Page 1

DIRECT-VENT DOWNFLOW

CONDENSING GAS FURNACE

for MANUFACTURED HOUSING

351DAS

Size 080

Series A

Utilizing the extensive resources available to Bryant, a new

standard of excellence has been achieved with the model

351DAS Downflow Furnace for manufactured (mobile) or

modular homes.

The model 351DAS is a unique downflow condensing furnace with features like no other product in its class. The

351DAS builds on the many Bryant successes in the furnace

industry and establishes a new standard for high-efficiency

gas furnaces.

FEATURES

Factory Configuration —Factory configured for downflow ap-

plications in manufactured (mobile) or modular homes.

The model 351DAS is available in 3 heat/airflow combina-

tions.

Sealed Combustion (Direct-Vent) System —Enclosed burner

assembly isolates operating noise without the expense of

sound deadening devices. The sealed combustion (directvent) system brings outdoor air directly into the combustion

chamber, reducing infiltration of cold air into the structure and

reducing heat loss.

3-Pass Primary Heat Exchangers —This design accelerates

heat transfer and extracts heat that conventional heat exchangers waste up the flue. The weld-free primary heat exchangers are made of aluminized steel for corrosion

resistance.

Flow-Through Secondary Heat Exchangers —Each cell is lami-

nated with our patented Everlastic

resistance to corrosion. This breakthrough in heating technology

helps extend the life of the furnace for years of trouble-free performance.

Warranty —Limited 20-year Warranty on the heat exchangers

for the original owner in single family residence. Contact your

dealer for details. Two-year limited parts and labor warranty on

entire unit.

Monoport Inshot Burners —Produce precise air-to-gas mixture

which gives a clean burn. The large monoport on the inshot or

injection-type burners seldom, if ever, needs cleaning.

Control Center —The printed-circuit board and all internal wiring

are factory installed. Convenient terminals permit quick-connection of a thermostat, a humidifier, an air cleaner, and air conditioning control circuits.

As an added feature, the control has a built-in status indicator

and self-test feature. The status indicator flashes to indicate a

problem condition and assists the servicer in diagnosis. The selftest feature allows for a complete check of the major components in only seconds.

Combustion Air and Ventilation —The 351DAS advanced design

allows Schedule 40PVC, PVC-DWV, SDR-21 PVC, SDR-26

PVC (not approved in Canada), ABS-DWV, or ABS-F628

Schedule 40 pipe to bring outdoor air into the furnace for combustion. The extracted heat lowers the temperature of the combustion products to a point (typically below 115°F) that any of the

approved types of pipe can also be used for venting combustion

products outside the structure. The combustion-air and vent

pipes can terminate through a side wall or through the roof when

using 1 of our approved vent termination kits.

Fully-Insulated Casing —Foil-faced insulation in the heat ex-

changer section cuts heat loss, and insulation in the blower section reduces noise levels. The casing also has the required

openings for left- or right-side connection of gas, electric, drain,

and vent connections.

Certifications —The 351DAS units are A.G.A. and C.G.A. design

certified for use with natural and propane gases, as well as

GAMA efficiency rating certified. The furnace is factory-shipped

for use with natural and propane gases. (All parts necessary to

convert the gas valve for propane gas use are shipped with the

furnace.) Model 351DAS is design certified for installation in

manufactured (mobile) homes.

Quality Registration —The 351DAS is engineered and manu-

factured under an ISO 9001 registered quality system.

TM

polypropylene for greater

Form No. PDS 351D.80.1

Page 2

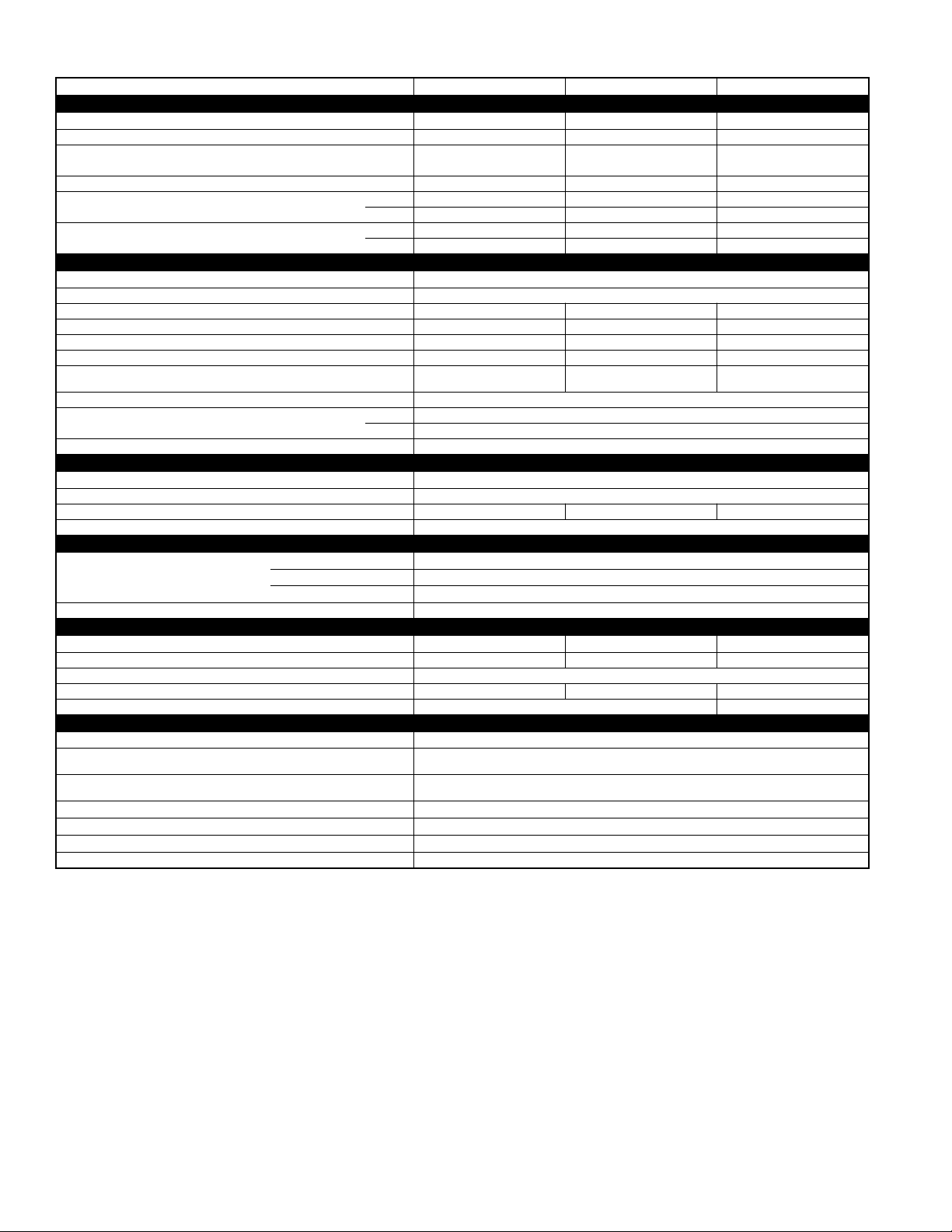

"

16

⁄

11

22

-IN. DIA

2

⁄

1

-IN. DIA

8

⁄

7

ACCESSORY

POWER ENTRY

"

2

⁄

1

"

24

16

⁄

9

TYP

27

"

8

⁄

5

27

"

16

⁄

11

TYP

"

29

16

⁄

13

30

"

8

⁄

5

32

"

16

/

11

-IN. DIA

2

⁄

1

GAS CONN

2-IN. VENT CONN

THERMOSTAT ENTRY

-IN. DIA

8

⁄

7

POWER CONN

TYP

"

4

⁄

1

TYP

33

"

16

⁄

5

"

2-IN.

COMBUSTION

-AIR CONN

2

⁄

1

22

"

4

⁄

"

1

24

16

⁄

26

15

26

TRAP LOCATION

CONDENSATE DRAIN

OUTLET FLANGE

AS SHIPPED

(REMOVE IN FIELD)

"

16

/

13

A98647

in. rectangle.

in. rectangle.

2

4

/

/

1

1

X 19-

X 23-

2

2

X 12-in. rectangle.

/

/

2

1

1

/

1

"

16

⁄

3

24

INLET

E

INLET

"

16

/

11

"

2

⁄

1

30

"

4

⁄

1

-IN. DIA GAS CONN

2

⁄

CONDENSATE DRAIN

TRAP LOCATION

OR ALTERNATE

1

D

OUTLET

"

16

/

13

A

AIRFLOW

DIMENSIONS (In.)

2. For 1200 CFM 20-in. round or 14-

NOTES: Minimum return-air opening at furnace, based on metal

duct. If flex duct is used, see flex duct manufacturer's

3. For 1600 CFM 22-in. round or 14-

recommendation for equivalent diameters:

1. For 800 CFM 16-in. round or 14-

036080 17-1/2 15-7/8 16 172

048080 17-1/2 15-7/8 16 175

UNIT SIZE A D E SHIP. WEIGHT (Lb)

060080 21 19-3/8 19-1/2 197

18

"

2

⁄

1

"

16

28

⁄

15

19"

OUTLET

"

4

⁄

1

26

"

26

16

⁄

5

22

"

16

⁄

11

22

-IN. DIA

2

⁄

1

-IN. DIA

8

⁄

7

2-IN. VENT CONN

THERMOSTAT ENTRY

POWER CONN

2-IN.

-IN. DIA

2

⁄

1

GAS CONN

AIR CONN

COMBUSTION-

"

16

⁄

11

"

8

⁄

7

"

"

8

⁄

16

⁄

5

13

39

—2—

Page 3

INSTALLATION

This forced air furnace is equipped for use with natural or propane gas at altitudes 0 - 10,000 ft (0 - 3,050m).

This furnace is for indoor installation in a manufactured (mobile) or modular home.

This furnace may be installed on combustible flooring in alcove or closet at minimum clearance from combustible material.

This appliance requires a special venting system. Refer to the installation instructions for parts list and method of installation. This furnace is for use with schedule-40 PVC,

PVC-DWV, or ABS-DWV pipe, and must not be vented in common with other gas-fired appliances. Construction through which vent/air intake pipes may be installed is

maximum 24 inches (600 mm), minimum 3/4 inches (19 mm) thickness (including roofing materials).

Furnace must be installed level, or pitched forward within 1/2 inch of level for proper drainage. Failure w ill result

in equipment or property damage.

MINIMUM INCHES CLEARANCE TO

COMBUSTIBLE CONSTRUCTION

DOWNFLO W POS ITION:

Mimimum front clearance for service 30 inches (762mm).

*

For installation on combustible floors only when installed on special base No. KGASB0201ALL,

†

Coil Assembly, Part No. CD5 or CK5, or Coil Casin g , Part No. KCAKC .

MANUFACTURED MOBILE HOME STANDARDS

This furnace must be installed in accordance with the manufacturer's instructions and Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280 or, when such standard is not

applicable, the ANSI A225.1, Standard for Manufactured Home Installation (Manufactured Home Sites,

Communities and Set-Ups), or the Mobile Homes Standard CAN/CSA-Z240 MH Series-M86.

This furnace must be installed with a direct vent (combustion air and flue) system, and use a factory

accessory termination kit.

This furnace is approved for

DOWNF LOW installation.

0"

0"

Clearance in inches

B

A

C

LEVEL (0")

1/2" MAX

DOWNFLOW

K

E

D

I

S

TO

FRONT

1"

TOP/PLENUM

E

C

A

N

R

U

F

T

N

O

R

F

F

R

O

N

T

BOTTOM

0"

†

0"

E

D

I

S

S

E

R

V

I

C

E

*

30

3"

MIN

Condensate Trap

on LEFT Side

COLLECTOR BOX

DRAIN TUBE

CONDENSATE TRAP

INDUCER HOUSING

DRAIN TUBE

BURNER ENCLOSURE

PRESSURE REFERENCE

TUBE ASSEMBLY

NOTE:

CONTROLS—THERMOSTATS AND ZONING

THERMOSTAT—NON-PROGRAMMABLE

THERMOSTAT—PROGRAMMABLE

THERMIDISTAT—PROGRAMMABLE THERMOSTAT

—with Humidity Control

TUBE ROUTING

BURNER ENCLOSURE

PRESSURE

REFERENCE TUBE

ASSEMBLY

CAP / PLUG

LOWER CO LLECTOR

BOX PRESSURE TUBE

UPPER COLLECTOR

BOX PRESSURE TUBE

GAS VALVE

1. All tubing must be connected securely and routed to avoid kinks and traps.

COLLECTOR BOX

DRAIN TUBE

INDUCER HOUSING

DRAIN TUBE

DRAIN TUBE

COUPLING

For Use with 1-Speed Air Conditioner—TSTATBBNAC01-B

For Use with 2-Speed Air Conditioner—TSTATBBN2S01-B

For Use with 2-Speed Heat Pump—TSTATBBN2S01-B

For Use with 1-Speed Air Conditioner—TSTATBBPAC01-B

For Use with 2-Speed Air Conditioner—TSTATBBP2S01-B

For Use with 2-Speed Heat Pump—TSTATBBP2S01-B or TSTATBBPDF01-B

For Use with 1-Speed Heat Pump—TSTATBBPDF01-B

TSTATBBPRH01-B

Condensate Trap

on RIGHT Side

CAP / PLUG

LOWER CO LLECTOR BOX

PRESSURE TUBE

UPPER COLLECTOR BOX

PRESSURE TUBE

GAS VALVE

COLLECTOR BOX EXTENSION DRAIN

TUBE

DRAIN TUBES ROUTED IN

FRONT OF GAS VALVE

CONDENSATE TRAP

324997-201 REV. A / LIT

A99001e

—3—

Page 4

*

SPECIFICATIONS

UNIT SIZE 036080 048080 060080

RATINGS AND PERFORMANCE

Input Btuh *

Output Capacity† ICS Downflow 75,000 75,000 75,000

AFUE%†

Nonweatherized ICS Downflow 90.0 90.0 90.0

Certified Temperature Rise Range °F 40—70 30—60 20—50

Certified External Static Pressure Heating 0.15 0.15 0.15

Cooling 0.50 0.50 0.50

Airflow CFM‡ Heating 1190 1285 1785

ELECTRICAL

Unit Volts—Hertz—Phase 115—60—1

Operating Voltage Range Min—Max **

Maximum Unit Amps 7.6 10.0 14.1

Unit Ampacity†† 10.4 13.4 18.4

Minimum Wire Size 14 14 12

Maximum Wire Length (Ft)‡‡ 36 28 31

Maximum Fuse Size or Ckt Bkr Amps

(Time-Delay Fuse Recommended) 15 15 20

Transformer (24v) 40va

External Control Heating 12va

Power Available Cooling 21va

Air Conditioning Blower Relay Standard

CONTROLS

Limit Control SPST

Heating Blower Control (Off Delay) Factory Set at 135 Sec

Burners (Monoport) 4 4 4

Gas Connection Size 1/2-in. NPT

GAS CONTROLS

Gas Valve (Redundant/Gas Convertible) Manufacturer White-Rodgers

Min Inlet Pressure (In. wc) 4.5 (Natural Gas) 11.0 (Propane)

Max Inlet Pressure (In. wc) 13.6 (Natural and Propane Gases)

Ignition Device Hot Surface

BLOWER DATA

Direct-Drive Motor HP (Permanent Split Capacitor) 1/3 1/2 3/4

Motor Full Load Amps 5.8 7.9 11.1

RPM (Nominal)—Speeds 1075—4

Blower Wheel Diameter x Width (In.) 10 x 7 11 x 8 11 x 10

Filter Size (In.)—Permanent Washable (1) 16 x 25 x 1 (1) 20 x 25 x 1

FACTORY-AUTHORIZED AND LISTED, DEALER-INSTALLED OPTIONS

Cooling 1245 1525 1925

Downflow Base ***

Vent Termination Kit (Bracket Only for 2 Pipes)

Concentric Vent Termination Kit (Single Exit)

Condensate Freeze Protection Kit KGAHT0101CFP

Electronic/Mechanical Air Cleaner Model AIRA or 902B or MACA

Humidifier Model HUM

Heat/Energy Recovery Ventilator Model VA3B, VB5B, VC5B, or VL3A

Gas input ratings are certified for elevations to 2000 ft. For elevations above 2000 ft, reduce ratings 2% for each 1000 ft above sea level. In Canada, derate

the unit 5% from 2000 to 4500 ft above sea level.

† Capacity and AFUE in accordance with U.S. Government DOE test procedures.

‡ Airflow shown is for top only return-air supply.

Permissible voltage limits for proper furnace operation.

**

†† Unit ampacity = 125% of largest component’s full load amps plus 100% of all other potential operating components (EAC, humidifier, etc.).

‡‡ Length shown is measured 1 way along wire path between unit and service panel for maximum 2% voltage drop.

*** Required for installation on combustible floors when no coil box is used, or when any coil box other than a Bryant CD5 or CK5 cased coil is used.

ICS—Isolated Combustion System

80,000 80,000 80,000

104—127

KGASB0201ALL

2-in.—KGAVT0101BRA

3-in.—KGAVT0201BRA

2-in.—KGAVT0501CVT

3-in.—KGAVT0601CVT

—4—

Page 5

*

COMBUSTION-AIR AND VENT PIPING

MAXIMUM ALLOWABLE PIPE LENGTH (FT)

ALTITUDE

ABOVE SEA

LEVEL (FT) UNIT SIZE TERMINATION TYPE

0 to 2000

2001 to 3000

3001 to 4000

4001 to 5000†

5001 to 6000†

6001 to 7000†

7001 to 8000†

8001 to 9000†

9001 to

10,000†

Disk usage—Unless otherwise specified, use perforated disk assembly (factory-supplied in loose parts bag).

*

† Vent sizing for Canadian installations over 4500 ft (1370m) above sea level are subject to acceptance by the local authorities having jurisdiction.

NA—Not Allowed; pressure switch will not make.

NOTES:

1. Do not use pipe size greater than those specified in table or incomplete combustion, flame disturbance, or flame sense lockout may occur.

2. Size both the combustion-air and vent pipe independently, then use the larger diameter for both pipes.

3. Assume two 45° elbows equal one 90° elbow. Long radius elbows are desirable and may be required in some cases.

4. Elbows and pipe sections within the furnace casing and at the vent termination should not be included in vent length or elbow count.

5. The minimum pipe length is 5 ft for all applications.

036080

048080

060080

036080

048080

060080

036080

048080

060080

036080

048080

060080

036080

048080

060080

036080

048080

060080

036080

048080

060080

036080

048080

060080

036080

048080

060080

2 Pipe or 2-In. Concentric

2 Pipe or 2-In. Concentric

2 Pipe or 2-In. Concentric

2 Pipe or 2-in Concentric

2 Pipe or 2-In. Concentric

2 Pipe or 2-In. Concentric

2 Pipe or 2-In. Concentric

2 Pipe or 2-In. Concentric

2 Pipe or 2-In. Concentric

PIPE DIA

(IN.) *

1-1/2 10 NA NA NA NA NA

2 555035303020

2-1/2 70 70 70 70 70 70

2 494430252515

2-1/2 70 70 70 70 70 70

2 464128232213

2-/12 70 70 70 70 70 70

2 443926212011

2-1/2 70 70 70 70 70 70

2 4136231817 8

2-1/2 70 70 70 70 70 70

2 3833211615 6

2-1/2 70 70 68 67 66 64

2 3631191412NA

2-1/2 66 65 63 62 60 59

2 3328171210NA

2-1/2 62 60 58 56 55 53

2 302514 9 7NA

2-1/2 57 55 53 51 49 47

123456

NUMBER OF 90° ELBOWS

MAXIMUM ALLOWABLE EXPOSED VENT PIPE LENGTH (FT) WITH AND WITHOUT INSULATION

IN WINTER DESIGN TEMPERATURE AMBIENT *

WINTER DESIGN

TEMPERATURE

UNIT SIZE

036080

048080

060080

(°F)

20 2-1/2 70 70

0 2-1/2 47 70

–20 2-1/2 28 70

Pipe length (ft) specified for maximum vent pipe lengths located in unconditioned spaces. Vent pipes located in unconditioned space cannot exceed the

total allowable pipe length as specified in Maximum Allowable Pipe Length table.

† Insulation thickness based on R value of 3.5 per in.

MAX PIPE

DIAMETER

(IN.)

WITHOUT

INSULATION

WITH 3/8-IN. OR

THICKER INSULATION†

—5—

Page 6

CONDENSATE TRAP

FURNACE

DOOR

FIELD

DRAIN

CONN

CONDENSATE

TRAP

1

4

26

FURNACE

SIDE

1

1

2

SIDE VIEW FRONT VIEW

(SHOWN ON RIGHT-HAND SIDE. MAY

BE INSTALLED ON LEFT-HAND SIDE.)

®

ama

1

⁄4 OD

COLLECTOR BOX TO

1

2

1

3

4

7

8

4

3

4

1

WIRE TIE

GUIDES

(WHEN USED)

1

8

7

7

8

1

4

2

TRAP RELIEF PORT

1

⁄2 OD

INDUCER HOUSING

DRAIN CONNECTION

5

⁄8 OD

COLLECTOR BOX

DRAIN CONNECTION

SCREW HOLES FOR

DOWNFLOW (OPTIONAL)

1

⁄2-IN. PVC OR CPVC

FRONT VIEW SIDE VIEW

A98648

CANADIAN GAS ASSOCIATION

APPROVED

R

MEETS DOE RESIDENTIAL CONSERVATION SERVICES

PROGRAM STANDARDS.

Before purchasing this appliance, read important

energy cost and efficiency information available

from your retailer.

REGISTERED QUALITY SYSTEM

SM

As an ENERGY STAR

Partner, Bryant Heating & Cooling

Systems has determined that this product meets the

ENERGY STAR guidelines for energy efficiency.

These products are engineered and manufactured under an

ISO 9001 registered quality system.

—6—

Page 7

*

B IN. DIA PVC

VENT/EXHAUST

1

1

/2

*

ACCESSORIES

CONCENTRIC VENT

C IN. DIA

13/16

D

F

E

LOCATING

TAB

LOCATING

TAB

B IN. DIA PVC

A

INTAKE/COMBUSTION AIR

DIMENSIONS (In.)

A97110

PART NO. A *

KGAVT0501CVT 33-3/8 2 3-1/2 16-5/8 6-1/4 5-3/4

KGAVT0601CVT 38-7/8 3 4-1/2 21-1/8 7-3/8 6-1/2

Dimension A will change accordingly as dimension D is lengthened or shortened.

†Dimension D may be lengthened to 60 in. maximum. Dimension D may also be shortened by

cutting the pipes provided in the kit to 12 in. minimum.

B C D† E F

ACCESSORY DOWNFLOW SUBBASE

1 1/4″ TYP

PLENUM

B

4

3

D

2

1

A

OPENING

1

2

3

4

A88207

FACTORY-SUPPLIED

FIELD-INSTALLED

INSULATION

Disassembled Assembled

FURNACE

CASING

WIDTH FURNACE IN DOWNFLOW APPLICATION

17-1/2

21

Furnace with or without CD5 or CK5 Coil

Assembly or KCAKC Coil Box

Furnace with or without CD5 or CK5 Coil

Assembly or KCAKC Coil Box

The plenum should be constructed 1/4 in. smaller in width and depth than the plenum dimensions shown above.

PLENUM OPENING * FLOOR OPENING HOLE NO.

15-1/8 19 16-3/4 20-3/8 3

18-5/8 19 20-1/4 20-3/8 2

—7—

C

A97427

FOR WIDTH

ADJUSTMENTABCD

Page 8

UNIT SIZE

036080 Top

048080 Top

060080 Top

*

A filter is required for return-air supply.

RETURN-AIR

SUPPLY SPEED

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

High

Med-High

Med-Low

Low

AIR DELIVERY—CFM (With Filter) *

EXTERNAL STATIC PRESSURE (In. wc)

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

1535

1395

1200

1040

1750

1495

1310

1135

2200

2100

1815

1560

1470

1350

1175

1020

1685

1455

1260

1105

2175

2025

1760

1555

1405

1300

1125

990

1635

1405

1225

1075

2085

1945

1720

1515

1330

1225

1065

960

1575

1355

1170

1040

2025

1865

1670

1460

1245

1155

1030

910

1525

1305

1125

995

1925

1785

1620

1435

1160

1080

970

860

1445

1250

1095

995

1820

1700

1550

1390

1065

985

890

785

1380

1185

1040

910

1735

1620

1480

1340

SERVICE TRAINING

935

880

780

680

1310

1120

980

860

1635

1540

1405

1270

Packaged Service Training programs are an excellent way to increase your

knowledge of the equipment discussed in this manual, including:

• Unit Familiarization • Maintenance

• Installation Overview • Operating Sequence

A large selection of product, theory, and skills programs is available, using popular

video-based formats and materials. All include video and/or slides, plus companion

book.

Classroom Service Training plus "hands-on" the products in our labs can mean

increased confidence that really pays dividends in faster troubleshooting, fewer

callbacks. Course descriptions and schedules are in our catalog.

CALL FOR FREE CATALOG 1-800-962-9212

[ ] Packaged Service Training [ ] Classroom Service Training

A94328

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

UNIT MUST BE INSTALLED IN ACCORDANCE

WITH INSTALLATION INSTRUCTIONS

Cancels: New

© 1999 Bryant Heating & Cooling Systems, 7310 W. Morris St., Indianapolis, IN 46231 PRINTED IN U.S.A. Catalog No. 5235-100 1-99

—8—

Loading...

Loading...