Page 1

SERVICE MANUAL

MODEL: LX-200/LX-900/LX-910D

REVISED EDITION May, 2000

Page 2

Unauthorized copying of all or part of the contents of this manual is prohibited.

The contents of this manual may change without notice.

Page 3

INTRODUCTION

This Service Manual describes the Cool Laminator LX-200/900/910D specifications, operating

principles of the mechanisms, disassembly and reassembly procedures, and maintenance and

troubleshooting procedures.

This Service Manual is intended for use by trained technicians. It is not intended for use by the

user.

The manual is divided into the following chapters.

Chapter 1. Specifications

Chapter 2. Mechanism

Chapter 3. Disassembly Procedures

Chapter 4. Reassembly Procedures

Chapter 5. Electronic Controllers

Chapter 6. Maintenance

Chapter 7. Troubleshooting

Appendix Main PCB Circuit Diagram

Page 4

Chapter 1.

SPECIFICATIONS

Page 5

CONTENTS

Chapter 1. SPECIFICATIONS

1.1 Mechanical Specifications.................................................................................................1-1

1.1.1 Appearance...........................................................................................................1-1

1.1.2 Operating Panel ....................................................................................................1-1

1.1.3 Indicators...............................................................................................................1-2

1.2 Electrical Specifications ....................................................................................................1-2

1.2.1 Power Supply........................................................................................................ 1-2

1-i

Page 6

1

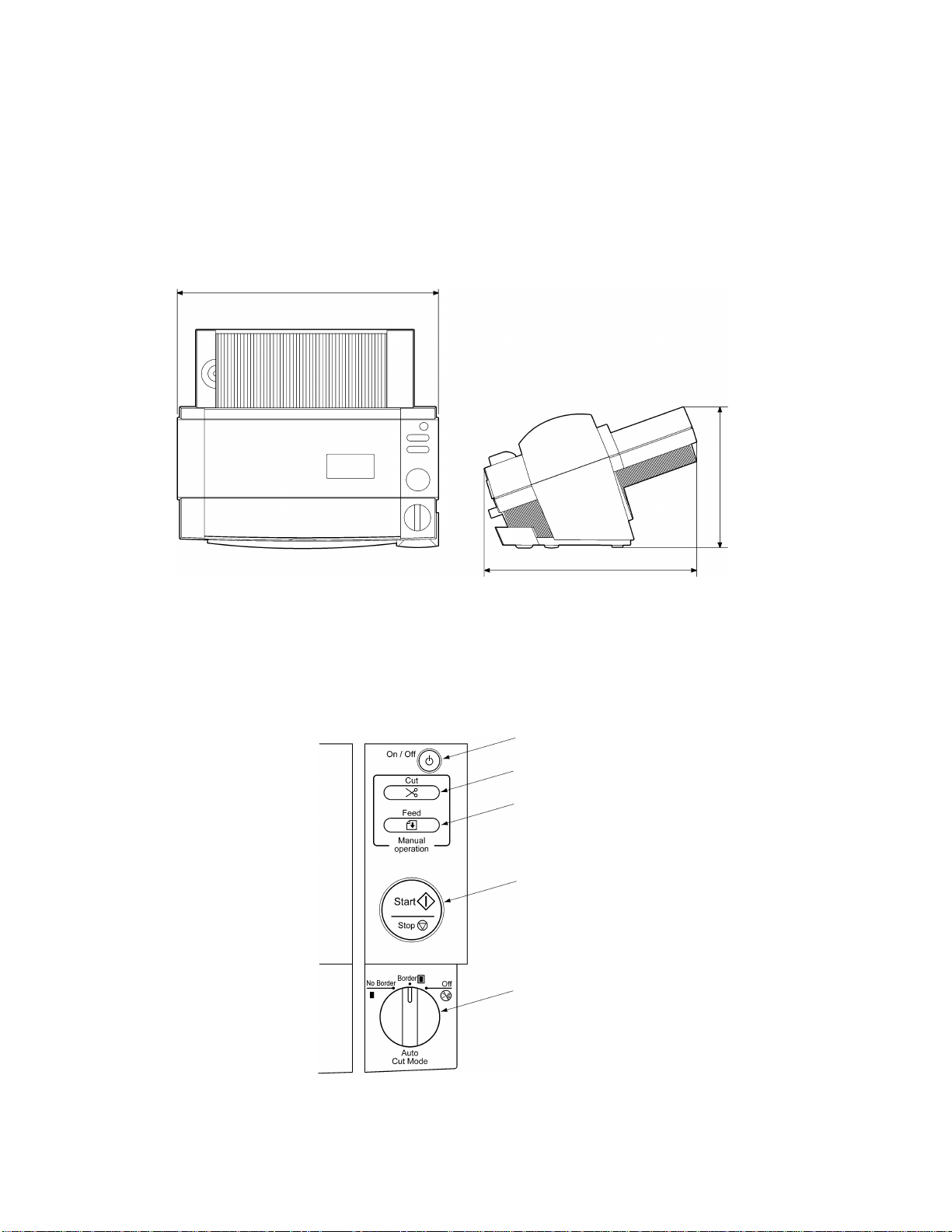

1.1 Mechanical Specifications

1.1.1 Appearance

[1] External dimensions (W x D x H) 357 mm x 293 mm x 195 mm

[2] Mass Approx. 4.6 kg (main unit only)

357 mm

195 mm

1.1.2 Operating Panel

[1] Number of Keys 5 ( Power switch, Cut key, Feed key,

Start/Stop button, Cutting mode selector)

[2] Key Arrangement

Fig. 1.1-1 Appearance

Power switch

Cut key (Horizontal)

Feed key

Start/Stop button

Cutting mode selector

293 mm

Fig. 1.1-2 Key Arrangement

1-

Page 7

2

1.1.3 Indicators

[1] Positions Start/Stop button LED indicators (red, green, orange)

1.2 Electrical Specifications

1.2.1 Power Supply

[1] Power supply Commercial power supply (locally available power supply).

Converted to DC by the AC adaptor.

1-

Page 8

Chapter 2.

MECHANISMS

Page 9

CONTENTS

Chapter 2. MECHANISMS

2.1 Mechanical Operating Principles......................................................................................2-1

2.1.1 Description of Mechanisms (Border Mode)..........................................................2-1

2.1.2 Feed and Compression Mechanisms...................................................................2-2

2.1.3 Cutter Mechanism (Border Mode)........................................................................2-4

2.1.4 Paper Size Detector Mechanism..........................................................................2-6

2.1.5 Trimming Mechanism...........................................................................................2-8

i

Page 10

1

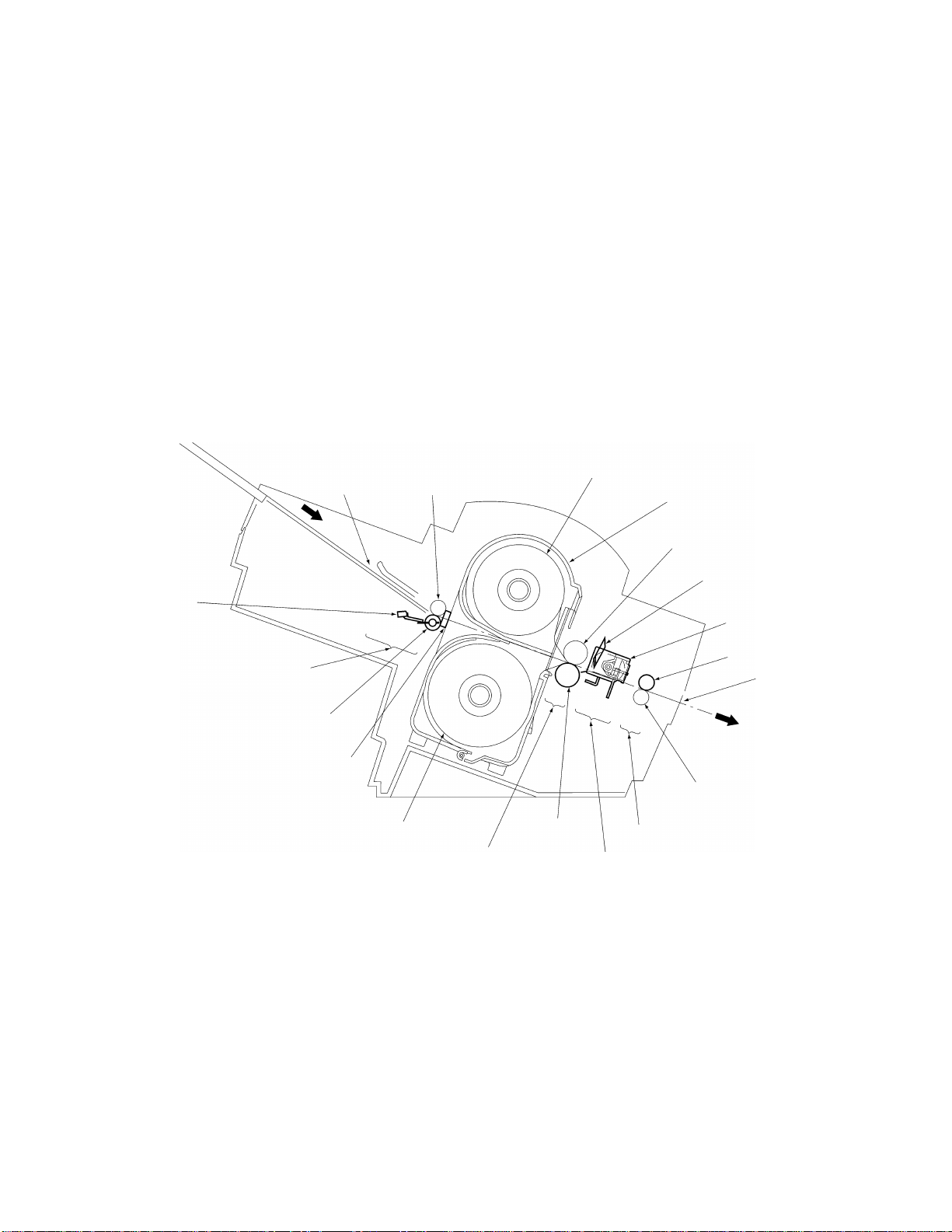

2.1 Mechanical Operating Principles

2.1.1 Description of Mechanisms (Border Mode)

1. When a document is inserted into the paper loading gate, the paper feed rollers feed

it to the driving roller.

2. As the document passes between the paper feed rollers, the paper size detector

determines its size (length and width).

3. When the document passes between the film cartridges it is sandwiched between

the upper and lower films in the compression-feed area, where the films and

document are compressed between the driving roller and sub-roller.

4. The compressed document and film is fed to the cutting area, where it is cut to the

document size detected by the paper size detector with borders added. It is then

transported to the next stage.

5. The laminated document is fed out of the eject gate by the paper eject rollers.

Paper length

detector

Paper loading gate Paper feed sub-roller

Paper loading area

Paper feed roller

Paper width detector

Roll film (upper)

Roll film (lower)

Compression-feed area

Driving roller

Fig. 2.1-1 Description of Mechanisms

Film cartridge

Sub-roller

Y-cutter blade

X-cutter unit

Paper eject roller

Eject gate

Paper eject sub-roller

Ejecting area

Cutting area

2-

Page 11

2

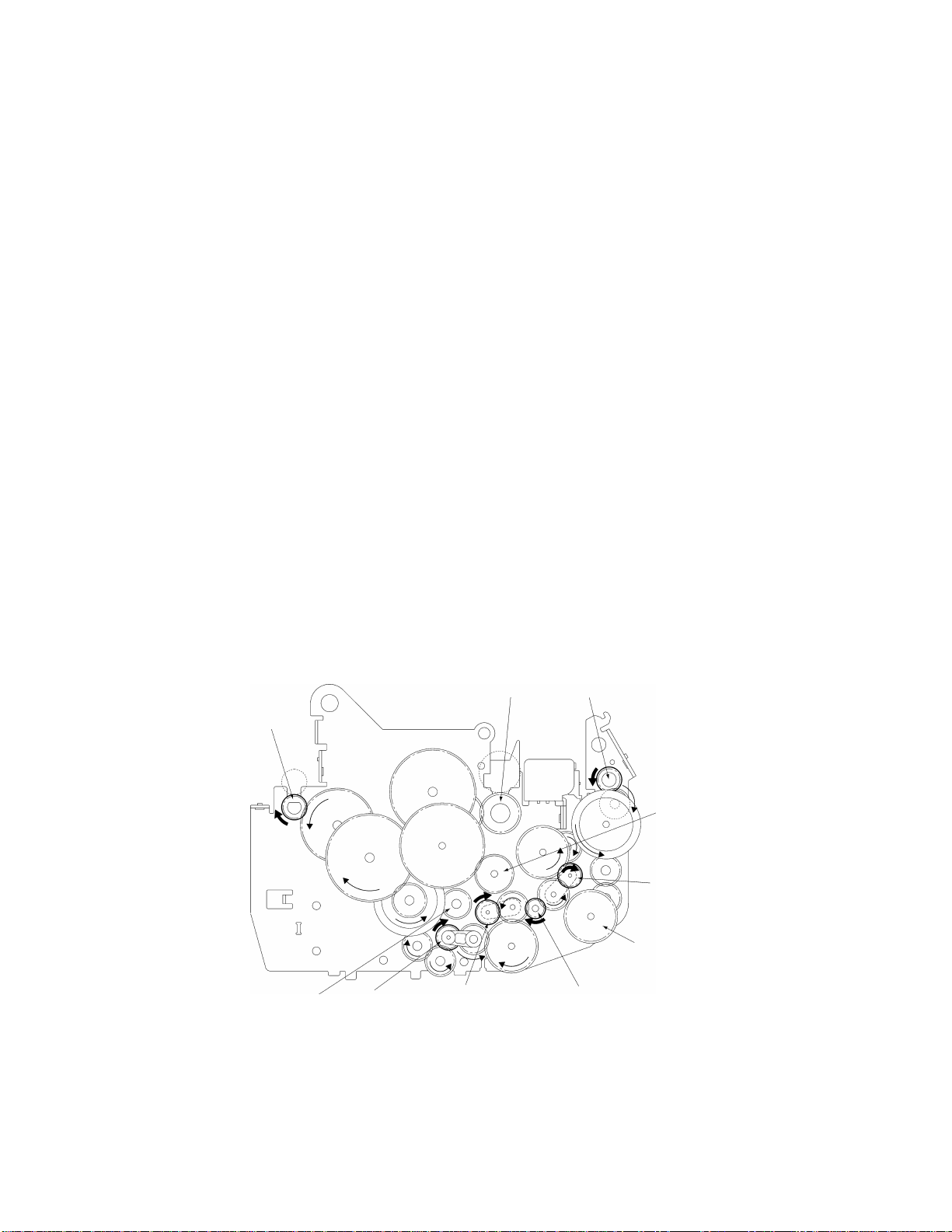

2.1.2 Feed and Compression Mechanisms

The feed and compression mechanism controls the motor drive to feed the document

into the film cartridge, compression-feed the films, and eject the laminated document.

When no compression-feed is applied while feeding a document into the film cartridge

or ejecting a laminated document, the LF motor rotates clockwise and the motor drive is

transmitted via gears to the paper feed roller and paper eject roller.

At this time, the planet gear (A) is free from the drive gear (A), such that the drive is not

transmitted to the driving roller.

During compression-feeding of the films, LF motor rotates counterclockwise to move the

planet gear (A) against the drive gear (A), such that the drive from the LF motor is

transmitted to the driving roller.

Also, planet gear (B) moves against the drive gear (B) and planet gear (C) moves

against the drive gear (C), such that the LF motor drive continues to be transmitted to

the paper feed roller and paper eject roller, without changing the direction of roller

rotation.

• Operation when Feeding Document into the Film Cartridge or when Ejecting a

Laminated Document

1. When the LF motor rotates clockwise (as indicated by the arrow in the diagram),

the drive is transmitted via a series of gears to drive the paper feed roller and

paper eject roller in the directions indicated by the arrows. At this time, planet

gear (A) is free, such that no drive is transmitted to drive gear (A) and the driving

roller does not rotate.

2. The document is fed into the film cartridge when the paper feed roller rotates in

the direction indicated by the arrow.

3. The laminated document is ejected from the eject gate when the paper eject

roller rotates in the direction indicated by the arrow.

Driving roller Paper eject roller

Paper feed roller

Drive gear (A)

Planet gear (C)

Drive gear (C)

Drive gear (B)

Planet gear (B)

LF motor gearPlanet gear (A)

Fig. 2.1-2 Operation when Feeding Document into the Film Cartridge or when Ejecting a Laminated Document

2-

Page 12

3

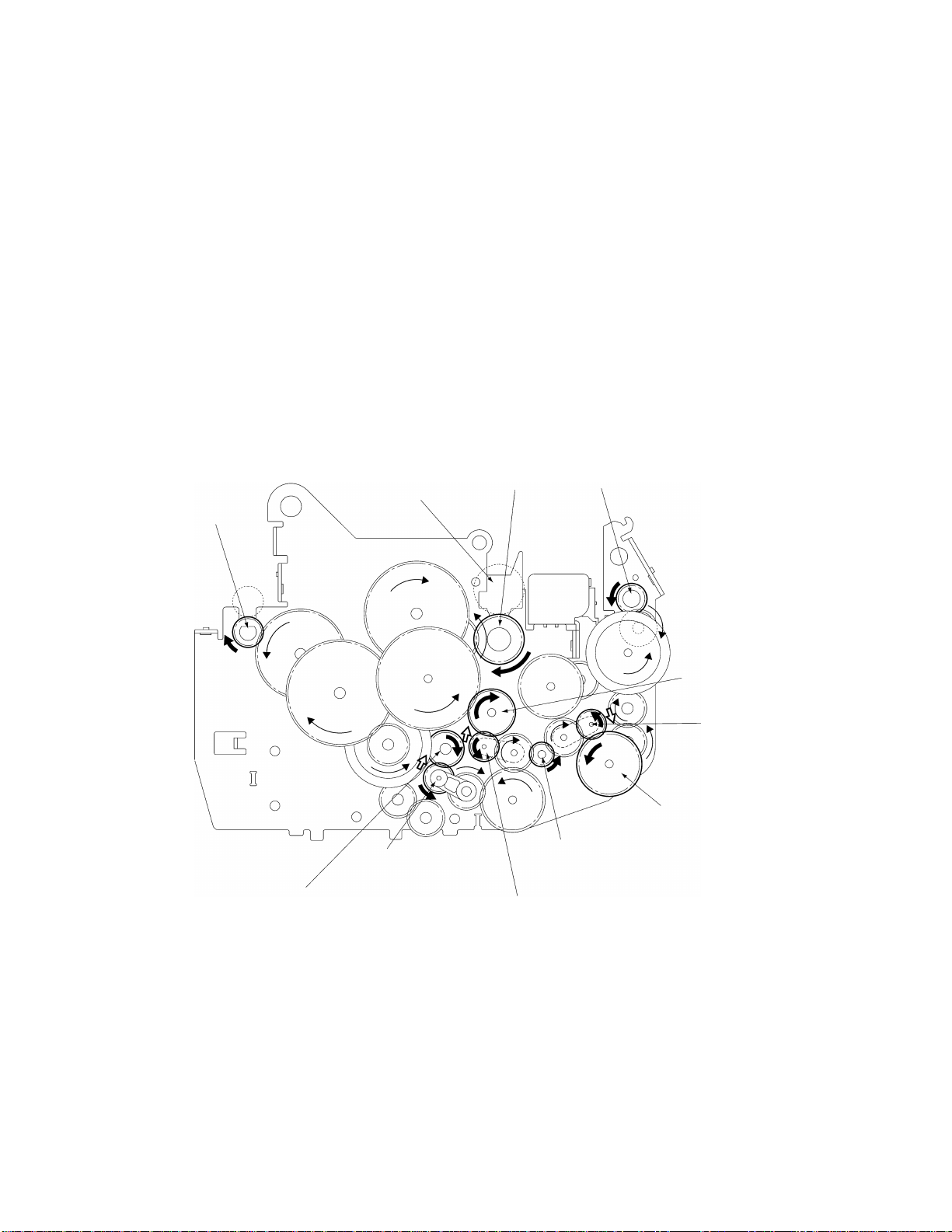

•

Operation During Film Compression-Feed

1. When the leading edge of the document enters the compression-feed area, LF

motor starts to rotate counterclockwise, as indicated by the arrow.

2. Planet gear (A), which had been free, moves to engage with drive gear (A). The

drive from the LF motor is then transmitted to the various gears, as shown in the

diagram, and the driving roller rotates as indicated by the arrow. Also, planet

gear (B) moves against the drive gear (B) and planet gear (C) moves against the

drive gear (C), such that the LF motor drive continues to be transmitted to the

paper feed roller and paper eject roller, without changing the direction of roller

rotation.

3. The rotation of the driving roller is transmitted to the sub-roller. These rollers

feed the films and press them against the document. At this time, the rotations

of the paper feed roller and paper eject roller continue uninterrupted.

4. When the trailing edge of the document leaves the compression-feed area and

the X-cutters finish cutting the film, the LF motor reverses to rotate

counterclockwise. Planet gear (A) again becomes free such that the driving

roller rotation stops and feeding of the films also stops.

Paper feed roller

Drive gear (B)

Sub-roller

Planet gear (B)

Fig. 2.1-3 Operation During Film Compression-Feed

Driving roller Paper eject roller

LF motor gear

Planet gear (A)

Drive gear (A)

Planet gear (C)

Drive gear (C)

2-

Page 13

4

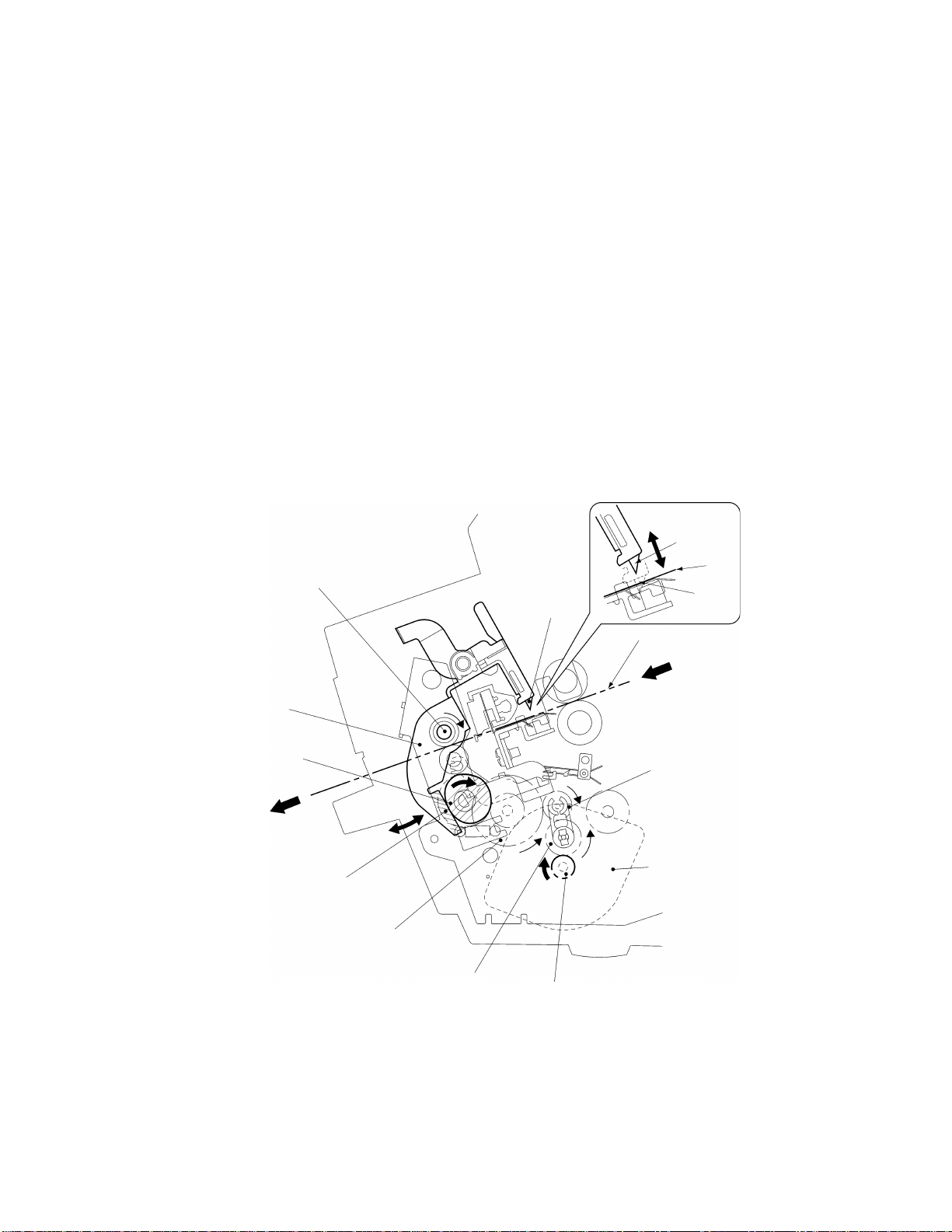

2.1.3 Cutter Mechanism (Border Mode)

The cutter mechanism cuts the laminated document to the size of the document plus an

added border. Both edges of the films are cut to suit the width of the document and the

leading edge and trailing edge are cut according to the document length.

•

Y-Cutter Vertical Drive Operation

1. The TC motor rotates clockwise from its reference position to drive the cam

clockwise via a series of gears. The cam rotates the Y-diversion lever clockwise

about its pivot. (All rotations indicated by arrows. )

When the Y-diversion lever reaches its maximum displacement position with the

cam at approximately its 180°‹ rotated position, rotation of the TC motor pauses.

2. When the Y-diversion lever reaches its maximum displacement position, its

movement lowers the two Y-cutter blades from the standby position to the

cutting position, where they start cutting the edges of the laminated film.

3. When the Y-axis cutters reach the trailing edge cutting position, the TC motor

starts rotating again and stops when it reaches its reference position. This

rotation returns the cam and Y-diversion lever to their original positions and the

cutters move to their standby positions.

Pivot

Y-diversion lever

Cam (hatched area)

Idle gear 3

Y-cutter blade

Idle gear 2

Idle gear 1

Fig. 2.1-4 Y-Cutter Vertical Drive Operation

TC motor gear

Standby position

Film surface

Planet gear

TC motor

Film

Cutting

position

2-

Page 14

5

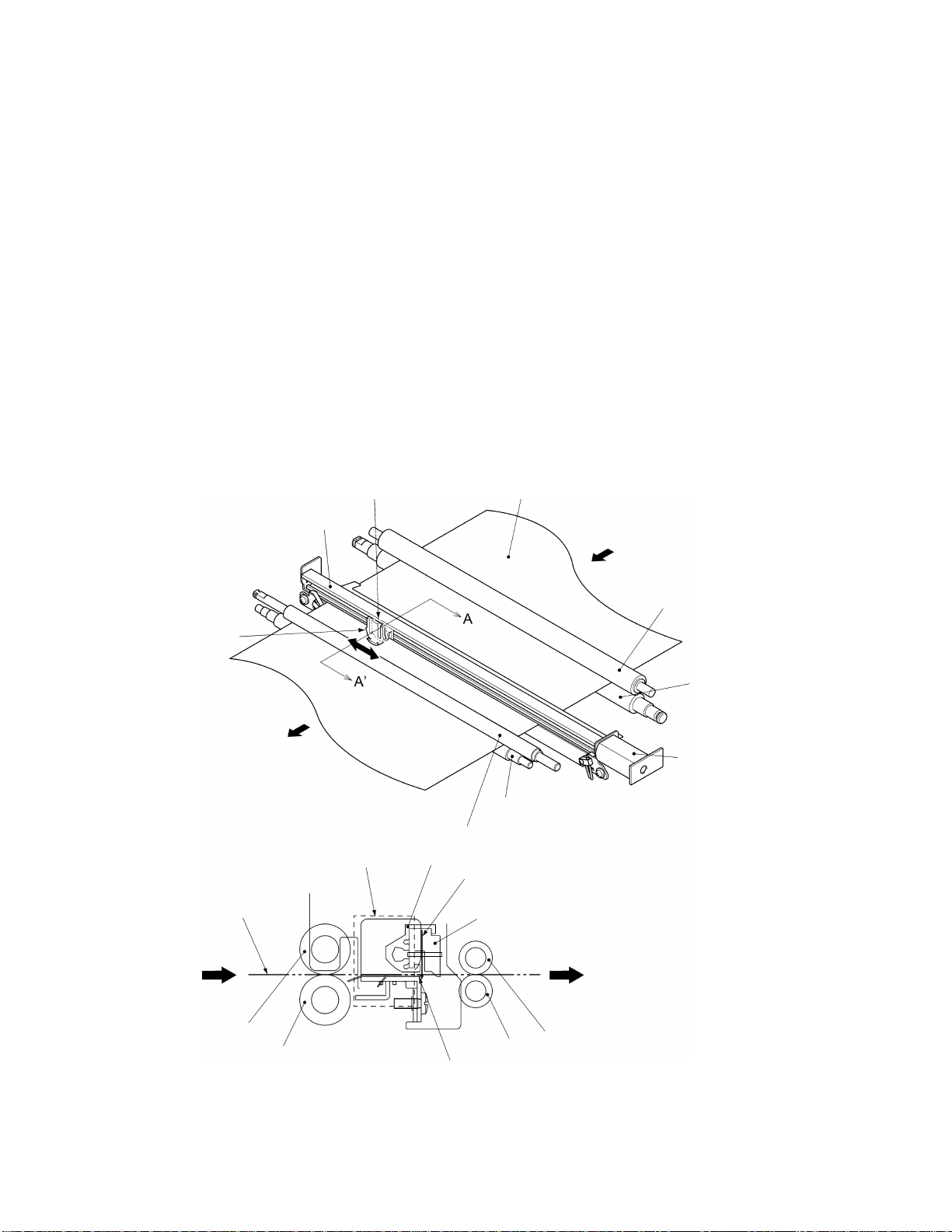

•

Cutting Leading and Trailing Edges (X-cutter Mechanism)

1. All the rollers which feed the document stop when the cut position at the leading

edge of the document reaches the cutting position of the rotary cutter and fixedblade cutter.

2. The DC motor rotates to drive the carriage in the X-cutter assembly via the spiral

mechanism (not illustrated).

3. As the carriage makes a reciprocal movement, the rotary cutter attached to the

carriage moves against the fixed cutter to cut the compressed leading edge of

the document.

4. The rotation of the rollers which feed the document restarts when the cutting of

the leading edge is complete. Then, when the cut position at the trailing edge of

the document reaches the cutting position of the rotary cutter and fixed-blade

cutter, the feed rollers stop again.

5. The document trailing edge is cut in the same way as the leading edge, by a

reciprocal movement of the rotary cutter attached to the carriage.

6. The rotation of the rollers restarts to feed the laminated document from the eject

gate after the cutting of the trailing edge is complete.

Rotary cutter Document

X-cutter

Document

Section A-A’

Frame

DC motor

Sub-roller

Driving roller

DC motor

Paper eject sub-roller

Paper eject roller

Frame

Rotary cutter

Carriage

Sub-roller

Driving roller

Paper eject sub-roller

Fixed cutter

Paper eject roller

Fig. 2.1-5 Cutting Leading and Trailing Edges (X-cutter Mechanism)

2-

Page 15

6

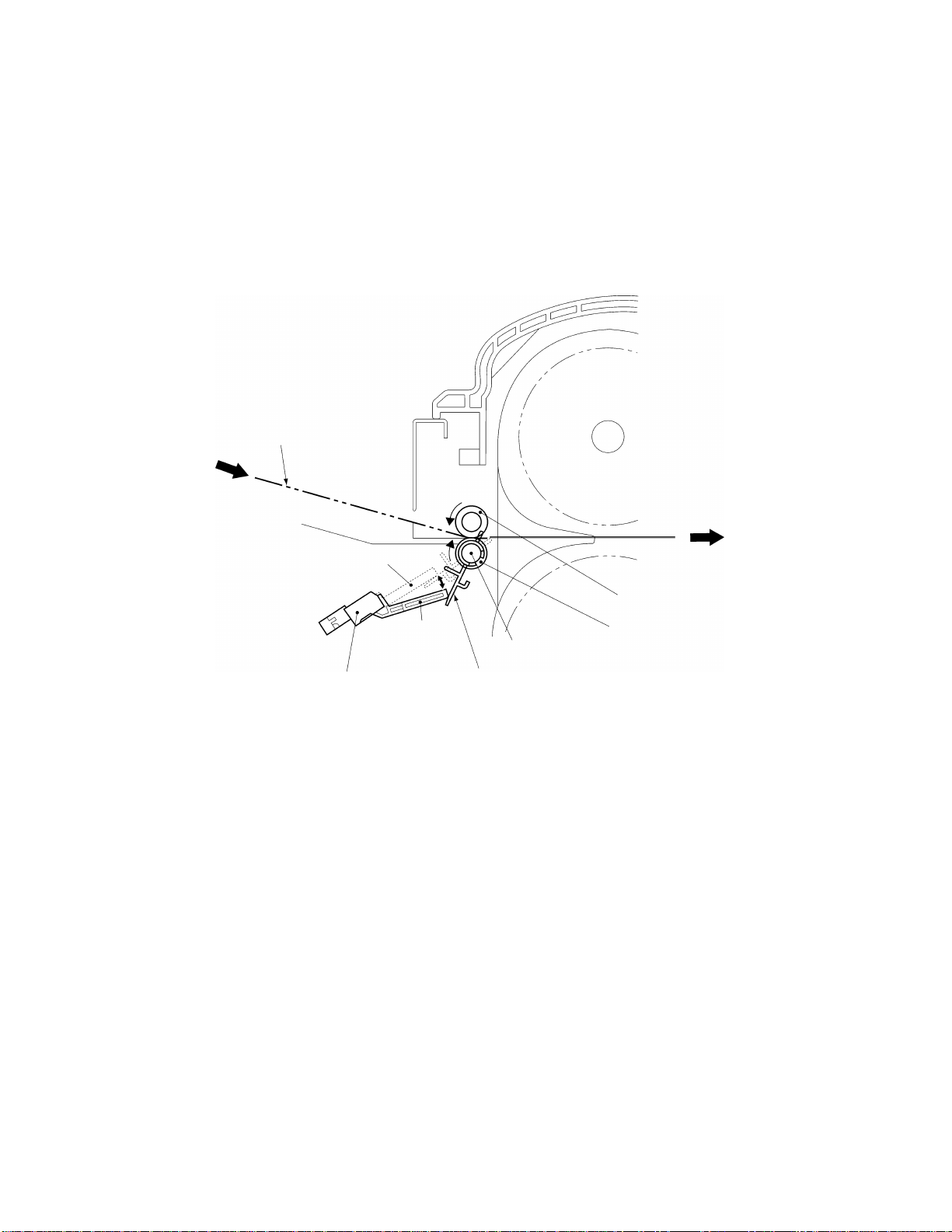

2.1.4 Paper Size Detector Mechanism

• Paper Length Detection

1. When the leading edge of the document passes between the paper feed rollers,

it rotates the paper sensor crank about the pivot to turn on the paper sensor

which detects the document leading edge.

2. When the trailing edge of the document passes out of the paper feed rollers, the

paper sensor crank reverts to its original position to turn off the paper sensor to

detect the document trailing edge.

Document feed surface

ON

Paper sensor

OFF

Pivot

Paper sensor crank

Fig. 2.1-6 Paper Length Detection

Paper feed sub-roller

Paper feed roller

2-

Page 16

7

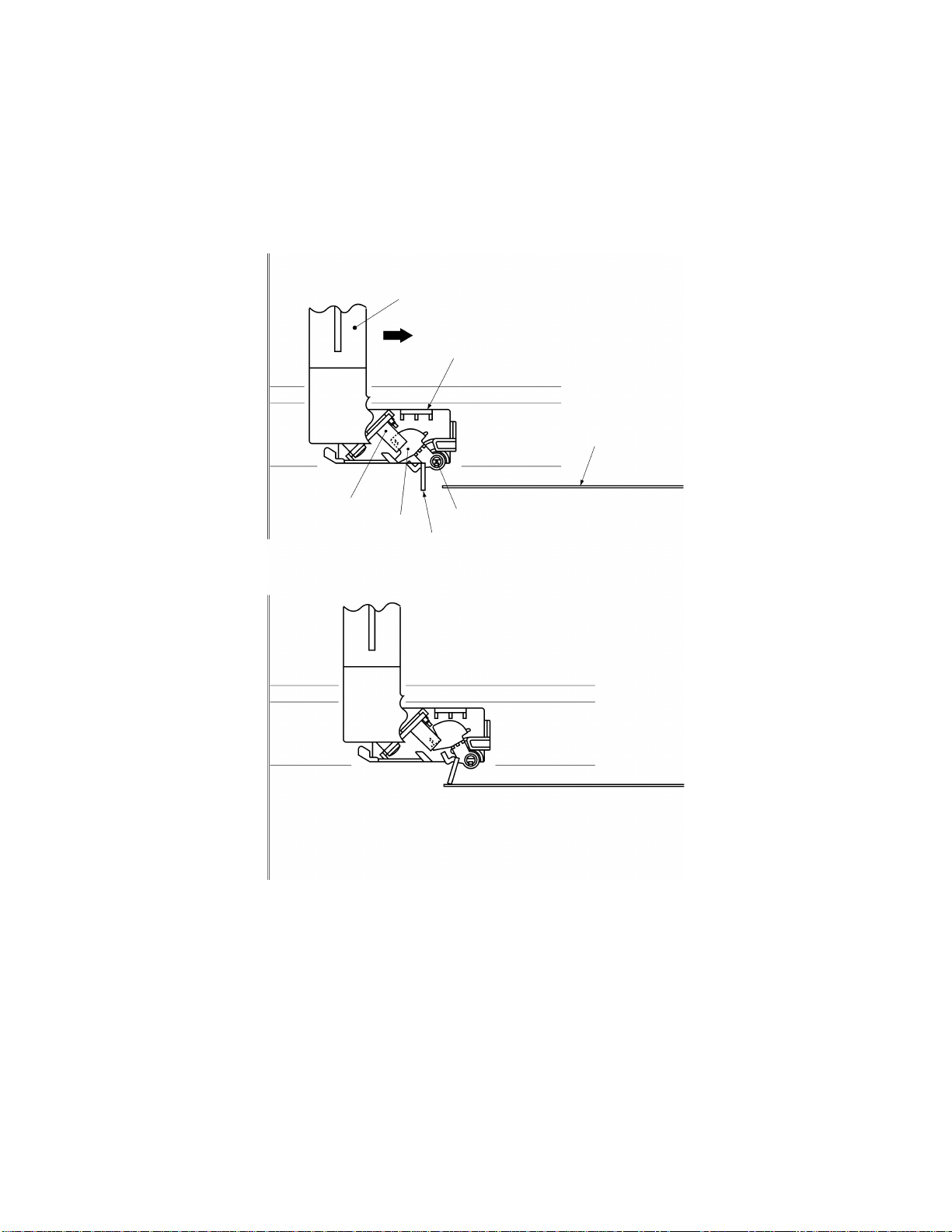

•

Paper Width Detection

1. The Y-cutter arm L (sensor unit) moves in the direction of the arrow. When the

PL detect lever touches the document, it rotates about the pivot to switch off the

photosensor.

2. When the photosensor turns off, the Y-cutter arm L movement stops and this

position is detected as the document width.

Y-cutter arm L

Sensor unit

Document

Photosensor

PL detect lever

Part of the PL detect lever that touches the document.

* Photosensor ON status

* Photosensor OFF status

Fig. 2.1-7 Paper Width Detection

Pivot

2-

Page 17

8

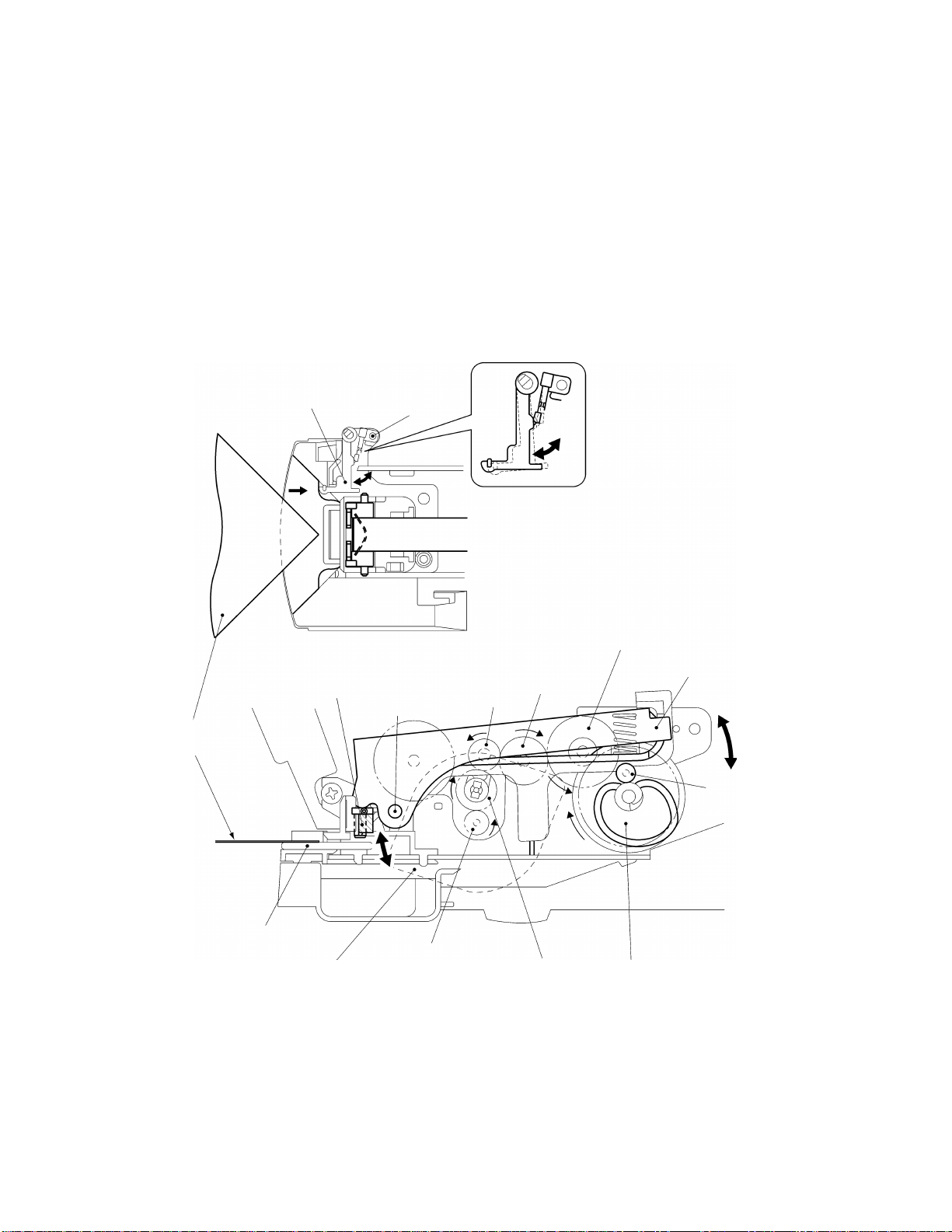

2.1.5 Trimming Mechanism

1. When a corner of the laminated document is inserted over the T-cutter plate, the

sensor lever operates a leaf switch that detects the document.

2. When the document is detected, the motor gear of TC motor rotates in the direction

of the arrow (counterclockwise) from its reference position to drive the T-cam gear in

the direction indicated by the arrow (clockwise) via a series of gears.

3. Rotation of the T-cam gear forces the T-cam roller to make a vertical movement,

such that T-lever1 moves vertically, rotating around its pivot.

4. As T-lever 1 moves vertically, the T-cutter mounted on the end of T-lever 1 moves

up and down, trimming the corner of the laminated document into a rounded radius.

Laminated

document

T-sensor lever

T-cutter

Leaf switch

Pivot

Planet gear

Idle gear 3

T-lever 1

Idle gear 2

T-cam roller

T-cutter plate

Motor gear

T-cam gearIdle gear 1TC motor

Fig. 2.1-8 Trimming Mechanism

2-

Page 18

Chapter 3.

DISASSEMBLY PROCEDURES

Page 19

CONTENTS

Chapter 3. DISASSEMBLY PROCEDURES

3.1 Safety Precautions ............................................................................................................3-1

3.2 Removing the Film Cartridge............................................................................................3-1

3.3 Covers...............................................................................................................................3-2

3.3.1 Removing the Trimmer Upper Cover...................................................................3-2

3.3.2 Removing the Top Cover......................................................................................3-3

3.3.3 Removing the Sub-tray.........................................................................................3-4

3.3.4 Removing the Paper Tray and Paper Guide.........................................................3-4

3.3.5 Removing the Body Cover B.................................................................................3-5

3.3.6 Removing the Front Cover....................................................................................3-7

3.3.7 Removing the Cover Switch Assy ........................................................................3-8

3.3.8 Removing the Dial Switch Holder Assy B.............................................................3-9

3.3.9 Disassembling the Dial Switch Holder Assy B ...................................................3-10

3.4 Chassis............................................................................................................................3-12

3.4.1 Removing the Harness Connectors....................................................................3-12

3.4.2 Removing the PE Sensor Unit............................................................................3-12

3.4.3 Removing the Chassis Unit ................................................................................3-13

3.5 PCBs................................................................................................................................3-15

3.5.1 Removing the Main PCB Assy............................................................................ 3-15

3.5.2 Removing the Jack PCB Assy............................................................................3-15

3.5.3 Removing the Switch PCB Assy.........................................................................3-16

3.6 T-Chassis ........................................................................................................................3-17

3.6.1 Removing the T-Chassis Unit............................................................................. 3-17

3.6.2 Disassembling the T-Chassis Unit...................................................................... 3-18

3.7 Y-CA Chassis .................................................................................................................. 3-19

3.7.1 Removing the Y-CA Chassis Assy .....................................................................3-19

3.7.2 Disassembling the Y-CA Chassis Assy..............................................................3-20

3.7.3 Removing the Roller Holder Assy.......................................................................3-21

3.7.4 Disassembling the Roller Holder Assy ...............................................................3-22

3.8 Sensor Frame and Y-cutter Arm L..................................................................................3-23

3.8.1 Removing the Sensor Frame..............................................................................3-23

3.8.2 Removing the Y-cutter Arm L .............................................................................3-23

3.8.3 Disassembling the Sensor Frame ......................................................................3-24

3.8.4 Disassembling the Y-cutter Arm L...................................................................... 3-25

3.9 Paper Feed Roller ........................................................................................................... 3-26

3.9.1 Removing the Paper Feed Sub-roller Assy........................................................3-26

3.9.2 Removing the Paper Feed Roller Assy...............................................................3-27

i

Page 20

3.10 Paper Eject Roller ...........................................................................................................3-28

3.10.1 Removing the Y-D Shaft.....................................................................................3-28

3.10.2 Removing the Paper Eject Sub-roller Unit.......................................................... 3-29

3.10.3 Removing the Paper Eject Roller Unit................................................................ 3-29

3.11 Y-diversion Lever ............................................................................................................3-30

3.11.1 Removing the Y-diversion Lever Assy................................................................ 3-30

3.11.2 Disassembling the Y-diversion Lever Assy ........................................................ 3-31

3.12 X-cutter............................................................................................................................3-32

3.12.1 Removing the X-cutter Unit.................................................................................3-32

3.12.2 Disassembling the Tape Sensor Unit .................................................................3-32

3.13 Driving Roller................................................................................................................... 3-33

3.13.1 Removing the Driving Roller...............................................................................3-33

3.14 Left Side of the Chassis ..................................................................................................3-33

3.14.1 Removing the Gears...........................................................................................3-33

3.14.2 Disassembling the Left Side of the Chassis.......................................................3-35

3.15 Right Side of the Chassis................................................................................................3-36

3.15.1 Disassembling the Right Side of the Chassis..................................................... 3-36

3.16 Lower Chassis.................................................................................................................3-37

3.16.1 Removing the Left and Right Sides of the Chassis............................................3-37

3.16.2 Removing the Cassette Holder...........................................................................3-38

3.16.3 Removing the Encoder (ENC) Sensor PCB.......................................................3-38

3.16.4 Removing the Cassette Detect Switch...............................................................3-39

ii

Page 21

3.1 Safety Precautions

When conducting disassembly operations, place the unit on a grounded anti-static

sheet. LSI and other electronic components are sensitive to static electricity

and may be damaged if touched while charged.

Before transporting a circuit board, wrap it in a conducting sheet such as aluminum

foil.

When using a soldering iron or other heat-producing tool, ensure that heat does not

damage wires, circuit boards, or plastic parts such as covers.

Take care not to lose small screws or washers removed when replacing parts.

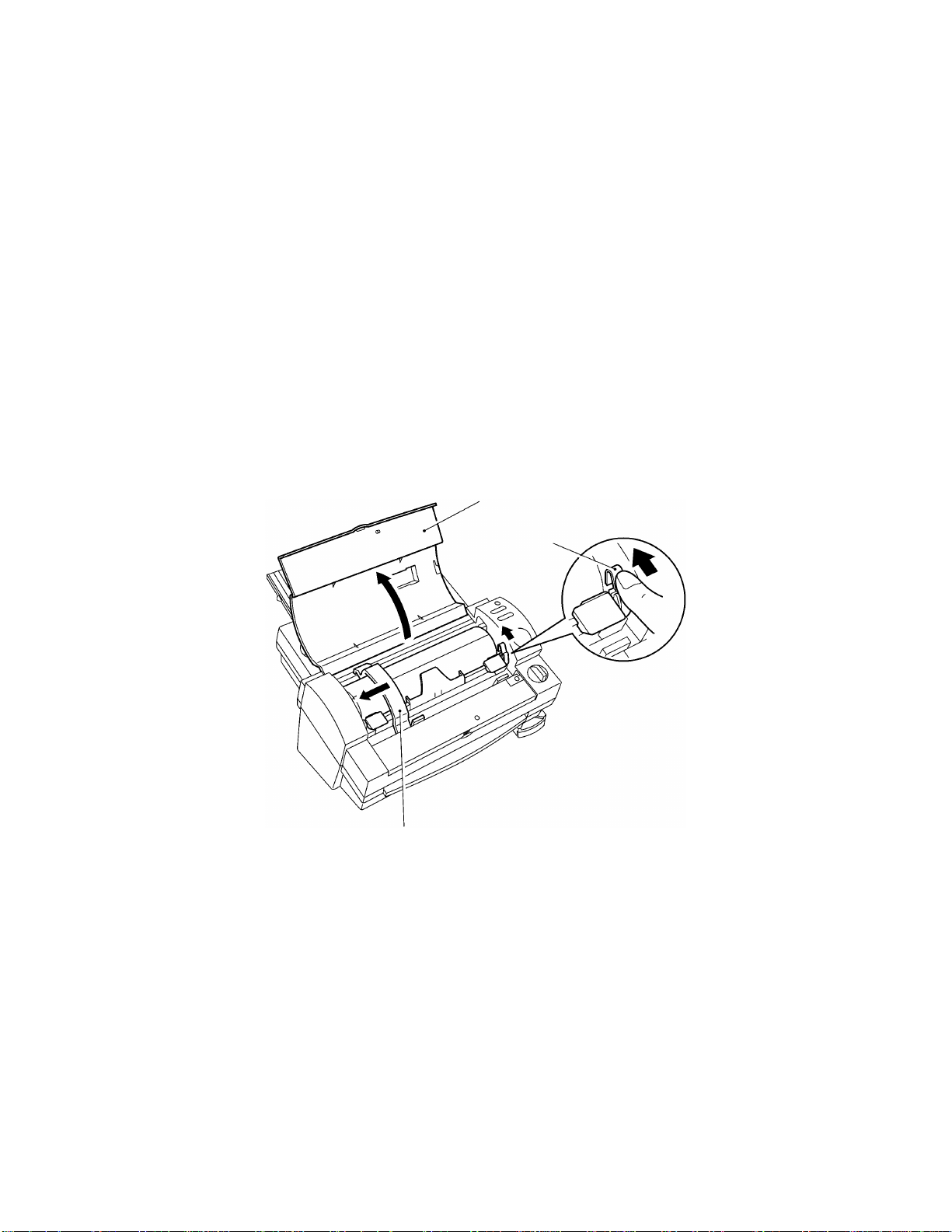

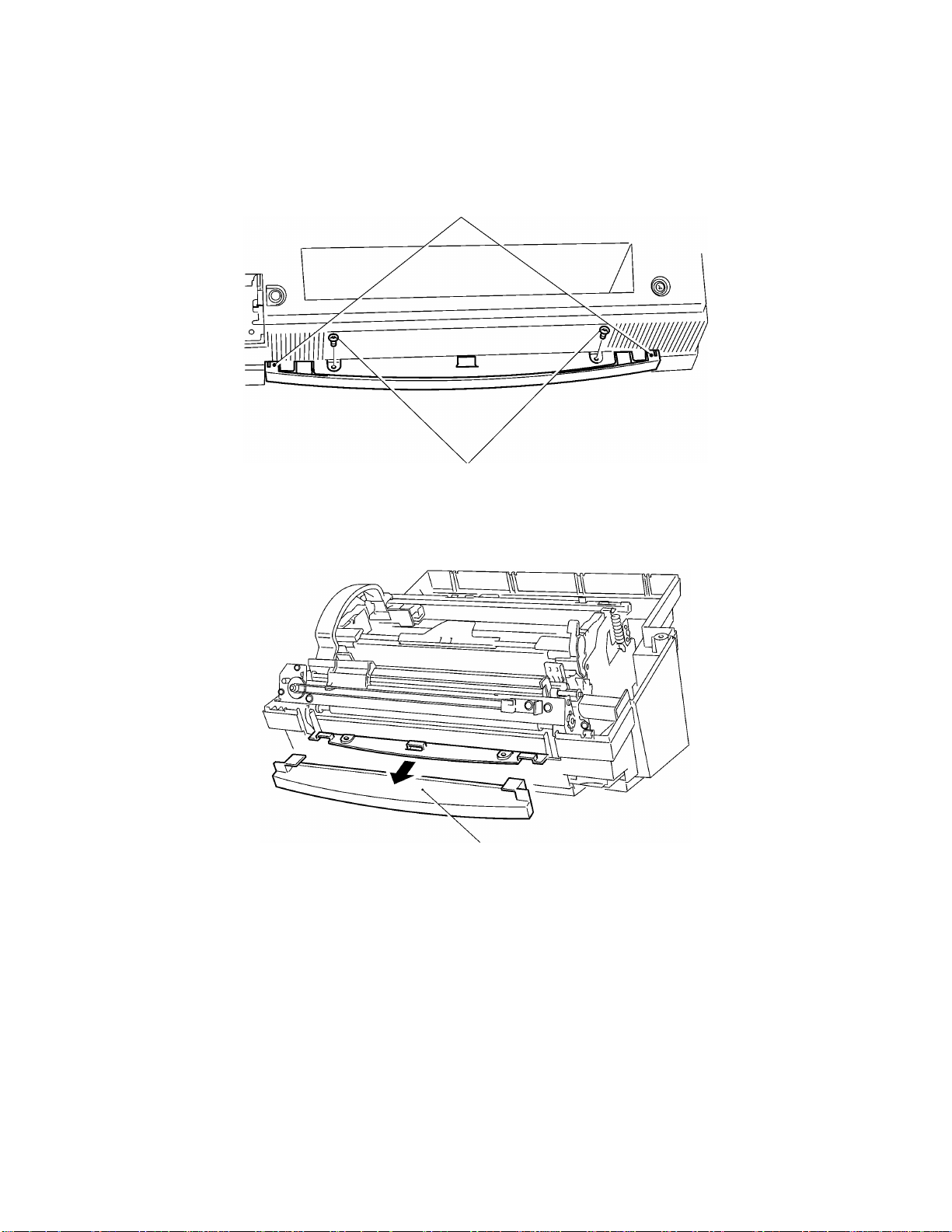

3.2 Removing the Film Cartridge

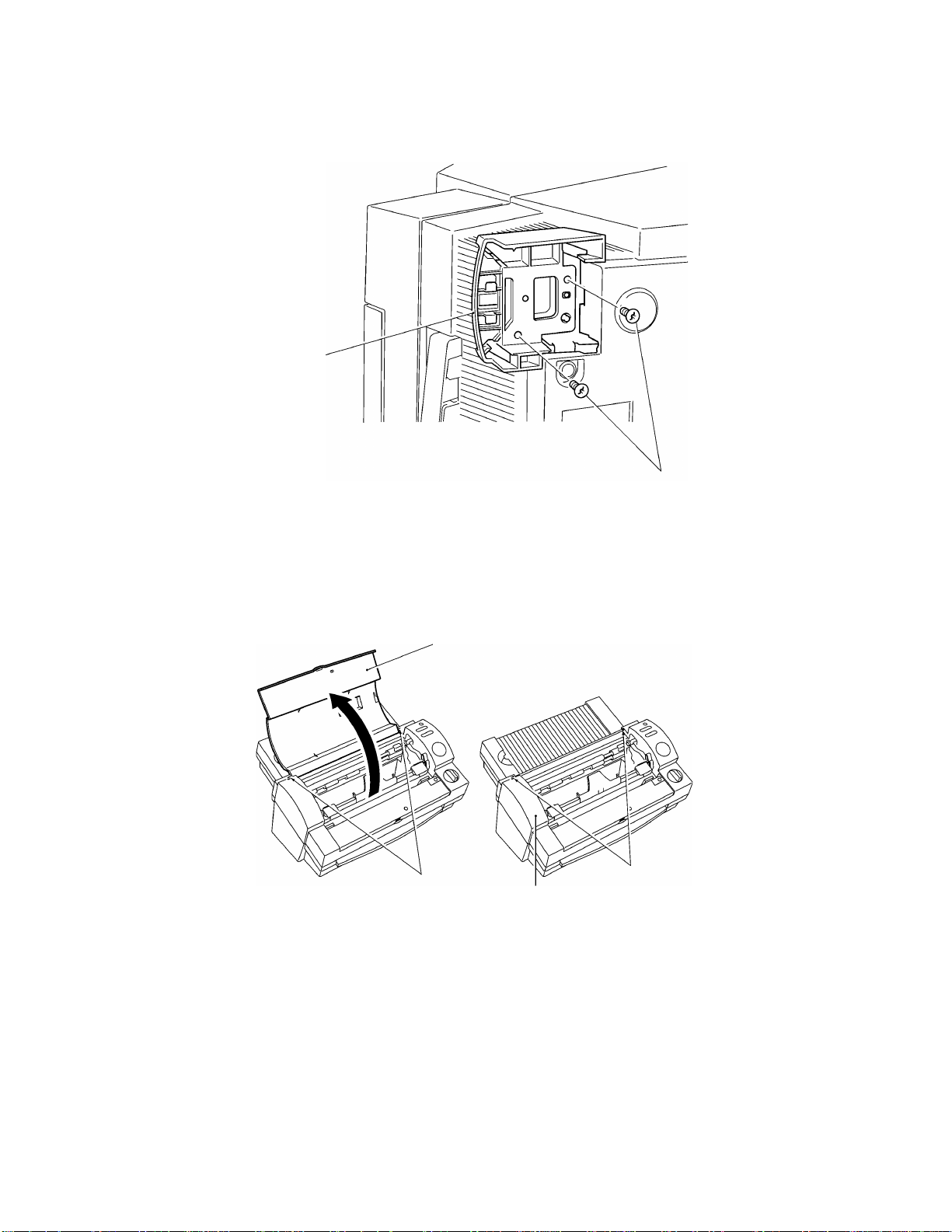

1.Open the top cover and move the Y-cutter arm L as far as possible to the left.

2.Push the lock lever R in the direction indicated by the arrow to unlock the roller

holder assy.

Top cover

Lock lever R

Y-cutter arm L

Fig. 3.2-1 Removing the Film Cartridge 1

3-1

Page 22

3.Lift up the roller holder assy and pull out the film cartridge.

3.3 Covers

Roller holder assy

Film cartridge

Fig. 3.2-2 Removing the Film Cartridge 2

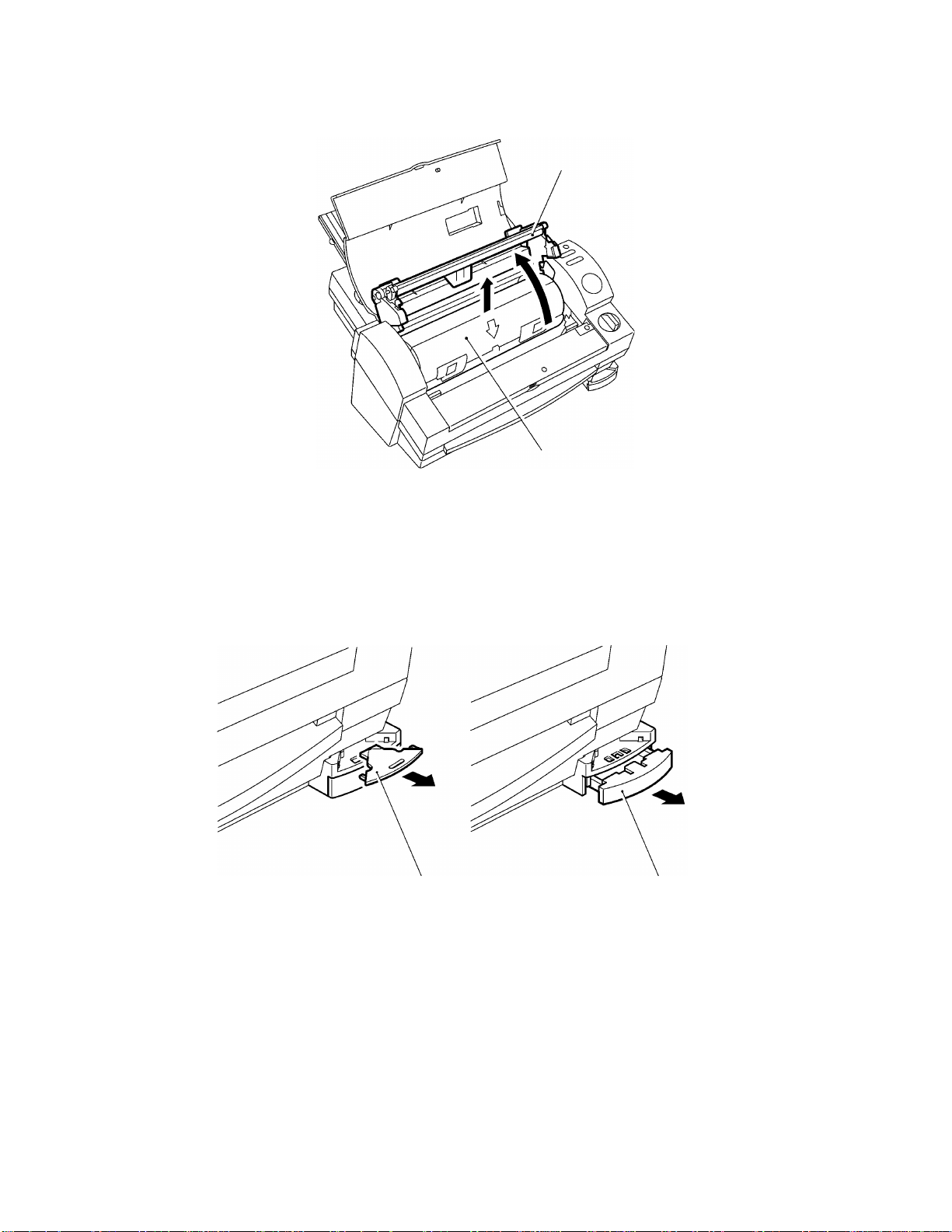

3.3.1 Removing the Trimmer Upper Cover

1.Pull out the T-cutter plate and the trimmer bottom cover.

T-cutter plate Trimmer bottom cover

Fig. 3.3-1 Removing the Trimmer Cover 1

3-2

Page 23

2.Set the unit on its side with the trimmer cover uppermost.

Remove the two trimmer cover screws. Remove the trimmer upper cover.

Trimmer upper

cover

Fig. 3.3-2 Removing the Trimmer Upper Cover 2

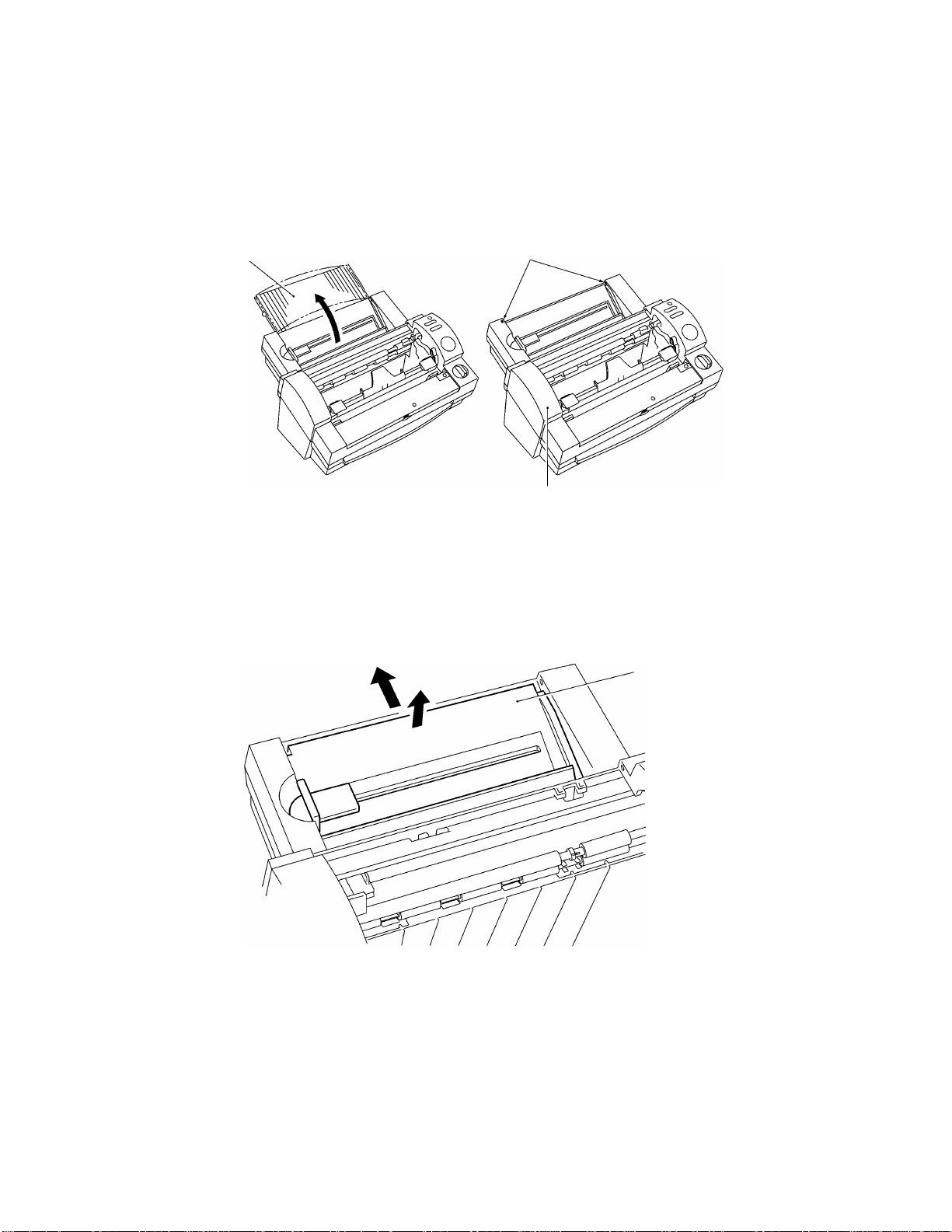

3.3.2 Removing the Top Cover

Trimmer cover screws

Open the top cover. Lift the top cover shafts out of the shaft recesses in the body

cover and remove the cover.

Top cover

Shaft recesses

Body cover

Shafts

Fig. 3.3-3 Removing the Top Cover

3-3

Page 24

3.3.3 Removing the Sub-tray

1.Open the sub-tray.

2.Flex the center of the sub-tray toward you to release the shafts from the shaft

recesses in the body cover. Remove the sub-tray.

Sub-tray

Fig. 3.3-4 Removing the Sub-tray

Shaft recesses

Body cover

3.3.4 Removing the Paper Tray and Paper Guide

1.Lift the top of the paper tray in the direction of arrow A, then pull it in the direction

of arrow B. Remove the paper tray.

“B”

“A”

Paper tray

Fig. 3.3-5 Removing the Paper Tray

3-4

Page 25

2.Disengage the paper guide hook (at the rear of the paper tray) from the paper

tray. Remove the paper guide.

Paper tray film

Fig. 3.3-6 Removing the Paper Guide

3.3.5 Removing the Body Cover B

1.Remove the two bottom cover screws A from the bottom of the bottom cover.

Paper tray

Hook

Paper guide

Bottom cover screws A

Fig. 3.3-7 Removing the Body Cover B (1)

3-5

Page 26

2.Lift the rear of the bottom cover in the direction of arrow B while pushing it in the

direction of arrow A. Release the four hooks at the rear face.

3.Push the body cover in the directions indicated by the arrows C to release the

hook at the left and right side.

4.Release the two hooks from the front of the body cover.

Hook

“B”

“A”

“C”

Body cover

“C”

Rear hooks

Side hook

Front hooks

Bottom cover

Fig. 3.3-8 Removing the Body Cover (2)

5.Disconnect the switch harness assy (white CN1) from the main PCB and remove

the body cover. (The body cover switch PCB is connected to the main PCB of

bottom cover via the switch harness assy.)

Fig. 3.3-9 Removing the Body Cover (3)

Switch harness assy

3-6

Page 27

3.3.6 Removing the Front Cover

1.Remove the two front cover screws under the bottom cover.

Front cover screws

Fig. 3.3-10 Removing the Front Cover (1)

2.While pressing up the two hooks on the front cover from underneath, pull the front

cover out to remove it.

Hook

Front cover

Fig. 3.3-11 Removing the Front Cover (2)

3-7

Page 28

3.3.7 Removing the Cover Switch Assy

1.Disconnect the cover switch assy harness connector (yellow CN4) located under

the body cover from the switch PCB.

2.Remove the cover switch screw. Remove the cover switch assy.

Cover switch assy

Cover switch screw

Harness connector

Front

Fig. 3.3-12 Removing the Cover Switch Assy

3-8

Page 29

3.3.8 Removing the Dial Switch Holder Assy B

1.Disconnect the leaf switch R assy (red CN2) and leaf switch L assy (white CN3)

harness connectors from the switch PCB.

2.Remove the dial lock arm and the dial lock arm spring that is hooked on the body

cover.

3.Remove the switch harness assy from switch PCB.

4.Remove the two dial holder screws. Remove the Dial Switch Holder Assy B.

Leaf switch R assy

Dial holder screws

Dial switch holder

assy B

Leaf switch L assy

Dial lock arm spring

Dial lock arm

Fig. 3.3-13 Removing the Dial Switch Holder Assy B

3-9

Page 30

3.3.9 Disassembling the Dial Switch Holder Assy B

1.Pull the plate spring in the direction of the arrow. Remove dial switch B.

2.Remove the two leaf switch R/L screws. Remove the leaf switch R assy (red

CN2) and the leaf switch L assy (white CN3).

Dial switch B

Leaf switch R/L assy’s

Plate spring

Leaf switch R/L screws

Fig. 3.3-14 Disassembling the Dial Switch Holder Assy B (1)

3.Remove the slide plate spring screw. Remove the plate spring.

4.Lift the slide plate 1B diagonally upward. Disengage slide plate 1B from the hook

and remove it.

Slide plate spring screw

Slide plate 1B

Plate spring

Fig. 3.3-15 Disassembling the Dial Switch Holder Assy B (2)

3-10

Page 31

5.Remove the slide plate screw. Remove slide plate 2 from slide plate 1B.

Dial Switch holder

Slide plate screw

Slide plate 2

Slide plate 1B

Fig. 3.3-16 Disassembling the Dial Switch Holder Assy B (3)

6.Disconnect lug A on the dial lock arm from the dial switch holder. Pull the dial

lock arm off the shaft.

D ial lock arm

Lug “A”

Fig. 3.3-17 Disassembling the Dial Switch Holder Assy B (4)

3-11

Page 32

3.4 Chassis

3.4.1 Removing the Harness Connectors

Remove 12 harness connectors from the main PCB. Do not remove the power

harness assy (red/black CN13).

Power harness assy

Fig. 3.4-1 Removing the Harness Connectors

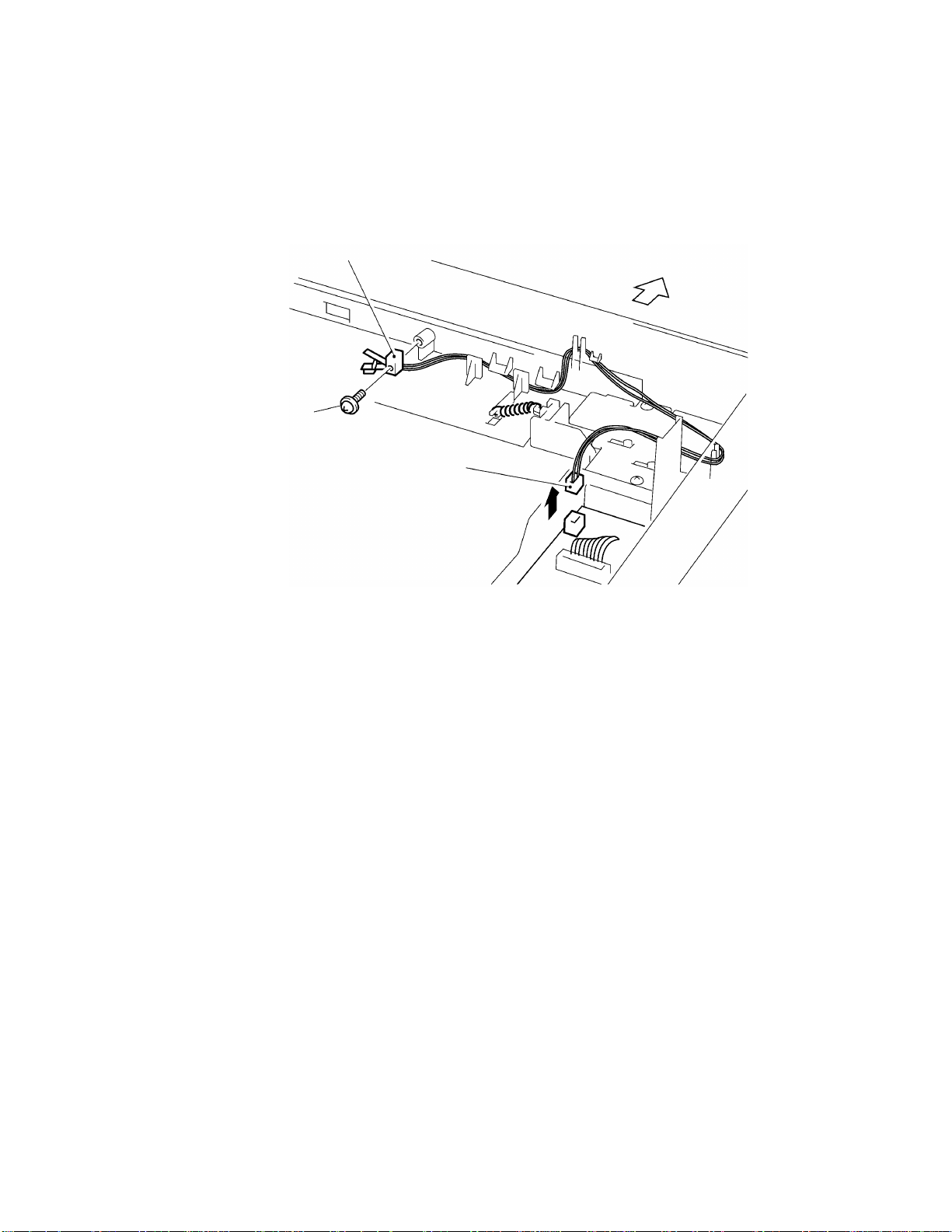

3.4.2 Removing the PE Sensor Unit

Open the bearing supports in the bottom cover outward. Lift the PE sensor unit out

of the bottom cover bearing supports. Pull the tip of the PE sensor unit off the

paper feed roller shaft and remove the PE sensor unit. Take care not to damage

the tip of the PE sensor unit when disconnecting it.

PE sensor unit

Bearing supports

Fig. 3.4-2 Removing the PE Sensor Unit

Paper feed roller Assy

3-12

Page 33

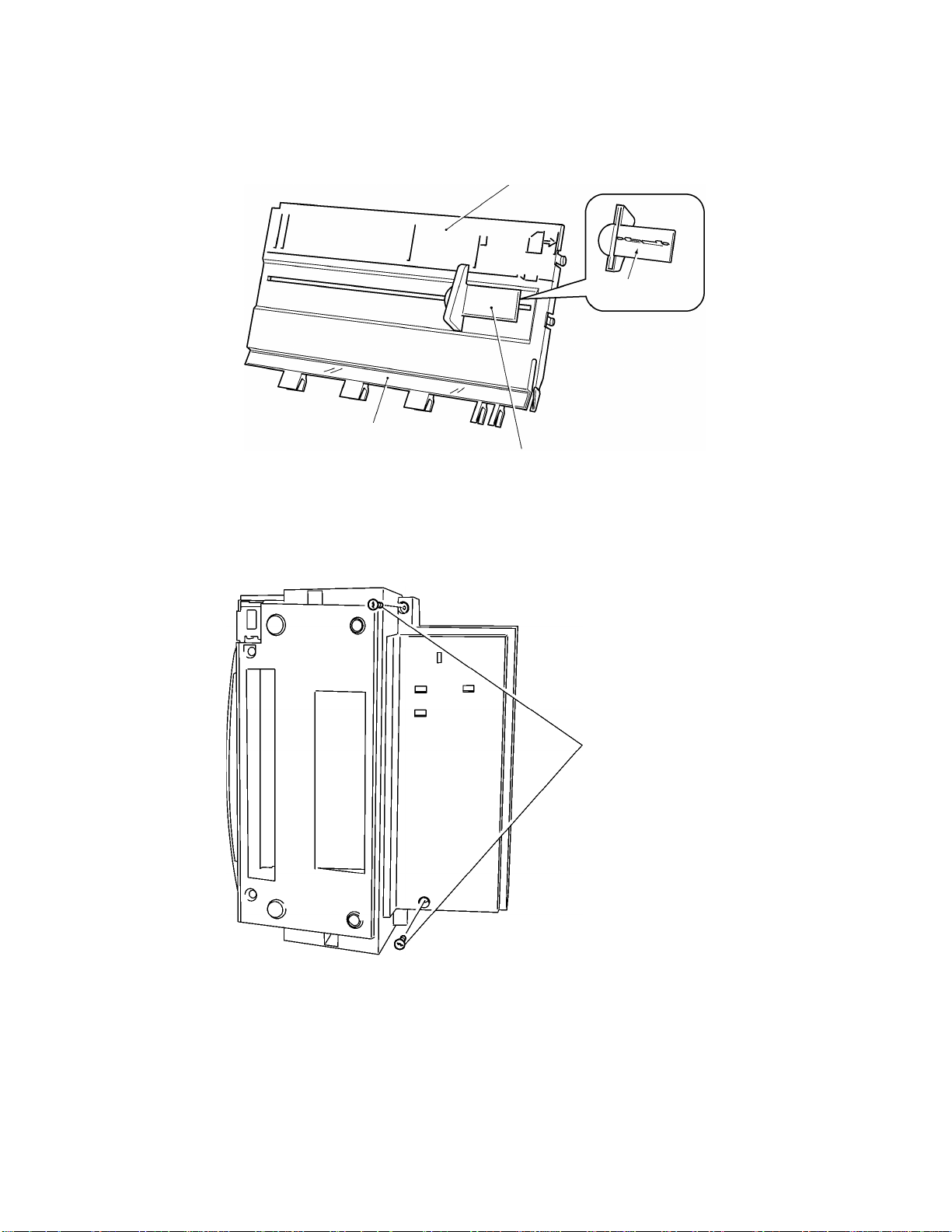

3.4.3 Removing the Chassis Unit

1.Remove the sensor frame screw from the sensor frame. Remove the ground wire

(jack PCB). After removing the wire, reinsert the sensor frame screw to fasten

the sensor frame to the chassis.

Ground wire (jack PCB)

Sensor frame

Sensor frame screw

Fig. 3.4-3 Removing the Chassis Unit (1)

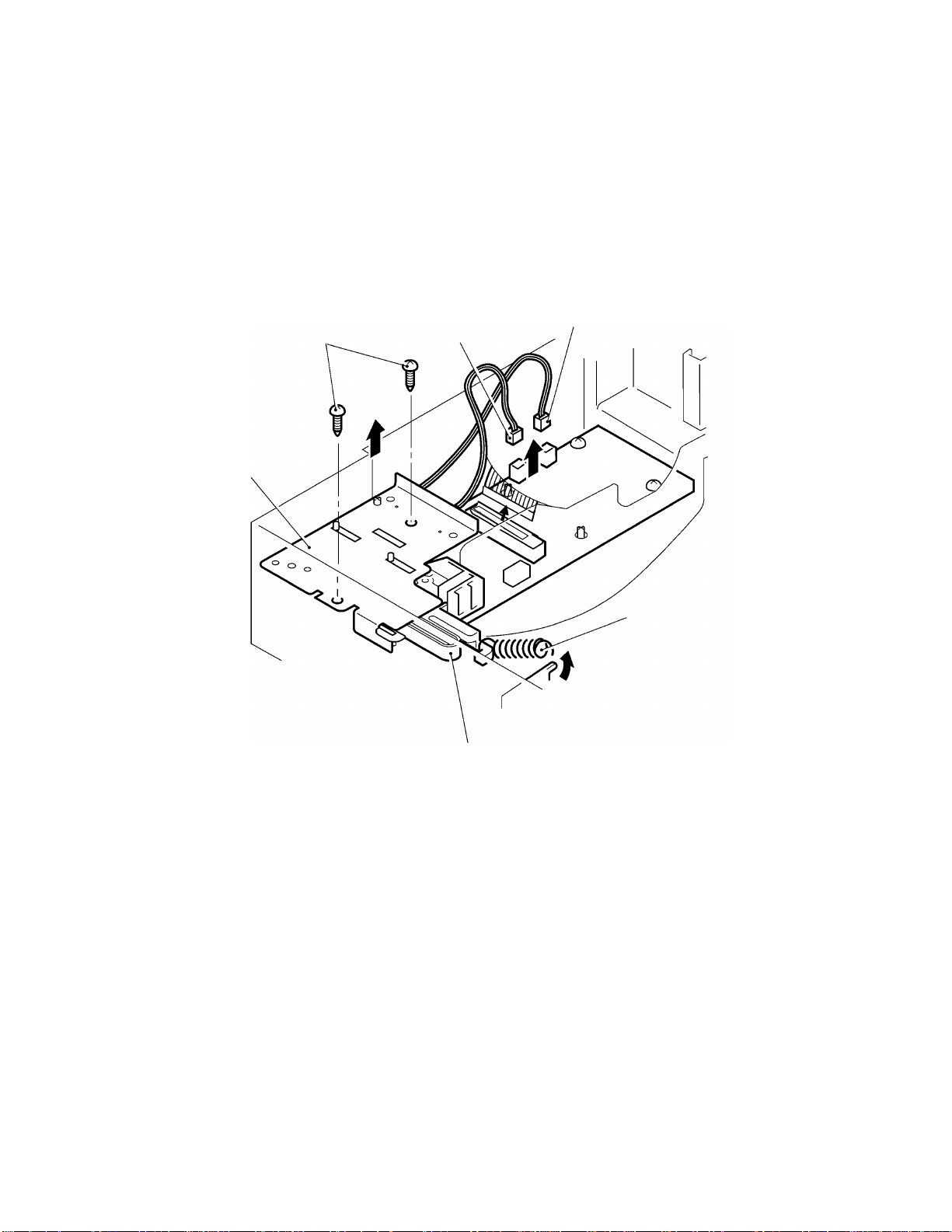

2.Remove the two bottom cover screws B and the spring washers from under the

bottom cover B.

Bottom cover

Bottom cover screws

Fig. 3.4-4 Removing the Chassis Unit (2)

3-13

Page 34

3.Remove the cassette holder screws from under the chassis unit.

Cassette holder screws

Fig. 3.4-5 Removing the Chassis Unit (3)

4.Pull out the chassis unit.

Chassis unit

Fig. 3.4-6 Removing the Chassis Unit (4)

3-14

Page 35

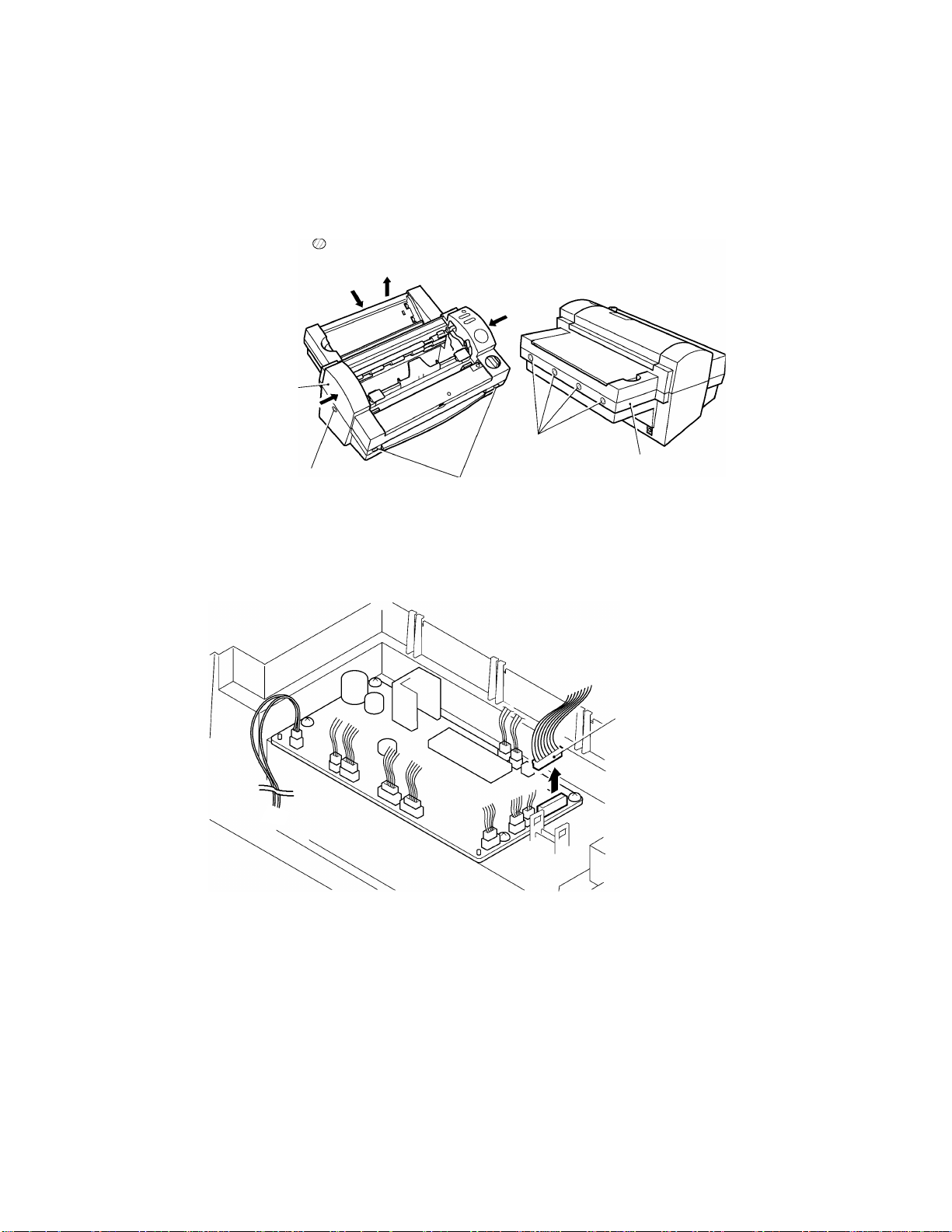

3.5 PCBs

3.5.1 Removing the Main PCB Assy

1.Disconnect the power harness assy (red/black CN13) from the Main PCB assy 1.

2.Remove the four main PCB screws. Remove the Main PCB assy 1.

Main PCB screws

P ower harness assy

Main PCB assy 1 Main PCB screws

Fig. 3.5-1 Removing the Main PCB Assy

3.5.2 Removing the Jack PCB Assy

Remove the Jack PCB screw and remove the jack PCB assy 1.

Jack PCB screw

Fig. 3.5-2 Removing the Jack PCB Assy

Ferrite core

Jack PCB assy 1

3-15

Page 36

3.5.3 Removing the Switch PCB Assy

1.Remove the two switch PCB screws A and three switch PCB screws B from

under the body cover B. Remove the switch PCB assy 1.

Switch PCB screws B

SW PCB

Switch PCB screws A

assy 1

Fig. 3.5-3 Removing the Switch PCB Assy (1)

2.Remove the start switch B,start key film, start key actuator, two-connection

switch, and power switch.

wo-connection switch

T

tart key actuator

S

Fig. 3.5-4 Removing the Switch PCB Assy (2)

3-16

Page 37

3.6 T-Chassis

3.6.1 Removing the T-Chassis Unit

1.Remove the plate spring screw. Remove the plate spring.

2.Remove the two T-chassis screws and remove the T-chassis unit.

T-chassis unit

Plate spring screw

Plate spring

T-chassis screw

Fig. 3.6-1 Removing the T-Chassis Unit

3-17

Page 38

3.6.2 Disassembling the T-Chassis Unit

1.Open hook A on the T-paper guide in the direction A'. Pull out the T-lever shaft to

remove the T-lever unit.

2.Remove T-lever 2 from T-lever 1. Remove the T-push spring and T-cam roller.

3.Remove the leaf switch TRI screw and remove the leaf switch TRI assy.

4.Disconnect the switch lever from the shaft hook on the T-paper guide and remove

the switch lever.

5.Remove the T-cutter upper unit from the T-paper guide. Remove the T-cutter

stopper from the T-cutter holder, then remove the T-cutter.

6.Remove the paper guide screw and remove the T-paper guide.

7.Remove the leaf switch TRG screw and remove the leaf switch TRG assy.

8.Turn the T-sensor lever until lug A aligns with the slot in the T-chassis and

remove the T-sensor lever.

9.Disengage hook B on the T-cam gear. Pull out the T-cam shaft to release T-gear

35-14 and T-idle gear.

T-cutter stopper

Leaf switch TRI screw

Paper

guide

screw

T-cutter holder

T-cutter upper unit

Leaf switch TRG screw

T-sensor lever

Leaf switch TRG assy

Leaf switch TRI assy

Switch lever

Shaft hook

T-paper guide

T-lever 1

T-push spring

A ’

T-lever 2

Lug “A”

T-cutter

Hook A

Slot

T-gear 35-14

T-idle gear

T-lever shaft

T-chassis

T-lever unit

T cam roller

Hook B

T-cam gear

T-cam shaft

Fig. 3.6-2 Disassembling the T-Chassis Unit

3-18

Page 39

3.7 Y-CA Chassis

3.7.1 Removing the Y-CA Chassis Assy

1. Remove the Y-extension spring L.

2. Remove the two Y-CA chassis screws

3. Remove the Y-CA timing belt from the Y-cutter arm and remove the Y-CA chassis

assy.

Y-extension spring L

Y-cutter arm

Y-CA timing belt

Y-CA chassis screws

Fig. 3.7-1 Removing the Y-CA Chassis Assy

Y-CA chassis assy

3-19

Page 40

3.7.2 Disassembling the Y-CA Chassis Assy

1. Remove the pulley holder screw. Move the Y-CA pulley holder in the direction of

arrow A and remove the Y-CA timing belt.

2. Move the Y-CA pulley holder in the direction of arrow B and remove it.

3. Move the Y-CA idle pulley in the direction of arrow B and remove it.

4. Remove the Y-CA driving pulley ring and pull off the Y-CA driving pulley.

5. Remove the two Y-CA motor screws and remove the Y-CA motor.

Y-CA driving pulley ring

Y-CA driving pulley

Y-CA motor

screws

Y-CA motor

Y-CA timing belt

“A”

Anti-static brush

Fig. 3.7-2 Disassembling the Y-CA Chassis Assy

Y-CA idle pulley

Y-CA pulley

holder screw

“B”

Y-CA pulley holder

3-20

Page 41

3.7.3 Removing the Roller Holder Assy

1. Move the Y-cutter arm L as far as possible to the left.

2. Lift up the roller holder assy and remove the roller holder spring.

3. Remove the two roller holder rings. Push the roller holder assy to the right to

disengage it from the chassis unit L boss shaft. Disengage the roller holder assy

from the chassis unit R boss shaft.

Roller holder assy

Y-cutter arm L

Chassis unit L boss shaft

Roller holder rings

Fig. 3.7-3 Removing the Roller Holder Assy

Chassis unit R boss

Roller holder ring

3-21

Page 42

3.7.4 Disassembling the Roller Holder Assy

1. Disengage the two hooks A and remove the side covers L/R.

2. Remove the lock lever springs L/R from inside the lock levers L/R to allow the lock

levers L/R to move freely.

3. Turn hook B on lock lever L to the position of the cut-out on the roller holder and

remove lock lever L. Pull out the lock lever shaft and remove the set buttons L/R,

lock lever springs L/R, and the interference board.

4. Turn hook C on lock lever R to the position of the cut-out on the roller holder and

remove lock lever R.

5. Remove the extension springs 0.4 from the left and right.

6. Pull the sub-roller bearings L/R out of the boss holes and remove them from the

release plates L/R.

7. Remove the sub-roller bearings L/R, tape hold bearings L/R, and tape hold shaft

from the sub-roller assy.

8. Remove the press roller springs L/R.

9. Remove the release plate rings. Remove the release plates L/R.

Hooks A

Lock

Hook B

lever L

Side cover L

Release plate L

Press roller spring L

Boss hole

Release

plate ring

Sub-roller

bearing L

Tape hold

bearing L

Tape hold shaft

Set button L

Cut-out

Roller holder

Lock lever

spring L

Extension

spring 0.4

Sub-roller assy

Fig. 3.7-4 Disassembling the Roller Holder Assy

Lock lever

shaft

Interference

board

Tape hold bearing R

Sub-roller bearing

Extension

spring 0.4

Lock lever

spring R

Cut-out

Set button

R

Boss hole

Release plate R

Lock lever R

Hook C

Hook A

Press roller spring R

Release plate ring

Side

cover R

Hook A

3-22

Page 43

3.8 Sensor Frame and Y-cutter Arm L

3.8.1 Removing the Sensor Frame

1. Position the chassis unit as shown in the diagram. Remove the paper sensor crank

from the paper feed roller.

2. Remove the two sensor frame screws.

3. Lift the right end of the sensor frame to release it from the top-right boss. Move the

sensor frame to the left to release it from the two bosses at the left. Remove the

sensor frame.

Sensor frame screws

Paper sensor crank

Sensor frame

Fig. 3.8-1 Removing the Sensor Frame

Chassis left sideChassis right side

3.8.2 Removing the Y-cutter Arm L

Remove the two arm shaft rings and pull the Y-cutter arm shaft in the direction of the

arrow to remove the Y-cutter arm L.

Y-cutter arm L

Y-CA chassis screw

Fig. 3.8-2 Removing the Y-cutter Arm L

Y-cutter arm L

Y-CA timing belt

3-23

Page 44

3.8.3 Disassembling the Sensor Frame

1. Disengage the hooks on FPC holder A from the cut-outs in the sensor frame. Move

the FPC holder A in the direction of the arrow to remove it.

2. Release the FPC holder B from the boss hole in the sensor frame. Move the FPC

holder B in the direction of the arrow to remove it.

3. Remove the paper sensor harness assy (flat cable) from the FPC holder A and FPC

holder B.

4. Remove the sensor crank protect film from the sensor frame, if it requires replacing.

Sensor frame

Cut-out

FPC holder A

Hook

Boss hole

Sensor crank

protect film

Paper sensor harness assy

Fig. 3.8-3 Disassembling the Sensor Frame

FPC holder B

3-24

Page 45

3.8.4 Disassembling the Y-cutter Arm L

1. Remove the sensor holder screw. Remove the photosensor (PS) PCB holder from

the Y-cutter arm L.

2. Disengage the PS PCB holder hook. Turn the PL detect lever to a position where it

does not engage with the sensor, then remove it.

3. Remove the Y-CA sensor screw and remove the Y-CA sensor.

Sensor holder screw

Y-CA sensor

Hook

Y-CA sensor screw

Photosensor (PS) PCB holder

PL detect lever

Y-cutter arm L

Fig. 3.8-4 Disassembling the Y-cutter Arm L

3-25

Page 46

3.9 Paper Feed Roller

3.9.1 Removing the Paper Feed Sub-roller Assy

1. Position the chassis unit as shown in the diagram. Release the gear 16 hook from

the paper feed sub-roller assy. Take care not to damage the gear hook by opening

too far.

2. Remove the paper feed shaft spring R and paper feed shaft spring.

Paper feed sub-roller assy

Gear 16 hook

Chassis right side

Paper feed shaft spring R

Paper feed shaft spring

Fig. 3.9-1 Removing the Paper Feed Sub-roller Assy

Chassis left side

3. Remove the left and right rod holder from the chassis L/R units. Pull the paper feed

sub-roller assy up from the bearings to remove it.

Paper feed sub-roller assy

Bearings

Rod holders

Fig. 3.9-2 Removing the Paper Feed Sub-roller Assy

3-26

Page 47

3.9.2 Removing the Paper Feed Roller Assy

1. Position the chassis unit as shown in the diagram. Release the gear 16 hook from

the paper feed sub-roller assy. Take care not to damage the gear hook by opening

too far.

2. Remove the paper feed roller ring from the chassis right side.

Paper feed roller ring

Chassis right side

Gear 16 hookPaper feed roller assy

Chassis left side

Fig. 3.9-3 Removing the Paper Feed Roller Assy (1)

3. Remove the left and right bearing.

4. Remove the paper feed roller assy from the left and right sides of the chassis.

Bearings

Paper feed roller assy

Fig. 3.9-4 Removing the Paper Feed Roller Assy (2)

3-27

Page 48

3.10 Paper Eject Roller

3.10.1 Removing the Y-D Shaft

1. Remove the left and right paper eject sub-roller springs.

2. Remove the left and right Y-extension springs L/R.

3. Pull out the Y-gear 40-20 from the shaft and remove the Y-driving gear. Take care

not to damage the gear hook by opening too far while removing the Y-gear 40-20.

4. Push the Y-D shaft to the right, then remove from the left.

Paper eject sub-roller springs

Y-D shaft

Y-driving gear

Y-gear 40-20

Y-extension spring L

Fig. 3.10-1 Removing the Y-D Shaft (1)

Y-extension spring R

5. Remove the Y-cutter cams L/R from the removed Y-D shaft.

Y-D shaft

Y-cutter cam L

Y-cutter cam R

Fig. 3.10-2 Removing the Y-D Shaft (2)

3-28

Page 49

3.10.2 Removing the Paper Eject Sub-roller Unit

1. Remove the paper eject shaft holders L/R attached to the paper eject sub-roller unit

by pulling them from the paper eject roller shaft in the direction of the arrow.

2. Remove the paper eject shaft holders L/R from the removed paper eject sub-roller

unit.

Paper eject roller unit

Paper eject sub-roller unit

Paper eject shaft holders L/R

Fig. 3.10-3 Removing the Paper Eject Sub-roller Unit

3.10.3 Removing the Paper Eject Roller Unit

1. Pull out the Y-gear 40-16 from the shaft and remove the gear 20. Take care not to

damage the gear hook by opening too far while removing the Y-gear 40-16.

2. Remove the gear 16 hook from the paper eject roller unit. Take care not to damage

the gear hook by opening too far.

3. Turn the paper eject roller bearing L clockwise at the chassis left side with needlenosed pliers and remove it. Remove the paper eject roller screw then turn the paper

eject roller bearing R counterclockwise at the chassis right side with needle-nosed

pliers and remove it.

Gear 40-16 hook

Fig. 3.10-4 Removing the Paper Eject Roller Unit (1)

Gear 16 hook

Paper eject roller Bearing

Gear 20

Paper eject roller bearing

Paper eject roller unit

Paper eject roller screw

3-29

Page 50

4. Push the paper eject roller unit to the left, then remove from the right.

Y-cutter units

Paper eject roller unit

Fig. 3.10-5 Removing the Paper Eject Roller Unit (2)

3.11 Y-diversion Lever

3.11.1 Removing the Y-diversion Lever Assy

1. Press the tabs on the two Y-cutter units in the direction of arrow 1 to release the

hooks. Move them down in the direction of arrow 2 and then in the direction of

arrow 3 to release.

1

2

3

1

2

Fig. 3.11-1 Removing the Y-diversion Lever Assy (1)

3-30

Page 51

2. Lift up the right end and the left end of the Y-diversion lever assy in sequence to

remove it.

Fig. 3.11-2 Removing the Y-diversion Lever Assy (2)

Y-diversion lever assy

3.11.2 Disassembling the Y-diversion Lever Assy

1. Release the two Y-cutter guide shaft rings from the right end.

2. Pull up the Y-cutter guide shaft then remove the Y-cutter guides L/R from each end.

3. Remove the Y-diversion lever film, if it requires replacing.

Y-cutter guide L

Y-cutter guide shaft

Y-cutter guide shaft rings

Y-cutter guide R

Y-diversion lever film

Fig. 3.11-3 Disassembling the Y-diversion Lever Assy

3-31

Page 52

3.12 X-cutter

3.12.1 Removing the X-cutter Unit

1. Remove the two X-cutter screws. Lift up the X-cutter unit.

X-cutter screws

Fig. 3.12-1 Removing the X-cutter Unit

X-cutter unit

3.12.2 Disassembling the Tape Sensor Unit

1. Remove the leaf switch screw. Remove the leaf switch F assy.

2. Remove the sensor holder screw. Remove the tape sensor holder from the X-cutter

unit.

3. Remove the tape sensor lever from the tape sensor holder.

X-cutter unit

Tape sensor lever

Tape sensor holder

Leaf switch screw

Sensor holder screw

Fig. 3.12-2 Disassembling the Tape Sensor Unit

Leaf switch F assy

3-32

Page 53

3.13 Driving Roller Shaft

3.13.1 Removing the Driving Roller Shaft

1. Remove the driving roller C ring. Remove the gear 16M1 hook and driving roller

bearing. Take care not to open the driving roller C ring too far.

2. Remove the driving roller E ring. Remove the driving roller bearing.

3. Remove the driving roller shaft.

Driving roller C ring

Gear 16M1 hook

Bearing

Driving roller shaft

Driving roller E ring

Fig. 3.13-1 Removing the Driving Roller

3.14 Left Side of the Chassis

3.14.1 Removing the Gears

Remove the gears from the left side of the chassis in the sequence described below.

If the gear has one or two hooks, disengage the hooks from the locking groove in the

shaft before removing. Gear 20, removed at step 18 is fastened by a ring. Remove the

ring before removing the gear.

1. Gear 37 hook

2. TY-planet gear unit

Remove the TY-planet gear holder, before removing the felt, TY-idle gear, and TY-

spring washer from the shaft. Remove the TY-planet gear from the TY-planet gear

holder.

3. Gear 25 hook

4. Planet 20 hook (two)

Remove the planet 20 hook, before removing the felt, TY-planet gear holder, TY-spring

washer, and TY-planet gear.

Bearing

3-33

Page 54

5. Gear 36/12 hook

6. Gear 21

7. Gear 37 hook

8. Gear 21

9. Gear 40/16 hook (This is removed when removing the paper eject roller.)

10. Gear 21

11. Gear 20 (This is removed when removing the paper eject roller.)

12. Gear 60/20 hook

13. Gear 60/16M1

14. Gear 60/16

15. Gear 16M1

16. Gear 48/24

17. Gear 20

18. Gear 20

19. Gear 20

20. Gear 50

Planet 20 hook unit

Planet 20 hook

Planet gear holder

TY-spring washer

Gear 20 ring

Gear 37 hook

TY-planet gear

Felt

Gear 40/16 hook

Gear 36/12 hook

TY planet gear

TY planet gear holder

Gear 20

Gear 25 hook

Felt

TY-idle gear

Gear 60/16M1

Gear 60/20 hook

Gear 16M1

Gear 21

TY-planet gear unit

TY-spring washer

Fig. 3.14-1 Removing the Gears

Gear 50

Gear 37 hook

Gear 60/16

Gear 48/24

3-34

Page 55

3.14.2 Disassembling the Left Side of the Chassis

1. Release roller guide L from the boss hole. Incline the guide and remove it.

2. Remove the LF motor screw and TC/LF motor screw. Remove the LF motor.

Boss hole

Roller guide L

TC/LF motor screw

LF motor

LF motor screw

Fig. 3.14-2 Disassembling the Left Side of the Chassis

3-35

Page 56

3.15 Right Side of the Chassis

3.15.1 Disassembling the Right Side of the Chassis

1. Remove the leaf switch Y screw. Remove the leaf switch Y assy.

2. Release the Y-sensor lever hook and remove the Y-sensor lever.

3. Incline the edging saddle EDS-1 and remove it.

4. Release roller guide R from the boss hole. Incline the guide and remove it.

5. Remove the TY-planet gear holder, before removing the felt, TY-idle gear, and TYspring washer from the shaft. Take care not to damage the TY-planet gear holder

hooks by opening too far.

6. Remove the TY-planet gear from the TY-planet gear holder.

Roller guide R

Y-sensor lever hook

Y-sensor lever

TY-spring washer

Fig. 3.15-1 Disassembling the Right Side of the Chassis (1)

Edging saddle EDS-1

Leaf switch Y screw

Leaf switch Y assy

TY-idle gear

Felt

TY-planet gear

TY-planet gear holder

3-36

Page 57

7. Remove the two TC motor screws. Remove the TC motor.

TC motor

TC motor screws

Fig. 3.15-2 Disassembling the Right Side of the Chassis (2)

3.16 Lower Chassis

3.16.1 Removing the Left and Right Sides of the Chassis

Remove the six side chassis screws and remove the left and right sides of the chassis.

Side chassis screws

Fig. 3.16-1 Removing the Left and Right Sides of the Chassis

3-37

Page 58

3.16.2 Removing the Cassette Holder

1. Release the two side hooks fastening the cassette holder.

2. Flex the rear face of the cassette holder inward to release the two lugs. Remove the

cassette holder from the bottom chassis.

Hooks

Bottom chassis

Fig. 3.16-2 Removing the Cassette Holder

Lug

Cassette holder

3.16.3 Removing the Encoder (ENC) Sensor PCB

Remove the ENC sensor screw. Remove the ENC sensor assy.

ENC sensor screw

ENC sensor assy

Fig. 3.16-3 Removing the ENC Sensor PCB

3-38

Page 59

3.16.4 Removing the Cassette Detect Switch

Remove the leaf switch (SW) C screw. Remove the leaf switch C assy.

Leaf switch (SW) C screw

Leaf switch C assy

Fig. 3.16-4 Removing the Cassette Detect Switch

3-39

Page 60

Chapter 4.

REASSEMBLY PROCEDURES

Page 61

CONTENTS

Chapter 4. REASSEMBLY PROCEDURES

4.1 Safety Precautions ............................................................................................................4-1

4.2 Table of Tightening Torque...............................................................................................4-1

4.3 Lower Chassis...................................................................................................................4-2

4.3.1 Installing the Cassette Detect Switch....................................................................4-2

4.3.2 Installing the Encoder (ENC) Sensor PCB ...........................................................4-2

4.3.3 Installing the Cassette Holder...............................................................................4-3

4.3.4 Installing the Left and Right Sides of the Chassis................................................4-3

4.4 Right Side of the Chassis..................................................................................................4-4

4.4.1 Reassembling the Right Side of the Chassis........................................................4-4

4.5 Left Side of the Chassis ....................................................................................................4-6

4.5.1 Reassembling the Left Side of the Chassis..........................................................4-6

4.5.2 Installing the Gears...............................................................................................4-6

4.6 Driving Roller Shaft............................................................................................................4-9

4.6.1 Installing the Driving Roller Shaft..........................................................................4-9

4.7 X-cutter............................................................................................................................4-10

4.7.1 Reassembling the Tape Sensor Unit..................................................................4-10

4.7.2 Installing the X-cutter Unit...................................................................................4-10

4.8 Y-diversion Lever.............................................................................................................4-11

4.8.1 Reassembling the Y-diversion Lever Assy.........................................................4-11

4.8.2 Installing the Y-diversion Lever Assy..................................................................4-12

4.9 Paper Eject Roller............................................................................................................4-13

4.9.1 Installing the Paper Eject Roller Unit ..................................................................4-13

4.9.2 Installing the Paper Eject Sub-roller Unit............................................................4-15

4.9.3 Installing the Y-D Shaft .......................................................................................4-15

4.10 Paper Feed Roller ...........................................................................................................4-17

4.10.1 Installing the Paper Feed Roller Assy.................................................................4-17

4.10.2 Installing the Paper Feed Sub-roller Assy ..........................................................4-18

4.11 Sensor Frame and Y-cutter Arm L..................................................................................4-19

4.11.1 Reassembling the Y-cutter Arm L.......................................................................4-19

4.11.2 Reassembling the Sensor Frame .......................................................................4-20

4.11.3 Installing the Y-cutter Arm L................................................................................4-21

4.11.4 Installing the Sensor Frame................................................................................4-22

4.12 Roller Holder....................................................................................................................4-22

4.12.1 Reassembling the Roller Holder Assy ................................................................4-22

4.12.2 Installing the Roller Holder Assy.........................................................................4-24

4.13 Y-CA Chassis..................................................................................................................4-25

4.13.1 Reassembling the Y-CA Chassis Assy...............................................................4-25

4.13.2 Installing the Y-CA Chassis Assy........................................................................4-26

i

Page 62

ii

4.14 T-Chassis.........................................................................................................................4-27

4.14.1 Reassembling the T-Chassis Unit.......................................................................4-27

4.14.2 Installing the T-Chassis Unit...............................................................................4-28

4.15 PCBs................................................................................................................................4-29

4.15.1 Installing the Switch PCB Assy...........................................................................4-29

4.15.2 Installing the Jack PCB Assy..............................................................................4-30

4.15.3 Installing the Main PCB Assy..............................................................................4-30

4.16 Chassis............................................................................................................................4-31

4.16.1 Installing the Chassis Unit...................................................................................4-31

4.16.2 Installing the PE Sensor Unit..............................................................................4-32

4.16.3 Installing the Harness Connectors......................................................................4-33

4.17 Covers .............................................................................................................................4-33

4.17.1 Reassembling the Dial Switch Holder Assy B ....................................................4-33

4.17.2 Installing the Dial Switch Holder Assy B.............................................................4-35

4.17.3 Installing the Cover Switch Assy.........................................................................4-36

4.17.4 Installing the Front Cover....................................................................................4-37

4.17.5 Installing the Body Cover....................................................................................4-38

4.17.6 Installing the Paper Tray and Paper Guide.........................................................4-41

4.17.7 Installing the Sub-tray .........................................................................................4-42

4.17.8 Installing the Top Cover......................................................................................4-42

4.17.9 Installing the Trimmer Upper Cover....................................................................4-43

4.18 Installing the Film Cartridge.............................................................................................4-44

Page 63

1

4.1 Safety Precautions

• When conducting reassembly operations, place the unit on a grounded anti-static

sheet. LSI and other electronic components are sensitive to static electricity and

may be damaged if touched while charged.

• Before transporting a circuit board, wrap it in a conducting sheet such as aluminum

foil.

• When using a soldering iron or other heat-producing tool, ensure that heat does not

damage wires, circuit boards, or plastic parts such as covers.

• Take care not to lose small screws or washers removed when replacing parts.

• Tighten all screws to the torque specified in the table below.

4.2 Table of Tightening Torque

Name of Screw Qty. Screw Size Tightening Torque See

Leaf switch (SW) C screw 1

ENC sensor screw 1

Side chassis screw 6

TC/LF motor screw 2

Leaf switch Y screw 1

TC/LF motor screw 1

LF motor screw 1

X-cutter screw 2

Leaf switch screw 1

Sensor holder screw 1

Paper eject roller screw 1 TAPTITE,CUP M3 × 5 0.49 to 0.686N•m 4-14

Y-CA sensor screw 1

Sensor holder screw 1

Sensor frame screw 2

Y-CA motor screw 2

Y-CA pulley holder screw 1

Y-CA frame screw 2

Leaf switch TRI screw 1

Paper guide screw 1

Leaf switch TRG screw 1

T-chassis unit screw 2

Plate spring screw 1

Switch PCB screw A 2

Switch PCB screw B 3

Jack PCB screw 1

Main PCB screw 4

Cassette holder screw 4

Bottom cover screw B 2

Slide plate screw 1

Slide plate spring screw 1

SCREW FLANGED2.6 × 8

TAPTITE,BIND B M2.6 × 6

TAPTITE,CUP M3 × 5

SCREW,BIND M3 × 6

PAN-HEAD MACHINE SCREW M2.6 × 8

TAPTITE,CUP M3 × 6

TAPTITE,CUP M3 × 16

TAPTITE,CUP M 3 × 5

TAPTITE,PAN B M2 × 6

TAPTITE BIND B M2.6 × 6

TAPTITE,BIND B M2.6 × 6

TAPTITE,BIND B M2.6 × 6

TAPTITE,CUP M3 × 5

SCREW,FLANGED M2.6 × 5

TAPTITE,CUP M3 × 5

TAPTITE,CUP M3 × 5

TAPTITE,PAN B M2 × 6

SCREW,BIND M3 × 6

PAN-HEAD MACHINE SCREW M2.6 × 8

TAPTITE,CUP M3 × 5

TAPTITE,CUP M3 × 5

TAPTITE,BIND B M3 × 12

TAPTITE,BIND B M3 × 14

TAPTITE,BIND B M 3 × 8

TAPTITE,BIND B M3 × 8

TAPTITE,CUP B M4 × 12

TAPTITE,BIND B M3 × 8

TAPTITE,BIND B M3 × 8

SCREW,FLANGED M2.6 × 5

0.196 to 0.392N•m 4-2

0.196 to 0.392N•m 4-2

0.49 to 0.686N•m 4-3

0.49 to 0.686N•m 4-4

0.196 to 0.392N•m 4-5

0.49 to 0.686N•m 4-6

0.49 to 0.686N•m 4-6

0.49 to 0.686N•m 4-10

0.196 to 0.392N•m 4-10

0.686 to 0.882N•m 4-10

0.196 to 0.392N•m 4-19

0.196 to 0.392N•m 4-19

0.49 to 0.686N•m 4-22, 32

0.196 to 0.392N•m 4-25

0.49 to 0.686N•m 4-25

0.49 to 0.686N•m 4-26

0.196 to 0.392N•m 4-27

0.49 to 0.686N•m 4-27

0.196 to 0.392N•m 4-27

0.49 to 0.686N•m 4-28

0.49 to 0.686N•m 4-28

0.49 to 0.686N•m 4-29

0.49 to 0.686N•m 4-29

0.49 to 0.686N•m 4-30

0.49 to 0.686N•m 4-30

0.98 to 1.176N•m 4-31

0.49 to 0.686N•m 4-31

0.49 to 0.686N•m 4-34

0.196 to 0.392N•m 4-34

Page

4-

Page 64

2

Name of Screw Qty. Screw Size Tightening Torque See

Leaf switch R/L screw 2

Dial holder screw 2

Cover switch screw 1

Front cover screw 2 TAPTITE,BIND B M2.6X6 0.294 to 0.49N•m 4-37

Bottom cover screw A 2 TAPTITE,BIND B M3X12 0.196 to 0.392N•m 4-40

Trimmer cover screw 2

PAN-HEAD MACHINE SCREW M2.6 × 8

TAPTITE,BIND B M3 × 8

PHILLIPS PAN-HEAD TAPTILE B M2.6 ×

12

SCREW,BIND M3 × 6

0.196 to 0.392N•m 4-35

0.49 to 0.686N•m 4-35

0.49 to 0.686N•m 4-36

0.49 to 0.686N•m 4-43

Page

4.3 Lower Chassis

4.3.1 Installing the Cassette Detect Switch

Align the leaf switch C assy with the boss hole in the lower chassis and fasten it in

position with the leaf switch (SW) C screw. Take care not to deform the tip of the leaf

switch C assy during installation.

Leaf switch (SW) C screw

Lower chassis

Boss hole

Leaf switch C assy

Fig. 4.3-1 Installing the Cassette Detect Switch

4.3.2 Installing the Encoder (ENC) Sensor PCB

Align the ENC sensor assy with the two bosses. Fasten the assembly to the cassette

holder with the ENC sensor screw.

Fig. 4.3-2 Installing the ENC Sensor PCB

Bosses

ENC sensor assy

ENC sensor screw

4-

Page 65

3

4.3.3 Installing the Cassette Holder

Engage the two side hooks and four claws on the cassette holder with the bottom

chassis. Insert the two rear lugs into the slots to fasten the cassette holder.

Lug

Cassette holder

Claws

Hooks

Bottom chassis

Fig. 4.3-3 Installing the Cassette Holder

Slot

4.3.4 Installing the Left and Right Sides of the Chassis

Insert the two lugs on the left or right side of the chassis into the rectangular holes in the

lower chassis. Fasten each side chassis in position with the three side chassis screws.

Side chassis screws

Lower chassis

Lugs

Fig. 4.3-4 Installing the Left and Right Sides of the Chassis

4-

Page 66

4

4.4 Right Side of the Chassis

4.4.1 Reassembling the Right Side of the Chassis

1. Attach the TC motor with the two TC/LF motor screws.

TC motor

Fig. 4.4-1 Reassembling the Right Side of the Chassis (1)

TC/LF motor screws

4-

Page 67

5

2. Put the TY-spring washer, TY-idle gear, and felt (stick onto the TY-idle gear) on the

shaft.

3. Attach the TY-planet gear to the TY-planet gear holder. Put the TY-planet gear

holder on the shaft and push it until the hooks engage.

4. Incline the roller guide R and push the cut-out and align the roller guide R with the

boss hole A to engage with chassis R.

5. Incline the edging saddle EDS-1 and push it into position.

6. Align the Y-sensor lever hook with boss hole B in the chassis R and push it into

hooking position.

7. Align the leaf switch Y assy with the chassis R boss hole C and fasten it in position

with the leaf switch Y screw. Install the contacts of the leaf switch Y assy over the Ysensor lever.

Y-sensor lever

Boss hole B

Y-sensor lever hook

Roller guide R

Edging saddle EDS-1

Boss hole A

TY-planet gear

Leaf switch Y screw

Leaf switch Y assy

TY-spring washer

TY-idle gear

Boss hole C

Fig. 4.4-2 Reassembling the Right Side of the Chassis (2)

Felt

TY-planet gear holder

4-

Page 68

6

4.5 Left Side of the Chassis

4.5.1 Reassembling the Left Side of the Chassis

1. Fasten the LF motor with one TC/LF motor screw and one LF motor screw.

2. Incline the roller guide L. Insert the cut-out into chassis L and push it into place until

the hooks engage in the boss hole.

Roller guide L

Boss hole

TC/LF motor screw

LF motor

Fig. 4.5-1 Reassembling the Left Side of the Chassis

4.5.2 Installing the Gears

Install the gears at the left side of the chassis in the sequence described below.

If the gear (or holder) has one or two hooks, push it into place until the hooks engage in

the locking groove in the shaft.

Gear 20, installed at step 3, is fastened by a ring.

1. Gear 50

2. Gear 20

3. Gear 20

4. Gear 20

5. Gear 48/24 (48-tooth side against chassis)

6. Gear 16M1

7. Gear 60/16 (16-tooth side against chassis)

8. Gear 60/16M1 (16-tooth side against chassis)

9. Gear 60/20 hook

10. Gear 20

11. Gear 21

12. Gear 40/16 hook

LF motor screw

4-

Page 69

7

13. Gear 21

14. Gear 37 hook

15. Gear 21

16. Gear 36/12 hook

17. Planet 20 hook (two)

Attach the TY-planet gear to the planet gear holder. Put the TY-spring washer, planet

gear holder, felt (stick onto the TY-planet gear holder), and planet 20 hook on the

shaft.

18. Gear 25 hook

19. TY-planet gear unit

Attach the TY-planet gear to the TY-planet gear holder. Put the TY-spring washer, TY-

idle gear, felt (stick onto the TY-idle gear), and TY-planet gear holder on the shaft.

20. Gear 37 hook

Gear 20 ring

Gear 20

Gear 25 hook

Gear 60/16M1

Gear 60/20 hook

Gear 50

Gear 60/16

Gear 48/24

TY-planet gear

Planet 20 hook unit

Planet 20 hook

Planet gear holder

TY-spring washer

TY-planet gear holder

Gear 37 hook

Felt

Gear 40/16 hook

Gear 36/12 hook

TY-planet gear

Gear 16M1

Felt

TY-idle gear

TY-spring washer

Fig. 4.5-2 Installing the Gears (1)

Gear 21

Gear 37 hook

TY-planet gear unit

4-

Page 70

8

Gear 60/20 hook

Gear 50

Gear 60/16M1

Gear 16M1

Gear 25 hook

Gear 36/12 hook

Gear 20

Gear 40/16

hook

Gear 60/16

Gear 48/24

TY-planet gear

Gear 20

TY-planet gear

TY-idle gear

Planet gear 20 hook

Gear 37 hook

TY-planet gear

Gear 21

Gear 36/12

hook

Fig. 4.5-3 Installing the Gears (2)

4-

Page 71

9

4.6 Driving Roller Shaft

4.6.1 Installing the Driving Roller Shaft

1. Insert the semicircular end of the driving roller shaft into the hole in chassis L.

2. Put the driving roller bearing from the left and attach it to chassis L. (Align the lug on

the bearing with the cut-out in the chassis.)

3. Insert the right end of the driving roller shaft into the hole in chassis R.

4. Put the driving roller bearing from the right and attach it to chassis R. (Align the lug

on the bearing with the cut-out in the chassis.)

5. Fasten the right end of the driving roller shaft with the driving roller E ring.

6. Put the gear 16M1 hook on the left end of the driving roller shaft and fasten it with

the driving roller C ring. Take care not to open the driving roller C ring too far.

Driving roller C ring

Gear 16M1 hook

Driving roller

bearing

Driving roller shaft

Driving roller E ring

Fig. 4.6-1 Installing the Driving Roller Shaft

Driving roller bearing

4-

Page 72

4.7 X-cutter

4.7.1 Reassembling the Tape Sensor Unit

1. Fasten the leaf switch F assy to the tape sensor holder with the leaf switch screw.

2. Attach the tape sensor lever to the tape sensor holder.

3. Attach the tape sensor holder to the X-cutter unit with the sensor holder screw.

X-cutter unit

Tape sensor lever

Tape sensor holder

Sensor holder screw

Fig. 4.7-1 Reassembling the Tape Sensor Unit

4.7.2 Installing the X-cutter Unit

Leaf switch F assy

Leaf switch screw

Install the X-cutter unit into the chassis unit from above. Fasten it in position with the

two X-cutter screws.

X-cutter screws

X-cutter unit

Fig. 4.7-2 Installing the X-cutter Unit

4-10

Page 73

4.8 Y-diversion Lever

4.8.1 Reassembling the Y-diversion Lever Assy

1. Hold the Y-cutter guide shaft with the two rings at the right end. Insert the left end

into Y-cutter guide L and the right end into Y-cutter guide R.

2. Insert the Y-cutter guide shaft through the holes in the Y-diversion lever. Fasten with

the two Y-cutter guide shaft rings.

3. Stick new Y-diversion lever film on the Y-diversion lever, if it requires replacing.

Y-cutter guide L

Y-cutter guide shaft

Y-cutter guide R

Y-cutter guide shaft rings

Y-diversion lever

Fig. 4.8-1 Reassembling the Y-diversion Lever Assy

Y-diversion lever film

4-11

Page 74

4.8.2 Installing the Y-diversion Lever Assy

1. Mount the Y-diversion lever assy on the X-cutter unit by inserting the left end into

chassis L then the right end into chassis R.

X-cutter unit

Fig. 4.8-2 Installing the Y-diversion Lever Assy 1

2. Press each of the two Y-cutter assy’s against the Y-diversion lever assy and move it

in the direction of arrow 1 up to the position of the Y-cutter guide L/R.

3. Install the Y-cutter guides by lifting the tab on each Y-cutter assy in the direction of

arrow 2, then pushing in the direction of arrow 3 to engage the hook.

Y-diversion lever assy

1

2

3

Y-cutter assy

2 3

1

Y-cutter guide L

Y-cutter guide R

Fig. 4.8-3 Installing the Y-diversion Lever Assy 2

4-12

2

3 1

Page 75

4.9 Paper Eject Roller

4.9.1 Installing the Paper Eject Roller Unit

1. Temporarily remove gear 40-16 and gear 20 when installing the paper eject roller

unit, as these can interfere with the installation.

2. Hold the paper eject roller unit with the end where the gears mount at the left. Insert

the left end into the hole in chassis L, then the right end into the hole in chassis R.

Paper eject roller unit

Gear 40-16 hook

Gear 20

Fig. 4.9-1 Installing the Paper Eject Roller Unit (1)

4-13

Page 76

3. Insert the left and right paper eject roller bearings into the chassis L/R. The paper

eject roller bearings can only be inserted if the lugs on the bearings are aligned with

the grooves in the chassis.

4. Turn the paper eject roller bearing L counterclockwise to the boss hole to insert it in

the chassis left side. Likewise, turn the paper eject roller bearing R clockwise to the

boss hole to insert it in the chassis right side.

5. After inserting the paper eject roller bearing R in the chassis right side, fasten it in

position with the paper eject roller screw.

6. Align the gear 16 hook with the semicircular end of the paper eject roller unit and

push the gear until the hook engages.

7. Replace gear 40-16 hook and gear 20 which were temporarily removed previously.

Gear 16 hook

Paper eject roller bearing

Paper eject roller unit

Gear 20

Gear 40-16 hook

Paper eject roller screw

Paper eject roller bearing

Fig. 4.9-2 Installing the Paper Eject Roller Unit (2)

4-14

Page 77

4.9.2 Installing the Paper Eject Sub-roller Unit

1. Orient the left paper eject shaft holder L (narrow) and right paper eject shaft holder

R (wide) with the flat face inward and attach them to the paper eject sub-roller unit.

2. Attach the paper eject shaft holders L/R attached to paper eject sub-roller unit to the

paper eject roller shaft in the chassis.

Paper eject shaft holders L/R

Fig. 4.9-3 Installing the Paper Eject Sub-roller Unit

Paper eject roller unit

Paper eject sub-roller unit

4.9.3 Installing the Y-D Shaft

1. Align the Y-D shaft with the long semicircular end to the right. Align the Y-cutter

cams L/R with each semicircular end of the Y-D shaft and attach them to the shaft.

Y-cutter cam L

Fig. 4.9-4 Installing the Y-D Shaft (1)

Y-D shaft

Y-cutter cam R

4-15

Page 78

2. Insert the Y-D shaft (with cams) first into chassis R, then into chassis L. The Y-D

LF motor mounting

shaft should be inserted behind the paper eject shaft holders L/R.

3. Put the Y-driving gear onto the right semicircular end of the Y-D shaft. Next put the

Y-gear 40-20 on this shaft and push the gear until the hook engages.

4. Attach the left and right Y-extension springs (L/R). Attach the Y-extension spring L

(the longer one) to the LF motor mounting screw.

5. Attach the left and right paper eject sub-roller springs.

Paper eject sub-roller springs

Fig. 4.9-5 Installing the Y-driving Shaft (2)

Y-driving gear

shaft holder L

Y-D shaft

Y-extension spring L

Y-cutter cam L/R

screw

Paper eject

shaft holder

R

Y-gear 40-20

Y-extension spring R

4-16

Page 79

4.10 Paper Feed Roller

4.10.1 Installing the Paper Feed Roller Assy

1. Insert the bearings into the chassis L/R.

2. Attach the left and right rod holders to the paper feed roller assy with the hooks

inward.

Paper feed roller assy

Bearings

Rod holders

Fig. 4.10-1 Installing the Paper Feed Roller Assy (1)

3. Hold the paper feed roller assy with the semicircular end to the right. Insert the right

bearing, then insert the left bearing. Fasten by attaching the paper feed roller ring to

the shaft.

4. Align the gear 16 hook with the semicircular end of the paper feed roller assy and

push the gear until the hook engages.

Paper feed roller ring

Bearings

Paper feed roller assy

Gear 16 hook

Fig. 4.10-2 Installing the Paper Feed Roller Assy (2)

4-17

Page 80

4.10.2 Installing the Paper Feed Sub-roller Assy

1. Hold the paper feed sub-roller assy with the semicircular end to the right. Push

through the left and right rod holders and engage the paper feed roller grooves in the

bearings.

Paper feed sub-roller assy

Rod holders

Bearings

Fig. 4.10-3 Installing the Paper Feed Sub-roller Assy (1)

2. Align the lower boss of the left and right rod holders with the slots in the chassis L/R.

3. Attach the left and right paper feed shaft spring (L)/R.

4. Align the gear 16 hook with the semicircular end of the paper feed sub-roller assy

and push the gear until the hook engages.

Paper feed sub-roller assy

Gear 16 hook

Paper feed shaft spring R

Fig. 4.10-4 Installing the Paper Feed Sub-roller Assy (2)

4-18

Slot Paper feed shaft spring

Page 81

4.11 Sensor Frame and Y-cutter Arm L

4.11.1 Reassembling the Y-cutter Arm L

1. Fasten the Y-CA sensor to the photosensor (PS) PCB holder with the Y-CA sensor

screw.

2. Put the PL detect lever on the photosensor (PS) PCB holder shaft. Turn the PL

detect lever to the position where the sensor is cut off and push it until the hook

engages.

3. Align the boss hole in the photosensor (PS) PCB holder with the Y-cutter arm L and

fasten it in position with the sensor holder screw.

Y-CA sensor

Sensor holder screw

Photosensor (PS) PCB holder

Boss hole

Hook

Y-CA sensor screw

PL detect lever

Y-cutter arm L

Fig. 4.11-1 Reassembling the Y-cutter Arm L

4-19

Page 82

4.11.2 Reassembling the Sensor Frame

1. Attach the paper sensor harness assy (flat cable) to the FPC holder A and FPC

holder B.

2. Insert the hooks on FPC holder A into slots A in the sensor frame. Attach FPC

holder A by moving it in the direction of the arrow until the hook tip engages in the

groove.

3. Insert the hooks on FPC holder B into slot B and the end hole in the sensor frame.

Attach FPC holder B by moving it in the direction of the arrow until it engages with

the boss holes.

4. Stick new sensor crank protect film aligned with the sensor frame boss, if the film

requires replacing.

FPC holder A

Sensor frame

Slot A

Hook tip

Hooks A

Groove

Bosses

Boss hole

Slot B

End hole

Sensor crank

protect film

Paper sensor harness assy

Fig. 4.11-2 Reassembling the Sensor Frame

FPC holder B

Hooks B

4-20

Page 83

4.11.3 Installing the Y-cutter Arm L

1. Engage the lug on Y-cutter guide L with the groove in Y-cutter arm L. Insert the Ycutter arm shaft in Y-cutter arm L.

2. Insert the Y-cutter arm shaft in holes in the chassis L/R. Fasten with the two arm

shaft rings.

Groove

Lug

Y-cutter arm L

Y-cutter arm shaft

Arm shaft rings

Fig. 4.11-3 Installing the Y-cutter Arm L

4-21

Page 84

4.11.4 Installing the Sensor Frame

1. Align the left end of the sensor frame with boss A on the side of chassis R. Align the

right end of the sensor frame above boss B on chassis L.

2. Insert the paper sensor crank through the cut-out in the in the sensor crank

protective film and engage it with the paper feed roller unit shaft. Pass the bottom

edge of the sensor crank protective film between the paper feed sub-roller and the