Inkjet MFC

SERVICE MANUAL

MODEL: MFC5890CN

MFC5895CW

August 2010

SM-FAX097

8CAH17(4)

Read this manual thoroughly before maintenance work.

Keep this manual in a convenient place for quick and easy reference at all times.

Confidential

© Copyright Brother 2010

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

Trademarks

The Brother logo is a registered trademark of Brother Industries, Ltd.

Brother is a registered trademark of Brother Industries, Ltd.

Multi-Function Link is a registered trademark of Brother International Corporation.

Windows Vista is ei ther a re gistered trademark or a trade mar k of M ic ros oft Co rp orati on i n t he Un ite d

States and other countries. Microso ft, Windows and Windows Server are reg istered trademarks of

Microsoft Corporation in the United States and/or other countries.

Macintosh and TrueType are registered trademarks of Apple Inc.

Nuance, the Nuance logo, PaperPort and ScanSoft are trademarks or registered trademarks of

Nuance Communications, Inc. or its affiliates in the United States and/or other countries.

Presto! PageManager is a registered trademark of NewSoft Technology Corporation.

Microdrive is a trademark of International Business Machines Corporation.

CompactFlash is a registered trademark of SanDisk Corporation.

Memory Stick is a registered trademark of Sony Corporation.

SanDisk is a licensee of the SD and miniSD trademarks.

xD-Picture Card is a trademark of Fujifilm Co. Ltd., Toshiba Corporation and Olympus Optical Co. Ltd.

PictBridge is a trademark.

Memory Stick Pro, Memory Stick Pro Duo, Memory Stick Duo and MagicGate are trademarks of Sony

Corporation.

BROADCOM, SecureEasySetup and the SecureEasySetup logo are trademarks or registered

trademarks of Broadcom Corporation in the United States and/or other countries.

AOSS is a trademark of Buffalo Inc.

Wi-Fi, WPA and WP A 2 are r e gis ter ed trade mar k s and Wi -Fi P ro tec ted Se tup i s a tr ad ema rk of Wi-Fi

Alliance.

FaceFilter Studio is a trademark of Reallusion, Inc.

Each company who se softw are title is mentione d in thi s manual has a S oftware Lic ense Agreeme nt

specific to its proprietary programs.

All other brand and product names mentioned in this manual are trademarks or registered

trademarks of their respective companies.

Confidential

Preface

This Service Manual is intended for use by service personnel and details the specifications,

construction, theory of operation, and maintenance for the Brother machines noted on the front

cover. It includes information required for troubleshooting and service--disassembly,

reassembly, and lubrication--so that service personnel will be able to understand equipment

function, repair the equipment in a timely manner and order spare parts as necessary.

To perform appropriate maintenance so that the machine is always in the best possible

condition for the customer, service personnel must adequately understand and apply this

manual.

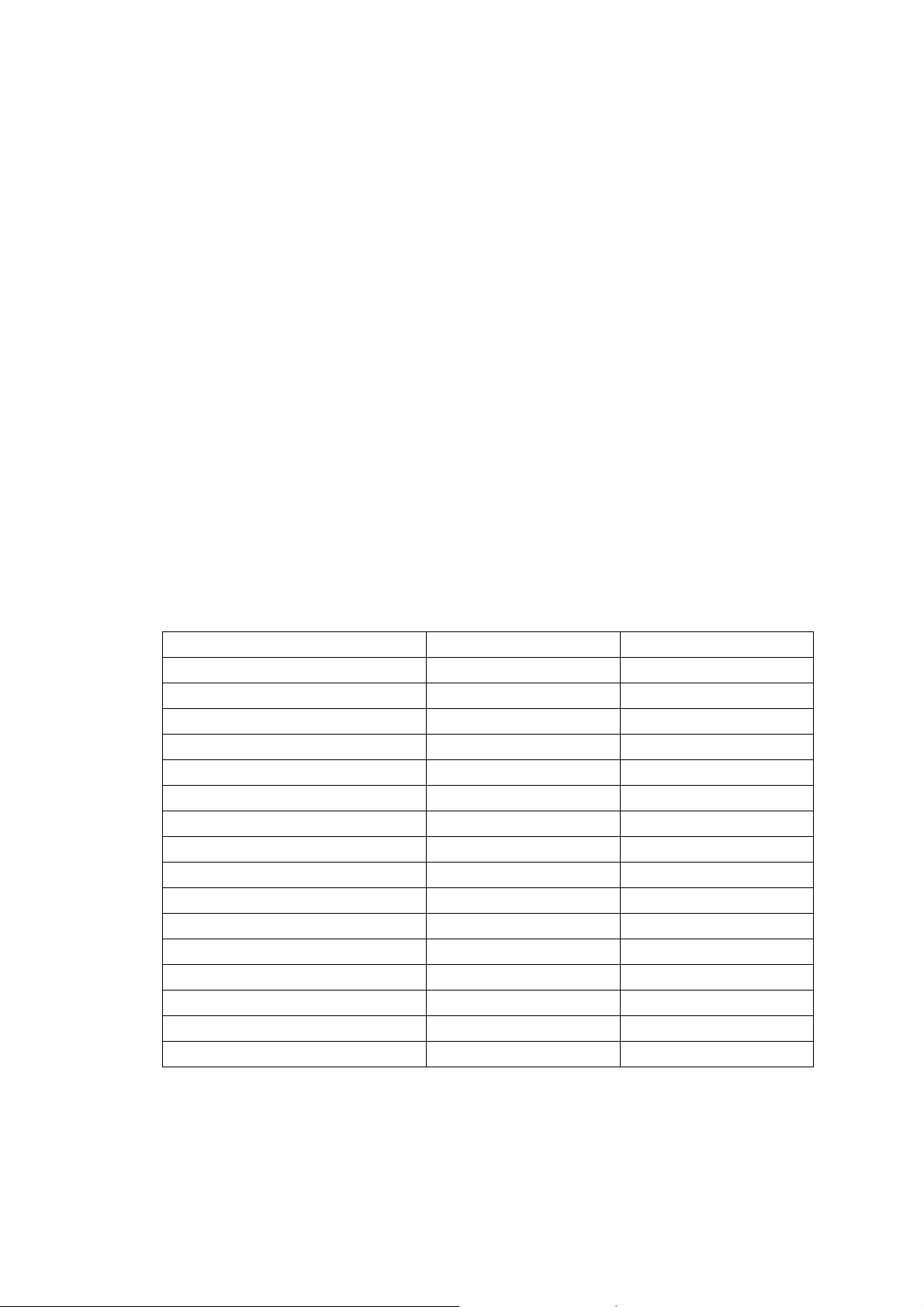

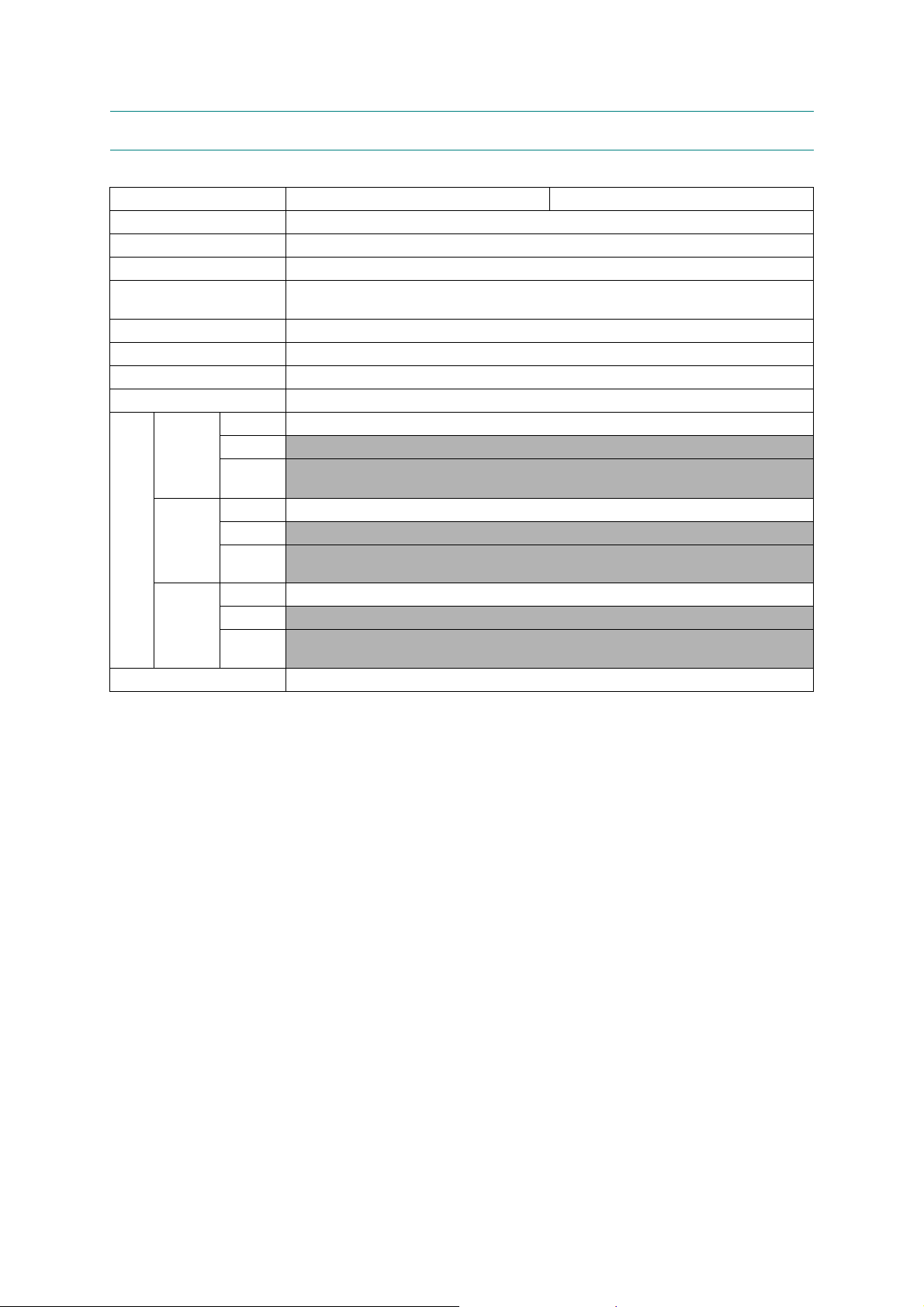

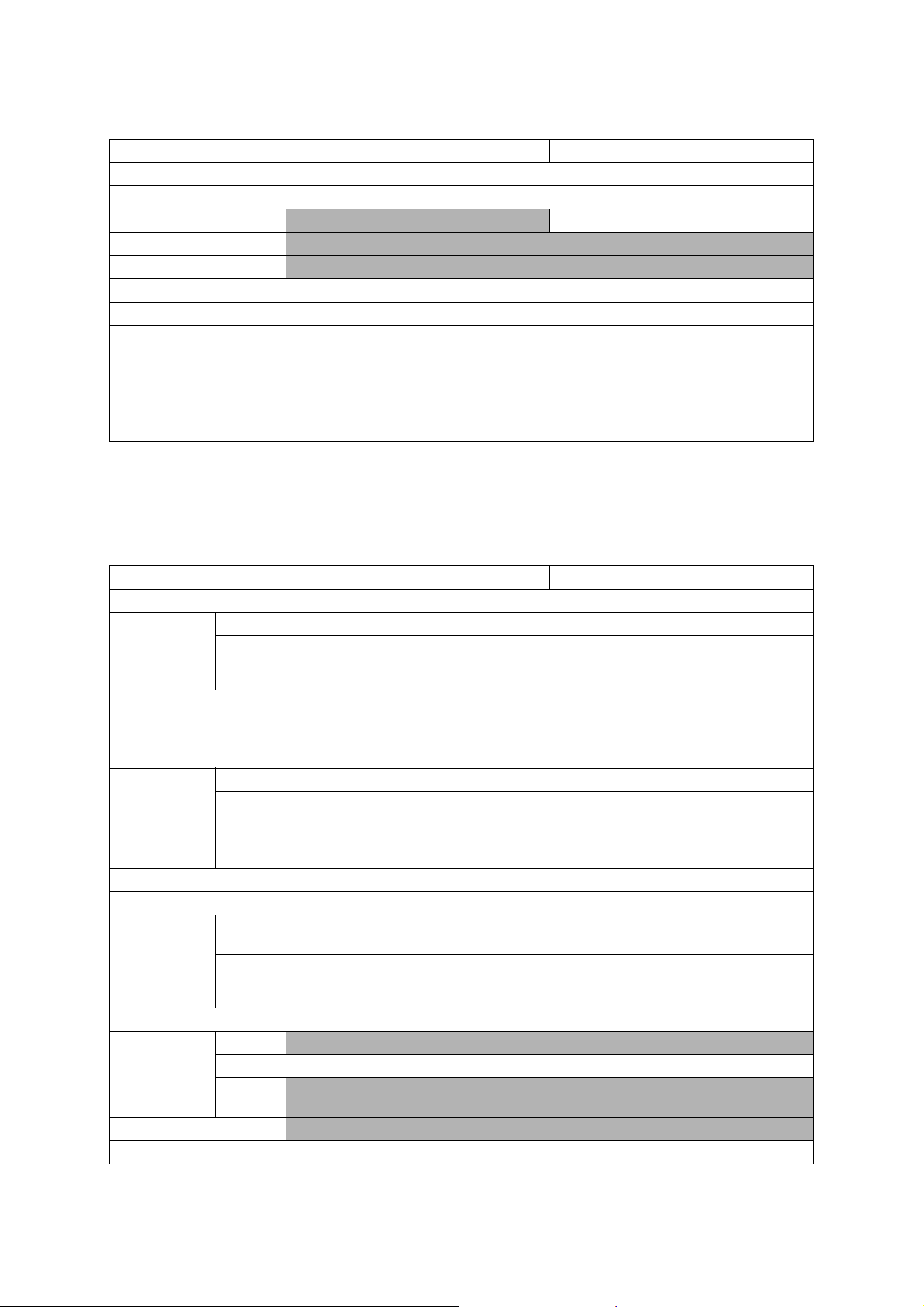

The table below shows the functional comparison between the models covered by this manual.

Model MFC5890CN MFC5895CW

RAM 64 MB 64 MB

LCD (with backlight) 3.3-inch wide color 3.3-inch wide c olor

T o uc h pa nel --- --Wired LAN √√

Wireless LAN (WLAN PCB) --- √

PhotoCapture Center √√

PictBridge/USB flash memory drive √√

Movable platen --- --Slide tray --- --ADF √√

High-yield ink car tr i dg e sensor --- --Ink cartridge detection sensors √√

Ink empty sensors √√

Handset (Hook switch PCB) --- --Duplex printing --- --Backup battery √√

This manual describes the models and their versions destined for major countries. The specifications and

functions are subject to change depending upon each dest ination.

i

Confidential

How this manual is organized

This manual is made up of nine chapters and appendices.

CHAPTER 1 PARTS NAMES AND FUNCTIONS

Contains external views and names of components and describes their functions. Information

about the keys on the control panel is included to help you check operation or make

adjustments.

CHAPTER 2 SPECIFICATIONS

Lists the specifications of each model, which enables you to make a comparison of different

models.

CHAPTER 3 THEORY OF OPERATION

Gives an overview of the scanning and printing mechanisms as well as the sensors, actuators,

and control electronics. It aids in understanding the basic principles of operation as well as

locating defects for troubleshooting.

CHAPTER 4 ERROR INDICATION AND TROUBLESHOOTING

Details error messages and codes that the incorporated self-diagnostic functions display if any

error or malfunction occurs. If any error message appears, refer to this chapter to find which

components should be checked or replaced.

The latter half of this chapter provides sample prob lems that could occ ur in the main sections of

the machine and related troubleshooting procedures. This will help service personnel pinpoint

and repair defective components.

CHAPTER 5 HANDLING DATA HELD IN THE MACHINE PRIOR TO

REPAIR

Describes how to handle data held in the machine to be repaired.

At the user s ite, if the m achine ca nnot print FAX data receiv ed and left in the mach ine due to

the printing mechanism defective, the service personnel should instruct the end user to follow

the transfer procedure given in this chapter to transfer the FAX data to another machine before

sending the machine for repair.

At the service site, the service personnel should back up the machine information and user

setting infor mation held in the machin e into an external memor y for restoration after r epair,

using the backup procedure given in this chapter.

CHAPTER 6 DISASSEMBLY/REASSEMBLY AND LUBRICATION

Details procedures for disassembling and rea sse mbli ng t he mac h ine tog et her with related notes.

The disassembly order flow provided enables you to see at a glance the quickest way to get to

component(s) involved.

At the start of a disassembly job, you check th e dis assembly order flow that guides you throu gh

a shortcut to the target components.

This chapter also covers screw tightening torques and lubrication points to which the specified

lubricants should be applied during reassembly jobs.

ii

Confidential

CHAPTER 7 ADJUSTMENTS AND UPDATING OF SETTINGS,

REQUIRED AFTER PARTS REPLACEMENT

Details adjustments and updating of settings, which are required if the head/carriage unit, main

PCB and some other parts have been replaced.

CHAPTER 8 CLEANING

Provides cleaning procedures not covered by the User's Guide. Before starting any repair work,

clean the machine as it may solve the problem concerned.

CHAPTER 9 MAINTENANCE MODE

Describes the maintenance mode which is exclusively designed for the purpose of checks,

settings and adjustments of the machine using the keys on the control panel.

In the maintenance mode, you can update memory (EEPROM: electrically erasable

programmable read-only memory) contents for optimizing the drive conditions of the head/

carriage unit or the paper feed roller and paper ejection roller in the engine unit, if those units

have been replaced, or for setting the CIS scanner area, for example. You can also customize

the EEPROM according to the shipment destination of the machine concerned. In addition, you

can perform operational checks of the LCD, control panel PCB or sensors, perform a print test,

display the log information or error codes, and modify firmware switches (WSW).

Appendix 1 Reading Labels

Shows the location of labels put on some parts and describes the coding information for serial

number and head property data.

Appendix 2 Firmware Installation

Provides instructions on how to change firmware stored in the flash ROM on the main PCB or

load firmware to a new main PCB from the host PC.

Appendix 3 EEPROM Customizing Codes

Provides instructions on how to set up the EEPROM customizing codes for the various

preferences exclusively designed for each destination. The specified customizing code is stored

in the EEPROM mounted on the main PCB. If the main PCB is replaced, t her efore, you need to

set up the proper customizing code with the machine in the maintenance mode.

Customizing codes customize firmware for individual models, enabling the common firmware

to be used for various models. A list of EEPROM customizing codes comes with the firmware

data provided by Brother Industries.

Appendix 4 Firmware Switches (WSW)

Describes the functions of the firmware switches, which can be divided into two groups: one is

for customizing preferences designed for the shipping destination (as described in Appendix 3)

and the other is for modifying preferences that match the machine to the environmental

conditions. Use the latter group if the machine malfunctions due to mismatching.

Appendix 5 Wiring Diagrams

Provides the wiring diagrams that help you understand the connections between PCBs.

iii

Confidential

Appendix 6 Circuit Diagrams

Provides the circuit diagrams of the MJ PCB and power supply PCB.

Appendix 7 Deletion of User Setting Information

Provides instructions on how to delete user setting information recorded in the machine.

iv

Confidential

SAFETY INFORMATION

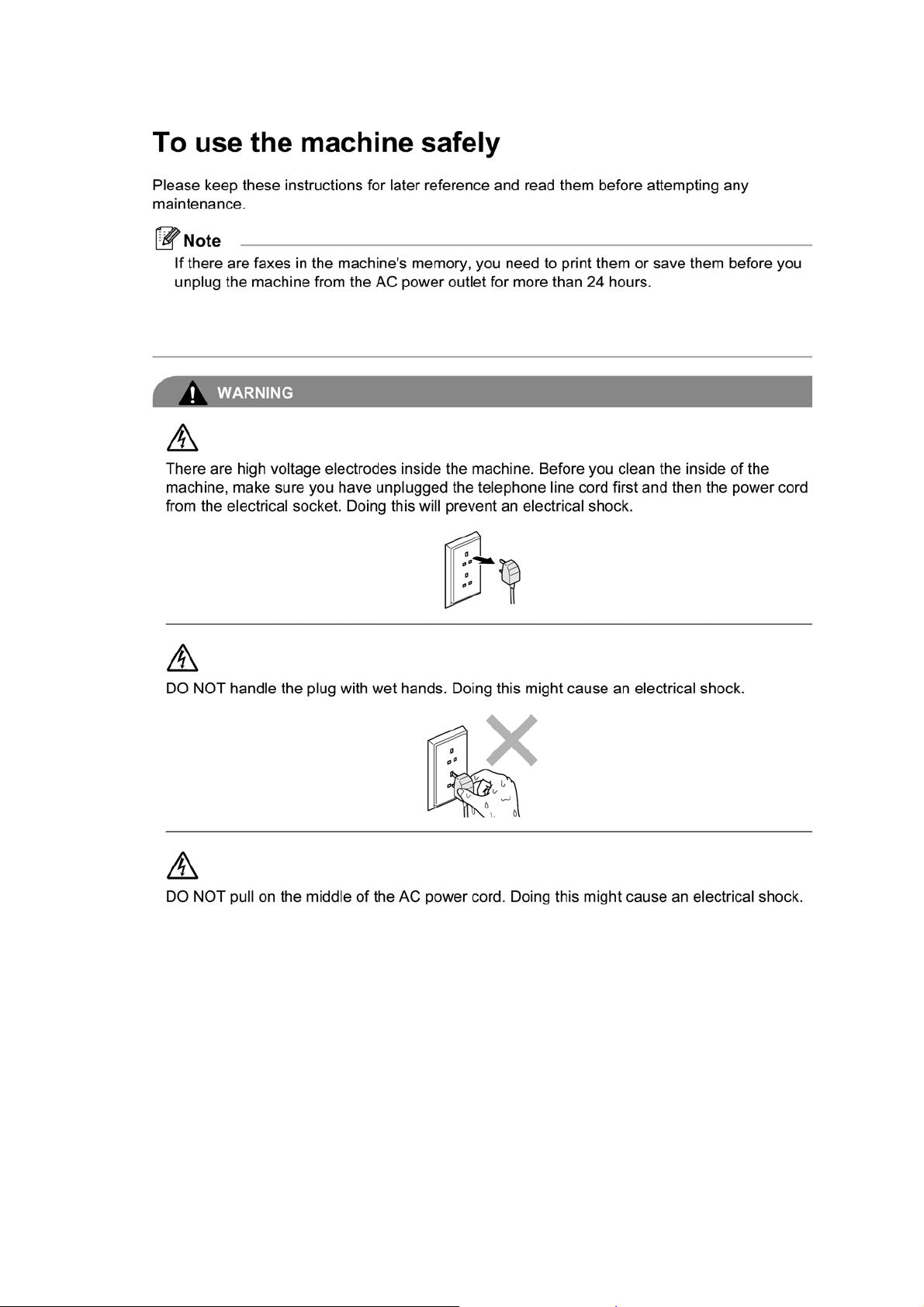

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injuries.

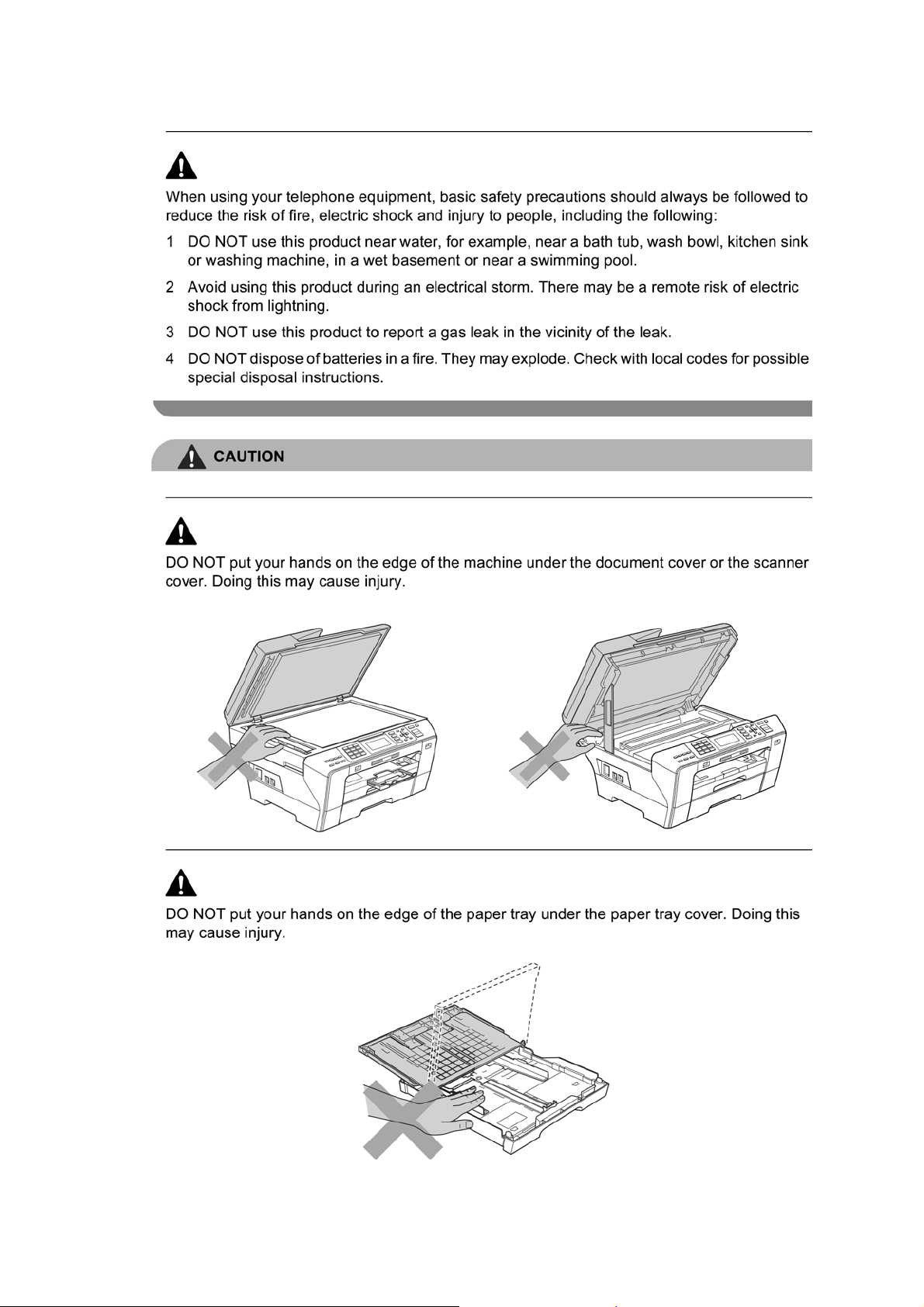

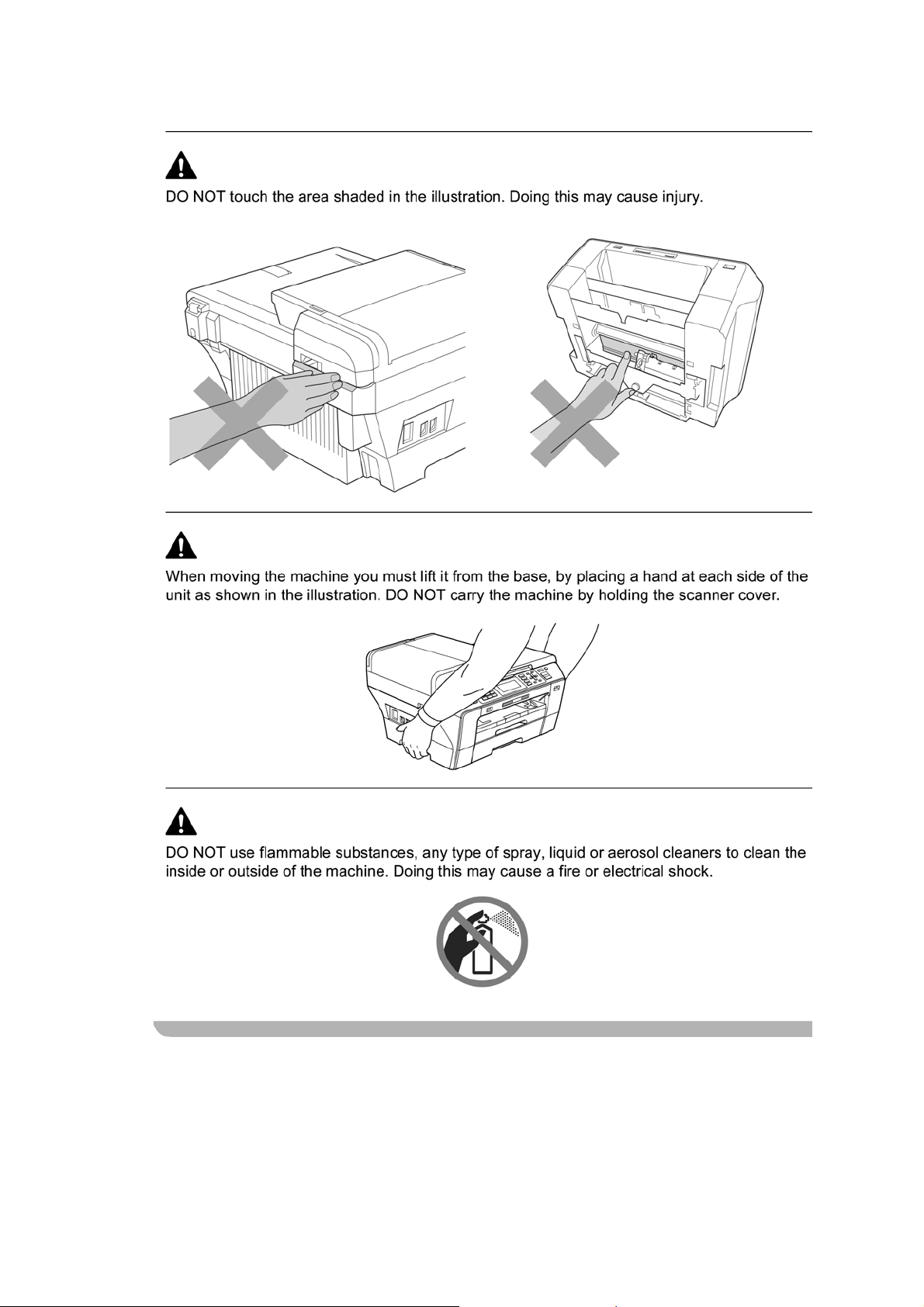

CAUTION

CAUTION

or moderate injuries.

indicates a potentially hazardous situation which, if not avoided, may result in minor

IMPORTANT

IMPORTANT

damage to property or loss of product functionality.

Follow all warnings and instructions marked on the machine.

indicate a potentially hazardous situation which, if not avoided, may result in

Notes tell you how you should respond to a situation that may arise or give tips about

how the operation works with other features.

Electrical Hazard icons alert you to possible electrical shock.

v

Confidential

vi

Confidential

vii

Confidential

viii

Confidential

ix

Confidential

x

Confidential

xi

Confidential

xii

Confidential

xiii

Confidential

CHAPTER 1

PARTS NAMES AND FUNCTIONS

Confidential

CHAPTER 1 PARTS NAMES AND FUNCTIONS

This chapter contains external views and names of components and describes their functions.

Information about the keys on the control panel is included to help you check operation or make

adjustments.

CONTENTS

1.1 OUTLINE................................................................................................................1-1

1.2 CONTROL PANEL ....... ...... ....... ...... ....... ...... ....... ...... ...... ....... ...... ....... ...................1-3

1.3 COMPONENTS......................................................................................................1-6

Confidential

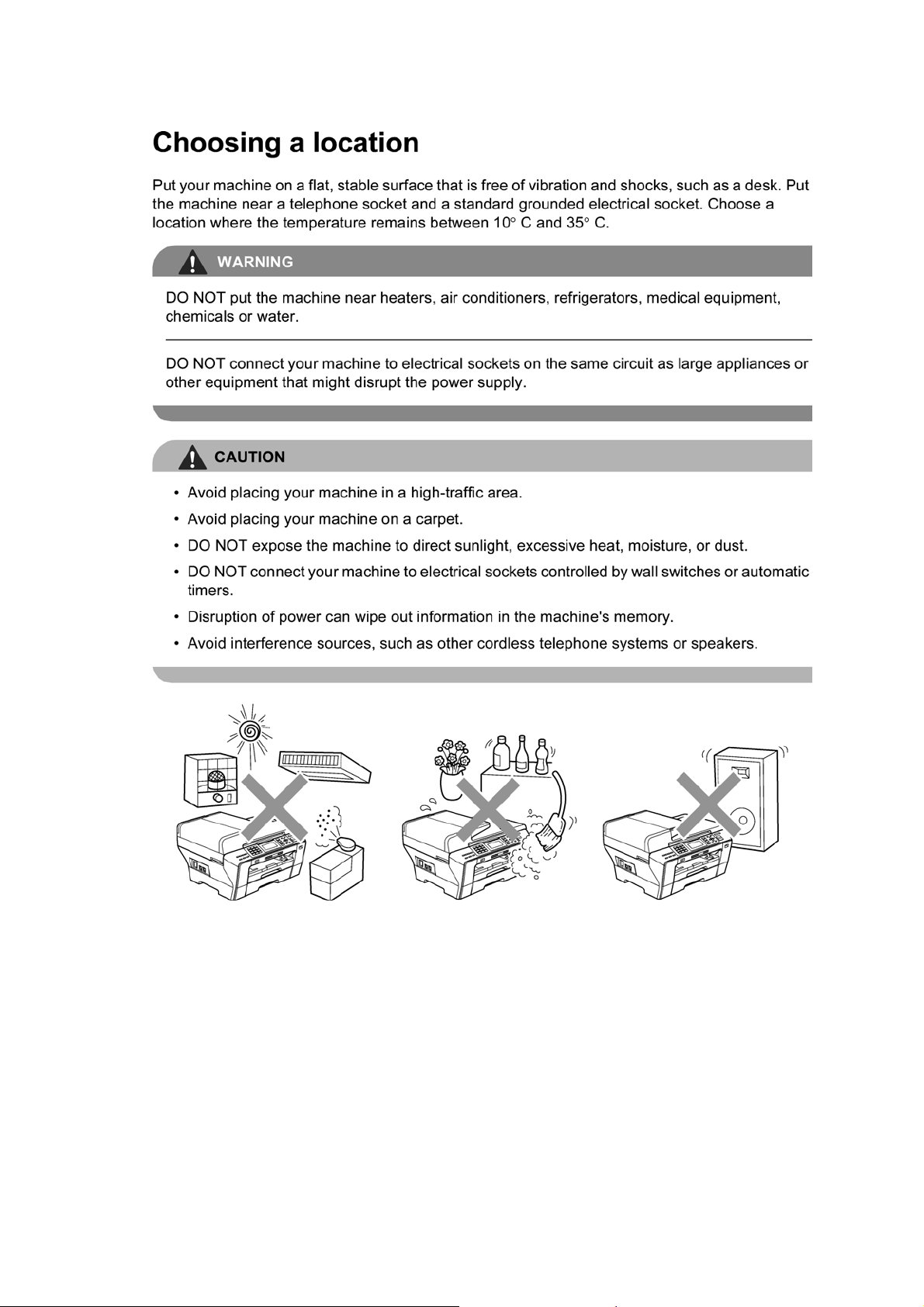

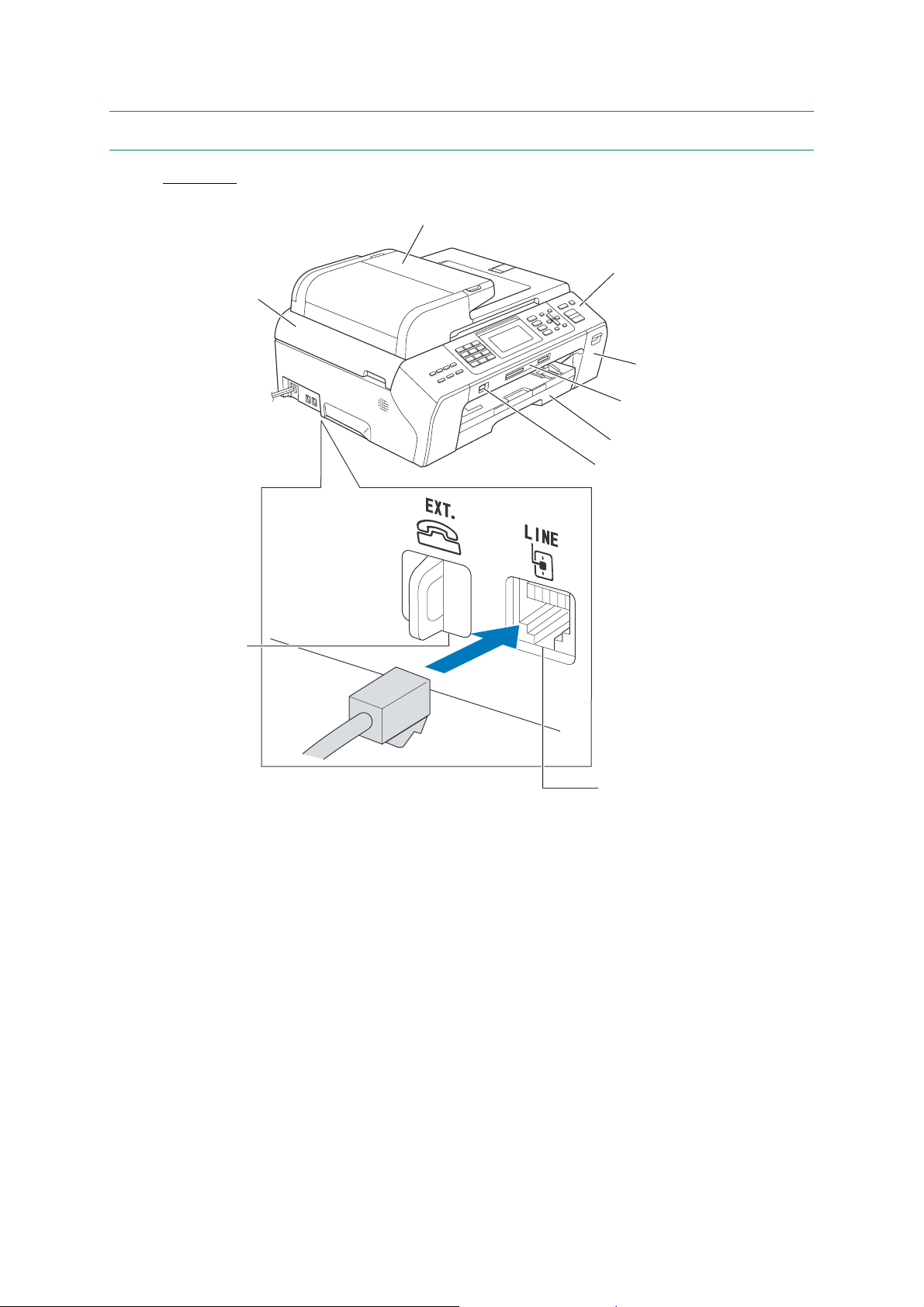

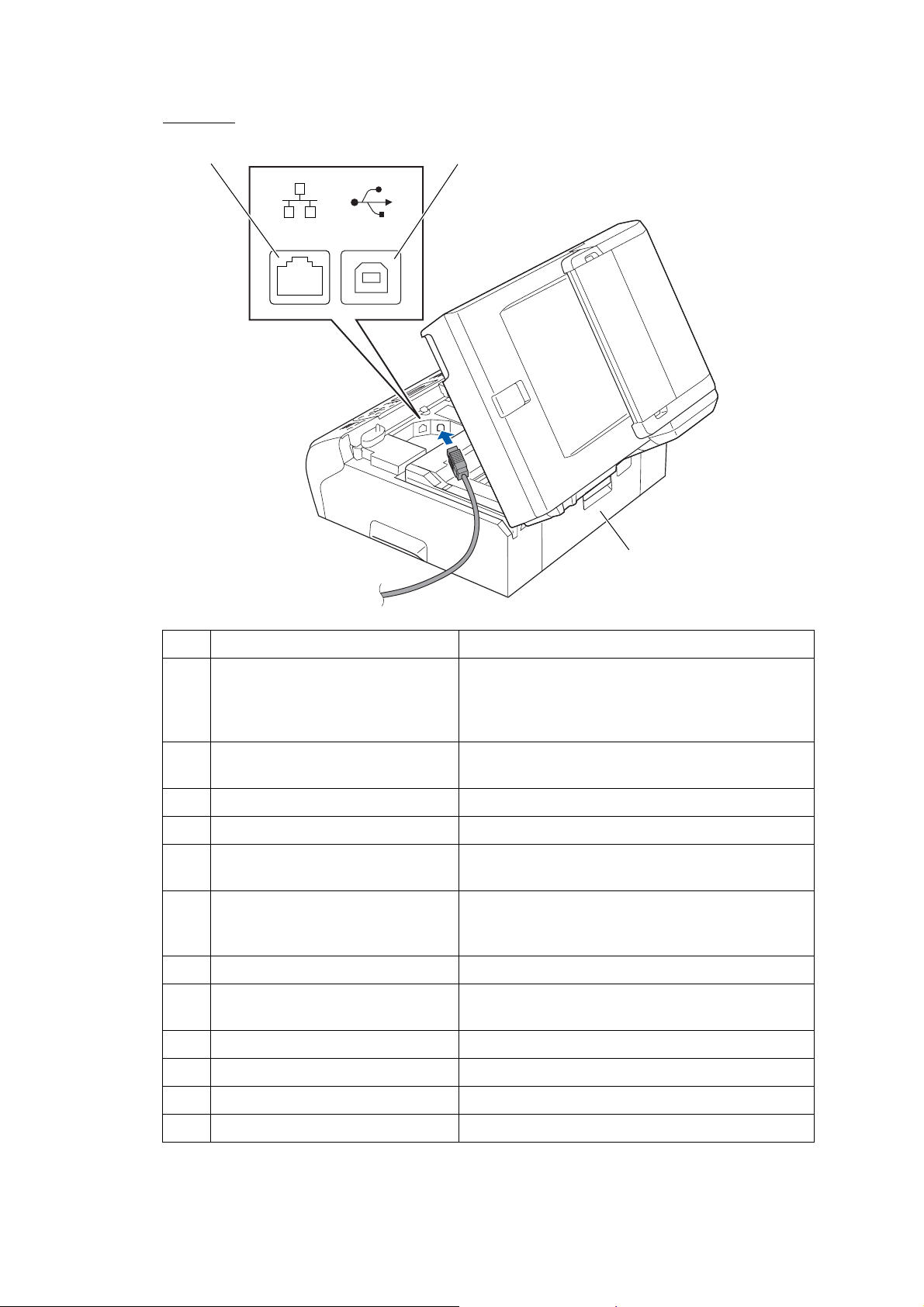

1.1 OUTLINE

Front view

(1) ADF & document cover ASSY

(9) Scanner cover

(Scanner unit)

(8) External telephone

line jack

(2) Control panel

(3) Ink cartridge cover

(4) Media slots for

PhotoCapture Center

(5) Paper tray

(6) Port for PictBridge /

USB flash memory drive

1-1

(7) Telephone line jack

(frontview)

Confidential

Back view

(12) LAN cable connector

LAN USB

(11) USB interface connector

(10) Jam clear cover

(backview)

No. Name Description

ADF: Load documents (originals) here. Documents

(1) ADF & document cover ASSY

will be fed into the machine, page by page.

Document cover: Open to place the document

(original) on the scanner glass.

(2) Control panel

Use the keys to operate the machine. The liquid crystal

display (LCD) shows the machine operation status.

(3) Ink cartridge cover Open to replace ink cartridges.

(4) Media slots for PhotoCapture Center Insert a memory card here.

(5) Paper tray

Port for PictBridge / USB flash

(6)

memory drive

Telephone line jack

(7)

External telephone line jack

(8)

Load paper here. Paper will be fed into the machine,

sheet by sheet.

Connect a digital camera (with PictBridge) to this

connector using the USB cable.

Insert a USB flash memory drive her e.

Plug in the modular plug on the telephone line here.

Plug in the modular plug o n the external tel ephone line

here.

(9) Scanner cover (Scanner unit) Open to remove jammed paper.

(10) Jam clear cover Open to remove paper jammed inside the machine.

(11) USB interface connector Connect the USB cable here.

(12) LAN cable connector Connect the LAN cable here.

1-2

Confidential

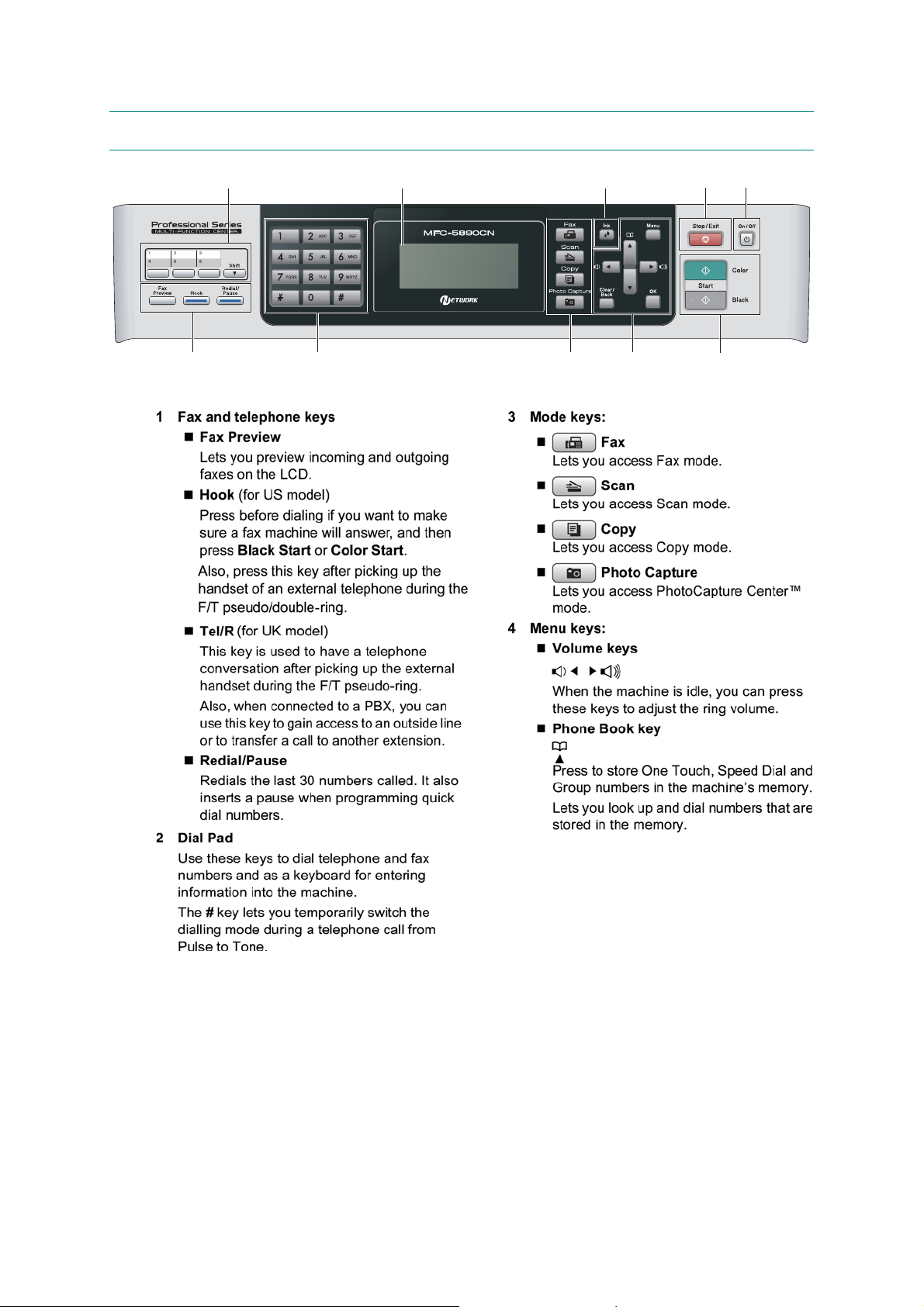

1.2 CONTROL PANEL

10

12

9

786

3

4

5

1-3

Confidential

1-4

Confidential

1-5

Confidential

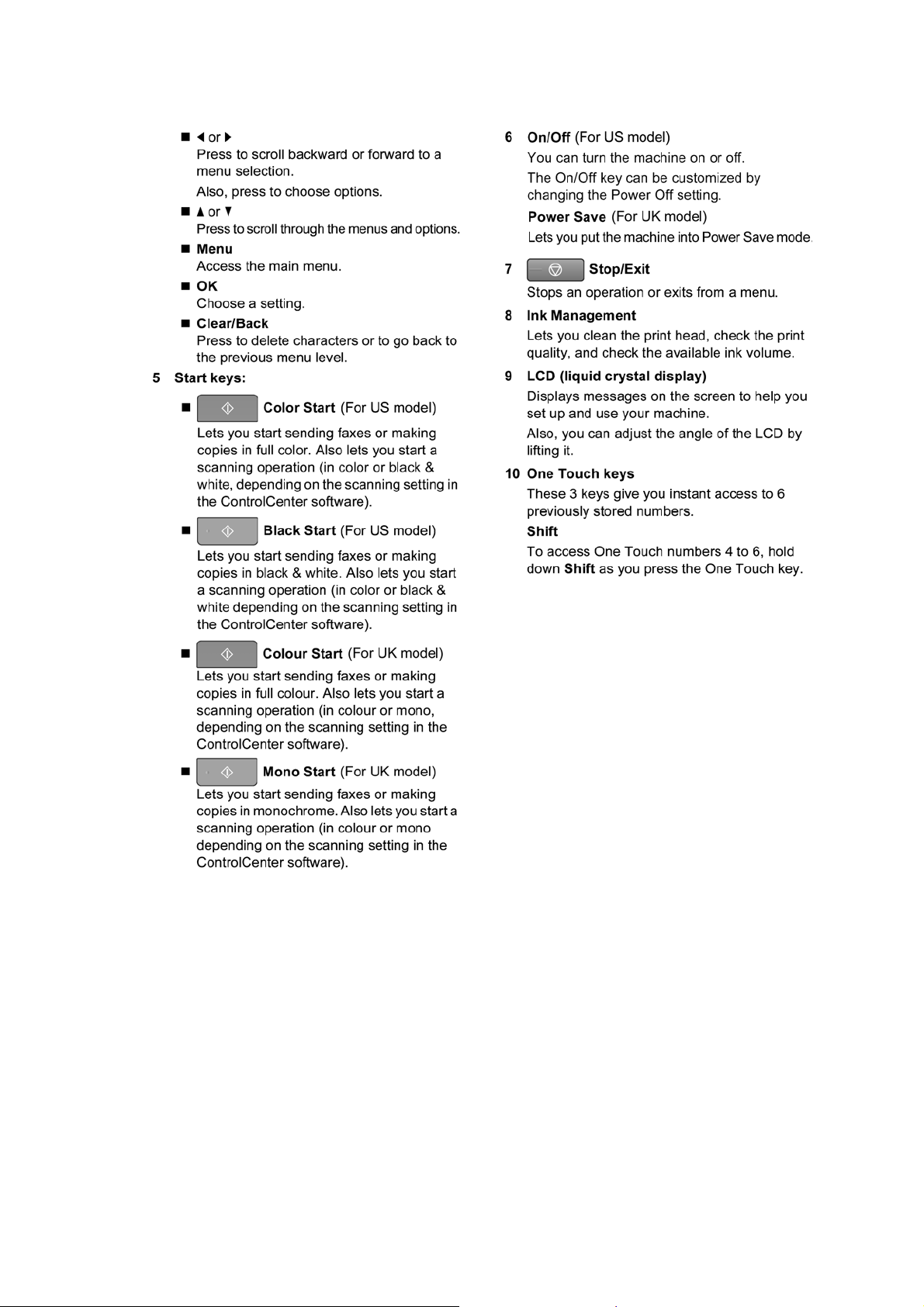

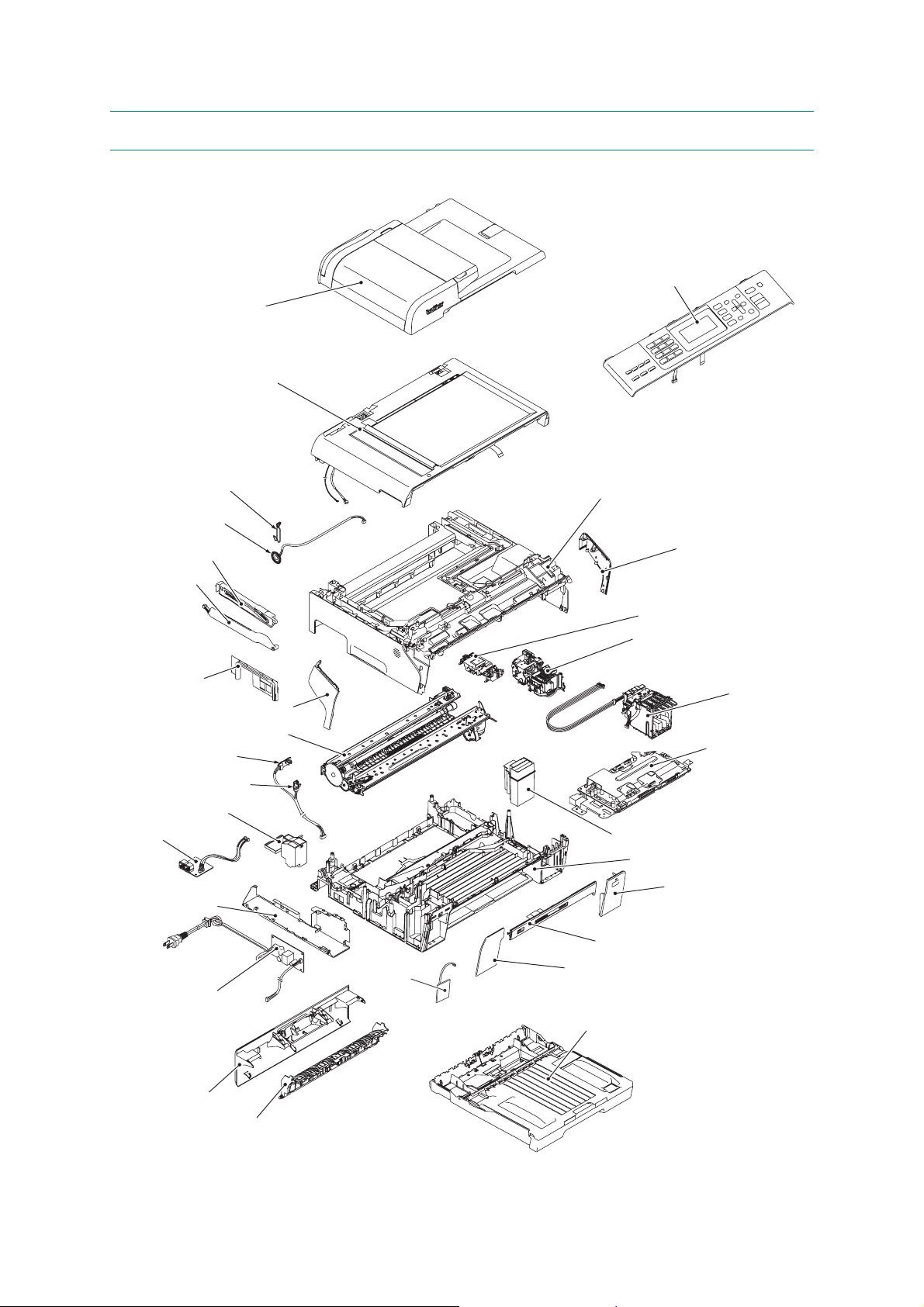

1.3 COMPONENTS

The machine consists of the following major components:

ADF & document cover

ASSY

Scanner cover

(Scanner unit)

Control panel ASSY

Wire spring

Speaker

Scanner cover damper

Scanner cover

support

MJ side cover

Registration sensor

PCB

PF encoder PCB

Flushing box

MJ PCB

MJ/PS shield unit

Upper cover

Side cover R

Head/carriage unit

Maintenance unit

Ink refill ASSY

Side cover L

Engine unit

Main PCB ASSY

Ink absorber box

Lower cover

Ink cartridge cover

Power supply PCB

Jam clear cover

Inner back cover

WLAN

PCB*

1-6

Media module cover

Front cover

Paper tray ASSY

(COMPONENTS_BHL9_MFC5890CN)

* For wireless LAN-enabled model.

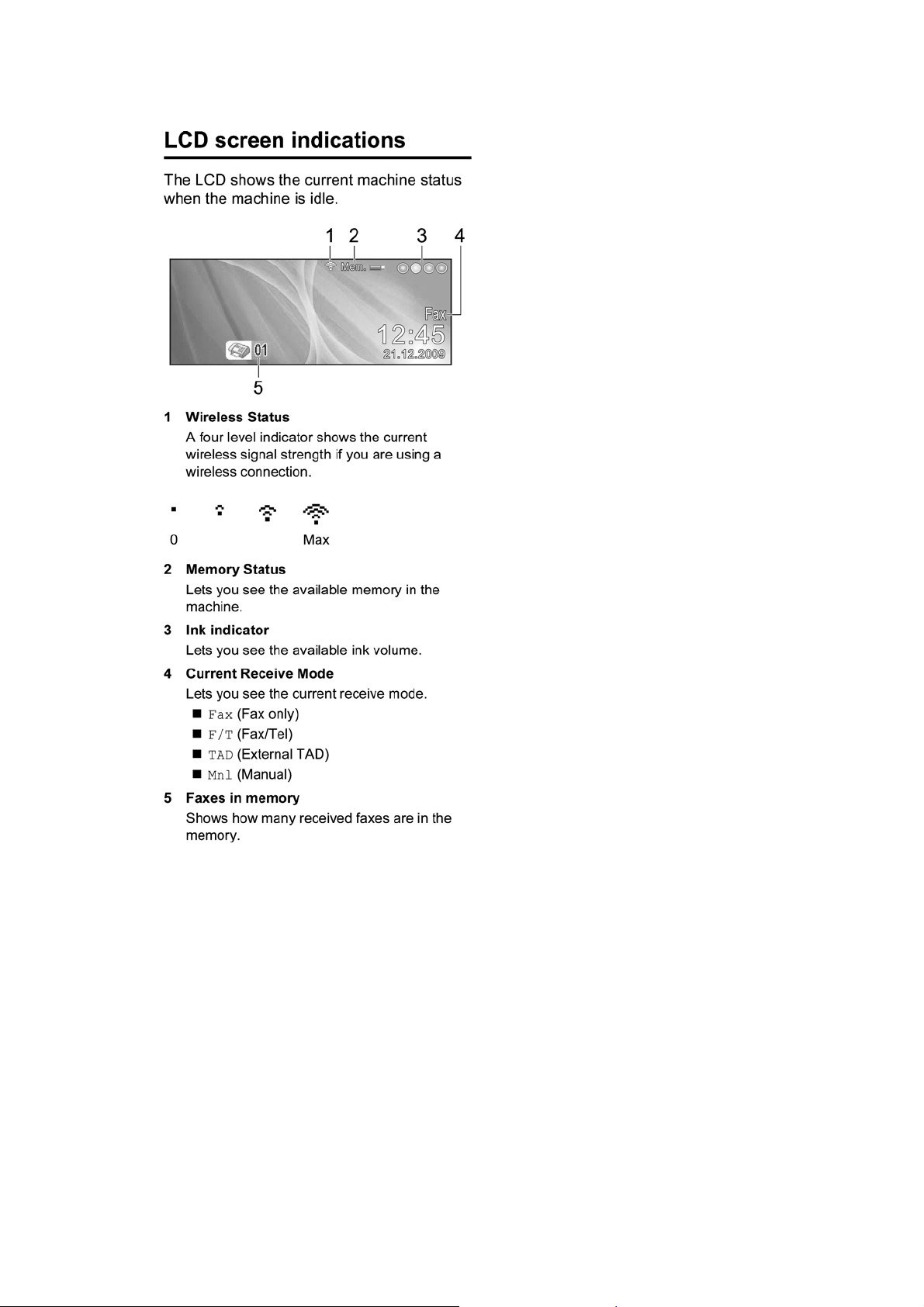

Confidential

CHAPTER 2

SPECIFICATIONS

Confidential

CHAPTER 2 SPECIFICATIONS

This chapter lists the specifications of each model, which enables you to make a comparison of

different models.

CONTENTS

2.1 GENERAL ..............................................................................................................2-1

2.1.1 Media Specifications..................................................................................2-2

2.1.2 Paper Handling...... ....... ...... ....... ...... ....... ...... ...... ....... ...... ....... ...................2-2

2.1.3 LCD/LED/Panel.........................................................................................2-3

2.1.4 Memory .....................................................................................................2-3

2.1.5 Security .....................................................................................................2-3

2.1.6 Interface ....................................................................................................2-4

2.1.7 Others........................................................................................................2-4

2.2 TELEPHONE..........................................................................................................2-5

2.2.1 Volume ......................................................................................................2-5

2.2.2 Quick/Auto Dials........................................................................................2-5

2.2.3 Tel Service.................................................................................................2-6

2.2.4 Message Center........................................................................................2-6

2.2.5 List/Report.................................................................................................2-6

2.3 FAX.........................................................................................................................2-7

2.3.1 Sending .....................................................................................................2-8

2.3.2 Receiving...................................................................................................2-8

2.3.3 PC FAX......................................................................................................2-9

2.4 PRINTER................................................................................................................2-9

2.5 COPY .....................................................................................................................2-10

2.6 SCANNER..............................................................................................................2-11

2.7 PHOTO CAPTURE.................................................................................................2-12

2.7.1 PictBridge..................................................................................................2-13

2.8 SOFTWARE ...........................................................................................................2-13

2.9 NETWORK .............................................................................................................2-14

2.9.1 Wired.........................................................................................................2-14

2.9.2 Wireless.....................................................................................................2-15

2.10 SUPPLIES/OPTIONS.............................................................................................2-16

2.11 SERVICE INFORMATION......................................................................................2-16

Confidential

2.12 PAPER....................................................................................................................2-17

2.12.1 Paper Specifications ..... ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ......2-17

2.12.2 Printable Area............................................................................................2-20

Language List ..................................................................................................................2-21

ITU-T Test Chart #1.........................................................................................................2-22

Brother Chart ...................................................................................................................2-23

Confidential

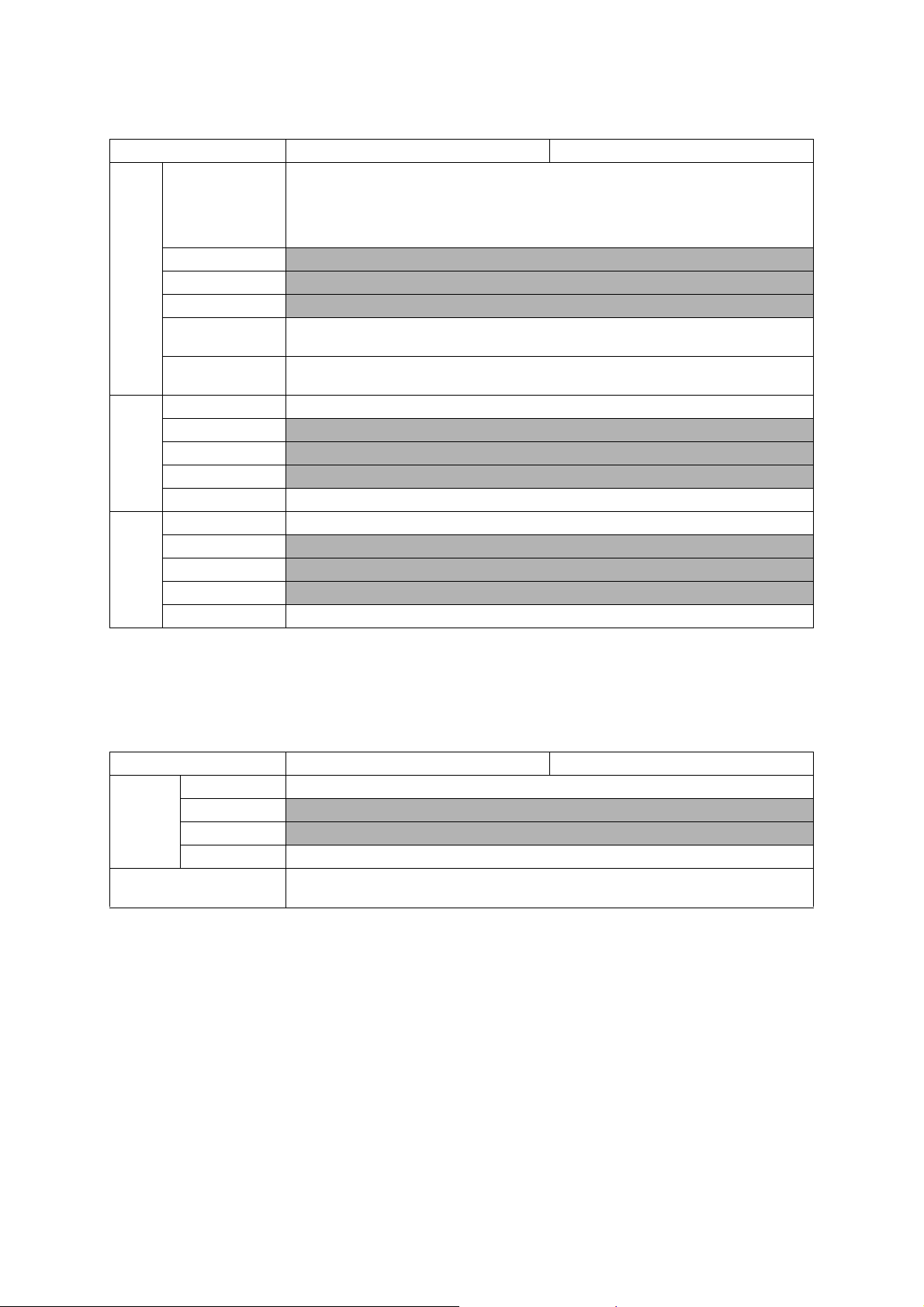

2.1 GENERAL

Model MFC5890CN MFC5895CW

Technology Inkjet

Print Head 94 nozzles/line, 5 lines

Variable Dot Print Yes (3 sizes)

Minimum Droplet Size

Scanning Method CIS

CPU Speed RISC 192 MHz

Backup Clock Yes

Simultaneous Operation Yes

U.S.A. Yes (Letter size)

Demo

Sheet

Panel Key

Demo

for Demo

LCD

Demo

Tes t Print Print Quality & Alignment Check Sheet (by pressing the Ink key . )

Europe

Asia/

Oceania

U.S.A.

Europe

Asia/

Oceania

U.S.A. Yes

Europe

Asia/

Oceania

FAX + COPY (Print + LCD demo)

BK: 4 pl

CMY: 1.5 pl

N/A

N/A

N/A

N/A

N/A

N/A

2-1

Confidential

2.1.1 Media Specifications

Model MFC5890CN MFC5895CW

A3, A4, LGR, LTR, LGL, EXE, B4 (JIS), B5 (JIS), A5, A6, Photo (102 x 152 mm/4 x 6 inches),

Indexcard (127 x 203 mm/5 x 8 inches), Photo-L (89 x 127 mm/3.5 x 5 inches),

Photo-2L (127 x 178 mm/5 x 7 inches), Post Card 1 (100 x 148 mm/3.9 x 5.8 inches),

Media

Sizes

Media

Weights

Media

Types

Standard Tray

Photo Tray

Lower Tray

Duplex Print

ADF

(width/length)

Scanner Glass

(width/length)

Standard Tray 64-220 g/m

Photo Tray

Lower Tray

Duplex Print

ADF 64-90 g/m

Standard Tray Plain, Inkjet, Glossy (cast/resin coated), Transparency

Photo Tray

Lower Tray

Duplex Print

ADF Plain

Post Card 2 (Double) (148 x 200 mm/5.8 x 7.9 inches), C5 Envelope, Com-10,

DL Envelope, Monarch, JE4 Envelope

N/A

N/A

N/A

148/148 mm to 215.9/355.6 mm (5.8/5.8 inches to 8.5/14.0 inches)

Up to 215.9/297 mm (up to 8.5/11.7 inches)

2

(17-58 lb.)

N/A

N/A

N/A

2

(17-24 lb.)

N/A

N/A

N/A

2.1.2 Paper Handling

Model MFC5890CN MFC5895CW

Standard Tray 150 (80 g/m

Paper Input

(sheets)

Output Paper Capacity

(sheets)

Photo Tray

Lower Tray

ADF 50 (90 g/m

N/A

N/A

50 (80 g/m

2

)

2

)

2

)

2-2

Confidential

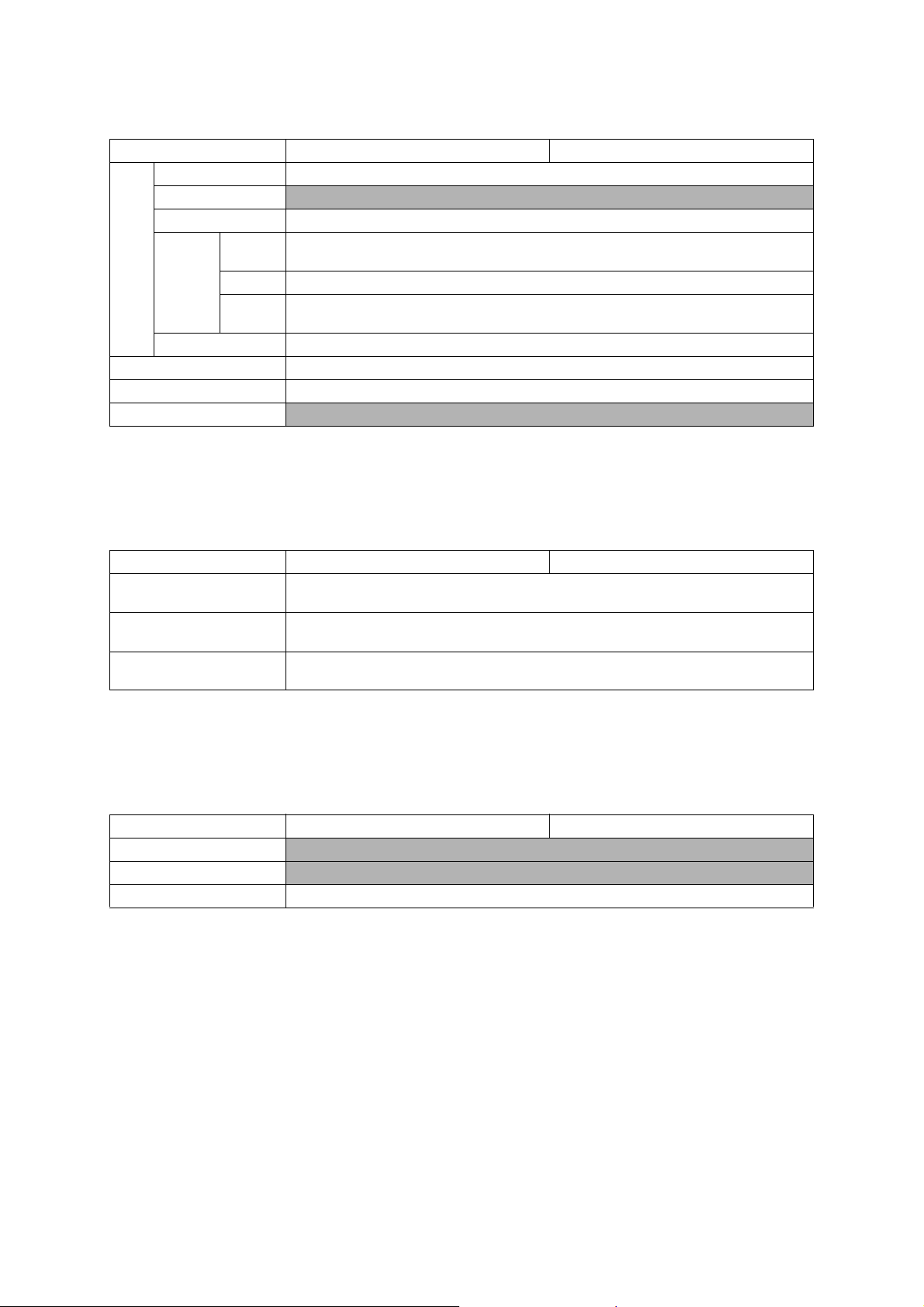

2.1.3 LCD/LED/Panel

Model MFC5890CN MFC5895CW

Type & Size 3.3-inch Wide Color LCD

Touch Panel

Backlight & Color Yes

LCD

Language

Selectable Wallpaper Yes (4 patterns)

Illuminated Key/LED Fax/Scan/Copy/Photo Capture

Illuminated Key Color Blue

Status LED Color

U.S.A.

Europe See "Language List (page 2-21)."

Asia/

Oceania

U.S.A.: English/Spanish,

Canada: English/Canada-French

N/A

English/Spanish

N/A

2.1.4 Memory

Model MFC5890CN MFC5895CW

Memory Capacity

(physical: megabytes)

Memory Backup

(with battery, 24 hours)

Backup Print: ON/OFF

(in function menu)

64 MB

Yes

Yes

2.1.5 Security

Model MFC5890CN MFC5895CW

Memory Security

Transmission Lock

Secure Function Lock Yes

2-3

N/A

N/A

Confidential

2.1.6 Interface

Model MFC5890CN MFC5895CW

Host Interface USB 2.0 Hi-Speed

LAN Yes

Wireless LAN

Bluetooth

IrSimple

PictBridge Yes

USB Flash Memory Yes

Acceptable Media Cards

N/A Yes

N/A

N/A

"Compact Flash"

"Memory Stick"

"Memory Stick Pro"

"Secure Digital"

"Secure Digital High Capacity"

"xD Picture Card"

"xD Picture Card TypeM/TypeM+/TypeH"

2.1.7 Others

Model MFC5890CN MFC5895CW

On/Off Switch Yes

U.S.A. 100-120 VAC, 50/60 Hz

Power Source

Operating Environment

Tem perature (Best Print

Quality)

Humidity 20 - 80% (w/o condensation)

Power

Consumption

Average

(Operating/

Standby/Sleep/

OFF mode)

Machine Noise (Operating) 50 dBA (Maximum) (Belgium only)

Machine Dimensions 485 x 408 x 242 mm

Machine Weight

Energy Star Compliant Yes

Blue Angel

TCO99

Speaker Yes

Europe/

Asia/

Oceania

U.S.A. 28 / 6.5 / 4 / 0.9 W

Europe/

Asia/

Oceania

U.S.A.

Europe/

Asia/

Oceania

U.S.A.

Europe Yes

Asia/

Oceania

220-240 VAC, 50/60 Hz

5-40 (18-33) degrees centigrade

28 / 6.5 / 4 / 0.9 W

10.7 kg

(23.6 lb.)

10.9 kg

(24.0 lb.)

N/A

N/A

N/A

2-4

Confidential

2.2 TELEPHONE

Model MFC5890CN MFC5895CW

Handset

Digital Cordless Phone

(Cordless Handset)

SKYPE API support

Hook/ Tel R/

Recall/On Hook

Key

Duplex Speaker Phone Key

PBX Feature (Europe Only) Yes

Hold/Mute

Music on Hold

Monitoring the Line on Hold

with Music

U.S.A. H ook

Europe Tel R

Asia/

Oceania

N/A

N/A

N/A

Hook

N/A

N/A

N/A

N/A

2.2.1 Volume

Model MFC5890CN MFC5895CW

Handset Volume

Speaker V olume Yes (3 steps + OFF)

Ring Volume Yes (3 steps + OFF)

N/A

2.2.2 Quick/Auto Dials

Model MFC5890CN MFC5895CW

One Touch Dial

Speed Dial 80 x 2 numbers

Figures of One T ouch & S peed

Dial

Registerable Number Of

Characters

Group Dial (Up to X groups) Yes (6)

Telephone Index

(Search/Speed dial key)

Yes - 6 locations

(3 keys + Shift key)

20 digits

16 characters

Yes

2-5

Confidential

2.2.3 Tel Service

Model MFC5890CN MFC5895CW

Caller ID Yes

Call Waiting Caller ID

Call from Caller ID List Yes

Call from Call List Yes

Call waiting Ready

Backup Caller ID list Yes

Call List Indication Yes

External TAD Interface Yes

Distinctive Ringing Yes

N/A

N/A

2.2.4 Message Center

Model MFC5890CN MFC5895CW

TAD

ICM Recording Time

Toll Saver

Recording Conversation

OGM/User Recording Time

(MC/TAD, F/T)

N/A

N/A

N/A

N/A

N/A

2.2.5 List/Report

Model MFC5890CN MFC5895CW

Activity Report/Journal Report Yes (up to 200)

Transmission Verification

Report

Help List Yes

Caller ID List Yes

Quick Dial List Yes (Print/Display)

Tel Index List ABC

User Setting List Yes

Order Form

Network Configuration Yes

Yes

N/A

2-6

Confidential

2.3 FAX

Model MFC5890CN MFC5895CW

Modem Speed 33,600 bps

Transmission Speed Approx. 3 seconds (Brother #1, MMR)

ITU-T Group Super G3

Coding Method

Paper Handling Size LTR, A4, LGL (with ADF)

Document Scanning Width

Document

Color FAX

Display FAX

Super Fine Yes (TX & RX : B&W only)

Gray Scale

Contrast

(Auto/S.Light/S.Dark)

Dual Access Yes (B&W only)

Enhanced Remote Activate Yes

Station ID

Remote Maintenance Yes

Remote Access Ye s

Fax Retrieval Yes (B&W only)

Paging Yes (U.S.A. only)

(Send/Receive)

Memory (Send/

Receive)

Send Yes

Receive Yes

Mono: MH/MR/MMR

Color: JPEG

LTR (FB): 208 mm

A4 (FB): 204 mm

LTR/LGL (ADF): 208 mm

A4 (ADF): 208 mm

Yes/Yes (ITU-T color FAX)

No/Yes (ITU-T color FAX)

Mono: 64,

Color: 256

Yes

Yes

20 digits/20 characters

2-7

Confidential

2.3.1 Sending

Model MFC5890CN MFC5895CW

Delayed Timer Up to 50 / B&W only

Polled

Sending

(type)

*B&W only

Batch Transmission Yes (B&W only/not color)

Quick-Scan

(Memory transmission)

(ITU-T Test Chart #1 on page

2-22)

Memory

Transmission

Broadcasting (Speed/

One Touch + Manual)

Manual Broadcasting Yes (50 locations)

Fax Forwarding Yes (B&W only)

U.S.A. Yes (Standard)

Europe/Asia/

Oceania

ITU-T Test

Chart #1

(see page 2-

22) / MMR

Brother Chart

(see page 2-

23) / MMR

Yes (Standard/Secure)

Approx. 3.30 seconds/page @LTR

Approx. 3.50 seconds/page @A4

Up to 400 pages

Up to 480 pages

Yes (216 locations)

2.3.2 Receiving

Model MFC5890CN MFC5895CW

Easy Receive/Fax Detect Yes (Fax detect only)

Polling

Receiving

(type)

* B&W only

Auto Reduction Yes

Out-of-Paper

Reception

U.S.A. Yes (Standard/Sequential)

Europe/Asia/

Oceania

ITU-T Test

Chart #1

(see page 2-

22) / MMR

Brother Chart

(see page 2-

23) / MMR

(Standard/Sequential/Secure/Timer)

Yes

Up to 400 pages

Up to 480 pages

2-8

Confidential

2.3.3 PC FA X

Model MFC5890CN MFC5895CW

Color/Mono Mono (A4 only)

Sending Yes (Network/USB)

Receiving

PC-Fax Protocol

Broadcasting Up to 50

Yes (Network/USB),

N/A for MAC

RX: Class 2

TX: PC-FAX Driver

2.4 PRINTER

Model MFC5890CN MFC5895CW

Mono/Color

Print Speed (A4/LTR)

*Including paper feeding

Resolution

(horizontal x vertical)

Fonts (CD Based)

Auto Duplex Print

Manual Duplex Print Yes

(Mono: 450 x 300 dpi/Color: 600 x 15 0 dpi):

<Borderless printing>

On: 0, 0, 0, 0 mm/0, 0, 0, 0 inch (*)

Off: 3, 3, 3, 3 mm/0.12, 0.12, 0.12, 0.12 inches (**)

Color

Up to 35/28 ppm

Up to 1200 x 6000 dpi

N/A

N/A

Print Paper Margin

(upper, lower, left, right)

Easy Print Setting for Printer

Driver (Japan only)

Color Enhancement

(Color Printer)

(*) Borderless for A3, A4, B4, LGR, LTR, A6,

Photo (102 x 152 mm/4 x 6 inches),

Index card (127 x 203 mm/5 x 8 inches),

Photo-L (89 x 127 mm/3.5 x 5 inches),

Photo-2L (127 x 178 mm/5 x 7 inches),

Post Card 1 (100 x 148 mm/3.9 x 5.8 inches) only

(**) 12, 24, 3, 3 mm/0.47, 0.95, 0.12, 0.12 inches for Envelops

N/A

Yes

2-9

Confidential

2.5 COPY

Model MFC5890CN MFC5895CW

Mono/Color (Color Copy) Color

Copy Speed (A4/LTR)

*Including paper feeding

**Europe's default is calculated

by "normal mode" speed

Resolution

(horizontal x

vertical)

Multi Copy

Reduction/Enlargement (%) 25 - 400 in 1% increments

N in 1

Poster Yes (3 x 3, 2 x 2)

Auto Skew Adjustment

Fit to Page Yes

Copy

Enhancement

Duplex Copy

Print Paper Margin

(upper, lower, left, right)

Paper Sizes

(Color Copy)

Mono

Color

Stack Yes (99)

Sort Yes

Book Copy

(Shadow

Correction &

Skew

Adjustment for

book)

Watermark

Copy

Standard T ray LGR, LTR, LGL, A3, A4, A5, 10 x 15 cm (4 x 6 inches)

Photo Tray

Lower Tray

Print: Maximum 1200 x 1200 dpi

Scan: Maximum 1200 x 1200 dpi

Print: Maximum 1200 x 1200 dpi

Scan: Maximum 1200 x 1200 dpi

LGR/LTR/A3/A4 only (*Mono & Color)

3, 3, 3, 3 mm/0.12, 0.12, 0.12, 0.12 inches

23/20 cpm

8/8 cpm (Belgium only)

2 in 1 / 4 in 1

N/A

Yes

Yes

N/A

N/A

N/A

2-10

Confidential

2.6 SCANNER

Model MFC5890CN MFC5895CW

Mono/Color (Color Scanner) Color

Scan Speed (Mono/Color)

*@100 dpi

Resolution

(horizontal x

vertical)

Gray Scale 256

Scan to

Document Scanning Width 210 mm

Color Depth Input: 48 bits, Output: 24 bits

Optical 1200 x 2400 dpi

Interpolated

Image Yes (Scan Key)

OCR Yes (Scan Key)

E-mail Yes (Scan Key)

File Yes (Scan Key)

Media

(Media Card

or USB Flash

Memory)

FTP Yes (Scan Key)

E-mail Server Yes (Download/Scan Key)

(For Windows XP/Vista, up to 19200 x 19200 dpi with Scanner Utility)

Maximum 3.24/4.55 seconds (LTR)

Maximum 3.44/4.83 seconds (A4)

1200 x 1200 dpi

Yes (Scan Key)

2-11

Confidential

2.7 PHOTO CAPTURE

Model MFC5890CN MFC5895CW

Memory Stick: 16-128 MB (Duo with Adapter)

Memory Stick Pro: 256 MB - 8 GB

(MagicGate: YES if not use MG function)

Secure Digital: 16 MB - 2 GB (MiniSD with

Acceptable

Media

(Type & Size)

Paper Sizes

Paper Types

Print Paper Margin (upper,

lower, left, right) (PCC)

Available Paper Size for Full

(Maximum) Size Printing

Direct Print Size for A4/LTR

(N/A for A3, LGR, B4)

Borderless/Cropping

(Full Auto)

Media Format

Image Format Print by Media

Card/USB Flash Memory

Color Enhancement

(PCC)

Removable Disk (Media Card/

USB Flash Memory)

Scan to Media (Media = Media

Card or USB Flash Memory)

Network Media Card/USB

Flash Memory Access

Monochrome/Sepia Yes

Trimming Yes

Search from D a te Yes

Slide-show Yes

Photo Enhance

Media Cards

USB Flash

Memory

Standard T ray LGR, LTR, A3, A4, 10 x 15 cm (4 x 6 inches), 13 x 18 cm (5 x 7 inches)

Photo Tray

Lower Tray

Standard T ray Plain, Inkjet, Glossy

Photo Tray

Lower Tray

Adapter)

Secure Digital High Capacity (SDHC): 4-8 GB

xD Picture Card: 16-512 MB

xD Picture Card TypeM/Ty peM+/ TypeH:

256 MB - 2 GB

Compact Flash: 4 MB - 8 GB

(Type1 only, Type2 & Microdrive are not

compatible)

Up to 8 GB Up to 32 GB

N/A

N/A

N/A

N/A

<Borderless printing>

On: 0, 0, 0, 0 mm/0, 0, 0, 0 inch

Off: 3, 3, 3, 3 mm/0.12, 0.12, 0.12, 0.12 inches

All sizes

8 x 10 cm (3 x 4 inches), 9 x 13 cm (3.5 x 5 inches), 10 x 15 cm (4 x 6 inches),

13 x 18 cm (5 x 7 inches), 15 x 20 cm (6 x 8 inches), Maximum Size

Yes/Yes

DPOF (Ver. 1.0, Ver. 1.1)

Exif DCF (Up to Ver. 2.1)

Photo Print: JPEG/JPEG

Yes

Yes (read & write)

(both Card & USB flash memory)

Color: JPEG/PDF

B&W: TIFF/PDF

Yes (read & write)

(both Card & USB flash memory)

Yes

(Remove red-eye/Skin-Tone/Scenery/Auto correct)

Memory Stick: 16-128 MB (Duo, micro with

Adapter)

Memory Stick Pro: 256 MB - 32 GB

(MagicGate: YES if not use MG function)

(Duo, micro with Adapter)

Secure Digital: 16 MB - 2 GB (MiniSD,

microSD with Adapter)

Secure Digital High Capacity (SDHC): 4-32

GB

xD Picture Card: 16-512 MB

xD Picture Card TypeM/TypeM+/TypeH:

256 MB - 2 GB

Compact Flash: 4 MB - 32 GB

(Type1 only, Tpye2 & Microdrive are not

compatible)

2-12

Confidential

2.7.1 PictBridge

Model MFC5890CN MFC5895CW

Paper Size A3, A4, LGR, LTR, 4 x 6 inches, Printer Setting

Paper Type Plain Paper, Inkjet Paper, Glossy, Printer Setting

Direct Print Size for A4/LTR Maximum size only

Borderless / Cropping

(Full Auto)

Index Print

DPOF Yes

Color Enhancement Yes

Print Quality Normal, Fine, Printer Setting

Yes/No

N/A

2.8 SOFTWARE

Model MFC5890CN MFC5895CW

Support OS

Version

PC Application

Windows Windows 2K/XP/XP Professional x64/Vista

Mac Mac OS X 10.2.4 (greater) Mac OS X 10.4.11, 5.x, 6.x

Win 2K Professional

Win XP Home/XP Professional

Win XP Professional x64

Win Vista

Win Server 2003 (print only via network)

Win Server 2003 x64 (print only via network)

Win Server 2008 (print only via network)

Mac OS X 10.3.9 - 10.4.3

Mac OS X 10.4.4 or greater

Windows 2K/XP/XP Professional X64/

Vista/Win7

Windows® 2000 Professional

Windows® XP Home

Windows® XP Professional

Windows® XP Professional x64 Edition

Windows Vista®

Windows7

Windows Server® 2003 (print only via network)

Windows Server® 2003 x64 Edition

(print only via network)

Windows Server® 2003 R2

(print only via network)

Windows Server® 2003 R2 x64 Edition

(print only via network)

Windows Server® 2008 (print only via network)

Windows Server® 2008 R2

(print only via network)

Mac OS® X 10.4.11, 5.x

Mac OS® X 10.6.x

2-13

Confidential

2.9 NETWORK

Model MFC5890CN MFC5895CW

ITU SUB Addressing

Printer Yes

Scanner Yes

PC FAX Yes

Internet FAX (Firmware) Yes (Download)

Format (Scan to E-mail server)

ARP, RARP, BOOTP, DHCP, APIPA (Auto IP), NetBIOS/WINS, LPR/LPD,

Protocols (IPv4)

Protocols (IPv6)

LDAP

FAX to E-mail Y e s

Network Management

(BRAdmin Light)

Network Management (MIB-II

as well as Brother private MIB)

Network Reset Yes (for WLAN & WIRED LAN at once) (in LAN Menu)

Custom Raw Port/Port9100, DNS Resolver, mDNS, FTP Server, TELNET,

SNMPv1, TFTP, Scanner Port, LLTD Responder, Web Services, SMTP Client,

POP before SMTP, SMTP- AUTH, POP3, APOP, FTP Client

(Turned off by default) NDP, RA, LPR/LPD, Custom Raw Port/Port9100, mDNS,

FTP Server, TELNET, SNMPv1, TFTP, Scanner Port, LLTD Responder, Web Services,

SMTP Client, POP before SMTP, SMTP-AUTH, POP3, APOP, FTP Client

N/A

Color: PDF/JPEG

B/W: TIFF/PD F

N/A

Yes

Yes

2.9.1 Wired

Model MFC5890CN MFC5895CW

Model Name (Ethernet) Embedded (NC-170h)

Network Connection (Ethernet) Ethernet 10/100 BASE-TX Auto Negotiation

2-14

Confidential

2.9.2 Wireless

Model MFC5890CN MFC5895CW

Model Name (Wireless)

Network Connection

(Wireless)

Wireless Security

WiFi Certification

WCN

(Windows Connect Now)

Secure EZ

Setup

Setup Support

Utility

Auto Switch WLAN/WIRED

LAN

AOSS

(WLAN model

only)

WPS (WiFi

Protected

Setup)

N/A Embedded (NC-180w)

N/A IEEE 802.11b/g

N/A

N/A Wifi B and G

N/A

N/A

N/A Yes

N/A Yes

N/A

SSID (32 chr), WEP 64/128 bit,

WPA-PSK (TKIP/AES), WPA2-PSK (AES)

**NO LEAP**

2-15

Confidential

2.10 SUPPLIES/OPTIONS

Model MFC5890CN MFC5895CW

LC61BK/ LC65HY-BK

U.S.A.

Ink Cartridge Model

Name

Bundled Ink Cartridge Type High yield

Bundled Cartridges Approx. 770/540 pages

Ink

Cartridge

Yield

(@ISO

pattern/

normal)

Brother Paper (for

Plain, Glossy and

Inkjet)

Recommended Paper Only for

Transparency

Supply Standard

Cartridges

Supply Low Yield

Cartridges

Supply High Yield

Cartridges

Europe

Asia/

Oceania

U.S.A.

Europe/

Asia/

Oceania

Glossy (resin coated): LGR/LTR/4 x 6 inches

Glossy (resin coated): A3/A4/4 x 6 inches

LC61C/ LC65HY-C

LC61M/ LC65HY-M

LC61Y/ LC65HY-Y

LC1100BK/ LC1100HY-BK

LC1100C/ LC1100HY-C

LC1100M/ LC1100HY-M

LC1100Y/ LC1100HY-Y

LC67BK/ LC67HY-BK

LC67C/ LC67HY-C

LC67M/ LC67HY-M

LC67Y/ LC67HY-Y

Approx. 450/325 pages

N/A

Approx. 900/750 pages

Plain: LGR/LTR

Inkjet: LGR/LTR

Plain: A3/A4

Inkjet: A3/A4

3M 3410 Transparency Film

2.11 SERVICE INFORMATION

Model MFC5890CN MFC5895CW

Monthly Volume 4000 pages

Machine Life (year) 50000 pages or 5 years

MTBF (Mean Time Between

Failures)

MTTR (Mean Time To Be

Repaired)

2-16

4000 hours

30 minutes

Confidential

2.12 PAPER

2.12.1 Paper Specifications

Paper type and size for each operation

Paper Type Paper Size Usage

Fax Copy Photo

Capture

Cut Sheet Ledger 11 x 17 inches (279.4 x 431.8 mm) Yes Yes Yes Yes

A3 11.7 x 16.5 inches (297 x 420 mm) Yes Yes Yes Yes

Letter 8 1/2 x 11 inches (215.9 x 279.4 mm) Yes Yes Yes Yes

A4 8.3 x 1 1.7 inc he s (210 x 297 mm ) Yes Yes Yes Yes

Legal 8 1/2 x 14 inches (215.9 x 355.6 mm) Yes Yes -- Yes

Executive 7 1/4 x 10 1/2 inches (184 x 267 mm) -- -- -- Yes

B4 (JIS) 10.1 x 14.3 inches (257 x 364 mm) -- -- -- Yes

B5 (JIS) 7.2 x 10.1 inches (182 x 257 mm) -- -- -- Yes

A5 5.8 x 8.3 inches (148 x 210 mm) -- Yes -- Yes

A6 4.1 x 5.8 inches (105 x 148 mm) -- -- -- Yes

Cards Photo 4 x 6 inches (10 x 15 cm) -- Yes Yes Yes

Photo L 3 1/2 x 5 inches (89 x 127 mm) -- -- -- Yes

Photo 2L 5 x 7 inches (13 x 18 cm) -- -- Yes Yes

Index Card 5 x 8 inches (127 x 203 mm) -- -- -- Yes

Post Card 1 3.9 x 5.8 inches (100 x 148 mm) -- -- -- Yes

Post Card 2

(Double)

Envelopes C5 Envelope 6.4 x 9 inches (162 x 229 mm) -- -- -- Yes

DL Envelope 4.3 x 8. 7 inches (110 x 220 mm) -- -- -- Yes

COM-10 4 1/8 x 9 1/2 inches (105 x 241 mm) -- -- -- Yes

Monarch 3 7/8 x 7 1/2 inches (98 x 191 mm) -- -- -- Yes

JE4 Envelope 4.1 x 9.3 inches (105 x 235 mm) -- -- -- Yes

Transparencies Letter 8 1/2 x 11 inches (215.9 x 279.4 mm) -- Yes -- Yes

A4 8.3 x 1 1.7 inc he s (210 x 297 mm ) -- Yes -- Yes

5.8 x 7.9 inches (148 x 20 0 mm) -- -- -- Yes

Printer

Paper weight, thickness and capacity

Paper Type Weight Thickness No. of

2

Cut Sheet Plain Paper 17 to 32 lb. (64 to 120 g/m

) 3 to 6 mil (0.08 to 0.15 mm) 150

Inkjet Paper 17 to 53 lb. (64 to 200 g/m2) 3 to 10 mil (0.08 to 0.25 mm) 20

2

Glossy Paper Up to 58 lb. (Up to 220 g/m

Cards Photo 4 x 6 inches Up to 58 lb. (Up to 220 g/m

Index Card Up to 32 lb. (Up to 120 g/m

Post Card Up to 53 lb. (Up to 200 g/m

Envelopes 20 to 25 lb. (75 to 95 g/m

) Up to 10 mil (Up to 0.25 mm) 20

2

) Up to 10 mil (Up to 0.25 mm) 20

2

) Up to 6 mil (Up to 0.15 mm) 30

2

) Up to 10 mil (Up to 0.25 mm) 30

2

) Up to 20 mil (Up to 0.52 mm) 10

Transparencies -- -- 10

*

Up to 150 sheets of plain paper 20 lb. (80 g/m2).

2-17

sheets

Confidential

*

Recommended print media

Brother paper

Paper Type Item

Ledger Plain BP60PLGR (USA only)

Ledger Glossy Photo BP71GLGR

Letter Plain BP60PL (USA only)

Letter Glossy Photo BP71GP

Letter Inkjet (Matte) BP60ML (USA only)

4 x 6 in. Glossy Photo BP71GP

A3 Plain BP60PA3

A3 Glossy Photo BP71GA3

A3 Inkjet (Matte) BP60MA3

A4 Plain BP60PA

A4 Glossy Photo BP71GA4

A4 Inkjet (Matte) BP60MA

10 x 15 cm Glossy Photo BP71GP

2-18

Confidential

Handling and using print media

Store paper in its origin al pac kagi ng, an d keep i t sea led. K eep th e pape r flat a nd away fro m

moisture, direct sunlight and heat.

Avoid touching the shiny (coa ted) side o f ph oto pap er. Load p hoto pa per wi th the shiny s ide

facing down.

Avoid touching either side of transparencies because they absorb water and perspiration

easily, and this may cause decreased output quality. Transparencies designed for laser

printers/copiers ma y stain your next doc ument. Use only transpar encies recommended for

inkjet printing.

You can only print on both sides of the paper with PC printing using Windows.

1 0.08 inches (2 mm) or greater curve

may cause jams to occur

2-19

Confidential

2.12.2 Printable Area

Top (1) Bottom (2) Left (3) Right (4)

Cut Sheet 0.12 inches (3 mm) 0.12 inches (3 mm) 0.12 inches (3 mm) 0.12 inches (3 mm)

Envelopes 0.47 inches (12 mm) 0.95 inches (24 mm) 0.12 inches (3 mm) 0.12 inches (3 mm)

2-20

Confidential

Language List

Product

Category

MFC U.S.A. English English

Country Languages Default

Canada English/French English

Belgium Dutch/French/English Dutch

Switzerland German/French/English Germ an

Pan Nordic/Denmark English/Norwegian/Swedish/Finnish/

Danish

General English/Czech/Hungarian/Polish/

Bulgarian/Romanian/Slovak

Russia Russian/English Russian

Asia English English

Oceania English English

Hong Kong Traditional Chinese/English Traditional Chinese

Depends on first country

setting

English

2-21

Confidential

ITU-T Test Chart #1

2-22

Confidential

Brother Chart

2-23

Confidential

CHAPTER 3

THEORY OF OPERATION

Confidential

CHAPTER 3 THEORY OF OPERATION

This chapter gives an overview of the scanning and printing mechanisms as well as the sensors,

actuators, and control electronics. It aids in understanding the basic principles of operation as well as

locating defects for troubleshooting.

CONTENTS

3.1 OVERVIEW ............................................................................................................3-1

3.2 MECHANICAL COMPONENTS.............................................................................3-2

3.2.1 Scanner Mechanism..................................... ...... ....... ...... ....... ...................3-5

3.2.2 Printing Mechanism...................................................................................3-8

3.2.2.1 Ink supply and ink jet mechanism .........................................................3-10

[ 1 ] Overview ...........................................................................................3-10

[ 2 ] Features............................................................................................3-11

[ 3 ] Head/carriage unit.............................................................................3-12

[ 4 ] Ink cartridges........ ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ......3-17

[ 5 ] Ink refill assembly. ...... ....... ...... ....... ...... .............................................3-19

[ 6 ] Ink supply tubes ................ ...... ....... ...... .............................................3-20

3.2.2.2 Head maintenance mechanism.............................................................3-21

[ 1 ] Overview ...........................................................................................3-21

[ 2 ] Maintenance unit components ..........................................................3-22

[ 3 ] Mechanisms constituting the head maintenance mechanism...........3-24

[ 4 ] Power transmission route to the head maintenance mechanism

and motor rotational direction............................................................3-29

[ 5 ] Purge types, ink usage, purge counts, and purge codes ..................3-32

[ 6 ] Ink cartridge capacities ........................................... ....... ...... ....... ......3-32

3.2.2.3 Carriage drive mechanism ....................................................................3-33

3.2.2.4 Paper pulling-in, registration, feeding and ejecting mechanisms..........3-37

3.2.3 Sensors and Actuators..............................................................................3-41

3.3 CONTROL ELECTRONICS ......................... ....... ...... ...... .......................................3-44

3.3.1 Components..............................................................................................3-44

Confidential

3.1 OVERVIEW

Line

Color

LCD

Fax Control Section

SDAA

MJ PCB

Control

panel

Speaker

ADF unit

- ADF motor

Backup

battery

Scanner unit

- CIS unit

- CIS motor

Host

USB

interface

WLAN*

WLAN

PCB

Ink jet printer unit

- Head/carriage unit

- Carriage PCB with

head flat cables

- Carriage motor

- Ink refill ASSY

- Maintenance unit

LAN

*

LAN

interface

Printer Control Section

Print data

- Compact Flash

- Memory Stick

- SD Memory Card

- xD-Picture Card

PhotoCapture

Center

Paper feeding

mechanism

- Paper feed

motor

- ASF motor

- Digital camera

(with PictBridge)

- USB flash

memory drive

USB

interface

Power

supply

AC

(Overview_BHL9_A3)

* For wireless LAN-enabled model.

3-1

Confidential

3.2 MECHANICAL COMPONENTS

This machine consists of the scanner mechanism and printing mechanism. It uses five motors

(CIS motor, ADF motor, paper feed motor, ASF motor, and carriage motor), three encoders (PF

encoder, ASF encoder, and CR encoder), various sensors, and two thermistors.

Scanner Mechanism

Document path for ADF scanning

(Left)

Document for flat-bed scanning

Printing Mechanism

Ink supply and ink jet mechanism, head maintenance mechanism, and carriage drive

mechanism.

(Right)

(BHL9A3_ADF_1)

(Front)

- Carriage drive mechanism

3-2

(Rear)

- Ink supply and ink jet mechanism

- Head maintenance mechanism

(3_01_BHL9_A3)

Confidential

Paper pulling-in, registration, feeding and ejecting mechanisms

Recording paper path

(Front)

(Rear)

(3_02_BHL9_A3)

3-3

Confidential

Scanner Mechanism

(See Section 3.2.1.)

- Document scanning mechanism CIS motor

(stepping motor)

Printing Mechanism

(See Section 3.2.2.)

Encoders

(See Section 3.2.3.)

- Automatic document feeder (ADF)

mechanism

- Ink supply and ink jet mechanism

(See Section 3.2.2.1.)

- Head maintenance mechanism

(See Section 3.2.2.2.)

(Head capping and carriage lock)

+

(Purge, air removing, and head wiper)

-Carriage drive mechanism

(See Section 3.2.2.3.)

- Paper pulling-in, registration, feeding

and ejecting mechanisms

(See Section 3.2.2.4.)

- Paper feed motor encoder (PF encoder)

- ASF motor encoder (ASF e ncoder)

- Carriage motor encoder (CR encoder)

ADF motor

(stepping motor)

ASF motor*

(DC motor)

+

Paper feed motor

(DC motor)

Carriage motor

(DC motor)

ASF motor*

(DC motor)

+

Paper feed motor

(DC motor)

Sensors

(See Section 3.2.3.)

Thermistors

(See Section 3.2.3.)

- Document front sensor

- Document rear sensor

- Scanner cover sensor

- Ink cartridge cover sensor

- Registration sensor

- Paper width (media) sensor

- Purge cam switch

- Cap lift cam switch

- Ink empty sensors (black, yellow, cyan and magenta)

- Ink cartridge detection sensors (black, yellow, cyan and magenta)

- Head thermistor

- Casing internal temperature thermistor

* ASF motor: Auto Sheet Feeder motor

3-4

Confidential

3.2.1 Scanner Mechanism

This mechanism consists of the automatic document feeder (ADF), document cover, and

scanner unit (scanner cover).

The scanner unit consists of a scanner top cover, CIS unit, CIS drive assembly, and scanner

base.

The detailed illustration on the nex t page s hows the components making up the ADF: document

pull-in roller, document separation roller, document feed rollers, document ejection rollers,

ADF motor, and document front and rear sensors.

For further details on the sensors, see Section 3.2.3.

ADF unit

ADF & document

cover ASSY

Document cover

White reference film

CIS drive assembly

(CIS motor)

CIS unit

Scanner top cover

CIS drive belt

CIS flat cable

Scanner unit

(Scanner cover)

Scanner base

CIS idle pulley

CIS rail

(3_03_BHL9)

3-5

Confidential

Document feed rollers

Document pressure rollers 1

Document separation roller

Document pull-in roller

Document support

Document ejection rollers

Document path for ADF scanning

(Left)

CIS unit

Document rear sensor actuator

Document pressure rollers 2

Pinch rollers

ADF motor

Document front sensor actuator

ADF parts

Document pressure bar

Document for flat-bed scanning

(BHL9A3_ADF_2)

(Right)

The scanner mechanism offers two types of scanning: ADF scanning and flat-bed scanning. It

automatically swi tches to the for mer a t t he start of a scan operation if the document front sensor

inside the ADF detects a document.

3-6

Confidential

(1) ADF scanning: Document moves acros s stationary CIS unit

Placing a doc um ent face up in the ADF activates the document front sensor, switching to ADF

scanning.

The CIS drive mechanism (details below) operates for each scanning command executed. First,

the CIS mot or moves the CIS unit to the white reference film for white level compensation.

Secondly, the ADF motor rotates the docu me nt pul l-in roller to pul l the document int o t he ADF.

Thirdly, the CIS motor again moves the CIS unit to the ADF scanning position.

The document separation roller feeds the pages one at a time, starting from the top, to the

document feed roller, which rotates to move the page in a curve left, down, and right. The page

is scanned as it passes over the CIS unit. It then leaves the machine face down onto the

document cover. The machine ejects subsequent pages above this one to preserve the document

page order.

(2) Flat-bed scanning: CIS unit moves under stationary document

The user lifts the document cover, places a page (or open book) face down with the left and top

edges fitting on the left and top guidelines on the glass plate, and closes the document cover.

The CIS drive mechanism (details below) operates for each scanning command executed. The

CIS unit first moves to the white reference film for white level compensation. It then moves

right, scanning as it goes. It returns to its home position after the scan.

CIS drive mechanism

The contact image sensor (CIS) unit rides along the CIS rail, driven by the CIS drive belt.

Clockwise motion of the CIS motor moves the unit to the left; counterclockwise motion, to the

right.

This unit consists of the document illumination LED array, the lens array gathering the light

reflected from the scanned image, the CIS PCB converting the light input to pixel data output,

and the CIS glass.

The CIS unit used in the machine supports color scanning. In scanning color documents, the

CIS unit illuminates them by turning on the red (R), green (G), and blue (B) LEDs alternately.

In scanning monochrome documents, it turns on the green LEDs only.

3-7

Confidential

3.2.2 Printing Mechanism

The printing mechanism co nsists of the following.

Ink supply and ink jet mechanism (Section 3.2.2.1)

Head maintenance mechanism (Section 3.2.2.2)

Carriage drive mechanism (Section 3.2.2.3)

Paper pulling-in, registration, feeding and ejecting mechanisms (Section 3.2.2.4)

The ink supply mechanism

supplies ink to the head/carriage unit, in which the ink jet

mechanism sprays ink droplets from the head nozzles onto paper.

The major components of the ink supply mechanism (shown on page 3-10) are:

- Ink refill assembly: This secures the ink cartridges and connects them to the corresponding

ink supply tubes.

- Ink supply tubes: These supply the head/carriage unit with ink fed from the ink cartridges via

the ink refill assembly.

The major components of the ink jet mechanism (head/carriage unit shown on page 3-12) are:

- Front end: This is an ink-jet head consisting of piezoelectric plate (PZT), metal plates, nozzle

plate, and head driver.It jets out ink to produce images on paper.

- Back end: This consists of damper assemblies and air vent unit. Each damper assembly

dampens the ink pressure fluctuations in the corresponding ink supply tube and collects air

bubbles that result from pressure changes on the ink.

To keep the optimum head performance, the head maintena nce mechanism

(shown on page 3-

31) uses the rotational torque of the ASF motor* to cap the head nozzles in order to prevent

them from drying up. It also uses the rotational torque of the paper feed motor to purge for

removing air bubbles from the head/carriage unit and wipe off any ink remaining on the head

nozzle surface.

The carriage drive mechanism

(shown on page 3-33) moves the head/carriage unit with a

carriage motor (DC motor) along the recording paper. The CR encoder sensor mounted on the

head/carriage unit scans the CR encoder strip and monitors the current head position relative to

the home position and the current travel speed.

The paper pulling-in, registration, feeding and ejecting mechanisms

motor* and paper feed motor (both are DC motors).

The major components are:

- Paper tray: Recording paper is stored in this tray.

- Paper pull-in rollers (shown on page 3-38):

These rollers pull in paper into the machine.

- Bank ASSY (shown on page 6-73):

This separates paper, sheet by sheet to feed it into the

printing section.

- Jam clear cover (shown on page 3-37):

Opening this cover allows the user to access paper jammed.

It also guides paper pulled in from the paper tray into the

printing section.

*ASF motor: Auto Sheet Feeder motor

3-8

are driven by th e ASF

Confidential

- Paper feed roller (shown on page 3-38):

This roller performs paper registration and feeds paper to

the printing section precisely.

- Paper ejection roller (shown on page 3-37):

This roller ejects paper and keeps paper tension tight.

- ASF motor* (shown on page 3-38):

This motor pulls in paper, switches the paper feed operation

modes, and drives the head capping mechanism and

carriage lock mechanism of the maintenance unit.

- Paper feed motor (shown on page 3-38):

This motor feeds recording paper and drives the purge

mechanism, air removing mechanism and head wiper

mechanism of the maintenance unit.

- Clutch gears L and R (shown on page 3-38):

Clutch ge ar L switches the transm ission route of the AS F

motor rotation between the paper pulling-in mechanism and

the head capping & carriage lock mechanisms.

Clutch gear R transmits the rotational torque of the paper

feed motor to the purge gear (for purge, air removing and

head wiper mechanisms).

- ASF rotary encoder: This generates a signal indicating the rotation speed of the

ASF motor shaft. The signal is sent to the controller and

used for controlling the paper pull-in position and speed.

- PF rotary encoder: This generates a signal indicating the rotation speed of the

PF roller gear. The signal is sent to the controller and used

for controlling the paper feed position and speed.

*ASF motor: Auto Sheet Feeder motor

3-9

Confidential

3.2.2.1 Ink supply and ink jet mec hanism [ 1 ] Overview

The ink supply and ink-jet mec hanism con sist s of the he ad/car riag e unit, four ink cart ridge s, ink

refill assembly, and four ink supply tubes.

The head/carriage unit scans the surface of the recording paper, jetting out ink supplied through

the ink supply tubes onto the paper to produce images. For further details, see "[ 3 ] Head/

carriage unit" below.

The four ink cartridges (black, yellow, cyan, and magenta) are mounted on the ink refill

assembly. For further details, see "[ 4 ] Ink cartridges" below.

The ink refill assembly secures the ink cartridges and connects them to the corresponding ink

supply tubes. For further details, see "[ 5 ] Ink refill assembly" below.

The ink supply tubes supply the head/carriage unit with ink fed from the ink cartridges via the

ink refill assembly. For further details, see "[ 6 ] Ink supply tubes" below.

(Maintenance unit)

Head/carriage unit

(Flushing box)

Engine unit

(Ink absorber box)

Ink refill assembly

Ink supply tubes

(3_04_BHL9)

3-10

Confidential

[ 2 ] Features

A distinct feature of this machine is the use of ink supply tubes between the ink cartridges and

the head/carriage unit. Relieving the head/carriage unit of the task of carrying heavy ink

cartridges back and forth across the page, the approach generally adopted by other ink-jet

printers, offers the following advantages.

- Lower po wer consumption

- Lower noise levels

- Lower vibration

During print operation, the ink-jet mechanism inside the head/carriage unit sprays ink droplets

from the head nozzles. The loss of this ink from the head produces a negative pressure that

replenishes the head with ink from the ink tank through the supply tubes.

Note, however, that the above ink flow is only possible when the ink supply tubes are full of

ink. The factory therefore primes the ink supply path by applying strong suction to the head

nozzles with the maintenance unit to suck both air and ink through the ink supply tubes.

Leaving too long interval between this priming and actual use, however, risks air bubbles,

increased viscosity, and other quality issues with the ink in the supply tubes. Before using this

machine for the first time, therefore, this machine automatically replaces the ink supply path

contents with fresh ink using an initial purge, a repeat of this priming operation.

When the machine is on standby, a constant negative pressure (which is produced according to

the difference in height between the head/carriage unit and ink cartridges) is applied to the rear

of the print head, thus preventing ink from leading out of those nozzles.

Note: The above applies only as long as this machine rests on a horizontal surface. Standing

this machine on end or even just tilting it backwards with the print head uncapped risks

overcoming this slight negative pressure preventing ink leakage from the head nozzles.

Piezoelectric ceramic actuators inside the print head convert this ink to droplets sprayed onto

the paper. For further details, see "[ 3 ] Head/carriage unit" below.

3-11

Confidential

[ 3 ] Head/carriage unit

)

(

)

The head/carriage unit con sist s of a fr ont end ( ink-j et hea d) a nd a back e nd (damper and air vent

unit) as shown below.

The front end consists of metal plates laminated together and etched to form ink flow channels.

Piezoelectric ceramic actuators generate the spray pressure. The response of individual front

ends to applied voltages and waveforms varies, however, because of the nature of piezoelectric

materials, fluctuation in manufacturing accuracy, and other factors. The front end therefore

leaves the production line with head property labels giving property data. The manufacturer

writes this prope rty data to the EEPROM on the main PCB incorporating this unit. Based on the

property data of the front end, the processor drives piezoelectric ceramic actuators to insure

consistent performance without fluctuations.

Back end

(Buffer and air vent unit

(Front)

Head driver

Filter

Piezo plate

Metal plates

Front end

(Ink-jet head)

Nozzle plate

3-12

Head

Confidential

Front end

Front end components and their main roles

- Piezoelectric pla te

Applying a voltage stretches the plate, serving as the actuator for spraying ink. Consisting of

thin piezoelectric plates laminated together, this plate can be driven even by a low voltage.

- Filter

This removes foreign materials from the ink.

- Metal plates

These form the head nozzle pressure chambers, ink flow paths, and manifolds.

- Nozzle plate

This plate has a total of 470 nozzles--47 nozzles x 2 lines staggered x 5 rows (black x 2,

yellow, cyan, and magenta).

- Head driver

This flexible circuit board holds the piezoelectric driver chip.

Nozzle array (head bottom plate viewed from the bottom)

Yellow

Black

Black

Paper feed direction

Print head travel direction

Cyan

Magenta

Black

Black

Nozzles

Yellow

Channels

Cyan

Magenta

3-13

(Nozzle)

Confidential

Ink spray function

The head employs drop-on-demand ink-jet printing.

Print commands to the drive circuit apply a bias voltage to the layer electrodes on the

piezoelectric ceramic surface stretching the elements perpendicular to that surface. Drive

signals removing t hi s voltage for specif ic channel electrode s allow the piezoelect ri c elements to

return to their or iginal shape , suc king i nk into the co rresp ondi ng chann els*. Re applyi ng the b ias

voltage stretches the elements once again, applying pressure to the ink, spraying it from the

head nozzle. The ink drop hits the paper on the platen, forming a dot.

* Pressure chambers for individual nozzles

3-14

Confidential

Back end

Damper ASSY (Magenta)

Air bubbles

Left chamber

Damper ASSY (Cyan)

Air bubbles

Right

chamber

Left chamber

Damper ASSY (Y ellow)

Air bubbles

Left chamber

Damper ASSY (Black)

Air bubbles

Left chamber

Back end components and their main roles

Right chamber

Right

chamber

Right

chamber

Shut-off valves

Air vent unit

(Air vent rods)

(A part of maintenance unit)

(Air vent cap)

(BackEnd_E)

- Damper assemblies

Each assembly has two roles: dampening the ink pressure fluctuations* in the ink supply tube

as the carriage moves and collecting air bubbles that grow in the ink flow path.

* Ink pressure fluctuations: As the head/carriage unit travels, inertia means that the ink remains in the

same place, temporarily raising or lowering the pressure in the right chamber.

- Air vent unit

At regular scheduled in terva ls, thi s vents any air bubbl es that have accumul ate d in the damper

assemblies. The air ven t ro ds in the mai nt enance unit push up the shut-off valves, opening th e

air vent flow paths.

3-15

Confidential

Damping

Without damping, ink pressure fluctuations directly affect the size of ink-jet head droplets,

risking lower print quality.

Each damper assembly has two chambers. The one on the right in the illustration below has a

loose film across its top and serves as a damper. The film immediately flexes in and out in

response to falls and rises in pressure, adjusting the chamber volume to counteract pressure

fluctuations in the ink supply tubes.

Film

Left chamber

This loose film flexes in and out in

response to changes in ink pressure.

(DamperFunc)

Air buffering

Liquid ink contains trace amounts of air. These molecules coalesce into air bubbles as the

piezoelectric ceramic actuators vary t he pressure on the ink in the ink-jet head channel. (See the

illustration on page 3-13.) Removing as many of these bubbles as possible before the ink

reaches the in k-jet head is ess ential to main taining prop er print qualit y. The above ill ustration

shows how the damper assemblies provide air buffers, the chambers on the left, for

consolidating th ese ai r bu bbles a way fro m the ink-j et head and vent fl ow path s for pu r gi ng them

at regular scheduled intervals.

3-16

Confidential

[ 4 ] Ink cartridges

Filled with ink

Disc valve S

Sensor actuator

Air

Ink empty sensor

Ink

Disc valve D

Ink near-empty/Ink empty

Ink cartridge features

This machine uses four ink cartridges: a black one and three color ones with a slightly lower

capacity. It features horizontal insertion in the ink refill base over plastic needles.

Each cartridge has two ports: one supplying the ink for printing and another intaking air to

replace that ink. Both ports have a disc valve preventing ink leakage. When a cartridge is

mounted over the plastic needles in the ink refill base, these valves are opened to secure flow

paths for both the ink and the air.

(3_06)

These ink cartridges are single-use affairs. There is no provision for refilling them. The design

reduces environment load by using only burnable materials yielding no toxic substances.

Inks

This machine uses dye-based inks for colors and pigment-based ink for black. Using the

pigment-based black ink reduces fuzziness from print character outlines, boosts resolution for

black dots, and produces clearer images on plain paper.

3-17

Confidential

Ink near-empty/ink empty detection

The ink refill assembly has four ink empty sensors (photosensors of transparent type) that

monitor the ink levels with sensor actuators inside the ink cartridges.

Disc valve S

Air intake port

Air

Ink empty

sensor

Ink

Ink supply port

Ink empty sensor

Sensor actuator

Disc valve D

Sensor actuator

Float

(InkBackflowPrevention)

(InkEmptySensor_2)

Attached to one end of the sensor actuator is a float. When there is ink in the cartridge,

buoyancy lifts the float, rotating the sensor actuator about a pivot near the center of the actuator

to block the light beam to the ink empty sensor, indicating that there is ink.

As the ink level in t he ink cart ridge drops, howev er, th e fl oat f alls, event ually moving t he se nsor

actuator out of the beam.

Light hitting the s ensor outputs the "i nk ne ar -empt y" si gnal to the controll er t h at sho w s t he " I nk

low" message and activates a firmware counter tracking ink usage during ink-jet printing,

purges, and other operations. When this counter reaches a predetermined limit, the firmware

regards it as "ink empty" and shows the "Cannot Print" message to prompts the user to replace

it.

3-18

Confidential

[ 5 ] Ink refill assembly

Ink empty sensor PCB

Ink empty sensors

Cartridge release levers

Ink refill case

(3_07)

Ink cartridge detection sensors

Ink cartridge detection

sensor PCB

Ink foam case

Ink refill base

3-19

Ink foam

Ink refill base foam

(3_08)

Confidential

Ink refill as sembly components and thei r main roles

- Ink refill case

- Cartridge release levers

- Ink refill base and its foam

- Ink cartridge detection sensors (on the ink cartridge detection sensor PCB)

- Ink empty sensors (on the ink empty sensor PCB)

- Ink foam and its case

Pushing each ink cartridge into the ink refill case

until it clicks secures it and forces the

cartridges' ink supply port into close contact with the ink refill base to prevent ink leakage.

Pressing down the cartridge release lever

pops the ink cartridge out of the ink refill case.

The ink from the ink cartridges flows through the ink flow channels provided in the ink refill

base into the ink supply tubes. As the ink level in an ink cartridge drops, the pressure inside

falls, drawing air in the ink cartridge.

The ink cartridge detection sensors

detect ink car tridges inserted wh en the machine powe r is

ON.

The ink empty sensors

detect ink remaining in the ink cartridges loaded. An ink empty sensor

actuator blocking the light beam to an ink empty sensor indicates that there is ink in the ink

cartridge. When ink runs low, the actuator moves out of the beam, activating the sensor ("Ink

near-empty") and showing the "Ink low" message.

If any of the ink cartridges is replaced with the one having different ink volume when the

machine power is OFF, the corresponding ink cartridge detection sensor and ink empty sensor

issue different sig nal s when the power is turned ON next time so that the control ler prompt s th e

user to reload the ink cartridge.

At the back of the ink refill case is an ink foam

that absorbs any ink that leaks from the air

intake ports of the ink cartridges loaded when the machine is tilted during transportation or in

storage, preventing ink spread in the machine.

[ 6 ] Ink supply tubes

These are made of low-density polyethylene (LDPE) providing a highly impermeable barrier

against air ingress and drying out of the ink during extended periods of nonuse. This material is

also soft and highly flexible to better withstand the sharp and frequent bending associated with

high-speed head operation repeatedly over extended periods.

3-20

Confidential

3.2.2.2 Head maintenance mechanism [ 1 ] Overview

The head maintenance mechanism, which keeps the optimum head performance, consists of the

maintenance unit and the ink absorber box. (See the illustration below.)

The maintenance unit has the following mechanisms.

- Head capping mechanism (See page 3-24.)

- Carriage lock mechanism (See page 3-24.)

- Purge mechanism (See p age 3-2 5.)

- Air removing mechanism (See page 3-27.)

- Head wiper mechanism (See page 3-28.)

The ink absorber box absorbs the ink sucked out by purge operations.

(ASF motor)

Maintenance unit

(Head/carriage unit)

(Paper feed

motor)

(Flushing box)

(Engine unit)

Ink absorber box

(Ink refill assembly)

(Ink supply tubes)

(3_09_BHL9)

3-21

Confidential

[ 2 ] Maintenance unit components

k

(3_10)

Pump switching unit

Purge gear

Cap lift cam

Cap lift

cam gear

(ASF changeover

gear)

Head wiper

Maintenance unit

- Cap lift cam and its gear

These parts transmit the rotational torque of the ASF motor transmitted via the clutch gear L

to the head cap holder. (See [ 4 ] "Power transmission route to the head maintenance

mechanism and motor rota tional direction.")

- Head cap unit

When the power is off or the machine is not printing, the head cap unit fits tightly over the

print head to prevent the head nozzles from drying up and to seal the head nozzles for purge

operations to suck up old ink.

Air vent cap

Air vent rods

Carriage loc

(Part of head

cap holder)

Head cap holder

Head cap unit

Viewed from the top Viewed from the b ot t om

Purge cam

Purge bevel gear

(ASF changeover gear)

Cap lift cam gear

Purge gear

Planetary arm

Tube pump

(3_11)

- Head cap holder

This lifts up the head cap unit to fit it tightly over the print head to seal the head nozzles. (The

had cap holder is driven by the ASF motor.)

- Carriage lock

This is a part of the head cap hol der. It locks the head/carriage uni t in it s home posit ion so that

the head cap unit protects the head nozzles.

- Purge gear and purge bevel gear

These gears transmit the rotational torque of the paper feed motor via the clutch gear R to the

planetary arm. (See [ 4 ] "Power transmission route to the head maintenance mechanism and

motor rotational direction.")

-Planetary arm

This switches the rotational t orque of the paper feed motor ( t ran smitted via the purge gear a nd

purge bevel gear) to the pump switching unit or tube pump depending on the direction of

paper feed motor rotation .

-Purge cam

This rotating cam drives the pump switching unit, the air vent rods, and the head wiper. Each

drive position of the purge cam is detected by the purge cam switch. (See Section 3.2.3.)

3-22

Confidential

- Pump switching unit

This switches the application target of the negative pressure generated by the tube pump

between the head cap for black ink, the one for color ink, and the air vent cap. Usually the

pump switching un it is switc hed to the openin g tube to the at mospheri c air so that the pr es sure

in the head caps and air vent cap is equal to the normal atmospheric pressure.

- Air vent cap and rods

The air vent cap and rods remove air bubbles trapped in the damper assemblies in the back

end of the head/carriage unit.

During air venting with the tube pump, the air vent cap fits tightly over the ai r vent uni t in the

head/carriage unit so that the negative pressure applies to the air vent unit. Pushing up the air

vent rods opens the shut-off valves inside the air vent unit, removing air bubbles trapped in

the damper assemblies. (For the air vent unit, see Section 3.2.2.1, [ 3 ].)

- Head wiper

As the head/carriage unit moves, this wipes off any ink remaining on the head nozzle surface.

- Tube pump

A roller squeezes the main drain tube looped inside, forcing their contents toward the ink

absorber box and creating negative pressure.

3-23

Confidential

[ 3 ] Mechanisms constituting the head maintenance mechanism

p

(1) Head capping mechanism

The ASF motor drives the head capping mechanism. When the power is off or the machine is

not printing, this mechanism fits the head cap unit (which contains two head caps) tightly over