HTP® Installation Instruction

Center Distance

Take-Up

Installation

F O R M

8600-AE

Revised

September 2015

• Read and follow all instructions carefully.

• Disconnect and lock-out power before installation and maintenance.

Working on or near energized equipment can result in severe injury or death.

• Do not operate equipment without guards in place. Exposed equipment can

result in severe injury or death.

• Be sure drive system cannot rotate during installation. Failure to do so

can result in serious injury.

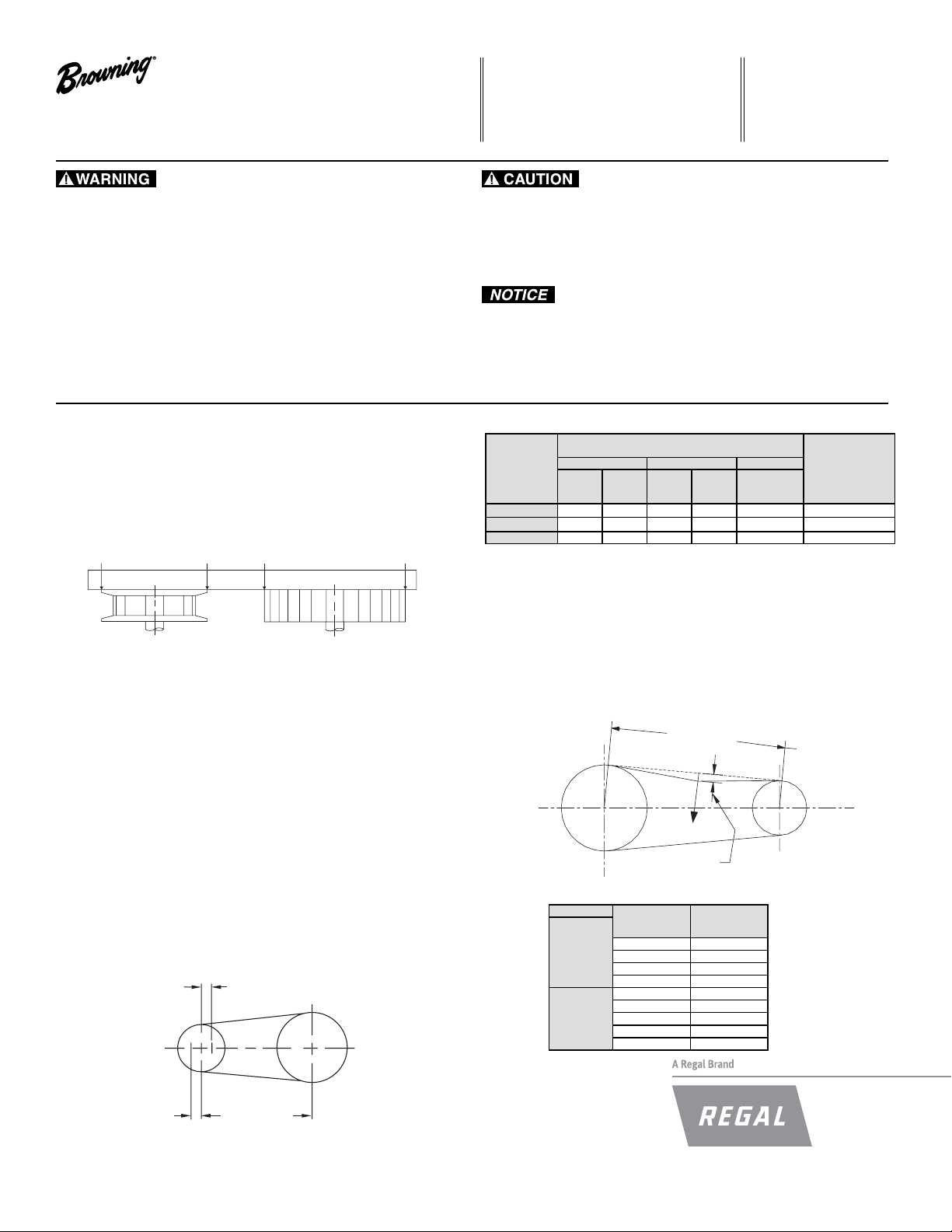

HPT Sprocket Alignment

Before installing bushings, refer to EPT Form #F20-23 for QD® Instructions and

to Form No. 4013 for Split Taper Instructions. After installing the bushings in the

sprockets and the resulting assemblies onto the shafts, use a straight edge, piano

wire, or string placed on the outside face of both sprockets to adjust parallel offset

and angular alignments. The straight edge, piano wire, or string should be close to

the shafts and contact each sprocket in two places on the anges (or on the face of

an unanged pulley). The objective is to have the shafts parallel and the center lines

of the two sprocket faces in line. See Figure 1 below.

Figure 1

Belt drives should be aligned as perfect as possible to maximize drive life. The

practical maximum misalignment is stated as the angle at which the belt enters the

sprocket. This angle is a result of both angular and parallel offset misalignment, and

is 1/4 degree.

HPT Belt Installation

Condition A – One Flanged Sprocket and One Unanged Sprocket.

After sprockets have been mounted and aligned, reduce the shaft center distance

as shown in Table 1. Put the belt over the anged sprocket rst, then slip onto the

unanged sprocket.

Condition B – Both Sprockets Flanged. After sprockets have been mounted and

aligned, reduce the shaft center distance as shown in Table 1. Put the belt over the

larger sprocket rst, then the smaller sprocket.

Condition C – Minimum Center Distance Adjustment.

1. Mount one sprocket onto the shaft loosely and put the belt on it.

2. Put the other sprocket into the belt loop and slip it onto the other shaft (bushing

loosely installed).

3. Align the drive and tighten the bushings. Timing belts have been designed to have

proper pitch dimensions under correct tensions. Belts may not fully seat in large

diameter pulleys without applying proper tension to the belt.

Figure 2

• Periodic inspections should be performed. Failure to perform proper maintenance

can result in premature product failure and personal injury.

• All electrical work should be performed by qualied personnel and compliant with

local and national electrical codes.

• Failure to use the cap screws that came with the Product may lead to an

unsafe assembly.

• To avoid damage, supporting structure including shafts and bearings must be

designed to handle transmitted loads and belt tension(s).

• Shaft horizontal drives must have at least one anged pulley; shaft vertical drives

must have all pulleys anged, otherwise belt may come off.

• Do not pry or otherwise force belts onto sprockets. Doing so can result in

permanent damage to the belt.

TABLE 1 - CENTER DISTANCE ALLOWANCE

Belt Pitch

Length

Range

(MM)

up to 1440 .7” 1.0” 1.2” 2.2” .1” .1”

1441 to 2600 .8” 1.1” 1.3” 2.3” .2” .2”

over 2600 .9” 1.2” 1.4” 2.4” .3” .3”

Allowance for Installation (Inches)

Condition A Condition B Condition C

8MM

Belts

14MM

Belts

8MM

Belts

14MM

Belts

8MM

and

14MM Belts

Allowance

for Take-Up

8MM and

14MM Belts

HPT INSTALLATION INSTRUCTIONS

Tensioning HPT Belts

Calculate or measure the belt span length as shown in Figure 3. Calculate the

required deection by multiplying this number by 1/64. For example, if the belt span

is 32 inches32 x 1/64 = 1/2 inch deection. Increase the belt tension by increasing

the center distance (or adjusting the idler, if present). Apply the force listed in Table 2

evenly across the width of the belt at the center of the belt span. A strip of keystock

or similar material may be used to help distribute the force evenly across the belt

width. Drives with shock loading or other unusual conditions may require increased

tension. Always check to be sure bearings can handle the loads.

Figure 3

Span Length, t

Force

Deflection (def)

TABLE 2 - DEFLECTION FORCE FOR HPT BELTS (Lbs)

Pitch

8MM

14MM

Width

MM

20 4

30 6

50 11

85 19

40 11

55 16

85 26

115 37

170 58

Force

LBS

Browning and HPT are trademarks of Regal Beloit Corporation or one of its afliated companies.

©2015 Regal Beloit Corporation, All Rights Reserved. MCIM15064E • Form 8600-AE • Printed in USA

Loading...

Loading...