Bryant 349HAV Series, 349HAV036050, 349HAV036075, 349HAV048075, 349HAV048100 Installation, Start-up, And Operating Instructions Manual

...

installation, start-up,

and operating instructions

HORIZONTAL INDUCED-COMBUSTION

GAS FURNACE

SIZES 050—125, SERIES B

NOTE: Read the entire instruction manual before starting the

installation.

This symbol → indicates a change since the last issue.

INDEX

Page

SAFETY CONSIDERATIONS ................................................1-2

Clearances From Combustible Materials.................................1

INTRODUCTION.......................................................................2-3

Dimensional Drawing...............................................................2

LOCATION....................................................................................3

General......................................................................................3

Furnace Location Relative to Cooling Equipment..................3

Hazardous Locations.................................................................3

AIR FOR COMBUSTION AND VENTILATION...................3-5

General...................................................................................3-4

Unconfined Space.....................................................................4

Confined Space......................................................................4-5

Contaminated Combustion Air.................................................5

INSTALLATION........................................................................5-9

Duct Work Recommendations..................................................5

Horizontal Attic Installation.....................................................6

Horizontal Crawlspace Installation ..........................................6

Filter Arrangement....................................................................6

Gas Piping..............................................................................6-7

Reversing Procedure..............................................................7-9

ELECTRICAL CONNECTIONS.............................................9-11

115-v Wiring........................................................................9-11

Wiring Diagram......................................................................10

24-v Wiring.............................................................................11

Accessories..............................................................................11

VENTING...............................................................................11-13

General Venting Requirements.........................................11-12

Pre-Installation Vent System Inspection................................12

Removal of Existing Furnace from Common

Venting System..................................................................12

Metal Vent Installations..........................................................12

Masonry Chimney Installations..............................................12

Multistory Installations...........................................................12

Sidewall Venting Installations................................................12

SEQUENCE OF OPERATION...................................................13

Heating Mode..........................................................................13

Cooling Mode .........................................................................13

START-UP, ADJUSTMENT, AND SAFETY CHECK.......13-18

General....................................................................................13

Remove Shipping Bracket......................................................13

Purge Gas Lines......................................................................13

Operational Checkout .............................................................13

Adjustments .......................................................................14-17

Adjust Pilot Flame..................................................................14

Set Gas Input Rate ............................................................14-17

Set Temperature Rise..............................................................17

Set Blower Off Delay.............................................................17

Set Thermostat Heat Anticipator............................................17

Check Safety Controls.......................................................17-18

CHECKLIST................................................................................18

349HAV

Cancels: II 349H-50-4 II 349H-50-5

®

SAFETY CONSIDERATIONS

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified personnel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by trained service personnel. When working on

heating equipment, observe precautions in the literature, on tags,

and on labels attached to or shipped with the unit and other safety

precautions that may apply.

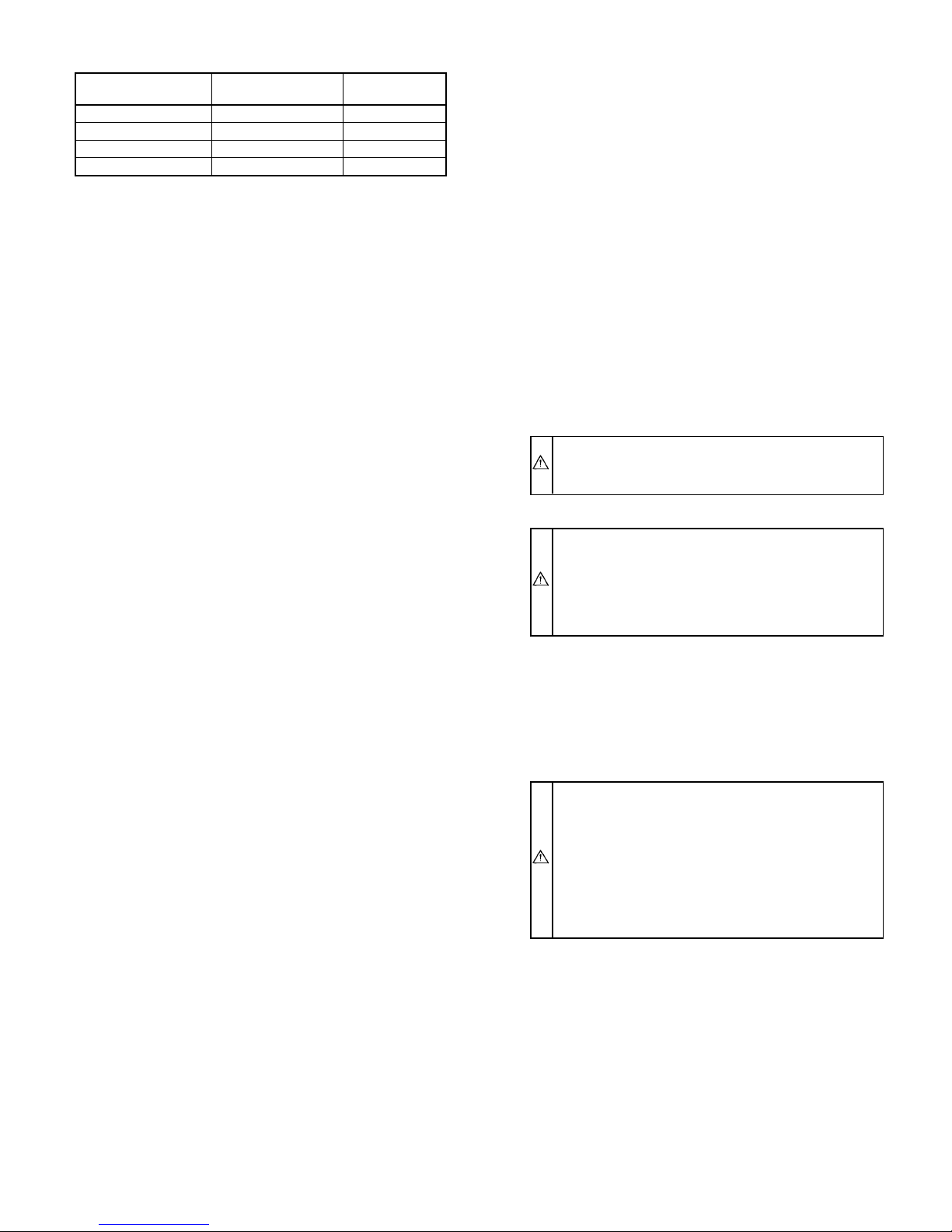

TABLE 1—ATTIC, CLOSET*, OR ALCOVE CLEARANCES

FROM COMBUSTIBLE MATERIALS (IN.)

UNIT SIZE 050, 075, 100, & 125

Sides 6

Back 6

Top of Plenum 2

Vent Connector 6

Front Casing 6†

Front Service 30

* For closet installations, refer to Air for Combustion and Ventilation section.

† Measured from end of inducer motor.

WARNING: Failure to comply with all of the above

clearances will create a fire hazard.

→

Follow all safety codes. In the United States, follow all safety

codes including the National Fuel Gas Code (NFGC) NFPA No.

54-1996/ANSI Z223.1-1996 and the Installation Standards, Warm

Air Heating and Air Conditioning Systems (NFPA 90B)

ANSI/NFPA 90B. In Canada, refer to the current edition of the

National Standard of Canada CAN/CGA-B149.1- and .2-M95

Natural Gas and Propane Installation Codes (NSCNGPIC). Wear

safety glasses and work gloves. Have fire extinguisher available

during start-up and adjustment procedures and service calls.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the furnace and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage.

ama

CANADIAN GAS ASSOCIATION

APPROVED

R

6-98

.

—1—

These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept up with changing residential construction practices. We require these instructions as a

minimum for a safe installation.

INTRODUCTION

The design of the 349HAV Horizontal Induced-Combustion Gas

Furnace is A.G.A./C.G.A. certified as a Category I furnace for

natural and propane gases and for installation in alcoves, basements, crawlspaces, utility rooms, and attics. The design of the

horizontal gas-fired furnace is A.G.A./C.G.A. certified for installation on noncombustible floors. This furnace may be installed on

combustible wood flooring, however, it may not be installed

directly on carpeting, tile, or other combustible material other than

wood. The design of this furnace line is not A.G.A. certified for

installation in recreational vehicles, manufactured housing (mobile

homes), or outdoors.

The furnace is shipped as a packaged unit, complete with burners

and controls, and requires a 115-v line voltage connection to

junction box, a thermostat hook-up as shown in the wiring

diagram, and a gas line connection. The furnace is shipped in the

horizontal left configuration (for right-to-left airflow) but is easily

converted to the horizontal right configuration (for left-to-right

airflow). Refer to Reversing Procedure section for details.

The furnace is designed to interface with split system cooling

equipment (approved by UL) to provide year-round air conditioning. The blower is sized for both heating and cooling, and the

furnace control includes a cooling fan relay.

Before installing the furnace, refer to the current edition of the

NFGC and the NFPA 90B. Canadian installations must be installed

in accordance NSCNGPIC and all authorities having jurisdiction.

For a copy of the NFGC NFPA54/Z223.1, contact International

Approval Services U.S. Inc., 8501 E. Pleasant Valley Road,

Cleveland, OH 44131 or National Fire Protection Association Inc.,

Batterymarch Park, Quincy, MA 02269. For a copy of NFPA 90B,

contact National Fire Protection Association Inc., Batterymarch

Park, Quincy, MA 02269.

Before installing furnace in Canada, refer to the current edition of

the NSCNGPIC. Contact Standards Department of Canadian Gas

Association, 55 Scarsdale Road, Don Mills, Ontario, Canada M3B

2R3. Canadian installations must be made in accordance with

CAN/CGA-B149 Installation Codes and authorities having jurisdiction.

→

Installations must comply with the regulations of the serving gas

supplier and the local building, heating, plumbing, or other codes

in effect in the area in which the installation is made. In the

absence of local codes, the installation must conform with the

NFGC, NFPA No. 54-1996/ANSI Z223.1-1996.

CAUTION: Application of this furnace should be indoors with special attention given to vent sizing and

material, gas input rate, air temperature rise, and unit

sizing. Improper installation or misapplication of the

furnace can require excessive servicing or cause premature component failure.

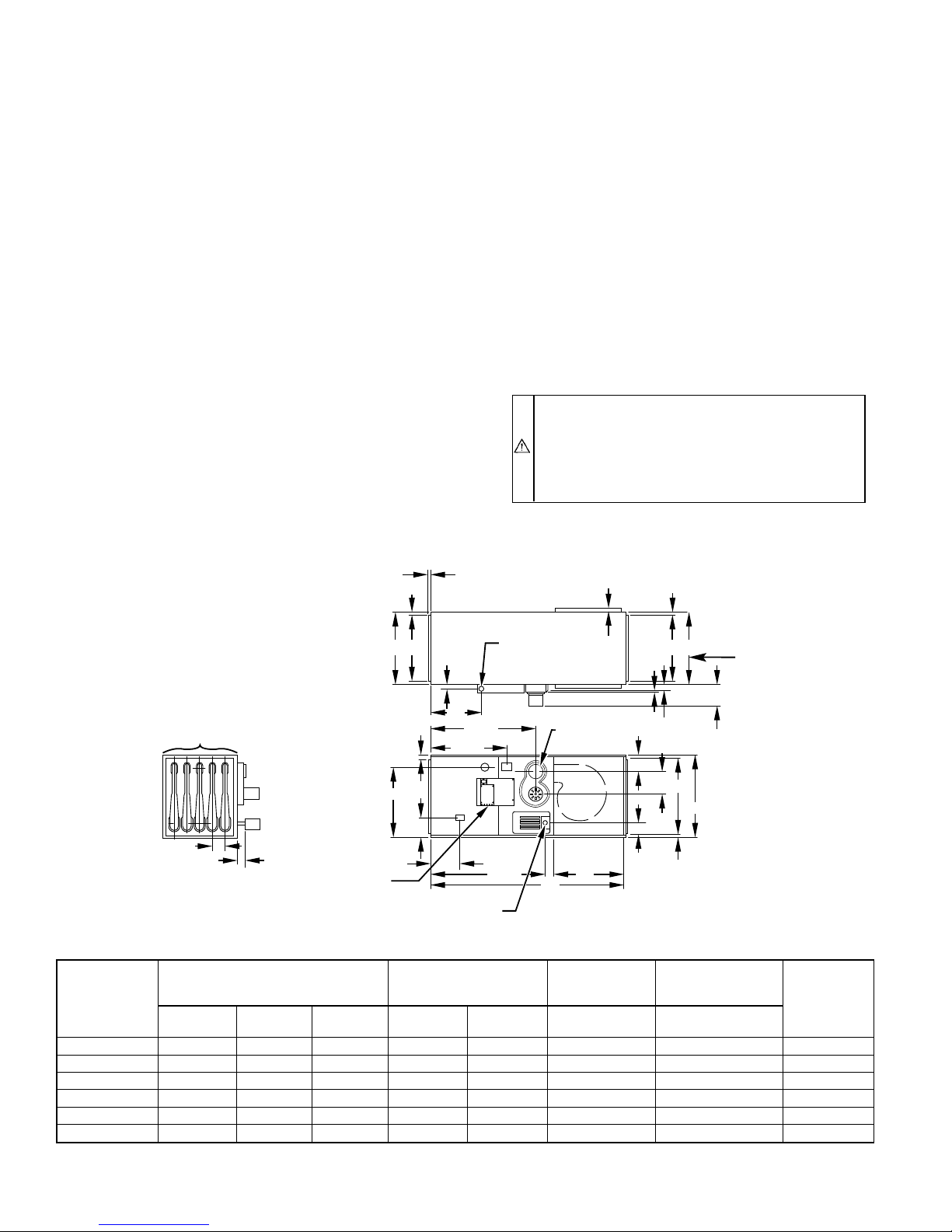

(EXTEND BLOWER DOOR)

5

⁄8″

D ( NUMBER OF CELLS)

3 1⁄2″

1 3⁄4″

T-STAT

CONNECTION

1

⁄2-IN. GAS CONNECTION

A

19 1⁄2″

5

⁄16″

B

7

5 5⁄8″

(HIGH AIR FLOW UNITS ONLY)

2 1⁄2″

10″

⁄8″

26 5⁄8″

19 1⁄4″

7″

(2 PLACES)

7

⁄8-IN. ELECTRICAL

CONNECTION

28 7⁄8″

50″

C

4-IN. DIA VENT

CONNECTION

18″

5

4 9⁄16″

6 5⁄16″

4 1⁄8″

⁄8″

1 7⁄8″

5

⁄16″

B

21 3⁄8″

23 1⁄8″

7

⁄8″

A

AIR FLOW

5 7⁄8″

DIMENSIONS (IN.)

UNIT DIMENSIONS

UNIT SIZE

Length

036050 50 13-1/2 23-1/8 11-5/8 21-3/8 Flush 2 112

036075 50 13-1/2 23-1/8 11-5/8 21-3/8 Flush 3 121

048075 50 13-1/2 23-1/8 11-5/8 21-3/8 1 3 125

048100 50 17 23-1/8 15-1/8 21-3/8 Flush 4 141

060100 50 17 23-1/8 15-1/8 21-3/8 1 4 149

060125 50 20-1/2 23-1/8 18-5/8 21-3/8 Flush 5 161

* High airflow units only.

Width

A

Height

DUCT SUPPLY

AND RETURN

OPENINGS

Width

B

Height C D

EXTENDED

BLOWER

DOOR*

NUMBER

OF HEAT

EXCHANGERS

Fig. 1—Dimensional Drawing

A96068

NET

WEIGHT

(LB)

—2—

This furnace is designed for a minimum continuous return-air

temperature of 60°F db or intermittent operation down to 55°F db

such as when used with a night setback thermostat. Return-air

temperature must not exceed a maximum of 85°F db.

WARNING: Improper installation, adjustment, alter-

ation, service, maintenance, or use can cause carbon

monoxide poisoning, explosion, fire, electrical shock, or

other conditions which may cause personal injury or

property damage. Consult a qualified installer, service

agency, local gas supplier, your distributor, or your

branch for information or assistance. The qualified in-

staller or agency must use only factory-authorized and

listed kits or accessories when modifying this product.

Failure to follow this warning could result in electrical

shock, fire, personal injury, or death.

Locate furnace where available electrical and gas supplies meet the

specifications on furnace rating plate.

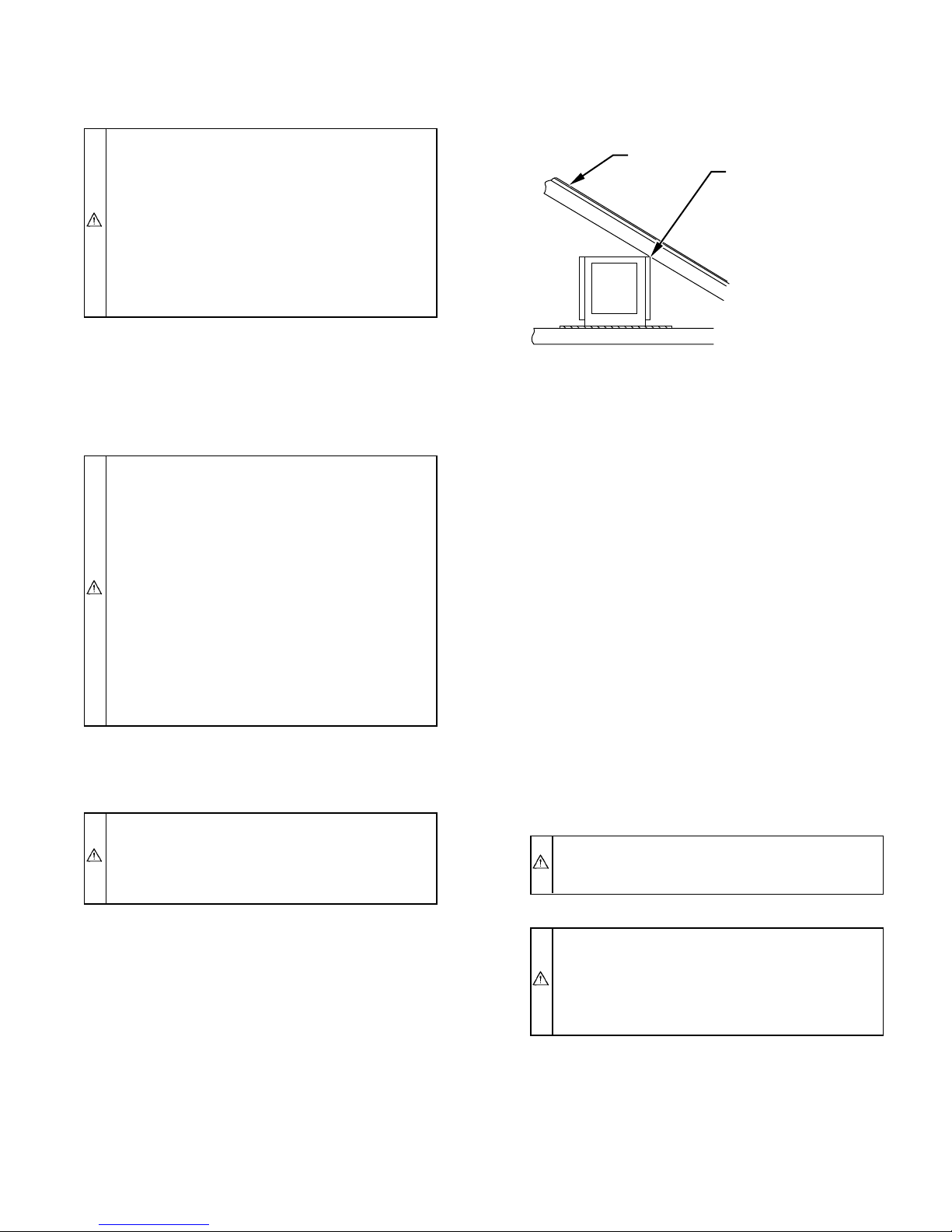

Line contact is only permissible between lines formed by the

intersection of furnace top and front and back sides and building

joists, studs, or framing. (See Fig. 2.)

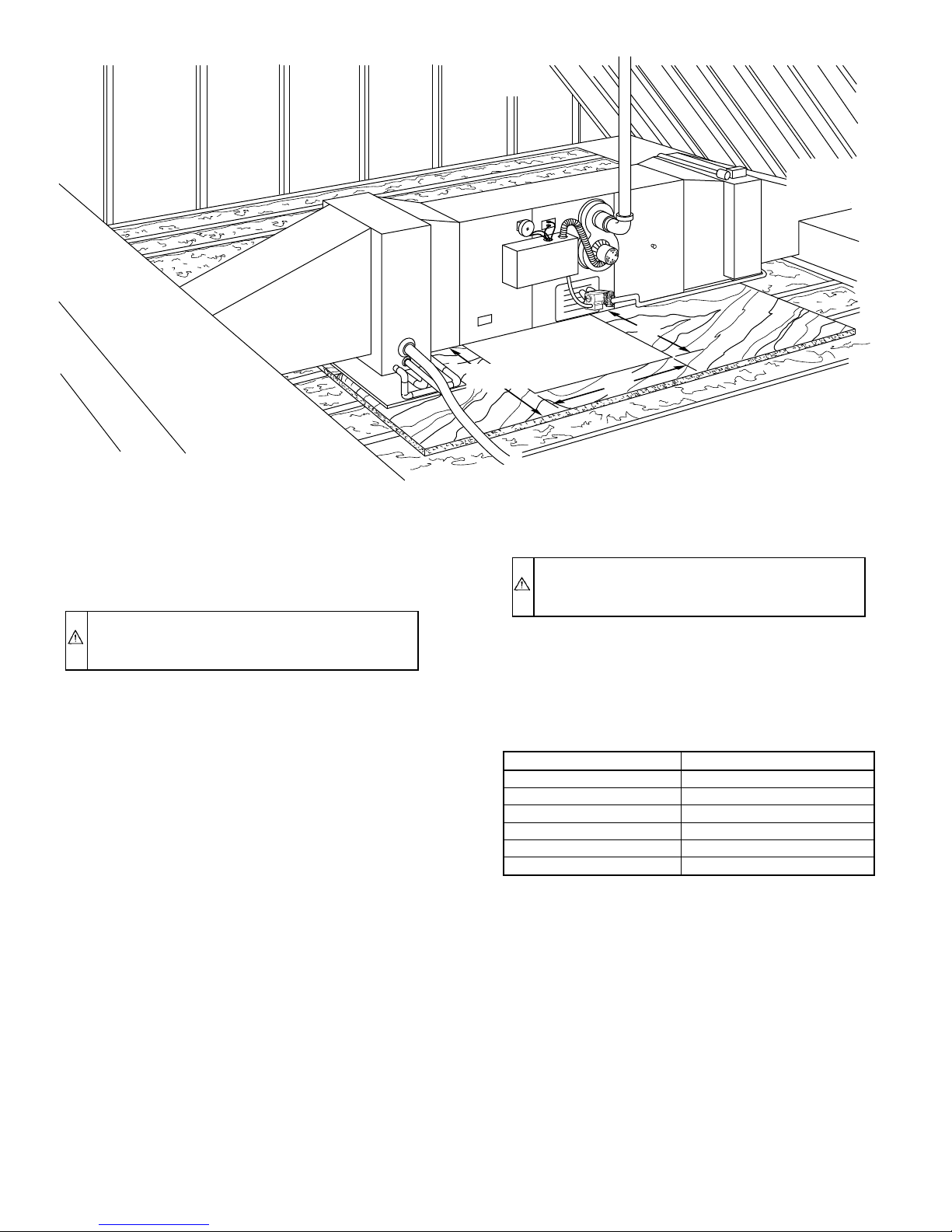

ROOF

LINE CONTACT ONLY

PERMISSIBLE BETWEEN

TOP CORNERS OF

FURNACE AND BUILDING

JOISTS, STUDS, OR

FRAMING.

For accessory installation details, refer to the applicable installation literature.

NOTE: Remove all shipping brackets and materials before operating furnace.

LOCATION

I. GENERAL

CAUTION: Do not install furnace in a corrosive or

contaminated atmosphere. Make sure all combustion and

circulating air requirements are followed, in addition to

all local codes and ordinances.

Do not use this furnace during construction when adhe-

sives, sealers, and/or new carpets are being installed. If

the furnace is required during construction, use clean

outside air for combustion and ventilation. Compounds of

chlorine and fluorine when burned with combustion air

form acids which cause corrosion of the heat exchangers

and metal vent system. Some of these compounds are

found in paneling and dry wall adhesives, paints, thin-

ners, masonry cleaning materials, and many other sol-

vents commonly used in the construction process. Exces-

sive exposure to contaminated combustion air will result

in safety and performance related problems.

This furnace may be located in an attic, basement, crawlspace,

alcove, or suspended from the ceiling of a utility room or

basement.

WARNING: Do not install the furnace on its back or

side. Safety control operation will be adversely affected.

Never connect return-air ducts to the back of the furnace.

Failure to follow this warning could result in a fire,

personal injury, or death.

KEEP ALL INSULATING MATERIAL

CLEAR OF FURNACE. INSULATING

MATERIAL MAY BE COMBUSTIBLE.

A96069

Fig. 2—Attic Installation Showing Point Contact

For attic installations, the passageway and servicing area adjacent

to furnace should be floored.

If furnace is to be installed in a crawlspace, consult local codes.

Use of a concrete pad 1 to 2 in. thick is recommended.

II. FURNACE LOCATION RELATIVE TO COOLING

EQUIPMENT

The cooling coil must be installed parallel with or on the

downstream side of the furnace to avoid condensation in the heat

exchanger. When installed parallel with a furnace, dampers or

other means used to control the flow of air must prevent chilled air

from entering the furnace. If the dampers are manually operated,

they must be equipped with a means to prevent operation of either

unit unless the damper is in the full-heat or full-cool position.

III. HAZARDOUS LOCATIONS

When furnace is installed in a residential garage, it must be

installed so that the burners and ignition source are located a

minimum of 18 in. above the floor. Furnace must be located or

protected to avoid physical damage by vehicles.

When furnace is installed in a public garage, airplane hangar, or

another building having a hazardous atmosphere, the unit must be

installed in accordance with the requirements of the National Fire

Protection Association, Inc.

WARNING: Do not place combustible material on furnace jacket. Failure to comply with this warning will

cause an explosion.

When a furnace is installed so that the supply ducts carry air to

areas outside the space containing the furnace, return air must also

be handled by duct(s) sealed to furnace casing and terminating

outside the space containing furnace to ensure there will not be a

negative pressure condition within the equipment room or space.

This furnace must be located so electrical components are protected from water.

Locate furnace close to the chimney/vent and as near the center of

air distribution system as possible. The furnace should not be

connected to an operating chimney that also serves a solid fuel

burning appliance.

Provide ample space for servicing and cleaning. Always comply

with the minimum fire protection clearances shown on the unit

rating plate and in Table 1. A clurance of at least 30 in. should be

provided at front of unit for servicing.

WARNING: This furnace is not watertight and is not

designed for outdoor installation. This furnace shall be

installed in such a manner as to protect the electrical

components from water. Outdoor installation would lead

to a hazardous electrical condition and premature component failure.

AIR FOR COMBUSTION AND VENTILATION

I. GENERAL

Provisions for adequate combustion and ventilation air must be

provided in accordance with Section 5.3, Air for Combustion and

Ventilation, of the NFGC, or applicable provisions of local

building codes.

—3—

Canadian installations must be installed in accordance with the

NSCNGPIC and all authorities having jurisdiction.

WARNING: Do not block combustion air openings in

furnace. Any blockage will result in improper combustion

and may result in a fire hazard or unsafe condition.

CAUTION: Air for combustion must not be contaminated by halogen compounds which include fluoride,

chloride, bromide, and iodide. These elements are found

in aerosol sprays, detergents, bleaches, cleaning solvents,

salts, air fresheners, and other household products.

Excessive exposure to contaminated combustion air will

result in safety and performance related problems.

CAUTION: The operation of exhaust fans, kitchen ventilation fans, clothes dryers, or fireplaces could create a

negative pressure condition at the furnace. Make-up air

must be provided for the ventilation devices, in addition

to that required by the furnace.

All fuel-burning equipment must be supplied with air for combustion of the fuel. Sufficient air MUST be provided to ensure there

will not be a negative pressure in the equipment room or space. In

addition, a positive seal MUST be made between furnace cabinet

and return-air duct to avoid pulling air from burner area and draft

safeguard opening.

The furnace shall be installed in a location in which the facilities

for ventilation permit satisfactory combustion of gas, proper

venting, and maintenance of ambient temperature at safe limits

under normal conditions of use. The furnace shall be located so as

not to interfere with proper circulation of air.

In addition to air needed for combustion, process air must be

provided as required for cooling of equipment or material, controlling dew point, heating, drying, oxidation or dilution, safety

exhaust, and odor control. Air must be supplied for ventilation,

including all air required for comfort and proper working conditions for personnel.

CAUTION: Whenever this furnace is installed in an area

along with 1 or more gas appliances, the total Btuh input

of all appliances must be included when determining the

free area requirements for combustion and ventilation

openings.

The requirements for combustion and ventilation air depend upon

whether the furnace is located in a confined or unconfined space.

II. UNCONFINED SPACE

An unconfined space must have at least 50 cu ft for each 1000

Btuh of input for all appliances such as furnaces, clothes dryer,

water heaters, etc. in that space. Rooms communicating with the

space in which the appliances are installed through openings not

furnished with doors are considered a part of the unconfined space.

If the unconfined space is of unusually tight construction, air for

combustion and ventilation MUST come from either the outdoors

or spaces freely communicating with the outdoors. Combustion

and ventilation openings must be sized the same as for a confined

space. A minimum opening with a total of at least 1 sq in. per 5000

Btuh of total input rating for all equipment must be provided.

Return air must not be taken from the room unless an equal or

greater amount of air is supplied to the room.

III. CONFINED SPACE

A confined space has less than 50 cu ft for each 1000 Btuh of the

total input ratings of all appliances installed in that space.

A confined space MUST have 2 permanent openings, 1 within 12

in. of the ceiling and the other within 12 in. of the floor.

NOTE: In determining the free area of an opening, the blocking

effect of the louvers, grilles, and screens must be considered. If the

free area of a louver or grille design is unknown, assume that wood

louvers have a 20 percent free area and metal louvers or grilles

have a 60 percent free area. Screens, when used, must not be

smaller than 1/4-in. mesh. Louvers and grilles must be constructed

so they cannot be closed.

The size of the openings depends upon whether the air comes from

inside or outside of the structure.

A. All Air from Inside the Structure:

1. Each opening MUST have at least 1 sq in. of free area per

1000 Btuh of the total input for all equipment within the

confined space, but not less than 100 sq in. per opening.

For Example:

349HAV FURNACE

INPUT BTUH

50,000 100

75,000 100

100,000 100

125,000 125

FREE AREA PER

OPENING (SQ IN.)

2. If the building is of unusually tight construction, in addition

to the 2 permanent openings that freely communicate with

an unconfined space, a permanent opening directly communicating with the outdoors should be provided. This opening

should have a minimum free area of 1 sq in. per 5000 Btuh

of total input rating for all equipment in the enclosure.

3. If the furnace is installed on a raised platform to provide a

return-air plenum, and return air is taken directly from the

hallway or space adjacent to the furnace, all air for

combustion must come from outdoors.

B. All Air from Outdoors:

1. If combustion air is taken from outdoors through vertical

ducts, the openings and ducts MUST have at least 1 sq in.

of free area per 4000 Btuh of the total input for all

equipment within the confined space.

For Example:

349HAV FURNACE

INPUT BTUH

50,000 12.5 4

75,000 18.8 5

100,000 25.0 6

125,000 31.3 7

FREE AREA PER

OPENING (SQ IN.)

ROUND PIPE

(IN. DIA)

2. If combustion air is taken from the outdoors through

horizontal ducts, the openings and ducts MUST have at

least 1 sq in. of free area per 2000 Btuh of the total input for

all equipment within the confined space.

—4—

For Example:

349HAV FURNACE

INPUT BTUH

50,000 25.0 6

75,000 37.5 7

100,000 50.0 8

125,000 62.5 9

FREE AREA PER

OPENING (SQ IN.)

ROUND PIPE

(IN. DIA)

When ducts are used, they must be of the same cross-sectional area

as the free area of the openings to which they connect. The

minimum dimension of rectangular ducts must not be less than 3

in.

IV. CONTAMINATED COMBUSTION AIR

Contaminated combustion air must be avoided in order not to

adversely affect the long term life of furnace, especially heat

exchanger and burners.

The recommended source of combustion air is to use the outdoor

air supply. Use of indoor air in most applications is acceptable as

long as there is no exposure to the types of installation or

substances listed below and all provisions for indoor combustion

air meet the requirements for combustion air supply indicated in

the NFGC Section 5.3; CAN1-B149 Installation Codes; and/or any

applicable local codes.

A. Installations Requiring Outdoor Combustion Air

1. The following types of installations require OUTDOOR

AIR for combustion due to chemical exposures:

a. Commercial buildings

b. Buildings with indoor pools

c. Furnaces installed in laundry rooms

d. Furnaces installed in hobby or craft rooms

e. Furnaces installed near chemical storage areas

2. Exposure to the following substances in the combustion air

supply also require OUTDOOR AIR for combustion:

a. Permanent wave solutions

b. Chlorinated waxes or cleaners

c. Chlorine based swimming pool chemicals

d. Water softening chemicals

e. De-icing salts or chemicals

f. Carbon tetrachloride

g. Halogen-type refrigerants

h. Cleaning solvents (such as perchloroethylene)

i. Printing inks, paint removers, varnishes, etc.

j. Hydrochloric acid

k. Cements and glues

l. Anti-static fabric softeners for clothes dryers

m. Masonry acid washing materials

The following recommendations should be followed when installing duct work:

1. Install locking type dampers in all branches of individual

ducts to balance out system. Dampers should be adjusted to

impose proper static at outlet of furnace.

2. Noncombustible flexible duct connectors are recommended

to connect both supply- and return-air ducts to furnace.

3. In cases where return-air grille is located close to fan inlet,

there should be at least one 90° air turn between fan and

inlet grille. Further reduction in sound can be accomplished

by installing acoustical air turning vanes and/or lining

inside of duct with acoustical material.

4. It is recommended that outlet duct be provided with a

removable access panel. The opening shall be accessible

when furnace is installed and shall be of such a size that

heat exchanger can be viewed for possible openings using

light assistance or so a probe can be inserted for sampling

air stream. The access panel shall be designed so as to

prevent leaks when locked in position. If an air conditioning

coil is installed, access panel to coil can be used for this

purpose.

CAUTION: Air openings, intake and outlet pipes,

return-air grilles, and warm air registers must not be

obstructed.

WARNING: When supply ducts carry air circulated by

furnace to areas outside spaces containing furnace, return

air shall also be handled by a duct sealed to furnace

casing and terminating outside space containing furnace.

Incorrect duct work termination and sealing will create a

hazardous condition which could lead to bodily harm.

5. When installing furnace with cooling equipment for yearround operation, the following recommendations must be

followed for series or parallel airflow:

a. In series airflow applications, coil is mounted after

furnace in an enclosure in supply-air stream. The furnace

blower is used for both heating and cooling airflow.

WARNING: The coil MUST be installed on air discharge side of furnace. Under no circumstances should

airflow be such that cooled, conditioned air can pass over

furnace heat exchanger. This will cause condensation in

heat exchanger and possible failure of heat exchanger

which could lead to a fire hazard and/or a hazardous

condition which may lead to bodily harm. Heat exchanger

failure due to improper installation may not be covered by

warranty.

INSTALLATION

I. DUCT WORK RECOMMENDATIONS

IMPORTANT: This furnace is equipped with a metal heat

exchanger shipping bracket which must be removed before installing furnace. The No. 10 screws which fasten bracket to furnace

will interfere with attachment of outlet duct if not removed.

Remove bracket by removing No. 10 screws located on bottom

panel duct supply flange, rotating bracket forward and lifting out.

The proper sizing of warm air ducts is necessary to ensure

satisfactory furnace operation. Duct work should be in accordance

with the latest editions of U.S. NFPA-90A (Air Conditioning

Systems) and NFPA-90B (Warm Air Heating and Air Conditioning Systems) or Canadian equivalent.

b. In parallel airflow installation, dampers must be pro-

vided to direct air over furnace heat exchanger when

heat is desired and over cooling coil when cooling is

desired.

IMPORTANT: The dampers should be adequate to prevent

cooled air from entering furnace. If manually operated, dampers

must be equipped with means to prevent operation of either

cooling unit or furnace unless damper is in full cool or full heat

position.

—5—

SHEET

30-IN. MIN

WORK AREA

METAL

Fig. 3—Typical Attic Installation

24″

24″

A96070

II. HORIZONTAL ATTIC INSTALLATION

The furnace can be installed horizontally for either left- or

right-side supply. See Fig. 3 for a typical attic installation and

Reversing Procedure section for reversing airflow direction.

CAUTION: In attic installations, it is necessary to keep

insulation at least 12 in. away from any furnace opening.

Some types of insulating materials are combustible.

1. Construct a working platform on location where all required

furnace clearances are met. (See Table 1 and Fig. 3.)

2. Position furnace in desired location.

3. Connect gas supply pipe. See Fig. 4 for typical gas piping.

4. Connect supply- and return-air ducts.

5. Install 24- X 24-in. sheet metal shield on platform in front

of controls as shown in Fig. 3.

III. HORIZONTAL CRAWLSPACE INSTALLATION

The furnace can be installed horizontally for either left- or

right-side supply. In a crawlspace, the furnace can either be hung

from floor joists or installed on suitable blocks or a pad. The

furnace can be suspended using steel pipe straps around each end

of furnace. These straps should be attached to furnace with sheet

metal screws and to floor joists with lag bolts. A framed assembly

of angle iron suspended with all-thread rod of suitable diameter

may be used to support the length of furnace. Refer to Fig. 1 for

size and weight of furnace. Care must be taken to allow for blower

door access.

The horizontal crawlspace installation is very similar to the attic.

Refer to Horizontal Attic Installation section, items 2, 3, 4, and 5.

A 24- X 24-in. sheet metal shield must be installed above the

controls for crawlspace installations. Extend sheet metal shield

over furnace top far enough to cover gas pipe entry hole.

IV. FILTER ARRANGEMENT

CAUTION: Never operate the unit without a filter or

with the filter removed. Failure to follow this caution can

result in a fire, personal injury, or death.

A factory-supplied filter and wire filter retainer are shipped with

furnace. After return-air duct has been connected to furnace, install

filter in blower compartment, just ahead of return-air plenum, and

secure it with wire filter retainer. The cross-mesh binding side of

filter should face blower. Refer to Table 2 for filter sizes.

TABLE 2—FILTER SIZE (IN.)

UNIT SIZE FILTER SIZE

036050 13X23

036075 13X23

048075 13X23

048100 16-1/2 X 23

060100 16-1/2 X 23

060125 20X23

V. GAS PIPING

Gas piping must be installed in accordance with national and local

codes. Refer to the current edition of the NFGC.

Canadian installations must be installed in accordance with the

NSCNGPIC and all authorities having jurisdiction.

Gas piping shall be of such size and so installed as to provide a

supply of gas sufficient to meet maximum demands without undue

loss of pressure between gas meter and furnace. It is recommended

that the gas supply line be a separate line running directly from

meter to furnace, unless existing gas line is of ample capacity.

Refer to Table 3 for recommended gas pipe sizing. Risers must be

used to connect to furnace and to meter.

Support all piping with appropriate straps, hangers, etc. Use a

minimum of 1 hanger every 72 in.

Joint compounds (pipe dope) should be applied sparingly and only

to male threads of joints. This pipe dope must be resistant to the

action of propane gas.

—6—

Loading...

Loading...