Bryant 569J Series Installation, Start-up And Service Instructions Manual

569J

AIR--COOLED CONDENSING UNITS

60 Hz, with PURONR(R--410A) REFRIGERANT

SIZES 07--14

Installation, Start--Up and

Service Instructions

TABLE OF CONTENTS

SAFETY CONSIDERATIONS 2....................

INSTALLATION GUIDELINES 2..................

Replacement/Retrofit — R--22 to Puron 2...........

Rated Indoor Airflow (cfm) 3.....................

Matching 569J Model to Evaporator Coil 10.........

INSTALLATION 10 -- 26.........................

Jobsite Survey 10...............................

Step 1 -- Plan for Unit Location 10.................

Step 2 -- Complete Pre--Installation Checks 10........

Step 3 -- Prepare Unit Mounting Support 11..........

Step 4 -- Rig and Mount the Unit 11................

Step 5 -- Determine Refrigerant Line Sizes 11........

Step 6 -- Complete Refrigerant Piping Connections 16...

Step 7 -- Install Accessories 19....................

Step 8 -- Complete Electrical Connections 19.........

Step 9 -- Wind Baffles for Low Ambient Controls 26...

PRE-START-UP 26...............................

System Check 26...............................

Turn On Crankcase Heater 26.....................

Preliminary Charge 26...........................

START--UP 26 -- 36..............................

Preliminary Checks 26...........................

Start Unit 27...................................

OPERATING SEQUENCE 37......................

Base Unit Controls 37...........................

Indoor (Supply) Fan 37..........................

Cooling, Unit Without Economizer 37..............

569J*12F, Unit with Hot Gas Bypass (HGBP) 37......

Cooling, Unit with Economizer 39.................

Heating 39....................................

ROUTINE SYSTEM MAINTENANCE 39............

Quarterly Inspection (and 30 days after initial start) 39...

Seasonal Maintenance 39........................

SERVICE 39 -- 47................................

Refrigeration System 39.........................

Compressor Oil 39..............................

Servicing Systems on Roofs with

Synthetic Materials 39...........................

Liquid Line Filter Drier 40.......................

Field Refrigerant Access Ports 40..................

Factory High--Flow Access Ports 40................

Hot Gas Bypass Valve Adjustments 40..............

Comfort Alert Diagnostic Module 41...............

Compressor Protection 43........................

Crankcase Heater 43............................

Low--Pressure Switch 43.........................

High--Pressure Switch 43.........................

Outdoor Fans 43................................

Lubrication 43.................................

Routine Cleaning of Round-Tube Plate Fin

(RTPF) Coils 46................................

Fastener Torque Values 47

TROUBLESHOOTING 47 -- 48.....................

APPENDIX A

Air Conditioner & Heat Pump with Puron

Quick Reference Guide 49.........................

APPENDIX B

Wiring Diagram List 49...........................

APPENDIX C

Low Ambient Option — Factory Installed 50..........

START--UP CHECKLIST 55 -- 56...................

........................

R

—

1

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock or other conditions which may cause personal

injury or property damage. Consult a qualified installer,

service agency, or your distributor or branch for

information or assistance. The qualified installer or

agency must use factory-authorized kits or accessories

when modifying this product. Refer to the individual

instructions package

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloths for brazing operations and

have a fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions attached to

the unit. Consult local building codes and appropriate

national electrical codes (in USA, ANSI/NFPA70,

National Electrical Code (NEC); in Canada, CSA C22.1)

for special requirements.

569J

It is important to recognize safety information. This is the

safety--alert symbol

unit and in instructions or manuals, be alert to the

potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety-alert symbol. DANGER identifies the most serious

hazards which will result in severe personal injury or

death. WARNING signifies hazards which could result in

personal injury or death. CAUTION is used to identify

unsafe practices, which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced

installation, reliability, or operation.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury or death.

Before performing service or maintenance operations

on unit, turn off main power switch to unit and install

lock(s) and lockout tag(s). Ensure electrical service to

rooftop unit agrees with voltage and amperage listed

on the unit rating plate. Unit may have more than one

power switch.

!

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause in personal

injury,death and/or equipment damage.

R

Puron

higher pressures than standard R--22 systems. Do not

use R--22 service equipment or components on Puron

refrigerant equipment.

(R--410A) refrigerant systems operate at

. When you see this symbol on the

WARNING

WARNING

!

WARNING

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could cause in personal

injury or death.

Relieve pressure and recover all refrigerant before

system repair or final unit disposal.

Wear safety glasses and gloves when handling

refrigerants. Keep torches and other ignition sources

away from refrigerants and oils.

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses and gloves when handling parts and servicing

569J units.

INSTALLATION GUIDELINE

Replacement/Retrofit — R--22 to Puron

Replacement/retrofit installations require change-out of

outdoor unit, metering device, and filter driers.

Change-out of indoor coil (evaporator) and

interconnecting tubing is recommended.

Existing evaporator coil – If the existing evaporator coil

may be re-used, check with the coil manufacturer to verify

the coil construction is suitable for operation with the

higher pressures of Puron

the existing TXV valve is compatible with R-410A,

replace if necessary. The minimum factory test pressure

rating must be 250 psig (1725 kPa). Existing coil will

need to be purged with Nitrogen to remove as much

mineral oil as possible to eliminate cross contamination of

oils.

Acid test – If the existing system is being replaced

because of a compressor electrical failure, assume acid is

in system. If system is being replaced for any other

reason, use an approved acid test kit to determine acid

level. If even low levels of acid are detected, install a 100

percent activated alumina suction-line filter drier in

addition to the replacement liquid-line filter drier.

Remove the suction line filter drier as soon as possible,

with a maximum of 72 hr of operation. Recommendation:

Install a ball valve in the liquid line at the filter drier

location when installing a suction filter in the suction line.

Existing refrigeration piping – Reuse of existing refrigerant

piping involves three issues: quality (strength) of existing

tubing, cleanliness and tube size. Inspect all tube segments

and joints for signs of damage, corrosion or poor brazing.

Flush the interconnecting piping system with dry Nitrogen to

eliminate as much trace of mineral oil as possible.

R

(R-410A). Also determine if

R

2

Same tube sizes are capable of handling higher flowrates

(expressed as tons of cooling capacity) with Puron

refrigerant compared to R--22 at constant pressure drops.

1

For example, a

higher tons with Puron

drop). A 1

/2--inch OD liquid line is rated at 33%

R

1

/8--inch OD suction line is rated at 53% higher

than with R--22 (at 5_F pressure

tons with Puron than with R--22 (at 2_F pressure drop).

Refrigeration lines selected for R--22 use are typically

oversized for Puron applications. Carefully check the

existing suction line size against the table for maximum size

(see Table 8); replace vertical riser segments if necessary.

Check existing liquid line size against sizing data in Table 5

or 6; replace with smaller lines when feasible.

Installation –

1. Remove the existing evaporator coil or fan coil and

install the replacement coil when appropriate.

2. Drain oil from low points and traps in suction line

tubing (and hot gas bypass tubing if appropriate) and

evaporator if they were not replaced. Removing oil

from evaporator coil may require purging of the

tubing with dry nitrogen.

3. Unless indoor unit is equipped with a Puron

approved metering device, change the metering

device to a thermal expansion valve (TXV) designed

for Puron

R

(R-410A).

4. Remove the existing outdoor unit. Install the new outdoor unit according to these installation instructions.

5. Install a new field-supplied liquid-line filter drier at

the indoor coil just upstream of the TXV or fix orifice

metering device.

6. If a suction line filter drier is also to be installed, install suction line drier downstream of suction line service valve at condensing unit.

!

CAUTION

7. If required, install a 100% activated alumina suction

line filter drier at the outdoor unit.

8. Evacuate and charge the system according to the instructions in this installation manual.

9. Operate the system for 10 hr. Monitor the pressure

drop across the suction line filter drier. If pressure

drop exceeds 3 psig (21kPa), replace suction-line and

liquid-line filter driers. Be sure to purge system with

dry nitrogen and evacuate when replacing filter

driers. Continue to monitor the pressure drop across

suction-line filter drier. Repeat filter changes if necessary. Never leave suction-line filter drier in system

longer than 72 hr (actual time).

Rated Indoor Airflow (cfm)

The table below lists the rated indoor airflow used for the

AHRI efficiency rating for the units covered in this

document.

569J

569J***A/B/G/H with 524J***A

Model Numbers Full Load Airflow (cfm)

569J*07A/B --- 524J*07A 2400

569J*07G/H --- 524J*07A 2625

569J*08A/B --- 524J*08A 3000

569J*12A/B --- 524J*12A 4000

569J*14A/B --- 524J*14A 4375

569J***D/E/F with 524J***A

Model Numbers Full Load Airflow (cfm)

569J*12D/E/F --- 524J*12A 4000

569J*14D/E --- 524J*14A 4400

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never install suction--line filter drier in the liquid--line

of a Puron

R

system.

3

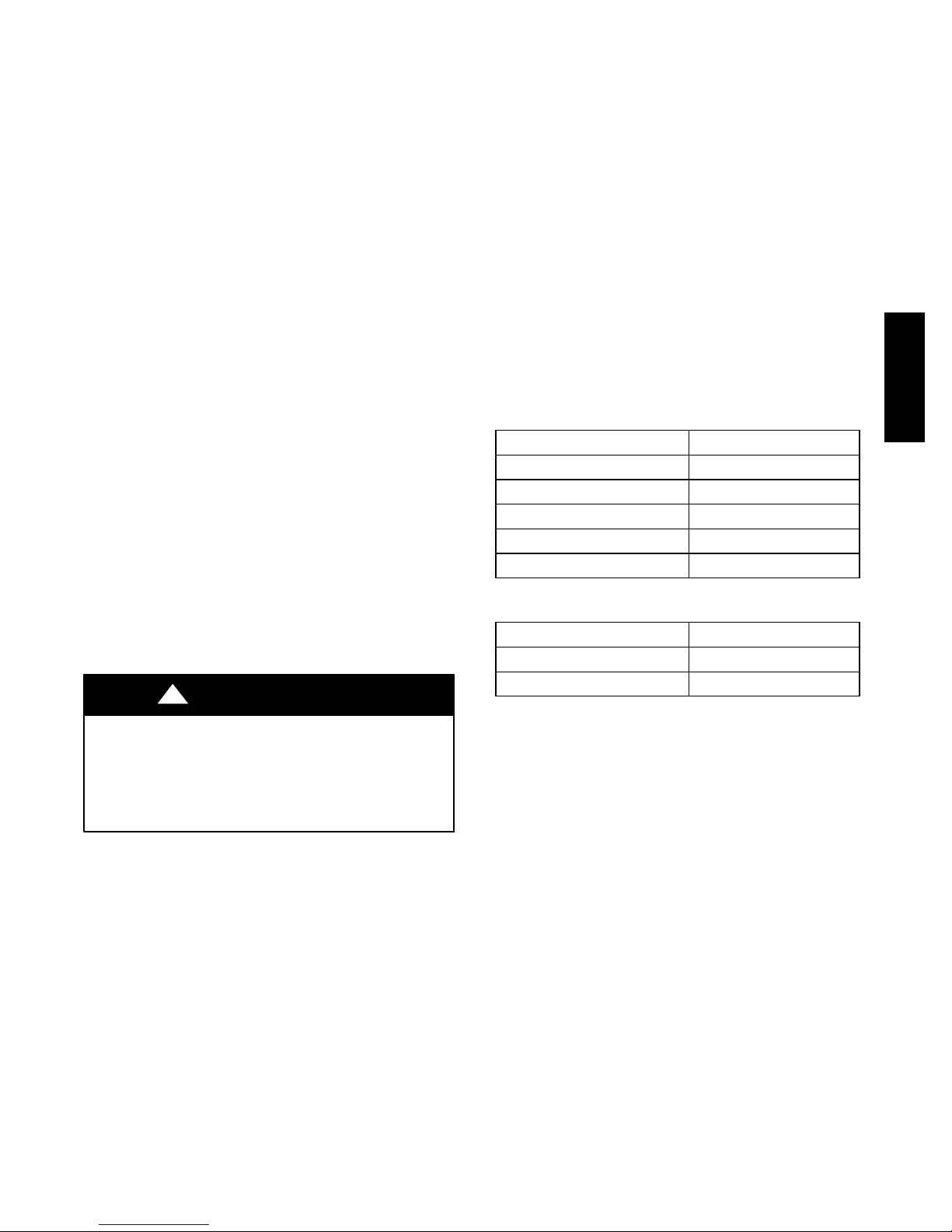

Identify Factory Options —

Factory options will affect 569J unit pipe sizing selections.

Coil type impacts liquid lift limits; Hot Gas Bypass impacts

the selection of suction tube size in vertical riser segments.

Check this unit’s Model Number against the Model Number

Nomenclature, Fig. 1. Determine the significance of this

Enter this unit’s

Model Number

Position

Example

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

569JE12F000A00A0A

unit’s values in Position 9 (Coil type) and Position 6 (Hot

Gas Bypass, 569J*12F only). Copy the unit’s Model Number

from the unit’s dataplate into the open line in the header

above Fig. 1 to facilitate this step.

Model Type

569J = Bryant Condensing Unit

®

R–410A Refrigerant

Puron

Voltage

E = 460/3/60

P = 208 / 230/3/6

569J

T = 575/3/60

Nominal Tonnage

07 = 6 Tons

08 = 7.5 Tons

12 = 10 Tons

14 = 12.5 Tons

Refrigerant Circuit

A = Single Circuit

B = Single Circuit with Low Ambient Controller

D = Dual Circuit

E = Dual Circuit with Low Ambient Controller

F = Dual Circuit with Hot Gas Bypass (569J* size 12 only)

G = Single Circuit, Two Stage

H = Single Circuit, Two Stage with Low Ambient Controller

Not Used

0 = Not Used

Not Used

0 = Not Used

Packaging

A=Standard

B=LTL

Base Unit Controls

0 = Electro-Mechanical Controls

Electrical Options

A = None

C = Non-Fused Disconnect

Service Options

0 = None

1 = Unpowered Convenience Outlet

2 = Powered Convenience Outlet

Not Used

0 = Not Used

CoilOptions

RTPF

A = Al/Cu Standard

B = Pre Coated Al/Cu

C = E-Coated Al/Cu

E = Cu/CuM=Al/Cu Standard with Louvered Hail Guard

N = Pre Coated Al/Cu with Louvered Hail Guard

P = E-Coated Al/Cu with Louvered Hail Guard

R = Cu/Cu with Louvered Hail Guard

Not Used

0 = Not Used

C150349

Fig. 1 -- Model Number Nomenclature

POSITION NUMBER

TYPICAL

12345678910

0515C12345

DESIGNATESPOSITION

1−2

3−4

Week of manufacture (fiscal calander)

Year of manufacture (”15” = 2015)

Manufacturing location5

6−10

Sequence number

C150336

Fig. 2 -- Serial Number Nomenclature

4

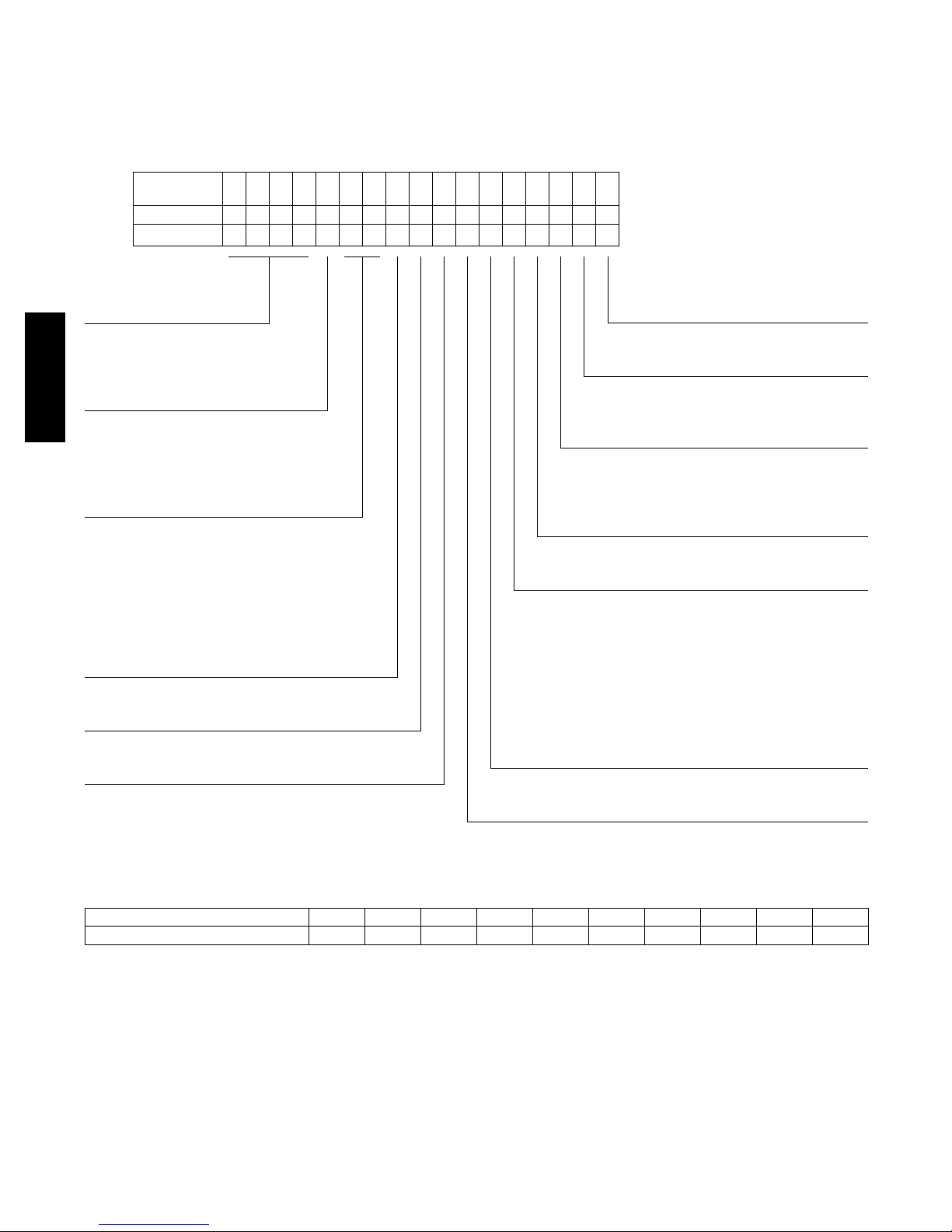

UNIT

569J*07A/B/G/ H

(RTPF)

569J*08A/B

(RTPF)

569J*12A/B

(RTPF)

569J*14A/B

(RTPF)

569J*12D/E/F

(RTPF)

569J*14D/E/

(RTPF)

LEGEND: RTPF = Round Tube/Plate Fin coil

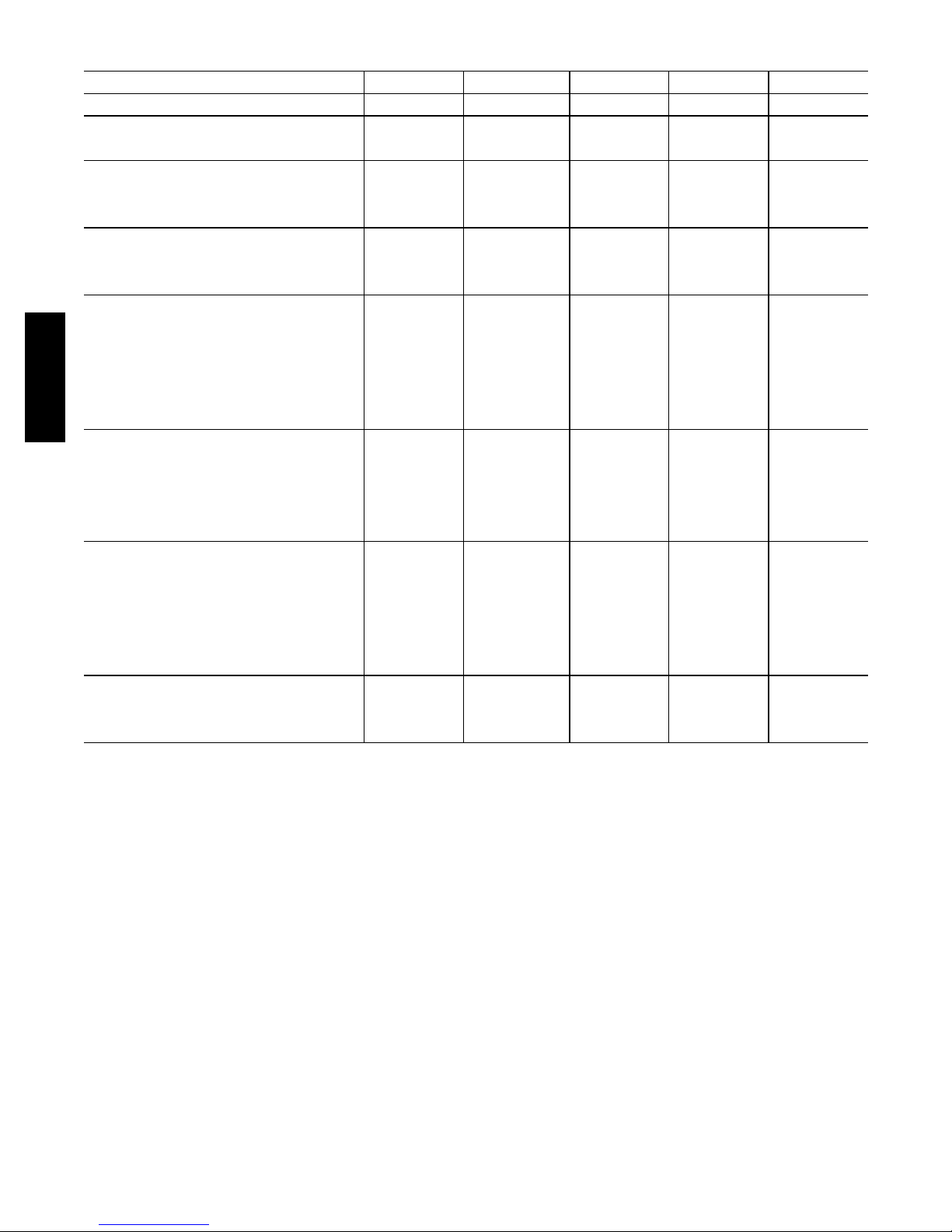

STD. UNIT WT. CORNER A CORNER B CORNER C CORNER D CENTER OF GRAVITY UNIT HEIGHT

lbs. kg. lbs. kg. lbs. kg. lbs. kg. lbs. kg. X Y Z H

389 176 141 64 96 44 62 28 91 41

391 177 142 64 96 44 62 28 91 41

490 222 177 80 120 54 78 35 114 52

598 271 195 88 142 64 110 50 151 68

516 234 185 84 117 53 83 38 131 59

654 297 214 97 155 70 120 54 165 75

Fig. 3 -- 569J Unit Dimensions

18

[457.2]24[609.6]21[533.4]

18

[457.2]24[609.6]21[533.4]

18

[457.2]24[609.6]24[609.6]

20

[508.0]25[635.0]24[609.6]

19

[482.6]23[584.2]24[609.6]

20

[508.0]25[635.0]24[609.6]

C150350

423/

8

[1076.0]

423/

8

[1076.0]

503/

8

[1279.2]

503/

8

[1279.2]

503/

8

[1279.2]

503/

8

[1279.2]

569J

5

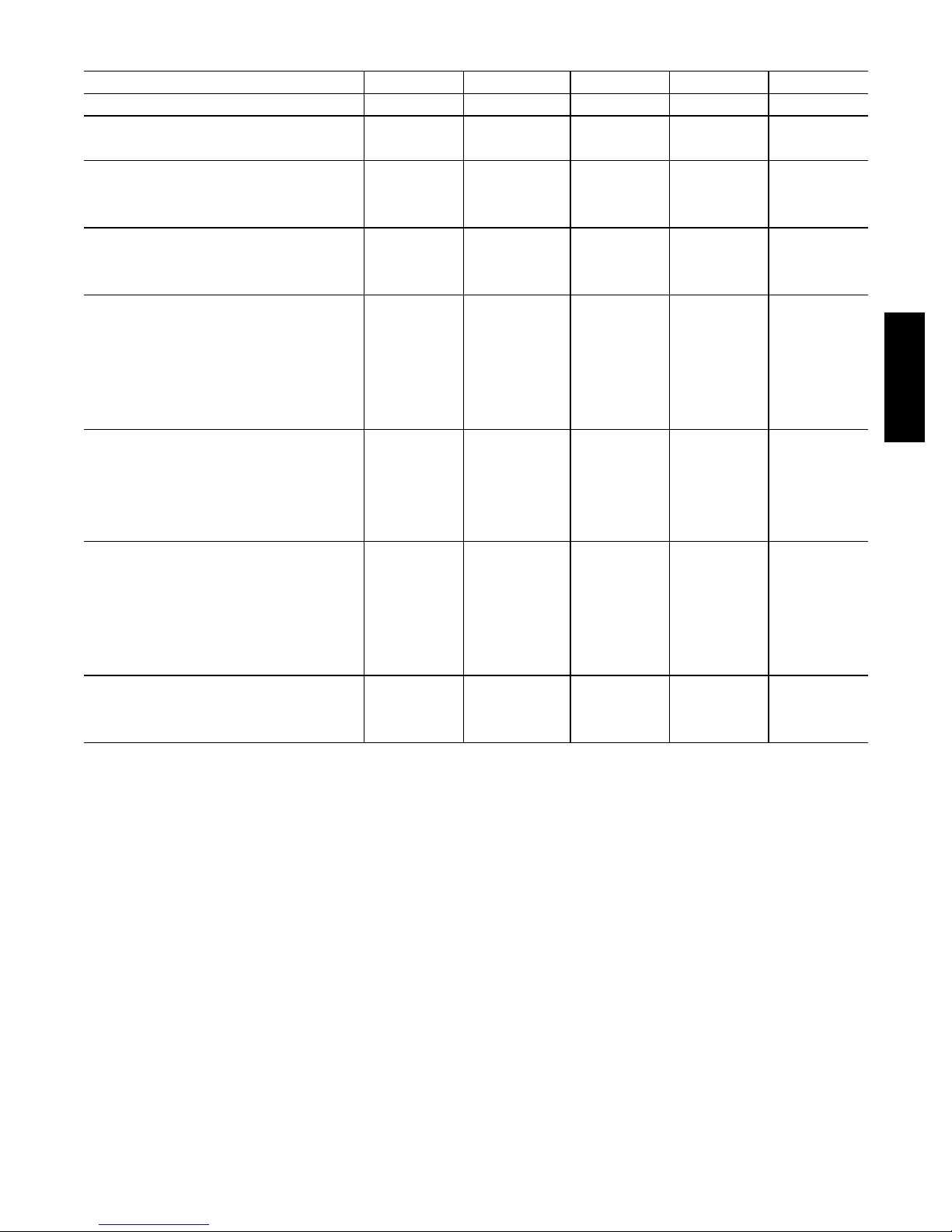

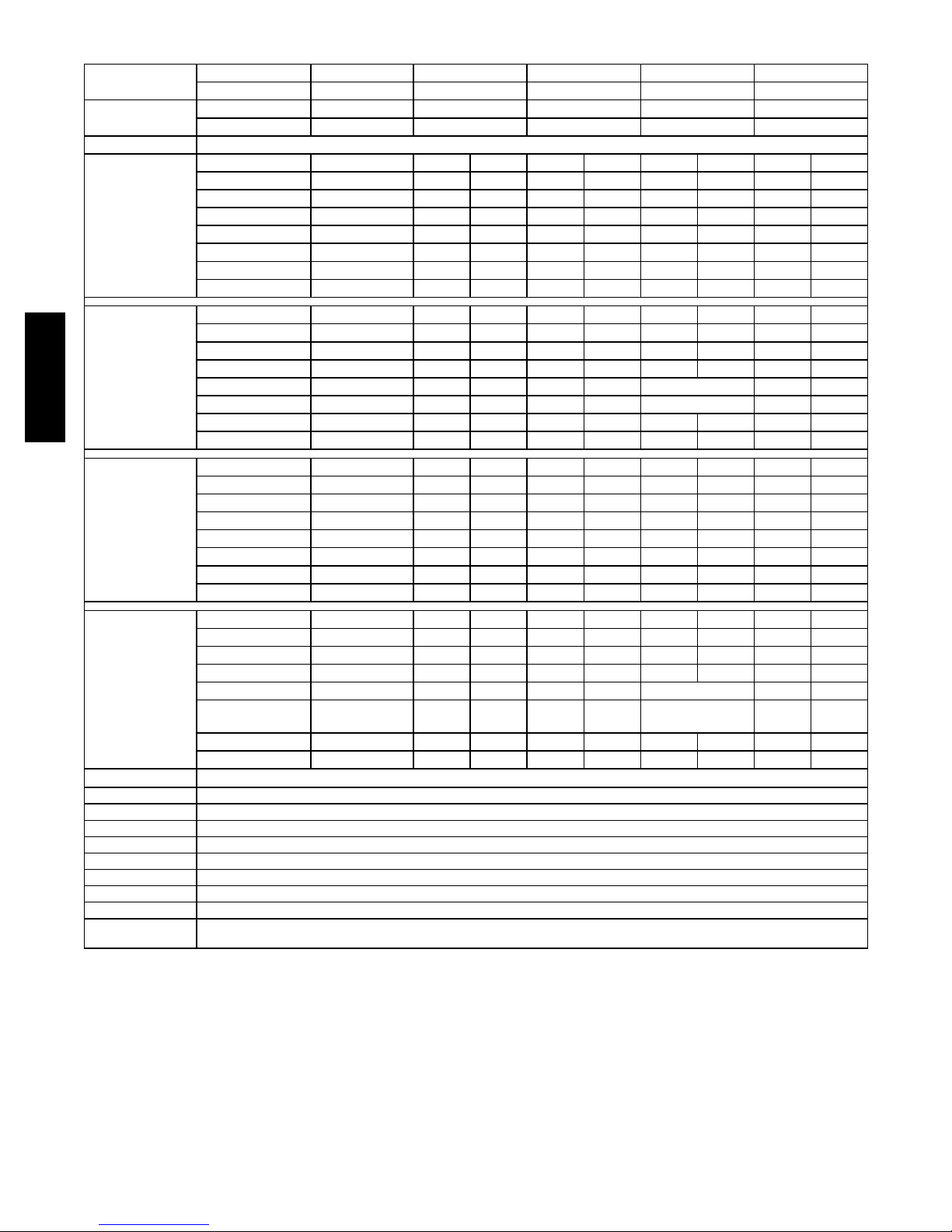

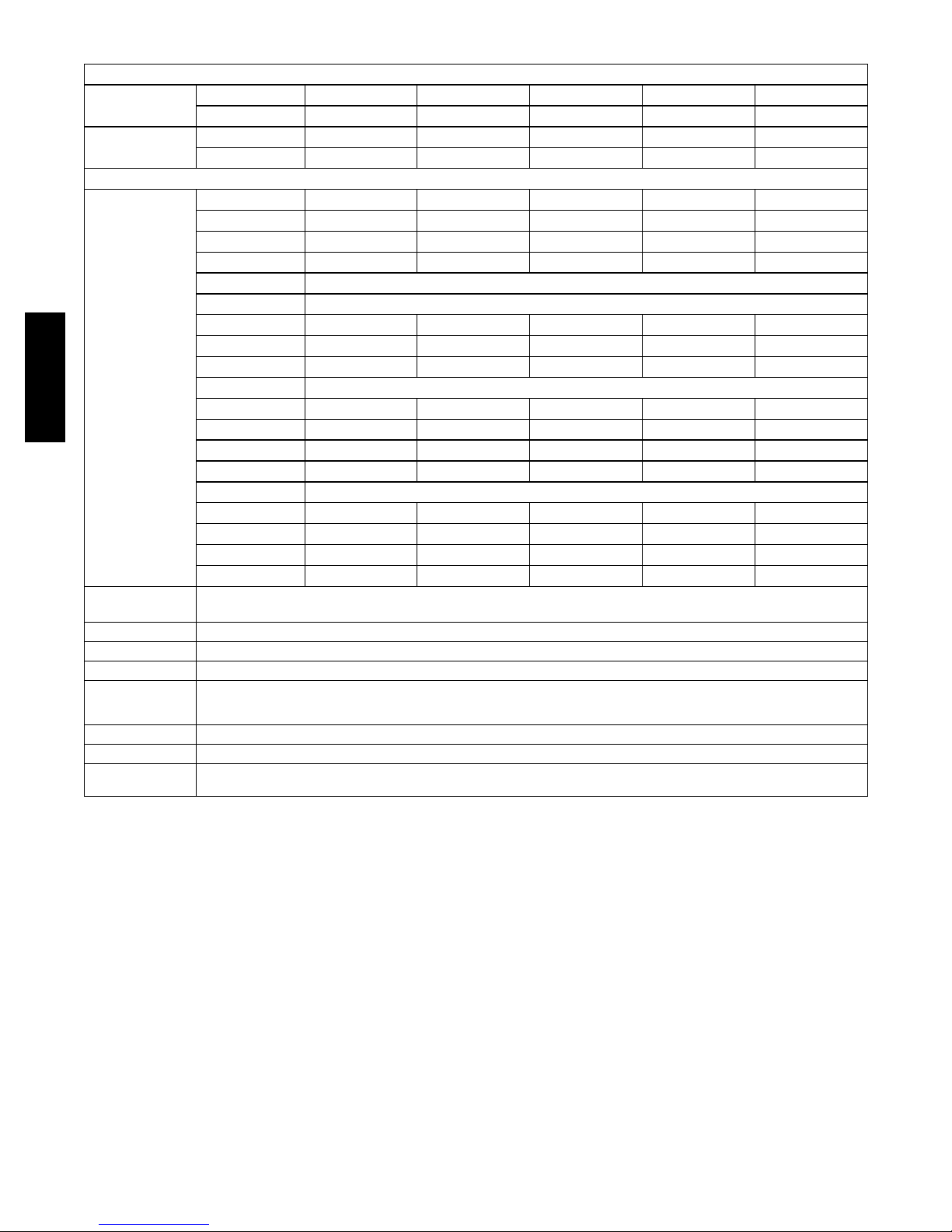

Table 1A — Physical Data — 569J*07-14A/B/G/H Units — 60 Hz English

UNIT 569J*07A/B 569J*07G/H 569J*08A/B 569J*12A/B 569J*14A/B

NOMINAL CAPACITY (tons) 6 6 7.5 10 12.5

OPERATING WEIGHTS (lb)

Round Tube/Plate Fin Coil (Cu/Al) 389 389 391 490 598

REFRIGERANT TYPE

Operating Charge (w/ fan coil), Typical (lb)

Shipping Charge (lb) 9.0 9.0 9.0 9.0 9.0

COMPRESSOR

Qty...Type 1...Scroll 1...2 Stage Scroll 1...Scroll 1...Scroll 1...Scroll

Oil Charge (oz) 56 56 60 110 110

CONDENSER FANS

Qty...Rpm 2...1100 2...1100 2...1100 2...1100 2...1100

Motor Hp

Diameter 22 22 22 22 22

569J

Nominal Airflow (Cfm Total) 6000 6000 6000 6000 6000

Watts (Total) 610 610 610 610 610

RTPF CONDENSER COIL

Material (Tube/Fin) Cu / Al Cu / Al Cu / Al Cu / Al Cu / Al

Coil Type

Rows/Fins per inch (FPI) 2/17 2/17 2/17 2/17 3/17

Face Area (sq ft total) 17.5 17.5 17.5 25.1 31.8

CONTROLS

Pressurestat Settings (psig)

High Cutout 630 10 630 10 630 10 630 10 630 10

Cut-in 505 20 505 20 505 20 505 20 505 20

Low Cutout 54 3 54 3 54 3 54 3 54 3

Cut-in 117 5 117 5 117 5 117 5 117 5

PIPING CONNECTIONS (in. ODS)

Qty...Suction 1...11/

Qty...Liquid 1...3/

LEGEND

RTPF — Round Tube/Plate Fin

ODS — Outside Diameter Sweat (socket)

‡

Unit is factory-supplied with partial charge only.

†

Typical operating charge with 25 ft of interconn ecting pipin g.

‡

R-410A R-410A R-410A R-410A R-410A

†

14.0 14.0 17.0 20.0 43.0

1

/

4

3

/8--- i n R TP F

8

8

1

/

4

3

/8--- i n R TP F

1...11/

1...3/

1

/

4

3

/8--- i n R TP F

8

8

1...11/

1...1/

8

2

1

/

4

3

/8--- i n R TP F

1...13/

1...1/

8

2

1

/

4

3

/8--- i n R TP F

1...13/

1...5/

8

8

6

Table 1B — Physical Data — 569J*07-14A/B/G/H Units — 60 Hz SI

UNIT 569J*07A/B 569J*07G/H 569J*08A/B 569J*12A/B 569J*14A/B

NOMINAL CAPACITY (kW) 21.1 21.1 26.4 35.1 44

OPERATING WEIGHTS (lb )

Round Tube / P late Fin Coil (Cu/Al) 176 176 177 222 271

REFRIGERANT TYPE

Operating Charge (w/ fan coil), T yp i c al (kg )

Shipping Charge (kg) 4.1 4.1 4.1 4.1 4.1

COMPRESSOR

Qty...T ype 1...Scroll 1...2 Stage Scroll 1...Scroll 1...Scroll 1...Scroll

Oil Charge (oz) 1.7 1.7 1.8 3.3 3.3

CONDENS ER FANS

Qty...r/s 2...18 2...18 2...18 2...18 2...18

Motor Hp NEMA

Diameter (mm) 560 560 560 560 560

Nominal Airflow (L/s) 2832 2832 2832 2832 2832

Watts (T otal) 610 610 610 610 610

RTPF CONDENSER COIL

Material (T ub e/ Fin) Cu / Al Cu / Al Cu / Al Cu / Al Cu / Al

Coil Type

Rows/Fins per Meter (Fins/m) 2 / 670 2 / 670 2 / 670 2 / 670 3 / 670

Face Area (sq m total) 1.6 1.6 1.6 2.3 3.0

CONTROLS

Pressurestat Settings (kPa)

High Cutout 4347 70 4347 70 4347 70 4347 70 4347 70

Cut-in 3482 138 3482 138 3482 138 3482 138 3482 138

Low Cutout 372 21 372 21 372 21 372 21 372 21

Cut-in 807 34 807 34 807 34 807 34 807 34

PIPING CONNECTIONS (in. ODS)

Qty...Suction 1...11/

Qty...Liquid 1...3/

LEGEND

RTPF — Round Tube/Plate Fin

NEMA — National Electrical Manufacturers Association

ODS — Outside Diameter Sweat (socket)

‡

Unit is factory-supplied with partial charge only.

†

Typical operating charge with 25 ft of interconn ecting pipin g.

‡

†

R-410A R-410A R-410A R-410A R-410A

6.4 6.4 7.7 9.1 19.5

1

/

4

3

/8--- i n R TP F

8

8

1

/

4

3

/8--- i n R TP F

1...11/

1...3/

1

/

4

3

/8--- i n R TP F

8

8

1...11/

1...1/

8

2

1

/

4

3

/8--- i n R TP F

1...13/

1...1/

3

/8--- i n R TP F

8

2

1...13/

1

1...5/

/

4

8

8

569J

7

569J

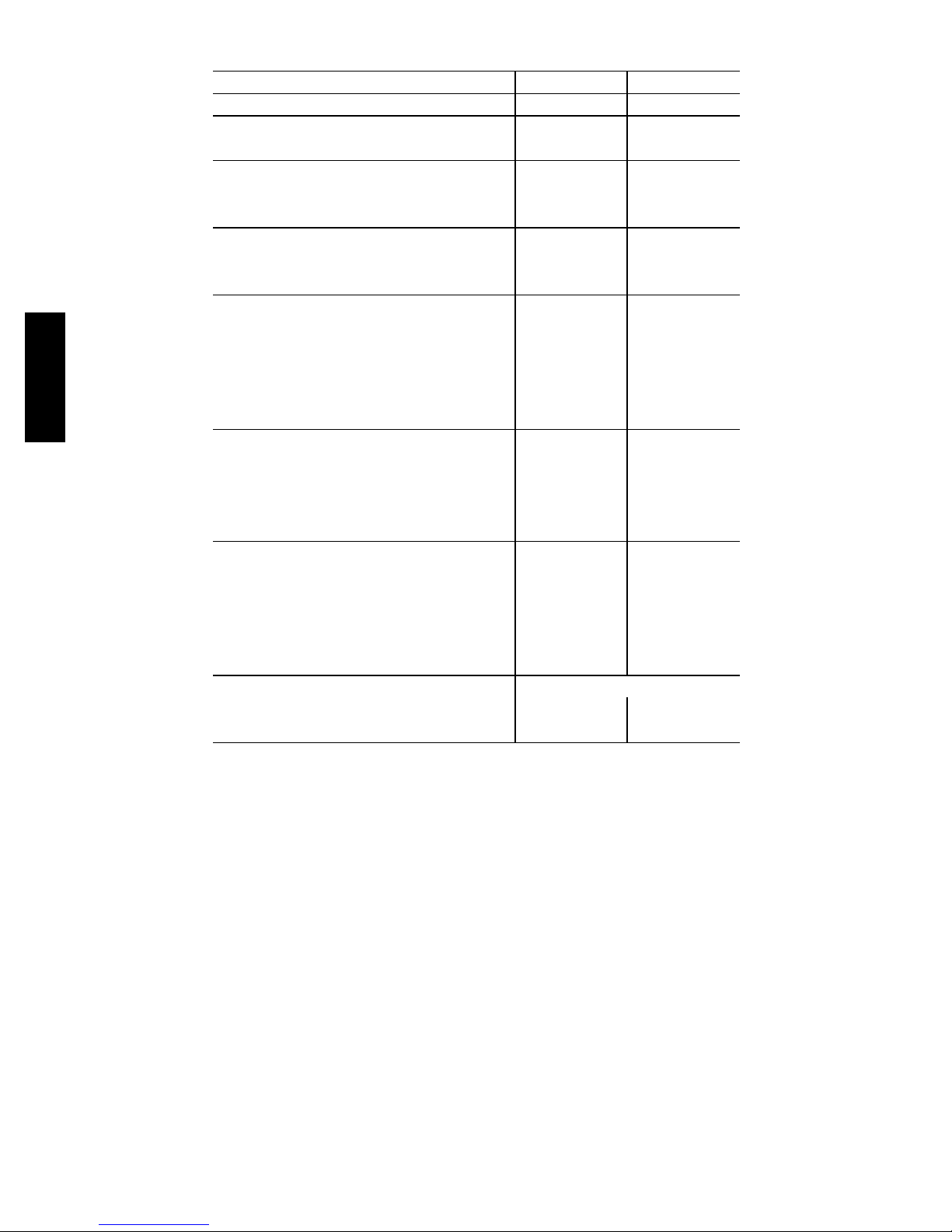

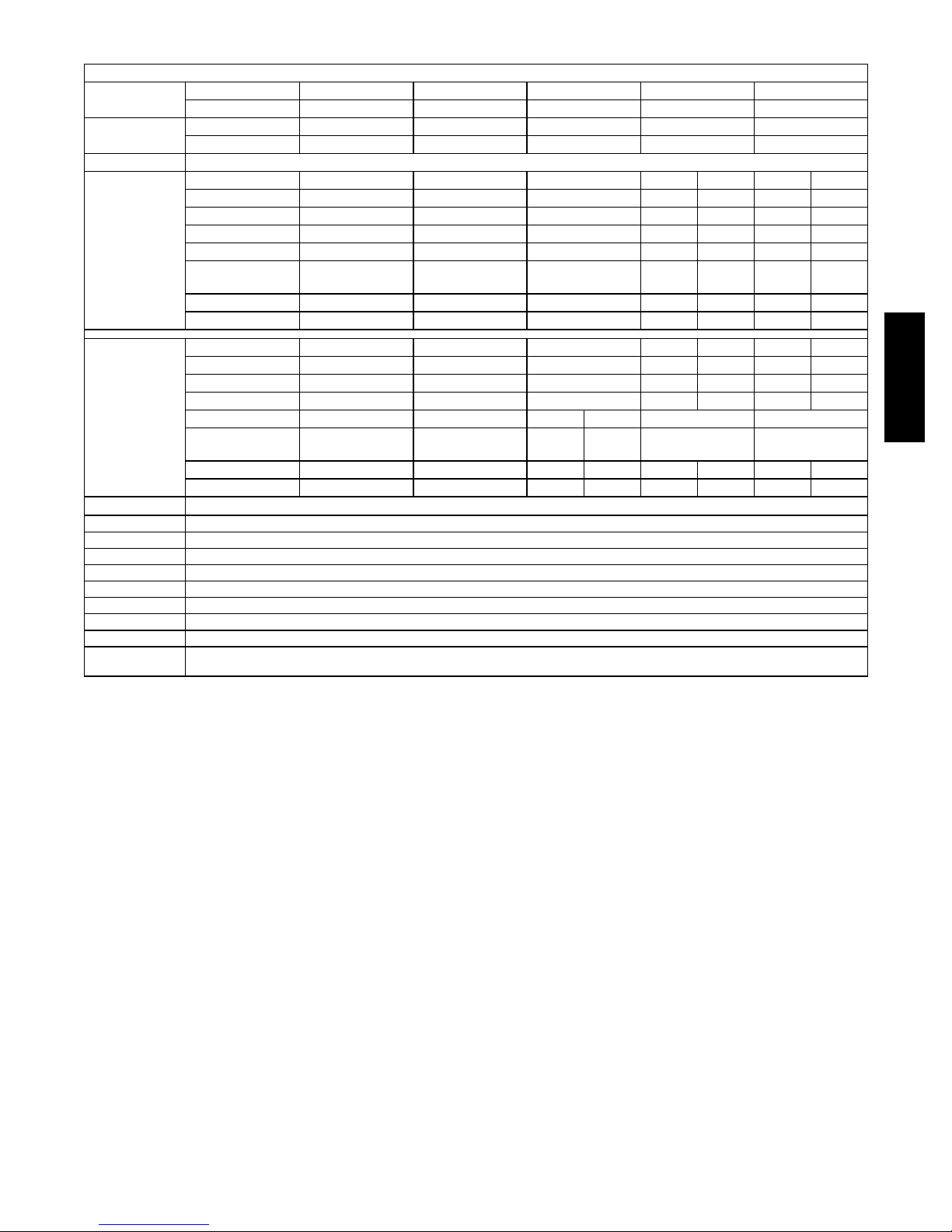

Table 2A — Physical Data — 569J*12-14D/E/F Units — 60 Hz English

UNIT 569J*12D/E/F 569J*14D/E

NOMINAL CAPACITY (tons) 10 12.5

OPERATING WEIGHTS (lb)

Round Tube/Plate Fin Coil (Cu/Al) 516 654

REFRIGERANT TYPE

Operati ng Charge 1/2 (w/ fan coil), T y p i c al (lb )

Shipping Charge 1/2 (lb) 9.0 / 9.0 9.0/9.0

COMPRESSOR

Qty...Type 2...Scroll 2...Scroll

Oil Charge 1/2 (oz) 42 60

CONDENSER FANS

Qty...Rpm 2...1100 2...1100

Motor Hp

Diameter 22 22

Nominal Airflow (Cfm Total) 6000 6000

Watts (Total) 610 610

RTPF CONDENSER COIL

Material (Tube/Fin) Cu / Al Cu / Al

Coil Type

Rows/Fins per inch (FPI) 2/17 3/17

Face Area (sq ft total) 25.1 31.8

CONTROLS

Pressurestat Settings (psig)

High Cutout 630 10 630 10

Cut-in 505 20 505 20

Low Cutout 54 3 54 3

Cut-in 117 5 117 5

PIPING CONNECTIONS (in. ODS)

Qty...Suction 1/2 1...11/8/ 1...11/81...13/8/ 1...13/

Qty...Liquid 1/2 1...3/8/ 1...3/

LEGEND

RTPF — Round Tube/Plate Fin

ODS — Outside Diameter Sweat (socket)

‡

Unit is factory-supplied with partial charge only.

†

Typical operating charge with 25 ft of interconn ecting pipin g.

‡

†

R-410A R-410A

11.0 / 11.0 22.0/22.0

1

/

4

3

/8--- i n R TP F

8

1

/

4

3

/8--- i n R TP F

1...1/2/ 1...1/

8

2

8

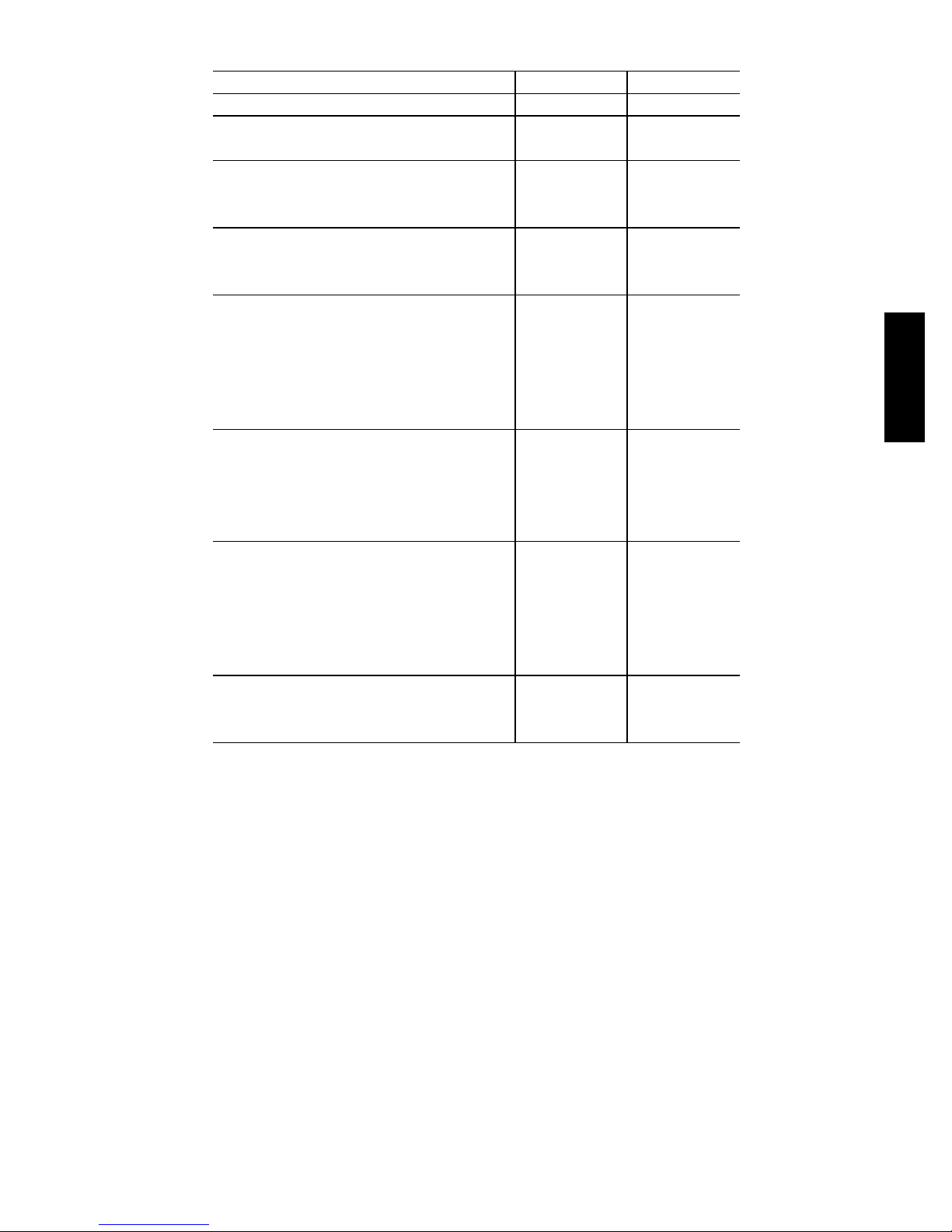

Table 2B — Physical Data — 569J*12-14D/E/F Units — 60 Hz SI

UNIT 569J*12D/E/F 569J*14D/E

NOMINAL CAPACITY (kW) 35.1 44

OPERATING WEIGHTS (kg)

Round Tube/Plate Fin Coil (Cu/Al) 234 297

REFRIGERANT TYPE

Operati ng Charge 1/2 (w/ fan coil), T y p i c al (kg )

Shipping Charge 1/2 (kg) 4.1 / 4.1 4.1 / 4.1

COMPRESSOR

Qty...Type 2...Scroll 2...Scroll

Oil Charge 1/2 (L) 1.2 1.7

CONDENSER FANS

Qty...r/s 2...1100 2...1100

Motor Hp NEMA

Diameter (mm) 560 560

Nominal Airflow (Cfm Total) 6000 6000

Watts (Total) 610 610

RTPF CONDENSER COIL

Material (Tube/Fin) Cu / Al Cu / Al

Coil Type

Rows/Fins per Meter (Fins/m) 2 / 670 3 / 670

Face Area (sq m total) 2.3 3.0

CONTROLS

Pressurestat Settings (kPa)

High Cutout 4347 70 4347 70

Cut-in 3482 138 3482 138

Low Cutout 372 21 372 21

Cut-in 807 34 807 34

PIPING CONNECTIONS (in. ODS)

Qty...Suction 1/2 1...11/8/ 1...11/81...13/8/ 1...13/

Qty...Liquid 1/2 1...3/8/ 1...3/

LEGEND

RTPF — Round Tube/Plate Fin

NEMA — National Electrical Manufacturers Association

ODS — Outside Diameter Sweat (socket)

‡

Unit is factory-supplied with partial charge only.

†

Typical operating charge with 7.62 m of interconnecting piping.

‡

†

R-410A R-410A

5.0 / 5.0 10.0 / 10.0

1

/

4

3

/8--- i n R TP F

8

3

/8--- i n R TP F

1...1/2/ 1...1/

1

/

4

569J

8

2

9

Matching 569J Model to Evaporator Coil

The Model 569J***A/B/G/H is a single-circuit unit design,

requiring one set of refrigeration piping. This model can be

connected to an evaporator coil with one circuit or with two

circuits (by manifolding the evaporator connections into a

single piping system).

The Model 569J***D/E/F is a dual-circuit unit design that

requires two sets of refrigeration piping between the

outdoor unit and the evaporator coil (or coils). This model

can only be connected to an evaporator coil that has two

refrigeration circuits (or to two separate evaporator coils).

The Model 569J***D/E/F CANNOT be connected to a

single-circuit evaporator coil. The Model 569J***D/E/F

CANNOT be field-converted to a single-circuit design.

Table 3 – Evaporator Coil Connections

Evaporator Coil has Connect to Model Notes

569J

Single Circuit 569J***A/B/G/H

Two Circuits

569J***A/B/G/H

Or

569J***D/E/F

Before unpacking this new 569J model, compare the

evaporator coil design to the 569J model.

Manifold evaporator

circuits into single

piping system

Use two separate

piping systems

RIGHT:

REAR:

Min 18” (457 mm)

requried for service

LEFT:

Min 18” (457 mm)

requried for service

FRONT:

42” (1067 mm)

Note: Observe requirements for 39” (914 mm) operating clearance

on either Left or Rear coil opening.

requried for service

Min 18” (457 mm)

requried for service

C110201

Fig. 4 -- Service Clearance Dimensional Drawing

Do not install the outdoor unit in an area where fresh air

supply to the outdoor coil may be restricted or when

recirculation from the condenser fan discharge is possible.

Do not locate the unit in a well or next to high walls.

Evaluate the path and required line length for

interconnecting refrigeration piping, including suction

riser requirements (outdoor unit above indoor unit), liquid

line lift (outdoor unit below indoor unit) and hot gas

bypass line. Relocate sections to minimize the length of

interconnecting tubing.

DO NOT BURY REFRIGERATION LINES.

.INSTALLATION

Jobsite Survey

Complete the following checks before installation.

1. Consult local building codes and the NEC (National

Electrical Code) ANSI/NFPA 70 for special installation requirements.

2. Determine unit location (from project plans) or select

unit location.

3. Check for possible overhead obstructions which may

interfere with unit lifting or rigging.

Step 1 — Plan for Unit Location

The 569J units are designed and approved for outdoor

installation only. Do not locate these units indoors. Do not

add ducting to unit fan system.

Select a location for the unit and its support system (pad,

rails or other) that provides for the minimum clearances

required for safety. This includes the clearance to

combustible surfaces, unit performance and service access

below, around and above unit as specified in unit drawings.

See Fig. 4.

NOTE: Local codes may require different clearances

than specified in Fig. 4. It is the responsibility of installers

to be knowledgeable in local codes and to modify the

recommended clearances to satisfy local codes.

NOTE: Consider also the effect of adjacent units on

airflow performance and control box safety clearance.

Although unit is weatherproof, avoid locations that permit

water from higher level runoff and overhangs to fall onto

the unit.

Step 2 — Complete Pre-Installation Checks

Check Unit Electrical Characteristics: Confirm before

installation of unit that voltage, amperage and circuit

protection requirements listed on unit data plate agree with

power supply provided.

Un--crate Unit: Remove unit packaging except for the top

skid assembly, which should be left in place until after the

unit is rigged into its final location.

Inspect Shipment: File a claim with shipping company if

the shipment is damaged or incomplete.

Consider System Requirements:

S Consult local building codes and National Electrical Code

(NEC, U.S.A.) for special installation requirements.

S Allow sufficient space for airflow clearance, wiring,

refrigerant piping, and servicing unit. See Fig. 3 for unit

dimensions and weight distribution data.

S Locate the unit so that the outdoor coil (condenser)

airflow is unrestricted on all sides and above.

S The unit may be mounted on a level pad directly on the

base channels or mounted on raised pads at support

points. See Tables 1A through 2B for unit operating

weights. See Fig. 3 for weight distribution based on

recommended support points.

10

NOTE: If vibration isolators are required for a particular

installation, use the data in Fig. 3 to make the proper

selection.

Step 3 — Prepare Unit Mounting Support

Slab Mount —

Provide a level concrete slab that extends a minimum of 6

in. (150 mm) beyond unit cabinet. Install a gravel apron in

front of condenser coil air inlet to prevent grass and

foliage from obstructing airflow.

Step 4 — Rig and Mount the Unit

!

CAUTION

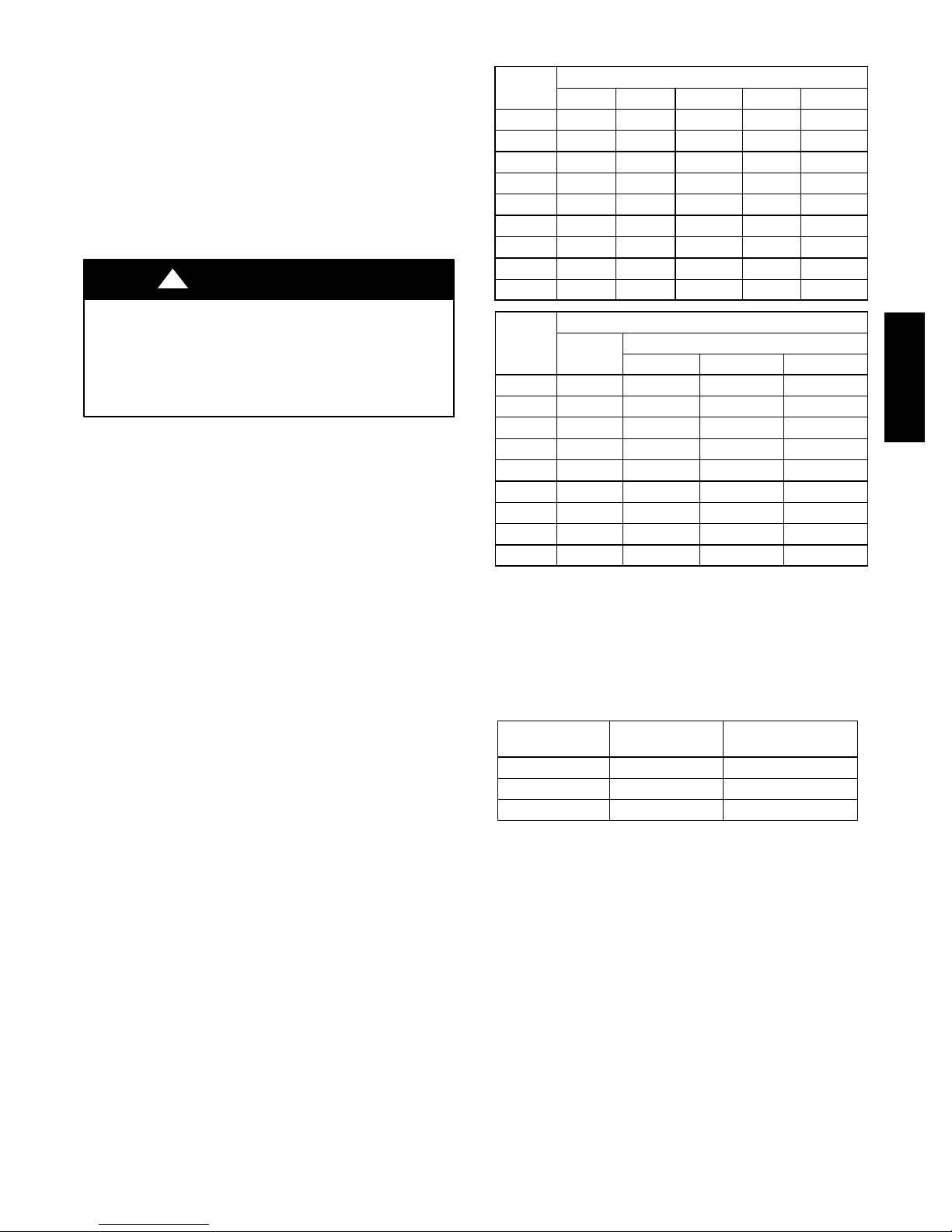

Table 4 – Equivalent Lengths for Common Fittings (ft)

Nominal

Tube OD

3

/

8

1

/

2

5

/

8

3

/

4

7/

8

11/

8

13/

8

15/

8

21/

8

90 Std 90 Lrad 90 Street 45 Std 45 Street

1.3 0.8 2.2 0.6 1

1.4 0.9 2.3 0.7 1.1

1.6 1 2.5 0.8 1.3

1.8 1.2 2.9 0.9 1.5

2 1.4 3.2 0.9 1.6

2.6 1.7 4.1 1.3 2.1

3.3 2.3 5.6 1.7 3

4 2.6 6.3 2.1 3.4

5 3.3 8.2 2.6 4.5

Elbows

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage.

All panels must be in place when rigging. Unit is not

designed for handling by fork truck.

Rigging: These units are designed for overhead rigging.

Refer to the rigging label for preferred rigging method.

Spreader bars are not required if top crating is left on the

unit. All panels must be in place when rigging. As further

protection for coil faces, plywood sheets may be placed

against the sides of the unit, behind cables. Run cables to

a central suspension point so that the angle from the

horizontal is not less than 45 degrees. Raise and set the

unit down carefully.

If it is necessary to roll the unit into position, mount the

unit on longitudinal rails, using a minimum of 3 rollers.

Apply force to the rails, not the unit. If the unit is to be

skidded into position, place it on a large pad and drag it

by the pad. Do not apply any force to the unit.

Raise from above to lift the unit from the rails or pad

when unit is in its final position.

After the unit is in position, remove all shipping materials

and top crating.

Step 5 — Determine Refrigerant Line Sizes

Select the recommended line sizes for 569J***A/B/G/H

and 569J***D/E/F unit from the appropriate tables.

Determine the linear length of interconnecting piping

required between the outdoor unit and indoor unit

(evaporator). Consider and identify also the arrangement

of the tubing path (quantity and type of elbows in both

lines), liquid line solenoid size, filter drier and any other

refrigeration specialties located in the liquid line. Refer to

the indoor unit installation instructions for additional

details on refrigeration specialties devices.

Determine equivalent line length adjustments for path and

components and add to linear line lengths. See Table 4,

Equivalent Lengths for Common Fittings, for usual fitting

types. Also identify adjustments for refrigeration

specialties. Contact Bryant Applications Engineering for

additional data and information on equivalent lengths.

Nominal

Tube OD

3

/

8

1

/

2

5

/

8

3

/

4

7/

8

11/

8

13/

8

15/

8

21/

8

Branch

Flow

2.6 0.8 1.1 1.3

2.7 0.9 1.2 1.4

3.5 1.2 1.7 1.8

10 3.3 4.7 5

No Reduct Reduce 25% Reduce 50%

3 1 1.4 1.6

4 1.4 1.9 2

5 1.7 2.3 2.6

7 2.3 3.1 3.3

8 2.6 3.7 4

Tees

Straight-Thru

NOTE: Equivalent line lengths will vary based on tube

diameter. Calculate equivalent line length for each pipe by

adding equivalent length adjustments to linear lengths for

each pipe.

Enter the appropriate table to select the recommended line

sizes.

Model/

Position #8

569J***A/B/G/H 5 1

569J***D/E 6 2

569J*12F 7 2

Ta ble Quantity of Line Sets

Liquid Lift —

A liquid lift condition exists when the outdoor unit is located

below the indoor (evaporator) unit and liquid flows vertically

up in a portion of the liquid line. The vertical column of

liquid reduces the available state point subcooling at the

evaporator coil’s thermal expansion valve. This effect

reduces the length of liquid lift (feet of elevation) that a

liquid line size can accommodate. Longer linear tube lengths

will also reduce the amount of liquid lift possible.

Check Tables 5 (569J***A/B/G/H), 6 (569J***D/E) and 7

(569J*12F) for maximum liquid lift capabilities for line

sizes. Reselect the liquid line tube size if necessary. If

maximum available tube size cannot provide the required lift

distance on this installation, relocate the outdoor unit to

reduce the equivalent line length or the lift requirement.

569J

11

Table 5 – 569J*07-14A/B/G/H Piping Recommendations (Single-Circuit Unit)

Linear Length Ft 0 --- 2 5 25 --- 50 50 --- 75 75 --- 100 100 --- 125

m 0 --- 8 8 --- 1 5 15 - -- 23 23 --- 30 30 --- 38

Equivalent

Length

Model

569J*07A/B/G/ H

569J*08A/B

569J

569J*12A/B

569J*14A/B

Legend:

TC Total Capacity, MBH (at 45 F Saturated suction, 95 F outdoor air temp)

SC Sub ---cooling, degrees F (at liquid line valve)

Liquid PD (_F) Liquid line pressure drop, saturated temperature, degrees F

Max Lift Maximum liquid lift (Indoor unit ABOVE outdoor unit only), at maximum permitted pressure drop.

Max Lift PD (_F) Pr essure drop inclu ding Maximum liquid lift value

SuctionLnPD(_F) Suction line pressure drop, saturated temperature, degree F

(Cap Red) Capacity reduction caused by suction line pressure drop GT 2 deg F

#/TR Charge to unit capacity ratio, lbs per ton (at 45 F SST, 95 F ODA)

NOTE: For applications with equivalent length greater than 188 ft (57 m) and/or linear length greater than 125 ft (38 m), contact your local

Ft 0 --- 3 8 38 --- 75 75 --- 113 113 --- 150 150 --- 188

m 0 --- 1 2 12 --- 23 23 --- 34 34 --- 46 46 --- 57

Liquid Line size

3

/8”

3

/8”

1

/2”

1

/2”

5

/8”

1

/2”

5

/8”

Liquid PD (_F) 2.0 4.0 0.7 1.1 0.3 1.4 0.4 1.8 0.5

Max Lift 18 7 34 31 39 44 57 41 57

Max Lift PD (_F) 3.5 4.6 3.5 3.5 3.5 5.0 5.0 5.0 5.0

Suction Line size 7/8”

7

/8” 1 ---1/8”7/8” 1 ---1/8”7/8” 1 ---1/8”7/8” 1 ---1/8”

SuctionLnPD(_F) 0.9 1.8 0.5 2.7 0.8 3.6 1.0 4.5 1.3

Charge 10.8 11.8 13.7 15.2 18.5 16.9 21.3 18.7 24.2

#/TR 1.90 2.07 2.41 2.67 3.25 2.97 3.74 3.28 4.25

Liquid Line size

1

/2”

1

/2”

5

/8”

1

/2”

5

/8”

1

/2”

5

/8”

Liquid PD (_F) 0.6 1.3 0.3 1.9 0.5 2.5 0.7 3.2 0.9

Max Lift 25 50 50 75 75 100 100 97 97

Max Lift PD (_F) 2.7 5.4 4.5 8.1 6.7 10.8 9.0 11.2 8.9

Suction Line size 7/8”

7

/8” 1 ---1/8”7/8” 1 ---1/8” 1 ---1/8” 1 ---1/8” 1 ---3/8”

SuctionLnPD(_F) 1.5 3.1 0.8 4.6 1.2 1.6 2.1 0.7

Charge 13.6 15.4 16.1 17.2 20.5 19.5 23.3 21.5 27.1

#/TR 1.78 2.02 2.11 2.25 2.68 2.55 3.05 2.81 3.54

Liquid Line size

1

/2”

1

/2”

5

/8”

1

/2”

5

/8”

1

/2”

5

/8”

Liquid PD (_F) 0.9 1.9 0.5 2.8 0.8 3.8 1.0 4.7 1.3

Max Lift 25 40 50 28 54 34 68 22 65

Max Lift PD (_F) 2.9 5.0 4.5 5.0 5.0 6.5 6.4 6.5 6.4

Suction Line size 7/8”

7

/8” 1 ---1/8” 1 ---1/8” 1 ---3/8” 1 ---1/8” 1 ---3/8” 1 ---1/8” 1 ---3/8”

SuctionLnPD(_F) 2.4 4.8 1.2 1.8 0.6 2.4 0.9 3.1 1.1

Charge 15.7 17.5 19.7 19.8 23.1 21.6 26.1 23.6 29.2

#/TR 1.67 1.86 2.09 2.10 2.45 2.29 2.77 2.50 3.10

Liquid Line size 5/8”

5

/8” 3/4”

5

/8”

3

/4”

5

/8”

3

/4”

Liquid PD (_F) 0.4 0.8 0.4 1.2 0.6 1.6 0.8 2.0 1.1

Max Lift 23 16 23 10 18 28 38 21 36

Max Lift PD (_F) 1.8 1.84 1.84 1.8 1.8 3.3 3.3 3.3 3.3

Suction Line size 1 -- -1/8” 1 ---1/8” 1 ---3/8” 1 ---1/8” 1 ---3/8” 1 ---3/8” 1 ---3/8” 1 ---5/8”

SuctionLnPD(_F)

(Cap Red)

1.1 2.2 0.8 3.3

(---2.3%)

1.2 1.6 2.0 0.8

Charge 31.8 34.7 37.6 37.6 41.8 41.1 46.1 44.2 51.6

#/TR 2.62 2.86 3.09 3.09 3.44 3.38 3.79 3.64 4.24

Bryant representative.

1

/2”

1

/2”

1

/2”

5

/8”

5

/8”

5

/8”

5

/8”

3

/4”

12

Table 6 – 569J*12-14D/E Piping Recommendations (Two-Circuit Unit)

NOTE: 569J*D/E requires TWO sets of refrigeration piping

Linear Length

Equivalent

Length

Model

569J*12D/E

569J*14D/E

Legend:

TC Total Capacity, MBH (at 45 F Saturated suction, 95 F outdoor air temp)

SC Sub -- -cooling, degrees F (at liqu id line valve)

Liquid PD (_F) Liquid line pressure drop, saturated temperature, degrees F

Max Lift Maximum liquid lift (Indoor unit ABOVE outdoor unit only), at maximum permitted pressure drop.

Max Lift PD (_F) Pressure drop including Maximum liquid lift value

SuctionLnPD(_F) Suction line pressure drop, saturated temperature, degree F

(Cap Red) Capacity reduction caused by suction line pressure drop GT 2 deg F

#/TR Charge to unit capacity ratio, lbs per ton (at 45 F SST, 95 F ODA)

NOTE: For applications with equivalent length greater than 188 ft (57 m) and/or linear length greater than 125 ft (38 m), contact your local Bryant

Ft 0 --- 2 5 25 --- 50 50 --- 75 75 --- 100 100 --- 125

m 0 --- 8 8 --- 1 5 15 --- 23 23 --- 30 30 --- 38

Ft 0 --- 3 8 38 --- 75 75 --- 113 113 --- 150 150 --- 188

m 0 --- 1 2 12 --- 23 23 --- 34 34 --- 46 46 --- 57

Liquid Line size

3

/8”

3

/8”

3

/8”

3

/8”

1

/2”

3

/8”

1

/2”

Liquid PD (_F) 1.4 2.7 5.5 5.5 0.9 6.9 1.1

Max Lift 25 50 75 82 100 66 125

Max Lift PD (_F) 3.4 6.8 10.2 12.1 9.0 12.1 11.2

Suction Line size3/4”

SuctionLnPD(_F)

(Cap Red)

1.4 1.2 1.8

7

/8”

7

/8”

7

/8” 1 ---1/8”7/8” 1 ---1/8”

2.5

(---0.8%)

0.8

3.1

(---1.9%)

0.9

Charge 9.0 10.0 11.0 12.1 15.7 13.1 17.7

#/TR 0.73 0.81 0.89 0.97 1.27 1.05 1.42

Liquid Line size

3

/8”

3

/8”

3

/8”

3

/8”

1

/2”

3

/8”

1

/2”

Liquid PD (_F) 2.1 4.1 6.2 8.2 1.5 10.3 1.8

Max Lift 128 50 75 69 155 42 125

Max Lift PD (_F) 4.0 8.1 12.1 13.6 9.4 13.6 11.7

Suction Line size7/8”

SuctionLnPD(_F)

1.0 1.9 2.9

(Cap Red)

7

/8”

7

/8” 1 ---1/8” 1 ---1/8” 1 ---1/8”

0.8 1.1 1.4

(---1.5%)

Charge 17.0 18.0 19.0 19.5 20.6 23.7 21.8 25.7

#/TR 1.36 1.44 1.52 1.56 1.65 1.90 1.74 2.05

representative.

569J

13

Table 7 – 569J*12F HGBP Piping Recommendations (Two-Circuit Unit)

NOTE: 569J*12F units require TWO sets of refrigeration piping

Linear Length Ft 0-25 25-50 50-75 75-100 100-125

m 0-8 8-15 15-23 23-30 30-38

Equivalent

Length

Model

569J*12F Liquid Line

569J

Ft 0-38 38-75 75-113 113-150 150-188

m 0-12 12-23 23-34 34-46 46-57

3

/

8

3

/

8

3

/

8

3

/

1

8

/

Pressure Drop 1.8 3.5 5.2 8.7 1.2 8.7 1.5

Max Lift 25 50 75 65 100 62 125

Pressure Drop 3.8 7.5 11.3 12.2 9.4 13.7 11.7

Suction Line

Circuit 1: VAPOR RISER REQUIRED, NOT GREATER THAN 20 FT (6.1 M) --- See Fig. 5)

Tube S

Tube A

5

/

8

5

/

8

1-1/

5

/

8

8

1-3/

5

/

8

8

1-3/

5

/

8

8

Pressure Drop 2.0 2.0 1.9 2.0 2.0

Circuit 1: VAPOR RISER GREATER THAN 20 FT (6.1 M) --- See Fig. 6)

Tube S

Tube A

5

5

Tube B NR

/

8

/

8

7

/

8

5

/

8

1

/

2

7

/

8

5

/

8

5

/

8

1-1/

5

/

5

/

8

8

8

Pressure Drop 2.0 1.6 1.7 1.7 2.1

Circuit 1: NO VAPOR RISER REQUIRED

Circui t 2:

7

/

8

7

/

8

7

/

8

7

/

8

1-1/

1-1/

8

8

1-1/

1-1/

8

8

Pressure Drop 1.1 2.1 0.9 1.2 1.5

Charge (lbs) 1/2 13.3 14.3 15.8 16.9 20.0 18.1 22.0

3

2

/

8

1-3/

5

/

8

1-1/

5

/

8

5

/

8

1-1/

1-1/

1

/

2

8

8

8

8

Legend:

Equivalent Length Equivalent tubing length, including effects of refrigeration specialties devices

Linear Length Typical linear tubing length (50% added to linear to define Equivalent Length for this table)

Liquid Line Tubing size, inches OD.

Max Lift Maximum liquid lift (indoor unit ABOVE outdoor unit only), at maximum permitted liquid line pressure drop —

Suction Line Tube size, inches OD

Charge Charge Quantity, lbs. Calculated for both liquid line sizes (where applicable), but only with larger suction line size (where applicable)

NOTE: For applications with equivalent length greater than 188 ft (57 m) and/or linear length greater than 125 ft (38 m), contact your local

S Linear Length Less than 75 ft (23 m): Minimum 2.0° F subcooling entering TXV

S Linear Length Greater than 75 ft (23m): Minimum 0.5° F subcooling entering TXV

Bryant representative.

14

Suction Riser —

A suction riser condition exists when the outdoor unit is

located above the indoor (evaporator) unit and suction

vapor must flow vertically up to return to the compressor.

Oil return is a concern when the suction tube size is too

large to produce the minimum refrigerant velocity to

ensure oil return at minimum load conditions.

569J***A/B/G/H and 569J***D/E (WITHOUT HGBP)

Check Table 8 for maximum suction tube size for 569J units

at minimum load conditions. Consider suction speed riser

(reduced tube size for vertical segment only) or double

suction riser arrangement if the planned suction tube size

does not provide necessary minimum flowrates for this riser.

Ta bl e 8 –

Model: Unit Size Maximum Tube Size

569J***A/B 07 13/

569J*07G/H 07 11/

569J***D/E 12 13/

569J*12F 12 See Table 7

569J Maximum Suction Pipe Size

8

08 15/

12 15/

14 21/

14 15/

8

8

8

8

8

8

A

20-FT (6.1 M) MAX

S

LEGEND

A - Suction Riser Without Trap

S - Suction Line to Condensing Unit

CONDENSING

UNIT

C12404

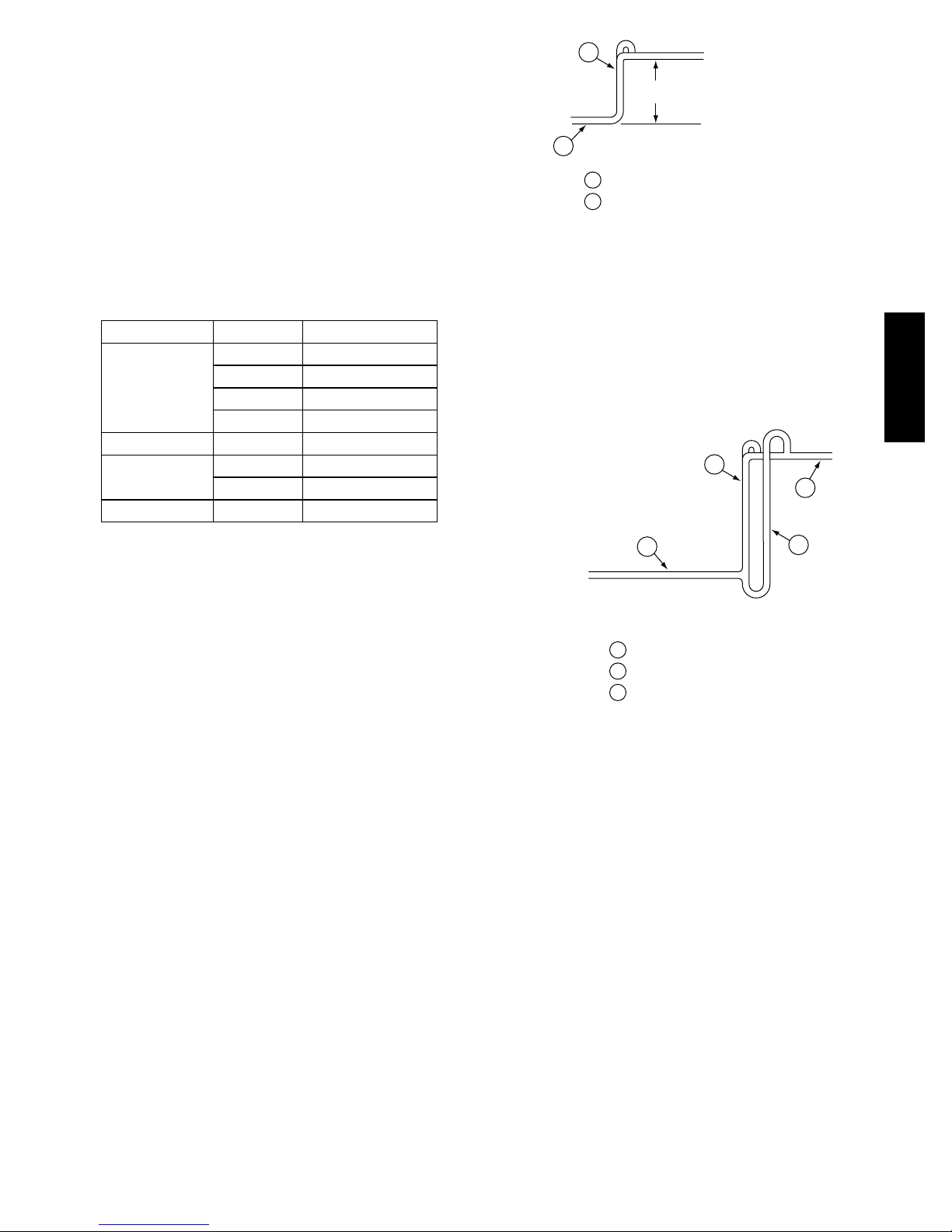

Fig. 5 -- Suction Line Piping -- Speed Riser

If the vertical elevation difference is greater than 20--ft

(6.1--m) linear feet or requires more than two short lift

segments, select the Circuit 1 suction line size from

Double Suction Riser lines data under VAPOR RISER

GREATER THAN 20 FT (6.1 M). See Fig. 6. Tube S is

the horizontal line size. Tube A is the reduced diameter

riser size without bottom trap; Tube B is the parallel riser

size with bottom oil trap.

A

S

569J

569J*12F UNIT WITH OPTIONAL HOT GAS BYPASS

Special consideration for suction riser requirements must

be considered when applying this factory--installed hot gas

bypass. It is extremely important to consider the lowest

possible refrigerant tons of refrigerant flow when hot gas

bypass is functioning to assure proper oil return up suction

risers.

Table 7 provides recommended tube sizes for model

569J*12F unit which includes the factory--installed hot

gas bypass system on Circuit 1. The selections in this

table are based on evaluations of system minimum load

operating conditions for comfort cooling applications,

with compressor saturated suction pressure to 28_F

(--2.2_C) minimum.

Table 7 includes liquid line size selections based on use of

RTPF coil option only.

Table 7 includes three different suction line size selections

for Circuit 1 based on the elevation difference conditions

between the 569J unit and the evaporator coil location.

Outdoor unit ABOVE evaporator coil: This installation

will have at least one suction riser segment. If the vertical

elevation difference is less than 20--ft (6.1 m) linear feet

and requires only one or two segments, consider a speed

riser selection for Circuit 1; use the line marked VAPOR

RISER REQUIRED; NOT GREATER THAN 20 FT

(6.1 M). See Fig. 5. Tube S is the horizontal line size;

tube A is the reduced diameter riser size.

S

FROM

EVAPORATOR

LEGEND

A - Suction Riser Without Trap

B - Suction Riser With Trap

S - Suction Line to Condensing Unit

B

C12405

Fig. 6 -- Suction Line Piping -- Double Riser

Outdoor unit BELOW evaporator coil and no vertical

riser segments: Select Circuit 1 suction line size from

NO VAPOR RISER line.

Circuit 2 suction line: Because there is no hot gas bypass

system in Circuit 2, no special riser selections are

necessary. Select Circuit 2 suction line from bottom line

for all 569J*12F installations.

Vertical Separation (outdoor unit above indoor unit) –

Vertical elevation difference of 200 ft (60 m) is permitted

when the outdoor unit (569J***A/B/G/H or

569J***D/E/F) is located above the indoor unit.

15

Step 6 — Complete Refrigerant Piping Connections

IMPORTANT: Do not bury refrigerant piping

underground.

IMPORTANT: A refrigerant receiver is not provided

with the unit. Do not install a receiver.

Provide Safety Relief —

If local codes dictate an additional safety relief device,

purchase locally and install locally. Installation will

require the recovery of the factory shipping charge before

the factory tubing can be cut and the supplemental relief

device is installed.

Model 568J***D/E/F has two separate refrigeration systems.

If required, each circuit will require a field-supplied/installed

supplemental relief device.

Check 569J Model with Evaporator Coil Connections —

569J

Confirm before installation of unit that the evaporator coil

connections are consistent with this 569J model. See

Table 3 on page 10.

Insulate Suction Lines —

Apply closed-cell tubular insulation to all suction lines

between evaporator coil connection and 569J unit’s suction

service valve.

569J***D/E/F Piping Connections —

The 569J***D/E/F’s two circuits are designated Circuit 1

and Circuit 2. Circuit 1 is controlled by the thermostat’s Y1

(or TC1) contact and will be the first circuit on and last

circuit off. Circuit 2 is controlled by the thermostat’s Y2 (or

TC2) contact and this circuit is always the “lag” circuit.

Plan the Circuit 1 and Circuit 2 tubing segments carefully,

mark each segment and check constantly as piping

systems are assembled to avoid piping errors.

569J***D/E/F unit cannot be field-piped as a

single-circuit/tandem system.

Final Tubing Check. 569J***D/E/F —

Before completing the field piping connections to the

569J***D/E/F unit service valves, confirm that the

suction line to the indoor coil’s first--on/last--off circuit

(and its companion liquid line) are correctly identified as

Circuit 1 use for the 569J***D/E/F unit. If a suction riser

is required, it must be in Circuit 1.

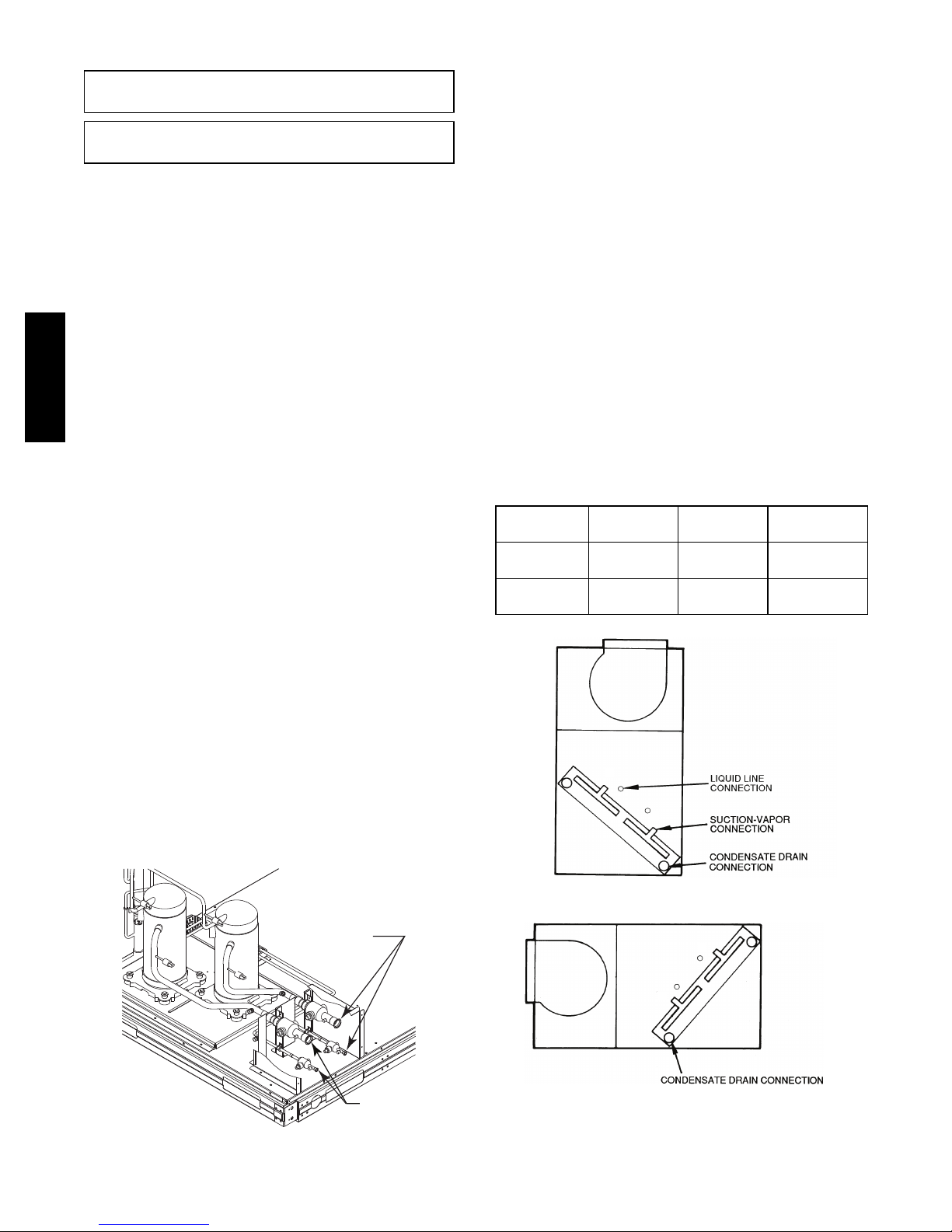

Connecting 524J to 569J***D/E/F: The 524J fan coil in

sizes 12, 14 and 16 is a face-split coil design that also has its

circuits designated as 1 and 2. See Fig. 8. Note that the

lower coil segment changes as the arrangement of the 524J

changes. In a vertical arrangement, the 524J’s lower coil

segment is segment 2; this segment should be connected to

the 569J***D/E/F’s Circuit 1. In a horizontal arrangement,

the 524J’s lower segment is now segment 1; this segment

should be connected to the 569J***D/E/F’s Circuit 1.

Note that refrigerant suction piping should be insulated.

524J

Arrangement

Vertical

Horizontal

Cooling

Stage

Y1

Y2

Y1

Y2

524J Coil

Segment

2

1

1

2

Connect to

569J***D/E/F

Circuit 1

Circuit 2

Circuit 1

Circuit 2

See Fig. 7 for location of Circuit 1 and Circuit 2 service

valves and field piping connections. Circuit 1 is on the

right-hand side of the service valve compartment; Circuit 2

is on the left.

When a single piece evaporator coil with two separate circuits

is connected to a 569J***D/E/F, the lower coil circuit should

be connected to the 569J***D/E/F’s Circuit 1 so that the

evaporator’s lower coil segment is first-on/last-off (to avoid

re-evaporation of condensate on dry lower coil segments).

CKT

2

CKT

1

Circuit 1

Connections

Connections

Circuit 2

C10912

Fig. 7 -- 569J***D/E/F Service Valve Locations

1

2

FIRS T ON/LA ST OFF = 2

VERTICAL INSTALLATION

2

1

FIRS T ON /LAST OF F = 1

HORIZONTAL INSTALLATIO N

C10071

Fig. 8 -- Typical Evaporator Coil Connections (524J)

16

Install Filter Drier(s) and Moisture Indicator(s) —

Every unit MUST have a filter drier in the liquid line.

569J***D/E/F models require two filter driers (one in each

liquid line). Locate the filter drier(s) at the indoor unit, close to

the evaporator coil’s thermal expansion valve (TXV) inlets.

569J units include one (569J***A/B/G/H) or two

(569J***D/E/F) Puron-duty filter drier(s), shipped in cartons

attached to the unit basepan. Remove the filter drier(s) and

prepare to install in the liquid line(s) at the evaporator coil.

Do not remove connection fitting plugs until ready to

connect and braze the filter drier into the liquid line position.

Table 9 – Puron-duty Filter Drier(s)

Model-Size Qty

569J*07

A/B/G/H

569J*08A/B 1

569J*12A/B 1

569J*14A/B 1

569J*12D/E/F 2

569J*14D/E 2

Liquid

Line OD

3

1

/8-in 8cu.in. KH43LG091

1

/2-in 16 cu. in. KH43LG085

1

/2-in 16 cu. in. KH43LG085

5

/8-in 16 cu. in. KH43LG086

3

/8-in 8cu.in. KH43LG091

1

/2-in 16 cu. in. KH43LG085

Desiccant

Volume

Part

Number Ref

Installation of liquid line moisture indicating sightglass in

each circuit is recommended. Locate the sightglass(es)

between the outlet of the filter drier and the TXV inlet.

Refer to Table 10 for recommendations on refrigeration

specialties.

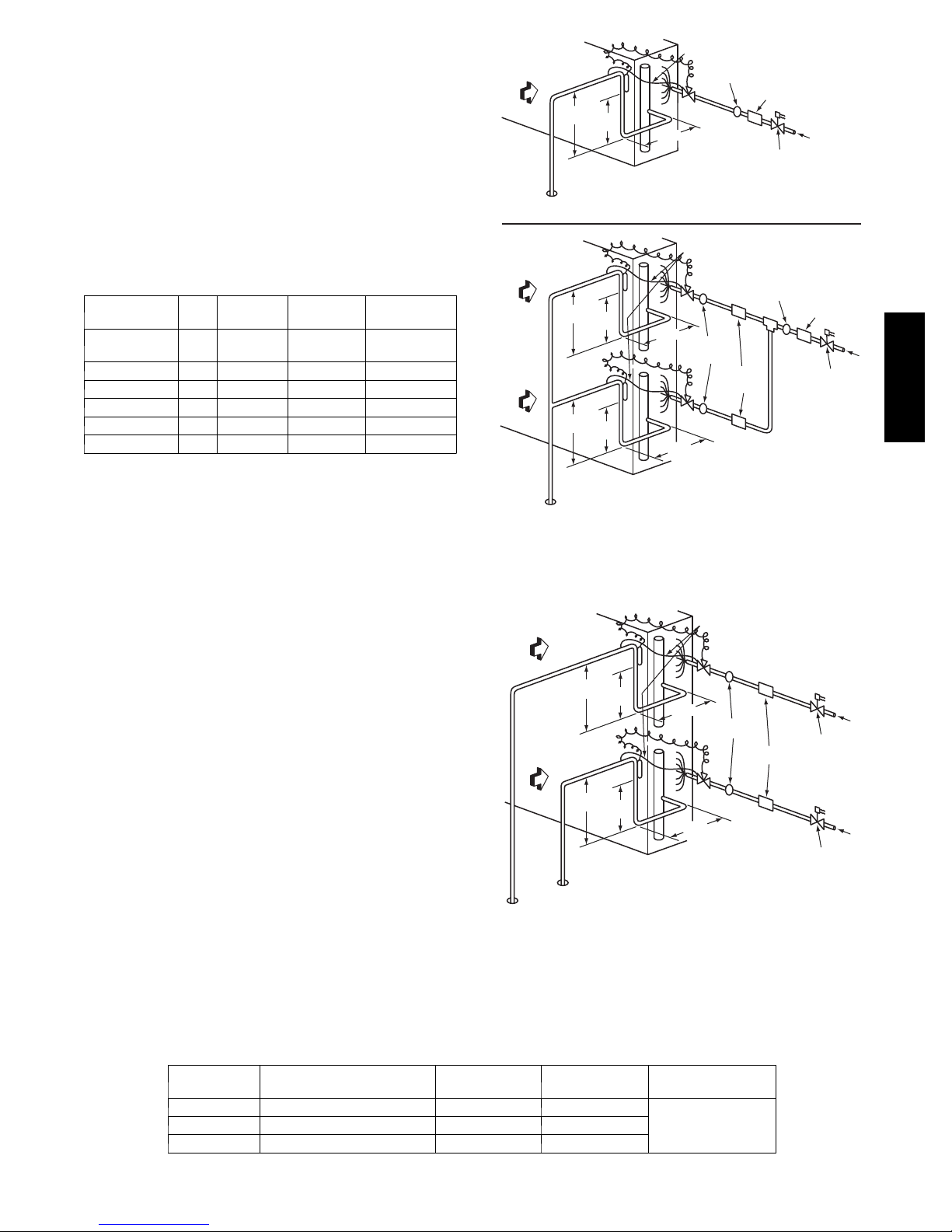

In some applications, depending on space and convenience

requirements, it may be desirable to install 2 filter driers and

sight glasses in a single circuit application. One filter drier

and sight glass may be installed at A locations (see Fig. 9)

or 2 filter driers and sight glasses may be installed at B

locations (see Figs. 9 and 10).

Select the filter drier for maximum unit capacity and

minimum pressure drop. Complete the refrigerant piping

from the indoor unit to the outdoor unit before opening

the liquid and suction lines at the outdoor unit.

Install Liquid Line Solenoid Valve —

It is recommended that a solenoid valve be placed in the

main liquid line (see Figs. 9 and 10) between the condensing

unit and the evaporator coil. Locate the solenoid valve at the

outlet end of the liquid line, near the evaporator coil

connections, with flow direction arrow pointed at the

evaporator coil. Refer to Table 10. (A liquid line solenoid

valve is required when the liquid line length exceeds 75 ft

[23 m].) This valve prevents refrigerant migration (which

causes oil dilution) to the compressor during the off cycle, at

low outdoor ambient temperatures. Wire the solenoid in

parallel with the compressor contactor coil (see Figs. 9 and

10). This means of electrical control is referred to as

solenoid drop control.

Table 10 – Refrigerant Specialties Part Numbers

LIQUID LINE

SIZE (in.)

3

/

8

1

/

2

5

/

8

569J***D/E/F units require TWO sets of parts.

LIQUID LINE

SOLENOID VALVE (LLSV)

EF680033 EF680037 KM680008

EF680035 EF680037 KM680004

EF680028 EF680032 KM680005

8 DIAMS

MIN

8 DIAMS

MIN

8 DIAMS

EQUALIZER LINE

TXV

EQUALIZER LINE

TXV

CKT 2

SIGHT

GLASSES

B LOCATION

TXV

CKT 1

MIN

SIGHT GLASS

A LOCATION

FILTER

DRIERS

B LOCATION

FILTER DRIER

A LOCATION

LIQUID LINE

SOLENOID

VALVE

SIGHT GLASS

A LOCATION

INDOOR

COIL CKT

AIRFLOW

INDOOR

COIL CKT 2

AIRFLOW

INDOOR

COIL CKT 1

AIRFLOW

TXV

SENSING

BULB

15 DIAMS

10

MIN

DIAMS

Single Circuit Coil Piping Configuration

For single compressor condensing units

TXV

SENSING

BULB

15 DIAMS

10

MIN

DIAMS

TXV

SENSING

BULB

15 DIAMS

10

MIN

DIAMS

Dual Circuit Coil Piping Configuration

For single compressor condensing units

Fig. 9 -- Location of Sight Glass(es) and Filter Driers

Typical 569J***A/B/G/H Systems

8 DIAMS

MIN

8 DIAMS

EQUALIZER LINE

TXV

CKT 2

TXV

CKT 1

MIN

SIGHT

GLASSES

FILTER

DRIERS

AIRFLOW

AIRFLOW

SUCTION

CIRCUIT 2

TXV

SENSING

BULB

15 DIAMS

10

MIN

DIAMS

TXV

SENSING

BULB

15 DIAMS

10

MIN

DIAMS

SUCTION

CIRCUIT 1

Dual Circuit Coil Piping Configuration

For two circuit condensing units

Fig. 10 -- Location of Sight Glasses and Filter Driers

Typical 569J***D/E/F Systems

LLSV

COIL

17

SIGHT

GLASS

FILTER

DRIER

provided with unit

see Table 9

FLOW

FILTER DRIER

A LOCATION

LIQUID LINE

SOLENOID

VALVE

LIQUID LINE

SOLENOID VALVE

CIRCUIT 2

LIQUID LINE

SOLENOID VALVE

CIRCUIT 1

FLOW

569J

C10202

FLOW

FLOW

C10072

Loading...

Loading...