Page 1

Page 2

SERVICE MANUAL

MODEL: MP-21C / 21CDX

Page 3

© Copyright Brother 1999

All rights reserved.

No part of this publication may be reproduced in any form or by any means without permission in

writing from the publisher.

Specifications are subject to change without notice.

Trademarks:

The brother logo is a registered trademark of Brother Industries, Ltd.

Microsoft is a registered trademark of Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the U.S. and other countries.

Page 4

TABLE OF CONTENTS

CHAPTER I FEATURES AND SPECIFICATIONS

1. SYSTEM REQUIREMENT---------------------------------------------------I-1

2. FEATURES ----------------------------------------------------------------------I-1

3. CONFIGURATION-------------------------------------------------------------I-3

3.1 Mechanics------------------------------------------------------------------------------------I-3

3.2 Electronics -----------------------------------------------------------------------------------I-4

4. SPECIFICATIONS------------------------------------------------------------- I-5

4.1 Printing----------------------------------------------------------------------------------------I-5

4.2 Functions-------------------------------------------------------------------------------------I-5

4.3 Electrical and Mechanical ----------------------------------------------------------------I-6

4.4 Environment ---------------------------------------------------------------------------------I-6

4.5 Dimensions and Weight ------------------------------------------------------------------I-6

4.6 Recommended Paper --------------------------------------------------------------------I-6

4.7 Paper Specifications ----------------------------------------------------------------------I-7

4.8 Printable Area ------------------------------------------------------------------------------I-8

4.9 Control Panel (LED and Buttons) ---------------------------------------------------- I-10

4.10 How To Clean the Print Head - Purge -------------------------------------------- I-14

4.11 Replacing The Ink Cartridges ------------------------------------------------------- I-15

4.12 Recovery Function - Purge----------------------------------------------------------- I-16

5. SAFETY INFORMATION -------------------------------------------------- I-19

5.1 Ink Safety ---------------------------------------------------------------------------------- I-19

6. CONSUMABLES AND SERVICE ACCESSORIES ---------------- I-19

6.1 Brother Special Paper ------------------------------------------------------------------ I-19

6.2 Ink Cartridges ----------------------------------------------------------------------------- I-19

6.3 ACSF and Parallel I/F Cable ---------------------------------------------------------- I-20

CHAPTER II THEORY OF OPERATION

1. GENERAL----------------------------------------------------------------------- II-1

1.1 Normal Interlace Processing (360dpi) ----------------------------------------------- II-1

1.2 Super Fine Interlace Processing (720dpi) ------------------------------------------II-2

2. ELECTRONICS---------------------------------------------------------------- II-3

2.1 General Block Diagram (MP-21C/MP-21CDX) ------------------------------------ II-3

2.2 Electric Cofiguration ---------------------------------------------------------------------- II-4

2.3 Main PCB -----------------------------------------------------------------------------------II-5

2.4 Head PCB ---------------------------------------------------------------------------------- II-9

2.5 Carriage PCB ------------------------------------------------------------------------------II-9

2.6 Carriage Sensor PCB -------------------------------------------------------------------- II-9

2.7 Power Supply ---------------------------------------------------------------------------- II-10

Page 5

3. MECHANICS -----------------------------------------------------------------II-11

3.1 Overview of Printing Mechanism ---------------------------------------------------- II-11

3.2 Print Head -------------------------------------------------------------------------------- II-12

3.3 Ink Cartridge ----------------------------------------------------------------------------- II-14

3.4 Head Maintenance Mechanism ----------------------------------------------------- II-15

3.5 Sensors ----------------------------------------------------------------------------------- II-16

3.6 Carriage Drive Mechanism ----------------------------------------------------------- II-20

3.7 Paper Feed Mechanism --------------------------------------------------------------- II-21

CHAPTER III DISASSEMBLY AND REASSEMBLY

1. PRECAUTIONS -------------------------------------------------------------- III-1

1.1 Safe Precautions ------------------------------------------------------------------------ III-1

1.2 Attention ----------------------------------------------------------------------------------- III-1

2. TIGHTENING TORQUE LIST--------------------------------------------- III-2

3. DISASSEMBLY ORDER FLOW ----------------------------------------- III-3

PR99052

4. DISASSEMBLING AND REASSEMBLING PROCEDURE ------- III-4

4.1 Ink Cartridge, ACSF --------------------------------------------------------------------- III-4

4.2 Top Cover, Paper Guide, Front Cover, Release Plate, Rear Cover --------- III-5

4.3 Head PCB ASSY ------------------------------------------------------------------------ III-8

4.4 Ink Head Base Unit, Print Head------------------------------------------------------- III-9

4.5 Bottom Cover ----------------------------------------------------------------------------III-12

4.6 Main PCB, Power Supply PCB ASSY ---------------------------------------------III-14

4.7 Paper Feed Motor ASSY -------------------------------------------------------------III-16

4.8 Purge Unit ASSY -----------------------------------------------------------------------III-18

4.9 Paper Feed Frame ASSY ------------------------------------------------------------III-22

4.10 ACSF ------------------------------------------------------------------------------------III-34

5. LUBRICATION---------------------------------------------------------------III-38

6. CLEANING THE PRINTER ----------------------------------------------III-43

6.1 Cleaning The Platen Cover -----------------------------------------------------------III-43

6.2 Cleaning The Edge Of The Head Cap ---------------------------------------------III-43

6.3 Cleaning The Pick-up Roller On The ACSF --------------------------------------III-44

7. PACKING ---------------------------------------------------------------------III-45

Page 6

CHAPTER IV TROUBLESHOOTING

1. INTRODUCTION-------------------------------------------------------------IV-1

1.1 Initial Check -------------------------------------------------------------------------------IV-1

1.2 Basic Procedure -------------------------------------------------------------------------IV-2

2. TROUBLESHOOTING -----------------------------------------------------IV-3

2.1 Troubleshooting Procedure ------------------------------------------------------ IV-3

3. INSPECTION MODE ----------------------------------------------------- IV-10

3.1 Extended Functions ------------------------------------------------------------------- IV-10

3.2 Hidden Functions ---------------------------------------------------------------------- IV-11

3.3 Error Codes ----------------------------------------------------------------------------- IV-13

APPENDIX A

Appendix A1 Head PCB Circuit Diagram ------------------------------------------------A-1

Appendix A2 Main PCB Circuit Diagram (1/3) ------------------------------------------A-2

Appendix A3 Main PCB Circuit Diagram (2/3) ------------------------------------------A-3

Appendix A4 Main PCB Circuit Diagram (3/3) ------------------------------------------A-4

Appendix A5 Cartridge Sensor Circuit Diagram ----------------------------------------A-5

PR99065

APPENDIX B

Appendix B Head Cleaning -----------------------------------------------------------------B-1

Page 7

Chapter I

FEATURES AND

SPECIFICATIONS

Page 8

CONTENTS

1. SYSTEM REQUIREMENTS------------------------------------------------I-1

2. FEATURES----------------------------------------------------------------------I-1

3. CONFIGURATION ------------------------------------------------------------ I-3

3.1 Mechanics------------------------------------------------------------------------------------I-3

3.2 Electronics -----------------------------------------------------------------------------------I-4

4. SPECIFICATIONS ------------------------------------------------------------ I-5

4.1 Printing----------------------------------------------------------------------------------------I-5

4.2 Functions-------------------------------------------------------------------------------------I-5

4.3 Electrical and Mechanical ----------------------------------------------------------------I-6

4.4 Environment ---------------------------------------------------------------------------------I-6

4.5 Dimensions and Weight ------------------------------------------------------------------I-6

4.6 Recommended Paper --------------------------------------------------------------------I-6

4.7 Paper Specifications ----------------------------------------------------------------------I-7

4.8 Printable Area ------------------------------------------------------------------------------I-8

4.9 Control Panel (LED and Buttons) ---------------------------------------------------- I-10

4.9.1 Power LED --------------------------------------------------------------------------- I-10

4.9.2 Alarm LED ---------------------------------------------------------------------------- I-10

4.9.3 Ink LEDs (BC LED and MY LED) ----------------------------------------------- I-11

4.9.4

4.9.5 Clean Button ------------------------------------------------------------------------- I-11

4.9.6 Printer Status ------------------------------------------------------------------------ I-12

4.9.7 Control Panel ------------------------------------------------------------------------ I-12

4.9.8 LEDs ----------------------------------------------------------------------------------- I-13

4.9.9 Printer Status ------------------------------------------------------------------------ I-14

4.10 How to clean the Print Head - Purge ---------------------------------------------- I-14

4.11 Replacing the Ink Cartridges -------------------------------------------------------- I-15

4.12 Recovery Function - Purge ---------------------------------------------------------- I-16

4.12.1 Definition of Terms --------------------------------------------------------------- I-16

4.12.2 Automatic Purge ------------------------------------------------------------------ I-17

4.12.3 Manual Purge ---------------------------------------------------------------------- I-17

4.12.4 Automatic Purge Frequency ---------------------------------------------------- I-17

4.12.5 Purge Sequence ------------------------------------------------------------------ I-18

(On/Off) / Retry Button --------------------------------------------------------- I-11

PR99052

5. SAFETY INFORMATION ------------------------------------------------- I-19

5.1 Ink Safety ---------------------------------------------------------------------------------- I-19

6. CONSUMABLES AND SERVICE ACCESSORIES --------------- I-19

6.1 Brother Special Paper ------------------------------------------------------------------ I-19

6.2 Ink Cartridges ----------------------------------------------------------------------------- I-19

6.3 ACSF and Parallel I/F Cable ---------------------------------------------------------- I-20

Page 9

CHAPTER I FEATURES AND SPECIFICATIONS

1. SYSTEM REQUIREMENTS

Minimum operation environment

• IBM PC or compatible with i486DX 66 Mhz or higher

• Parallel interface port

• PCMCIA card slot supporting PCMCIA 2.1 / JEIDA 4.2 or higher

• 8 MB or more memory on PC

• 40 MB free space available on your hard disk

• Microsoft Windows 3.1x/ 95/98/NT4.0

2. FEATURES

This printer has the following features:

Small and Light InkJet Printer

This printer weights about 1kg (2.2 lbs.) and the footprint is very small.

You can take the printer with you anywhere, any time you want.

Lowest Power Consumption in the World

Power consumption is so small that it is possible to take power from a notebook PC

through the Printer Interface Card. Even if you use the AC adapter (MP-21CDX or

optional PA-21MP users only), it’s also easy to carry around.

Quietest InkJet Printer in the World

The printer is so quiet (less than 40dB A during printing), that the printer never disturbs

you while you are working.

No need for an AC adapter or Printer Cable

The printer can take power from the notebook PC through the Printer Interface Card.

Therefore you do not have to carry an AC adapter and a printer cable with you all the

time.

Brilliant 4 Color Output at 720dpi

You can get wonderful output at 720 by 720dpi resolution. When you print on Brother

special coated paper and glossy paper, you can get excellent high resolution output.

Two Color Print Mode

When you select this mode through the printer driver, you can print the color output in two

colors. You can select from Black/Cyan, Black/Magenta or Black/Yellow.

I-1

Page 10

Low Running Cost

You don't have to throw the print head of your printer away every time you have emptied

an ink cartridge. When you run out of ink, you have to change only the ink cartridges.

Straight Paper Path

The printer can print on various types of paper - plain paper, coated paper, glossy paper,

transparencies and envelopes with fewer paper jams.

Auto Cut Sheet Feeder (MP-21CDX or SF-21MP users only)

When using the Feeder, you can easily load up to 30 sheets of paper.

When carried with the printer it fits on the top of the printer and the total size including the

printer is about A4 size.

AC Adapter and Parallel Interface Connector (MP-21CDX or PA-21MP users only)

When you want to print faster, use the AC Adapter. It will take half the printing time

compared to when you are using the Printer Interface Card.

When you cannot print using the PC card slot, use the Parallel Interface Connector

instead. You need to use the AC Adapter to print using the Parallel Interface Connector.

I-2

Page 11

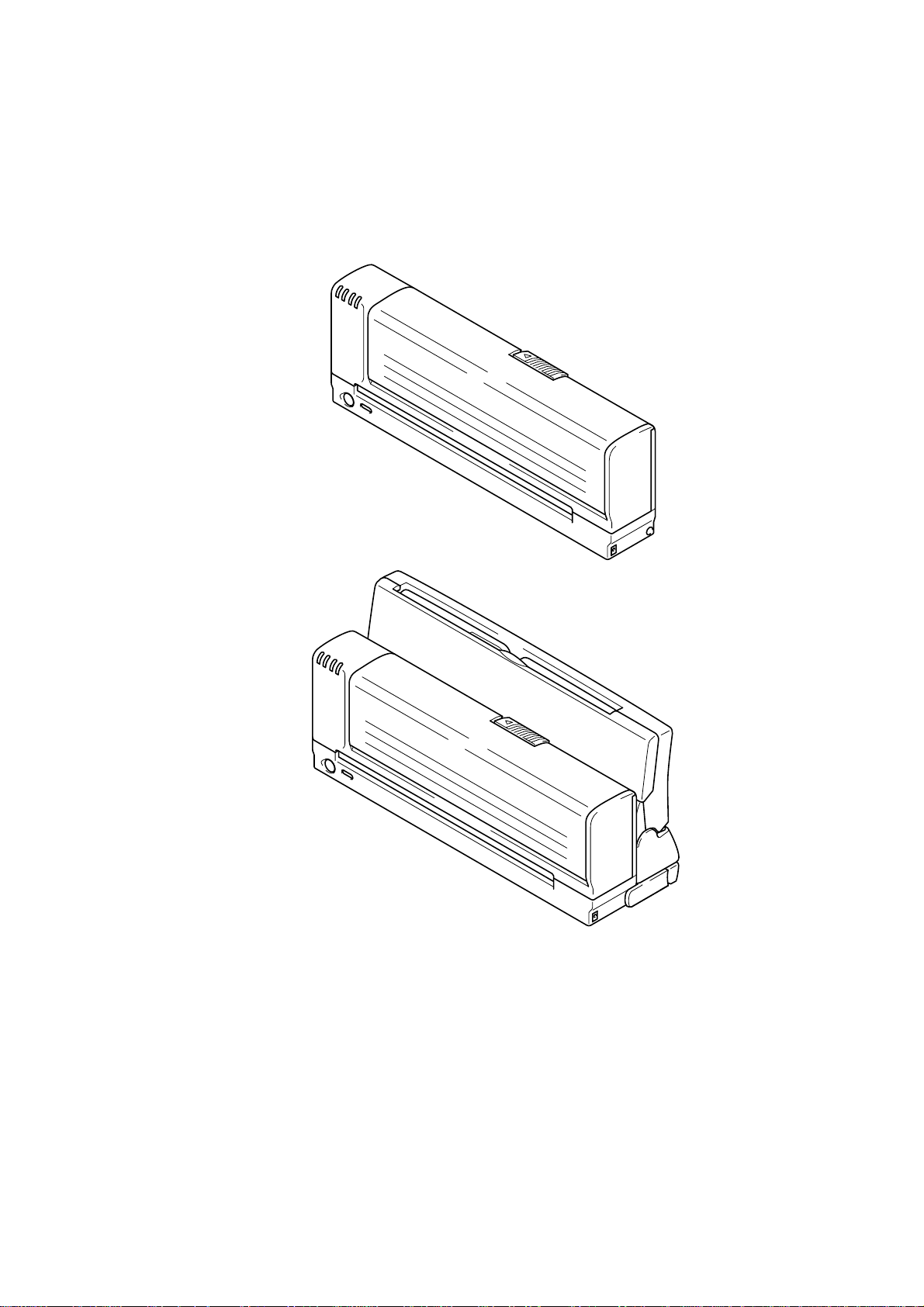

3. CONFIGURATION

3.1 Mechanics

< Overview >

MP-21C

MP-21CDX

Fig. 1.1

I-3

Page 12

3.2 Electronics

The configuration diagram is as shown below.

Head

sensor

Linear encoder

Head driver

DC

motor

Stepping

driver

Stepping motor

motor

driver

DC motor

I/F

PCMCIA

controller

PCMCIA

controller

IEEE1284

PC card

EEPROM

Print buffer

SRAM

EEPROM

sensor

PE sensor

Paper eject

sensor

Purge unit

sensor

Ink cartridge

+ CR motor control

+ Encoder operation

G/A (upd99250GJ)

CPU (H8S)

ACSF sensor

+ LF motor control

+ IRQ

+ I/O

+ ROM

+ A/D

temperature

Head driver

Cover sensor

+ Head control

+ I/F control

+ Memory control

+ RAM

Power SW

Clean SW

Logic 1 (+3.3V)

Logic 2 (+5V)

DC/DC

LED (POWER)

LED (INK)

LED (ALARM)

+5V

Motor (+12V)

Head (13-30V)

AC adapter

Fig. 1.2

I-4

Page 13

4. SPECIFICATIONS

4.1 Printing

Print Method Piezotronic dot matrix ink jet

Head Nozzle 32 x 4 nozzles

Print Quality Super Fine / Normal / Draft

Resolution (V x H) 720 x 720 dots/inch (Super Fine)

Print Speed With Printer Interface Card:

PR99052, PR99062

360 x 360 dots/inch (Normal)

180 x 360 dots/inch (Draft)

Up to 107 cps at 10 cpi in normal or super fine print mode

Up to 1.3 PPM in normal or super fine print mode

Up to 1.7 PPM in draft print mode

Up to 2.1 PPM in Blue-Black draft print mode (A4)

Up to 2.2 PPM in Blue-Black draft print mode (Ltr)

With AC Adapter:

Up to 180 cps at 10 cpi

Up to 1.3 PPM in normal print mode

Up to 2.0 PPM in draft print mode

Up to 2.4 PPM in Blue-Black draft print mode (A4)

Up to 2.5 PPM in Blue-Black draft print mode (Ltr)

Print Width 203.2 mm (8 inches)

Print Media Liquid ink in cartridges

Life Expectancy of Printer 5 years or 10,000 pages

Ink Twin cartridge system: separate from the print head

Life Expectancy of Ink Black/Cyan (LC03BC): 250 pages/cartridge

4.2 Functions

Printer Driver Windows 3.1x/ 95/98/NT4.0

Emulation Windows GDI

Interface PCMCIA interface card

Control Panel 2 buttons and 4 LEDs

Diagnostics Self-diagnostics program at power on

Magenta/Yellow (LC03MY): 150 pages/cartridge

(When printing A4 or letter size at 5% coverage.)

Parallel interface (IEEE1284 compliant)

I-5

Page 14

4.3 Electrical and Mechanical

AC Adapter Power Source 100V model: AC 100 to 120 V, 60 Hz

Power Consumption Printer interface card Stand-by (Max.) 1.0 W

Noise Stand-by: 35 dB A or less

4.4 Environment

Temperature Operating: 10 to 35°C (50 to 95°F)

Humidity Operating: 20 to 80% (without condensation)

4.5 Dimensions and Weight

200V model: AC 220 to 240 V, 50 Hz

Printing (Max.) 4.2 W

Printing (Ave.) 2.5 W

Power save mode 0.6W

AC adapter Stand-by (Max.) 1.1 W

Printing (Max.) 4.5 W

Printing (Ave.) 3.2 W

Power save mode 0.7W

Printing: 40 dB A or less

Storage: -20 to 60°C (-4 to 140°F)

Storage: 5 to 95% (without condensation)

Dimensions (WxDxH) MP-21C: 50.8 x 300 x 106 mm (Without ACSF)

Weight MP-21C: Approx. 1,000g (2.2 lbs)

4.6 Recommended Paper

• Plain paper USA: Xerox 4200

• Special paper Brother Quality Coated Paper for 360dpi printing

Brother High Quality Coated Paper for 720dpi printing

Brother Color Inkjet Glossy Paper

Transparencies Brother Transparencies BPTRL (Letter)

MP-21CDX: 90 x 305 x 140 mm (With ACSF)

MP-21CDX: Approx. 1,460g (3.21 lbs)

Europe: Xerox Premier 80g/m

2

or equivalent

BP36CL (Letter), BP36CA (A4)

BP72CL (Letter), BP72CA (A4)

BPGLL (Letter), BPGLA (A4)

3M CG3410

3M CG3460 (For super fine mode)

I-6

Page 15

4.7 Paper Specification

The printer can handle plain paper, transparencies and envelopes that meet the following

specifications.

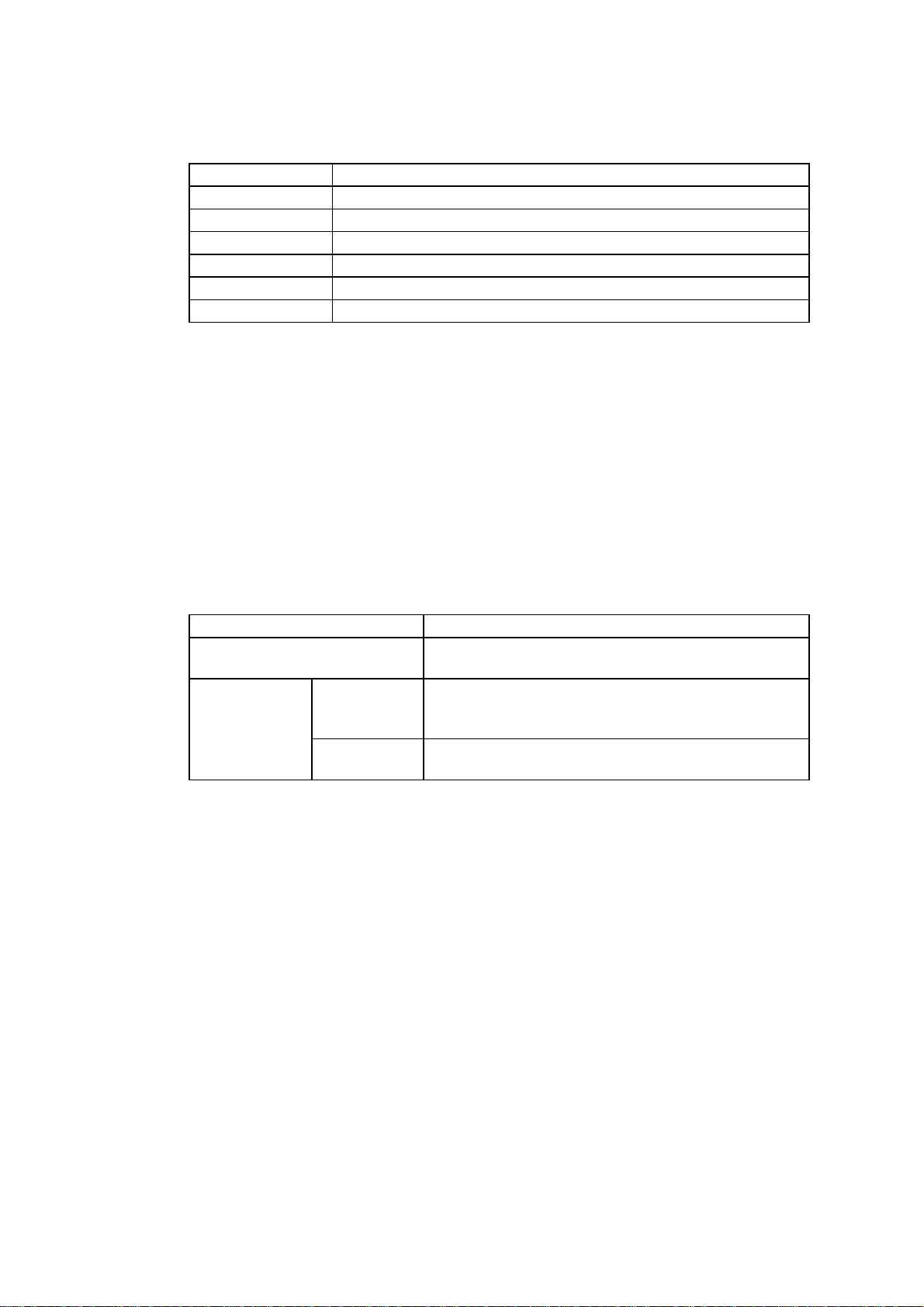

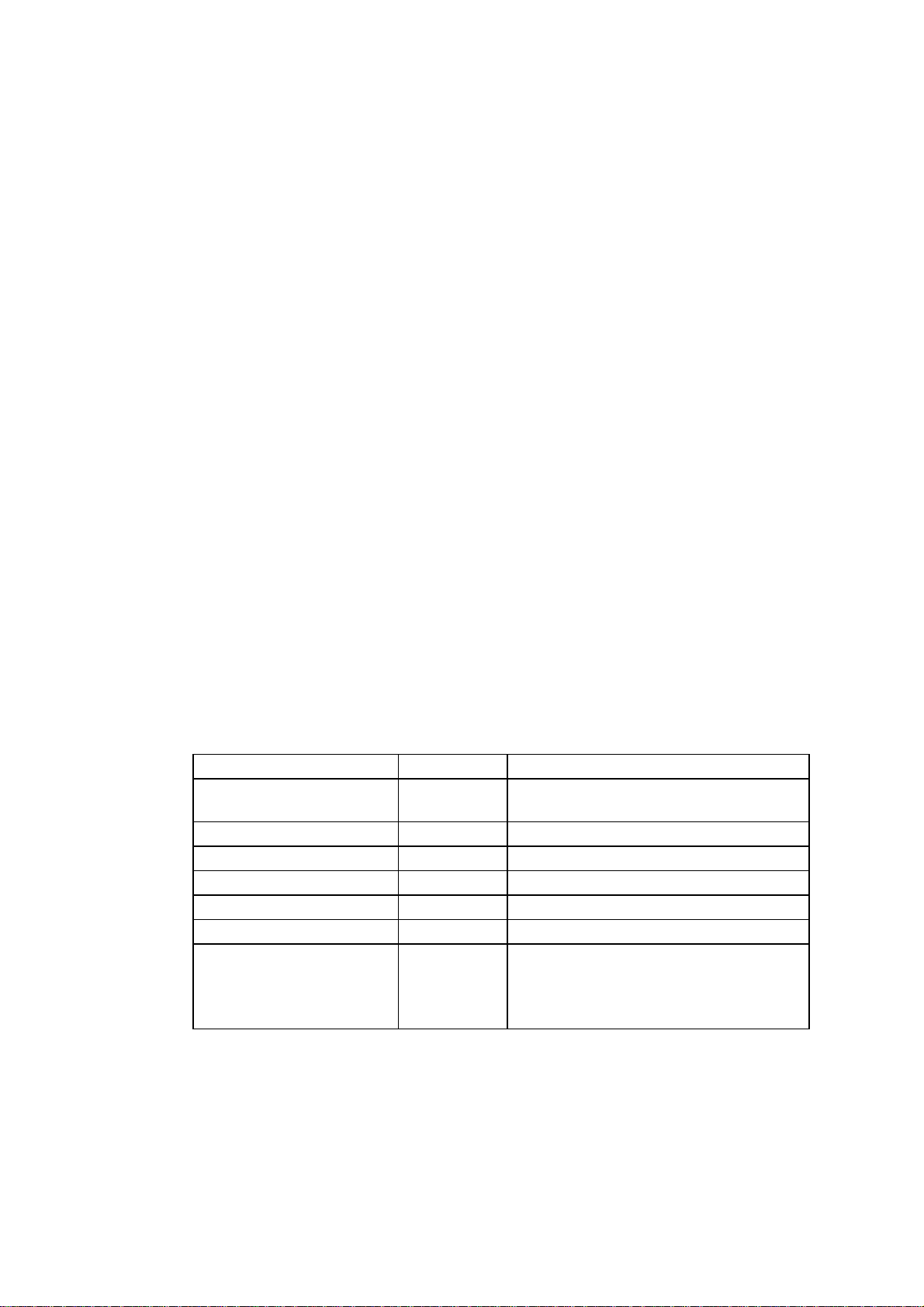

Feeder Paper Size Capacity

Manual

feed

ACSF

(MP-21CDX only)

Straight

paper

path slot

Paper

feeding

guide

Plain paper: A4, Letter, A5, Legal, Executive,

Envelope: DL, C5, B5, COM-10, Monarch, User defined

Coated paper: A4, Letter

Transparencies: A4, Letter

Organizer: K, L

(95.25 ~ 216 x 100 ~ 356 mm, 3.94 ~ 8.5 x 3.94 ~

14.02 inches, 60 ~ 157 g/m2, 16 ~ 42 lbs)

Plain paper: A4, Letter, A5, Legal, Executive

Transparencies: A4, Letter

Organizer: K, L

(95.25 ~ 216 x 100 ~ 356 mm, 3.94 ~ 8.5 x 3.94 ~

14.02 inches, 60 ~ 105 g/m2, 16 ~ 28 lbs)

Plain paper: A4, Letter, A5, Custom size

(100 ~ 216 x 100 ~ 356 mm, 3.94 ~ 8.5 x 3.94 ~14.02

inches, 60 ~ 105g/m2, 16 ~ 28 lbs)

* It is recommended to feed transparencies from the

straight paper path slot or the paper feeding guide.

Sheet by sheet

Sheet by sheet

Approx. 20 sheets of 75 g/m

•

~ 105g/m2 (20 lbs ~ 28 lbs)

plain paper (A4/Letter)

Approx. 30 sheets of 60 ~ 75

•

g/m2 (16 ~ 20 lbs) plain

paper (A4/Letter)

Approx. 20 sheets of Brother

•

coated paper (A4/Letter)

2

Cut Sheet Envelope

Caliper ± 0.03~± 0.08 in. (0.09 ~ 0.2mm) 0.0033 to 0.0058 in.

(0.084 to 0.14mm)

single thickness

Moisture 4% to 6% by weight 4% to 6% by weight

Smoothness 100 to 250 (Sheffield) 100 to 250 (Sheffield)

Remarks:

Avoid feeding labels. If the label jammed, glue may stick on the rollers

positioned on the way of the paper transportation pass and it may cause

further problems.

DO NOT

use ordinary transparencies designed for photocopiers or laser

printers. Use the recommended transparencies for the MP-21C/CDX

printers to obtain optimum print quality

If the paper will not feed from the ACSF, try the manual feed.

I-7

Page 16

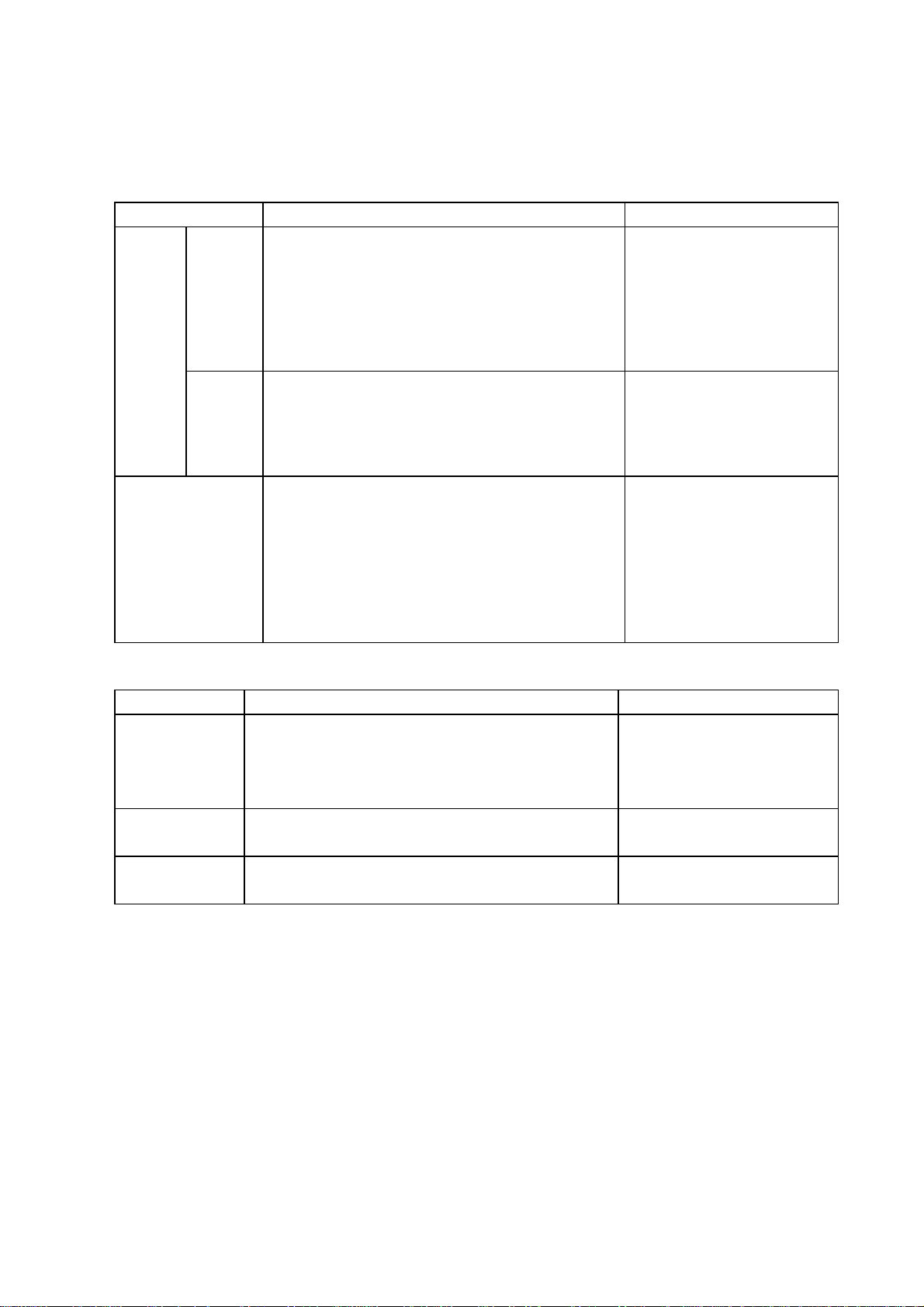

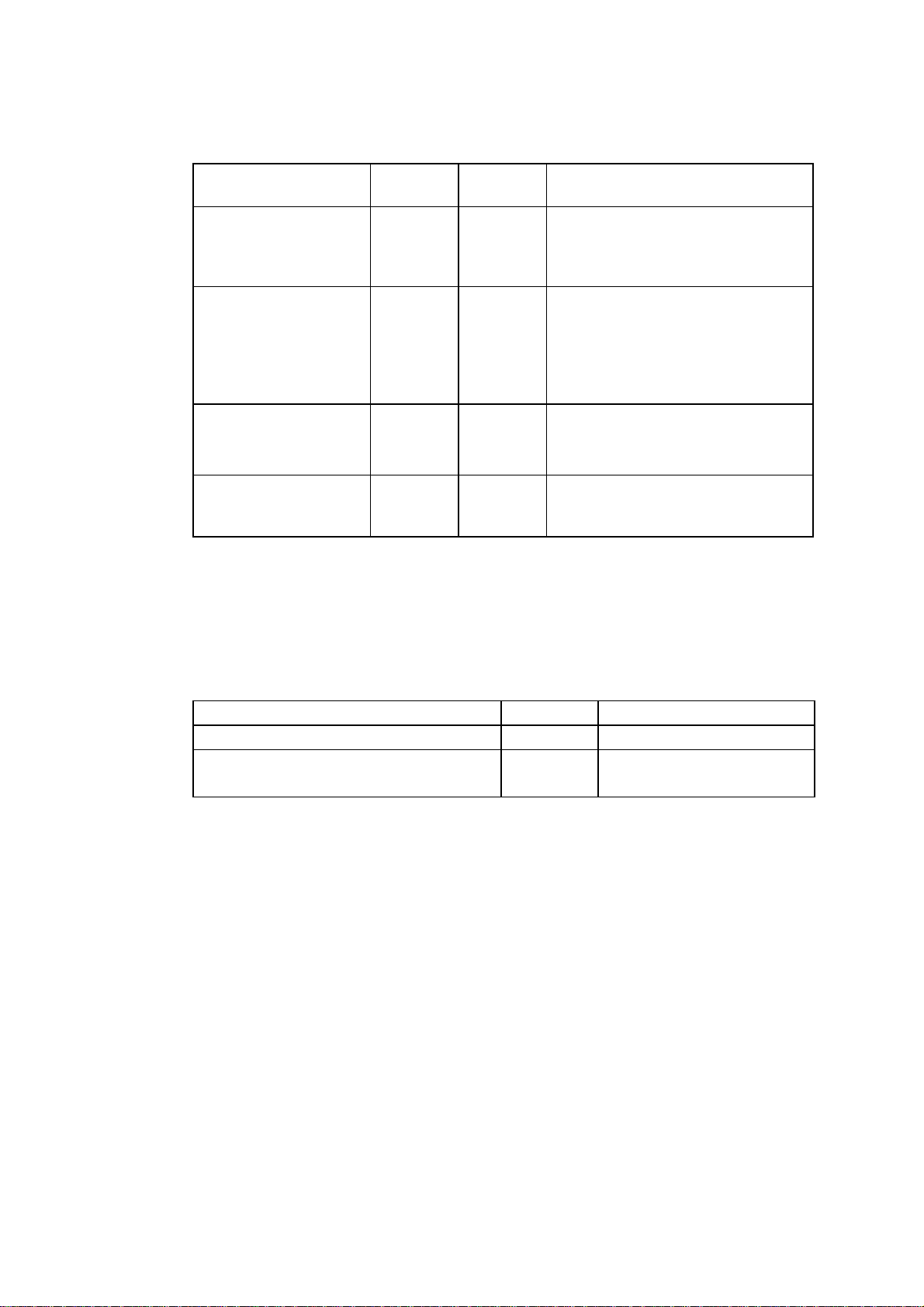

4.8 Printable Area

The table below shows the effective printable areas.

Plain paper

SIZE A B C D E F G H

A4 210.0

Letter 215.9

Legal 215.9

Executive 184.2

A5 148.5

Special paper

SIZE A B C D E F G H

Organizer K 95.25

Organizer L 139.7

B5* 176

C5* 162

MONARCH* 98.43

COM-10* 104.78

DL* 110

USER

DEFINED*

(8.2”)

(8.5")

(8.5")

(7.25")

(5.8”)

(3.75")

(5.5")

(6.9“)

(6.3“)

(3.8")

(4.1")

(4.3“)

215.9

(8.5“)

(Max.)

297.0

(11.5”)

279.4

(11.0")

355.6

(14.0")

266.7

(10.5")

210.0

(8.2”)

171.45

(6.75")

215.9

(8.5")

250

(9.8“)

229

(9.0“)

190.5

(7.5")

241.3

(9.5")

220

(8.6“)

355.6

(14.0“)

(Max.)

203.2

(8.0”)

203.2

(8.0”)

203.2

(8.0”)

177.4

(7.2”)

141.7

(5.5”)

88.45

(3.4“)

132.9

(5.2“)

169.2

(6.6“)

155.2

(6.1“)

91.63

(3.6“)

84.65

(3.3“)

103.2

(4.0“)

203.2

(8.0“)

282.5

(11.1”)

264.9

(10.4”)

341.1

(13.4”)

252.2

(9.9”)

195.5

(7.6”)

156.95

(6.1“)

201.4

(7.9“)

210

(9.2“)

180

(8.4“)

150.5

(6.9“)

201.3

(8.6“)

180

(7.0“)

341.1

(13.4“)

3.4

(0.13”)3(0.11”)

6.35

(0.25”)3(0.11”)

6.35

(0.25”)3(0.11”)

3.4

(0.13”)3(0.11”)

3.4

(0.13”)3(0.11”)

* : Envelope,

3.4

(0.13”)3(0.11”)

3.4

(0.13”)3(0.11”)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)20(0.78”)

3.4

(0.39”)20(0.78”)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)3(0.12”)

(Unit = mm)

3.4

(0.13”)

6.35

(0.25”)

6.35

(0.25”)

3.4

(0.13”)

3.4

(0.13”)

11.5

(0.45”)

11.5

(0.45”)

11.5

(0.45”)

11.5

(0.45”)

11.5

(0.45”)

(Unit = mm)

3.4

(0.13”)

3.4

(0.13”)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)20(0.78”)

10.0

(0.39”)20(0.78”)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)

11.5

(0.45”)

11.5

(0.45”)

11.5

(0.45”)

A

EG

F

C

Effective

printable area

E

F

A

C

Effective

printable area

G

A: Paper width

B: Paper length

C: Width

D

B

D

B

D: Length

E: Left margin

F: Top margin

G: Right margin

H

H

Fig. 1.3

H: Bottom margin

I-8

Page 17

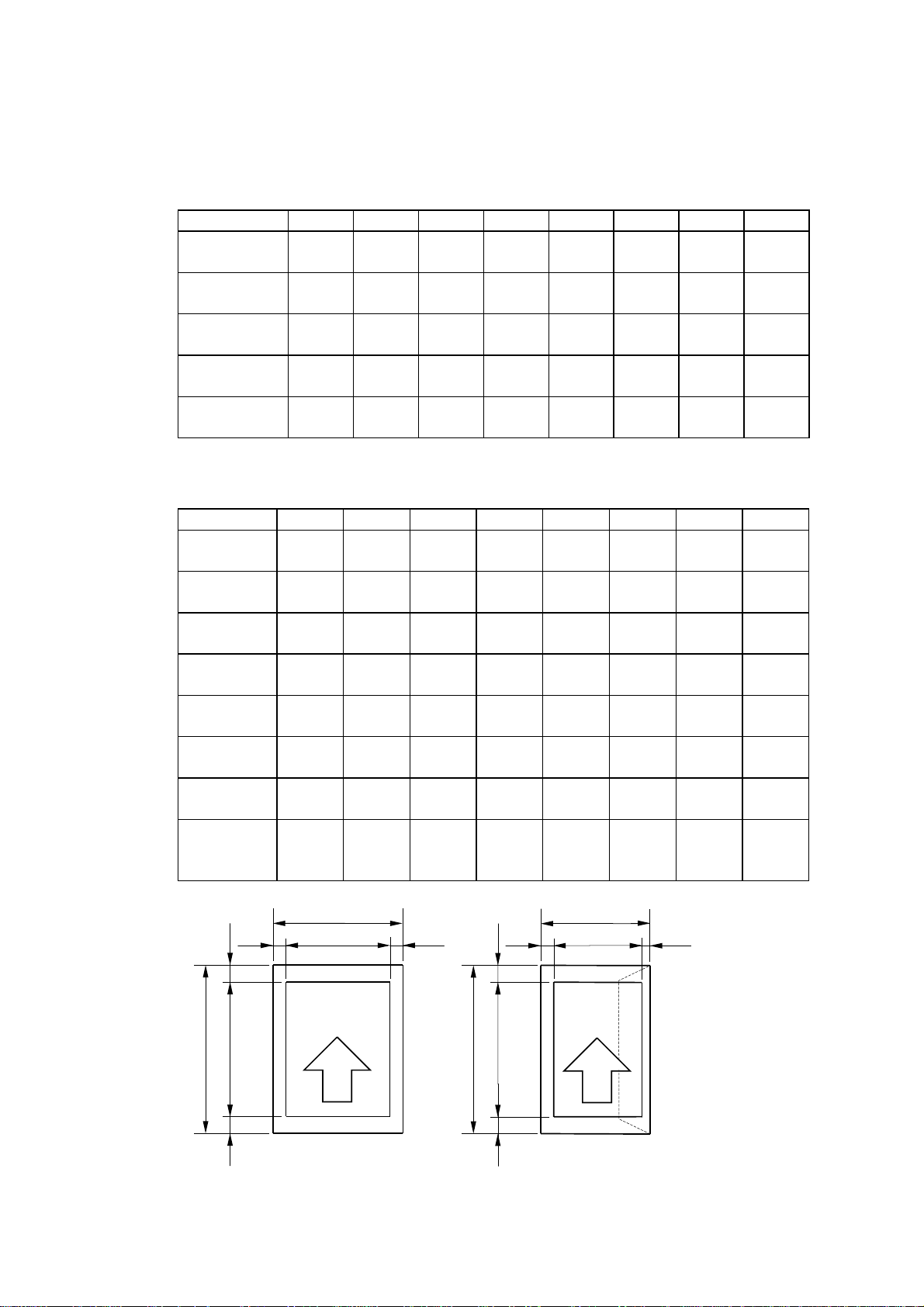

The table below shows the recommended printable areas.

Plain paper

SIZE A’ B’ C’ D’ E’ F’ G’ H’

A4 210.0

(8.2”)

Letter 215.9

(8.5")

Legal 215.9

(8.5")

Executive 184.2

(7.25")

A5 148.5

(5.8”)

297.0

(11.5”)

279.4

(11.0")

341.1

(14.0")

266.7

(10.5")

210.0

(8.2”)

203.2

(8.0”)

203.2

(8.0”)

203.2

(8.0”)

177.4

(7.2”)

141.7

(5.5”)

265.5

(10.4”)

247.9

(9.7”)

324.1

(12.7”)

235.2

(9.2”)

178.5

(7.0”)

3.4

(0.13”)20(0.78”)

6.35

(0.25”)20(0.78”)

6.35

(0.25”)20(0.78”)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)20(0.78”)

(0.13”)

(0.25”)

(0.25”)

(0.13”)

(0.13”)

Special paper

* : Envelope,

SIZE A B C D E F G H

Organizer K 95.25

(3.75")

Organizer L 139.7

(5.5")

B5* 176

(6.9“)

C5* 162

(6.3“)

MONARCH* 98.43

(3.8")

COM-10* 104.78

(4.1")

DL* 110

(4.3“)

USER

DEFINED*

215.9

(8.5“)

(Max.)

171.45

(6.75")

215.9

(8.5")

250

(9.8“)

229

(9.0“)

190.5

(7.5")

241.3

(9.5")

220

(8.6“)

355.6

(14.0“)

(Max.)

88.45

(3.4“)

132.9

(5.2“)

169.2

(6.6“)

155.2

(6.1“)

91.63

(3.6“)

84.65

(3.3“)

103.2

(4.0“)

203.2

(8.0“)

139.95

(5.4“)

184.4

(7.2“)

210

(8.2“)

180

(7.08“)

150.5

(5.9“)

201.3

(7.9“)

180

(7.08“)

324.1

(12.7“)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)20(0.78”)

3.4

(0.39”)20(0.78”)

3.4

(0.13”)20(0.78”)

3.4

(0.13”)20(0.78”)

(0.13”)

(0.13”)

(0.13”)20(0.78”)

(0.13”)20(0.78”)

(0.13”)20(0.78”)

(0.39”)20(0.78”)

(0.13”)20(0.78”)

(0.13”)

(Unit = mm)

3.4

6.35

6.35

3.4

3.4

11.5

(0.45”)

11.5

(0.45”)

11.5

(0.45”)

11.5

(0.45”)

11.5

(0.45”)

(Unit = mm)

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

11.5

(0.45”)

11.5

(0.45”)

11.5

(0.45”)

A'

E' G'

F'

C'

A’: Paper width

B’: Paper length

C’: Width

Recommended

printable area

D'

B'

D’: Length

E’: Left margin

F’: Top margin

G’: Right margin

H’: Bottom margin

H'

Fig. 1.4

I-9

Page 18

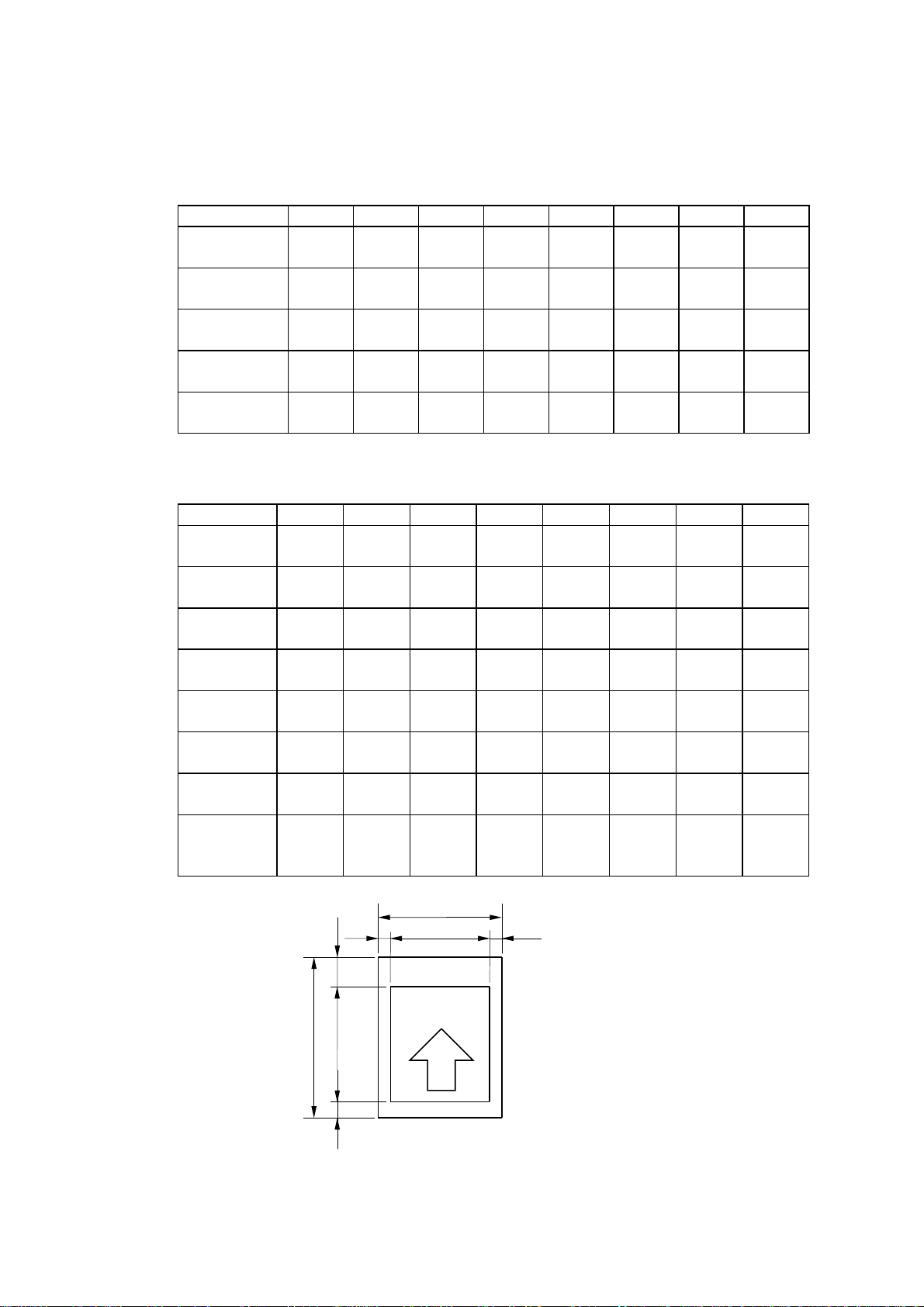

4.9 Control Panel (LEDs and Buttons)

This printer is equipped with a minimal control panel. Settings and status indication are

available on the printer driver status monitor.

The control panel includes the following LEDs and buttons.

< LEDs >

4.9.1 Power LED

The Power LED indicates the current power status of the printer.

LED Printer status

On

●

Off

❍

Blinking

❍↔●

Fast

Blinking

❍↔●

Power LED

Alarm LED

Ink (MY) LED

Ink (BC) LED

< Buttons >

Clean button

(On/Off) button

Fig. 1.5

The printer is turned on and ready to print.

The printer is turned off.

The printer is receiving data.

The printer is ready to feed paper.

(Only for manual paper feed)

4.9.2 Alarm LED

The Alarm LED indicates a printer error status.

LED Printer status

On

●

Blinking

❍↔●

When the Alarm LED is on or blinking and the printer has detected an error

condition,

problem to make the printer ready to print.

When Power LED + Alarm LED and Ink LEDs (BC LED+MY LED) Blink in Turn

The printer is making itself ready to print.

The printer is cleaning the print head.

When All the LEDs Blink at the Same Time

Service call occurred. Refer to Section 3.3.2 Service Calls in Chapter 4.

Paper empty, paper jam or mis-feeding. If a

paper jam occurs.

The Top cover of the printer is open and

should be closed so that the printer can print.

refer to Section 3.3 Error codes in Chapter 4 and clear the

I-10

Page 19

4.9.3 Ink LEDs (BC LED and MY LED)

Each Ink LED indicates when the ink is low or empty with the Alarm LED on.

LED Printer status

Blinking

❍↔●

On

●

The color ink cartridge is running out of ink. You

should prepare a new ink cartridge for that

color.

The color ink cartridge is empty. You should

replace it with a new one immediately for

optimum print quality. See Section 4.11

Replacing the ink cartridge in Chapter 1.

This may also indicate that one or more ink

cartridges may not be installed correctly.

4.9.4

4.9.5 Clean Button

(On/Off) / Retry Button

When you press this button and when the Power LED is on, the printer becomes ready to

operate.

When the Alarm LED is on with Power LED blinking, pressing this button will resume

printing. A paper jam or mis-feed will be cleared.

Make sure that the Power LED is on after you press this button.

When you want to clean the print head, press this button.

Note: Even if you turn the

(On/Off) button off, power is not completely shut off.

In case of emergency, you must remove the Printer Interface Card from the

computer and remove the AC Adapter from the mains if connected (MP21CDX or PA-21MP users only) in order to shut off power completely.

I-11

Page 20

4.9.6 Printer Status

The table below shows the details of the various printer status conditions.

Status Description

Not energized Power is not supplied.

Power off Power is turned off (low power consumption mode).

Online Ready to receive data.

Operator call An operator call has occurred. It can be recovered by users

Cleaning The print head is cleaning.

Service call A service call has occurred.

The printer is energized up when you:

Insert the Printer Interface card in the PCMCIA slot with the PC powered on.

➀

Turn on the PC with the Printer Interface card inserted in the PCMCIA slot.

➁

Plug in the AC adapter jack to the printer.

➂

All the four LEDs flash once and they turned OFF, however the power is supplied to the

printer.

Any status indication that occurs when the printer is powered up with the power button

pressed is a hidden status.

The printer operates in the following 3 modes.

Mode Description

Normal mode After initialization and error detection are carried out,

Hidden

function mode

4.9.7 Control Panel

The control panel monitors the switches and sensors, as well as indicating the status on

the LEDs.

Switch status is detected after noise cancellation and switch debouncing. Data read for

two successive times detects the switch status (noise cancellation), then the current

status is defined after a further confirmation of three more switch reads.

LEDs turn off, light, or blink to indicate the printer status. Blinking includes 3 patterns:

4 LEDs blink at the same time,

Inspection

mode

PCB check

mode

the printer goes into normal print mode.

Initialization is not carried out on the mechanical

parts; mechanical operation is controlled using

commands and switches.

Mechanical operation is not performed; hardware

operation is checked.

4 LEDs blink alternately,

➁

* For factory use only *

* For factory use only *

3 LEDs blink successively.

➂

➀

I-12

Page 21

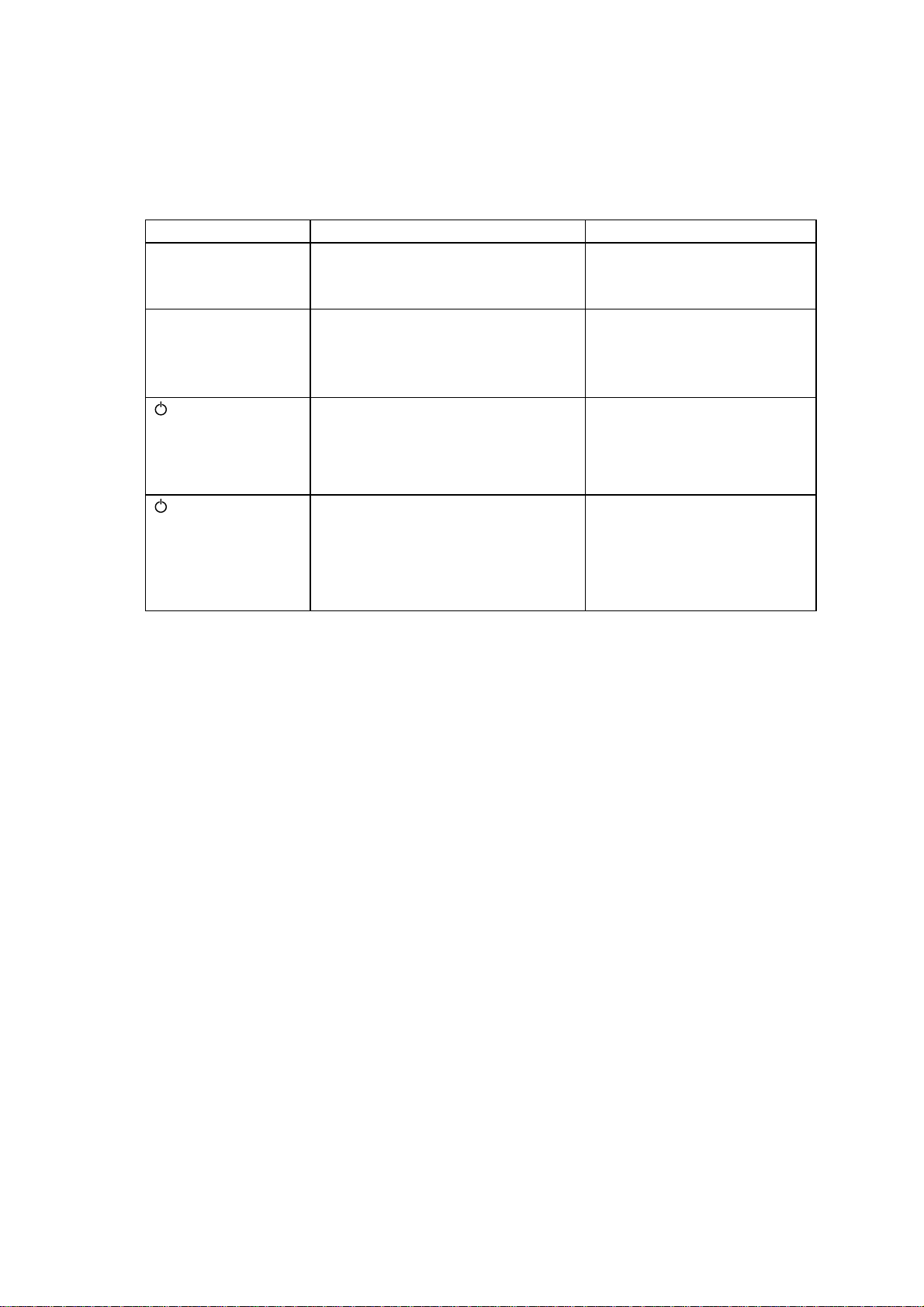

4.9.8 LEDs

The table below shows the LED indications.

Status

Not energized

Energized/Power OFF

Being initialized/Device being busy

Online No alarm

Receiving No alarm

data/Printing Ink near empty

Operator call Ink near empty

Cover open No alarm

Purging

Service call

Ink near empty

Ink empty

Ink empty

Ink empty

Ink near empty

Ink empty

(Power) (Alarm) (Ink BC) (Ink MY)

{{{{

zzzz

z

z

z

{

{

z

z

z

{{{

{

{

{{{

{

{

z

✩

/

{{

z

z

/

{{

zzz

{{

zz

✩

/

z

z

/

z

: Indicates an LED is ON

{

: Indicates an LED is OFF

,

When a service call has occurred, its error type and error code are indicated using 4 bits

(LED1 to LED4).

Refer to service codes for details. LED1 does not turn off during mechanical operation.

, ✩: Indicate an LED is blinking

,

(LEDs with the same symbol means that they blink at the same speed)

I-13

Page 22

4.9.9 Printer Status

(1) Not energized

This status means that power is not supplied to the printer.

The table below shows the printer operation when power is supplied.

Condition Printer operation Status

Power applied

Clean button pressed

then power applied

(On/Off) button

and Clean button

pressed

simultaneously, then

power applied

(On/Off) button

and Clean button

pressed

simultaneously with

the cover open, then

power applied

All the LEDs light, then turn off.

➀

Initializing for energizing

➁

Status

➂

All the LEDs light, then turn off.

➀

Initializing for energizing

➁

Initializing for turning on power

➂

Status

➃

All the LEDs light, then turn off.

➀

Initializing for energizing

➁

Initializing for turning on power

➂

Status

➃

All the LEDs light, then turn off.

➀

Initializing for energizing

➁

Initializing for turning on power

➂

Status

➃

Normal mode

Ready for power to be applied.

Preparing for printing test

Ready for power to be applied

Preparing for EEPROM reset

Ready for power to be applied

Process support mode

(2) Power off

This status is the power consumption save mode where only the control panel

operates.

<Buttons>

Power/Online button

Pressing this button allows the printer to become online and offline. When in

manual feed mode and there is no paper, the printer becomes offline and does not

print. If this happens when using the manual feed slot, load a sheet of paper, the

printer will detect the paper and start printing. If this happens when using the

ACSF, press this button after loading paper. The printer will then start printing.

4.10 How to Clean the Print Head - Purge

When you get white lines in text or graphics on your printed document, clean the print

head.

You can clean the 2 print heads by pressing the Clean button on the control panel.

1. Make sure the printer is Online with the Top cover closed.

2. Push the Clean button.

3. The printer starts cleaning the print head automatically. When the cleaning is

finished, the printer becomes online automatically.

Note: You can clean the print head from the printer driver. Select

[Control/Maintenance] tab from the MP-21C/MP-21CDX Windows printer

driver and click the [Maintenance] button.

I-14

Page 23

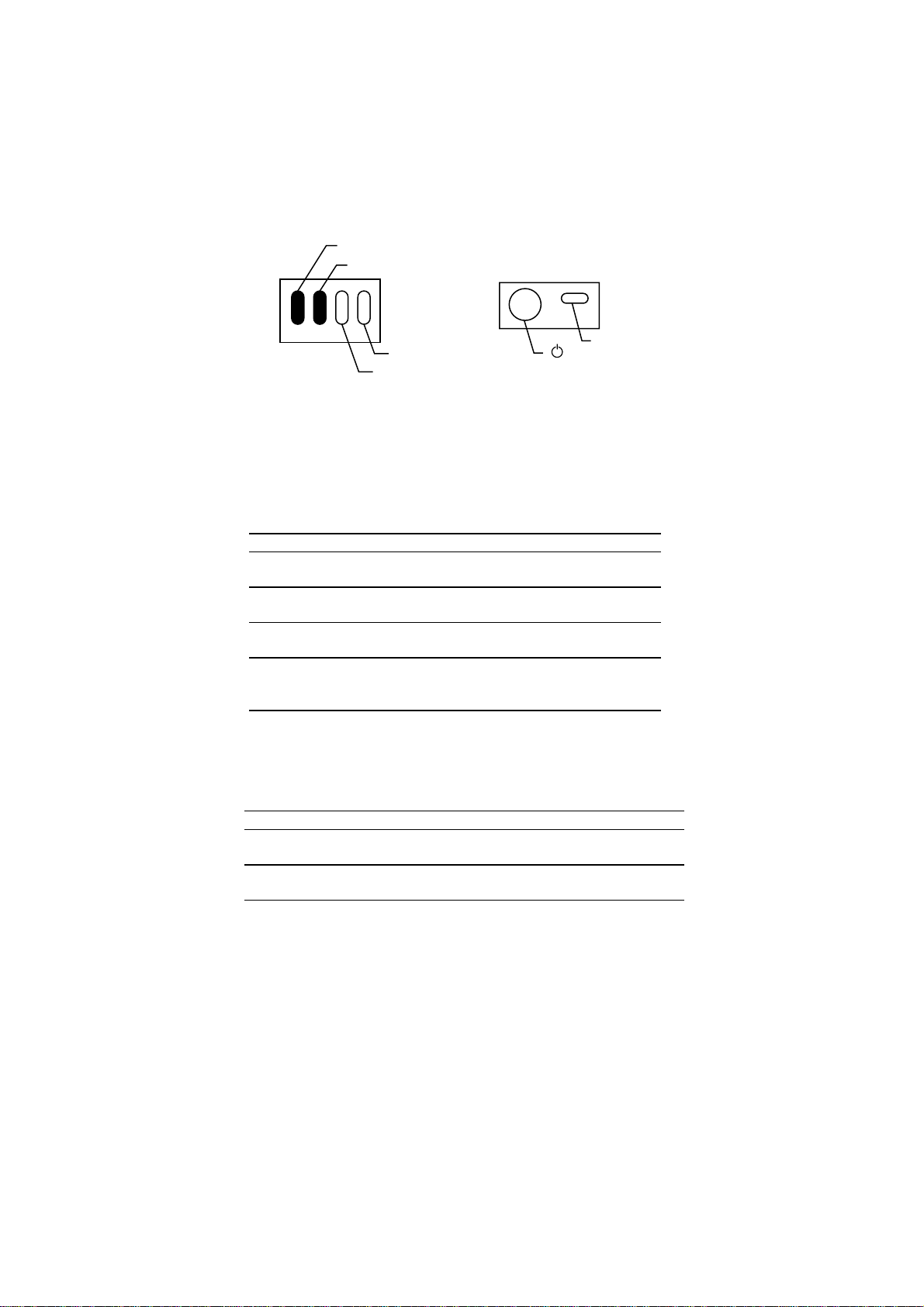

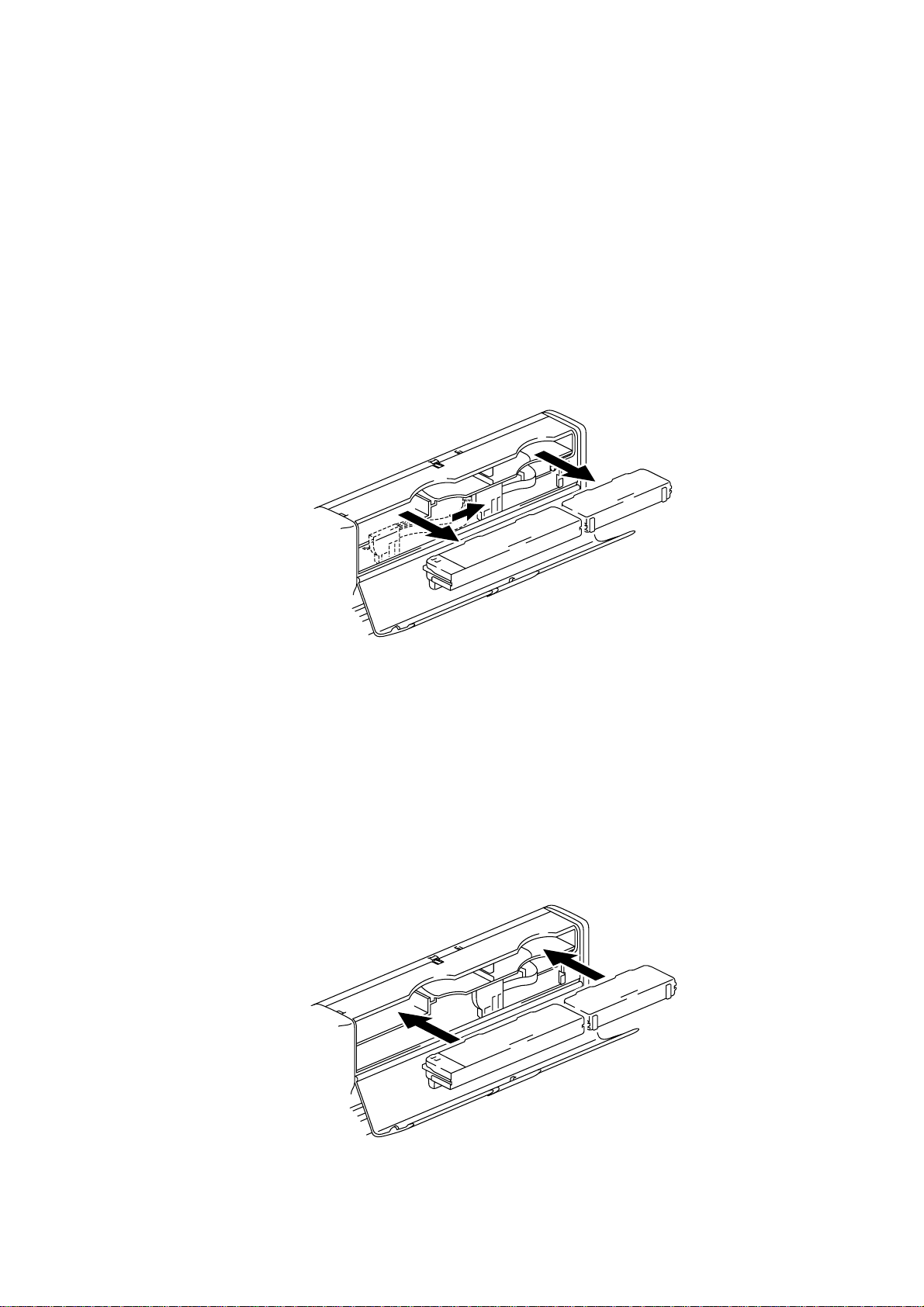

4.11 Replacing the Ink Cartridges

When the LED(s) shows an ink empty or an ink near empty status, replace the indicated

ink cartridge(s) with a new one. We strongly recommend you use Brother original ink

cartridges for the best print quality. Using other ink may void the warranty for this printer.

Black and Cyan No. LC03BC

Magenta and Yellow No. LC03MY

<How to replace the cartridges>

1. Make sure the

Power

LED is on.

2. Open the Top cover. Make sure the carriage is resting in the home position at the

right hand side of the printer.

3. Pull out the empty ink cartridge in the direction of the arrow.

Note: Make sure that the Power LED is ON, otherwise the ink used counter will not

be cleared.

Fig. 1.6

Caution:DO NOT remove ink cartridges when you do not need to replace them.

Insert a new ink cartridge within a few seconds of taking out the empty ink

cartridge.

Once you have removed a cartridge, DO NOT attempt to re-use it.

4. Open the new ink cartridge box and take the cartridge out of the bag.

5. Insert the new cartridge, making sure to put it the correct position and push it until

it stops.

Fig. 1.7

I-15

Page 24

6. Close the Top cover. The printer will automatically start initial purge. When the

initial purge is done, the Power LED comes on.

Warning: If ink stains your body or clothing, wash with soap or detergent

immediately.

If ink gets in your eyes, irrigate them with water immediately and consult a

doctor if you are concerned.

Caution:Once you have installed the cartridge, DO NOT take it out until the ink empty

status is indicated as this may reduce the print quality.

Once you have opened an ink cartridge, use it up within 6 months.

Note: If an ink empty status still remain after you have installed the ink cartridges,

check that the ink cartridges are installed correctly.

Both the ink cartridge BC and the ink cartridge YM should be installed. A

printer with only one ink cartridge installed cannot perform printing

operations.

PR99052

4.12 Recovery Function - Purge

The purge operation is carried out just before the first print job when more than a certain

number of days have passed(see below) since the last purge was carried out. The printer

memorizes the time when the last purge was conducted in the EEPROM. When the

printer has been left with power off, the time and date is sent from the PC just before

printing by the printer driver. The printer conducts the designated purge by comparing

this date with the date of the last purge. To operate the automatic recovery function

correctly, the date of the PC needs be correct.

4.12.1 Definition of Terms

Purge type Abbrieviation Description

Single purge SP This is a normal purge. All colors are

Initial purge IP Single purge x 7 times

Double purge WP Single purge x 2 times

Triple purge TP Single purge x 3 times

Cartridge purge CP Single purge x 5 times

Power purge PP Single purge x 5 times

Manual purge MP The single purge begins by pressing the

purged.

Clean button on the control pane.

The single or power purge can be

executed from the printer driver.

I-16

Page 25

4.12.2 Automatic Purge

PR99052

Date condition Condition

First ink cartridges are

installed into a brandnew printer.

First automatic purge

after a new cartridge

installed and the

specified time has

passed with no print

operations.

Date defined purge 3-1

Only after the empty

cartridges are replaced

with new ones.

4.12.3 Manual Purge

Purge

type

1 IP Just after the ink cartridges

2-1

2-2

2-3

3-2

3-3

4CP

SP

WP

TP

SP

WP

TP

type

installation. The IP is carried out

only one time in the whole printer

life.

3 days

6 days

9 days

5 days

7 days

9 days

Time condition

Pressing the Clean button on the printer control panel or clicking the [Clean button on the

[Maintenance] of the Windows driver executes the purge.

How to execute Purge type Remark

Pressing the Clean button on the printer SP Only SP is available.

Clicking the [Clean] button in the Windows

printer driver

4.12.4 Automatic Purge Frequency

In case the manual purge was carried out 3 times by pressing the Clean button on the

control panel, the PP begins automatically and continuously after the 3rd single purge

finishes. The 3rd purge operation performs the single purge 6 times in total.

The special purge sequence starts when the two conditions below are achieved.

- The printer is powered ON, in the Ready status and is connected to a PC.

- Pressing the Clean button on the control panel 3 times within 1 hour.

Note: As the Windows printer driver sends a command to execute the PP, the

printer must be connected to a PC.

SP

PP

You can select SP or PP.

The number of manual purges executed by the Windows printer driver is not

counted.

I-17

Page 26

The number of automatic purges such as the date defined and cartridge

purge are ignored.

When the printer is in the following condition, the printer cannot detect that

the Clean button is pressed.

- The power is OFF.

- The printer is in a printing operation.

- The printer is performing a purge operation.

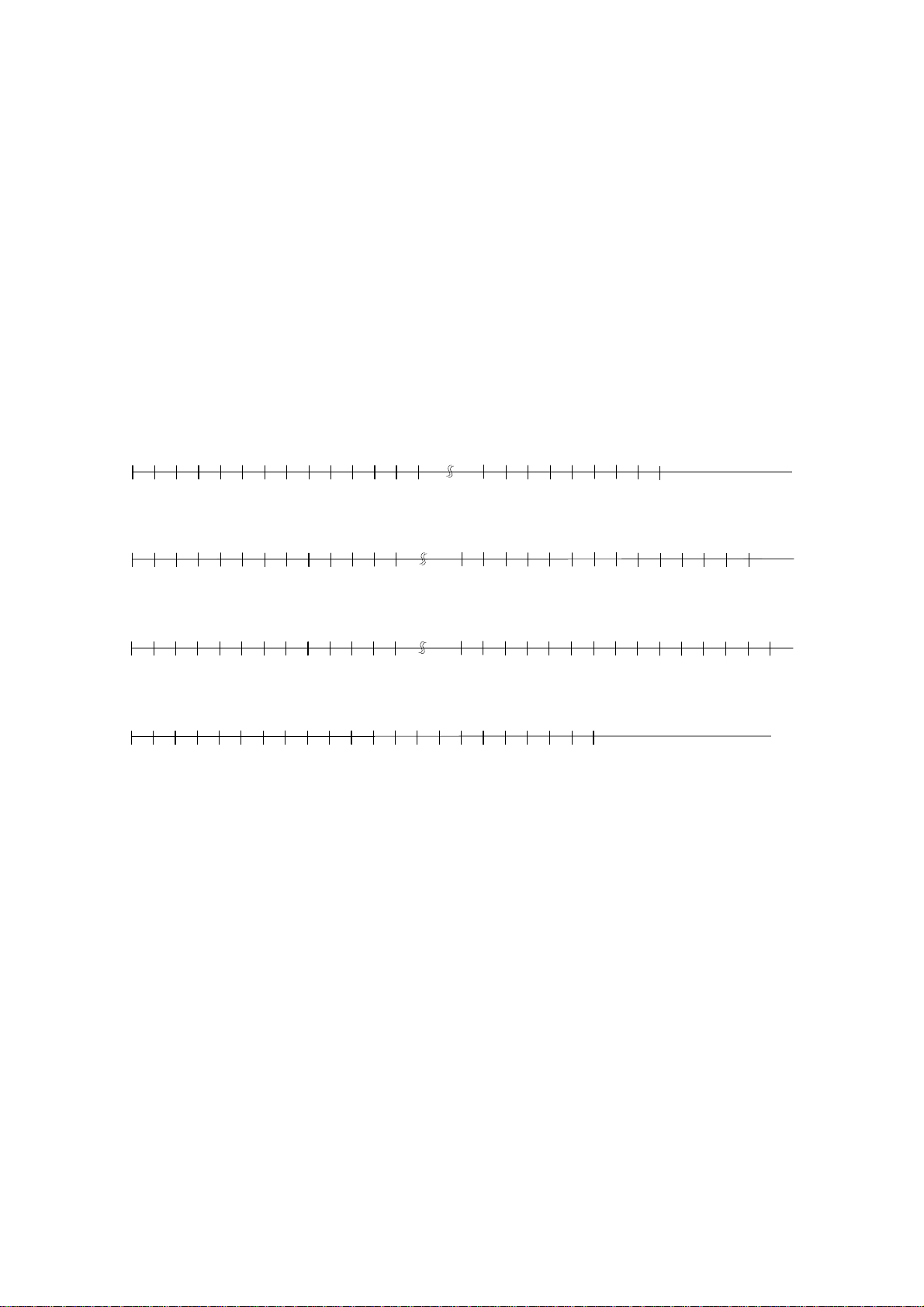

4.12.5 Purge Sequence

Print operations are performed everyday.

IP

SP SP SP

CP

SP

PR99052

SP

MP is performed before an automatic purge is carried out.

IP

MP

MP is performed after an automatic purge is carried out.

IP

SP

MP

In case no print operations are not performed in 6 days.

IP

SP

SP

WP SP

SP

In case no print operations

are not performed in 7 days.

CP

In case no print operations

are not performed in 9 days.

CP

WP

TP

SP

SP

I-18

Page 27

5. SAFETY INFORMATION

5.1 Ink Safety

Potential Health Effects

EYE CONTACT: May cause slight irritation.

SKIN CONTACT: Prolonged exposure may cause skin irritation.

INGESTION: Small amounts swallowed during normal handling operations are

not likely to cause injury; swallowing larger amounts may cause

injury.

INHALATION: Excessive vapor concentrations may cause irritation of respiratory

tract.

First Aid Measures

EYE CONTACT: Flash immediately with running water for at least 15 min.

If necessary, get medical attention.

SKIN CONTACT: Wash with water and soap or detergent.

INGESTION: Dilute with water and if necessary get medical attention.

(Never give anything by mouth to an unconscious person)

INHALATION: Remove to fresh air area.

Help with breathing and if necessary get medical attention.

6. CONSUMABLES AND ACCESSORIES

6.1 Brother Special Paper

• Quality Coated Paper for 360 dpi printing

Letter size No. BP36CL

A4 size No. BP36CA

• High Quality Coated Paper for 720 dpi printing

Letter size No. BP72CL

A4 size No. BP72CA

• Color Inkjet Glossy Paper for 720 dpi fine mode

Letter size No. BPGLL

A4 size No. BPGLA

6.2 Ink Cartridge

Black & Cyan ink cartridge No. LC03BC

Magenta & Yellow ink cartridge No. LC03MY

I-19

Page 28

6.3 AC Adapter, ACSF and Parallel I/F Cable

AC Adapter and Parallel I/F cable No. PA21MP

ASCF only No. SF21MP

PR99052

I-20

Page 29

Chapter II

THEORY OF OPERATION

Page 30

CONTENTS

1. GENERAL----------------------------------------------------------------------II-1

1.1 Normal Interlace Processing (360dpi) -----------------------------------------------II-1

1.2 Super Fine Interlace Processing (720dpi) ------------------------------------------II-2

2. ELECTRONICS -------------------------------------------------------------- II-3

2.1 General Block Diagram (MP-21C/MP-21CDX) ------------------------------------II-3

2.2 Electrical Configuration ------------------------------------------------------------------ II-4

2.3 Main PCB -----------------------------------------------------------------------------------II-5

2.3.1 Data Reception --------------------------------------------------------------------II-5

2.3.2 Control Panel -----------------------------------------------------------------------II-5

2.3.3 Paper Feed and Carriage Motor Drive Circuit ------------------------------ II-6

2.3.4 Paper Sensor -----------------------------------------------------------------------II-7

2.3.5 Cartridge Detection --------------------------------------------------------------- II-8

2.3.6 Head Voltage Control ------------------------------------------------------------ II-9

2.3.7 Home Position Detection of the Maintenance Mechanism -------------- II-9

2.3.8 Memory Circuit --------------------------------------------------------------------- II-9

2.4 Head PCB ---------------------------------------------------------------------------------- II-9

2.5 Carriage PCB ------------------------------------------------------------------------------II-9

2.6 Carriage Sensor PCB -------------------------------------------------------------------- II-9

2.7 Power Supply ---------------------------------------------------------------------------- II-10

PR99052

3. MECHANICS ---------------------------------------------------------------- II-11

3.1 Overview of Printing Mechanism ---------------------------------------------------- II-11

3.2 Print Head -------------------------------------------------------------------------------- II-12

3.3 Ink Cartridge ----------------------------------------------------------------------------- II-14

3.4 Head Maintenance Mechanism ----------------------------------------------------- II-15

3.4.1 Components and Functions -------------------------------------------------- II-15

3.4.2 Mechanism ----------------------------------------------------------------------- II-15

3.5 Sensors ----------------------------------------------------------------------------------- II-16

3.5.1 Top Cover Sensor --------------------------------------------------------------- II-16

3.5.2 Paper Feed Sensor, Paper Eject Sensor ---------------------------------- II-17

3.5.3 Maintenance Sensor (Purge Unit) ------------------------------------------- II-19

3.6 Carriage Drive Mechanism ----------------------------------------------------------- II-20

3.7 Paper Feed Mechanism --------------------------------------------------------------- II-21

Page 31

CHAPTER II THEORY OF OPERATION

1. GENERAL

1.1 Normal Interlace Processing (360dpi)

Fig. 2.1 below shows the relationship between the printing area and the line feed amount

for each print head pass.

pass 4

pass 1 (Position to start printing)

pass 2

pass 3

Interlace table 1

(Line feed amount)

124/1440

pass 4

pass 1

pass 2

Area covered by

the printing head

The printing operation is performed by repeating the following sequence:(120/1440 line feeding + 32 nozzle printing + 124/1440 line feeding + 32 nozzle printing +

124/1440 line feeding + 32 nozzle printing + 124/1440 line feeding + 62 nozzle printing +).

A buffer stores the data for each pass and interlace tables indicating how to allocate the

raster data for each pass are used for the printing operation.

To which pass (storing buffer) the binary raster data is loaded sequentially is allocated

and is initially determined according to the interlace table.

Interlace table 2

Interlace table 3

Interlace table 4

Fig. 2.1

124/1440

124/1440

124/1440

4 rasters of color print data and 1 raster of monochrome print data are converted to raster

graphics transfer commands (G/Z) and stored in the buffer. After the above conversion,

TIFF compression or mirroring is performed if necessary.

The number of rasters handled by each interlace table corresponds to the line feed

amount. Rasters are handled sequentially and the buffer store for sending commands for

1 pass is generated when the last raster of each table (the 1st raster of the next table in

normal and draft modes) is reached. Therefore, once data in the buffer is sent to the

printer with the line feed command (F), the buffer is initialized so that it will be ready for

use for later passes and processing of the next raster starts in the same manner.

II-1

Page 32

1.2 Super Fine Interlace Processing (720dpi)

This is a method to perform printing using nozzles moved at 4/360 inch pitch using

nozzles spaced at 2/360 inch pitch. Fig. 2.2 below shows the relationship between the

printing area and the line feed amount for each head print pass.

pass2

pass1 (Position to start to printing) (Line feed amount)

pass2

pass3

pass4

pass3

pass4

pass5

pass6

pass7

pass8

Area covered by

the printing head

pass5

pass6

pass7

pass8

pass1

pass2

Interlace table 1

Interlace table 2

Interlace table 3

Interlace table 4

Interlace table 5

Interlace table 6

Interlace table 7

Interlace table 8

Interlace table 1

Interlace table 2

Interlace table 3

Interlace table 4

Interlace table 5

Interlace table 6

Interlace table 7

Interlace table 8

62/1440

62/1440

62/1440

62/1440

62/1440

62/1440

62/1440

62/1440

62/1440

62/1440

62/1440

62/1440

62/1440

62/1440

62/1440

62/1440

Fig. 2.2

The printing operation is performed by repeating the following sequence:(30/720 line feeding + 30 nozzle printing + 30/720 line feeding + 30 nozzle printing +

30/720 line feeding + 30 nozzle printing + 33/720 line feeding + 30 nozzle printing +

30/720 line feeding + 30 nozzle printing + 30/720 line feeding + 30 nozzle printing +

30/720 line feeding + 30 nozzle printing + 27/720 line feeding + 30 nozzle printing +).

Detailed operations in the fine interlace processing are the same as those in the normal

interlace processing.

II-2

Page 33

2. ELECTRONICS

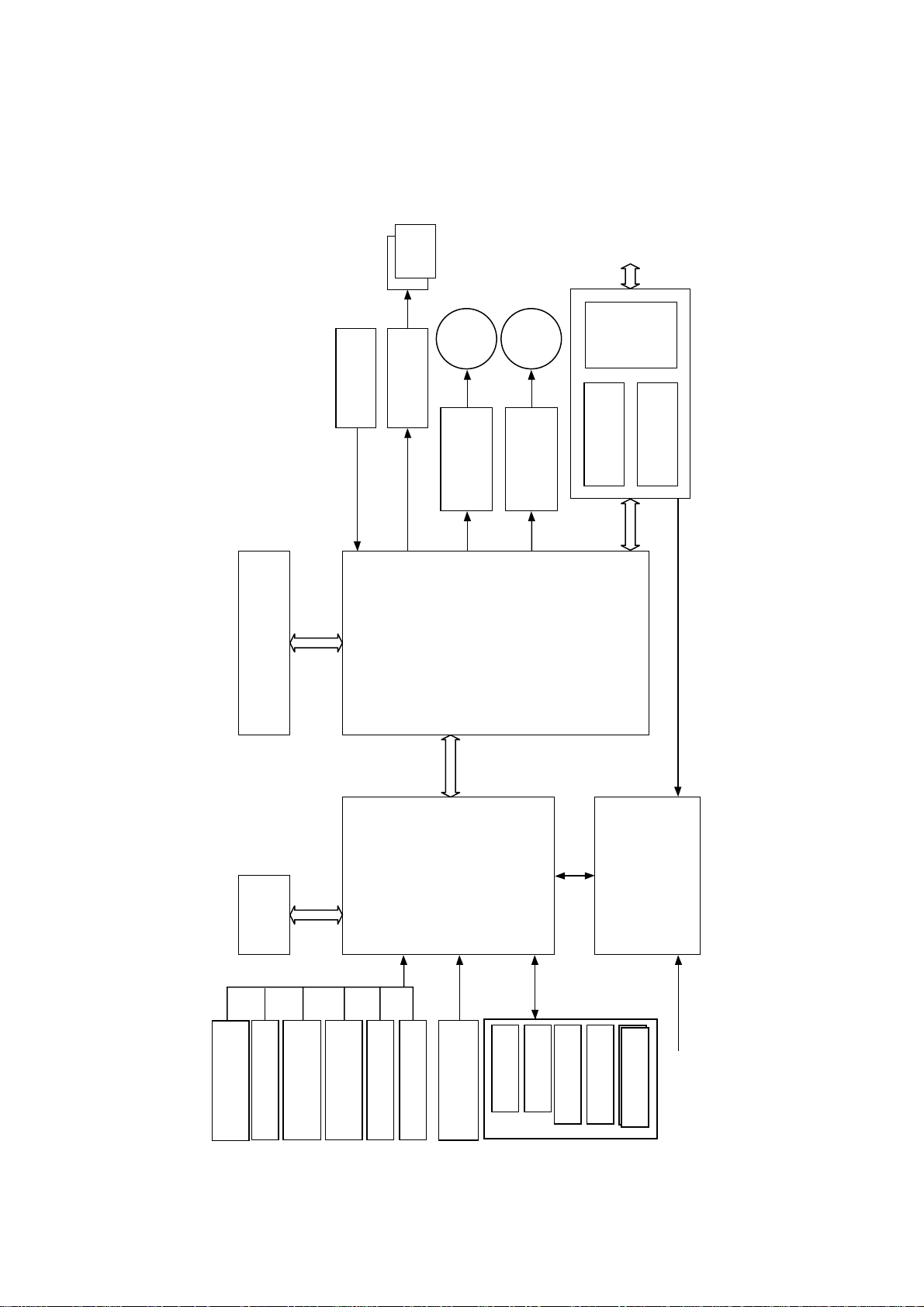

2.1 General Block Diagram (MP-21C/MP-21CDX)

Head

Stepping

sensor

Linear encoder

Head driver

Stepping motor

motor

driver

DC

motor

driver

DC motor

I/F

PCMCIA

controller

PCMCIA

controller

IEEE1284

PC card

EEPROM

Print buffer

SRAM

EEPROM

sensor

PE sensor

Paper eject

sensor

Purge unit

sensor

Ink cartridge

+ CR motor control

+ Encoder operation

G/A (upd99250GJ)

CPU (H8S)

ACSF sensor

+ LF motor control

+ IRQ

+ I/O

+ ROM

+ A/D

temperature

Head driver

Cover sensor

+ Head control

+ I/F control

+ Memory control

+ RAM

Power SW

Clean SW

Logic 1 (+3.3V)

Logic 2 (+5V)

DC/DC

LED (POWER)

LED (INK)

LED (ALARM)

+5V

Motor (+12V)

Head (13-30V)

AC adapter

Fig. 2.3

II-3

Page 34

2.2 Electrical Configuration

(1) Main PCB

• The Main PCB controls the following functions :

Data reception, Control panel control, Paper feed and carriage motor control,

Paper sensing, Cartridge detection, Head voltage control, Data transmission to

the head driver

• A one chip type CPU with a program of 128 KB is used.

• 2 buttons (the

(2) Head PCB

• The Head PCB has the following components

4 LEDs, 1 cover sensor

The head drive IC is on the Head PCB and is connected via 4 FPC cables from the

head unit.

The Head PCB is connected to the Head FFC cable.

(3) Carriage PCB

• The Carriage PCB has 1 linear encoder sensor.

• The Carriage PCB has a head temperature detect sensor.

PR99052

(On/Off) button and the Clean button) are on the Main PCB.

(4) DC/DC unit

• The power supply unit has the following functions :

3.3V or 5V power supply for the logic, 12V for the motor, 13 - 30V for the print

head.

(5) Cartridge sensor PCB

• The Cartridge sensor PCB has 2 cartridge sensors.

• This PCB is connected to the Head PCB via a harness.

II-4

Page 35

2.3 Main PCB

2.3.1 Data Reception

IEEE1284 bi-directional nibble mode is supported. The data reception operation is

performed by the gate array. The CINT-N signal from the gate array indicates the

reception of data to the CPU and control data is processed by the CPU. The printing

data is transmitted directly to the memory without being transmitted to the CPU.

#4 #7 #8 P8

SRAM

Parallel

I/F connector

2.3.2 Control Panel

The control panel controls two switch signal inputs and four LEDs. Two out of four LEDs

correspond to each of the ink cartridges. The cover switch is contained in the switch

panel. When this switch is OFF, the cover is open and printing is disabled. However,

operations associated with cartridge replacement with the cover open are allowed.

SW 1 on the Main PCB functions as the

and turns off the LEDs, but does not turn the power off.

ONLINE / Power SW

CPU

IPINT-N

CINT-N

G/A

SELECT IN-N

19

INPUTPRIME-N

18

Fig. 2.4

(On/Off) button and stops all the operations

P7

Purge SW

MHP Sensor

Maintenance

unit

P2

CPU

Fig. 2.5

II-5

COVER SW

5

11

LED POWER

LED ALARM

10

9

LED INKBC

8

LED INKMY

Page 36

2.3.3 Paper Feed and Carriage Motor Drive Circuit

A PM-type stepper motor is used to feed paper and is driven at a constant voltage. A DC

motor is used for the carriage. It uses the feedback signal (EINT-P) from the linear

encoder and its speed is controlled via the gate array by the CPU using the PWM control

method. The paper feed driving circuit is turned on and off by the M5VCNT signal from

the CPU.

#4

M5VCNT

#7

CPU

G/A

STPM0

STPM1

STPM0N

STPM1N

STPPWM0

STPPWM1

12V

#1

LF Driver

M54676

P1

To LF Motor

#4 #7

EINT-P

CPU

G/A

Fig. 2.6

DCM0

DCM1

DCM0N

DCM1N

Fig. 2.7

ENC 2-P

ENC 1-P

#2

#3

P6

To

Encoder sensor on

the carriage PCB

P4

To CR Motor

CR Drive motor

II-6

Page 37

2.3.4 Paper Sensor

The photo type sensor is contained on the Main PCB. The movable part of the

mechanism detects if there is paper or not and turns the sensor on and off. When light is

transmitted, there is no paper.

The CH1 level of the sensor output is less than 2.5V without paper and 2.5V or more with

paper present.

CPU

(

<Without paper>

Pin

)

PH1

Fig. 2.8

Movable tip

<With paper>

PH1

CPU

()

Movable tip

Pin

Main PCB Main PCB

Fig. 2.9

II-7

Page 38

2.3.5 Cartridge Detection

The detection switch is on the Cartridge PCB and detects the placement of each

cartridge separately. The detection signal is at a low level when a cartridge is fitted.

Fig. 2.10

• ACTRG and BCTRG are signals indicating the cartridges are fitted.

• SIN0-P, SIN1-P, SIN2-P, and SIN3-P are drive data (serial data) signals to the head

driver.

• HCLK-P and HSTB-P are the clock and shift signals of the drive data signals.

• HVDD is a head driving power supply voltage and is variable according to the output

of the thermistor (HDTHM-P signal) on the Head PCB.

• FIRE0-N, FIRE1-N, FIRE2-N, and FIRE3-N are signals setting the timing to apply the

head driving voltage to the head actuator. VDD1 is a signal indicating 5V to the head

driver and its state is controlled by the CPU according to the H5VCNT signal.

II-8

Page 39

2.3.6 Head Voltage Control

The head voltage varies with temperature and head ranks. The VSEL signal from the

CPU generates the HVDSEL signal indicating the analogue value which is transmitted

back to the power supply unit. The power supply unit outputs the head voltage (HVDD)

corresponding to the voltage of the HVDSEL signal.

Pin

#4 CPU

Fig. 2.11

2.3.7 Home Position Detection of the Maintenance Mechanism

MHPSENSOR is the position detection sensor of the maintenance mechanism. The

Home position of the mechanism is used during the purge sequence and is detected

when the power is turned on. (Refer to Fig. 2.5)

2.3.8 Memory Circuit

Location #7 is the LSI which is the gate array to control printing.

Location #8 is the static RAM of 1Mb.

Location #5 is the EEPROM.

Location #6 is the reset IC.

Location #5 and #6 are connected to the CPU.

Pin

)

(

2.4 Head PCB

4 LEDs, a cover switch, the head drive IC, 4 head FPC connectors and 2 cartridge

sensor connectors are contained on the Head PCB.

The connector CNI is connected to the Main PCB by an FFC cable.

Refer to the Head PCB circuit diagram.

2.5 Carriage PCB

The HEDR-8100 is the linear encoder sensor.

The PCB is connected to the Main PCB by an FPC cable.

Refer to the Carriage PCB circuit diagram.

2.6 Carriage sensor PCB

The connector is connected to the Head PCB.

II-9

Page 40

2.7 Power Supply

The power supply uses the switching regulation system to generate the regulated DC

power (+3.3V, +5V, +12V and HVDD), which are converted from the DC input.

(When HVDSEL is open)

Connector pin #1: NC

Connector pin #2 - #4: PCM5V

Connector pin #5 - #7: PCM5V RET

Connector pin #8: +5V

Connector pin #9: +3.3V

Connector pin #10, #11: SGND

Connector pin #12: HVDCUTOUT

Connector pin #13: ADPT

Connector pin #14: HVDSEL

Connector pin #15 - #16: P-RET

Connector pin #17: +12V

Connector pin #18: +24V

II-10

Page 41

3. MECHANICS

3.1 Overview of Printing Mechanism

Extension guide

Carriage ASSY

Paper eject roller

ASSY

Bottom cover

Power supply PCB

ACSF

Pick-up roller ASSY

Separation pad ASSY

Main roller ASSY

Fig. 2.12

II-11

Page 42

3.2 Print Head

,,

,,

,,,

,

,

,

,

,

,,

,

,

,

This is an on-demand ink jet printer and ejects ink by the firing of a piezoelectric ceramic

actuator. Refer to Fig. 2.13 for the print head structure. A narrow channel filled with ink is

sandwiched between two actuators. When a voltage is applied to an electrode formed on

the surface of the actuator, ink is pulled into the channel from the manifold with the

actuator deformed as shown in the Fig. 2.13. When the voltage becomes 0, the actuator

returns to the previous position and pressure is generated in the ink in the channel. Thus,

the nozzle ejects ink drops. Ink drops are propelled forwards by this action and are fired

onto the paper held by the platen and form dots of the respective color. This printer

incorporates thirty-two ink firing mechanisms per color as explained above, 2 colors per

head with 2 print heads, 126 in total.

Piezo

Dummy channelCeramic

Channel

Nozzle plate

Piezo

Fig. 2.13

< Head Specifications >

(1) Method PZT(Xaar) method with the dummy channel

(2) Driving frequency 3.85 KHz, 6.5 KHz, 7.7 Khz

(3) Injection droplet amount Normal mode :40 ± 5pl

Super fine mode :25 ± 2.5pl

(4) Composition Separate color type

(5) Number of ink 4 colors (Y/M/C/K)

(6) Number of nozzles 128 nozzles (32 nozzles x 4 colors)

Ink

Manifold

II-12

Page 43

(7) Nozzle layout

30/360"

31

30

160/360"

31

30

Head

PR99052

30/360"

31

31

30

30

2

1/90"

1/180"

2

1

1

0

0

Black Cyan

FWD PRINT

FWD FEED

2

1

0

Magenta Yellow

Fig. 2.14

(8) Driving voltage 13 V - 30 V

(The driving voltage is controlled according to the

head temperature see 2.3.6 Head Voltage

Control.)

(9) Driving pulse SP, SPT or SPIT

(No droplet gradation control)

Fire 3

2

1

0

Fire 2

Fire 1

Fire 0

µs

2

2

µs

2

µs

Overall cycle change ± 5 % or less

<When printing in the REV direction.>

(When printing is in the FWD is direction, the order of the Fire 3 to Fire 0 signals is

reversed.)

Fig. 2.15

II-13

Page 44

3.3 Ink Cartridge

Ink Cartridge BC

A liquid ink bag is placed inside the ink cartridge. By inserting the ink cartridge into the

printer, an ink needle punctures the seal and is inserted into the ink bag. Ink is supplied to

the print head through the ink needle and the ink tube. 3 needles in total stick into the Ink

cartridge BC. 2 of them are for the ink supply of Black and Cyan and the other one is for

the waste ink.

The spring plate which is placed over and under the ink bag applies pressure to the ink

bag in order to keep the most suitable internal pressure for printing.

When operating the purge system, the waste ink of all 4 colors is delivered from the

Purge unit ASSY to the waste ink absorber through the waste ink tube and needle.

Ink Cartridge MY

The basic structure of the Ink cartridge MY is the same as the Ink cartridge BC but there

is no waste ink absorber. The Magenta and Yellow waste ink is delivered to the waste

ink absorber inside the Ink cartridge BC, the ink cartridge MY does not have a waste ink

absorber. Therefore, only 2 needles stick into this cartridge.

PR99052

Liquid ink bag

Cap

Rib

Sealing

Ink cartridge BC Ink cartridge MY

Spring plate

Spring plate

Waste ink absorber

Cap

Rib

Rib

Fig. 2.16

Spring plate

Sealing

Spring plate

II-14

Page 45

3.4 Head Maintenance Mechanism

3.4.1 Components and Functions

(1) Suction Mechanism

Components : Suction cap, Pump, Maintenance cam

Functions : Guides ink to the head channel.

(2) Storage Mechanism

Components : Storage cap

Functions : Prevents the nozzle tip from drying out when it is

(3) Wiper Mechanism

Components : Wiper, Maintenance cam

Functions : Removes ink deposited on the nozzle surface

(4) Carriage Lock Mechanism

Components : Carriage locker, Maintenance cam

Functions : Aligns t h e s u ct i o n cap and the head for the

(5) Sensor

Components : Photo detector

Functions : Detects the Maintenance cam position.

Removes dry ink from around the nozzle.

Removes air and waste in the head channel.

Ejects sucked ink towards the ink absorber.

not printing.

after the ink has been purged by the suction

mechanism.

cleaning of each color.

Prevents carriage movement so that the head will

not move away from the storage cap when the

power is off.

3.4.2 Mechanisms

• The Maintenance cam connects the drive from the Paper feed motor to the Purge unit

ASSY and rotates it.

• The up-and-down movements of the suction cap, the cap, the wiper and the carriage

locker and suction and ejection operations of the pump are performed by one rotation of

the Maintenance cam.

(1) Suction Mechanism :

The suction cap is pressed on the nozzle plate by rotating the Maintenance cam.

After the cap is pressed onto the nozzle face, the piston in the pump is activated to

generate negative pressure in the pump. The negative pressure is sent to the

suction cap and ink is sucked from the head nozzle. The pump ejects the sucked

ink and feeds it into the waste ink foam of the Ink cartridge BC.

(2) Wiping Mechanism :

The wiper goes up after the suction mechanism has ejected the ink. When it

reaches the upper limit, the Maintenance cam stops rotating and the carriage

moves one head width and the wiper wipes the nozzle surface. After the wiping

operation, the carriage moves another head width distance and the wiper goes

down.

II-15

Page 46

(3) Storage mechanism :

The suction cap and the cap are pressed onto the nozzle plate by rotating the

Maintenance cam.

(4) Carriage Lock Mechanism :

The Maintenance cam rotates and the carriage lock pin goes up before the suction

operation to lock the carriage and goes down again before the wiping operation.

(5) Sensor :

The sensor is on during stand-by. It goes off when it detects the home position to

start the suction operation after the Maintenance cam rotates. The sensor goes on

after the suction, ejection and wiping operations.

3.5 Sensors

3.5.1 Top Cover Sensor

Cover sensor

Top cover

Fig. 2.17

II-16

Page 47

3.5.2 Paper Feed Sensor, Paper Eject sensor

The Paper feed/eject sensor actuator and a photo sensor detect whether there is paper

or not. The Paper feed/eject sensor actuator has a paper a sensing arm and the photo

sensor operating arm. When paper hits the paper sensing part as paper is ejected the

photo actuator arm goes up and detects the paper.

When the paper has ejected out of the printer, the Paper eject sensor actuator returns to

the former status and detects that there is no paper.

The Paper feed sensor detects;

• If a paper is inserted into the Straight paper path slot or the Paper feeding guide.

• The top edge of the paper which is fed from the ACSF

• The bottom edge of the paper

The Paper eject sensor detects;

• The top edge of the paper which is fed from the Straight paper path slot or the Paper

feeding guide

• The bottom edge of the paper

Pressure roller ASSY

Paper hold ASSY

Platen cover

Paper eject

sensor actuator

Paper feed sensor

Paper eject sensor

Main PCB

Paper

Fig. 2.18

Paper feeding can be from the Straight paper path slot or the Paper feeding guide. (Manual

feeding)

Paper feeding starts when the Paper feed sensor turns into ON. In a manual feeding, the paper is

fed until it hits the sensing point of the Paper eject sensor. If the Paper eject sensor turns ON, the

paper is continuously fed further to the print starting position. If not, a paper mis-pick error will be

detected.

Paper feeding from the ACSF

After the ACSF starts to pick-up the paper and the Paper feed sensor turns ON, the printer starts

the feeding operation. If the Paper eject sensor does not turn ON, the ACSF repeats the paper

pick-up operation twice more. If the Paper eject sensor stays in the OFF status after theses

additional retries, a paper miss-pick error will be detected.

II-17

Page 48

During printing

If the Paper feed sensor OFF states is detected (In case that a paper of different size from the one

selected on the printer driver is fed.), the printer stops printing and ejects the paper. The remaining

print data will be printed out on the next sheet.

Ejecting the paper

Upon finishing the print, the printer keeps the paper eject operation running until both the Paper

feed sensor and the Paper eject sensor go into the OFF status. During the paper eject operation, if

the Paper eject sensor does not turn OFF after the specified amount of paper feeding performed

after the Paper feed sensor returns to the OFF status, the printer feeds the paper intermittently. If

the Paper eject sensor still does not returns to OFF, a paper jam will be detected. When both the

Paper feed sensor and the Paper eject sensor do not returns the OFF condition in 30 sec. of the

paper feeding operation, the printer detects a paper jam has occurred.

II-18

Page 49

3.5.3 Maintenance Sensor (Purge Unit)

The Maintenance sensor uses a photo sensor to detect the home position of the

Maintenance cam.

The sensor is on during stand-by ( home position ) and goes off when the Maintenance

cam rotates and detects the Maintenance cam's position to start the suction operation.

The sensor goes on after the purge, ejection, wiping and capping operations are

completed.

Cylinder ASSY

Purge unit FFC

Maintenance cam

Head cap

Flushing foam R2

Flushing foam R1

Maintenance gear 10

Maintenance sensor

Fig. 2.19

II-19

Page 50

3.6 Carriage Drive Mechanism

The carriage motor controls horizontal movement of the carriage unit.

The motor rotation is transmitted to the timing belt via the motor pulley.

The guide shaft supports the carriage.

The carriage holds the timing belt.

The direction of the carriage motor rotation corresponds to the direction of the carriage

movement.

The position of the carriage is controlled by the encoder strip.

Carriage motor ASSY

Idle pulley

Timing belt

Carriage ASSY

Print head

Fig. 2.20

Guide bar

Encoder strip

Drive pulley

Carriage guide

II-20

Page 51

3.7 Paper Feed Mechanism

ACSF (MP-21C option)

When the line feed motor is driven in the reverse direction (reverse rotation) to the normal

paper feeding direction, the change-over 1 frame moves to engage the separation roller

gear via the idler gear. The separation roller rotates in the paper separation direction

(normal rotation) and separates a sheet of paper. The separation roller rotates with the

paper feeding operation and returns to the initial position and is registered by the paper

feed pressure spring behind the separation roller gear.

Separated paper is fed to the contact point of the Main roller and the Pressure roller by

the Pick-up roller where the top of the paper is registered.

After the paper is registered, the Paper feed motor is driven in the paper feeding direction

(normal rotation) and paper is fed by the Main roller and the Pressure roller.

After printing, paper is ejected by the Paper eject roller and the Star wheels.

Paper

Pick-up roller ASSY

Separation pad ASSY

Fig. 2.21

II-21

Page 52

Chapter III

DISASSEMBLY AND

REASSEMBLY

Page 53

CONTENTS

1. PRECAUTIONS-------------------------------------------------------------- III-1

1.1 Safety Precautions --------------------------------------------------------------------- III-1

1.2 Attention ---------------------------------------------------------------------------------- III-1

2. TIGHTENING TORQUE LIST-------------------------------------------- III-2

3. DISASSEMBLY ORDER FLOW ---------------------------------------- III-3

4. DISASSEMBLING AND REASSEMBLING PROCEDURE------ III-4

4.1 Ink Cartridge, ACSF-------------------------------------------------------------------- III-4

4.2 Top Cover, Paper Guide, Front Cover, Release Plate, Rear Cover ------- III-5

4.2.1 Top Cover ------------------------------------------------------------------------ III-5

4.2.2 Paper Guide --------------------------------------------------------------------- III-5

4.2.3 Front Cover ---------------------------------------------------------------------- III-6

4.2.4 Release Plate ------------------------------------------------------------------- III-7

4.2.5 Rear Cover ----------------------------------------------------------------------- III-7

4.3 Head PCB ASSY ----------------------------------------------------------------------- III-8

4.4 Ink Head Base Unit, Print Head ----------------------------------------------------- III-9

4.5 Bottom Cover ---------------------------------------------------------------------------III-12

4.6 Main PCB, Power Supply PCB ASSY --------------------------------------------III-14

4.7 Paper Feed Motor ASSY ------------------------------------------------------------III-16

4.8 Purge Unit ASSY ----------------------------------------------------------------------III-18

4.8.1 Flushing Foam R1 and R2---------------------------------------------------III-20

4.9 Paper Feed Frame ASSY -----------------------------------------------------------III-22

4.9.1 Paper Feed Motor Holder ---------------------------------------------------III-22

4.9.2 Arm Stopper --------------------------------------------------------------------III-23

4.9.3 Paper Eject Idle Gear 25 ----------------------------------------------------III-24

4.9.4 Carriage Guide -----------------------------------------------------------------III-24

4.9.5 Paper Eject Roller ASSY ----------------------------------------------------III-25

4.9.6 Platen Cover, Flushing Foam L1 and L2 ---------------------------------III-26

4.9.7 Main Roller ASSY -------------------------------------------------------------III-29

4.9.8 Encoder Strip -------------------------------------------------------------------III-33

4.10 ACSF -----------------------------------------------------------------------------------III-34

4.10.1 ACSF Support ----------------------------------------------------------------III-34

4.10.2 Pick-Up Roller Cover --------------------------------------------------------III-34

4.10.3 ACSF Front Cover, Pick-Up Roller ASSY, Gear Frame R ---------III-35

4.10.4 Separation Pad ASSY ------------------------------------------------------III-36

4.10.5 Extension Guide L and R --------------------------------------------------III-37

5. LUBRICATION -------------------------------------------------------------III-38

6. CLEANING THE PRINTER ---------------------------------------------III-43

6.1 Cleaning The Platen Cover ---------------------------------------------------------III-43

6.2 Cleaning The Edge Of The Head Cap -------------------------------------------III-43

6.3 Cleaning The Pick-up Roller On The ACSF ------------------------------------III-44

7. PACKING---------------------------------------------------------------------III-45

Page 54

CHAPTER III DISASSEMBLY AND REASSEMBLY

1. PRECAUTIONS

1.1 Safety Precautions

(1) Always turn off the

accessing any parts inside the printer.

Note: Even if you turn the (On/Off) button off, the power is not completely shut

(2) The ink contains no harmful substances.

a. If the ink stains your body or clothes, wash with soap or detergent immediately.

b. If the ink gets in your eyes, irrigate them with water immediately and consult a

doctor if you are concerned.

c. If you swallow the ink by accident, drink plenty of water and consult a doctor if

you are concerned.

(3) Do not put your hands into the printer while it is printing in order to avoid getting

hurt.

1.2 Attention

(1) Be careful not to lose screws, washers or other parts removed during the following

operations.

(2) Be sure to apply grease to the gears and applicable positions specified in this

chapter.

(3) When using soldering irons or other heat-generating tools, take care not to

damage parts such as cables, PCBs and covers.

(4) Before handling the PCBs, touch a metal portion of the equipment to discharge any

static electric charge in your body, or the electronic parts or components may be

damaged.

(5) When transporting PCBs, be sure to wrap them in the correct protective packaging.