Bryant 574DNWA24040AA, 574DNWA24060NA, 574DNWA24040NA, 574DNWA24060AA, 574DNWA30040AA Product Data

...

574D----A

LEGACYt 13 SEER

SINGLE--PACKAGED AIR CONDITIONER AND GAS FURNACE SYSTEM

WITH PURONR (R--410A) REFRIGERANT SINGLE AND THREE PHASE

2 TO 5 NOMINAL TONS (SIZES 24--60)

Product Data

Innovative Unit Base Design

On the inside a high --tech composite material will not rust and

incorporates a sloped drain pan which improves drainage and helps

inhibit mold, algae and bacterial growth. On the outside metal base

rails provide added stability as well as easier handling and rigging.

Convertible duct configuration

Unit is designed for use in either downflow or horizontal

applications. Each unit can be converted from horizontal to

downflow and includes horizontal duct covers. Downflow

operation is provided in the field to allow vertical ductwork

connections. The basepan seals on the bottom openings to ensure a

positive seal in the vertical airflow mode.

Efficient operation High--efficiency design offers SEER

(Seasonal Energy Efficiency Ratios) of up to 13.5 and AFUE

(Annual Fuel Utilization Efficiency) ratings as high as 80.4%.

Energy--saving, direct spark ignition saves gas by operating only

when the room thermostat calls for heating. Standard units are

furnished with natural gas controls. A low--cost field installed kit

for propane conversion is available for all units.

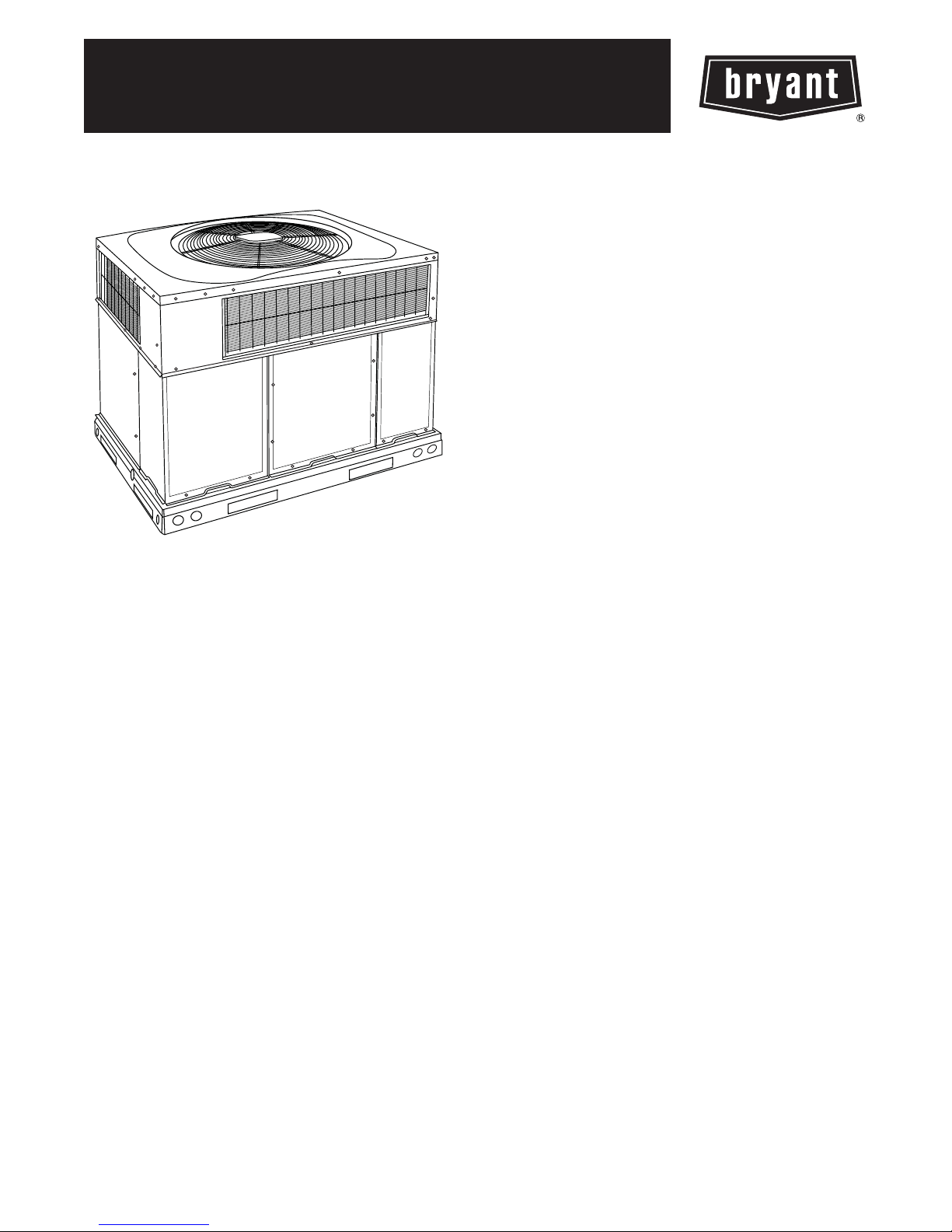

A09034

Fig. 1 -- Unit 574D----A

Single--Packaged Products with Energy-- Saving Features and

PuronR refrigerant.

S Up to 13.5 SEER

S Up to 80.4% AFUE

S Factory--Installed TXV

S ECM Motor--Standard

S Direct Spark Ignition

S Low Sound Levels

S Dehumidification Feature

FEATURES/BENEFITS

One--piece heating and cooling units with low sound levels, easy

installation, low maintenance, and dependable performance.

Puron Environmentally Sound Refrigerant is Bryant’s unique

refrigerant designed to help protect the environment. Puron is an

HFC refrigerant which does not contain chlorine that can harm the

ozone layer. Puron refrigerant is in service in millions of systems,

proving highly reliable, environmentally sound performance.

Easy Installation

Factory--assembled package is a compact, fully self--contained,

combination gas heating/electric cooling unit that is prewired,

pre--piped, and pre--charged for minimum installation expense.

These units are available in a variety of standard and optional

heating/ cooling size combinations with voltage options to meet

residential and light commercial requirements. Units are

lightweight and install easily on a rooftop or at ground level. The

high tech composite base eliminates rust problems associated with

ground level applications.

Low NOx units are designed for California installations. These

models meet the California maximum oxides of nitrogen (NOx)

emissions requirement of 40 nanograms/joule or less as shipped

from the factory and MUST be installed in California Air Quality

Management Districts and wherever a Low NOx rule exists.

Durable, dependable components Compressors are designed

for high efficiency. Each compressor is hermetically sealed against

contamination to help promote longer life and dependable

operation. Each compressor also has vibration isolation to provide

quieter operation. All compressors have internal high pressure and

overcurrent protection.

Monoport inshot burners produce precise air--to--gas mixture,

which provides for clean and efficient combustion. The large

monoport on the inshot (or injection type) burners seldom, if ever,

requires cleaning. All gas furnace components are accessible in one

compartment.

Turbo--tubulart heat exchangers are constructed of aluminized

steel for corrosion resistance and optimum heat transfer for

improved efficiency. The tubular design permits hot gases to make

multiple passes across the path of the supply air.

In addition, dimples located on the heat exchanger walls force the

hot gases to stay in close contact with the walls, improving heat

transfer.

ECM Motor is standard on all 574D-- -- A models.

Direct--drive PSC (Permanent Split Capacitor) condenser--fan

motors are designed to help reduce energy consumption and

provide for cooing operation down to 40_F(4.4_C) outdoor

temperature. Motormasterr II low ambient kit is available as a

field--installed accessory.

Thermostatic Expansion Valve -- A hard shutoff, balance port

TXV maintains a constant superheat at the evaporator exit (cooling

cycle) resulting in higher overall system efficiency.

Refrigerant system is designed to provide dependability. Liquid

filter driers are used to promote clean, unrestricted operation. Each

unit leaves the factory with a full refrigerant charge. Refrigerant

service connections make checking operating pressures easier.

1

High and Low Pressure Switches provide added reliability for the

compressor.

Indoor and Outdoor coils are computer--designed for optimum

heat transfer and efficiency. The indoor coil is fabricated from

copper tube and aluminum fins and is located inside the unit for

protection against damage. The outdoor coil is internally mounted

on the top tier of the unit. Copper fin coils and pre--coated fin coils

are available from the factory by special order. These coils are

recommended in applications where aluminum fins are likely to be

damaged due to corrosion. They are ideal for seacoast applications.

Low sound ratings ensure a quiet indoor and outdoor

environment with sound ratings as low as 75dBA.

Easy to service cabinets provide easy 3--panel accessibility to

serviceable components during maintenance and installation. The

basepan with integrated drain pan provides easy ground level

installation with a mounting pad. A nesting feature ensures a

positive basepan to roof curb seal when the unit is roof mounted. A

convenient 3/4--in. (19.05 mm) wide perimeter flange makes frame

mounting on a rooftop easy.

Horizontal metal duct covers are standard with insulation come

with the unit and cover the horizontal duct openings. These can be

left in place if the units are converted to downflow.

Integrated Gas Control (IGC) board provides safe and efficient

control of heating and simplifies trouble--shooting through its

built--in diagnostic function.

Cabinets are constructed of heavyduty, phosphated, zinc--coated

prepainted steel capable of withstanding 500 hours in salt spray.

Interior surfaces of the evaporator/heat exchanger compartment are

insulated with cleanable semi--rigid insulation board, which keeps

the conditioned air from being affected by the outdoor ambient

temperature and provides improved indoor air quality. (Conforms

to American Society of Heating, Refrigeration and Air

Conditioning Engineers 62.2.) The sloped drain pan minimizes

standing water in the drain. An external drain is provided.

574D-- --A

Features/Benefits 1---2..............................

Model Number Nomenclature 3.......................

AHRI Capacities 4..................................

P h y s i c a l Da t a 5 --- 6..................................

Options and Accessories 7...........................

Base Unit Dimensions 9---10.........................

Accessory Dimensions 11............................

Selection Procedure 12..............................

Pe r f o r m a n c e D a ta 1 3 --- 2 9............................

Typical Piping and Wiring 30..........................

Application Data 31.................................

Electrical Data 32...................................

TABLE OF CONTENTS

Typical Wiring Schematics 33---38.....................

Controls 39........................................

Guide Specifications 40---41..........................

2

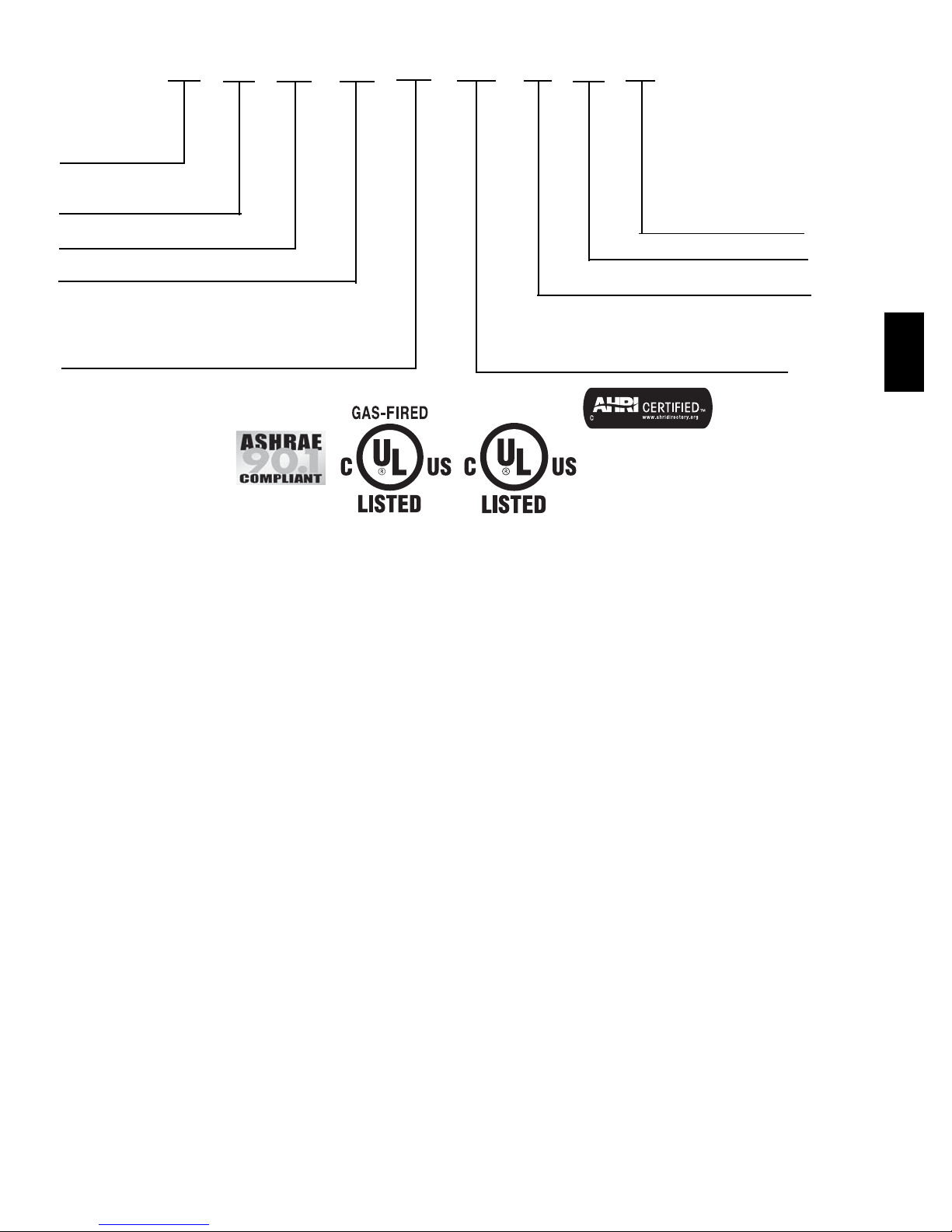

MODEL NUMBER NOMENCLATURE

574D

N

W

A

24

000

A

A

--- ---

Typ e o f Un i t

574D --- Single Packaged

Gas Heating/Electric

Cooling Unit

Electrical Supply

N --- 208/230--- 1--- 60

P --- 208/230--- 3--- 60

E --- 46 0 --- 3 --- 6 0

Fuel and Controls

W --- Na t u r a l G a s

Major Series

Nominal Cooling Capacity

24 --- 2.0 Tons

30 --- 2.5 Tons

36 --- 3.0 Tons

42 --- 3.5 Tons

48 --- 4.0 Tons

60 --- 5.0 Tons

Brand Name

A --- Co m m o n U n i t

Heat Input Size (Btuh)

40,000

60,000

90,000

115,000

130,000

Vari a ti ons

FE --- Economizer (3 Phase Only)

GP--- Tin plated i ndoor coil hairpins and Stai nless Steel

HX (Single Phase Only)

GS --- Stainless Steel HX

SE --- Economizer and Stainless Steel HX (3 Phase

Only)

TP --- Base unit wi th tin plated i ndoor coil hairpins

(Single Phase Onl y)

See Price Page f or full list of factory options.

Only used if ordering an option

Minor Series

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

574D-- --A

3

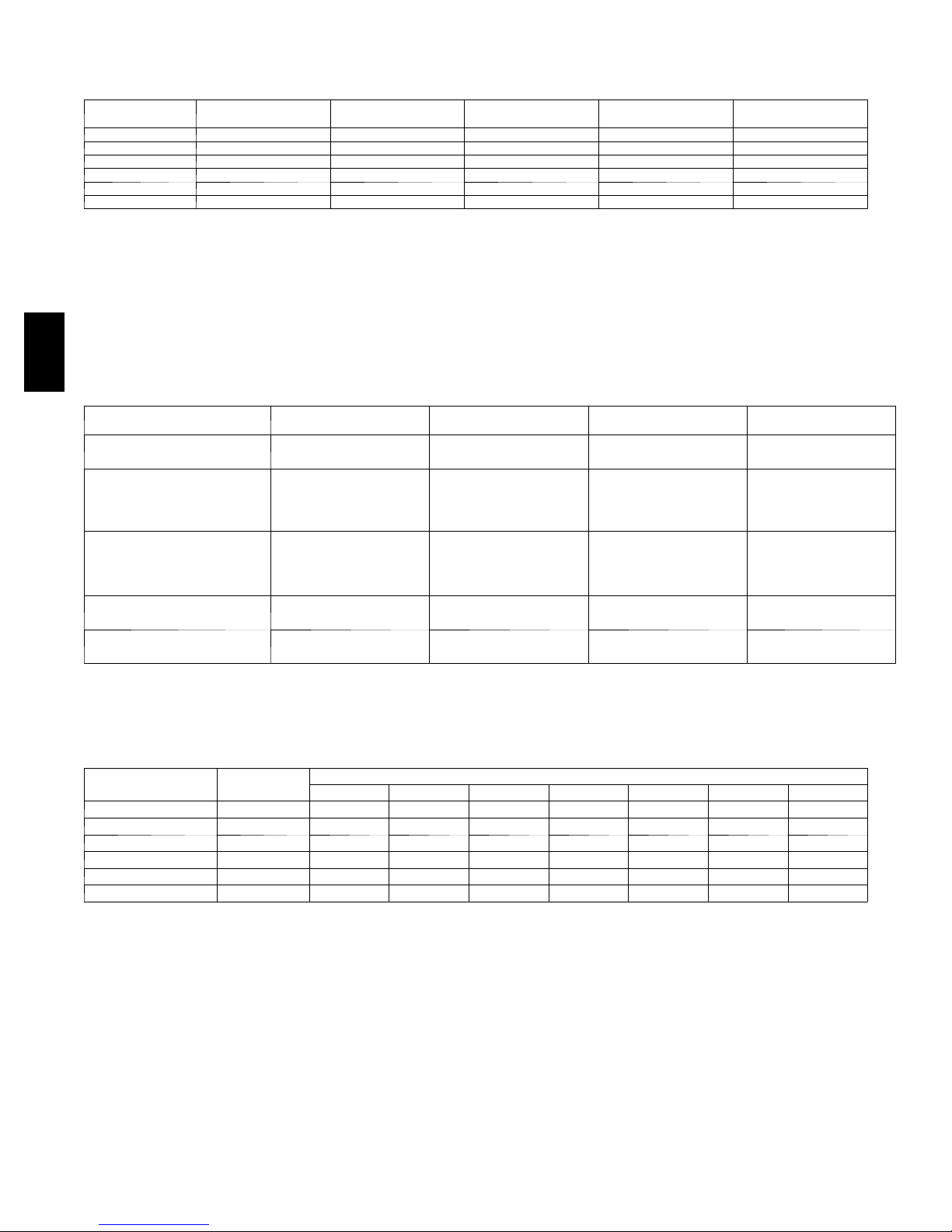

AHRI* CAPACITIES

Cooling Capacities and Efficiencies

UNIT 574D-- --A NOMINAL TONS STANDARD CFM

24 2 800 23,000 11.0 13.2

30 2-- 1/2 1000 28,400 11.2 13.5

36 3 1200 34,400 11.0 13.0

42 3-- 1/2 1400 40,500 11.2 13.2

48 4 1600 46,500 11.2 13.2

60 5 1750 57,000 11.0 13.4

LEGEND

d B --- Sound Levels (decibels)

db—Dry Bu lb

SEER—Seasonal Energy Efficiency Ratio

wb—Wet Bulb

COP---Coefficient of Performance

* Air Conditioning, Heating & Refrigeration Institute.

**At “ A” condition s - --80_F (26.7_C) indoor db/67_F ( 19.4_ C) indoor wb &

95_F(35_C) outdoor db.

{ Rated in accordance with U.S. Government DOE Department of Energy)

test procedures and/or ARI Stan dards 210/240.

574D-- --A

Gas Heating Capacities and Efficiencies

UNIT 574D-- --A HEATING INPUT (Btuh)

24040

30040

40,000 32,000

24060

30060

36060

60,000

42060

36090

42090

48090

90,000

60090

48115

60115

48130

60130

LEGEND

AFUE—Annual Fuel Utilization Efficiency

NOTE: Before purchasing this appliance, read importan t en ergy cost and efficiency information available from your retailer.

115,000 93,000

130,000 103,000

NET COOLING

CAPACITIES (Btuh)

Notes:

1. Ratings are net values, reflecting the effects of circulating fan heat.

Ratings are based on:

Cooling Standard: 80°F (26.7_C) db, 67°F wb (19.4_C ) i n d o o r e n t e r i n g --- a ir

temperature and 95°Fdb(35_C) outdoor entering ---air temperature.

2. Before purchasing this appliance, read important energy cost and efficiency information available from your retailer.

OUTPUT CAPACITY

(Btuh)

48,000

48,000

48,000

47,000

72,000

73,000

73,000

73,000

EER** SEER†

TEMPERATURE RISE

RANGE °F(°C)

30--60

(16.7--33.3)

25--55

(13.9--30.6)

35--65

(19.4--36.1)

30--60

(16.7--33.3)

35--65

(19.4--36.1)

AFUE (%)

80.0

80.0

80.0

80.0

78.5

79.3

80.4

80.4

80.4

80.3

78.9

A--Weighted Sound Power Level (dBA)

UNIT 574D-- --A

24 76 66.0 66.0 70.5 71.5 67.5 62.5 58.5

30 75 66.0 63.5 68.0 68.5 67.5 61.5 55.0

36 75 64.0 63.5 68.0 70.5 64.5 61.0 61.0

42 77 67.0 67.0 69.5 70.5 68.0 65.5 61.0

48 78 71.5 66.5 73.0 71.5 68.0 64.0 57.0

60 78 74.5 66.5 70.0 70.0 66.5 64.0 57.0

* Tested in accordance with AHRI Standard 270 (not listed in AHRI).

STANDARD

RATING dBA

125 250 500 1000 2000 4000 8000

TYPICAL OCTAVE BAND SPECTRUM (dBA without tone adjustment)

4

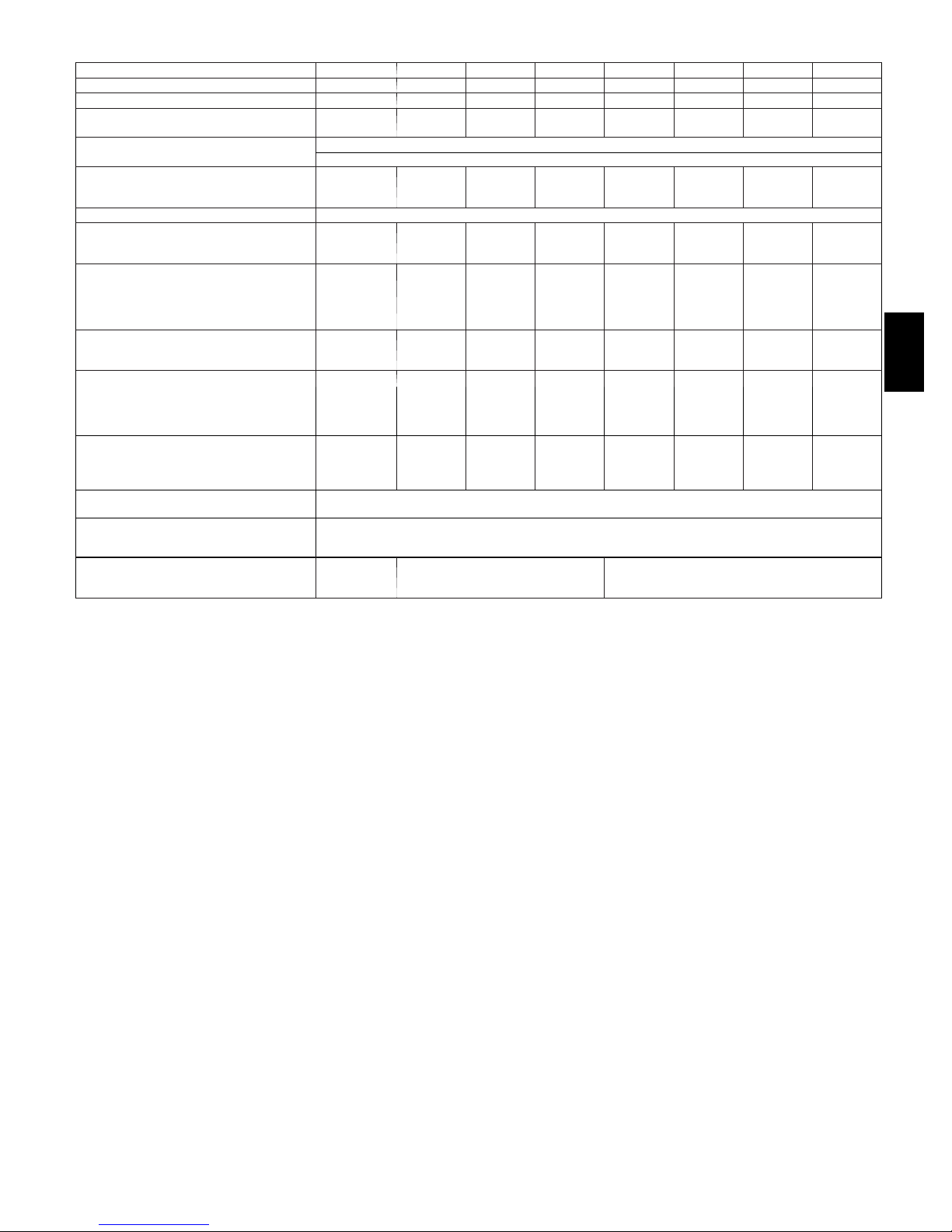

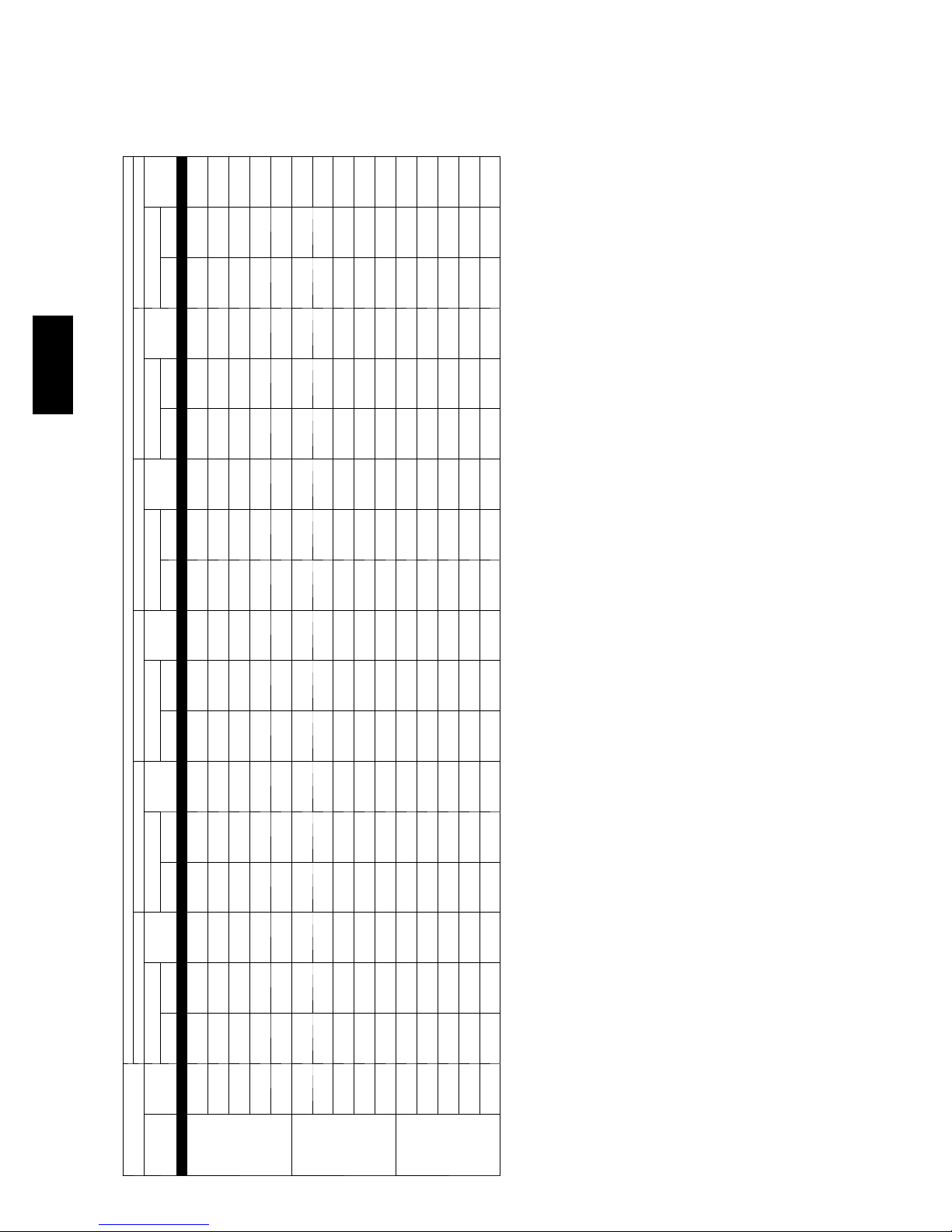

PHYSICAL DATA

UNIT SIZE 24040 24060 30040 30060 36060 36090 42060 42090

NOMINAL COOLING CAPACITY (ton) 2 2 2 --- 1 / 2 2 --- 1 / 2 3 3 3 --- 1 / 2 3 --- 1 / 2

NOMINAL HEATING INPUT (Btu/hr) 40,000 60,000 40,000 60,000 60,000 90,000 60,000 90,000

SHIPPING WEIGHT* * lb.

SHIPPING WEIGHT* * (kg)

COMPRESSORS

Quantity

REFRIGERANT (R -- -410A)

Quantity lb.

Quantity (kg)

REFRIGERANT METERING DEVICE TXV

OUTDOOR COIL

Rows...Fins/in.

Face Area ( sq ft)

OUTDOOR FAN

Nominal CFM

Diameter in.

Diameter (mm)

Motor Hp (Rpm)

INDOOR COIL

Rows...Fins/in.

Face Area ( sq ft)

INDOOR BLOWER

Nominal Cooling Airflow (Cfm)

Size in.

Size (mm.)

Motor HP (RPM)

FURNACE SECTION*

Burner Orifice No. (Qty...Drill Size)

Natural Gas Factory Installed

Propane Gas

HIGH--PRESSURE SWITCH

(psig) Cut-- out Reset (Auto)

LOSS-- OF--CHARGE / LOW--PRESSURE

SWITCH (Liquid Line) (psig) cut-- out Reset

(auto)

RETURN--- AIR FILTERS†}

Throwaway Size in.

(mm)

311

141

4.8

2.2

1..21

10.2

2800

24

609.6

1/5 (810)

2...17

3.7

800

10x10

254x254

1/2 (1050)

2...44

2...55

20x20x1

508x508x25

311

141

4.8

2.2

1...21

10.2

2800

24

609.6

1/5 (810)

2...17

3.7

800

10x10

254x254

1/2 (1050)

2...38

2...53

316

143

6.2

2.8

1...21

11.9

3000

24

609.6

1/5 (810)

3...17

3.7

1000

10x10

254x254

1/2 (1050)

2...44

2...55

20x24x1

508x610x25

316

143

6.2

2.8

1...21

11.9

3000

24

609.6

1/5 (810)

3...17

3.7

1000

10x10

254x254

1/2 (1050)

2...38

2...53

650 +/-- 15

420 +/-- 25

45 +/-- 10

Scroll

1

20 +/-- 5

326

148

6.4

2.9

1...21

15.4

3200

24

609.6

1/5 (810)

3...17

3.7

1200

11x10

279.4x254

3/4 (1000)

2...38

2...53

326

148

6.4

2.9

1...21

15.4

3200

24

609.6

1/5 (810)

3...17

3.7

1200

11x10

279.4x254

3/4 (1000)

3...38

3...53

610x762x25

24x30x1

420

191

6.1

2.7

1...21

13.6

3600

26

660.4

1/5 (810

3...17

4.7

1400

11x10

279.4x254

3/4 (1075)

2...38

2...53

420

191

6.1

2.7

1...21

13.6

3600

26

660.4

1/5 (810)

3...17

4.7

1400

11x10

279.4x254

3/4 (1075)

3...38

3...53

574D-- --A

5

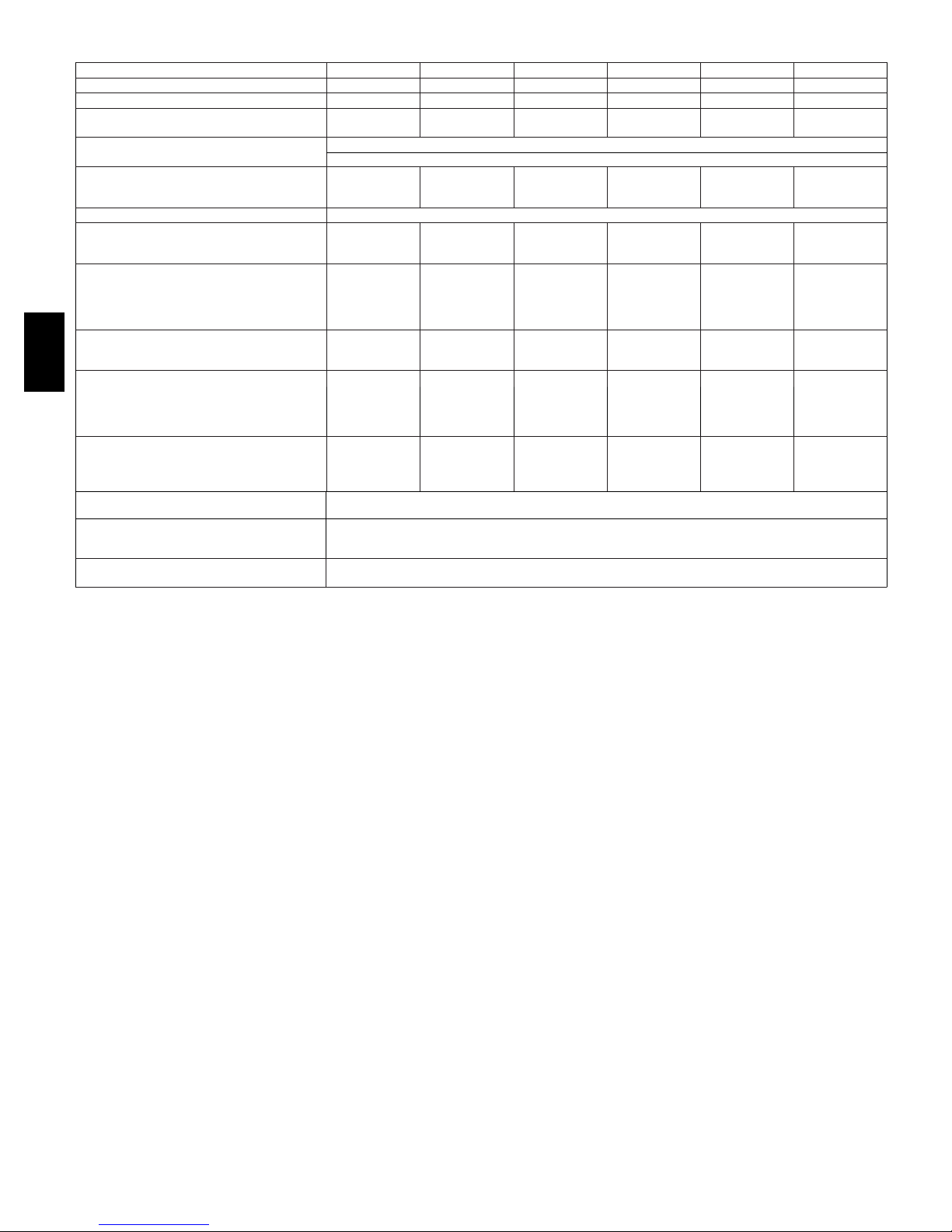

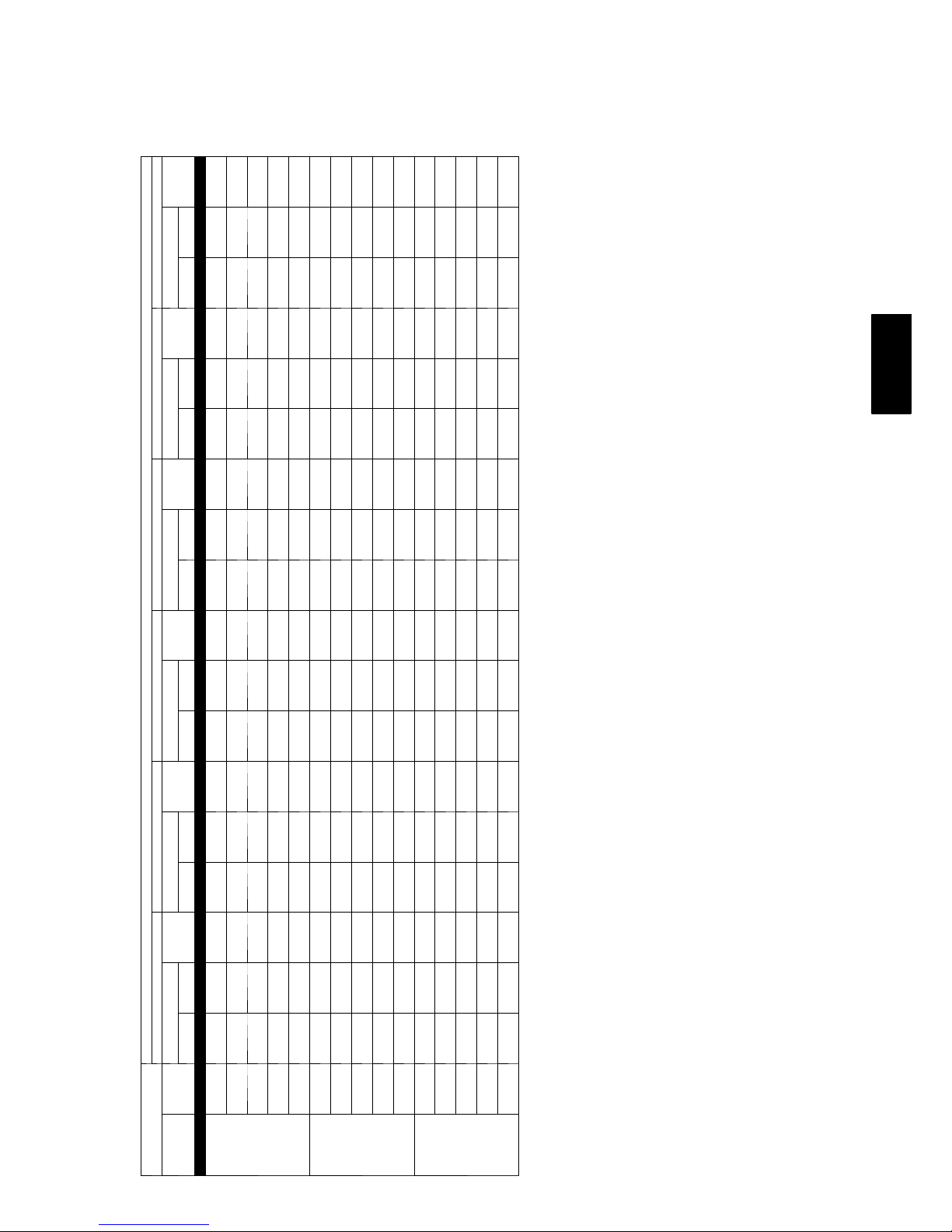

PHYSICAL DATA (CONT)

1600

1600

1600

1750

1750

UNIT SIZE 48090 48115 48130 60090 60115 60130

NOMINAL CAPACITY (ton) 4 4 4 5 5 5

NOMINAL HEATING INPUT (Btu/hr) 90,000 115,000 130,000 90,000 115,000 130,000

SHIPPING WEIGHT* * lb

SHIPPING WEIGHT* * kg

COMPRESSORS

Quantity

REFRIGERANT (R -- -410A)

Quantity lb

Quantity (kg.)

REFRIGERANT METERING DEVICE TXV

OUTDOOR COIL

Rows...Fins/in.

Face Area ( sq ft)

OUTDOOR FAN

Nominal Cfm

Diameter in.

Diameter (mm)

Motor Hp (Rpm)

INDOOR COIL

Rows...Fins/in.

Face Area ( sq ft)

INDOOR BLOWER

574D-- --A

Nominal Cooling Airflow (Cfm)

Size in.

Size (mm)

Motor HP (RPM)

FURNACE SECTION*

Burner Orifice No.

Natural Gas Qty...Drill Size (Factory Installed)

Propane Gas

HIGH--PRESSURE SWITCH

(psig) Cut-- out Reset (Auto)

LOSS-- OF--CHARGE / LOW--PRESSURE

SWITCH (Liquid Line) (psig) cut-- out Reset

(auto)

RETURN--AIR FILTERS Throwaway†} in.

(mm)

*Based on altitude of 0 to 2000 ft (0 ---610 m).

{ Required filter sizes shown are based on the larger of the AHRI (Air Conditioning, Heating and Refrigeration Institute) rated cooling airflow or the heating

airflow velocity of 300 ft/minute for throwaway type. Air filter pressure drop for non---standard filters must not exceed 0.08 IN. W.C.

} If using accessory filter rack refer to the filter rack installation instructions for correct filter sizes and quantity.

** For 460 volt units, a dd 14 lbs (6.35 kg) to the shipping weight.

428

194

6.4

2.9

1...21

15.5

4000

26

660.4

1/5 (810)

3...17

4.7

1600 1600 1600 1750 1750

11x10

279.4x254

1.0 (1075)

3...38

3...53

428

194

6.4

2.9

1...21

15.5

4000

26

660.4

1/5 (810)

3...17

4.7

11x10

279.4x254

1.0 (1075)

3...33

3...51

428

194

6.4

2.9

1...21

15.5

4000

26

660.4

1/5 (810)

3...17

4.7

11x10

279.4x254

1.0 (1075)

3...31

3...49

Scroll

1

650 +/-- 15

420 +/-- 25

20 +/-- 5

45 +/-- 10

24x36x1

610x914x25

450

204

10.0

4.5

2...21

15.5

3200

26

660.4

1/5 (810)

3...17

5.7

11x10

279.4x254

1.0 (1040)

3...38

3...53

450

204

10.0

4.5

2...21

15.5

3200

26

660.4

1/5 (810)

3...17

5.7

11x10

279.4x254

1.0 (1040)

3...33

3...51

450

204

10.0

4.5

2...21

15.5

3200

26

660.4

1/5 (810)

3...17

5.7

1750

11x10

279.4x254

1.0 (1040)

3...31

3...49

6

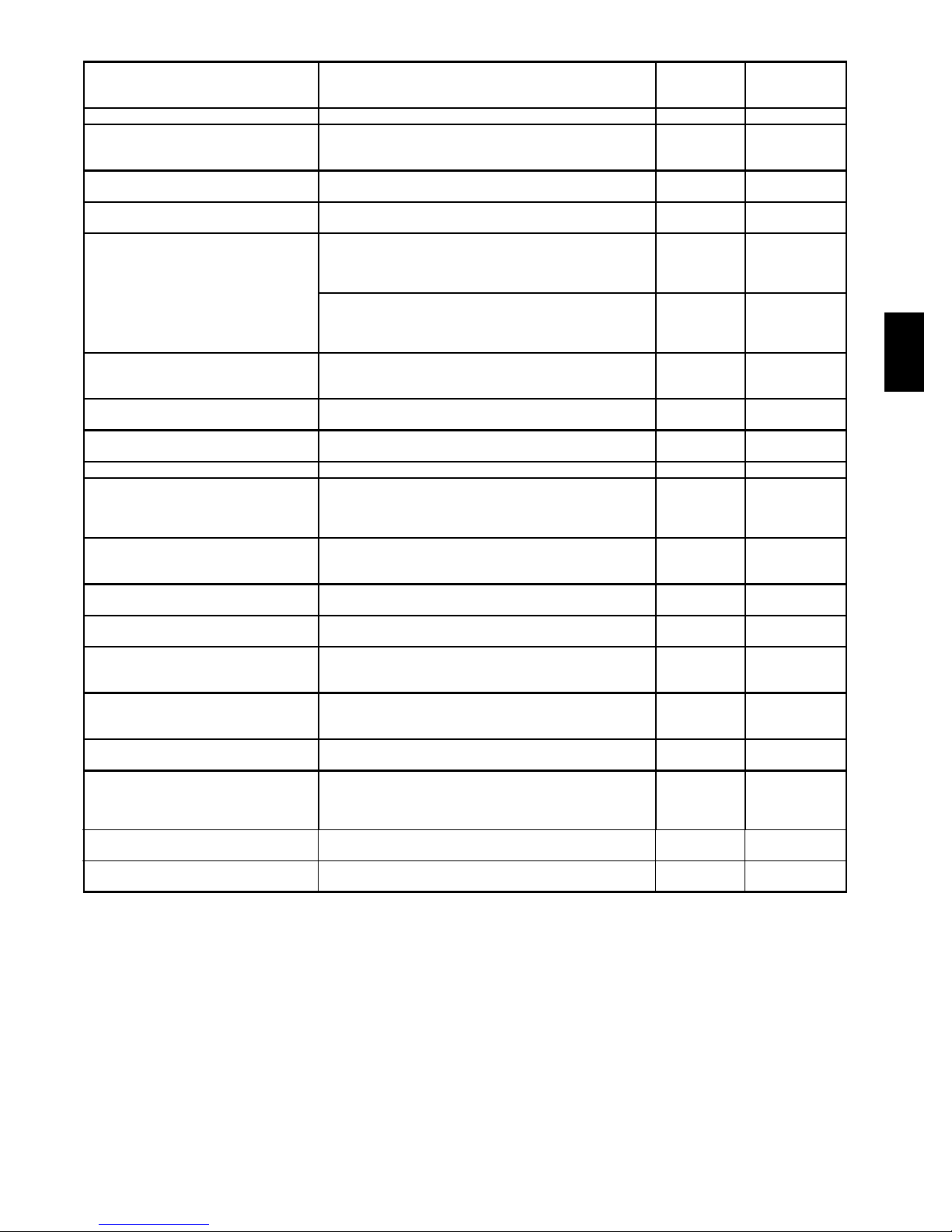

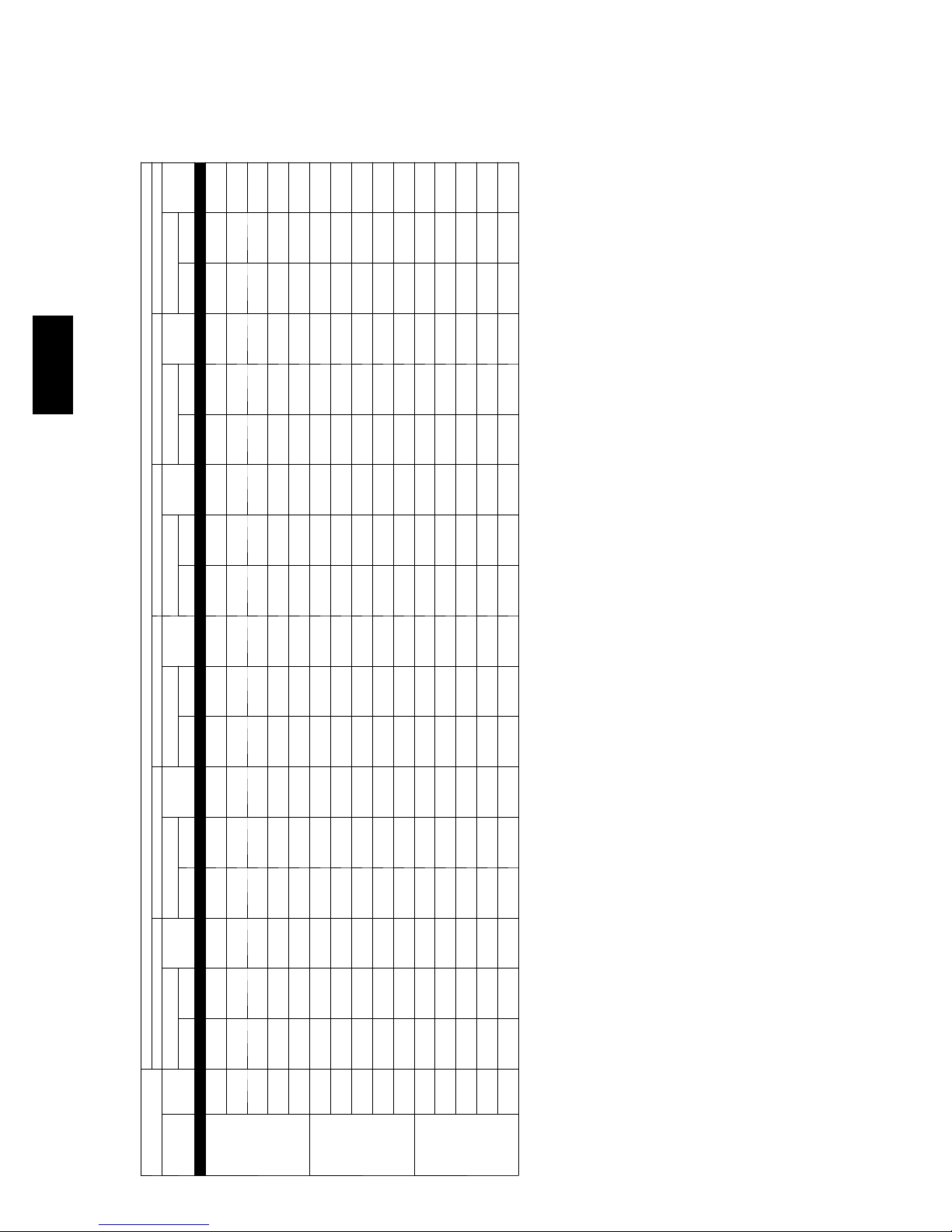

OPTIONS AND ACCESSORIES

FACTORY

ITEM DESCRIPTION

Coil Options Base unit with tin plated indoor coil hairpins X

Compressor Start Kit assists compressor start---up by

Compressor Start Kit

Corporate Thermostats

Crankcase Heater

Economizer

Filter Rack

Flat Roof Curbs

Flue Discharge Deflector

Heat Exchanger Stainless Steel Heat Exchanger X

High Altitude Propane Conversion Kit

Low Ambient Kit

Louver Metal Outdoor Coil Grilles

Manual Outside Air Damper

Natural to Propane Gas Conversion Kit

Propane to Natural Gas Conversion Kit

S q u a r e --- t o --- R o u n d D u c t T r a n s i t i o n K i t

Time Guard II

Curb Adapter

Gasket Kit

*Refer to Price Page for application detail.

providing additional starting torque on sing phase units

only.

Thermostats provide control for the system heating and

cooling functions.

Crankcase Heater provides anti--- floodback protection for

low--- load cooling applications.

Horizontal Economizer with solid state controls and barometric relief dampers includes filter racks and provide

outdoor air during cooling and reduce compressor operation.

Vertical Economizer with solid state controls and barometric relief dampers includes filter racks and provide

outdoor air during cooling and reduce compressor operation.

Filter Rack features easy installation, serviceability, and

high--- filtering performance for vertical applications.

Includes 1 --- in. (25 mm) filter.

F l a t R o o f C u r b s i n b o t h 1 1 --- i n ( 2 7 9 m m ) a n d 1 4 --- i n . ( 3 5 6

mm) sizes are available for roof mounted applications.

Directs flue gas exhaust 90 degrees upward from current

discharge.

High Altitude Propane Conversion Kit is for use at 2001 to

6000 ft. (611 ---1829 m) above sea level. Kit consists of

propane g as orifices that compensate for gas heat operation at high altitude.

Low Ambient Kit (Motormaster II Control) allows the use of

mechanical cooling down to outdoor temperatures as low

as 0° F (--- 18° C) when properly installed.

Louver Metal Outdoor Coil Grilles provides hail and

vandalism protection.

Manual Outside Air Damper includes hood and filter rack

with adjustable damper blade for up to 25% outdoor air.

Natural to Propane Gas Conversion Kit allows for conversion from natural gas to propane gas (0 --- 2000 ft) (0--- 610

m)

Propane to Natural Gas Conversion Kit allows for conversion from propane to natural gas for altitudes of 0--- 2000 ft

( 0 --- 6 1 0 m )

S q u a r e --- t o --- R o u n d D u c t T r a n s i t i o n K i t e n a b l e 2 4 --- 4 8 s i z e

units to be fitted to 14 in. (356 mm) round ductwork.

Automatically prevents the compressor from restarting for

at least 4 minutes and 45 seconds after shutdown of the

compressor. Not required when a corporate programmable thermostat is applied.

Adapter curb for new unit with base rail installed on existing curb

For field modified existing roof curb with new base rail

unit.

INSTALLED

OPTION

X X

FIELD

INSTALLED

ACCESSORY

X

X

X*

X

X

X

X

X

X

X

X

X

X

X

X

X

574D-- --A

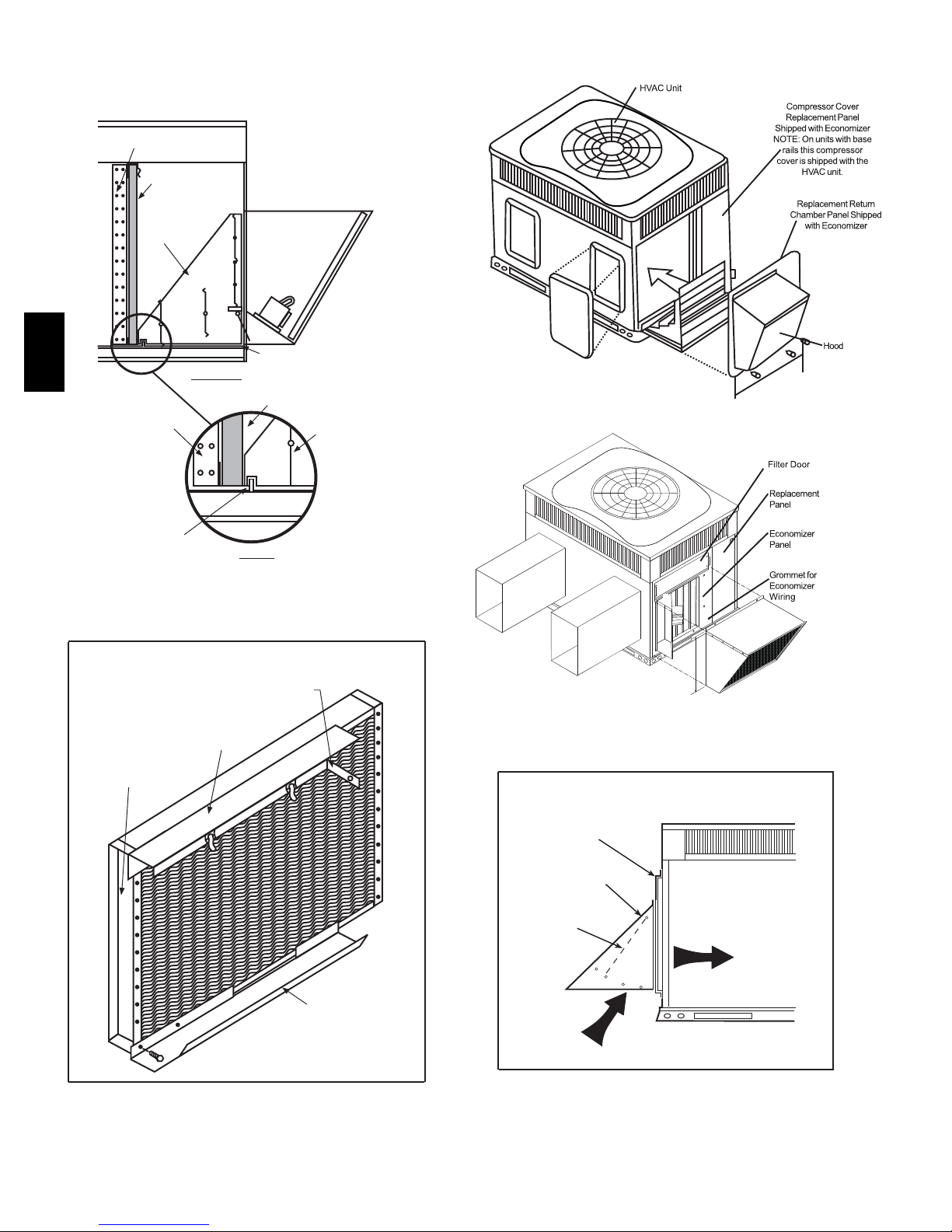

7

BASE

ECONOMIZER

COIL

FILTER

ECONOMIZER

CAULK BOTTOM CORNER

OF ECONOMIZER

574D-- --A

SIDE VIEW

COIL

ON EACH SIDE

FI LT ER

Vertical Economizer

ECONOMIZER

FLANGE

ON BASE

EV APORATOR

COIL

AIL

DET

FILTER RACK

BEND FLANGE AT 90° -SCREW TO

DIVIDER WITH 1-IN. (25 mm)

TOP FILTER RACK

SCREW

Horizontal Economizer

MANUAL OUTSIDE AIR DAMPER

REPLACEMENT

PANEL

MANUAL OUTSIDE

AIR HOOD

DAMPER

BLADE

BOTTOM FILTER

RACK

A09375

8

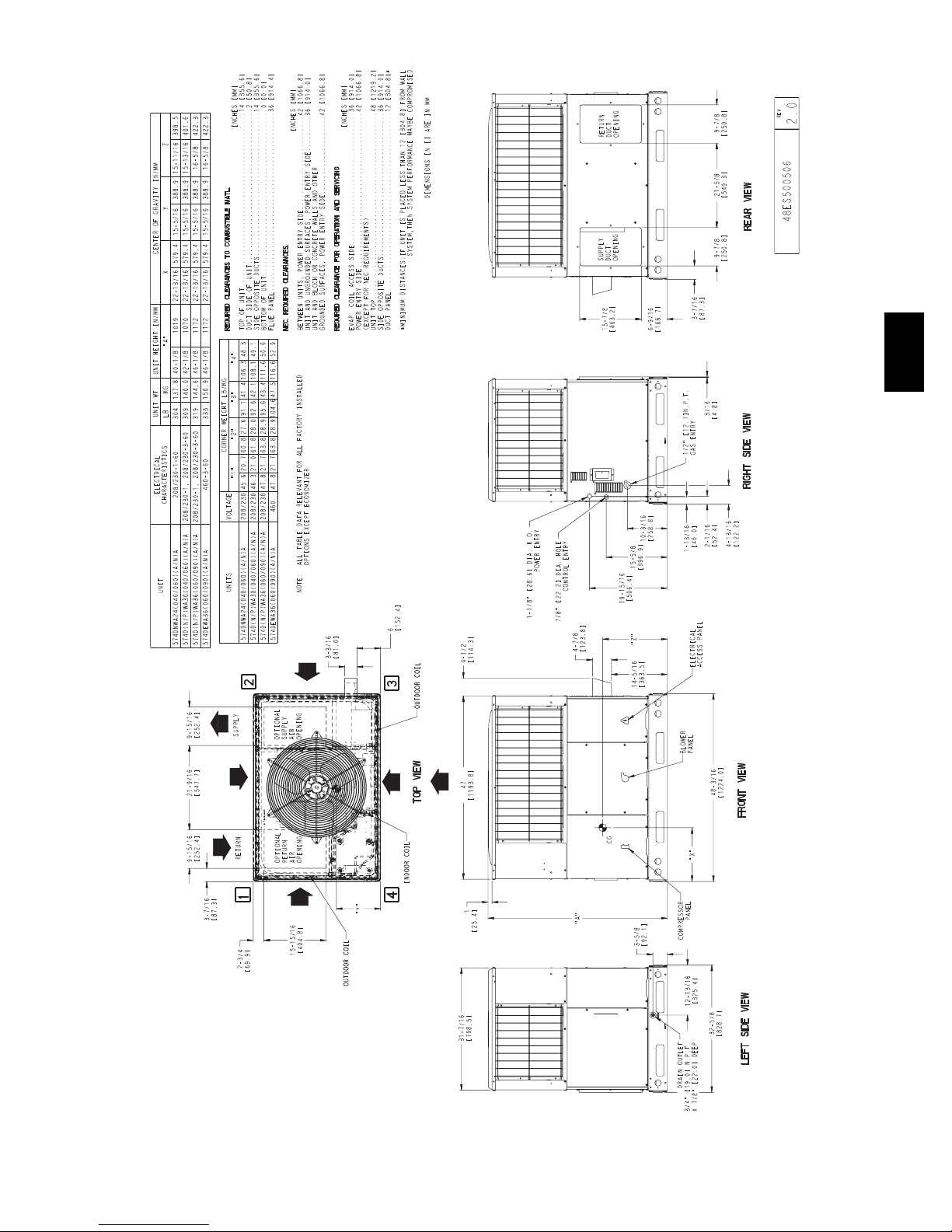

UNIT DIMENSIONS -- 574D----A24--36

574D-- --A

A09469

9

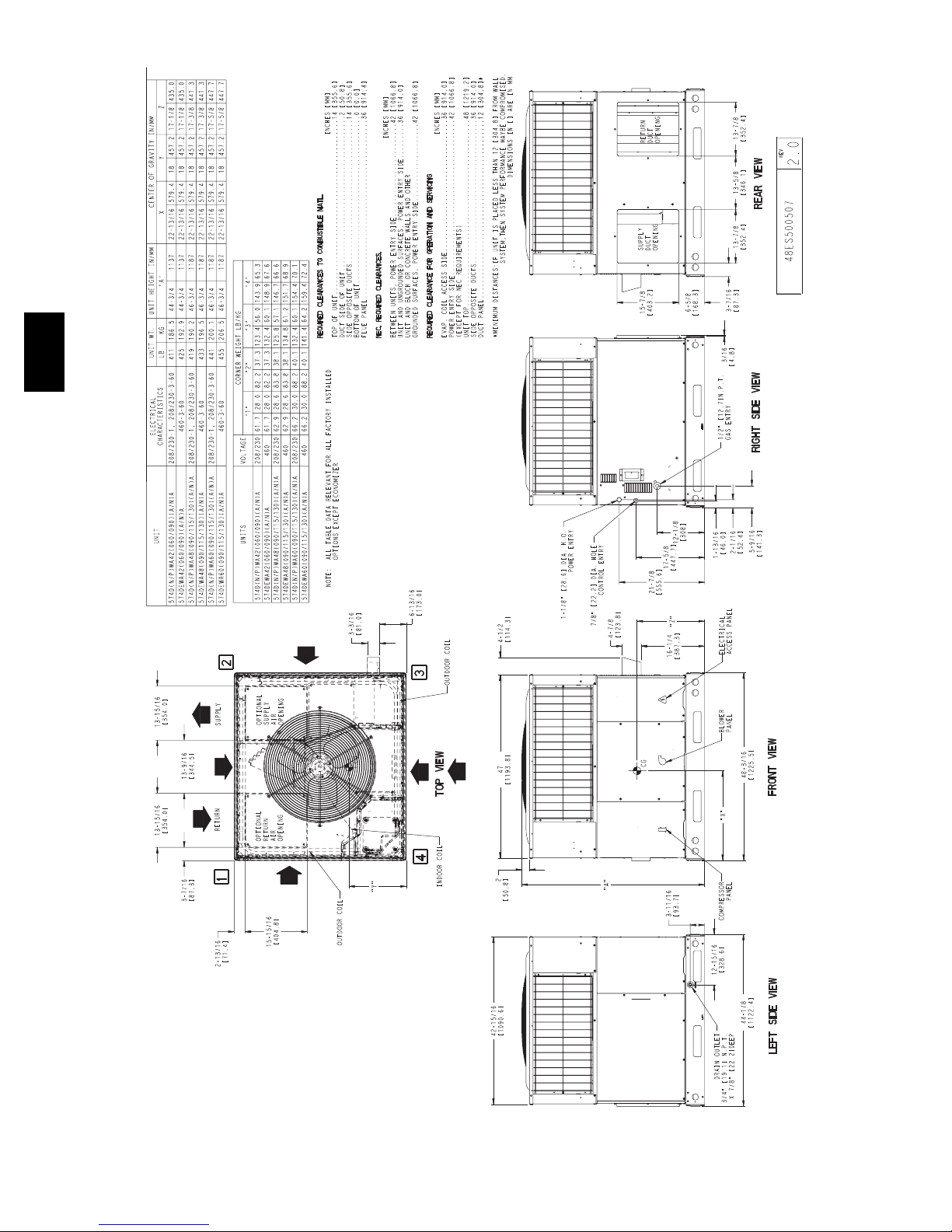

UNIT DIMENSIONS -- 574D----A42--60

574D-- --A

A09470

10

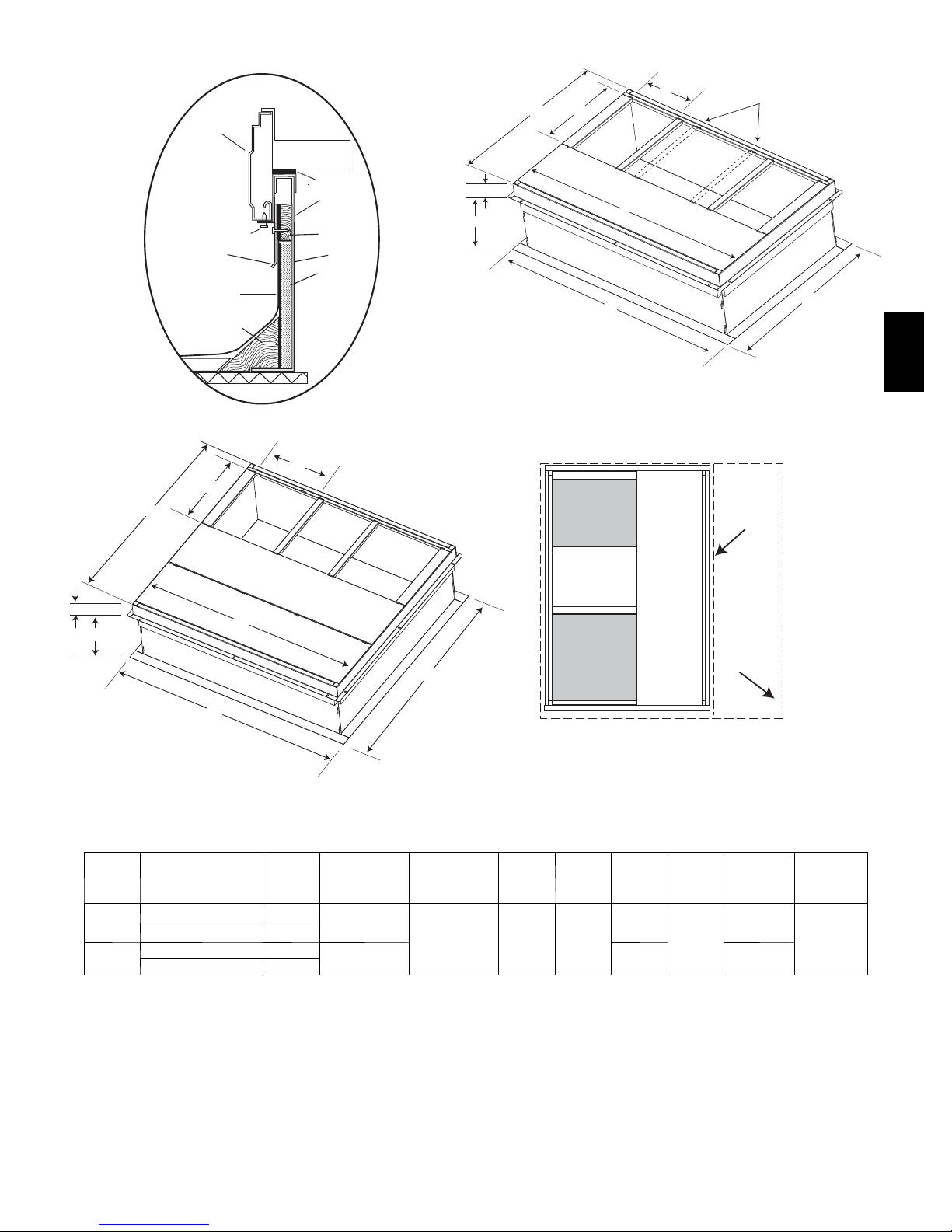

ACCESSORY DIMENSIONS

G

HVAC unit

base rails

Anchor screw

Flashing field

supplied

Roofing material

field supplied

Cant strip

field supplied

*Provided with roofcurb

HVAC unit

basepan

ROOF CURB DETAIL

B

C

Sealing

Gasket

Roofcurb

Wood nailer*

Roofcurb*

Insulation

(field supplied)

A09090

G

C

F

A

SMALL/COMMON CURB

SUPPLY

AIR

B

H

D

Dashed lines show cross support

location for large basepan units.

E

A09413

574D-- --A

SMALL

BASE

UNIT

A

F

RETURN

E

AIR

LARGE

BASE

UNIT

D

UNIT PLACEMENT ON

H

COMMON CURB

B (small /

common

base)

IN. (mm)*

10 (254)

14 (356)

A09415

B (large base)

IN. (mm)*

14 (356) 16 (406)

C

IN.

(mm)

LARGE CURB

UNIT

SIZE

Small

or

Large

Large

* Part Numbers CPRCURB010A00 and CPRCURB011A00 can be used on both small and large basepan un its. T he cross supports must be located based on

whether the unit is a small basepan or a large basepan.

NOTES:

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied, as required, to unit being installed.

3. Roof curb is made of 16-- gauge steel.

4. Attach ductwork to curb (flanges of duct rest on curb).

5. Insulated panels: 1--in. (25.4 mm) thick fiberglass 1 lb. density.

CATALOG

NUMBER

CPRFCURB010A00 11 (279)

CPRFCURB011A00 14 (356)

CPRFCURB012A00 11 (279)

CPRFCURB013A00 14 (356)

A

IN.

(mm)

SMALL OR LARGE BASE UNIT

D

IN.

(mm)

47.8

(1214)

E

IN.

(mm)

32.4

(822)

43.9

(1116)

F

IN.

(mm)

2.7 (69)

G

IN. (mm)HIN. (mm)

30.6 (778)

42.2 (1072)

A09094

46.1 (1170)

A09414

11

SELECTION PROCEDURE (WITH EXAMPLE)

1. Determine cooling and heating requirements at

design conditions:

Given:

Required Cooling Capacity (TC) 34,000 Btuh..........

Sensible Heat Capacity (SHC) 25,000 Btuh............

Required Heating Capacity 60,000 Btuh...............

Condenser Entering Air Temperature 95°F(35°C).......

Indoor--Air Temperature 80°F(26°C)edb 67°F(19°C) ewb

Evaporator Air Quantity 1200 CFM..................

External Static Pressure 0.30 in. W.C..................

Electrical Characteristics 230--1--60...................

2. Select uni t based on required cooling capacity.

Enter Net Cooling Capacities table at condenser entering

temperature of 95°F(35°C). Unit 036 at 1200 CFM and 67°F

(19°C) ewb (entering wet bulb) will provide a total capacity of

34,400 Btuh and a SHC of 25,900 Btuh. Calculate SHC correction,

if required, using Note 4 under Cooling Capacities tables.

574D-- --A

3. Select heating capacity of unit to provide design

condition requirement.

In the Heating Capacities and Efficiencies table, note that the unit

036090 will provide 72,000 Btuh with an input of 90,000 Btuh.

4. Determine fan speed and power requirements at

design conditions.

Before entering the air delivery tables, calculate the total static

pressure required. From the given example, the Wet Coil Pressure

Drop Table, and the Filter Pressure Drop Table:

External Static Pressure 0.30 in. W.C.

Filter 0.13 in. W.C.

Wet Coil Pressure Drop 0.10 in. W

Total Static Pressure 0.53 in. W.C

Enter the table for Dry Coil Air Delivery—Horizontal and

Downflow Discharge. At .53 in. W.C. ESP, the closest speed to

1200 CFM is Med--High (orange wire), which delivers 1316 CFM

at .6 in ESP.

.C

5. Select unit that corresponds to power source

available.

The Electrical Data Table shows that the unit is designed to operate

at 230--1--60.

12

KW

Sys

Tot a l

Capacity MBtuh

KW

Sys

Tot a l

574D-- --A

Capacity MBtuh

KW

Sys

Tot a l

Capacity MBtuh

CONDEN SER ENTER ING AIR TEMPERATURES _F(_C)

Tot a l

Tot a l

Tot a l

75 (23.9) 85 (29.4) 95 (35) 105 (40.6) 115 (46.1) 125 (51.7)

EWB

Capacity MBtuh

Capacity MBtuh

Capacity MBtuh

KW

Sys

KW

Sys

kW

Sys

Tot a l Sens Tot a l Sens Tot a l Sens To t a l Sens To t al Sens Tot a l Sens

22.74 22.74 1.66 21.26 21.26 1.85 19.77 19.77 2.06 18.28 18.28 2.29 16.77 16.77 2.54 15.24 15.24 2.80

23.94 20.55 1.66 22.18 19.57 1.86 20.42 18.59 2.07 18.67 17.59 2.30 16.93 16.57 2.54 15.24 15.24 2.80

24.48 17.00 1.67 22.68 16.12 1.86 20.88 15.23 2.07 19.08 14.35 2.30 17.27 13.46 2.54 15.45 12.56 2.81

26.34 17.55 1.67 24.42 16.65 1.86 22.49 15.76 2.07 20.57 14.86 2.30 18.64 13.97 2.55 16.70 13.07 2.82

28.95 14.51 1.67 26.85 13.70 1.87 24.76 12.88 2.08 22.66 12.07 2.31 20.56 11.25 2.56 18.45 10.43 2.83

23.78 23.78 1.68 22.21 22.21 1.87 20.64 20.64 2.08 19.06 19.06 2.31 17.46 17.46 2.56 15.85 15.85 2.82

24.57 22.03 1.68 22.75 20.99 1.87 20.94 19.93 2.08 19.15 18.83 2.31 17.46 17.46 2.56 15.85 15.85 2.82

25.10 18.06 1.68 23.23 17.14 1.88 21.36 16.21 2.09 19.49 15.29 2.32 17.62 14.37 2.56 15.74 13.44 2.82

27.00 18.66 1.69 25.00 17.73 1.88 23.00 16.80 2.09 21.01 15.87 2.32 19.01 14.94 2.57 17.00 14.00 2.83

29.65 15.23 1.69 27.48 14.39 1.89 25.30 13.54 2.10 23.13 12.71 2.33 20.96 11.86 2.58 18.77 11.01 2.84

24.67 24.67 1.70 23.02 23.02 1.89 21.37 21.37 2.10 19.71 19.71 2.33 18.05 18.05 2.58 16.36 16.36 2.84

25.09 23.40 1.70 23.23 22.27 1.89 21.39 21.39 2.10 19.71 19.71 2.33 18.04 18.04 2.58 16.35 16.35 2.84

25.60 19.06 1.70 23.66 18.11 1.89 21.74 17.15 2.10 19.81 16.20 2.33 17.89 15.24 2.58 15.96 14.27 2.84

27.52 19.73 1.70 25.45 18.76 1.90 23.40 17.80 2.11 21.34 16.83 2.34 19.29 15.87 2.59 17.23 14.89 2.85

30.21 15.91 1.71 27.97 15.04 1.90 25.72 14.18 2.11 23.50 13.31 2.35 21.26 12.45 2.60 19.02 11.58 2.86

57

62

67

72

57

62

67

72

57

62

67

_F

(_C)

63*

(13.8)

(16.6)

(17.2)

(19.4)

(22.2)

63*

(13.8)

(16.6)

(17.2)

(19.4)

(22.2)

(13.8)

(16.6)

63*

72

(17.2)

(19.4)

(22.2)

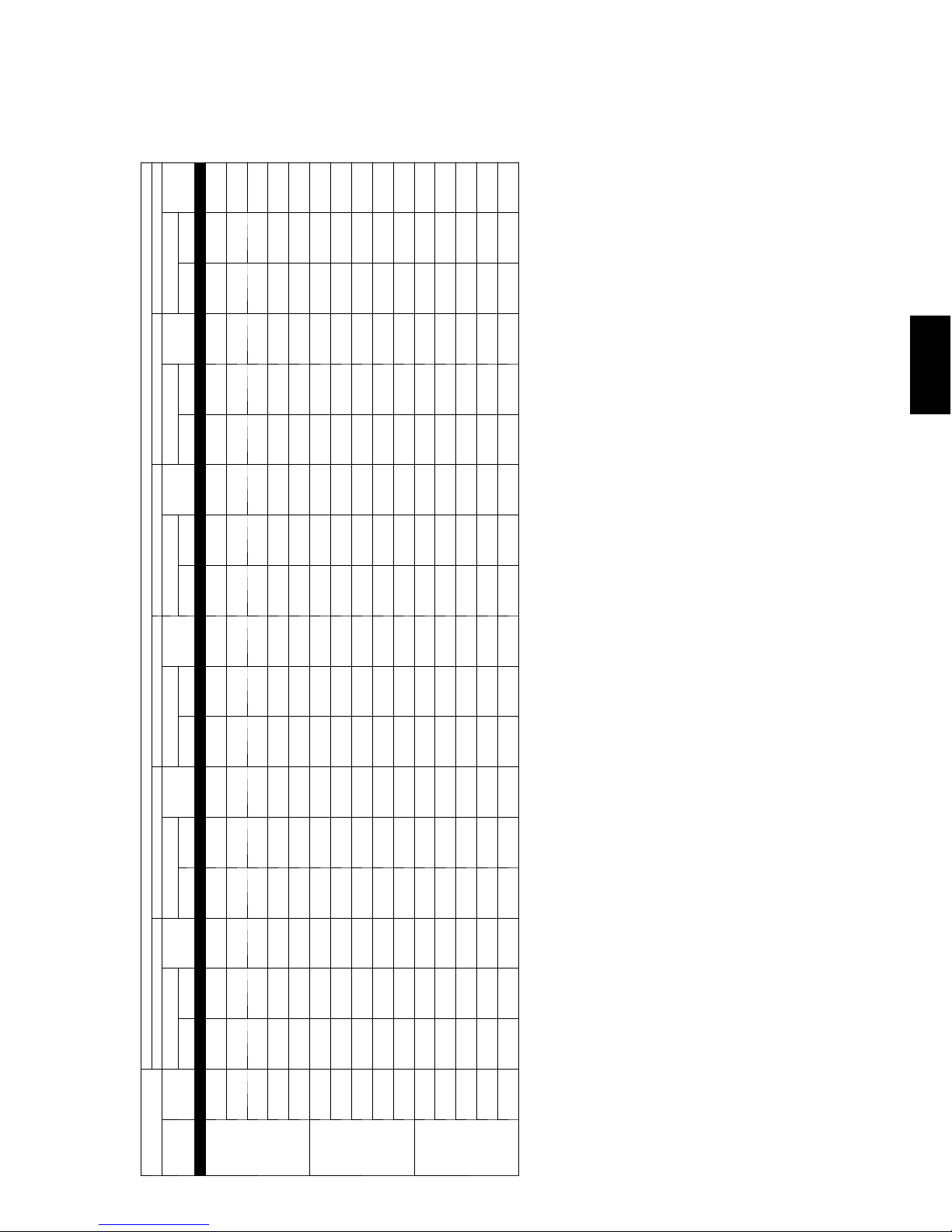

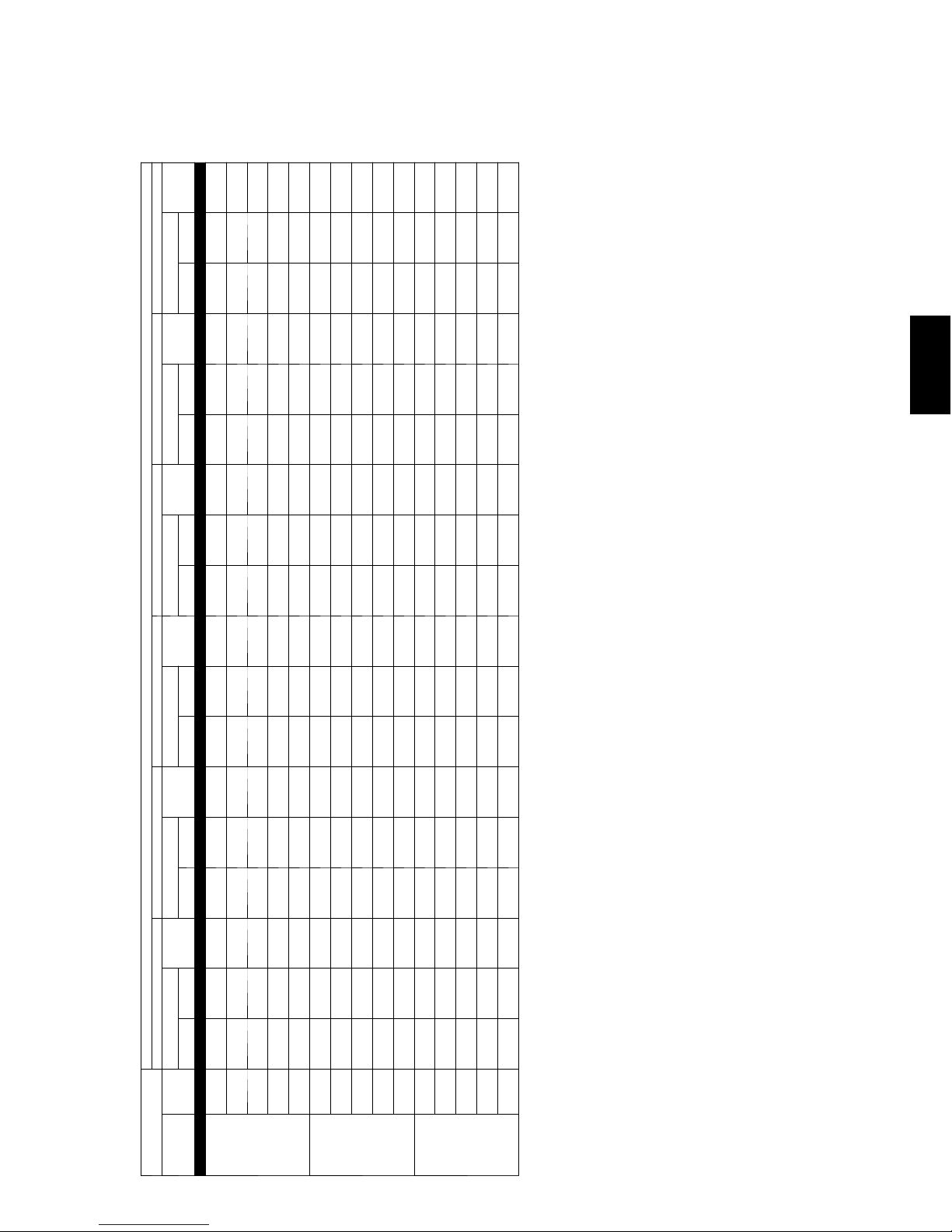

PERFORMANCE DATA

574D----A24

CFM/BF

700/0.07

EVAPORATOR AIR

800/0.09

900/0.1

See Legend and Notes on Page 19.

13

KW

Sys

Tot a l

Capacity MBtuh

KW

Sys

Tot a l

574D-- --A

Capacity MBtuh

KW

Sys

Tot a l

Capacity MBtuh

CONDEN SER ENTER ING AIR TEMPERATURES _F(_C)

Tot a l

Tot a l

Tot a l

75 (23.9) 85 (29.4) 95 (35) 105 (40.6) 115 (46.1) 125 (51.7)

EWB

Capacity MBtuh

Capacity MBtuh

Capacity MBtuh

KW

Sys

KW

Sys

KW

Sys

Tot a l Sens To t a l Sens To tal Sens To t a l Sens To t a l Sens Tot a l Sens

29.20 29.20 2.09 27.20 27.20 2.30 25.19 25.19 2.52 23.18 23.18 2.77 21.16 21.16 3.04 19.13 19.13 3.32

30.09 26.44 2.09 27.78 25.28 2.30 25.48 24.10 2.52 23.22 23.12 2.77 21.16 21.16 3.04 19.12 19.12 3.32

30.75 21.65 2.09 28.36 20.61 2.30 25.99 19.56 2.52 23.63 18.51 2.77 21.26 17.45 3.04 18.90 16.38 3.32

33.12 22.39 2.08 30.58 21.34 2.29 28.05 20.29 2.52 25.52 19.23 2.77 23.00 18.16 3.04 20.48 17.08 3.32

36.50 18.28 2.08 33.73 17.33 2.29 30.97 16.37 2.52 28.22 15.41 2.77 25.48 14.44 3.04 22.73 13.46 3.32

30.51 30.51 2.12 28.39 28.39 2.33 26.27 26.27 2.56 24.14 24.14 2.80 22.01 22.01 3.07 19.87 19.87 3.35

30.85 28.45 2.12 28.49 28.24 2.33 26.26 26.26 2.56 24.14 24.14 2.80 22.01 22.01 3.07 19.86 19.86 3.35

31.44 23.11 2.12 28.97 22.02 2.33 26.51 20.93 2.56 24.07 19.84 2.81 21.63 18.73 3.07 19.21 17.60 3.35

33.86 23.94 2.12 31.22 22.85 2.33 28.60 21.75 2.55 25.99 20.65 2.80 23.40 19.53 3.07 20.80 18.40 3.35

37.30 19.27 2.11 34.43 18.29 2.32 31.58 17.30 2.55 28.74 16.31 2.80 25.91 15.31 3.07 23.07 14.29 3.35

31.61 31.61 2.15 29.39 29.39 2.36 27.17 27.17 2.59 24.95 24.95 2.84 22.72 22.72 3.10 20.48 20.48 3.39

31.61 31.61 2.15 29.39 29.39 2.36 27.17 27.17 2.59 24.95 24.95 2.84 22.72 22.72 3.10 20.48 20.48 3.39

31.97 24.51 2.15 29.43 23.38 2.36 26.91 22.25 2.59 24.41 21.10 2.84 21.92 19.95 3.10 19.45 18.75 3.39

34.42 25.44 2.15 31.71 24.30 2.36 29.02 23.16 2.59 26.35 22.01 2.84 23.69 20.84 3.10 21.05 19.65 3.39

37.91 20.22 2.14 34.96 19.20 2.35 32.03 18.19 2.58 29.12 17.17 2.83 26.22 16.14 3.10 23.32 15.10 3.39

_F

57

62

67

72

57

62

67

72

57

62

67

(_C)

63*

(13.8)

(16.6)

(19.4)

(22.2)

(17.2)

63*

(13.8)

(16.6)

(19.4)

(22.2)

(13.8)

(17.2)

(16.6)

63*

72

(19.4)

(22.2)

(17.2)

EVAPORATOR AIR

PERFORMANCE DATA

574D----A30

CFM/BF

875/0.03

1000/0.03

1125/0.04

See Legend and Notes on Page 19.

14

KW

Sys

Tot a l

Capacity MBtuh

KW

Sys

Tot a l

574D-- --A

Capacity MBtuh

KW

Sys

Tot a l

Capacity MBtuh

CONDEN SER ENTER ING AIR TEMPERATURES _F(_C)

Tot a l

Tot a l

Tot a l

75 (23.9) 85 (29.4) 95 (35) 105 (40.6) 115 (46.1) 125 (51.7)

EWB

Capacity MBtuh

Capacity MBtuh

Capacity MBtuh

KW

Sys

KW

Sys

KW

Sys

Tot a l Sens To t a l Sens To tal Sens To t a l Sens To t a l Sens Tot a l Sens

35.66 35.66 2.38 32.84 32.84 2.71 30.06 30.06 3.07 27.32 27.32 3.47 24.62 24.62 3.91 21.93 21.93 4.39

37.06 32.25 2.39 33.82 30.46 2.71 30.65 28.68 3.07 27.56 26.88 3.47 24.62 24.62 3.91 21.93 21.93 4.39

37.87 26.52 2.39 34.55 24.93 2.71 31.28 23.37 3.08 28.09 21.82 3.48 24.95 20.29 3.91 21.88 18.77 4.39

40.79 27.41 2.39 37.23 25.80 2.72 33.74 24.21 3.08 30.32 22.64 3.48 26.96 21.09 3.92 23.65 19.54 4.39

44.91 22.49 2.39 41.02 21.04 2.72 37.19 19.62 3.09 33.45 18.21 3.49 29.78 16.82 3.93 26.16 15.44 4.40

37.24 37.24 2.43 34.27 34.27 2.76 31.33 31.33 3.12 28.44 28.44 3.52 25.58 25.58 3.96 22.76 22.76 4.44

37.97 34.65 2.43 34.64 32.72 2.76 31.35 31.35 3.12 28.43 28.43 3.52 25.58 25.58 3.96 22.75 22.75 4.44

38.73 28.25 2.43 35.29 26.59 2.76 31.91 24.95 3.12 28.60 23.33 3.52 25.37 21.73 3.96 22.21 20.12 4.44

41.71 29.24 2.44 38.02 27.56 2.76 34.40 25.90 3.13 30.86 24.26 3.53 27.40 22.63 3.97 24.00 21.00 4.44

45.90 23.65 2.44 41.86 22.16 2.77 37.91 20.68 3.13 34.05 19.23 3.54 30.26 17.79 3.98 26.53 16.36 4.45

38.59 38.59 2.48 35.47 35.47 2.81 32.40 32.40 3.17 29.37 29.37 3.57 26.39 26.39 4.01 23.43 23.43 4.49

38.77 36.79 2.48 35.46 35.46 2.81 32.39 32.39 3.17 29.37 29.37 3.57 26.38 26.38 4.01 23.43 23.43 4.49

39.40 29.91 2.48 35.85 28.18 2.81 32.38 26.47 3.17 28.99 24.78 3.57 25.69 23.09 4.01 22.46 21.40 4.49

42.41 31.01 2.48 38.61 29.26 2.81 34.89 27.52 3.18 31.27 25.81 3.58 27.72 24.10 4.02 24.26 22.39 4.49

46.65 24.77 2.49 42.51 23.22 2.82 38.45 21.70 3.18 34.49 20.20 3.58 30.61 18.72 4.03 26.80 17.24 4.50

_F

57

62

67

72

57

62

67

72

57

62

67

(_C)

63*

(13.8)

(16.6)

(19.4)

(22.2)

(17.2)

63*

(13.8)

(16.6)

(19.4)

(22.2)

(13.8)

(17.2)

(16.6)

63*

72

(19.4)

(22.2)

(17.2)

PERFORMANCE DATA

574D----A36

CFM/BF

1050/0.04

EVAPORATOR AIR

1200/0.04

1350/0.05

See Legend and Notes on Page 19.

15

KW

Sys

Tot a l

Capacity MBtuh

KW

Sys

Tot a l

574D-- --A

Capacity MBtuh

KW

Sys

Tot a l

Capacity MBtuh

CONDEN SER ENTER ING AIR TEMPERATURES _F(_C)

Tot a l

Tot a l

Tot a l

75 (23.9) 85 (29.4) 95 (35) 105 (40.6) 115 (46.1) 125 (51.7)

Capacity MBtuh

Capacity MBtuh

Capacity MBtuh

KW

Sys

KW

Sys

KW

Sys

Tot a l Sens To t a l Sens To tal Sens To t a l Sens To t a l Sens Tot a l Sens

40.45 40.45 3.00 37.98 37.98 3.37 35.49 35.49 3.78 32.98 32.98 4.20 30.44 30.44 4.65 27.84 27.84 5.10

42.06 37.63 2.94 39.15 35.73 3.33 36.25 33.83 3.74 33.37 31.92 4.18 30.48 30.39 4.64 27.88 27.88 5.10

42.93 30.96 2.91 39.95 29.27 3.31 36.96 27.59 3.72 33.97 25.92 4.17 30.95 24.26 4.63 27.90 22.59 5.10

46.12 31.94 2.80 42.92 30.23 3.19 39.72 28.52 3.61 36.53 26.83 4.05 33.31 25.15 4.52 30.04 23.46 4.99

50.58 26.16 2.65 47.09 24.61 3.04 43.59 23.08 3.46 40.11 21.56 3.90 36.60 20.05 4.37 33.04 18.53 4.84

42.24 42.24 2.98 39.61 39.61 3.35 36.97 36.97 3.76 34.32 34.32 4.18 31.63 31.63 4.63 28.88 28.88 5.08

43.11 40.44 2.95 40.11 38.38 3.34 37.15 36.28 3.75 34.31 34.31 4.18 31.62 31.62 4.63 28.88 28.88 5.08

43.91 32.97 2.92 40.81 31.21 3.32 37.71 29.45 3.73 34.61 27.70 4.18 31.49 25.96 4.64 28.35 24.21 5.12

47.15 34.07 2.81 43.82 32.28 3.20 40.50 30.50 3.62 37.19 28.73 4.06 33.86 26.97 4.53 30.50 25.20 5.00

51.67 27.51 2.65 48.05 25.91 3.05 44.42 24.32 3.46 40.81 22.75 3.91 37.19 21.19 4.38 33.51 19.62 4.85

43.75 43.75 2.97 40.99 40.99 3.34 38.22 38.22 3.75 35.43 35.43 4.17 32.62 32.62 4.62 29.74 29.74 5.07

44.02 42.95 2.96 41.01 41.01 3.34 38.21 38.21 3.75 35.43 35.43 4.17 32.61 32.61 4.62 29.74 29.74 5.07

44.67 34.90 2.94 41.47 33.06 3.33 38.28 31.23 3.75 35.10 29.41 4.20 31.91 27.58 4.66 28.70 25.74 5.14

47.93 36.13 2.82 44.51 34.26 3.21 41.09 32.40 3.63 37.69 30.56 4.08 34.28 28.71 4.54 30.85 26.85 5.02

52.51 28.80 2.67 48.78 27.15 3.06 45.05 25.51 3.48 41.34 23.89 3.93 37.63 22.28 4.39 33.86 20.67 4.87

57

62

67

72

57

62

67

72

57

62

67

63*

(13.8)

(16.6)

(19.4)

(22.2)

(17.2)

63*

(13.8)

(16.6)

(19.4)

(22.2)

(13.8)

(17.2)

(16.6)

63*

72

(19.4)

(22.2)

(17.2)

PERFORMANCE DATA

EVAPORATOR AIR

574D----A42

1225/0.03

CFM/BF EWB

1400/0.04

1575/0.05

See Legend and Notes on Page 19.

16

KW

Sys

Capacity MBtuh To t a l

KW

Sys

Tot a l

Sens To t a l Sens

Capacity MBtuh

KW

Sys

Tot a l

Capacity MBtuh

KW

Sys

Tot a l

CONDEN SER ENTER ING AIR TEMPERATURES _F(_C)

Capacity MBtuh

KW

Sys

Tot a l

574D-- --A

Capacity MBtuh

KW

Sys

Tot a l

75 (23.9) 85 (29.4) 95 (35) 105 (40.6) 115 (46.1) 125 (51.7)

Capacity MBtuh

Tot a l Sens To t a l Sens To tal Sens To t a l Sens To t a l

46.51 46.51 3.29 43.60 43.60 3.68 40.66 40.66 4.11 37.70 37.70 4.56 34.70 34.70 5.05 31.64 31.64 5.55

48.43 41.91 3.29 45.02 40.09 3.68 41.60 38.24 4.10 38.19 36.35 4.56 34.81 34.56 5.05 31.64 31.64 5.55

49.45 34.51 3.29 45.95 32.87 3.68 42.43 31.22 4.10 38.89 29.56 4.56 35.34 27.89 5.05 31.75 26.19 5.55

53.14 35.61 3.29 49.39 33.95 3.68 45.62 32.29 4.10 41.85 30.61 4.55 38.05 28.93 5.04 34.20 27.21 5.55

58.33 29.19 3.28 54.23 27.68 3.67 50.11 26.15 4.09 46.00 24.62 4.55 41.85 23.08 5.03 37.64 21.51 5.54

57

62

67

72

57

(19.4)

(22.2)

PERFORMANCE DATA

EVAPORATOR AIR

574D----A48

EWB

_F

(_C)

CFMBF

63*

(13.8)

(16.6)

(17.2)

1400/0.04

48.55 48.55 3.35 45.46 45.46 3.74 42.35 42.35 4.16 39.21 39.21 4.61 36.04 36.04 5.10 32.81 32.81 5.60

49.62 44.99 3.35 46.10 43.02 3.74 42.60 40.97 4.16 39.21 39.21 4.61 36.04 36.04 5.10 32.80 32.80 5.60

50.57 36.73 3.35 46.92 35.02 3.74 43.27 33.30 4.16 39.61 31.57 4.61 35.94 29.83 5.10 32.24 28.05 5.60

54.31 37.96 3.34 50.41 36.23 3.73 46.50 34.50 4.15 42.59 32.76 4.61 38.66 30.99 5.09 34.70 29.20 5.60

59.58 30.68 3.34 55.32 29.12 3.73 51.05 27.54 4.15 46.80 25.97 4.60 42.51 24.38 5.08 38.17 22.76 5.59

50.26 50.26 3.40 47.02 47.02 3.79 43.76 43.76 4.21 40.47 40.47 4.66 37.15 37.15 5.15 33.76 33.76 5.65

50.64 47.75 3.40 47.06 47.06 3.79 43.75 43.75 4.21 40.46 40.46 4.66 37.14 37.14 5.15 33.76 33.76 5.65

51.44 38.88 3.40 47.67 37.10 3.79 43.92 35.31 4.21 40.16 33.51 4.67 36.40 31.68 5.15 32.62 29.81 5.66

55.22 40.25 3.40 51.19 38.45 3.79 47.17 36.64 4.21 43.16 34.83 4.66 39.13 32.98 5.14 35.08 31.10 5.65

60.54 32.12 3.40 56.16 30.51 3.78 51.77 28.89 4.20 47.40 27.27 4.65 43.00 25.64 5.13 38.55 23.98 5.64

62

67

72

57

62

67

63*

(13.8)

(16.6)

(19.4)

(22.2)

(13.8)

(17.2)

1600/0.05

(16.6)

63*

72

(19.4)

(22.2)

(17.2)

1800/0.06

See Legend and Notes on Page 19.

17

Loading...

Loading...