Page 1

INSTRUCTION MANUAL

S-7250A

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

SINGLE NEEDLE DIRECT DRIVE LOCK STITCHER WITH

ELECTRONIC FEEDING SYSTEM AND THREAD TRIMMER

Page 2

Thank you very much for buying a BROTHER sewing machine. Before using your new machine,

please read the safety instructions and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of

moving parts such as the needle and thread take-up, and consequently there is always a danger of

injury that can be caused by these parts. Follow the instructions from training personnel and

instructors regarding safe and correct operation before operating the machine so that you will know

how to use it correctly.

S-7250A

Page 3

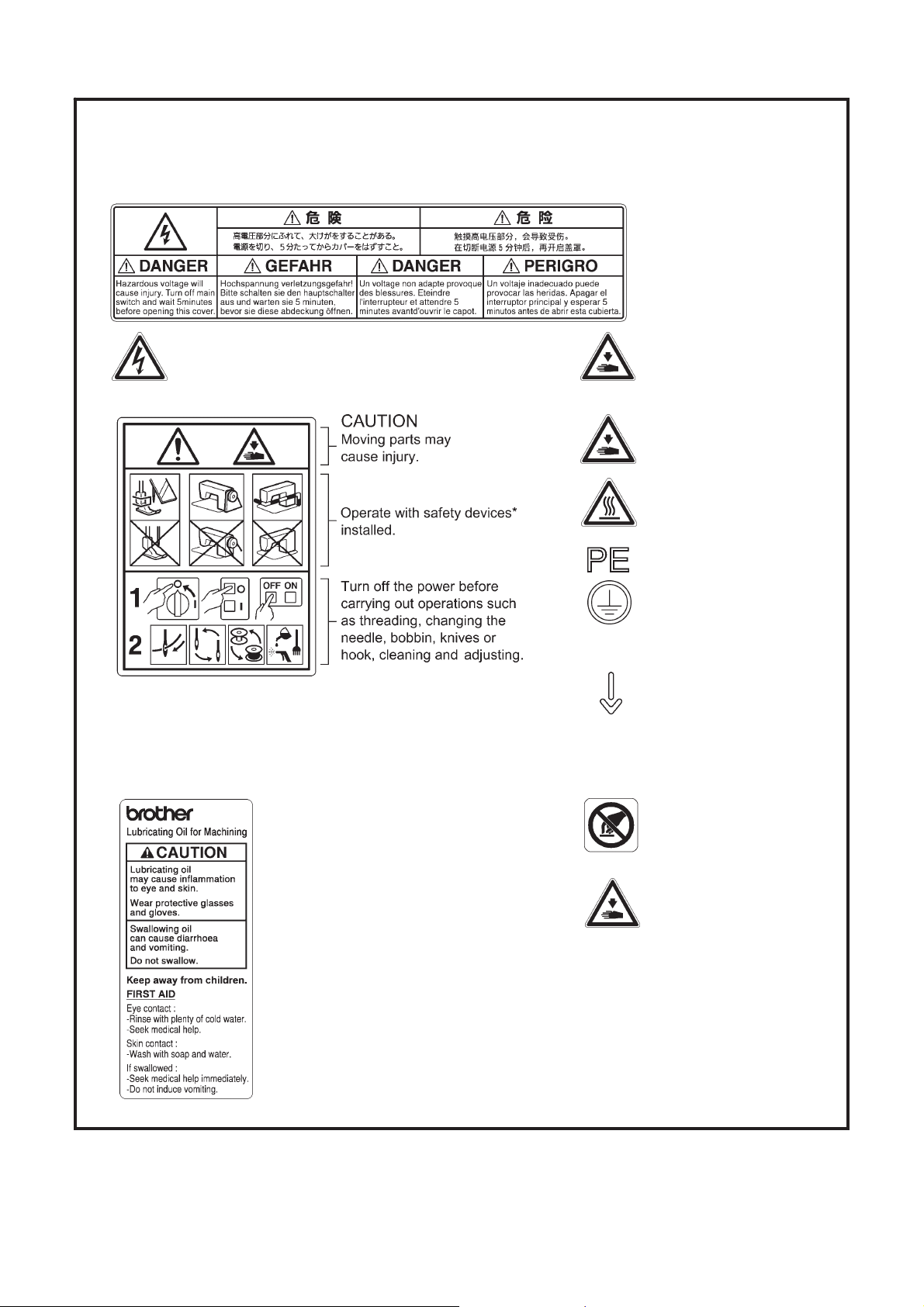

SAFETY INSTRUCTIONS

[1] Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided in order to ensure

safe operation of this machine and to prevent accidents and injury to yourself or other people.

The meanings of these indications and symbols are given below.

Indications

DANGER

CAUTION

Symbols

WARNING

· · · · ·

· · · · ·

· · · · ·

This symbol ( ) indicates something that you should be careful of. The picture inside the triangle

indicates the nature of the caution that must be taken.

(For example, the symbol at left means “beware of injury”.)

This symbol ( ) indicates something that you must not do.

This symbol ( ) indicates something that you must do. The picture inside the circle indicates the

nature of the thing that must be done.

(For example, the symbol at left means “you must make the ground connection”.)

The instructions which follow this term indicate situations where failure to follow the

instructions will result in death or serious injury.

The instructions which follow this term indicate situations where failure to follow the

instructions could result in death or serious injury.

The instructions which follow this term indicate situations where failure to follow the

instructions may result in minor or moderate injury.

S-7250A

i

Page 4

[2] Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet

before opening the cover of the control box. Touching areas where high voltages are present can result in severe

injury.

Do not allow any liquids to get onto this sewing machine, otherwise fire, electric shocks or operating problems may

occur.

If any liquid gets inside the sewing machine (machine head or control box), immediately turn off the power and

disconnect the power plug from the electrical outlet, and then contact the place of purchase or a qualified

technician.

DANGER

WARNING

CAUTION

Environmental requirements

Use the sewing machine in an area which is free

from sources of strong electrical noise such as

electrical line noise or static electric noise.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltage

should be within 10% of the rated voltage for the

machine.

Voltage fluctuations which are greater than this

may cause problems with correct operation.

The power supply capacity should be greater than

the requirements for the sewing machine's power

consumption.

Insufficient power supply capacity may cause

problems with correct operation.

Machine installation should only be carried out by

a qualified technician.

Contact your Brother dealer or a qualified

electrician for any electrical work that may need to

be done.

The sewing machine weighs approximately 35 kg

(77lb). The installation should be carried out by

two or more people.

Do not connect the power cord until installation is

complete. The machine may operate if the treadle

is depressed by mistake, which could result in

injury.

Turn off the power switch before inserting or

removing the plug, otherwise damage to the

control box could result.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

When securing the cords, do not bend the cords

excessively or fasten them too hard with staples,

otherwise there is the danger that fire or electric

shocks could occur.

Installation

The ambient temperature should be within the

range of 5C to 35C during use.

Temperatures which are lower or higher than this

may cause problems with correct operation.

The relative humidity should be within the range of

45% to 85% during use, and no dew formation

should occur in any devices.

Excessively dry or humid environments and dew

formation may cause problems with correct

operation.

In the event of an electrical storm, turn off the power

and disconnect the power cord from the wall outlet.

Lightning may cause problems with correct

operation.

Do not connect anything to the USB port other than

the USB memory. If this is not observed, problems

with operation may result.

If using a work table which has casters, the casters

should be secured in such a way so that they

cannot move.

Secure the table so that it will not move when tilting

back the machine head. If the table moves, it may

crush your feet or cause other injuries.

Use both hands to hold the machine head when

tilting it back or returning it to its original position. If

only one hand is used, the weight of the machine

head may cause your hand to slip, and your hand

may get caught.

Be sure to wear protective goggles and gloves

when handling the lubricating oil and grease, so that

they do not get into your eyes or onto your skin,

otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease

under any circumstances, as they can cause

vomiting and diarrhea.

Keep the oil out of the reach of children.

ii

S-7250A

Page 5

This sewing machine should only be used by

operators who have received the necessary training

in safe use beforehand.

The sewing machine should not be used for any

applications other than sewing.

Be sure to wear protective goggles when using the

machine.

If goggles are not worn, there is the danger that if a

needle breaks, parts of the broken needle may enter

your eyes and injury may result.

Turn off the power switch at the following times.

The machine may operate if the treadle is

depressed by mistake, which could result in injury.

When threading the needle

When replacing the bobbin and needle

When not using the machine and when leaving

the machine unattended

If using a work table which has casters, the casters

should be secured in such a way so that they

cannot move.

CAUTION

Sewing

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Do not touch any of the moving parts or press any

objects against the machine while sewing, as this

may result in personal injury or damage to the

machine.

Secure the table so that it will not move when tilting

back the machine head. If the table moves, it may

crush your feet or cause other injuries.

Use both hands to hold the machine head when

tilting it back or returning it to its original position. If

only one hand is used, the weight of the machine

head may cause your hand to slip, and your hand

may get caught.

If an error occurs in machine operation, or if

abnormal noises or smells are noticed, immediately

turn off the power switch. Then contact your nearest

Brother dealer or a qualified technician.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

Cleaning

Turn off the power switch before carrying out

cleaning. The machine may operate if the treadle is

depressed by mistake, which could result in injury.

Secure the table so that it will not move when tilting

back the machine head. If the table moves, it may

crush your feet or cause other injuries.

Use both hands to hold the machine head when

tilting it back or returning it to its original position. If

only one hand is used, the weight of the machine

head may cause your hand to slip, and your hand

may get caught.

Maintenance and inspection

Maintenance and inspection of the sewing machine

should only be carried out by a qualified technician.

Ask your Brother dealer or a qualified electrician to

carry out any maintenance and inspection of the

electrical system.

Turn off the power switch and disconnect the power

cord from the wall outlet at the following times,

otherwise the machine may operate if the treadle is

depressed by mistake, which could result in injury.

When carrying out inspection, adjustment and

maintenance

When replacing consumable parts such as the

rotary hook and knife

Always be sure to turn off the power switch and then

wait one minute before opening the pulley cover. If

you touch the surface of the motor, it may cause

burns.

If the power switch needs to be left on when carrying

out some adjustment, make sure that you switch the

sewing machine to maintenance mode. Pay careful

attention to safety.

Be sure to wear protective goggles and gloves when

handling the lubricating oil and grease, so that they

do not get into your eyes or onto your skin,

otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease

under any circumstances, as they can cause

vomiting and diarrhea.

Keep the oil out of the reach of children.

Secure the table so that it will not move when tilting

back the machine head. If the table moves, it may

crush your feet or cause other injuries.

Use both hands to hold the machine head when

tilting it back or returning it to its original position.

If only one hand is used, the weight of the machine

head may cause your hand to slip, and your hand

may get caught.

When replacing parts and installing optional

accessories, be sure to use only genuine Brother

parts.

Brother will not be held responsible for any

accidents or problems resulting from the use of

non-genuine parts.

If any safety devices have been removed, be

absolutely sure to re-install them to their original

positions and check that they operate correctly

before using the machine.

To prevent accidents and problems, do not modify

the machine yourself.

Brother will not be held responsible for any

accidents or problems resulting from modifications

made to the machine.

S-7250A

iii

Page 6

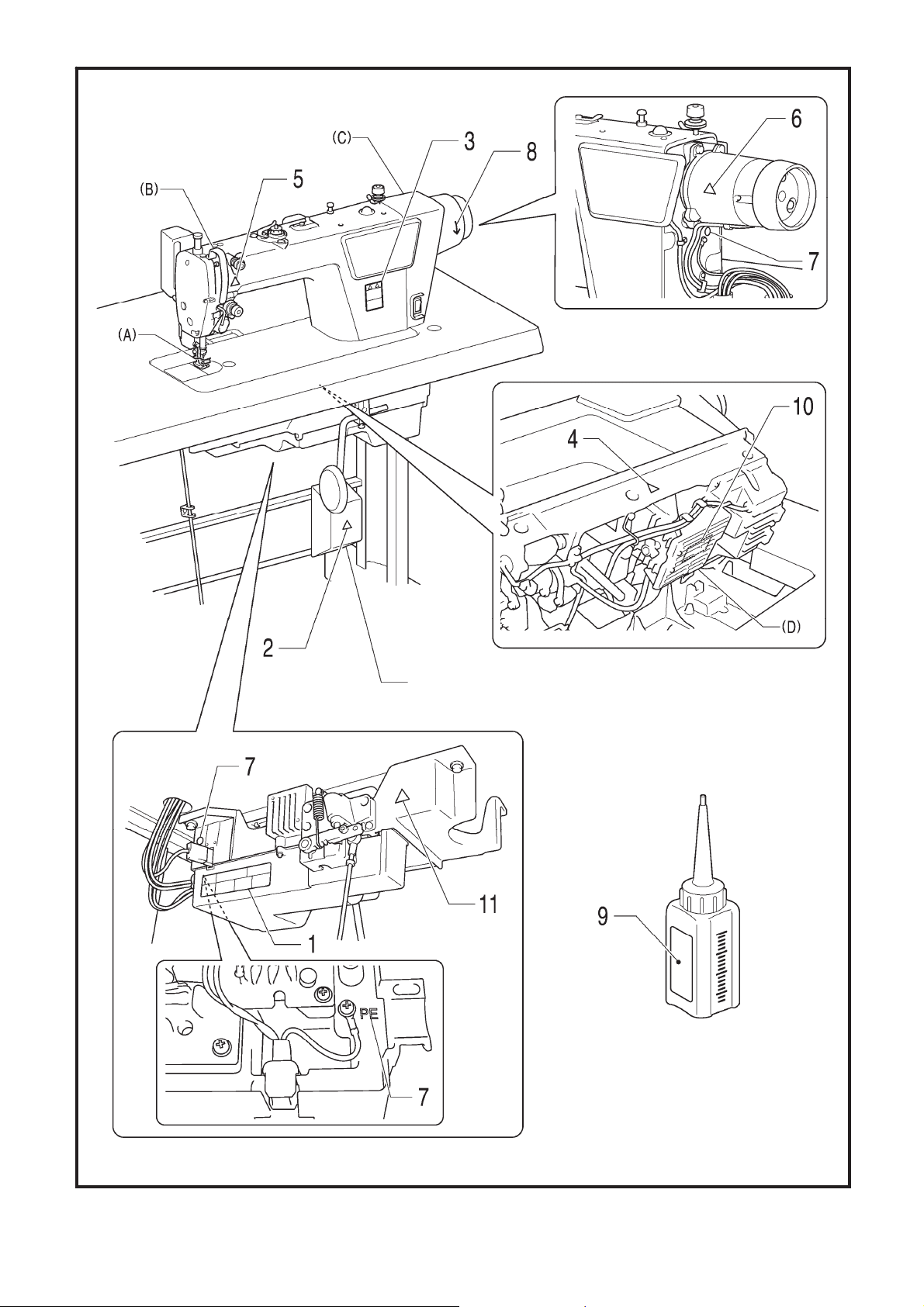

[3] Warning labels

The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have been removed or are

difficult to read, please contact your nearest Brother dealer.

1

2

3

* Safety devices: (A) Finger guard

Touching areas where high voltages are present can

result in severe injury. Turn off the power before

opening the cover.

(B) Thread take-up cover

(C) Motor cover

(D) Pulse motor cover

9

4

5

6

7

8

10

Be careful not to get your

hands caught when returning

the machine head to its

original position after it has

been tilted.

Be careful to avoid injury from

the moving thread take-up.

High temperature warning

display

Be sure to connect the ground.

If the ground connection is not

secure, you run a high risk of

receiving a serious electric

shock, and problems with

correct operation may also

occur.

Direction of operation

Do not hold. Problems with

operation or injury may

occur.

iv

S-7250A

11

Do not place your hands

inside the bottom cover.

Problems with operation or

injury may occur.

Page 7

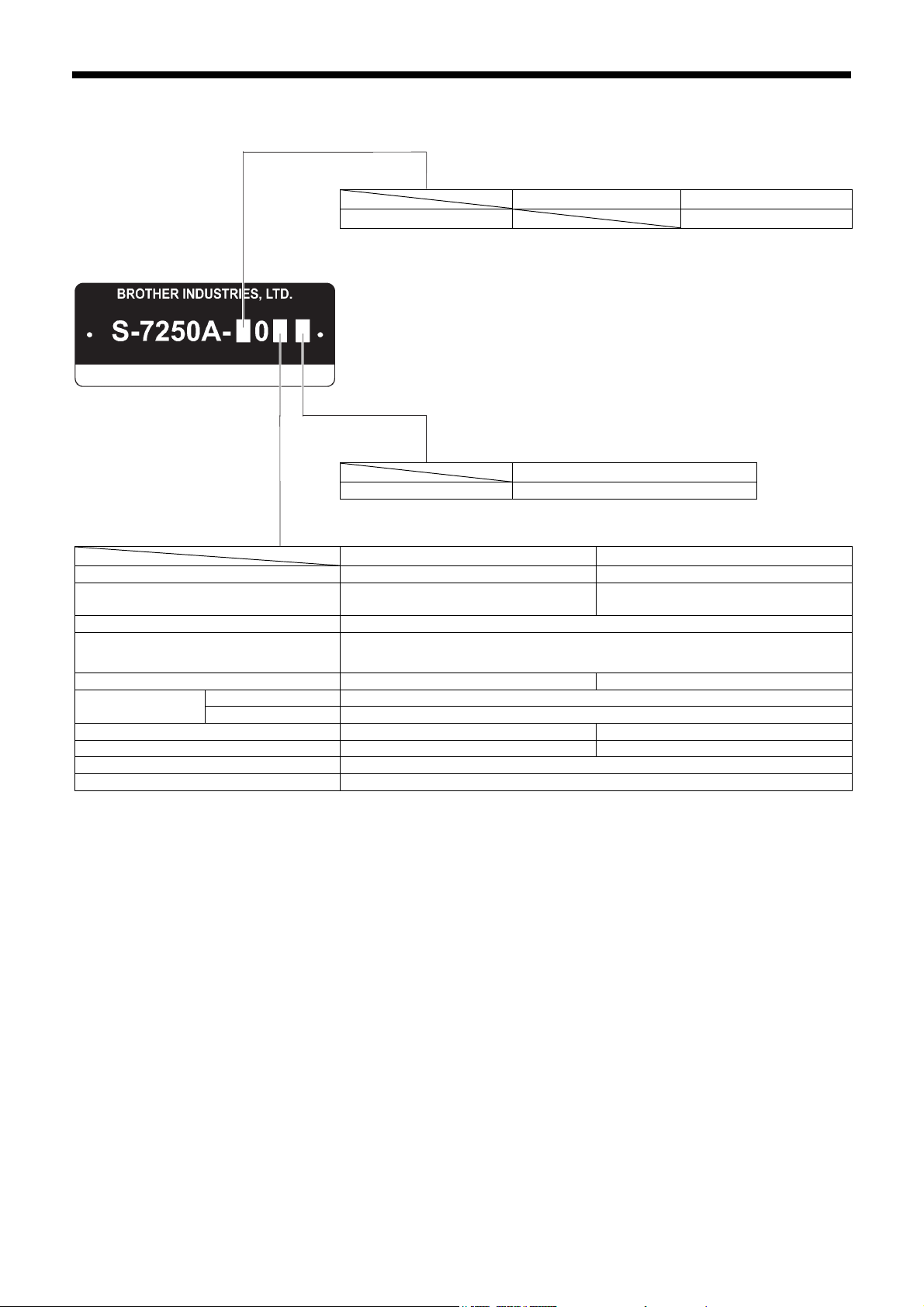

Transformer box

(100V/110V/380V/400V)

Oil tank

S-7250A

1460D

v

Page 8

CONTENTS

1. MACHINE SPECIFICATIONS ............... 1

2. INSTALLATION ..................................... 2

2-1. Table processing diagram ................................ 3

2-2. Installation ........................................................ 3

2-3. Lubrication ........................................................ 6

2-4. Connecting the cords ........................................ 7

2-4-1. Connecting the cords ............................. 7

2-4-2. Other cords ............................................ 9

3. USING THE OPERATION PANEL

(BASIC OPERATIONS) ........................ 13

3-1. Names and functions ...................................... 13

3-2. Sewing start and end backtack stitches ......... 15

3-3. Sewing continuous backtack stitches ............. 16

4. USING THE OPERATION PANEL

(ADVANCED OPERATIONS) .............. 17

4-1. Sewing pitch setting method .......................... 17

4-2. Switching the 4-digit display ........................... 18

4-3. Setting the sewing speed ............................... 18

4-3-1. Setting the maximum sewing speed .... 18

4-3-2. Backtack sewing speed setting

method ................................................. 19

4-4. Setting the counters ........................................ 20

4-4-1. Lower thread counter ........................... 20

4-4-2. Production counter ............................... 21

4-4-3. Needle replacement counter ................ 22

4-5. Sewing locus setting meth .............................. 23

4-6. Setting basic functions .................................... 24

4-6-1. Changing the needle stop position ...... 25

4-6-2. Thread trimming disable ...................... 26

4-6-3. Thread wiping ...................................... 27

4-6-4. Correction sewing ................................ 28

4-6-5. Slow start ............................................. 29

4-6-6. Setting the illumination LED light ......... 30

4-6-7.

Setting lower thread counter operation

4-6-8. Prev. thread away ................................ 32

4-6-9. Short trailing thread .............................. 33

4-6-10. Correction sewing function (1) ........... 34

4-6-11. Correction sewing function (2) ........... 35

4-7. Memory switch setting method ....................... 36

4-8. List of memory switch settings ....................... 37

4-9. Reading and writing data using USB media ... 41

4-10. Resetting all settings to their defaults ........... 42

4-11. Hand switch .................................................. 43

4-11-1. Hand switch function setting .............. 45

4-11-2. 2nd correction pitch setting ................ 46

4-11-3. 2nd pitch setting ................................. 46

. 31

4-11-4. Menu numbers for setting functions for

the hand switch .................................. 46

5. CLEANING ........................................... 47

6. STANDARD ADJUSTMENTS .............. 48

6-1. Arm thread guide R ......................................... 48

6-2. Presser foot height .......................................... 49

6-3. Adjusting the feed dog height ......................... 50

6-4. Adjusting the feed dog angle .......................... 51

6-5. Adjusting the needle bar height ...................... 51

6-6. Adjusting the needle and feed mechanism

timing ............................................................... 52

6-7. Needle and rotary hook timing ........................ 53

6-8. ADJUSTING THE ROTARY HOOK

LUBRICATION AMOUNT ............................... 54

6-9. Thread trimming (Other than short trailing thread

specifications) ................................................. 55

6-10. Thread trimming (Short trailing thread

specifications) ............................................... 58

7. TROUBLESHOOTING .......................... 61

7-1. Sewing ............................................................ 61

7-2. Error code displays ......................................... 68

8. 7-SEGMENT DISPLAY ......................... 72

S-7250A

Page 9

S-7250A

Page 10

1. MACHINE SPECIFICATIONS

1. MACHINE SPECIFICATIONS

Thread wiper

1424D

Specifications Short trailing thread specifications

Use For medium-weight materials For heavy-weight materials

Max. sewing speed

* Standard feed locus

Sewing speed at the time of shipment 4,000 sti/min

Backtack sewing speed

* Standard feed locus

Max. stitch length 5 mm 5 mm (can be set to 7 mm)

Presser foot

height

Feed dog height 0.8 mm 1.2 mm

Needle (DB×1, DP×5) #11 - #18 #19 - #22

Motor AC servo motor

Control circuit Microprocessor

Lifting lever 6 mm

Knee lifter 13 mm

Stitch length 2.0 mm or less/

Automatic 150 (*1) - 3000 sti/min, Manual 150 (*1) - 4000 sti/min*

3 5

5,000 sti/min

(*1) Inching setting speed

3 4

P

4,000 sti/min

O

1

S-7250A

Page 11

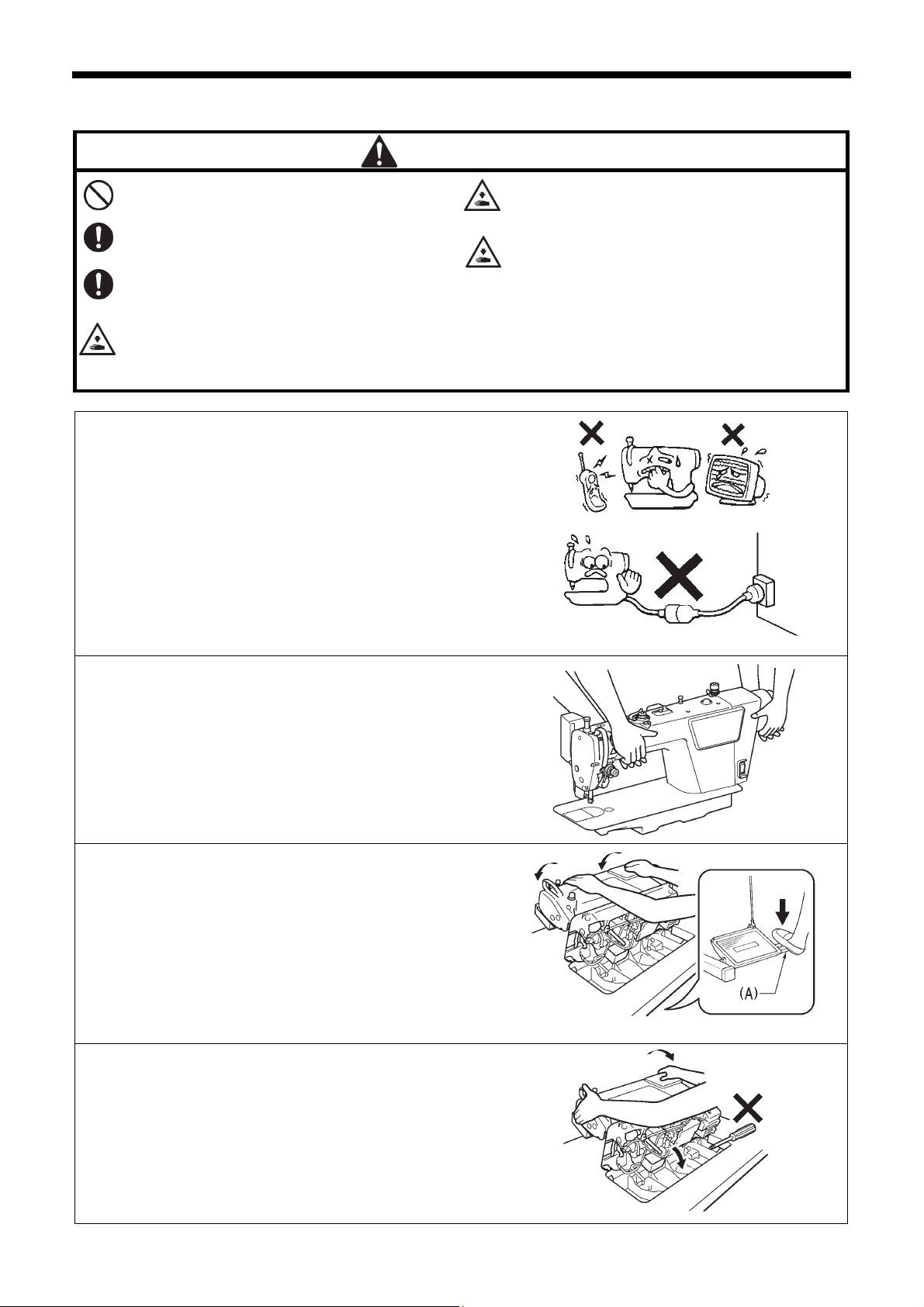

2. INSTALLATION

CAUTION

Machine installation should only be carried out by a

qualified technician.

Contact your Brother dealer or a qualified electrician

for any electrical work that may need to be done.

The sewing machine weighs approximately 35 kg

(77lb). The installation should be carried out by two

or more people.

Do not connect the power cord until installation is

complete.

The machine may operate if the treadle is

depressed by mistake, which could result in injury.

About the machine set-up location

・ Do not set up this sewing machine near other equipment such as

televisions, radios or cordless telephones, otherwise such

equipment may be affected by electronic interference from the

sewing machine.

・ The sewing machine should be plugged directly into an AC wall

outlet. Operation problems may result if extension cords are

used.

2. INSTALLATION

Secure the table so that it will not move when tilting

back the machine head. If the table moves, it may

crush your feet or cause other injuries.

Use both hands to hold the machine head when

tilting it back or returning it to its original position.

If only one hand is used, the weight of the machine

head may cause your hand to slip, and your hand

may get caught.

0475D

Carrying the machine

・ The sewing machine should be carried by the arm and the motor

cover by two people as shown in the illustration.

* Do not hold by any part other than the motor cover. If this is not

observed, it may result in damage to the sewing machine.

Tilting back the machine head

・ Hold section (A) with your foot so that the table does not move,

and then push the arm with both hands to tilt back the machine

head.

Returning the machine head to the upright position

1. Clear away any tools, etc. which may be near the table holes.

2. While holding the face plate with your left hand, gently return the

machine head to the upright position with your right hand.

1341D

1342D

1343D

S-7250A

2

Page 12

2. INSTALLATION

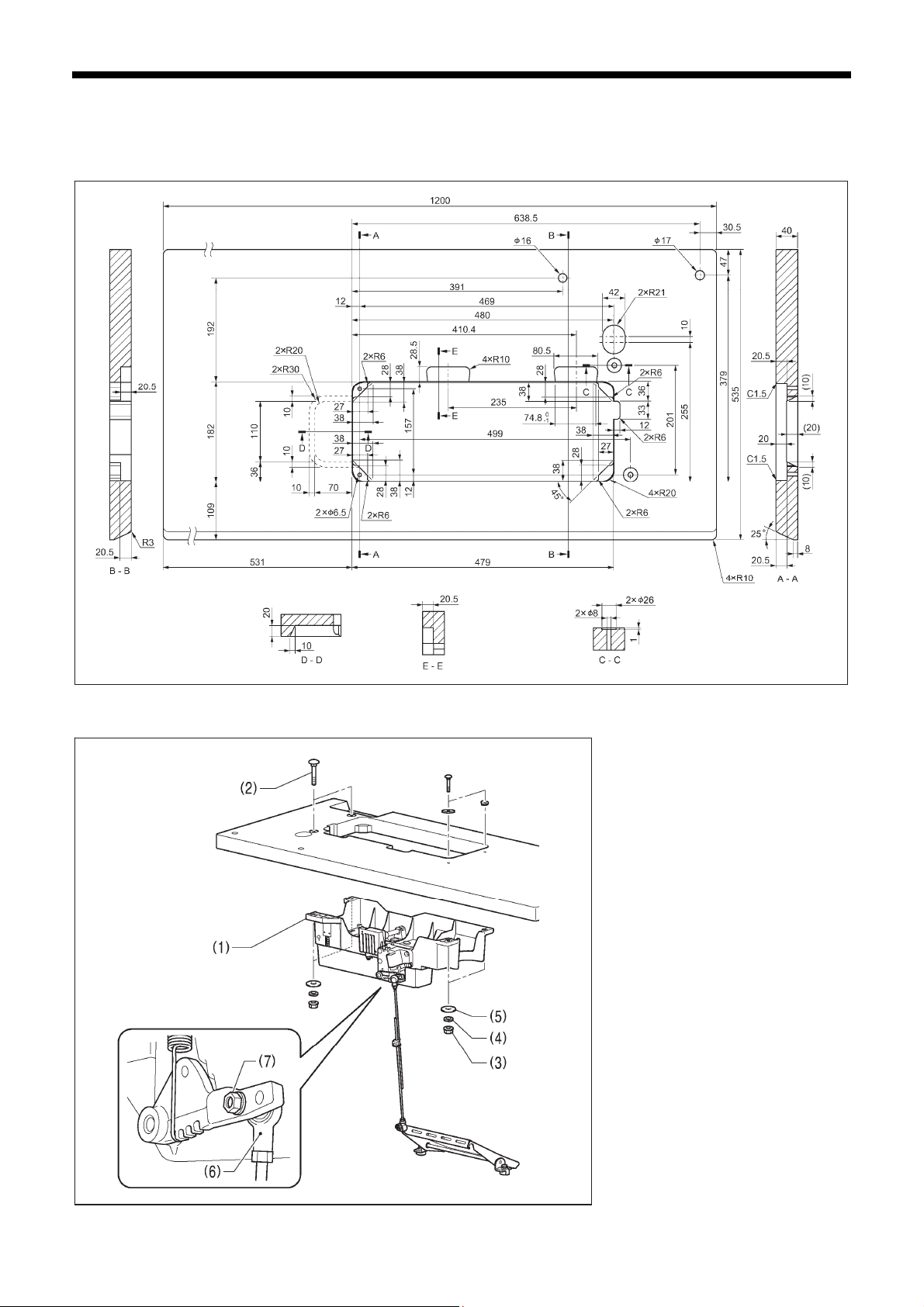

2-1. Table processing diagram

・ The top of the table should be 40 mm in thickness and should be strong enough to hold the weight and withstand the

vibration of the sewing machine.

・ Drill holes as indicated in the illustration below.

Head rest hole

Cotton stand hole

Cord hole

Control box

mounting hole

Control box

mounting hole

1412D

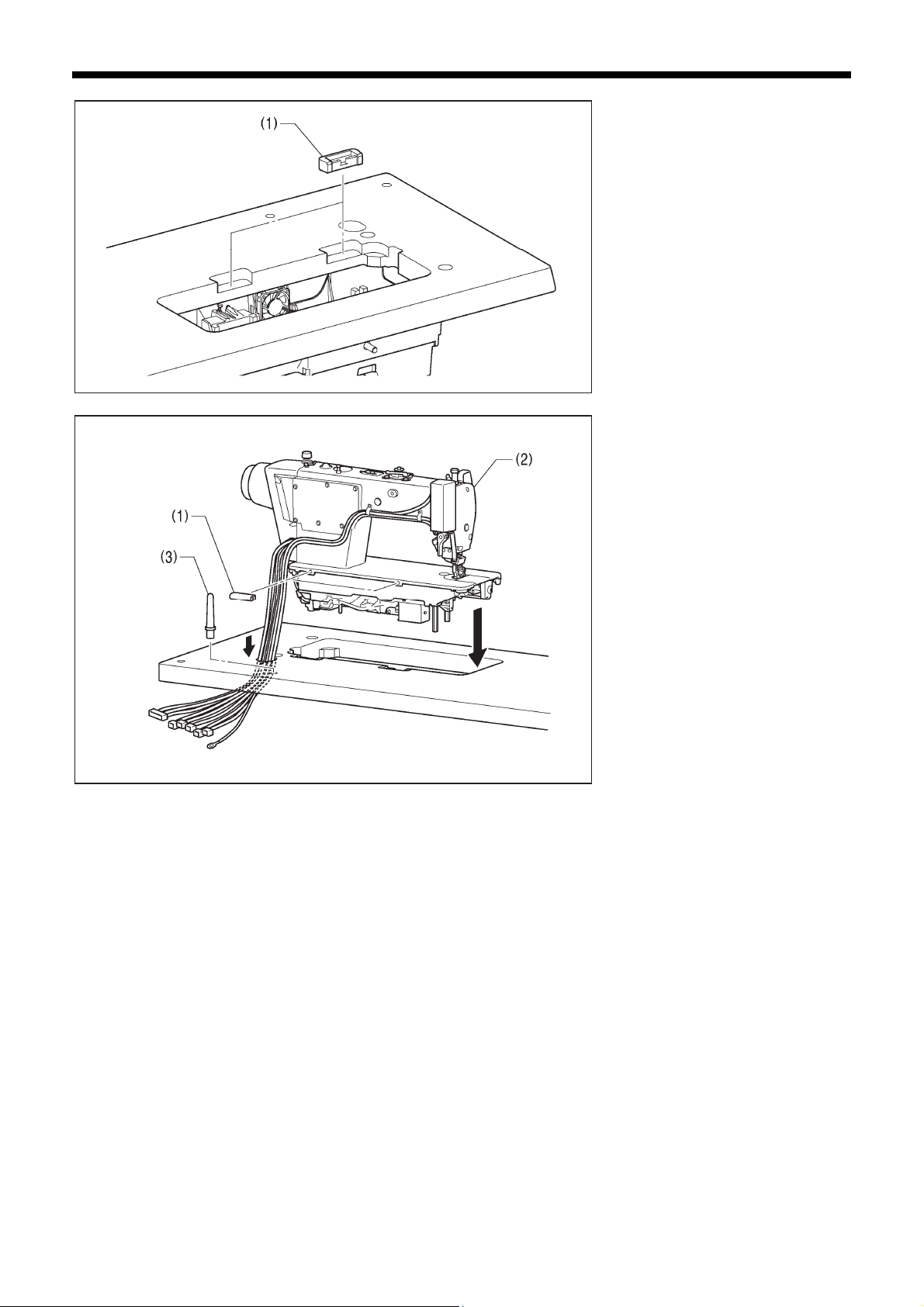

2-2. Installation

1. Control box + Oil pan

(1) Control box

(2) Bolts [4 pcs]

(3) Nuts [4 pcs]

(4) Spring washers [4 pcs]

(5) Washers [4 pcs]

2. Connecting rod

(6) Connecting rod

(7) Nut

3

S-7250A

Page 13

2. INSTALLATION

3. Rubber cushions

(1) Rubber cushions [2 pcs]

1414D

4. Machine head

(1) Hinges [2 pcs]

(2) Machine head

(3) Head rest

NOTE:

・ Bind the cords together and pass

them through the cord hole.

・ Tap the head rest (3) securely into

the table hole.

・ If the head rest (3) is not pushed in

as far as it will go, the machine head

will not be sufficiently stable when it

is tilted back.

1415D

S-7250A

4

Page 14

2. INSTALLATION

10mm

5

1416D

Within 13 mm

1417D

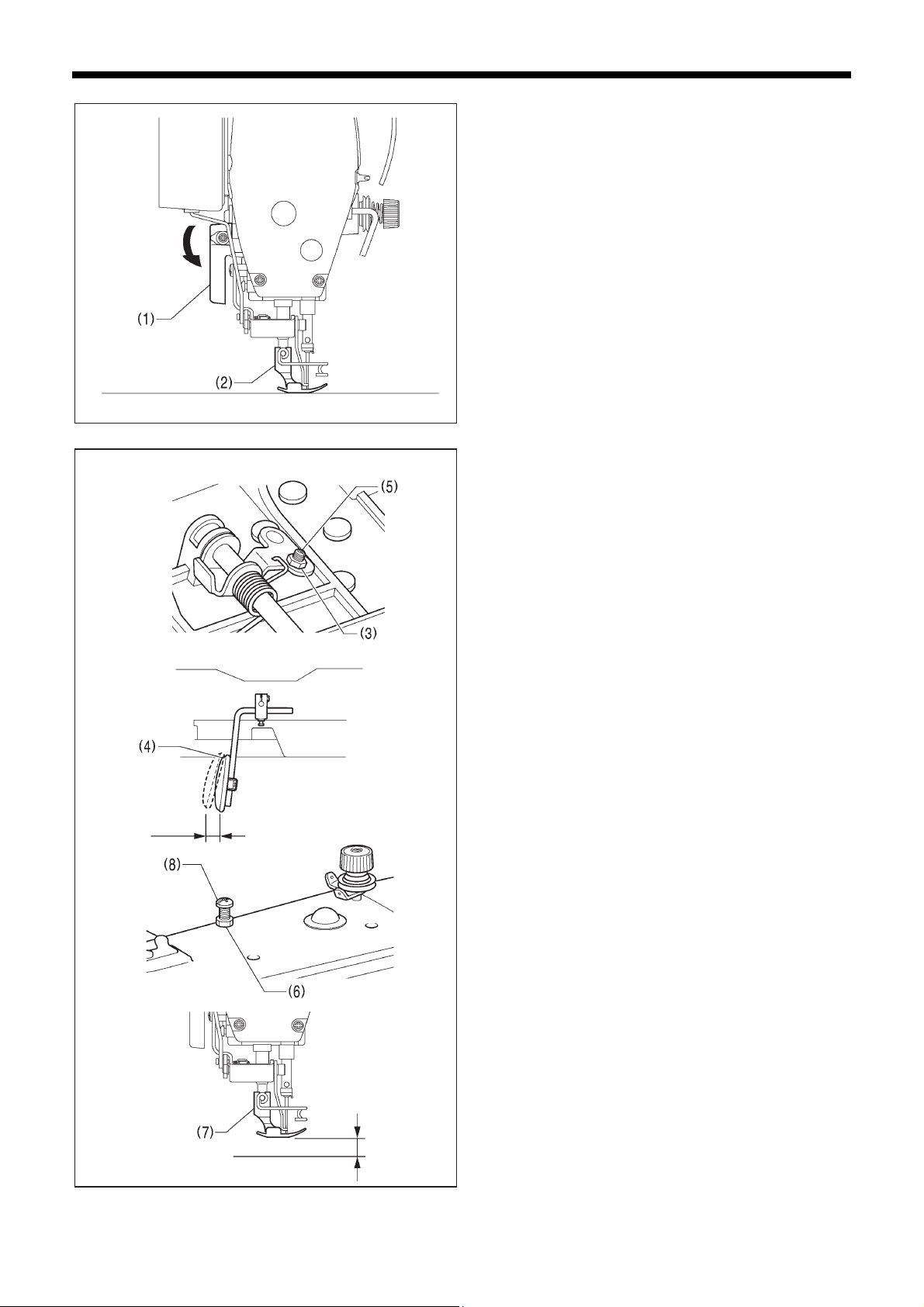

5. Knee lifter plate

<Knee lifter adjustment>

1. Turn the machine pulley so that the feed dog is below the

top of the needle plate.

2. Lower the presser foot (1) by using the lifting lever (2).

3. Loosen the nut (3).

4. Turn the screw (5) to adjust so that the amount of play in

the knee lifter plate (4) is approximately 10 mm.

5. After adjustment is completed, securely tighten the nut

(3).

6. Loosen the nut (6).

7. Turn the adjusting screw (8) to adjust so that the presser

foot (7) is at the desired position within a distance of 13

mm from the needle plate when the knee lifter plate is

fully pressed.

8. After adjustment is completed, securely tighten the nut

(6).

S-7250A

Page 15

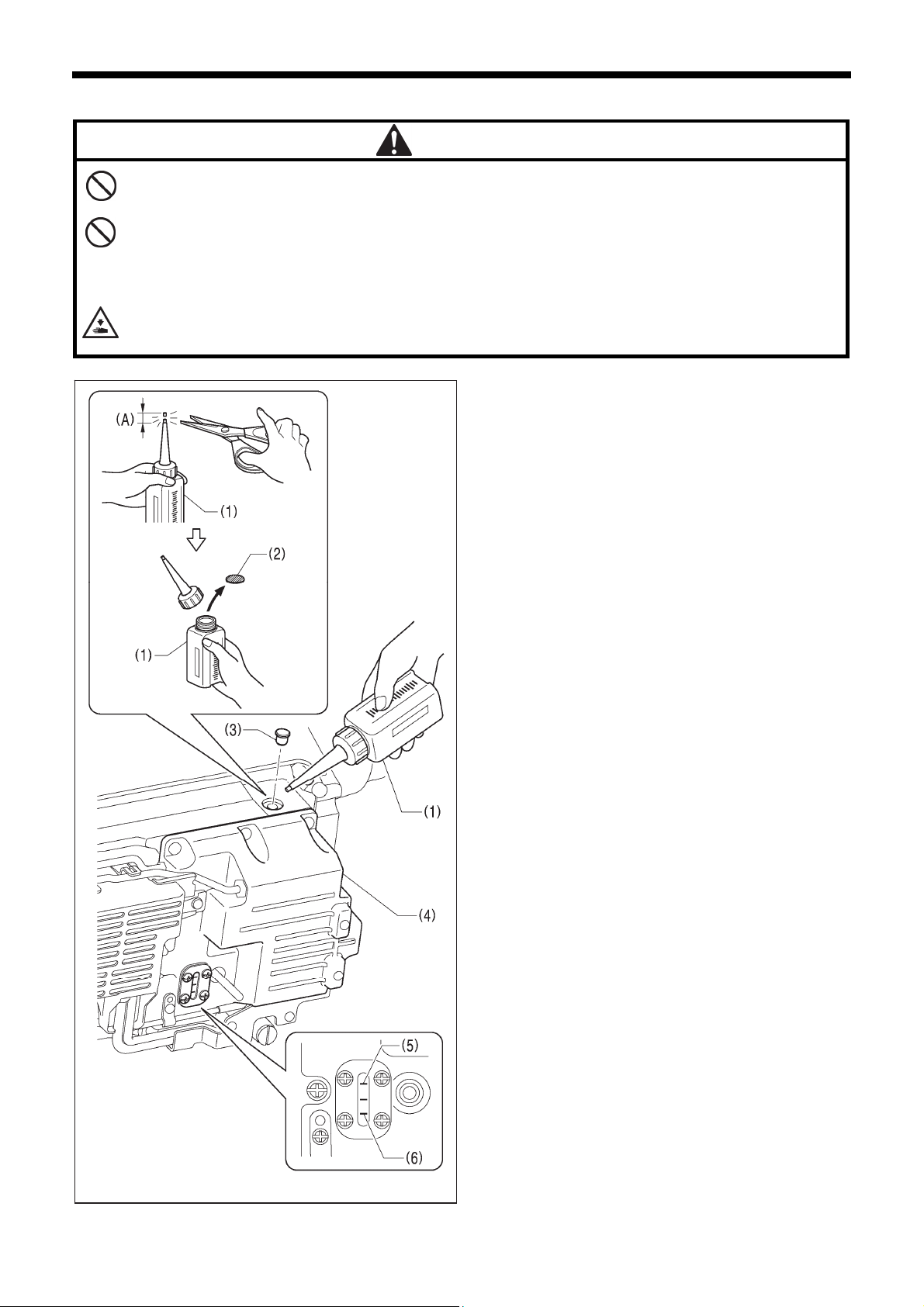

2-3. Lubrication

Do not connect the power cord until lubrication has been completed, otherwise the machine may operate if the

treadle is depressed by mistake, which could result in injury.

Be sure to wear protective goggles and gloves when handling the lubricating oil, so that it does not get into your

eyes or onto your skin.

If care is not taken, inflammation can result. Furthermore, do not drink the lubricating oil. Diarrhea or vomiting may

result.

Keep the oil out of the reach of children.

When cutting the nozzle of the oil tank, hold the base of the nozzle securely.

If you hold the end of the nozzle, injury from the scissors may result.

2. INSTALLATION

CAUTION

The sewing machine should always be lubricated and the oil

supply replenished before it is used for the first time, and also

after long periods of non-use.

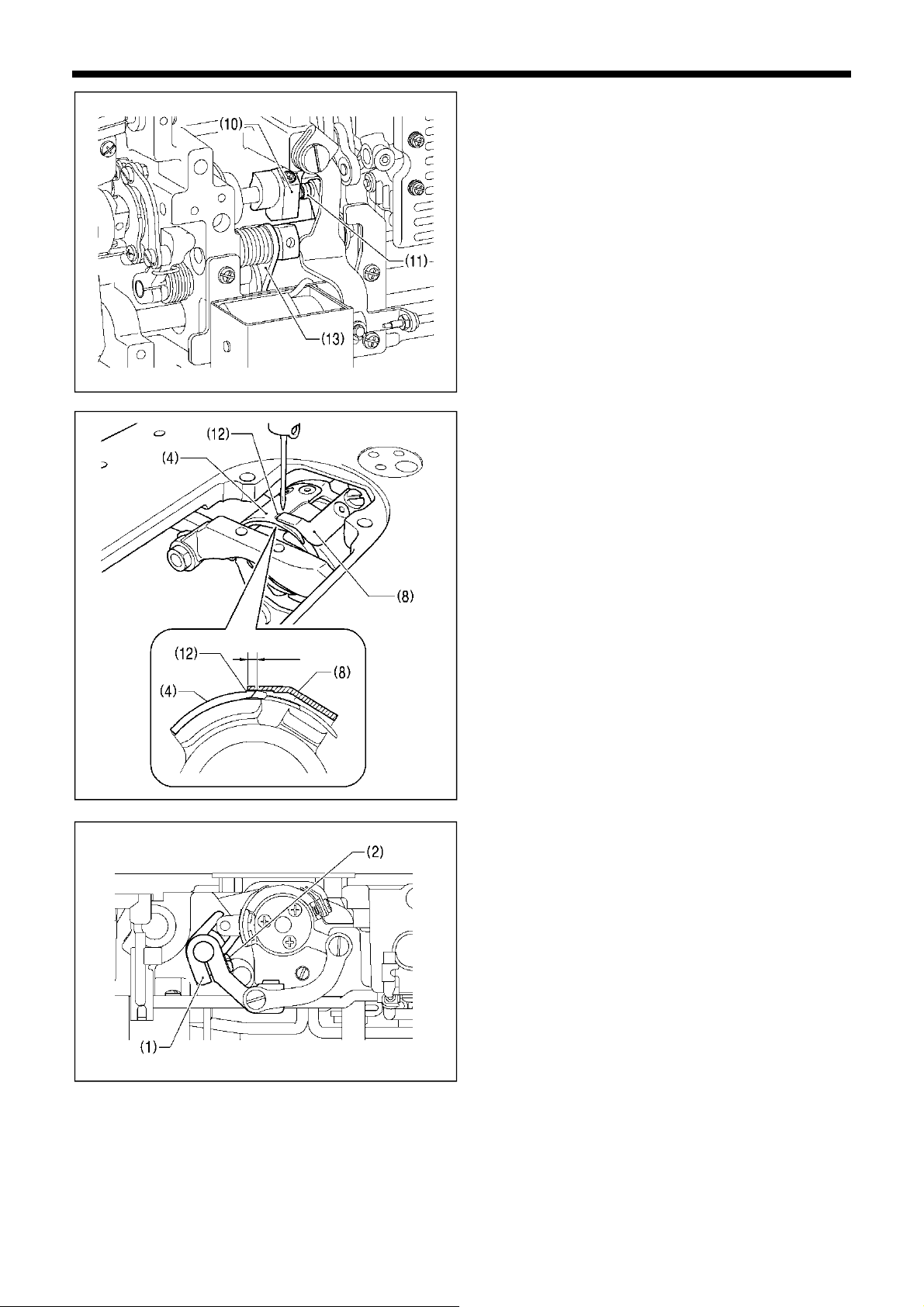

1. Hold the base of the nozzle of the accessory oil tank (1),

and use scissors to cut about half-way along the straight

section (A) of the nozzle.

2. Loosen and remove the nozzle, and then remove the seal

(2).

3. Tighten the nozzle.

4. Tilt back the machine head.

5. Remove the rubber cap (3), and pour lubricating oil into

the oil cover (4) until it reaches the upper reference line

(5).

6. Replace the rubber cap (3).

7. Return the machine head to its original position.

NOTE:

When the machine head is tilted back at times such as the

following, lubricating oil may leak out from the oil cover (4).

1) If lubricating oil is added until the oil level goes above

the upper reference line (5) on the oil cover (4).

<Lubrication oil replenishment interval>

If the oil level drops below the lower reference line (6) on the

oil cover (4), be sure to replenish the oil.

Upper

reference line

Lower

reference line

1418D

S-7250A

6

Page 16

2. INSTALLATION

2-4. Connecting the cords

Contact your Brother dealer or a qualified electrician for any electrical work that may need to be done.

Do not connect the power cord until all cords have been connected.

The machine may operate if the treadle is depressed by mistake, which could result in injury.

When securing the cords, do not bend the cords excessively or fasten them too hard with staples, otherwise there is

the danger that fire or electric shocks could occur.

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a serious

electric shock, and problems with correct operation may also occur.

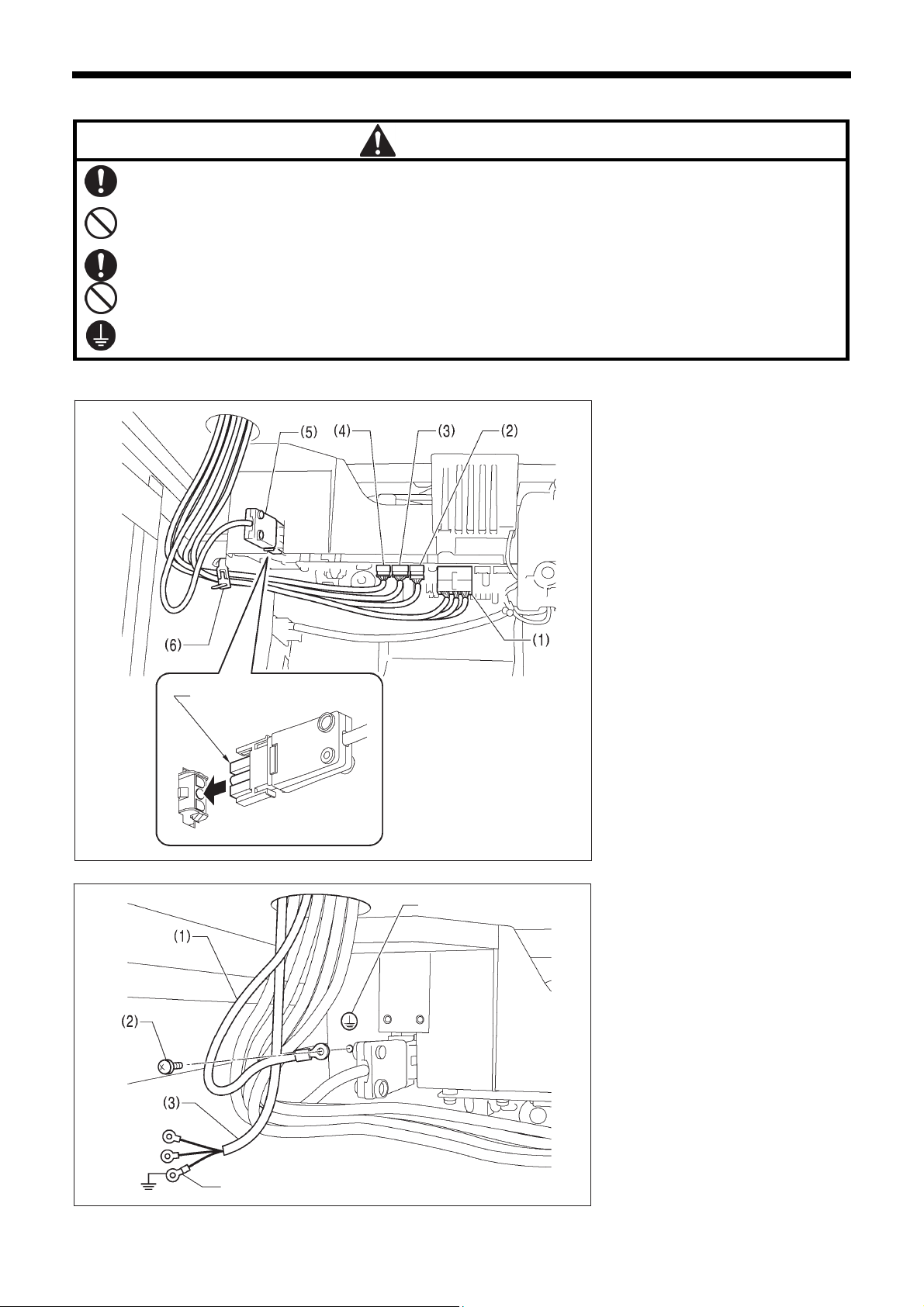

2-4-1. Connecting the cords

Align the flat edges

CAUTION

Ground symbol

1419D

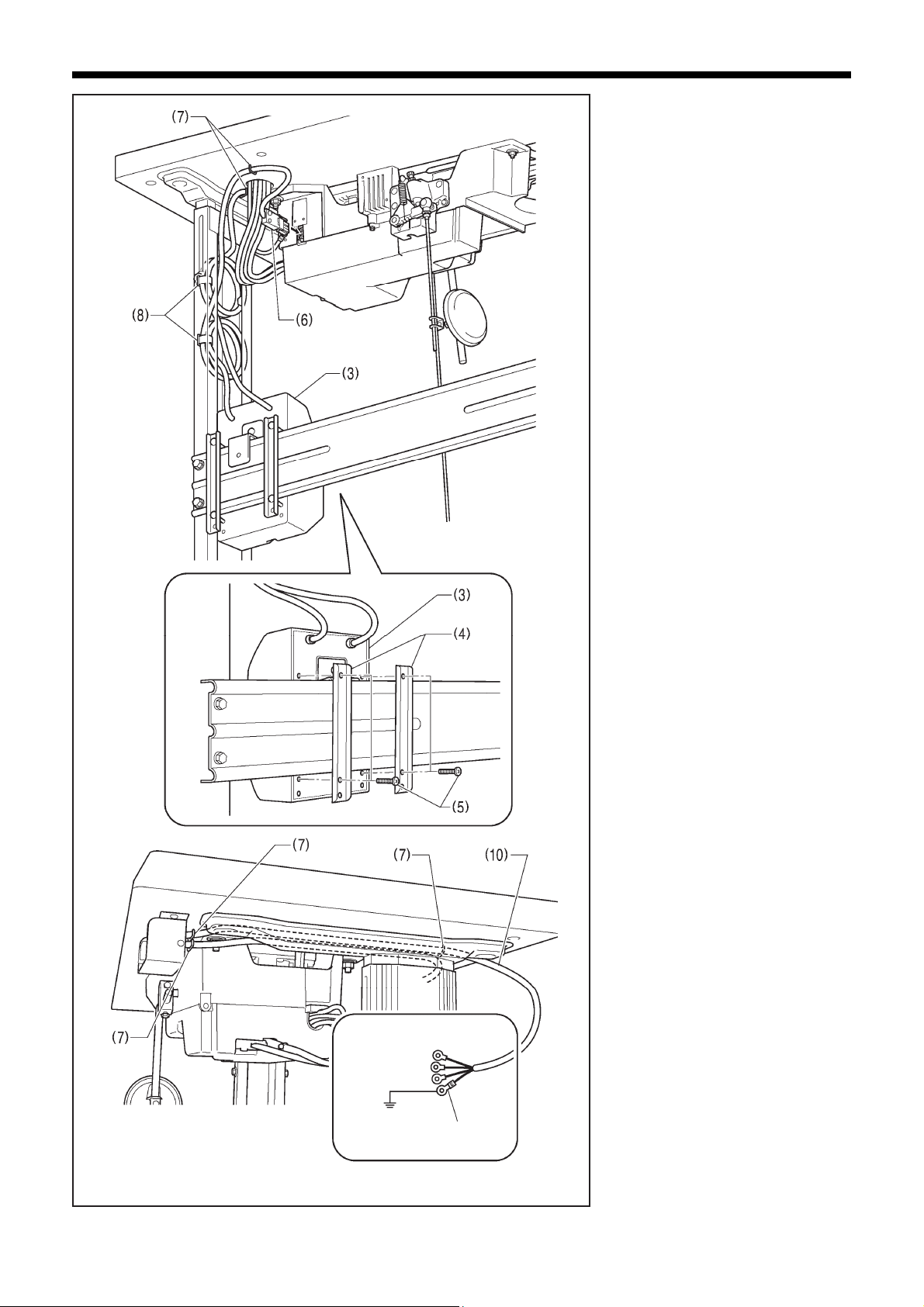

1. Cor ds ( 1)

(1) Solenoid connector 14-pin

(2) Sewing machine motor encoder

connector 10-pin

(3) Feed motor encoder connector

6-pin

(4) Operation panel connector 5-pin

(5) Power connector 3-pin

1. Secure the cords to the control box

with the black band (6).

NOTE:

For Europe specifications, Americas

220 V specifications and 100 V/400

V system specifications, refer to

“2-4-2. Other cords”.

2. Ground wire

(1) Ground wire

(2)

Screw

(3) Power cord

1. Attach an appropriate plug to the

power cord (3).

(The green and yellow wire is the

ground wire.)

2. Insert the power plug into a

properly-grounded electrical outlet.

7

Green and yellow wire (ground wire)

S-7250A

1420D

NOTE:

・ Make sure that the ground

connections are secure in order to

ensure safety.

・ For Europe specifications, Americas

220 V specifications and 100 V/400

V system specifications, refer to

“2-4-2. Other cords”.

Page 17

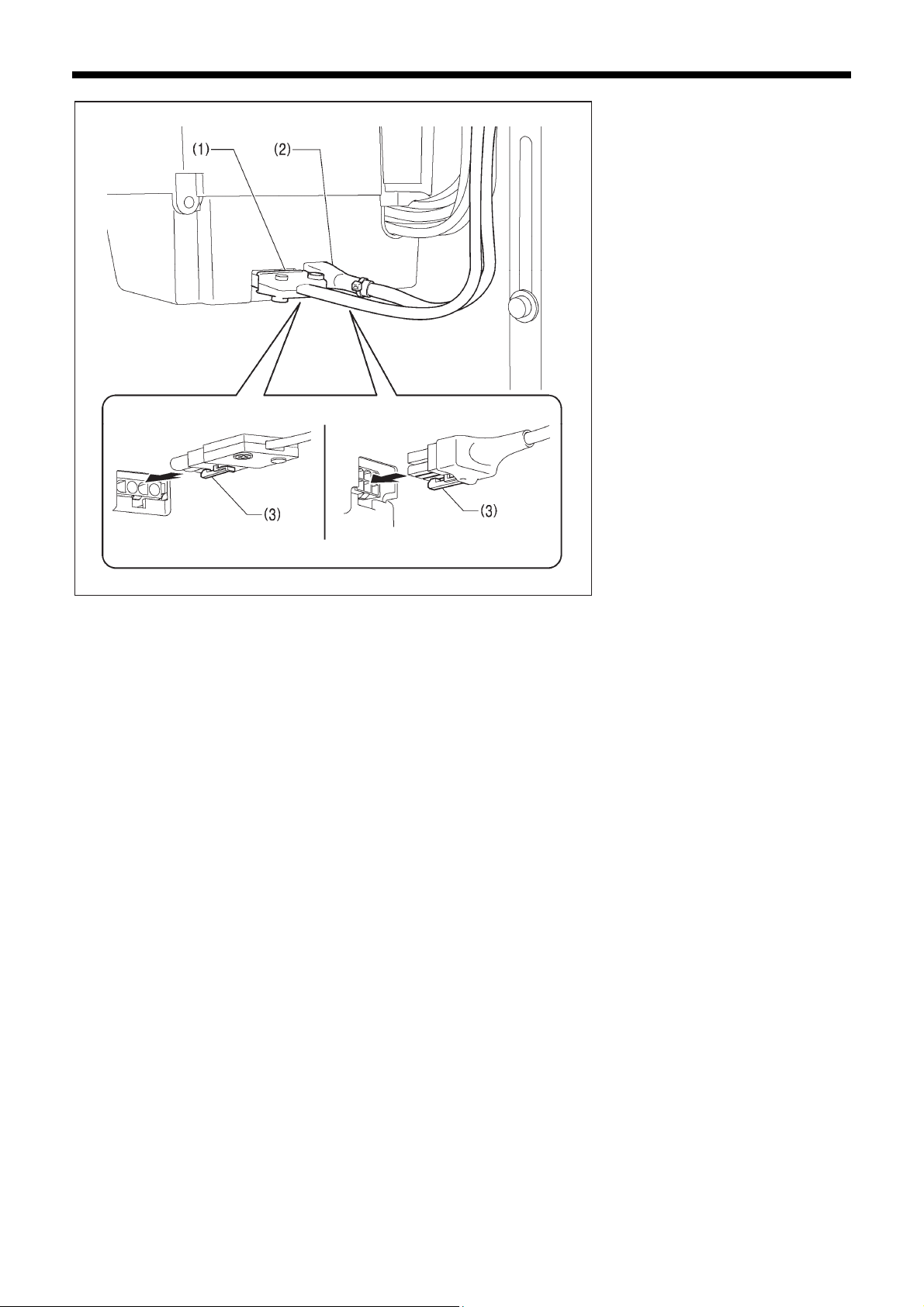

2. INSTALLATION

3. Cords (2)

(1) Machine motor connector 4-pin

(2) Feed motor connector 6-pin

Lower the tab (3).

Push in securely until the tabs (3) engage.

1421D

S-7250A

8

Page 18

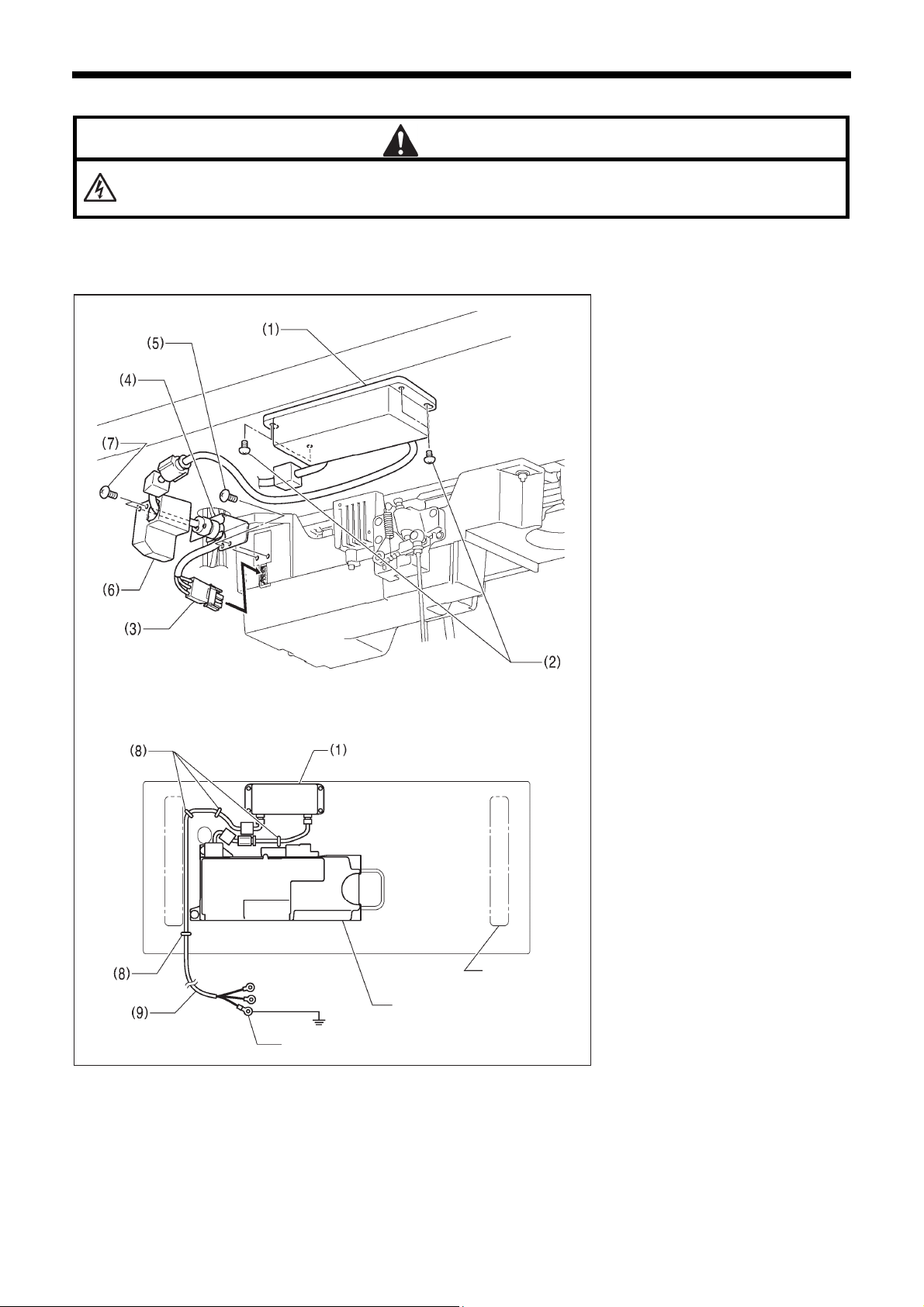

2. INSTALLATION

2-4-2. Other cords

DANGER

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet

before opening the cover of the control box. Touching areas where high voltages are present can result in severe

injury.

For Europe specifications, Americas 220 V specifications and 100 V/400 V system specifications, connect the cords

according to the respective specifications.

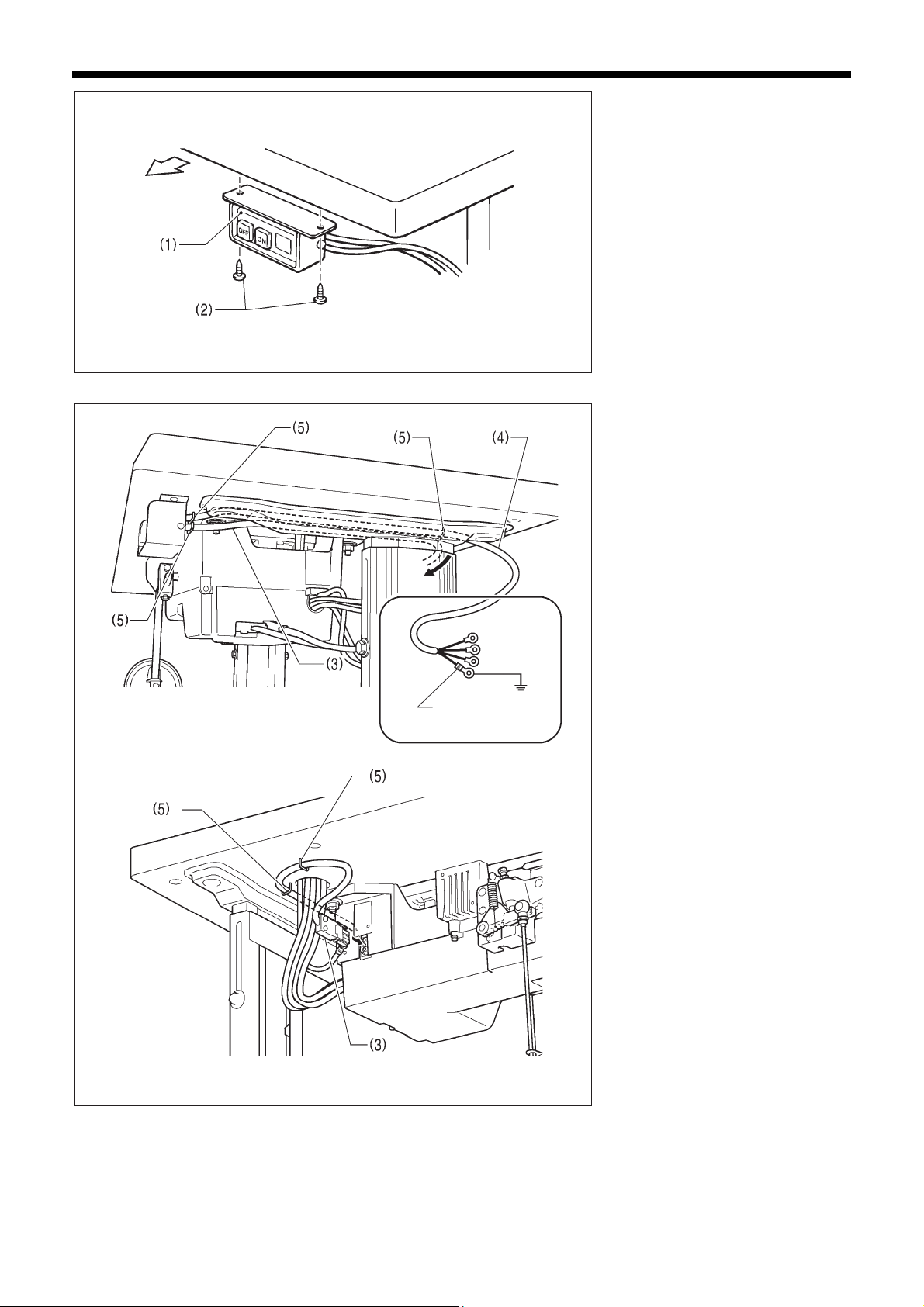

<Europe specifications>

(1) Filter box

(2) Screws [4 pcs]

(3) Connector

(4) CE bush plate

(5) Screws [2 pcs]

(6) CE D cord cover

(7) Screws [2 pcs]

(8) Staples [4 pcs]

(9) Power cord

1. Attach an appropriate plug to the

power cord (9). (The green and

yellow wire is the ground wire.)

2. Insert the power plug into a

properly-grounded electrical outlet.

<Seen from underneath table>

NOTE:

・ Take care when tapping in the

staples (8) to make sure that they do

not pierce the cords.

・ Do not use extension cords,

otherwise machine operation

problems may result.

Leg

Control box

Green and yellow wire (ground wire)

1480D

9

S-7250A

Page 19

For Europe specifications, Americas 220 V specifications and 100 V/400 V system specifications, connect the cords

according to the respective specifications.

<For 100 V/400 V system

specifications>

(1) Power switch

(2) Screws [2 pcs]

2. INSTALLATION

Operator

4145M

S-7250A

10

Page 20

2. INSTALLATION

(3) Transformer box

(4) Transformer box plates [2 pcs]

(5) Screws [with washer] [4 pcs]

(6) Power supply connector 3-pin

(7) Staples [5 pcs]

(8) Cord clamps [2 pcs]

(9) Power cord

1. Attach an appropriate plug to the

power cord (10).

(The green and yellow wire is the

ground wire.)

2. Insert the power plug into a

properly-grounded electrical outlet.

NOTE:

・ Take care when tapping in the

staples (7) to make sure that they do

not pierce the cords.

・ Do not use extension cords,

otherwise machine operation

problems may result.

11

Green and yellow wire

(ground wire)

1479D

S-7250A

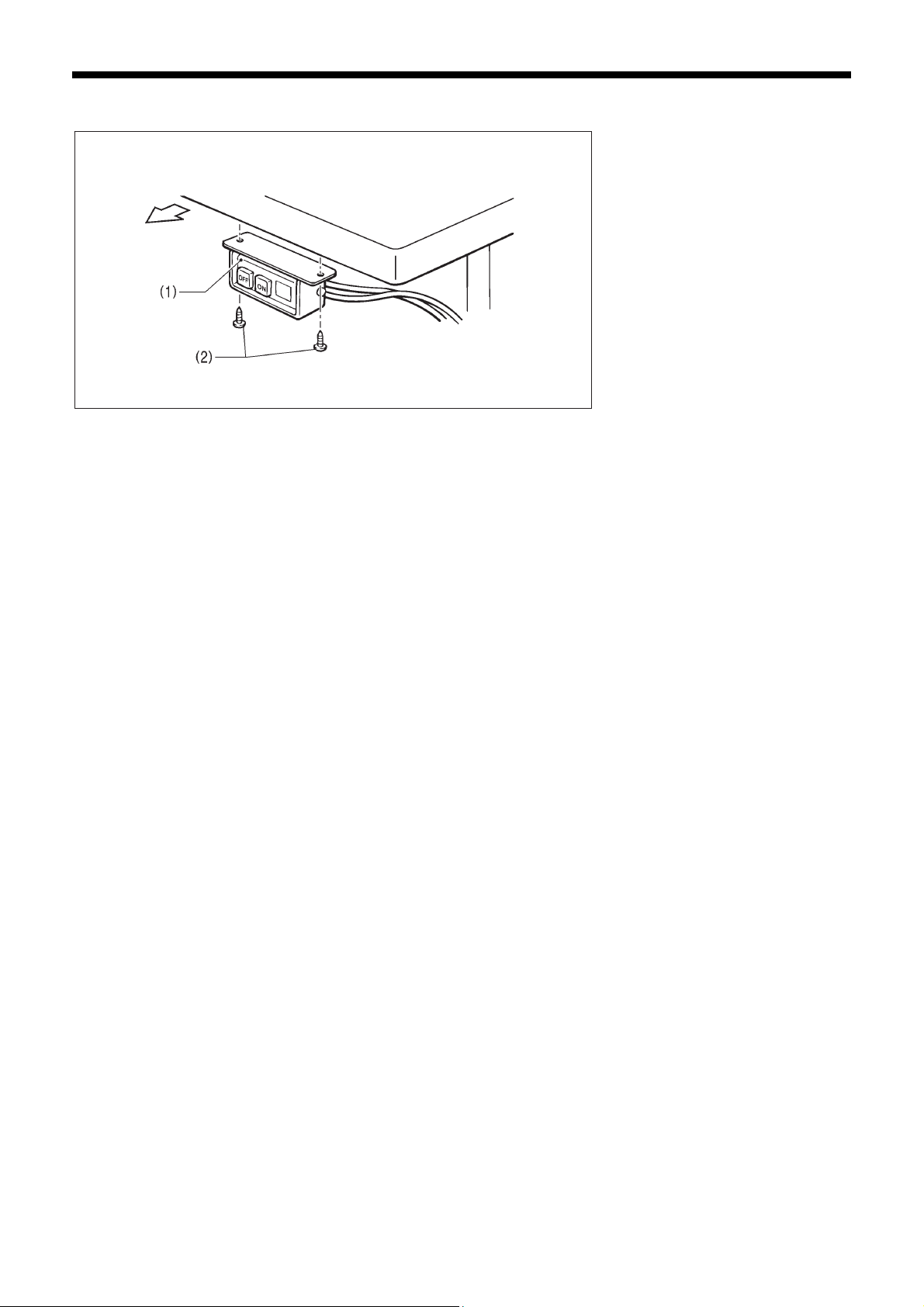

Page 21

2. INSTALLATION

<For Americas 220 V

specifications>

(1) Power switch

(2) Screws [2 pcs]

Operator

4145M

(3) Power supply connector 3-pin

(4) Power cord

(5) Staples [5 pcs]

1. Attach an appropriate plug to the

power cord (4).

(The green and yellow wire is the

ground wire.)

2. Insert the power plug into a

properly-grounded electrical outlet.

Green and yellow

wire (ground wire)

NOTE:

・ Take care when tapping in the

staples (5) to make sure that they do

not pierce the cords.

・ Do not use extension cords,

otherwise machine operation

problems may result.

S-7250A

1423D

12

Page 22

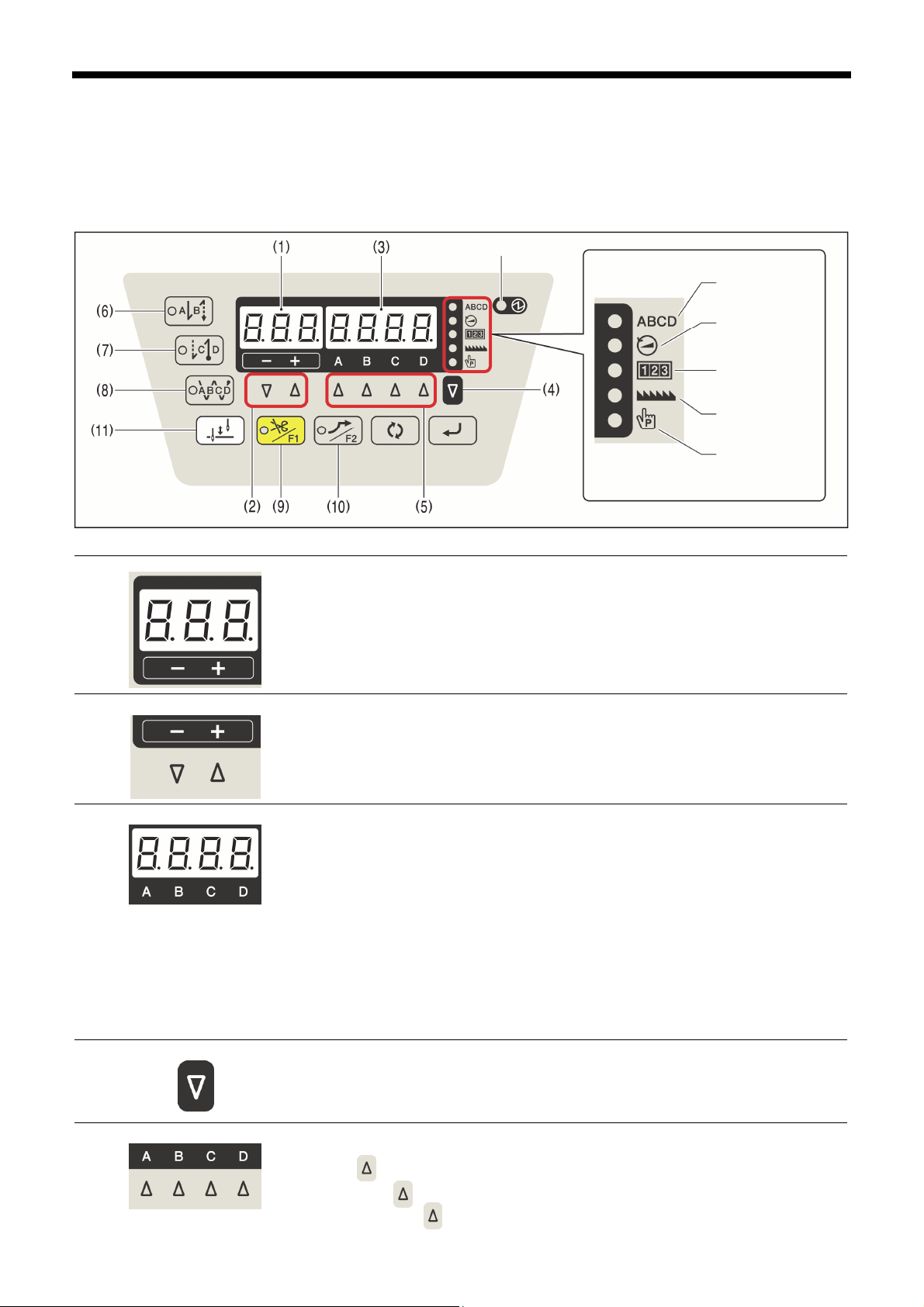

3. USING THE OPERATION PANEL (BASIC OPERATIONS)

3.

USING THE OPERATION PANEL (BASIC OPERATIONS)

3-1. Names and functions

・ The operation panel keys cannot be operated while sewing is in progress.

Select the keys and set the number of stitches before starting sewing.

・ In the case of keys with indicators, the indicator illuminates when that function is operating, and the indicator switches off

when the key is pressed once more.

Power indicator

Stitch No. indicator

Speed indicator

Counter indicator

Locus indicator

Program indicator

1425D

The power indicator illuminates when the power switch is turned on.

(1) 3-digit display

Displays the sewing pitch.

(2) Pitch setting keys

(3) 4-digit display

(4) SEL (Select) key

Use these keys to set the sewing pitch.

・When the - key is pressed, the setting decreases in steps of 0.05 within a range of 0.05 to

5.00.

When the + key is pressed, the setting increases in steps of 0.05 within a range of 0.05 to

・

5.00.

・ When start backtack stitches are being displayed, the indicator of the start backtack key

(6) will illuminate, and the number of A stitches will appear in the A column and the

number of B stitches will appear in the B column.

・ When end backtack stitches are being displayed, the indicator of the end backtack key

(7) will illuminate, and the number of C stitches will appear in the C column and the

number of D stitches will appear in the D column.

・ When continuous backtack stitches are displayed, the indicator of the continuous

backtack key (8) will illuminate, and the number of A, B, C and D stitches will appear in

order starting from the left column of the display.

・ The five indicators on the right side of the window show which value is appearing in the

4-digit display. The 4-digit display shows the number of stitches, speed, counter, locus

and program. When the number of stitches is being displayed, the ABCD indicator (Stitch

No. indicator) will illuminate.

The value in the 4-digit display (3) can be changed each time this key is pressed.

(5) Setting keys

These keys are used to set the number of backtack stitches for A, B, C and D.

・ When the key is pressed, the setting increases from 0 up to 9.

・ If you press the key once more when “9” is displayed, the value will return to “0”.

・ If you hold down the key, the value will change continuously.

1426D

1427D

1428D

1340D

1429D

13

S-7250A

Page 23

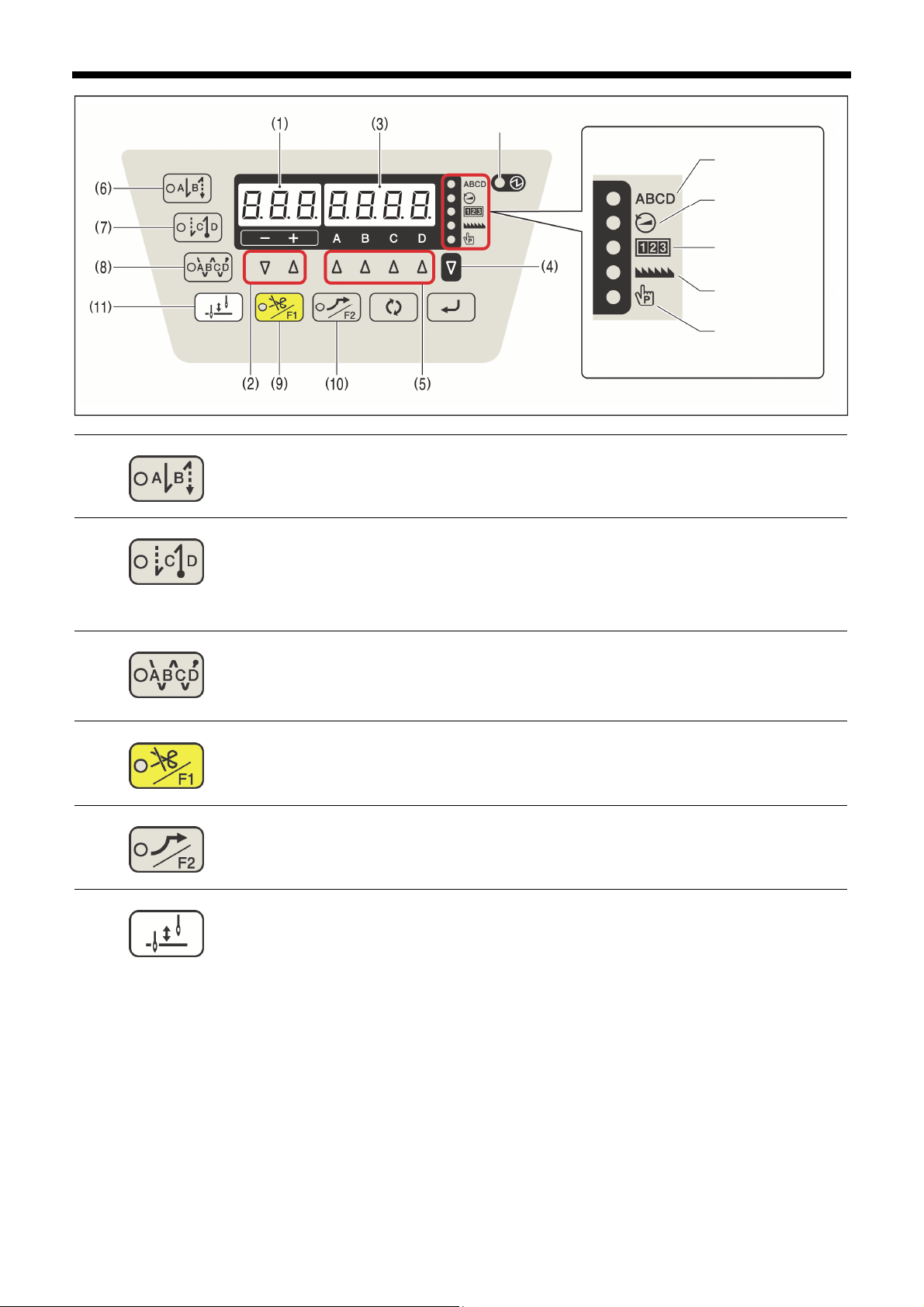

(6) Start backtack key

(7) End backtack key

(8) Continuous backtack key

(9) Thread trimming disable/F1 key

(10) Slow start/F2 key

(11) Half stitch key

3. USING THE OPERATION PANEL (BASIC OPERATIONS)

Power indicator

Stitch No. indicator

Speed indicator

Counter indicator

Locus indicator

Program indicator

1425D

When this key is pressed so that the indicator illuminates, the number of start backtack

stitches (0 - 9) in the A and B columns of the display are sewn.

1323D

When this key is pressed so that the indicator illuminates, the number of end backtack

stitches (0 to 9) in the C and D columns of the display are sewn. When the treadle is

depressed backward, the end backtack stitches are sewn and then the thread is trimmed.

If the treadle has not yet been depressed backward, the end backtack function can be set to

ON, the number of stitches can be changed and the function can be set back to OFF.

1325D

When this key is pressed so that the indicator illuminates, the number of backtack stitches

(0 to 9) in the A, B, C and D columns of the display are sewn continuously. After the sewing

machine sews a full cycle of stitches set by A, B, C and D, the thread is trimmed.

1327D

When this key is pressed so that the indicator illuminates, the sewing machine stops in the

needle up position without thread trimming being carried out even if the treadle is depressed

backward.

1330D

When this key is pressed so that the indicator illuminates, sewing is carried out at 700

sti/min for the first two stitches at the next sewing start after thread trimming.

After this, the sewing speed corresponds to the treadle depression amount.

1332D

When the sewing machine is stopped, the needle bar can be moved up and down by

pressing this key.

1329D

S-7250A

14

Page 24

3. USING THE OPERATION PANEL (BASIC OPERATIONS)

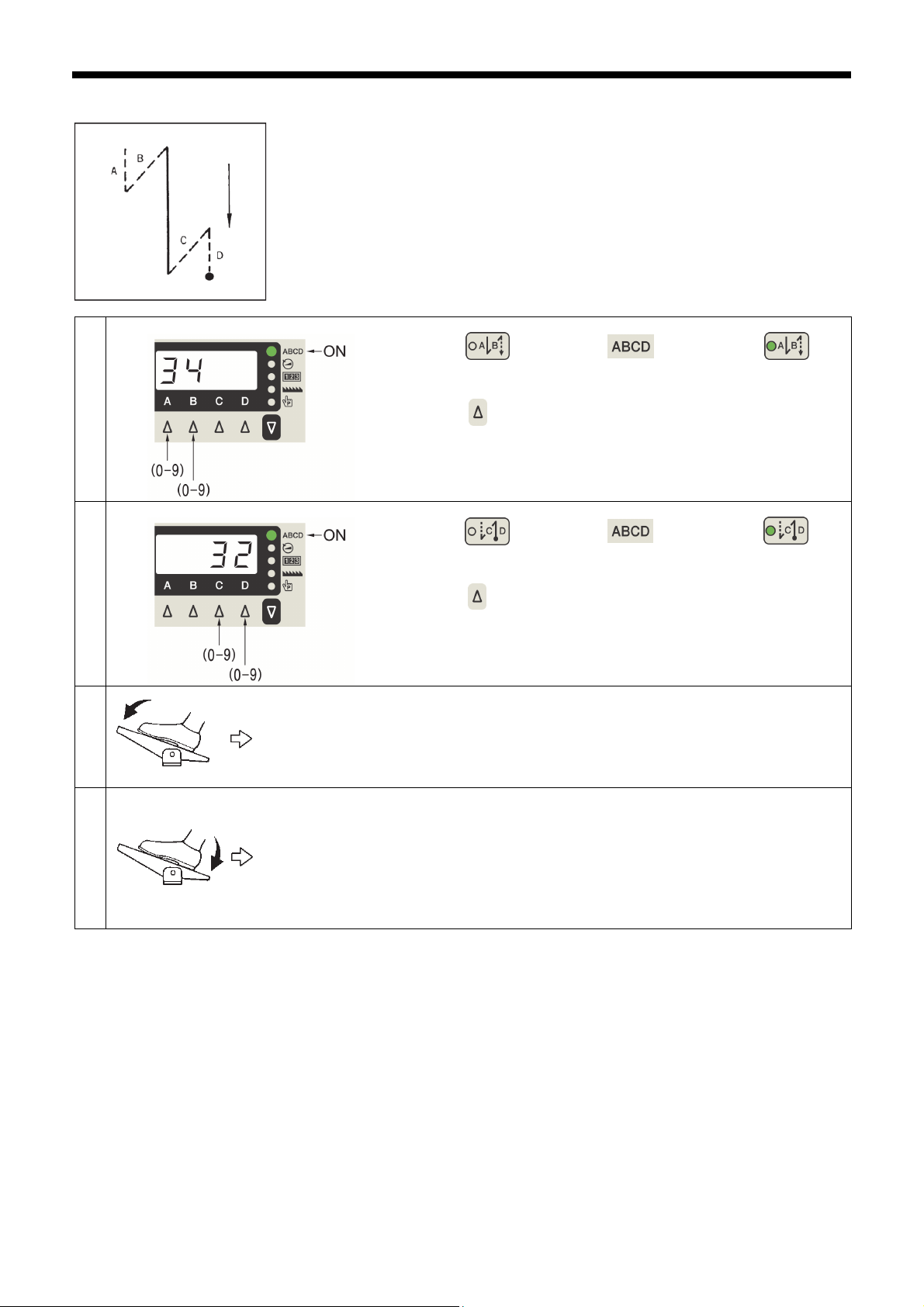

3-2. Sewing start and end backtack stitches

Setting start backtack stitches

1

Setting end backtack stitches

2

0841M

Press the key so that the indicator and the keys

illuminate.

Press the key to set the number of stitches for A and B.

For example, to select 3 stitches and 4 stitches: A-3, B-4

Press the key so that the indicator and the keys

illuminate.

1350D

3

4

Press the key to set the number of stitches for C and D.

For example, to select 3 stitches and 2 stitches: C-3, D-2

Start backtacking is carried out. After it has finished, normal sewing continues for as long as

the treadle remains depressed.

NOTE:

If the treadle is returned to the neutral position, the sewing machine will continue operating

until the set number of start backtack stitches has been sewn.

End backtacking is carried out. After it has finished, the thread is trimmed automatically and

the sewing machine stops in the needle up position.

NOTE:

・ If the treadle is depressed backward before sewing of the set number of start backtack

stitches is complete, end backtacking will not be carried out.

・ If thread trimming lock is set, the sewing machine will stop in the needle up position without

thread trimming being carried out.

1351D

2159M

2160M

15

S-7250A

Page 25

3. USING THE OPERATION PANEL (BASIC OPERATIONS)

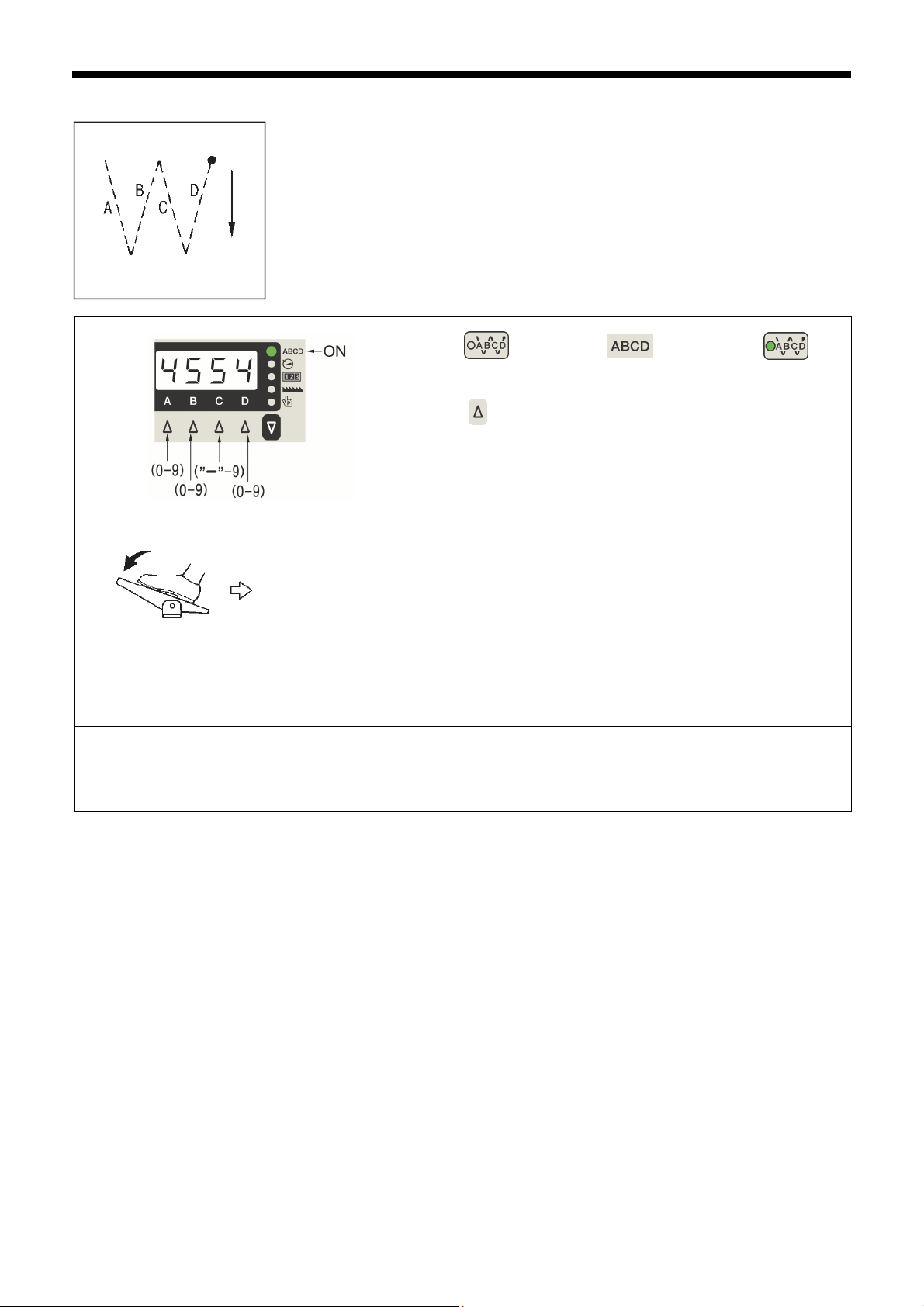

3-3. Sewing continuous backtack stitches

Sewing continuous backtack stitches

1

2

3

3655M

Press the key so that the indicator and the keys

illuminate.

Press the key to set the number of stitches for A, B, C and D.

For example, to select 4 stitches for A and 5 stitches for B: A-4, B-5

To select 5 stitches for C and 4 stitches for D: C-5, D-4

If the treadle is simply depressed continuously, the number of stitches set for A, B, C and D will

be sewn in a single cycle, the thread will be trimmed automatically and then the needle bar will

stop in the needle up position.

NOTE:

・ If the treadle is returned to the neutral position while continuous backtacking is being carried

out, the sewing machine will stop at the point where the treadle returns to the neutral

position. If the treadle is depressed again, operation will resume from the point where it was

interrupted.

・ If thread trimming lock is set, the sewing machine will stop in the needle up position without

thread trimming being carried out.

If "-" is set as the number of stitches for C, the number of stitches set by AB can be sewn D

times.

For example, if D=3: ABA

If D=6: ABABAB

1352D

2159M

S-7250A

16

Page 26

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4.

USING THE OPERATION PANEL (ADVANCED OPERATIONS)

The operations described in this section should only be carried out by a technician.

4-1. Sewing pitch setting method

1

2

Any

indicator

illuminates

Any

indicator

illuminates

Press the key so that the stitch no., speed, counter, locus or

program indicator illuminates.

・ The sewing pitch can be set regardless of whether the stitch no.,

speed, counter, locus or program is being displayed in the 4-digit

display.

(Refer to the Service Manual for details on programs.)

Press the - /+ keys to change the setting value.

・ When the + key is pressed, the setting value increases by

0.05.

・ When the - key is pressed, the setting value decreases by

0.05.

1353D

3

NOTE:

The setting range is from 0.05 to 5.00.

The backtack pitch can only be set when the stitch number and

sewing speed indicators are illuminated.

(Refer to "4-3-2. Backtack sewing speed setting method".)

1354D

1461D

17

S-7250A

Page 27

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-2. Switching the 4-digit display

・ The 4-digit display can be changed to one of the following four statuses each time the key is pressed.

Stitch no. display or no display -> Speed display -> Counter display -> Locus display

・ When the speed display or counter display appears, you can press the key to switch to another display.

Display mode

Stitch number

display

Sewing speed

display

Counter display

Flashing Flashing

Locus display

ON

ON

ON ON

ON

Flashing

ON ON Production counter value

ON ON

4-3. Setting the sewing speed

4-3-1. Setting the maximum sewing speed

1

2

Press the key so that the indicator illuminates.

・ The maximum sewing speed setting value will appear in the 4-digit

display.

Press the C /D keys to change the setting value.

4-digit display

Maximum sewing speed setting

Backtack sewing speed setting

Lower thread counter warning

Needle replacement counter

Needle replacement counter

ON

ABCD stitch number display

value

value

Lower thread counter value

enabled

value

warning enabled

Locus setting value

1355D

・ When the D key is pressed, the setting increases by 100.

・ When the C key is pressed, the setting decreases by 100.

NOTE:

The setting range is from 220 to 4000 sti/min.

1356D

S-7250A

18

Page 28

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-3-2. Backtack sewing speed setting method

1

2

Press the key so that the indicator illuminates.

・ The maximum sewing speed setting value will appear in the 4-digit

display.

Press the key.

・ The indicator will illuminate and the setting value for the

backtack sewing speed will appear in the 4-digit display.

1355D

3

NOTE:

If you press the key once more, the indicator

will switch off and the display will return to the maximum sewing

speed setting value.

Press the C /D keys to change the setting value.

・ When the D key is pressed, the setting increases by 100.

・ When the C key is pressed, the setting decreases by 100.

NOTE:

The setting range is from 220 to 3000 sti/min.

1357D

1358D

19

S-7250A

Page 29

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-4. Setting the counters

The lower thread counter, production counter and needle replacement counter are available.

The three counters can be operated at the same time.

4-4-1. Lower thread counter

The lower thread counter can be used to let you know approximately how much lower thread is remaining.

* This function is only displayed when "A09: Lower thread counter operation" is set to "ON".

Refer to "4-6-7. Lower thread counter operation".

<Setting the lower thread counter initial value>

1

2

Press the key so that the indicator illuminates.

・ The lower thread counter value will appear in the 4-digit display.

Press the A key for 2 seconds or more, and then press the C

or D key to set the initial value.

・ When the D key is pressed, the setting value increases by 0.1.

・ When the C key is pressed, the setting value decreases by

0.1.

NOTE:

・ The setting range is from 0.1 to 99.9.

1359D

1360D

<Lower thread counter operation>

・ The lower thread counter can be used to let you know approximately how much lower thread is remaining.

* The lower thread counter should be used as a guide only.

・ The value displayed by the lower thread counter display is reduced by 0.1 from the initial setting value each time the number

of stitches x sewing pitch reaches 0.1 m, and a warning is given when the counter goes below 0.

When the warning occurs, the counter indicator blinks and the buzzer sounds

for 5 seconds.

1361D

・ Sewing will be possible even after the treadle is returned to the neutral position and the sewing machine stops. However,

after the treadle has been depressed backward and thread trimming has been carried out, sewing using the treadle will no

longer be possible.

If the treadle is depressed at this time, “ Ent” will appear in the display. When the treadle is returned to the neutral position,

the display will return to the current counter display.

・ If the key is pressed during a warning, the indicator will change to illuminated and sewing can then be

carried out using the treadle.

If the A key is pressed again for 2 seconds or more, the counter display will return to the initial value and counting from

the initial value will be possible.

S-7250A

20

Page 30

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-4-2. Production counter

The production counter can be used to let you know how many items have been sewn.

1

2

After the thread trimming operation is complete, the

counter will be incremented.

3

4

Press the key so that the indicator illuminates.

・ The lower thread counter value will appear in the 4-digit

display.

When the key is pressed once, the production counter

will be displayed.

・ The production counter value will appear in the 4-digit

display.

NOTE:

The counter is incremented when the treadle is depressed

backward even if thread trimming is set to disabled.

When the production counter is displayed, you can press the C

or D key to adjust the counter value (0 to 9999).

1359D

1362D

・ When the D key is pressed, the counter value increases

by 1.

・ When the C key is pressed, the counter value decreases

by 1.

・ If you press the A key for 2 seconds or more, the counter

value can be reset to "0".

1363D

21

S-7250A

Page 31

4-4-3. Needle replacement counter

<Setting the needle replacement counter initial value>

1

2

3

Press the key so that the indicator illuminates.

・ The lower thread counter value will appear in the 4-digit display.

When the key is pressed two or more times, the needle

replacement counter display will appear.

・ The needle replacement counter value will appear in the 4-digit

Press the A key for 2 seconds or more, and then press the C

or D key to set the initial value.

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

1359D

display.

1364D

・ When the D key is pressed, the setting value increases by 1.

・ When the C key is pressed, the setting value decreases by 1.

NOTE:

・ The setting range is from 0 to 9999.

・ If an initial value of “0” is set, the needle replacement counter will

not operate.

1365D

<Needle replacement counter operation>

・ The needle replacement counter is reduced by 1 from the initial setting value each time the sewing machine sews 100

stitches, and a warning is given when the counter goes below “0”.

When the warning occurs, the indicator and the indicator flash,

and the buzzer sounds for 5 seconds.

1366D

・ Sewing will be possible even after the treadle is returned to the neutral position and the sewing machine stops. However,

after the treadle has been depressed backward and thread trimming has been carried out, sewing using the treadle will no

longer be possible.

If the treadle is depressed at this time, “Ent” will appear in the display. When the treadle is returned to the neutral position,

the display will return to the current counter display.

・ If the key is pressed during a warning, the indicator and the indicator will change to illuminated and

sewing can then be carried out using the treadle.

If the A key is pressed again for 2 seconds or more, the counter display will return to the initial value and counting from

the initial value will be possible.

S-7250A

22

Page 32

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-5. Sewing locus setting method

Sewing locus setting method

1

2

Press the key so that the indicator illuminates.

・ The sewing locus setting value will appear in the 4-digit display.

Press the C /D keys to change the setting value.

・ When the D key is pressed, the setting value increases by 1.

・ When the C key is pressed, the setting value decreases by 1.

NOTE:

The setting range is from 0 to 3.

0: The feed dog moves along the standard locus.

1: The feed dog moves along special locus 1.

2: The feed dog moves along special locus 2.

3: The feed dog moves along special locus 3.

1367D

1368D

1478D

23

S-7250A

Page 33

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-6. Setting basic functions

If you hold down the key and press the key while the stitch no., speed, counter, locus or program is displayed,

the following items can be set.

Setting item 3-digit

display

Needle up/down

Thread trimming disable

『A01』 『UPdn』

『A02』 『trdi』

4-digit

display

Initial value Reference item

Needle down stop Refer to ”4-6-1”.

None

(Thread trimming

operation enabled)

Press the key to

make the setting.

Thread wiping

Correction sewing

AUTO

Auto thread trimming

Slow start

Illumination LED brightness

Lower thread counter operation

Prev. thread away

Prev. thread away pitch at 1st stitch

Prev. thread away pitch at 2nd stitch

Short trailing thread

Short trailing thread sewing speed at 1st

stitch

Short trailing thread sewing speed at

2nd stitch

Short trailing thread pitch at 1st stitch

Short trailing thread pitch at 2nd stitch

Short trailing thread pitch at 3rd stitch

Short trailing thread direction

Standard switch correction sewing

function

Function other than standard switch

correction sewing

2nd pitch ratio 『A33』 『 2Pt』

Correction 2nd pitch ratio 『A34』 『A2Pt』

Option switch correction sewing function

Function other than option switch

correction sewing

『A03』 『 WiP』

『A04』 『Corr』

『A05』 『AUto』

『A06』 『AtiM』

『A07』 『SLoW』

『A08』 『 LEd』

『A09』 『UtCt』

『A11』 『 PtA』

『A12』 『PtP1』

『A13』 『PtP2』

『A21』 『ttSH』

『A22』 『ttr1』

『A23』 『ttr2』

『A24』 『ttP1』

『A25』 『ttP2』

『A26』 『ttP3』

『A27』 『ttCS』

『A31』 『HSCF』

『A32』 『HSoF』

『A35』 『oSCF』

『A36』 『oSoF』

Specifications with

thread wiper: Enabled

Specifications without

thread wiper: Disabled

None

None Refer to the Service Manual.

None Refer to the Service Manual.

None

Level 5

None

None

3.30

2.20

P specifications:

Enabled

S specifications:

Disabled

1400

400

0.70

0.70

1.20

Fw: Forward direction

1: Single correction

sewing

1: Reverse

50

50

1: Single correction

sewing

1: Reverse

Refer to ”4-6-3”.

Press the key to

make the setting.

S-7250A

24

Page 34

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

(

p)

(

p)

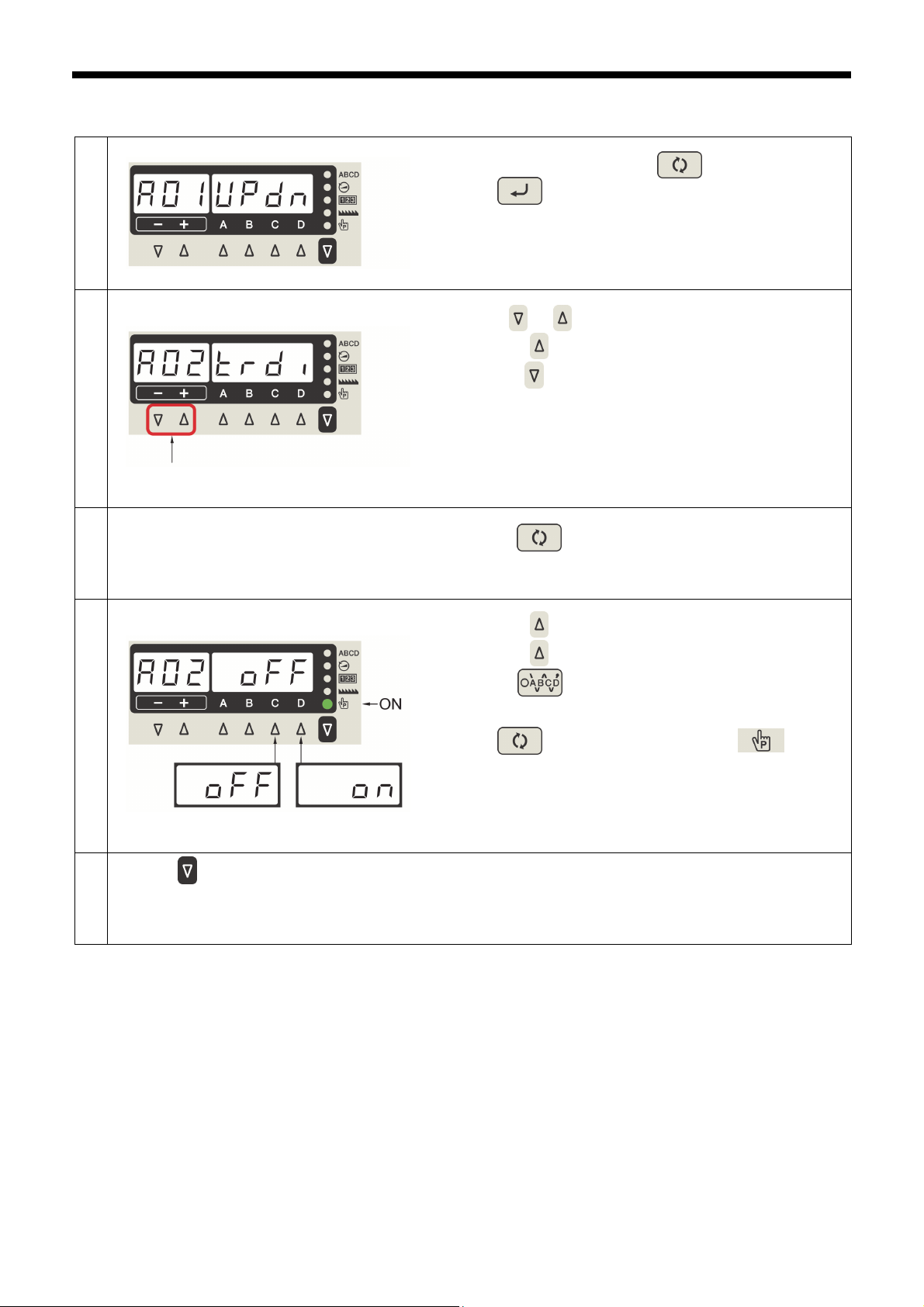

4-6-1. Changing the needle stop position

This sets whether the needle bar stops in the needle up stop position or the needle down stop position when the treadle is

returned to the neutral position and sewing stops.

1

Displaying the needle up stop and needle down

stop setting values

2

Setting the needle up stop and needle down

stop positions

3

In sewing standby mode, press the key while holding down

the key to switch to function setting mode.

・ "A01 UPdn" will be displayed.

1369D

・ When the key is pressed, the setting value is displayed.

・ When the D key is pressed, the “UP” display will appear.

・ When the C key is pressed, the “dn” display will appear.

・ When the key is pressed, the initial value will be reset.

Press the key.

4

Needle down sto

Needle up sto

NOTE:

If the key is pressed once more, the indicator

will switch off and the display will return to the setting item.

1370D

Setting mode will be exited and normal operation will be possible.

25

S-7250A

Page 35

)

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-6-2. Thread trimming disable

If thread trimming is set to be disabled, thread trimming will not be carried out even when the pedal is depressed backward.

1

Selecting “A02 Trdi” (thread trimming disable)

2

In sewing standby mode, press the key while holding

down the key to switch to function setting mode.

・ "A01 UPdn" will be displayed.

Press the - / + keys to select "A02 Trdi".

1369D

Press either.

Displaying the thread trimming disabled setting

value

3

Setting thread trimming to disabled or enabled

4

Press the key.

5

(Thread trimming

operation enabled)

(Thread trimming

disable

・ When the

・ When the - key is pressed, the previous setting is displayed.

・ When the key is pressed, the setting value is displayed.

・ When the D key is pressed, the “on” display will appear.

・ When the C key is pressed, the “oFF” display will appear.

・ When the key is pressed, the initial value will be reset.

NOTE:

If the key is pressed once more, the indicator

will switch off and the display will return to the setting item.

Setting mode will be exited and normal operation will be possible.

+ key is pressed, the next setting is displayed.

1371D

1372D

S-7250A

26

Page 36

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

(

)

4-6-3. Thread wiping

You can set whether thread wiper operation is enabled or disabled.

1

Selecting “A03 Wip” (thread wiping)

2

Press either.

Displaying the thread wiping setting value

3

In sewing standby mode, press the key while holding down

the key to switch to function setting mode.

・ "A01 UPdn" will be displayed.

Press the - / + keys to select "A03 Wip".

・ When the + key is pressed, the next setting is displayed.

・ When the - key is pressed, the previous setting is displayed.

・ When the key is pressed, the setting value is displayed.

1369D

1373D

Setting thread wiping

4

Press the key.

5

Thread wiping disabled) (Thread wiping enabled

・ When the D key is pressed, the “on” display will appear.

・ When the C key is pressed, the “oFF” display will appear.

・ When the key is pressed, the initial value will be reset.

NOTE:

If the key is pressed once more, the indicator

will switch off and the display will return to the setting item.

Setting mode will be exited and normal operation will be possible.

1374D

27

S-7250A

Page 37

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-6-4. Correction sewing

When correction sewing is enabled, if the hand switch is pressed while sewing is stopped before thread trimming, one stitch

will be sewn and sewing will then stop.

* The function can be changed. (Refer to "4-11. Hand switch".)

1

Selecting “A04 Corr” (correction sewing)

2

Press either.

Displaying the correction sewing setting value

3

In sewing standby mode, press the key while holding down

the key to switch to function setting mode.

・ "A01 UPdn" will be displayed.

1369D

Press the - or + key to select "A04 Corr".

・ When the + key is pressed, the next setting is displayed.

・ When the - key is pressed, the previous setting is displayed.

1375D

・ When the key is pressed, the setting value is displayed.

Setting correction sewing

4

(Correction sewing disabled)

Press the key.

5

(Correction sewing enabled)

・ When the D key is pressed, the “on” display will appear.

・ When the C key is pressed, the “oFF” display will appear.

・ When the key is pressed, the initial value will be reset.

NOTE:

If the key is pressed once more, the indicator

will switch off and the display will return to the setting item.

Setting mode will be exited and normal operation will be possible.

1376D

S-7250A

28

Page 38

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

(

)

(

)

4-6-5. Slow start

If slow start is enabled, occurrences of the thread pulling out can be reduced.

1

Selecting “A07 SLow” (slow start)

2

Press either.

Displaying the slow start setting value

3

In sewing standby mode, press the key while holding down

the key to switch to function setting mode.

・ "A01 UPdn" will be displayed.

Press the - or + key to select "A07 SLow".

・ When the + key is pressed, the next setting is displayed.

・ When the - key is pressed, the previous setting is displayed.

・ When the key is pressed, the setting value is displayed.

1369D

1377D

Setting slow start

4

Press the key.

5

Slow start disabled

Slow start enabled

・ When the D key is pressed, the setting value increases in the

order "oFF", "1", "2", "3".

・ When the C key is pressed, the setting value decreases in the

order "3", "2", "1", "oFF".

・ When the key is pressed, the initial value will be reset.

・ Sewing speed for first 4 stitches when slow start is enabled

1: 400, 400, 400, 4000*

2: 400, 400, 4000*, 4000*

3: 700, 700, 4000*, 4000*

4: Set using memory switch Nos. 403 to 406.

* If the maximum sewing speed is set to 4,000 sti/min

NOTE:

If the key is pressed once more, the indicator

will switch off and the display will return to the setting item.

Setting mode will be exited and normal operation will be possible.

1378D

29

S-7250A

Page 39

4-6-6. Setting the illumination LED light

You can set the brightness of the illumination LED light.

1

Selecting "A08 LEd" (illumination LED light)

2

Press either.

Displaying the illumination LED light setting

value

3

Setting the illumination LED light

4

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

In sewing standby mode, press the key while holding down

the key to switch to function setting mode.

・ "A01 UPdn" will be displayed.

1369D

Press the - or + key to select "A08 LEd".

・ When the + key is pressed, the next setting is displayed.

・ When the - key is pressed, the previous setting is displayed.

1379D

・ When the key is pressed, the setting value is displayed.

・ When the D key is pressed, the setting value increases from

"1" through to "9".

・ When the C key is pressed, the setting value decreases from

"9" through to "1".

・ When the key is pressed, the initial value will be reset.

Press the key.

5

(Dark) (Bright)

NOTE:

If the key is pressed once more, the indicator

will switch off and the display will return to the setting item.

Setting mode will be exited and normal operation will be possible.

1380D

S-7250A

30

Page 40

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-6-7. Setting lower thread counter operation

The lower thread counter function can be set to enabled or disabled.

1

Selecting "A09 UtCt" (lower thread counter

operation)

2

Press either.

Displaying the lower thread counter operation

setting value

3

In sewing standby mode, press the key while holding down

the key to switch to function setting mode.

・ "A01 UPdn" will be displayed.

Press the - or + key to select "A09 UtCt".

・ When the + key is pressed, the next setting is displayed.

・ When the - key is pressed, the previous setting is displayed.

・ When the key is pressed, the setting value is displayed.

1369D

1462D

Setting lower thread counter operation

4

Press the key.

5

(Lower thread

counter disabled)

(Lower thread

counter enabled)

・ When the D key is pressed, the “on” display will appear.

・ When the C key is pressed, the “oFF” display will appear.

・ When the key is pressed, the initial value will be reset.

NOTE:

If the key is pressed once more, the indicator

will switch off and the display will return to the setting item.

Setting mode will be exited and normal operation will be possible.

1463D

31

S-7250A

Page 41

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-6-8. Prev. thread away

When "Prev. thread away" is enabled, the pitch at the sewing start can be increased in order to reduce cases of the thread

pulling out.

1

Selecting “A11 PtA” (prev. thread away)

2

Press either.

Displaying the "Prev. thread away" setting

value

3

Setting "Prev. thread away"

4

In sewing standby mode, press the key while holding down

the key to switch to function setting mode.

・ "A01 UPdn" will be displayed.

1369D

Press the - or + key to select "A11 PtA".

・ When the + key is pressed, the next setting is displayed.

・ When the - key is pressed, the previous setting is displayed.

1381D

・ When the key is pressed, the setting value is displayed.

・ When the D key is pressed, the “on” display will appear.

Press the key.

5

("Prev. thread

away" function

is disabled)

("Prev. thread

away" function

is enabled)

・ When the C key is pressed, the “oFF” display will appear.

・ When the key is pressed, the initial value will be reset.

NOTE:

If the key is pressed once more, the indicator

will switch off and the display will return to the setting item.

1382D

Setting mode will be exited and normal operation will be possible.

S-7250A

32

Page 42

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-6-9. Short trailing thread

When short trailing thread is enabled, the trailing length of the thread can be made shorter.

1

Selecting "A21 ttSH" (short trailing thread)

2

Press either.

Displaying the short trailing thread setting value

3

In sewing standby mode, press the key while holding down

the key to switch to function setting mode.

・ "A01 UPdn" will be displayed.

Press the - or + key to select "A21 ttSH".

・ When the + key is pressed, the next setting is displayed.

・ When the - key is pressed, the previous setting is displayed.

・ When the key is pressed, the setting value is displayed.

1369D

1383D

Setting short trailing thread

4

Press the key.

5

(Short trailing

thread function

disabled)

(Short trailing

thread function

enabled)

・ When the D key is pressed, the “on” display will appear.

・ When the C key is pressed, the “oFF” display will appear.

・ When the key is pressed, the initial value will be reset.

NOTE:

If the key is pressed once more, the indicator

will switch off and the display will return to the setting item.

Setting mode will be exited and normal operation will be possible.

1384D

33

S-7250A

Page 43

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-6-10. Correction sewing function (1)

When the correction sewing function (A04) is enabled, the hand switch correction sewing function can be set.

For details on the functions which can be set, refer to "4-11. Hand switch" for the settings when the hand switch is set as a

correction sewing switch.

1

Selecting "A31 HSCF" (correction sewing

function)

2

In sewing standby mode, press the key while holding down

the key to switch to function setting mode.

・ "A01 UPdn" will be displayed.

1369D

Press the - or + key to select "A31 HSCF".

・ When the + key is pressed, the next setting is displayed.

・ When the - key is pressed, the previous setting is displayed.

Press either.

Displaying the correction sewing function

setting value

3

Setting the correction sewing function

4

Press the key.

5

(Correction

sewing function

disabled)

(Correction

sewing function

enabled)

1385D

・ When the key is pressed, the setting value is displayed.

・ When the D key is pressed, the setting value increases from

"oFF" to "1" through to "9".

・ When the C key is pressed, the setting value decreases from

"9" through to "1" to "oFF".

・ When the key is pressed, the initial value will be reset.

NOTE:

If the key is pressed once more, the indicator

will switch off and the display will return to the setting item.

Setting mode will be exited and normal operation will be possible.

1386D

S-7250A

34

Page 44

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-6-11. Correction sewing function (2)

When the correction sewing function (A04) is disabled, the hand switch functions other than correction sewing can be set.

For details on the functions which can be set, refer to "4-11. Hand switch" for the settings when the hand switch is set to other

than a correction sewing switch.

1

Selecting "A32 HSoF" (correction sewing

function)

2

In sewing standby mode, press the key while holding down

the key to switch to function setting mode.

・ "A01 UPdn" will be displayed.

1369D

Press the - or + keys to select "A32 HSoF".

・ When the + key is pressed, the next setting is displayed.

・ When the - key is pressed, the previous setting is displayed.

Press either.

Displaying the setting value for a function other

than correction sewing

3

・ When the key is pressed, the setting value is displayed.

Setting a function other than correction sewing

4

・ When the D key is pressed, the setting value increases from

"oFF" to "1" through to "16".

・ When the C key is pressed, the setting value decreases from

"16" through to "1" to "oFF".

・ When the key is pressed, the initial value will be reset.

NOTE:

If the key is pressed once more, the indicator

(Function other

than correction

sewing is disabled)

(Function other

than correction

sewing is enabled)

will switch off and the display will return to the setting item.

Press the key.

5

Setting mode will be exited and normal operation will be possible.

1387D

1388D

35

S-7250A

Page 45

4-7. Memory switch setting method

1

Selecting a memory switch number

2

Previous

item

Next item

Selecting a memory switch number which is

different from the initial value

3

In sewing standby mode, press the key while holding down the

・ "001" or the memory switch number which was set previously will

Press the - / + keys to select the number for the memory

switch to be set.

・ When the + key is pressed, the next setting is displayed.

・ When the - key is pressed, the previous setting is displayed.

While pressing the key, press the - / + keys to select

the number for the memory switch which is different from the initial

value.

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

key to switch to memory switch setting mode.

be displayed.

1389D

1390D

Previous

item

Next item

Changing the memory switch setting value

4

Decreases the value

Confirming the memory switch setting value

Increases the value

5

・ When the + key is pressed while holding down the key,

the next setting item is displayed.

・ When the - key is pressed while holding down the key,

the previous setting item is displayed.

・ When the D key is pressed, the setting value increases or it

turns ON.

・ When the C key is pressed, the setting value decreases or it

turns OFF.

・ When the key is pressed the initial value will be set.

・ When the key is pressed, the setting value is confirmed.

1390D

1392D

Press the key.

6

Setting mode will be exited and normal operation will be possible.

S-7250A

36

Page 46

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4-8. List of memory switch settings

Presser foot lifter and treadle settings (001 to 099)

No.

001 ON/OFF

002 ON/OFF OFF -

003 ON/OFF ON -

004 ON/OFF ON -

010 ON/OFF OFF -

011 0 - 1 0 1

012

013 ON/OFF ON -

014 ON/OFF ON -

015 ON/OFF ON -

Setting

range

0 - 500

(ms)

Initial value

ON : Other

than

Europe and

America /

OFF :

Europe and

America

80

(ms)

Setting

units

-

10

(ms)

Presser foot condition when treadle is returned to neutral position after

thread trimming

ON: Presser foot is raised

OFF: Presser foot is not raised

(*) The presser foot lifts when No.851 is set to "OFF".

Presser foot condition when operation stops at the neutral treadle position

ON: Presser foot is raised

OFF: Presser foot is not raised

Presser foot raising after treadle is returned to neutral position to stop

sewing and is then depressed backward to the 1st step

ON : Enabled

OFF: Disabled

Operation when treadle is depressed backward

ON: Thread trimming and end backtack sewing operations are enabled

(However, if thread trimming operation is locked, needle up

operations will be carried out without thread trimming.)

OFF: Thread trimming and end backtack sewing operations are disabled

(presser foot lifts when the treadle is depressed backward)

Alternating operation of standing operation pedal and treadle

(*) For simultaneous operation which includes operation of the presser

foot lifter pedal, operation of the standing operation pedal takes priority.

ON: Treadle operation is still enabled after standing operation pedal has

been used (alternating operation is possible)

OFF: Treadle operation is disabled after standing operation pedal has

been used

Operation when standing up variable speed pedal is ON

0: Sewing speed corresponds to treadle depression amount

1: Operates at the sewing speed for the main section (constant speed)

Delay time from standing pedal turning on until motor starts operating

Stop function using the work clamp pedal during standing operation when

the AUTO function is on

ON: Sewing is interrupted when presser foot lifter pedal turns on (pause

operation)

(*) This function is disabled during start backtacking.

OFF: No operation

Pause function using the high-speed pedal during standing operation

when the AUTO function is on

ON: When the high-speed pedal turns on, sewing is momentarily stopped,

and it is resumed when the pedal turns off.

(*) This function is disabled when No. 010 is set to "ON".

(*) This function is disabled during start backtacking.

OFF: No operation

Presser foot lifting operation from thread trimming pedal after thread is

trimmed during standing operation

ON: Presser foot can be raised and lowered

(*) If No.051 is set to "ON", thread trimming pedal operation is disabled

after the presser foot lifter pedal has been operated during standing

operation.

OFF: No operation (only possible using presser foot lifter pedal)

Setting details

37

S-7250A

Page 47

Sewing machine motor settings (100 to 199)

No.

100 OFF, 1 - 3 OFF 1

101 1 - 5 1 1

102

103

Setting

range

-20 - 10

(Degrees) 0 (Degrees)1 (Degrees)

-10 - 10

(Degrees) 0 (Degrees)1 (Degrees)

Initial

value

Setting

units

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

Pedal response switching settings immediately after sewing has started

OFF: No switching

1: Slow start only when sewing starts after thread trimming

2: Slow start only when sewing starts after sewing has been paused

3: Slow start always when sewing starts

Pedal response immediately after sewing has started

(The larger the value, the slower the speed when sewing starts.)

* When No. 100 is set to "OFF", nothing is displayed. (The setting is

disabled.)

Needle up stop position correction value

Needle up stop position = Needle up stop position initial setting value +

Upper shaft reference position correction value + Needle up stop position

correction value

Needle down stop position correction value

Needle down stop position = Needle down stop position initial setting

value + Upper shaft reference position correction value + Needle down

stop position correction value

Feed motor settings (200 to 299)

No.

200

201

202

203

204

205

206

Setting

range

50 - 150

(%)

50 - 150

(%)

50 - 150

(%)

50 - 150

(%)

50 - 150

(%)

50 - 150

(%)

50 - 150

(%)

Initial

value

100

(%)

100

(%)

100

(%)

100

(%)

100

(%)

-3: 100

-5: 97

(%)

92

(%)

Setting

units

1

(%)

1

(%)

1

(%)

1

(%)

1

(%)

1

(%)

1

(%)

Forward direction pitch correction ratio

Reverse direction pitch length correction ratio

Start backtacking B pitch correction ratio

End backtacking C pitch correction ratio

Special locus 1 pitch correction ratio

Special locus 2 pitch correction ratio

Special locus 3 pitch correction ratio

Panel operation settings (300 to 399)

No.

300 1 - 3 1 1

312 0 - 2 0 1

Setting

range

Initial

value

Setting

units

Operation after lower thread counter warning

1: Sewing can continue until thread trimming is carried out

2: After sewing stops, it cannot continue until the [ENTER] key is pressed

and the warning is canceled.

3: If the counter goes below "0", sewing stops, and the warning operation

for a setting of "2" occurs.

Feed pitch display mode

0: mm display

1: stitch per inch display

2: stitch per 30 mm display

Setting details

Setting details

Setting details

S-7250A

38

Page 48

4. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

Sewing program settings (400 to 499)

No.

400 ON/OFF OFF -

401 ON/OFF ON -

Setting

range

Initial

value

Setting

units

Stopping while start backtacking is in progress, and speed during start

backtacking

ON: When the treadle is returned to the neutral position, start backtacking

can be stopped before it is finished, and the speed during start

backtacking becomes the speed corresponding to the treadle

depression amount (low speed - start backtacking speed)

OFF: When the treadle is returned to the neutral position, start backtacking

ends, sewing stops and the sewing speed becomes the start

backtacking speed (constant)

Feed direction when sewing machine motor is stopped immediately after

start backtacking is complete

OFF: Sewing machine motor stops after start backtacking

is complete

(*) If No. 400 is set to "OFF", operation occurs when the

treadle is depressed slightly.

ON: After start backtack sewing, the feed moves forward,

then the sewing machine motor stops.

403

404

405

406

408 2 - 6 2 1

300 - 4000

(sti/min)

300 - 4000

(sti/min)

300 - 4000

(sti/min)

300 - 4000

(sti/min)

4000

(sti/min)

4000

(sti/min)

4000

(sti/min)

4000

(sti/min)

100

(sti/min)

100

(sti/min)

100

(sti/min)

100

(sti/min)

1st stitch sewing speed for slow start

2nd stitch sewing speed for slow start

3rd stitch sewing speed for slow start

4th stitch sewing speed for slow start

Repeat pattern when start backtacking sewing pattern (AB) is selected

2: A - B

3: B - A - B

4: A - B - A - B *Same as AB (x2)

5: B - A - B - A - B

6: A - B - A - B - A - B *Same as AB (x3)

Setting details

Operation mode for manual production counter increment function using

hand switch

409 0 - 1 0 1

0: Counter can be incremented at any time

1: Counter can only be incremented after sewing stops and thread has

been trimmed

39

S-7250A

Page 49

Standard device settings (500 to 599)

No.

500 OFF, 1 - 3 1 1

501 OFF, 1 - 2 OFF 1

502

503

504

505

506

507

508

509

Setting

range

90 - 270

(Degrees)

270 - 430

(Degrees)

-50 - 50

(Degrees) 0 (Degrees)

-50 - 50

(Degrees) 0 (Degrees)

-50 - 50

(Degrees) 0 (Degrees)

-50 - 50

(Degrees) 0 (Degrees)

-50 - 50

(Degrees) 0 (Degrees)

-50 - 50

(Degrees) 0 (Degrees)

Initial

value

180

(Degrees)

320

(Degrees)

Setting

units

Presser foot lifter SW function

OFF: Disabled

1: Presser foot lifter switch

2: Puller switch (switching)

3: Puller switch

* Puller operation is enabled when No. 960 is set to "1", and it does not

operate when set to other than "OFF".

Thread holder operation setting

OFF: Thread holder does not operate