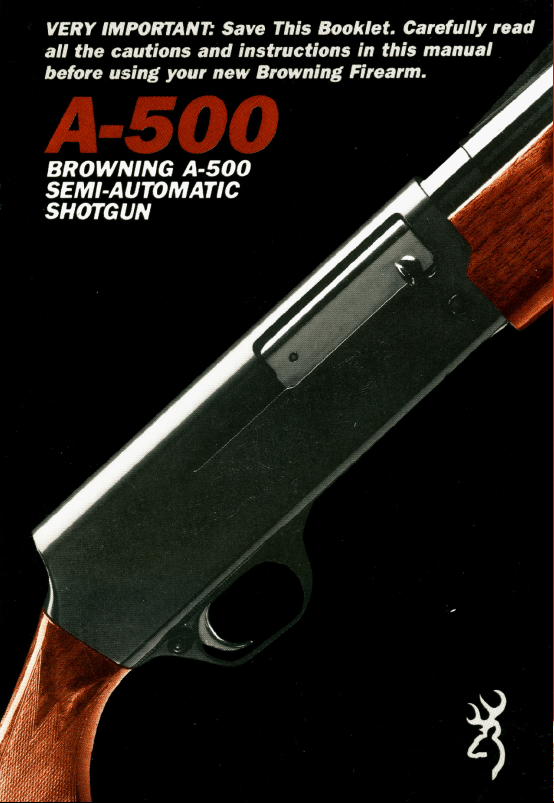

Browning A500 SEMI-AUTOMATIC SHOTGUN User Manual

New Gun Owner’s Record

(KEEP THIS RECORD FOR FUTURE REFERENCE)

Browning Model

Serial Number

Gauge

Purchase Price

Purchased From

Date of Purchase

Please fill out and mail the Market Survey Card at the back of this booklet.

We are pleased that you have chosen a

Browning A-500 shotgun.

It is certainly a gun you can be proud to own. It

represents the state-of-the-art in modern gun design

and manufacturing. The processes of design, testing

and manufacturing were all assisted by advanced

computer systems. The result is superior dependability,

greater ease-of-operation, smoother handling and

more reliable overall function. With a reasonable

amount of care, your A-500 shotgun should give you

many years of dependable, enjoyable service. Please

feel free to write us immediately if you have any

observations regarding its performance and operation.

Also, please take a moment to complete and mail in

the brief attached marketing survey card found on our

back cover. It helps us considerably in our constant

effort to provide you with better service.

NOTE: All current production A-500 shotguns have an

improved trigger group assembly. You can confirm this

by the letter “H” stamped on the trigger guard. (See

Figure 10 on page 37 of this manual.)

If your trigger guard does not have the letter “H”

stamped on it then please contact our Browning

Service Department toll free at 1-800-322-4626 for

information on how to get the improved trigger

assembly installed on your A-500.

Thank You.

Route #1 Morgan, Utah 84050

Distributed in Canada by Browning Canada Sports Ltd./Ltee, St-Laurent, Quebec H4S 1SO

1

You Are Responsible for Firearms

Safety

As a gun owner, you accept a set of demanding

responsibilities. How seriously you take these

responsibilities can be the difference between life

and death. Mistakes made with guns are final

and cannot be paid for with money or regret.

There is no excuse for careless or abusive

handling of any firearm. At all times handle your

shotgun and any other firearm with intense

respect for its power and potential danger.

PLEASE READ AND UNDERSTAND ALL OF

THE CAUTIONS, PROPER HANDLING

PROCEDURES AND INSTRUCTIONS

OUTLINED IN THIS BOOKLET BEFORE

USING YOUR NEW FIREARM.

ALWAYS KEEP THE MUZZLE OF YOUR

SHOTGUN POINTED IN A SAFE

DIRECTION

the shotgun is unloaded. Never point any

firearm at anything you do not intend to

shoot. Be extremely alert and aware of all

persons and property within the range of

your ammunition.

even though you are certain

NEVER TRUST YOUR SHOTGUN’S

MECHANICAL “SAFETY” DEVICE.

2

The

word “safety” describes a gun’s trigger

block mechanism, sear block mechanism,

hammer block mechanism or firing pin

block mechanism. These mechanical

devices are designed to place your gun in

a SAFER status. No guarantee can be made

that the gun will not fire even if the

“safety” is in the “on safe” position. The

A-500 has a cross bolt “safety” which

blocks the gun’s trigger. See “Operation of

the Safety” on page 15 for instructions on

operation of this gun’s safety.

Like any mechanical device, a “safety” can

sometimes fail; it can be jarred or

inadvertently manipulated into an unsafe

condition. Mechanical “safeties” merely aid

safe gun handling and are no excuse for

pointing your shotgun’s muzzle in an

unsafe direction.

While it is a good idea to “test” your

shotgun’s mechanical “safeties” periodically

for proper function,

“SAFETY” WHILE YOUR SHOTGUN IS

LOADED OR POINTED IN AN UNSAFE

DIRECTION.

NEVER TEST THE

Safe gun handling does not stop with your

gun’s mechanical “safety” devices — it

starts there. Always treat this shotgun with

the respect due a loaded, ready-to-fire

firearm.

3

WHENEVER YOU HANDLE A FIREARM,

OR HAND IT TO SOMEONE, ALWAYS

OPEN THE ACTION IMMEDIATELY,

VISUALLY CHECK YOUR SHOTGUN’S

CHAMBER, FEED MECHANISM AND

MAGAZINE to be certain that they do not

inadvertently contain any ammunition.

Always keep the chamber empty and the

“safety” in the “on safe” position unless

shooting is imminent.

DO NOT TRANSPORT YOUR SHOTGUN

LOADED, WHETHER IN A SCABBARD

GUN CASE, OR OTHER CONTAINER.

BEWARE OF BARREL OBSTRUCTIONS,

for the safety of both your gun and

yourself. Mud, snow, and an infinite variety

of other objects may inadvertently lodge in

a barrel bore. It takes only one small

obstruction to cause dangerously increased

pressures that can ruin (swell or rupture)

the finest shotgun barrels.

BEFORE CHECKING FOR A BARREL

OBSTRUCTION, BE CERTAIN NO LIVE

ROUND IS IN THE CHAMBER AND

THAT THE MAGAZINE AND FEED

MECHANISMS ARE COMPLETELY

EMPTY. PLACE THE “SAFETY” IN THE

“ON SAFE” POSITION

(See page 28 for

instructions on unloading). After assuring

4

yourself that the shotgun is completely empty,

again, open the breechblock, locking it to

the rear, and look through the barrel to be

sure it is clear of any obstruction. If an

obstruction is seen, no matter how small it

may be, clean the bore with a cleaning rod

and patch as described in “Cleaning and

Maintenance Suggestions” on page 54.

Before the first firing, clean the bore with a

cleaning rod and patch, and wipe away

any anti-rust compounds in the action/

chamber areas.

ALWAYS UNLOAD YOUR SHOTGUN WHEN

NOT IN USE. REFER TO PAGE 28 OF THIS

INSTRUCTION BOOKLET EXPLAINING

THE UNLOADING OF YOUR SHOTGUN.

As a safety precaution, it is preferable to

disassemble your gun for storage. Store

your gun and ammunition separately —

well beyond the reach of children. Take all

safeguards to ensure your shotgun does

not become available to untrained,

inexperienced or unwelcome hands.

USE THE PROPER AMMUNITION. The

barrel and action of this shotgun have

been made with substantial safety margins

over the pressures developed by

established American commercial loads.

Nevertheless, Browning assumes no

5

liability for incidents which occur through

the use of cartridges of nonstandard

dimensions which develop pressures in

excess of commercially available

ammunition which has been loaded in

accordance with standards established by

SAAMI (Sporting Arms and Ammunition

Manufacturers Institute).

DO NOT PUT A 20 GAUGE SHELL IN A

12 GAUGE GUN.

Store all shells of

different gauges in completely separate

and well-marked containers. Do not store

shells of mixed gauges in a common

container or in your pockets.

EVERY SHELL YOU PUT IN YOUR GUN.

EXAMINE

The most certain way to bulge or rupture

a barrel is to drop a 20 gauge shell into a

12 gauge chamber. The 20 gauge shell,

unfortunately, will not fall completely

through the barrel; its rim is caught by the

front of a 12 gauge chamber. Your gun will

misfire (with the chamber appearing to be

empty). It is then possible to load a 12

gauge shell behind the 20 gauge shell. If

the 12 gauge shell is then fired, the result

will be a so-called “12-20 burst” which can

cause extensive damage to your gun and

possible serious injury to you.

6

DO NOT USE 3” SHOTGUN SHELLS IN

A BARREL WITH A 2 3/4” CHAMBER.

THE SIZE OF THE CHAMBER IS

INSCRIBED, ALONG WITH CHOKE

DESIGNATIONS, ON THE SIDE OF THE

BARREL.

DO NOT SNAP THE FIRING PIN ON AN

EMPTY CHAMBER — THE CHAMBER

MAY NOT BE EMPTY!

Treat every gun

with the respect due a loaded gun, even

though you are certain the gun is unloaded.

KEEP YOUR FINGERS AWAY FROM THE

TRIGGER WHILE UNLOADING,

LOADING

BE SURE OF YOUR TARGET AND

BACKSTOP,

or until you are ready to shoot.

particularly during low light

periods. Know the range of your ammunition.

Never shoot at water or hard objects.

ALWAYS UNLOAD YOUR SHOTGUN’S

CHAMBER BEFORE CROSSING A

FENCE, CLIMBING A TREE, JUMPING

A DITCH OR NEGOTIATING OTHER

OBSTACLES. Refer to page 28 of this

instruction book for instructions on the

unloading of your shotgun. Never place

your shotgun on or against a fence, tree,

car, or other similar object.

7

WEAR EYE AND EAR PROTECTION

WHEN SHOOTING.

Unprotected, repeated

exposure to gunfire can cause hearing

damage. Wear ear protectors (shooting ear

plugs or muffs) to guard against such

damage. Wear shooting glasses to protect

your eyes from flying particles. Also, wear

eye protection when disassembling and

cleaning your shotgun to prevent the

possibility of springs, spring-tensioned

parts, solvents or other agents from

contacting your eyes.

DROPPING A WADED GUN CAN CAUSE

AN ACCIDENTAL DISCHARGE

even with

the “safety” in the “on safe” position. Be

extremely careful while hunting or during

any shooting activity, to avoid dropping

any firearm.

IF YOUR SHOTGUN FAILS TO FIRE,

KEEP THE MUZZLE POINTED IN A

SAFE DIRECTION.

Hold this position for a

minimum of 30 seconds. Carefully open

the action and remove the cartridge. If the

primer is indented, the cartridge should be

disposed of in a way that cannot cause

harm. If the primer is not indented, your

firearm should be examined by a qualified

gunsmith and the cause of the malfunction

should be corrected before further use.

8

BE DEFENSIVE AND ON GUARD

AGAINST UNSAFE GUN HANDLING

AROUND YOU AND OTHERS.

Don’t be

timid when it comes to gun safety. If you

observe other shooters violating any of

these safety precautions, politely suggest

safer handling practices.

BE CERTAIN YOUR SHOTGUN IS

UNLOADED BEFORE CLEANING.

Because so many gun accidents occur

when a firearm is being cleaned, special

and extreme care should be taken to be

sure your gun is unloaded before disassembly,

cleaning and reassembly. Keep ammunition

away from the cleaning location. Never test

the mechanical function of any firearm

with live ammunition.

EDUCATE AND SUPERVISE FIREARMS

SAFETY TO ALL MEMBERS OF YOUR

FAMILY —

especially to children and

nonshooters. Closely supervise newcomers

to the shooting sports. Encourage

enrollment in hunting/shooting safety

courses.

NEVER DRINK ALCOHOLIC

BEVERAGES OR TAKE ANY TYPE OF

DRUGS BEFORE OR DURING

SHOOTING.

Your vision and judgment

9

could be dangerously impaired, making your

gun handling unsafe to you and to others.

READ AND HEED ALL WARNINGS in

this instruction book and on ammunition

boxes. It is your responsibility to secure the

most up-to-date information on the safe

handling procedures for your Browning

gun. Browning cannot assume any

responsibility when unsafe or improper

arms and ammunition combinations are used.

PERIODIC MAINTENANCE — AVOID

UNAUTHORIZED SERVICING.

Your

shotgun is a mechanical device which will

not last forever, and as such, is subject to

wear and requires periodic inspection,

adjustment, and service. Browning firearms

should be serviced by a Browning

Recommended Service Center or by

Browning’s service facility in Arnold,

Missouri. Browning cannot assume any

responsibility for injuries suffered or caused

by unauthorized servicing, alterations or

modifications of Browning firearms.

CAN BE VERY DANGEROUS TO ALTER

THE TRIGGER, SAFETY OR OTHER

FIRING MECHANISM PARTS OF THIS

OR ANY OTHER FIREARM.

IT

10

BE CAREFUL!

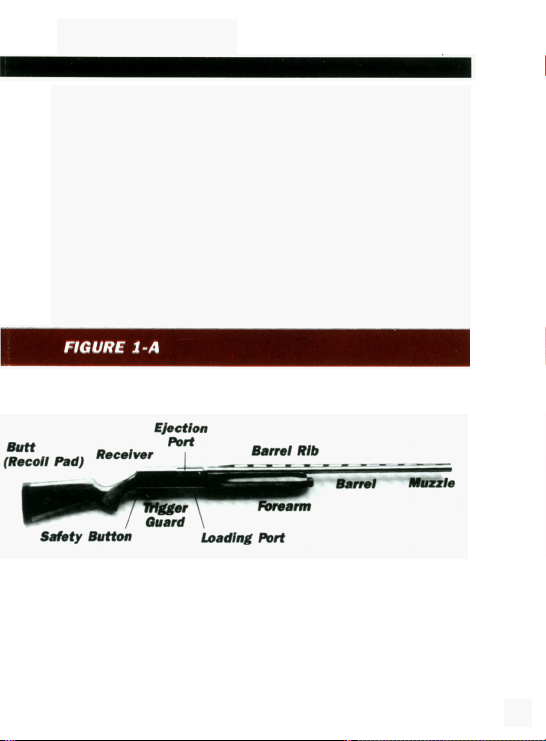

Nomenclature

In conventional gun terminology, the position

and movement of gun parts are described as

they occur with the gun horizontal and in

normal firing position; i.e., the muzzle is forward

or front; butt stock is rearward or rear; trigger is

downward or underneath; the rib is upward or

on top. For general parts nomenclature refer to

Figure 1-A. See Figure 1-B for names of all parts

and assemblies covered in disassembly and

cleaning procedures.

11

A. Barrel Extension Guides

B. Barrel Ring Guide

C. Front Action Springs

D. Bolt Release Button

(Carrier Latch Button)

E. Breechblock Assembly

E Carrier

G. Forearm R. Trigger Group

H. Forearm Buffer Rings

I. Magazine Tube

J. Magazine Cap

K. Magazine Spring Retainer

L. Magazine Follower

M. Magazine Spring

N. Operating Handle

O. Recoil Spring

P. Rotary Bolt Head

Q. Three Shot Adapter

S. Trigger Guard Retaining Nut

T. Trigger Guard Retaining Screw

General Operating Procedures

The Browning A-500 shotgun is a short recoil-

operated, semi-automatic shotgun. It is capable

of shooting five shots (with the magazine plug

removed) in rapid succession, with each pull of

the trigger. The rotary bolt locks into the barrel

12

with four lugs. Upon firing, recoil causes the

barrel to travel rearward. Energy differences

between loads are absorbed by an internal

breechblock spring. A special buffer surrounding

the magazine tube stops the rearward motion of

the barrel after about 1/2”. Inertia from the

barrel causes the breechblock to continue

rearward, turning and unlocking the 4-lug rotary

bolt, recocking the hammer, and ejecting the

fired shell.

After full rearward travel, the breechblock

returns forward, picking up a new shell from the

magazine and chambering it automatically. After

the last shell has been fired, the breechblock

locks to the rear, instead of returning forward.

This facilitates speedy, convenient reloading.

NOTE: The A-500 is delivered with the magazine

adaptor in the magazine which limits the gun to

three shots, in accordance with federal migratory

bird laws. If you do not want your gun to be so

limited, merely take out the three shot adapter

as explained on page 42 under “Three Shot

Adapter.”

Initial Cleaning

Various exposed metal parts of your new A-500

have been coated at the factory with a rust

13

preventative compound. Before assembling your

A-500, clean the anti-rust compound from the

inside of the barrel, receiver and the action/

chamber areas. Browning Oil is ideal for

removing this compound and for giving your

new gun its first lubrication. However, any

quality gun oil may be used. Use a cleaning rod

and patch as explained under “Cleaning and

Maintenance Suggestions” on page 54.

Serial Number

The serial number of your A-500 shotgun is

found on the left side of the receiver, at the

lower rear, near the grip portion of the buttstock.

Ammunition

The A-500 has a 3-inch chamber and is designed

to shoot and function with all 12 gauge factory

loads: 3-inch Magnum, 2 3/4” Magnum, 2 3/4”

High Velocity loads, 2 3/4” Field and 2 3/4”

Target loads. It is especially suited to shooting

factory steel shot loads. Loads can be

intermixed, in any order. However, Browning

can assume no responsibility for incidents which

occur through the use of cartridges of

nonstandard dimension or those developing

14

pressures in excess of SAAMI (Sporting Arms

and Ammunition Manufacturer’s Institute)

established standards.

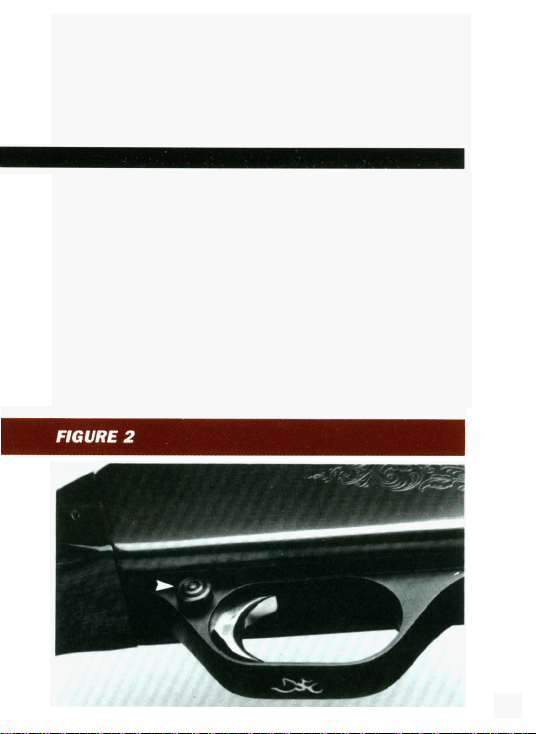

Operation of the “Safety”

The cross bolt “safety” prevents the trigger from

being pulled when in the “on safe” position. The

safety is located conveniently at the rear of the

trigger guard (See Figure 2). In the “off safe” or

“fire” position a conspicuous red warning band is

visible on the safety button on the left side of

the trigger guard. To place the gun “ON SAFE,”

press the “safety” button to the right. To move

the “safety” to the FIRE position, press the

“safety” to the left.

15

An optional left-handed “safety” can be installed

by a competent gunsmith. When installed, the

left-handed “safety” will have the “safety”

button’s red warning band on the RIGHT side of

the trigger guard.

DO NOT DEPEND ON THE RED COLOR

ALONE TO INDICATE YOUR GUN’S SAFETY

STATUS.

well as the abrasive action of cleaning agents

can erase it.

As previously explained on page 2, never rely

on your shotgun’s mechanical “safety” devices as

the sole provision for safety.

YOUR SHOTGUN AT ANYTHING YOU DO NOT

INTEND TO SHOOT.

even when unloaded, with the respect due any

loaded, ready-to-fire firearm.

Time, exposure to the elements, as

NEVER POINT

Always treat your shotgun,

Assembly Procedures — Barrel to

Receiver

The A-500 is delivered, in the box, with the

barrel removed and the forearm (with recoil

spring and forearm buffer inside) attached to the

magazine tube. There are two ways to install the

barrel on the receiver: As a barrel/forearm

assembly, and part by part.

16

ASSEMBLY AS A BARREL ASSEMBLY — This

is the easiest way to install your barrel on the

receiver. If your A-500’s forearm assembly is

already removed go to step 2.

Take the receiver in hand and first, lock

the breechblock rearward by pulling the

operating handle fully to the rear. Then,

remove the forearm, recoil spring and

forearm buffer from the magazine tube by

unscrewing the magazine cap and sliding

the parts forward, off of the magazine

tube.

OPEN REAR END OF THE FOREARM.

TOO MUCH PRESSURE COULD CAUSE

THE WOOD TO SPLIT.

Install the forearm on the barrel by sliding

it over the barrel ring and seating it fully

rearward .

With the barrel pointing down, insert the

recoil spring in the opening at the rear of

the forearm and let it slide forward fully in

the forearm cavity.

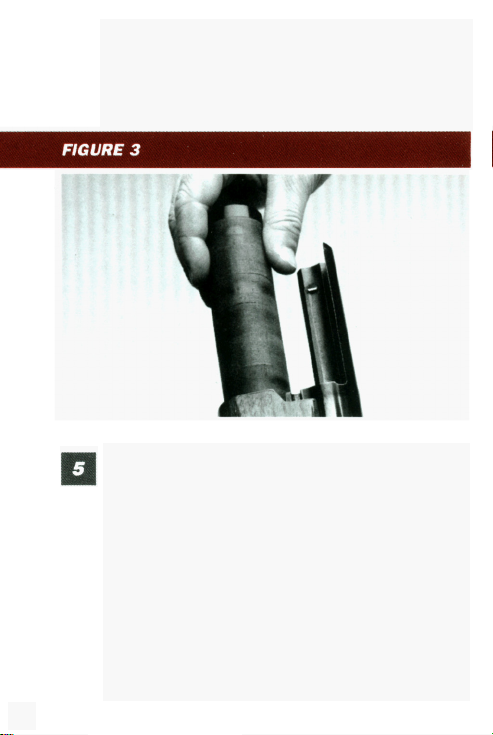

Insert the forearm buffer into the same

cavity in the forearm and let it slide fully

forward (See Figure 3).

NOTE: The recoil spring must always be

installed at the muzzle end of the magazine

17

tube. The forearm buffer must be toward

the receiver. However, both the spring and

the buffer, individually, can be installed in

either direction.

With the gun in a horizontal position,

install the entire barrel/forearm assembly

onto the receiver by sliding the forearm

(with buffer and spring inside) over the

magazine tube (See Figure 4). Position the

gun vertically (barrel up), then slide the

barrel/forearm assembly fully rearward,

making sure that the barrel extension rails

are fully seated in the receiver tracks. The

barrel extension may hang up slightly

where the extension contacts the face of

18

Loading...

Loading...