MVP® Variable Speed Sheaves

Mounting and Adjusting Instructions

F O R M

4044E

Revised

December 2017

• Arc flash and shock hazard. Appropriate PPE required.

Failure to wear appropriate PPE will result in death or serious

injury.

• Read and follow all instructions carefully.

• Disconnect and lock out power before installation and

maintenance. Working on or near energized equipment can

result in severe injury or death.

• Do not operate equipment without guards in place. Exposed

equipment can result in severe injury or death.

• Periodic inspections should be performed. Failure to perform

proper maintenance can result in premature product failure and

personal injury.

• Do not pry or otherwise force belts onto sheave. Doing so may

result in permanent damage to the belt..

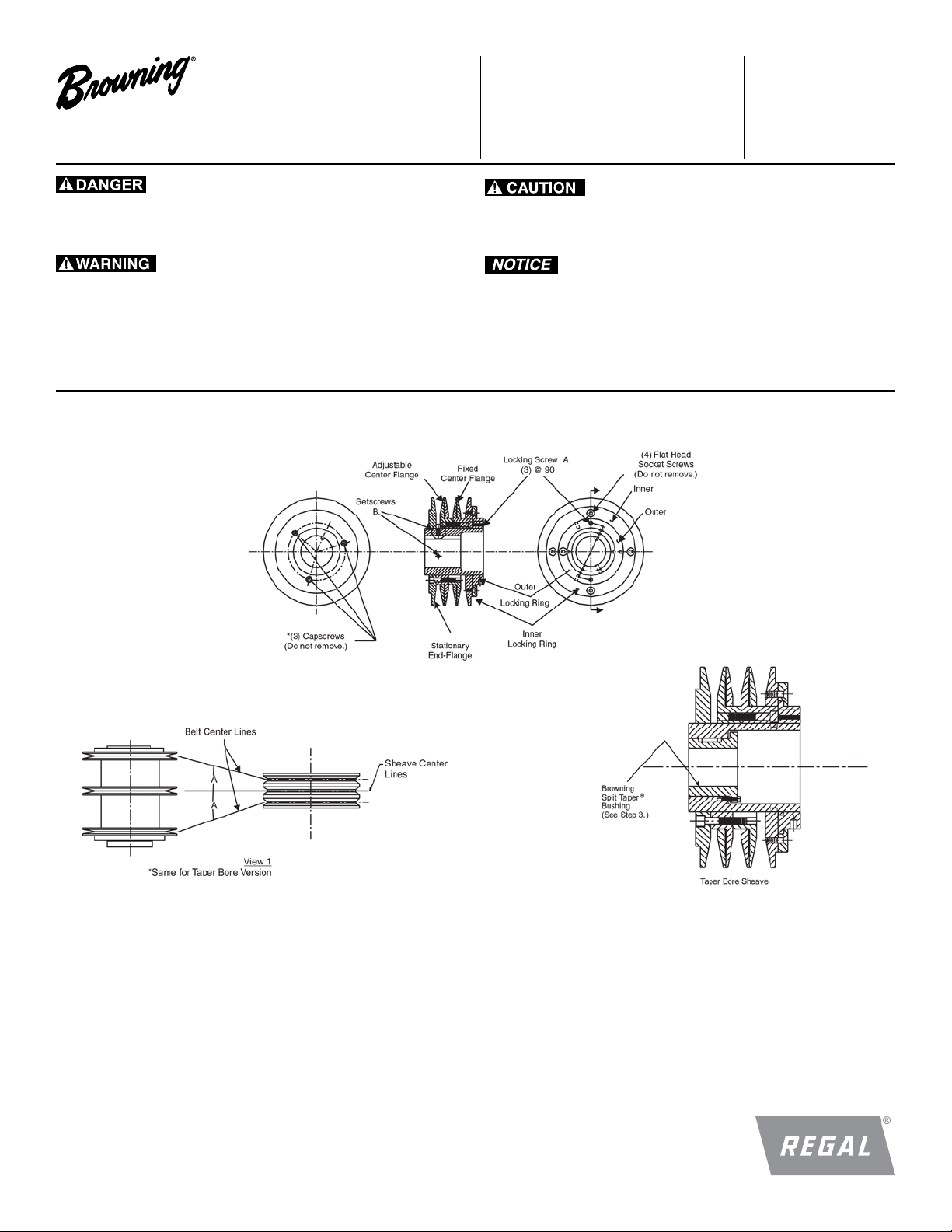

Straight Bore Sheave

Mounting:

1. Make sure the shaft, sheave bore, keys and keyways are free of burrs,

paint,

etc.

2. All straight bore sheaves should be mounted on the motor or driving

shaft with the end containing set screws “B” toward the motor.

Sheave should be located as close to the motor as possible with the

set screws “B” in full contact with the key and shaft. The shaft key is

provided with the sheave on some sizes.

3. If the sheave has a tapered bore to accommodate a Browning Split

Taper® Bushing, follow the instructions on the split taper bushing

box, or refer to Regal Form No. 4013 (Browning Split Taper bushing

instructions).

4. Be sure both driving and driven sheaves are in alignment and that

shafts are parallel. The centerline of the driving sheave must

line up with the centerline of the driven sheave. Angle “A” cannot

exceed 1/2° for raw edge belts and 2° for wrapped belts. See View 1.

5. For straight bore sheaves, tighten set screws “B” in place.

6. Be sure that all setscrews and capscrews are torqued to values

shown in Table A with a torque wrench before starting drive. Check

setscrew torque and belt tension after 24 hours service.

See Table A. Refer to Regal® Browning® Components Catalog,

“Tensioning V-Belt Drives,” or Regal Form No. 5453 (Belt Tension

Checker) for tensioning instructions.

1

Adjusting:

7. Slack off all belt tension by moving motor toward the driven shaft until

belts are free of grooves. For easiest adjustment, remove the belts

from the grooves.

8. Loosen, but don’t remove the three locking set screws “A” in outer

locking ring, by using a hex key or torque wrench with hex bit (key).

9. Adjust sheave to desired pitch diameter by turning the outer locking

ring. Three holes 120° apart are provided for a spanner wrench or drift

for ease of turning.

10. Any pitch diameter can be obtained within the sheave range. One

complete turn of the outer locking ring will result in a .233” change in

pitch diameter.

11. Opening sheaves more than shown below may lead to poor sheave

and belt performance.

Do not open “B” sheaves more than 4-3/4 turns for “A” belts or 6

turns for “B” belts.

Do not open “C” sheaves more than 9-1/2 turns.

Do not open “D” sheaves more than 13 turns.

Do not open “5V” sheaves more than 6 turns.

Do not open “8V” sheaves more than 8-1/2 turns.

12. Tighten all three locking screws “A” in the outer locking ring to the

value shown in Table A with a torque wrench and hex bit (key).

13. Replace belts and move motor away from driven shaft to tension

belts properly. Refer to Regal® Browning® Components Catalog,

“Tensioning V-Belt Drives”, or Regal Form No. 5453 (Belt Tension

Checker) for tensioning instructions. Check speed. If further

adjustment is needed, repeat the steps 7-12 above.

14. Do not loosen any screws other than the three locking screws “A” in

the outer locking ring. These screws should be loosened only while

the drive is at rest and adjustment is being made. Locking screws “A”

must be tightened before drive is operated after adjustment.

CAUTION: Tighten locking screws “A” to value shown with a torque

wrench and hex bit (key). Otherwise locking ring and flange may come off

the assembly during operation.

15. Field disassembly of sheave is not recommended. If it is felt that

complete disassembly is necessary, please contact application

engineering at 1-800-626-2093.

Table A

Nominal

screw size

(Dia.-Threads/In)

1

/4 - 20NC 150 12.5 100 87 7. 3

5

/

- 18NC 305 25.4 200 165 13.8

16

3

/8 - 16NC 545 45.4 350 290 24.2

1

/2 - 13NC 130 0 108.3 n/a 620 51.7 n/a n/a

5

/8 - 11NC n/a n/a n/a 1225 102.1 n/a n/a

SocketHead

Capscrews

Seating Torque Seating Torque Seating Torque Seating Torque Length (L) Seating Torque

(In. - Lbs.) (Ft. - Lbs.) (In. - Lbs.) (In. - Lbs.) (Ft. - Lbs.) (In.) (Ft. - Lbs.)

FlatHead

Socketscrews

For Lengths Equal to or

Greater than Diameter

Hollow Head Setscrews Only

For Lengths (L) Less than Diameter

3

/

16

1

/

4

5

1

/4 -

/

16

50

90

150 - 250

Regal, MVP, Browning and Browning Split Taper are trademarks of Regal Beloit Corporation or one of its affiliated companies.

©2017 Regal Beloit Corporation, All Rights Reserved. MCIM17074E • Form# 4044E

2

Loading...

Loading...