Page 1

393U

Installation Instructions

GAS FIRED FORCED AIR FURi^ACE

The Bryant Model 393 forced air, gas-fired furnace

may be installed as an

1.2.Upflow Furnace

Counter-Flow Furnace

(except sizes 175 and 200)

Basement Furnace

This instruction contains complete procedures for

installing the unit as an Upflow Furnace.

When the furnace is used as a counter-flow, a

counter-flow box and instructions are provided.

When it is used as a basement model, a drop duct

and instructions are provided. The Series C and D

Counter-Flow Boxes are interchangeable.

/1 \ fr

"iKJ V fl

Series D

39393D2

I

Rev. 3/17/65

Before beginning installation, read these instruc

tions carefully.

When making a Counter-Flow or Basement installa

tion, also read the separate instructions furnished

with the additional equipment required.

install the furnace in accordance with the require

ments of the local utility or authority having juris

diction.

The installer is referred to the American Standard

“Installation of Gas Appliances and Gas Piping,”

ASA Z21.30-1964, as a sound and practical guide

to be followed when making the installation.

INSPECTION

Check the power supply available to be sure it

agrees with the information on the wiring diagram

and the blower motor in the furnace.

Check the gas specification on the A.G.A. rating

plate to be sure that the type of gas for which the

unit is equipped is the same as the gas supply

available.

Model 393 Furnace

FILTERS

When the furnace air distribution system is used for

cooling, it is recommended in certain instances that

the throw-away filters be discarded and the perma

nent type, multi-velocity filters be substituted. The

following table gives the air flows above which

these high velocity filters should be used.

Size

80

100 1000

125

150

175

200

Air Flow - cfm

800

1240

1490

1800

1800

Leave these instructions on or near the furnace. Permanent filters are not required on Size 50.

Page 2

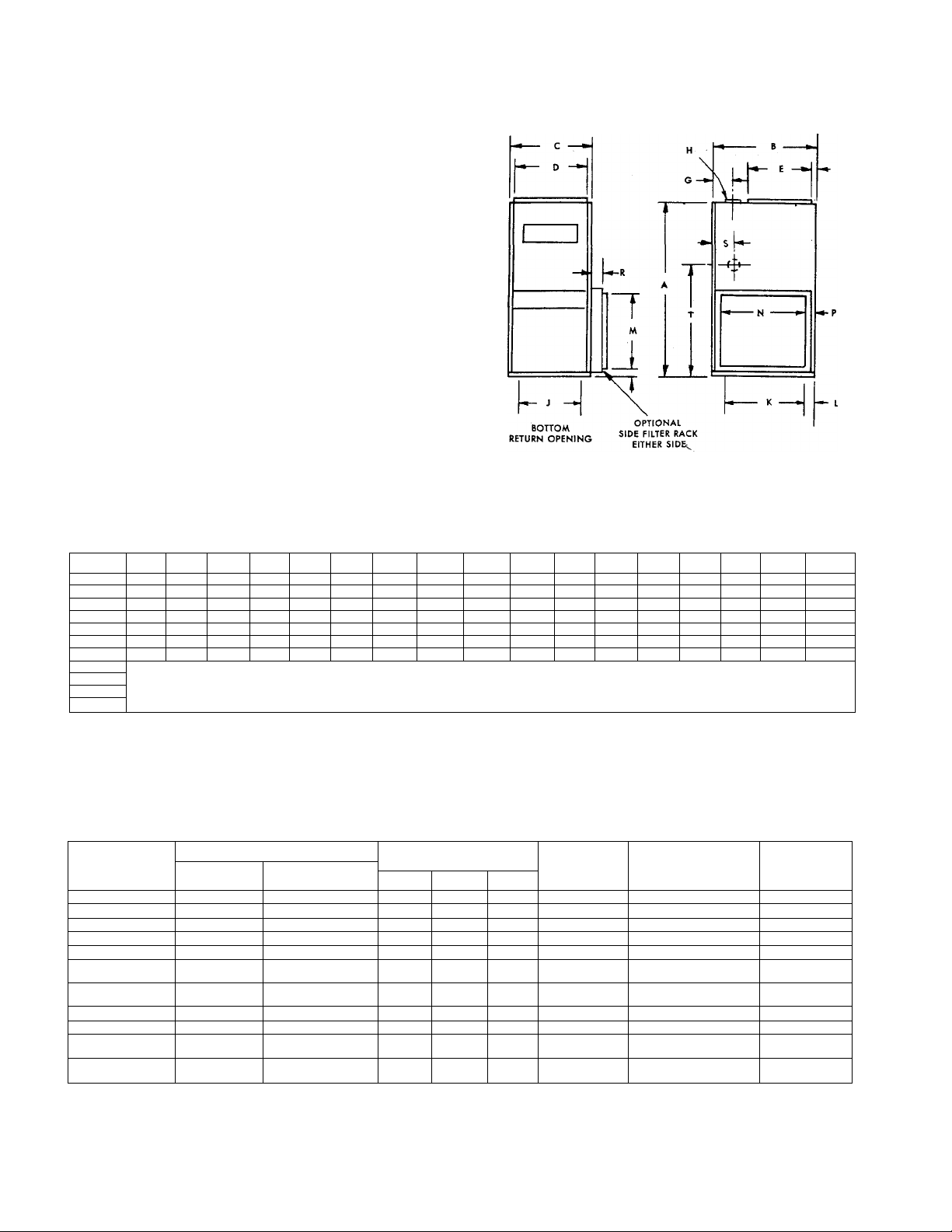

UPFLOW

FURNACE

Model No.

50-393 46 26 16% 14% 20

80-393 46

100-393 46 26 18% 165% 20

125-393 46

150-393

175-393 51

200-393

250-393

300-393

350-393

400-393

A

51

•28%

■ 51 28%

MODEL

NO.

50-393 50,000

*80-393 !

100-393 100,000

125-393

150-393 150,000

175-393 175,000 140,000

200-393 200,000 160,000

250-393 250,000

300-393

350-393

400-393

The 250, 300, 350 & 400 sizes are multiples of the 1 25, 1 50,

*For LP Gas, ModeJ Designation 80-V-393, A.G.A. Input 75,000,

283% 36%

Sizes 250 thru. 400 are multiples of sizes 125, 150, 175 and 200 respectively. Refer to the dimensions of smaller sizes to obtain overall’ dimensions for the

larger sizes. Provide clearance dimension between units for gas service and casing expansion. Refer to installation instructions for clearance.

C D E F G H

В

26 16%

26 20%

INPUT

*80,000

125,000

300,000 240,000

350,000 280,000

400,000 320,000

145% 20

185% 20

265%

28%

345%

345% 173%

36%

A.G.A. RATINGS BTU/HR GAS CONNECTION

23%

1%

23%

1%

3

1%

3 5" 18%

BONNET

40,000

64,000

80,000

100,000

120,000

200,000

'%

53%

2'%

43% (2)5" 33%

2'%

43% (2)5" 33%

21%

'%

1% 1% 1/2

'%

'%

% % %

%

% % %

(2) 1%

(2) % (2) 5%

(21 % (2) % (2) %

(2) %

175 & 200 respectively.

Bonnet Capacity 60,000.

173%

173%

CAPACITY NAT.

J К

4" 12% 22%

4" 12%

5"

6" 25%

SIZES

MFD. Prop.

. '/2

’% '%

% 1/2

% %

(2) % (2) 1/2

(2) % (2) %

22%

14% 22%

22%

23%

23% 25%

23% 25%

1%

(2) %

L M N P

23

12

1%

12 23

1%

14 23

1%

18 23

11%

25%

23

23

23

BOTTOM FILTER

SIZES

14 X 25 X 1

14 X 25 X 1

16 X 25 X 1 1 6 X 25 X 1

20 X 25 X 1

(2) 14 X 25 X 1 (2} 16 X 25 X 1

(1} 16 X 25 X 1

(1) 20 X 25 X 1

(1) 16 X 25 X 1

(1) 20 X 25 X 1

(2) 20 X 25 X 1

(4) 14 X 25 X 1

(2} 16 X 25 X 1

.(2) 20 X 25 X 1

(2) 16 X 25 X 1

(2) 20 X 25 X 1

24

24

24

SIDE FILTER

SIZES

14 X 25 X 1

14 X 25 X 1

20 X 25 X 1

(2) 16 X 25 X 1

(2) 16 X 25 X 1

(2) 20 X 25 X 1

[4} 1 6 X 25 X 1

[4} 1 6 X 25 X 1

(4) 16 X 25 X 1

1%

1%

1%

2% 8%

2%

2'%

R s

23%

2

1%

2 23%

2 23%

23%

2

4 30%

8% 4

8%

4

APPROX.

SHIPPING

WEIGHT

135

155

178

200

275

355

355

400

550

710

710

27%

27%

27%

27%

30%

30% .

t

393U

-2-

Page 3

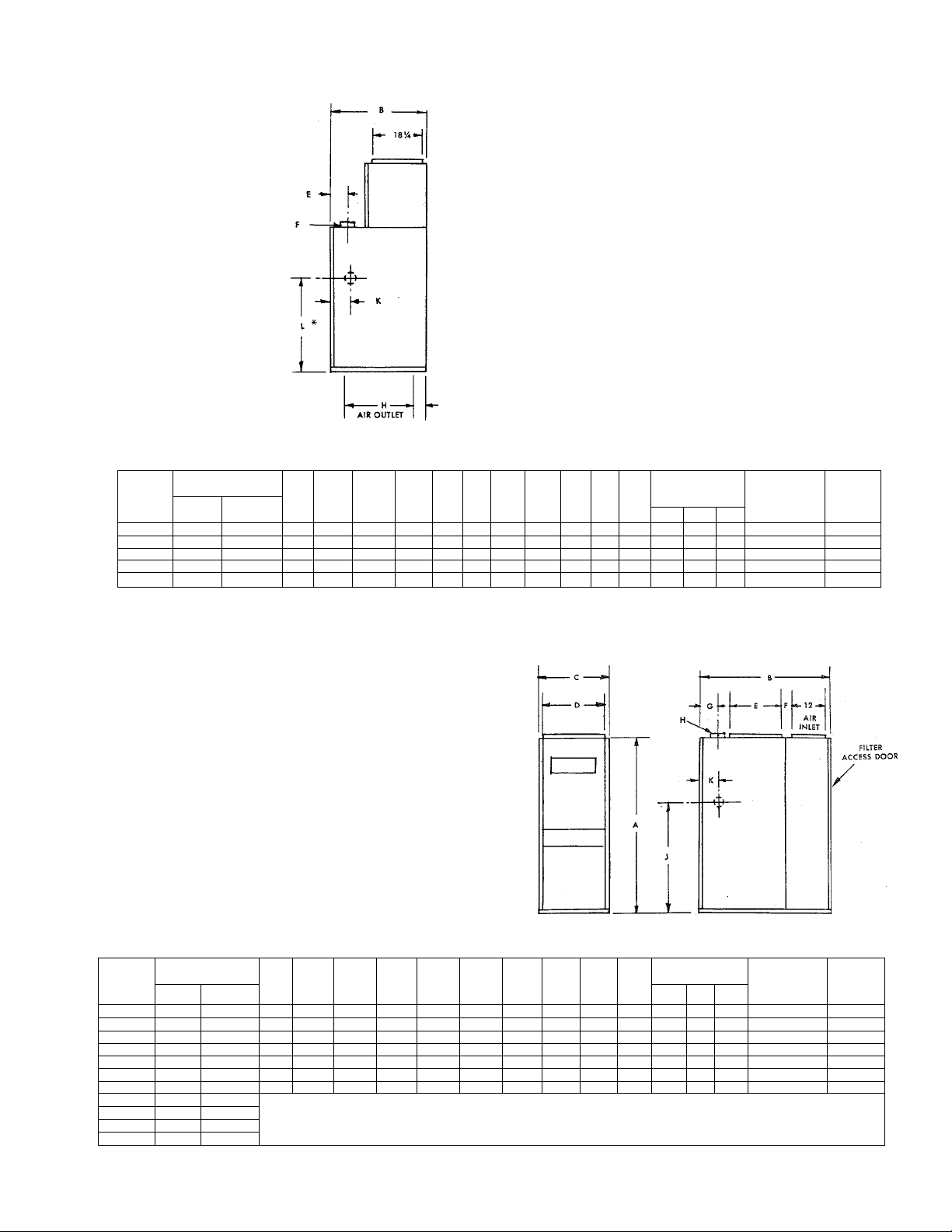

COUNTERFLOW

EZD

G

AIR OUTLET

A.G.A. RATINGS

MODEL

NO.

50-393, ^0,000

**80-393

100-393

125-393 1 25,000 1 00,000 75

150-393 150,000 120,000 80

* Add 1 when installed with base on combustible fioor.

** For LP Gas, Model Designation 80-V-393, A.G.A. Input 75,000, Bonnet Capacity 60,000.

BTU/HR

BONNET

CAPACITY

INPUT

80,000 64,000

100,000

40,000

80,000 75

*

A В C D E F

75

26 16V4

75

26

26

26 20Й 18% 3 5"

283Л

143^

16'Л 14?4

16%

1814

28 26%

2%

2%

3 5"

5Ув 6" 25% 23%

4"

4"

G

22%

12%

12% 22%

14% 22%

18% 22%

FURNACE

*

H

J К

2% 27%

1%

2% 27%

1%

2% 27%

l'/2

2%

1%

4

2Ув

GAS CONNECTION

1

NAT. MFD.

% 'A

Vi

'A

27%

'Л % 'A

30%

% %

SIZES

.'A 'A

'A 'A

Prop.

'A

%

FILTERS

16 X 20 X 1

16 X 20 X 1

Two 10 X 20 X 1

Two 14 X 20 X 1

Two 16 X 20 X 1

APPROX.

SHIPPING

WEIGHT

(LB.)

166

185

210

235

325

BASEMENT

FURNACE

RATINGS

A.G.A.

ВТ

INPUT

200,000

250,000

400,000

U/HR

BONNET

CAPACITY

64,000

80,000 46

100,000 46

120,000

140,000

160,000

200,000

240,000

280,000

320.000

MODEL

NO.

50-393 50,000 40,000

*80-393 80,000

100-393 1 00,000

125-393 1 25,000

150-393 150,000

175-393 175,000

200-393

250-393

300-393 300,000

350-393 350,000

400-393

Ratings ore approved for altitudes to

less for each 1,000 feet above sea

* For LP Gas, Model Designation 80-V-

A В c D

46 40% 16%

.46

40% 16%

40%

40% 20%

51 43% 28% 26% 17%

51 43% 36% 34% 17%

43% 36% 34%

51.

Sizes 250 through 400 are multiples of sizes 125, 150, 1.75, and 200 respectively. Refer to the dimensions

of the smaller sizes to obtain overall dimensions for the larger sizes. Provide clearance dimensions between

units for gas service and casing expansion. Refer to tnstallation instructions for minimum clearances.

2,000 feet for all gases. Ratings for altitudes over 2,000 feet are 4%

level. Return air compartment shipped separately, knocked down.

393, A.G.A. Input 75,000 Bonnet Capacity 60,000.

14%

14У, 20

18% 16У,

18Уа

E F G H J К

20

20

20

173%

23%

23%

3

3

53/s b"

43%

2-5" 30%

43%

2-5" 30%

4" 27%

4" 27%

5"

27% 2%

5"

27% 23%

30% 4

2%

2%

2%

2%

4%

4%

4%

2%

23%

4

4

■ 3 -

GAS CONNECTION

SIZES

NAT. MFD. Prop.

'A 'A

'A 'A

'A 'A 'A

'A

% % %

3%

%

% 'A

%

3% •

'A

'A

3%

•%

FILTERS

14 X 25 X 1 166

14 X 25 X 1

16 X 25 X 1 213

20 X 25 X 1

Two 1 6 X 25 X 1

Two 1 6 X 25 X 1

Two 1 6 X 25 X 1

APPROX.

SHIPPING

WEIGHT

(LB.)

192

238

343

428

428

393U

Page 4

GAS

CONTROL

OPTIONS

Gas and Control Type

Components

City Gas

04 05

Bryant Automatic Pilot

Bryant Gas Control Valve

Gas Pressure Regulator *

Transformer

Pilot Gas Filter **

X

X

X

X X X

X X

100% Shut Off

T. C. Pilot

Pilot Relay

Inline 100% Shut Off Valve

- X -

- -

* On the sizes 50, 80, 100 & 125 for natural gas only,

the regulator is part of a combination regulator, main

gas shut-off and pilot shut-off.

** Mfd. gas only.

LP Gas

02

— —

X

X

X X

X

X

Figure 2 — Thermocouple Pilot

02 & 05 Controls

-

-

nr

4

Figure 4 — Slotted Port Burner

393U

Figure 1 - D2 Controls

641 Valve - 732 Pilot

-4-

Page 5

LOCATING THE UNIT

1. This gas furnace is approved for use on combus

tible floors except when installed as a counter-flow

furnace. When installed as a counter-flow furnace

on a combustible floor it must be installed on an

approved base.

2. The furnace is A.G.A. approved for the following

clearances from combustible construction in a clos

et or alcove installation.

Sides

.......................

0" (!")*

Back........................0" (1")*

t Top of plenum. . . 3" (0")*

Vent connector . . 6" (6")*

Front

.......................

6" (6")*

* Figures shown in parentheses are approved clear

ances when the furnace is installed as a counter

flow furnace.

t Refer to ASA Z21.30-1954 for clearances in open

area installations.

This gas furnace is not approved for use with air

conditioning units mounted upstream from the fur

nace heat exchanger. The cooling coil should either

be downstream of the furnace heat exchanger or the

flow of cooling air should be by-passed around the

heat exchanger. If this parallel arrangement is used,

the dampers or other means used to control the flow

of air must be adequate to prevent chilled air from

entering the furnace. If these dampers are manually

operated, they must be equipped with means to pre

vent operation of either unit unless the damper is

in the full heat or full cool position.

8. In general, when the furnace is installed in a

large open space, there will be enough air for com

bustion and ventilation. However, when the unit is

installed in buildings of unusually air-tight con

struction, or when the furnace is located in very

restricted spaces such as closets or utility rooms,

special provisions must be made for combustion,

ventilating, and draft hood dilution air.

3. Locate the furnace as close to the chimney as

possible. The furnace should also be located as

centrally as possible to the distribution system.

4. Provide ample space for servicing and cleaning.

Consult your local approval agency for any special

clearance requirements.

5. The furnace should be level. Use shims as

required, if the floor or foundation is not completely

level.

6. Advise owner to leave all air passageways to

the furnace free of obstruction in order that there

will be no interference with combustion and venti

lating air.

7. The furnace is designed for use with summer air

conditioning. Therefore consideration should be

given to leaving ample space for a later installation

of air conditioning equipment, if the air conditioning

equipment is not being installed as part of the orig

inal furnace installation.

Bryant manufactures a coil box for upflow furnaces.

If air conditioning will be added at a later date, the

coil box, if installed on the original installation,

will save time and money later. A coil box is not

needed for counter-flow furnaces.

When the unit is installed in a confined space, pro

vide the confined space with two permanent open

ings, one near the top of the enclosure and one near

the bottom. These openings must freely communicate

with interior areas that have adequate infiltration

air from the outside. Each opening must have a free

area of not less than one square inch for each

1000 Btu/hr of rated input of oil appliances located

within the enclosure.

If it is not practicable to connect the two openings

to interior space, or if the interior space has in

sufficient infiltration air, then it is necessary to

connect the openings to the outside. If air openings

are directly to outdoors, the minimum free area

should be one square inch per 3000 Btu/hr of input

rating or in accordance with Z21.30-1964 or latest

edition, “American Standards for Installation of Gas

Appliances and Gas Piping.”

It is strongly recommended that the installer consult

the “American Standards Installation of Gas Ap

pliances and Gas Piping,” ASA Z21.30-1964.

9. In restricted spaces it is very important that the

return air ducts be sealed firmly into the furnace so

that the return air will be kept separate from the

combustion and ventilating air.

- 5 -

393U

Page 6

GAS PIPING

The gas supply line should be a separate line direct

from the meter to the furnace. Check local utility for

recommendations concerning existing lines. Choose

a supply pipe size large enough to keep the pres

sure loss as low as practicable. The supply pipe

should never be smaller than the inlet to the gas

valve. For pipe capacities at 0.3 inches w.c. pres

sure drop, see Iron Pipe Capacity table below.

Observe local codes for all gas pipe installation.

The following are pertinent recommendations:

1. Avoid low spots in long runs of pipe. These low

spots may trap water in the supply line. It is best

to slope all pipe 1/4 inch in 15 feet to prevent

traps. All horizontal runs should slope to risers.

Risers should be used to connect to the furnace and

to the meter.

2. Install a drip leg in the riser leading to the

furnace. This drip leg will serve as a trap for dirt

or condensate.

This drip leg can be installed by connecting a TEE

to the riser leading to the furnace, so that the

straight-through section of the TEE is vertical.

Then connect a capped nipple to this TEE. The

capped nipple should extend below the level of the

gas controls, with the cap resting on the floor.

3. Install the main manual gas shut-off valve in the

supply line five feet above the floor. Install the

valve (supplied) so that the pilot manual cock is on

the inlet side of the valve. (See Figure 5.)

IRON PIPE CAPACITY (See Notes 1 & 2)

Length of Pipe

in Feet

15

30

45

60

75

90

105

120

150 109

180

1. All values shown are based on a pressure drop of 0.3" w.c. and using gas with a specific gravity value

of 0.60 Consult local utility for local variations.

2. To convert to capacities for gas of different specific gravity, multiply the capacity values by the multi

pliers shown at the extreme right on table.

Pipe Capacity in Cubic Feet Per Hour

for Diameters Shown

1/2" 3/4"

76

52

43 99

38 86 173 380

172

120 241 535 .40

77

70 141

65

1"

345

199

155

131

120 270

100

1-1/4" Specific Gravity

750 .35

435 .45

345 .55

310

285

242

225

Figure 6

Multiplier to Use

for Different Specific Gravity

Multiplier

1.31

1.23

1.16

.50

.60

.65 .962

.70

1.10

1.04

1.00

.926

393U

- 6 -

Page 7

Sizes 50, 80,100 8s 125 using natural gas are equip

ped with a factory-installed combination pressure

regulator and main shut off - pilot supply shut off

valve. This control is inside the furnace cabinet.

A separate manual shut-off valve is not supplied

with these furnaces. Consult local codes regarding

the need for placing a separate shut-off valve out

side the furnace cabinet as shown in Figure 5.

Where a gum filter is required by local regulations,

place filter between manual gas cock and pilot

cock. See Figure 6.

Place a ground joint union between the gas control

manifold and the manual gas shut-off valve.

4. Support all piping with appropriate straps, hang

ers, etc. This will maintain proper slope of the lines

as installed and will remove unnecessary strain on

the furnace and its controls. It will also prevent

the piping from being moved accidentally from its

installed position.

5. Joint compounds — (pipe dope) should be applied

sparingly and only to the male threads of the joints.

Consult local supplier for type of compound to be

used with LP gas.

6. After all connections have been made, purge

the lines and check for leakage. Never purge a line

into a combustion chamber. Never use matches,

candles, flame, or other sources of ignition for the

purpose of checking leakage.

3. Run pipe as directly as possible with a minimum

number of turns. The maximum length of horizontal

run should not exceed 75 percent of the height of

the chimney.

4. Maintain a minimum of 1/4 inch per linear foot

upward slope from the furnace to the chimney on all,

horizontal runs.

5. Rigidly support the flue pipe with hangers and

straps to insure that there will be no movement

after installation.

6. Extend the flue connection pipe through the

chimney wall flush with the inner face of the chim

ney liner. Never connect into a chimney serving an

open fireplace, unless the fireplace opening is

sealed off.

7. The chimney or gas vent should extend high

enough above the roof or neighboring obstruction

so that wind from any direction will not create a

positive pressure in the vicinity of the outlet of

the chimney or gas vent. The installer is referred

to Part V of American Standard “Installation of

Gas Appliances and Gas Piping, ASA Z21.30-1964

for detailed information on chimney and gas vent

use. In general the chimney or gas vent should

extend 3 feet higher than the point of emergence

through the roof, and at least 2 feet higher than any

object within a radius of 15 feet.

8. If more than one appliance is vented into the

same chimney, the cross sectional area of the chim

ney must be as large as the largest flue pipe being

connected, plus 50 percent of the cross sectional

areas of the additional flue pipes being connected.

VENTING THE FURNACE

Consult local codes. Unless the local codes direct

otherwise the furnace may be vented to a permanent

chimney, or to a listed Type B or Type C gas vent.

This Bryant gas-fired furnace has a built in draft

diverter. Therefore, it remains only to connect the

furnace vent collar to the chimney or gas vent to be

used. The following recommendations are made:

1. Select a flue connection material that is satis

factory for the installation, and that meets the

requirements of the local codes.

2. The flue connection pipe must be the same size

as the outlet collar on the furnace. No reduction in

this size is permissible in the pipe run.

9. If more than one appliance is manifolded into

the same flue connecting pipe, the cross sectional

area of this manifold pipe must be as large as the

sum of the cross sectional areas of the pipes con

necting into it.

393U

- 7 -

Page 8

BLOWERS

Direct Drive:

Listed below are the color codes for the different

motor speed taps:

High Speed — Black

Medium Speed - Blue

Medium-low Speed — Yellow

Low Speed - Red

Wiring Diagram, Figure 10 shows these furnaces as

wired at the factory. Remove the transformer (two

screws) from the junction box and expose the termi

nal block. Check the fan control lead to see if it is

connected to the motor speed tap that will give the

blower speed needed for the installation. If the fan

control lead is not connected to the proper motor

speed tap, or if you wish to change to another

speed, simply switch the lead to the motor speed

tap that you want connected. The lead is equipped

with a spade connector.

Important:

If there are variations in voltage at the motor,

there will be significant variations in the air de

livery and temperature rise values. If the supplied

voltage is less than 115 volts the blower will run

slower and the temperature rise will be greater. On

the other hand, if the voltage is greater than 115

volts the blower will run faster and the temperature

rise values will be lower. If there is doubt about

the value and fluctuation of voltage consult local

electric utility. The Number 4 tap should be used

on installations where the voltage is 125 volts or

higher.

Larger Motors:

For some installations the installer may wish to

substitute a larger motor than the one supplied the

furnace. A separate mounting hole is provided in

each end plate of the blower cage to be used when

motors larger than 1/3 HP are installed. This is an

extruded hole requiring self-tapping bolts. Figure 7

is a photo of a 1/2 HP motor mounted in place of a

smaller motor. Note that the lower mounting hole is

used. When ordering a 1/2 HP motor for installation

be sure that the frame is a size 56. When ordering

still larger motors, be sure that the frame size is

compatible with space available in the blower com

partment.

When the lower mounting holes are used it will, of

course, be necessary to use a longer belt than the

one supplied with the smaller motors.

Belt Drive:

The motors supplied with the belt drive have an

adjustable motor pulley. The air delivery rate is

controlled by the position of this adjustable motor

pulley. When the pulley is in the fully open position,

the air delivery rate is at a minimum, and conse

quently the temperature rise across the furnace is

at the maximum.

When the pulley is in the fully closed position, the

air delivery rate is maximum and consequently the

temperature rise across the furnace is at a minimum.

In order to change the opening on the pulley simply

loosen the set screw with an Allen wrench. Screw

the pulley clockwise to close, and counter-clockwise

open. Once positioned, tighten the set screw on the

flat of the motor shaft.

393U

Figure 7

- 8 -

Page 9

TABLE [

DIRECT DRIVE BLOWERS - HEATING ONLY

Furnace

Size

50 1/6

80 1/6

100

125

Motor

H.P.

1/5

1/4

No. of

Speed Taps

4

4

4

2

Ext. S. P.

Inches Water

0.12

0.12

0.15

0.20

Temp. Rise

Degrees F.

50-70

75-95

75-95 1 870

75-95

Factory

Setting

3

3

1

t Values shown are for 115 volt power supply

tt Temp rise is 60° F TABLE II

HEATING AND COOLING BLOWERS

Furnace

Size

50 1/6

80 1/6

80 1/3 4

100

100 1/3

125

d n a — does not apply * _ speed tap not recommended for heating § Values shown are for 115 volt power supply

Motor

H.P.

1/6

1/3

No. of

Speed Taps

4

4

4

4

4

80-90

Temp. Rise Degrees F.

Motor Speed Taps

Hi

*

*

* ie

*

*

Med

*

80-90

90-100

70-75

80-90

Med-Lo Lo

60-70

95-105

★

*

75-85

90-100

80-90

*

*

*

*

Ext. S.P.

In. w.c.

0.32

0.30

0.35

0.40

0.30

0.35

0.40

0.50

0.30

0.35

0.40

0.30

0.35

0.40

0.50

0.30

0.35

0.40

0.50

Cooling Air Flow-CFM§

at Motor Speeds Shown

Hi Med

710

810

785

760

1185

1160

1130

1080

830

805

775

1250

1215

1200

1110

1525

1500

1470

1400

85° F Temp. Rise

Med-Lo

610

660

645

625

980

965

940

895

675

655

635

1030

1015

1000

960

1060

1045

1030

1010

tCFM at

tt 615

695

1090

485

510

500

490

865

850

830

815

505

495

490

900

890

870

830

925

910

900

860

Lo

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

d n a

TABLE III

BELT DRIVE BLOWERS

Heating Heating and Cooling

Furnace

Size

80

100

125

150

175 1/3 5„ T.O. 1475 83° F 1/2 5 T.O.

200

Motor

H.P.

1/6 3 T.O.

1/4

. 1/4 4/2 T.O.

1/3

1/3

Factory

Setting

3 T.O. 730

5 T.O.

5 T.O.

CFM

@ 0.20

570

950

1160

1475 94° F

Temp.

Rise

97° F

95° F

92° F

90° F 1/2 5 T.O. 1160

Motor

H.P.

1/3 4

1/3

1/3

1/2 5 T.O. 1280 68° F

3/4

3/4

1/2

3/4 5

Factory

Setting

4 T.O. 930 75° F

4/2 T.O.

5 T.O. 1600

5 T.O. 1500

5

CFM

@0.20

T.O.

T.O. 1500

T.O. 1500

790

950 92° F 1080 36M

1500

Temp.

Rise

70° F 1080

90° F

65° F 2280 60M

81° F

81° F

93° F 2400 54M

93° F 2400 66M

Max. CFM

@ 0.40

1270

1800

1840

2400 54M

2400 66M

Approx.

A/C Capacity

30M

36M

48M

48M

393U

Page 10

ELECTRICAL CONNECTIONS

START-UP AND ADJUSTMENT

All electrical connections are to be made in accord

ance with the local codes governing such wiring.

A permanent, live, separately fused electric power

supply, complete with manual switch, should be

provided for the furnace.

The room thermostat should be located where it will

be in the natural circulating path of room air. Avoid

locations where the thermostat would be exposed to

cold air infiltration, drafts from windows, doors, or

other openings leading to the outside; or exposure

to air currents from warm or cold air registers; or to

exposure where the natural circulation of the air is

cut off such as behind doors, above or below man

tels, shelves, etc.

The thermostat should not be exposed to heat from

nearby radiators, fireplaces, radios, televisions,

lamps, or rays from the sun. Nor should the thermo

stat be mounted on a wall containing pipes or warm

air ducts, or a flue or vent which could affect its

operation and prevent it from properly controlling

the room temperature. Any hole in the plaster or

panel through which the wires pass from the thermo

stat should be adequately sealed with suitable

material to prevent drafts from affecting the thermo

stat.

INSTALLING THE UNIT

Sizes 50, 80,100 & 125 for natural gas are complete

ly assembled at the factory. All other units are

shipped fully assembled with the exception of the

manual main shut-off valve, pilot feed tube, and

pilot gas filter, which are shipped loose. The filter

is snpplied for manufactured gas units only.

The order to be followed in setting the unit in place

and making all the necessary connections (gas,

electric, venting, duct work, etc.) is left to the

discretion of the installer. Recommendations listed

on pages 5 to 7 of this instruction should be fol

lowed. When making the gas piping installation as

described on page 6, assemble the pilot manual shut

off valve in the threaded boss provided at the inlet

side of the main manual gas shut-off valve. If the

installation is for manufactured gas, install the gum

filter between the two valves. Cut the pilot feed

tube to the desired length and connect the pilot

manual shut-off to the pilot.

Check to be sure that all connections have been

properly made, then proceed as follows:

Light the pilot using the procedure outlined on the

Lighting Instruction Plate attached to the furnace.

However, when lighting the pilot for the first time,

perform the following additional steps:

1. If the supply line was not purged prior to con

necting the furnace, it will be full of air. Since it

would take a long time to vent this air through the

small pilot port, it is recommended that the pilot

supply line be disconnected at the pilot shut-off

valve and the supply line be allowed to purge until

the odor of gas is detected. Never purge gas lines

into the combustion chamber. Immediately upon

detection of gas odor, re-connect the pilot supply

tube. Allow 5 minutes to elapse and light the pilot

in accordance with the instructions on the front of

the furnace.

2. The pilot flame should be soft blue in color.

a. For city gas controls (D4) this flame should be

of sufficient length to provide good impingment on

the mono-metal element of the Bryant pilot. Flame

should extend upward between the carry-over ports

of the two adjacent burners.

b. For LP gas controls (D2), the flame should

surround the tip of the thermocouple element of the

pilot and extend downward to include 3/8 inch to

1/2 inch of the thermocouple. The flame must never

come in contact with any other part of the thermo

couple or its lead wire. The flame lies under the

carry-over ports of the burners and merges with the

carry-over flames. D5 controls have the same pilot.

3. If the pilot flame does not have the appearance

described above, it may be adjusted by means of the

manual pilot shut-off valve.

a. If the valve is equipped with an adjustable

screw, turn the handle to the full-open position and

remove the screw cap on the valve handle, thus

exposing the adjustable screw. Turn adjusting screw

until flame has the desir-ed appearance. Replace

screw cap.

b. If the valve is not equipped with the adjusting

screw, adjustment of the flame is effected by alter

ing the position of the valve handle.

For furnaces with D2 or D5 controls the pilot feed

tube is connected to the pilot relay.

393U

- 10 -

Page 11

Light Main Burners using the procedure contained on

the metal Lighting Instruction Plate attached to the

front of the furnace.

Adjust Gas Rate. Set the room thermostat on call

for heat and adjust the gas rate as follows:

1. City Gases - Measure gas input at the meter.

The burners are equipped with fixed orifices, sized

to produce the rated input shown on the rating plate.

If measured and rated input are not approximately

the same, the gas pressure regulator may be adjusted

as follows:

a. To increase input: Turn pas pressure regu

lator adjusting screw ‘clockwise’. (Adjusting screw

is concealed under the regulator sealing cap).

b. To decrease input: Turn the adjusting screw

‘counter-clockwise’. The manifold pressure should

be set as follows:

Manufactured Gas - 3 inches w.c.

Natural Gas - 3 inches w.c.

Maximum pressure departure from recommended pres

sure should be plus or minus 0.3 inches w.c.

2. LP Gas - LP gas units are not equipped with

gas pressure regulators. Burner orifices are sized

to give the rated input at a manifold pressure of

11 inches w.c. Since meters are not normally used

with LP gas, it will be necessary in most cases to

check the manifold pressure and adjust the regulator

at the supply tank to provide a pressure of 11 inches

w.c.

3. If the input in item (1) or (2) above is too great

or too little, install new orifices or re-drill the

existing orifices (whichever is necessary) to obtain

the rated input. Be sure the rated input is obtained

without any appreciable change in manifold gas

pressure.

Adjust Main Burner Flame — The main burner flame

should be clear blue, almost transparent, with a welldefined inner cone. If there is insufficient primary

air, the flame will be yellow-tipped. If there is too

much primary air the flame will be well-defined, but

with a tendency to dance or lift off the burner ports.

CHECK CONTROLS

Bryant Diaphragm Gas Control Valve —if not already

checked when lighting the main burner, check the

proper operation of this valve by moving the room

thermostat pointer above and below room temperature

and observe that the main burners light on call for

heat and go off when the pointer is moved below the

room temperature setting. However, there will be

approximately a 30 second delay on ignition and

extinction.

Automatic Pilot - To check the pilot operation

follow the instructions below:

1. Set the room thermostat on call for heat.

There is a delay before burners light.

2. After burners have lit, shut off the pilot gas

valve.

3. The automatic pilot will break the electrical

circuit to the gas valve and the burners will shut off.

Limit Control - This control functions to shut off

the gas if the furnace becomes over-heated. The

method of checking satisfactory operation is left to

the discretion of the installer. Extreme caution

should always be employed.

Blower Adjustment - It is important that the blower

speed be adjusted before there is any attempt to

adjust the fan control switch.

The blower speed is set at the factory. Under no

circumstances should the temperature rise across

the furnace be allowed to exceed 105 degrees F

on all sizes except the size 50. On the size 50,

the temperature rise must not be allowed to exceed

70 degrees F. After the desired air flow or tempera

ture rise across the furnace has been obtained, the

installation should be complete. However, it may be

necessary to change the factory setting on the Fan

Control Switch. This may be done as described

under the discussion on controls.

1. Allow furnace to operate 15 minutes.

2. Adjust each burner by closing the air shutter

until a slight yellow tip appears on the flame; then

open the air shutter just enough to clear the yellow

from the flame.

- n -

393U

Page 12

CLEANING THE FURNACE

L Disconnect gas tubing from pilot.

2. Disconnect electrical lead from pilot. (In case

of 100% shut-off controls disconnect pilot thermo

couple lead from pilot relay).

3. Remove front plate from draft diverter (4 sheet

metal screws.)

4. Remove burners and pilot as follows.

a. Remove tinnerman clamp from burner holding

stud.

b. Lift burner off holding stud, twist and pull

forward.

c. Pilot is attached to one burner and is removed

with that burner. It is not necessary to detach pilot

before removing burner. See Figure 3 for photograph

of burner; also pilot attached.

5. Remove metal angle strip holding flue baffles in

place. See Figure 8.

6. Remove flue baffles. See Figure 9.

7. Use a flexible-handled steel cleaning brush to

loosen scale and soot. Remove these scrapings from

bottom of combustion chamber.

8. Re-assemble furnace by reversing the above pro

cedure. Note: There is a slot in the back of the

heat exchanger for the back tip of the burner to fit

into. When properly placed, the burner will fit into

this slot and will be level.

CARE AND MAINTENANCE

Care of Blowers. All motors on the belt drive blow

ers are provided with oil cups and should be oiled

at least twice a year with a good grade of SAE 30

oil. The motors on the direct drive blowers are

sealed units and do not require the addition of oil.

Blower bearings are semi-permanently lubricated.

This lubrication is normally good for 3 to 5 years.

When necessary to add lubricant, use Plastic E,

obtainable from Bryant’s Service Parts Department.

Filters. Filters should be examined frequently for

clogging due to dirt. The disposable filters should

be replaced when they become dirty. Permanent type

of filters may be cleaned using clear water. Be sure

to coat the filter with water soluble oil after clean

ing.

Cleaning. The heat exchanger should be examined

periodically to see if there has been an accumula

tion of rust, soot, etc. Clean as required.

Figure 8 — Note metal angle strip held by 3 screws

393Ü

Figure 9 — Remove baffles

- 12 -

Page 13

Figure 10 — Wiring for 4-Speed Direct Drive

Figure 11 — Wiring for 4-Speed Direct Drive Using Relay

- 13-

393U

Page 14

393U

Figure 13 - Belt Drive Wiring

- 14-

Page 15

<n

c

<

o

3

-+

3*

CQ

Q

3

(£2

O

3

o

3

TOP VIEW

ITEM DESCRIPTION

7” DIA MANIFOLD

5" PIPE

7” PIPE

10” X 7” REDUCING CAP

10” TEE

10” PIPE

7” ELBOW /

FRONT VIEW

NOTE:USE THIS

ARRANGEMENT

FOR HIGH CEILING

INSTALLATIONS.

Sizes 350 iV. 400

CO

VO

CO

c

c

•5’

c

3

SIZE

2.50

ELBOW

A

5”

6”

REDUCING CAP

B

8" X S’8” X 6”

TEE

C

8”

PIPE (fccomm)

D

5” dia X 6” Ig

6” dia X 6” Ig

•“SPACF. SIZF 250 (TWO 125’&)

4” APART TO PROVIDE SPACE

FOR GAS PIPING.

►—SPACE 300 (TWO ISO’s)

1” APART TO PERMIT EXPANSION

AND CONTRACTION

PIPE

PIPE

F

8” 10”

S"

MI N MIN

G

11” 0“

II

8”

E

5”

6“

Loading...

Loading...