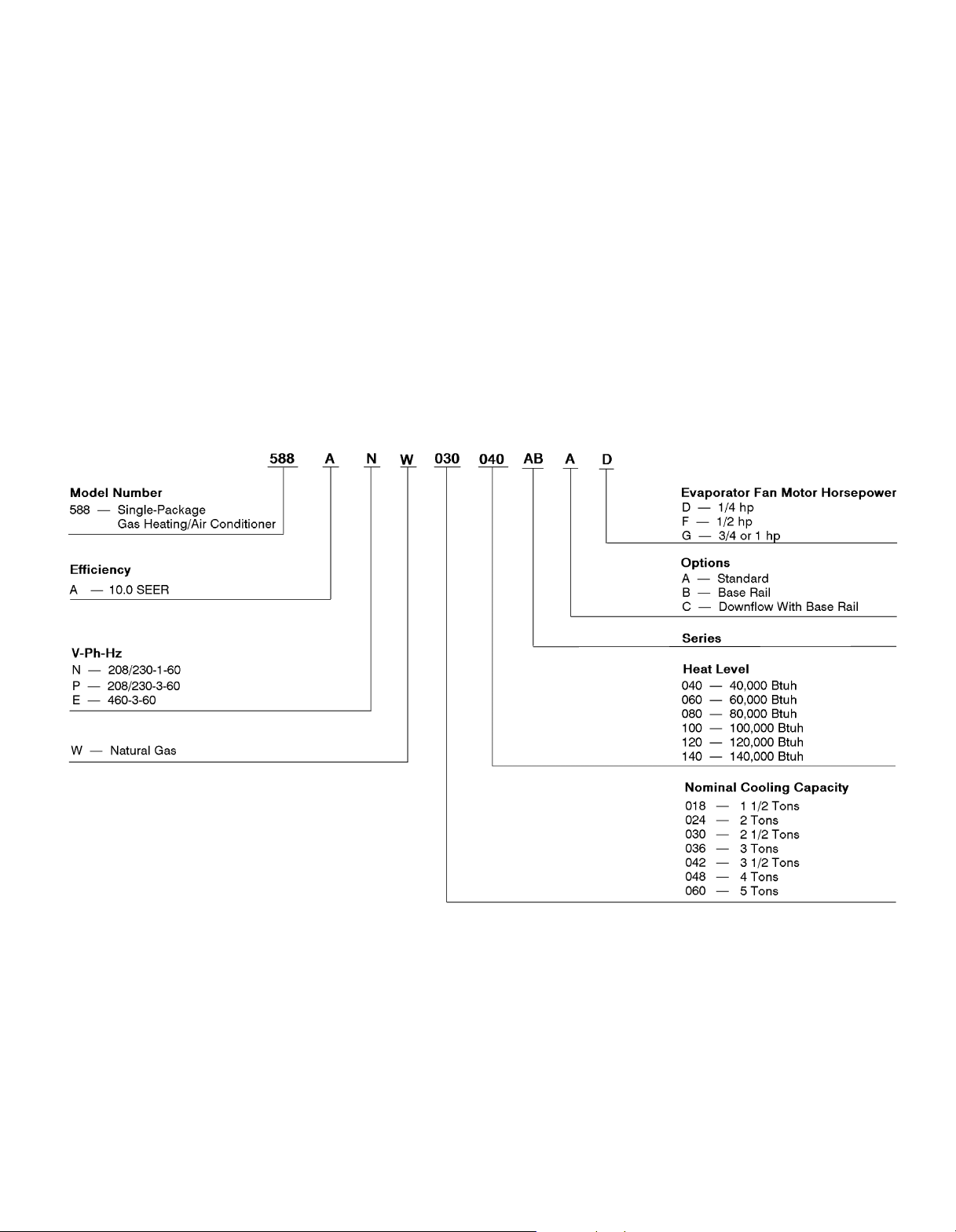

MODEL DESCRIPTION

CONTENTS

Page

Model Description .................................3

ARI Cooling Capacities .............................4

Heating Capacities and Efficiencies ...................4

Dimensional Drawings ............................5-10

Specifications ..................................11,12

Selection Procedure ..............................13

Net Cooling Capacities ..........................14-16

Air Delivery ....................................17,18

Electrical Data ...................................20

Operating Sequence ..............................21

Typical Field Wiring .............................22-24

Typical Installation ................................25

Application Data .................................25

Engineers’ Specification Guide ......................26

3

Page 4

ARI* COOLING CAPACITIES

UNIT 588A

018 1

NOMINAL STANDARD NET COOLING†

TONS CFM CAPACITIES (Btuh) (Bels)

1

⁄

2

600 17,000 10.0 7.4

024 2 800 24,000 10.0 7.6

030 2

1

⁄

2

1000 29,200 10.0 8.0

036 3 1200 36,000 10.0 8.0

042 3

1

⁄

2

1400 42,500 10.0 8.2

048 4 1600 47,000 10.0 8.2

060 5 1995 59,500 10.0 8.2

LEGEND

Bels — Sound Levels (1 bel = 10 decibels)

db — dry bulb

SEER — Seasonal Energy Efficiency Ratio

wb — wet bulb

*ARI — Air-conditioning and Refrigeration Institute.

†Rated in accordance with U.S. Government DOE (Department of En-

ergy) test procedures and/or ARI (Air Conditioning and Refrigeration

Institute) Standard 210/240-89.

**All units have factory-installed time-delay relay.

††Rated in accordance with ARI Standard 270-84.

NOTE: Ratings are net values, reflecting the effects of circulating fan

heat. Ratings are based on 80 F db, 67 F wb indoor entering-air temperature and 95 F db air entering outdoor unit.

OUTDOOR SOUND: ONE-THIRD OCTAVE BAND DATA — DECIBELS

MODEL NO. 588A

Frequency (Hz) 018 024 030 036 042 048 060

63 49.8 38.1 45.7 47.8 45.5 56.0 54.3

125 56.5 55.0 58.1 59.3 61.2 65.6 65.1

250 60.3 65.3 68.7 67.4 70.4 71.5 71.5

500 59.8 67.2 64.7 68.8 69.9 71.4 72.7

1000 64.1 68.9 73.0 73.1 76.5 74.2 73.9

2000 64.1 65.5 70.2 69.5 71.3 73.3 73.4

4000 65.2 63.8 68.8 68.2 73.7 69.6 71.7

8000 56.0 60.3 66.6 65.8 65.5 67.1 66.3

SEER†**

SOUND RATINGS††

HEATING CAPACITIES AND EFFICIENCIES

UNIT 588A

018040

024040

030040

024060

030060

036060

042060

030080

036080

042080

048080

060080

036100

042100

048100

060100

036120

042120

048120

060120

048140

060140

HEATING INPUT

(Btuh)

40,000 32,800

60,000 48,600

80,000 64,800

100,000 81,000

120,000 97,200

140,000 113,000

LEGEND

AFUE — Annual Fuel Utilization Efficiency

CSE — California Seasonal Efficiency

NOTE: Before purchasing this appliance, read important energy cost

and efficiency information available from your retailer.

OUTPUT CAPACITY

(Btuh)

TEMPERATURE

RISE RANGE (°F)

20-50

20-50

20-50

25-55

25-55

25-55

25-55

40-70

40-70

40-70

40-70

40-70

50-80

50-80

50-80

50-80

60-90

60-90

60-90

60-90

50-80

50-80

AFUE (%) CSE (%)

81.0

81.0

81.0

81.0

81.0

81.0

81.0

81.0

81.0

81.0

81.0

81.0

81.0

81.0

81.0

81.0

80.0

80.0

80.0

80.0

80.0

80.0

76.5

76.5

76.5

77.5

77.5

77.5

77.5

77.5

77.5

77.5

77.5

77.5

78.0

78.0

78.0

78.0

77.5

77.5

77.5

77.5

77.5

77.5

4

Page 5

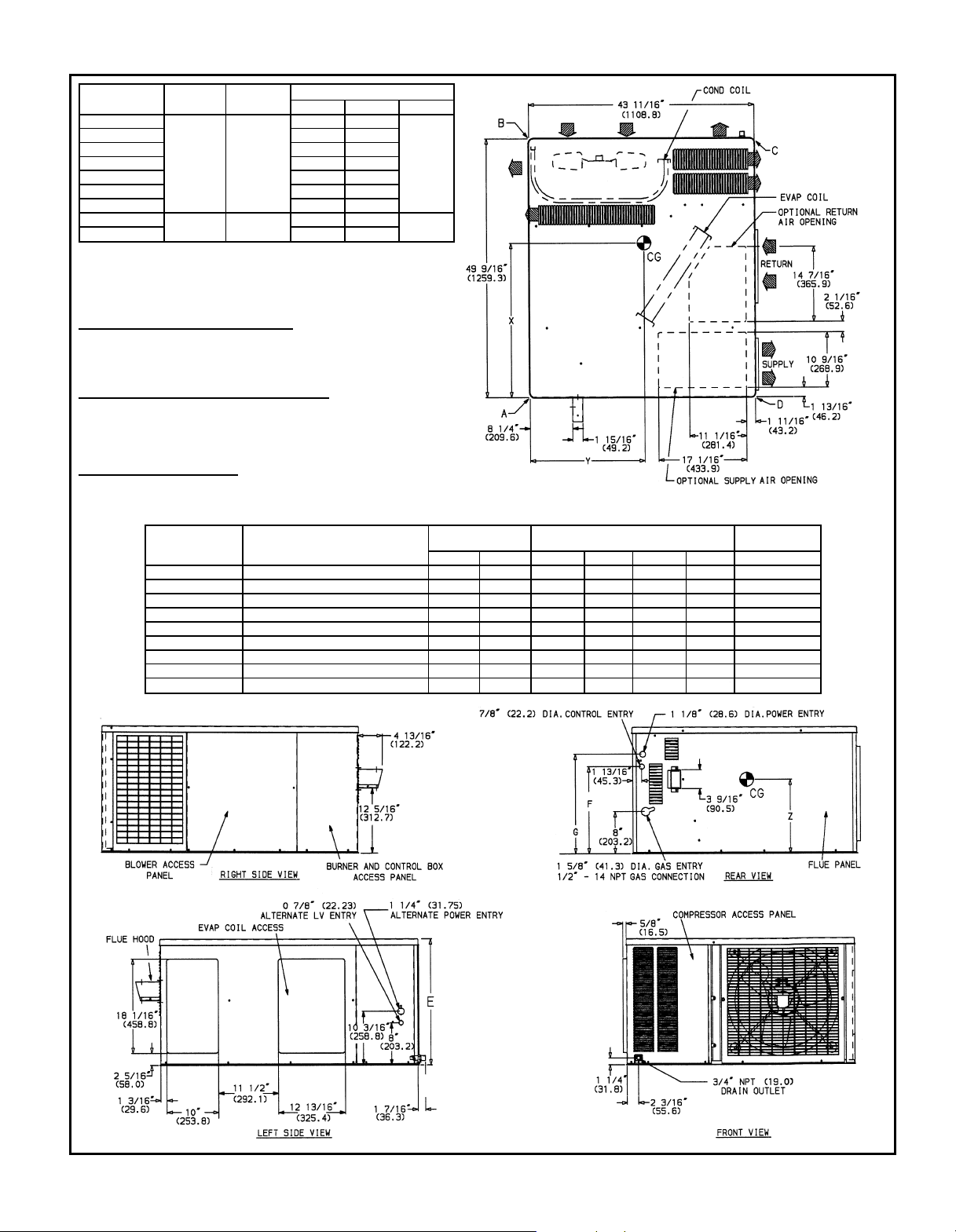

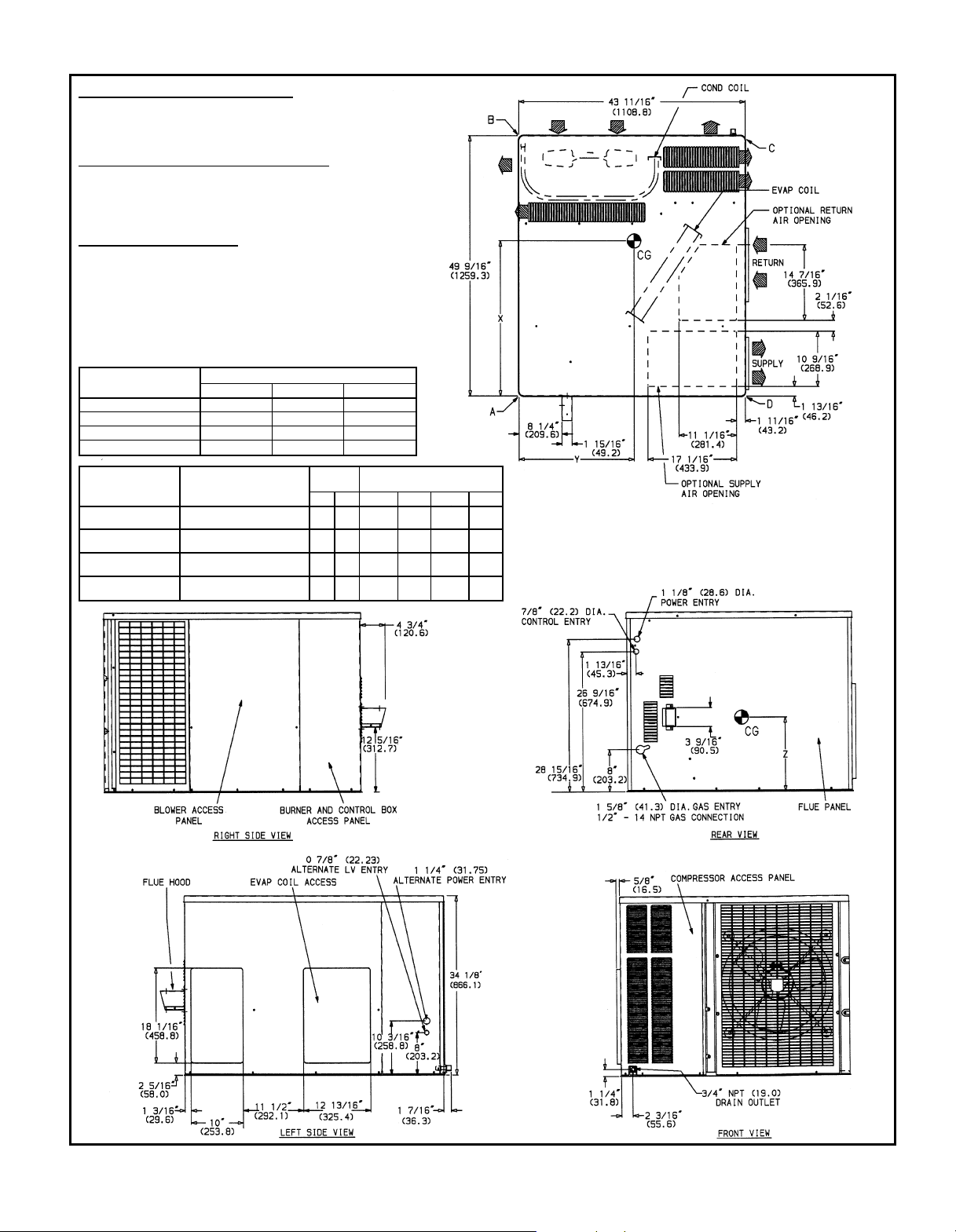

DIMENSIONAL DRAWINGS

UNIT

588A018040

588A024040 27.07/688 23.35/593

588A024060 26.98/685 23.27/591

588A030040 26.71/678 23.46/596

588A030060/080 27.15/689 22.36/568

588A036060/080 27.50/698 22.48/571

588A036100/120 27.40/696 22.44/570

588A042060/080

588A042100/120 26.94/684 22.44/570

CG — Center of Gravity

COND — Condenser

LV — Low Voltage

NOTE: Clearances must be maintained to prevent recirculation of air from

outdoor-fan discharge.

REQ’D CLEARANCES FOR SERVICING. in. (mm)

Duct panel..................................0

Unit top ................................36(914)

Side opposite ducts .........................36(914)

Compressor access .........................36(914)

(Except for NEC requirements)

REQ’D CLEARANCES TO COMBUSTIBLE MATL. in. (mm)

Maximum extension of overhangs .................48(1219)

Unit top ................................14(356)

Duct side of unit ...............................0

Side opposite ducts ..........................9(229)

Bottom of unit ................................0

Flue panel ..............................30(762)

NEC REQ’D CLEARANCES. in. (mm)

Between units, control box side ..................42(1067)

Unit and ungrounded surfaces, control box side ..........36(914)

Unit and block or concrete walls and other

grounded surfaces, control box side ...............42(1067)

F

in./mm

9

⁄16/420.7 1815⁄16/481.0

16

9

⁄16/522.3 2215⁄16/582.6

20

UNIT

588A018040 208/230-1-60 272 123 81/37 62/28 76/35 53/24 24.1/613

588A024040 208/230-1-60 303 138 97/44 43/20 123/56 40/18 24.1/613

588A024060 208/230-1-60 315 143 100/45 46/21 126/57 43/20 24.1/613

588A030040 208/230-1-60, 208/230-3-60 320 145 100/45 47/21 126/57 47/21 24.1/613

588A030060/080 208/230-1-60, 208/230-3-60 324 147 94/43 63/29 115/52 52/24 24.1/613

588A036060/080 208/230-1-60, 208/230-3-60, 460-3-60 336 153 86/39 76/35 111/50 63/29 24.1/613

588A036100/120 208/230-1-60, 208/230-3-60, 460-3-60 348 158 89/40 79/36 114/52 66/30 24.1/613

588A042060/080 208/230-1-60, 208/230-3-60, 460-3-60 375 170 95/43 86/39 119/54 75/34 28.1/714

588A042100/120 208/230-1-60, 208/230-3-60, 460-3-60 387 176 98/45 89/40 122/55 78/35 28.1/714

G

in./mm

LEGEND

MAT’L — Material

NEC — National Electrical Code

REQ’D — Required

CENTER OF GRAVITY in./mm

XYZ

25.07/637 20.59/523

27.01/686 22.44/570

ELECTRICAL

CHARACTERISTICS

10.85/276

12.65/321

UNIT WEIGHT

lbkgABCD E

CORNER WEIGHT

(lb/kg)

UNIT HEIGHT

(in./mm)

Unit 588A Sizes 018-042 Without Base Rail

5

Page 6

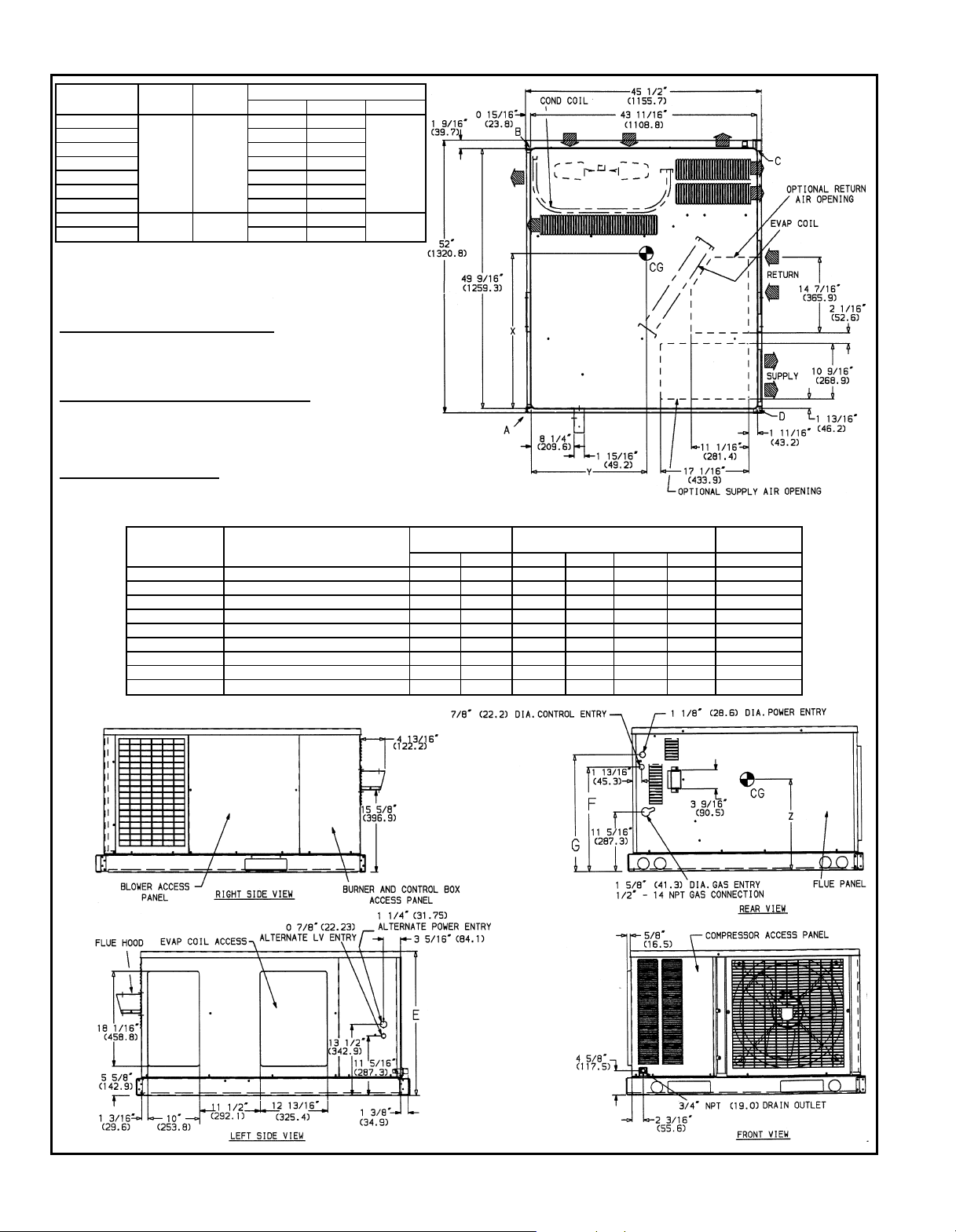

DIMENSIONAL DRAWINGS (cont)

UNIT

588A018040

588A024040 26.90/683.3 20.17/512.3

588A024060 26.82/681.2 20.22/513.6

588A030040 26.57/674.9 20.1 /509.3

588A030060/080 26.93/684 21.1 /535.4

588A036060/080 27.31/693.7 21.0 /532.6

588A036100/120 27.23/691.6 21.0 /533.1

588A042060/080

588A042100/120 26.81/681 21.0 /533.7

CG — Center of Gravity

COND — Condenser

LV — Low Voltage

NOTE: Clearances must be maintained to prevent recirculation of air from

outdoor-fan discharge.

REQ’D CLEARANCES FOR SERVICING. in. (mm)

Duct panel..................................0

Unit top ................................36(914)

Side opposite ducts .........................36(914)

Compressor access .........................36(914)

(Except for NEC requirements)

REQ’D CLEARANCES TO COMBUSTIBLE MATL. in. (mm)

Maximum extension of overhangs .................48(1219)

Unit top ................................14(356)

Duct side of unit ...............................0

Side opposite ducts ..........................9(229)

Bottom of unit ................................0

Flue panel ..............................30(762)

NEC REQ’D CLEARANCES. in. (mm)

Between units, control box side ..................42(1067)

Unit and ungrounded surfaces, control box side ..........36(914)

Unit and block or concrete walls and other

grounded surfaces, control box side ...............42(1067)

F

in./mmGin./mm

7

⁄8/504.8 221⁄4/565.4

19

7

⁄8/606.4 261⁄4/666.8

23

LEGEND

UNIT

588A018040 208/230-1-60 296 135 87/40 68/31 82/37 59/27 27.4/697

588A024040 208/230-1-60 327 149 103/47 49/22 129/59 46/21 27.4/697

588A024060 208/230-1-60 339 155 106/48 52/24 132/60 49/22 27.4/697

588A030040 208/230-1-60, 208/230-3-60 344 157 106/48 53/24 132/60 53/24 27.4/697

588A030060/080 208/230-1-60, 208/230-3-60 356 162 102/46 71/32 123/56 60/27 27.4/697

588A036060/080 208/230-1-60, 208/230-3-60, 460-3-60 360 164 92/42 82/37 117/53 69/31 27.4/697

588A036100/120 208/230-1-60, 208/230-3-60, 460-3-60 372 169 95/43 85/39 120/55 72/33 27.4/697

588A042060/080 208/230-1-60, 208/230-3-60, 460-3-60 399 181 101/46 92/42 125/57 81/37 31.4/798

588A042100/120 208/230-1-60, 208/230-3-60, 460-3-60 411 187 104/47 95/43 128/58 84/38 31.4/798

CENTER OF GRAVITY in./mm

XYZ

25.04/636 22.72/577

13.16/334.3

26.87/682.5 21.0 /533.1

MAT’L — Material

NEC — National Electrical Code

REQ’D — Required

ELECTRICAL

CHARACTERISTICS

14.96/380

UNIT WEIGHT

lbkgABCD E

CORNER WEIGHT

(lb/kg)

UNIT HEIGHT

(in./mm)

Unit 588A Sizes 018-060 With Optional Base Rail

6

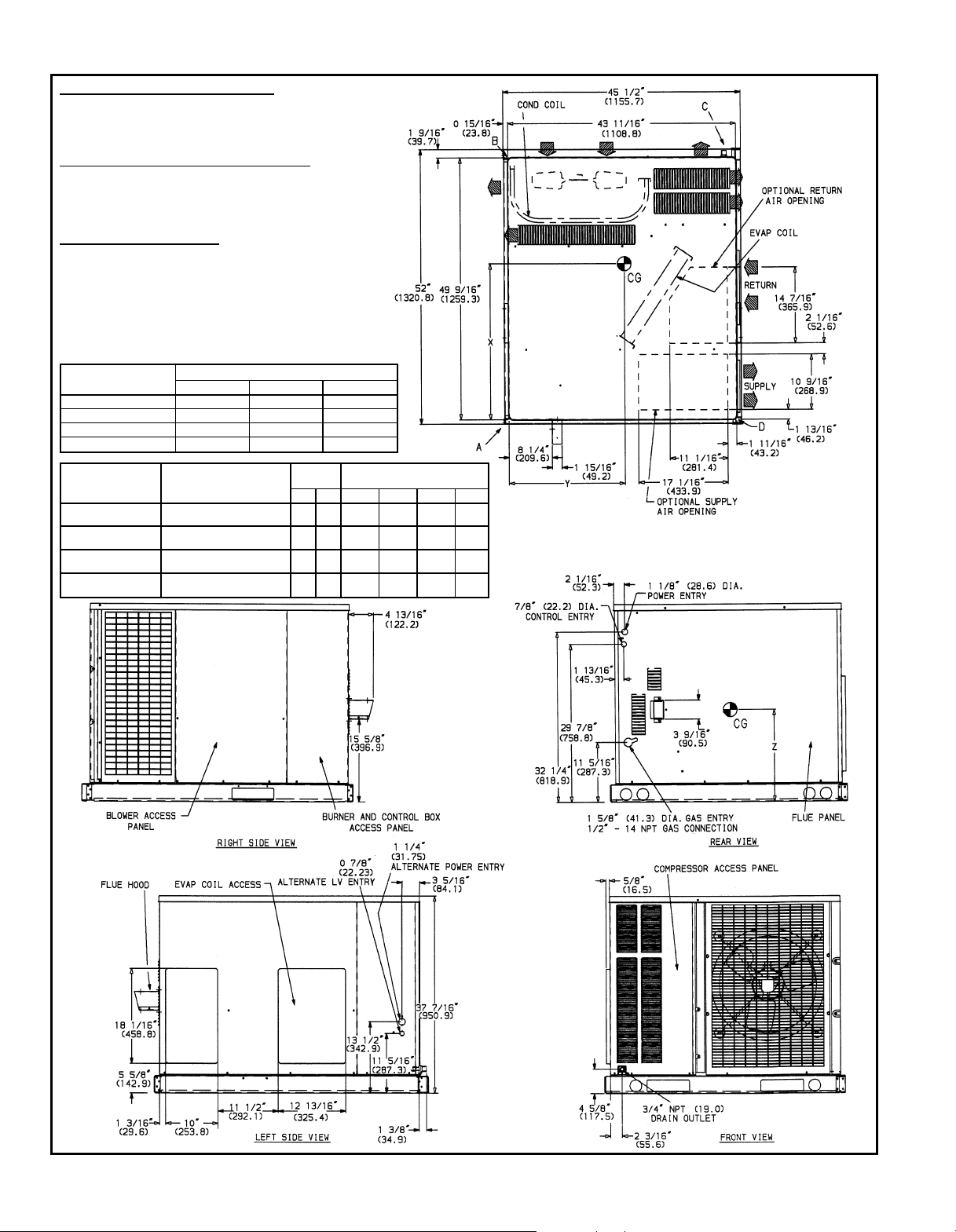

Page 7

DIMENSIONAL DRAWINGS (cont)

REQ’D CLEARANCES FOR SERVICING. in. (mm)

Duct panel..................................0

Unit top ................................36(914)

Side opposite ducts .........................36(914)

Compressor access .........................36(914)

(Except for NEC requirements)

REQ’D CLEARANCES TO COMBUSTIBLE MATL. in. (mm)

Maximum extension of overhangs .................48(1219)

Unit top ................................14(356)

Duct side of unit ...............................0

Side opposite ducts ..........................9(229)

Bottom of unit ................................0

Flue panel ..............................30(762)

NEC REQ’D CLEARANCES. in. (mm)

Between units, control box side ..................42(1067)

Unit and ungrounded surfaces, control box side ..........36(914)

Unit and block or concrete walls and other grounded

surfaces, control box side .....................42(1067)

CG — Center of Gravity

COND — Condenser

LV — Low Voltage

NOTE: Clearances must be maintained to prevent recirculation of air from

outdoor-fan discharge.

UNIT

588A048080 28.76/731 23.46/596 15.35/390

588A048100/120/140 28.42/722 23.42/595 15.35/390

588A060080 28.36/720 23.27/591 15.35/390

588A060100/120/140 27.95/710 23.23/590 15.35/390

LEGEND

MAT’L — Material

NEC — National Electrical Code

REQ’D — Required

CENTER OF GRAVITY (in./mm)

XYZ

UNIT

588A048080

588A048100/120/140

588A060080

588A060100/120/140

ELECTRICAL

CHARACTERISTICS

208/230-1-60, 208/230-3-60,

460-3-60

208/230-1-60, 208/230-3-60,

460-3-60

208/230-1-60, 208/230-3-60,

460-3-60

208/230-1-60, 208/230-3-60,

460-3-60

UNIT

WEIGHT

lbkgABCD

414 188 107/49 83/38 158/72 66/30

426 193 110/50 86/39 159/72 71/32

453 206 117/53 93/42 167/76 76/35

465 211 120/55 96/44 167/76 82/37

CORNER WEIGHT

(lb/kg)

Unit 588A, Sizes 048,060 Without Base Rail

7

Page 8

DIMENSIONAL DRAWINGS (cont)

REQ’D CLEARANCES FOR SERVICING. in. (mm)

Duct panel..................................0

Unit top ................................36(914)

Side opposite ducts .........................36(914)

Compressor access .........................36(914)

(Except for NEC requirements)

REQ’D CLEARANCES TO COMBUSTIBLE MATL. in. (mm)

Maximum extension of overhangs .................48(1219)

Unit top ................................14(356)

Duct side of unit ...............................0

Side opposite ducts ..........................9(229)

Bottom of unit ................................0

Flue panel ..............................30(762)

NEC REQ’D CLEARANCES. in. (mm)

Between units, control box side ..................42(1067)

Unit and ungrounded surfaces, control box side ..........36(914)

Unit and block or concrete walls and other grounded

surfaces, control box side .....................42(1067)

CG — Center of Gravity

COND — Condenser

LV — Low Voltage

NOTE: Clearances must be maintained to prevent recirculation of air from

outdoor-fan discharge.

UNIT

588A048080 28.54/724.9 20.00/508 17.66/448.6

588A048100/120/140 28.22/716.8 20.05/509.3 17.66/448.6

588A060080 28.18/715.6 20.19/512.8 17.66/448.6

588A060100/120/140 27.79/705.9 20.23/513.8 17.66/448.6

LEGEND

MAT’L — Material

NEC — National Electrical Code

REQ’D — Required

CENTER OF GRAVITY (in./mm)

XYZ

UNIT

588A048080

588A048100/120/140

588A060080

588A060100/120/140

ELECTRICAL

CHARACTERISTICS

208/230-1-60, 208/230-3-60,

460-3-60

208/230-1-60, 208/230-3-60,

460-3-60

208/230-1-60, 208/230-3-60,

460-3-60

208/230-1-60, 208/230-3-60,

460-3-60

UNIT

WEIGHT

lb kg A B C D

438 199 113/51 89/40 164/75 72/33

450 205 116/53 92/42 165/75 77/35

477 217 123/56 99/45 173/79 82/37

489 222 126/57 102/46 173/79 88/40

CORNER WEIGHT

(lb/kg)

Unit 588A Sizes 048,060 With Optional Base Rail

8

Page 9

DIMENSIONAL DRAWINGS (cont)

PART NUMBER ‘‘A’’ ‘‘B’’ PITCH

FLAT

PITCHED

NOTES:

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied as required for unit being installed.

3. Dimensions in [ ] are in millimeters.

4. Roof curb is made of 16 gage steel.

5. Attach ductwork to curb (flanges of duct rest on curb).

6. Service clearance 4 ft on each side.

7. Direction of airflow.

8. Insulated panels: 1-in. thick fiberglass, 1 lb density.

389099-701 89 [203] — —

389100-701 119 [279] — —

389101-701 149 [356] — —

389103-701 89 [203] 10

389104-701 89 [203] 13

389105-701 89 [203] 16

389106-701 89 [203] 19

389107-701 89 [203] 22

389108-701 89 [203] 25

7

⁄89 [276] 1:12

9

⁄169 [344] 2:12

3

⁄89 [416] 3:12

1

⁄49 [489] 4:12

3

⁄89 [568] 5:12

5

⁄89 [651] 6:12

Roof Curb, Sizes 018-060

9

Page 10

DIMENSIONAL DRAWINGS (cont)

Manual Outdoor-Air Damper

Two-Position Damper

ACCESSORY PART NUMBER ‘‘A’’

FILTER

RACK

Filter Racks and Filters

10

389093-701 21

389094-701 31

389125-701 25

11

⁄

16

9

11

⁄

16

9

11

⁄

16

9

Page 11

SPECIFICATIONS

UNIT SIZE 588A 018040 024040 024060 030040 030060 030080

NOMINAL CAPACITY (tons) 1

1

⁄

2

222

1

⁄

2

1

2

⁄

2

1

2

⁄

2

OPERATING WEIGHT (lb)

Without Base Rail 272 303 315 320 324 324

With Optional Base Rail 296 327 339 344 356 356

COMPRESSOR

Type Rotary Reciprocating

Quantity 11

REFRIGERANT R-22

Charge (lb) 2.60 2.75 2.75 3.40 3.40 3.40

REFRIGERANT METERING DEVICE Fixed Orifice Metering Device

CONDENSER COIL

Face Area (sq ft) 5.95 5.95 5.95 5.95 5.95 5.95

Rows...Fins/in. 1...17 1...17 1...17 2...17 2...17 2...17

CONDENSER FAN

Nominal Airflow (cfm) 1700 1700 1700 1900 1900 1900

Nominal Speed (rpm) 850 850 850 1050 1050 1050

Quantity...Diameter (in.) 1...18 1...18 1...18 1...18 1...18 1...18

Motor Hp

1

⁄

8

1

⁄

8

1

⁄

8

1

⁄

4

1

⁄

4

1

⁄

4

EVAPORATOR COIL

Face Area (sq ft) 1.83 2.29 2.29 2.29 2.29 2.29

Rows...Fins/in. 3...15 3...15 3...15 3...15 3...15 3...15

EVAPORATOR FAN

Nominal Airflow (cfm) 600 800 800 1000 1000 1000

Nominal Speed (rpm) 825 1075 1075 1075 1075 1075

Diameter x Width (in.) 10x10 10x10 10x10 10x10 10x10 10x10

Motor Hp (single-phase)

(three-phase) ———

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

FURNACE SECTION*

Burner Orifice No. (Qty...drill size)

Natural Gas 1...32 1...32 2...38 1...32 2...38 2...32

Burner Orifice No. (Qty...drill size)

Propane Gas 1...41 1...41 2...46 1...41 2...46 2...42

RETURN-AIR FILTERS (in.)†

Throwaway 20x20 20x20 20x20 20x24 20x24 20x24

UNIT SIZE 588A 036060 036080 036100 036120 042060 042080

1

⁄

NOMINAL CAPACITY (tons) 33333

2

1

3

⁄

2

OPERATING WEIGHT (lb)

Without Base Rail 336 336 348 348 375 375

With Optional Base Rail 360 360 372 372 399 399

COMPRESSOR

Type Reciprocating

Quantity 1

REFRIGERANT R-22

Charge (lb-oz) 4.30 4.30 4.30 4.30 5.20 5.20

REFRIGERANT METERING DEVICE Fixed Orifice Metering Device

CONDENSER COIL

Face Area (sq ft) 5.95 5.95 5.95 5.95 7.04 7.04

Rows...Fins/in. 2...17 2...17 2...17 2...17 2...17 2...17

CONDENSER FAN

Nominal Airflow (cfm) 1900 1900 1900 1900 1900 1900

Nominal Speed (rpm) 1050 1050 1050 1050 1050 1050

Quantity...Diameter (in.) 1...18 1...18 1...18 1...18 1...18 1...18

Motor Hp

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

EVAPORATOR COIL

Face Area (sq ft) 3.06 3.06 3.06 3.06 3.33 3.33

Rows...Fins/in. 3...15 3...15 3...15 3...15 3...15 3...15

EVAPORATOR FAN

Nominal Airflow (cfm) 1200 1200 1200 1200 1400 1400

Nominal Speed (rpm) 1100 1100 1100 1100 1100 1100

Diameter x Width (in.) 10x10 10x10 10x10 10x10 10x10 10x10

Motor Hp (single-phase)

(three-phase)

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

FURNACE SECTION*

Burner Orifice No. (Qty...drill size)

Natural Gas 2...38 2...32 3...35 3...32 2...38 2...32

Burner Orifice No. (Qty...drill size)

Propane Gas 2...46 2...42 3...44 3...42 2...46 2...42

RETURN-AIR FILTERS (in.)†

Throwaway 20x24 20x24 20x24 20x24 24x24 24x24

*Based on an altitude of 0-2000 ft.

†Required field-supplied filter sizes are based on the larger of the ARI-rated (Air Conditioning & Refrigeration Institute) cooling airflow or the heating

airflow at a velocity of 300 ft/min for throwaway type. Air filter pressure drop for non-standard filters must not exceed 0.08 in. wg.

**Sq inch. Filter is mounted external to unit.

11

Page 12

SPECIFICATIONS (cont)

UNIT SIZE 588A 042100 042120 048080 048100 048120 048140

NOMINAL CAPACITY (tons) 3

OPERATING WEIGHT (lb)

Without Base Rail 387 387 414 426 426 426

With Optional Base Rail 411 411 438 450 450 450

COMPRESSOR

Type Reciprocating Hermetic Scroll

Quantity 11

REFRIGERANT R-22

Charge (lb) 5.20 5.20 6.50 6.50 6.50 6.50

REFRIGERANT METERING DEVICE Fixed Orifice Metering Device

CONDENSER COIL

Face Area (sq ft) 7.04 7.04 8.67 8.67 8.67 8.67

Rows...Fins/in. 2...17 2...17 2...17 2...17 2...17 2...17

CONDENSER FAN

Nominal Airflow (cfm) 1900 1900 2400 2400 2400 2400

Nominal Speed (rpm) 1050 1050 1050 1050 1050 1050

Diameter x Width (in.) 1...18 1...18 1...20 1...20 1...20 1...20

Motor Hp

EVAPORATOR COIL

Face Area (sq ft) 3.33 3.33 4.44 4.44 4.44 4.44

Rows...Fins/in. 3...15 3...15 3..15 3...15 3...15 3...15

EVAPORATOR FAN

Nominal Airflow (cfm) 1400 1400 1600 1600 1600 1600

Nominal Speed (rpm) 1100 1100 1100 1100 1100 1100

Diameter x Width (in.) 10x10 10x10 10x10 10x10 10x10 10x10

Motor Hp (single-phase)

(three-phase)

FURNACE SECTION*

Burner Orifice No. (Qty...drill size)

Natural Gas 3...35 3...32 2...32 3...35 3...32 3...30

Burner Orifice No. (Qty...drill size)

Propane Gas 3...44 3...42 2...42 3...44 3...42 3...41

RETURN-AIR FILTERS (in.)†

Throwaway 24 x 24 24 x 24 24 x 30 24 x 30 24 x 30 816**

1

⁄

2

1

⁄

4

3

⁄

4

3

⁄

4

31⁄

2

1

⁄

4

3

⁄

4

3

⁄

4

4444

1

⁄

4

3

⁄

4

3

⁄

4

1

⁄

3

3

⁄

4

3

⁄

4

1

⁄

3

3

⁄

4

3

⁄

4

1

⁄

3

3

⁄

4

3

⁄

4

UNIT SIZE 588A 060080 060100 060120 060140

NOMINAL CAPACITY (tons) 5555

OPERATING WEIGHT (lb)

Without Base Rail 453 465 465 465

With Optional Base Rail 477 489 489 489

COMPRESSOR

Type Hermetic Scroll

Quantity 1

REFRIGERANT R-22

Charge (lb) 7.00 7.00 7.00 7.00

REFRIGERANT METERING DEVICE Fixed Orifice Metering Device

CONDENSER COIL

Face Area (sq ft) 8.67 8.67 8.67 8.67

Rows...Fins/in. 2...17 2...17 2...17 2...17

CONDENSER FAN

Nominal Airflow (cfm) 2400 2400 2400 2400

Nominal Speed (rpm) 1050 1050 1050 1050

Quantity...Diameter (in.) 1...20 1...20 1...20 1...20

Motor Hp

1

⁄

3

1

⁄

3

1

⁄

3

1

⁄

3

EVAPORATOR COIL

Face Area (sq ft) 4.44 4.44 4.44 4.44

Rows...Fins/in. 4...15 4...15 4...15 4...15

EVAPORATOR FAN

Nominal Airflow (cfm) 1995 1995 1995 1995

Nominal Speed (rpm) 1100 1100 1100 1100

Diameter x Width (in.) 10x10 10x10 10x10 10x10

Motor Hp (single-phase) 1111

(three-phase) 1111

FURNACE SECTION*

Burner Orifice No. (Qty...drill size)

Natural Gas 2...32 3...35 3...32 3...30

Burner Orifice No. (Qty...drill size)

Propane Gas 2...42 3...44 3...42 3...41

RETURN-AIR FILTERS (in.)†

Throwaway 24 x 30 24 x 30 24 x 30 960**

*Based on an altitude of 0-2000 ft.

†Required field-supplied filter sizes are based on the larger of the ARI-rated (Air Conditioning & Refrigeration Institute) cooling airflow or the heating

airflow at a velocity of 300 ft/min for throwaway type. Air filter pressure drop for non-standard filters must not exceed 0.08 in. wg.

**Sq inch. Filter is mounted external to unit.

12

Page 13

SELECTION PROCEDURE

I DETERMINE COOLING AND HEATING REQUIRE-

MENTS AT DESIGN CONDITIONS:

Given:

Required Cooling Capacity (TC) ..........34,000 Btuh

Sensible Heat Capacity (SHC) ...........24,000 Btuh

Required Heating Capacity ..............60,000 Btuh

Condenser Entering-Air Temperature ............95F

Indoor-Air Temperature ...........80Fedb, 67 F ewb

Evaporator-Air Quantity ...................1200 cfm

External Static Pressure .................0.20 in. wg

Electrical Characteristics (V-Ph-Hz) ..........208-1-60

II SELECT UNIT BASED ON REQUIRED COOLING

CAPACITY.

Enter Net Cooling Capacities table at condenser entering

temperature of 95 F. Unit 588A036 at 1200 cfm and 67 F

ewb (entering wet bulb) will provide a total capacity of

36,000 Btuh and an SHC of 26,200 Btuh. Calculate SHC

correction, if required, using Note 4 under Net Cooling Capacities tables.

III SELECT HEATING CAPACITY OF UNIT TO PROVIDE

DESIGN CONDITION REQUIREMENT.

In the Heating Capacities and Efficiencies table on page 4,

note that unit 588A036080 will provide 64,800 Btuh with an

input of 80,000 Btuh.

IV DETERMINE FAN SPEED AND POWER REQUIRE-

MENTS AT DESIGN CONDITIONS.

Before entering the air delivery tables, calculate the total

static pressure required. From the given, the Wet Coil

Pressure Drop table, and the Filter Pressure Drop table on

page 19, find at 1200 cfm:

External static pressure 0.20 in. wg

Wet Coil 0.088 in. wg

Filter 0.13 in. wg

Total static pressure 0.42 in. wg (rounded)

Enter the table for Dry Coil Air Delivery — Horizontal Discharge for 230 and 460 V on page 17. For 208 v operation,

deduct 10% from value given. The fan will deliver 1233 cfm

at 0.4 external static pressure (1370 x 0.9) at high speed

and 852 cfm at 0.5 external static pressure (946 x 0.9) at

low speed. The fan speed should be set at high to satisfy

job requirements.

V SELECT UNIT THAT CORRESPONDS TO POWER

SOURCE AVAILABLE.

The Electrical Data table on page 20 shows that the unit

is designed to operate at 208-1-60.

13

Page 14

588A018 (11⁄2TONS)

Indoor

Coil Air

Cfm BF

525 0.10

600 0.12

675 0.13

588A024 (2 TONS)

Indoor

Coil Air

Cfm BF

700 0.06

800 0.07

900 0.08

Ewb

(F)

72 19.0 8.70 1.85 18.5 8.56 2.00 17.9 8.37 2.15 17.1 8.10 2.31

67 17.4 11.2 1.80 16.9 11.1 1.95 16.2 10.9 2.10 15.5 10.6 2.26

62 15.8 13.6 1.76 15.3 13.4 1.90 14.6 13.2 2.05 13.8 12.8 2.20

72 19.2 8.97 1.90 18.7 8.87 2.05 18.0 8.60 2.20 17.3 8.44 2.37

67 17.6 11.8 1.86 17.0 11.6 2.00 16.3 11.4 2.15 15.6 11.2 2.31

62 16.0 14.4 1.81 15.5 14.2 1.95 14.9 14.0 2.10 14.1 13.6 2.25

72 19.3 9.18 1.95 18.8 9.08 2.10 18.0 8.83 2.25 17.4 8.73 2.42

67 17.8 12.4 1.91 17.1 12.2 2.05 16.4 12.0 2.20 15.7 11.7 2.36

62 16.1 15.1 1.86 15.6 14.9 2.01 14.9 14.6 2.15 14.3 14.2 2.31

Ewb

(F)

72 27.8 13.2 2.69 26.3 12.7 2.84 24.6 12.1 2.97 22.9 11.6 3.10

67 25.1 16.6 2.60 23.6 16.1 2.73 22.0 15.5 2.86 20.3 14.9 2.97

62 22.5 19.8 2.51 21.1 19.3 2.63 19.6 18.5 2.74 17.9 17.6 2.85

72 28.3 13.7 2.75 26.6 13.1 2.89 25.0 12.7 3.03 23.2 12.2 3.16

67 25.6 17.6 2.65 24.0 17.1 2.82 22.4 16.5 2.92 20.6 15.9 3.03

62 23.0 21.2 2.56 21.5 20.5 2.69 20.0 19.7 2.81 18.6 18.5 2.93

72 28.7 14.2 2.80 27.0 13.7 2.95 25.3 13.2 3.09 23.5 12.7 3.21

67 26.0 18.6 2.71 24.4 18.1 2.85 22.6 17.4 2.97 20.9 16.9 3.09

62 23.4 22.3 2.62 21.9 21.5 2.75 20.5 20.5 2.88 19.2 19.2 3.01

NET COOLING CAPACITIES

Outdoor Coil Entering-Air Temperature (F)

85 95 105 115

Capacity

(Btuh x 1000)

Total Sensible Total Sensible Total Sensible Total Sensible

85 95 105 115

Capacity

(Btuh x 1000)

Total Sensible Total Sensible Total Sensible Total Sensible

Total

System

kW

Total

System

kW

Capacity

(Btuh x 1000)

Outdoor Coil Entering-Air Temperature (F)

Capacity

(Btuh x 1000)

Total

System

kW

Total

System

kW

Capacity

(Btuh x 1000)

Capacity

(Btuh x 1000)

Total

System

kW

Total

System

kW

Capacity

(Btuh x 1000)

Capacity

(Btuh x 1000)

Total

System

kW

Total

System

kW

588A030 (21⁄2TONS)

Indoor

Coil Air

Capacity

(Btuh x 1000)

Total Sensible Total Sensible Total Sensible Total Sensible

LEGEND

Ewb

(F)

72 33.7 16.3 3.16 31.7 15.6 3.33 29.9 15.0 3.49 27.6 14.2 3.62

67 30.7 21.0 3.09 28.8 20.4 3.25 26.9 19.6 3.40 24.8 18.8 3.53

62 27.5 25.2 3.01 25.8 24.4 3.16 23.9 23.4 3.30 21.9 21.9 3.44

72 34.0 16.9 3.22 32.3 16.4 3.40 30.1 15.6 3.54 28.0 15.0 3.89

67 31.1 22.3 3.15 29.2 21.6 3.32 27.2 20.9 3.46 25.0 20.1 3.59

62 28.0 26.8 3.07 26.3 25.9 3.23 24.6 24.6 3.38 22.9 22.9 3.52

72 34.5 17.6 3.28 32.4 16.9 3.44 30.5 16.4 3.61 28.1 15.6 3.74

67 31.3 23.4 3.20 29.4 22.7 3.37 27.5 22.1 3.62 25.2 21.2 3.64

62 28.4 28.2 3.13 26.9 26.9 3.30 25.3 25.3 3.45 23.6 23.6 3.59

sensible capacity (Btuh x 1000)

Cfm BF

875 0.08

1000 0.09

1125 0.10

BF — Bypass Factor

Ewb — Entering Wet-Bulb

SHC — Sensible Heat Capacity (1000 Btuh)

NOTES:

1. Ratings are net; they account for the effects of the indoor-fan motor

power and heat.

2. Direct interpolation is permissible. Do not extrapolate.

3. The following formulas may be used:

t=t –

ldb edb

85 95 105 115

Total

System

kW

1.10 x cfm

Outdoor Coil Entering-Air Temperature (F)

Capacity

(Btuh x 1000)

Total

System

kW

t = Wet-bulb temperature corresponding to enthalpy of air

lwb

h=h –

lwb ewb

Where: h = Enthalpy of air entering indoor coil

4. The SHC is based on 80 F edb temperature of air entering indoor

coil.

Below 80 F edb, subtract (corr factor x cfm) from SHC.

Above 80 F edb, add (corr factor x cfm) to SHC.

Correction Factor = 1.10 x (1 – BF) x (edb – 80).

Capacity

(Btuh x 1000)

leaving indoor coil (h )

total capacity (Btuh x 1000)

ewb

Total

System

kW

lwb

4.5 x cfm

Capacity

(Btuh x 1000)

Total

System

kW

14

Page 15

588A036 (3 TONS)

Indoor

Coil Air

Cfm BF

1050 0.07

1200 0.08

1350 0.09

588A042 (31⁄2TONS)

Indoor

Coil Air

Cfm BF

1225 0.11

1400 0.12

1575 0.14

Ewb

(F)

72 41.7 19.9 3.99 39.3 19.1 4.18 37.2 18.4 4.39 34.7 17.5 4.57

67 37.6 25.4 3.86 35.5 24.7 4.05 33.2 23.8 4.23 30.9 22.9 4.41

62 33.6 30.5 3.72 31.2 29.4 3.90 28.8 28.2 4.08 26.7 26.7 4.26

72 42.3 20.7 4.08 40.2 20.1 4.29 37.6 19.2 4.48 35.0 18.3 4.66

67 38.3 27.1 3.95 36.0 26.2 4.14 33.7 25.4 4.32 31.3 24.5 4.50

62 34.2 32.5 3.81 31.9 31.4 3.99 30.0 30.0 4.17 28.1 28.1 4.37

72 42.6 21.4 4.15 40.4 20.8 4.36 37.9 20.0 4.56 35.2 19.0 4.73

67 38.7 28.5 4.03 36.4 27.7 4.22 34.0 26.8 4.41 31.6 25.9 4.58

62 34.8 34.2 3.90 32.8 32.8 4.09 31.1 31.0 4.29 29.2 29.2 4.48

Ewb

(F)

72 47.9 23.5 4.57 45.3 22.5 4.81 43.0 21.8 5.08 40.1 20.7 5.30

67 44.2 30.0 4.43 41.8 29.2 4.67 39.3 28.2 4.90 36.7 27.2 5.12

62 40.3 36.1 4.28 38.0 34.9 4.50 35.7 33.8 4.73 33.3 32.5 4.94

72 48.5 24.3 4.66 45.9 23.4 4.91 43.3 22.5 5.17 40.4 21.4 5.39

67 44.9 31.7 4.52 42.5 30.9 4.77 39.9 29.9 5.01 37.2 28.8 5.23

62 41.1 38.3 4.38 38.8 37.1 4.61 36.4 35.8 4.84 34.1 34.1 5.06

72 49.0 25.0 4.75 46.4 24.2 5.00 43.7 23.4 5.26 40.8 22.3 5.49

67 45.4 33.2 4.61 43.0 32.5 4.87 40.4 31.5 5.10 37.6 30.4 5.32

62 41.8 40.2 4.48 39.4 38.9 4.71 37.2 37.2 4.94 35.0 35.0 5.18

NET COOLING CAPACITIES (cont)

Outdoor Coil Entering-Air Temperature (F)

85 95 105 115

Capacity

(Btuh x 1000)

Total Sensible Total Sensible Total Sensible Total Sensible

85 95 105 115

Capacity

(Btuh x 1000)

Total Sensible Total Sensible Total Sensible Total Sensible

Total

System

kW

Total

System

kW

Capacity

(Btuh x 1000)

Outdoor Coil Entering-Air Temperature (F)

Capacity

(Btuh x 1000)

Total

System

kW

Total

System

kW

Capacity

(Btuh x 1000)

Capacity

(Btuh x 1000)

Total

System

kW

Total

System

kW

Capacity

(Btuh x 1000)

Capacity

(Btuh x 1000)

Total

System

kW

Total

System

kW

588A048 (4 TONS)

Indoor

Coil Air

Capacity

(Btuh x 1000)

Total Sensible Total Sensible Total Sensible Total Sensible

LEGEND

Ewb

(F)

72 52.9 25.6 4.95 50.9 24.8 5.38 48.8 24.1 5.83 46.4 23.4 6.34

67 48.3 32.7 4.85 46.4 32.1 5.28 44.2 31.2 5.73 41.5 30.2 6.22

62 43.8 39.4 4.76 41.9 38.6 5.17 39.3 37.3 5.61 36.6 35.9 6.08

72 53.7 26.4 5.07 51.7 25.9 5.50 49.2 25.1 5.95 47.0 24.3 6.45

67 49.1 34.6 4.97 47.0 33.9 5.40 44.7 33.1 5.85 42.4 32.4 6.34

62 44.5 41.9 4.87 42.6 41.1 5.29 40.1 39.7 5.74 37.7 37.6 6.22

72 53.9 27.1 5.17 52.2 26.8 5.61 49.6 26.0 6.06 47.4 25.4 6.57

67 49.6 36.4 5.08 47.5 35.9 5.51 45.2 35.1 5.96 42.8 34.2 6.46

62 45.1 44.1 4.99 43.3 43.1 5.41 41.2 41.2 5.87 39.0 39.0 6.36

sensible capacity (Btuh x 1000)

Cfm BF

1400 0.08

1600 0.10

1800 0.11

BF — Bypass Factor

Ewb — Entering Wet-Bulb

SHC — Sensible Heat Capacity (1000 Btuh)

NOTES:

1. Ratings are net; they account for the effects of the indoor-fan motor

power and heat.

2. Direct interpolation is permissible. Do not extrapolate.

3. The following formulas may be used:

t=t –

ldb edb

85 95 105 115

Total

System

kW

1.10 x cfm

Outdoor Coil Entering-Air Temperature (F)

Capacity

(Btuh x 1000)

Total

System

kW

t = Wet-bulb temperature corresponding to enthalpy of air

lwb

h=h –

lwb ewb

Where: h = Enthalpy of air entering indoor coil

4. The SHC is based on 80 F edb temperature of air entering indoor

coil.

Below 80 F edb, subtract (corr factor x cfm) from SHC.

Above 80 F edb, add (corr factor x cfm) to SHC.

Correction Factor = 1.10 x (1 – BF) x (edb – 80).

Capacity

(Btuh x 1000)

leaving indoor coil (h )

total capacity (Btuh x 1000)

ewb

Total

System

kW

lwb

4.5 x cfm

Capacity

(Btuh x 1000)

Total

System

kW

15

Page 16

NET COOLING CAPACITIES (cont)

588A060 (5 TONS)

Indoor

Coil Air

Capacity

(Btuh x 1000)

Total Sensible Total Sensible Total Sensible Total Sensible

LEGEND

Ewb

(F)

72 69.4 34.2 6.53 66.2 33.2 7.05 62.9 32.1 7.60 59.5 30.9 8.19

67 62.0 43.7 6.33 58.8 42.4 6.82 55.1 41.1 7.37 52.0 40.0 7.94

62 55.0 52.4 6.14 51.8 51.0 6.62 48.7 48.7 7.17 45.8 45.8 7.77

72 70.5 35.8 6.70 67.3 34.8 7.22 63.9 33.7 7.78 60.5 32.6 8.36

67 63.1 46.7 6.50 59.5 45.3 7.00 56.0 44.0 7.54 52.8 42.8 8.12

62 56.3 56.1 6.32 53.6 53.5 6.83 51.0 50.9 7.39 48.5 48.4 7.98

72 71.3 37.4 6.88 68.1 36.3 7.39 64.5 35.3 7.95 60.8 34.1 8.53

67 63.9 49.5 6.67 60.2 48.2 7.17 56.7 46.9 7.71 53.4 45.6 8.29

62 58.2 58.1 6.52 55.6 55.6 7.03 53.0 52.8 7.59 50.4 50.3 8.18

sensible capacity (Btuh x 1000)

Cfm BF

1750 0.03

2000 0.04

2250 0.05

BF — Bypass Factor

Ewb — Entering Wet-Bulb

SHC — Sensible Heat Capacity (1000 Btuh)

NOTES:

1. Ratings are net; they account for the effects of the indoor-fan motor

power and heat.

2. Direct interpolation is permissible. Do not extrapolate.

3. The following formulas may be used:

t=t –

ldb edb

85 95 105 115

Total

System

kW

1.10 x cfm

Outdoor Coil Entering-Air Temperature (F)

Capacity

(Btuh x 1000)

Total

System

kW

t = Wet-bulb temperature corresponding to enthalpy of air

lwb

h=h –

lwb ewb

Where: h = Enthalpy of air entering indoor coil

4. The SHC is based on 80 F edb temperature of air entering indoor

coil.

Below 80 F edb, subtract (corr factor x cfm) from SHC.

Above 80 F edb, add (corr factor x cfm) to SHC.

Correction Factor = 1.10 x (1 – BF) x (edb – 80).

Capacity

(Btuh x 1000)

leaving indoor coil (h )

total capacity (Btuh x 1000)

ewb

Total

System

kW

4.5 x cfm

lwb

Capacity

(Btuh x 1000)

Total

System

kW

16

Page 17

DRY COIL AIR DELIVERY* — HORIZONTAL DISCHARGE

(Deduct 10% for 208 v)

UNIT

SIZE

588A

018

024,

030

036

042

048

060

*Air delivery values are based on operating voltage of 230 v or 460 v, dry coil, without filter. De-

duct wet coil and filter pressure drops to obtain external static pressure available for ducting.

NOTES:

1. Do not operate the unit at a cooling airflow that is less than 350 cfm for each 12,000 Btuh of

rated cooling capacity. Evaporator coil frosting may occur at airflows below this point.

2. Dashes indicate portions of table that are beyond the blower motor capacity or are not

recommended.

MOTOR

SPEED

Low

High

Low

Med

High

Low

Med

High

Low

High

Low

High

Low

Med

High

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Watts 230 225 220 210 195 170 —————

Cfm760745725695640540—————

Watts ————270235200————

Cfm————850700450————

Watts 275 275 273 269 260 257 249 — — — —

Cfm 857 835 802 782 745 717 663 — — — —

Watts 371 368 360 349 345 326 319 304 293 — —

Cfm 1079 1063 1027 996 978 919 865 783 726 — —

Watts 514 493 476 460 443 425 401 378 344 — —

Cfm 1409 1383 1324 1282 1223 1156 1068 984 857 — —

Watts 473 447 427 418 395 367 346 337 323 — —

Cfm 1253 1253 1172 1130 1047 946 865 829 768 — —

Watts 519 500 478 459 439 410 377 357 340 — —

Cfm 1414 1366 1287 1234 1162 1074 920 829 743 — —

Watts 667 634 609 593 564 541 506 469 436 422 —

Cfm 1734 1639 1563 1461 1370 1292 1157 960 829 743 —

Watts 678 635 604 580 550 520 493 455 430 — —

Cfm 1540 1515 1475 1430 1375 1280 1225 1128 1020 — —

Watts — 820 785 750 700 680 649 612 570 — —

Cfm — 1825 1750 1685 1610 1525 1485 1335 1215 — —

Watts — — 854 786 744 706 641 606 557 511 —

Cfm — — 2026 1905 1830 1752 1603 1513 1367 1228 —

Watts — — — 905 846 824 804 748 683 637 —

Cfm — — — 2025 1905 1830 1752 1603 1398 1228 —

Watts 1000 991 970 925 904 875 849 830 819 — —

Cfm 2125 2110 2085 2046 2009 1960 1900 1845 1775 — —

Watts 1355 1315 1265 1212 1158 1103 987 925 880 — —

Cfm 2480 2440 2388 2336 2266 2198 2050 1968 1890 — —

Watts — — 1435 1375 1310 1265 1175 1108 1010 915 —

Cfm — — 2509 2450 2380 2310 2235 2160 2083 1888

230 AND 460 VOLT HORIZONTAL DISCHARGE

External Static Pressure (in. wg)

17

Page 18

DRY COIL AIR DELIVERY* — VERTICAL DISCHARGE

(Deduct 10% for 208 v)

UNIT

SIZE

588A

018

024,

030

036

042

048

060

*Air delivery values are based on operating voltage of 230 v or 460 v, dry coil, without filter. De-

duct wet coil and filter pressure drops to obtain external static pressure available for ducting.

NOTES:

1. Do not operate the unit at a cooling airflow that is less than 350 cfm for each 12,000 Btuh of

rated cooling capacity. Evaporator coil frosting may occur at airflows below this point.

2. Dashes indicate portions of table that are beyond the blower motor capacity or are not

recommended.

MOTOR

SPEED

Low

High

Low

Med

High

Low

Med

High

Low

High

Low

High

Low

Med

High

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Watts — 295 251 223 201 176 149 124 — — —

Cfm — 821 817 753 665 536 343 164 — — —

Watts 401 376 346 322 294 272 250 229 219 — —

Cfm 1334 1253 1128 996 816 658 461 246 167 — —

Watts — 285 284 282 278 274 270 261 251 244 230

Cfm — 798 761 727 682 634 581 525 450 371 304

Watts — 378 371 368 362 357 343 332 315 301 283

Cfm — 1011 982 948 906 858 771 703 597 492 387

Watts — 520 511 487 472 451 431 411 385 362 341

Cfm — 1342 1289 1237 1181 1106 1007 892 745 610 471

Watts — 460 439 423 898 379 349 322 297 270 246

Cfm — 1191 1136 1081 1005 907 795 687 579 471 349

Watts — 511 492 470 450 420 392 364 332 308 275

Cfm — 1316 1244 1178 1104 1005 891 784 657 535 389

Watts — 655 631 603 584 552 522 492 459 433 398

Cfm — 1541 1458 1367 1292 1178 1053 920 806 662 509

Watts — 637 612 587 560 536 493 455 — — —

Cfm — 1500 1450 1405 1350 1290 1200 1105 — — —

Watts — 790 750 700 699 639 608 574 547 — —

Cfm — 1750 1625 1604 1509 1421 1323 1221 1094 — —

Watts — 847 784 746 708 646 609 563 516 — —

Cfm — 1995 1901 1822 1730 1580 1477 1319 1178 — —

Watts — — 909 852 820 801 751 687 639 — —

Cfm — — 2018 1896 1814 1729 1582 1380 1220 — —

Watts — 970 952 928 905 880 847 804 760 — —

Cfm — 2075 2054 2024 1994 1945 1890 1830 1762 — —

Watts — — 1291 1247 1195 1076 1025 970 921 833 810

Cfm — — 2395 2348 2291 2164 2099 2022 1950 1827 1804

Watts — 1490 1400 1312 1270 1219 1161 1104 1045 985 930

Cfm — 2530 2475 2420 2355 2289 2223 2150 2079 2008 1932

230 AND 460 VOLT VERTICAL DISCHARGE

External Static Pressure (in. wg)

18

Page 19

WET COIL PRESSURE DROP

UNIT SIZE

588A

018

024

030

036

042

048

060

AIRFLOW

(cfm)

600 0.069

700 0.082

800 0.102

900 0.116

600 0.039

700 0.058

800 0.075

900 0.088

900 0.088

1000 0.095

1200 0.123

1000 0.068

1200 0.088

1400 0.108

1600 0.123

1000 0.048

1200 0.069

1400 0.088

1600 0.102

1400 0.068

1600 0.075

1800 0.088

1700 0.082

1900 0.095

2100 0.108

2300 0.123

PRESSURE DROP

(in. wg)

FILTER PRESSURE DROP (in. wg)

UNIT SIZE

588A

018, 024 20 x 20 0.05 0.07 0.08 0.10 0.12 0.13 — ————————————

030, 036 20x24————0.09 0.10 0.11 0.13 0.14 0.15 0.16 ————————

042 24x24—————— — —0.110.12 0.14 0.15 ———————

048, 060 24x30—————— — — —0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.16 0.17 0.18

FILTER

SIZE (in.)

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300

CFM

19

Page 20

ELECTRICAL DATA

UNIT

588A

018

024 12.4 61 0.7 2.0 18.2 30 12 80

030 14.4 82 1.4 2.0 21.8 30 10 100

036 18.0 96 1.4 2.8 26.7 40 10 90

042 20.4 104 1.4 4.0 30.9 50 8 100

048 26.4 129 2.1 5.0 40.1 60 6 100

060 32.1 169 2.1 6.8 49.0 60 6 100

030

036 11.7 75 1.4 2.8 18.8 30 12 65

042 14.0 91 1.4 4.0 22.9 35 10 85

048 15.0 99 2.1 5.0 25.9 40 10 75

060 19.3 123 2.1 6.8 33.0 50 8 90

036

042 6.4 42 0.8 2.0 10.8 15 14 100

048 8.2 50 1.1 2.3 13.7 20 14 100

060 10.0 62 1.1 3.2 16.8 25 12 100

AWG — American Wire Gage

CSA — Canadian Standards Association

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection (fuses or HACR-type

NEC — National Electrical Code

RLA — Rated Load Amps

*Fuse or HACR breaker.

†Minimum wire size is based on 60 C copper wire. If other than 60 C is

used, determine size from NEC. Voltagedrop of wire must be less than

2% of rated voltage.

NOTES:

1. In compliance with NEC requirements for multimotor and combination

load equipment (refer to NEC Articles 430 and 440), the overcurrent

protective device for the unit shall be fuse or HACR breaker.The CSA

units may be fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is

greater than 2%.

of voltage imbalance.

% Voltage Imbalance

V-PH-HZ

208/230-1-60 187 253

208/230-3-60 187 253

460-3-60 414 506

LEGEND

circuit breaker)

Use the following formula to determine the percent

= 100 x

max voltage deviation from average voltage

VOLTAGE

RANGE

Min Max RLA LRA FLA MCA MOCP*

average voltage

COMPRESSOR

7.6 45 0.7 1.8 12.0 15 14 75

9.4 66 1.4 2.0 15.5 25 12 80

5.6 40 0.8 1.4 9.2 10 14 100

COND.

FAN

MOTOR

INDOOR

FAN

FLA

Example: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 – 452=5v

(BC) 464 – 457=7v

(AC) 457 – 455=2v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than

2%, contact your local electric utility company immediately.

POWER SUPPLY

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

= 1.53%

AWG60C

MIN WIRE

SIZE

452 + 464 + 455

1371

=

3

= 457

7

457

3

MAX WIRE

LENGTH

(ft)

20

Page 21

OPERATING SEQUENCE

HEATING

On a call for heating, terminal ‘‘W’’ of the thermostat is energized, starting the induced-draft motor. When the hall-effect

sensor on the induced-draft motor senses that it has reached

the required speed, the burner sequence begins. This sequence

is performed by the integrated gas control board (IGC). The

indoor-fan motor is energized 45 seconds after flame is established. When the thermostat is satisfied and ‘‘W’’ is deenergized, the indoor-fan motor stops after a 45-second time-off

delay.

COOLING

With the room thermostat SYSTEM switch in the COOL position

and the FAN switch in theAUTO. position, the cooling sequence

of operation is as follows:

When the room temperature rises to a point that is slightly

above the cooling control setting of the thermostat, the thermostat completes the circuit between thermostat terminal R to terminals Y and G. These completed circuits through the

thermostat connect contactor coil (C) (through unit wire Y) and

blower relay coil (BR) (through unit wire G) across the 24-v secondary of transformer (TRAN).

The normally-open contacts of energized contactor (C) close

and complete the circuit through compressor motor (COMP) to

condenser (outdoor) fan motor (OFM). Both motors start

instantly.

The set of normally-open contacts of energized relay BR close

and complete the circuit through evaporator blower (indoor) fan

motor (IFM). The blower motor starts instantly.

NOTE: Once the compressor has started and then has stopped,

it should not be started again until 5 minutes have elapsed.

The cooling cycle remains ‘‘on’’ until the room temperature

drops to point that is slightly below the cooling control setting of

the room thermostat. At this point, the thermostat ‘‘breaks’’ the

circuit between thermostat terminal R to terminals Y and G.

These open circuits deenergize contactor coil C and relay coil

BR. The condenser and compressor motors stop. After a

30-second delay, the blower motor stops. The unit is in a

‘‘standby’’ condition, waiting for the next ‘‘call for cooling’’ from

the room thermostat.

21

Page 22

TYPICAL FIELD WIRING

NOTES:

1. If any of the original wire furnished must be replaced, it must be replaced with type 90 C wire or its equivalent.

2. Thermostat: HH07AT174, HH01AD040, HH01AD046, HH01PC184,

HH01PC185, HH07AT196 Subbase: HH93AZ040, HH93AZ207,

HH93AZ176

3. Use copper conductors only.

Unit 588A Sizes 018-060; 208/230-1-60

LEGEND

AWG — American Wire Gage

BR — Blower Relay

C—Contactor

CAP — Capacitor

CH — Crankcase Heater

COMP — Compressor Motor

CR — Combustion Relay

EQUIP — Equipment

FL — Fuse Link

FS — Flame Sensor

FU — Fuse

GND — Ground

GVR — Gas Valve Relay

HS — Hall Effect Sensor

HV TRAN — High-Voltage Transformer

I—Ignitor

IDM — Induced-Draft Motor

IFM — Indoor-Fan Motor

IGC — Integrated Gas Control

IP — Internal Protector

LS — Limit Switch

MGV — Main Gas Valve

22

NEC — National Electrical Code

OFM — Outdoor-Fan Motor

PWR — Power

QT — Quadruple Terminal

RS — Rollout Switch

TRAN — Transformer

Field Splice

Terminal (Marked)

Terminal (Unmarked)

Splice

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory or Optional Wiring

To Indicate Common Potential

Only, Not to Represent Wiring

Page 23

TYPICAL FIELD WIRING (cont)

NOTES:

1. If any of the original wire furnished must be replaced, it must be replaced with type 90 C wire or its equivalent.

2. Thermostat: HH07AT174, HH01AD040, HH01AD046, HH01PC184,

HH01PC185, HH07AT196 Subbase: HH93AZ040, HH93AZ207,

HH93AZ176

3. Use copper conductors only.

Unit 588A Sizes 030-060; 208/230-3-60

LEGEND

AWG — American Wire Gage

BR — Blower Relay

C—Contactor

CAP — Capacitor

CH — Crankcase Heater

COMP — Compressor Motor

CR — Combustion Relay

EQUIP — Equipment

FL — Fuse Link

FS — Flame Sensor

FU — Fuse

GND — Ground

GVR — Gas Valve Relay

HS — Hall Effect Sensor

HV TRAN — High-Voltage Transformer

I—Ignitor

IDM — Induced-Draft Motor

IFM — Indoor-Fan Motor

IGC — Integrated Gas Control

IP — Internal Protector

LS — Limit Switch

MGV — Main Gas Valve

23

NEC — National Electrical Code

OFM — Outdoor-Fan Motor

PWR — Power

QT — Quadruple Terminal

RS — Rollout Switch

TRAN — Transformer

Field Splice

Terminal (Marked)

Terminal (Unmarked)

Splice

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory or Optional Wiring

To Indicate Common Potential

Only, Not to Represent Wiring

Page 24

TYPICAL FIELD WIRING (cont)

NOTES:

1. If any of the original wire furnished must be replaced, it must be replaced with type 90 C wire or its equivalent.

2. Thermostat: HH07AT174, HH01AD040, HH01AD046, HH01PC184,

HH01PC185, HH07AT196 Subbase: HH93AZ040, HH93AZ207,

HH93AZ176

3. Use copper conductors only.

Unit 588A Sizes 036-060; 460-3-60

LEGEND

AWG — American Wire Gage

BR — Blower Relay

C—Contactor

CAP — Capacitor

CH — Crankcase Heater

COMP — Compressor Motor

CR — Combustion Relay

EQUIP — Equipment

FL — Fuse Link

FS — Flame Sensor

FU — Fuse

GND — Ground

GVR — Gas Valve Relay

HS — Hall Effect Sensor

HV TRAN — High-Voltage Transformer

I—Ignitor

IDM — Induced-Draft Motor

IFM — Indoor-Fan Motor

IGC — Integrated Gas Control

IP — Internal Protector

LS — Limit Switch

MGV — Main Gas Valve

24

NEC — National Electrical Code

OFM — Outdoor-Fan Motor

PWR — Power

QT — Quadruple Terminal

RS — Rollout Switch

TRAN — Transformer

Field Splice

Terminal (Marked)

Terminal (Unmarked)

Splice

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory or Optional Wiring

To Indicate Common Potential

Only, Not to Represent Wiring

Page 25

TYPICAL INSTALLATION

APPLICATION DATA

1. Condensate trap — A 2-in. condensate trap must be field

supplied.

2. Ductwork — Secure downflow discharge ductwork to roof

curb. For horizontal discharge applications, attach ductwork

to unit with flanges.

Units are equipped with factory-installed duct covers on both

the downflow and horizontal openings. Remove appropriate

duct panel covers for intended discharge application. Units

utilizing downflow option do not require duct panel cover

removal.

3. Thermostat — Toachieve simultaneous economizer cooling

and mechanical cooling, use of 2-stage cooling thermostat

is recommended for all units equipped with accessory

economizer.

4. Airflow — Units are draw-thru on cooling and blow-thru on

heating.

5. Maximum cooling airflow — To minimize the possibility of

condensate blow-off from evaporator, airflow through units

should not exceed 450 cfm/ton.

Minimum cooling airflow is 350 cfm/ton.

Minimum ambient operating temperature for standard units

is 40 F. With accessory low ambient temperature kit, units

can operate at temperatures down to 0° F.

25

Page 26

ENGINEERS’ SPECIFICATION GUIDE

GENERAL: Furnish and install single-package, outdoor heating

and cooling unit utilizing a rotary, reciprocating, or scroll hermetic compressor for cooling and gas combustion for heating

duty. Unit shall discharge supply air either in downflow or horizontal application as shown on the contract drawings. Unit shall

be capable of starting and running at 125 F ambient outdoor

temperature per maximum load criteria of ARI Standard 210/

240-89. Unit shall be provided with fan time-delay to prevent

cold air delivery before heat exchanger warms up. Unit shall be

provided with 30-second fan time-delay after the thermostat is

satisfied.

Nominal unit electrical characteristics shall be v,

ph, 60 Hz. The unit shall be capable of satisfactory operation within voltage limits of to v.All unit power wiring shall enter unit cabinet at a single location.

COOLING CAPACITY: Total cooling capacity of the unit shall be

Btuh or greater, and sensible capacity shall be

Btuh or greater at conditions of cfm evaporator entering

air of F dry bulb, F wet bulb, and condenser entering air of F dry bulb. Total design conditions shall be a

minimum of Btuh/Watt. The unit shall be capable of cooling operation down to 40 F.

HEATINGCAPACITY:Totalheating capacity of the unit shall be

Btuh or greater with a gas input of Btuh.

CABINET:The cabinet shall be constructed of heavy duty, phos-

phated, zinc-coated, prepainted steel capable of withstanding

500 hours in salt spray. Cabinet panels shall be easily removable for servicing. Unit shall be equipped with factory-supplied

condensate drain connection for evaporator coil. Indoor (evaporator) blower compartment interior cabinet surfaces shall be insulated with a minimum

1

⁄2-in. thick, flexible fiberglass

insulation, coated on the air side. Aluminum foil-faced fiberglass

insulation shall be used to meet ASHRAE standard no. 62P.

COMPRESSOR: Compressor shall be welded, fully hermetic

type with factory-installed vibration isolation. Compressor motor

shall be of the refrigerant-cooled type with line break thermal

and current overload protection. Rotary compressors shall be

standard on unit size 018. Reciprocating compressors shall be

standard on unit sizes 024-042. Scroll compressors shall be

standard on unit sizes 048 and 060.

CONDENSER SECTION: The condenser coils shall have

aluminum-plate fins mechanically bonded to seamless copper

tubes with all joints brazed. Condenser fan wheel shall be dynamically balanced. Fan-motor bearings shall be sealed and

permanently lubricated. Condenser-fan motor shall have inher-

ent automatic-reset thermal overload protection and shall be totally enclosed.

EVAPORATOR SECTION: Evaporator coils shall have aluminum plate fins mechanically bonded to seamless copper tubes

with all joints brazed. Evaporator fan shall be of the forwardcurved, centrifugal, direct-driven type. Fan wheel shall be made

from steel, be double-inlet type with forward curved blades with

corrosion resistant finish and be dynamically balanced. Fanmotor bearings shall be sealed and permanently lubricated.

Evaporator-fan motor shall have inherent automatic-reset thermal overload protection and shall be open drip-proof.

HEATING SECTION: The unit shall be equipped with an

induced-draft combustion system with energy saving direct

spark ignition system and redundant main gas valve. The heat

exchanger shall be constructed of aluminized steel for corrosion

resistance. Burners shall be of the inshot type constructed of

aluminum coated steel. An integrated gas control board shall

provide control of heating and simplify troubleshooting through

its built-in diagnostics. All gas piping and electric supply shall

enter the unit cabinet at a single location.

REFRIGERANT SYSTEM: Refrigerant system shall include a

fixed orifice metering device.

CONTROLS: Unit shall be complete with self-contained control

system. Unit staging shall be minimum one-cool, one-heat. In

the event of a power failure, unit control system shall sequence

the unit to restart. Thermostat set points shall have adjustable

deadband between heat and cool. Compressors shall be provided with inherent internal line break safety feature, and also

overcurrent and overtemperature protection.

AGENCY CERTIFICATIONSAND STANDARDS: The unit shall

be UL listed and CSA certified for safety requirements. All wiring

shall be in accordance with NEC. The unit shall be rated in accordance with ARI Standards 210/240-89 and 270-84. Insulation and adhesive shall meet NFPA 90A requirements for flame

spread and smoke generation.

OPTIONS: Factory-installed options shall include: base rail and

downflow application.

ACCESSORIES: Field-installed accessories shall include: flat

roof curb (8, 11, or 14 in.), pitched roof curb, modulating economizer,2-position damper,thermostat and subbase, low-ambient

kit (Weatherprobe™ II device), natural-to-propane conversion

kit, manual outdoor-air damper, filter rack, flexible duct kit, highand low-pressure switches, ComprotecT kit, crankcase heater,

lifting brackets, and concentric diffuser box.

26

Page 27

Bryant

Air Conditioning

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Copyright 1995 Carrier Corporation

Printed in U.S.A. 8/94 CATALOG NO. BY-3258-803

Loading...

Loading...