Page 1

SERVICE

MANUAL

FOR

LZ2-B852

LZ2-B853

LZ2-B854

< <

.

~

r

.

•

BROTHER

INDUSTRIES,

NAGOYA, JAPAN

LTD.

Page 2

«

MECHANISM~

[I]

Upper shaft and needle

[I]

Lower shaft and rotary hook mechanism

Zig-zag mechanism . . . . . . . . . . . . . . . . . . . 2

m

Feed mechanism . . . . . . . . . . . . . . . . . . . . . 3

m

Presser mechanism

m

II)

Tension release mechanism

Lubrication mechanism

m

...................

bar

mechanism .

..................

...........

..............

CONTENTS

.

.

4

.

4

.

5

1TI1

Sewing tension . . . . . . . . . . . . . . . . . . . . . .

[g)

Feed dog height and level adjustment

[!l] Adjustment

[ill Rotary hook oil level adjustment

[!]] Replacement

[!!] Adjustment

[Q]

Adjustment

winding

of

rotary hook

of

thread cutter

of

thread tension release

of

the quantity

.............................

............

.......

..........

of

the bobbin

...

...

22

22

23

23

24

24

24

DISASSEMBl.ING

PROCEDURES

[I]

Cover

[I]

Rotary hook . . . . . . . . . . . . . . . . . . . . . . . . 7

11]

Feed mechanism . . . . . . . . . . . . . . . . . . . . . 7

[TI

Presser bar and Needle bar . . . . . . . . . . . . 8

[[) Timing belt . . . . . . . . . . . . . . . . . . . . . . . . . 9

~

ASSEMBLING PROCEDURES

[I]

Timing belt . . . . . . . . . . . . . . . . . . . . . . . . . I 0

(I]

Presser bar and Needle bar . . . . . . . . . . . .

[!]

Feed mechanism . . . . . . . . . . . . . . . . . . . . .

III Rotary hook . . . . . . . . . . . . . . . . . . . . . . . .

m (,over

~ADJUSTING

ITJ

Needle

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .

(I]

Needle bar position

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .

11]

Stitch lenght adjustment . . . . . . . . . . . . . .

[TI

Reference position adjustment lever (Needle

position) adjustment . . . . . . . . . . . . . . . . . .

[[) Zigzag width reference position

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .

II)

Zigzag regulator position (Front and Back)

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .

[I]

Needle and feed timing adjustment

[!]

Adjustment

II]

Needle and rotary hook timing adjustment

[ID

Presser foot height adjustment

..................

..............................

PROCEDURES

bar

position (Left and Right)

(Front

of

needle sidewise movement

; . . . . . . . . . . . 6

~-

~

...

and Back)

.....

.........

10

II

13

14

15

16

16

16

16

17

18

19

20

20

21

21

«TROUBLESHOOTING

6

GUIDE~

.

25

Page 3

~

MECHANISM

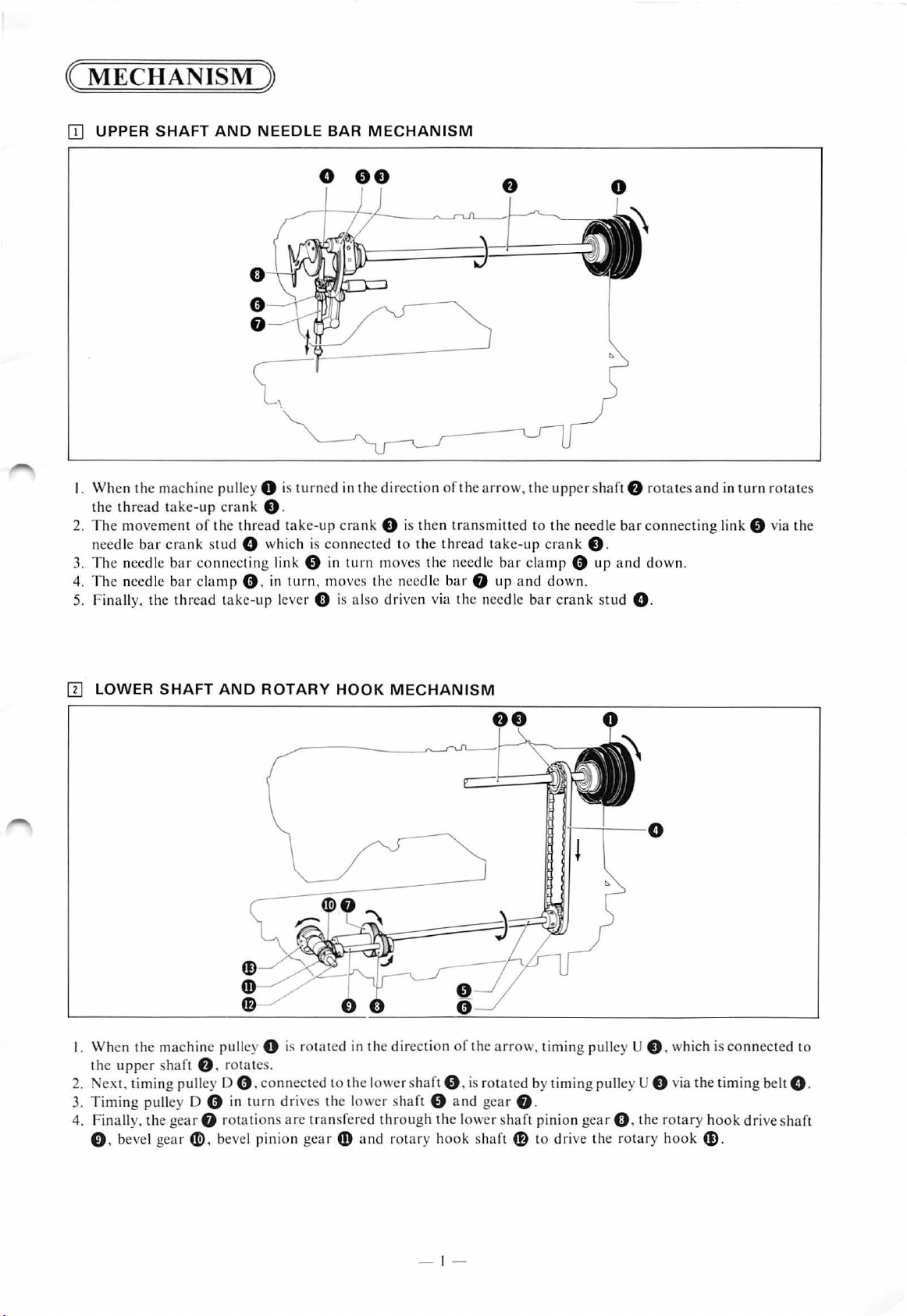

[I]

UPPER

I.

When the machine pulley 0 is turned in the direction

the thread take-up crank

2. The movement

needle

3.

The needle

4. The needle b

5.

Finally, the

SHAFT

bar

crank stud 0 which

AND

of

the thread take-up crank e is then

bar

connecting link 0 in tu rn moves the n

ar

cla

thr

ead take-up lever 0 is also driven v

mp

~

NEEDL

e.

0 ,

E BAR

o

oe

is

connected to the

in

turn

. moves the needle bar

MECHANISM

oft

he

arrow,

the

upper

tr

ansmitted to the needle

thr

ead

ee

dle bar cla

f)

ia

the needle

take-up

up

crank

mp

and

down.

bar

crank stud 0 .

shaft

e.

0 up

f)

rotates and

bar

connecting link 0 via the

and

down.

in

turn

rotate

s

IT]

LOWER

I. When the machine pulley 0 is rota ted in the direction

the

2.

ext. timing pulley D 0 . connected to the lower shaft 0 , is rotated by timing pulley U e via the timing belt 0 .

3.

Timing pulley D 0 in turn dri ves the lower sha

4.

Finally,

e. be

upper

the gear

ve

SHAFT

sha

ft f). rotates.

l gear

4]!)

AND

ROTARY

f)

rotations arc transfered

, bevel pinion gea r

HOOK

4D

MECHANISM

ft

0 a nd gear

through

and rotary hook sha

the lower

of

the

ar

row, timing pulley U e, w

f)

.

shaf

ft

t pinion

41}

gear(). the rotary h

to dri

ve

the rotary h

hi

ch is connecte d to

ook

ook

G)

.

drive shaft

- 1 -

Page 4

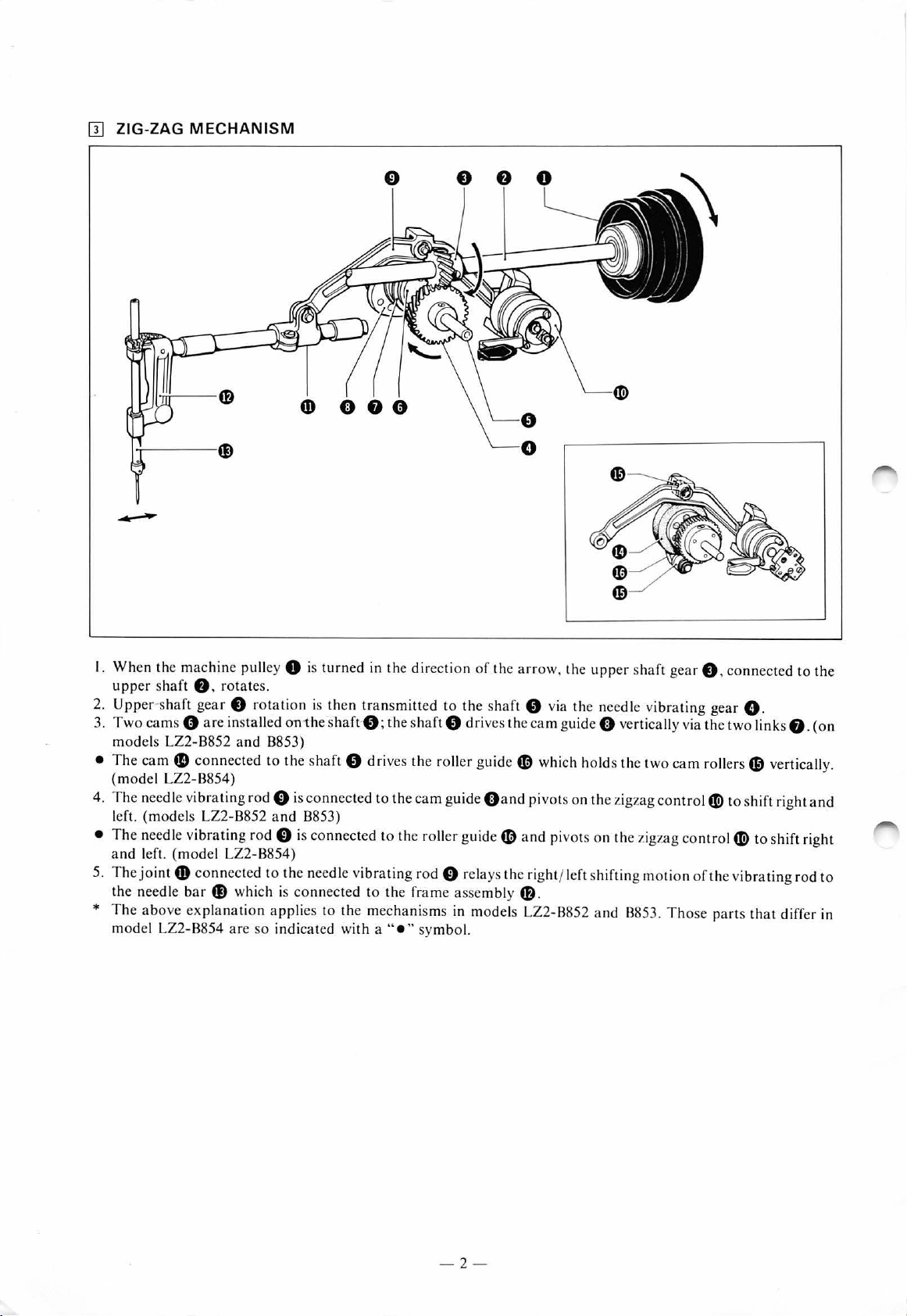

IIJ

ZIG-ZAG

MECHANISM

I. When the machine pull

upp

er sha

ft

8 ,

Upp

er s

haft

2.

3. T wo cams 0 are installed oni he s

mod

els LZ2-B8

• The cam

(mod

el LZ2-B854)

4. The needle v

left. (models LZ

• The needle v

a

nd

left. (model LZ2-88

5. The joint

th

e needle bar

*

Th

e a bove explanation a pplies to the mec hanisms

model

gea r 0 rotatio n is

52 and

fD

connected to the s

ibr

ating

ibrating

4D

connecte

4J)

LZ

2-8854

ey

0 is

turn

ed in the

rot

ates.

th

en

transmitt

haft

-8 ;

8853)

haft 8 drive

ro

d 0 is c

2-8852 and

rod 0 is

d to the needle v

whi ch is connected to the fra me asse mbly

are

so

8853)

54)

indic

onn

ected to

connec

ted

ibr

ated with a

direction

ed to the sha

th

e shaft 8

s the roller

the

cam

to the roller

ating rod 0 relays the right

"e

" sy

of the arrow,

ft

8 via

dri

ves the cam guid

guide~

guid

e O a

g

uide~

in models LZ2-B852 and 8853. Those

mbol.

whi ch hol

nd pivo

a nd pivots on the zigzag

f)

.

the upper s

the need

e 0 verti

ds

the t

ts on

the

zigzag

jlc

ft shifting moti

haft gea

le v

ibr

ating gear G.

cally via the t

wo cam

control

control

on

r 0 ,

connected to the

wo

links

rollers G) verticall

G>

to s

hif

t right and

G>

to shift right

of the v

par

ibrating r

ts that

differ in

f).

od

(

on

y.

to

- 2 -

Page 5

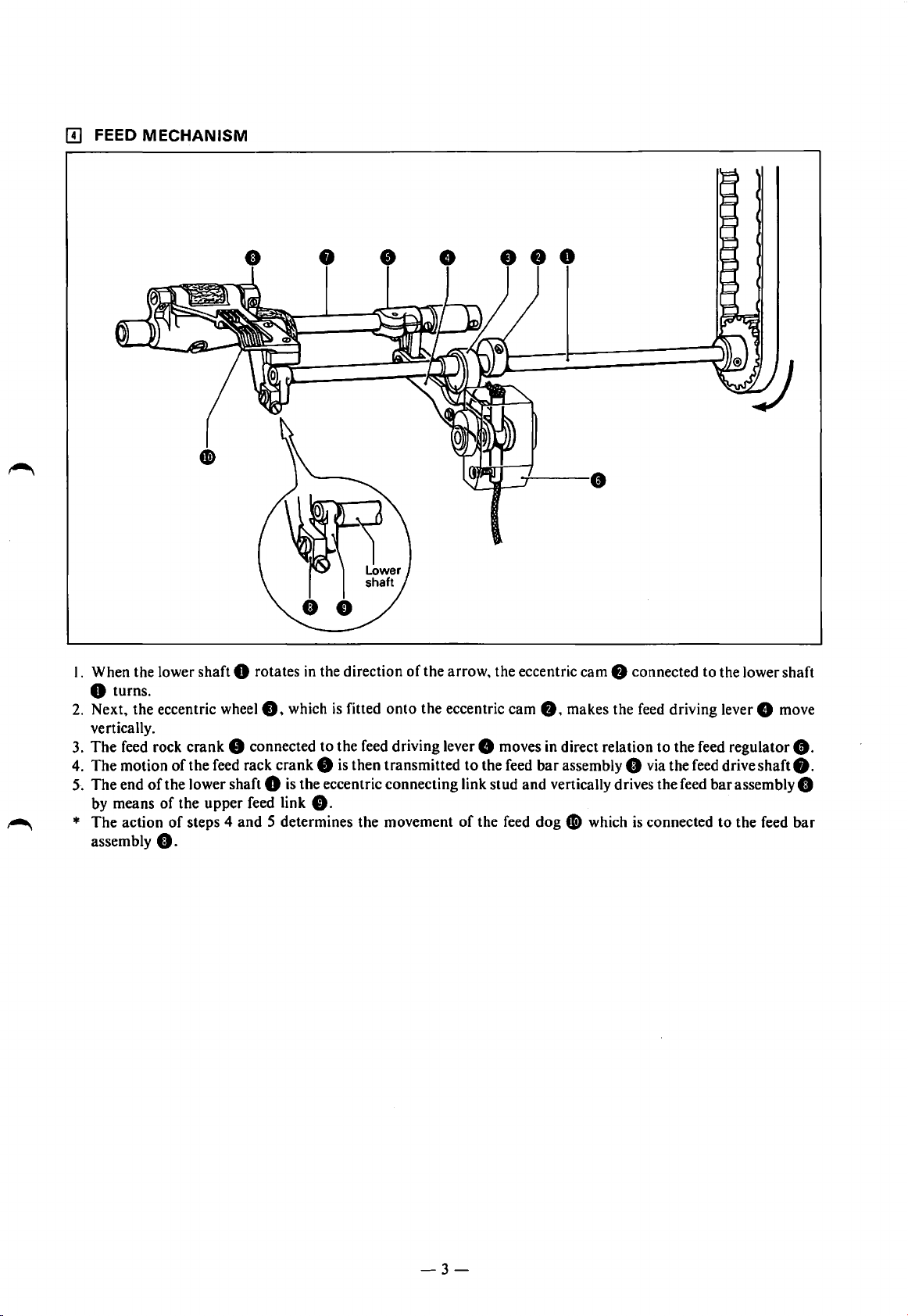

[II FEED

MECHANISM

I. When the lower shaft 0 rotates in the direction

0 turns.

2.

Next, the eccentric

vertically.

3.

The

feed rock

4. The motion

5·.

The end

by means

*

The

assembly

of

the lower shaft 0

of

action

of

0.

of

wheel8,

crank

8 connected to the feed driving lever 8 moves in direct relation

the feed rack crank 8

the upper feed link

steps 4 and 5 determines the movement

which

is

fitted

onto

is

then transmitted

is

the eccentric connecting link stud and vertically drives the feed bar assembly 8

8.

of

the arrow, the eccentric cam 8 connected to the lower shaft

the eccentric cam

to

the feed

of

the feed dog

8,

makes the feed driving lever 8 move

to

the feed regulator

bar

assembly 0 via the feed drive shaft

I)

which

is

connected

to

the feed

8.

8.

bar

-3-

Page 6

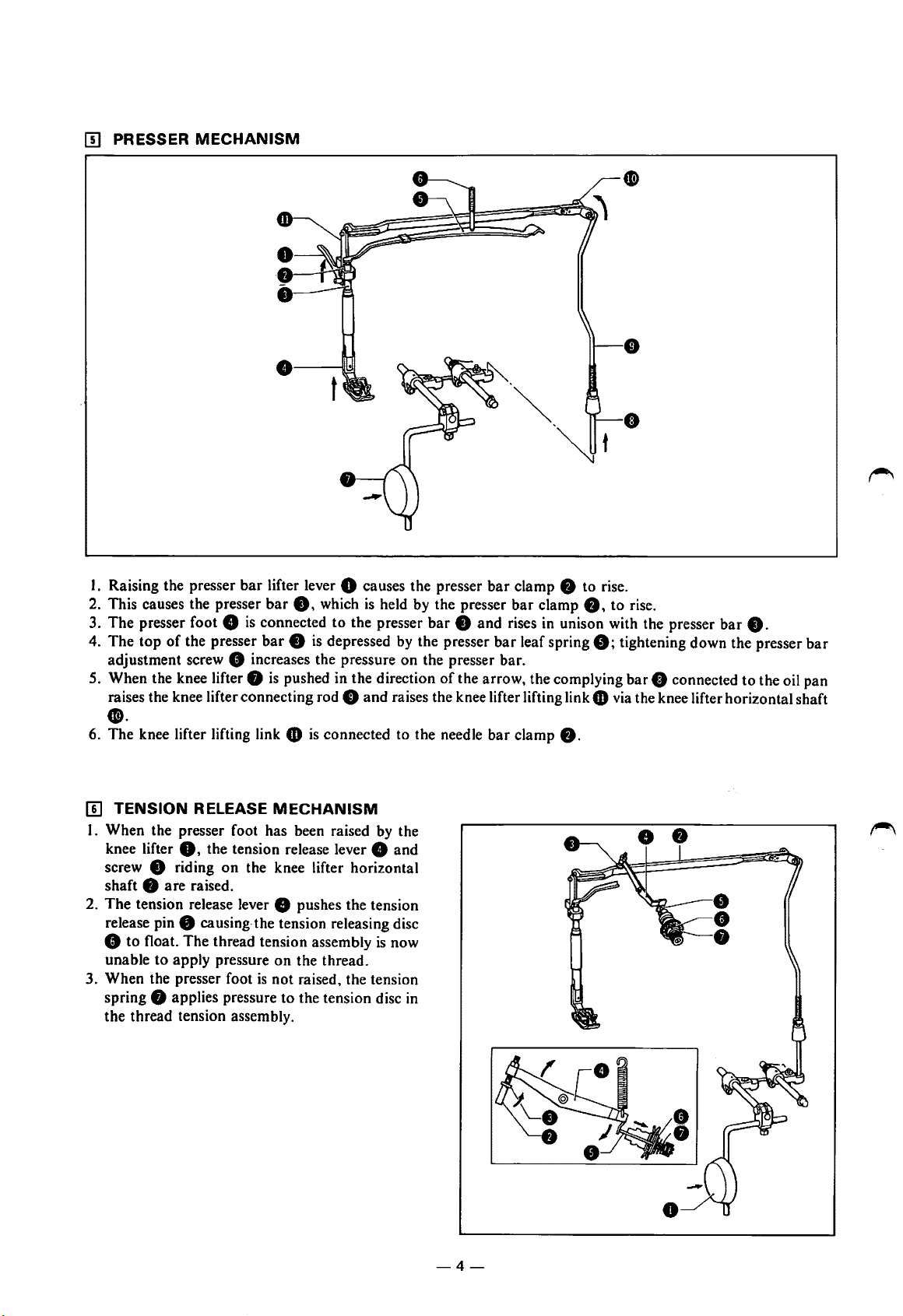

[!]

PRESSER

MECHANISM

•

I. Raising the presser

2. This causes the presser

3.

The

presser foot 8

4.

The

top

of

the presser

adjustment screw 8 increases the pressure on the presser bar.

5. When the knee lifter 8

raises the knee lifter connecting rod 0 and raises the knee lifter lifting link e via the knee lifter horizontal shaft

••

6. The knee lifter lifting link e

[!]

TENSION RELEASE

I. When the presser foot has been raised by the

knee lifter

screw 8 riding on the knee lifter horizontal

shaft 8

2.

The

release pin 8 causing-the tension releasing disc

0,

are

raised.

tension release lever 8 pushes the tension

8 to float. The thread tension assembly

unable

3. When the presser foot

spring 8 applies pressure to the tension disc

the thread tension assembly.

to

apply pressure on the thread.

bar

lifter lever 0 causes the presser

bar

8,

which

is

held by the presser

is

connected

bar 8 is

is

pushed in the direction

MECHANISM

the tension release lever 8 and

is

not raised, the tension

to

the presser

depressed by the presser

is

connected to the needle

is

now

in

bar

clamp 0 to rise.

bar

clamp

0,

to rise.

bar

8 and rises

bar

of

the arrow, the complying bar 8 connected to the oil pan

bar

in

unison with the presser

leaf spring

clamp

8;

0.

bar

8.

tightening down the presser

bar

-4-

Page 7

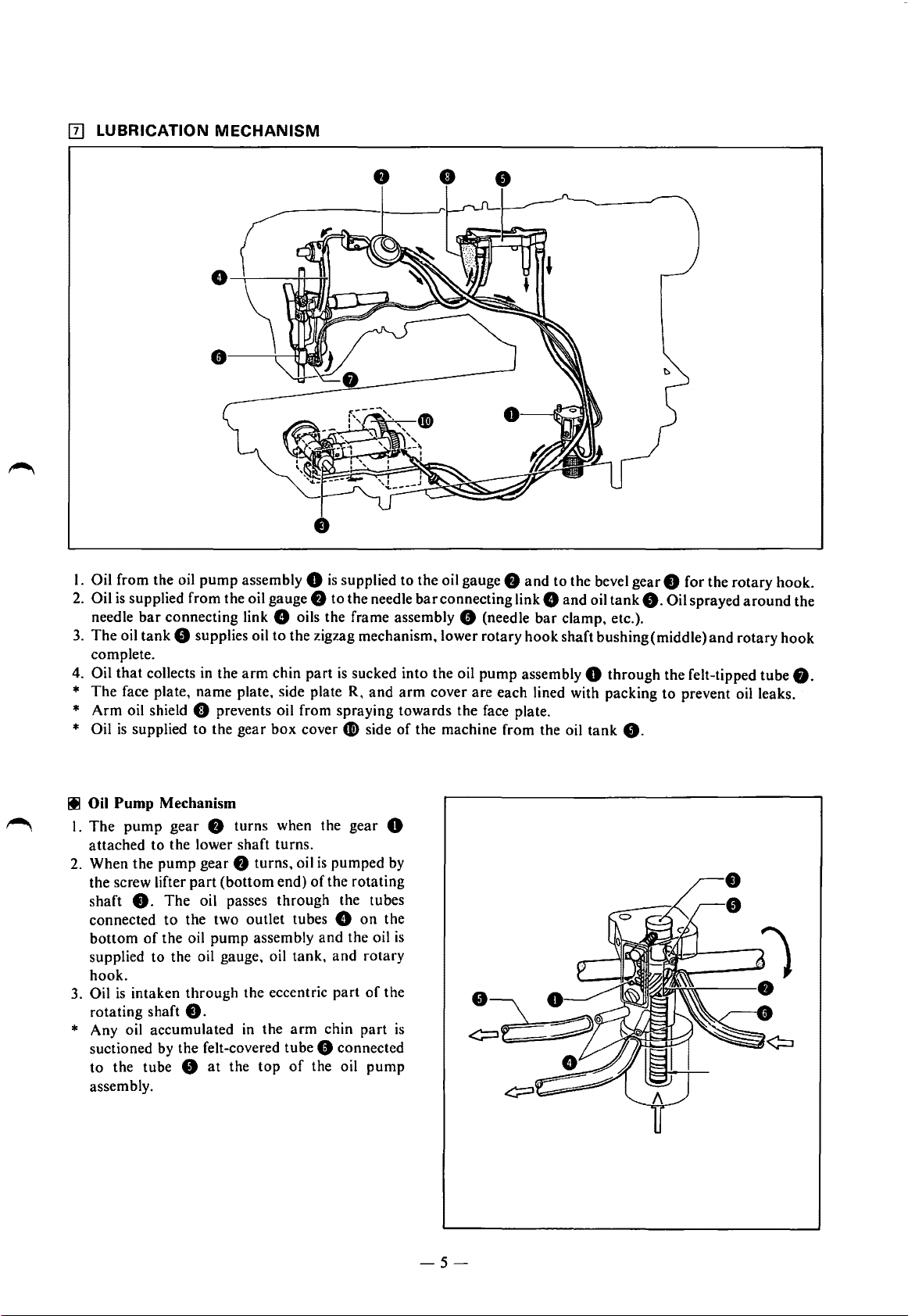

[II LUBRICATION

MECHANISM

I. Oil from the oil

2.

Oil

is

supplied from the oil gauge

bar

needle

3.

The

oil

tank

complete.

Oil

that

4.

*

The

*

Arm

* Oil

collects

face plate, name plate, side plate R,

oil shield 0 prevents oil from spraying towards the face plate.

is

supplied to the gear

pump

assembly 0

connecting link 8 oils the frame assembly 0 (needle

8 supplies oil

in

the

arm

to

chin

box

is

supplied to the oil gauge

f)

to the needle

the zigzag mechanism, lower rotary

part

is

sucked into the oil

cover

CJi)

Ill Oil Pump Mechanism

The

pump

gear

f)

I.

attached

2. When the

the screw lifter

shaft

connected

bottom

supplied to the oil gauge, oil tank,

hook.

3.

Oil

rotating shaft

8.

is

intaken

to

the lower shaft turns.

pump

The

to

the two outlet tubes 8

of

the oil

through

8.

* Any oil accumulated in the

suctioned by the felt-covered tube 0 connected

to

the tube 8

assembly.

turns when the

gear

f)

part

(bottom

oil passes

pump

at

the

turns, oil

end)

through

assembly

the eccentric

arm

top

of

gear

is

pumped by

of

the rotating

the tubes

and

the oil

and

part

chin

the oil

and

side

0

on

the

rotary

of

the

part

pump

f)

and

to the bevel gear 8 for the rotary hook.

bar

connecting link 8

pump

arm

cover are each lined with packing

of

the machine from the oil

is

is

and

bar

clamp, etc.).

hook

shaft bushing (middle)

assembly 0 through the felt-tipped tube

oil

tank

tank

8.

8.

Oil sprayed

to

prevent oil leaks.

and

around

rotary

the

hook

O.

-5-

Page 8

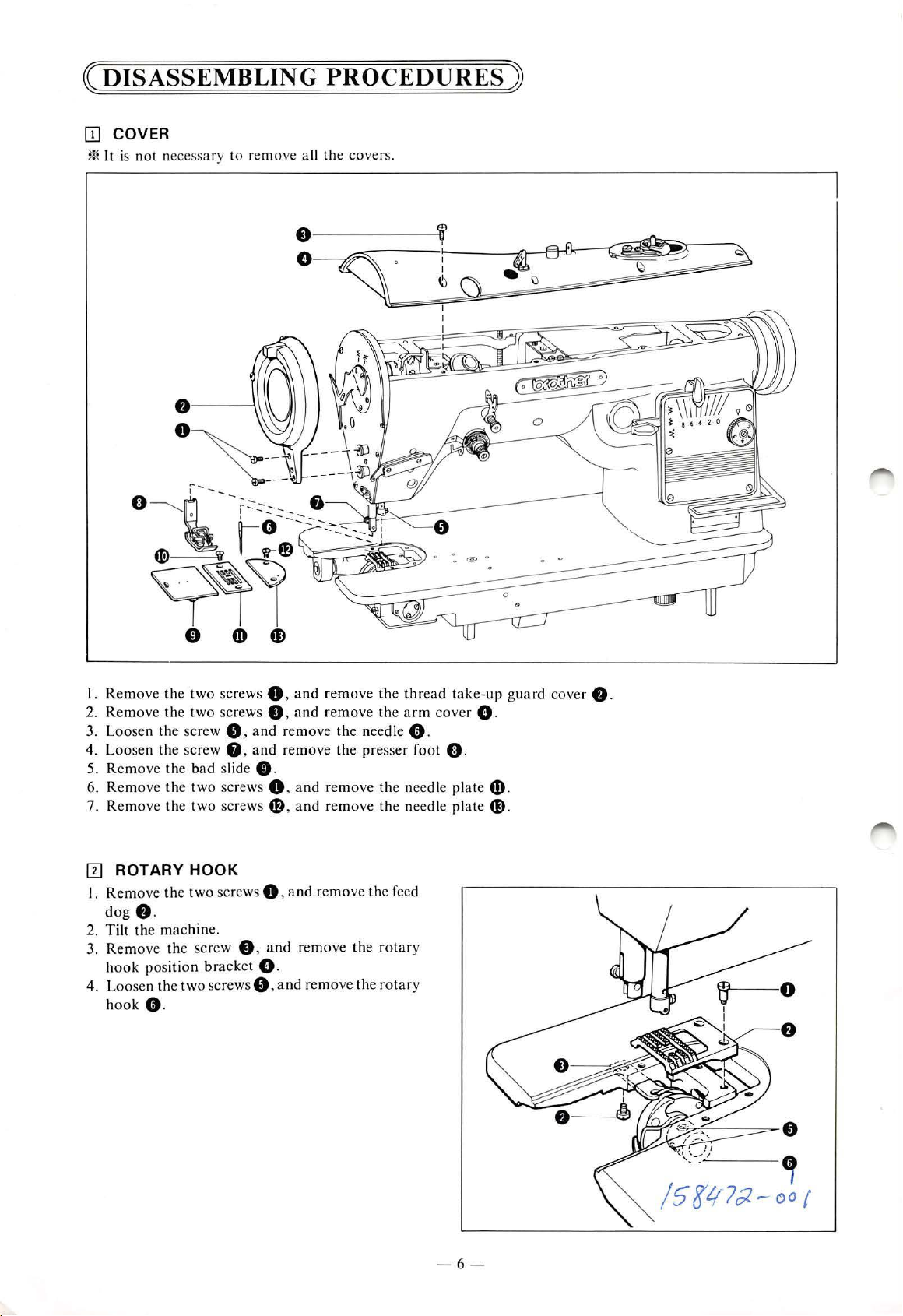

~

DISASSEMBLING

OJ

COVER

*

It

is n

ot

necessary to remove all the covers.

PROCEDURES

~

I.

Remove

2. Remove

3. L

oose

4. Loose n the screw 8 ,

5. Remove the b

6. Remove

7. Remove the two sc rews

IIJ

ROTARY

I.

Rem

dog

2. Tilt the machine.

3. Remove

h

ook position bracke

4. Loosen the

h

ook

th

e two screws 0 ,

th

e two sc rews 8 ,

n the s

cr

ew 0 ,

ad

slide C).

th

e two screws 0 , and

HOOK

ove the

f).

tw

o screws 0 ,

th

e screw 8 ,

two

scre

0 .

t 0 .

wsO,and

and

remove

and

remove the arm

and

remove the need le 0 .

and

remove the presser fo

remo

ve the need le plate

4D

,

an

d remove

and

remove

and

remove

the

remove the

the

thread

the need

the feed

rot

ary

rotary

take-up

cover

ot ().

le plate

0 .

fD

fD

guard

.

.

cover

f)

.

- 6 -

Page 9

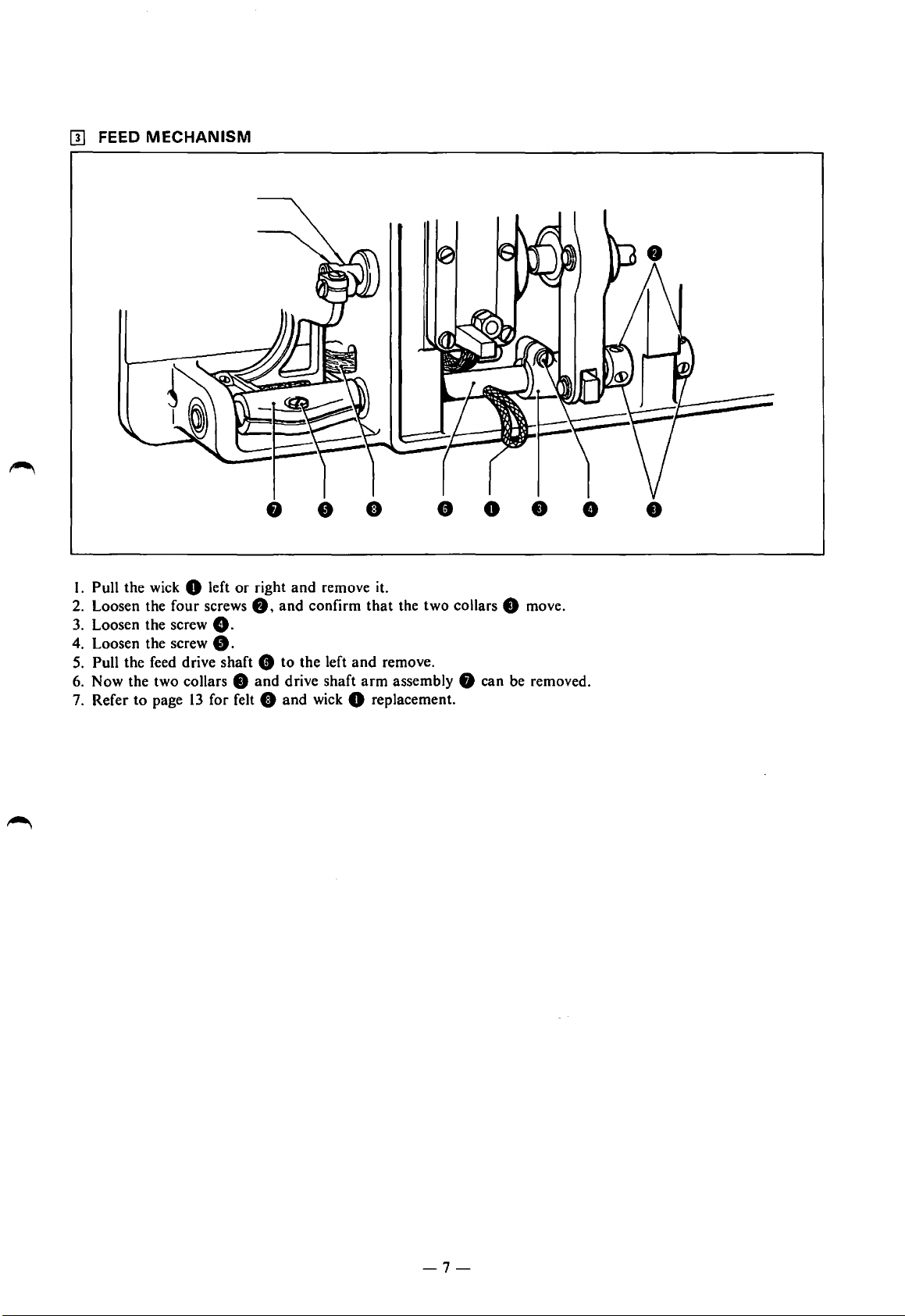

IT]

FEED

MECHANISM

•

I. Pull the wick 0 left

2. Loosen the four screws

3.

Loosen the screw

4. Loosen the screw

5.

Pull the feed drive shaft 8 to the left

6. Now the two collars

7. Refer to page

or

right

and

8,

and

8.

8.

8

and

drive shaft

13

for felt 0 and wick 0 replacement.

•

remove it.

confirm

and

•

that

remove.

arm

•

the two collars 8 move.

assembly 8 can be removed.

0

•

•

-7-

Page 10

[!]

PRESSER BAR

AND

NEEDLE BAR

• •

• •

•

•

Presser Bar

I. Raise the machine.

2.

Remove the two screws

also be removed.

3.

Remove the eight screws

4. Loosen the work clamp adjustment screw

* Note

5.

6. After removing the screw

*

Needle Bar

7.

8. Loosen the screw

that

if the screw

Loosen the screw

I)

and link

Be

careful not

Remove the screw 8 and remove the needle bar thread guide

assembly.

to

* When the needle

9. Loosen the screw

10.

Loosen the screw fJ, and remove the needle

* Loosen the screws e

connecting link

8 can be removed.

0,

and

remove the thread take-up lever

8,

and remove the face plate

is

loosened

G)

for the presser

together.

1),

remove the presser

lose the presser

e·,

and remove the needle

bar 8 is

f),

and pull pin F

and

fJ

bar

removed, the needle

to

the thread take-up crank

8 until there

too

much the presser bar leaf spring 8 will come out.

bar

clamp

1),

and lower the presser

bar

ball bearing

fD

forward

CD

bar

8 from the top.

bar

clamp

and

bar

frame

8.

The thread take-up mounting disc 8 can

8.

The packing 8 can also be removed.

is

no pressure applied to the presser

bar

0;

remove the presser

0 from the top.

on the

top

of

the presser bar

8.

G)

can be removed.

out.

f).

fl,

and the needle

bar

crank

0.

stud.

bar

and

0.

bar

clamp

needle bar

r-'\

-8-

Page 11

[I]

TIMING

BELT

I. T ilt the

Loosen

2.

3.

Loosen

4. Whi

* Be

5. Take the timin g

6. Raise the

Loo

7.

8.

Take the timing

machin

screw 0 a

screw 0

le depr

ess ing pin 8 wi

carefu

l not

machin

sen the two

e.

nd

remo

and remo

to

lose

the

belt

~

e.

scr

ew

s 0

belt~

ve

the

thr

ee screws

ve the feed regula

th

a screw

pin 8 o r

off

of

and

off of the a

dri

sp

timing

remov

rm.

f)

;

remo

ve

tor stud

ver, remove the length

ring C) .

pulley D

e the machin

e.

4D.

e pulley

the

reverse lever s

cont

ass

embl

y

haft

rol di al ().

G)

.

8 and rev

er

se l

ever

e.

- 9 -

Page 12

~ASSEMBLING

[J]

TIMING

BELT

PROCEDURES )

jj

0

I. Raise the

2.

Mount

3.

Mount

*

Tighten the

machine

4. Tilt the

5.

Mount

6.

Turn

*

Turn

7. Inse rt the s

*

Mount the edge

Mount

8.

screw

9. Mo

mounting

10

. Install th e reverse lever

II. Loo

12. Turn

*

The

machine.

the

timing

the

machine

front

pull

ey, a

mach

ine.

the

timing

the

machine

ing

the

machin

pring 8 and

of

the feed

4D

unt the reverse

sen sc r

the length

reverse lever

regulator

.

screw e.

ew

8 . set the reverse lever

control

belt 0

mounting

djacent

belt 0

pulley G b y

G)

from

pulley G

screw

to

the

onto

e pulley G will

pin 0 .

the

len

gth

stud

shaft

4B

from

shaft

dial

and

s

hould

not

the

hole

onto the

8 ,

the

screw in the

timing

hand, and

mount

and

install the le

control

41)

4B

in link D

the

and

set

move

dial into

reverse lever

the

vertically.

on the t

upp

pull

arm

op

of

er shaft 8 and

screw

found

upper

shaf

ey U 0 .

mount

the

the

timing belt

ngth

the Y-groove

and

feed regula

side, pass it

6)

6)

to the

center

feed length to "0"

(If

it moves, tighten the le

the a

rm

onto

timing

on

the.f

t 8 .

timing

tighten

orwa

belt 0

the

rd si de

0 firml y

control

with

position and retight

of

tor lever D

through

three

(the

dial

C).

the

backstich unit.

feed

set screws

lowest setti ng).

pulley U 0

two

mounting

of the

rotational

onto

timing

onto

and

regulator lever

ngth contr

pulley D 0 .

pulley D

tight

en it in place with

fn

.

en

the screw.

of

the

upper

shaft

8 .

screws

8.

direction

of

the

0.

mounting

U

4J)

an

d secure with

ol dial. Refer to page 16.)

-

10

-

Page 13

11]

PRESSER BAR

AND

NEEDLE BAR

• •

•

• •

•

0

Needle Bar

1.

Mount

2. Push pin

3.

Mount

8 and temporarily tighten set screw

4. Set the zigzag width scale

temporarily tighten set screw

5.

Install the needle

* Before installing the needle

with screws

Presser

6.

Insert the presser

7.

Hook

temporarily tighten set screw

8.

Set

presser

Make the adjustments on the following pages after assembling the machine as above. After adjustments are

completed, install the face plate

and presser plate spring • with two screws

the needle

F 8 all the way in,

the needle

CB

and

Bar

the link

the presser

bar

leaf spring

tD

bar

bar

crank

bar

8 from the top

rod assembly 0 in the

and

temporarily tighten set screw

of

needle

bar

crank rod

arm

chin part.

assembly8;

8.

to

"0". With the needle

bar

8 in the center

8.

bar

thread guide 0 anq set screw 0 onto the needle

bar

above, install the needle

bar

crank

48.

bar

8 into the

hole onto the horizontal shaft

ball bearing 8

fJ

does not come off the presser bar.

arm

1).

onto

fl

and packing

chin

the top

part

and

screw set screw e into the presser

8.

Pass the presser

of

the presser

fD

with eight screws fl. Then install the thread take-up lever e

bar

e.

8.

pass it through the needle

of

the oval hole in the

bar

G.

stud

I)

and

needle

bar

Cl

through the presser

Cl.

Tighten adjustment screw

bar

arm

chin part,

bar

connecting link e

bar

CJ.

bar

clamp

fl

so

clamp

C1

that

and

the

-11-

Page 14

•

Center, front-back,

of

oval hole

·~

Center, left-right,

of oval hole

Adjust the left-right position

I. Install the needle plate and needle.

2. Set the zigzag width scale to "0". (Turn the machine pulley and confirm that the needle tip does not move either

or

right.)

left

*

If

the zigzag width will not assume a

3. Loosen the set screw

centered left and right in the needle hole

4. Firmly tighten set screw

Adjust the front-back position

I. Loosen screw

centered front and back in the needle hole

2.

Make sure there

lightly when the needle zigzags.

3. Firmly tighten set

8;

depress pin F

is

no play in the forward-back direction of the needle bar crank rod assembly and that it moves

screw

of

the needle bar.

"0"

position, refer to page

e and move the needle

of

•.

of

the needle bar.

and/

orR

and move the needle bar crank rod assembly 0 so that the needle tip

of

8.

18

and

bar

crank rod assembly 0 left or right so that the needle tip

the needle plate.

the needle plate.

I

•

7.1

mm

19

for adjustment.

is

is

Adjust the presser foot height

I. Install the presser foot

2. Raise the presser foot • with the presser

3. Place a 7 .I mm thick block gauge under the presser

tighten set screw

When adjustments are completed, install the needle, presser foot and needle plate.

fl.

•.

bar

lifter lever

foot.;

-12-

e.

while pushing the presser

bar

clamp

G)

down, firmly

Page 15

IT]

FEED

I. Tilt the machine.

2.

* Mount the link connected to the feed driving shaft

3.

4. Make sure there

5.

6.

*

7. Adjust the needle and feed timing.

* When the adjustment

8.

9.

MECHANISM

Mount the feed driving shaft 0 from the left side

8,

crank

8,

and collar 8 in that order.

Align the left end

Remove the oil cap 8 and insert the wick 8 through the feed

8 from center

wick

Replace the oil cap

To

replace the felt: loosen the set screw, remove the feed

(I)

On

models LZ2-8852, 8853 and 8854: On 8852, set the mark on the thread take-up lever 8 to the

on the face plate;

(2) After properly positioning the mark on the thread take-up lever

the marks

Set

the feed length regulator to "0

Turn

the machine pulley

of

the feed driving shaft 0 with the

is

no left-right play in the feed driving shaft

of

the feed driving shaft

8.

on

8854, set it

on

the eccentric cam 0

is

ended, firmly retighten the two set screws

and

with the crank 8 positioned where it does not move, firmly tighten fillister screw

to

:E

and

..

, the smallest setting.

of

the

arm

arm 8 on

arm

0.)

; on model 8853, center the mark between the

eccentric wheel

bed, passing it through the feed driving shaft

the end

bed and tighten the set screw 8 for the collar

of

the lower shaft.

0.

drivingshaftO.

bar

hinge pin,

8.

Cf).

(Pull

out

aprox.

and

replace.

~

and

loosen the two set screws

100

CD

mm

~

:~:

marks.

and

fD.

arm

8.

of

the

mark

align

••

10.

Temporarily tighten set screw 8 until the front-back position adjustment

[Model LZ2-B852

·853]

[Model LZ2-B854]

-13-

of

the feed

dog

is

completed.

Page 16

[!]

ROTARY HOOK

Zigzag

width

0 mm

~·

Maximum

zigzag

width

0

0.1

......

0.5

mm

Highest position

~-~~~~.._..

I. Temporarily install the

2.

Temporarily install the rotary

3. Install the needle.

4. Adjust the needle

*

Set

the zigzag width to '"0".

Turn

the machine pulley

Now, align the rotary

between 0

f"V

0.05 mm.

* Set the zigzag width to the

8854.)

Turn

the machine pulley

Loosen needle

hook

point 8

is

aligned with the needle center.

Also, reconfirm

5. Install the feed

6.

Install the needle plate 0 with the two screws

7.

Set

the length control dial

8. Adjust the

bar

and

dog

centering·of the feed

* Loosen set screw e

dog

feed

9. Adjust the feed

Feed

I.

Standard

2.

Loosen the set screw

above the needle plate.

·*

After adjustment, firmly tighten the set screw

Feed

I. When the feed

parallel.

To

To

lowered.

2. When adjusting the feed

90° range from the

* When the feed dog 8 level

dog

* After adjustment, firmly tighten the two set screws

8 does

dog

Dog

Height Adjustment

height when the feed

Dog

Level Adjustment

dog 8 is

prevent puckering,

prevent material from slipping (stitching from skipping), adjust the feed

height.

rotary

and

rotary hook timing.

hook

Then

clamp set screw 8 and vertically shift the needle

top edge

that

the rotary

8 with the two set screws

and

not

strike the needle

height

1),

hook 0 with two screws

hook

position bracket 0 with set screw

(On

model LZ2-B853, set the needle position adjustment lever

and

align the

point

firmly tighten the screw

maximum

and

set the needle to its furthest left position.

of

the

mark

on

the

0 with the needle center,

thread

hook

setting.

to

(5

hole

rotary

mm

in

the needle

hook

8.

thread

take-up lever with the

8.

on

model LZ2-B852,

to

point gap

0.

1).

to

the

maximum

dog

in the needle plate.

adjust the front-back,

and

bias.

dog 8 is

turn

the feed

setting.

and

right-left gaps with the feed driving shaft

plate

0 when the machine pulley

raised

to

its highest position above the needle plate

bar

lifting link hinge pin

between

G).

raised

above

adjust

dog

standard

is

the needle plate,

the feed

dog

bias so

8 level, loosen the two set screws

(reference) position.

adjusted, the feed

standard

that

the front

dog

height will change, making it necessary

CJ.

0"'

0.5 mm

•

•

Ll.O

mm

..

r

~!.?~~~

8.

and

set the needle to rotary

and

8 mm

bar

8.

adjusting the gap between the rotary

0.1

f"V

0.5 mm when the rotary

is

between 0

1),

and

level

is

when the feed dog 8

is

raised.

41.

and

-v

is

turned.

adjust the feed

dog

adjust the feed

Front lowered

''cp''

mark

on

models LZ2-B853

0.05 mm.

dog

and

8 level so

bar

to

the center.)

on

the face plate.

hook

point 8

hook

arm

41

so

is

0.8 mm.

to

a height 0.8

needle plate

that

the front

hinge pin

to

4D

recheck the feed

point

that

with a

•

gap

and

the

mm

are

is

-14-

Page 17

[II

COVER

0 0

I.

Rai

se the

tall the need le pl

2. In s

3. Ins

tall the slide pl

4. Ins

tall

5. In

sta

ll

6. Ins

tall the a

7. Ins

tall

the

the

the

machin

pre

sser

nee

dl

rm

thread

e.

ate

0 with t

ate

0 .

foot

8 w

e 0

with

top

cover 0 with

take-up guard

set

ith

sc

wo scr

set scr

ew

rew 8 .

eig

ht

cover

ews

9 .

screws

4i)

with two

8 .

0.

screws

4)

.

-

15

-

Page 18

~ADJUSTING

PRO.CEDURES

~

[I] NEEDLE BAR POSITION (LEFT

I. Remove the

adjustment.

2.

Set the

3. Loosen set screw 8 from the

4. Adjust the needle

needle

hole in the needle plate.

5.

Firmly retighten set screw

arm

top

cover

zig1.ag

width scale

bar

is

positioned in the center

to

crank rod 8 so

8.

and

..

0".

AND

then make the

top

of

the arm.

of

the needle

[I] NEEDLE BAR POSITION (FRONT

I. Remove the thread take-up guard cover

and

plate

2.

Loosen the two screws

3. Push pin R 8

needle so

hole in the needle plate.

4. Firmly retighten the two screws

* When the adjustment

needle

back, and

smoothly when

then make the adjustment.

8.

and/

or

pin F 0 to adjust the

that

it comes to the center

of

the needle

8.

is

completed make sure the

bar

frame does not move forward and

that

the needle moves easily and

it

zigzags.

that

AND

and

RIGHT)

the

BACK)

face

ADJUSTMENT

~---------------------------------------,

Center, left-right

ADJUSTMENT

~--------------------------------------~

•

0

of

oval hole

[I] STITCH LENGTH

I.

Turn

the length dial 8 clockwise all the way

(in the direction

reverse

reverse lever 8 moves, loosen set screw 0 and

turn

back. Then retighten set screw

any vertical movement

Repeat this operation until the reverse lever 0

will not move when the length control

turned all the way in.

2.

Turn

scale reaches

loosen set screw 8 and adjust the feed carrier 8

bias with the

lever&

the length control

the machine pulley

"0". If the feed scale

crank

* When set screw 8

no movement in the feed regulator shaft

3. Loosen set screw 0 and install the reverse lever

that

it

is

so

Make the following adjustments on models LZ2B852

and

4. Set the length control dial

setting.

5.

Check if the length set

8

and

If the actual

reset the length control

setting and loosen set screw

control dial

and

then retighten set screw

level.

8854.

the actual stitch length are nearly equal.

and

0

just

ADJUSTMENT

ofthe

arrow),

does not move up

dial&

and

make sure the

ordown.lfthe

counter-clockwise

0 and check for

in

the reverse lever

dial&

and

make sure the feed

will

read "0",

8.

is

loosened, make sure there

f).

0 to the maximum

on

the length control dial

set stitch lengths are not equal,

the

dial&

amount

to

the minimum

8.

Turn the length

the lengths differ.

0.

in

8.

is

is

•

-16-

Page 19

It is

possib

l

ever action

s

prin

g h

ook ~ to

!IJ

REFERENCE

* o

adjustm

*

If

adjustments

th

e needle raised.

le

to change

. Rel

ease

adjust.

the

spr

stiffness

ing 0 .

POSITION

ent is needed on model

arc made

with

of the re verse

and

turn the

ADJUSTMENT

LZ2-B854

the need

le in the material. the needle wi

LEVER

because the zi

(NEEDLE

gzag

POSITION)

cam

sets

the

ll

be

bent.

ADJUSTMENT

refere n

ce

position.

Always

make

adjustments

with

[M

odel

LZ2-B852]

* T

urn

off the machine a nd

* Re

mo

ve the

oil

cap

If

the connectin

link s

tud

a

fter

adjustment.

[M

odel LZ2-B853)

* If

th

e need le positi

If

the

needl

I. Set the zig

2.

Set the needle

position.

0 (i.e.

•

If the lin

a

that the needle position

become

th

nd

adjust the needle

s leve

g link s

f)

is

turn

e positio n adju

zag lever

adjustment lever 8 to

Align

the

e lin

es

on the

es are not align

l.

Finall

e.

• L

oose

n set screw

on the l

re

For

turn set screw

For th

turn

*

When the

f

irmly retighten

*

The stopp

scr

Zigzag

I. Remove the

machin

2. L

oosen nut

3. Set

th

the cente

arge

tight

en set scr

the left

e right referen

set screw$ .

ews

0

Width Pos

e.

to

the maxi

at the n

r.

f)

and small b

ew

referen

0 to

adjustment

se

er

4D

shou ld contact the

a

nd~

iti o n

rubb

4!)

.

and turn

mum

eed

le d

rop

confirm

0 a

nd

tu rn the conn

tud

f)

is

turn

ed to the left

on adjustin

sti ng l

to

"0"

refer

ence

large

ed. loosen set screw

pos

y. firml y tig ht e n se t

, and

align the

f)

.

ce

line, l

adjust.

ce

line. l

is

completed.

t screws 0

during

Adjustment

er plug on the b

zigzag width

posi ti on (stitch) com

(counter-cloc

g lever 8 is

eve

.

mark

s on

a nd sma ll bus

iti

on set s

adjustmen

reference

ear

ings. T hen firmly

oose

n screw 0

oose

n

and~

use.

[LZ2-B854]

the ecce

ntr

that

th e mo to r h

ed

to the right (cl

r 8 is

se

a l

bushing

hings).

prin

g 0

t lever e

screw

screw

~

be sure to

.

tip

of

ack

of the

ic shaft

and adju

as com

ecting

lin k s

ockwise), the

kwise), the needle will move to

se

t to the ~ ·

t to the ~ mark (bottom

eve

l

L

0 .

so

lines

and

and

set

6)

.

st

so

es

to

tud

plete

ly sto pped r

f)

to

adjus

needle will

mark

(to p). the need le wi

).

0

- 17 -

t.

the

needle will

unnin

g.

mov

e to

the

lef

t.lfthe connecti

the right. Replace

ll move

move

to the

to

the

00

the

oil

cap

left position.

rig

ht position.

ng

0

Page 20

II]

ZIGZAG

Zigz

ag

* Zi

gzag

* If

adjustments

th

e needle

[

Model LZ2-88

I.

Loosen the set screw

brating leve

vi

desired zigz

set

screw 0 after

2.

The

indicate z

width

WIDTH

Width Adjustm

widt h

adjustment

arc

raised.

52]

r 8

ag

width.

figures in

is 5

igzag

mm.

the

width

[Model LZ2-B853]

I. The

farther left the n

set,

the greater

2. The figures in the

indicate zig

width

is 8

zag

mm.

the zigzag

width

[Model LZ2-B854]

I.

Loosen the set scr

vibra

ting lev

es

ired zi

d

set

screw 0 af

2. The figures in the

indicate zigz

wid

th

is 8

er e up

gzag

ag width

mm.

width.

ter adjus

REFERENCE

ent

s s

hould

made with the n

0 .

and mo

up

and down.

Remember to tig

adjustme

sca

le

on

in mm.

eed

le \·ibra tin g leve r 8 is

sca

le

on

in

mm. Max

ew

0 . and move

or

down. adjusting

Remember to

tment.

sca

le in the

in

mm.

adjusting to

nt.

the

fron

Maximum zigzag

width

the

front

front

Maximum zigng

POSITON

be

made after

eed

le in the

ve

the

hten

t a

rm

becomes.

arm cove r

imum

the needle

tighten the

arm cover

ADJUSTMENT

the

material.

needle

the

the

cover

zigzag

to the

machin

e is st o

the

need le will be bent. A l

e

Zigzag

width

[Model LZ2-

o-

B852) [Model

5mm

pped.

ways

LZ2-B853

o-

make adjust

[Mod

amm

el

) [

LZ2-

B854]

Mode

o- a

ment s

with

l LZ2 -B854)

mm

* If the above

Zigzag Lever Reference Posit ion Adjust me

(

minimum and max

<For

mode

I. Rem

2.

3. L

4.

5.

6. L

7.

*

ove the

Comp

oose

Turn

p

osition

Comp

oosen

Turn

maximum

8854).

Wh

en

retighten

adju

stments cann

imum

ls

LZ2-8

852

nam

e pla te.

letely lower zig

n set screw

set scr

where

let

ely

set scr

set sc

zigzag

the adju

set scr

0 .

ew 8 adjusting the

it does n

rai

se zigzag l

ew

0 .

rew 0 and adju

width (5

stment

ews 0 and

ot

zigz

ag

width a

and

8854>

zag levers

ot vibr

8 and

a te.

evers 8 and

st the needl e to the

mm

on 13852:8

is

completed.

0 .

be

needle

mad

djustm

e.

e.

nt

e.

to

mm

firmly

make th

ent)

a

on

e a

djustm

r-

--=====

ent

8852

below.

;:::===

18 -

========~::===

::=;

~---:;;;;:

0

~1

Page 21

<

For

model LZ2-

I. R

emove the zi

2.

Remove the nam

3. Ali

gn

the

zigzag lever 0 with the

nam

e plate.

4.

Loosen

zigzag

5. Re

6.

M

sid e (ar

7. L

needle

8853).

8. Retighten

zi

If the

following.

I.

Rem

2. Move

3.

Loosen

assemby

move.

4. Retighten set

*

The

adjuste

zi

op

sm

nut

lever 0 a

tight

en

nut

ove the zi

ound

oosen nut ~ and

to

its

nut~

gzag wid

gzag lever

eration , a

oot

th sca le

above adjustment

ove side pl

the

zigz

set

~

stiffn ess in the zi

d with set screw

hly

when the zi

B85

3>

gzag width

e plate.

Q)

and

adjust set

li

gns

Q).

gzag lever

"8"

on the

turn scr

maximum

-

Reinsta

dial.

ate

R.

ag lever

screw

0 wi

nd

6)

ang

le

so that the needle will not

screw

ll

so

that

scale

screw 0 so that the

exactly

0 a

s cannot be m

0 a

6)

.

gzag

not move

the

gzag

with

ll the

name

plate).

ew

tD

zigzag width (8

ll

the

ll the

and

adju

lever 0

fD

.

Adju

during machin

zigzag lever

width

dia l ass

name plate

way

emb

"0"

the

"0".

way

to the left

,

adjus

ting the

ade,

to the right.

st

the

ac

tion can be

st so

that the

on the

mm

0 m

is c ha nged.

ly.

on

a nd

do the

crank

e

oves

[}]

ZIGZAG

I.

Loose

2.

Adju

p

os

ition where the needle

and zi

* The

shaft.

*

After the adjust

screw

se t

REGULATOR

n set

sc

st the

gzag

regul

po

sitio n

O.

rew 0 .

pos

ition contr

ator

control s

ment

POSITION

ol s

tud

bar vibr

0 m

ove lightly.

tud

f)

is a n eccentri c

is completed, firmly tighten

f)

ating r

(FRONT

to the

od

0

AND

BACK)

ADJUSTMENT

0

-

19

-

Page 22

*When

completely stopped before

II]

making

NEEDLE

any

AND

FEED

of

the

standard

making

TIMING

adjustments, always

the adjustments.

ADJUSTMENT

turn

the power

off

and

make sure the

motor

has

[Model LZ2-8852

*

On

model LZ2-B852 set the thread

set it

to

Now make sure the

* If

the

needle

the

~

wheel

8

*

After

the

*

Put

a pointed screw 8 into the P-marked screw

hole

on

screw into the lower shaft screw stop.

·8853]

the

:~

mark;

and

feed timing

or

:~

marks

and

eccentric

adjustment

the eccentric

[Model LZ2-8854]

on

model LZ2-B853, center it between the ~ and

marks

on

the eccentric wheel 8

is

out

on

the face plate.

cam

0.

is

completed, firmly tighten the two set screws

cam

0 and tighten the

take-up

of

leverO

adjustment, first

Then

loosen the two set screws 0

mark

to

the ~ mark

and

eccentric

appropriately

on

the face plate;

:!

marks.

cam 0 on

align the thread

the lower shaft

and

align

0.

•

on

take-up

the

marks

model LZ2-B854,

are

aligned.

leverO

on

mark

the

eccentric

with

----·

[!]

ADJUSTMENT

I.

Loosen the set screw 0 in the upper shaft gear

0

on

the

upper

2.

Adjust the

tip moves in

* Adjust so

small as possible when the needle enters the

needle plate.

firmly retighten set screw

upper

that

OF NEEDLE SIDEWISE

shaft.

shaft

gear

0 so

that

an

inverted

needle sidewise movement

After

"U"

shape.

the adjustment

is

0.

the needle

is

as

completed.

MOVEMENT

[Model LZ2-8852 ·

[Model LZ2-8854]

• •

-20-

8853]

•

within

0.5

Page 23

[!]

NEEDLE

AND

ROTARY HOOK

TIMING

Zigzag width 0 mm

ADJUSTMENT

•

Maximum zigzag

•

0.1

"'0.5

I. Set the zigzag width

2.

Turn

the machine pulley,

this point, the rotary

Also, check

When the rotary hook point

rotary hook point

hook.

Set the zigzag width

3.

B854, set to 8 mm.)

4.

Turn

At this time, check

between

5.

If

the clearance

that

the machine pulley, setting the needle 8

0.1

I'V

* After adjustment, firmly tighten all

I!Ql

PRESSER FOOT HEIGHT

* Make adjustment after turning the power

and

confirming

stopped.

*

Standard

raised by the presser foot lifter 0

I. Raise the presser foot

cover

2.

Place a

foot

3. Loosen the set screw

4. Push the presser

and

height when the presser foot 8

8.

7.1

mm thick object under the presser

8.

screw

in

the set screw G.

* Firmly tighten the set screw G.

to

0 mm.

hook

the clearance between rotary hook point 8

0

and

to

the maximum setting. (On the LZ2-B852 model, set

that

0.5 mm.

is

not correct, loosen the set screw 8

that

the

On

model LZ2-B853 set the needle position adjusting lever

and

adjust the reference line

point 8 should be aligned with the center

0

is

not aligned with the center

needle 8

the clearance between the

motor

is

not within 0

of

the set screws

ADJUSTMENT

has completely

is

7 .I mm.

8 with the knee lifter

8.

bar

position guide 8 down,

width

•

mm

oft

he rotary take-up

and

needle 8

of

the needle,

I'V

0.05 mm, loosen the two set screws

to

the furthest left position.

upper

lip

of

the needle hole and rotary hook point 0

and

adjust by raising

8,

8.

off

is

to

the center.

to

the

"cf>"

mark

on

the face plate. At

of

the needle

is

or

when the clearance between the

to

5 mm; on the LZ2-B853

or

8.

between 0

lowering the needle

8.

I'V

0.05 mm.

and

adjust the rotary

•

•

and

bar

LZ2-

is

8.

Presser Foot Pressure Adjustment

* Presser foot pressure

bar

presser

screwdriver.

spring screw stud 0 with a

is

adjusted by turning the

* Presser foot pressure can be adjusted between 0

rv

9 kg

to

correspond

to

the material being sewn.

-21-

Page 24

[ill SEWING TENSION

Upper Thread

Weaker

* Lower thread tension

* Because the strength

adjustments should be made by the rotary tension

* Note

* The standard operational range

*

*

that

if the pretension 8

Thread

take-up spring

standard strength

a

To

take-up spring

turn

To

spring

slot in the tension stud

the desired strength.

Take-up Spring

15

"-J

25g.

adjust the operational range

the

rotary

change the strength

8.

insert the tip

is

adjusted by turning the thread tension screw

of

the pretension adjustment 8

is

too

weak, the thread would

of

the thread

8

is

a 8

"-J

12

mm. Also, the

of

the thread take-up spring

of

the thread

8.

loosen the set screw 8 and

tension stud bracket.

o'f

the thread take-up

of

a screwdriver into the

8 and turn, adjusting to

is

8.

0.

is

stronger than that

around

the rotary tens10n 8 may shp.

Lower Thread

Stitches

tension is too

Stitches

-

tension is too tight.

ldal seam

-

of

the rotary tension

when

upper thread

loose.

when

upper thread

. .

8.

fine

Weaker

[ffi FEED

Feed

1.

Standard height when the feed dog 0

2.

Loosen the set screw

above the needle plate.

* After adjustment, firmly tighten the set screw

Feed

I. When the feed

parallel.

To

To

lowered.

2.

When adjusting the feed dog 0 level, loosen the two set screws

90° range from the standard (reference) position.

* When the feed

dog

* After adjustment, firmly tighten the two set screws

DOG

HEIGHT

r-~--r;=~~~~----,-r

Dog

Height Adjustment

AND

8.

turn the feed

LEVEL

ADJUSTMENT

Highest position

1

1.0 mm

Highest position

is

raised

to

its highest position above the needle plate

bar

lifting link hinge pin

Lowest position

8.

and adjust the feed dog

Standard

2llllllllllll.a

Front

lowered

~

{j

{j

r-....

~

r---.

'--""

to

8.

Dog

Level Adjustment

dog 0 is

prevent puckering, adjust the feed

prevent material from slipping (stitching from skipping}, adjust the feed dog 0 level so that the front

dog

height.

raised above the needle plate, standard level

dog

bias so

that

the front

is

when the feed dog 0

is

raised.

8.

and adjust the feed

and

bar

hinge pin 8 with a

0 level is adjusted, the feed dog height will change, making it necessary to recheck the feed

8.

~

~

~

~

is

a height

needle plate are

1.0

1.0 mm

mm.

1.0

mm

is

-22-

Page 25

!!!]

ADJUSTMENT

OF ROTARY HOOK

0

.....

0.05

Needle guard

0"'0.5

I

I

I

I

I Fig. 8

mm

Needle

mm

Removal

I.

Turn

the machine pulley, setting the needle

2.

Remove the needle, presser foot, bed slide, bed plate, needle plate, feed dog and bobbin case.

3. Remove the set screw 0

4. Loosen the two hexagon socket set screws

Installation Adjustment

I. Install the rotary hook 8 by loosely screwing in the two hexagon socket set screws

2.

Install the bobbin case stop 8 by loosely screwing in the set screw

3.

After adjusting the needle

hexagon socket set screws

needle will not come

When replacing the rotary hook, always adjust the needle guard position. (Refer to Inset A.)

4. Adjust so that the edge

hook bracket (dotted line)

Make sure the end

bracket (dotted line).

5.

Install the feed dog, needle plate, bed plate, bed slide, presser foot, bobbin case, and needle.

and

remove the bobbin case stop

and

rotary hook timing(refer

8.

Adjust the rotary hook 8 needle guard so

in

contact, thus protecting against rotary hook point damage.

of

the bobbin case stop 8

of

the inner hook. (Refer to Inset

of

the bobbin case stop 8 does not extend to the right beyond the end

to

the highest position.

8.

8,

and remove the rotary hook

to

Section 2

is

installed between 0

of

B.)

8.

8.

0.

the previous page), firmly tighten the two

that

the rotary

t'V

0.5 mm below the end

* Finally, tighten all screws firmly.

[H)

ROTARY HOOK OIL LEVEL

* Loosen the nut

level adjustment screw 8 to regulate the oil

level.

Note: Always check the rotary hook oil level

whenever the rotary hook

While running the machine, place a piece

paper under the rotary hook for approx. 5

seconds. Adjust the oil so

sprayed from the rotary hook forms 2 dotted

lines

on

the paper.

* When oil adjustment

adjustment screw 8 with the nut

0.

and turn the rotary hook oil

is

completed. secure the

ADJUSTMENT

is

changed.

that

the oil being

0.

of

Measuring sheet

'

i

·:i

about

0.8

mm

•

hook

point

and

of

the rotary

of

the rotary, hook

the

-23-

Page 26

[ill

REPLACEMENT

I.

Remove eight

2. Re

move the screw

f).

3.

Adjust

l

insta lling the

4. Loosen the

~

[ill

I.

When the

foot

pushes

e

between

weak.

2.

t

the

eve

r e

1.0

mm with

ADJUSTMENT

lifter

up

pushes

Loosen the

urni

ng the

OF

screws,

clearance between

and

the thread cutt

thread cut

nut 0 and adju

press

or the

the

screw

the

re l

the

upper tens

nut

screw

and next the

0 a

nd then

ter

the scr

ew

OF

THREAD

er foot is lifted

knee

lif

f)

,

and tension

ease

pin, therefore

ion reg

0 a

nd

f)

.

THREAD

the thread cutt

the thread t

er 8 in

f)

.

st

the clea

0 .

up

ter lever,

ulators becomes

adjust

the

CUTTER

face

pla te.

ake-up

case

ra n

ce of0.

TENSION

by the

presser

the shaf

rel

ease

lever

the

ten

tensio

n by

er

of

8

RELEASE

t 0

sion

.---------------

0

0

--

-----------------------,

0

8

[ill

ADJUSTMENT

I.

Push the

2.

Thread

direction

3.

Pre

ss the

*

When

the

ud

0 .

st

*

Loosen

80% of

4.

Adjust

removing

f)

. and

o.

bobb

in fully onto the b

the

mach

of the a

bobbin wind

thread

the

set

screw 0 and

bobbin

the

moving

capac

dri

vin g

the o il

OF

THE

QUANTITY

obbi

n w

ine

as shown

rro

w.

er lever

will not wind evenly

ity.

power of bobbin winding by

cap

e. l

the

bobb

in

L

move th

oose

in

winder driv

the

picture at

f)

onto

.loosen

e bobbin winder lever

ning two

ing

OF

THE

inder spi

the

the

bobbin and

the clampi

screws

wheel

BOBBIN

ndle

0 .

left,

wind

ng sc

WINDING

ing the

run the

rew

L

f)

in

X 0 X

thread onto the

mac

hine.

8 .

and

adjust the height ofthcth

and out.

adjusting

bobbin

so that

seve

the

ral

tim

es in t

read tensio

thread wi

nds

he

n

to

- 24 -

Page 27

~TROUBLESHOOTING

GUIDE)

Trouble

Thread

breaks

Stitches skips

~-----C--au_s_e

Thread

is

thread

take-up.

Improper

Needle incorrectly installed

Thread

is

rotary

hook.

Flaw in the

Needle incorrectly installed

Needle bent. needle tip

crushed

Poor

needle

hook

timing (needle

rotary

height. needle

hook

clearance)

wound

threading

wound

thread

hook.

______

around

around

passage

and

rotary

needle

and

rotary

~l

~~-----I_n_sp_e_c_ti_o_n

the

the

and

bar

Thread

Needle position

Rotary

Rotary hook. bobbin. rotary

take-up. etc.

Needle

Needle

t----------------1

take-up

hook

__

~ll

~------R--em

Remove the

thread.

Install needle in

direction

Remove the

thread.

Clear

replace with a new part.

Install needle in correct

direction

Replace the needle.

Refer

Hook Timing Adjustment".

the

to

"Needle

__

e_d_Y

thread

____

wound-up

correct

wound-up

path.

and

Rotary

~I_P_a_ge~~

or

21

Unever stitches

Thread

loose fighten

breaks

Needle

Rotary

hook

crushed

Presser foot pressure

great.

Improper

Improper

sion

Improper

sion

Improper

spring tension

:'\eedle incorrectly installed

~cedlc

crushed

Improper

hook

Improper

timing timing

Needle

thread

sewn. sewn.

point-bent

feed

dog

lower

upper

thread

bent. :'\cedlc tip

needle

timing

needle

is

too

slender for the Use a needle

or

material being

height

thread

thread

take-up

and

and

or

t----------------1

is

too

ten-

ten-

rotary

feed

Presser foot pressure

Feed

dog

height

thread

take-up

or

movement

tension

Lower

Upper thread tension

Thread

strength

Needle

Needle

~--------------1

~--------------1

t-----------------1

spring

Repair the rotary

point

part.

Refer

sure Adjustment".

Refer

and

Refer

Refer

Refer

Install needle in

direction

Replace the needle.

Referto"Needleand

Hook

Improper

L-----------~-~

thread

or

replace

it

with a new

to

"Presser

to

Bias Adjustment".

to

to

"Sewing Tension".

to

"Sewing Tension".

Timing Adjustment".

or

Foot Pres-

"Feed Dog Height

"Sewing Tension".

correct

Rotary

needle

and

to

suit the

material being

hook

21

feed

Low needle 4uality

t----------------1

-25-

Replace a quality needle.

Page 28

BROTHER

HEAD

HORITA-DORI, MIZUHO-KU. NAGOYA,

CA

TELEX: BROTHER

INDUSTRIES,

OFFICE

: No . 35. 9-CHOME.

BLE

: BROTHER NAGOYA.

4473696J

I 21

201

& J

J(>

lTD.

59743

Prin

JAPAN

ted

in Japan

467

Loading...

Loading...