Brother Model KH--830, Model KR-830, Model KL-116, Model KRC-830, Model KHC-820 Service Manual

Model KH--830

Model KR-830

Model KL-116

Model KHC-820

Model KRC-830

INDE

X

Operation sequence

of

needle selection

by

punched card . . . . . . . . . . . . . . . . . . . I

Construction

and

operation

of

knitting machine . . . . . . . . . . . . . . . . . . . . . . . . 2

Machine body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

• . . . . . . . . . . 4

KH-&30

needle selection mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Disassembling the carriage . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assembling

the

carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Checking the carriage functions -

1-

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Checking the carriage functions - 2- . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . 18

How

to

adjust the carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Disassembling the

bed ..............

....

.............

.

......

....

21

Di.uuembling

the needle selector plate holder . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Disauembling the needle selector unit .................

.

.......

.....

.

26

Assembling the needle selec

tor

unit

.......

..

............

.

...........

27

Assembling the needle selector plate holder . . . . . . . . . . . . . . . . . . . . . . . . . . .

29

Assembli

ng

the

needle selector

unit

in the needle plate holder . . . . . . . . . . . . . . . . 30

Assembling the needle selector plate holder

in

the

body

........

..

......

...

31

Inspection

of

needle selec

torfun

ction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34

How to adjust the macbin.e body

............

.....

.................

35

How to adjust L carriage

......

.

........

....

..

. . . .... .

.........

..

47

Knit·

~ader

K

L-116

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . .

49

Ribbing attachment

KR-830

........

..

.....

....

........

.

.........

50

Combinations

of

knitters

and

ribbers

..............

....

. .

............

52

Mounting demensions

of

each part

of KR-830

.......

....

..

.....

. ....

..

53

How

to

adjust the colour changer .

..........

..

...........

. .

...•....

54

Trouble shooti.

ng

. . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . .

55

OPERATION SEQUEN

CE

OF NEEDLE SELECTION ..

BY

PUNCHED . CA

RD

Up

and.

down

movement of

cud

feed

lever

Up

and down

mOYement

of

ratcl>ed

Rotation

of

card

feed

tooth

I

'

I

I Feeding of card I

Rotatloo of

c,tuteh

wlteel

I

...

I

I Rotation of bevel

JW

J !Half

tum

of

cud

reader!

I

rdeue

com

l ,

I Rotation

of

roury

cam I

IUp

and

down

movement

ofl

L card reader

"'le-

plate 1

- I-

IUp a.n

d dbwn

m-ment ofl

I

cud

reader I

I

I

!Side

way

movement of card

reader!

I

Sid.eway

movement

of

card

I

signal

!ncr

Sideway

moY~nt

of

needle

selec

tor plato

Selec

tkm of

needl

e

by

" Medlel

selector

plate

1

Positioning

of

need.le

by j

camaae

CONSTRUCTION

AND

OPERATION

OF

KNITTING

MACHINE

H

.C.L

...•

P\aio B

pool

1ion

ocedlo

C

alft

bu

ttOfl

·-Tuck

stitch-es..

fiPt and

k!

t

D

a.

£

J)QMdo

n needle ... Kninina st

iiC'h

N'eedk Mkclor

dt.a.Ap!

knob

-·

hua:n

stitch

n.et sti

tc

h

Skip

stitch.

Fair-

hie

To

acquire a full knowledge o f operation

of

the knitting machine, you

must

undentand the construction and function

of

each

~ectlon

of

the

machine.

A

better

knowledge

of

the oper

ation

theory

enabl

e~

you

to

locate the

cause

of

trouble

wi

th

eue

If

It

lhould

occur. Also

you

wiii be able

to

explain the

de

tilled

mechaDIJm

of

the

machine

to

your

clients.

CA

RRJA

GE

I. Stitch

cam

and

raisins

cam

1.1

Stitch cam

The

stit

ch

cam moves the needle ba

ck

and

forth,

thus

making

ruches.

1.2

Raising

cam

The

raising cam changes the

route of

the needle

in

the B

position.

2.

Cam

butt

on

The

cam

button

is

used for pattern

kni

tti

ng.

It

changes the

route

of

the

needle by operating

five

buttons, tuck, right and

left,

MC, and

part,

right

and

left.

The

route

of

needles w

hen

each

button

js depressed is illustrated

below:

.

...

Plain stitch

Holcllac

cam

Stitcll

3. Holding

cun

k'l'•

(H.C.L.) .

The

holdin&

cam lever chan

ges

the rou

te

of

the needle Ia the E

position.

4.

Tmsiou

dill

The teMion dial chan

ges

the

sin

of

stitches by c

b.nPR&

the

stitch

cam

positJon back and forth.

S.

CbaDge

knob

The

cbanae

knob

hu

three positions, (N .L.) "Plaln/Lsce st!t.:h".

(KC)

"Patt.rn stitch"

111d

(CR) "Carriage releue", and

it

functions

as folloM:

S.l

The

pcmti011

of

(N.L.) "PPaln/uce

stl

tch

~'

Is

1111d

when

plain

or

lice

stitches are perfonned. The needle moves Into

an

open

hole

in !be punched card.

S

.2

The position

of

(KC)

"Pattern stitch" is

111e

d for pat!ml

stitch

based

on

p1111ched

cuds.

The

needle pocitioned in

an

open hole

Is

selected.

5.3

The p01ition

of

(C

R)

is

used

for releasing the curia

ge

from

the needle bed.

1

6.

Needle

tolect«

cam

When

the

change knob

ia

set to (KC) "Pattern stitch," t

he

needle

sel

ector cam

moves

down

to

brin& the needlea In B and D to the

se

lecting cam, thus holding the Medles.

7. Tuck

cam

The tuck

cam

reducej the am

01mt

of

upward thrust

of

the needle

In B, and causes the needle to hook the next stitch without pull·

lng

of

f

the

latch from the

fml

stitch

in

ordtr to produce double

stitches.

8. Sepuation

cam

The separatioo

cam

separat

es

the needle

whic

h

is

caught

by

the

nee

dle

selecting plate coupled to the punched card and the needle

(pushed upward)

whi

ch

II not caught

by

the needle selecting

plate

int

o

the

Band

D positions, r!'spectively.

9. Y&nl feeder

Two

types

of

yam feeder a

te

· in use.

The

main

yam

feeder guides

the

yam

so

tb.t

the

Yllll

is

boolted ooto

the

needle

hoo

k moved

up

to

the

stitch cam (the CCGiralt oolor

yam

feeder is operated

by

the MC stitch cam), and at the

aame

time

It

protects the latch

against

damage.

I 0. Sinker plate

The stnker plate

preve

nts

the

knitting

from

moving up,

IOIJII!Iher

with the needle railed

by

the

cam

.

. .

II. Weaviq._.

-3-

The

weaving

brush

holds

doW!!

the

thread

so

tb.t

it

m0'1

el to

the

undel'lide

of

the needle Ia B podtion when the needle

Is

lowtred

by

the

stitch

cam

.

MACHINE

BODY

1. Needle

bed

The

needle bed

guides

the back

and

forth movement

of

the needle

an

d detennlnes the pitch

of

stitches.

2.

Combs

Th

~

combs make sinker loops

of

stitches

and

also make

the

stitches

eve

n.

3. Plain needle

The

plain needle is moved back and forth

by

the cam attached to

the

carriage

In

order

to

make needle loops.

4. Belt

When the carriage is moved

to

select

the

needle

by

the card ,

the

belt

begins

to

tum

and drive the needle selecting mechanism and

also synchronizes the

carria~e

and

needle selecting timing.

S. Needle ltkctOI' plate

The

needle selector

plat

e is made

up

of eight pattern plates

of

the

sa

me design which

are

overlapped

with

an

offset

of

one pitch.

It

causes

the

hook

of

the

needle selector plate

to

hook

the

plain

needle shunk when the needle selector plate corresponding

to

an

open hole

in the punched card

Is

moved

to

the right.

6.

Out

ch wheel

The

clutch wheel operates t

he

needle selector mechanism and feeds

th

e punched c

ard by

one

pitch

.

7. Rotary

cam

The rotary cam Is driven

by

the belt and pushes the card reader

(corresponding

to an open hole) to the left. The cam

has

lobes

spac

ed

at 1/2

4 pit

ch

aro

und the circumference.

I

8.

Cud

feediDg

cam

1

The

card feeding cam is driven

by

the

rotary motion carried

from the

belt

clutch wheeL When

it

is

rotated ~ tum

, the card

feeding lever ro

Uer

rolls over

the

cam lobe, and thus the card

feed

lev~

is made to move

up

and

down .

9.

Cud

reader

releasinal

cam

T

he

card reader releasing cam is rotat

ed ~ tum

by the rotary

motion

of

the

belt

clut

ch

wheel,

and

thus

the

cam lobe comes

in

co

ntact

with the card reader return plate

roU

er.

Whe

n the ro

Uer

moves around the cam lobe, the card reader is forced down

by

the

card

reader return plate.

L

CARRIAGE

I. Plate cam

Three types

of

plat

e cam,

A,

B and C, are

in

use

for the following

purposes:

Plate

cam

B ....

Raises

the plain needle selected for B position

higher than the

comb

.

Plate

cam

A ....

J<eepc

the p

lain

needle held upward

10

that the

needles

In

B position are correctly moved

by

the

feed

hook Into

the

stitch formed

by

the intersect·

ing plain

needlu

.

~late

cam C ..

..

Removes the

int

ersecting plain needle when the

stitch

has moves to the next needle. ·

2.

Feedhook

The

feed

hoo

k carries the plain needle, which is raised by

the

plate

cam,

lo the

next

plain needle.

3. Leaf spring

The

leaf

spring keeps the needle

latch

open and helps the plain

A

8

D

E

needle stitch (wruch intersects with

the

feed hook)

to

move

the

next

plain needle.

4.

tobin

cam

The main cam moves and selects

the

plain needle when

it

changes

stitches.

5.

Se~tion

cam

As in

the

case

of

the separation cam

on

the K canlage,

the

separa-

tion c

am

guides the knitting needle, wruch is held down

by

the

main cam, to

B

or

D position.

Needl

es

in B position .... When

the

needles carried

by

the

feed

hooks

from

D position intersect with

each

other, the

stit

ch

Is moved

up

just

before

the

combs

by

the

main cam.

The feed

hook

holds this stitch, and sepa·

rate

the

needles into B and D position

.

Needles

In

D position ....

While

staying

in 0 po&

ltlon, the needle is

caused

to

inte~t

with tbc

needle

in

B

position by the feed hook, and thon the

needle

is

raised

by

the

main cam IUitil the

needle

btch

pane

s

the

stitch. After the

needles intersect with

p~te

cam

C,

they

are separated into B and D positions

by

the

main cam

and

separation cam.

6. Lacetelect:ina

lev«

-S-

The lace selecting lever has

two

positions " N"

and

"F",

and

it

funclio

ll$

as

follows:

6.1 The position

of

N

is

normal

bee

position.

6.2

The polition

ofF

is

used

for knitting

the

flne

lace.

KH- 830 NEEDLE SELECTION MECHANISM

Fig. A

Fig. B

-6-

. -

• In the IQf- 830 needle selection mechanism, when the needle is

moved

downward

by

the needle select

or

c.am attached t o the car-

rbge

, the c

ard

rea

der

in

the position

of

open

hole In the punched

card moves up. When the card reader moves

up.

the

card reader

is

forced to the left

by

the rotary

cam

, thus ca

us.lng

the c

ii'C!

ligna!

lever {which is

coupl

ed

to

the

car

d reader)

to

mo~e

.

Thus,

the

card

sipal

lever causes the needle selector pl

ate

to

the rigltt,

and

the needle shunk is caught

by

the

book

of the needle selector

plate. This keeps the needle forced down, and the need

le

is led

to

the D position by the separation cam.

On

the needle which

Is not

positioned

in

an open hole, the card

reader does

not

move

up,

and u a result, the needle cannot be

held down (in

oth

er words,

it

n>tums

to

the home position even

if

held down}, it

is

pushed back

to

the B position by the separation

earn attached

to

the

carriage.

MaiP

body

I)

If

there

Is

an

open hole,

the

card rea

der

ia.moved

up

by

the spring.

2) The

card reader

is

moved

to

the

left

by

the needle selector cam.

3)

The signal lever

is

moved to the left

by

the

card reader.

4)

The signal lever pivots

upon

A (see Fig. A), and t

he

needle

sel

ector

plate moves

to

the

righ

t.

5)

The

needle selector plate

in

this posit

ion

is

moved

to

the right

until

it

catc

hes

the

needle shunk, thus keeping the needle forced

down.

6) When

there is no hole, the needle selector plate does

not

move,

and

as

a resu

lt,

the needie returns

to

the home position from

where

It

is

held down.

eama.

Since the needle positioned

in

an

open hole

lJ

under the needle

select

or

plate, it is carried

to

the D position through

the

separa-

tio

n earn.

Th

e needle which is not positioned

in

an open hole

is

immediate·

ly forced b:u:k

to

the

home

position from

the

pocltlon where

it

is

held, it operat

es

at

A (see Fig. B) and forced back

to

B.

DISASSEMBLING THE CARRIAGE

1------------------

-----··---

I . Removing the carriage handle

1.1 Keep the handle down and remove the two right and left

handle

screws. Then the handle

can

be taken

off

the carriage.

2. Removing the carriage cover

2,

I Loosen, from the back

of

the carriage, and remove the two

right and left

carriage cover clamp screws.

2.2.

Pun

off

the carriage cover upward. Then the H.C.L knob, the

-

7-

Fig. 1

Name

of

parts

<D

Handle

® Carriage cover

'

®·1

H.C.L knob

®·2

Plain

lever knob

® ·3

Change

knob

® Stitch dial cap

plain lever knob and

the

change knob will come off.

2.3

Pull

off

upward

the

H.C.L knob spring mounted

under

the

H.C.L.

knob.

3. Removing the

sti

tch dial

3

.1

Pull

off

the stitch dial cap upward.

3.2 Remove the fastening

screw and pull

offthestitchdialupwud.

Name

or

parrs

Cam

buuon

unit

Raising cam change

(!)-I

spring

4.

Removing

the cam button unit

4. 1

Remove

the raising cam change spring by means

of

a wo

rk

hook

used

from the side

of

the raising cam calking pin.

4

.2

Remove

the two

cam

button unit clamp screws.

4.3

Remove

the

cam

button unit by

Urting

it while p

ulli

ng it

toward you.

5.

Re

moving the row counter tripper

S .I Remove the

rigb.t

row counter tripper clamp screw and the left

nut using a b

ox

driver, then

puD orr

the tripper upward.

- 8-

Fig. 2

--

Row count

er

tripper

Handle

se

tting base

Uppor

sUde

plate

5.2 Take care nor

to

lose

the collars placed beneath the row

counter tripper.

6. Removing the handle setting

base

6.1

Remove

the two right and left

clamp screws

and then the leaf

spring.

6.2

Remove

the four

righ

t and left clamp screws.

7. R

emov

ing

the upper slide plate

7

.I

Remove

the snap rin

gs

from the change k

nob

shaft and left

side

shaft

using

a 5 screw driver.

7.2 Remove the upper

slide plate by

Uft.ing

its

rigb.

t and le

ft

ends

at

the same rime.

,

8.

Re

movin

g the needle selection

change spring

8.1

Remove

the right a

nd left rfoedle

selection change spring.

9.

RomoviJia

the

stl~hcam

guide

pllto spring

9

.I

Remove

the stitch

cam

guide

plate spring

by

preuing this

center toward the stitch

cam

guide plate.

10.

~the

tuck

cam

opcratlna plate

In

left and right

10.1

2 springs

of

tuck cam operating plate will

be

remoYed

at the

place

of

calldns.

10

.2

Uft

and p

uU

off the

presser

ring and the tuck cam operating

plate.

1 1.

Rm.O'ring

the chanse plate

11.1

Remove

the

four

righ

t and le

ft

MC cam

spdnp

from

the MC

cam.

®

®

@

®·I

®

®·I

rft

·2

i @ -4

@

@

@··I

Name

of

partS

Needle

adection

manse spring

Stitch

cam guid

e

plate spring

Tuck

cam

opera ling

plate

Tuck

cam

1pring

Chan

go

plate

MC

cam

sprtog

Chan

se

plate

~pring

Chanae

plate guide

stud

Con

Meting plate

spring

Rear

plate

Clamp

nut

I

I

I

I

I

I

I

I

Fig. 3 1

I I

.2

Remove

the

right

and left ends

of

the chan&e

pla

te

spring

from

I

the c

hange

plate. '

11.3

Remove

the nutJ

from

the

clwtJe

plate

camp

acrawa

using a

box

drtvor

from

the beck

of

the

cacrtase

.

I 1.4

Remove

the

change

plate clamp

screw(s

)

wi

th a d

rtvor.

Uft

and pull off the

plate.

I 2.

RemOYIJII

the conoectillg plate spring

12

. I

Uft

and pull

off

the

two

sprinp on the left and right.

13

.

Removing

the·carriift

mor

plate ·

- 9-

13

.1

Remooe

the

tar

plate clamp nut,

an

d the rear plate will come

off.

' Caution:

The 5Ub stitch cam clamp screws (a) and the

carria

ge

rur

~g

screws (b) are fastened with nuts

on

the

outer side

of

the cant.ge.

~move

the

llCtews after removing the nuts.

Fig. 4

-10-

Name

of parts

Froat slide

pl

ate

Carriaae front

le

g

Guide

c.m

A

noem

bly

Guido cam B

CuldecamC

Stitch cam

MCcarn

Guide

cam

D

Needle

teloctlng cam

Guide

com

F ·

Separation

com

Tu

ck

cam

Carrla,e rear

leg

Connecting p

late

Stripe adjuster plllte

14.

Removing

the front slide plate

14

.1

Remove snap ring 3 and

washm

put on the H.C.L. knob shaft

oo the outer

side

of

the carriage.

14.2 Remo

ve

the two front

sli

de plate

set-screws

. Then lift and pull

off

the froot

slide

pla!e.

(When

pulling

off

the

plate, keep

the

H.C.L knob

at

position H

.)

1

S.

Removing the

carriage

front

leg

1 S .1

Remove

the

two carriage front

leg

damp

screws

and

then the

le

g itsel

f.

16. Removing

guide

cam

A

16.1

Remove

the two right and left guide c

am

A clamp

screws

and

then the

cam

itlelf. (Slide

cam

as

well)

I 7. Removing

guide

cam

B

17

.I

Remove

the left

guide

cam

B clamp screw and then the left

aectic>n

of

the cam.

17.2

Remove

the right

se

ction in the

wne

I!Wloe

r.

18

.

Re

moving

guide

cam

C

18.1

Remove

the guide cam C clamp

screw

, and guide

cam

C,

Y3hoe

cam

C,

the

valve

cam

C sprins, guide

cam

C shaft, slide

cam

guide

and clamp screw

will

come off.

19.

Removing

the stitch cam

19.1

Remov

e snap ring and

washer

from the stitch

cam

shaft

on

the

outer side of the

carriage.

19.2

Remove

the nut from the sub stitch cam

using

a box driver

from

the outer sid e

of

the caniage. (See F

ig.

4)

19.3 Remo

ve

the left stitch cam clamp scre

w,

and the left part

of

valve

cam

D,

the·left pa.

rt

of the

valve

cam D spring, the sub

stitch

cam

shaft (collar), the left part

of

the MC cam and the

clamp

screw

will come

off

.

19.4

Remove

the right part

of

the stitch

cam

in a similar way.

20. Removing the stitch cam plate

20.1

Re

move

the snap ring 7 and wather from the stitch cam plate

shaft, and

th

e

cam

plate will come off.

(See

Fig.

4.)

2

1.

Removing

guide

cam

D

21.1

Remove

the left guide earn D clamp

scre

w, and guide

cam

D,

t

he

guide cam D shaft and the clamp

screw

will come off.

21.2

Re

move the right part

of

guide earn D in a

simil

u way.

22. Removing the

needle

!<!l

ecting

cam

22.

1

Remove

the two left needle

!<!lecting

cam clamp

screws

, and

the left pan

of

the needle selecting

cam

will

come

off.

22.2

Remove

the

right

part

of

the needle selecting cam In a similar

wa

y.

23. Removing

guide

cam F

23.1

Rem

ove

the right and left guide cam f clamp screws,

and

the

right

and

left pans

of

guide

cam F will

come

off.

24. Removing the separation

cam

24.1

Remove

the right and left separation cam clamp

acrews

and

then

the

cam

itaelf.

2S.

Removing the

tuck

cam

25.1 Rem

ove

the right and left tuck cam

clamp

screws,

and the

tuck

cam plate, the right and left parts

of

the tuck

cam

, the

ruck

cam

spring,

the

ruck cam

shafu

and the clamp

screws

will

come off. .

26.

Removing

the carriage

rear

leg.

26.1

Remove

the six carriage rear leg clamp

screws.

and the leg

will

come

off

.

27.

Rem

ovill

a the coMecting plate

27

.I

Pull

off

the connecting plate by lifting

it

by

its right and left

parts near the front l

eg

.

28.

Removing

the stripe adjuster

28.1

Remove

the stripe adjuster plate clamp screw and

then

the

plate

Ltaelf

.

-11-

ASSEMBLING

THE

CARRIAGE

--

----

--

------

--

Fit . 6

Name

of

parts

(i)

Stripe

adjU$ter

plate

® Connecting plate

®

Carriage

rear

leg

@

T1.1ek

cam

® Separat

ion

earn

®Guide

cam

F

®

Need

le

ltlectln&

cam

® GuidecamD

@

MCcarn

@

Sti1cb

cam

@ GuldecamC

@

Guid

ecamB

@

Guide

cam A aasemb)y

@

Carrl,!ce

front

leg

@ F r

orlt

slide

pl"e

12.

Mou

ntinuul~

cam

a

IS. Mounting

the

front slide plate

Fit the

valve

cam B spring

onto

the

val'fe

cam

B shaft

and

put

gul~

cam

B in

p<nltlon B and

clamp

with a screw

while

keeping

valve

cam

Bat

the

ring

part

of

the

valve

cain

B sprinJ.

Note: Turn

me

cam

B

IDside

the

Nb

stitch

cam.

13.

Mountinu

uldecamA

Mount guide

cam

A and

slide

cam

clamp

wUh

right

and

left

screws.

14.

Mounting

the

carrlaee

front

leg

lishten

the

two

screws

provided

near

the

center

of

the

carriaee

front

leg.

-12-

IS.! Put the front

sUd

e pbte

on

the

carrlo,ee

front

leg

and

clamp

with

s:et·screws. (The

longer

screw

Is

used

for left

side

.)

No

te:

See

to

it

that the llide

pliate

will wotk

eully

aDd

!.bat

the

hold-

lac

cam

wil

ao

clown

when

doe

llide pl8te

is

laO'Ied

to

dte 8

(Boldillg) pooition.

I

5.2

Fix the holding

cam

levet

shaft with a wuher and map rtng 3

from the outer

aide

of

the carnage. (See

Fig.

6)

,.:""1

,

I. Moun

tin&

the stripe adjuster plate

Mount the stripe adjuster plate a

nd

clamp provisionally.

2. Mounting the connecting plate

Fit

the right

and

left

pam

of

the

connecting pl

ate

into

the carriage

piaU. (Take ca re

not

to

mistake the right part

for

the

left

part

or

vice versa.)

3. Mo

unting

the

carria

JIC

rear leg

Put

the

carriage rear leg

into

position

and

clamp w

ith

screws.

4.

Mountlns

the

tuck

cam

Fit

rf&ht

and

left c

lamp

.aews

into

Ute

ruck

cam

piau.

moun

t t

ht

right

and

left parts

of

the tuck cam, the tuck

cam

collar

and

the

tuck

c

am

spring

on

the

screws.

and

clamp. (Be coreful

of

the direc·

tlon

of

the

tuck cam

spring.)

Note:

Keep the tuck

cam

open

siclewa)'1.

It

should

return

euily

under sprias praaure.

S.

Mou

ntin&

the

sopmtion

cam

5.1

Put

the

left

part

of

the separation cam

on

the

left

end

of

the

carriage.

Then

clamp

the

separa

tion cam

clamp screw

into

the

outer

screw hole.

5.2 Fit the

right part

of

the oeparation cam In a simOar

way.

6. Mountln& auJde

cam

F

6.1 M

ount

the left part

of

guide

cam

F a

nd

clamp.

6.2

Mount

the right part

of

guide cam

FIn

a similar

way

.

7. Mount

in&

the needle selectiri&

cam

7 .I

Fit

the left

part

of

the

needle select

in&

cam

and

clamp with a

screw.

7.2

M

ount

the

ri&ht

part

of

the

needle

seloctln&

cam

In a similar

way

.

8.

Moun

tirc

folld•

cam o

8.1

Combine

the

ri3bt

and

left

pans

olaulde

cam D

and

the

guide

am

D shaft (collar)

and

clamp

with

sc,..,.

..

9.

Mountinlthe

stitch

cam

auJde plate

9.1 Mount

tha

stitch

cam

guide plate from the

outer

aide

of

the

carriaae. Put waahers

on

tha

right

and

left

parts

of

the

stitch

cam ahaft bearing from the back side

of

the carriage

and

stop

with

snap ring

7.

10. Mounting the stitch cam

10.1 Fit the left part

of

the

MC

cam

.

the

sub stitch

cam

shaft

(col·

lor),

the left part

of the valve

cam

D spring,

the

left

part

of

valve

cam D and

the left

part

of

tbe

sub

stitch

cam

into

the

carriage plate

in

this

order

and

clamp

with

a screw.

Fix

with

a

nut

from the

outer

side

of

tha

curia

£0. (The

rit>g

part

of

the

val•·e

cam

D spring should

be

hung

from

valve

cam D and

the

hook

part

from

the

left

part

of t

he

sub stitch cam.)

10.2 M

ount tha

right part

of

the

stitch

earn in a slmllar

ny.

10.3 Clamp

the

stitch

cam

shaJt with

a \!lasher

and

snap ring 3

on

the

outer

side

of

the carrlaae.

.:

Note:

I.

The

MC

cam,

•alv•

cam

D lnd

ll1e

stltcb'

<:am

should

worlr.

...

ily.

2.

Valve

cam

D

shot&ld

return

uodcr spring

pmatm.

II

. Mo

unting

guide cam C

Buikl valve

cam

C.

the

valve c

am

C spring,

the

guide

cam

C ahaft

(collar)

ond

tha

sUde

cam.auide

into

guide cam C and

mount

guide

cam C on

the

carriage.

(

The

ring

part

of

the

valve

cam C ahould

be

bung from valve cam C

and

the

hook

part

from

the

rtcht-

hand

notch

of

auJde cam C.)

Note: The

vllve cam C

should

work eolily. Valve

cam

C

should

"'tum

to

the

ce•ter

under

apri1sa

JlfCIIUft.

-13-

•

@

~

16. Mounting

the

carriage

bac

.k plate

16.t M

ount the

back

plate

on the carriag

e,

put a nut

on

the back

plate clamp screw and clamp.

Note:

~

to

it

that

tbe back plate

will

went

easily.

1

7.

Mounting the connecting plate spring

·

Put

the

right and left parts

of

the connecting plate spring

on

the

con·

necting plate calking pin and

the

change knob

shaft

.

'

18

. Mountins

the

cbange pl

ate

18

.1 Mo

unt

the

cllange plate

with

the

change plate guide

stud.

18

.2 Tighten the

clamp

screw

with a nut from

the

back

Jide

of

the

carriage.

18

.3

Hook

the

change plate pulling spring

to

the righ

t and left parts

of

the

chan

ge plate.

18

.4 Hook four points

of

the

MC

cam

spring to

the right

and

left

parts of

the

MC

cam

and

the

right

and

left parts

of

the

MC knit-

ting chan

ge

cam

.

Name of

part

s

@

of.~

-

I

<l.4l

Rear

plate

@

.J

Nut

@

CoiUifttinB plate

sprlJ!a

@

Chafleeplate

@-1

Change plate

gu

ide

stud

@-

3

Change

plat

e pulling

spring

{il

-4

MC

cam spring

@

Tuck

cam

operating

plate

8

Sritcb

c

am

gulde p

la

t

spring

®

Needle selector spring

Fig

. 8

Note:

Tbe

cllJ.nae

plate..

the

ri&ht

and

l

dl

parta

of

the

MC

cam

and

the

riJht

and

left parts of

the

.MC knitt:irlt

chonae

cam

should

rerum

under

..,r~,.

preilllre

after beiiiJ

pressed.

The

change

pla

te

thould opentt

ea1

Uy.

19.

Mounting the

tuck

cam

operating plate

I 9

.I

Put

the

right

part

of

the

tuck

cam

opera

ting plate·

on

the terai

on

dial shaft

and pbce

on

it

the

left pert

of

the

tuck

cam

operating

plate

and

the

collar. ·

19.2 H

ook

the righ

t and le

ft

ends

of

the

tuck cam operating plate

spring

to

the

tuc

k cam calking pin.

20. Mounting the

sll

tch cam guide plate spring

Mount

the

stit

ch cam gui

de

plate spring.

21.

Mounllng the needle selec

tor

spring

21.1 Put

the

needle selector spring, hook Its right

and

lef

t parts

to

the

~edle

selector cam calking pins.

'

-14-

>

,.

..

.

·>

22. Mounting the upp

er

J!ide plate

22.1

l\lountthe upper

slide

pla

te, inserting the connecting plate pin

into the hole at the back and inserting the

needle

selector

spring in the

suicle

groove

on the plate.

22.2 Fix

the

upper sllde plate to the chan

ge

knob

s.h.aft

on the right

of

the upper slide plate with

two

snap r

ings

and left side with

oot

uup

ring.

23. Mounting the row counter tripper

23.1 Put a

sttp

toUar on the left screw

ofup

pcu

lid

e plate, place a

oo

Uar

on the right SCJew hall. Then

put

the row counter

tripper

on

them,

and

cl

amp with

nut

on

the

le

ft

side and screw

on

!he

r.igh l side

.

Name

of

P

uts

@ Upper slide plate

@

Row

counter trippct

®

~

eb'a.e'

, .

@

·'~

am'tltit

ton

uRl'i · .....

@

•2

· Rauins

cam

dumB"

sprlll&

f ig.

7

2

4.

Mountina the hondle

ba

..

24.1 Clamp the rilbt and left

puts

of

the handle base w

ith

fo

ur .

clamp

screws.

24

.2

Clamp the

riS)lt

and left

puts

of

the handle lock tprina with,.

screws.

25.

M

<>un

tins the

cam

button unit ,

2S.J Moun! the cam button unit on the tension d

ial

shaft a

nd

clamp

with

screws

a~right

and left.

2S.2 Hook

th

e raising

cam

change spring to

the

raisins cam calking

pin.

Note:

lbe

CIJil

abollld

be

awitdled

acClate

ly when the

npr

or

left

of

the

TUCK,

the

rilht

or left

of

the

PART

or

MC buttoa

i.a

p-.1

.

I

-I

S-

I

.\

@- 1

26.

Mounting tile atltch dial

26.1 Fit the stitch

dtal

on

the shaft and clamp with a screw

In

such

a maMer that the notch

in

the stitch

dial

presser cap

comes

in

front. ·

26.2

Brin

g

tho

mark of the stitch dial

presser

cap

to the notch in

the

knob

retainer and put the c

ap

In position.

Notc

:Tbe

nwk

Jl>ou.ld come

filht

abole

the

oumbes>

011

the

stitch

dill

I

I

Fig. 8

27. Mounting the

carriage

cove

r

Name

of

parts

8 Stitch

dial

; stitch dial

pr-rcap

@ ·1

HoldJng

cam

lever

@ ·2

PWn

lever knob

@ ·3

Chanp

knob

@

-4

Carriage

c

~r

8

Handle

'

27.1 Put the holcllns

cam

l

ever

spri

ng

on the

holdJng

cam

lever

shaft

and

mount the hol

dJng

cam

lever

.

27.2

Put

the p

lain

lever

knob on the cam button unit.

27.3

Put

the clunse knob on the knob shaft.

(Be

caref\JI

of Its potltion.)

27.4 Mount

tho

carrla

se

cover

and clamp with a

screw from

the

back

of

the ca

niase

.

28. Mountin

g the lundle

Clamp

the

han

dle pin

wtdle

keeping

the

handle

horizontal.

-16-

·.

CHECKING THE CARRIAGE FUNCTIONS -1-

--

-

1.

Change

knob

function

1.1

Wh

en

the

change knob is switch

ed

to each position,

it

should move smoothly; the ri

ght

or

left

part

of

the

connecting plate and the needle selecti

on

switching cam should work

without

fail.

2.

MC

cam operating

2.1 When

the

end

of

the right

or

left part

of

the

MC

cam is pressed fully down and then

quietly

lifted with

your

finger while keeping the MC

button depressed all the time,

the

right

and

left

parts

of

the MC cam should

return

to

thelt original po$ition under spring

prenure

.

. -

. _

..

.

...

--

..

.

·--

--·

-

..

3.

MC

knittin

g change cam

operation

3.1

The

right and left pa

rts

of

the MC cam shou.ld sh

ift

withou

t fail while

the

MC

button

is kept

depressed.

·-·-

4.

Raising cam operation 4.1

When

the

end

of

the right

or

left

part

of

the

railing cam ·is

lifted

fully

with

the

stit

ch dial

at

the

0,

5,

or

10

position

and

quietly

lowered

with

your

fin

ger

,

the

right

or

left

part

of

the

raising

cam

should

return

to

its original position witho11t fail under spring presrure.

5.

Needle

selection cam o

perat

ion

0

5.1

When

the

needle selection c

am

is

set

at

.. KC" ,

and

when the end

of

the

rlght or l

eft

part

of

the needle selection cam is fu lly

lifted

and

then

quietly lowered

wilh

your finger,

the

cam

$hou

ld

return

to

its

original position

without

fail under spring pressure.

-··-

..

·-

,

- - ·

6.

Tuck

cam

operation

6

.1

When the right

or

left part

of

the c

am

button

is depressed, and when

the

end

of the right

or

left

part

of

the

cam is fully lifted and

then

quietly lowered with

your

fillger, the right

or

left

part

of

the tuck

cam should

return

to

its original position witho

ut

fail under spring pres$Ute.

6.

2 When the cam

button

is

set

at plain, and when

the

end

of

the right

or

left part

of

the tuc

k cam

·-f-·

should return

to its original posi

tion

without fall und

er spring pres:sure.

7.

Ca.

m butto

n unit fu n

ction

7.1 When the cam button

is

shifted

to

"TUCK right and left," "MC"

, or " PA

RT

ri&ht

and

left,"

the

button shoul

d move smoothly

and

the

tuck

cam,

the MC

cam

and

the raising cam should

shift

their

places

without

fall.

8. Holding cam

lover func.tion

8.1

When

the

holding cam lever is shift ed to "H"

or

"N",

it

should move

smoothly

and

the

holding

cam should make accu

rate

ojleration wi

thout

fail.

9. Plain

knitting

lever f

unction

9

.1

When the plain knitting

lever

is

thrown rightward while pressing '"TUCK r

l&ht

and left

,"

..

MC'"

or

"PART

right

and

left" buttons, the l

e"'r

should move

smoothly and

the

earn

button

should

return

to

its original position

withou

t fail.

-17-

CHECKING THE CARRIAGE FUNCTIONS

-2-

Make

su~

that the needle

butt

pwes

smoothly

througlt the following:

(1) Between the sub raising cam and the separating cam.

(2) Between the tuck cam plate and guide

cam C.

(3)

Between guide cam C

and

slide cam.

(4)

Between the sub raising cam and guide cam

B.

(

S)

Between

guide

cams A and

D.

(6) Between guide cam D and the needle selecting cam.

(7)

Between guide cams A and B.

(8)

Between guide cam F and the separating cam.

-18-

Fig, 9

The fabric floats (stitcb

OOAt)

.

HOW

TO ADJUST THE

CA~RIAGE

. ..

Cause

I. The sinker plate is

in

touch with comb teeth.

There is too much gap between

the

sinker plate and

the

comb teeth..

120.5m/m

Fig. 10

2. The sinker plate

Jceeps

the

kn

itting needles

up

.

There

is

too mucll

gap

between the sinker plate and the needle.

Fig. 11

'

Adjustment

P

01i1icoi

adjumnent

of

the

link~

plate .

I. For KH- 830, it is not necessary to adjust the .

I_)C)Citi

on

of

sill;~~

..

·'

plate because there are two

bosses

on the

~dag6

· p(a.- .t9 get ·

pro~

position.

(The

sinker

plate

s~

oppers'

ar&"dlscon

tl

nued

for

this model.)

"'

2. Mounting dlmenlliom

of

sinker plate

The

linker plate should.be I i8.S

m/

m apart

from

the ca.

rrl

age

rear

le

g.

~

·

,.

: . ·

If

it

is

not

correct, loose screws

and

adjust.

..

..

.

'

M

oulinJ

dlmemioos

ol

yarn

feeder

I.

The yam

fee

der should be 120.Sm/m apart from the carriage rear

leg. ·

Vertical

adjuat..at of the liaker

plalle

I. Fit

the

caniage

on

the

needle bed and set

the

holding cam l

ove

r at

"~

.

2. Brlns about

fwe

knittins

needles each

to

position Eat

the

left end,

center and

right

end

of

the needle bed.

3.

Bend

the sinker plate to adjust the

gap

between the knitting needle

s

tem

and the sinker plate

to

O.Sm/m

or

less

.

-19

-

2. A lateral stripe

is

produced

every

second

row

Cause

I.

The

righ't

.and left parts

of

the stit

ch

cam

are positioned differently.

Reuleg

3. The caniaae

refuses

to

JO

midw.y

The latch

of

the knitting needle is bent

I.

Gui

de

cam A is

in

wrong position.

(Refer to

above

Fig.

I

2)

adj

usteJ

Fig.

12

Adjustment

··

···-··

·-···

·-----------1

• The stripe adjusting plate l$ connected with the stitch cam,

and

the

stitch

cam

guide plate

is

connected with the

right

and

le

ft stitch

caDI$.

I.

Loosen

the stripe adjusting plate clamp

screw. Use

slide

calipers to

adjust

the

stripe adjusting plate so that

the

length (at a and a')

of

the right and

lef

t parts

of

the stitch

cam

will

become

even.

Then

tighten

the

stripe adjusting plate c

lamp

screw.

Note:

The length difference at the stitch

cam

(bet"'"n

a

and

a')

should not

exceed

0.35

mm.

Hint:

When the stitch dial is set at 5, the length at

the

stitch

cam

:

32.5

mm

.

2. After the adjustment, be awe to check

it

by

knitting plain stitch

using a medium

yam

and

with

the

stitch dial set at

s.

Mounting

dlmensions

of

pjde

cam

A.

I. loosen the right and left

guide

cam A

clamp

screws

and the plate

clamp nut.

Clamp

again

after adjusting the

distance

between

guide

cam

A and the car

riage

rear

leg

to

56.Smrn.

(Fig. I 2)

Note

I: If

guide

cam

A

Is

not

more

than S6.

Srnm

apart from the

rear

leg

,

the

gap

between guide cams A and B will be too

narrow

for

the knitting

needle

.

Note 2: If t

he

distance between guide

cam

A and

the

rear leg

far

exce

eds

S6.Smm,

the

yam

guide

might

darnaae

the

latch.

-20-

..

~

DI

SASS

EMBL

ING THE BED

®Puts

box

®-I

l

(j)- -

-----tl1!!l

~R'

(j)-

I

<!:-

2

Pane

l

'

~-

·

' '

F

ig.

13

Name

of parts

(!).J

Card

stop

lev

er knob

CD

-2

Needle

sele

ctor panel

clamp screw

(D-4 Direction Indicator

®-I

Parts

box

clamp screw

®-I

Case

reinforcing plate

clamp screw

@--

2 Needle bed clamp

screw A

@-3 Needle bed clamp

screw

B

(_3)-4

Fastening scr

ew

I. Removing the needle selector panel 3. Taking out the needle bed

1.1 l.lft and pull

off

the card stop lever knob.

1.2

Remove

the three needle selector panel clamp screw.

13

Slide the panel to the right, lift and

talce

It

of

f.

1

.4

l.lft and pull off the direction indicator (plastics) .

2: Removing the

putt

box

2.1

Remove

the lld

of

the parts-box and take out

the

accessories.

Remove

one

parts box clamp screw.

· 2.2 Slide the part.-box to the.rigbt; lift and take

it

ofl

-21-

3

.I

Remove

the two

case

reinforcing plate A clamp

SCTews

and one

case

reinforcing plate B clamp screw.

3.2

Remove

the four right and left needle bed clamp screws (A).

3.3

Remove

the two needle bed clamp screws (B) and the right

and left parts

of

the

lea

f spring.

3.4

Remove

the four right and left fastening screws working from

the back

of

the bed and the right and left parts

of

the mount

will

become

free.

3.5 Take the bed out

of

its

case

.

@-I

@- 2

4. Removing tha belt

AI

Bl

oj

El

0 O

O!

•

<=

0 0

Fig.

14

4

.1

Rem()Ve

the pulley spring clamp screw and pull

off

the pulley

spring.

4.2

.l.oo5eo

the right and left pulley bearing clamp screws.

4.3

Rem()ve

the belt connecting pin and pull

off

the belt.

4.4 Take care

ll()t

to lose the rubber

washer

on

the pulley shaft.

-

22-

Name

of

plllts

@)·1 Pulley leaf spring;

pulley leaf spring

clamp screw

<D

-2 Pulley bearing clamp

Me-asure

the

distance

between

the

needle

selector

plate

holder and the needle b<d

lower plate

with

~

caliper~

(Points

of

measwement:

right

and

left

onds

and

the

oentu.)

Fig. 15

screw

Meuurement

of

the distance between

the

needle

aele<:tor

plate

holder

and

the

~le

bed lower plate.

Measwe

the

above

distance with slide calipers and

jot

down

the result.

When

reassembling this section, see

to

it

that the

same distance will be reproduced.

..

·.

·

~--:

.

·

..

£

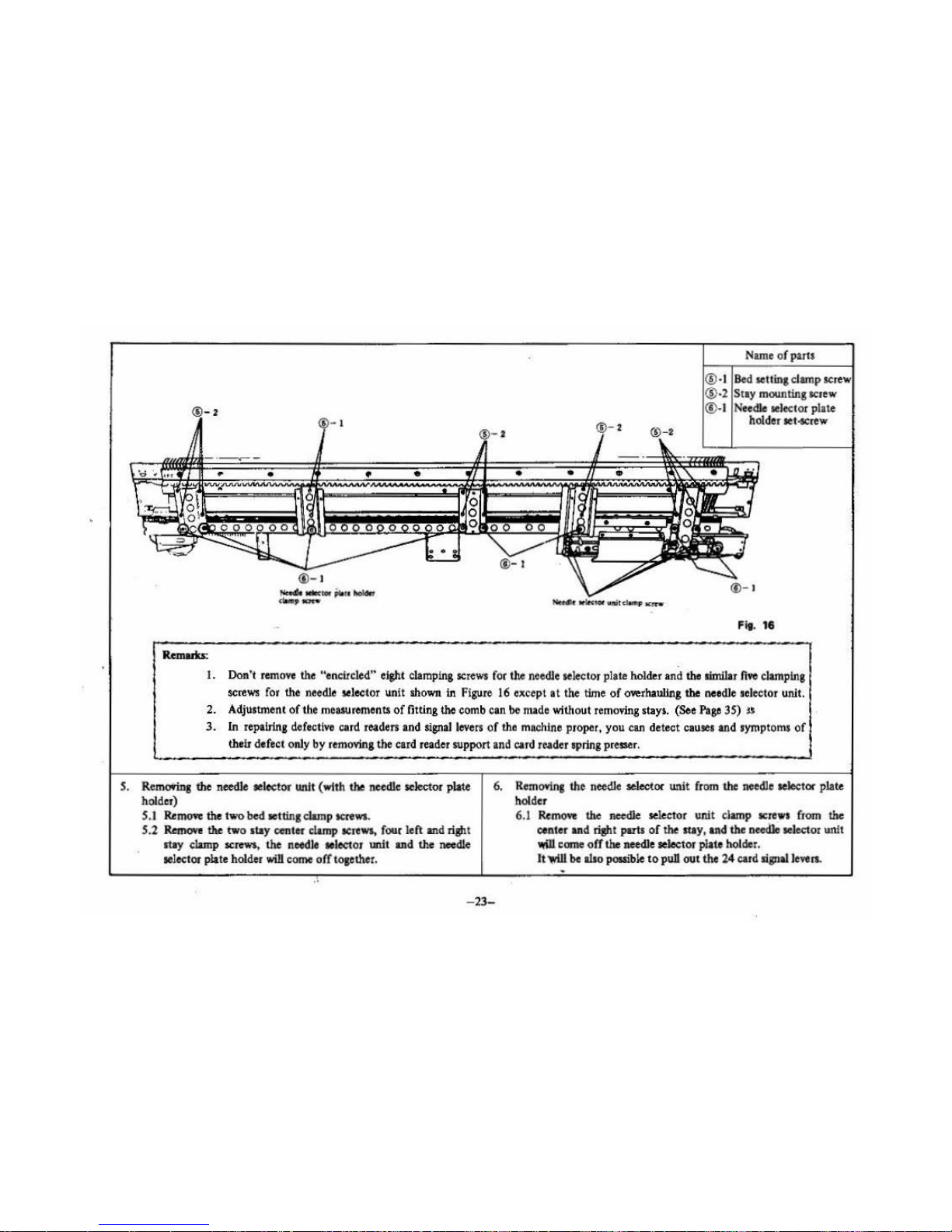

Remuka:

Nam

.e of parts

®

·I

Bed

setting clamp

screw

®

·2

Sr

ay

mounting

scr

ew

®·

I

Needle

sele<:lor

plate

holder

tel-screw

Fit. 11

I.

Don

't

remove

the

"encircled" eight

clamping

screws

for

the

needle

selector plate holder

and

the limllar fl.e

clamping

screws

for

the

needle

selector unit shown in

Figure

16

except

at

the

time

of

overhauling

the

needle selector unit.

2. Adjustment

of

the

meuuremenu

of

fitting the

com

b can be

made

without

removing

stays. (See

Page

35) n

3.

In

repairing defective card readers

and

signal

levers

of

the

machine proper, you

can

detect

causes

and symptoms

of

their defect only by

removing

the

card reader support and

card

reader spring presser.

S.

Remotms the needle selector unit (with the needle selector plate

holder)

S.l

Remo.e the two bed tetting clamp screws.

S.2

Remove

the two stay center

clamp

screws,

four left and right

st1y

clamp

screws

,

the

needle aelector unit and

the

needle

~elector

plate holder

will

come

off

together.

6.

Remcmng

the

needle

lle!ector

unit

from

the

needle selector plate

holder

6.1

Remove

the needle

~elector

uni

t c

lamp

ttrewt from the

center

and riJbt

puts

of

the

my

,

and

the

neeclle

~elector

unit

..W

come

off

the

needle

~elec

tor

plate holder.

It~

be

also

possible

to

puB

out

the

24

card

signalle.e n.

-23-

DISASSEMBLING THE NEEDLE SELECTOR PLATE HOLDER

---

·--

··---·-·--

···-

······---·--------,-

-------!

Signal

lev

er

haoldet

Fig.

17

'#>

UPPER

IDWER

U,

/

Needle seloctor

plate No. 7

..

s

" I

L,

U,

L.

u.

L.

1.1 Remove

two

screws securing the signal lever holder, and

remove the

signal

lever holder,

1.2 Remove eight needle selector plate springs. (Before removing

the

springs, take

note

of

their positions.)

L3

Remove tho E-shaped snap ring (2.5) from

the

needle selector

3

8

6

4

2

Name

of

parts

1----

7

-I

Signal lever holder

clamp

&erew

7

-2

Needle selector plate

7

-3

E-shaped snap ring

(2.5)

Needle selector plate holder

Fi

g.

18

plate shaft (square}

on

the

rear

of

the

needle selector plate

holder, and

remove

the

shaft. ' ·

1.4

WhUe

sliding the eight needle selector places one

by

one

to

the

right, remove them through

slots

in

the needle selector plate

shafts

A~

shafts).

-24-.

l

f.

tay,

right

@-6

Card reader

re&t

ase

cam

®-

6

Snap

rl~~g

9

Cud reed

ing lever

Cudpidepm

@-3

®-

a

holclet Can! f

codln&

k

nob

Intermittent

feeding lever

(i)-

.

Clutch spring

®

-•

Beh

guide

@

-II

Ca

rd

guide

@- 6 ® - 6

Bevel gear

stop

per

pla

te

Card

feeding cam

-25

-

Name

of

parLS

®-I

Need

le selector un

it

clamp screw

®-2

Card

rea

der spting

presser

pta te c

lamp

scr

ew

1

®·3 Spring plate clamp

screw

: @-3 Spring plate

t®4

.Be

lt gui

de

1

®-5

Clutch spring

®

-6

Clutch cam assembly

®

-7

Car

d feeding roller

assembly

<_

8).8

Card

feeding knob

I

nt

ermittent feeding

le

ver

® ·9 Card feeding lever

@-

1 0 Card reader

re

lease

sp

ring

®-

II Card guide clamp

screw

DISASSEMBLING THE NEEDLE SELECTOR UNIT

8.1

RJ.moYe

five

screws

securing the

needle

selector units on the

center

suy

and

right stay,

and

rem

oYe

both st

ays

.

•

When

installing

the

center

lily

and righ

t stay, they must

be

placed correctly in the oriainal

posiliOil$.

Therefore,

it

is

advisable

to

marie

their poli

tl011

1 on both stays with a llotted·

head screwdriver.

8.2

RJ.move

three

screws securing the card reader

apriDJ

presser plate,

and

the card

re.tdor spring preuer plate

a11d

card reader spring can

be removed.

8.3

Remove

two

screws

securing

tho

'Card

reader hold

er

plate,

and

pull

it

out toward you. (Tho card

guide

pin holder .

made

of

plastic· can

also

be

removed

at the

same

time.)

Also

24 card

readm

can

be pulled out.

8.4

Remove

two

screws

(tosether with

washers

) on the belt

guide

plate (right), and pull out the

belt

guide plate to the rigltt.

8

.S

RJ.move

the clutch spring.

8.6

Remove

the

map ring located under the clutch

shift fitt

ed Into

the

clutch

wheel.

Now the wuher, card reader rele

ase

cam,

clutch

wheel (aet) and clutch

cam

A (shaft) c

an

be

removed

. Also

the card feed

cam

beve

l sear stopper plate in the needle selector

u

nl!_can

be

removed.

8

.7 Remove

the

card feeding

roUer.

8.8 Remove the

E-eiip

2 located under

the

card

feed knob,

and

the

card feed !mob abaft can

be

pulled out upward.

Also

the

Inter·

mitten! feeding l

eve

r,

chana<

lever

, intermittent f

eedinJ

l

ever

spring

and

card feed

kn

ob lock cam

c:ao

be

pulled

out

upward

.

8.9

RemoYe

the step

screw

from

the

card

fee

d lever,

and

the card

f

eed lever

can

be

removed.

Also

the

car

d feed adjust

in

g plate can

be

puU

ed out.

8.10

Re

move

the card reader release spring from the

side

of

card

reader re

lease

abaft.

8.11

Remo

ve two

screws

(rigltt and left) securing the card guide. The

card

feed

base

(left)

ca11

be

pulled out to the left, and the rigltt

one can

be

puUed

out to the righL

..

-2

6-

Spring plate

ASSEMBLING

THE

NEEDLE SELECTOR

UNIT

rec.~ma

kno

b stopper

cam~==~===s

~;~~~~

~~==

==~~~

~~~

(i)-5

Ca.r

d

RadtJ

rel

ease cam

@-

3

Cud

feed.i.na

knob

CD

-4

<D·

4

Cud

feedlns lever

1

lntennit~nt

feoclinJ lever

Fig. 21

(!)

Card

feed.i.na

cam

How

to

adjust

the

~tary

cam and C

lut

ch

wheel

(i) P

o*

needle

se*"

'-

nto

the

bact-:·.·

-TT-

(U

PPER

VlEWf

the

cut

pordo.n

clut

cb

wheel

with

top

of

the

roWy

cam

shaft.

,.~

··

Fig.

22

Fig.

23

Card Feed Lever Adjustment

Turn clutch cam A in either direction so that the card feedcam pushes the

card feed lever upward. Then push down the right side of the card feed

lever until the ratchet begins to move, and lock with step screw.

--··

t

1.1

Insert the card suide between the card roller and rotary cam from

the left side, and

insen

the card roller shaft and rotary

cam

into

two

holes in the c

ard

feed base. Then lock the card feed bases,

right and left, with card guide mounting screws.

• Clearance

bet

ween the card roller and card

suide

should equal

the total

tltickness

0.6

mm

of

three punch cards.

}

.2

Insert

the

card rol.ler

unit

into

the

needle selector

unit.

It

is neces·

suy

to

hook

the ratchet

onto

the

card feed

stopp

er plate on the

card feed base (rigth).

Next,

lock

the

card feed bases, right and

left,

to

the rear

of

the needle selector unit by means

of

spring plate

and clamp

screM

temporarily.

1.3

I

I •

1.4

..

1.5

Insert

the

card feed

knob

stopper

cam

into

the needle selector

unit

from underside,

then

ft

.x

the

intermi

ttent

feeding lever, change

lever and sprln&. Insert the card feeding

knob

shaf

t into

the

card

feed kOob stopp

er

cam, intermittent

feeding lever and change lever

. from

top

of

the

needle selector

uint.

Insert the card feed adjusting plate

into

the needle selector unit,

and· secure the c

ard

feed l

mr with

step

screws.

Mako ......

tha~

.

the intermittertt

fee

ding lever should go between

·

the;~

feedJng lever and

round

plate.

(Please refer to Fig.

42

on

page 40.)

Insert

the

card

feed

cam

and bevel gear stopper plate in

to

the

needle selector

unit

frorn

the

right side, and insert the

clutch

wheel

and

clutch

cam A into

the needle selector

unit

from

its

top.

{Aiipl

die

eu

t portion

of

die clutch wheel wlrh

top

or

!he

needle

3dector plate

cam,

aod

polition the needle

~elector

cam

so

that

die

cam lobes

we

on

rhe

other

side and rhe flat portion is in a horizon-

tal

po8itlon.

lbm

mall

the

bevel

JHII. Refer to

the

f'J3U"'

on

die

risJ!t

oft

p•

'l7

.) Next, pass the

clutch

cam

A between the card

feed c

am

lobes, and place

the

card reader return cam from the

bottom

side

of

the needle selector

unit,

and lock with washer and

E-shaped stopper ring 2.5.

1.6 Install the clutch spring.

1

.7

Insert the b

elt

guide plat e (right) into the needle aeclector

unit

from the right side, and lock with scre

ws

(with washera).

I

.8

Install the card reader release spring.

I .9 Install

the

center

stay

and

right

stay

in

the

poslti~

(

anabd

on

the needle selcetor

unit

with

a slotted-bead

scre.,....ll!~

1111\an

disassembled), and secure with screws (

with

washers).

...

..

. -··. . . .

.,

-28-

-·

·-

---

.

ASSEMBLING

THE

NEEDLE SELECTOR

PLATE

HOLDER

_j)

Q

Q

n n

Q ®-t

No. of

.-dle

..

leetor plato

ac=>

•

~

~(:IIQ

c::J: Q

c:::!od

~

c:::>c=

0

c=>

00

olt

Qc::)<::)

c::)<::)t:)t::IC)

c::>C)~Q

C)

c=>

~~~c::::)Qc=r~

QQc:;)t::IQ

0

c:::>

00

olt

UPPER

Noodle oolec

tet

plate No. 1

• 0 0

(:)0

C::::.

c::t

c:::tCI 0

c::t

C)

LOWER

ol3

s

ac=>

~Q~c:§=l'C)~~

o~&:...

oc;;:;,oc

0

c=>

00

u.

I

a

c=>

Q Q

c=

<:::::)

c;::)

c::::l «:::1

c:::t

t::)

<=

C)

0

0

c=>

00

ol•

L.

3

~

·

c::I<:::IOO

C)QOO

Q O

u.

ols

8

"

a(

:::::>

"b=

~c§"~

=c:§'===~

&,

0

c=>

00

L.

6

a .

c=>

CIOC)CIClQQQO

Qc:::>c:::l

0

c=>

0 0

ol6

u.

4

,

c;:)c::t•c::;)QC::.OC)O

CIOt::l

L.

oc=>

coo

•

ooc(J

c::;:,ooc:3'

0

~00

olr

2

c::Jt:)C)c::)c;::)Q

QQC':)

0

_Jl

Q

ll n !l

!l

%Ja

oc=>

Ql:::'""===;=d"~~~~

=<=i.

0

<::::=>

00

•

Si.

· .

Sipl&l le'rer

OJ->:&tion

bolo

Fig. 24

.,

®·

t

Shaf

t B

'

®-·

I Noedle select

or

plate

lhaft A

Needk

oele

ctor plate bolder

truer! needle

!doctor

plato Into

thil

silts

Fig.

25

2.1

Install the needle selector plates on the needle selector plate

holder

in the order

of

7, S, I, 3, 8, 6, 4

and

2.

Align

the

needle selector plates

with the

sU

is of needle selector plate

shafts A (6 pieces), then insert the needle

se

lector plate shafts

B and secure with E«<aped

map

ring .

. -

( .

2.3 H

oole

eight needle selector plate

sprinp

on

sprina hoolcs as

illustnte!labove

Fig

. 26.

Sprlnas

should be hoo

ked

on

to the lower part

of

needle se·

lect

or

plates, S, 3, 6 and 2 and on

to

the

upper of

~die ~elcc-

. .

tor

plate., 7, 1, 8 and

4.

In otber

word&,

!lprinp

ue

posi·

tioned up and down alternately.

~--------~--------------~-----------

---'~

--

---~-----------------------------------------------r~

-29-

3.1

3.2

3.3

3.4

3.5

ASSEMBLING THE NEEDLE .SELECTOR

UNIT

IN THE NEEOLE PLATE HOLDER

®·I

Fig.

28

(~

- I

®-2

®·3

;@·S

!®

-6

I

Name

of

parts

Needle

sel~tor

unit

clainp~

S.lgnal

- holder