Browning 9566E Instruction Manual

Ball and Roller Bearings Installation Instructions

F O R M

PN 786515, PS-740-0001

9566E

Revised

July 2016

• Read and follow all instructions carefully.

• Disconnect and lock-out power before installation and maintenance.

Working on or near energized equipment can result in severe injury or death.

• Do not operate equipment without guards in place. Exposed equipment can

result in severe injury or death.

These instructions cover the set screw, eccentric locking and BOA™ concentric lock

ball and setscrew roller bearings. It is important that they be read in their entirety

before attempting installation or removal. The procedures indicated should be

carefully followed. Failure to do so can result in misinstallation which could cause

bearing performance problems as well as serious personal injury.

BEARINGS IN BOLT-ON HOUSINGS (UNITS)

1. CHECK AREA - Clean and organize bearing installation area, and keep well lit.

Be sure mounting surfaces are clean and flat.

2. CHECK SHAFT - Shaft should be within tolerance range shown in Table

1, clean, and free of nicks and burrs. Mount bearing on unused section of

shafting or repair/replace shafting as required.

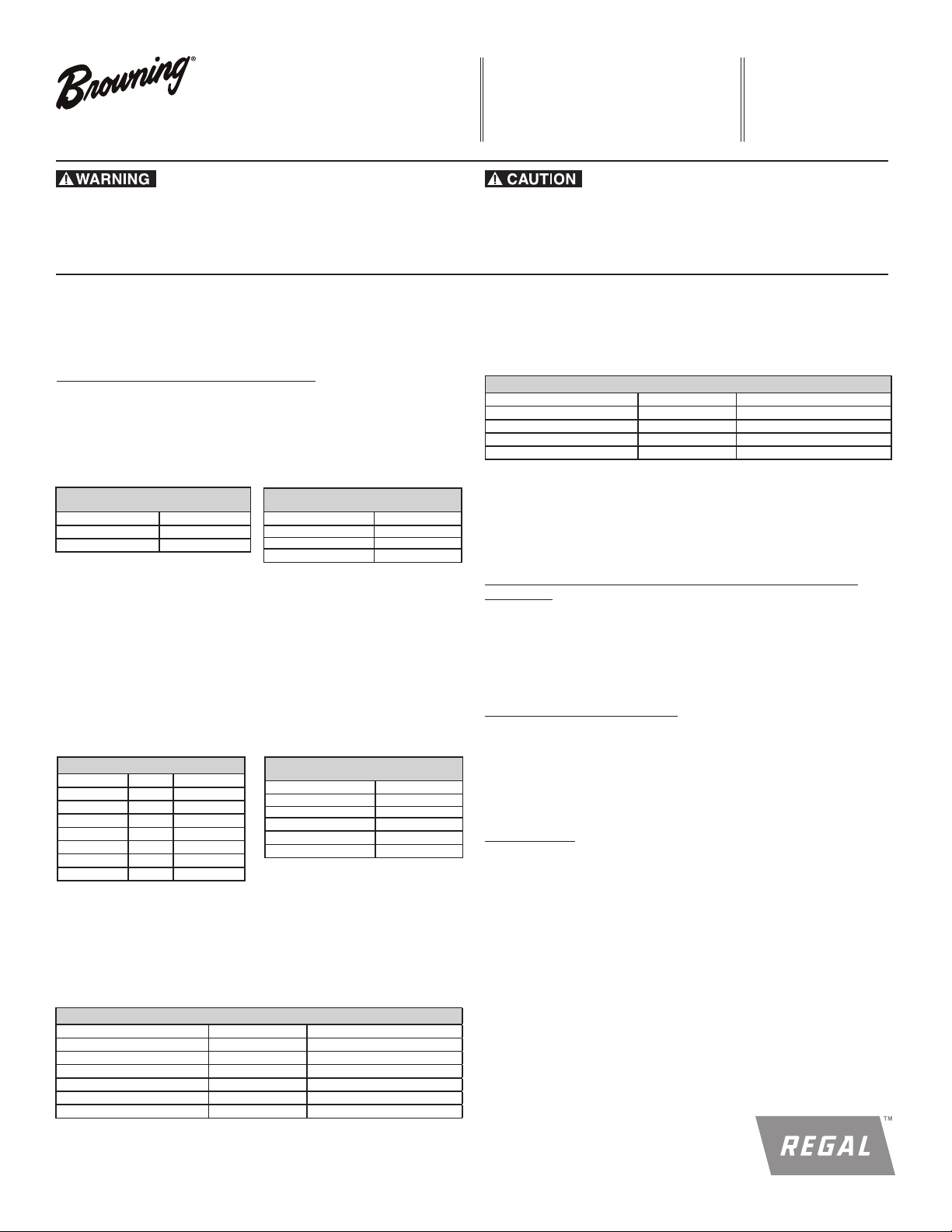

Table 1

Nominal Bore Diameter Tolerance (Inches)

3. INSTALL UNIT - Slide unit onto shaft. If it is difficult to mount bearing on

4. FASTEN UNIT IN PLACE - Install housing mounting bolts, check and align

5.1 SET SCREW INSERTS

Table 2

Ball Bearing Recommended Torque

Screw Size Hex Size Inch-Pounds

1/4-28 1/8 65 - 85

5/16-24 5/32 125 - 165

3/8-24 3/16 230 - 300

7/16-20 7/32 350 - 450

1/2-20 1/4 500 - 650

5/8-18 5/16 1100 - 1440

5.2 ECCENTRIC LOCK INSERTS

Table 3

Ball Bearing

Recommended Shaft Tolerances

1/2 - 1 15/16 +0.0000 / -0.0005

2 - 2 7/16 +0.0000 / -0.0010

Nominal Bore Diameter Tolerance (Inches)

Roller Bearing

Recommended Shaft Tolerances

1 1/8 - 2 +0.0000 / -0.0005

2 3/16 - 4 +0.0000 / -0.0010

4 7/16 -5 +0.0000 / -0.0015

shaft, use a piece of emery cloth to reduce any high spots on shaft. Do not

hammer on any component of the bearing

bearing and tighten mounting bolts to recommended fastener torques.

Exercising extreme caution and safety, rotate shaft slowly to center bearing.

a. Setscrews in a multiple bearing setup should be aligned.

b. Torque first set screw to one half recommended torque in Table 2. Torque

second set screw to full torque. Torque first set screw to full torque.

c. Repeat step 5b on opposite end of inner ring for roller bearings.

Roller Bearing

Lock Collar Setscrew Torque

10-32 3/32 30 - 35

Bore Size Foot-Pounds

1 3/16 - 1 11/16 12

1 3/4 - 2 1/2 19

2 11/16 - 3 1/2 45

3 15/16 - 4 95

4 7/16 - 5 150

a. Place collar on inner race and rotate by hand in direction of shaft rotation

until eccentrics are engaged.

b. Insert drift pin into the hole in the collar O.D. and lock in direction of shaft

rotation with the aid of small hammer.

c. Torque single setscrew to recommended torque in Table 3.

Screw Size Hex Size Inch-Pounds

1/4-28 1/8 65 - 85

5/16-24 5/32 125 - 165

3/8-24 3/16 230 - 300

7/16-20 7/32 350 - 450

1/2-20 1/4 500 - 650

5/8-18 5/16 1100 - 1400

Eccentric Locking Recommended Torque

• Periodic inspections should be performed. Failure to perform proper maintenance

can result in premature product failure and personal injury.

5.3 BOA CONCENTRIC INSERTS

a. Be sure that the BOA collar is fitted square and snug against the shoulder

on the inner ring.

b. Torque the BOA collar cap screw to torque recommended in Table 4.

Table 4

BOA Concentric Locking Collar Cap Screw Torque

Screw Size Hex Size Inch-Pounds

# 8-32 T-25 70

# 10-24 T-27 100

1/4-20 T-30 240

5/16-18 T-45 495

6. MONITOR INSTALLED BEARING - After bearing has been run for several

minutes, and again after several hours, check bearing for excessive noise or

vibration. Shutdown machine and check housing temp: typical applications

operate at 100°F - 150°F (38°C - 66°C). Check tightness of all locking devices

after 500 hours or 3 months, whichever comes first.

CYLINDRICAL OD INSERTS AND INSERTS IN CYLINDRICAL OD

HOUSINGS

INSTALL INSERT- Be sure housing bore is clean and free of debris. Press bearing

into housing by applying force to face of outer ring. Do not hammer on any

component of the bearing or apply force to inner ring. Proceed with Step

#1- 6 above. For recommended housing bore tolerance, consult catalog or contact

Application Engineering.

SPHERICAL OD BALL BEARINGS

Important: Replacement Browning bearing inserts are intended for use in

Browning housings. Housings should be thoroughly inspected for damage

such as cracks, excessive wear or galling of the spherical seat, obstruction of

grease port, etc. prior to installation.

INSTALL INSERT- Housing bearing seat should be wiped clean. Check grease

port and clean free of debris. Wet housing bearing seat with oil or grease. Secure

housing in a vise.

For Spherical OD:

a. Place the bearing insert into the housing load slots, positioning the anti

rotation rivet on the outer ring in the load slot as to not shear it off when

swinging insert into place. Also, position the outer ring lubrication hole so it

will install in line with the housing lubrication hole.

b. Using a bar placed in the insert bore as a lever, swing the insert into place

within the housing. Insert should have a snug fit in the housing. If insert can

be made to swivel by hand in the housing bore, fit is too lose and entire unit

should be replaced. If heavy force is required, fit is too tight and entire unit

should be replaced.

c. Ensure alignment of the anti rotation rivet in the load slot and outer ring

lubrication hole in the housing lubrication hole.

RELUBRICATION INSTRUCTIONS

All Browning Ball bearings and E920 Tapered Roller bearings are delivered with a

high quality lithium complex grease with an EP additive. The bearing is ready for

use with no initial lubrication required. The grease consists of a lithium complex

thickener, mineral oil, and NLGI grade 2 consistency.

Compatibility of grease is critical; therefore consult with Application Engineering

and your grease supplier to insure greases are compatible. For best performance

it is recommended to relubricate with lithium complex thickened grease with a

comparable NLGI consistency and base oil properties.

Relubricatable Browning bearings are supplied with grease fittings or zerks for

ease of lubrication with hand or automatic grease guns. Always wipe the fitting and

grease nozzle clean.

CAUTION: If possible, it is recommended to lubricate the bearing while rotating,

until grease purge is seen from the seals. If this is not an option due to safety

reasons, follow the alternate lubrication procedure below.

Re-Lubrication Procedure:

Stop rotating equipment. Add one half of the recommended amount shown in

Table 5 or 6. Start the bearing and run for a few minutes. Stop the bearing and add

the second half of the recommended amount. A temperature rise after lubrication,

sometimes 30°F (17°C), is normal. Bearing should operate at temperatures less than

200°F (94°C) and should not exceed 250° (121°C) for intermittent operation. For

lubrication guidelines, see Table 7.

Note: Grease charges in Table 5 and 6 are based on the use of lithium complex

thickened grease with a NLGI grade 2 consistency.

Note: Table 7 contains general recommendations. Experience and testing may be

required for specific applications.

Table 5

Ball Bearing

Recommended Lubrication Grease Charge

Shaft Size

100 & 200 Series 300 Series

Intermediate &

Standard Duty

1/2 -5/8 x 0.02

3/4 x 0.03

13/16 - 1 x 0.03

1 1/16 -1/4S 15/16 - 1 0.06

1 1/4 - 1 7/16 1 3/16 0.09

1 1/2 - 1 9/16 1 7/16 0.14

1 5/8 - 1 3/4 1 1/2 0.16

1 13/16 - 2S 1 11/16 - 1 3/4 0.18

2 - 2 3/16 1 15/16 0.25

2 1/4 - 2 7/16 2 3/16 0.35

Table 6

Medium Duty

Roller Bearing

Recommended Lubrication Grease Charge

Bore Size Grease Charge (Mass - Ounces)

1 3/16 - 1 1/4 0.26

1 3/8 - 1 7/16 0.30

1 1/2 - 1 11/16 0.36

1 3/4 - 2 0.42

2 3/16 0.69

2 1/4 - 2 1/2 0.75

2 11/16 - 3 0.92

3 3/16 - 3 1/2 1.50

3 15/16 - 4 1.92

4 7/16 - 4 1/2 2.79

4 15/16 - 5 4.17

Grease Charge

(Mass - Ounces)

Table 7

Ball and Roller Bearing

General Lubrication Schedule

Environment Temperature (°F)

Dirty -20 to 200 0 - 100% Daily to 1 Week

-20 to 125

Clean

125 to 175

175 to 200 0 - 100% Daily to 1 Week

Table 8

Speed

(% Catalog Max)

0 - 25% 4 to 10 Months

26 - 50% 1 to 4 Months

51 - 75% 1 Week to 1 Month

76 - 100% Daily to 1 Week

0 - 25% 2 to 6 Weeks

26 - 50% 1 Week to 1 Month

51 - 75%

76 - 100%

Daily to 1 Week

Ball Bearing

Maximum Operational Speed

100 & 200 Series 300 Series

Bore Size Speed (RPM) Bore Size Speed (RPM)

1/2 -5/8 7500 1 4500

3/4 6500 1 3/16 - 1 1/4 4000

7/8 - 1 5500 1 7/16 3500

1 1/6 -1 1/4S 4500 1 1/2 - 1 3/4 3000

1 1/4 - 1 7/16 4000 1 15/16 - 2 3/16 2500

1 1/2 - 1 9/16 3500 - -

1 5/8 - 2S 3000 - -

2 - 2 7/16 2500 - -

Table 9

Roller Bearing

Maximum Operational Speed

Maximum Operational Speed

Bore Size Speed (RPM)

1 3/16 - 1 1/4 3500

1 3/8 - 1 7/16 3000

1 1/2 - 1 11/16 2500

1 3/4 - 2 3/16 2000

2 1/4 - 2 1/2 1750

2 11/16 - 3 150 0

3 3/16 - 4 1000

4 7/16 - 5 750

Frequency

Regal and Browning are trademarks of Regal Beloit Corporation or one of its affiliated companies.

©2016 Regal Beloit Corporation, All Rights Reserved. MCIM16046E • Form 9566E • Printed in USA

Loading...

Loading...