Browning 8658E Instruction Manual

V-Belt

Installation Instructions

F O R M

8658E

Revised

July 2018

• Read and follow all instructions carefully.

• Disconnect and lock out power before installation and

maintenance. Working on or near energized equipment can

result in severe injury or death.

• Do not operate equipment without guards in place. Exposed

equipment can result in severe injury or death.

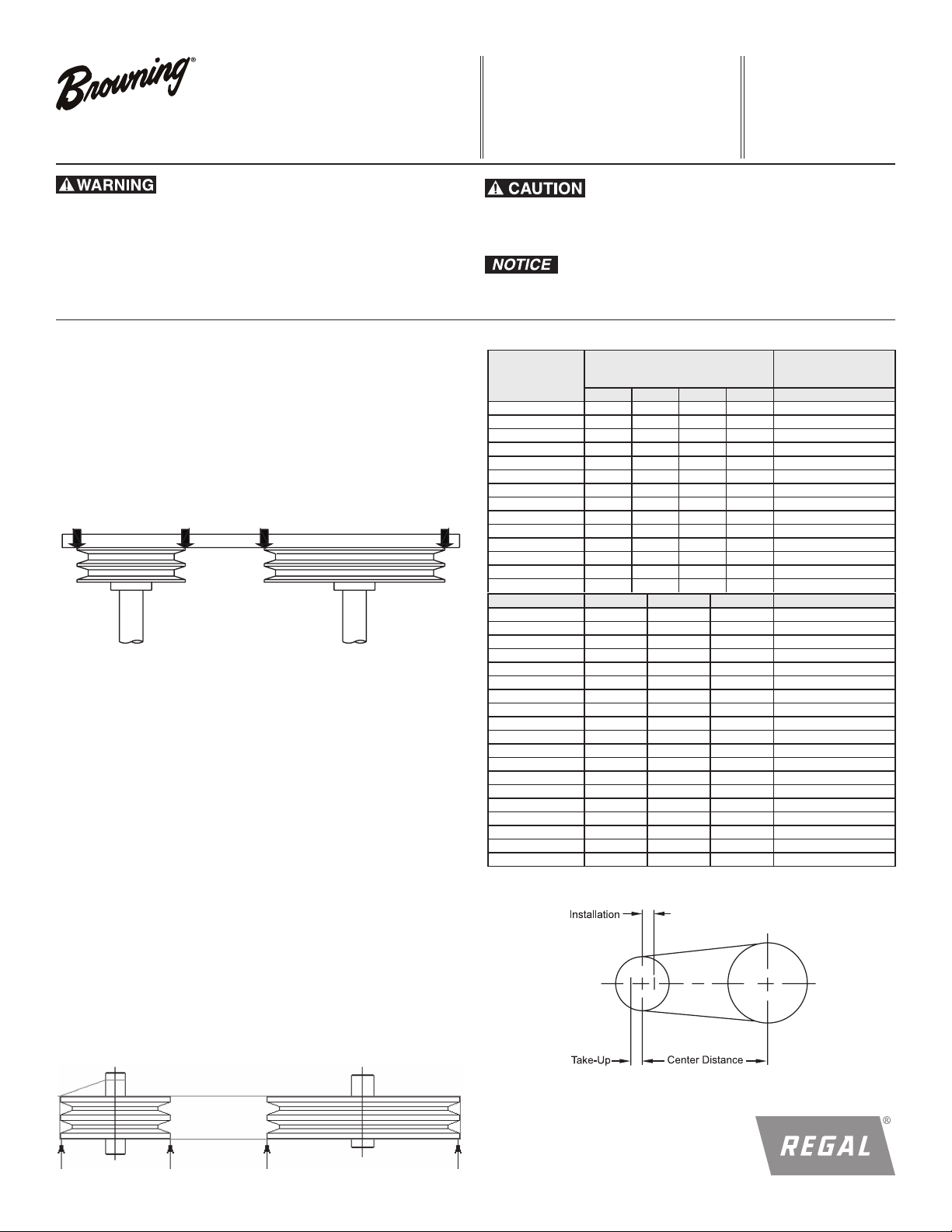

V-Belt Sheave Alignment

Before installing the bushings, refer to Form No. F20-23 for Q-D® instructions and Form No. 4013 for Browning Split Taper® instructions. After

installing the bushings in the sheaves and the resulting assemblies onto

the shafts, use a straight edge or string placed on the outside face of both

sheaves to adjust parallel offset and angular alignments. The straight edge

or string should be close to the shafts and contact each sheave as shown

in the figure 1 and 2 below. The objective is to have the shafts parallel and

the center lines of the two sheaves in line.

Figure 1

Four Point Contact with Straightedge

• Periodic inspections should be performed. Failure to perform

proper maintenance can result in premature product failure and

personal injury.

• Do not pry or otherwise force belts onto sheave. Doing so may

result in permanent damage to the belt.

TABLE 1: CENTER DISTANCE ALLOWANCE

Belt No.

26 - 35 .8 1. 0 - - 1. 0

38 - 55 .8 1. 0 1. 5 - 1. 5

60 - 85 .8 1. 3 1. 5 - 2.0

90 - 112 1. 0 1. 3 1. 5 - 2.5

120 - 144 1. 0 1. 3 1. 5 2.0 3.0

158 - 180 - 1.3 2.0 2.0 3.5

195 - 210 - 1.5 2.0 2.0 4.0

240 - 1.5 2.0 2.5 4.5

220 - 300 - 1. 5 2.0 2.5 5.0

330 - 390 - - 2.0 2.5 6.0

420 and over - - 2.3 3.0 1 1/2% of Belt Length

250 - 475 .5 1. 0

500 - 710 .8 1.0 1. 2

750 - 1060 .8 1. 0 1. 5 1. 5

Allowance for Installation

4L, A 5L, B C D All Sections

3V 5V 8V All Sections

Allowance for Initial

Tensioning and

Subsequent Take-Up

Belt drives should be aligned as perfect as possible to maximize drive life.

The practical maximum misalignment is stated as the angle at which the

belt enters the sheave, and is 1/2 degree. This angle is a result of both

angular and parallel offset misalignment.

V-Belt Installation

Some means must be employed to allow tensioning the belts. These

steps describe an application having adjustable center distance. If the

design has fixed, non-movable centers then other means of tensioning

must be considered such as idlers and drive tighteners. Contact

Application Engineering at 1-800-626-2093 for additional assistance.

Step 1: Loosen moveable base bolts (or motor base bolts) and move

sheaves close to facilitate installation of belt. See Table 1 for minimum

installation allowance.

Step 2: Move all the slack in multiple belt drives to one side, then

remove the slack (increase centers). Then rotate sheaves several

revolutions by hand to equalize belt tensions.

Step 3: Tension belts as outlined on the next page.

Note: If Browning Tension Checker is used, only 35 lbs maximum force

(F) can be obtained. If higher forces are required, use other means such

as dead weights or hydraulic pressure to apply a known force.

Figure 2

Four Point Contact on Both Sides with String

1120 - 1250 .8 1. 0 1. 5 1. 8

1320 - 1700 .8 1. 0 1. 5 2.2

1800 - 2000 1. 0 1. 8 2.5

2120 - 2240 1.2 1. 8 2.8

2360 1. 2 1. 8 3.0

2500 - 2650 1. 2 1. 8 3.2

2800 - 3000 1. 2 1. 8 3.5

3150 1.2 1. 8 4.0

3350 - 3550 1. 5 2.0 4.0

3750 - 2.0 4.5

4000 - 5000 - 2.0 5.5

5600 - 2.0 6.0

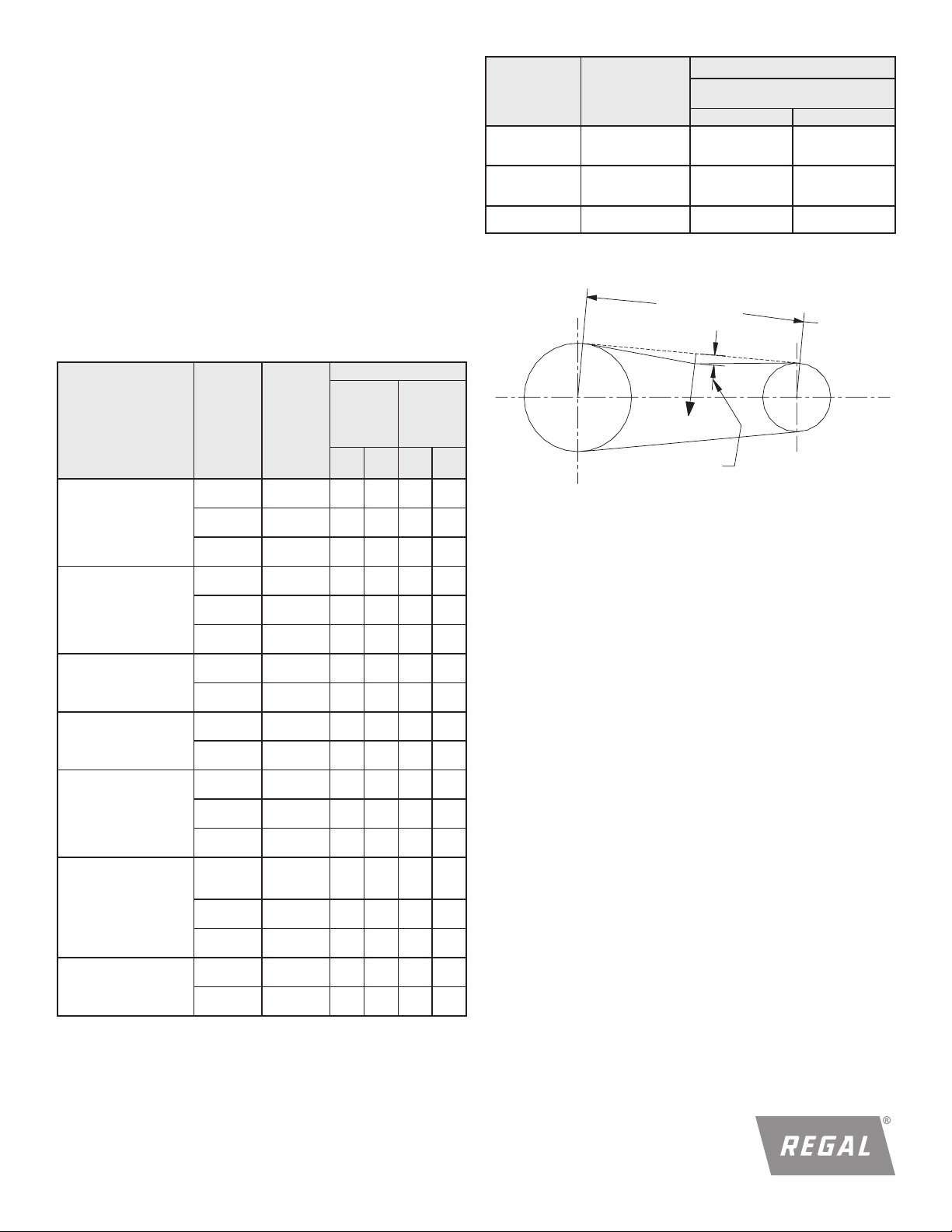

Figure 3

1

Force

Span Length, t

Deflection (def)

Tensioning V-Belts

Calculate or measure the belt span length as shown in Figure 3. Calculate

the required deflection by multiplying this number by 1/64. For example,

if the belt span is 32 inches, 32 x 1/64 = 1/2 inch deflection. Increase the

belt tension by increasing the center distance (or adjusting the idler, if

present). Apply the force listed in Table 2 to any one of the belts in the

drive at the center of the belt span until the calculated deflection amount

is reached. Drives with shock loading or other unusual conditions may require increased tension. Always check to be sure bearings can handle the

loads. Excessively high or low tensions will affect belt life. Recheck belt

tensions after jog start or 1-3 minutes of operation, and 8 hours, 24 hours,

100 hours, and periodically thereafter.

Belt

Cross

Section

3L

4L

5L

Smallest Sheave

Diameter Range

1.25 - 1.75

2.00 - 2.25

2.50 - 3.00

2.10 - 2.80

3.00 - 3.50

3.70 - 5.00

3.00 - 4.20

4.50 - 5.20

Belt deection force

Super Gripbelts and

Unnotched Gripbands

Used Belt New Belt

1 5/

1

2 1/

3

/

8

3

/

4

1

5

/

8

8

2

1

/

2

2

1 1/

1 1/

2

2 5/

3 1/

5

/

8

4

2

1

1

/

2

3

8

2

TABLE 2

SHEAVE DIAM - INCHES

DEFLECTION FORCE - LBS.

The values in Table 2 are general in nature providing deflection force to

cover a wide range of drives. For precise deflection force refer to our

EDGE online V-Belt Drive Selection Program.

Belt deection force

Belt Cross Section

A - AX

B - BX

C - CX

D

3V - 3VX

5V - 5VX

8V

Smallest

Sheave

Diameter

Range

3.0 - 3.6

3.8 - 4.8

5.0 - 7.0

3.4 - 4.2

4.4 - 5.6

5.8 - 8.6

7.0 - 9.0

9.5 - 16.0

12.0 - 16.0

18.0 - 20.0

2.2 - 2.4

2.65 - 3.65

4.12 - 6.90

4.4 - 6.7

7.1 - 10.9

11.8 - 16.0

12.5 - 17.0

18.0 - 22.4

Super

Gripbelts

RPM

Range

1000 - 2500

2501 - 4000

1000 - 2500

2501 - 4000

1000 - 2500

2501 - 4000

860 - 2500

2501 - 4000----

860 - 2500

2501 - 4000

860 - 2500

2501 - 4000

500 - 1740

1741 - 3000

500 - 1740

1741 - 3000

200 - 850

851 - 1500

200 - 850

851 - 1500

1000 - 2500

2501 - 4000----

1000 - 2500

2501 - 4000

1000 - 2500

2501 - 4000

500 - 1749

1750 - 3000

3001 - 4000

500 - 1740

1741 - 3000

500 - 1740

1741 - 3000

200 - 850

851 - 1500

200 - 850

851 - 1500

and

Unnotched

Gripbands

Used

Belt

3.7

2.8

4.5

3.8

5.4

4.7

5.3

4.5

6.3

6.0

11.5

9.4

14.1

12.5

24.9

21.2

30.4

25.6

3.6

3.0

4.9

4.4

-

-

-

12.7

11.2

15.5

14.6

33.0

26.8

39.6

35.3

New

Used

Belt

5.5

4.2

6.8

5.7

8.0

7.0

7.9

6.7

9.4

8.9

17.0

13.8

21.0

18.5

37.0

31.3--

45.2

38.0--

5.1

4.4

7.3

6.6

-

-

-

18.9

16.7

23.4

21.8

49.3

39.9--

59.2

52.7--

Gripnotch

Belts and

Notched

Gripbands

Belt

4.1

3.4

5.0

4.3

5.7

5.1

4.9

4.2

7.1

6.1

8.5

7.3

14.7

11.9

15.9

14.6

3.3

2.9

4.2

3.8

5.3

4.9

10.2

8.8

5.6

14.8

13.7

17.1

16.8

New

Belt

6.1

5.0

7.4

6.4

8.4

7.6

7.2

6.2

10.5

9.1

12.6

10.9

21.8

17.5

23.5

21.6

-

-

-

-

4.9

4.3

6.2

5.6

7.9

7.3

15.2

13.2

8.5

22.1

20.1

25.5

25.0

-

-

-

-

Figure 4

Note: For gripbands (multiple or banded belts), the belt deflection force table

2 must be multiplied by the number of ribs in the gripband. Lay a narrow steel

bar such as keystock across the gripband belt and apply the belt deflection

force to the bar such that all the individual ribs are deflected evenly.

General Notes

Do not install new belts in worn sheave grooves. Such sheaves should be

replaced with new ones to insure a proper fit of the belts in the grooves.

Keep belts clean. Do not use belt dressing.

When replacing belts on a drive, be sure to replace the entire set with a

new set of matched belts. Keep extra belts stored in a cool, dark, dry

place.

Regal, Browning, Q-D and Spilt Taper are trademarks of Regal Beloit Corporation or one of its afliated companies.

©2015, 2018 Regal Beloit Corporation, All Rights Reserved. MCIM18014E • Form# 658E

2

Loading...

Loading...