Page 1

SERVICE MANUAL

MODEL: LX-1200/LX-300

Page 2

COOL LAMINATOR

SERVICE MANUAL

MODEL: LX-1200/LX-300

Page 3

Unauthorized copying of all or part of the contents of this manual is prohibit ed.

The contents of this manual may change without notice.

Page 4

INTRODUCTION

This Service Manual describes the Cool Laminator LX-1200/LX-300 specifications, operating

principles of the mechanisms, disassembly and reassembly procedures, and maintenance and

troubleshooting procedures.

This Service Manual is intended for use by trained technicians. It is not intended f or use by the

user.

The manual is divided into the following chapters.

Chapter 1. Specifications

Chapter 2. Mechanisms

Chapter 3. Disassembly Procedures

Chapter 4. Reassembly Procedures

Chapter 5. Electronic Controllers

Chapter 6. Maintenance

Chapter 7. Troubleshooting

Appendix Main PCB Circuit Diagram

Page 5

Chapter 1.

SPECIFICATIONS

Page 6

i

CONTENTS

Chapter 1. SPECIFICATIONS

1.1 Mechanical Specifications................................................................................................. 1-1

1.1.1 Appearance........................................................................................................... 1-1

1.1.2 Operating Panel....................................................................................................1-2

1.1.3 Indicators...............................................................................................................1-2

1.2 Electrical Specifications ....................................................................................................1-2

1.2.1 Power Supply........................................................................................................1-2

Page 7

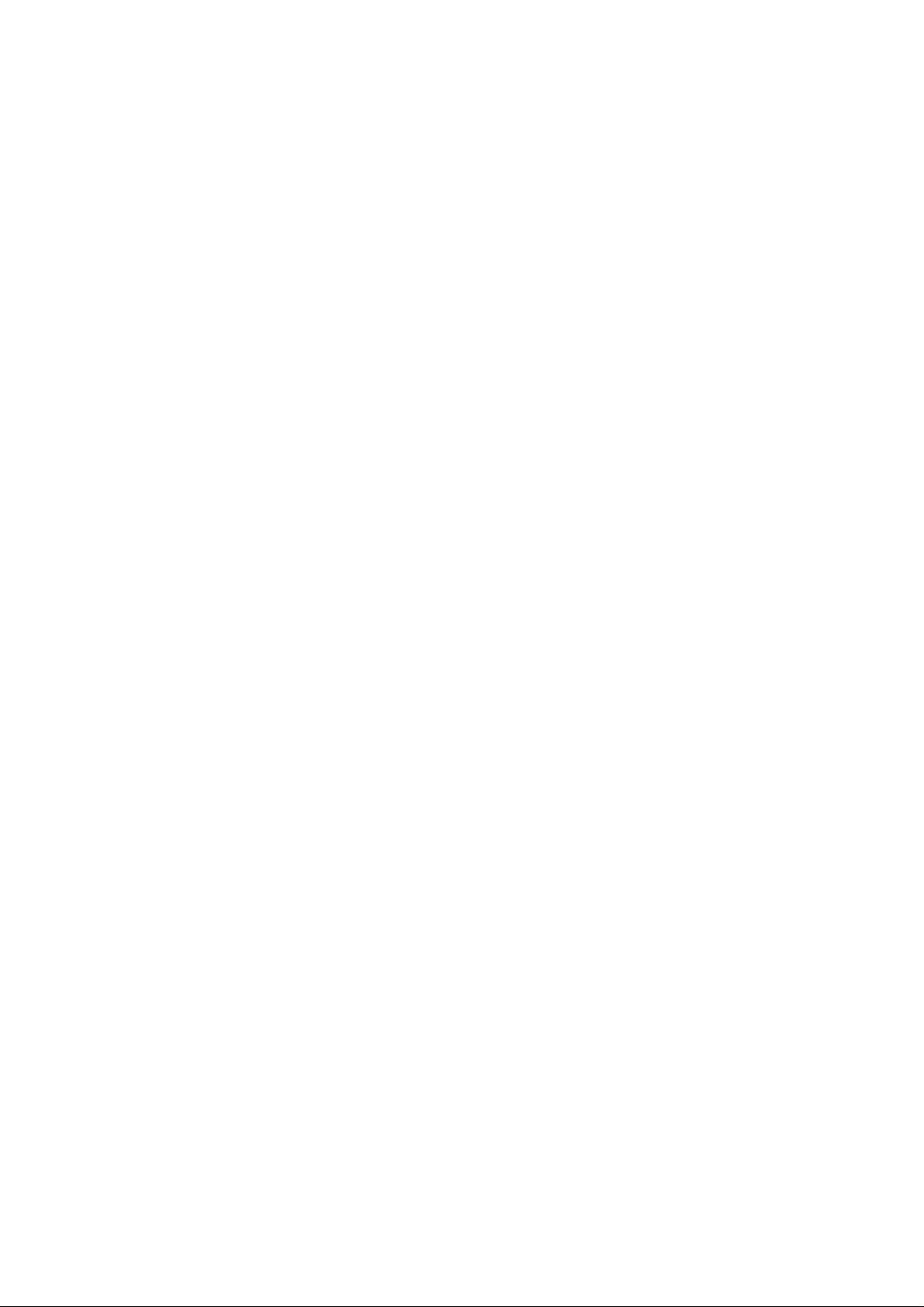

1.1 Mechanical Specifications

1.1.1 Appearance

[1] External dimensions (W x D x H) 468 mm x 387 mm x 273 mm

[2] Weight Approx. 8.3 kg (main unit only)

468 mm

273 mm

Fig. 1.1-1 Appearance

387 mm

1-1

Page 8

1-2

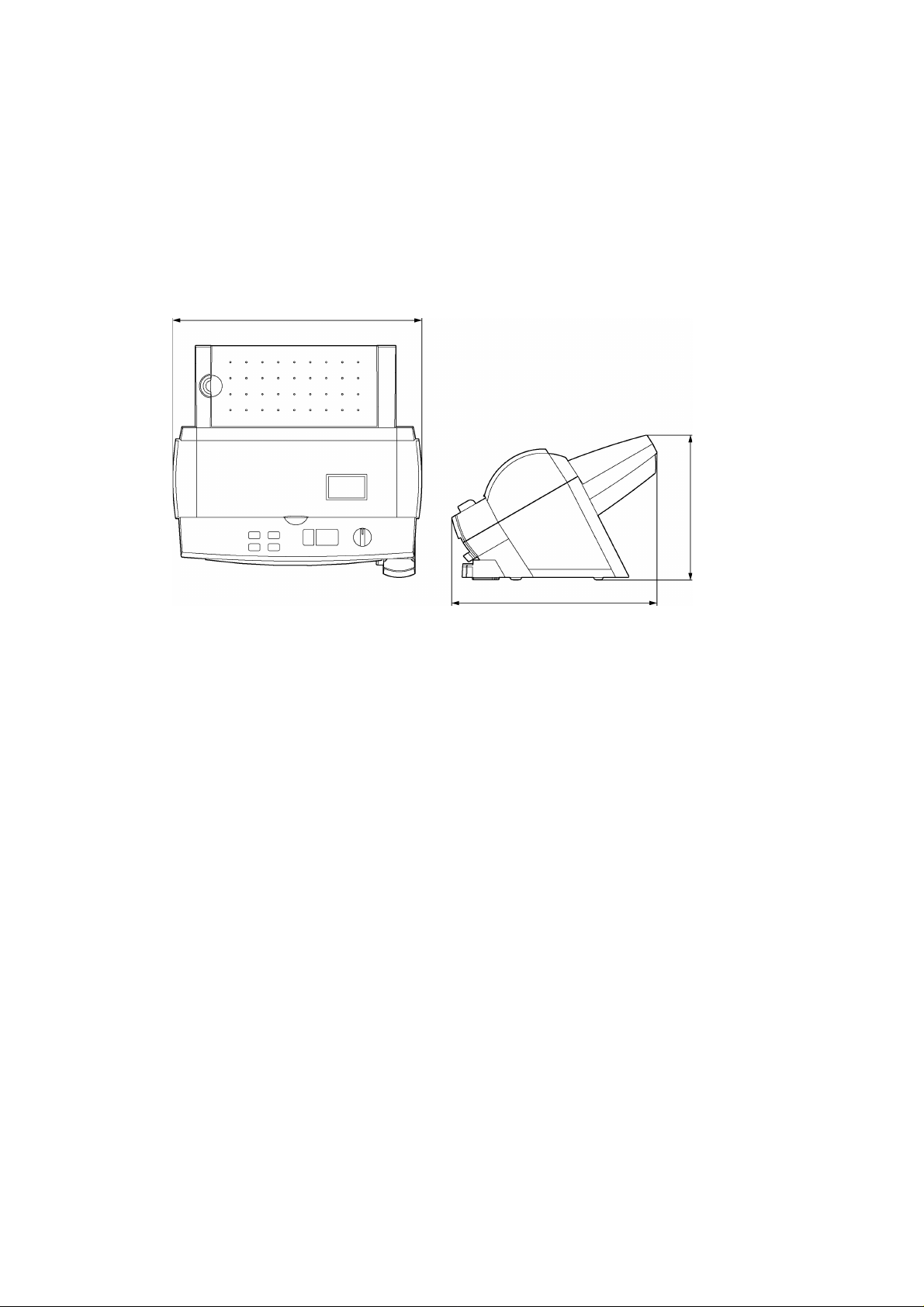

1.1.2 Operating Panel

P

C

C

S

S

[1] Number of Keys 7 (Start key, Stop key, Cut key, Feed key,

Extra border key, Continuous key, Cutting mode selector)

[2] Key Arrangement

Cut key

Feed key

1.1.3 Indicators

[1] Positions Start key LED (green)

Continuous key LED (green)

Extra border key LED (green)

Error LED (red)

ontinuous key

top ke y

Extra border key

Fig. 1.1-2 Key Arrangement

tart key

ower switch

utting mode selector

1.2 Electrical Specifications

1.2.1 Power Supply

[1] Power supply Commercial power supply (locally available power supply).

Converted to DC by the AC adaptor.

Page 9

Chapter 2.

MECHANISMS

Page 10

i

CONTENTS

Chapter 2. MECHANISMS

2.1 Mechanical Operating Principles......................................................................................2-1

2.1.1 Description of Mechanisms (Border Mode)..........................................................2-1

2.1.2 Feed and Compression Mechanisms...................................................................2-2

2.1.3 Cutter Mechanism (Border Mode) ........................................................................2-5

2.1.4 Paper Size Detector Mechanism..........................................................................2-7

2.1.5 Trimming Mechanism........................................................................................... 2-9

Page 11

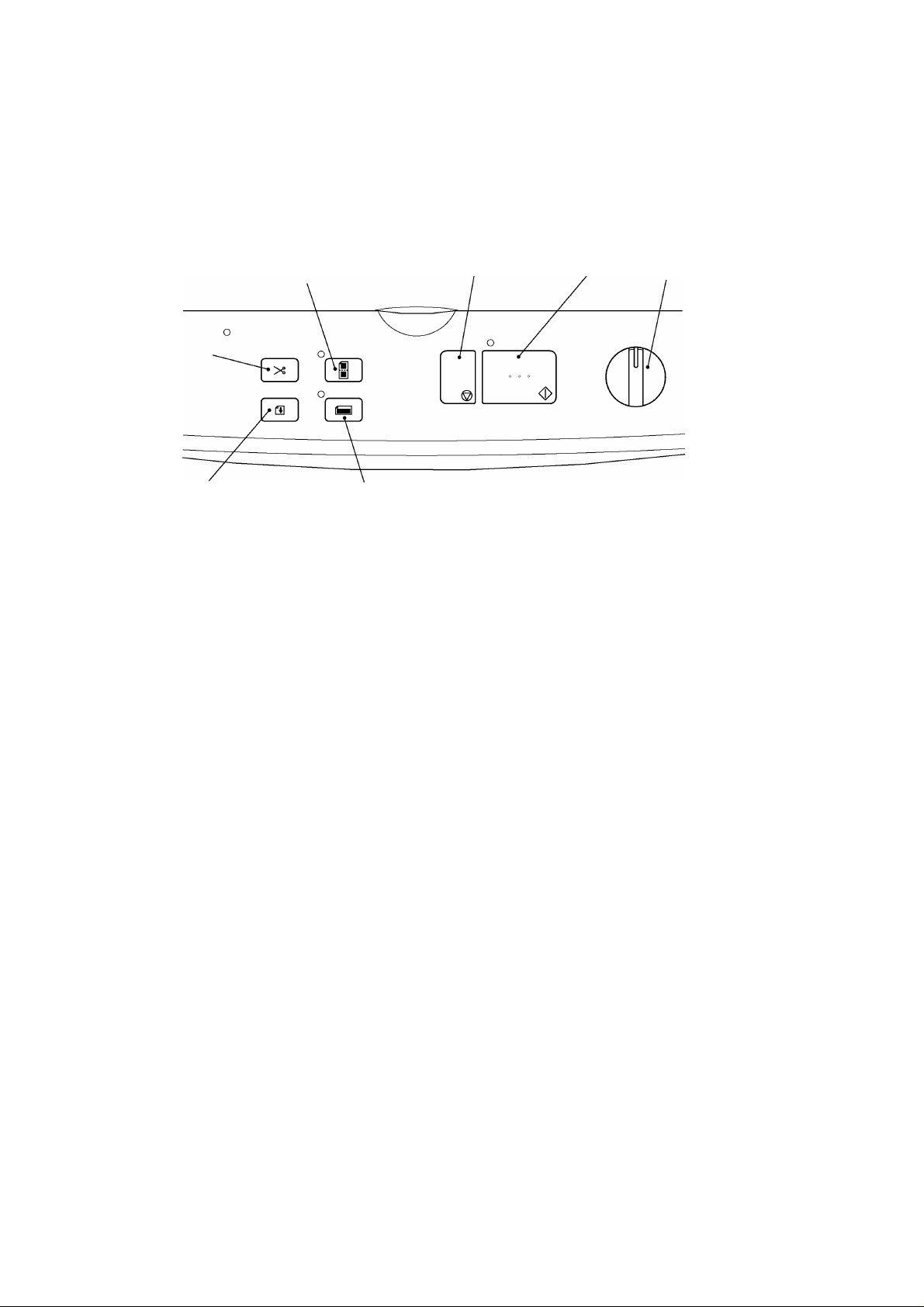

2.1 Mechanical Operating Principles

E

C

D

R

P

P

P

s

R

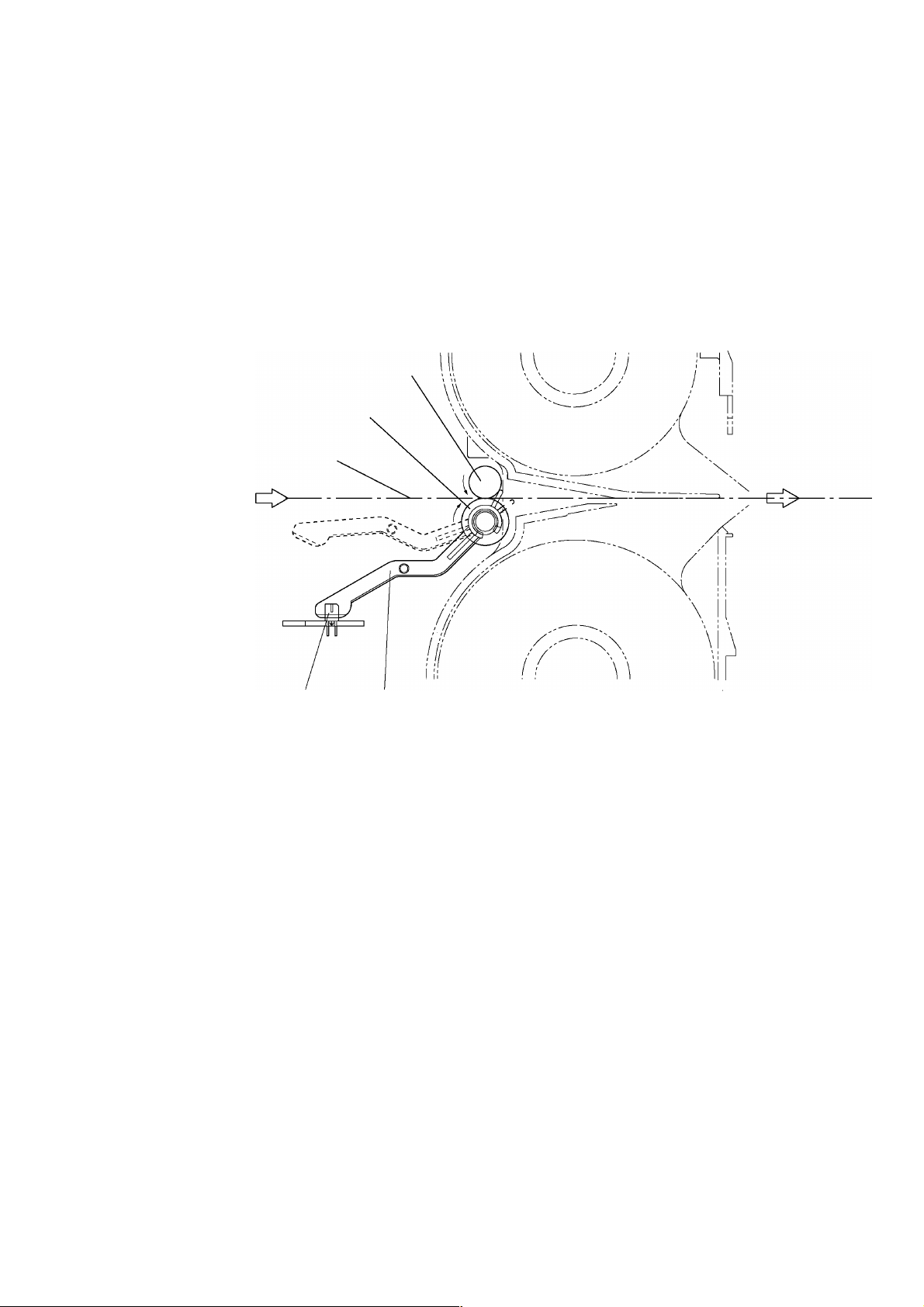

2.1.1 Description of Mechanisms (Border Mode)

1. When a document is inserted into the paper loading gate, the paper feed rollers feed

it to the driving roller.

2. As the document passes between the paper feed rollers, the paper size detector

determines its size (length and width).

3. When the document passes between the film cartridges it is sandwiched between

the upper and lower films in the compression-feed area, where the films and

document are compressed between the driving roller and sub-roller.

4. The compressed document and film is fed to the cutting area, where it is cut to the

document size detected by the paper size detector with borders added. It is t hen

transported to the next stage.

5. The laminated document is fed out of the eject gate by the paper eject rollers.

Paper length detector

Paper loading area

Paper feed roller

aper loading gate

oll film (lower)

Compression-feed area

aper width de tector

aper feed

ub-roller

riving roller

oll film (upper)

Film cartridge

Sub-roller

Y-cutter blad e

X-cutter unit

Paper eject roller

ject gate

Paper eject sub-roller

Ejecting area

utting area

Fig. 2.1-1 Description of Mechanis m s

2-1

Page 12

2-2

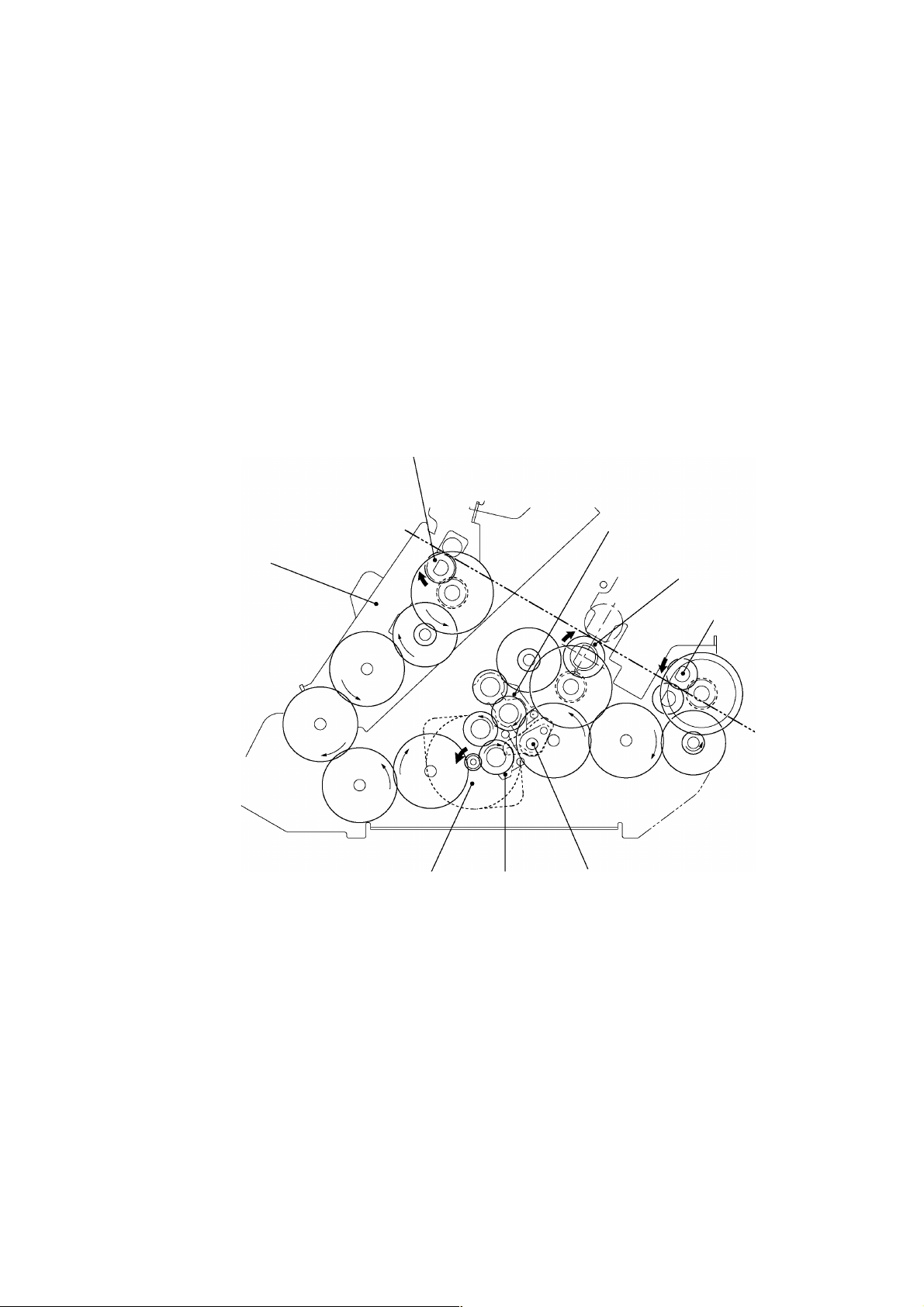

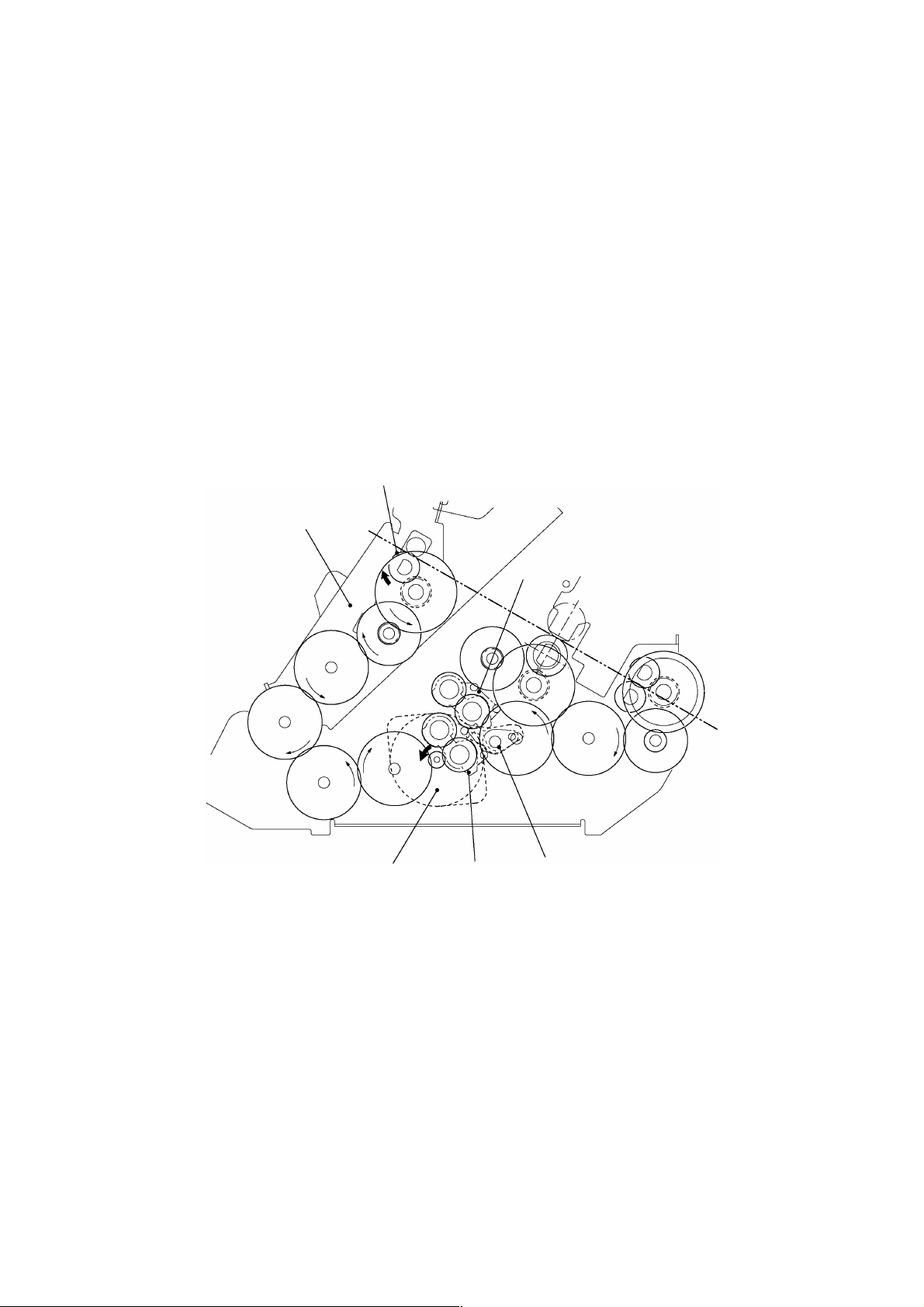

2.1.2 Feed and Compression Mechanisms

G

L

G

D

The feed and compression mechanism controls the motor drive to feed the document

into the film cartridge, compression-feed the films, and eject t he laminat ed document .

The operation is basically divided into three separate operations: feeding a document

into the Film cartridge, compression-feeding the films, and ejecting the laminat ed

document.

Normal Mode

When documents are laminated one at a time (that is, not in the Continuous mode), t he

lamination operation comprises the operations A and B below.

A. Feeding document into Film cartridge and ejecting the laminated document

S

1. The SG motor mounted at the right of the chassis runs to rotate the Control cam

gear (also mounted at the right of the chassis) to its prescribed position.

2. As the Control cam gear rotates, the LF change shaft is rotated to its prescribed

position by the cam on the Control cam gear.

3. A cam is mounted on the LF motor end of the LF change shaft (at the left of t he

chassis). As the LF change shaft rotates, this cam rotates the t wo Gear holders

at the left of the chassis, which transmit t he LF mot or drive as shown in t he

diagram.

4. As a result of steps 1 to 3 above, the drive is transmitted to the Paper f eed roller

and Paper eject roller. The document is fed into the Film cartridge by the Paper

feed roller as the LF motor rotates. After the trailing edge has been cut by the X

cutter, the laminated document is ejected by the Paper eject roller.

ear holder

Paper feed roller

riving roller

Paper eject roller

LF moto r

ear holder

Fig. 2.1-2 Operation when Feeding Document into the Fil m Cart ri dge or when Ejecting a Laminated Document

F change shaft

Page 13

2-3

B. Compression-feeding the films

G

L

G

S

1. The SG motor mounted at the right of the chassis runs to rotate the Control cam

gear (also mounted at the right of the chassis) to its prescribed position.

2. As the Control cam gear rotates, the LF change shaft is rotated to its prescribed

position by the cam on the Control cam gear.

3. A cam is mounted on the LF motor end of the LF change shaft (at the left of t he

chassis). As the LF change shaft rotates, this cam rotates the t wo Gear holders

at the left of the chassis, which transmit t he LF mot or drive as shown in t he

diagram.

4. As a result of steps 1 to 3 above, the drive is transmitted to the Driving roller t hat

compresses the films. During this operation, the Paper feed roller and Paper

eject roller rotate continuously to feed in documents and eject laminated

documents.

Paper feed roller

ear holder

Paper feed holder

LF moto r

Fig. 2.1-3 Operation during Film Compression-Feed

ear holder

F change shaft

Driving roller

Paper eject roller

Page 14

2-4

Continuous Mode

G

L

P

G

When the second or subsequent document are inserted in the Continuous mode, the

operation C described below feeds the documents to the prescribed position.

C. Feeding Document Only into Film Cartridge

S

1. The SG motor mounted at the right of the chassis runs to rotate t he Control cam

gear (also mounted at the right of the chassis) to its prescribed position.

2. As the Control cam gear rotates, the LF change shaft is rotated t o it s prescribed

position by the cam on the Control cam gear.

3. A cam is mounted on the LF motor end of the LF change shaft (at the left of t he

chassis). As the LF change shaft rotates, this cam rotates the t wo Gear holders at

the left of the chassis, which transmit the LF mot or drive as shown in t he diagram.

4. As a result of steps 1 to 3 above, the drive is transmitted t o t he Paper f eed roller

only. A document is fed into the Film cartridge by the Paper feed roller as the LF

motor rotates.

aper feed roller

Paper feed holder

ear holder

LF moto r

ear holder

F change shaft

Fig. 2.1-4 Operation when Feeding Document into the Fil m Cart ri dge i n the Continuous Mode

Page 15

2-5

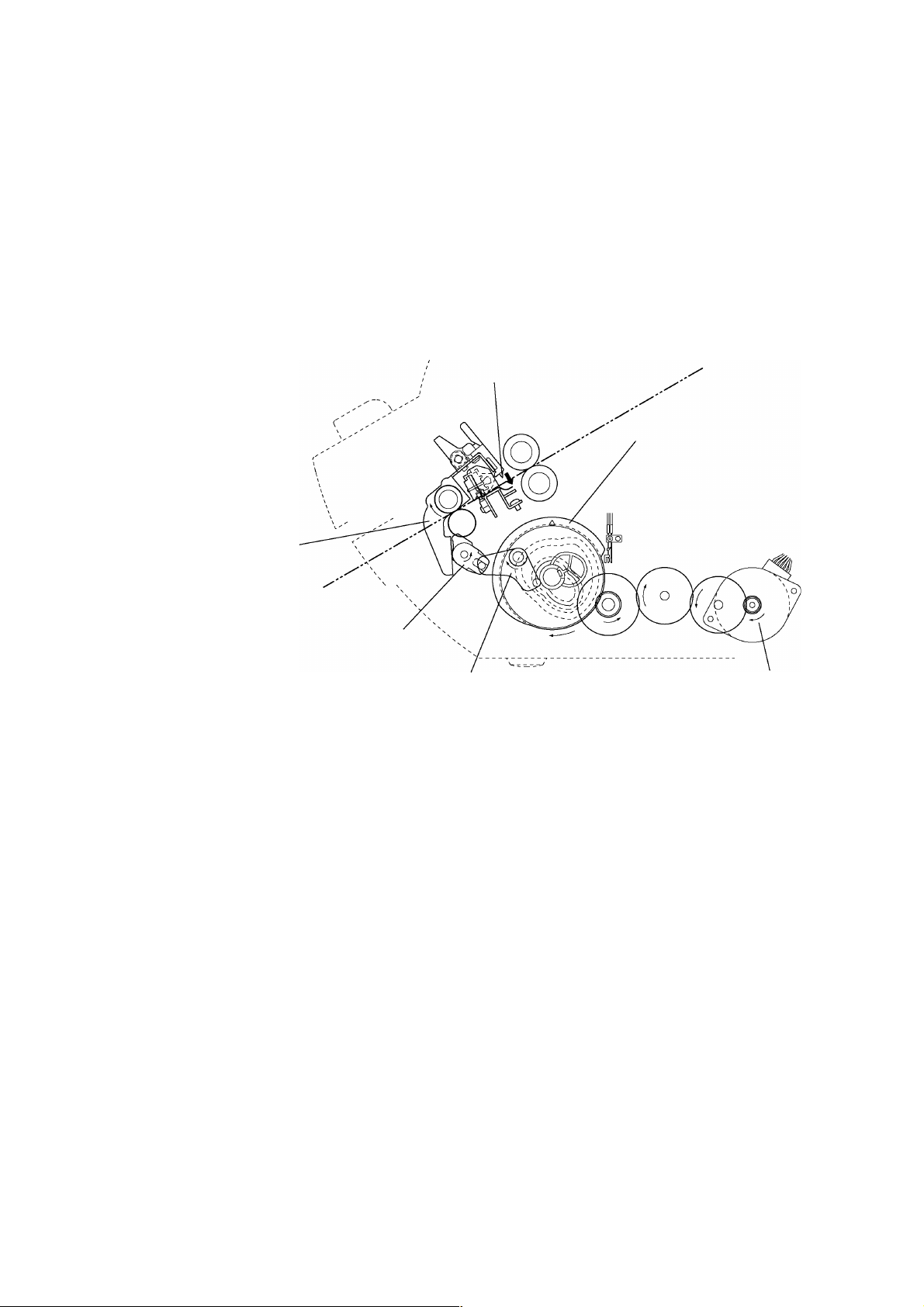

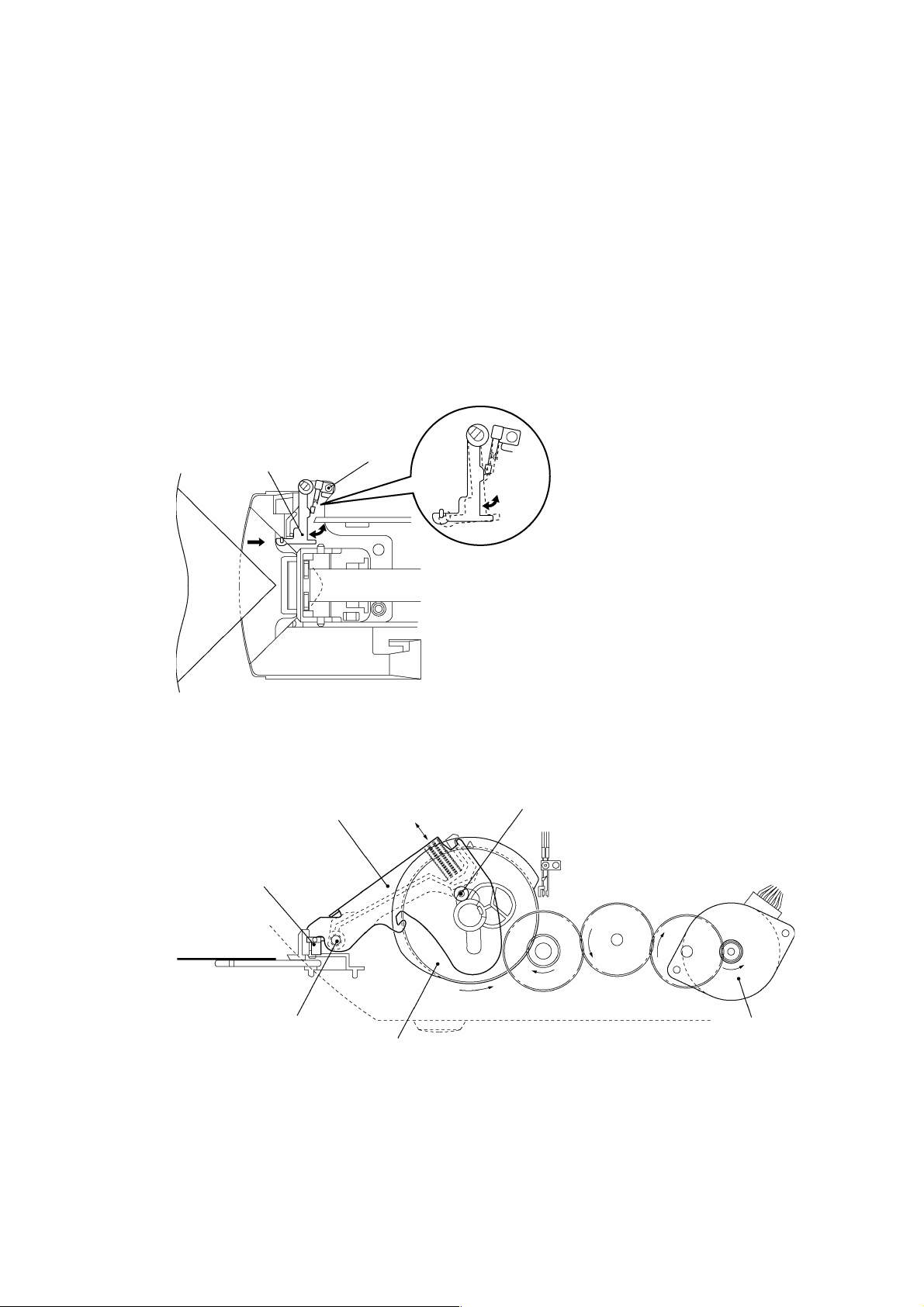

2.1.3 Cutter Mechanism (Border Mode)

C

Y

Y

The cutter mechanism cuts the laminated document to the size of the document plus an

added border. Both edges of the films are cut to suit the width of the document and the

leading edge and trailing edge are cut according to the document length.

Y-Cutter Vertical Drive Operation

S

The SG motor drive rotates the Control cam gear to its prescribed position. This

rotation is transmitted via the YC lift arm and YC lift shaf t t o rotate the Y-diversion

lever and set the Y cutter to the cutting position.

Y-diversion lever

-cutter blade

ontrol cam gear

YC lift shaft

C lift arm

Fig. 2.1-5 Y-Cutter Vertical Driv e Operat i on

SG motor

Page 16

2-6

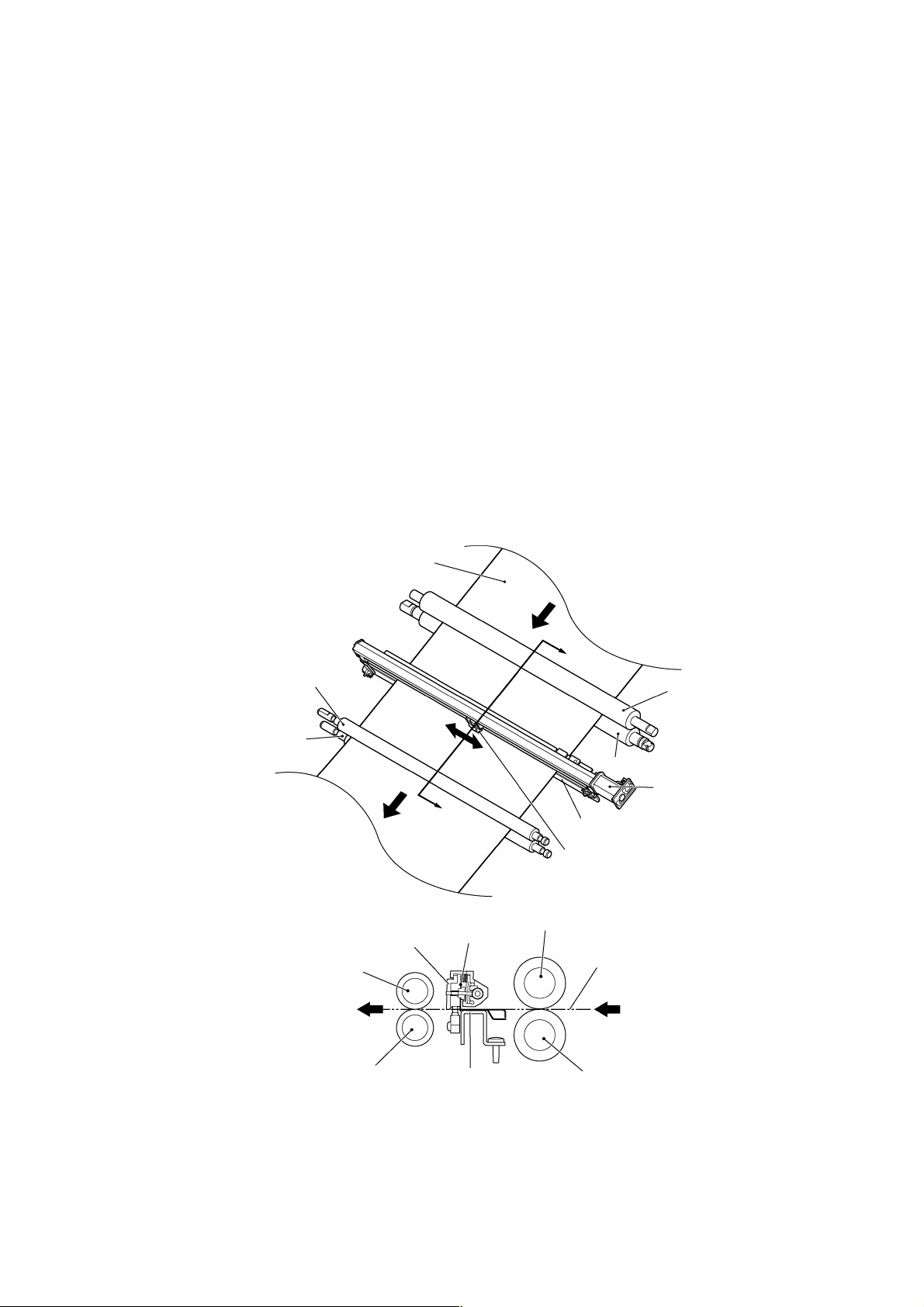

Cutting Leading and Trailing Edges (X-cutter Mechanism)

D

F

R

D

D

S

R

S

A

A

F

S

1. All the rollers which feed the document stop when the cut position at the leading

edge of the document reaches the cutting position of the rotary cutt er and f ixedblade cutter.

2. The DC motor rotates to drive the carriage in the X-cutter assy via the spiral

mechanism (not illustrated).

3. As the carriage makes a reciprocal movement, the rotary cutter attached to the

carriage moves against the fixed cutter to cut the compressed leading edge of

the document.

4. The rotation of the rollers which feed the document restarts when the cutting of

the leading edge is complete. Then, when the cut position at t he trailing edge of

the document reaches the cutting position of the rotary cutter and f ixed-blade

cutter, the feed rollers stop again.

5. The document trailing edge is cut in the same way as the leading edge by a

reciprocal movement of the rotary cutter attached to the carriage.

6. The rotation of the Paper eject roller and Paper feed roller restarts to feed the

laminated document from the eject gate after the cut t ing of t he t r ailing edge is

complete. (In this timing, the driving roller does not rotate.)

Document

Paper eject roller

Paper eject sub-roller

ection A-A'

Paper eject roller

Paper eject sub-roller

Fig. 2.1-6 Cutting Leading and Trailing Edges (X-cutter Mechanism)

Carriage

'

otary cutter

ixed cutter

Sub-roller

riving roller

Carriage

ixed cutter

otary cutter

ub-roller

ocument

riving roller

Page 17

2-7

2.1.4 Paper Size Detector Mechanism

Paper Length Detection

S

1. When the leading edge of the document passes between the Paper feed rollers,

the Actuator top operates about the pivot to turn on t he Paper sensor and det ect

the document leading edge.

2. When the trailing edge of the document passes out of the Paper feed r oller s, t he

Actuator top reverts to its original position to turn off t he Paper sensor and

detect the document trailing edge.

Paper feed sub-roller

Paper feed roller

Document feed surface

Paper sensor

Actuator top

Fig. 2.1-7 Paper Length Detection

Page 18

2-8

Paper Width Detection (Y-CA sensor)

Y

Y

Y

D

S

1. As the Y-cutter arm (Y-CA sensor carriage) moves in the direction of the arrow,

the document contacts the Actuator Y, which rotat es about t he pivot t o swit ch of f

the Y-CA sensor (photosensor).

2. When the Y-CA sensor turns off, the Y-cutter arm movement stops and this

position is detected as the document width.

-cutter a rm

sensor carriage

Actuator Y

Photosensor ON status

∗

Photosensor OFF status

∗

Pivot

Fig. 2.1-8 Paper Width Detection

-CA sensor

ocument

Page 19

2-9

2.1.5 Trimming Mechanism

T

T

1. When a corner of the laminated document is inserted over the T-cutter plate, t he Tsensor lever operates a leaf switch (TRI) that detects the document.

2. When the document is detected, the motor gear of the SG Motor rot at es f r om it s

reference position to the prescribed position to rotate the Control cam gear in the

direction of the arrow (counterclockwise) via a series of gears.

3. Rotation of the Control cam gear forces the T-cam roller to move vertically, such

that T-lever also moves vertically, rotating around its pivot.

4. As T-lever moves vertically, the T-cutter assy mounted on the end of T-lever moves

up and down, trimming the corner of the laminated document into a rounded radius.

Leaf switch

T-sensor lever

-cam roller

-lever

T-cutter unit

Pivot

Control cam gea r

SG motor

Fig. 2.1-9 Trimming Mechanism

Page 20

Chapter 3.

DISASSEMBLY PROCEDURES

Page 21

CONTENTS

Chapter 3. DISASSEMBLY PROCEDURES

3.1 Safety Precautions............................................................................................................3-1

3.2 Removing the Film Cartridge ............................................................................................3-1

3.3 Covers ...............................................................................................................................3-2

3.3.1 Removing the Trimmer Cover ..............................................................................3-2

3.3.2 Removing the Top Cover B ..................................................................................3-3

3.3.3 Removing the Sub-tray.........................................................................................3-4

3.3.4 Removing Paper Tray A and Paper Guide...........................................................3-4

3.3.5 Removing the Body Cover....................................................................................3-5

3.3.6 Removing the Front Cover.................................................................................... 3-7

3.3.7 Removing Paper Tray B .......................................................................................3-8

3.3.8 Removing the Back Cover....................................................................................3-8

3.3.9 Removing the Cover Switch .................................................................................3-9

3.3.10 Removing the Dial Switch Holder Assy B ..........................................................3-10

3.3.11 Removing the Push Switch Assy........................................................................ 3-11

3.4 Chassis Assy................................................................................................................... 3-12

3.4.1 Removing the Harness Connectors ...................................................................3-12

3.4.2 Removing the PST PCB (Paper Sensor PCB)................................................... 3-13

3.4.3 Removing the Chassis Assy...............................................................................3-14

3.5 PCBs ............................................................................................................................... 3-16

3.5.1 Removing the Main PCB ....................................................................................3-16

3.5.2 Removing the Jack PCB Assy............................................................................ 3-16

3.5.3 Removing the SW PCB Assy .............................................................................3-17

3.6 X-cutter Unit ....................................................................................................................3-18

3.6.1 Removing the X-cutter Unit.................................................................................3-18

3.6.2 Removing the Leaf Switch F Assy......................................................................3-18

3.7 Y-CA Chassis Assy and Y-cutter Arm............................................................................ 3-19

3.7.1 Removing the Y-CA Chassis Assy.....................................................................3-19

3.7.2 Removing the Y-CA Motor..................................................................................3-20

3.7.3 Removing the Y-cutter Arm ................................................................................3-20

3.8 Y-sensor Rail Unit ...........................................................................................................3-21

3.8.1 Removing the Y-sensor Rail Unit .......................................................................3-21

3.8.2 Disassembling the Y-sensor Rail Unit................................................................3-22

3.9 Roller Holder Assy ..........................................................................................................3-23

3.9.1 Removing the Roller Holder Assy ......................................................................3-23

3.10 Paper Feed Roller...........................................................................................................3-24

3.10.1 Removing the Paper Feed Holder Assy.............................................................3-24

3.11 Left Side of the Main Chassis .........................................................................................3-25

i

Page 22

ii

3.11.1 Removing the LF Motor ......................................................................................3-25

3.11.2 Removing the Gears...........................................................................................3-26

3.12 Right Side of the Main Chassis.......................................................................................3-27

3.12.1 Removing the Right Side of the Chassis............................................................3-27

3.12.2 Removing the YC Lift Shaft and LF Change Shaft ............................................3-28

3.13 Paper Eject Roller ...........................................................................................................3-30

3.13.1 Removing the Paper Eject Roller Unit................................................................3-30

3.14 Y-diversi on Lever............................................................................................................3-31

3.14.1 Removing the Y-diversion Lever Assy ...............................................................3-31

3.15 Trimming Mechanism...................................................................................................... 3-32

3.15.1 Disassembling the Trimming Mechanism ..........................................................3-32

3.16 Driving Roller ...................................................................................................................3-32

3.16.1 Removing the Driving Roller...............................................................................3-32

3.17 Main Chassis B ...............................................................................................................3-33

3.17.1 Removing the Main Chassis B ...........................................................................3-33

3.17.2 Removing the Cassette Holder...........................................................................3-34

3.17.3 Removing the ENC Sensor PCB........................................................................3-34

3.17.4 Removing the Main Chassis L, R, and F............................................................3-35

Page 23

3-1

3.1 Safety Precautions

T

•

When conducting disassembly operations, place the unit on a grounded anti-static

sheet. LSI and other electronic components are sensitive to static electricity and

may be damaged if touched while charged.

•

Before transporting a circuit board, wrap it in a conducting sheet such as aluminum

foil.

•

When using a soldering iron or other heat-producing tool, ensure that heat does not

damage wires, circuit boards, or plastic parts such as covers.

•

Take care not to lose small screws or washers removed when replacing parts.

•

As a safety precaution, wear gloves when conducting disassembly operations.

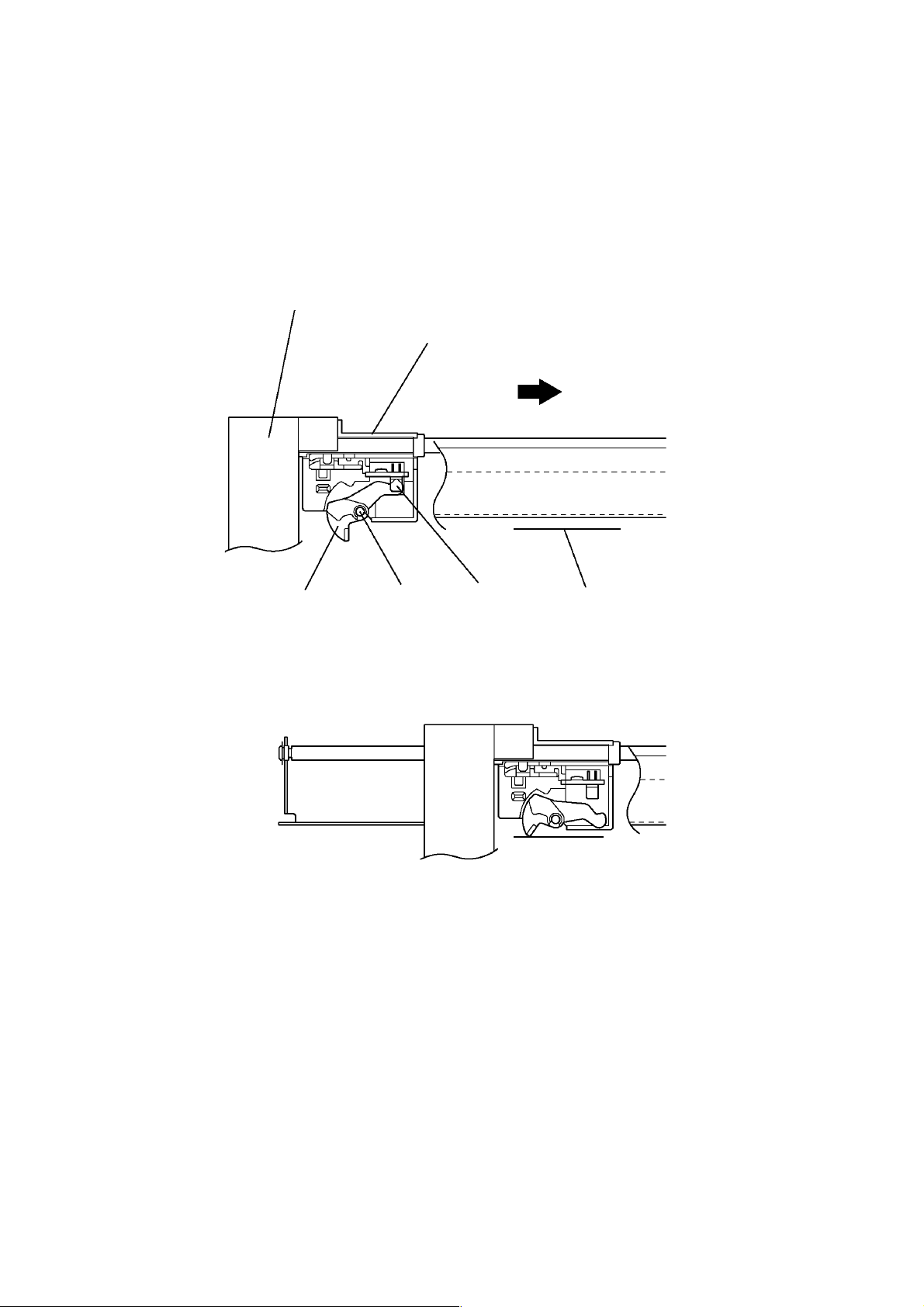

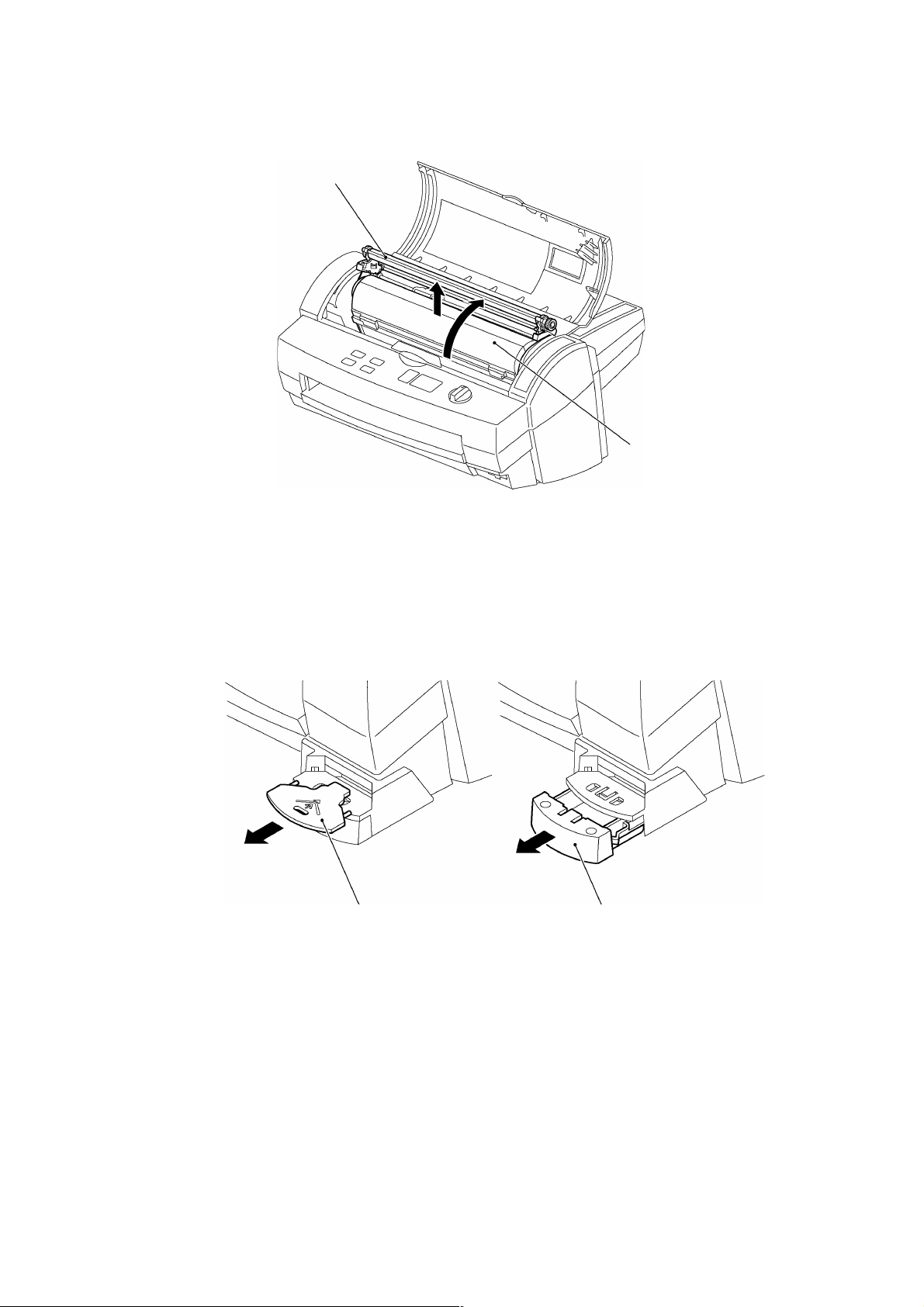

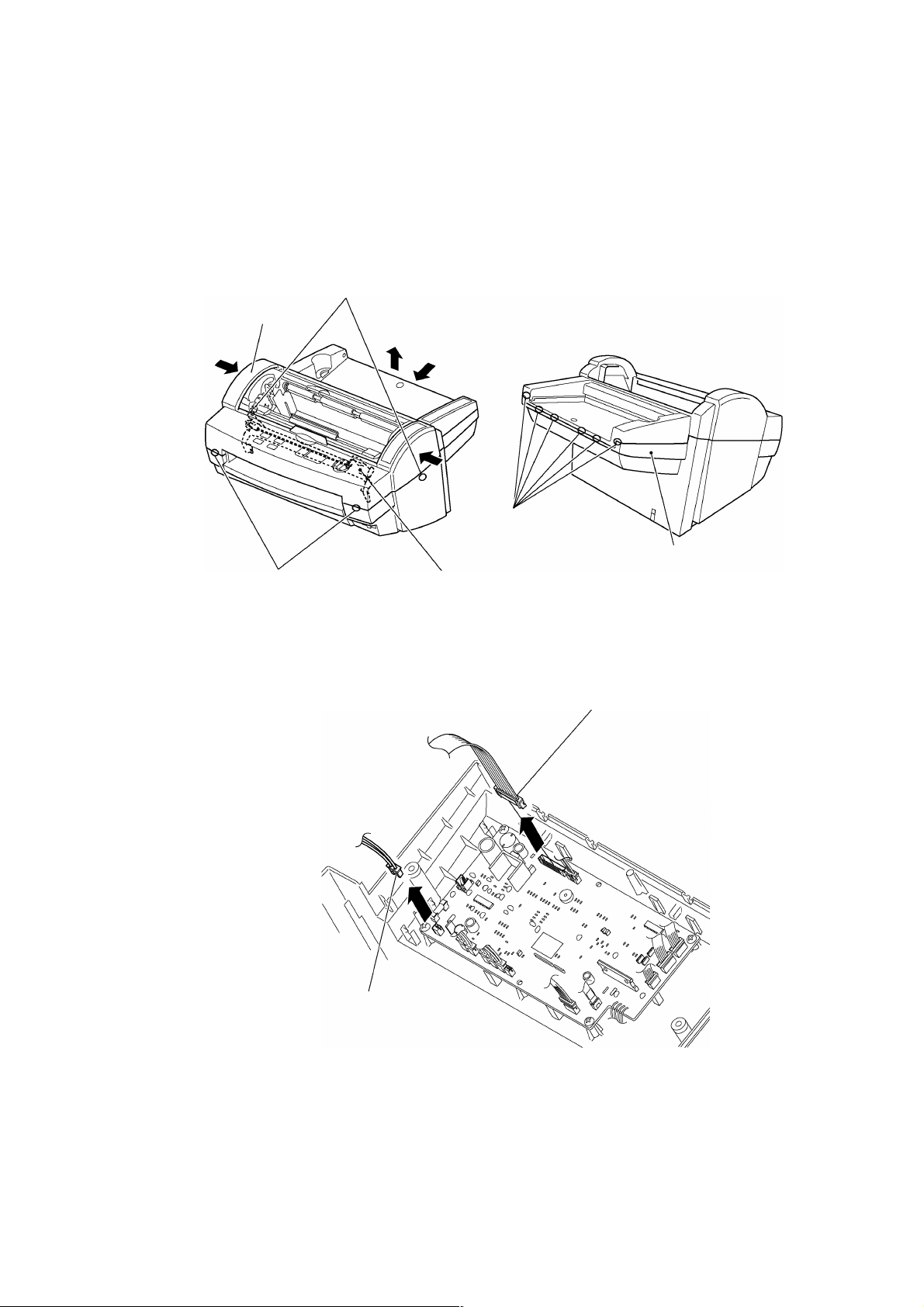

3.2 Removing the Film Cartridge

1. Open the top cover and move the Y-cutter arm as far as possible to the left.

2. Push the Set buttons R/L in the direction indicated by the arrow t o unlock t he Roller

holder assy.

Y-cutter arm

op cover

Set butto n R/L

Fig. 3.2-1 Removing the Film Cartridge 1

Page 24

3-2

3. Lift up the Roller holder assy and pull out the Film cartridge.

F

T

Roller holder assy

3.3 Covers

ilm cartrid ge

Fig. 3.2-2 Removing the Film Cartridge 2

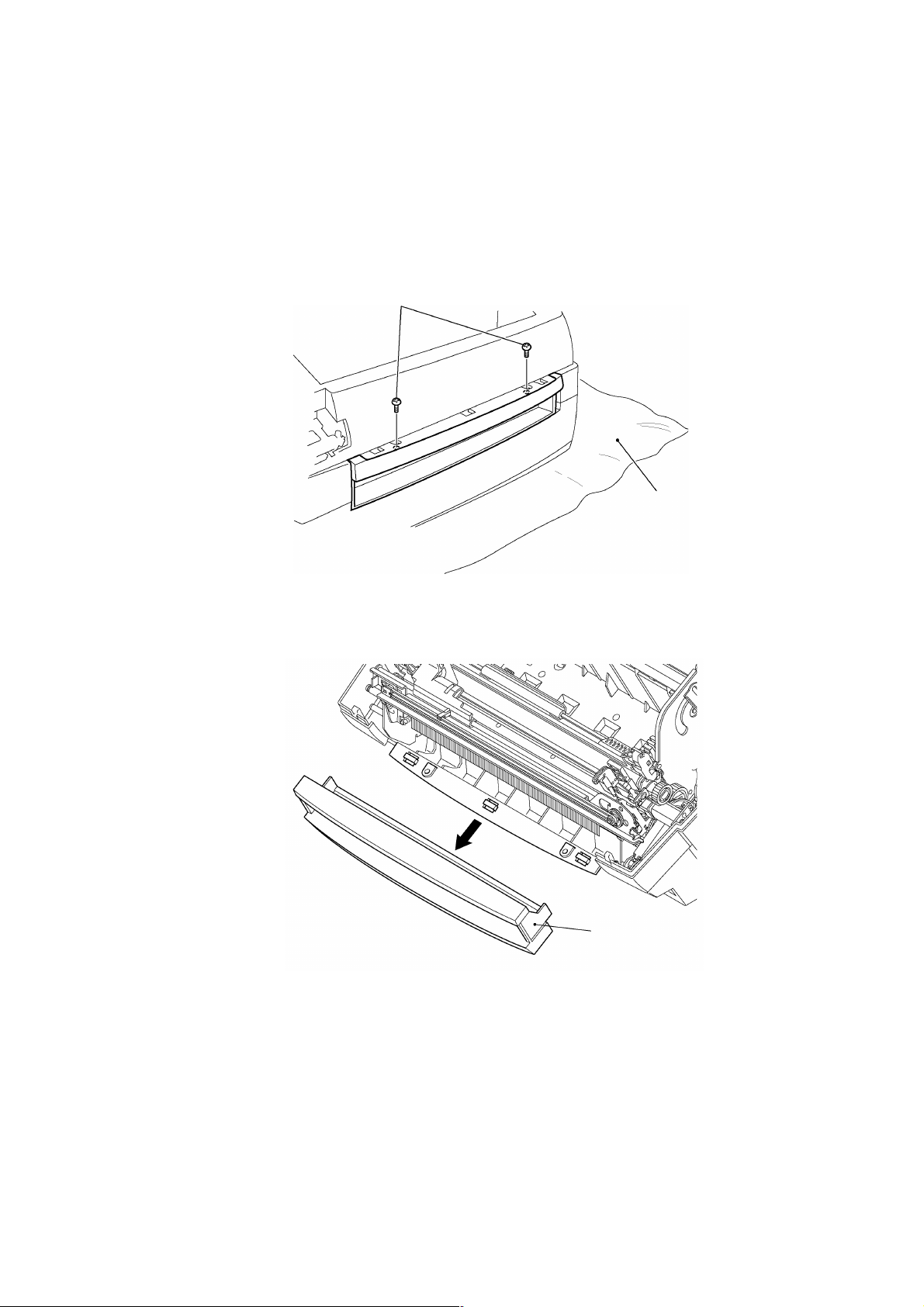

3.3.1 Removing the Trimmer Cover

1. Pull out the T-cutter plate and the Trimmer bottom cover.

T-cutter plate

Fig. 3.3-1 Removing the Trimmer cover 1

rimmer bottom cover

Page 25

3-3

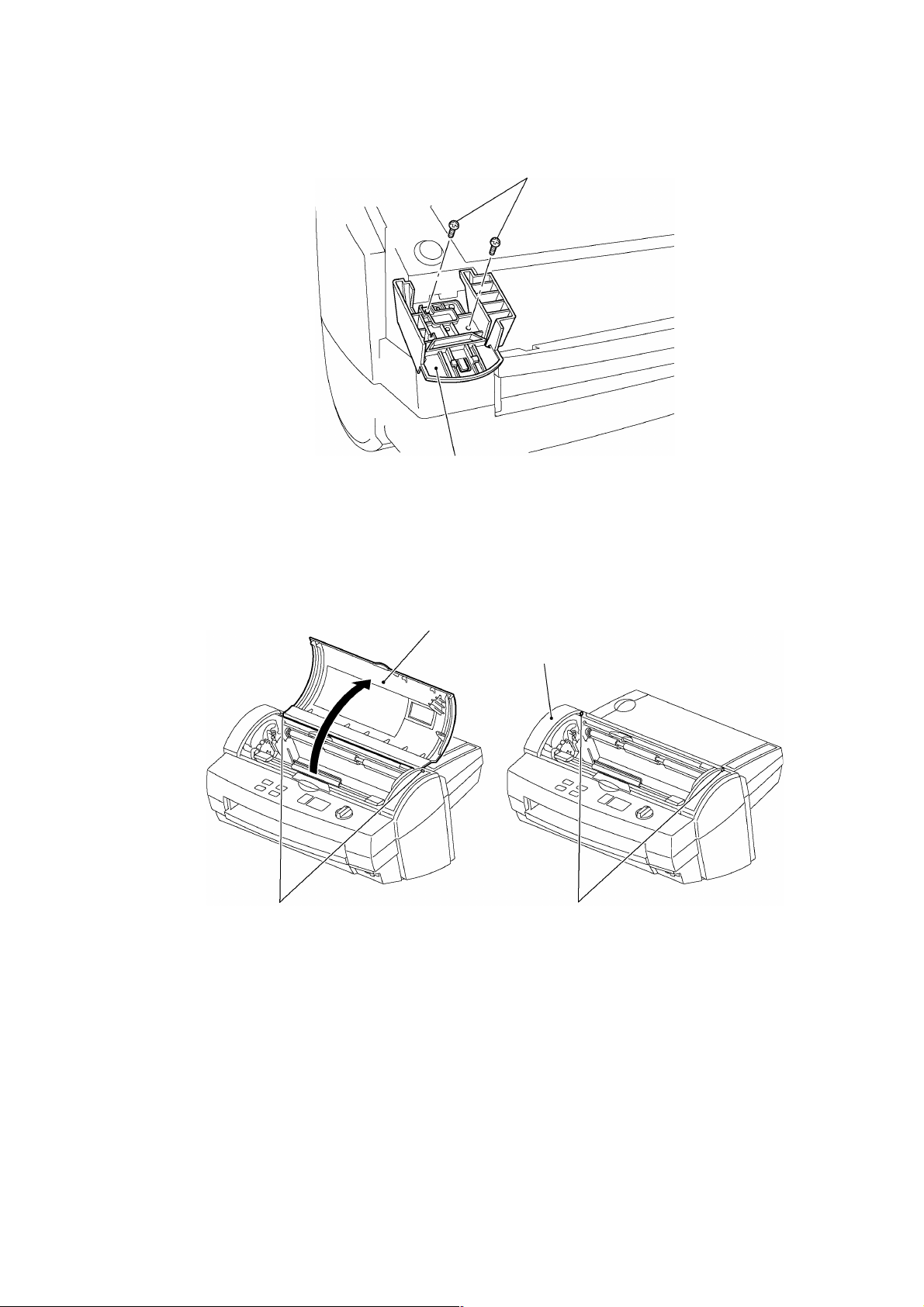

2. Remove the two Trimmer cover screws. Remove the Trimmer upper cover.

T

T

B

S

rimmer cover screws

Fig. 3.3-2 Removing the Trimmer cover 2

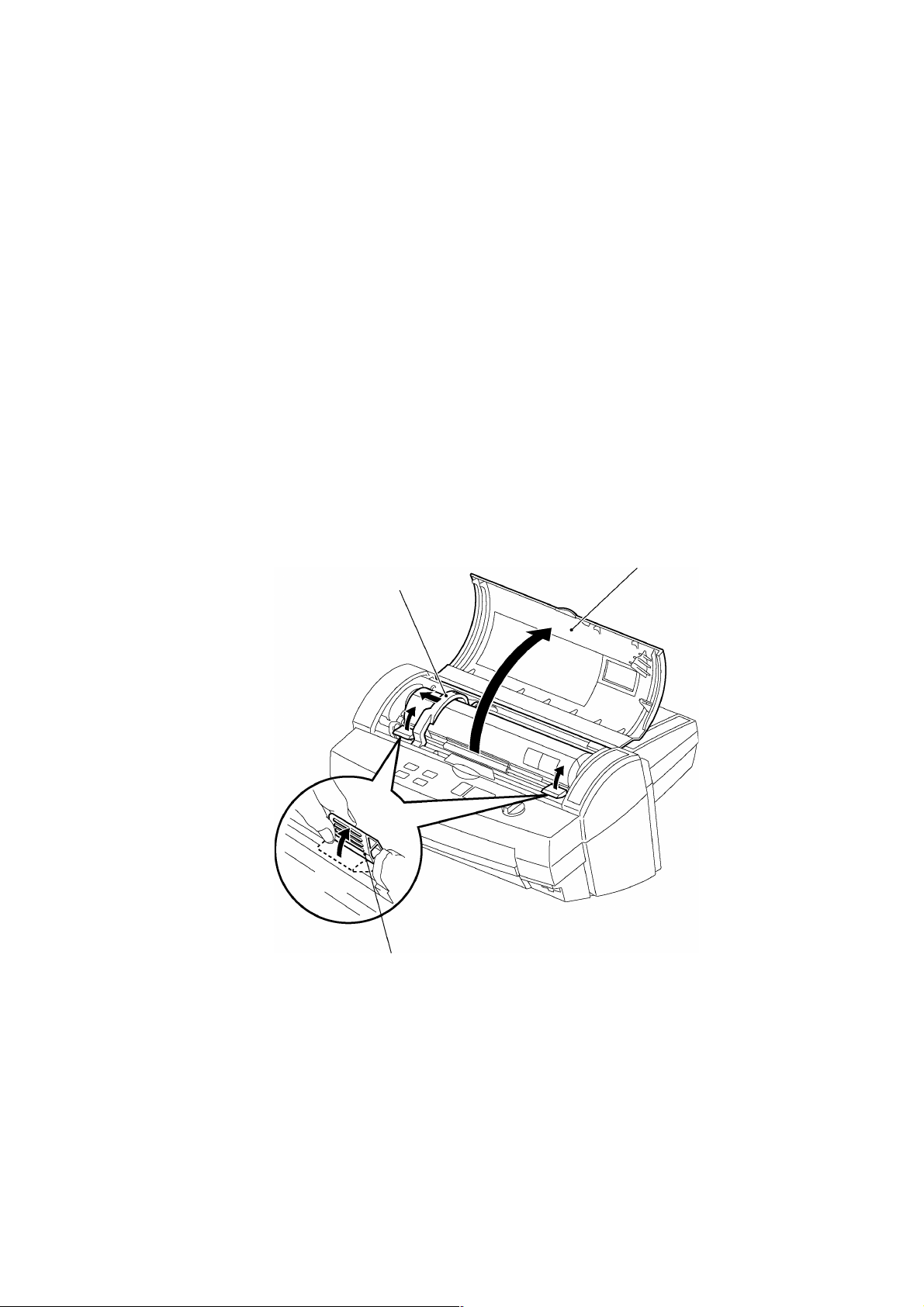

3.3.2 Removing the Top Cover B

Open the Top cover B. Lift the Top cover B shafts out of t he shaf t recesses in the Body

cover and remove Top cover B.

rimmer upper cover

Top co ver B

ody cover

Shafts

Fig. 3.3-3 Removing the Top Cover B

haft recesses

Page 26

3-4

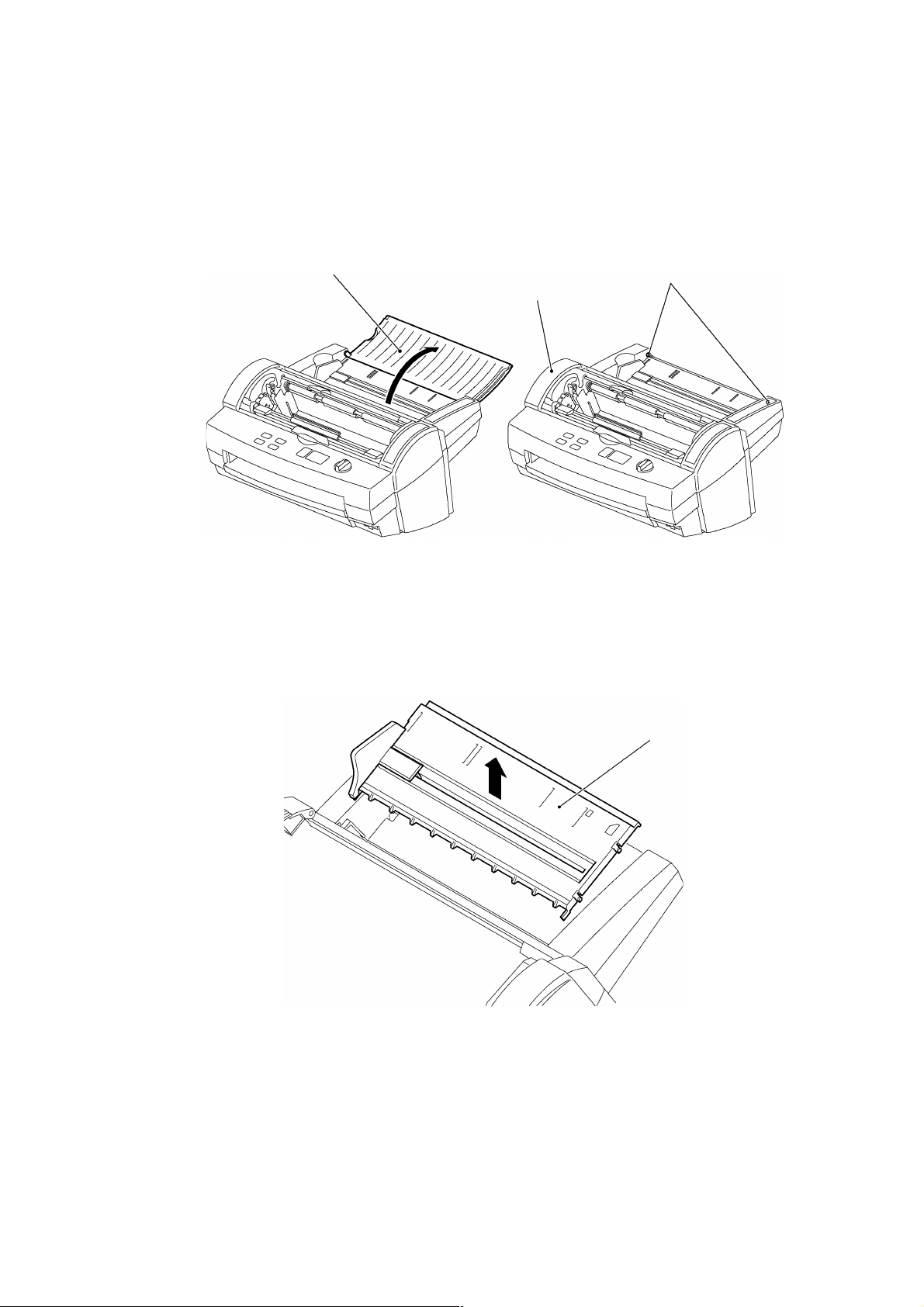

3.3.3 Removing the Sub-tray

S

1. Open the Sub-tray.

2. Flex the center of the sub-tray toward you to release the shafts from the shaft

recesses in the Body cover. Remove the sub-tray.

ub-tray

Fig. 3.3-4 Removing the Sub-tray

3.3.4 Removing Paper Tray A and Paper Guide

1. Flex the center of the top of Paper tray A in the direction of the arrow, then release

the left and right hooks. Pull Paper tray A upward to remove it.

Shaft re cesses

Body cover

Fig. 3.3-5 Removing Paper Tray A

Paper tray A

Page 27

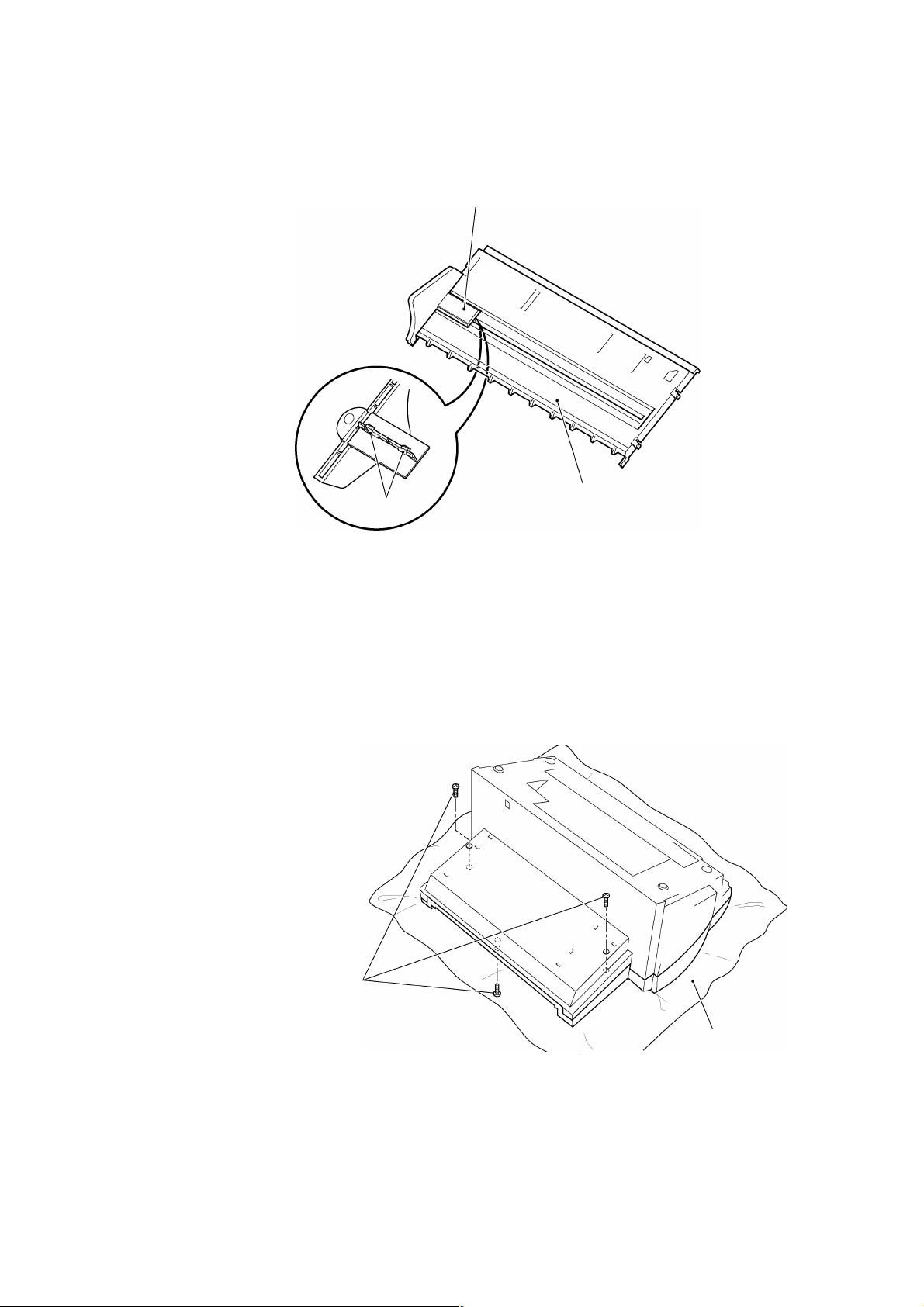

2. Disengage the Paper guide hooks (at the rear of the Paper tray) CL2000011

from Paper tray A. Remove the Paper guide.

Paper gu ide

Hooks

Fig. 3.3-6 Removing the Paper Guide

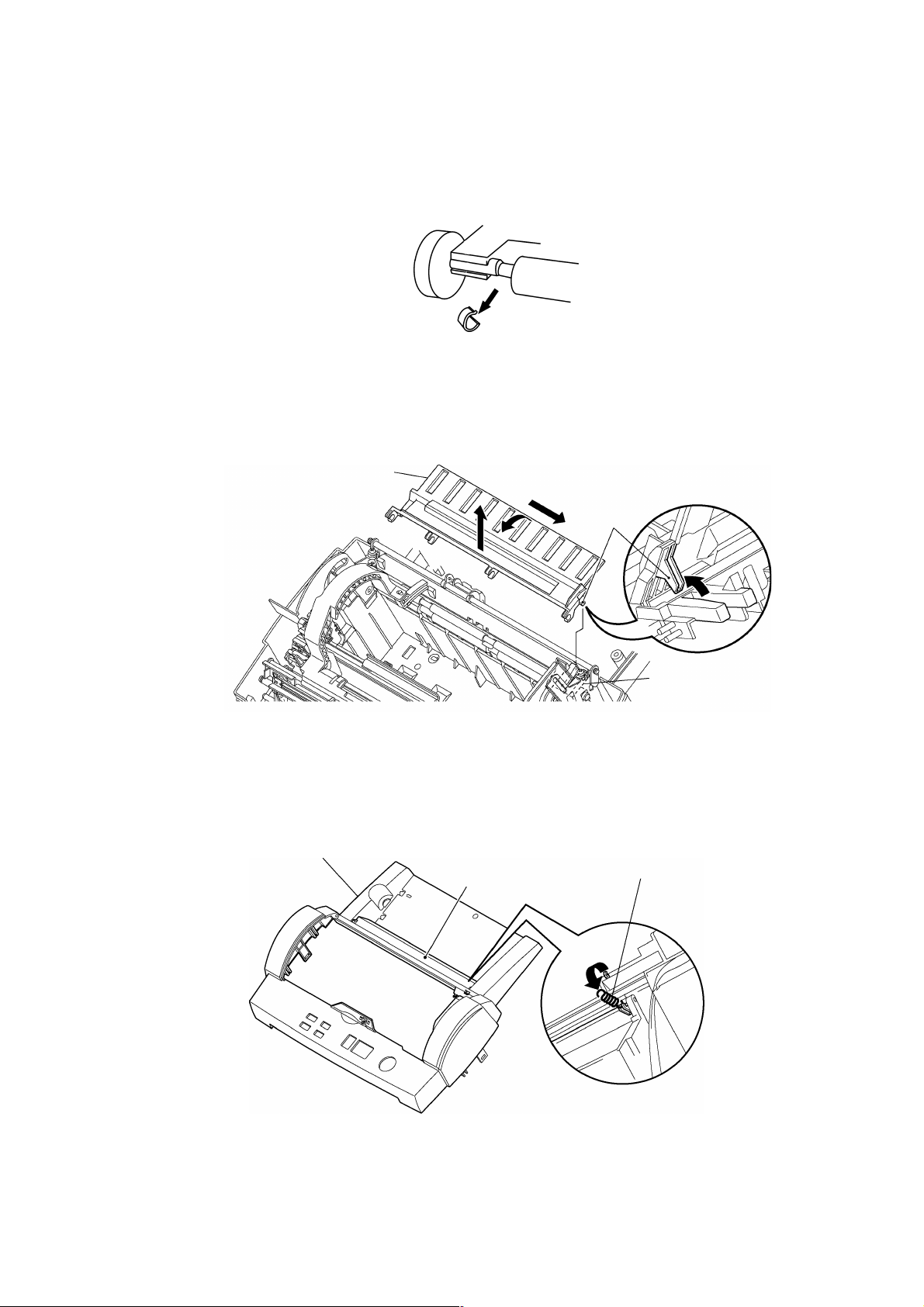

3.3.5 Removing the Body Cover

1. Remove the two Bottom cover screws B from the bottom of the Bottom cov er B.

And remove one screw from the surface of Body cover.

∗ When inverting the unit to perform this work, place it on a soft cloth to avoid

scratching the cover.

Pape r tray

Bottom cover screws B

Soft cloth

Fig. 3.3-7 Removing the Body Cover 1

3-5

Page 28

3-6

2. Lift the rear of the Bottom cover in the direction of arrow B while pushing it in t he

R

A

Y

S

C

direction of arrow A to release the six hooks on the rear face.

3. Push the sides of Body cover in the directions indicated by the arrows C to release

the hook at the left and right side.

4. Push on the Y-diversion lever assy and release the two hooks from the front of the

Body cover.

Side hook s

Body cover

B

C

ear hooks

Bottom cove r B

Front hooks

Fig. 3.3-8 Removing the Body Cover 2

-diversion lever assy

5. Disconnect the Switch harness assy and the Cover switch assy connectors from the

Main PCB and remove the Body cover.

witch harness assy

over swit ch assy

Fig. 3.3-9 Removing the Body Cover 3

Page 29

3-7

3.3.6 Removing the Front Cover

F

F

1. Remove the two Front cover screws under the Bottom cover B.

∗

When removing the Body cover, remove the two Front cover screws and the two

screws at the rear of the Bottom cover B at the same time.

∗

When inverting the unit to perform this work, place it on a soft cloth to avoid

scratching the cover.

ront cover screws

Fig. 3.3-10 Removing the Front Cover 1

Soft cloth

2. Pull the front cover forward to remove it.

(The Body cover must be removed before removing the Front cover.)

ront cover

Fig. 3.3-11 Removing the Front Cover 2

Page 30

3.3.7 Removing Paper Tray B CL2000011

1. Remove Tray B Stopper.

2. Lift the top of Paper tray B in the direction of arrow A to disengage t he lug from the

Cassette holder.

3. Slide Paper tray B in the direction of arrow B, then lift it in t he direct ion of arrow C t o

remove it.

Paper tray B

B

Lug

A

C

Fig. 3.3-12 Removi ng Paper Tray B

3.3.8 Removing the Back Cover

1. Remove the Back cover spring.

Body cover

Back cover

Cassette hold er

Back cover sprin g

Fig. 3.3-13 Rem ovi ng t he Back Cover 1

3-8

Page 31

3-9

2. Flex the center of the Back cover toward you to release the shafts from t he shaf t

B

S

F

C

C

recesses in the Body cover. Remove the Back cover.

During this operation, take care not to deform the film att ached t o t he Back Cover.

hafts

ack cover

ilm

Body cover

Fig. 3.3-14 Removing the Back Cover 2

3.3.9 Removing the Cover Switch

1. Remove the cover switch screw. Remove the cover switch assy.

Fig. 3.3-15 Removing the Cover Switch Assy

over switch assy

over switch screw

Page 32

3

3.3.10 Removing the Dial Switch Holder Assy B

D

D

D

1. Remove the eight Dial holder screws. Remove the Dial switch holder assy B.

2. Disconnect the Push SW assy 1 (white) and Push SW assy 2 (red) connectors from

the SW PCB.

∗

Take care not to apply force to the connectors between switch and harness in

Push switch assy 1 and 2.

ial holder screws

Push switch assy 1 and 2

ial holder screws

Fig. 3.3-16 Removing the Dial Switch Holder Assy

ial switch holder a ssy

-10

Page 33

3

3.3.11 Removing the Push Switch Assy

P

P

1. Remove the two Push switch screws. Remove the Push SW assy 1 (white) and

Push SW assy 2 (red).

∗

Before removing the Push SW assy 1 and 2, turn the Dial switch such that it

does not touch the push switches (mid-point between Push SW assy 1 and

Push SW assy 2).

∗

Take care not to apply force to the connectors between the Push switch and

harness.

ush switch scr ews

ush switch assy 1 and 2

Fig. 3.3-17 Removing the Push Switches

-11

Page 34

3

3.4 Chassis Assy

3.4.1 Removing the Harness Connectors

1. Remove 11 harness connectors from the Main PCB. Do not remove the power

harness assy (red/black CN13).

Power harne ss assy

Fig. 3.4-1 Removing the Harness Connectors 1

2. Disconnect the harnesses from the eight hooks on the Bottom cover B.

Fig. 3.4-2 Removing the Harness Connectors 2

3. Peel off the tape that holds the harnesses inside the right of Bot t om cover B, then

remove the harnesses from the Bottom cover B.

-12

Page 35

3

3.4.2 Removing the PST PCB (Paper Sensor PCB)

Remove the PST PCB (Paper sensor PCB) screws from the Main chassis B, then

remove the PST PCB (Paper sensor PCB).

PST PCB screw

PST PCB

Fig. 3.4-3 Removing the PST PCB (Paper S ensor PCB)

-13

Page 36

3

3.4.3 Removing the Chassis Assy

G

G

B

1. Remove the Ground wire screw from the Main chassis B, then disconnect the

ground wire.

Ma in chassis B

round wire

Fig. 3.4-4 Removing the Chassis Assy 1

round wire screw

2. Remove the two Bottom cover screws B and the washers from under the Bottom

cover B.

∗

When inverting the unit to perform this work, place it on a soft cloth to avoid

scratching the cover.

ottom cover B

Bottom cover screws B

Washers

Fig. 3.4-5 Removing the Chassis Assy 2

-14

Page 37

3. Open the Roller holder assy, then remove the four Bottom cover screws CL2000011

with four washers from under the Chassis assy.

Bottom Cover Screw A

Roller Holder Assy

Fig. 3.4-6 Removing the Chassis Assy 3

4. Pull out the Chassis assy from Bottom cover.

Chassis assy

Fig. 3.4-7 Removing the Chassis Assy 4

3-15

Page 38

3

3.5 PCBs

M

M

P

M

J

3.5.1 Removing the Main PCB

1. Disconnect the power harness assy (red/black) from the Main PCB.

2. Remove the four Main PCB screws. Remove the Main PCB.

ower harness assy

Fig. 3.5-1 Removing the Main PCB

3.5.2 Removing the Jack PCB Assy

Remove the Jack PCB screw and remove the Jack PCB assy.

∗

The core shown in the diagram is fitted in the EU-specification LX-300 only.

ain PCB screw

ain PCB assy

ain PCB screw

ack PCB screw

Jack PCB a ssy

Fig. 3.5-2 Removing the Jack PCB Assy

-16

Page 39

3

3.5.3 Removing the Switch PCB Assy

S

S

L

S

C

1. Remove the eight Switch PCB screws from under the Body cover. Remove the

Switch PCB assy.

witch PCB assy

Switch PCB screws

witch PCB screws

Fig. 3.5-3 Removing the Switch PCB Assy 1

2. Remove the Start key, Stop key, Two-connection switch, Continuous key, and Ext r a

border key.

The LED lenses can be removed from the Top cover by pushing them hard with a

fine object such as a pen tip.

LED lenses

ED lens

Extra border key

Two -con nection switch

ontinuous key

top ke y

Start key

Fig. 3.5-4 Removing the Switch PCB Assy 2

-17

Page 40

3

3.6 X-cutter Unit

X

X

L

X

L

3.6.1 Removing the X-cutter Unit

1. Remove the Y-cutter assy.

2. Remove the two X-cutter screws. Move the X-cutter unit toward the right to remove

it.

∗

Remove the Chassis assy from the Bottom cover when replacing the X-cutter

unit.

Y-cutter assy

-cutter screw s

Fig. 3.6-1 Removing the X-cutter Unit

3.6.2 Removing the Leaf Switch F Assy.

Remove the Leaf switch F screw, then remove the Leaf switch F assy.

∗

Take care not to bend the connector root on the Leaf switch F assy harness.

-cutter unit

Tape sensor holde r

Fig. 3.6-2 Removing the Leaf Switch F Assy

-cutter unit

eaf switch F assy

eaf switch F screw

-18

Page 41

3

3.7 Y-CA Chassis Assy and Y-cutter Arm

Y

R

Y

A

3.7.1 Removing the Y-CA Chassis Assy

1. Remove the Y extension springs.

2. While the Roller holder is locked, remove the two Y-CA chassis screws.

3. Disengage the end of the Y-cutter arm from the Y sensor carriage by moving it in

direction A. Remove the Y-CA chassis assy.

sensor carriage

-cutter a rm

Y-cutter arm

Y-CA chassis screws

oller holder

Y ex tension spring

Fig. 3.7-1 Removing the Y-CA Chassis Assy

-19

Page 42

3

3.7.2 Removing the Y-CA Motor

Y

Y

Y

Y

c

s

1. Remove the Y-CA motor screws and remove the Y-CA motor.

-CA motor

Fig. 3.7-2 Removing the Y-CA Motor

3.7.3 Removing the Y-cutter Arm

1. Remove the retaining ring from the Y-cutter arm shaft, pull out the Y-cutter arm shaft,

and remove the Y-cutter arm.

2. Remove the Y-CA arm screw, then remove the Y-CA arm.

Y-cutter arm

-CA motor screw

sensor

arriage arm

crew

Y-CA arm

-cutter a rm shaft

Retaining rings

Fig. 3.7-3 Removing the Y-cutter Arm

-20

Page 43

3

3.8 Y-sensor Rail Unit

Y

F

Y

3.8.1 Removing the Y-sensor Rail Unit

1. Remove the F cable from the Cassette holder.

2. Remove the two Y-sensor rail screws.

3. Disengage the tip of the Actuator top from the film hole, t hen remove t he Y-sensor

rail unit in the direction of the arrow.

Film

The tip of the

Actuator top

-sensor rail screw

-sensor rail unit

Fig. 3.8-1 Removing the Y-sensor Rail Unit

cable

Cassette hold er

-21

Page 44

3

3.8.2 Disassembling the Y-sensor Rail Unit

R

F

P

f

Y

1. Remove the Retaining ring from the Y-sensor shaft, then pull out the Y sensor shaft.

2. Remove the FPC holder A from the Y-sensor rail, then remove the Y-sensor

carriage.

Retaining ring

Y-sensor rail screw

FPC holder

-sensor carriage

Y-sensor shaft

aper feed

ilm

PC holder

Y-sensor rail

Y-sensor rail screw

Fig. 3.8-2 Disassembling the Y-s ensor Rail Unit

Reinforcement

film

etaining ring

-22

Page 45

3

3.9 Roller Holder Assy

R

R

3.9.1 Removing the Roller Holder Assy

1. Lift up the Roller holder unit and disconnect the Roller holder return spring.

2. Remove the four Retaining rings (two from the Roller holder, two from t he Paper

feed holder), then remove the Roller holder unit.

3. Remove the plastic spacer from the rivet pins at each end of the Roller holder assy.

Retaining rings

Spacer

Fig. 3.9-1 Removing the Roller Holder Assy

oller holder return spring

oller holder unit

Retaining rings

Spacer

-23

Page 46

3

3.10 Paper Feed Roller

I

P

P

3.10.1 Removing the Paper Feed Holder Assy

1. Remove the two Idle gears A, one Double gear B, one Double gear A, the Roller

gear AD, and the two Paper feed roller springs from the Paper feed holder L assy,

then remove the Paper feed roller unit.

aper feed roller spri ngs

Roller gear AD

Double gear B

Double gear A

Idle gear A

dle gear A

Fig. 3.10-1 Removing the Paper Feed Holder Assy

2. Rotate the Paper feed holder plates L/R backward. Remove the Paper feed holder

plates L/R by pulling the hooks out of the cut-outs in t he Chassis L/ R.

Paper feed holder plate L

aper feed holder plate R

Fig. 3.10-2 Removing the Paper Feed Holder Plates L/R

-24

Page 47

3

3. Remove the Bearing and Sub-bearing and remove the Actuator top from the Paper

B

S

S

L

L

feed roller assy.

Actuator top

Fig. 3.10-3 Removing the Actuator Top

3.11 Left Side of the Main Chassis

3.11.1 Removing the LF Motor

1. Remove the three LF motor holder screws, then remove the LF motor holder assy

and the three Spacers.

2. Remove the two LF motor screws from the LF motor holder assy, then remove the

LF motor.

ub bearing

earing

F motor screw

pacer

F motor holder screw

LF moto r

Fig. 3.11-1 Removing the LF Motor

-25

Page 48

3

3.11.2 Removing the Gears

5

G

789

3

4

6

G

1. Remove the gears according to the sequence of numbers in the diagram below.

ear holders

1

2

10

Fig. 3.11-2 Removing the Gears

2. Remove the two Gear holders simultaneously. Remove the Gear holder spring from

the Gear holders.

∗

The Gear holder spring may be stretched if the Gear holders are removed

separately.

Gear holde r

Gear holder spring

Idle gears B

ear holder

Fig. 3.11-3 Removing the Gear Holders and Gear Holder Spring

-26

Page 49

3

3.12 Right Side of the Main Chassis

S

S

I

C

L

T

L

C

T

T

T

S

T

3.12.1 Removing the Right Side of the Chassis

1. Remove the two Idle gears A.

2. Remove the two SG motor screws and remove the SG motor.

3. Remove the Leaf switch SG screw, then remove the Leaf switch SG assy.

4. Remove the T-lever shaft.

dle gears A

hassis R support

-lever shaft

eaf switch SG assy

Fig. 3.12-1 Removing the Right Side of the Chass i s 1

hassis R support screw

eaf switch SG assy screw

G motor

G motor screws

5. Push down on the T-lever unit to align the slot hole with the shaft, then remove the

unit.

-lever A

lot

T-lever unit

-lever spring

-lever B

cam roller

Fig. 3.12-2 Removing the T-lever Unit

-27

Page 50

3

6. Remove the Control cam gear and Double gear S.

D

ouble gear S

Control cam gea r

Fig. 3.12-3 Removing the Right Side of the Chass i s 2

7. Remove the screws, then remove the Chassis R support. (See Fig. 3.12-1.)

3.12.2 Removing the YC Lift Shaft and LF Change Shaft

1. Remove the Paper eject roller springs.

2. Remove the Y extension spring.

3. Remove the Retaining ring for the YC lift shaft at t he lef t side of the Main chassis.

Retaining ring

Paper eject roller springs

Y ex tension springs

Fig. 3.12-4 Removing the YC Lift Shaft and LF Change Shaf t 1

-28

Page 51

3

4. Move the YC lift shaft sever al m illim eters toward the right side of the Main c hass is

and remove the YC Lift arm.

LF lift arm

YC lift shaft

YC lift arm

Fig. 3.12-5 Removing the YC Lift Shaft and LF Change Shaf t 2

5. Remove the left end of the YC lift shaft f r om the Chassis L. Remove the YC lift shaft

by pulling the right end of the YC lift shaft through the hole in Chassis R toward the

middle of the chassis.

6. Move the LF change shaft several millimeters t owar d t he M ain chassis R. Remove

the LF change shaft by pulling the right end of the shaft t hr ough t he hole in Chassis

R toward the middle of the chassis.

∗

When pulling the right end of the YC lift shaft and LF change shaft t h rough the

hole in Chassis R, tilt the shafts so that they can be pulled smoothly. Never pull

them through the hole forcibly.

-29

Page 52

3

3.13 Paper Eject Roller

P

P

H

3.13.1 Removing the Paper Eject Roller Unit

1. Push down the Paper eject shaft holder until they becomes free.

2. Push the Paper eject roller toward the left and remove it from the right end.

3. Remove the Paper eject sub-roller in exactly the same manner as the Paper eject

roller: move it toward the left then remove it from t he right end.

aper eject roller

Paper eject sub roller

Fig. 3.13-1 Removing the Paper Eject Roller Unit 1

aper eject shaft holder

4. Remove the Paper eject roller bearing hook, then remove the Paper eject roller

bearing.

Paper eject roller bearings

ooks

Fig. 3.13-2 Removing the Paper Eject Roller Unit 2

-30

Page 53

3

3.14 Y-diversion Lever

Y

3.14.1 Removing the Y-diversion Lever Assy

1. Lift the Y-diversion lever assy to remove it.

Fig. 3.14-1 Removing the Y-diversion Lever

-diversion lever assy

-31

Page 54

3

3.15 Trimming Mechanism

L

B

R

R

D

R

3.15.1 Disassembling the Trimming Mechanism

1. Remove the Leaf switch TRI screw, then remove the Leaf switch assy TRI .

2. Remove the T-cutter screw, then remove the T-cutter assy.

Leaf switch TRI screw

T-cutter screw

T-cutter unit

Fig. 3.15-1 Disassembling the Trimming Mec hanism

3.16 Driving Roller

3.16.1 Removing the Driving Roller

1. Remove the Roller gear CD.

2. Remove the Retaining ring, push the Driving roller assy toward the left then remove

it from the right end.

3. Remove the Bearings R/L.

eaf switch TRI assy

Bearing L

etaining ring

riving roller assy

etaining ring

earing R

oller ge ar CD

Fig. 3.16-1 Removing the Driving Roller

-32

Page 55

3

3.17 Main Chassis B

E

C

H

E

E

T

3.17.1 Removing the Main Chassis B

1. Disengage the harness from the hooks under the Cassette holder and the Edging

saddle at the rear of the main chassis B.

2. Remove the Edging saddle from the rear of the main chassis B.

3. Remove the tape holding the ENC sensor harness.

4. Remove the Leaf switch C3/C4 screws, then remove the Leaf switch C3/C4

assemblies.

5. Remove the two Cassette actuators.

assette holder

dging saddle

Leaf switch C3 assy

Leaf switch C3 scr ew

Cassette actuator

Leaf switch C4 scr ew

Leaf switch

C4 assy

he bottom face of cassette holder

Fig. 3.17-1 Removing the Main Chassis B

NC senso r

NC sensor harness

Tape

arness

Rear of the main chassis B

-33

Page 56

3

3.17.2 Removing the Cassette Holder

H

E

E

1. Push in the three hooks on the front face that fix the Casset t e holder.

2. Pull out the Cassette holder in the direction of the arrow.

Fig. 3.17-2 Removing the Cassette Holder

3.17.3 Removing the ENC Sensor PCB

ooks

Remove the ENC sensor PCB screw, then remove the ENC sensor assy.

NC sensor assy

NC sensor PCB screw

Fig. 3.17-3 Removing the ENC Sensor PCB

-34

Page 57

3

3.17.4 Removing the Main Chassis L, R, and F

M

M

Remove the ten Side chassis screws (five each side), then remove the Main chassis L,

R, and F.

Side chassis screws

Ma in chassis F

ain chassis L

ain chassis B

Ma in chassis R

Side chassis screws

Fig. 3.17-4 Removing the Main Chassis L, R, and F

-35

Page 58

Chapter 4.

ASSEMBLY PROCEDURES

Page 59

CONTENTS

Chapter 4. ASSEMBLY PROCEDURES

4.1 Safety Precautions............................................................................................................4-1

4.2 Table of Tightening Torques............................................................................................. 4-2

4.3 Main Chassis B .................................................................................................................4-3

4.3.1 Installing the Main Chassis L, R, and F................................................................ 4-3

4.3.2 Installing the ENC Sensor PCB............................................................................4-3

4.3.3 Installing the Cassette Holder...............................................................................4-4

4.3.4 Installing the Main Chassis B ...............................................................................4-5

4.4 Driving Roller.....................................................................................................................4-6

4.4.1 Installing the Driving Roller...................................................................................4-6

4.5 Trimming Mechanism........................................................................................................4-7

4.5.1 Assembling the Trimming Assy............................................................................4-7

4.6 Paper Eject Roller and Y-diversion Lever.........................................................................4-8

4.6.1 Installing the Paper Eject Roller Unit and Y-diversion Lever...............................4-8

4.6.2 Installing the Paper Eject Roller ...........................................................................4-9

4.7 Right Side of the Main Chassis.......................................................................................4-10

4.7.1 Installing the YC Lift Shaft and LF Change Shaft...............................................4-10

4.7.2 Installing the Right Side of the Chassis..............................................................4-11

4.8 Left Side of the Chassis.................................................................................................. 4-14

4.8.1 Installing the Gears............................................................................................. 4-14

4.8.2 Installing the LF Motor ........................................................................................4-15

4.9 Paper Feed Roller...........................................................................................................4-16

4.9.1 Installing the Paper Feed Holder Assy and the Paper Feed Roller Assy..........4-16

4.10 Roller Holder Assy ..........................................................................................................4-19

4.10.1 Installing the Roller Holder Assy ........................................................................4-19

4.11 Y-sensor Rail Unit ...........................................................................................................4-20

4.11.1 Assembling the Y-sensor Rail Unit (Attaching Y-sensor PCB Assy).................4-20

4.11.2 Installing the Y-sensor Rail Unit .........................................................................4-22

4.12 Y-CA Chassis Assy and Y-Cutter Arm............................................................................4-23

4.12.1 Installing the Y-cutter Arm ..................................................................................4-23

4.12.2 Installing the Y-CA Motor....................................................................................4-24

4.12.3 Installing the Y-CA Chassis Assy.......................................................................4-24

4.13 X-cutter U nit ....................................................................................................................4-26

4.13.1 Installing the Leaf Switch F Assy........................................................................4-26

4.13.2 Installing the X-cutter Unit...................................................................................4-26

4.14 Harnesses .......................................................................................................................4-27

4.14.1 Installing the Harnesses .....................................................................................4-27

i

Page 60

ii

4.15 PCBs ...............................................................................................................................4-28

4.15.1 Installing the Jack PCB Assy..............................................................................4-28

4.15.2 Installing Main PCB Assy 1 ................................................................................4-28

4.16 Chassis Assy ...................................................................................................................4-29

4.16.1 Installing the Chassis Assy.................................................................................4-29

4.16.2 Installing the PST PCB Assy..............................................................................4-30

4.16.3 Installing the Harness Connectors .....................................................................4-31

4.17 Covers .............................................................................................................................4-32

4.17.1 Installing the Push SW Assy...............................................................................4-32

4.17.2 Installing the Dial Switch Holder Assy................................................................4-33

4.17.3 Installing the Cover Switch................................................................................. 4-35

4.17.4 Installing the Back Cover....................................................................................4-35

4.17.5 Installing Paper Tray B ....................................................................................... 4-36

4.17.6 Installing the Front Cover....................................................................................4-36

4.17.7 Installing the Body Cover....................................................................................4-37

4.17.8 Installing the Paper Tray A and Paper Guide.....................................................4-39

4.17.9 Installing the Sub-tray.........................................................................................4-40

4.17.10 Installing the Top Cover B.................................................................................. 4-41

4.17.11 Installing the Trimmer Upper Cover ...................................................................4-41

4.18 Installing the Y-cutter ......................................................................................................4-42

4.19 Installing the Film Cartridge ............................................................................................4-43

4.19.1 Installing the A3 Cartridge.................................................................................. 4-43

4.19.2 Installing the A4/A6 Cassette Attachment..........................................................4-44

Page 61

4-1

4.1 Safety Precautions

•

When conducting reassembly operations, place the unit on a grounded anti-static

sheet. LSI and other electronic components are sensitive to static electricity and

may be damaged if touched while charged.

•

Before transporting a circuit board, wrap it in a conducting sheet such as aluminum

foil.

•

When using a soldering iron or other heat-producing tool, ensure that heat does not

damage wires, circuit boards, or plastic parts such as covers.

•

Take care not to lose small screws or washers installed when replacing parts.

•

Tighten all screws to the torque specified in the table below.

•

As a safety precaution, wear gloves when conducting assembly operations.

Page 62

4-2

4.2 Table of Tightening Torques

Name of screw Qty. Screw size Tightening torque See page

Side chassis screw 10 TAPTITE, CUP M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Reinforcing plate for frame R screw 2 TAPTITE, CUP M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

ENC PCB screw 1 TAPTITE, BIND B M3 × 8 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Leaf switch C3 screw 1 SCREW, PAN M2.6 × 10 0.196 to 0.392 N•m (2 to 4 kgf•cm)

Leaf switch C4 screw 1 SCREW, PAN M2.6 × 10 0.196 to 0.392 N•m (2 to 4 kgf•cm)

Leaf switch TRI screw 1 TAPTITE, PAN B M2 × 6 0.196 to 0.392 N•m (2 to 4 kgf•cm)

Leaf switch F screw 1 TAPTITE, PA N B M 2 × 6 0.196 to 0.392 N•m (2 to 4 kgf•cm)

Sensor holder screw 1 TAPTITE, CUP S M2.6 × 6 0.49 to 0.686 N•m (5 to 7 kgf•cm)

X-cutter screw 2 SCREW, BIND M3 × 6 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Detent plate screw 1 TAPTITE, BIND B M3 × 8 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Plate spring 3 screw 1 TAPTITE,CUP M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Leaf switch SG sc rew 1 SCREW, PAN M2.6 × 10 0.196 to 0.392 N•m (2 to 4 kgf•cm)

SG motor screw 2 TAPTITE, CUP M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

LF motor screw 2 TAPTITE, CUP M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

LF motor holder screw 3 TAPTITE, CUP M 3 × 20 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Y-CA sensor PCB screw 1 TAPTITE, PAN B M2 × 8 0.196 to 0.392 N•m (2 to 4 kgf•cm)

Y-sensor rail screw 2 TAPTITE,CUP M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Y-sensor carriage arm screw 1 SCREW, B IND B TITE

M3 × 10

Y-CA motor screw 1 SCREW, F LANGED M2.6 × 5 0.196 to 0.392 N•m (2 to 4 kgf•cm)

Sensor holder screw 1 TAPTITE, CUP M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Y-CA chassis screw 2 TAPTITE, CUP M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Switch PCB screw 8 TAPTITE, BIND B M3 × 12 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Jack PCB screw 1 TAPTITE, BIND B M3 × 8 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Main PCB screw 4 TAPTITE, BIND B M3 × 8 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Bottom cover screw A 4 TAPTITE, CUP B M4 × 12 0.98 to 1. 176 N•m (10 to 12 kgf•cm)

Bottom cover screw B 2 SCREW, BIND M3 × 6 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Ground wire screw 1 SCREW, CUP M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

PST PCB screw 1 SCREW, BIND M3 × 6 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Push switch 1 screw 1 SCREW, PAN M1.7 × 6 0.075 to 0.125 N•m

Push switch 2 screw 1 SCREW, PAN M1.7 × 6 0.075 to 0.125 N•m

Dial holder screw 8 TAPTITE, BIND B M3 × 8 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Plate spring screw 1 SCREW, FLANGED M2.6 × 5 0.196 to 0.392 N•m (2 to 4 kgf•cm)

Plate spring 2 screw 1 SCREW, FLA NGED M2.6 × 5 0.196 to 0.392 N•m (2 to 4 kgf•cm)

Adjustment plate screw 1 TAPTITE, BIND B M3 × 8 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Cover switch screw 1 TAPTITE, PAN B M2.6 × 12 0.196 to 0.392 N•m (2 to 4 kgf•cm)

Front cover screw 2 TAPTITE, BIND B M2.6 × 8 0.25 to 0.35 N•m

Bottom cover screw A 3 TAPTITE, BIND B M3 × 8 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Trimmer bottom cover 2 SCREW, BIND M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

T-cutter screw 1 TAPTITE, CUP M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

Chassis R support sc rew 1 TAPTITE, CUP M3 × 5 0.49 to 0.686 N•m (5 to 7 kgf•cm)

0.49 to 0.686 N•m (5 to 7 kgf•cm)

(0.77 to 1.26 kgf•cm)

(0.77 to 1.26 kgf•cm)

(2.55 to 3.57 kgf•cm)

Page 63

4-3

4.3 Main Chassis B

M

E

B

E

E

P

4.3.1 Installing the Main Chassis L, R, and F

1. Insert the lugs on the Main chassis B and F into the square holes in the Main

chassis L and R. Assemble the Main chassis L, R, F, and B with the ten Side

chassis screws (five each side).

2. Attach the Edging saddle to the Main chassis B.

Side chassis screws

Ma in chassis R

Ma in chassis F

ain chassis B

dging saddle

Ma in chassis L

Side chassis screws

Fig. 4.3-1 Installing the Main Chass i s L, R, and F

4.3.2 Installing the ENC Sensor PCB

Align the boss on the ENC sensor PCB assy. Attach the ENC sensor PCB assy to the

Cassette holder with the ENC sensor PCB screw.

Pass the ENC sensor harness through the hole in the Cassette holder.

oss

NC Sensor PCB assy

NC Sensor

CB screw

Fig. 4.3-2 Installing the ENC Sens or P CB

Page 64

4-4

4.3.3 Installing the Cassette Holder

H

E

M

H

1. Pass the ENC sensor PCB harness through the hole in the bottom of Main chassis

B.

2. Insert the lugs at the front of the Casset t e holder and click t he hooks at t he rear ont o

Main chassis B.

Lugs

Fig. 4.3-3 Installing the Casset te Holder

ooks

NC sensor PCB assy

ain chassis B

arness

(Chassis R, L and F are omitted for explanation.)

Page 65

4-5

4.3.4 Installing the Main Chassis B

C

E

E

H

C

a

H

T

C

1. Install the two Cassette actuators.

2. Install the Leaf switch C3 (red) and C4 (yellow) assemblies using the Leaf switch

C3/C4 screws.

∗

Take care not to deform the tip of the leaf switch.

3. Engage the Leaf switch C3 and C4 harness into the hook under the Cassette holder,

then pass it through the Edging saddle under the Chassis B.

assette holder

Leaf switch

C3 assy

assette

ctuator

Leaf switch C4 scr ews

Leaf switch

C3/C4 a ssy

he bottom face of

assette holder

Fig. 4.3-4 Installing the Main Chass i s B

NC senso r

NC sensor harness

arness

Tape

ook

4. Tape the ENC sensor PCB harness inside the marked line (the side of the Cassette

holder hooks) under the Chassis B, then return the harness to the Edging saddle

under the Chassis B.

Page 66

4-6

4.4 Driving Roller

R

D

B

B

4.4.1 Installing the Driving Roller

1. Attach the Retaining ring to the right end of the Driving roller assy (wit h t he short er

metal part).

2. Insert the Bearings L/R into the Driving roller. Mount it sequent ially into Main

chassis L and Main chassis R.

3. After installing Bearings L/R into the Main chassis L/R, at t ach t he Retaining ring to

the left end of the Driving roller assy.

4. Install the Roller gear CD.

earing L

riving roller assy

etaining ring

earing R

Retaining ring

Roller gear CD

Fig. 4.4-1 Installing the Driving Rol l er

Page 67

4-7

4.5 Trimming Mechanism

L

L

T

4.5.1 Assembling the Trimming Assy

1. Align the Leaf switch assy TRI with the T-cutter assy boss hole and attach it with the

Leaf switch TRI screw.

2. Fasten the harness to the hooks.

Engage the harness into the hook under the Cassette holder, then fix it wit h t ape on

the two marked areas (Chassis B front face and Chassis R inside surface).

3. Align the T-cutter assy with the boss holes and install it with the T-cut t e r screw.

eaf switch TRI assy

eaf switch TRI screw

T-cutter screw

Leaf switch TRI harness

-cutter a ssy

The botto m face of

cassette holder

Fig. 4.5-1 Assembling the Trimming Assy

Page 68

4-8

4.6 Paper Eject Roller and Y-diversion Lever

Y

4.6.1 Installing the Paper Eject Roller Unit and Y-diversion Lever

1. Temporarily position the Y-diversion Lever assy on the Main chassis F.

-diversion lever assy

Fig. 4.6-1 Installing the Y-diversion Lever 1

2. Install the Paper eject roller bearings such that the Y-diversion lever arms are

sandwiched between the Paper eject roller bearing and the Main chassis L/R.

Fasten the Paper eject roller bearings with the Hooks (both L/R).

Paper eject roller bearings

Hook

Fig. 4.6-2 Installing the Y-diversion Lever 2

Page 69

4-9

4.6.2 Installing the Paper Eject Roller

P

P

P

G

P

1. With both ends of the Paper eject roller inserted in the Paper eject shaft holders,

move the Paper eject roller first to the left, then to the right, to insert it into the Paper

eject roller bearings. (Insert them to the end of the rubber, ensuring that t he Paper

eject roller shaft holders are correctly oriented vertically.)

2. After inserting the Paper eject roller into the bearings, move the Paper eject roller

shaft holders outward to engage with the groove in the Paper eject roller.

3. Move the paper eject sub-roller to the left, then to the right, to insert it into the Paper

eject shaft holders and the Paper eject roller bearings.

Paper eject roller

Paper eject sub roller

Fig. 4.6-3 Installing the Paper Ejec t Roller 1

aper eject roller bearings

aper eject shaft holder

4. Align the grooves in the Paper eject roller and Paper eject sub-roller shafts at the

Paper eject shaft holders and push up the Paper eject shaft holders to lock them

(both sides).

rooves

aper eject roller

Paper eject roller shaft holder

aper eject sub roller

Fig. 4.6-4 Installing the Paper Ejec t Roller 2

Page 70

4

4.7 Right Side of the Main Chassis

Y

L

B

Y

G

M

P

Y

4.7.1 Installing the YC Lift Shaft and LF Change Shaft

1. Move the LF change shaft first to the right, then to the left, to install it into the Main

chassis L and R.

2. Insert the right end of the YC Lift Shaft int o the Main chassis R, then attach the YC

lift arm to it.

3. With the boss of the YC lift arm inserted into the groove at t he right end of t he YC lift

shaft, insert the left end of the YC lift shaft into the Main chassis L and attach the

retaining ring outside Chassis L.

Retaining ring

ain Chassis L side

F change shaft

YC lift shaft

C lift shaft

roove

C lift arm

oss

Fig. 4.7-1 Installing the YC Lift S haft and LF Change Shaft 1

4. Attach the Y extension springs between the hooks inside the Main chassis L/R and

the Y-diversion lever.

5. Attach the Paper eject roller springs between the Paper eject shaft holder hooks and

the Main chassis L/R.

Paper eject roller shaft holder

-diversion lever

Y ex tension spring

ain chassis R

aper eject roller spring

Fig. 4.7-2 Installing the YC Lift S haft and LF Change Shaft 2

-10

Page 71

4

4.7.2 Installing the Right Side of the Chassis

C

L

B

B

1. Install the Double gear S.

2. Position the YC lift shaft as shown in the diagram.

3. Install the Control cam gear with the triangular mark on the Control cam gear

aligned with the triangular hole in the Chassis.

∗

Ensure that the boss at the right end of the LF change shaft and YC lif t arm is

inserted correctly into the grooves in the Control cam gear. The bosses are

correctly inserted if the Control cam gear rotates smoothly when the Y-diversion

lever is pressed.

oss

F change shaft

Double gear S

Triangular hole in the Chassis

oss

YC lift arm

ontrol cam gear

The triangular mark on the Control cam gear

Fig. 4.7-3 Installing the Right Si de of the Chassis 1

4. Install the T-lever A to the Main chassis R.

Ma in chassis R

T-cutter assy

Fig. 4.7-4 Installing the Right Si de of the Chassis 2

T-lever A

-11

Page 72

4

5. Install the T-lever B, T-cam roller, and T-cam spring onto T-lever A.

T

T

T

T

T

G

T

-cam spring

-cam roller

-lever A

-lever B

Fig. 4.7-5 Installing the Right Si de of the Chassis 3

6. Insert the T-lever shaft into the shaft holes in the Main chassis R and T-lever A/B.

Push in the T-lever shaft until the groove in the shaft engages with t he hook on t he

T-cutter assy.

T-lever B

T-cutter assy

-lever shaft

-lever A

roove

Fig. 4.7-6 Installing the Right Si de of the Chassis 4

-12

Page 73

4

7. Align the Leaf switch SG assy with the boss hole and fasten it wit h the Leaf switch

S

C

C

L

SG screw.

Before installing the Leaf switch SG assy, turn the Cont rol cam gear t o a posit ion

where it cannot interfere with the Leaf switch.

8. Install the SG motor with the two SG motor A screws.

9. Install the Idle gears A.

10. Attach the Chassis R support with the Chassis R support screw.

G motor

SG motor screws A

Leaf switch SG assy

Fig. 4.7-7 Installing the Right Si de of the Chassis 5

eaf switch SG assy screw

Idle gears A

hassis R support

hassis R support screw

-13

Page 74

4

4.8 Left Side of the Chassis

G

G

7

G

9

3

1

2

468

4.8.1 Installing the Gears

1. Mount the two Gear holders to the Main chassis L, then attach the G ear holder

springs.

ear holders

ear holder spring

Fig. 4.8-1 Installing the Gears 1

2. Install the gears according to the sequence shown in the diagram below.

Push the shaft into a gear or holder with a hook until the hook engages.

5

ear holders

10

1 (× 4)

1

Fig. 4.8-2 Installing the Gears 2

-14

Page 75

4

4.8.2 Installing the LF Motor

L

M

S

L

1. Attach the LF motor to the LF motor holder using the LF motor screws.

2. Insert the LF motor holder screws into the LF motor holder assy. Put the Spacers

over the three protruding screws. Mount the LF motor holder assy to the Main

chassis L.

∗

Fix the LF motor holder to the positioning pins, then fasten it firmly and correctly

in place with the screws.

LF moto r screw

F motor

ain chassis L

LF motor holder screw

F motor holder

Fig. 4.8-3 Installing the LF Motor

pacer

-15

Page 76

4

4.9 Paper Feed Roller

P

4.9.1 Installing the Paper Feed Holder Assy and the Paper Feed Roller Assy

1. Attach the Paper feed holder plates L (with shaft) and R to the Main chassis L and R.

∗

Assemble with the hooks on the Paper feed holder plates L/R engaged in the

cut-outs in the Chassis L/R.

Paper feed holder plate L

aper feed holder plate R

Fig. 4.9-1 Installing the Paper Feed Holder Assy

-16

Page 77

4

2. Install the Actuator top in the Paper feed holder assy.

S

P

P

P

S

C

3. Install the Bearing and Sub-bearing onto the Paper feed roller and Paper feed subroller. Insert the rollers through the slots in the Paper feed holder plates L and R.

∗

Ensure that the Actuator top fits into Part A of t he Casset t e holder.

Bearing

ub bearing

aper feed roller assy

aper feed sub roller

per feed holder plate L

Slot

Actuator top

Fig. 4.9-2 Installing the Paper Feed Roller Assy 1

Actuator top

Sub bearing

Bearing

lot

Paper feed holder plate R

assette Holder

art A

-17

Page 78

4

4. Attach the Paper feed roller springs to the left and right Sub bearing hooks and the

P

S

P

s

R

Paper feed holder plates L and R.

ub bearing

aper feed holder plate R

aper feed roller

pring

Fig. 4.9-3 Installing the Paper Feed Roller Assy 2

5. Attach the two Idle gears A, one Double gear B, one Double gear A, and the Roller

gear AD to the Paper feed holder plate L.

Double gear A

Idle gear A

Idle gear A

oller ge ar AD

Double gear B

Fig. 4.9-4 Installing the Paper Feed Roller Assy 3

-18

Page 79

4

4.10 Roller Holder Assy

R

M

R

h

r

R

4.10.1 Installing the Roller Holder Assy

1. Install the pivots for Roller holder rotation onto the Main chassis shaft s.

2. Mount the plastic spacers to the lugs (rivet pins) at each end of the Roller holder

assy.

3. Pass the lugs (rivet pins) on the roller holder unit through the curved slots on the

Main chassis L and R and the slots on top of the Paper feed roller plate.

4. Fasten the Roller holder in position with the four Retaining rings.

5. Install the Roller holder return spring while the Roller holder unit is open.

Spacer

Retaining rings

ain chassis shafts

oller

older

eturn spring

etaining ring

Fig. 4.10-1 Installing the Roller Holder Assy

oller holder assy

Spacer

Retaining ring

-19

Page 80

4

4.11 Y-sensor Rail Unit

A

F

A

2

4.11.1 Assembling the Y-sensor Rail Unit (Attaching Y-sensor PCB Assy)

1. Bend the sensor flat cable to the dimensions shown in the diagram below.

pprox. 350mm

Fig. 4.11-1 Bending the Sensor Flat Cable to the Dimensi ons

2. Attach the FPC holders A to the flat cable.

3. Locate the sensor flat cable inside the Y-sensor rail unit.

FPC holder A

Approx.

170 mm

Fig. 4.11-2 Sensor Flat Cable Location

PC holder A

pprox.

5 mm

-20

Page 81

4

4. Stick the Film and Reinforcement film to the Y-sensor rail unit.

F

R

F

Y

S

Y

R

S

5. Install the FPC holders A in the Slots in the Y sensor rail unit.

6. Pass the Y-sensor shaft through the Y-sensor rail and Y-sensor carriage and fasten

with a Retaining ring at each end.

7. Check that the sensor cable is not tight when the Y-sensor carriage is moved to the

left end, as shown in the diagram below.

Retaining ring

ilm

Y sensor shaft

-CA sensor carriage

FPC

holder A

lot

sensor rail

Fig. 4.11-3 Assembling the Y-sensor Rail Unit

einforcement film

PC holder A

lot

etaining ring

-21

Page 82

4

4.11.2 Installing the Y-sensor Rail Unit

Y

Y

F

P

1. Locate the groove on the Y-sensor shaft into the Paper feed holder plate and fast en

with the two Y-sensor rail screws.

∗

Ensure that film is inserted between the Paper feed roller and Paper feed subroller during installation.

∗

Pass the part of the Paper feed film with the Reinforcement f ilm at t ached

between the Paper feed roller and Paper feed sub-roller, then pass the end of

the Actuator top through the hole in the Paper feed film.

sensor rail scr ew

Paper feed sub roller

sensor rail unit

ilm

Paper feed roller

The end of the Actuator top

Fig. 4.11-4 Assembling the Y-sensor Rail Unit

aper feed film

-22

Page 83

4

4.12 Y-CA Chassis Assy and Y-Cutter Arm

Y

Y

R

4.12.1 Installing the Y-cutter Arm

1. Mount the Y-sensor carriage arm to the Y-cutter arm with the Y-CA arm screw.

Y-CA arm screw

Y-cutter arm

sensor carriage arm

Fig. 4.12-1 Installing the Y-cutter Arm 1

2. Pass the Y-cutter arm shaft through the Y-CA chassis assy and Y-cutter arm and

fasten with a Retaining ring at each end.

-cutter a rm

Y-CA chassis assy

Y-cutter arm shaft

etaining rings

Fig. 4.12-2 Installing the Y-cutter Arm 2

-23

Page 84

4

4.12.2 Installing the Y-CA Motor

Y

Y

1. Mount the Y-CA motor to the Y-CA chassis assy with the Y-CA motor screws.

Y-CA chassis assy

-CA motor

Y-CA moto r screw

Fig. 4.12-3 Installing the Y-CA Motor

4.12.3 Installing the Y-CA Chassis Assy

1. Insert the end of the Y-cutter arm into the Y sensor carriage.

Y sensor carriage arm

Fig. 4.12-4 Installing the Y-CA Chassis Assy 1

sensor carriage

-24

Page 85

4

2. Insert the lugs on the Y-cutter guide L into the slots (Part A) on the Y-cut t er arm.

Y

P

Y

Y

Y

3. Insert the Y-CA timing belt into the groove in the Y-cutter arm.

4. Install the Y-CA chassis assy with the two Y-CA chassis screws.

∗

Set the left and right Embosses into the holes in the Y-CA chassis before

tightening the screws.

5. Attach the Y extension spring to the Y-diversion lever and the Y-CA chassis assy.

art A

-cutter guide L

Y-cutter arm

-CA sensor carriage

Y-CA timing belt

Y-cutter arm

-CA chassis assy

Y-CA chassis screws

Fig. 4.12-5 Installing the Y-CA Chassis Assy 2

extension spring

-25

Page 86

4

4.13 X-cutter Unit

T

X

S

L

X

X

4.13.1 Installing the Leaf Switch F Assy

1. Attach the Leaf switch F assy to the Tape sensor holder with the Leaf switch F

screw.

Sensor holder

-cutter unit

ensor holder screw

Leaf switch F screw

Fig. 4.13-1 Installing the Leaf Switch F Assy

4.13.2 Installing the X-cutter Unit

Slide the X-cutter unit into position from the right side of the main unit and fasten it in

position with the two X-cutter screws.

ape sensor lever

eaf switch F assy

-cutter screw s

-cutter unit

Fig. 4.13-2 Installing the X-cutter Unit

-26

Page 87

4

4.14 Harnesses

H

E

4.14.1 Installing the Harnesses

Attach the following harnesses to the Main chassis B Edging saddle.

•

SG motor harness (black)

•

ENC harness assy (white)

•

Leaf switch TRI harnesses (black) x 2

•

Leaf switch C3 (red)/C4 (yellow) harness

dging saddle

arnesses

Fig. 4.14-1 Installing the Harnesses

-27

Page 88

4

4.15 PCBs

J

J

M

M

P

M

4.15.1 Installing the Jack PCB Assy

Install the Jack PCB assy with the Jack PCB screw.

∗

The Core shown in the diagram is applicable to EU-specification units only (LX-300).

ack PCB screw

Fig. 4.15-1 Installing the Jack PCB Assy

4.15.2 Installing Main PCB Assy 1

1. Install the Main PCB assy 1 to the Bottom cover with the four Main PCB screws.

∗

On a newly supplied part, cut away the PST SENSOR PCB assy.

2. Attach the Jack PCB Power harness assy (red/black) to the Main PCB assy 1.

Power harne ss assy

ain PCB screw s

ack PCB assy

ain PCB screw s

ain PCB assy

ST SENSOR PCB assy

Fig. 4.15-2 Installing Main PCB Assy 1

-28

Page 89

4.16 Chassis Assy CL2000011

4.16.1 Installing the Chassis Assy

1. Locate the Chassis assy aligned with the two bosses on the Bot t om cov er B.

Fasten it with the four Bottom cover screws A with four washers.

Bottom cover screws A

Fig. 4.16-1 Installing the Chassis Assy 1

2. Install the Chassis assy under the Bottom cover B using t he t w o Bot tom cover

screws B and Spring washers.

Bottom cove r B

Bottom cove r

screws B

Soft cloth

Fig. 4.16-2 Installing the Chassis Assy 2

4-29

Page 90

4

3. Attach the Ground wire to the Main chassis B using the Ground wire screw.

M

G

M

round wire screw

ain chassis B

Ground wire

Fig. 4.16-3 Installing the Chassis Assy 3

∗

The Chassis perpendicularity must be adjusted after the Chassis assy is

installed to the Bottom cover. See Section 6. Maintenance.

4.16.2 Installing the PST SENSOR PCB Assy

Attach the PST SENSOR PCB assy to the Main chassis B with the PST SENSOR PCB

screws.

PST SENSOR PCB screw

PST SENSOR PCB assy

ain chassis B

Fig. 4.16-4 Installing the PST SENSOR PCB Assy

-30

Page 91

4.16.3 Installing the Harness Connectors CL2000011

1. Attach the harness connectors (except the power harness assy) to the Main PCB

according to the color sequence shown in the diagram.

2. Connect the harnesses along the paths shown in the diagram.

3. Tape harnesses *1, *3, and *4 to the right face of Bottom cover B.

Pass the *5 Black (4P) cable through the three harness retainers.

4. Install the F cable as shown in the diagram below.

White (4P)

Harness

retainers

White (2P)

(6P)

Yellow (2P)

*4 Yellow, blue, white, red, gray (5P)

Black (2P)

*1 Orange (2P)

*3 Blue (2P)

FPC holder A

Red (2P)

*2 Red (5 P )

F cable

*5 Black (4P)

Black (6P)

Installation of the *2 harne ss.

Tape

Pass the F cable loosely

round the tips of the lugs on

the Cassette h older.

Installation of the

*1, *3, *4 harnesses.

Insert the core with

the harness wound on

it to the rib in the

cover.

F cable

Cassette holder lug