Page 1

352AAV

4-Way Multipoise Two-Stage Condensing Gas Furnace

Sizes 060 thru 120

Product Data

running at line voltage and does not require complex voltage

regulators as do other brands. This unique feature further enhances

the reliability of Bryant’s 352AAV gas furnace and continues

Bryant’s tradition of providing a reliable and durable product.

A05085

Utilizing the extensive resources available to Bryant, a new standard of excellence has been achieved with the model 352AAV

Plus 90t

The model 352AAV is a unique 4-way multipoise condensing furnace with features like no other product in its class. The 352AAV

builds on the many Bryant successes in the furnace industry and

establishes a new standard for all high-efficiency gas furnaces.

Perfect Heat™

vary the amount of gas being used from low-heat to high-heat

stage. The low-stage operation allows longer running periods,

which helps maintain your most comfortable temperature, prevents

drafts, reduces noise, and enhances the air quality of your home.

During extreme cold, the high-heat stage will run to ensure that you

are still comfortable.

Primary Heat Exchanger & Secondary Heat

primary heat exchanger is corrosion resistant and maintains a

proven track record for long-term reliability and high-efficiency

performance. The secondary heat exchanger is built with a

patented lamination process that bonds a corrosion-proof lining of

polypropylene to a heavy, galvanized steel shell. The unique

secondary clamshell design allows wider spacing between cells for

reduced air resistance through the furnace, reduced load on the

blower motor, and reduced need for cleaning.

Perfect Light™ Igniter

physically robust but it is also ele

TM

4-Way Multipoise Furnace.

FEATURES

— The Plus 90t™ combines two heating stages to

Exchanger

— Bryant’s unique SiN igniter is not only

ctrically robust. It is capable of

— The

Fan On

to select the continuous fan speed right at the thermostat.

SmartEvap™

humidity levels by nearly 10% over standard systems.

Media Filter Cabinet

is made easier wi

on all furnaces. When installed as a part of your system, this cabinet

allows for an easy and convenient addition of a Bryant highefficiency air filter.

Adaptive Logic Control Board

board contains a microprocessor which automatically calculates

the precise amount of time your furnace should run and at what

speed it should run to obtain the best comfort and energy efficiency.

This control board also includes an extensive troubleshooting and

component test sequence that can mo

ensure that it is operating properly.

4-Way Multipoise Design

installed in an upflow, downflow, or horizontal orientation. Factory

configured for upflow applications with only simple drain connection

changes required for conversion to downflow or horizontal.

Direct or Non-direct Venting

a Non-Direct 1-pipe vent or Direct 2-pipe vent furnace. This

provides added flexibility to meet diverse installation needs.

Full Cabinet Insulation

the internal furnace casing allowing for reduced and dampened

sounds and maintained efficiencies.

Two-Speed Inducer Motor

fan to optimize combustion efficiency and exhaust the flue gases

out of the house. The motor has two speeds and an incorporated

fan to keep the motor cool while reducing sound.

Permanent Split Capacitor (PSC) Blower Motor

has a PSC blower motor that has several preselected fixed speeds

which can be customized to duct work installation requirements.

The motor has a wide application of use, a basic control scheme,

and is extremely reliable.

Soft Motor Mounts

decrease the vibration of the motor, and minimize noise.

Two Stage Gas Valve

vary the amount of gas being used from low-heat to high-heat

stage. The low-stage operation allows longer running periods,

which helps maintain your most comfortable temperature, prevents

drafts, reduces noise, and enhances the air quality of your home.

During the extreme cold, the high-heat levels will run to ensure that

you are still comfortable.

Plus™ — Improves comfort all year long by allowing you

— Allows your system to reduce summertime

— Enhanced indoor air quality in your home

th our media filter cabinet—a standard accessory

— This self-adjusting control

nitor your heating system to

— Allows the model 352AAV to be

— The 352AAV can be installed as

— This insulation completely surrounds

— This motor works with the inducer

352AAV

— The

— These

motor mounts help to absorb shock,

—The 352AAV has a 2-stage gas valve to

Page 2

"

8

⁄

"

16

"

16

⁄

13

⁄

5

"

8

⁄

5

7

39

1"

"

"

16

⁄

16

⁄

7

11

352AAV

"

16

⁄

5

19"

"

22

4

⁄

1

"

16

⁄

26

15

"

2

⁄

26

1

OUTLET

2-IN. COMBUSTION-

AIR CONN

1

⁄2-IN. DIA

GAS CONN

7

⁄8-IN. DIA

POWER CONN

1

⁄2-IN. DIA

THERMOSTAT ENTRY

28

"

16

⁄

9

TYP

1

(DOWNFLOW &

OR ALTERNATE

TRAP LOCATION

"

16

/

13

A

D

"

16

/

13

OUTLET

AIRFLOW

HORIZONTAL RIGHT)

CONDENSATE DRAIN

-IN. DIA GAS CONN

2

⁄

1

"

4

⁄

1

TYP

33

"

8

⁄

5

TYP

32

"

16

⁄

13

30

⁄8-IN. DIA

7

POWER CONN

TRAP LOCATION

(DOWNFLOW &

HORIZONTAL LEFT)

CONDENSATE DRAIN

7

"

2

⁄

30

⁄8-IN. DIA

2-IN. VENT CONN

"

16

⁄

11

TYP

29

ACCESSORY

POWER ENTRY

11

"

8

⁄

5

27

CONDENSAT E

"

16

⁄

22

SIDE INLET

"

16

⁄

9

TYP

"

27

2

⁄

1

24

DRAIN TRAP

LOCATION

(ALTERNATE

UPFLOW)

"

" TYP

4

⁄

16

⁄

1

3

22

24

BOTTOM INLET

"

4

⁄

1

18

HANGING

(UPFLOW)

CONDENSAT E

DRAIN LOCATION

FOR HORIZONTAL

DIMPLE LOCATORS

"

16

/

11

-in. rectangle.

-in. rectangle.

2

4

/

/

1

1

x 19

x 23

2

2

x 12-in. rectangle.

/

/

2

1

1

/

1

INLET

E

"

16

/

11

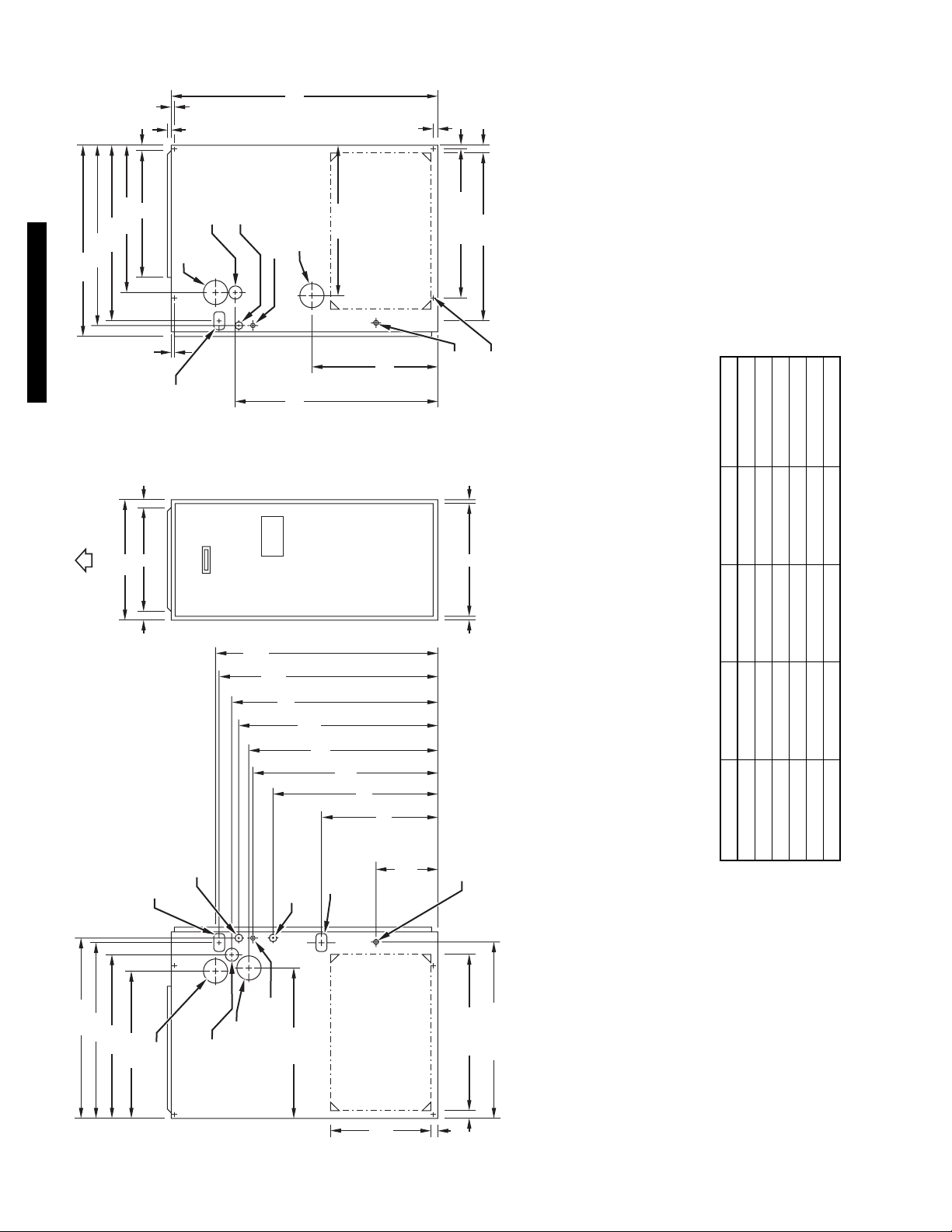

DIMENSIONS (In.)

return air openings for airflow requirements above 1800 CFM at 0.5” W.C. ESP.

combination of 1 side and the bottom, or the bottom only will ensure adequate

b. For 1200 CFM–20-in. round or 14

c. For 1600 CFM–22-in. round or 14

d. For airflow requirements above 1800 CFM, see Air Delivery table in Product Data

literature for specific use of single side inlets. The use of both side inlets, a

036060 17-1/2 15-7/8 16 189

048080 17-1/2 15-7/8 16 205

036080 17-1/2 15-7/8 16 200

UNIT SIZE A D E SHIP. WEIGHT (Lb)

048100 21 19-3/8 19-1/2 231

060100 21 19-3/8 19-1/2 234

060120 24-1/2 22-7/8 23 262

a. For 800 CFM–16-in. round or 14

"

16

⁄

5

17

"

16

⁄

7

TYP

9

CONDENSAT E

DRAIN LOCATION

(UPFLOW)

see flex duct manufacturerís recommendations for equivalent diameters.

2. Minimum return-air opening at furnace:

NOTES: 1. Minimum return-air openings at furnace, based on metal duct. If flex duct is used,

A05070

"

16

⁄

"

15

4

⁄

1

"

26

2

⁄

1

26

"

16

⁄

24

5

22

⁄2-IN. DIA

2-IN. COMBUSTION-

AIR CONN

1

GAS CONN

2-IN. VENT CONN

ENTRY

"

16

⁄

11

22

⁄2-IN. DIA THERMOSTAT

1

SIDE INLET

"

2

⁄

1

TYP

14

"

4

⁄

1

1

" TYP

4

⁄

1

23

SIDE INLET

1"

15

" TYP

16

⁄

26

times

times italic

times bold

—2—

Page 3

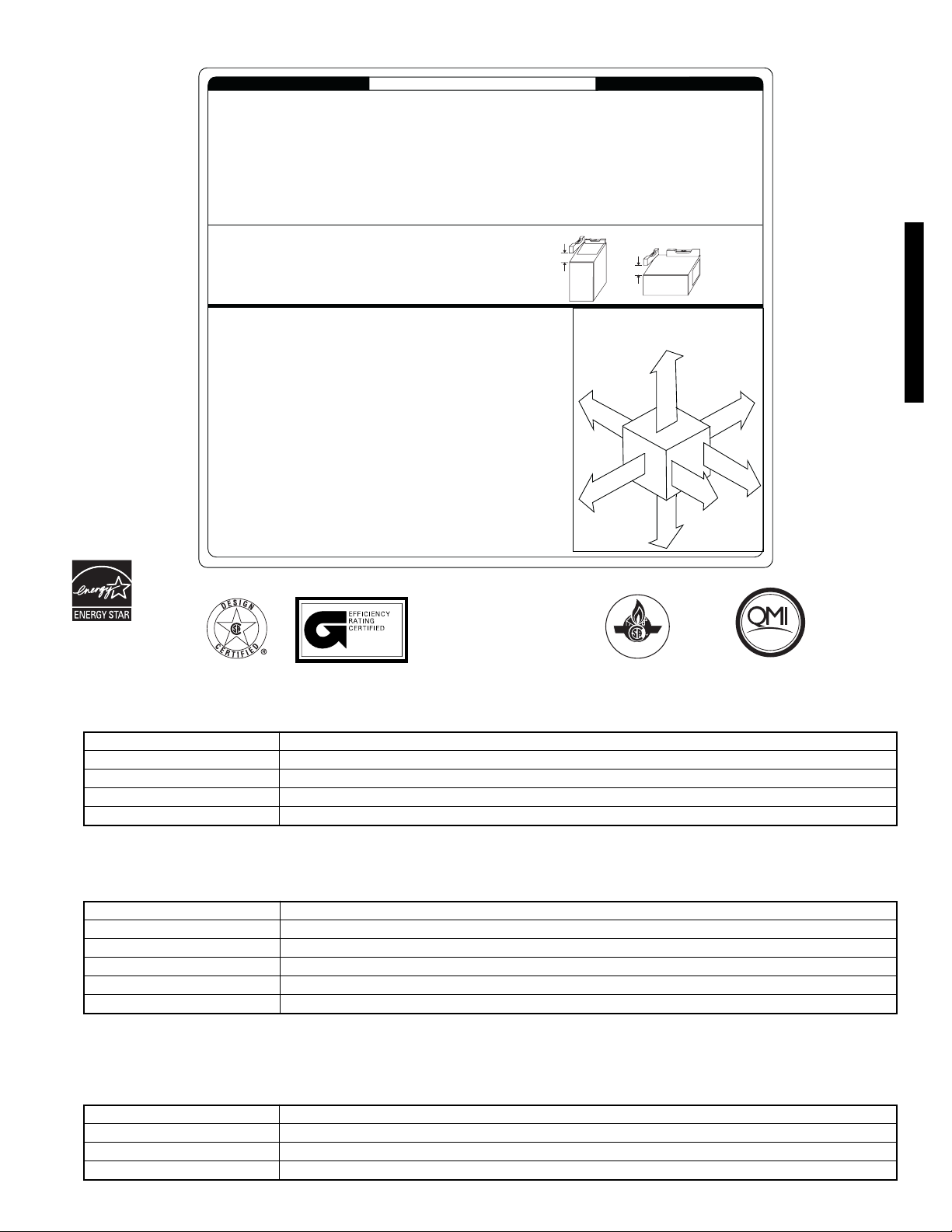

Clearance to Combustibles

This for ced air furnace i s equipped for us e with natural gas at altitudes 0 - 10,000 ft (0 - 3,050m), except 140 si ze Furnaces are only approved for altitudes 0 - 7,000 f t. (0 - 2,135m).

An accesso ry kit, supplied by the manuf acturer, shall be used to convert to propane gas use or may be required for some natural gas applic ations.

This f urnace is for indo or instal lation in a bui lding cons tructed on site. This fur nace may be i nstalled in a manuf actured (mob ile) home when stated on rati ng plate and using factory

authorized kit.

This f urnace may be install ed on combust ible fl ooring i n alcove or closet at minimum clearance f rom combustibl e materi al.

This appl iance r equires a special v enting syst em. Refer to the i nstallat ion ins tructions for par ts list and method of inst allati on. This furnace i s for us e with sch edule-40 PVC, PVC-DWV,

CPVC, or ABS-DWV pipe, and must not be vented in common wit h other gas-fire d appliances . Construc tion thr ough which vent/air intake pipes may be inst alled is maximum 24 inches

(600 mm), minimum 3/4 inches (19 mm) thickness (including roofing materials).

Cette fournaise à ai r pulsé est équipée pour util isation avec gaz naturel et altitudes comprises entre 0 - 3,050m

(0-10,000 pi), except é queles fournaises de 140 tail le sont pour altit udes comprises entre 0 - 2,135m (0 - 7,000 pi).

Utili ser une t rousse de co nversion, fournie par le f abricant, pour passer au gaz propane ou pour certai nes instal lations au gaz naturel.

Cette fournaise à ai r pulsé est pour inst allation à l´int érieur dans un bâtiment construit sur place. Cette fournaise à air pulsé peut être i nstallée dans une mai son préfabr iquée

(maison mobile) si prescri t par l a plaque si gnaléti que et si l´on ut ilise une trousse specifi ée par le fabricant .

Cette fournaise peut être installée sur un plancher combustible dans un enfoncement ou un placard en observant les dégagements minimums avec l es matériaux combustibl es.

Cet appareil nécessite un système d´évacuation spécial. La méthode d´inst allation et la l iste des pièces nécessaires fi gurent dans les instructi ons d´installation.Cett e fournaise doit

s´uti liser avec la tuy auterie des nomencl atures 40 PVC, PVC-DWV, CPVC, ou ABS-DWV et elle ne peut pas être venti lée conjointm ent avec d´autres appareil s à gaz. Épaisseur de la

construc tion au travers de laquelle il est possibl e de fair e passer l es tuyaux d´aérati on (admissi on/évacuati on): 24 po (600 mm) maximum, 3 /4 po (1 9 mm) mini mum (y comp ris l a toit ure).

For upflow and downflow applications, furnace must be installed level, or pitched within 1/2"

of level. For a horizontal applicat ion, the furnace must be pitched minimum 1/4" to

maximum of 1/2" forward for proper drai nage. See Installation Manual for IMPORTANT unit

support details on horizontal appli cations.

Pour des applications de f lux ascendant et descendant, la fournaise doit être install ée de

niveau ou inclinée à pas plus de 1/2" du niveau. Pour une application hori zontale, la

fournaise doit êtr e inclinée entre minimum 1/4" et maximum 1/2" du niveau pour le drainage

approprié. En cas d'i nstallation en position hor izontale, consulter les renseignements

IMPORTANTS sur le suppor t dans le manuel d'i nstallation.

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

ALL POSITIONS:

Minimum front cl earance for servi ce 30 inches (762mm).

*

†

†

140 size furnaces requi re 1 inc h back clearanc e to combusti ble materials.

DOWNFLOW POSITIONS:

For inst allati on on combustible f loors only when installe d on special base No. KGASB0201ALL, Coil

†

Assembly, Part No. CD5 or CK5, or Coil Casing, Part No. KCAKC.

HORIZONTAL POSITIONS:

Line cont act is per missible onl y between li nes formed by i ntersections of top and two sides of furnace

jacket, and buil ding joists, studs, or framing.

Clearance shown is for air inlet and air outlet ends.

§

120 and 140 size furnaces requir e 1 inch bottom clearance to combustible material s.

Ø

DÉGAGEMENT MINIMUM EN POUCES AVEC ÉLÉMENTS DE CONSTRUCTION COMBUSTIBLES

POUR TOUS LES POSITIONS :

Dégagement avant minimum de 762mm (30 po) pour l´entreti en.

*

Pour les four naises de 140 taill e, 1 po (25mm) dégagement des matériau x combusti bl es est requis

†

†

au-arriere.

POUR LA POSITION COURANT DESCENDANT:

Pour l´instal lation sur le plancher combustible seul ement quand on uti lise la base spéciale, pi èce

†

n° KGASB0201ALL, l´ ensemble serpentin, pi èce n° CD5 ou CK5, ou le car ter de serpentin, pièce

n° KCAKC.

POUR LA POSITION HORIZONTALE:

Le contact n´est permis qúentre les lignes formées par les i ntersections du dessus et des deuxcôtés de la

chemi se de la f ournaise, et des soli ves, des montant s ou de la charpente du bátiment.

La distance indiquée concerne l´ extrémité du tuyau d´arrivée d´air et l´extrémité du tuyau de sorti e d´air.

§

Pour les four naises de 120 et 140 tail le, 1 po (25mm) dégagement des matéri aux combustibles est re quis

Ø

au-dessous.

INSTALLATION

LEVEL (0")

TO

1/2" MAX

UPFLOW OR

DOWNFLOW

R

324999-201 REV. D (LIT TOP)

MIN 1/4"

TO

1/2" MAX

FRONT

This furnace is approved f or UPFLOW, DOWNFLOW and

HORIZONTAL i nstall ations.

Cette fournaise est approuvée pour l´ins tallation HORIZONTALE

et l a circul ation d´ air VERS LE HAUT et VERS LE BAS.

Clearance arrows

do not change with

furnace orientati on.

†

†

0"

B

A

A

R

R

0"

§

Clearance in inches

Dégagement (po).

FRONT

C

K

I

E

R

E

E

D

S

I

S

E

T

O

C

HORIZONTAL

1"

Les fléches de dégagement

générateur d´air chaud.

TOP/PLENUM

DESSUS/CHA MBRE D´AI

E

C

E

A

S

I

N

A

R

U

N

F

R

T

U

N

O

O

F

T

R

N

F

A

V

A

F

R

O

A

N

V

T

A

N

T

3"

BOTTOM

DESSOUS

0"

Ø

†

d´évent avec combustibles.

ne change pas avec

l´ori entation de la

I

S

O

C

S

L

È

N

T

Vent clearance to

combustibles 0".

0 (po) Dégagement

352AAV

§

0"

E

D

S

E

T

E

R

V

I

R

C

E

E

T

I

E

*

N

30

MIN

A02148

ISO 9001:2000

MEETS DOE RESIDENTIAL

CONSERVATION SERVICES

As an ENERGY STAR

®

Partner, Bryant Heating &

Cooling Systems has determined that this product meets

the ENERGY STAR

®

guide-

lines for energy efficiency.

TSTATBBNAC01-C

TSTATBBNHP01-C*

TSTATBBN2S01-C*

TSTATBBBAC01-B

TSTATBBPRH01-B**

PROGRAM STANDARDS.

ama

Before purchasing this appliance,

read important energy cost and

efficiency information available

from your retailer.

CERTIFIED

®

REGISTERED QUALITY SYSTEM

These products are engineered and manufactured

under an ISO 9001 registered quality system.

Non-Programmable Thermostat Selection

For use with 1-spd. Air Conditioner - deg. F/C, Auto Changeover

For use with 1-spd. Air Conditioner - deg. F/C, Auto Changeover

For use with 2-spd. Air Conditioner - deg. F/C, Auto Changeover

For use with 1-spd. Air Conditioner - deg. F/C

For multi-use / stage configurations - deg. F/C, Auto Changeover/Temperature and Humidity Control

REGISTERED

* Model HP and 2S thermostat must be field converted to air conditioner operation.

**Thermidistat Control is versatile and can be configured for multiple use and staging, it must be configured for each specific application.

Programmable Thermostat Selection

TSTATBBPAC01-B

TSTATBBPHP01-B*

TSTATBBP2S01-B*

TSTATBBSAC01

TSTATBBPDF01-B**

TSTATBBPRH01-B***

* Model HP and 2S thermostat must be field converted to air conditioner operation.

**Dual Fuel thermostat is used with furnace and heat pump application

***Thermidistat Control can be configured for multiple use and staging, it must be configured for each specific application.

For use with 1-spd. Air Conditioner - deg. F/C, Auto Changeover, 7-Day Programmable

For use with 1-spd. Air Conditioner - deg. F/C, Auto Changeover, 7-Day Programmable

For use with 2-spd. Air Conditioner - deg. F/C, Auto Changeover, 7-Day Programmable

For use with 1-spd. Air Conditioner - deg. F/C, 5-2 Day Programmable

For use with multi-stage applications - deg. F/C, Auto Changeover, 7-Day Programmable

For multi-use / stage configurations - deg. F/C, Auto Changeover, 7-Day Programmable/Temperature and Humidity Control

ZONEBB3Z(AC/HP)01

ZONEBB2KIT01-B

ZONEBB4KIT01-B

ZONEBB8KIT01-B

Zoning Control Selection

Zone Perfect Two-Zone kit

Zone Perfect Plus 2-Zone kit/Temperature and Humidity Control

Zone Perfect Plus 4-Zone kit/Temperature and Humidity Control

Zone Perfect Plus 8-Zone kit/Temperature and Humidity Control

—3—

Page 4

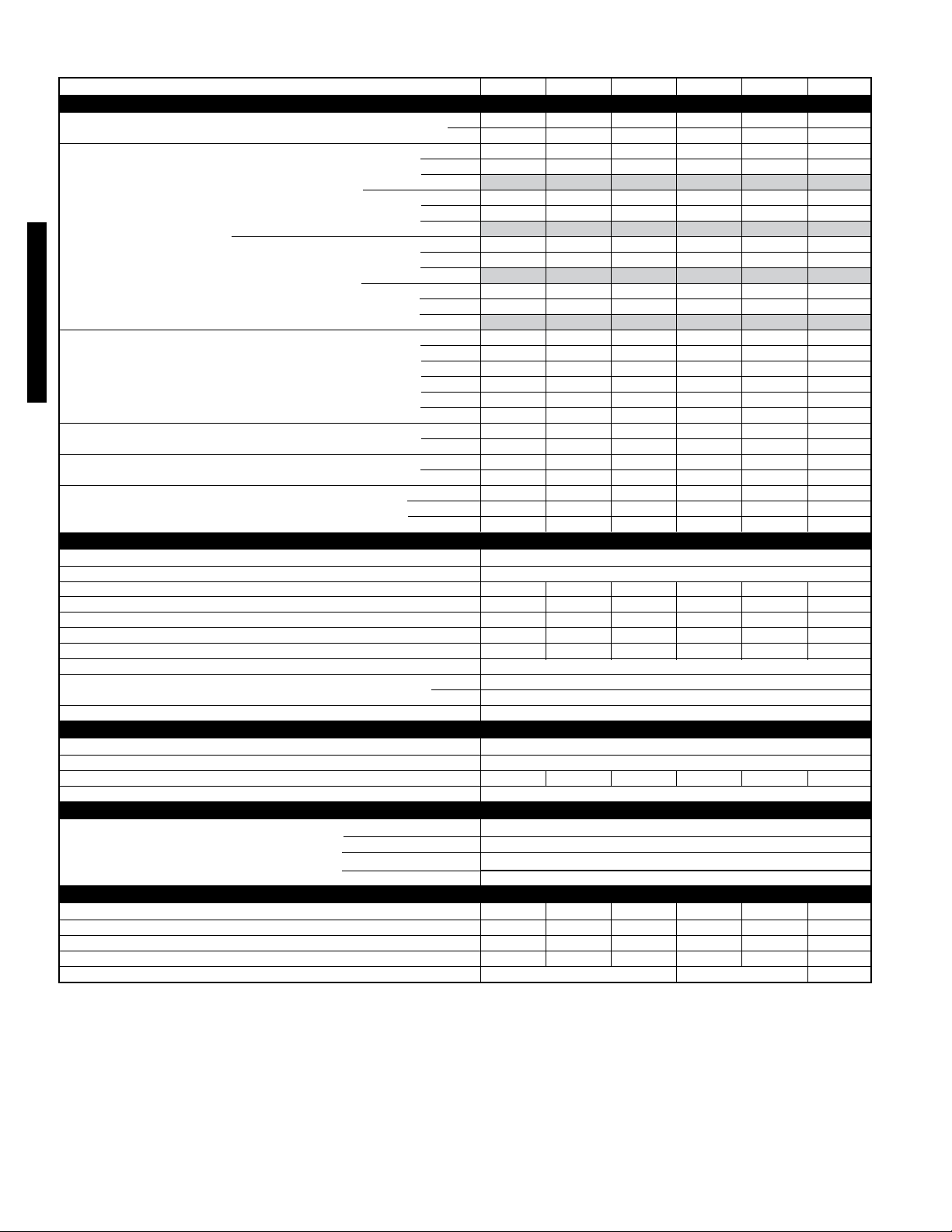

SPECIFICATIONS

UNIT SIZE 036060 036080 048080 048100 060100 060120

RATINGS AND PERFORMANCE

Input Btuh† Low 39,000 52,000 52,000 65,000 65,000 78,000

High 60,000 80,000 80,000 100,000 100,000 120,000

Output Capacity BTUH* (ICS) Direct Vent (2-Pipe) Low Upflow 37,000 49,000 49,000 61,000 61,000 74,000

(Shaded capacities are specified Downflow 37,000 49,000 49,000 61,000 61,000 74,000

on rating plate) Horizontal

High Upflow

Downflow 57,000 75,000 75,000 94,000 94,000 113,000

Non-Direct Vent (1-Pipe) Low Upflow 37,000 49,000 49,000 61,000 61,000 73,000

High Upflow 56,000 75,000 75,000 94,000 94,000 112,000

352AAV

AFUE† Direct Vent (2-Pipe) Upflow 93.0 93.0 93.0 93.0 93.0 93.0

Nonweatherized ICS

Non-Direct Vent (1-Pipe) Upflow 92.4 92.4 92.4 92.4 92.4 92.4

Certified Temperature Rise Range °F Low 20—50 30—60 30—60 25—55 30—60 30—60

Certified External Static Pressure (ESP)

(In. wc)

Airflow CFM‡ Heating Low 680 790 775 1175 1205 1215

ELECTRICAL

Unit Volts—Hertz—Phase 115—60—1

Operating Voltage Range Min-Max **

Maximum Unit Amps 8.4 8.1 11.6 11.6 13.3 12.9

Unit Ampacity†† 11.3 10.8 15.3 15.4 17.5 16.8

Minimum Wire Size 14 14 12 12 12 12

Maximum Wire Length (Ft)‡‡ 33 34 37 37 33 34

Maximum Fuse Size or Ckt Bkr Amps ††† 15 15 20 20 20 20

Transformer (24v) 40va

External Control Power Available Heating 19

Air Conditioning Blower Relay Standard

CONTROLS

Limit Control SPST

Heating Blower Control (Off Delay) Selectable 90, 120, 150, or 180 Seconds

Burners (Monoport) 344556

Gas Connection Size 1/2-in. NPT

GAS CONTROLS

2-Stage Redundant Gas Valve Manufacturer White-Rodgers

Min Inlet Pressure (In. wc) 4.5 (Natural Gas)

Max Inlet Pressure (In. wc) 13.6 (Natural Gas)

Ignition Device Hot Surface

BLOWER DATA

Direct-Drive Motor HP (Permanent Split Capacitor) 1/3 1/3 1/2 1/2 3/4 3/4

Motor Full Load Amps 5.1 5.1 7.4 7.9 11 11

RPM (Nominal)—Speeds 1075—5 1075—5 1075—5 1075—4 1075—5 1075—5

Blower Wheel Diameter x Width (In.) 10 7 10 7 11 8 11 8 11 10 11 10

Filter Size (In.)—Permanent Washable

Horizontal

Downflow 37,000 49,000 49,000 61,000 61,000 73,000

Horizontal

Downflow 56,000 75,000 75,000 94,000 94,000 112,000

Horizontal

Downflow 91.5 91.5 91.5 91.5 91.5 91.5

Horizontal 92.3 92.3 92.3 92.3 92.3 92.3

Downflow 91.4 91.4 91.4 91.4 91.4 91.4

Horizontal 91.4 91.4 91.4 91.4 91.4 91.4

High 30—60 40—70 30—60 45—75 30—60 40—70

Heating 0.12 0.15 0.15 0.2 0.2 0.2

Cooling 0.5 0.5 0.5 0.5 0.5 0.5

Heating High 1010 1130 1190 1315 1795 1770

Cooling 1275 1380 1565 1570 2035 2075

Cooling 35

See notes on page 5.

37,000 49,000 49,000 61,000 61,000 73,000

56,000 75,000 75,000 94,000 94,000 113,000

56,000 75,000 75,000 94,000 94,000 112,000

36,000 48,000 48,000 60,000 61,000 73,000

56,000 74,000 75,000 93,000 93,000 112,000

104—127

(1) 16 25 1 (1) 20 25 1 (1) 24 25 1

—4—

Page 5

*

SPECIFICATIONS Continued

FACTORY-AUTHORIZED AND LISTED DEALER-INSTALLED OPTIONS

Gas Conversion Kit—Natural-to-Propane KGANP4001ALL

Gas Conversion Kit—Propane-to-Natural KGAPN3301ALL

Twinning Kit KGATW0601HSI#

Downflow Base ***

Vent Termination Kit (Bracket Only for 2 Pipes) 2-in.—KGAVT0101BRA aaaa3-in.—KGAVT0201BRA

Concentric Vent Termination Kit (Single Exit) 2-in.—KGAVT0501CVT aaaa3-in.—KGAVT0601CVT

Condensate Freeze Protection Kit KGAHT0101CFP

Condensate Neutralizer Kit (Obtained Thru RCD) P908-0001

Electronic/Mechanical Air Cleaner Model EACB, EZXCAB or FILCAB

Humidifier Model HUM

Heat/Energy Recovery Ventilator Model HRV, ERV

Vent/Exhaust Pipe External Trap Kit KGAET0106ETK

UV Lights Model UVL

Door Gasket Kit KGBAC0110DGK

Gas input ratings are certified for elevations to 2000 ft. For elevations above 2000 ft, reduce ratings 2% for each 1000 ft above sea level. In Canada, derate

the unit 5% from 2000 to 4500 ft above sea level.

† Capacity and AFUE in accordance with U.S. Government DOE test procedures effective November 10, 1997.

‡ • Airflow shown is with factory-supplied 1-in. washable filter(s).

• For air delivery above 1800 CFM, see Air Delivery table for other options.

• An airflow reduction of up to 7% may occur when using the factory-specified 4 5/16-inch wide, high efficiency media filter.

• For best furnace efficiency when using the 4 5/16-inch wide media filter, adjust the blower speed tap to near the mid-point of the rise range.

**

Permissible voltage limits for proper furnace operation.

†† Unit ampacity = 125% of largest component’s full load amps plus 100% of all other potential operating components (EAC, humidifier, etc.).

‡‡ Length shown is measured 1 way along wire path between unit and service panel for maximum 2% voltage drop.

*** Required for installation on combustible floors when no coil box is used, or when any coil box other than a Bryant CD5 or CK5 cased coil is used.

N/A—Not applicable

ICS—Isolated Combustion System

#

For 048 and 060 airflow sizes only. See kit installation instructions for details.

KGASB0201ALL

352AAV

—5—

Page 6

ALTITUDE (FT)

0 to 2000

352AAV

ALTITUDE (FT)

2001 to 3000

ALTITUDE (FT)

3001 to 4000

See notesat end of table

COMBUSTION-AIR AND VENT PIPING FOR DIRECT VENT (2-PIPE)

AND NON-DIRECT VENT (1-PIPE) APPLICATIONS

MAXIMUM ALLOWABLE PIPE LENGTH (FT)

UNIT MAX

INPUT RATE

(BTUH)

60,000

80,000

100,000

120,000

UNIT MAX

INPUT RATE

(BTUH)

60,000

80,000

100,000

120,000

UNIT MAX

INPUT RATE

(BTUH)

60,000

80,000

100,000

120,000

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

4† no disk 4†nodisk 4†nodisk 707070707070

PIPE DIA

(IN.)*

1-1/2 1-1/2 20 15 10 5 NA NA

2 2 70 70 70 70 70 70

1-1/2 1-1/2 10 NA NA NA NA NA

22555035 30 3020

2-1/2 2-1/2 70 70 70 70 70 70

2 2 5 NANANANANA

2-1/2 2-1/2 40 30202010NA

3370 70 70 70 70 70

2-1/2 one disk 2-1/2 10 NA NA NA NA NA

3†NA454035 302520

3†nodisk 3† 707070707070

PIPE DIA

(IN.)*

1-1/2 1-1/2 17 12 7 NA NA NA

2 2 70 67 66 61 61 61

2 2 49 44 30252515

2-1/2 2-1/2 70 70 70 70 70 70

2-1/2 2-1/2 35261616 6NA

33

3 NA 14 9 NANANANA

NA 3†63 62 62 61 61 61

3†nodiskNA707063 56 50 43

4† no disk4†nodisk 707070707070

PIPE DIA

(IN)*

1-1/2 1-1/2 16 11 6 NA NA NA

226863 62 57 57 56

2 2 46 41 28 23 22 13

2-1/2 2-1/2 707070707070

2-1/2 2-1/2 33 24 15 14 5 NA

3370 70 70 66 61 56

3†nodisk NA 6558514438 31

NA 3† 595958575756

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

12 3 4 56

NUMBER OF 90° ELBOWS

12 3 4 56

70 70 70 70 66 61

NUMBER OF 90° ELBOWS

12 3 4 56

—6—

Page 7

ALTITUDE (FT)

COMBUSTION-AIR AND VENT PIPING FOR DIRECT VENT (2-PIPE)

AND NON-DIRECT VENT (1-PIPE) APPLICATIONS continued

MAXIMUM ALLOWABLE PIPE LENGTH (FT) (CONTINUED)

UNIT MAX

INPUT RATE

(BTUH)

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

12 3 4 5 6

4001 to 5000‡

ALTITUDE (FT)

5001 to 6000‡

ALTITUDE (FT)

60,000

80,000

100,000

120,000

UNIT MAX

INPUT RATE

(BTUH)

60,000

80,000

100,000

120,000

UNIT MAX

INPUT RATE

(BTUH)

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2Pipeor3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2Pipeor3-in

Concentric

2Pipeor3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

1-1/2 1-1/2 15 10 5 NA NA NA

2 2 64 59 58 53 52 52

22443926212011

2-1/2 2-1/2 70 70 70 70 70 70

2-1/2 2-1/2 312213 12 NA NA

3370 70 67 62 57 52

3†nodiskNA53 46 40 33 26 20

NA 3†56555453 52 52

4† no disk 4†nodisk 707070707070

PIPE DIA

(IN.)*

1-1/2 1-1/2 14 9 NA NA NA NA

2 2 60 55 54 49 48 47

22413623 18 17 8

2-1/2 2-1/2 70 70 70 70 70 70

2-1/2 2-1/2 29 21 12 11 NA NA

3370 67 62 57 52 47

3†nodiskNA4235292215 9

NA 3†53 52 50 49 48 47

4† no disk4†nodisk 707070707070

PIPE DIA

(IN)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN)*

352AAV

NUMBER OF 90° ELBOWS

12 3 4 5 6

NUMBER OF 90° ELBOWS

12 3 4 5 6

6001 to 7000‡

See notesat end of table

60,000

80,000

100,000

120,000

2 Pipe or 2-in

Concentric

2Pipeor2-in

Concentric

2 Pipe or 3-in

Concentric

2Pipeor3-in.

Concentric

1-1/2 1-1/2 13 8 NANANANA

2 2 57 52 50 45 44 43

2238 33 21 16 15 6

2-1/2 2-1/2 70 70 68 67 66 64

2-1/2 2-1/2 27 19 10 9 NA NA

3368 63 58 53 48 43

3†nodiskNA312418 11NANA

NA 3† 494847454443

4† no disk4†nodisk 707070706762

—7—

Page 8

ALTITUDE (FT)

COMBUSTION-AIR AND VENT PIPING FOR DIRECT VENT (2-PIPE)

AND NON-DIRECT VENT (1-PIPE) APPLICATIONS continued

MAXIMUM ALLOWABLE PIPE LENGTH (FT) (CONTINUED)

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

UNIT SIZE

(BTUH)

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

PIPE DIA

(IN.)*

7001 to 8000‡

352AAV

ALTITUDE (FT)

8001 to 9000‡

ALTITUDE (FT)

60,000

80,000

100,000

120,000

UNIT SIZE

(BTUH)

60,000

80,000

100,000

120,000

UNIT SIZE

(BTUH)

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3-in.

Concentric

DIRECT VENT (2-PIPE) ONLY

TERMINATION

TYPE

1-1/2 1-1/2 12 7 NANANANA

2253 48 46 41 40 38

2236 31191412NA

2-1/2 2-1/2 66 65 63 62 60 59

2-1/2 2-1/2 25 17 8 7 NA NA

3363 58 53 48 4338

3†nodiskNA2013 7NANANA

NA 3†464443 41 40 38

4† no disk4†nodisk615651464136

PIPE DIA

(IN.)*

1-1/2 1-1/2 11 6 NA NA NA NA

2 2 49 44 42 37 35 34

2233 28 17 12 10 NA

2-1/2 2-1/2 62 60 58 56 55 53

2-1/2 2-1/2 23 15 7 5 NA NA

3359 54 49 44 39 34

3†nodisk NA 10NANANANANA

NA 3†43 41 39 37 35 34

4† no disk4†nodisk 35 3025201510

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NON-DIRECT VENT

(1-PIPE) ONLY

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

NUMBER OF 90° ELBOWS

123456

60,000

9001 to 10,000‡

*Disk usage-Unless otherwise specified, use perforated disk assembly (factory-supplied in loosepartsbag). If one diskisstated, separate 2 halves of perforated disk

assembly and use shouldered diskhalf. When using shouldered diskhalf, install screen side toward inlet box.

†Wide radius elbow.

‡Vent sizing for Ca

NA-Not Allowed; pressure switch will not make.

NOTES:

1. Do not use pipe size greater thanthose specified in table or incomplete combustion, flame disturbance, or flame senselockoutmay occur.

2. Size both the combustion-air and vent pipe independently, then usethel

3.Assume two 45° elbows equal one 90° elbow.Wideradius elbowsare desirable and may berequired in some cases.

4. Elbowsand pipe sections within the furnace casing and at the vent termination should not beincluded in vent length or elbow count.

5. The minimum pipe length is 5ftforall a pplications.

6. Use 3-in. diameter vent termination kit for in

nadianinstallations over 4500 ft (1370 m) above sea level are subject to acceptance bythelocal authorities having jurisdiction.

80,000

100,000

120,000

2 Pipe or 2-in

Concentric

2 Pipe or 2-in

Concentric

2 Pipe or 3-in

Concentric

2 Pipe or 3

Concentric

stallations requiring 4-in diameter pipe.

-in.

22454038 33 3129

22302514 9 7 NA

2-1/2 2-1/2 57 55 53 51 49 47

2-1/2 2-1/2 21 13 5NANANA

3354 49 44 39 3429

NA 3† 39 37 35 33 3129

4† no disk 4†nodisk 10 5 NANANANA

arger diameter for both pipes.

—8—

Page 9

MAXIMUM ALLOWABLE EXPOSED VENT PIPE LENGTH (FT) WITH AND WITHOUT INSULATION

IN WINTER DESIGN TEMPERATURE AMBIENT *

WINTER DESIGN

UNIT SIZE

060

080

100

120

TEMPERATURE

(°F)

20 2 44 70

0 2 21 70

–20 2 20 57

20 2 55 55

0 2 30 55

–20 2 16 55

20 2.5 58 70

0 2.5 29 70

–20 2.5 14 67

20 2.5 40 40

0 2.5 38 40

–20 2.5 21 40

20 3 63 70

0 3 30 70

–20 3 12 70

20 3 70 70

0338 70

–20 3 19 70

20 4 65 70

0 4 26 70

–20 4 5 65

* Pipe length (ft) specified for maximum pipe lengths located in unconditioned spaces. Pipes located in unconditioned space cannot exceed total

allowable pipe length as specified in Table 6.

† Insulation thickness based on R value of 3.5 per inch.

MAX PIPE

DIAMETER

(IN.)

WITHOUT

INSULATION

WITH 3/8-IN. OR

THICKER INSULATION†

352AAV

—9—

Page 10

CONDENSATE TRAP

352AAV

BLOWER SHELF

CONDENSATE

TRAP (INSIDE)

ALTERNATE DRAIN

TUBE LOCATION

CONDENSATE TRAP

DRAIN TUBE LOCATION

UPFLOW APPLICATIONS

FURNACE

DOOR

FIELD

DRAIN

CONN

EXTERNAL UPFLOW APPLICATIONS

SLOT FOR SCREW

HORIZONTAL

APPLICATION

(OPTIONAL)

1

1

2

3

4

WIRE TIE

GUIDES

(WHEN USED)

CONDENSATE

TRAP

FURNACE

SIDE

7

4

8

FURNACE

DOOR

4

FURNACE

SIDE

3

5

4

3

5

4

1

26

1

26

4

1

1

2

FIELD

DRAIN

CONN

4

3

4

SIDE VIEW FRONT VIEW END VIEW FRONT VIEW

DOWNFLOW AND ALTERNATE

1

7

8

3

1

4

7

8

1

2

4

1

⁄4 OD

COLLECTOR BOX TO

TRAP RELIEF PORT

1

⁄2 OD

INDUCER HOUSING

DRAIN CONNECTION

5

⁄8 OD

COLLECTOR BOX

DRAIN CONNECTION

SCREW HOLE FOR

UPFLOW OR DOWNFLOW APPLICATIONS

(OPTIONAL)

1

⁄2-IN. PVC OR CPVC

HORIZONTAL

APPLICATIONS

4

FRONT VIEW SIDE VIEW

A93026

—10—

Page 11

LENGTH OF STRAIGHT

PIPE PORTION OF COMBUSTION

AIR INLET PIPE ASSEMBLY (IN.)

CASING WIDTH A

17-1/2 8-1/2 ± 1/2

21 10-1/2 ± 1/2

24-1/2 12 ± 1/2

*

*

ACCESSORIES

COMBUSTION-AIR PIPE FOR NON-DIRECT VENT (1-PIPE) APPLICATION (SIZES 040 THROUGH 120 ONLY)

FIELD-SUPPLIED

CONCENTRIC VENT FOR DIRECT VENT (2-PIPE) APPLICATION (ALL MODEL SIZES)

NOTE:

See furnace

Installation Instruction

when venting multiple

furnaces near each other.

2-IN. DIAMETER

PVC 90° ELBOW

COMBUSTION-AIR DISC

(FACTORY-SUPPLIED IN

LOOSE PARTS BAG)

FIELD-SUPPLIED

2-IN. DIAMETER

PVC PIPE

A

A96211

B IN. DIA PVC

VENT/EXHAUST

1

/2

1

C IN. DIA

13/

16

D

A

B IN. DIA PVC

INTAKE/COMBUSTION AIR

A97110

F

E

352AAV

KGAVT0501CVT 33-3/8 2 3-1/2 16-5/8 6-1/4 5-3/4

KGAVT0601CVT 38-7/8 3 4-1/2 21-1/8 7-3/8 6-1/2

Dimension A will change accordingly as dimension D is lengthened or shortened.

†Dimension D may be lengthened to 60 in. maximum. Dimension D may also be shortened by

cutting the pipes provided in the kit to 12 in. minimum.

LOCATING

TAB

B

LOCATING

TAB

D

FURNACE

CASING

WIDTH FURNACE IN DOWNFLOW APPLICATION

17-1/2

21

24-1/2

The plenum should be constructed 1/4 in. smaller in width and depth than the plenum dimensions shown above.

Furnace with or without Cased Coil

Assembly or KCAKC Coil Box

Furnace with or without Cased Coil

Assembly or KCAKC Coil Box

Furnace with or without Cased Coil

Assembly or KCAKC Coil Box

DIMENSIONS (In.)

PART NO. A *

B C D† E F

ACCESSORY DOWNFLOW SUBBASE

4

3

2

1

FACTORY-SUPPLIED

4

2

3

A88207

1

FIELD-INSTALLED

INSULATION

PLENUM OPENING * FLOOR OPENING HOLE NO.

15-1/8 19 16-3/4 20-3/8 3

18-5/8 19 20-1/4 20-3/8 2

22-1/8 19 23-3/4 20-3/8 1

—11—

1 1/

″

TYP

4

PLENUM

OPENING

A

C

A97427

FOR WIDTH

ADJUSTMENTABCD

Page 12

MEDIA FILTER CABINET

5

/

25

8

5

/

23

8

"

3

/

8

"

23

Opening with Flanges Bent

3

24

1

23

Opening

"

/

8

"

/

8

"

352AAV

Furnace Side

3

/

4

"

23

Centerline Screw Slots

A

Duct Side

3

/

4

"

5

Media

Filter Cabinet

16" 17" 16"

20" 21" 20"

24" 25" 24"

AB

Shipped with sizes

024040, 036040, 024060, 036060,

048060, 036080, 048080

060080, 048100, 060100

gninepO B

060120, 060140

A05218

AIR DELIVERY—CFM (With Filter)

UNIT SIZE

BRYANT

RETURN-AIR

SUPPLY SPEED

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

High 1490 1450 1400 1345 1275 1190 1080 960

Med-High 1190 1180 1155 1120 1070 1005 915 810

Med 1015 1010 995 965 920 875 800 715

Med-Low 870 860 840 820 780 735 670 580

036060

1 side

or

bottom

Low 685 670 645 620 595 545 495 420

High 1605 1560 1510 1450 1380 1300 1195 1045

036080

1 side

or

bottom

Med-High 1305 1290 1265 1225 1175 1100 995 895

Med 1135 1125 1110 1080 1030 965 885 800

Med-Low 990 980 965 930 880 825 760 685

Low 805 780 745 700 660 630 575 495

High 1810 1755 1690 1640 1565 1495 1410 1330

048080

1 side

or

bottom

Med-High 1420 1385 1350 1305 1260 1210 1145 1090

Med 1205 1175 1135 1100 1060 1010 960 905

Med-Low 1035 990 945 910 875 840 790 735

Low 805 750 705 660 620 585 540 490

High 1740 1705 1660 1615 1570 1500 1425 1355

Med-High 1500 1470 1445 1410 1375 1330 1280 1210

Med-Low 1340 1315 1300 1270 1235 1200 1140 1095

Low 1195 1175 1165 1130 1100 1070 1030 975

04810

1 side

or

bottom

High 2345 2265 2195 2110 2035 1940 1850 1745

Med-High 2110 2065 2010 1945 1875 1800 1710 1615

Med 1810 1795 1770 1725 1680 1615 1545 1460

Med-Low 1480 1465 1440 1415 1375 1330 1260 1190

Low 1235 1205 1180 1155 1115 1065 1015 950

High 2425 2365 2300 2240 2160 208019801880

Med-High 2045 2025 2000 1965 1910 1850 1785 1695

High 2305 2235 2170 2100 2005 1925 1825 1730

Med-High 2030 1995 1950 1905 1835 1775 1685 1600

060100

bottom

only

both sides or

1 side and bottom

1 side only

High 2385 2320 2245 2160 2075 1975 1870 1775

Med-High 2105 2060 2005 1945 1880 1795 1710 1620

Med 1785 1770 1740 1700 1650 1600 1525 1450

Med-Low 1495 1470 1450 1420 1385 1335 1280 1220

Low 1250 1215 1190 1155 1125 1085 1040 985

High 2475 2435 2385 2320 2260 2180 2095 1995

Med-High 2085 2075 2055 2030 1980 1930 1865 1785

High 2255 2190 2115 2045 1965 1890 1800 1710

Med-High 1985 1930 1890 1840 1780 1720 1645 1560

060120

bottom

only

both sides or

1 side and bottom

1 side only

• Airflow shown is with factory supplied 1-in. washable filter.

• A filter is required for each return air opening.

• An airflow reduction of up to 7% may occur when using the factory-specified 4-5/16-inch wide, high efficiency media filter.

• For best furnace efficiency when using the 4 5/16-inch wide media filter, adjust blower speed tap to near the mid-point of the rise range.

• For horizontal and downflow applications, use 1 side or bottom or bottom only as an airflow reference.

EXTERNAL STATIC PRESSURE (In. wc)

—12—

Page 13

OUTDOOR UNIT

COMBUSTION

AIR INLET

(NON-DIRECT

1-PIPE APPLICATION)

COMBUSTION AIR PIPE

(DIRECT VENT/2-PIPE APPLICATION)

A/C COIL

ELECTRONIC

AIR CLEANER

VENT PIPE

HUMIDIFIER

GAS-FIRED

WATER HEATER

352AAV

AIRFLOW

ELECTRONIC

AIR CLEANER

COMBUSTION AIR

INLET (NON-DIRECT

VENT/ 1-PIPE APPLICATION

HUMIDIFIER

FRONT OF

FURNACE

A05064

VENT

COMBUSTION

AIR (DIRECT VENT/

2 PIPE APPLICATION

OUTDOOR

UNIT

A/C COIL

FRONT OF

AIRFLOW

FURNACE

A05065

—13—

Page 14

COMBUSTION-AIR INLET

(NON-DIRECT VENT/1-PIPE APPLICATION)

352AAV

ELECTRONIC

AIR CLEANER

FRONT OF FURNACE

AIRFLOW

VENT PIPE

FURNACE

CONDENSATE

DRAIN

REFRIGERATION

COMBUSTION–AIR PIPE

DIRECT VENT/2-PIPE APPLICATION)

AIR CONDITIONING

COIL

PIPING

A05066

COMBUSTION - AIR INLET

(NON-DIRECT VENT/

1-PIPE APPLICATION)

REFRIGERATION

PIPING

AIR CONDITIONING

COIL

AIRFLOW

FURNACE CONDENSATE

DRAIN

FRONT OF

FURNACE

COMBUSTION– AIR PIPE

(DIRECT VENT/2-PIPE

APPLICATION)

VENT

PIPE

ELECTRONIC

AIR CLEANER

A05067

—14—

Page 15

352AAV

—15—

Page 16

GUIDE SPECIFICATIONS

GENERAL

System Description

Furnish a _________________ (4-way multipoise) dual capacity gas-fired condensing furnace for use with natural gas or propane (factory authorized conversion kit required for propane);

furnish cold air return plenum; furnish external medial cabinet for

use with accessory media filter or standard filter.

Quality Assurance

Unit will be designed, tested and constructed to the current ANSI

Z 21.47/CSA 2.3 design standard for gas-fired central furnaces.

Unit will be 3rd party certified by CSA to the current ANSI Z

21.47/CSA 2.3 design standard for gas-fired central furnaces.

Unit will carry the CSA Blue Star® and Blue Flame® labels.

Unit efficiency testing will be performed per the current DOE test

procedure as listed in the Federal Register.

Unit will be certified for capacity and efficiency and listed in the

latest GAMA Consumer's Directory of Certified Efficiency

Ratings.

Unit will carry the current Federal Trade Commission Energy

Guide efficiency label.

Delivery, Storage, and Handling

Unit will be shipped as single package only and is stored and

handled per unit manufacturer's recommendations.

Warranty (for inclusion by specifying engineer)

U.S. and Canada only. Warranty certificate available upon

request.

PRODUCTS

Equipment

Components shall include: slow-opening dual rate gas valve to

reduce ignition noise, regulate gas flow, with electric switch gas

shut-off; flame proving sensor, hot surface igniter, pressure

switch assembly verifies inducer operation; flame rollout switch,

drain tubing and installed condensate drain trap, blower and inducer assembly, 40va transformer; low-voltage (heating) (heating/cooling) thermostat.

Blower Wheel and Blower Motor

Galvanized blower wheel shall be centrifugal type, statically and

dynamically balanced. Blower motor of PSC type shall be permanently lubricated with sealed bearings, of _____ hp, and shall

be multiple-speed direct drive. Blower motor shall be soft mounted to the blower scroll to reduce vibration transmission.

Filters

Furnace shall have reusable-type filters. Filter shall be ______ in

(x) ______in. An accessory high efficiency Media Filter is available as an option _____________Media Filter.

Casing

Casing shall be of .030 in. thickness minimum, pre-painted galvanized steel.

Two Speed Inducer Motor

Two Speed Inducer motor shall be soft mounted to reduce vibration transmission.

Primary Heat Exchangers

Primary Heat exchangers shall be 3-Pass 20 gauge corrosion

resistant aluminized steel of fold-and-crimp sectional design,

which operates under negative pressure.

Secondary Heat Exchangers

Secondary Heat exchangers shall be of a flow-through design

having a patented interior laminate coating of polypropylene for

greater corrosion resistance with fold-and-crimp design, which

operates under negative pressure.

Controls

Controls shall include a microprocessor based integrated electronic control board with at least 11 service troubleshooting

codes displayed via diagnostic flashing LED light on the control,

has ability to store fault codes, when activated a self-test feature

checks all major functions of the furnace within one minute, and

a replaceable automotive-type circuit protection fuse. Multiple

operational settings available including, separate blower speeds

for low heat, high heat, low cooling, high cooling and continuous

fan. Continuous fan speed may be adjusted from the thermostat.

Cooling airflow will be selectable between 350 or 400 CFM per

ton of air conditioning. Features will also include temporary reduced airflow in the cooling mode for improved dehumidification

when a Thermidistat® is selected as the thermostat.

Operating Characteristics

Heating Capacity shall be _________ Btuh input;

____________ Btuh output capacity.

Fuel Gas Efficiency shall be 93% AFUE.

Air delivery shall be __________ cfm minimum at 0.50 in. wg.

external static pressure.

Dimensions shall be: depth __________ in.; width __________

in.; height _________ in. (casing only). Height shall be

__________ in. with A/C coil and ____________ in. overall with

plenum.

Electrical Requirements

Electrical supply shall be 115 volts, 60 Hz, single-phase (nominal). Minimum wire size shall be _________ AWG; maximum

fuse size or HACR-type, designated circuit breaker shall be

_______ Amps.

Special Features

Refer to section of the product data s

sories and descriptions for specific features and available

enhancements.

heet identifying acces-

©Bryant Heating & Cooling systems 7310 W. Morris St. Indianapolis, IN 46231 Printed in U.S.A. edition date: 09/09 Catalog No. PDS 352A.60.2

352a.60.1 Rev.A SDP :secalpeRsnoitagilbo dna eciton tuohtiw sngised ro snoitacificeps ,emit yna ta ,egnahc ot thgir eht sevreser rerutcafunaM

—16—

Loading...

Loading...