Page 1

Page 2

We are pleased that you have chosen a Browning A-500G shotgun.

It is certainly a gun you can be proud to own. It represents the state-of-the-art in modern

gun design and manufacturing. The processes of design, testing and manufacturing were all

assisted by advanced computer systems. The result is superior dependability, greater easeof-operation, smoother handling and more reliable overall function. With a reasonable

amount of care, your A-500G shotgun should give you many years of dependable, enjoyable

service. Please feel free to write us immediately if you have any observations regarding its

performance and operation.

Thank You.

Route One Morgan, Utah 84050

Distributed in Canada by Browning Canada Sports Ltd./Ltee, St-Laurent, Quebec H4S 1 W6

Printed in Portugal

Browning A-5OOG

Gas Operated

Semi-Automatic

Shotgun

Page 3

NEW GUN OWNERS RECORD

KEEP THIS RECORD FOR FUTURE REFERENCE

Browning Model

Serial Number

Gauge / Caliber

Purchase Price

Purchased From

Date of Purchase

Page 4

You Are Responsible for

Firearms Safety

As a gun owner, you accept a set of

demanding responsibilities. How seriously

you take these responsibilities can be the

difference between life and death.

There is no excuse for careless or abusive

handling of any firearm. At all times handle

your shotgun and any other firearm with

intense respect for its power and potential

danger.

PLEASE READ AND UNDERSTAND

ALL OF THE CAUTIONS, PROPER

HANDLING PROCEDURES AND IN

STRUCTIONS OUTLINED IN THIS

BOOKLET BEFORE USING YOUR

NEW FIREARM.

-

1.

ALWAYS KEEP THE MUZZLE OF YOUR

SHOTGUN POINTED IN A SAFE

DIRECTION,

even though you are certain the shotgun

is unloaded. Never point any firearm at

anything you do not intend to shoot. Be

extremely alert and aware of all persons

and property within the range of your

ammunition.

2. NEVER RELY TOTALLY ON YOUR

SHOTGUN’S MECHANICAL “SAFETY”

DEVICE.

The word “safety” describes a gun’s

trigger block mechanism, sear block

mechanism, hammer block mechanism

or firing pin block mechanism. These

mechanical devices are designed to place

your gun in a Safer status. No guarantee

can be made that the gun will not fire

even if the “safety” is in the “on safe”

position. The A

-

500G has a cross bolt

2

Page 5

“safety” which blocks the gun’s trigger.

See “Operation of the Safety” on page 14

for instructions on operation of this gun’s

safety.

LIKE ANY MECHANICAL DEVICE, A

“SAFETY” CAN SOMETIMES FAIL; IT

CAN BE JARRED OR INADVERTENTLY

MANIPULATED INTO AN UNSAFE

CONDITION.

Mechanical “safeties” merely aid safe gun

handling and are no excuse for pointing

your shotgun’s muzzle in an unsafe

direction.

While it is a good idea to “test” your

shotgun’s mechanical “safeties” periodi-

cally for proper function,

NEVER TEST THE “SAFETY” WHILE

YOUR SHOTGUN IS LOADED OR

POINTED IN AN UNSAFE DIRECTION.

Safe gun handling does not stop with

your gun’s mechanical “safety” devices

— it starts there. Always treat this

shotgun with the respect due a loaded,

ready-to-fire firearm.

3. WHENEVER YOU HANDLE A FIREARM,

OR HAND lT TO SOMEONE, ALWAYS

OPEN THE ACTION IMMEDIATELY,

VISUALLY CHECK YOUR SHOTGUN’S

CHAMBER, FEED MECHANISM AND

MAGAZINE.

Make certain that they do not inadvertently contain any ammunition. Always

keep the chamber empty and the “safety”

in the “on safe” position unless shooting

is imminent.

4. DO NOT TRANSPORT YOUR SHOTGUN

LOADED, WHETHER IN A SCABBARD,

GUN CASE, OR OTHER CONTAINER.

5. HUNTING FROM ELEVATED SURFACES SUCH AS TREE STANDS IS

DANGEROUS,

and may increase the risk of handling a

firearm. The following rules should

3

Page 6

always be observed by you and those

you hunt with: Always make certain that

the stand being used is safe and stable.

Always make certain that your firearm is

unloaded when it is being taken up and

down from the stand. Always make

certain that your firearm is not dropped

from the stand, or dropped while it is

being taken up or down from the stand.

Remember, a loaded firearm may

discharge when dropped, even with the

safety in the “on safe” position.

6. BEWARE OF BARREL OBSTRUCTIONS,

for the safety of both your gun and

yourself. Mud, snow, and an infinite

variety of other objects may inadvertently

lodge in a barrel bore. It takes only one

small obstruction to cause dangerously

increased pressures that can ruin (swell

or rupture) the finest shotgun barrels.

4

BEFORE CHECKING FOR A BARREL

OBSTRUCTION, BE CERTAIN NO LIVE

ROUND IS IN THE CHAMBER AND

THAT THE MAGAZINE AND FEED

MECHANISMS ARE COMPLETELY

EMPTY. PLACE THE “SAFETY” IN THE

“ON SAFE” POSITION

See page 23 for instructions on unloading). After assuring yourself that the

shotgun is completely empty, again,

open the breechblock, locking it to the

rear, and look through the barrel to be

sure it is clear of any obstruction. If an

obstruction is seen, no matter how small

it may be, clean the bore with a cleaning

rod and patch as described in “Cleaning

and Maintenance Suggestions” on page

44. Before the first firing, clean the bore

with a cleaning rod and patch, and wipe

away any anti-rust compounds in the

action/ chamber areas.

Page 7

7. ALWAYS UNLOAD YOUR SHOTGUN

WHEN NOT lN USE. REFER TO PAGE

20 OF THIS INSTRUCTION BOOKLET

EXPLAINING THE UNLOADING OF

YOUR SHOTGUN.

As a safety precaution, it is preferable to

disassemble your gun for storage. Store

your gun and ammunition separately —

well beyond the reach of children. Take

all safeguards to ensure your shotgun

does not become available to untrained,

inexperienced or unwelcome hands.

8. USE THE PROPER AMMUNITION.

The barrel and action of this shotgun

have been made with substantial safety

margins over the pressures developed by

established American commercial loads.

Nevertheless, Browning assumes no

liability for incidents which occur

through the use of cartridges of nonstandard dimensions which develop

pressures in excess of commercially

available ammunition which has been

loaded in accordance with standards

established by the Sporting Arms and

Ammunition Manufacturers Institute

(SAAMI).

BE ALERT TO THE SIGNS OF AMMUNITlON MALFUNCTION.

If you detect an off sound or light recoil

when a shell is fired,

DO NOT LOAD ANOTHER SHELL INTO

THE CHAMBER.

Open the action and remove all shells

from the magazine, chamber and action

areas. With the action open, glance

down the barrel to make sure that a wad

or other obstruction does not remain in

the barrel. Completely clear the barrel

before loading and firing again. Failure

to follow these instructions can cause

extensive damage to your gun and

possible serious injury to yourself and

others.

5

Page 8

9. DO NOT PUT A 20 GAUGE SHELL IN A

12 GAUGE GUN.

Store all shells of different gauges in

completely separate and well-marked

containers. Do not store shells of mixed

gauges in a common container or in

your pockets.

EXAMINE EVERY SHELL YOU PUT IN

YOUR GUN.

The most certain way to bulge or rupture

a barrel is to drop a 20 gauge shell into a

12 gauge chamber. The 20 gauge shell,

unfortunately, will not fall completely

through the barrel; its rim is caught by

the front of a 12 gauge chamber. Your

gun will misfire (with the chamber

appearing to be empty). It is then

possible to load a 12 gauge shell behind

the 20 gauge shell. If the 12 gauge shell

is then fired, the result will be a so-called

"12-20 burst" which can cause extensive

damage to your gun and possible serious

injury to you and others.

10. CAUTION: DO NOT USE 3 1/2" SHOT-

6

GUN SHELLS IN ANY SHOTGUN OR

BARREL WlTH A 2 3/4" OR 3" CHAMBER. DO NOT USE 3" SHELLS lN

SHOTGUN CHAMBERED FOR 2 3/4"

SHELLS. THE SIZE OF THE CHAMBER

lS lNSCRlBED, ALONG WITH GAUGE

AND CHOKE DESIGNATIONS, ON THE

SIDE OF THE BARREL.

Your A-500 is chambered for factory

2 3/4" and 3" shells only.

11. DO NOT SNAP THE FIRING PIN ON AN

EMPTY CHAMBER- THE CHAMBER

MAY NOT BE EMPTY!

Treat every gun with the respect due a

loaded gun, even though you are certain

the gun is unloaded.

12. KEEP YOUR FINGERS A WAY FROM

THE TRIGGER WHILE UNLOADING,

LOADING, UNTIL YOU ARE READY TO

SHOOT.

Page 9

13. BESURE OF YOUR TARGET AND

BACKSTOP.

Particularly, be sure during low light

periods. Know the range of your ammunition. Never shoot at water or hard

objects.

14. ALWAYS UNLOAD YOUR SHOTGUN’S

CHAMBER BEFORE CROSSING A

FENCE, CLlMBlNG A TREE, JUMPING A

DlTCH OR NEGOTlATlNG OTHER

OBSTACLES.

Refer to page 23 of this instruction book

for instructions on the unloading of your

shotgun. Never place your shotgun on or

against a fence, tree, car, or other similar

object.

15. WEAR EYE AND EAR PROTECTION

WHEN SHOOTING.

Unprotected, repeated exposure to

gunfire can cause hearing damage. Wear

ear protectors (shooting ear plugs or

muffs) to guard against such damage.

Wear shooting glasses to protect your

eyes from flying particles. Also, wear eye

protection when disassembling and

cleaning your shotgun to prevent the

possibility of springs, spring-tensioned

parts, solvents or other agents from contacting your eyes.

16. DROPPING A LOADED GUN CAN

CAUSE AN ACCIDENTAL DISCHARGE

even with the “safety” in the “on safe”

position. Be extremely careful while

hunting or during any shooting activity,

to avoid dropping any firearm.

17. IF YOUR SHOTGUN FAILS TO FIRE,

KEEP THE MUZZLE POINTED IN A

SAFE DIRECTION.

Hold this position for a minimum of 30

seconds. Carefully open the action and

remove the cartridge. If the primer is

indented, the cartridge should be

7

Page 10

disposed of in a way that cannot cause

harm. If the primer is not indented, your

firearm should be examined by a

qualified gunsmith and the cause of the

malfunction should be corrected before

further use.

18. BE DEFENSIVE AND ON GUARD

AGAINST UNSAFE GUN HANDLING

AROUND YOU AND

OTHERS.

Don't be timid when it comes to gun

safety. If you observe other shooters

violating any of these safety precautions,

politely suggest safer handling practices.

19. BE CERTAIN YOUR SHOTGUN IS

UNLOADED BEFORE CLEANING.

Because so many gun accidents occur

when a firearm is being cleaned, special

and extreme care should be taken to be

sure your gun is unloaded before

8

disassembly, cleaning and reassembly.

Keep ammunition away from the

cleaning location. Never test the

mechanical function of any firearm with

live ammunition.

20. EDUCATE AND SUPERVISE FIREARMS

SAFETY TO ALL MEMBERS OF YOUR

FAMILY- ESPECIALLY TO CHILDREN

AND NONSHOOTERS.

Closely supervise newcomers to the

shooting sports. Encourage enrollment in

hunting/shooting safety courses.

21. NEVER DRINK ALCOHOLIC BEVER-

AGES OR TAKE ANY TYPE OF DRUGS

BEFORE OR DURING SHOOTING.

Your vision and judgment could be

dangerously impaired, making your gun

handling unsafe to you and to others.

Page 11

22. READ AND HEED ALL WARNINGS IN

THIS INSTRUCTION BOOK AND ON

AMMUNITION BOXES.

It is your responsibility to secure the

most up-to-date information on the safe

handling procedures for your Browning

gun. Browning cannot assume any responsibility when unsafe or improper

arms and ammunition combinations are

used.

23. PERIODIC MAINTENANCE-AVOID

UNAUTHORIZED SERVICING.

Your shotgun is a mechanical device

which will not last forever, and as such,

is subject to wear and requires periodic

inspection, adjustment, and service.

Browning firearms should be serviced by

a Browning Recommended Service

Center or by Browning’s service facility

in Arnold, Missouri. Browning cannot

assume any responsibility for injuries

suffered or caused by unauthorized

servicing, alterations or modifications of

Browning firearms.

IT CAN BE VERY DANGEROUS TO

ALTER THE TRIGGER, SAFETY OR

OTHER FIRING MECHANISM PARTS OF

THIS OR ANY OTHER FIREARM.

BE CAREFUL!

9

Page 12

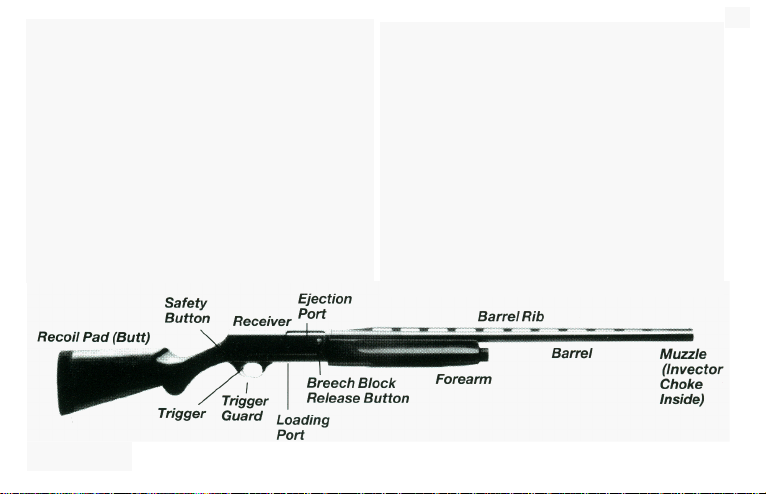

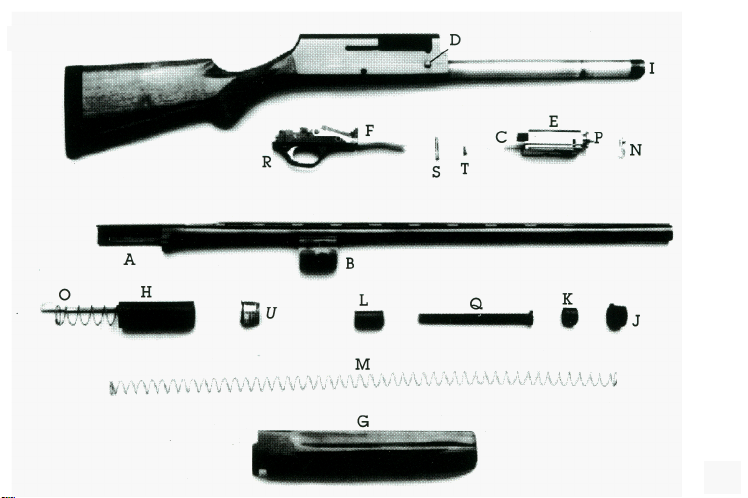

Nomenclature

In conventional gun terminology, the

position and movement of gun parts are

described as they occur with the gun

horizontal and in normal firing position; i.e.,

the muzzle is forward or front; butt stock is

rearward or rear; trigger is downward or

underneath; the rib is upward or on top. For

general parts nomenclature refer to Figure

1-A. See Figure 1-B for names of all parts

and assemblies covered in disassembly and

cleaning procedures.

FIGURE 1-A

10

General Operating Procedures

The Browning A-5OOG shotgun is a gasoperated, semi-automatic shotgun. It is

capable of shooting five shots (with the

magazine plug removed) in rapid succession

with each pull of the trigger. The rotary bolt

locks into the barrel with four lugs. Upon

firing, high pressure gas from the barrel

passes through two ports in the barrel,

through the barrel ring guide and into the

gas cylinder. The high pressure gases force

the gas piston rearward, applying pressure

to the sleeve bar assembly. The special gas

Page 13

FIGURE 1-B

11

Page 14

A. Barrel Extension Guides

B. Barrel Ring Guide/Gas Cylinder

C. Front Action Springs

D. Bolt Release Button (Carrier Latch Button)

E. Breechblock Assembly

F. Carrier

G. Forearm

H. Sleeve Bar Assembly

I. Magazine Tube

J. Magazine Cap

K. Magazine Spring Retainer

pressure regulation valve releases excess gas

pressure that is not necessary for operating

the action. This keeps bolt speed more

consistent and allows you to shoot all

factory 2 3/4" and 3"' loads interchangeably, without adjustment. As the

piston moves the sleeve reward, the action

bar -which extends from the sleeve —

pushes the breechblock rearward, operating

the action. As the breechblock moves

rearward, it turns and unlocks the 4-lug

rotary bolt, recocks the hammer, and ejects

the fired shell.

L. Magazine Follower

M. Magazine Spring

N. Operating Handle

O. Return Spring

P. Rotary Bolt Head

Q. Three Shot Adapter

R. Trigger Group

S. Trigger Guard Retaining Nut

T. Trigger Guard Retaining Screw

U. Gas Piston

After full rearward travel, the breech-block

returns forward, picking up a new shell

from the magazine and chambering it

automatically. After the last shell has been

fired, the breechblock locks to the rear,

instead of returning forward. This facilitates

speedy, convenient reloading.

NOTE: The A-500G is delivered with the

magazine adaptor in the magazine which

limits the gun to three shots, in accordance with federal migratory bird laws. If

you do not want your gun to be so lim-

12

Page 15

ited, merely take out the three shot

adapter as explained on page 34 under

“Three Shot Adapter.”

Initial Cleaning

Various exposed metal parts of your new A-

500 have been coated at the factory with a

rust preventative compound. Before

assembling your A-500G, clean the anti-rust

compound from the inside of the barrel,

receiver and the action/ chamber areas.

Browning Oil is ideal for removing this

compound and for giving your new gun its

first lubrication. However, any quality gun

oil may be used. Use a cleaning rod and

patch as explained under “Cleaning and

Maintenance Suggestions” on page 44.

Serial Number

The serial number of your A-500G shotgun

is found on the left side of the receiver, at

the lower rear, near the grip portion of the

buttstock.

Ammunition

The A-500G has a 3-inch chamber and is

designed to shoot and function with all 12

gauge factory loads: 3-inch Magnum, 2 3/4”

Magnum, 2 3/4” High Velocity loads, 2 3/4”

Field and 2 3/4” Target loads. It is especially

suited to shooting factory steel shot loads.

Loads can be intermixed, in any order.

Browning can assume no responsibility for

incidents which occur through the use of

cartridges of nonstandard dimension or

those developing pressures in excess of

standards established by the Sporting Arms

and Ammunition Manufacturer’s Institute

(SAAMI).

13

Page 16

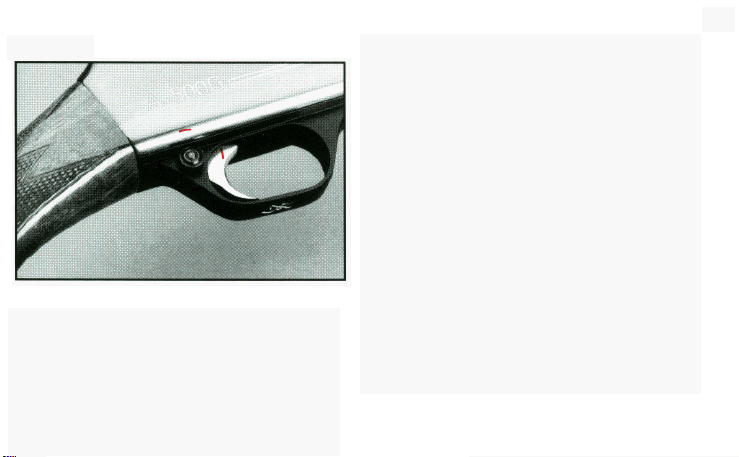

FIGURE 2

Operation of the “Safety”

The cross bolt “safety” prevents the trigger

from being pulled when in the “on safe”

position. The safety is located conveniently

at the rear of the trigger guard (See Figure

2). In the “off safe” or “fire” position a

conspicuous red warning band is visible on

the safety button on the left side of the

trigger guard. To place the gun “ON

SAFE,”

press the “safety” button to the right. To

move the “safety” to the

FIRE position,

press the “safety” to the left.

The safety is reversible and can be reversed

from right- to left-handed by a competent

gunsmith. When installed, the left-handed

“safety” will have the “safety” button’s red

warning band on the

RIGHT side of the

trigger guard.

DO NOT DEPENDON THE RED COLOR

ALONE TO INDICATE YOUR GUN’S SAFETY

STATUS.

Time, exposure to the elements, as well as

the abrasive action of cleaning agents can

erase it.

14

Page 17

As previously explained, never rely on your

shotgun’s mechanical “safety” devices as the

sole provision for safety.

NEVER POINT YOUR SHOTGUN AT ANYTHING YOU DO NOT INTEND TO SHOOT.

Always treat your shotgun, even when

unloaded, with the respect due any loaded,

ready-to-fire firearm.

Assembly of Barrel and Gas

System Components

CHECK YOUR GUN CAREFULLY TO BE

ABSOLUTELY CERTAIN THAT THE

CHAMBER, FEED MECHANISM AND

MAGAZINE CONTAIN NO SHELLS.

The A-500G is delivered, in the box, with

the barrel removed and the forearm-with

the gas piston, sleeve bar assembly and

return spring inside-assembled on the

magazine tube. Perform the following steps

to assemble your A-500G and make it ready

for shooting.

1. Take the receiver in hand. First, lock the

breechblock rearward by pulling the operating handle fully to the rear. Then remove the forearm from the magazine

tube by unscrewing the magazine cap

and sliding the forearm forward, off of

the magazine tube.

DO NOT SQUEEZE HARD ON THE OPEN

REAR END OF THE FOREARM. TOO

MUCH PRESSURE COULD CAUSE THE

WOOD TO SPLIT.

15

Page 18

FIGURE 3

FIGURE 4

2. The gas piston, sleeve bar and return

spring will remain in place and do not

need to be removed, except for cleaning.

If the forearm assembly parts have been

removed, reinstall them as explained below. Otherwise, proceed to step 6.

3. Insert the return spring into the round

hole in the end of the sleeve portion of

the sleeve bar assembly — the end

which has the action bar protruding —

not in the ten sided, decadon-shaped

end (See Figure 3). It is important to

note that the diameter of the spring is

different on each end. The large end is

inserted into the sleeve. The smaller diameter end goes toward the end of the

action bar.

Page 19

FIGURE 5

FIGURE 6

4. Slide the sleeve bar assembly onto the

magazine tube with action bar and return

spring first. Align the end of the action bar

so it rides in the track on the left side of the

receiver (See Figure 4).

5. Insert the gas piston onto the magazine

tube, flanged end first. Slide it down to

the sleeve bar assembly (See Figure 5).

6. With the gun in the horizontal position,

ejection port up, attach the barrel by

sliding the barrel guide ring/gas cylinder

over the magazine tube. You will need

to slide the sleeve bar and return spring

forward about 1/2" toward the end of the

magazine tube in order for the barrel extension rails to fit behind the sleeve and

allow the rails to properly engage in the

receiver tracks (See Figure 6). Do not

17

Page 20

slide it so far forward that the end of the

action bar disengages from the track in

the receiver.

7. When the barrel extension rails are fully

seated in the receiver tracks, position

your shotgun vertically, barrel up. The

barrel extension will usually hang up

slightly where the end of the extension

contacts the face of the rotary bolt, and

at this point is only partly engaged. To

fully seat the extension rails pull rearward on the operating handle (several

times if necessary) until the bolt rotates

slightly and the barrel slips solidly into

position.

8. Replace the forearm onto the magazine

tube by sliding it onto the magazine

tube, over gas piston and the sleeve bar

assembly. Install the magazine cap. Make

sure that the magazine cap is fully tight-

18

ened down. If the magazine cap threads

won’t engage the magazine tube threads

the barrel extension is still not properly

seated. You must repeat step 7 until it

fully engages. Your A-500G is now fully

assembled.

Disassembly of Barrel and Gas

System Components

CHECK YOUR GUN CAREFULLY TO BE

ABSOLUTELY CERTAIN THAT THE CHAM-

BER, FEED MECHANISM AND MAGAZINE

CONTAIN NO SHELLS.

Disassembly of the barrel from the receiver

is important for cleaning and is also a

convenient way to store your A-500G.

1. Unscrew the magazine cap.

2. Remove the forearm by sliding it forward

on the magazine tube.

Page 21

3. For cleaning, remove the gas piston and

sleeve bar assembly by sliding them forward off of the magazine tube. It is not

necessary to disassemble any part of the

gas pressure regulation valve. See

“Cleaning and Maintenance Suggestions”

on page 44 for suggested cleaning procedures.

If you are disassembling for storage, return the sleeve bar assembly and the gas

piston onto the magazine tube as shown

previously in Figure 6. Reinstall the forearm over the magazine tube and screw

on the magazine cap. You will then have

two compact units: the barrel, and the

action with forearm and stock.

CAUTION: AFTER THE BARREL HAS

BEEN REMOVED FROM YOUR GUN,

LEAVE THE BREECHBLOCK IN THE

OPEN POSITION. DO NOT PRESS

THE BOLT RELEASE BUTTON,

If the breechblock is released forward

with the barrel removed, the operating

handle will be driven against the edge of

the ejection port, which will cause damage to the receiver.

Loading Procedures

There are two basic methods for initially

getting a loaded shell into the chamber of

your A-500G.

CAUTION: AT ALL TIMES DURING THE

LOADING PROCEDURE, BE SURE YOUR

MUZZLE IS POINTING IN A SAFE DIREC-

TION AND THE “SAFETY” IS IN THE “ON

SAFE” POSITION. REMEMBER: DO NOT

PUT A 20 GAUGE OR 3 1/2” MAGNUM

SHELL IN YOUR A-500G 12 GAUGE

SHOTGUN. NEVER STORE SHELLS OF

MIXED GAUGES IN A COMMON CON-

TAINER OR IN YOUR POCKETS.

19

Page 22

See caution number 8 on page 5 of this

booklet for an explanation.

CAUTION: WHENEVER A SHELL HAS

BEEN CYCL ED INTO THE CHAMBER—

DURING LOADING OR ANY OTHER

TIME, AUTOMATICALLY OR MANUALLY- THE SHOTGUN IS READY TO

FIRE BY SIMPLY MOVING THE

“SAFETY” TO THE OFF SAFE POSI-

TION.

METHOD ONE: LOADING THE CHAMBER

THROUGH THE EJECTION PORT —

1. After making sure the “safety” is “on

safe,” pull the operating handle to the

rear until the breechblock locks in the

open position.

20

FIGURE 7

VISUALLY INSPECT THE CHAMBER,

CARRIER, AND MAGAZlNE TO MAKE

SURE THEY ARE CLEAR OF ANY OBSTRUCTIONS.

2. While pointing the muzzle in a safe direction, hold your A-500G with the ejection port up, and insert a cartridge of the

Page 23

proper gauge through the ejection port

into the open breech (See Figure 7).

Press the breechblock release button.

KEEP YOUR FINGERS CLEAROFTHE

EJECTION PORT.

This will automatically cause the shell to

be picked up and delivered to the chamber correctly. The chamber is now

loaded.

3. With the chamber loaded, load the

magazine to full capacity as explained

below under “Loading the Magazine.”

METHOD TWO: LOADING THE CHAMBER

MANUALLY FROM THE MAGAZINE —

1. Make sure the muzzle is pointed in a

safe direction and the “safety” is in the

“on safe” position.

2. To load the magazine, follow the instructions under “Loading the Magazine”

listed below. With the magazine loaded,

and the breechblock closed, merely pull

back on the operating handle, fully to

the rear, and release it, allowing the

breechblock to close. This will automatically cycle a shell from the magazine to

the chamber.

3. To again load the magazine to full capacity, thumb another shell into the

magazine as explained below under

“Loading the Magazine.”

LOADING THE MAGAZINE —

1. MAKE SURE THE MUZZLE IS POINTED

IN A SAFE DIRECTION AND THE

“SAFETY” IS IN THE “ON SAFE” POSITION.

Close the breechblock by pressing the

2.

breechblock release button (as explained

above).

21

Page 24

FIGURE 8

22

sure the rim of the shell engages the carrier latch and is held fully inside the

magazine tube. It will make an audible

click when fully inserted. Repeat this

procedure until the magazine is fully

loaded.

CAUTION: WHENEVER A SHELL HAS

BEEN CYCLED INTO THE CHAMBER-

AUTOMA TICAL L Y OR MANUAL L Y—

THE SHOTGUN IS READY TO FIRE BY

SIMPLY MOVING THE "SAFETY" TO

THE OFF SAFE POSITION.

MAKE SURE YOUR FINGERS ARE

CLEAR OF THE EJECTION PORT.

3. Insert a shell, of the proper gauge,

through the loading port at the bottom of

the receiver, up into the magazine, using

your thumb to position it fully forward in

the magazine tube (See Figure 8). Make

MAGAZINE CAPACITY —

With the three shot adapter installed, the

magazine will hold TWO 2 3/4" or 3-inch

shells. With the three shot adapter removed, the magazine holds FOUR 2 3/4"

or THREE 3-inch shells.

Page 25

Unloading your A-500G

CAUTION: WHENEVERUNLOADING, ALWAYS BECERTAIN THAT THE MUZZLE IS

POINTED IN A SAFE DIRECTION AND

THAT THE “SAFETY” IS IN THE “ON

SA FE” POSITlON.

1. One way to unload the A-500G is simply to grasp the operating handle and

cycle the action until all rounds are

ejected.

2. The magazine can also be unloaded

manually by reaching inside the loading

port with your index finger, and simultaneously pressing in on the bottom of the

carrier and pressing the carrier latch

(See Figure 18 on page 36). Release and

remove one shell at a time from the

magazine, until empty. Remove the shell

from the chamber by cycling the action.

ALWAYS INSPECT THE CHAMBER,

ACTION, CARRIER AND MAGAZINE

VERY CAREFULLY AFTER UNLOADING TO BE SURE ALL LIVE ROUNDS

ARE CLEARED FROM THE GUN.

Breech Remains Open After

the Last Shot

The breech of the A-500G remains open,

with the breechblock locked to the rear,

after the last shot has been fired. This allows

convenient and fast reloading as follows:

1. Place the “safety” in the “on safe” position.

2. Drop an appropriate shell into the open

breech.

3. Close the action by depressing the

breechblock release button.

23

Page 26

BROWNING A-500G GAS OPERATED SEMI-AUTOMATIC SHOTGUN

Schematic is provided for parts identification

only and should not be used as a guide to

assemble guns.

IMPORTANT: When ordering parts, list part

number, part name, caliber, model and serial

number.

CAUTION: Browning parts are made

exclusively for Browning guns and are not

recommended for use in other guns even

though models may be similar. Inadequately

fitted parts may be dangerous

24

25

Page 27

PARTS LIST A-500G SEMI-AUTOMATIC SHOTGUN

KEY BROWNING DESCRIPTION

NO. PART NO.

1 P014001

2 P014006

3 P014007

4 P014012

5 P014016 Action Spring Rear (2) 34 P014178 Firing Pin 61 P014350 Stock Screw

*6 P014030 Bolt Assembly 35 P014182 Firing Pin Cover 62 P014354 Stock Screw Lock

7 P014034 Boll Cam Pin 36 P014186 Firing Pin Spring Washer

*8 P014044 Breech Block 37 P014190 Firing Pin Stop Pin 63 P014358 Stock Screw Washer

*9 P014048 Breech Block Buffer 38 P014210 Front Sight *64 P014364 Trigger

*10 P014052 Breech Block Buffer *39 P014215 Hammer 65 P014370 Trigger Guard

*11 P014056 Breech Block Lever 41 P014225 Magazine Cap 66 P014375 Trigger Guard Pin

12 *P014060 Breech Block Lever Pin 42 P014230 Magazine Cap Sleeve

13 P014065 Breech Block Lever Retainer 67 P014385 Trigger Guard Screw &

14 P014076 Butt Stock

*15 P014084 Carrier 44 P014240 Magazine Cutoff & Pin 69 P014395 Trigger Spring

*16 P014069 Carrier Dog 45 P014248 Magazine Cutoff 70 P014420 Barrel Extension

17 P014095 Carrier Dog Pin Plunger Assembly 71 P014404 Magazine Tube

*18 P014101 Carrier & Car Dog 46 P014262 Magazine Follower **71 P014415 Receiver

19 P014105 Carrier Pin 48 P014274 Magazine Spring 73 P014424 Sleeve Bar

20 P014110 Carrier Pin Circlip Retainer 74 P014426 Intermediate Tube

*21 P014115 Carrier Latch 49 P014280 Magazine 3-Shot 75 P014428 Rear Piston

22 P014120 Carrier Latch Spring Adapter A-500 76 P014429 Front Piston

*23 P014125 Cartridge Stop 50 P014286 Mainspring 77 P014430 Regulation Valve

24 P014130 Cartridge Stop & 51 P014290 Mainspring Guide 78 P014432 Regulation Spring

25 P014134 Cartridge Stop & Pin 53 P014302 Operating Handle 80 P014436 Locking Ring

26 P014138 Cartridge Stop Spring *55 P014320 Safety 82 P014496 Forearm

*27 P014144 Disconnector

28 P014148

Action Spring Front (2)

Action Spring Guide (2)

Action Spring Guide Pin

Action Spring Guide

Washer 33 P014172 Extractor Pin 60 P014344 Sear Pin

Core 40 P014220 Hammer Pin Assembly

Spring

Spring 47 P014268 Magazine Spring 72 P014422 Return Spring

Carrier Latch Pin 52 P014294 Mainspring Guide Pin 79 P014434 Centering Washer

Clip 54 P208466 Recoil Pad 81 P014470 Bearing Ring

Disconnector Pin

KEY BROWNING DESCRIPTION

NO. PARTNO.

29 P014155

30 P014160

31 P014164

32 P014168

43 P014234 Magazine Cap With Nut Assembly

* Indicates pan must be fitted by Browning Service Department or by a Browning Recommended Service Center

**Pan may be purchased by holders of current. valid Federal Firearms License

Ejector *56 P014324

Extractor 57 P014328

Extractor Inner Spring 58 P014332

Extractor Outer Spring *59 P014340

Eyelet 68 P014390 Trigger Pin

KEY BROWNING DESCRIPTION

NO. PARTNO.

Safety Plunger

Safety Plunger Spring

Safety Spring Stop Pin

Sear

26

Page 28

Load the magazine as explained above

4.

under “Loading the Magazine” on page

23.

EVEN WITH THE BREECH LOCKED

OPEN AFTER SHOOTING, DO NOT ASSUME YOUR SHOTGUN IS UNLOADED.

ALWAYS INSPECT THE CHAMBER,

CARRIER AND MAGAZINE TUBE TO BE

SURE THEY CONTAIN NO CAR-

TRIDGES. THEN, REMEMBER TO ALWAYS TREAT ANY GUN AS IF IT WAS

LOADED. ALWAYS HANDLE YOUR

SHOTGUN WITH CAUTION.

Operation of the Magazine Cut-off

The magazine cut-off lever is located at the

front end of the left side of the receiver.

This cut-off has the purpose of locking the

shells in the magazine so that they will not

feed into the chamber. This permits you to

quickly change the load in the chamber of

the gun without going to the trouble of un-

FIGURE 9-A

loading the whole magazine. For instance,

in this way a duck load can quickly be

taken out and a goose load inserted, if the

need arises. To operate the magazine cutoff, merely manipulate the lever to the

“MC” or “R” positions. The “MC” position

engages the magazine cutoff (See Figure 9A). The “R position (See Figure 9-B) places

the magazine in conventional repeater posi-

FIGURE 9-B

27

Page 29

tion, chambering a shell from the magazine

each time the breechblock cycles rearward

(as when you shoot or manually cycle the

breechblock). Also, with the magazine cutoff in operation, and with the chamber

empty and the breechblock locked in the

rearward position, a loaded shell may be instantly delivered from the magazine to the

chamber by merely moving the lever from

the “MC” position (magazine cut-off), to the

“R” (repeater) position. When the breechblock is locked rearward,

BECAREFUL TO KEEP YOUR FINGERS

CLEAR OF THE LOADING PORT AND

EJECTION PORT WHEN MOVING THE

LEVER FROM “MC” TO “R”.

28

Full Disassembly:

Trigger Group and Breechblock

It is not necessary or recommended that the

trigger group or breechblock be removed

except if a malfunction occurs, or if the

action becomes excessively dirty or wet. If

this occurs, disassemble the action for a

complete cleaning as explained below.

Detailed cleaning procedures are outlined

under “Cleaning and Maintenance” on page

44. Full disassembly involves removal of the

breechblock assembly and the trigger group.

Any disassembly beyond this should only be

performed by a competent gunsmith.

ALWAYS WEAR EYE PROTECTION WHEN

PERFORMING ANY MAINTENANCE OR

DISASSEMBLY.

Page 30

REMOVING THE TRIGGER GROUP —

You will need two medium blade screw-

drivers to remove the trigger guard retaining

screws (the trigger guard retaining nut and

the trigger guard retaining screw). Make

sure the screwdrivers are of appropriate size

to prevent damage to the slotted heads. No

other tools are necessary.

1. Remove the barrel as explained under

“Disassembly’ on page 18. Set the forearm, as well as the forearm buffer and

spring, aside.

2. Release the breechblock to its forward

position as follows: While holding the

operating handle back (by applying rearward pressure) depress the breechblock

release button. Allow the breechblock to

travel slowly forward, controlling and

slowing its forward travel until it is fully

forward. The head of the rotary bolt

FIGURE 10

should project about 1/2” from the front

of the receiver.

3. Insert a screwdriver into the retaining nut

slot and the other screwdriver into the

retaining screw slot. Hold one side from

turning while unscrewing the opposite

side (See Figure 10).

29

Page 31

FIGURE 11

30

FIGURE 12-A FIGURE 12-B

4. Remove the retaining nut and screw

from the receiver.

5. With the gun inverted (trigger guard up),

grasp the trigger guard and pull it up,

forward and out from the receiver (See

Figure 11).

DO NOT DISASSEMBLE THE TRIGGER

GROUP BEYOND THIS POINT.

Perform all cleaning with the trigger

group kept intact as an assembly.

REMOVING THE BREECHBLOCK —

Normal procedure is to remove the barrel

and trigger group first, as explained

previously.

1. Remove the operating handle as follows:

Page 32

FIGURE 13

With your left hand, push on the bolt

head moving the breechblock about 1/2"

back into the receiver, lining up the operating handle with the notch at the bottom front of the ejection port (See Figure

12-A). With your right hand grasp the

operating handle and pull it outward,

removing it from the breechblock (See

Figure 12-B).

2. The breechblock will now be able to

move forward about another 1/2”. Again,

push rearward on the bolt head, depressing the breechblock back into the receiver about 1/4". With your right hand,

reach in with a finger and push on the

breechblock lever found on the bottom

side of the breech block (See Figure 13).

The breechblock lever serves to retain

the breechblock in the receiver.

SPEClAL NOTE: It is possible to remove

the breechblock first before removing

the trigger group. You will need to

simultaneously push rearward 1/4" on

the breechblock and "reach" in through

the opening at the front of the carrier to

depress the breechblock lever, using the

eraser end of a pencil, a small wood

dowel, a screwdriver, or other similar

object.)

31

Page 33

FIGURE 14

32

FIGURE 15

3. With the breechblock lever pressed, remove the breechblock, forward, out of

the front of the receiver. The action

springs will stay attached to the breechblock, projecting from the rear. The

breechblock is now fully removed.

DO NOT DISASSEMBLE THE

BLOCK BEYOND THIS POINT.

BREECH

Reassembly:

Trigger Group and Breechblock

REINSTALLING THE BREECHBLOCK

ASSEMBLY —

1. Insert the breechblock into the receiver

opening, action springs first. The guides

Page 34

on the breechblock must fit in the receiver tracks. Make sure the front action

springs fit over the ends of the action

spring guides (See Figure 14). Push the

breechblock in far enough so that the

breechblock lever engages, holding the

breechblock in the receiver. Simultaneously push back on the breechblock

while depressing the breechblock release button until the notch in the ejection port lines up with the operating

handle recess on the breechblock. Make

sure that the action springs are compressed inside the recesses in the

breechblock, and that the ends of the action spring guides start into the recesses

in the breechblock without kinking the

front action springs.

2. Insert the operating handle into the recess (Refer to Figure 12-B). The breechblock is now installed.

REINSTALLING THE TRIGGER GROUP —

1. Reinsert the trigger group into the bottom of the receiver, moving it rearward

to assure correct location of the rear pins

into the holes in the receiver. Then start

at the back and hinge the trigger guard

forward (See Figure 15).

2. Line up the hole in the trigger guard

with the holes on each side of the re-

ceiver. Insert the trigger guard retaining

nut completely through the receiver.

Start the retaining screw with your fin-

gers and tighten using two screwdrivers,

one for each slotted head on each side

of the receiver.

33

Page 35

Three-Shot Magazine Adapter

The A-500G shotgun is delivered with the

three-shot magazine adapter installed in the

magazine, limiting magazine capacity to two

shells — allowing three shots total in

compliance with federal migratory bird

regulations. If you do not wish to be limited

to three shots — when it is not required by

law — you can remove or reinstall the

three-shot adapter (plug) as follows:

ALWAYS WEAR PROTECTIVE SAFETY

GLASSES DURING THIS OPERATION.

1. Unscrew the forearm cap and remove

the forearm, BARREL, gas piston,

sleeve bar assembly, and return spring

from the gun as explained under “Disassembly of Barrel and Forearm Assembly”

on page 18.

UNDER NO CIRCUMSTANCES SHOULD

YOU PERFORM THE FOLLOWING

PROCEDURES WITH THE BARREL AT-

TACHED.

2. Reinstall the magazine cap on the magazine tube approximately one turn, engaging at least ONE FULL TURN Of

THREADS solidly.

3. Release the breechblock forward slowly

by pressing the breechblock release button and slowly allowing the breechblock

to travel forward. Do this

the button with one hand and offering

resistance on the operating handle with

the other hand, gently easing it forward

to the fully forward position.

4. Pull back approximately 1/4” of an inch

on the operating handle. With your other

hand: insert two 2 3/4” (or two 3-inch

magnum shells) into the magazine if you

by pressing

34

Page 36

are it removing the three-shot adapter

OR insert four 2 3/4" shells (or three 3inch magnums) if the three-shot adapter

was removed previously and you are it

reinstalling it. Position an additional

shells as if you were going to insert it

into the magazine (it will stop only partially inserted because of the full magazine).

5. Apply steady, hard pressure on the shell,

pushing all the shells forward in the

magazine until the magazine spring retainer is dislodged from its compressed

fitting at the end of the magazine (See

Figure 16). You will feel forward movement of the shells in the magazine when

it is dislodged.

IF IT WILL NOT DISLODGE WITH

STEADY PRESSURE you may have to

work the last shell in and out to increase

FIGURE 16

force on the shells in the magazine. If

this also fails to dislodge the magazine

spring retainer, place another shell behind the one partially inserted and apply

increased pressure with the palm of

your hand, or strike the back of the last

shell with the palm of your hand until

35

Page 37

FIGURE 17

36

FIGURE 18

the retainer is dislodged (See Figure 17).

DO NOTUSEANYOTHER OBJECT

THAN THE PALM OFYOURHANDTO

APPLY PRESSURE TO THE LAST

SHELL

6. With the retainer dislodged,

IMMEDIATELY REMOVE THESHELLS

FROM THE MAGAZINE. DO NOT UN-

SCREW THE MAGAZINE CAP WITH

SHELLS IN THE MAGAZINE.

Remove the shells as follows: first, hold

the operating handle back approximately

1/4". Then release the shells from the

magazine by reaching inside the loading

port and simultaneously pressing in on

the bottom of the carrier and pressing

Page 38

FIGURE 19

the carrier latch with your finger (See

Figure 18). Release and remove one shell

at a time from the magazine.

IMMEDIATELY PUT ALL THESHELLS

AWAY IN YOUR AMMUNITION STOR

AGE AREA—AWAY FROM YOUR

A-500G AND OTHER GUNS.

7. Carefully unscrew the magazine cap

from the magazine.

CAUTION: THE MAGAZINE SPRING IS

UNDER TENSION AND WILL FORCE

OUT THE RETAINER, THREESHOT

ADAPTER, AND THE SPRING ITSELF

UNLESS CARE IS TAKEN.

Slowly lift the magazine cap off of the

magazine. At the same time, catch the

spring with your other hand as it begins

to come out (See Figure 19). If already

installed, the three shot adapter will be

on top of the magazine spring.

8. Remove the spring and adapter, if pres

ent, from the magazine tube. Remove the

magazine spring retainer from the inside

-

of the magazine cap. The magazine fol

lower can be removed by pointing the

magazine tube downward and dumping

it out.

-

-

37

Page 39

REASSEMBLY WITH THE THREE-SHOT

MAGAZINE ADAPTER INSTALLED.

To reassemble the magazine with the three-

shot adapter installed, first, position the gun

vertically, butt down. Then reinstall the

magazine follower in the magazine tube,

closed end first. Place the three-shot adapter

inside one end of the magazine spring,

small end first. Place the magazine spring

retainer over the top of the adapter. Insert

the other end of the magazine spring into

the magazine tube and compress it into the

magazine tube (See Figure 20). With hand

pressure, seat the magazine spring retainer

fully into the compression fitting on the end

of the magazine tube.

REASSEMBLY WITHOUT THE THREESHOT MAGAZINE ADAPTER.

Reassembly of the magazine without the

three-shot adapter is identical to reassembly

with the three shot adapter, with one

38

FIGURE 20

exception: after inserting the magazine

follower into the magazine tube, place the

magazine spring retainer directly on the end

of the magazine spring. Then insert the

other end of the magazine spring into the

magazine tube and compress it into the

magazine tube. With hand pressure, seat the

magazine spring retainer fully into the

Page 40

compression fitting on the end of the

magazine tube. Reassembly of the

magazine, and removal/installation of the

three-shot magazine adapter is now

completed. To prepare for replacing the

barrel and forearm on your A-500G, pull the

operating handle on the breech-block fully

rearward, locking the breechblock back.

You are now ready to reinstall the barrel/

forearm assembly to the receiver as outlined

in “Assembly of Barrel and Gas System

Components” on page 18.

Invector Interchangeable

Choke System

All A-500G shotgun barrels have been

threaded to accept the Browning Standard

Invector Interchangeable Choke System.

You may confirm this by looking on the

right side of your barrel where the

specifications are inscribed, and where the

choke markings are normally located. The

word INVECTOR denotes that the barrels

are threaded. The degree of choke tube is

indicated twice on each choke tube:

Inscribed on the side of the tube, and

indicated with a “notch” code on the top

rim of the tube. Invector Choke Tubes are

made with tempered steel and are fully

compatible with all FACTORY

AMMUNITION (loaded in compliance with

SAAMI specifications) including Magnum

lead and steel shot loads and rifled slug

loads.

DONOTFIRE THIS SHOTGUN WITHOUT

HAVING AN INVECTOR CHOKE TUBE IN-

STALLED.

Permanent damage may result to the

threads.

DO NOT USE BROWNING INVECTOR

CHOKE TUBES IN ANY SHOTGUN BARRELS NOT SUPPLIED BY BROWNING.

ALSO, DO NOT USE ANY OTHER CHOKING DEVICE IN ANY SHOTGUN BARREL

SUPPLIED BY BROWNING. USE ONLY

CHOKE TUBES MARKED INVECTOR.

39

Page 41

CAUTION: WHENEVER HANDLING ANY

SHOTGUN FOR THE PURPOSE OF REMOVING OR INSTALLING A CHOKING DEVICE, MAKE ABSOLUTELY CERTAIN THE

GUN IS FULLY UNLOADED, AND THE

BOLT OR BREECH IS LOCKED OPEN!

NEVER ATTEMPT TO REMOVE OR INSTALL A SHOTGUN CHOKING DEVICE ON

A LOADED FIREARM!

TUBE REMOVAL-

1. UNLOAD YOUR A-500G FULLY, INSPECT THE CHAMBER, FEED MECHANISM AND MAGAZINE TO MAKE

THEY DO NOT CONTAIN ANY SHELLS.

2. Open the action, locking it rearward, and

place the “safety” in the “on safe” position.

3. Use the Invector wrench to loosen the

tube, turning it counterclockwise. Fingertwist the tube the rest of the way out of

the barrel.

SURE

40

TUBE INSTALLATION-

1. UNLOAD YOUR A-500G FULLY. INSPECT THE CHAMBER, FEED MECHANISM AND MAGAZINE TO MAKE SURE

THEY DO NOT CONTAIN ANY SHELLS.

2. Open the action locking it rearward and

place the “safety” in the “on safe” position.

3. Before installing a tube, check the internal choke tube threads in the muzzle, as

well as the threads on the Invector

choke tube to be sure they are clean.

Lightly oil the threads with an oil like

Browning Oil.

4. Using your fingers, screw the appropriate

tube into the muzzle end of the barrel,

tapered end first, notched end outward.

When it becomes finger-tight, use the Invector choke wrench to firmly seat the

tube.

Page 42

THEINVECTOR CHOKE TUBESHOULD

BE PERIODICALLY CHECKED TO ASSURE THAT IT IS TIGHT AND FIRMLY

SEATED. BEFORE CHECKING, FOLLO W THE SAFETY GUIDELINES OUTLINED ABOVE.

Replacement and additional tubes and

wrenches are available from your Browning

dealer, or by writing to the

Browning Consumer Department, Route 1,

Morgan, Utah 84050. (801) 876-271 1.

Canadian customers please call or write to

Browning Canada Sports Ltd./Ltee,

3167 De Miniac, St. Laurent, Canada H4S 1 W6.

(514) 333-7261.

INVECTOR CHOKE TUBE CODE —

To identify individual Invector tubes, refer

to the abbreviated indications on the side

of the tube, or use the identification mark(s)

located on the top rim of each tube (See

Figure 21).

INVECTOR TUBE SELECTION

To help you choose the correct choke tube

for each hunting situation, all Browning

Invector choke tubes are inscribed on the

side with the patterns they produce with

both lead and steel shot. Each Invector tube

also has notches in the top rim of the tube.

These notches are a code to allow you to

determine the choke designation while the

tube is installed. Rim notches refer

specifically to lead shot. You will need to

use the chart below to cross-reference from

lead to steel, and determine the appropriate

tubes for your ammunition and hunting/

shooting situation.

Several tubes are supplied with your

Browning shotgun. The tubes listed are also

available as accessories. Remember,

Invector-Plus and standard Invector tubes

are not interchangeable. Invector-Plus tubes

41

Page 43

FIGURE 21

are for Browning guns with back-bored

barrels and are not for use on your A-500G.

Before removing/installing tubes, or reading

the rim notch code, make sure your shotgun

is fully unloaded.

Rim

Notches

I

II

III

IIII

IIIII

No Notches

Knurled Ext

*Not for use with steel shot Using an over-tight choke

constriction with steelshot will result in an ineffective, "blown"

pattern.

**Extra Full Special with knurled rim and no rim code. Do not

use with steel shot.

***When more than one choke designation is listed for a given

steel shot pattern, use the more open choke listed for high

velocity, larger shot size steel shot loads

Pattern With

Lead Shot

Full

Imp. Modified

Modified

Imp. Cylinder

Skeet

Cylinder

X-Full Special

Pattern With

Steel Shot

*

Full***

Full***

Modified

Imp. Cylinder**

Imp. Cylinder ***

**

CAUTION: DO NOT USE STANDARD IN-

VECTOR CHOKE TUBES IN BARRELS

MARKED

INVECTOR-PLUS.

DO NOT USE

INVECTOR-PLUS CHOKE TUBES IN BARRELS MARKED INVECTOR. FAILURE TO

FOLLOW ALL OF THE ABOVE WARNINGS

CAN DAMAGE YOUR GUN AND CAUSE

INJURY TO YOURSELF AND OTHERS.

Page 44

Use of Extra Barrels

On all Browning A-500G shotguns, barrels

of the same gauge are completely

interchangeable, and no special fitting is

required. Thus, by merely buying another

barrel of a different length, or for a different

purpose (such as a Buck Special barrel),

and using the appropriate Invector choke

tube, you have acquired the utility of

another gun at a fraction of the cost of a

new gun; a duck gun becomes a fine

upland game gun, a pheasant gun becomes

a rifled slug deer gun.

Sight Adjustment for Buck Special

Barrels

Buck Special barrels are equipped with a

precision rear sight which is screw

adjustable for both horizontal and vertical

correction.

WINDAGE ADJUSTMENT —

To move point of impact to the RIGHT,

loosen the small screw on the right side of

the sight. Then tighten the small screw on

the left side of the sight. To move point of

impact to the LEFT loosen the small screw

on the left side of the sight and tighten the

screw on the right side. This is a process of

trial and error. Make small adjustments then

check the point of impact.

VERTICAL ADJUSTMENT —

Adjustment of the sight is controlled by the

screw located on top of the sight. To RAISE

the point of impact, turn the screw in a

counterclockwise direction. To LOWER the

point of impact, turn the screw in a

clockwise direction. Vertical adjustment is

also a process of trial and error.

43

Page 45

Cleaning and Maintenance

Suggestions

You should clean your A-500G whenever it

becomes excessively dirty — and perform a

thorough cleaning at least once a year. The

barrel should be cleaned, and the action

wiped clean and oiled after every day of

shooting. The gas system should require

only occasional cleaning. If a malfunction

occurs, perform a thorough cleaning, to see

if it solves the problem, before seeking the

services of a Browning Recommended

Service Center, the Browning Service Facility

in Arnold, Missouri, or a competent

gunsmith.

Normal maintenance can be accomplished

with the barrel still attached to the receiver

(oiling and wiping down). More careful

cleaning requires removal of only the barrel

from the receiver (cleaning the barrel), and

the removal of several gas system

FIGURE 22

44

components. A complete cleaning requires

removal of the breechblock and trigger

group.

PERIODIC OILING —

Ordinary good judgment will indicate that

the metal parts of the gun should receive a

light film of oil after the gun has been

exposed to weather or handling.

Occasionally, a small drop of oil may be

Page 46

placed on the end of the action bar where it

slides along the track in the receiver (See

Figure 22). This will help to relieve friction

and ensure smooth operation.

Also, lightly lubricate the breechblock,

rotary bolt and spring guides. If the gun has

been exposed to much dust, dirt, mud or

water, the principal working parts including

the gas system, should be wiped clean and

lubricated with a light film of oil. Browning

Oil is recommended.

DO NOT POUR LARGE QUANTlTlES OF

OIL INTO THEACTION. A LARGE EXCESS

OF OIL WILL RUN BACK INTO THE WOOD

OFTHESTOCKAND CAUSE SOFTENING

OFTHE WOOD, WITH CONSEQUENTIAL

LOOSENING OFTHE STOCK.

CLEANING THE BARREL —

The correct procedure for cleaning your

A-500 shotgun is as follows:

1. BE CERTAIN YOUR SHOTGUNS MAGAZINE, FEED MECHANISM AND CHAMBER ARE UNLOADED. PLACE THE

“SAFETY” IN THE “ON SAFE” POSI-

TlON AND LOCK THE BOLT ON THE

REAR. ALWAYS WEAR PROTECTIVE

SAFETY GLASSES DURING ALL DISASSEMBLY AND CLEANING PROCEDURES.

2. Remove the barrel so that it can be

cleaned from the breech end (See “Disassembly” on page 18).

3. Using a shotgun cleaning rod with tip

and patch large enough for a snug fit in

the bore, insert the rod and patch in the

breech end of the barrel and run back

and forth through the bore several times.

Remove and wipe the Invector tube,

tube threads and barrel threads, and

lightly oil.

45

Page 47

4. Inspect the bore from both ends for

leading by looking through bore toward

light. Leading will appear as dull longitudinal streaks and is usually more predominant near the muzzle and just forward of the chamber.

5. A normal amount of leading can be expected with today’s high velocity loads

and improved wads but this is not serious. If or when leading should become

heavy, it can be removed with a brass

bore brush. Make sure a choke tube is

installed. Spray the bore or the bore

brush with a good powder solvent, and

scrub the bore until leading is removed.

To prevent brass bristles from breaking

off, the brush should be pushed completely through the bore before being

withdrawn.

6. After leading has been removed, the

bore should be wiped dry with a clean

patch, and then a lightly oiled patch run

through it for preservation.

46

FIGURE 23

CLEANING THE GAS SYSTEM —

1. Remove the gas piston, sleeve bar assembly and return spring from the magazine tube. Spray the tube with Browning

oil (or a good quality powder solvent)

and wipe clean. Remove the return

spring from the sleeve and wipe clean.

Spray the inside of the sleeve and wipe

off of any buildup.

Page 48

To clean the gas system, first spray the

2.

gas piston with a good powder solvent

and brush it thoroughly to remove any

deposits (an old toothbrush is ideal for

this). Spray into the gap between the inner and outer portions of the piston.

3. Clean the gas regulation valve system (it

is located inside the barrel ring guide/gas

cylinder) by spraying it with a aerosol

Browning Oil or a good powder solvent,

and brushing any deposits free (See Figure 23). NEVER use a steel brush on any

of the gas components.

Pay special attention to the gas pressure

vents (two large holes on opposite sides

of the barrel ring guide/gas cylinder),

and the two gas ports (seen inside the

gas cylinder at the top, when viewed

from the breech end). Spray again to

wash away the loosened deposits and

wipe clean. A NONFLAMMABLE sol-

vent bath can be used to immerse the

parts, but it is not necessary.

CAUTION: NEVER DISASSEMBLE THE

GAS

The parts are under spring tension and

require special tools for removal. It is not

necessary to remove the gas pressure

regulation valve assembly (from its location inside of the barrel ring guide/gas

cylinder) to perform cleaning. You

should note that all gas system parts on

the A-500G have been given extra protection against corrosion: the magazine

tube is chrome-plated, and all other gas

system parts, including the piston,

springs, barrel guide ring and gas regulation valve, are made from stainless steel.

4. Complete the cleaning of the gas system

by applying a very light film of Brown-

ing Oil to all parts for protection and lu-

brication.

CYLINDER.

47

Page 49

CLEANING THE ACTION AND TRIGGER

GROUP —

1. When the action becomes excessively

dirty, remove the trigger group and

breechblock assembly from the receiver

as explained under “Full Disassembly”

on page 28. Clean with an oil such as

Browning Oil or a gun solvent as necessary, using an old toothbrush to loosen

any caked-on grime. Wipe the receiver

cavity clean. Lightly oil the cavity (aerosol Browning Oil is ideal) and wipe it

dry. No further disassembly is required

for cleaning.

2. Reassemble the trigger group,

breechblock, gas system and the barrel to

the receiver as explained previously.

Then wipe all exposed metal surfaces

with an oiled cloth making sure to wipe

your A-500G clean of all finger marks

where moisture will accumulate.

3. The barrel and action should be in-

48

spected to assure that all cleaning

patches have been removed and not inadvertently left in the barrel or action.

4. The wood surfaces can also be wiped

with Browning Oil or they can be pol-

ished with any quality furniture wax (but

not both).

DO NOT TAKE YOUR GUN’S ACTION

APART BEYOND THE EXTENT EXPLAINED IN THIS MANUAL.

This is a specialized, finely fitted mecha-

nism, and you may mar it for life by an

attempt to disassemble the inner mecha-

nism assemblies. Do not disassemble the

breechblock, gas system or trigger group

more than described. If further disassembly is required, take your gun to a

Browning Recommended Service Center

or a competent gunsmith.

Page 50

Service or Repair

If your firearm should require service or repairs, we suggest you first contact a local

recommended Browning Firearms Service

Center. Contact your Browning sporting

goods dealer or call our Service Department for the address of the Service Center

nearest you. Otherwise, you may send

your firearm directly to our own Service

Department. For technical questions about

your firearm or service call our Service

Department.

Browning Service Department

3005 Arnold Tenbrook Road

Arnold, Missouri 63010-9406

Phone: 1-800-322-4626

Canadian Customers call or write:

Browning Canada Sports Ltd./Ltee,

561 7 Chemin St-Francois

St-Laurent, Quebec H4S 1 W6

Phone: (514) 333-7261

When returning your firearm for servicing,

you must do the following:

a. Be sure it is completely unloaded.

b. Package it securely in a cardboard

container.

c. Enclose a letter with your firearm

that clearly describes the trouble

experienced and the repairs or

alterations desired.

d. If convenient, send a copy of the

letter to us separately.

e. Never return ammunition with your

firearm. It is against postal and most

commerce regulations.

If you have any questions about this

manual or about any other Browning

products, call or write our Consumer

Information Department:

Browning Consumer Information

Morgan, Utah 84050

Phone: (801) 876-2711

Page 51

You Are Responsible For Firearms Safety.

As a gun owner, you accept a set of demanding responsibilities. How seriously you take these

responsibilities can mean the difference between life and death. Failure to follow any of these

instructions can cause extensive damage to your gun and/or possible serious injury or death to

yourself and others. There is no excuse for careless or abusive handling of any firearm. At all

times handle any firearm with intense respect for its power and potential danger. READ AND

UNDERSTAND all of THE CAUTIONS AND PROPER HANDLING PROCEDURES

OUTLINED IN THIS BOOKLET BEFORE USING YOUR NEW FIREARM.

1.

ALWAYS KEEP THE MUZZLE OF ANY FIREARM POINTED IN A SAFE DIRECTION.

Do this even though you are certain the firearm is unloaded. Never point any firearm at

anything you do not intend to shoot. Be extremely alert and aware of all persons and property

within the range of your ammunition.

2.

NEVER RELY TOTALLY ON YOUR SHOTGUN'S MECHANICAL "SAFETY" DEVICE.

Always assume that your gun can be fired at any time, even with all the safety mechanism

engaged. The word "safety" describes a gun's trigger block mechanism, sear block mechanism,

hammer block mechanism or firing pin block mechanism. These mechanical devices are

designed to place your gun in a SAFER status. No guarantee can be made that the gun will not

fire even if the "safety" is in the "on safe" position. See "Operation of the Safety" in your

owner’s manual for instructions on operation of your gun's "safety."

3. LIKE ANY MECHANICAL DEVICE, A "SAFETY" CAN SOMETIMES FAIL; IT CAN BE

JARRED OR INADVERTENTLY MANIPULATED INTO AN UNSAFE CONDITION.

Mechanical "safeties" merely aid safe gun handling and are no excuse for pointing your

shotgun's muzzle in an unsafe direction.

While it is a good idea to "test" your shotgun's mechanical "safeties" periodically for proper

function, never test them while your firearm is loaded or pointed in an unsafe direction. Safe

gun handling does not stop with your gun's mechanical "safety" devices -- it starts there.

Always treat this shotgun with the respect a loaded, ready-to-fire firearm.

MECHANISM OF ANY FIREARM WHILE IT IS LOADED OR POINTED IN AN UNSAFE DIRECTION.

4. WHENEVER YOU HANDLE A FIREARM, OR HAND IT TO SOMEONE MAKE SURE IT IS

COMPLETELY UNLOADED.

NEVER TEST THE

Always open the action immediately and visually check the chamber magazine. Make certain

the chamber does not inadvertently contain any ammunition. Always keep the chamber empty

and the "safety" in the "on safe" position unless shooting is imminent.

5. DO NOT TRANSPORT ANY FIREARM LOADED. KEEP ALL FIREARMS UNLOADED

DURING TRANSPORT, WHETHER IN A SCABBARD, GUN CASE, OR OTHER CONTAINER.

6. HUNTING FROM ELEVATED SURFACES SUCH AS TREE STANDS IS DANGEROUS.

Doing so may increase the risk of handling a firearm. The following rules should always be

observed by you and those you hunt with: Always make certain that the stand being used is

safe and stable. Always make certain that your firearm is unloaded when it is being taken up

and down from the stand. Always make certain that your firearm is not dropped from the stand,

or dropped while it is being taken up or down from the stand. Remember, a loaded firearm

may discharge when dropped, even with the safety in the "on safe" position.

Page 52

7. BEWARE OF BARREL OBSTRUCTION.

Do this for the safety of both your gun and yourself. Mud, snow, and an infinite variety of

other objects may inadvertently lodge in a barrel bore. It takes only one small obstruction to

cause dangerously increased pressures that can ruin (swell or rupture) the finest shotgun barrel.

BEFORE CHECKING FOR A BARREL OBSTRUCTION, BE CERTAIN YOUR FIREARM IS FULLY

UNLOADED.

Make sure no live rounds are in the chamber. Place the safety in the "on safe" position, open

the breech or action and look through the barrel to be sure it is clear of any obstruction. If an

obstruction is seen, no matter how small it may be, clean the bore with a cleaning rod and

patch as instructed for your particular firearm. Before the first firing, clean the bore with a

cleaning rod and patch, and wipe away any anti-rust compounds in the action/chamber areas.

8. ALWAYS UNLOAD ALL FIREARMS WHEN NOT IN USE.

As a safety precaution, it is preferable to disassemble your gun for storage. Your

responsibilities do not end when your firearm is unattended. Store your gun and ammunition

separately -- well beyond the reach of children. Take all safeguards to ensure your firearm does

not become available to untrained, inexperienced or unwelcome hands.

9. USE THE PROPER AMMUNITION.

The barrel and action of all Browning firearms have been made with substantial safety margins

over the pressures developed by established American commercial loads. Nevertheless,

Browning assumes no liability for incidents which occur through the use of cartridges of

nonstandard dimensions which develop pressures in excess of commercially available

ammunition with standards established by the Sporting Arms and Ammunitions Manufacturers'

Institute (SAAMI).

BE ALERT TO THE SIGNS OF AMMUNITION MALFUNCTION.

If you detect an off sound or light recoil when ammunition is fired, DO NOT LOAD MORE

AMMUNITION INTO THE CHAMBER.

Open the action and remove all ammunition from the

chamber. With the action open, glance down the barrel to make sure that a wad or other

obstruction does not remain in the barrel. If there is an obstruction, completely clear the barrel

before loading and firing again. Failure to follow these instructions can cause extensive

damage to your gun and possible serious injury to yourself and others.

10.

DISCHARGE A FIREARM. WASH HANDS THOROUGHLY AFTER EXPOSURE TO AMMUNITION

OR CLEANING A FIREARM.

MAKE SURE OF ADEQUATE VENTILATION IN THE AREA THAT YOU

Lead exposure can be obtained from discharging firearms in poorly ventilated areas,

cleaning firearms or handling ammunition. Lead is

a substance that has been known to cause birth defects, reproductive harm and other serious

injury.

11.

NEVER INSERT A SHELL OF THE INCORRECT GAUGE IN ANY SHOTGUN. The gauge of

your shotgun is marked on the side of the barrel. Store all shells of different gauges in

completely separate and well-marked containers. Never store shells of mixed gauges in a

common container or in your pockets.

12 GAUGE GUN.

EXAMINE EVERY SHELL YOU PUT IN YOUR GUN. NEVER PUT A 20 GAUGE SHELL IN A

The most common way to bulge or rupture a shotgun barrel is to drop a 20

gauge shell into a 12 gauge chamber. The 20 gauge shell, unfortunately, will not fall

completely through the barrel; its rim is caught by the front of a 12 gauge chamber. Your gun

will misfire (with the chamber appearing to be empty). It is then possible to load a 12 gauge

shell behind the 20 gauge shell. If the 12 gauge shell is then fired, the result will be a so-called

“12-20 burst” which can cause extensive damage to your gun and possible serious injury to

you and others.

Page 53

12. USE SHELLS OF CORRECT LENGTH.

The size of the chamber is inscribed, along with gauge and choke designations, on the side of

the barrel. Do not use 31/2" shotgun shells in a shotgun or barrel with a 2 3/4" chamber or 3"

chamber. Do not use 3" shells in a shotgun chambered for a 2 3/4" shells. Doing so can result

in a build-up of dangerously high pressures that may damage your gun and possibly cause

serious injury to yourself or others.

13.

BE EMPTY!

DO NOT SNAP THE FIRING PIN ON AN EMPTY CHAMBER -- THE CHAMBER MAY NOT

Treat every gun with the respect due a loaded gun, even though you are certain the gun is

unloaded.

14.

UNTIL YOU ARE READY TO SHOOT.

KEEP YOUR FINGERS AWAY FROM THE TRIGGER WHILE LOADING AND UNLOADING

15. BE SURE OF YOUR TARGET AND BACKSTOP. Particularly during low light periods.

Know the range of your ammunition. Never shoot at water or hard objects.

16.

CROSSING A FENCE, CLIMBING A TREE, JUMPING A DITCH OR NEGOTIATING OTHER

OBSTACLES.

ALWAYS UNLOAD THE CHAMBER AND MAGAZINE OF ANY FIREARM BEFORE

Never lean or place your loaded shotgun on or against a fence, tree, car or other similar object.

17.

WEAR EYE AND EAR PROTECTION WHEN SHOOTING. Unprotected, repeated exposure

to gunfire can cause hearing damage. Wear ear protectors (shooting earplugs or muffs) to

guard against such damage. Wear shooting glasses to protect your eyes from flying particles.

Always keep a safe distance between the muzzle of your firearm and any persons nearby, as

muzzle blast, debris and ejecting shells could inflict serious injury. Also, wear eye protection

when disassembling and cleaning all firearms to prevent the possibility of springs, springtensioned parts, solvents or other agents from contacting your eyes.

18. DROPPING A LOADED GUN CAN CAUSE AN ACCIDENTAL DISCHARGE.

This can occur even with the "safety" in the "on safe" position. Be extremely careful while

hunting or during any shooting activity to avoid dropping any firearm.

19. IF ANY FIREARM FAILS TO FIRE, KEEP THE MUZZLE POINTED IN A SAFE DIRECTION.

Hold this position for a minimum of 30 seconds. Carefully open the action and remove the

shell. If the primer is indented, the shell should be disposed of in a way that cannot cause harm.

If the primer is not indented, your firearm should be examined by a qualified gunsmith and the

cause of the malfunction should be corrected before further use.

20. BE DEFENSIVE AND ON GUARD AGAINST UNSAFE GUN HANDLING AROUND YOU

AND OTHERS

. Don’t be timid when it comes to gun safety. If you observe other shooters

violating any of these safety precautions, politely suggest safer handling practices.

21. BE CERTAIN YOUR SHOTGUN IS UNLOADED BEFORE CLEANING.

Because so many accidents occur when a firearm is being cleaned, special and extreme care

should be taken to be sure your gun is unloaded before disassembly, cleaning and reassembly.

Keep ammunition away from the cleaning location. Never test the mechanical function of any

firearm with live ammunition.

Page 54

22. SUPERVISE AND TEACH FIREARMS SAFETY TO ALL MEMBERS OF YOUR FAMILY --

ESPECIALLY TO CHILDREN AND NONSHOOTERS.

Closely supervise newcomers to the shooting sports. Encourage enrollment in hunting/shooting

safety courses.

23. NEVER DRINK ALCOHOLIC BEVERAGES OR TAKE ANY TYPE OF DRUGS BEFORE OR

DURING SHOOTING.

Your vision and judgment could be dangerously impaired, making your gun handling unsafe to

you and to others.

24. PERFORM PERIODIC MAINTENANCE -- AVOID UNAUTHORIZED SERVICING.

Your firearm is a mechanical device which will not last forever, and as such, is subject to wear

and requires periodic inspection, adjustment and service. Browning firearms should be

serviced by a Browning Recommended Service Center or by Browning's service facility in

Arnold, Missouri. Browning cannot assume any responsibility for injuries suffered or caused

by unauthorized servicing, alterations or modifications of Browning firearms.

25.

READ AND HEED ALL WARNINGS in these instructions, on ammunition boxes and with

all accessories that you install on your firearm. It is your responsibility to secure the most upto-date information on the safe handling procedures of your Browning gun. Browning assumes

no liability for incidents which occur when unsafe or improper gun accessories or ammunition

combinations are used.

26. Browning reserves the right to refuse service on firearms that have been altered, added

to or substantially changed. Removal of metal from barrel(s), or modification of the firing

mechanism and/or operating parts may lead to Browning’s refusal of service on such firearms.

Browning will charge the owner for parts and labor to return the firearm to original Browning

specifications.

DO NOT, UNDER ANY CIRCUMSTANCES, ALTER THE TRIGGER, SAFETY OR

OTHER PARTS OF THE FIRING MECHANISM OF THIS OR ANY OTHER

FIREARM. FAILURE TO OBEY THIS WARNING MAY RESULT IN INJURY OR

DEATH TO YOURSELF OR OTHERS.

BE CAREFUL!

Page 55

Loading...

Loading...