Page 1

Page 2

Service or Repair

If your firearm should require service or repairs, we suggest you first contact a local

recommended Browning Firearms Service

Center. Contact your Browning sporting

goods dealer or call our Service Department for the address of the Service Center

nearest you. Otherwise, you may send

your firearm directly to our own Service

Department. For technical questions about

your firearm or service call our Service

Department.

Browning Service Department

One Browning Place commerce regulations.

Arnold, Missouri 6301 0-9406

Phone: 1-800-322-4626

Canadian Customers call or write:

Browning Canada Sports Ltd./Ltee,

561 7 Chemin St-François

St-Laurent, Quebec H4S 1 W6

Phone: (514) 333-7261

When returning your firearm for servicing,

you must do the following:

a. Be sure it is completely unloaded.

b. Package it securely in a cardboard

container.

c. Enclose a letter with your firearm

that clearly describes the trouble

experienced and the repairs or

alterations desired.

d. If convenient, send a copy of the

letter to us separately.

e. Never return ammunition with your

firearm. It is against postal and most

If you have any questions about this

manual or about any other Browning

products, call or write our Consumer

Information Department:

Browning Consumer Information

One Browning Place

Morgan, Utah 84050-9326

Phone: (801) 876-2711

Page 3

5 After leading has been removed, the bore

should be wiped dry with a clean patch, and

then a lightly oiled patch run through it for

9 The barrel and action should be inspected to

assure that all cleaning patches have been

removed and not inadvertently left in the bar-

preservation. rel or action.

6 If the gun has been exposed to much dust,

dirt, mud or water, the principal working

parts should be wiped clean and lubricated

with a light film of oil. Browning Oil is recommended.

7 The magazine tube on the Automatic-5

should be wiped clean of all dirt and grit, and

then lubricated lightly with an oiled patch.

The friction pieces should be assembled according to the loads to be used, as covered

previously.

8 Reassemble barrel and wipe all exposed

metal surfaces with an oiled cloth making

sure to wipe gun clean of all finger marks

10 The wood surfaces can also be wiped with

Browning Oil or they can be polished with

any quality furniture wax (but not both).

DO NOT TAKE YOUR GUN’S ACTION APART.

This is a specialized, finely fitted mechanism;

and you may mar it for life by an attempt to

remove the inner mechanism. It is unnecessary, and may do damage to the inner mechanism, to disassemble it for routine cleaning

and oiling. Of course, misfortunes (such as

dropping your gun in water) require appropriate attention, and in such circumstances

we recommend you immediately take your

gun to a competent gunsmith.

where moisture will accumulate.

Important Warning

DISCHARGING FIREARMS IN POORLY VENTILATED AREAS, CLEANING FIREARMS, OR HANDLING

AMMUNITION MAY RESULT IN EXPOSURE TO LEAD AND OTHER SUBSTANCES KNOWN TO CAUSE

BIRTH DEFECTS, REPRODUCTIVE HARM AND OTHER SERIOUS PHYSICAL INJURY. HAVE ADEQUATE VENTILATION AT ALL TIMES. WASH HANDS THOROUGHLY AFTER EXPOSURE.

Page 4

VERTICAL ADJUSTMENT —

Adjustment of the sight is controlled by the

screw located on top of the sight, To RAISE the

point of impact, turn the screw in a counterclockwise direction. To LOWER the point of impact, turn the screw in a clockwise direction.

Vertical adjustment is also a process of trial and

error.

CLEANING YOUR AUTO-5

The correct procedure for cleaning your Auto-5

shotgun is as follows:

BE CERTAIN YOUR SHOTGUN’S MAGAZINE,

FEED MECHANISM AND CHAMBER ARE

UNLOADED. PLACE THE “SAFETY” IN THE “ON

SAFE” POSITION AND LOCK THE BOLT TO THE

REAR. ALWAYS WEAR PROTECTIVE SAFETY

GLASSES DURING ALL DISASSEMBLY AND

CLEANING PROCEDURES.

1 Remove the barrel so that it can be cleaned

from the breech end.

2

Using a shotgun cleaning rod with tip and

patch large enough for a snug fit in the bore,

insert the rod and patch in the breech end of

the barrel and run back and forth through the

the bore several times. Remove and wipe the

Invector tube, tube threads and barrel

threads, and lightly oil.

Cleaning and Maintenance Suggestions

PERIODIC OILING —

Ordinary good judgment will indicate that the

metal parts of the gun should receive a light

film of oil after the gun has been exposed to

weather or handling.

Occasionally, a small drop of oil may be placed

on each receiver track in which the breech bolt

and barrel extension guides run during operation (See Figure 16). This will help to relieve

friction and insure smooth operation.

DO NOT POUR LARGE QUANTITIES OF OIL

INTO THE ACTION. A LARGE EXCESS OF OIL

WILL RUN BACK INTO THE WOOD OF THE

STOCK AND CAUSE SOFTENING OF THE

WOOD, WITH CONSEQUENTIAL LOOSENING

OF THE STOCK.

3 Inspect the bore from both ends for leading

by looking through the bore toward light.

Leading will appear as dull longitudinal

streaks and is usually more predominate near

the muzzle and just forward of the chamber.

4 A normal amount of leading can be expected

with today’s high velocity loads and improved

wads but this is not serious. If or when leading should become heavy, it can be removed

with a brass bore brush. Make sure a choke

tube is installed. Spray the bore or the bore

brush with a good powder solvent, and scrub

the bore until leading is removed. To prevent

brass bristles from breaking off, the brush

should be pushed completely through the

bore before being withdrawn.

Page 5

notch code, make sure your shotgun is fully un-

loaded.

Rim Pattern With Pattern With

Notches Lead Shot Steel Shot

Knurled X-Full Turkey

I Full

Special **

*

CAUTION: DO NOT USE STANDARD INVECTOR

CHOKE TUBES IN BARRELS MARKED

INVECTOR-PLUS. DO NOT USE INVECTOR-PLUS

CHOKE TUBES IN BARRELS MARKED

INVECTOR. FAILURE TO FOLLOW ALL OF THE

ABOVE WARNINGS CAN DAMAGE YOUR GUN

AND CAUSE INJURY TO YOURSELF AND

OTHERS.

Use of Extra Barrels

Your Auto-5 can be made suitable for multiple

shooting conditions merely by changing from

one barrel to another of different choke or

length. On all Browning Automatic-5 shotguns,

barrels of the same gauge and model are completely interchangeable and no special fitting is

required. Thus, by merely buying another barrel, you have acquired the utility of another gun

at a fraction of the cost of a new gun; a duck

gun becomes a fine upland game gun, a pheasant gun becomes a rifled slug deer gun.

II Imp. Modified Full***

III Modified Full***

IIII Imp. Cylinder Modified

IIIII Skeet Imp. Cylinder

No Notches Cylinder Cylinder

Rim Pattern With Pattern With

Notches Lead Shot Steel Shot

I Full

III Modified Imp. Modified

IIII Imp. Cylinder Modified***

IIIII Skeet Modified***

No Notches Cylinder Imp. Cylinder

*Not for use with steel shot. Using an ow-tight choke constriction with steel shot

will result in an ineffective, “blown” pattern

**Extra Full Special with knurled rim and no rim code. Do not use with steel

shot.

***When more than one choke designation is listed for a given steel shot pattern,

use the more open choke listed for high velocity, larger shot size steel shot loads

****Has knurled extension beyond muzzle.

*

NOTE: 3-inch Magnum 12 gauge and 3-inch

Magnum 20 gauge barrels will not fit or work in

a Light 12 gauge or a Light 20 gauge action de-

signed for 2 3/4" shells and vice versa because

the feeding and ejection mechanisms are differ-

ent.

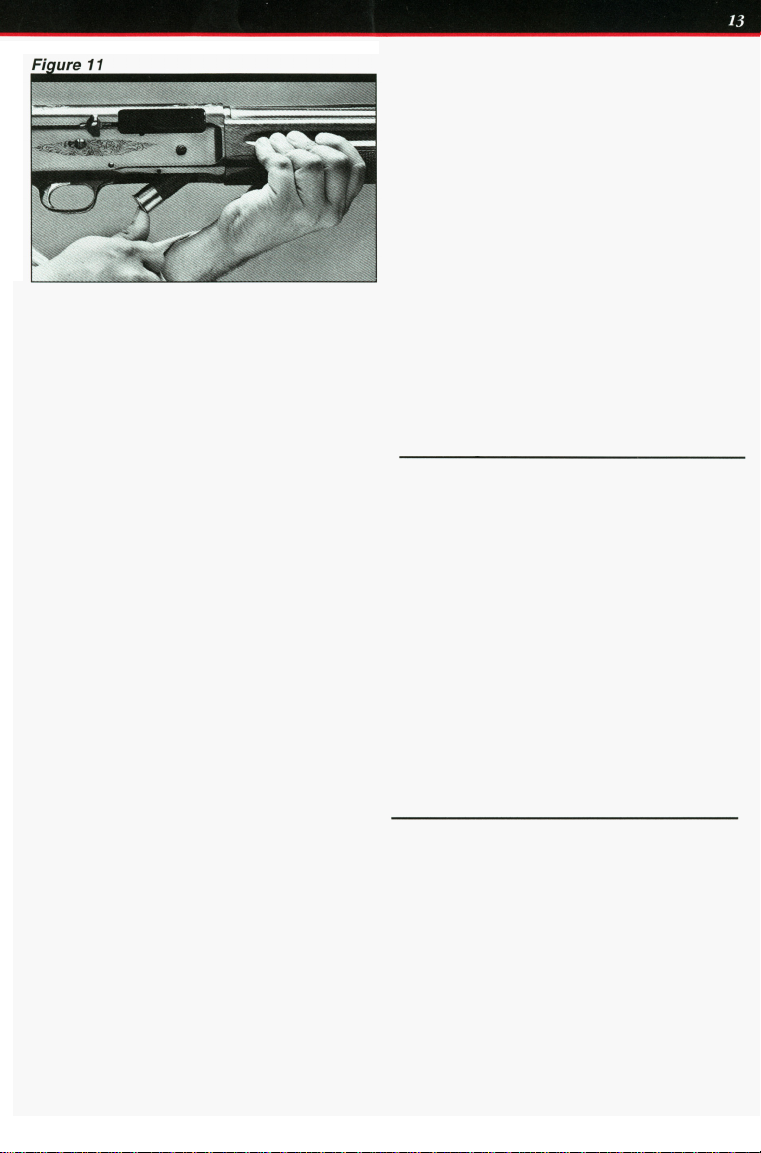

Sight Adjustment for the Buck Special

The Buck Special is equipped with a precision

rear sight which is screw adjustable for both horizontal and vertical correction (See Figure 15).

WINDAGE ADJUSTMENT-

To move point of impact to the RIGHT, loosen

the small screw on the right side of the sight.

Then tighten the small screw on the left side of

the sight, To move point of impact to the LEFT

loosen the small screw on the left side of the

sight and tighten the screw On the right side.

This is a process of trial and error. Make small

adjustments then check the point of impact.

Page 6

THE INVECTOR CHOKE TUBE SHOULD BE

PERIODICALLY CHECKED TO ASSURE THAT

IT IS TIGHT AND FIRMLY SEATED. BEFORE

CHECKING, FOLLOW THE SAFETY GUIDELINES OUTLINED ABOVE.

Replacement and additional tubes and wrenches

are available from your Browning dealer, or by

writing to:

Browning Consumer Department,

One Browning Place, Morgan, Utah 84050.

801-876-2711.

UNLOADED, AND THE BOLT OR BREECH IS

OPEN! NEVER ATTEMPT TO REMOVE OR

INSTALL A SHOTGUN CHOKING DEVICE ON A

LOADED FIREARM!

Canadian customers please call or write to:

Browning Canada Sports Ltd./Ltee,

5617 Chemin St-Francois,

St-Lament., Quebec, Canada H4S 1W6.

TUBE REMOVAL- (514) 333-7261.

UNLOAD YOUR A-5 FULLY. INSPECT THE

1

CHAMBER, FEED MECHANISM AND MAGAZINE TO MAKE SURE THEY DO NOT CONTAIN ANY SHELLS.

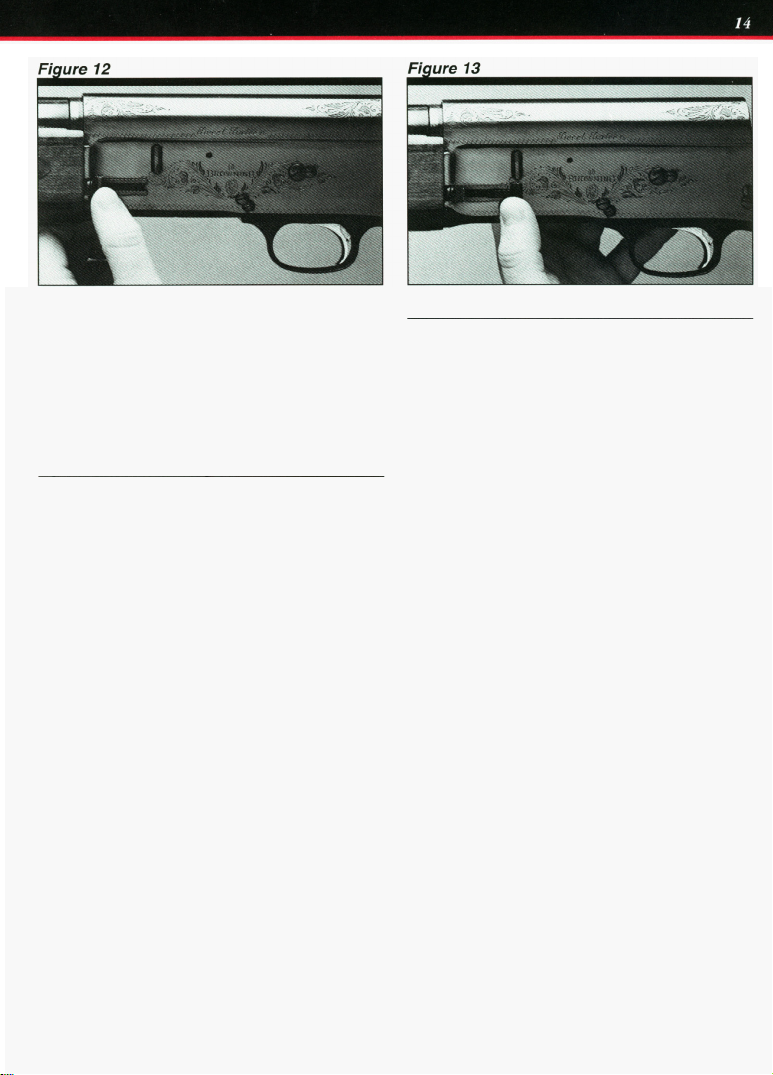

INVECTOR CHOKE TUBE CODE—

To identify individual Invector tubes, refer to

the abbreviated indications on the side of the

2 Open the action, locking it rearward, and

place the “safety” in the “on safe” position.

3 Use the Invector wrench to loosen the tube,

turning it counterclockwise. Finger twist the

tube the rest of the way out of the barrel.

TUBE INSTALLATION-

1

UNLOAD YOUR A-5 FULLY. INSPECT THE

CHAMBER, FEED MECHANISM AND MAGAZINE TO MAKE THEY DO NOT CONTAIN ANY

SHELLS.

2 Open the action and place the “safety” in the

“on safe” position.

3 Before installing a tube, check the internal

choke tube threads in the muzzle, as well as

the threads on the Invector choke tube to be

sure they are clean. Lightly oil the threads

with an oil like Browning Oil.

4 Using your fingers, screw the appropriate

tube into the muzzle end of the barrel, tapered end first, notched end outward. When

it becomes finger-tight, use the invector

choke tube wrench to firmly seat the tube.

tube, or use the identification mark(s) located

on the top rim of each tube. (See Figure 14).

INVECTOR TUBE SELECTION

To help you choose the correct choke tube for

each hunting situation, all Browning Invector

choke tubes are inscribed on the side with the

patterns they produce with both lead and steel

shot. Each Invector tube also has notches in the

top rim of the tube. These notches are a code to

allow you to determine the choke designation

while the tube is installed. Rim notches refer specifically to lead shot. you will need to use the

chart below to cross-reference from lead to steel,

and determine the appropriate tubes for your ammunition and hunting/shooting situation.

Several tubes are supplied with your Browning

shotgun. The tubes listed are also available as ac-

cessories. Remember, Standard Invector and

Invector-Plus tubes are not interchangeable.

Invector-Plus tubes are for Browning guns with

back-bored barrels, such as your new Auto-5.

Older Auto-5 shotguns are Standard Invector. Before removing/installing tubes, or reading the rim

Page 7

SHOTGUN IS UNLOADED. ALWAYS INSPECT

THE CHAMBER, CARRIER AND MAGAZINE

TUBE TO BE SURE THEY CONTAIN NO

CARTRIDGES. THEN, REMEMBER TO

ALWAYS TREAT ANY GUN AS IF IT WAS

LOADED. AL WA YS HANDLE YOUR SHOTGUN WITH CAUTION.

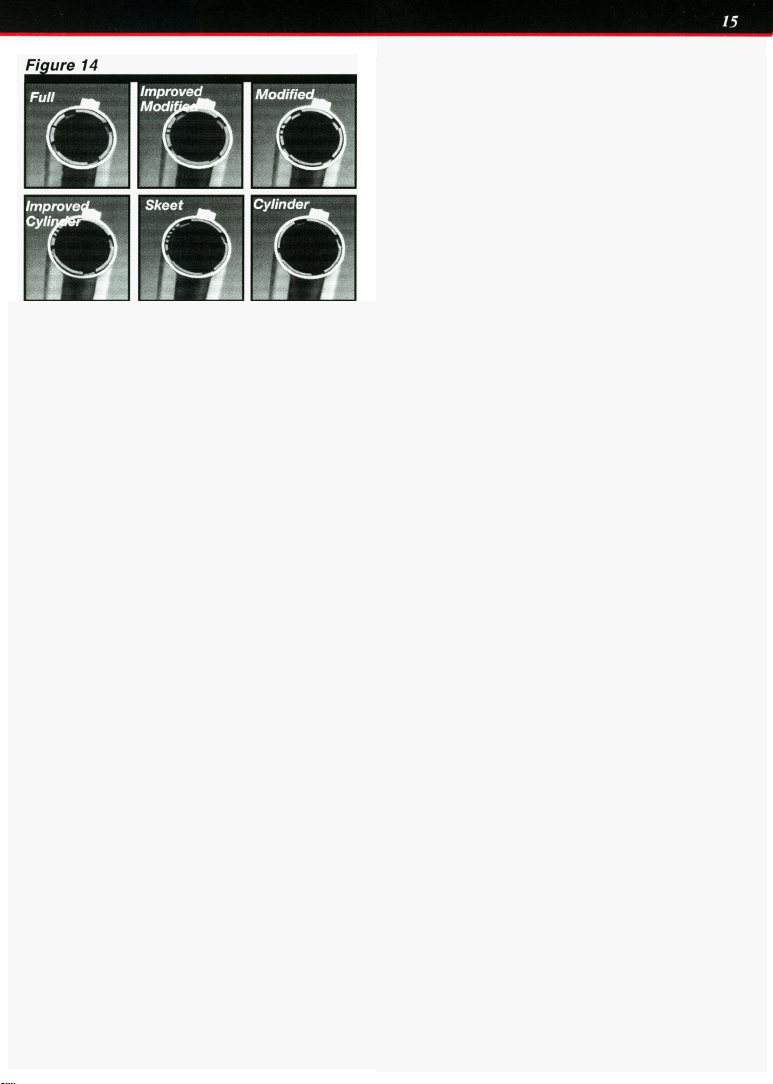

Operation of the Magazine Cut-off

The magazine cut-off is located at the front end

of the left side of the receiver (See Figure 12).

lnvector Interchangeable Choke System

All current Auto-5 shotguns have barrels that are

threaded to accept the Browning Invector-Plus

Interchangeable Choke System. You may confirm this by glancing on the right side of your

barrel where the specifications are inscribed,

and where the choke markings are normally located. All older Auto-5 models and the Auto-5

Buck Special are conventionally choked. The

word, INVECTOR denotes that the barrel is

This cut-off has the purpose of locking the

shells in the magazine so that they will not feed

into the chamber. This permits you quickly to

change the load in the chamber of the gun without going to the trouble of unloading the whole

magazine. In this way a duck load can quickly

be taken out and a goose load inserted, if the

need arises.

To operate the magazine cut-off, merely pull the

cut-off lever back (See Figure 13). This will lock

the shells in the magazine. Push the cut-off lever

forward when you desire to release the shells in

the magazine so that they will feed automatically as the gun is fired.

With the magazine cut-off in operation, the

chamber empty, and the breech bolt locked in

the rearward position, a shell may be instantly

delivered from the magazine to the chamber by

merely pushing the magazine cut-off forward.

threaded. The degree of choke tube is indicated

twice on each choke tube: Inscribed on the side

of the tube, and indicated with a “notch” code

on the top rim of the tube. Invector Choke

Tubes are made with tempered steel and are

fully compatible with all

(loaded in compliance with SAAMI specifi-

TION

FACTORY AMMUNI-

cations) including magnum lead and steel shot

loads and rifled slug loads.

DO NOT FIRE THIS SHOTGUN WITHOUT HAVING

AN INVECTOR CHOKE TUBE INSTALLED.

Permanent damage may result to the threads,

DO NOT USE BROWNING INVECTOR CHOKE

TUBES IN ANY SHOTGUN BARRELS NOT

SUPPLIED BY BROWNING. ALSO, DO NOT USE

ANY OTHER CHOKING DEVICE IN ANY SHOTGUN BARRELS SUPPLIED BY BROWNING. USE

ONLY CHOKE TUBES MARKED INVECTOR.

CAUTION: WHENEVER HANDLING ANY

SHOTGUN FOR THE PURPOSE OF REMOVING

OR INSTALLING A CHOKING DEVICE, MAKE

ABSOLUTELY CERTAIN THE GUN IS FULLY

Page 8

open, pull rearward on the operating handle

until the breech bolt locks back. The gun is

now ready to load.

2 Hold the gun with either right or left hand at

the grip or forearm as you prefer or are accustomed. With the opposite hand, merely

introduce the front end of the shell into the

under side of the receiver and thrust completely forward as if loading the magazine —

then release the pressure of your thumb.

side of the receiver to close the action. The

bolt release button is still provided to close

the action on an empty chamber, if desired.

CAUTION: DO NOT PRESS THE BOLT

RELEASE BUTTON AND LET THE BOLT

SLAM HOME WITH THE BARREL REMOVED

FROM THE ACTION.

When the barrel is installed, the breech bolt

stops against the barrel extension, preventing

any damage. With the barrel removed, however, the operating handle will forcefully

strike the front edge of the ejection port causing damage to the receiver. If you wish to

close the bolt with the barrel removed, be

sure to hold the operating handle as you depress the bolt release button. Let the bolt ride

home slowly.

Unloading Your Auto-5

CAUTION: WHENEVER UNLOADING, ALWAYS BE

CERTAIN THAT THE MUZZLE IS POINTED IN A SAFE

DIRECTION AND THAT THE “SAFETY” IS “ON SAFE’’.

(See Figure 11.) The shell is immediately and

automatically driven rearward, tripping the

feed mechanism, and delivered instantly into

the chamber without further manipulation.

The breech bolt automatically closes during

the loading operation.

THE GUN IS NOW LOADED AND READY FOR

3

FIRING.

To load the magazine, continue the same procedure, slipping shells past the carrier into

the magazine until the latter is full. (Without

the magazine plug, the magazine will hold 4

shells; 2 shells if the plug has been inserted.)

Be sure to insert each shell completely into

the magazine before releasing.

The speed loading system is equally convenient for right or left-hand shooters. The instant delivery of the first shell to the chamber

in one simple operation eliminates entirely

the conventional process of dropping the first

shell into the open receiver port and then

pressing the bolt release button on the right

The recommended way to unload the Auto-5 is

simply to grasp the operating handle and cycle

the action until all rounds are ejected.

ALWAYS lNSPECT THE CHAMBER, ACTlON AND

MAGAZINE VERY CAREFULLY AFTER UNLOADING TO BE SURE ALL LIVE ROUNDS ARE

CLEARED FROM THE GUN.

Breech Remains Open After the Last

Shot

The breech of the Auto-5 remains open after the

last shot has been fired. This allows convenient

and fast reloading as follows:

1 Place the “safety” in the “on safe” position.

2 Drop an appropriate shell into the open

breech.

3 Close the action by depressing the breech-

block release button.

EVEN WITH THE BREECH OPEN AFTER

SHOOTING, DO NOT ASSUME YOUR

Page 9

You will note, however, that the mechanism

must receive a certain amount of force if it is to

operate automatically. The addition of any sort

of weight to a barrel will have somewhat the

same effect. When such factors as these are introduced, care must be given to suitable adjustment of the friction ring setting. It is desirable to

utilize the setting for heavy loads as long as the

mechanism functions properly. When resistance

to recoil is too great to permit proper ejection,

the light load setting should be used.

Oil on the Magazine tube

Whether the friction ring is set for heavy loads

or light loads, the amount and kind of oil on the

magazine tube will, by varying the amount of

friction, have an effect upon the amount of recoil. In general, the more oil that is put on the

magazine tube (or bronze friction piece), the

easier this friction piece will slide on the tube;

hence, a greater degree of recoil will be obtained.

Should your gun at any time commence to give

ejection trouble, one or more of the following is

usually the cause:

1 Insufficient oil on the magazine tube, rust,

gum, or hardened grease, any of which may

interfere with normal operation of the recoil

spring and friction pieces.

2 The friction rings are not properly set.

A slight swelling of the forearm (sometimes

3

unavoidable under conditions of excessive

exposure to moisture) may cause sufficient

resistance to the barrel to affect normal operation. If a side of the barrel shows signs

that it is rubbing against the forearm, the application of a fine piece of emery cloth to the

interfering portion of the inside of the forearm will quickly rectify the problem.

Using the Speed Loading Feature

WARNING: WHENEVER LOADING, ALWAYS BE

CERTAIN THAT THE MUZZLE IS POINTED IN A

If you are firing a light load and the gun fails to

eject, the addition of oil to the magazine tube in

the region of the bronze friction piece will sufficiently increase recoil to a point satisfactory for

good ejection.

Oil which congeals in cold weather or deposits

gummy residue may reduce recoil to the point

where the gun will fail to eject, Use a high qual-

ity lubricant. Occasionally clean the magazine

tube and relubricate. If temperatures of ten to

thirty degrees below freezing are likely to be

encountered, it is best to utilize an oil which

maintains its fluidity in such temperatures.

Browning Gun Oil is particularly well suited for

this purpose.

At all times there should be a film of oil on the

magazine tube except when 12 gauge, 2 3/4”

magnum loads are being used. With this load it

is desirable to wipe the magazine tube practi-

cally dry. Function will not be affected and you

will find these heavy loads much more comfort-

able to shoot.

SAFE DIRECTION AND THAT THE SAFETY IS

“ON SAFE”. KEEP YOUR HAND AWAY FROM

THE EJECTION PORT TO A VOID BEING STRUCK

BY THE BREECH BOLT, WHEN THE ACTION

CLOSES.

The Browning Auto-5 shotgun is equipped with

the speed loading system. Its design will enable

you to load faster and easier. It is not necessary

to press the bolt release button on the right side

of the receiver during the loading process, and

the same procedure is used in loading the first

shell into the chamber as in loading the remaining shells into the magazine.

CAUTION: WHENEVER A SHELL HAS BEEN

CYCLED INTO THE CHAMBER-DURING

LOADING OR ANY OTHER TIME, AUTOMATICALLY OR MANUALLY—THE SHOTGUN IS

READY TO FIRE BY SIMPLY MOVING THE

“SAFETY” TO THE OFF SAFE POSITION.

1 BE SURE THE MUZZLE IS POINTED IN A

SAFE DIRECTION AND THE “SAFETY” IS

“ON SAFE”.

If the breech bolt is not already

Page 10

Parts List: Auto-5 Semi-Automatic Shotgun 12, 16 and 20 Gauge

PART NO. DESCRIPTION

01 P011001 Action Spring All Gauges 21 P011111 Carrier Spring Trigger

02 P011003 Action Spring Follower

03 P011005 Action Spring Plug

04 P01 1007 Action Spring Plug Pin All Gauges

05 P01 1009 Action Spring Tube Magnum 20 Gauge

06 *P011015 Barrel Extension Assembly, 20 Gauge

06 *P011017 Barrel Extension

06 *P011022 Barrel Extension

06 *P011024 Barrel Extension

06 *P011025 Barrel Extension Assembly, 29 P011147 Extractor Left 12M-12-16- 51 P011279 Locking Block Latch Spring 71 P011399 Sight Body-Rear-Buck

07 P011027 Breech Block 12M-12

07 P011032 Breech Block 16

07 P011035 Breech Block Magnum 31 P011149 Extractor Magnum

07 P011036 Breech Block 20

08 *P011040 Butt Plate All Gauges

09 P011042 Butt Plate Screws All Gauges

10 *P011046 Butt Stock Magnum W/ 12M-12-16-20 55 P011295 Magazine Cutoff - Magnum 76 *P011405 Satety Sear 12M-12

10 *P011048 Butt Stock Field 1 5/8”x 35 P011162 Extractor Spring Right 55 P011298 Magazine Cutoff 16 77 P01 1408 Safely Sear Pin All Gauges

10 *P011056 Butt Stock Field 1 5/8”x 36 P011163 Extractor Spring Magnum Gauges

All Gauges

All Gauges

All Gauges

All Gauges

Magnum 12 Gauge

Assembly, 12

Assembly, 16

Assembly, 20

Magnum 20 Gauge

20 Gauge

All Gauges

Recoil Pad 1 5/8”x2 1/2 “x 35 P01 1160 Extractor Spring Right

14 14”12M

2 1/2" x14 114" 12

PART NO. DESCRIPTION PART NO. DESCRIPTION

22

22 P011117 Cartridge Stop 16-20-20M 48 P011261 Locking Block 16-20-20M 66 P011382 Recoil Spring Magnum

23 P011120 Cartridge Stop Spring 49 P011264 Locking Block Latch 20 Gauge

24 P01 1121 Ejector & Ejector Rod 49 P01 1265 Locking Block Latch All Gauges

25 P011124 Ejector Spring Magnum 49 *P011269 Locking Block Latch All Gauges

26 P011126 Ejector Spring Retainer 49 *P011272 Locking Block Latch

27 *P011127 Ejector 12 & Prewar 16 50 P011275 Locking Block Latch Pin 70 P011397 Sight Base-Rear-Buck

27 *P011134 Ejector 16-20 & 12M All Gauges Special 16

28 *P011136 Ejector Rivet 12 51 P011277 Locking Block Latch Spring 70 P011398 Sight Base-Rear-Buck

28 *P011142 Ejector Rivet 12M 16 20

30 P011148 Extractor Spring Follower 52 P011280 Lock Screw All Gauges 72 P011400 Sight Aperture-Rear-Buck

32 P01 1 150 Extractor Right

33 P011155 Extractor Pin Left & Right

34 P011159 Extractor Spring Left

Plate Type 16-20-20M

P011115 Cartridge Stop 12M 12

Magnum 20 Gauge 2-Piece Carrier 16-20 Special 12-12M

20 16-20-2OM Special All Gauges

Magnum 20 Gauge 53 P011285 Magazine Cap-W/O Swivel

12M-12-16-20

12M-12 55 P011297 Magazine Cutoff 12

16-20 55 P01 1299 Magazine Cutoff 20-20M 78 P01 1410 Safety Sear Spring All

20 Gauge

47 *P011252 Link Pin 12M-12 66 P011378 Recoil Spring 12

47 *P011254 Link Pin 16-20-20M 66 P01 1379 Recoil Spring 16

48 P011256 Locking Block 12M-12 66 P011381 Recoil Spring 20

Magnum 20 Gauge 67 *P01 1385 Safety Crossbolt Right

Magnum 12 Gauge 68 *P01 1386 Safety Crossbolt Left

2-Piece Carrier 12 69 P01 1390 Safety Ball All Gauges

12M-12 Special 20-20M

53 P011287 Magazine Cap-W/O Swivel 20 Gauge

54 P011292 Magazine Cap W/Swivel 74 P011403 Sight Adjusting Screw-

54 P011294 Magazine Cap W/Swivel 75 P011404 Sight Roll Pin-Buck Special

Eyelet 12M-12 73 P011401 Sight Adjusting Screw-

Eyelet 16-20-20M

Eyelet 12-12M

Eyelet 16-20-20M

12 Gauge

PART NO. DESCRIPTION

70 P01 1395 Sight Base-Rear-Buck

Special All Gauges

Windage-Buck Special

All Gauge

Elevation. Buck Spec.

All Gauge

All Gauges

76 *P011406 Safely Sear 16-20-2OM

10 P01 1052 Bun Stock Composite 37 P011164 Extractor Spring Follower

11 P011057 Butt Stock Swivel Eyelet 38 P011165 Firing Pin 12M 12

12 *P011062 Carrier Assembly Magnum

12 *P011064 Carrier Assembly

12 *P011066 Carrier Assembly

12 *P01 1068 Carrier Assembly

13 *P011070 Carrier Dog 12M 12 40 *P011191 Forearm 5-Shot 20 60 P011330 Magazine Spring Retainer 83 P011435 Tang Screw for Pistol Grip

13 *P011071 Carrier Dog 16-20-20M 40 *P011192 Forearm Magnum 20 12M-12

14 P011076 Carrier Dog Follower

14 P011077 Carrier Dog Follower 40 P011176 Forearm Composite 12M 61 P011335 Magazine Tube 5-Shot 12 85 P011445 Trigger Pin All Gauges

15 P011079 Carrier Dog Pin 12M-12 Magnum 12 Gauge Safely 12-12M

15 P011080 Carrier Dog Pin 16-20-20M 41 P011197 Friction Piece Bronze 12

16 P011081 Carrier Dog Spring 12M-12 41 P011198 Friction Piece Bronze Safely 16-20-20M

16 P01 1083 Carrier Dog Spring 16-20-

17 P011085 Carrier Latch Assembly 42 P011205 Friction Ring 12M-12 61 P011343 Magazine Tube 5-Shot 20 87 P011477 Trigger Plate Screw-Front-

17 P011086 Carrier Latch Assembly 12 43 P011215 Friction Spring 12 62 P01 1344 Mainspring All Gauges 86 P01 1480 Trigger Plate Screw-Rear17 P011089 Carrier Latch Assembly 16 43 P011216 Friction Spring 16-20 63 P011345 Mainspring Screw All

17 P01 1090 Carrier Latch Assembly 44 *P01 1225 Hammer Assembly

18 P011092 Carrier Latch Button 12 44 *P011228 Hammer Assembly 64 P011347 Operating Handle

18 P01 1093 Carrier Latch Button Lightweight 12

18 P011094 Carrier Latch Button Lightweight 16-20-20M

19 P01 1098 Cartridge Stop-Carrier 46 *P01 1243 Link (Magnum) 20 Gauge

20 P01 1103 Carrier Screw All Gauges

21 P011107 Carrier Spring Trigger

12M-12 Right 16-20 All Gauges Follower All Gauges

(Buck Special)

12 Gauge

2 Piece 12

2 Piece 16

2 Piece 20-20M

12M-12

16-20-20M 41 P011 195 Friction Piece Bronze

20M

Magnum 12 Gauge 42 P011207 Friction Ring 16-20.20~ 61 P011338 Magazine Tube 12M 16-20-20M

20-20M Magnum 12 Gauge

12M-16 44 *P01 1232 Hammer Assembly

20-20M 45 *P011235 Hammer Pin AII Gauges 65 †*P011357 Receiver Magnum 20

Latch-Magazine Cutoff Pin 65

Plate Type 12M-12

38 P011167 Firing Pin 16-20-2OM

39 P011168 Firing Pin Stop Pin 12M 12

39 P011 169 Firing Pin Stop Pin

40 *P011170 Forearm 5-Shot Magnum 58 P011321 Magazine Follower 20-

40 *P011172 Forearm 5-Shot 12

40 *P011183 Forearm 5-Shot 16

40 P011 175 Forearm Composite 12 16-20-20M

41 P011199 Friction Piece Bronze 16-20 20M

46 *P011245 Link (Magnum) 12 Gauge

46 *P011247 Link 12

46 *P011251 Link 16-20

16-20-20M

12 Gauge

Gauge 60 P01 1333 Magazine Spring Retainer 84 *P01 1444 Trigger-Crossbolt Safety-

Magnum 20 Gauge

56 P011305 Magazine Cutoff Spring 79 P011414 Safety Sear Spring

57 P01 1310 Magazine Cutoff Spring 80 P01 1421 Sight Ramp-Front-Buck

58 P011315 Magazine Follower- 80 P01 1422 Sight Ramp-Front-Buck

58 P011319 Magazine Follower 16 81 P01 1423 Sight Gold Bead-Front-

59 P011325 Magazine Spring 12M-12

59 P011329 Magazine Spring

61 P011338 Magazine Tube 5-shot 86 *P011466 Trigger Plate for Crossbolt

61 P01 1339 Magazine Tube 5-Shot 16 86 *P011473 Trigger Plate for Crossboll

61 P011342 Magazine Tube 5-Shot 87 P011475 Trigger Plate Screw-Front-

64 P011346 Operating Handle 12M-12

65 †*P011355 Receiver Magnum 12

65 †*P011368 Receiver Sweet 16

65 †*P011372 Receiver Lightweight 20 valid Federal Firearms License.

66 P01 1375 Recoil Spring Magnum Do not order by key number.

Screw All Gauges Special 12M-12-16

12 Magnum & 12 Gauge

20M

16-20-20M

& 12M

12-M Only

Gauges 88 P01 1481 Trigger Plate Screw-Rear-

16-20-20M

Gauge

Gauge

†*P01 1362 Receiver Lightweight 1 2

12 Gauge

82 P011425 Sight Bead Plain & Vent

82 P011431 Sight Bead Plain & Vent

89 *P011486 Trigger Spring Pin

90 P011495 Trigger Spring Retaining

91 P01 1499 Magazine Plug Adapter 3

'Indicates part must be fitted by Browning

Service Department or qualified gunsmith.

†Part may be purchased by holders of current

Special 20M-20

Buck Special All Gauges

Magnum 12M

12-20-20M-16

Stock All Gauges

Gold Plated

12-16-20-20M

12M 12

12M-12

16-20-20M

Retained All Gauges

Pin All Gauges

Shot All Gauges

Page 11

BROWNING AUTO-5 SHOTGUN LIGHT 12. SWEET 16 AND 20 GAUGE

Schematic is provided for parts identification

only and should not be used as a guide to assemble guns.

IMPORTANT: When ordering parts, list part

number, part name, caliber, model and serial

number. Do not order by key number.

CAUTION: Browning parts are made exclusively

for Browning guns and should not be used in

other guns even though models may be similar.

Inadequately fitted parts may be dangerous.

Page 12

The safety is reversible and can be reversed

from right to left-handed by a competent gunsmith. When installed, the left-handed “safety”

will have the “safety” button’s red warning band

on the Right side of the trigger guard.

DO NOT DEPEND ON THE RED COLOR ALONE

TO INDICATE YOUR GUN’S SAFETY STATUS.

Time, exposure to the elements, as well as the

abrasive action of cleaning agents can erase it.

2 The bronze friction piece is then slipped over

the magazine tube with its beveled surface

up.

THE GUN SHOULD NEVER BE FIRED

WITHOUT BRONZE FRICTION PIECE IN

PLACE.

If the correct position of the recoil components

is not maintained you will get unnecessary recoil which will severely pound the mechanism

of your gun.

Friction Ring Adjustment for Auto-5 Light

12 and 20 Gauge Models

SETTINGS FOR SHOOTING 2 3/4-INCH MAGNUM,

STEEL SHOT, AND HIGH VELOCITY LOADS —

THE FOLLOWING INSTRUCTIONS ARE ONLY

FOR 2 3/4-lNCH 12, SWEET 16 AND 20 GAUGE

MODELS, NOT FOR THE 3” MAGNUM 12 GAUGE

OR 3” MAGNUM 20 GAUGE SEMI-AUTOMATIC

SPECIAL INSTRUCTIONS ARE PROVIDED FOR

THOSE MODELS IN A SEPARATE MANUAL.

A great deal of attention has gone into the design of the recoil absorbing mechanism to minimize the recoil of the magnum loads as much as

possible. It is a mechanism specially arranged

for those loads. As shown, it consists of a

bronze friction piece and one coned friction

ring (See Figure 9).

1 with the butt of the stock down and the

magazine tube pointing up, one friction ring

is placed on top of the spring with the beveled surface UP.

NOTE: If steel shot loads will not function with

the heavy load setting, then set friction ring adjustment for light load settings.

Friction ring setting for light loads

The single difference from the arrangement

given for heavy loads is a change in the position

of the friction ring. For light loads this friction

ring is taken off and placed at the extreme rear

end of the magazine tube, between the rear end

of the recoil spring and the receiver with the

beveled edge turned toward the receiver. (See

Figure 10).

NEVER UNDER ANY CIRCUMSTANCES REMOVE

THE BRONZE FRICTION PIECE FROM ITS POSI-

TION REARWARD OF THE BARREL GUIDE RING.

If the gun is fired with either the friction ring or

the recoil spring in direct contact with the barrel

guide ring, the rear surface of the barrel guide

ring will be deformed. Removal of the bronze

friction piece permits an excess of recoil. You

will be getting unnecessary recoil, thereby

pounding the mechanism of your gun severely.

Page 13

AFTER THE BARREL HAS BEEN REMOVED

4

FROM YOUR GUN, LEAVE THE BREECH BOLT

IN THE OPEN POSITION. DO NOT PRESS THE

BOLT RELEASE BUTTON.

If the breechbolt is released forward with the

barrel removed, the operating handle will be

driven against the front edge of the receiver

ejection port, which will cause damage to the

receiver.

The semicircular wood ridge at the rear of the

forearm should fit into the matching groove

in the front of the receiver (See Figure 6).

Disassembly Procedures

CHECK YOUR GUN CAREFULLY TO BE

CERTAIN THE CHAMBER, FEED MECHANISM

AND MAGAZINE CONTAIN NO SHELLS.

1 Draw the breech bolt rearward and lock it

open.

2 Rest the butt end of the stock on any conve-

nient rigid surface. With the left hand apply

rearward pressure to the barrel, then unscrew

the magazine cap with the right hand. While

maintaining rearward pressure on the barrel,

remove the forearm from the magazine tube.

5 For the convenience in casing and carrying the

dismantled gun, return the forearm to its position on the magazine tube and screw on the

magazine cap. You will then have two neat

units. One is the barrel; the other is the action

with forearm and stock.

Operation of the “Safety”

The cross bolt “safety” prevents the trigger from

being pulled when in the “on safe” position. The

safety is located conveniently at the rear of the

trigger guard and has an enlarged head on the

right side designed to be conspicuous “ON SAFE”,

hence, a shooter is not likely to lose a shot

through failure to notice that his “safety” is on.

The enlarged head also aids you to move the

safety to FIRE position with unusual speed and

3 While continuing to hold the barrel firmly, convenience.

gradually release pressure and slide the barrel

directly forward off the magazine tube.

NOT SUDDENly RELEASE PRESSURE AGAlNST

THE BARREL.

If this is done, the strong recoil

DO

spring may throw the barrel off the gun.

In the “off safe” Or “fire” position a red warning

band is visible on the safety button on the left

side of the trigger guard. To place the gun “ON

SAFE,” press the “safety” button to the right. To

move the “safety” to the FIRE position, press the

“safety” to the left (See figures 7 & 8).

Page 14

out the plug, the end of which you will see in

the exposed end of the magazine tube. The

gun will then be a 5 shot semi-automatic.(See

Figure 2.)

If at some future time you wish to limit your

gun to three shots again, take the adaptor

and pass the shaft through the hole in the

magazine spring retainer which is exposed in

the end of the magazine tube. With this shaft

projecting into the magazine, press or lightly

tap the head of the adaptor to force the

magazine spring retainer downward until the

head of the plug is on a level with the end of

the magazine tube if it is not already so. Then

proceed with assembly as follows:

Check the friction ring setting to be sure the

3

friction rings are set according to the loads

you plan to shoot. See page 9 for proper setting of friction rings. Place the barrel guide

ring around the magazine tube and force the

barrel rearward against the resistance of the

recoil spring while guiding the barrel exten-

sion into the receiver. Note the guides on the

barrel extension which must be placed in the

receiver tracks (See Figure 3).

With the left hand maintaining rearward pres-

4

sure against the barrel to the point where the

front end of the barrel extension is even with

or slightly inside of the front end of the receiver (See Figure 4), replace the forearm

over the magazine tube and screw the magazine cap on tightly. Be careful not to squeeze

the rearward end of the forearm. Squeezing

too hard may cause it to crack (See Figure 5).

BE CERTAIN THE MAGAZINE CAP IS

SCREWED COMPLETELY DOWN FORCING

THE REAR END OF THE FOREARM INTO

FIRM CONTACT WITH THE FRONT END OF

THE RECEIVER.

Page 15

Serial Number Initial Cleaning

The serial number of your Automatic-5 shotgun

is found on the underside of the receiver, just

forward of the loading port.

Ammunition

Automatic-5 Light Models are designed to shoot

and function with factory 2 3/4” lead and steel

shot loads. However, Browning can assume no

responsibility for incidents which occur through

the use of cartridges of nonstandard dimension

or those developing pressures in excess of standards established by the Sporting Arms and Ammunition Manufacturer’s Institute (SAAMI).

General Operating Procedures

The Browning Automatic-5 shotgun is a recoil

operated, semi-automatic shotgun. The breech

bolt locks into the barrel. Upon firing, recoil

causes the barrel and breech bolt to travel rearward, recocking the hammer. After full rearward

Various exposed metal parts of your new Auto-5

have been coated with a rust preventative compound for protection.

Before assembling your Auto-5, clean the antirust compound from the barrel, receiver, magazine tube and the action-chamber areas. Browning Oil is ideal for removing this compound and

for giving your new gun its first lubrication.

However, any quality gun oil may be used.

Assembly Procedures

CHECK YOUR GUN CAREFULLY TO BE

ABSOLUTELY CERTAIN THAT THE CHAMBER,

FEED MECHANISM AND MAGAZINE CONTAIN

NO SHELLS.

The Auto-5 is delivered, in the box, with the

barrel removed and the forearm assembled on

the magazine tube. Perform the following steps

to assemble your Auto-5 and make it ready for

shooting.

travel, the breech bolt unlocks from the barrel,

The barrel begins forward movement an instant

before the breech bolt begins forward travel.

This split second delay lets the barrel “get

ahead” of the breech bolt, which is holding the

spent shell with dual extractors. This accomplishes extraction. Ejection occurs when the

ejector, located in the barrel extension, strikes

the rim of the spent shell during forward travel

of the barrel. During forward travel of the bolt,

a fresh round from the magazine is fed into the

chamber. After the last shell has been fired, the

breech bolt locks open, instead of returning

fully home. This facilitates speedy, convenient

reloading.

This operation is semi-automatic; the trigger must

be released and pulled to fire each successive shot.

1 Pull rearward on the operating handle and

draw the breech bolt rearward where it will

remain locked back. Rest the butt end of the

stock firmly on any convenient rigid surface.

With the left hand, pull rearward on the forearm to counteract the forward thrust of the

recoil spring around the magazine tube. with

the right hand unscrew the magazine cap.

Slide the wooden forearm forward off the

magazine tube.

DO NOT SQUEEZE HARD ON THE OPEN

REAR END OF THE FOREARM. TOO MUCH

PRESSURE COULD CAUSE THE WOOD TO

SPLIT.

2 The Automatic-5 is delivered with the maga-

zine adaptor in the magazine which limits the

gun to three shots total (to comply with Federal migratory bird regulations), If you do not

want your gun to be so limited, merely take

Page 16

21 NEVER DRINK ALCOHOLIC BEVERAGES OR

TAKE ANY TYPE OF DRUGS BEFORE OR

DURING SHOOTING.

Your vision and judgment could be dangerously impaired, making your gun handling

unsafe to you and to others.

22

READ AND HEED ALL WARNINGS in this in-

struction book, on ammunition boxes and

with all accessories that you install on your

firearm. It is your responsibility to secure the

most up-to-date information on the safe han-

dling procedures for your Browning gun.

Browning assumes no liability for incidents

which occur when unsafe or improper gun

accessories or ammunition combinations are

used.

23. PERIODIC MAINTENANCE — AVOID

UNAUTHORIZED SERVICING.

Your shotgun is a mechanical device which

will not last forever, and as such, is subject to

wear and requires periodic inspection, adjustment, and service. Browning firearms should

be serviced by a Browning Recommended Service Center or by Browning’s service facility in

Arnold, Missouri. Browning cannot assume any

responsibility for injuries suffered or caused by

unauthorized servicing, alterations or modifications of Browning firearms.

IT CAN BE VERY DANGEROUS TO ALTER THE

TRIGGER, SAFETY OR OTHER FIRING

MECHANISM PARTS OF THIS OR ANY OTHER

FIREARM.

BE CAREFUL!

Nomenclature

In conventional gun terminology, the position and

movement of gun parts are described as they occur

with the gun horizontal and in normal firing posi-

tion; i.e., the muzzle is forward or front; butt stock

is rearward or rear; trigger is downward or underneath; the rib is upward or on top. See (Figure 1)

for names of all parts and assemblies covered in

disassembly and cleaning procedures.

Page 17

10 CAUTION: DO NOT USE 3-1/2" SHOTGUN

SHELLS IN ANY SHOTGUN OR BARREL

WITH A 2 3/4” CHAMBER OR 3" CHAMBER.

DO NOT USE 3" SHELLS IN A SHOTGUN

CHAMBERED FOR 2 3/4" SHELLS. THE SIZE

OF THE CHAMBER IS INSCRIBED, ALONG

WITH GAUGE AND CHOKE DESIGNATIONS,

ON THE SIDE OF THE BARREL.

11 DO NOT SNAP THE FIRING PIN ON AN

EMPTY CHAMBER — THE CHAMBER MAY

NOT BE EMPTY!

Treat every gun with the respect due a

loaded gun, even though you are certain the

gun is unloaded.

12

KEEP YOUR FINGERS AWAY FROM THE

TRIGGER WHILE UNLOADING, LOADING,

UNTIL YOU ARE READY TO SHOOT.

13 BE SURE OF YOUR TARGET AND BACK-

STOP. Particularly during low light

periods. Know the range of your

ammunition. Never shoot at water or

parts, solvents or other agents from contacting your eyes.

DROPPING A LOADED GUN CAN CAUSE AN

16

ACCIDENTAL DISCHARGE

even with the

"safety" in the "on safe" position. Be

extremely careful while hunting or during any

shooting activity, to avoid dropping any

firearm.

IF YOUR SHOTGUN FAILS TO FIRE, KEEP

17

THE MUZZLE POINTED IN A SAFE DIRECTION.

Hold this position for a minimum of 30 seconds. Carefully open the action and remove

the cartridge. If the primer is indented, the

cartridge should be disposed of in a way that

cannot cause harm. If the primer is not indented, your firearm should be examined by

a qualified gunsmith and the cause of the

malfunction should be corrected before further use.

18 BE DEFENSIVE AND ON GUARD AGAINST

hard objects.

14

ALWAYS UNLOAD YOUR SHOTGUN'S

CHAMBER BEFORE CROSSING A FENCE,

CLIMBING A TREE, JUMPING A DITCH OR

NEGOTIATING OTHER OBSTACLES.

Refer to page 13 of this instruction book for

instructions on the unloading of your shotgun. Never place your shotgun on or against

a fence, tree, car, or other similar object.

15

WEAR EYE AND EAR PROTECTION WHEN

SHOOTING. Unprotected, repeated exposure

to gunfire can cause hearing damage. Wear

ear protectors (shooting ear plugs or muffs)

to guard against such damage. Wear shooting

glasses to protect your eyes from flying

particles. Always keep a safe distance

between the muzzle of your firearm and any

persons nearby, as muzzle blast, debris and

ejecting shells could inflict serious injury.

Also, wear eye protection when disassembling and cleaning your shotgun to prevent

the possibility of springs, spring-tensioned

UNSAFE GUN HANDLING AROUND YOU AND

OTHERS.

Don't be timid when it comes to gun safety. If

you observe other shooters violating any of

these safety precautions, politely suggest safer

handling practices.

BE CERTAIN YOUR SHOTGUN IS UNLOADED

19

BEFORE CLEANING.

Because so many gun

accidents occur when a firearm is being

cleaned, special and extreme care should be

taken to be sure your gun is unloaded before

disassembly, cleaning and reassembly. Keep

ammunition away from the cleaning location.

Never test the mechanical function of any

firearm with live ammunition.

EDUCATE AND SUPERVISE FIREARMS

20

SAFETY TO ALL MEMBERS OF YOUR

FAMILY — ESPECIALLY TO CHILDREN AND

NONSHOOTERS.

Closely supervise newcomers to the shooting

sports. Encourage enrollment in hunting/

shooting safety courses.

Page 18

6 BEWARE OF BARREL OBSTRUCTIONS, for

the safety of both your gun and yourself.

Mud, snow, and an infinite variety of other

objects may inadvertently lodge in a barrel

bore. It takes only one small obstruction to

cause dangerously increased pressures that

can ruin (swell or rupture) the finest shotgun

Browning assumes no liability for incidents

which occur through the use of cartridges of

nonstandard dimensions which develop pressures in excess of commercially available ammunition which has been loaded in accordance with standards established by the

Sporting Arms and Ammunition Manufactur-

barrels. ers Institute (SAAMI).

BEFORE CHECKING FOR A BARREL

OBSTRUCTION, BE CERTAIN NO LIVE

ROUND IS IN THE CHAMBER AND THAT THE

MAGAZINE AND FEED MECHANISMS ARE

COMPLETELY EMPTY. PLACE THE

“SAFETY” IN THE “ON SAFE” POSITION

(See page 12 and 13 for instructions on

unloading). After assuring yourself that the

shotgun is Completely empty, again, open the

breechblock, locking it to the rear, and look

through the barrel to be sure it is clear of any

obstruction. If an obstruction is seen, no

matter how small it may be, clean the bore

BE ALERT TO THE SIGNS OF AMMUNITION

MAL FUNCTION.

If you detect an off sound or light recoil

when a shell is fired,

OTHER SHELL INTO THE CHAMBER.

the action and remove all shells from the

magazine, chamber and action areas. With the

action open, glance down the barrel to make

sure that a wad or other obstruction does not

remain in the barrel. If there is an obstruction, completely clear the barrel before loading and firing again. Failure to follow these

instructions can cause extensive damage to

DO NOT LOAD AN-

Open

with a cleaning rod and patch as described in

“Cleaning and Maintenance Suggestions” on

page 17. Before the first firing, clean the bore

with a cleaning rod and patch, and wipe

away any anti-rust compounds in the action/

chamber areas.

ALWAYS UNLOAD YOUR SHOTGUN WHEN

7

NOT IN USE. REFER TO PAGE 13 OF THIS

INSTRUCTION BOOKLET EXPLAINING THE

UNLOADING OF YOUR SHOTGUN.

As a safety precaution, it is preferable to dis-

assemble your gun for storage. Store your

gun and ammunition separately—well beyond

the reach of children. Take all safeguards to

ensure your shotgun does not become available to untrained, inexperienced or unwelcome hands.

USE THE PROPER AMMUNITION.

8

The barrel and action of this shotgun have

been made with substantial safety margins

over the pressures developed by established

American commercial loads. Nevertheless,

your gun and possible serious injury to yourself and others.

DO NOT PUT A 16 OR A 20 GAUGE SHELL IN A

9

12 GAUGE GUN.

Store all shells of different gauges in completely separate and well-marked containers.

Do not store shells of mixed gauges in a common container or in your pockets.

EXAMINE EVERY SHELL YOU PUT IN YOUR

GUN.

The most certain way to bulge or rupture a

barrel is to drop a 20 gauge shell into a 12

gauge chamber. The 20 gauge shell, unfortunately, will not fall completely through the barrel; its rim is caught by the front of a 12 gauge

chamber. Your gun will misfire (with the

chamber appearing to be empty). It is then

possible to load a 12 gauge shell behind the 20

gauge shell. If the 12 gauge shell is then fired,

the result will be a so-called “12-20 burst”

which can cause extensive damage to your gun

and possible serious injury to you.

Page 19

You Are

JARRED OR INADVERTENTLY MANIPULATED INTO AN UNSAFE CONDITION.

Mechanical “safeties” merely aid safe gun

Responsible For

handling and are no excuse for pointing your

shotgun’s muzzle in an unsafe direction,

Firearms Safety

As a gun owner, you accept a set of demanding

responsibilities. How seriously you take these

responsibilities can be the difference between

life and death.

There is no excuse for careless or abusive handling of any firearm. At all times handle your

shotgun and any other firearm with intense respect for its power and potential danger.

PLEASE READ AND UNDERSTAND ALL OF THE

CAUTIONS, PROPER HANDLING PROCEDURES 3 WHENEVER YOU HANDLE A FIREARM, OR

AND INSTRUCTIONS OUTLINED IN THIS

BOOKLET BEFORE USING YOUR NEW FIREARM.

ALWAYS KEEP THE MUZZLE OF YOUR

1

SHOTGUN POINTED IN A SAFE DIRECTION,

While it is a good idea to “test” your

shotgun’s mechanical “safeties” periodically

for proper function,

NEVER TEST IT WHILE YOUR SHOTGUN IS

LOADED OR POINTED IN AN UNSAFE

DIRECTION.

Safe gun handling does not stop with your

gun’s mechanical “safety” devices — it starts

there. Always treat this shotgun with the respect due a loaded, ready-to-fire firearm.

HAND IT TO SOMEONE, ALWAYS OPEN THE

ACTION IMMEDIATELY, VISUALLY CHECK

YOUR SHOTGUN’S CHAMBER, FEED

MECHANISM AND MAGAZINE

even though you are certain the shotgun is

unloaded. Never point any firearm at

anything you do not intend to shoot. Be

extremely alert and aware of all persons and

property within the range of your ammunition.

2 NEVER RELY TOTALLY ON YOUR CASE, OR OTHER CONTAINER.

SHOTGUN’S MECHANICAL “SAFETY”

DEVICE.

The word “safety” describes a gun’s trigger

block mechanism, sear block mechanism,

hammer block mechanism or firing pin block

mechanism. These mechanical devices are

designed to place your gun in a SAFER status. No guarantee can be made that the gun

will not fire even if the “safety” is in the “on

safe” position. The Auto-5 has a cross bolt

“safety” which blocks the gun’s trigger. See

“Operation of the Safety” on page 8 for instructions on operation of this gun’s “safety.”

LIKE ANY MECHANICAL DEVICE, A

“SAFETY” CAN SOMETIMES FAIL; IT CAN BE

Make certain that they do not inadvertently

contain any ammunition. Always keep the

chamber empty and “safety” in the “on safe”

position unless shooting is imminent.

DO NOT TRANSPORT YOUR SHOTGUN

4

LOADED, WHETHER IN A SCABBARD GUN

5 HUNTING FROM ELEVATED SURFACES

SUCH AS TREE STANDS IS DANGEROUS,

and may increase the risk of handling a firearm.

The following rules should always be

observed by you and those you hunt with:

Always make certain that the stand being

used is safe and stable. Always make certain

that your firearm is unloaded when it is being

taken up and down from the stand. Always

make certain that your firearm is not dropped

from the stand, or dropped while it is being

taken up or down from the stand. Remem-

ber, a loaded firearm may discharge when

dropped, even with the safety in the “on

safe” position.

Page 20

NEW GUN OWNERS RECORD

KEEP THIS RECORD FOR FUTURE REFERENCE

Browning Model

Serial Number

Gauge / Caliber

Purchase Price

Purchased From

Date of Purchase

We are pleased that you have chosen a Browning Automatic-5 shotgun.

It is certainly a gun you can be proud to own. For over 90 years the Auto-5 has been recognized as

the most proven and reliable semi-automatic shotgun ever designed. The time-tested Auto-5 is one

of the greatest inventions of John Moses Browning, and is a hallmark to his incredible genius. With

a reasonable amount of care, your Automatic-5 shotgun should give you many years of dependable,

enjoyable service. Please feel free to write us immediately if you have any observations regarding its

performance and operation.

Thank You

One Browning Place, Morgan, Utah 84050

Distributed in Canada by Browning Canada Sports Ltd/Ltee, 561 7 Chemin St-Francois, St-Laurent, Quebec, Canada H4S 1 W6

Printed in U.S.A.

Page 21

Page 22

You Are Responsible For Firearms Safety.

As a gun owner, you accept a set of demanding responsibilities. How seriously you take these

responsibilities can mean the difference between life and death. Failure to follow any of these

instructions can cause extensive damage to your gun and/or possible serious injury or death to

yourself and others. There is no excuse for careless or abusive handling of any firearm. At all

times handle any firearm with intense respect for its power and potential danger. READ AND

UNDERSTAND all of THE CAUTIONS AND PROPER HANDLING PROCEDURES

OUTLINED IN THIS BOOKLET BEFORE USING YOUR NEW FIREARM.

1.

ALWAYS KEEP THE MUZZLE OF ANY FIREARM POINTED IN A SAFE DIRECTION.

Do this even though you are certain the firearm is unloaded. Never point any firearm at

anything you do not intend to shoot. Be extremely alert and aware of all persons and property

within the range of your ammunition.

2.

NEVER RELY TOTALLY ON YOUR SHOTGUN'S MECHANICAL "SAFETY" DEVICE.

Always assume that your gun can be fired at any time, even with all the safety mechanism

engaged. The word "safety" describes a gun's trigger block mechanism, sear block mechanism,

hammer block mechanism or firing pin block mechanism. These mechanical devices are

designed to place your gun in a SAFER status. No guarantee can be made that the gun will not

fire even if the "safety" is in the "on safe" position. See "Operation of the Safety" in your

owner’s manual for instructions on operation of your gun's "safety."

3. LIKE ANY MECHANICAL DEVICE, A "SAFETY" CAN SOMETIMES FAIL; IT CAN BE

JARRED OR INADVERTENTLY MANIPULATED INTO AN UNSAFE CONDITION.

Mechanical "safeties" merely aid safe gun handling and are no excuse for pointing your

shotgun's muzzle in an unsafe direction.

While it is a good idea to "test" your shotgun's mechanical "safeties" periodically for proper

function, never test them while your firearm is loaded or pointed in an unsafe direction. Safe

gun handling does not stop with your gun's mechanical "safety" devices -- it starts there.

Always treat this shotgun with the respect a loaded, ready-to-fire firearm.

MECHANISM OF ANY FIREARM WHILE IT IS LOADED OR POINTED IN AN UNSAFE DIRECTION.

4. WHENEVER YOU HANDLE A FIREARM, OR HAND IT TO SOMEONE MAKE SURE IT IS

COMPLETELY UNLOADED.

NEVER TEST THE

Always open the action immediately and visually check the chamber magazine. Make certain

the chamber does not inadvertently contain any ammunition. Always keep the chamber empty

and the "safety" in the "on safe" position unless shooting is imminent.

5. DO NOT TRANSPORT ANY FIREARM LOADED. KEEP ALL FIREARMS UNLOADED

DURING TRANSPORT, WHETHER IN A SCABBARD, GUN CASE, OR OTHER CONTAINER.

6. HUNTING FROM ELEVATED SURFACES SUCH AS TREE STANDS IS DANGEROUS.

Doing so may increase the risk of handling a firearm. The following rules should always be

observed by you and those you hunt with: Always make certain that the stand being used is

safe and stable. Always make certain that your firearm is unloaded when it is being taken up

and down from the stand. Always make certain that your firearm is not dropped from the stand,

or dropped while it is being taken up or down from the stand. Remember, a loaded firearm

may discharge when dropped, even with the safety in the "on safe" position.

Page 23

7. BEWARE OF BARREL OBSTRUCTION.

Do this for the safety of both your gun and yourself. Mud, snow, and an infinite variety of

other objects may inadvertently lodge in a barrel bore. It takes only one small obstruction to

cause dangerously increased pressures that can ruin (swell or rupture) the finest shotgun barrel.

BEFORE CHECKING FOR A BARREL OBSTRUCTION, BE CERTAIN YOUR FIREARM IS FULLY

UNLOADED.

Make sure no live rounds are in the chamber. Place the safety in the "on safe" position, open

the breech or action and look through the barrel to be sure it is clear of any obstruction. If an

obstruction is seen, no matter how small it may be, clean the bore with a cleaning rod and

patch as instructed for your particular firearm. Before the first firing, clean the bore with a

cleaning rod and patch, and wipe away any anti-rust compounds in the action/chamber areas.

8. ALWAYS UNLOAD ALL FIREARMS WHEN NOT IN USE.

As a safety precaution, it is preferable to disassemble your gun for storage. Your

responsibilities do not end when your firearm is unattended. Store your gun and ammunition

separately -- well beyond the reach of children. Take all safeguards to ensure your firearm does

not become available to untrained, inexperienced or unwelcome hands.

9. USE THE PROPER AMMUNITION.

The barrel and action of all Browning firearms have been made with substantial safety margins

over the pressures developed by established American commercial loads. Nevertheless,

Browning assumes no liability for incidents which occur through the use of cartridges of

nonstandard dimensions which develop pressures in excess of commercially available

ammunition with standards established by the Sporting Arms and Ammunitions Manufacturers'

Institute (SAAMI).

BE ALERT TO THE SIGNS OF AMMUNITION MALFUNCTION.

If you detect an off sound or light recoil when ammunition is fired, DO NOT LOAD MORE

AMMUNITION INTO THE CHAMBER.

Open the action and remove all ammunition from the

chamber. With the action open, glance down the barrel to make sure that a wad or other

obstruction does not remain in the barrel. If there is an obstruction, completely clear the barrel

before loading and firing again. Failure to follow these instructions can cause extensive

damage to your gun and possible serious injury to yourself and others.

10.

DISCHARGE A FIREARM. WASH HANDS THOROUGHLY AFTER EXPOSURE TO AMMUNITION

OR CLEANING A FIREARM.

MAKE SURE OF ADEQUATE VENTILATION IN THE AREA THAT YOU

Lead exposure can be obtained from discharging firearms in poorly ventilated areas,

cleaning firearms or handling ammunition. Lead is

a substance that has been known to cause birth defects, reproductive harm and other serious

injury.

11.

NEVER INSERT A SHELL OF THE INCORRECT GAUGE IN ANY SHOTGUN. The gauge of

your shotgun is marked on the side of the barrel. Store all shells of different gauges in

completely separate and well-marked containers. Never store shells of mixed gauges in a

common container or in your pockets.

12 GAUGE GUN.

EXAMINE EVERY SHELL YOU PUT IN YOUR GUN. NEVER PUT A 20 GAUGE SHELL IN A

The most common way to bulge or rupture a shotgun barrel is to drop a 20

gauge shell into a 12 gauge chamber. The 20 gauge shell, unfortunately, will not fall

completely through the barrel; its rim is caught by the front of a 12 gauge chamber. Your gun

will misfire (with the chamber appearing to be empty). It is then possible to load a 12 gauge

shell behind the 20 gauge shell. If the 12 gauge shell is then fired, the result will be a so-called

“12-20 burst” which can cause extensive damage to your gun and possible serious injury to

you and others.

Page 24

12. USE SHELLS OF CORRECT LENGTH.

The size of the chamber is inscribed, along with gauge and choke designations, on the side of

the barrel. Do not use 31/2" shotgun shells in a shotgun or barrel with a 2 3/4" chamber or 3"

chamber. Do not use 3" shells in a shotgun chambered for a 2 3/4" shells. Doing so can result

in a build-up of dangerously high pressures that may damage your gun and possibly cause

serious injury to yourself or others.

13.

BE EMPTY!

DO NOT SNAP THE FIRING PIN ON AN EMPTY CHAMBER -- THE CHAMBER MAY NOT

Treat every gun with the respect due a loaded gun, even though you are certain the gun is

unloaded.

14.

UNTIL YOU ARE READY TO SHOOT.

KEEP YOUR FINGERS AWAY FROM THE TRIGGER WHILE LOADING AND UNLOADING

15. BE SURE OF YOUR TARGET AND BACKSTOP. Particularly during low light periods.

Know the range of your ammunition. Never shoot at water or hard objects.

16.

CROSSING A FENCE, CLIMBING A TREE, JUMPING A DITCH OR NEGOTIATING OTHER

OBSTACLES.

ALWAYS UNLOAD THE CHAMBER AND MAGAZINE OF ANY FIREARM BEFORE

Never lean or place your loaded shotgun on or against a fence, tree, car or other similar object.

17.

WEAR EYE AND EAR PROTECTION WHEN SHOOTING. Unprotected, repeated exposure

to gunfire can cause hearing damage. Wear ear protectors (shooting earplugs or muffs) to

guard against such damage. Wear shooting glasses to protect your eyes from flying particles.

Always keep a safe distance between the muzzle of your firearm and any persons nearby, as

muzzle blast, debris and ejecting shells could inflict serious injury. Also, wear eye protection

when disassembling and cleaning all firearms to prevent the possibility of springs, springtensioned parts, solvents or other agents from contacting your eyes.

18. DROPPING A LOADED GUN CAN CAUSE AN ACCIDENTAL DISCHARGE.

This can occur even with the "safety" in the "on safe" position. Be extremely careful while

hunting or during any shooting activity to avoid dropping any firearm.

19. IF ANY FIREARM FAILS TO FIRE, KEEP THE MUZZLE POINTED IN A SAFE DIRECTION.

Hold this position for a minimum of 30 seconds. Carefully open the action and remove the

shell. If the primer is indented, the shell should be disposed of in a way that cannot cause harm.

If the primer is not indented, your firearm should be examined by a qualified gunsmith and the

cause of the malfunction should be corrected before further use.

20. BE DEFENSIVE AND ON GUARD AGAINST UNSAFE GUN HANDLING AROUND YOU

AND OTHERS

. Don’t be timid when it comes to gun safety. If you observe other shooters

violating any of these safety precautions, politely suggest safer handling practices.

21. BE CERTAIN YOUR SHOTGUN IS UNLOADED BEFORE CLEANING.

Because so many accidents occur when a firearm is being cleaned, special and extreme care

should be taken to be sure your gun is unloaded before disassembly, cleaning and reassembly.

Keep ammunition away from the cleaning location. Never test the mechanical function of any

firearm with live ammunition.

Page 25

22. SUPERVISE AND TEACH FIREARMS SAFETY TO ALL MEMBERS OF YOUR FAMILY --

ESPECIALLY TO CHILDREN AND NONSHOOTERS.

Closely supervise newcomers to the shooting sports. Encourage enrollment in hunting/shooting

safety courses.

23. NEVER DRINK ALCOHOLIC BEVERAGES OR TAKE ANY TYPE OF DRUGS BEFORE OR

DURING SHOOTING.

Your vision and judgment could be dangerously impaired, making your gun handling unsafe to

you and to others.

24. PERFORM PERIODIC MAINTENANCE -- AVOID UNAUTHORIZED SERVICING.

Your firearm is a mechanical device which will not last forever, and as such, is subject to wear

and requires periodic inspection, adjustment and service. Browning firearms should be

serviced by a Browning Recommended Service Center or by Browning's service facility in

Arnold, Missouri. Browning cannot assume any responsibility for injuries suffered or caused

by unauthorized servicing, alterations or modifications of Browning firearms.

25.

READ AND HEED ALL WARNINGS in these instructions, on ammunition boxes and with

all accessories that you install on your firearm. It is your responsibility to secure the most upto-date information on the safe handling procedures of your Browning gun. Browning assumes

no liability for incidents which occur when unsafe or improper gun accessories or ammunition

combinations are used.

26. Browning reserves the right to refuse service on firearms that have been altered, added

to or substantially changed. Removal of metal from barrel(s), or modification of the firing

mechanism and/or operating parts may lead to Browning’s refusal of service on such firearms.

Browning will charge the owner for parts and labor to return the firearm to original Browning

specifications.

DO NOT, UNDER ANY CIRCUMSTANCES, ALTER THE TRIGGER, SAFETY OR

OTHER PARTS OF THE FIRING MECHANISM OF THIS OR ANY OTHER

FIREARM. FAILURE TO OBEY THIS WARNING MAY RESULT IN INJURY OR

DEATH TO YOURSELF OR OTHERS.

BE CAREFUL!

Loading...

Loading...