R

MAILBOX UNIT

FOR LASER PRINTER

SERVICE MANUAL

MODEL:MX-2001 / MX-2002 / MX-2003

Note:

While the MX-2001 Mailbox unit is available in all countries, the MX-

2003 is available in U.S. and Canada only, and the MX-2002 is

available in the other countries than U.S. and Canada.

Oct., 1998

54T050NE0

© Copyright Brother 1998

All rights reserved.

No part of this publication may be reproduced in any form or by any means without permission in

writing from the publisher.

Specifications are subject to change without notice.

Trademarks:

The brother logo is a registered trademark of Brother Industries, Ltd.

Apple, the Apple Logo, and Macintosh are trademarks, registered in the United States and other

countries and True Type is a trademark of Apple computer, Inc.

Epson is a registered trademark and FX-80 and FX-850 are trademarks of Seiko Epson

Corporation.

Hewlett Packard is a registered trademark and HP Laser Jet is a trademark of Hewlett Packard

Company.

IBM, IBM PC and Proprinter are registered trademarks of International Business Machines

Corporation.

Microsoft and MS-DOS are registered trademarks of Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the U.S. and other countries.

PREFACE

This service manual contains basic information required for after-sales service of the optional

Mailbox unit, MX-2001/MX-2002/MX-2003 for the HL-2060 laser printer (hereinafter referred to as

“this unit” or "the Mailbox unit"). This information is vital to the service technician to maintain the

high performance of the unit.

This service manual covers the MX-2001 / MX-2002 / MX-2003 Mailbox units.

The manual consists of the following chapters:

CHAPTER I : GENERAL

General view, specifications, etc.

CHAPTER II : THEORY OF OPERATION

Basic operation of the electrical system and the mechanical system

CHAPTER III : DISASSEMBLY

Procedures for disassembling the mechanical system.

CHAPTER IV : TROUBLESHOOTING

Reference values and adjustments, troubleshooting malfunctions, etc.

APPENDICES :

Information in this manual is subject to change due to improvement or re-design of the product. All

relevant information in such cases will be supplied in service information bulletins (Technical

Information).

A thorough understanding of this unit, based on information in this service manual and service

information bulletins, is required for maintaining its performance and for improving the practical

ability to find the cause of problems.

PCB CIRCUIT DIAGRAMS, ETC.

CONTENTS

CHAPTER I GENERAL............................................................................I-1

1. INSTRUCTIONS..........................................................................................................I-1

2. OVERVIEW.................................................................................................................I-2

3. SPECIFICATIONS.......................................................................................................I-3

3.1 Functions...............................................................................................................................I-3

3.2 Electrical and Mechanical .....................................................................................................I-3

3.3 Paper.....................................................................................................................................I-4

CHAPTER II THEORY OF OPERATION.................................................II-1

1. ELECTRONICS.........................................................................................................II-1

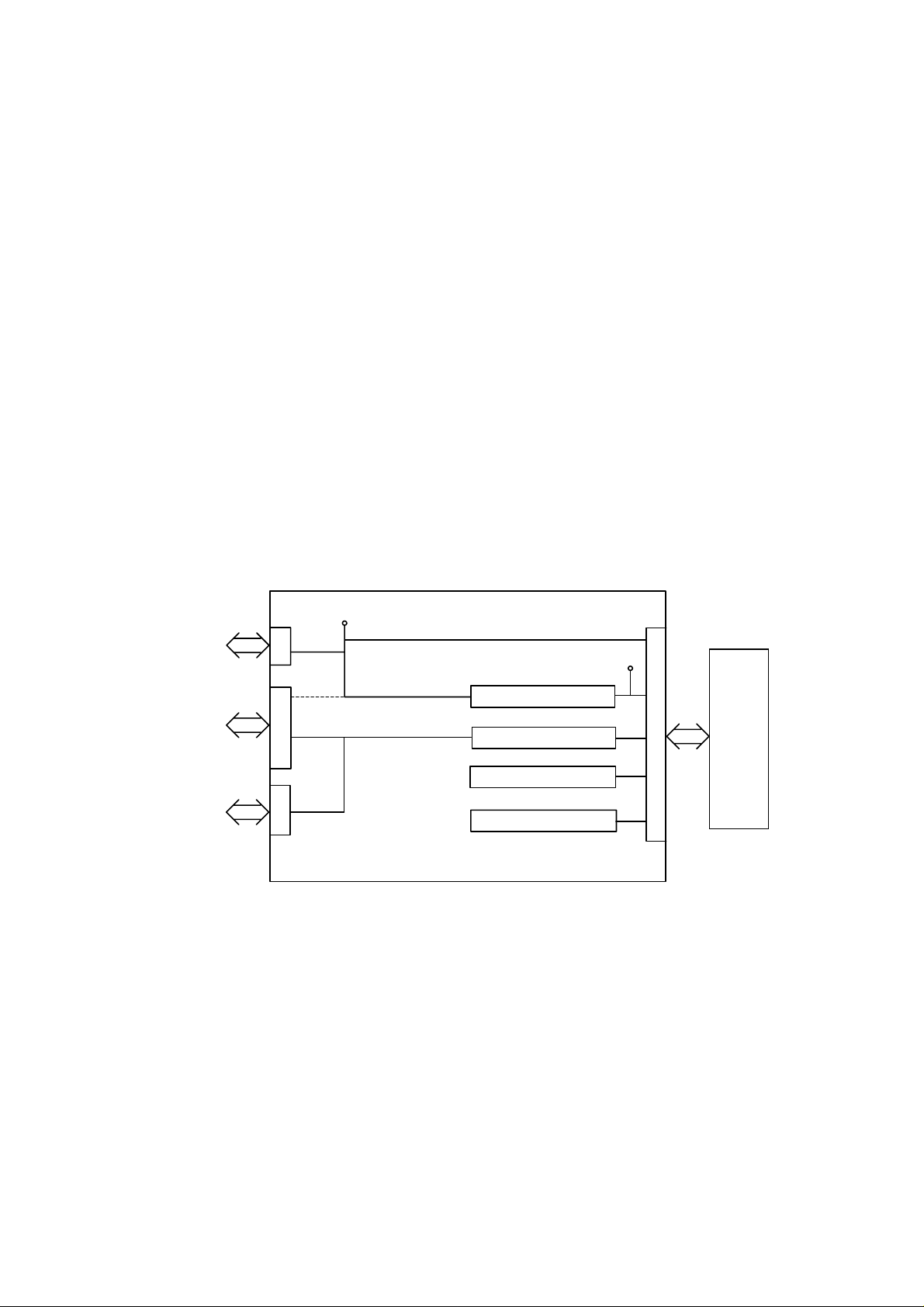

1.1 General Block Diagram...................................................................................................II-1

1.2 Main PCB........................................................................................................................II-3

1.2.1 CPU...............................................................................................................................II-3

1.2.2 Bin solenoid drive circuit................................................................................................II-3

1.2.3 Entrance solenoid drive circuit ......................................................................................II-3

1.2.4 Bin capacity sensor.......................................................................................................II-4

1.2.5 Infrared LED drive circuit...............................................................................................II-4

1.2.6 Power supply LED drive circuit......................................................................................II-4

1.3 I/F PCB ...........................................................................................................................II-4

1.3.1 Regulator.......................................................................................................................II-4

1.3.2 Serial I/F circuit..............................................................................................................II-5

1.3.3 Feeding motor drive circuit............................................................................................ II- 5

1.3.4 Entrance sensor input ................................................................................................... II-5

1.4 Sensor PCB....................................................................................................................II-5

1.5 Power supply LED PCB..................................................................................................II-5

1.6 Communication with the Printer......................................................................................II-5

2. MECHANICS.............................................................................................................II-7

2.1 General Overview of Mechanism....................................................................................II-7

2.2 Paper Feed Sequence....................................................................................................II-8

CHAPTER III DISASSEMBLY AND REASSEMBLY...............................III-1

1. SAFETY PRECAUTIONS.........................................................................................III-1

2. DISASSEMBLY FLOW.............................................................................................III-2

3. DISASSEMBLY PROCEDURE ................................................................................III-3

3.1 External Covers.............................................................................................................III-3

3.1.1 Cover UR (For MX-2001/2003 only)............................................................................. III-3

3.1.2 Cover UL (For MX-2001/2003 only) ............................................................................. III-3

3.1.3 Cover R........................................................................................................................III-4

3.1.4 Cover L.........................................................................................................................III-4

3.1.5 Rear Cover U ASSY (For MX-2001/2003 only)............................................................ III-5

3.1.6 Rear Cover A ASSY.....................................................................................................III-7

i

3.1.7 PCB Cover A (MX-2001) / PCB Cover B (MX-2002) / PCB Cover D (MX-2003 Upper

Unit)..............................................................................................................................III-8

3.1.8 Bin................................................................................................................................III-8

3.2 Remove the Main Frame Unit from the Under Frame Unit (For MX-2001/2003 only).III-10

3.3 Main Frame Unit ..........................................................................................................III-10

3.3.1 I/F PCB A ASSY (MX-2001) / I/F PCB B ASSY (MX-2002) / I/F PCB C ASSY (MX-2003

Lower Unit) / I/F PCB D ASSY (MX-2003 Upper Unit) ............................................... III-10

3.3.2 Feeding Motor ASSY.................................................................................................. III-11

3.3.3 Main PCB A ASSY (MX-2001, MX-2003 Lower Unit) / Main PCB B ASSY (MX-2002,

MX-2003 Upper Unit)..................................................................................................III-12

3.3.4 Solenoid A/B & LED PCB ASSY (MX-2001/2003 only)..............................................III-13

3.3.5 Sensor PCB ASSY.....................................................................................................III-14

3.3.6 Actuator A/B...............................................................................................................III-15

3.3.7 Eject Roller ASSY / Feed Rollers A/B ASSY..............................................................III-17

3.3.8 Eject Pinch Roller ASSY & Discharging Brush........................................................... III-19

3.4 Under Frame Unit (For MX-2001/2003 only)...............................................................III-20

3.4.1 Actuator U ..................................................................................................................III-20

3.4.2 Solenoid U..................................................................................................................III-21

3.4.3 Photo Interrupter ........................................................................................................III-21

3.4.4 Feed Roller U ASSY................................................................................................... III-22

3.4.5 Flap U.........................................................................................................................III-23

3.5 Remove the Upper Unit from the Lower Unit (For MX-2003 only)...............................III-24

3.6 Packing of MX-2003.....................................................................................................III-28

4. APPLICATION OF GREASE..................................................................................III-29

4.1 Rollers..........................................................................................................................III-29

4.1.1 Feed Roller A/B ASSY................................................................................................III-29

4.1.2 Eject Roller ASSY ......................................................................................................III -29

4.1.3 Feed Roller U ASSY................................................................................................... III-30

4.1.4 Pressure Roller / Pressure Roller U...........................................................................III-30

4.2 Gears...........................................................................................................................III-31

4.2.1 Gears on the Main Frame R.......................................................................................III-31

4.2.2 Gears on the Main Frame L........................................................................................III-31

4.2.3 Gears on the Frame UR.............................................................................................III-32

4.3 Others..........................................................................................................................III-32

CHAPTER IV TROUBLESHOOTING...................................................... IV-1

1. INITIAL CHECK ......................................................................................................IV-1

2. MTBF / MTTR .........................................................................................................IV-2

3. TROUBLESHOOTING............................................................................................ IV-3

APPENDICES

1. MAIN PCB CIRCUIT DIAGRAM (1/2).......................................................................A-1

2. MAIN PCB CIRCUIT DIAGRAM (2/2).......................................................................A-2

3. I/F PCB CIRCUIT DIAGRAM....................................................................................A-3

INDEX

ii

CHAPTER I GENERAL

1. INSTRUCTIONS

The MX-2001/2002/2003 Mailbox units are optionally installed onto the HL-2060 printer.

The MX-2001 Lower Mailbox unit consists of five bins. The MX-2002 Upper Mailbox

unit is additionally installed onto the MX-2001, and also consists of five bins. The MX2003 Mailbox unit consists of ten bins.

Note: While the MX-2001 Mailbox unit is available in all countries, the MX-2003 is

available in U.S. and Canada only, and the MX-2002 is available in the other

countries than U.S. and Canada.

The unit works as a

for each function.

Function Description

Stacker

Sorter

Mailbox

When you install the unit onto the printer, the printed paper is ejected to the output tray

of the printer and/or the bin(s) of the Mailbox unit by selection commands sent from the

printer.

stacker, sorter

Printed paper is ejected into the multiple bins behaving as a single

high-capacity tray.

Printed paper is ejected as a set for a print job into a bin when multiple

sets of documents are printed and collated.

Printed paper is ejected into the specific bin defined as your own mail

box.

and

mailbox

for the printer. See the table below

I-1

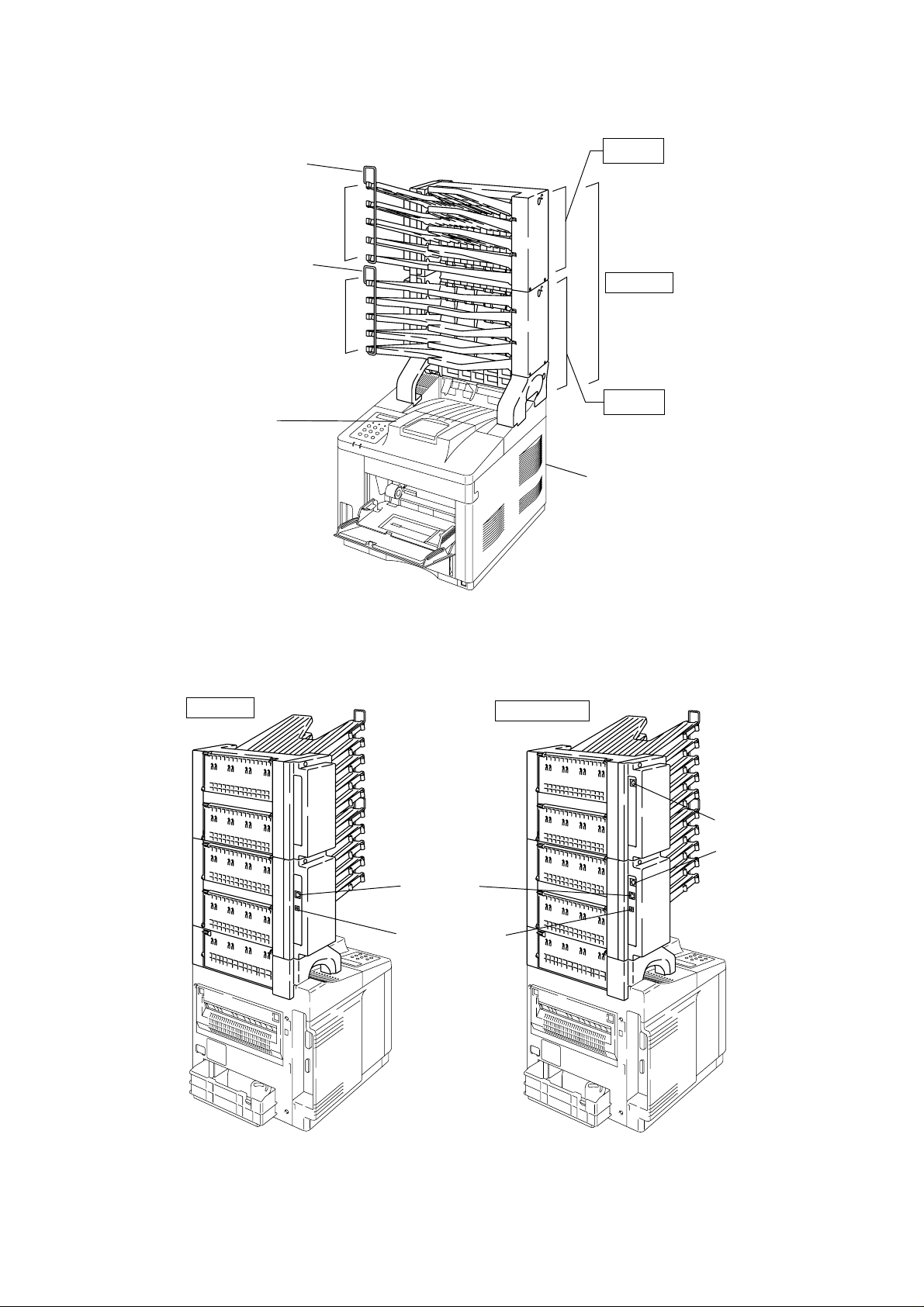

2. OVERVIEW

<Front View>

Printer Output

Paper Stopper

MX-2002

Bin 6 - 10

Paper Stopper

MX-2003

Bin 1 - 5

MX-2001

Tray

HL-2060 Printer

<Rear View>

MX-2003

Fig. 1.1

Modular jack

DC jack connector

MX-2001/2002

Mini DIN connector

Mini DIN connector

Fig. 1.2

I-2

3. SPECIFICATIONS

3.1 Function

(1) Stacking direction

Face down

(2) Feeding speed (when feeding A4 size paper)

Printer Mode When the paper is ejected into

multiple bins

20ppm mode 18 ppm 20 ppm

10ppm mode 9 ppm 10 ppm

(3) Bin capacity

Normal mode: 100 sheet/bin

Big stacker mode*: 300 sheet/bin

* When bins #2, #4, #7 and/or #9 are removed, bins #1, #3, #6 and/or #8 bin(s) as big

stacker bins with a capacity of 300 sheets each.

3.2 Electrical / Mechanical

(1) Power source

AC 100 to 240V, 50Hz/60Hz

When the paper is ejected

continuously into a single bin

(2) Power consumption

Printing: 25W or less (when MX-2001 is installed.)

45W or less (when both MX-2001 and MX-2002, or MX-2003 are

installed.)

Stand-by: 15W or less (when MX-2001 is installed.)

20W or less (when both MX-2001 and MX-2002, or MX-2003 are

installed.)

(3) Temperature

Operating: 10 to 32.5°C (50 to 90.5°F)

Storage: 0 to 40°C (38 to 104°F)

(4) Humidity

Operating: 20 to 80% (non condensing)

Storage: 10 to 85% (non condensing)

(5) Dimensions

MX-2001: 354 (W) x 356 (D) x 411 (H) mm

MX-2002: 354 (W) x 356 (D) x 337 (H) mm

MX-2003: 354 (W) x 356 (D) x 617 (H) mm

(6) Weight

MX-2001: Approx. 5.2 kg

MX-2002: Approx. 4.1 kg

MX-2003: Approx. 9.3 kg

I-3

3.3 Paper

(1) Paper type

Cut sheet

Normal paper / Specific recycled paper

*Special paper is not included.

(2) Feedable paper weight

60 ~ 90 g/m

2

(16 ~ 24lb.)

(3) Feedable paper thickness

0.075 ~ 0.12 mm

(4) Paper size

A4, Letter, Executive, ISO B5

(5) Recommended paper

Xerox 4200 (For U.S.) / RANK Xerox 80 g/m

2

Premier paper (For Europe)

I-4

CHAPTER II THEORY OF OPERATION

1. ELECTRONICS

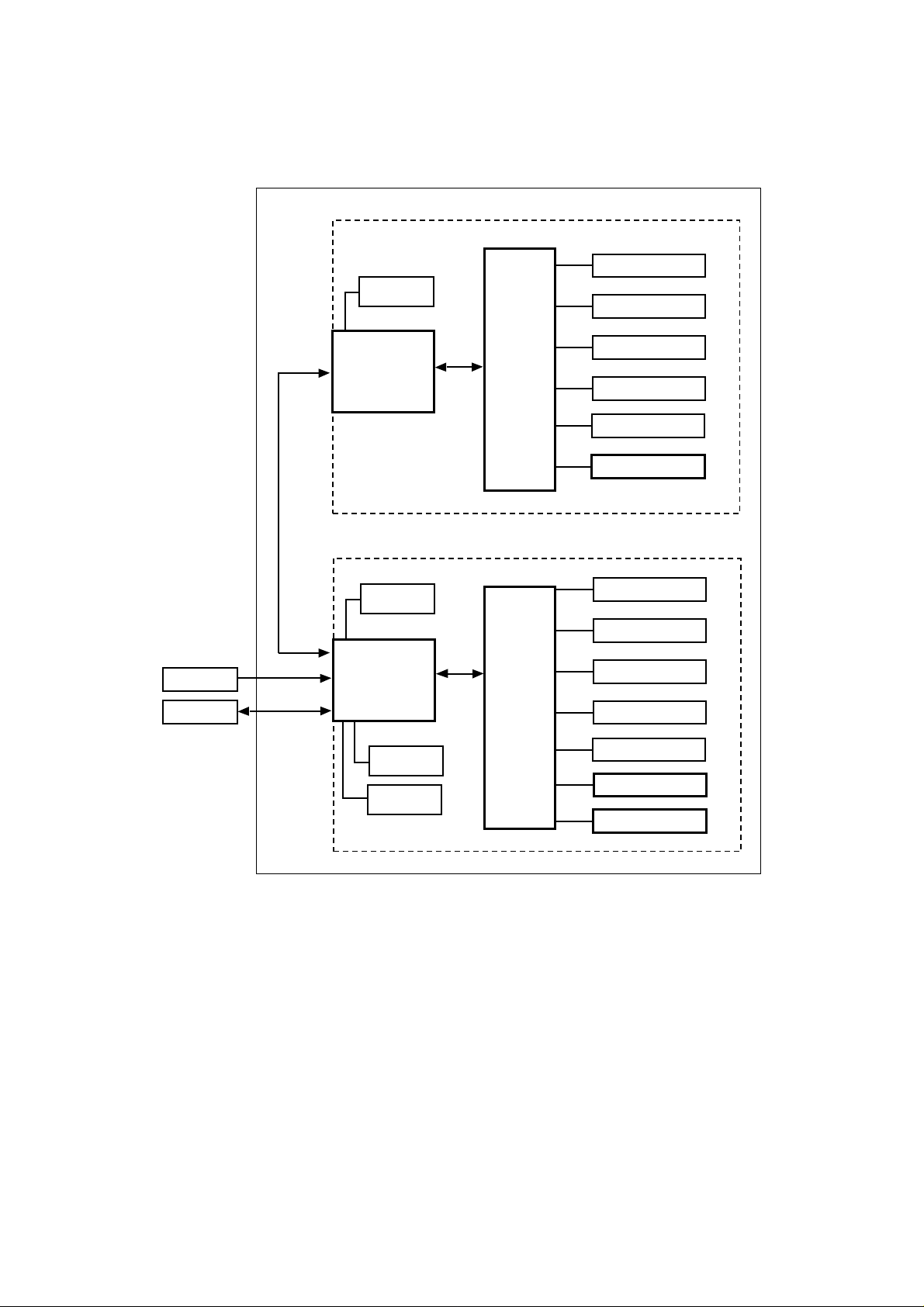

1.1 General Block Diagram

<MX-2001 & MX-2002>

The MX-2001 Mailbox unit is operated according to signals sent from the printer by serial

communication. The MX-2001 and MX-2002 also communicate with each other by serial

communication. Refer to Fig. 2.1 which shows the general block diagram of the MX-2001

and MX-2002.

<MX-2002>

Feeding

Motor

#10 bin solenoid

#9 bin solenoid

Adapter

Printer

Communication

Serial

+24V Input

Serial

Communication

I/F PCB

<MX-2001>

Feeding

Motor

I/F PCB

Entrance

Solenoid

Entrance

Sensor

Main PCB

Main PCB

#8 bin solenoid

#7 bin solenoid

#6 bin solenoid

Sensor PCB

#5 bin solenoid

#4 bin solenoid

#3 bin solenoid

#2 bin solenoid

#1 bin solenoid

Sensor PCB

LED PCB

Fig. 2.1

Note:

The following parts and circuits are not fitted on the PCBs in the MX-2002.

<Main PCB>

Entrance solenoid circuit

LED PCB circuit

<I/F PCB>

Entrance sensor circuit

DC jack connector for the adapter

Modular jack connection to the printer

II-1

<MX-2003>

The electronic system of the MX-2003 is basically the same with the one of MX2001/2002. Refer to Fig. 2.2 which shows the general block diagram of the MX-2003.

<MX-2003>

<Upper Unit>

#10 bin solenoid

Feeding

Serial

Communica-

tion

Motor

I/F PCB

Main PCB

#9 bin solenoid

#8 bin solenoid

#7 bin solenoid

#6 bin solenoid

Sensor PCB

Adapter

Printer

+24V Input

Serial

Communica-

tion

<Lower Unit>

Feeding

Motor

I/F PCB

Entrance

Solenoid

Entrance

Sensor

Fig. 2.2

Main PCB

#5 bin solenoid

#4 bin solenoid

#3 bin solenoid

#2 bin solenoid

#1 bin solenoid

Sensor PCB

LED PCB

II-2

1.2 Main PCB

Fig. 2.2 shows the block diagram of the main PCB.

I/F PCB

+24V

+5V

Entrance solenoid drive circuit

GND

Main PCB

M50727

CPU

Bin solenoid drive circuit

(for each bin)

Bin capacity sensor

(for each bin)

Infrared LED drive circuit

Power supply LED drive circuit

Printer

Fig. 2.2

1.2.1 CPU

The CPU M50727 is a 4 bit one-chip microcomputer which controls the Mailbox unit and

communicates with the printer using serial communications. According to the commands

from the printer, the CPU drives the feeding motor and the solenoid of each bin and then

feeds the paper to the specified bin. If it detects paper full in the specified bin, the CPU

sends the signal to the printer.

1.2.2 Bin solenoid drive circuit

The bin solenoid drive circuit drives the solenoid of each bin which controls the diverter

flap to send the paper to each bin. The diverter flap is opened when the solenoid is

energized and the flap is closed when the solenoid is de-energized. Each drive circuit for

each of the five bins works independently.

This circuit provides a constant current drive to the solenoid. The solenoid is driven at

600mA for 200msec when it is first energized and then it is held by being driven at

150mA.

1.2.3 Entrance solenoid drive circuit

The entrance solenoid drive circuit drives the solenoid which controls the flap to switch

the paper eject tray from the printer to the Mailbox unit. It is the same as the bin solenoid

drive circuit and connected to the entrance solenoid through the I/F PCB.

II-3

1.2.4 Bin capacity sensor

The bin capacity sensors, which are five infrared LEDs, detect whether the bin is full or

not.

The infrared sensor output generated from the sensor PCB is shut off when the bin is full

of paper. The CPU recognizes that the bin is full when the infrared sensor output is shut

off for 20 seconds.

These sensors also detect paper jams. When paper is ejected into the bin, the sensor is

covered temporarily by the actuator. The CPU recognizes that a paper jam has occurred

when the sensor has not cleared after a specified time has passed.

1.2.5 Infrared LED drive circuit

The infrared LED drive circuit drives the five infrared LEDs on the sensor PCB. This

drive circuit is controlled by the CPU.

1.2.6 Power supply LED drive circuit

The power supply LED drive circuit drives the power supply LED when the regulated DC

power, +24V, is supplied when the adapter is connected and plugged in.

1.3 I/F PCB

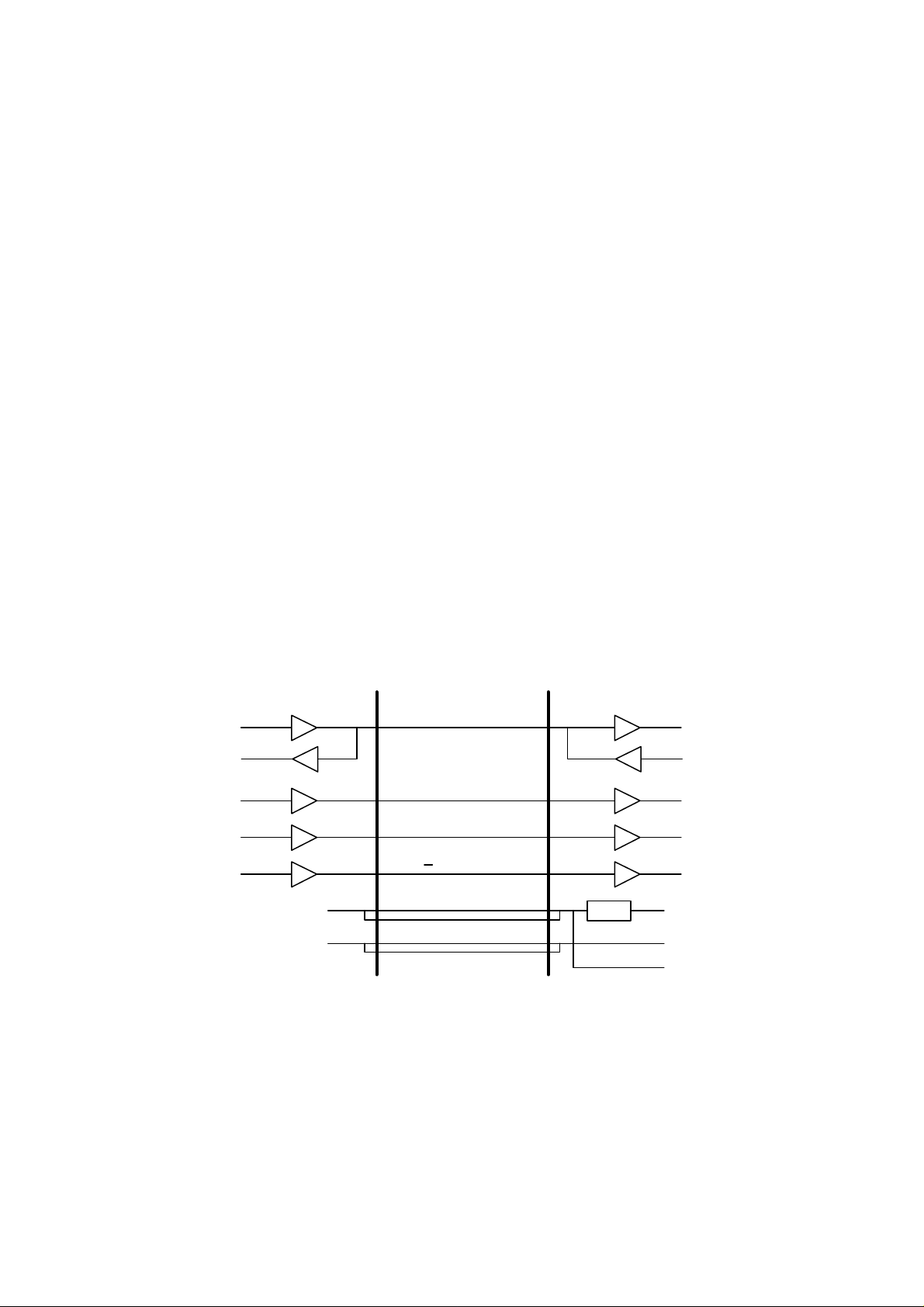

Fig. 2.3 shows the block diagram of the I/F PCB.

I/F PCB

+24V

Adapter

Printer

Mail Box Unit

+24V

+24V

Serial I/F drive circuit

Feeding motor drive circuit

Entrance sensor input

Fig. 2.3

+5V

Regulator

Main PCB

1.3.1 Regulator

The regulator generates and supplies the +5V logic power supply from the +24V supplied

by the adapter.

If the adapter is not connected, the regulator generates the +5V logic power supply from

the +24V supplied by the printer. In this case, the +24V supplied by the printer is not

connected with the +24V supply that should be provided to the Mailbox unit from the

adapter.

II-4

1.3.2 Serial I/F circuit

The serial interface circuit transmits and receives data to and from the printer.

1.3.3 Feeding motor drive circuit

The feeding motor drive circuit drives the motor which feeds the paper in the Mailbox unit

according to the signals from the CPU.

1.3.4 Entrance sensor input

The entrance sensor which is connected with the CPU detects whether the paper is fed

into the Mailbox unit or not.

1.4 Sensor PCB

The five infrared LEDs are mounted on the sensor PCB to detect whether the bin is full or

not. The sensor PCB is controlled according to signals from the CPU.

1.5 Power supply LED PCB

The LED which turns on when the +24V is supplied from the adapter is mounted on the

power supply LED PCB.

1.6 Communication with the Printer

A 3-line clock synchronous serial interface is used for communication between the

Mailbox unit and the printer.

The diagram below describes the timing of communications.

Printer Duplex unit

DATAOUT

DATAIN

CLKOUT

/ATNOUT

/OPRST

+24V

GND

SIDATA

SICLK

/ATTN

/OP RESET

+24V

GND

Fig. 2.4

REG.

DATAIN

DATAOUT

CLKIN

/ATNIN

/RESET

+5V

GND

+24V

II-5

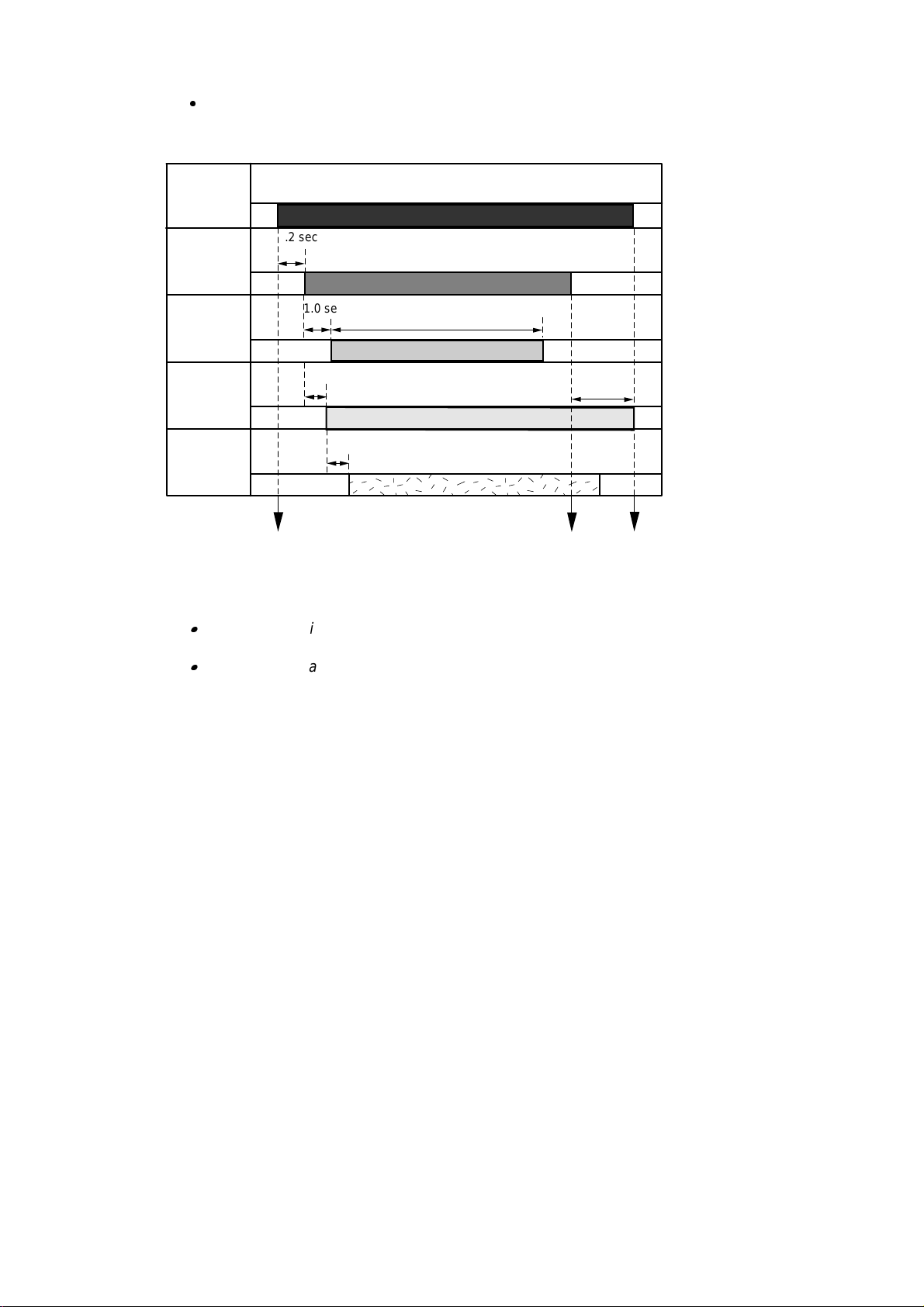

• Without a STATUS request

COMMAND transmission/receipt sequence

/ATTN

SICLK

500 min200 µs

II-6

400 min4µs

SIDATA

500 max

350 max

50 µs 12.8 µs

• Within a STATUS request

COMMAND transmission/receipt sequence

/ATTN

SICLK

400 min4µs

SIDATA

500 max

350 max

50 µs 350 max

6.4 min6.4 min

D0 D1 D2 D3 D4 D5 D6 D7

6.4 min

D0 D1 D2 D3 D4 D5 D6 D7

6.4 min

350 max

200 µs

350 max

200 µs

150 min

150 µs12.8 µs

STATUS transmission/receipt sequence

500 min

350 max

D0 D1 D2 D3 D4 D5 D6 D7

70 µs/1000 max 350 min

2. MECHANICS

r

2.1 General Overview of Mechanism

Paper Stoppe

Paper Stopper

#10 Bin

#9 Bin

#8 Bin

#7 Bin

#6 Bin

#5 Bin

#4 Bin

#3 Bin

MX-2002

Feed Roller A

Actuator A/B

Feed Roller B

Main Flap

Eject Roller

MX-2001

Feed Roller A

#2 Bin

#1 Bin

Eject Roller

Fig. 2.5

Actuator A/B

Feed Roller B

Main Flap

Actuator U

Feed Roller U

Flap U

Note:

The mechanical system of the MX-2003 is the same with the one of MX-2001/2002.

II-7

2.2 Paper Feed Sequence

This section describes the sequence when paper is fed from the printer to #1 bin as an

example.

(1) When the paper is sensed at the eject actuator in the fixing unit, the printer

specifies which bin of the Mailbox unit the paper is to be ejected to and sends the

command to start the operation of the Mailbox unit. (Refer to Fig. 2.6.)

When the Mailbox unit receives the command, it drives the feeding motor and

starts the timer to open the entrance flap (flap U).

MX-2001

HL-2060

Entrance Flap (Flap U)

Paper path

Eject actuator

Fixing Unit

Fig. 2. 6

(2) While the paper is being fed towards the entrance flap, the Mailbox unit starts

driving the entrance solenoid (solenoid U) and turns on the entrance flap so that

the paper is fed to the Mailbox unit. (Refer to Fig. 2.7.)

If the entrance sensor has not turned on after a specified time has passed, it

detects that a paper jam has occurred.

MX-2001

HL-2060

Entrance Flap (Flap U)

Paper path

Fig. 2. 7

II-8

(3) The Mailbox unit drives the #1 bin solenoid (solenoid A) and sets the #1 bin flap

(

)

(main flap) so that the paper is fed to #1 bin. (Refer to Fig. 2.8.)

If the eject sensor of #1 bin has not turned on after a specified time has passed, it

detects that a paper jam has occurred.

MX-2001

#1 Bin Actuator

(Actuator A/B)

Main Flap

HL-2060

#1 Bin

#1 Bin Flap

Entrance Actuator

(Actuator U)

Feed Motor U

Paper path

Fig. 2. 8

(4) After the paper end is ejected from the printer to the Mailbox unit, the printer sends

the command to stop the entrance solenoid to the unit. As soon as the Mailbox

unit receives the command, it stops driving the entrance solenoid.

(5) After the paper is correctly ejected into the #1 bin, the printer sends the command

to stop the operation of the Mailbox unit. As soon as the Mailbox unit receives the

command, it stops driving the feeding motor and the #1 bin solenoid.

II-9

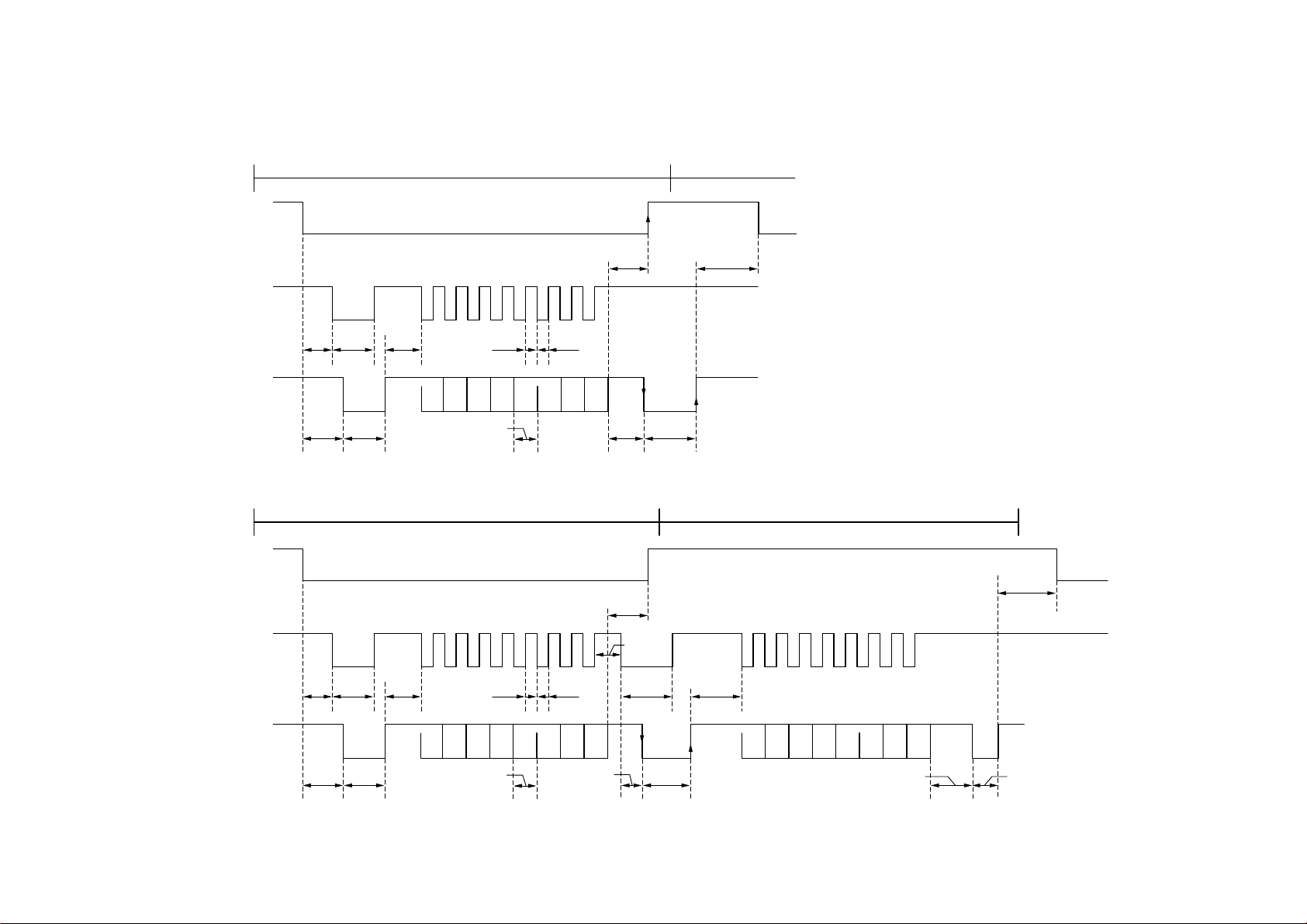

Paper Feed Timing Chart

<Example: #1 Bin >

Feeding

motor

Entrance

1.2 sec

solenoid

Entrance

1.0 sec

2.5 sec

sensor

#1 bin

0.7 sec

4.0 sec

solenoid

#1 bin eject

0.7 sec

sensor

The command to start the

operation received

The command to stop the

entrance solenoid received

Fig. 2.9

The command to stop the

operation received

Note:

The above timing applies to the 20ppm mode. It takes twice as long when the printer

is in the 10ppm (1200 dpi) mode.

The timing delay to eject the paper into the next bin upwards is about 0.3 seconds

later than the bin below because the distance between each bin is 39mm. Also, note

that the distance between the #5 bin and the #6 bin is 55mm and the timing is 0.43

seconds later.

II-10

CHAPTER III DISASSEMBLY

1. SAFETY PRECAUTIONS

To avoid creating secondary problems by mishandling, be careful to follow the following

precautions during maintenance work.

(1) Always unplug the power cord from the power outlet of the Mailbox unit before

accessing any parts inside the unit.

(2) Be careful not to lose screws, washers, or other parts removed during servicing.

(3) Be sure to apply grease to the gears and applicable positions specified in this chapter.

(4) When using soldering irons or other heat-generating tools, take care not to accidentally

damage parts such as wires, PCBs and covers.

(5) Before handling any PCBs, touch a metal portion of the equipment to discharge any

static electricity charge on your body, or the electronic parts or components may be

damaged.

(6) When transporting PCBs, be sure to wrap them in the correct protective packaging.

(7) Be sure to replace self-tapping screws correctly, if removed. Unless otherwise

specified, tighten screws to the following torque values.

TAPTITE, CUP B

M3 : 7kgf • cm

M4 : 10kgf • cm

TAPTITE, CUP S

M3 : 8kgf • cm

SCREW

M3 : 8kgf • cm

(8) When connecting or disconnecting cable connectors, hold the connector body, not the

cables. If the connector has a lock, release the connector lock first to release it.

(9) After a repair, check not only the repaired portion but also all connectors. Also check

that other related portions are functioning properly before operational checks.

III-1

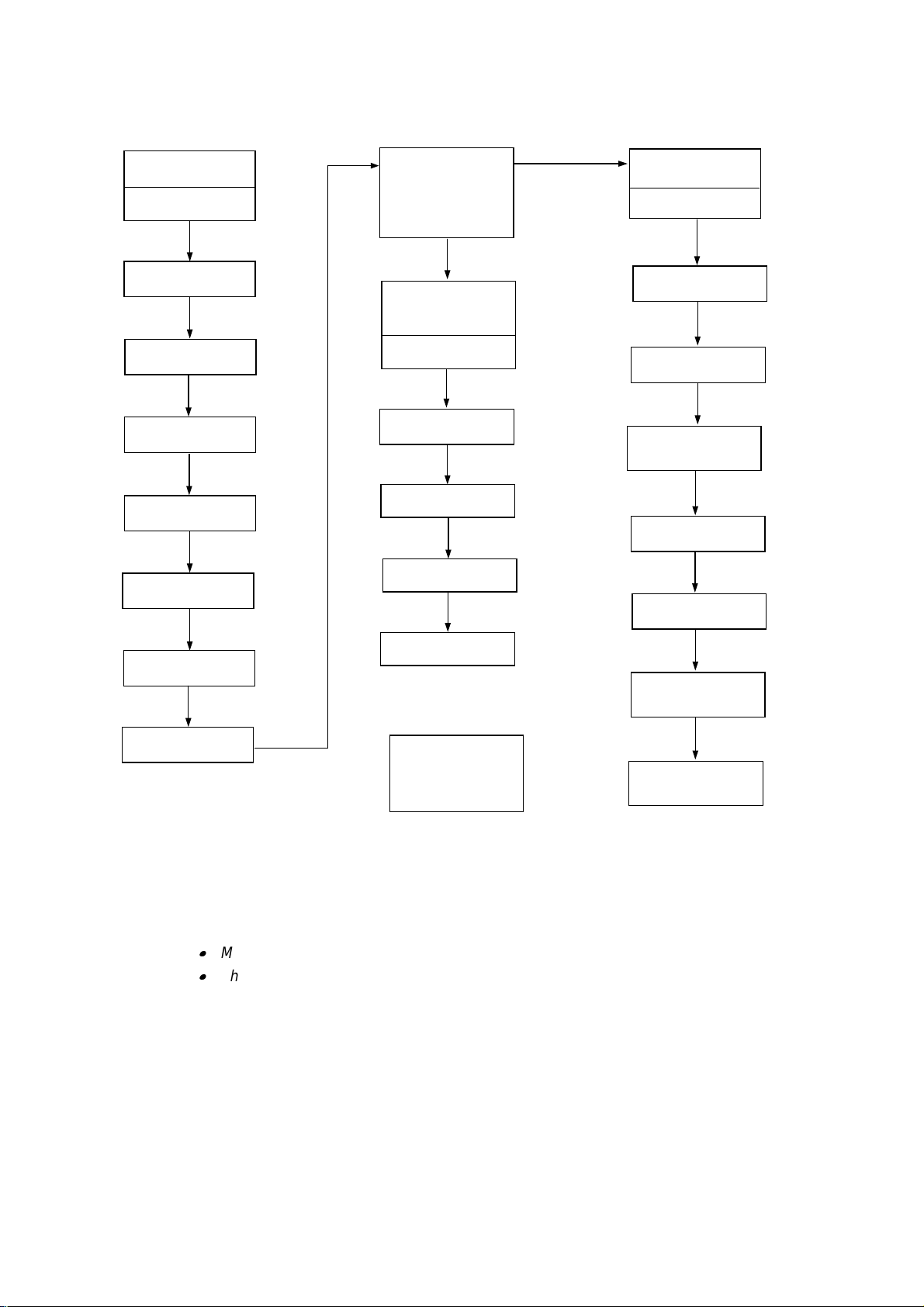

2. DISASSEMBLY FLOW

3.1 External

Covers

Cover UR

(MX-2001/2003 only)

Cover UL

(MX-2001/2003 only)

Cover R

Cover L

Rear Cover U ASSY

(MX-2001/2003 only)

Rear Cover A ASSY

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

3.1.6

3.2 Remove the

Main Frame Unit

from the Under

Frame Unit

(MX-2001/2003 only)

3.4 Under

Frame Unit

(MX-2001/2003 only)

Actuator U

Solenoid U

Photo Interrupter

Feed Roller U ASSY

3.4.1

3.4.2

3.4.3

3.4.4

3.3 Main Frame

Unit

I/F PCB A(B//C/D)

ASSY

Feeding Motor ASSY

Main PCB A(B)

ASSY

Solenoid A/B &

LED PCB ASSY

(MX-2001/2003 only)

Sensor PCB ASSY

Actuator A/B

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

3.3.6

3.4.5

PCB Cover A(B/D)

3.1.7

Flap U

Eject Roller ASSY

& Feed Roller

A/B ASSY

Bin

3.1.8

3.5 Remove the

Upper Unit from

the Lower Unit

(MX-2003 only)

Eject Pinch Roller

ASSY & Discharging

Brush

Note:

1) When disassembling the MX-2003, see Section 3.5 first to remove the upper unit from the

lower unit.

2) Most of the parts are common or similar among the MX-2001, the MX-2002 and the MX2003, and the procedures to disassemble them are also the same. Therefore;

MX-2001 is used for the figures in the following sections.

The parts name descriptions such as ‘Main PCB A(B)’ indicates ‘Main PCB A’ for MX2001 and ‘Main PCB B’ for MX-2002 in this chapter.

3.3.7

3.3.8

III-2

3. DISASSEMBLY PROCEDURE

,

3.1 External Covers

3.1.1 Cover UR (For MX-2001/2003 only)

(1) Remove the two screw cover sheets, then remove the two M3x6 Taptite screws.

(2) Remove the cover UR from the frame UR.

Frame UR

Taptite, M3x6

Screw Cover Sheet

Cover UR

Fig. 3.1

3.1.2 Cover UL (For MX-2001/2003 only)

(1) Remove the two screw cover sheets, then remove the two M3x6 Taptite screws.

(2) Remove the cover UL from the frame UL.

Taptite, M3x6

Screw Cover Sheet

Taptite

M3x6

Screw Cover Sheet

Frame UL

Taptite, M3x6

Screw Cover Sheet

Fig. 3.2

Cover UL

III-3

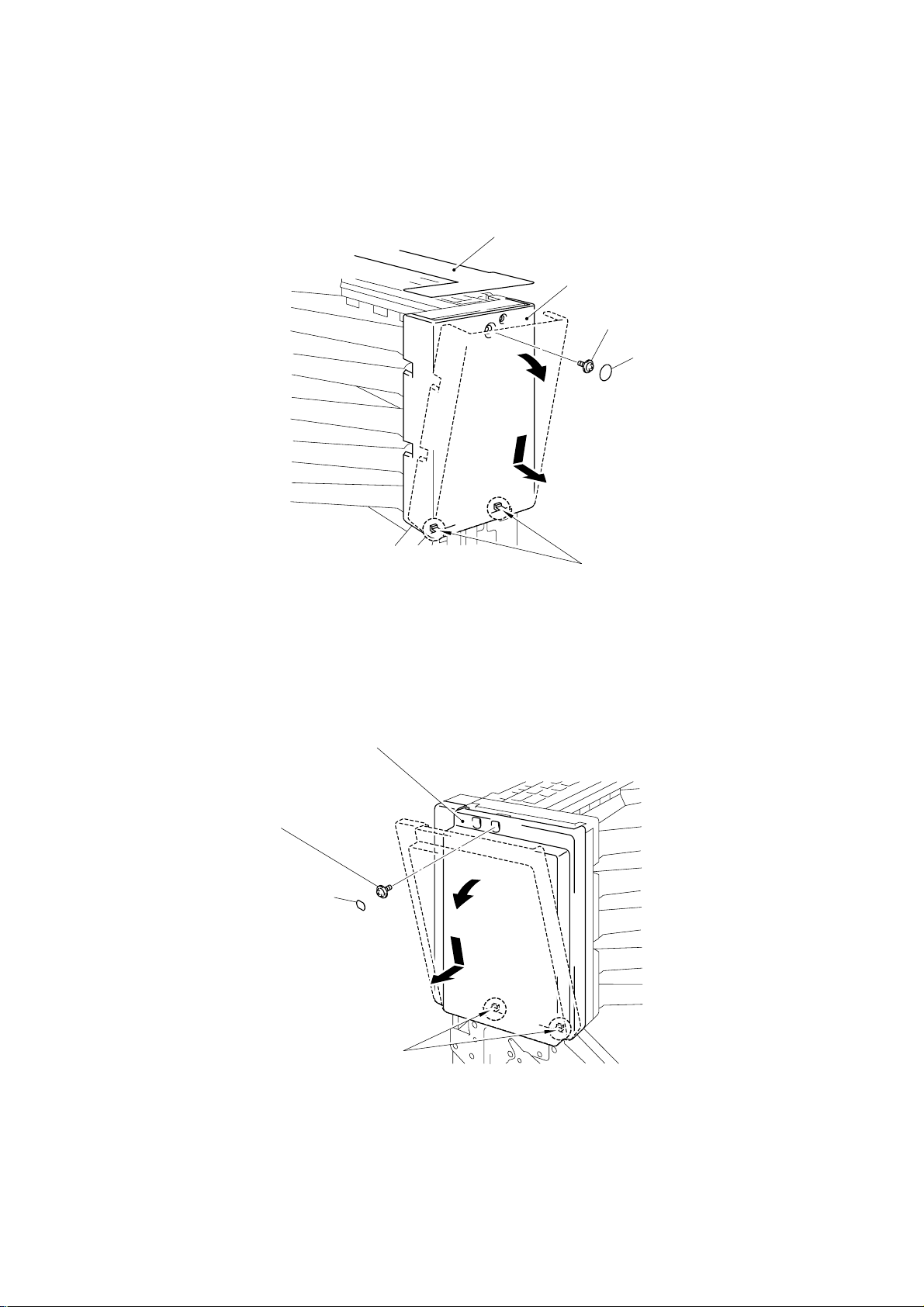

3.1.3 Cover R

(1) Unstick the upper sheet.

(2) Remove the one screw cover sheet, then remove the one M3x6 Taptite screw.

(3) Incline the cover R outwards using the two hooks as supporting points, then remove

the cover R.

Upper Sheet

Cover R

Taptite, M3x6

Screw Cover Sheet

3.1.4 Cover L

(1) Remove the one screw cover sheet L, then remove the one M3x6 Taptite screw.

(2) Incline the cover L outwards using the two hooks as supporting points, then remove

the cover L.

Taptite, M3x6

Screw Cover Sheet L

hook

Fig. 3.3

Cover L

hook

Fig. 3.4

Note:

When refitting cover L, ensure that the cover is lift fully upwards to reduce the gap on the

upper side of the cover.

III-4

3.1.5 Rear Cover U ASSY (For MX-2001/2003 only)

(1) Release the two hooks to open the rear cover U ASSY.

hook

Rear Cover U ASSY

Fig. 3.5

(2) Release the left hand side of the cover by pulling the hinge of the frame UR outwards,

then remove the cover from the right hand side.

hook

Frame UL

Frame UR

hinge

Rear Cover U ASSY

Fig. 3.6

III-5

(3) Remove the four feed roller springs from the rear cover U by pressing the projection on

the cover .

(4) Remove the pressure roller U from each of the four feed roller springs .

Pressure Roller U

Feed Roller Spring

Feed Roller Spring

Rear Cover U

Fig. 3.7

Note:

When reassembling the pressure roller U into the feed roller spring, note that the axle size on

each side is different as shown in the figure above.

III-6

3.1.6 Rear Cover A ASSY

k

(1) Release the two hooks to open each of the two rear cover A ASSYs.

(2) Release the left hand side of the cover by pulling the hinge of the frame R outwards,

then remove the cover from the right hand side.

hoo

Frame R

hinge

Rear Cover A ASSY

Rear Cover A ASSY

hook

Fig. 3.8

(3) Remove the four feed roller springs in each cover by pressing the projection of the

cover.

(4) Remove the pressure roller from each of the eight feed roller springs .

Pressure Roller

Feed Roller Spring

Feed Roller Spring

Rear Cover A

Fig. 3.9

Note:

When reassembling the pressure roller into the feed roller spring, note that the axle size on

each side is different as shown in the figure above.

III-7

3.1.7 PCB Cover A (MX-2001) / PCB Cover B (MX-2002) /

PCB Cover D (MX-2003 Upper Unit)

(1) Remove the four M3x6 Taptite screws.

(2) Remove the PCB cover A(B/D).

Main frame R

PCB Cover A(B)

Taptite, M3x6

Note:

For the PCB cover C (MX-2003 Lower unit), it is already removed when you remove the

upper unit from the lower unit.

3.1.8 Bin

(1) Remove the paper stopper from the bins.

Bin

Taptite, M3x6

Fig. 3.10

Paper Stopper

Bin

Paper Stopper

Fig. 3.11

III-8

(2) Slide bins #2 and #4 (MX-2001/2003 lower) or #7 and #9 (MX-2002/2003 upper)

(B)

towards you.

Bin #4(9)

Bin #2(7)

Fig. 3.12

(3) For other bins, slightly release the right side of the bin by pulling it toward you, then

incline the bin downward to remove it.

(4) Remove the front sheet A(B).

Bin #5(10)

Bin #3(8)

Bin #1(6)

Front Sheet A

Fig. 3.13

III-9

3.2 Remove the Main Frame Unit from the Under Frame Unit (For MX-2001/2003 only)

(1) Disconnect the harness connector of the solenoid U and the entrance sensor

connector from the I/F PCB A(C) ASSY.

(2) Remove the three M3x6 Taptite screws securing the arm AL and the arm UL. Remove

the three M3x6 Taptite screws securing the arm AR and the arm UR.

(3) Lift up the main frame unit .

Main Frame Unit

I/F PCB A

Taptite, M3x6

Entrance sensor

connector

Solenoid U harness

connector

Taptite, M3x6

Shell Clip

Under Frame Unit

Fig. 3.14

Note:

When reconnecting the entrance sensor connector and the solenoid U harness connector,

ensure the cables are hooked into the shell clip on the right hand side of the feeding motor.

3.3 Main Frame Unit

3.3.1 I/F PCB A ASSY (MX-2001) / I/F PCB B ASSY (MX-2002) /

I/F PCB C ASSY (MX-2003 Lower Unit) / I/F PCB D ASSY (MX-2003 Upper Unit)

(1) Disconnect the feeding motor harness connector.

(2) Remove the four M3x16 Taptite screws from the I/F PCB.

(3) Remove the flat cable from the I/F PCB, then remove the I/F PCB A(B/C/D) ASSY .

Taptite, M3x16

Taptite, M3x16

I/F PCB A(B/C/D) ASSY

Feeding motor

harness connector

Flat Cable

Fig. 3.15

III-10

3.3.2 Feeding Motor ASSY

(1) Remove the ten M3x4 screws from the four solenoids A and one solenoid B.

(2) Remove the M3x6 Taptite screw securing the MX ground wire.

(3) Remove the four M4x12 Taptite screws from the arm AL(BL).

Taptite, M4x12

Screw, M3x4

Screw, M3x4

Taptite, M4x12

Screw, M3x4

Arm AL(BL)

Screw, M3x4

Taptite, M3x6

MX Ground Wire

Taptite, M4x12

Main frame L

Taptite, M4x12

Fig. 3.16

(4) Remove the four spacers and the insulation sheet from the arm AL(BL).

(5) Remove the two M3x4 screws to remove the feeding motor ASSY.

Spacer

Arm AL(BL)

Feeding Motor

ASSY

Spacer

Screw, M3x4

Fig. 3.17

Insulation Sheet

III-11

3.3.3 Main PCB A ASSY (MX-2001, MX-2003 Lower Unit) / Main PCB B ASSY (MX-2002,

MX-2003 Upper Unit)

(1) Remove the four M3x10 Taptite screws from the main PCB A(B).

(2) Disconnect the five solenoid A/B harness connectors and the infrared LED harness

connector from the main PCB.

(3) Disconnect the LED harness connector from the main PCB. (MX-2001/2003 only)

(4) Remove the main PCB A(B) ASSY.

Solenoid A harness

Solenoid B

Solenoid B harness

connector

LED Harness

Connector

Solenoid A

connector

Taptite, M3x10

Fig. 3.18

Taptite, M3x10

Main PCB A(B) ASSY

(5) Remove the five sensor guides and the flat cable from the main PCB A(B).

Sensor Guide

Infrared LED harness

connector

Taptite, M3x10

Main frame L

Sensor Guide

Flat Cable

Sensor Guide

Main PCB A(B) ASSY

Fig. 3.19

III-12

3.3.4 Solenoid A/B & LED PCB ASSY (For MX-2001/2003 only)

(1) Remove the four solenoids A and one solenoid B from the main frame L.

(2) Remove the LED PCB ASSY and the LED harness from the main frame L. (MX-

2001/2003 only)

Solenoid A

Solenoid A

Solenoid B

LED Harness

Fig. 3.20

LED PCB ASSY

Main frame L

Note:

When replacing/reassembling the solenoid A/B ASSY, ensure that you reduce the gap at

the left hand side as shown in the figure below.

When replacing/reassembling the solenoid harnesses, the infrared LED harness and the

LED harness on the main frame L, refer to the figure below;

Harness guide

MX Ground Wire

Infrared LED Harness

For the first batch of products, a

clip is assembled on the main

frame L beside the harness guide.

Be sure to hook the infrared LED

harness and MX ground wire into

both the clip and the harness

guide.

Solenoid A

Solenoid B

LED Harness

Main PCB ASSY

Main frame L

Fig. 3.21

III-13

3.3.5 Sensor PCB ASSY

(1) Remove the one M3x6 Taptite screw securing the MX ground wire.

(2) Remove the four M4x12 Taptite screws to remove the arm AR(BR) from the main

frame R.

Taptite, M4x12

Arm AR(BR)

Taptite, M4x12

Taptite, M3x6

MX Ground Wire

Main frame R

Fig. 3.22

Caution:

After removing the arm AR (BR) from the main frame R, do not place the unit face downward.

Failure to do so will cause damage to the discharging brush holder and this will cause misfeeding of the paper

(3) Remove the two M3x10 Taptite screws to remove the sensor PCB ASSY.

(4) Disconnect the infrared LED harness connector from the sensor PCB.

Taptite, M3x10

Taptite, M3x10

Sensor PCB ASSY

Infrared LED Harness

MX Ground Wire

Fig. 3.23

III-14

Note:

g

g

g

g

j

j

k

When replacing/reassembling the infrared LED harness and MX ground wire, ensure that the

cable length for the main frame R side as follows;

Infrared LED harness: 130 ± 5mm

MX ground wire: 65 ± 5mm

3.3.6 Actuator A/B

(1) Release the hook on the right hand side on the rear cover B to remove it.

Main frame R

hook

Rear Cover B

Main frame L

Fig. 3.24

Main frame R

(2) Remove the five idle gears 34, five swing arms and two gears 24 from the main frame

R.

Idle Gear 34

Swin

arm

Idle Gear 34

Swin

arm

Swin

arm

Main frame R

Swin

arm

Pro

ection mar

Main flap shaft

ection mark

Pro

Fig. 3.25

Note:

When reassembling the swing arm onto the main flap shaft, refer to the figure above.

III-15

Idle Gear 34

Idle Gear 24

(3) Remove the five springs from the main flaps and the main frame L.

Spring 40

Main flap shaft

Spring 40

Spring 40

Main fame L

Fig. 3.26

(4) Release the left side of the five main flaps from the main frame R to remove them.

Main frame R

Main Flap

Main Flaps

Main frame L

Main Flap

Main Flap

Fig. 3.27

III-16

(5) Release the hook of the actuator B, then slightly slide the actuator A to the left hand

side to remove the five actuators B from the main frame L.

(6) Slide the five actuators A leftwards to remove them from the main frame A, B and C.

Actuator A

Main frame L

Feed Roller B

Actuator B

Actuator B

Gear 20

Fig. 3.28

Note:

Before removing the actuator A/B from the main frame

A,

remove the gear 20 from the left

side of the feed roller B. Refer to the figure above.

3.3.7 Eject Roller ASSY & Feed Rollers A/B ASSY

(1) Remove the two ground wires from the main frame R.

(2) Remove the two gears 20 from the right hand side of the feed rollers A/B and the five

gears 20 from the eject rollers.

Gear 20

Ground Wire

Gear 20

Gear 20

Main frame R

Gear 20

Ground Wire

Feed Roller A

Feed Roller B

Fig. 3.29

Gear 20

III-17

(3) Remove the 11 (eleven) M3x10 Taptite screws from the main frame R.

j

j

(4) Release the infrared LED harness from the hook of the main frame R.

(5) Remove the main frame R from the main frames A, B, C, and D.

Main frame R

Infrared LED

Harness

Taptite, M3x10

MX Ground Wire

Main frame A

Main frame B

Main frame L

Main frame C

Main frame B

Main frame D

Fig. 3.30

(6) Remove the feed roller A ASSY and feed roller B ASSY from the main frame L.

(7) Remove the two washers from each feed roller.

(8) Push the hook from the left side of the main frame to remove the five eject roller

ASSYs.

Washer

Taptite, M3x10

Taptite, M3x10

Taptite, M3x10

Taptite, M3x10

Feed Roller A ASSY

Washer

Main frame L

Washer

Feed Roller B

ASSY

Fig. 3.31

Washer

hook

ect Roller

E

E

ect Roller ASSY

III-18

3.3.8 Eject Pinch Roller ASSY & Discharging Brush

,

j

g

(1) Remove the 11 (eleven) M3x10 Taptite screws from the main frame L.

(2) Remove the main frame L from the main frames A, B, C, and D.

(3) Release the MX ground wire and infrared LED harness from the hook on the main

frame L to remove them.

Main frame A

Main frame B

Main frame C

Main frame B

Main frame D

Main frame L

Taptite, M3x10

Taptite

M3x10

Taptite, M3x10

Infrared LED

Harness

MX Ground Wire

Fig. 3.32

(4) Remove the 20 (twenty) eject pinch rollers and the 20 (twenty) pinch springs from the

main frames A, B, and C.

(5) Remove the five discharging brush ASSYs.

Eject Pinch Roller ASSY

ect Pinch Roller

E

Pinch Sprin

Main frame B/C/D

Discharging Brush ASSY

Fig. 3.33

III-19

Note:

When reassembling the main frame A, B, C and D, note that the shape and number of ribs on

each frame are different as shown in the figure below;

Ensure to assemble each frame on to the correct position.

Main Frame A

Main Frame B

Main Frame C

Main Frame D

Fig. 3.34

3.4. Under Frame Unit (For MX-2001/2003 only)

3.4.1 Actuator U

(1) Remove the rib U from the right hand side of the actuator U, then remove the actuator

U from the frame U.

Actuator U

Frame U

Rib U

Fig. 3.35

III-20

3.4.2 Solenoid U

(1) Remove the three M4x12 and one M3x10 Taptite screws from the arm UL.

(2) Remove the two M3x4 screws securing the solenoid U.

(3) Remove the arm UL, then remove the solenoid U from the frame UL.

Screw, M3x4

Taptite, M4x12

Solenoid U

Frame UL

Arm UL

Taptite, M3x10

Fig. 3.36

Note:

When replacing/reassembling the solenoid U ASSY, ensure that you reduce the gap at the

rear side of the frame UL.

3.4.3 Photo Interrupter

(1) Unstick the sheet U and the protect sheet U from the frame U.

(2) Release the hooks from the frame U to remove the photo interrupter.

(3) Disconnect the entrance sensor harness connector from the photo interrupter.

Photo Interrupter

hooks

Entrance Sensor

Harness

Frame U

Frame U

Protect Sheet U

Fig. 3.37

III-21

Sheet U

3.4.4 Feed Roller U ASSY

(1) Remove the four M4x12 Taptite screws to remove the arm UR from the frame UR.

Frame UR

Arm UR

Taptite, M4x12

Fig. 3.38

(2) Remove the eight ribs from the frame U.

Rib U

Feed Roller U ASSY

Fig. 3.39

Taptite, M4x12

Rib U

Frame U

(3) Remove the ground wire U.

(4) Release the hook to remove gear 20 from the feed roller U ASSY.

Frame U

hook

Ground Wire U

Gear 20

Fig. 3.40

III-22

(5) Slightly slide the feed roller U ASSY to the right hand side to release the left side of the

roller, then remove the feed roller.

3.4.5 Flap U

(1) Remove the spring 40 from the release link, then remove the release link.

(2) Remove the spring 35 from the flap U.

Frame U

Frame UL

Feed roller U ASSY

Fig. 3.41

Frame UL

Spring 35

Spring 40

Fig. 3.42

(3) Remove the flap U from the frame UL.

Frame UR

Release link

Flap U

Frame U

Flap U

Frame UL

Fig. 3.43

III-23

3.5 Remove the Upper Unit from the Lower Unit (For MX-2003 only)

When you disassemble the MX-2003 Mailbox unit, you have to remove the upper unit from

the lower unit first. Follow the steps below;

(1) Remove the two screw cover sheets, then remove the two M3x6 Taptite screws from

each of the cover UR and cover UL.

(2) Remove the cover UR and cover UL from the frame.

(3) Remove the two screw cover sheets, then remove the two screws from each of the

cover R and cover L of the lower unit..

(4) Remove the cover R and cover L.

Screw, TORX M3x8

Taptite, M3x6

Cover R

Screw Cover Sheet

Taptite, M3x6

Screw Cover Sheet

Taptite, M3x6

Screw, TORX M3x8

Cover L

Cover UL

Screw Cover Sheet

Taptite, M3x6

Note:

1) One of the two screws securing the cover R/L is very special. (They are indicated RED in

Cover UR

Screw Cover Sheet

Fig. 3.44

the figure above.) When disassembling/re-assembling the screw, you need a special

screw driver. Refer to the figure below and the parts reference list;

Screw, TORX M3x8

TORX screw driver

Fig. 3.45

2) Refer to Section 3.1.3 ‘Cover R’ and 3.1.4 ‘Cover L’ in this chapter for details on removing

the cover R/L from the main frame.

III-24

(5) Remove the four M3x6 Taptite screws, then remove the PCB cover C.

PCB Cover C

Taptite, M3x6

Fig. 3.46

(6) Remove the M3x4 screw securing the lower and upper units on the main frame R.

Upper Unit

Main frame R

Screw, M3x4

Fig. 3.47

III-25

(7) Remove the M3x4 screw securing the lower and upper units on the main frame L.

(8) Unhook the harness from the shell clip, then disconnect the harness connector from

the I/F PCB C.

Upper Unit

Shell Clip

Main frame L

I/F PCB C

Harness connector

Fig. 3.48

Screw, M3x4

Note:

When replacing/re-assembling the harness, refer to the figure below;

Fig. 3.49

III-26

(9) Lift up the upper unit from the lower unit.

Upper Unit

Lower Unit

Fig. 3.50

Disassembling steps for other parts are the same with the MX-2001/2002. See the previous

sections.

III-27

3.6 Packing of MX-2003

r

When unpacking/re-packing the MX-2003 mailbox unit, refer to the figure below;

Lower Pad (R)

Base Plate (R)

Carton Cove

AC Cord

Accessory bag

(Documents)

Accessory Carton

Accessory

Upper Pad (R)

MX-2003

Mailbox unit

AC Adapter

Base Plate (L)

Lower Pad (L)

Upper Pad (L)

Carton Pad

Carton

Fig. 3.51

III-28

4. APPLICATION OF GREASE

j

When replacing/reassembling the following parts, remove the old grease and apply a suitable

amount of grease referring to each figure.

4.1 Rollers

4.1.1 Feed Roller A/B ASSY

Apply 1 rice-grain size

KANTO KASEI FLOIL GE-676 to the points (

Main Frame L

4.1.2 Eject Roller ASSY

of grease, SHINETSU SILICON KS-64F to the points (

Feed Roller A ASSY

Feed Roller B ASSY

Ground Wire

Fig. 3. 52

), as shown below;

~

Main Frame R

Arm AR

Arm AR

) and

~

Apply 1 rice-grain size

shown below;

Main Frame L

of grease, SHINETSU SILICON KS-64F to the points (

Main Frame R

ect Roller ASSY

E

Fig. 3. 53

) as

~

III-29

Apply 1 sesame-grain size

(U)

)

shown below;

4.1.3 Feed Roller U ASSY

of grease, SHINETSU SILICON KS-64F to the points (

Main Frame A ~ D

Eject Roller ASSY

Fig. 3. 54

)

as

Apply 1 rice-grain size

KANTO KASEI FLOIL GE-676 to the points (

Apply 1 sesame-grain size

shown below;

of grease, SHINETSU SILICON KS-64F to the points (

of grease, SHINETSU SILICON KS-64F to the points (

Frame UR

Frame UL

Feed Roller U

ASSY

Fig. 3. 55

), as shown below;

~

Rib U (8 pcs

Ground Wire U

Arm UR

), and

~

)

as

4.1.4 Pressure Roller / Pressure Roller U

Apply 1 sesame-grain size

as shown below;

of grease, SHINETSU SILICON KS-64F to the points (

Feed Roller Spring

Pressure Roller

Fig. 3. 56

III-30

~

)

4.2 Gears

g

4.2.1 Gears on the Main Frame R

PR99011

Apply 1 rice-grain size

shown below;

Gear 16

of grease, SHINETSU SILICON KS-64F to the points (

Feed Roller Gear

c

Idle Gear 34

h

d

i

Gear 24

e

j

f

k

c ~

l

) as

Main Frame R

g

4.2.2 Gears on the Main Frame L

Apply 1 rice-grain size

shown below;

Feedin

Motor

of grease, SHINETSU SILICON KS-64F to the points (

c

Fig. 3.57

d

Gear 16/40

l

Arm AL

Feed Roller Gear

c

~

d

) as

Fig. 3. 58

III-31

4.2.3 Gears on the Frame UR

g

)

PR99011

Apply 1 rice-grain size

shown below;

Frame UR

of grease, SHINETSU SILICON KS-64F to the points (

Idle Gear 34

c

Feed Roller Gear

Frame UR

Idle Gear 34

Fig. 3. 59

d

c

~

d

) as

4.3 Others

Apply 1 rice-grain size

shown below;

Gear 16

c

Idle Gear 34

g

of grease, SHINETSU SILICON KS-64F to the points (

d

Main Frame R

Main Flap

f

e

Swing arm

Gear 24

h

arm

Swin

Fig. 3. 60

ij

~

c

j

Main Frame R

) as

Main Frame R

(Frame UR)

Solenoid A/B (U

Main Frame L

(Frame UL)

Main Flap (Flap U)

Fig. 3. 61

III-32

CHAPTER IV TROUBLESHOOTING

1. INITIAL CHECK

(1) Operating environment

Check if :

¸ The source voltage stays within ±10% of the rated voltage shown on the rating

plate.

¸ The room temperature is maintained between 10°C and 32.5°C. The relative

humidity is maintained between 20% and 80%.

¸ There is enough space around the unit so that the following operations are

possible.

a) The power cord and modular jack connector can be connected

b) The rear cover can be opened to remove jammed paper.

c) Various maintenance work can be easily implemented.

¸ The unit is installed on a solid, level surface.

¸ The unit is not exposed to direct sunlight.

¸ The unit is not located in a dusty place.

¸ The room is well-ventilated.

¸ The unit is not placed where the ventilation hole of the unit is blocked.

¸ The unit is not exposed to ammonia fumes or other harmful gases.

¸ The unit is not located in a hot or humid area (such as near water or a

humidifier).

(2) Print paper

Check if :

¸ A recommended type of print paper is being used. [If the paper is too thick or too

thin, or tends to curl, paper jams or paper feed problems may occur, or printed

images may be blurred.]

¸ The print paper is damped. [If so, use fresh paper, and check whether the print

quality improves or not.]

¸ The print paper is short-grained paper or acid paper. [If so, print quality

problems may occur. For further information, refer to paper specifications in

Chapter II.]

(3) Others

Condensation:

¸ When the unit is moved from a cold room into a warm room in cold weather,

condensation may occur inside the unit.

¸ Condensation on the hopper gate and separation pad may cause paper feed

problems.

If condensation has occurred, wipe the effected parts with a dry cloth and leave the

printer for 2 hours to allow it to reach room temperature.

IV-1

2. MTBF / MTTR

The meantime between failure (MTBF) and the meantime to repair (MTTR) for this printer

are as follows;

MTBF: 4,000 hours

MTTR: Less than 30 minutes

IV-2

3. TROUBLESHOOTING

Problem Cause Check Result Remedy

The paper is not ejected to the

Mailbox unit even though paper

output is set to the Mailbox unit in

the printer driver.

The ‘STACK PAPER JAM’

message appears when the printer

is turned on even though no paper

is ejected to the Mailbox unit.

The ‘STACK FULL’ message

appears even though no paper is

ejected to the Mailbox unit.

Installation error Is the modular cable connected correctly? No Turn off the printer power switch and

unplug the AC adapter cord of the Mailbox

unit from the outlet. Connect the modular

cable correctly, then plug in the AC

adapter cord and turn on the printer power

switch again.

Modular cable Is the timing of pins 2 and 4 of the P6

connector on the I/F PCB normal?

(Refer to the figure on page II-6 of

Chapter II.)

I/F PCB Is a voltage of +5V supplied to pin 16 of

the P1 connector on the I/F PCB?

I/F PCB

Main PCB

Installation error Is the AC adapter cord connected

Adapter

I/F PCB

Sensor PCB

Main PCB

Is the timing of pins 5 and 6 of the P1

connector on the I/F PCB normal?

(Refer to the figure on page II-6 of

Chapter II.)

correctly?

Is the AC adapter jack connected to the

Mailbox unit correctly?

Is a voltage of +5V supplied to pin 1 of the

P5 connector on the I/F PCB?

Does the error message appears for all

bins?

No Replace the modular cable.

No. Replace the I/F PCB.

No Replace the I/F PCB.

Yes Replace the main PCB.

No Turn off the printer power switch and

connect the AC adapter cord or the AC

adapter jack of the Mailbox unit correctly.

Then, plug in the AC adapter cord and

turn on the printer power switch again.

No Replace the adapter.

Yes Replace the I/F PCB.

Yes Replace the sensor PCB.

No Replace the main PCB.

IV-3

Problem Cause Check Result Remedy

The paper is ejected to the printer

output tray and the ‘STACK PAPER

JAM’ message appears, even

though paper output is set to the

Mailbox unit.

The ‘STACK PAPER JAM’

message appears even though the

paper is ejected to the Mailbox unit

correctly.

The paper is not ejected to the

specified bin but fed into the back of

the unit.

The ‘STACK PAPER JAM’

message also appears.

Flap U Does the flap U work correctly? No Apply the grease to the specified points of

the flap U.

For details, refer to Section 4 of Chapter

3.

Solenoid U

Main PCB

Actuator U Does the actuator U work correctly? No Check if there is any flash on the frame U

Main PCB

Photo interrupter

Feeding motor Does the feeding motor rotate? No Replace the feeding motor and the I/F

Main flap of

each bin

Solenoid A/B

Main PCB

Is a voltage of +24V supplied to pin 1 and

a voltage of app. 1V supplied to pin 2 of

the P2 connector on the I/F PCB when the

flap U operates?

Is the timing of pin 3 of the connector P3

on the I/F PCB normal when the actuator

U operates?

(Refer to the figure on page II-6 of

Chapter II.)

Does the main flap of each bin work

correctly?

Is a voltage of +24V supplied to pin 1 and

a voltage of app. 1V supplied to pin 2 of

the connector on the main PCB when

each flap operates?

<Connector No. for each bin>

#1 Bin: P7 #2 Bin: P6

#3 Bin: P5 #4 Bin: P3

#5 Bin: P2

Yes Replace the solenoid U.

No Replace the main PCB.

or actuator U.

If there is no flash, replace the actuator U.

Yes Replace the main PCB.

No Replace the photo interrupter.

PCB.

No Apply the grease to the specified point on

the main flap of each bin. For details,

refer to Section 4 of Chapter III.

Yes Replace the solenoid A/B.

No Replace the main PCB.

IV-4

Problem Cause Check Result Remedy

The ‘STACK PAPER JAM’

message appears when 100mm of

paper is ejected to the Mailbox unit.

Note:

‘Main PCB’ described in the above table is indicating ‘Main PCB A’ for MX-2001 or MX-2003 lower unit and ‘Main PCB B’ for MX-2002 or MX2003 upper unit.

‘I/F PCB’ described in the above table is indicating ‘I/F PCB A’ for MX-2001, ‘I/F PCB B’ for MX-2002, ‘I/F PCB C’ for MX-2003 lower unit and ‘I/F

PCB D’ for MX-2003 upper unit.

Harness wiring Does the infrared LED harness interfere

with the actuator A/B?

Actuator A/B of

each bin

Main PCB Yes Replace the main PCB.

Does the actuator A/B of each bin work

correctly?

Yes Re-wire the infrared LED harness not to

interfere with the actuator A/B.

No Replace the actuator A/B of each bin.

IV-5

Appendix 1. Main PCB Circuit Diagram, (1/2)

CODE UK4287-000

NAME

A - 1

B512015CIR

Appendix 2. Main PCB Circuit Diagram, (2/2)

CODE UK4287-000

NAME

A - 2

B512015CIR

Appendix 3. I/F PCB Circuit Diagram

CODE UK4292-000

NAME

B512017CIR

A - 3

INDEX

A

actuator A........................................II-7, III-17

actuator B........................................II-7, III-17

actuator U........................................II-7, III-20

feeding motor drive circuit......................... II-5

feeding speed ............................................ I-3

flap U..............................II-7, II-8, III-23, III-32

flat cable................................................. III-12

front sheet A............................................. III-9

front sheet B............................................. III-9

B

big stacker mode........................................I-3

bin............................................... I-2, II-7, III-9

bin capacity.................................................I-3

bin capacity sensor....................................II-4

bin solenoid drive circuit............................II-3

C

communication ..........................................II-5

condensation........................................... IV-1

cover L......................................................III-4

cover R.....................................................III-4

cover UL...................................................III-3

cover UR...................................................III-3

CPU...........................................................II-3

D

DC jack connector......................................I-2

dimensions .................................................I-3

discharging brush...................................III-19

G

gear........................................................ III-31

general block diagram............................... II-1

grease.................................................... III-29

I

I/F PCB ..................................................... II-4

block diagram........................................ II-4

circuit diagram.......................................A-3

I/F PCB A............................................... III-10

I/F PCB B............................................... III-10

I/F PCB C..................................... III-10, III-26

I/F PCB D............................................... III-10

infrared LED drive circuit .......................... II-4

infrared LED harness............................. III-14

insulation sheet...................................... III-11

L

LED harness.......................................... III-13

LED PCB................................................ III-13

E

eject pinch roller .....................................III-19

eject roller............................. II-7, III-18, III-29

entrance flap..............................................II-8

entrance sensor.........................................II-5

entrance sensor harness........................III-21

entrance solenoid......................................II-8

entrance solenoid drive circuit...................II-3

environment............................................. IV-1

F

feed roller A.......................... II-7, III-18, III-29

feed roller B.......................... II-7, III-18, III-29

feed roller U.......................... II-7, III-23, III-30

feeding motor...................................II-8, III-11

M

mailbox....................................................... I-1

main flap ........................II-7, II-9, III-16, III-32

main PCB.................................................. II-3

block diagram........................................ II-3

circuit diagram....................................A-1-2

main PCB A ........................................... III-12

main PCB B ........................................... III-12

mini DIN connector .................................... I-2

modular jack............................................... I-2

MTBF.......................................................IV-2

MTTR.......................................................IV-2

MX ground wire...................................... III-11

i

P

W

packing...................................................III-28

paper.................................................I-4, IV-1

paper size...............................................I-4

paper type...............................................I-4

feedable thickness..................................I-4

feedable weight.......................................I-4

recommended paper...............................I-4

paper stopper.............................I-2, II-7, III-8

PCB cover A.............................................III-8

PCB cover B.............................................III-8

PCB Cover C..........................................III-25

PCB Cover D............................................III-8

photo interrupter.....................................III-21

power consumption....................................I-3

power supply LED drive circuit..................II-4

power supply LED PCB.............................II-5

precaution.................................................III-1

pressure roller.................................III-7, III-30

pressure roller U.............................III-6, III-30

printer output tray.......................................I-2

pinch spring............................................III-19

protect sheet U.......................................III-21

weight.........................................................I-3

R

regulator....................................................II-4

rear cover A..............................................III-7

rear cover U..............................................III-5

S

sensor guide...........................................III-12

sensor PCB.....................................II-5, III-14

serial interface circuit.................................II-5

sheet U...................................................III-21

solenoid A........................................II-9, III-13

solenoid B...............................................III-13

solenoid U........................................II-8, III-21

sorter..........................................................I-1

spacer.....................................................III-11

stacker........................................................I-1

T

torque values............................................III-1

U

upper sheet...............................................III-4

ii

R

MAILBOX UNIT

FOR LASER PRINTER

PARTS REFERENCE LIST

MODEL:MX-2001/MX-2002/MX-2003

Note:

While the MX-2001 Mailbox unit is available in all countries, the

MX-2003 is available in U.S. and Canada only, and the MX-2002

is available in the other countries than U.S. and Canada.

Oct., '98

54T051NE0

NOTE FOR USING THIS PARTS REFERENCE LIST

REF.NO.

CODE

Q’TY

DESCRIPTION

SYMBOL

REMARK

(1)

(4)

(3)

(2)

Circuit board No.

(The first version has no sign.)

1. In the case of ordering parts, it needs mentioning the following items:

(1) Code

(2) Q'ty

(3) Description

(4) Symbol ( PCB No., Revision , and Parts location mounted on the PCB.)

Note : No orders without Parts Code or Tool No. can be accepted.

< Example >

Revision No.: marked on the main printed circuit board.

B48K056 - 201A

Design change indication

Specification No .

Pattern alteration No.

Revision No.: marked on the power supply printed circuit board.

Rev. A

Design change indication

2. Design-changed parts :

If the parts are changed, any one of the following symbols is indicated in the REMARKS

column.

#A : compatible between old and new

#B : replaceable from old to new

#D : incompatible

# : newly established

3. The original of this list was made based on the information available in October, 1998.

4. Parts are subject to change in design without prior notice.

CONTENTS

1. UNDER FRAME UNIT...........................................................................1

2. UNDER UNIT COVERS ........................................................................1

3. MAIN FRAME UNIT...............................................................................3

4. COVERS ...............................................................................................5

5. PCBS.....................................................................................................5

6. PCB RELATED......................................................................................7

7. POWER SUPPLY..................................................................................7

8. AC CORD..............................................................................................9

9. ACCESSORIES.....................................................................................9

10. PACKING MATERIALS (MX-2001/2002) ............................................11

11. PACKING MATERIALS (MX-2003) .....................................................11

12. ADJUSTING TOOL KIT.......................................................................13

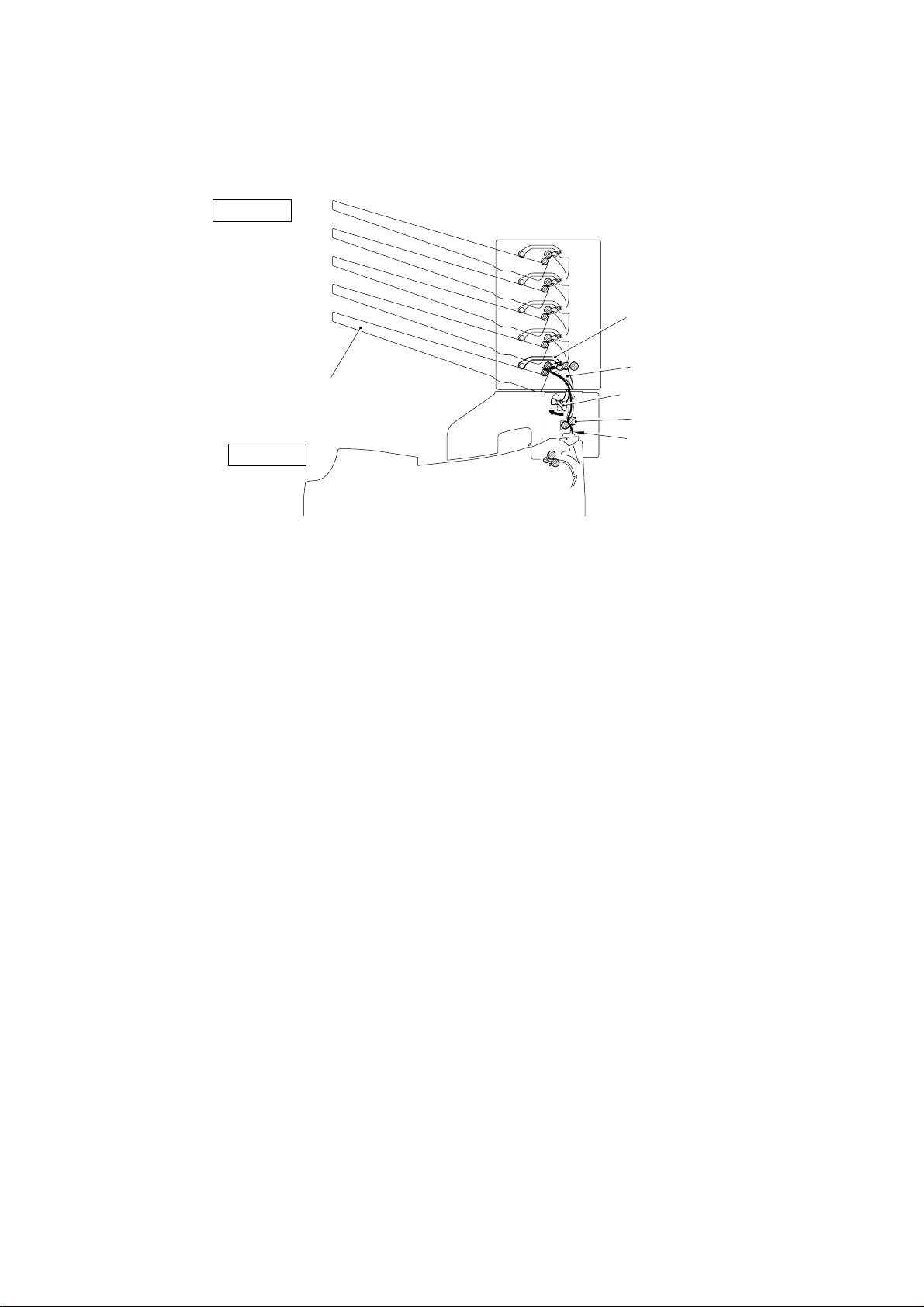

1. UNDER FRAME UNIT

PR98306

REF.NO.

CODE

Q'TY

DESCRIPTION

REMARK

1

UK4325000

1

PHOTO INTERRUPTER:1241

2

UK4314001

1

ENTRANCE SENSOR HARNESS 3P

3

UH3904001

1

SHEET U

4

UH3990001

1

PROTECT SHEET U

5

UH3907001

1

ACTUATOR U

6

UH3908001

1

FEED ROLLER U ASSY

7

UH3912001

1

GROUND WIRE U

8

UH3913001

1

FLAP U

9

UH3915001

1

SPRING 35

10

UH3916001

1

SPRING 40

11

UH3917001

1

SOLENOID U

12

060300416

2

SCREW, BIND M3X4

13

087411216

3

TAPTITE, CUP B M4X12

14

087311016

1

TAPTITE, CUP B M3X10

15

087411216

4

TAPTITE, CUP B M4X12

16

087320616

4

TAPTITE, CUP S M3X6

MODEL MX-2001/2003 54T-X20/X40-500

2. UNDER UNIT COVERS

REF.NO.

CODE

Q'TY

DESCRIPTION

REMARK

1

UH3930001

1

COVER UL

2

UH3931001

1

COVER UR

3

087320616

4

TAPTITE, CUP S M3X6

4

UH3932001

4

SCREW COVER SHEET

5

UH3933001

1

REAR COVER U ASSY

5-1

UH3935001

4

FEED ROLLER SPRING

5-2

UH3936001

4

PRESSURE ROLLER U

MODEL MX-2001/2003 54T-X20/X40-510

- 1 -

1. UNDER FRAME UNIT

16

13

12

14

16

8

6

15

7

5

1

15

2

11

9

3

4

10

2. UNDER UNIT COVERS

1

MODEL MX-2001/2003 54T-X20/X40-500

5

5-1

5-2

4

3

2

3

4

MODEL MX-2001/2003 54T-X20/X40-510

- 2 -

3. MAIN FRAME UNIT

REF.NO. CODE Q'TY DESCRIPTION REMARK

1 UK4298001 1INFRARED LED HARNESS 2P

2 UK4319001 1MX GROUND WIRE

3 UH3939001 5DISCHARGING BRUSH ASSY

4 UH3323001 20EJECT PINCH ROLLER ASSY

5 UH3948001 20PINCH SPRING

6 087311016 22TAPTITE, CUP B M3X10

7 UH3951001 5EJECT ROLLER ASSY

8 UH3953001 5ACTUATOR A

9 UH3954001 5ACTUATOR B

10 UH3955001 1FEED ROLLER A ASSY

11 UH3957001 1FEED ROLLER B ASSY

12 048040346 4WASHER E4

13 UH3959001 5MAIN FLAP

14 UH3916001 5SPRING 40

15 UH3962001 2GROUND WIRE

16 087411216 4TAPTITE, CUP B M4X12

17 UH3964001 4SOLENOID A

18 UH3965001 1SOLENOID B

19 UH3970001 4SPACER

20 UH3971001 1INSULATION SHEET

21 UH1565001 1FEEDING MOTOR ASSY

22 060300416 2SCREW, BIND M3X4

23 087411216 4TAPTITE, CUP B M4X12

24 060300416 10SCREW, BIND M3X4

25 UH4001001 1SHELL CLIP

26 060300416 2

SCREW, BIND M3X4 (MX-2003 LOWER,

FOR CONNECTION WITH UPPER UNIT)

MODEL MX-2001/2002/2003 54T-X20/X30-600, 54T-X40-600/601

T/I NO. PR98267 / PR98306

- 3 -

3. MAIN FRAME UNIT

12

12

17

17

12

10

11

12

13

15

7

1

6

13

7

6

6

8

6

8

5

14

6

4

5

5

4

9

6

14

5

4

14

6

9

2

16

5

4

4

5

4

5

5

5

6

9

26

18

24

23

19

24

23

24

21

24

19

25

MODEL MX-2001/2002/2003 54T-X20/X30-600, 54T-X40-600/601

T/I NO. PR98267 / PR98306

26

23

22

20

3

16

3

16

- 4 -

4. COVERS

REF.NO. CODE Q'TY DESCRIPTION REMARK

1 UH4018001 5BIN

2 UH3974001 2REAR COVER A ASSY

2-1 UH3935001 8FEED ROLLER SPRING

2-2 UH2360000 8PRESSURE ROLLER

3 UH3977001 1COVER L

4 UH3978001 1COVER R

5 087320616 2TAPTITE, CUP S M3X6

6 UH3932001 1SCREW COVER SHEET

7 UH3993001 1SCREW COVER SHEET L

8 UH3979001 1UPPER SHEET (MX-2001/2003 UPPER)

9 UH3981001 1FRONT SHEET A (MX-2001/2003 LOWER)

9 UH3987001 1FRONT SHEET B (MX-2002/2003 UPPER)

10 UH3989001 1PAPER STOPPER

11 UH4019001 2

SCREW, BIND(TORX) M3X8 (MX-2003 LOWER)

12 UH3993001 2SCREW COVER SHEET L (MX-2003)

MODEL MX-2001/2002/2003 54T-X20/X30-610, 54T-X40-610/611

T/I NO. PR98306 / PR98307

5. PCBS

REF.NO. CODE Q'TY DESCRIPTION SYMBOL REMARK

1 UK4283001 1MAIN PCB ASSY A (MX-2001/2003 LOWER)B512015-200D

1 UK4284001 1MAIN PCB ASSY B (MX-2002/2003 UPPER)B512015-201D

2 UH3901001 5SENSOR GUIDE

3 087311016 4TAPTITE, CUP B M3X10

4 UK4288001 1I/F PCB ASSY A (MX-2001) B512017-200B

4 UK4289001 1I/F PCB ASSY B (MX-2002) B512017-201B

4 UK4382001 1I/F PCB ASSY C (MX-2003 LOWER) B512017-202

4 UK4383001 1I/F PCB ASSY D (MX-2003 UPPER) B512017-203

5 087321616 4TAPTITE, CUP S M3X16

6 UK4293001 1SENSOR PCB ASSY B512016

7 087311016 2TAPTITE, CUP B M3X10

8 UK4317001 1LED PCB ASSY (MX-2001/2003 LOWER) B512036

MODEL MX-2001/2002/2003 54T-X20/X30-100, 54T-X40-100/101

T/I NO. PR98306, PR99026

- 5 -

4. COVERS

12

11

2-2

2-2

T/I NO. PR98306

5. PCBS

12

2-1

2

8

2-1

11

5

7

3

MODEL MX-2001/2002/2003 54T-X20/X30-610, 54T-X40-610/611

9

6

5

4

1

10

2

3

4

8

7

3

2

5

6

5

1

7

5

3

MODEL MX-2001/2002/2003 54T-X20/X30-100, 54T-X40-100/101

- 6 -

6. PCB RELATED

REF.NO. CODE Q'TY DESCRIPTION REMARK

1 UK4297000 1FLAT CABLE

2 UK4299001 1LED HARNESS 2P (MX-2001/2003 LOWER)

3 087320616 2TAPTITE, CUP S M3X6

4 UH3992001 1PCB COVER A (MX-2001)

4 UH3982001 1PCB COVER B (MX-2002)

4 UH4016001 1PCB COVER C (MX-2003 LOWER)

4 UH4017001 1PCB COVER D (MX-2003 UPPER)

5 087320616 4TAPTITE, CUP S M3X6

MODEL MX-2001/2002/2003 54T-X20/X30-110, 54T-X40-110/111

T/I NO. PR98306

7. POWER SUPPLY

REF.NO. CODE Q'TY DESCRIPTION REMARK

1 UK4300001 1MX AC ADAPTER

MODEL MX-2001/2003 54T-X20/X40-200

- 7 -

8. AC CORD

1A

1B

1C

1D

9. ACCESSORIES

MODEL MX-2001/2003 54T-X20/X40-230

2

5

1

3

T/I NO. PR99196

4

MODEL MX-2001/2002/2003 54T-X20/X30/X40-920

- 10 -

8. AC CORD

REF.NO.

CODE

Q'TY

DESCRIPTION

REMARK

1A

UK4302001

1

AC CORD, SAA

1B

UK4303001

1

AC CORD, BS

1C

UK4301001

1

AC CORD, EUR

1D

UK4332001

1

AC CORD UL/CSA ASSY

MODEL MX-2001/2003 54T-X20/X40-230

T/I NO. PR99191

9. ACCESSORIES

REF.NO.

CODE

Q'TY