Page 1

Product Code: 885-403

Be sure to read this document before using the machine.

We recommend that you keep this document nearby for future reference.

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using the sewing machine, basic safety precautions should always be followed,

including the following:

“Read all instructions before using.”

DANGER – To reduce the risk of electric shock:

1. The sewing machine should never be left unattended when plugged in.

Always unplug this sewing machine from the electrical outlet immediately

after using and before cleaning.

2. Always unplug before changing the light bulb. Replace bulb with same type

rated 15 watts.

WARNING – To reduce the risk of burns, fire, electric

shock, or injury to persons:

1. Do not allow this machine to be used as a toy. Close attention is necessary

when the sewing machine is used by or near children.

Use this sewing machine only for its intended use as described in this manual. Use

2.

only accessories recommended by the manufacturer as contained in this manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not

working properly, if it has been dropped or damaged, or dropped into water.

Return the sewing machine to the nearest authorized dealer or service center

for examination, repair, electrical or mechanical adjustment.

4. Never operate the sewing machine with any of the air openings blocked. Keep

the ventilation openings of the sewing machine and foot controller free from

the accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any openings.

6. Do not use this machine outdoors.

7. Do not operate this machine where aerosol (spray) products are being used or

where oxygen is being administered.

8. To disconnect, turn the main switch to the symbol “O” position which

represents off, then remove plug from outlet.

9

. Do not unplug by pulling on the cord. To unplug, grasp the plug and pull, not the cord.

10.Keep fingers away from all moving parts. Special care is required around the

sewing machine needle.

11

.Always use the proper needle plate. The wrong plate can cause the needle to break.

12.Do not use a bent needle.

13.Do not pull or push the fabric while stitching. It may deflect the needle

causing it to break.

14.Switch the sewing machine to the off, symbol “O” position when making any

adjustments in the needle area, such as threading the needle, changing the

needle, threading the bobbin, or changing the presser foot.

15.Always unplug the sewing machine from the electrical outlet when removing

covers, lubricating, or when making any other user service adjustments

mentioned in this instruction manual.

16.This sewing machine is not intended for use by young children or impaired

persons without supervision.

1

Page 3

17.Young children should be supervised to ensure that they do not play with this

sewing machine.

SAVE THESE INSTRUCTIONS

This sewing machine is intended for household use.

This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

CONGRATULATIONS ON CHOOSING OUR MACHINE

To fully enjoy all the features, we suggest that you study the manual before using the machine.

PLEASE READ BEFORE USING THIS MACHINE

For safe operation

1. Be sure to keep your eye on the needle while sewing. Do not touch the handwheel, thread takeup lever, needle, or other moving parts.

2. Remember to turn off the power switch and unplug the cord when:

• Operation is completed

• Replacing or removing the needle or any other parts

• A power failure occurs during use

• Maintaining the machine

• Leaving the machine unattended

3. Do not store anything on the foot controller.

4. Plug the machine directly into the wall. Do not use extension cords.

For a longer service life

1. When storing this machine, avoid direct sunlight and high humidity locations. Do not use or

store the machine near a space heater, iron, halogen lamp, or other hot objects.

2. Use only neutral soaps or detergents to clean the case. Benzene, thinner, and scouring powders

can damage the case and machine, and should never be used.

3. Do not drop or hit the machine.

4. Always consult the operation manual when replacing or installing any assemblies, the presser

feet, needle, or other parts to assure correct installation.

For repair or adjustment

In the event a malfunction occurs or adjustment is required, first follow the troubleshooting table in

the back of the operation manual to inspect and adjust the machine yourself. If the problem persists,

please consult your local authorized Brother dealer.

For additional product information and updates, visit our web site at www.brother.com

The contents of this manual and specifications of this product are subject to change without notice.

FOR USERS IN THE UK, EIRE, MALTA AND CYPRUS ONLY

IMPORTANT

• In the event of replacing the plug fuse, use a fuse approved by ASTA to BS 1362, i.e. carrying

the mark, rating as marked on plug.

• Always replace the fuse cover. Never use plugs with the fuse cover omitted.

• If the available electrical outlet is not suitable for the plug supplied with this equipment, you

should contact your authorized dealer to obtain the correct lead.

2

Page 4

—————————————————————————————————————————————————————————

—

CONTENTS

CONTENTS .........................................................................................................................3

1. KNOWING YOUR SEWING MACHINE ..........................................................5

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS ....................................................5

The main parts ................................................................................................................................................. 5

Needle and presser foot section ...................................................................................................................... 6

Flat bed attachment ......................................................................................................................................... 6

ACCESSORIES .....................................................................................................................7

OPTIONAL ACCESSORIES ..................................................................................................7

USING YOUR SEWING MACHINE .....................................................................................8

Power supply precautions ................................................................................................................................ 8

Power supply .................................................................................................................................................... 8

Foot controller .................................................................................................................................................. 9

Steadying the machine ..................................................................................................................................... 9

THREADING THE MACHINE ............................................................................................10

Winding the bobbin ........................................................................................................................................ 10

Lower threading ............................................................................................................................................. 11

Upper threading ............................................................................................................................................. 13

Drawing up the lower thread .......................................................................................................................... 14

REPLACING THE NEEDLE .................................................................................................15

Needle precautions ........................................................................................................................................ 15

Selecting the needle depending on the thread and fabric types .................................................................... 15

Checking the needle ...................................................................................................................................... 16

Replacing the needle ..................................................................................................................................... 16

Sewing with a twin needle (Option) ................................................................................................................ 18

REPLACING THE PRESSER FOOT ......................................................................................19

Replacing the presser foot ............................................................................................................................. 19

Removing the presser foot holder .................................................................................................................. 20

2. SEWING BASICS ...........................................................................................21

SEWING ............................................................................................................................21

General sewing procedure ............................................................................................................................. 21

Stitch width knob ............................................................................................................................................ 22

Stitch length knob ........................................................................................................................................... 22

Needle position selector ................................................................................................................................. 22

Starting to sew ............................................................................................................................................... 23

Sewing in reverse ........................................................................................................................................... 23

Thread tension ............................................................................................................................................... 24

USEFUL SEWING TIPS ......................................................................................................25

Trial sewing .................................................................................................................................................... 25

Changing the sewing direction ....................................................................................................................... 25

Sewing curves ................................................................................................................................................ 25

Sewing thick fabrics ....................................................................................................................................... 25

Sewing thin fabrics ......................................................................................................................................... 26

Sewing stretch fabrics .................................................................................................................................... 26

Using a free-arm style .................................................................................................................................... 26

3

Page 5

3. UTILITY STITCHES ........................................................................................27

USEFUL STITCHES ............................................................................................................27

Zigzag stitches ............................................................................................................................................... 27

Basic stitching ................................................................................................................................................ 27

Blind hem stitching ......................................................................................................................................... 28

Darning ........................................................................................................................................................... 29

Over edge stitch ............................................................................................................................................. 29

BUTTONHOLE SEWING/ BUTTON SEWING ...................................................................30

Buttonhole sewing .......................................................................................................................................... 30

Button sewing ................................................................................................................................................. 31

ZIPPER INSERTION ...........................................................................................................33

APPLIQUÉ, MONOGRAMMING AND EMBROIDERING .................................................34

Appliqués ....................................................................................................................................................... 34

Monogramming and embroidering ................................................................................................................. 34

DECORATIVE STITCHING ................................................................................................36

Gathering ....................................................................................................................................................... 36

Satin stitches .................................................................................................................................................. 36

Attaching the lace ........................................................................................................................................... 37

Cording ........................................................................................................................................................... 37

4. APPENDIX .....................................................................................................38

MAINTENANCE ................................................................................................................38

Precautions on storing the machine ............................................................................................................... 38

Oiling .............................................................................................................................................................. 38

Changing the bulb .......................................................................................................................................... 38

Cleaning the machine surface ........................................................................................................................ 39

Cleaning the shuttle race ............................................................................................................................... 39

Cleaning the feed dogs .................................................................................................................................. 40

Bobbin case tension adjustment .................................................................................................................... 41

TROUBLESHOOTING .......................................................................................................42

When the thread is entangled ........................................................................................................................ 45

INDEX ...............................................................................................................................46

4

Page 6

KNOWING YOUR SEWING MACHINE ————————————————————————————————————————

—

1 KNOWING YOUR SEWING MACHINE

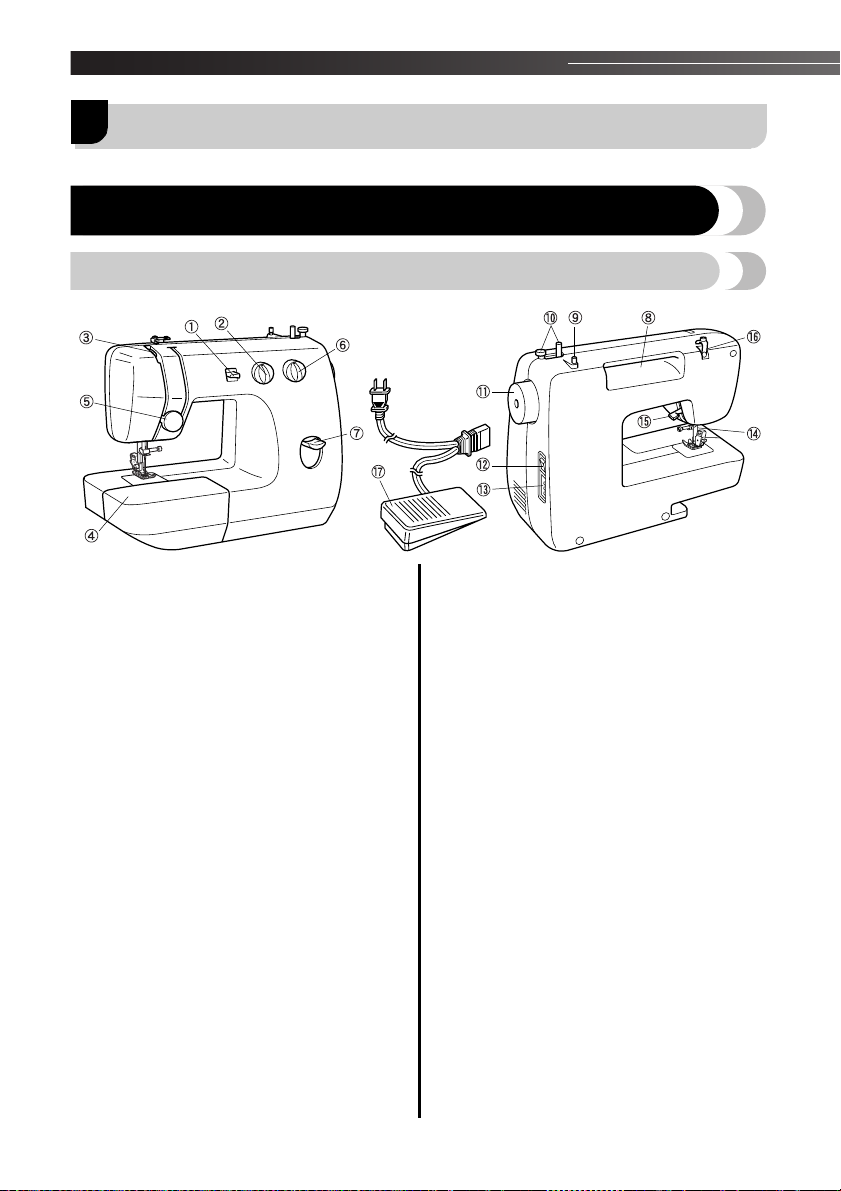

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

The main parts

a Needle position selector (page 22)

Shift this lever to select needle position.

b Stitch width knob (page 22)

Turn this knob to set the stitch width.

c Thread take-up lever (page 13)

d

Flat bed attachment with accessory storage (page 6 and 26)

e Upper tension control dial (page 24)

This controls the tension of the upper thread.

f Stitch length knob (page 22)

Turn this knob to set the stitch length.

g Reverse sewing lever (page 23)

Press and hold down the reverse sewing lever to sew in

the opposite direction.

5

h Built-in handle

i Spool pin (page 10 and 13)

The spool pin holds the spool of thread.

j Bobbin winder (page 10)

The bobbin winder winds thread onto the bobbin for

use as the lower thread.

k Handwheel

Use the handwheel to manually raise and lower the needle.

l Main power/sewing light switch (page 8)

Use this switch to turn on and off the main power and

sewing light.

m Foot controller jack

Insert the foot controller plug into the foot controller

jack, which also supplies power to this machine.

n Thread cutter (page 23)

Pass the threads through the thread cutter to cut them.

o

Presser foot lever (page 13)

Use the presser foot lever to raise and lower the presser foot.

p Bobbin winding pre-tension disc/thread guide (page 10

and 13)

The thread guide/bobbin winding pre-tension disc is

used when winding the thread onto the bobbin and

threading the machine.

q Foot controller (page 9)

Use the foot controller to control the sewing speed and

to start and stop sewing.

Foot Controller:

Model KD-1902 for 110-120V area

KD-1902 for 110-127V area (Brazil only)

Model KD-2902 for 220-240V area

The foot controller part code differs depending on the

country or region. Contact your dealer or the nearest

authorized service center.

Page 7

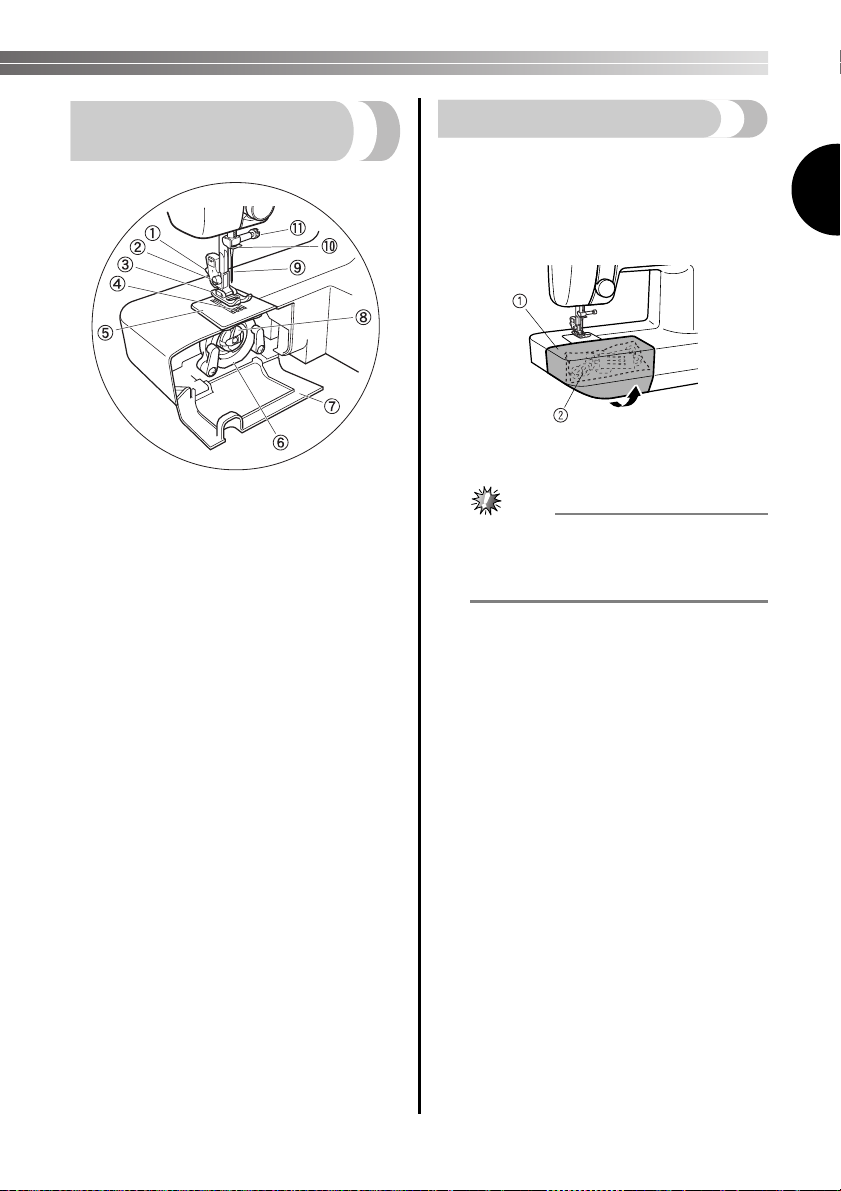

Needle and presser foot

Note

section

a Presser foot holder assembly

The presser foot is installed onto the presser foot holder

assembly.

b Presser foot screw

Use the presser foot screw to hold the presser foot

holder assembly in place.

c Presser foot (Zigzag)

The presser foot applies pressure consistently on the

fabric as the sewing takes place. Attach the appropriate

presser foot for the selected stitching.

d Feed dogs

The feed dogs feed the fabric in the sewing direction.

e Needle plate

The needle plate is marked with guides for sewing

straight seams.

f Shuttle hook

g Shuttle cover

Open the shuttle cover to set the bobbin.

h Bobbin case

i Needle

j Needle bar thread guide

k Needle clamp screw

Use the needle clamp screw to hold the needle in place.

Flat bed attachment

The accessories are stored in a compartment inside

the flat bed attachment.

Lift the bottom of the flat bed attachment

a

toward you, and then pull the flat bed

attachment out to remove it.

a Flat bed attachment

b Storage compartment

● Put the accessories in the bag, and then

store the bag inside the compartment. If the

accessories are not in a bag, they may fall

out, and be lost or damaged.

1

6

Page 8

KNOWING YOUR SEWING MACHINE ————————————————————————————————————————

—

Note

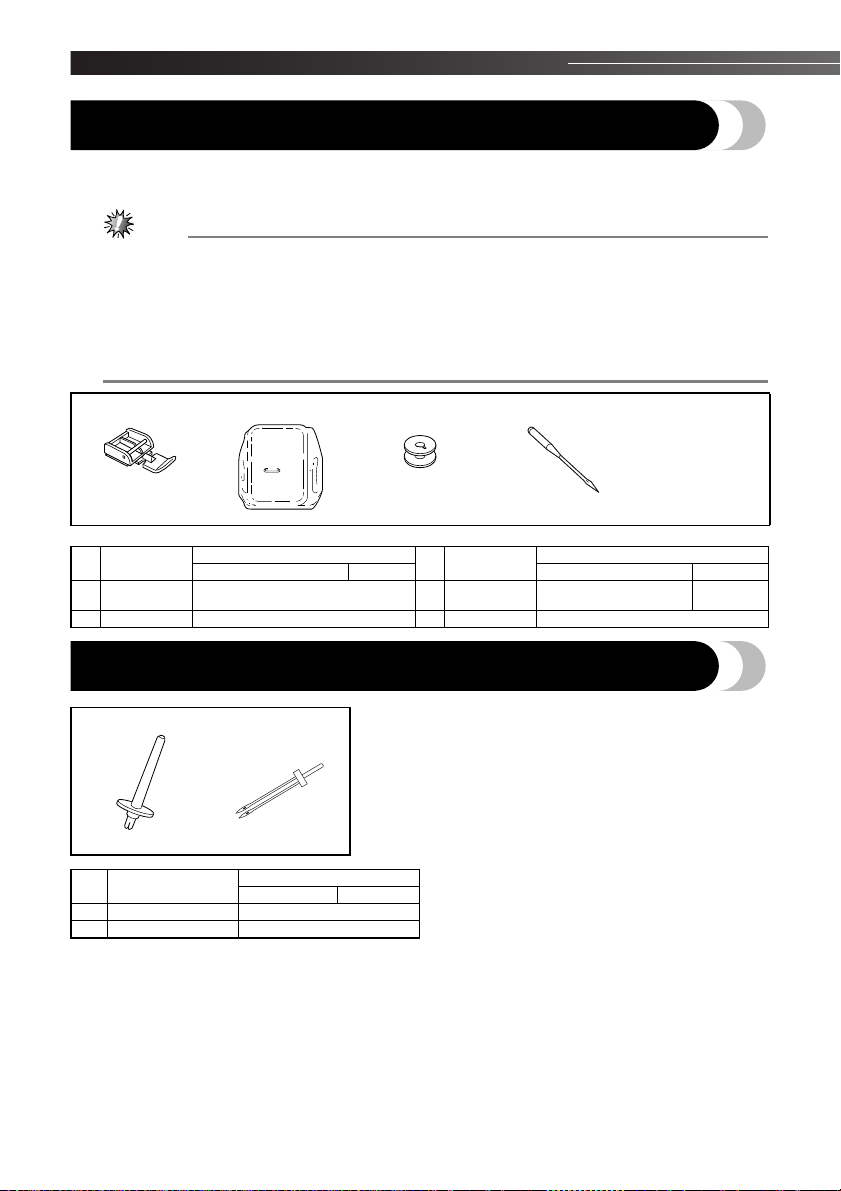

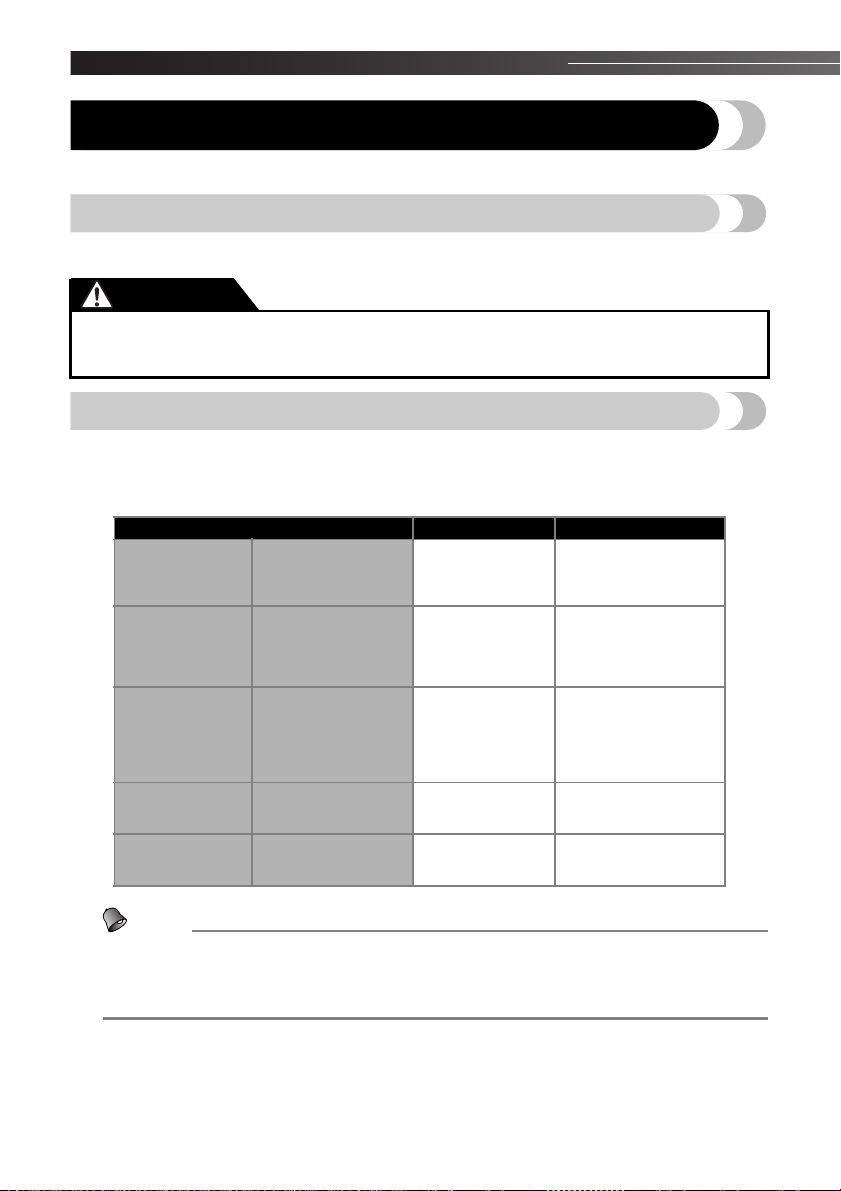

ACCESSORIES

The following accessories are stored in the flat bed attachment. We have designed these accessories to help you

be able to carry out most sewing tasks.

(For U.S.A. only)

● Foot controller: Model KD-1902

This foot controller can be used on the following machine models:

LS-2000/LS2250PRW/LS2300PRW/LS2350/LX2375.

● The screw of the presser foot holder is available through your authorized dealer. (Part code: 132730-122)

● A replacement for the factory-installed presser foot is available through your authorized dealer.

(Part number: 138135-122)

1. 2. 3. 4.

90/14 needle

No. Part Name

1 Zipper foot “I”

2 Darning plate XA3442-121 4 Needle set XE7064-001

X59370-021 (LS-2000/LS2250PRW)

Part Code

Americas Others Americas Others

XE9369-001 (Others)

No. Part Name

3 Bobbin

SABOBBIN (U.S.A. only)

Part Code

SA156 (Americas)

OPTIONAL ACCESSORIES

1. 2.

No. Part Name

1 Extra spool pin 130920-021

2 Twin needle 131096-121

Part Code

Americas Others

SFB:

XA5539-151

7

Page 9

USING YOUR SEWING MACHINE

WARNING

CAUTION

Power supply precautions

Be sure to observe the following precautions concerning the power supply.

● Use only regular household electricity for the power source. Using other power sources may result in

fire, electric shock, or damage to the machine.

● Make sure that the plugs on the power cord are firmly inserted into the electrical outlet and the power

supply jack on the machine. Otherwise, a fire or electric shock may result.

● Do not insert the plug on the power cord into an electrical outlet that is in poor condition.

● Turn off the main power and remove the plug in the following circumstances:

• When you are away from the machine

• After using the machine

• When the power fails during use

• When the machine does not operate correctly due to a bad connection or a disconnection

• During electrical storms

● Do not use extension cords or multi-plug adapters with many other appliances plugged in to them. Fire

or electric shock may result.

● Do not touch the plug with wet hands. Electric shock may result.

●

When unplugging the machine, always turn off the main power first. Always grasp the plug to remove it from

the outlet. Pulling on the cord may damage the cord, or lead to fire or electric shock.

● Do not allow the power cord to be cut, damaged, modified, forcefully bent, pulled, twisted, or bundled.

Do not place heavy objects on the cord. Do not subject the cord to heat. These things may damage the

cord and cause fire or electric shock. If the cord or plug is damaged, take the machine to your

authorized dealer for repairs before continuing use.

● Unplug the power cord if the machine is not to be used for a long period of time. Otherwise a fire may

result.

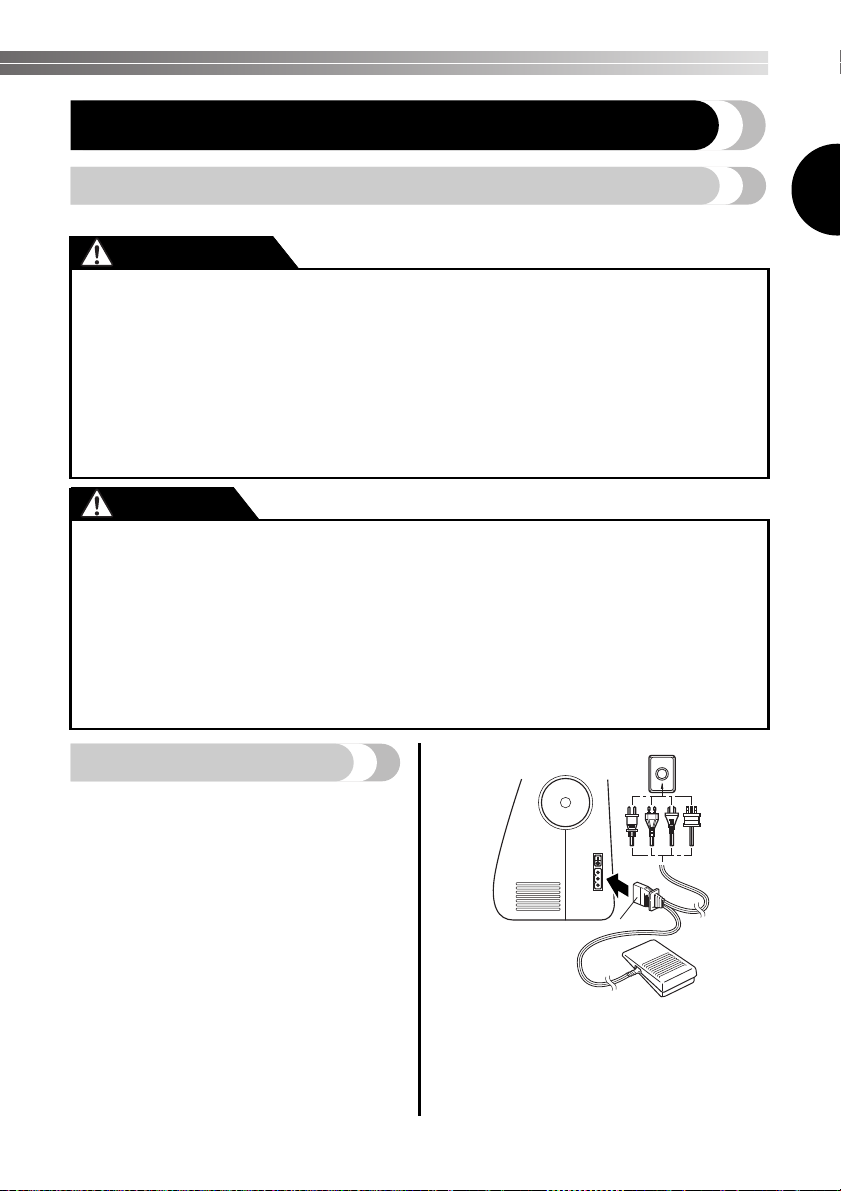

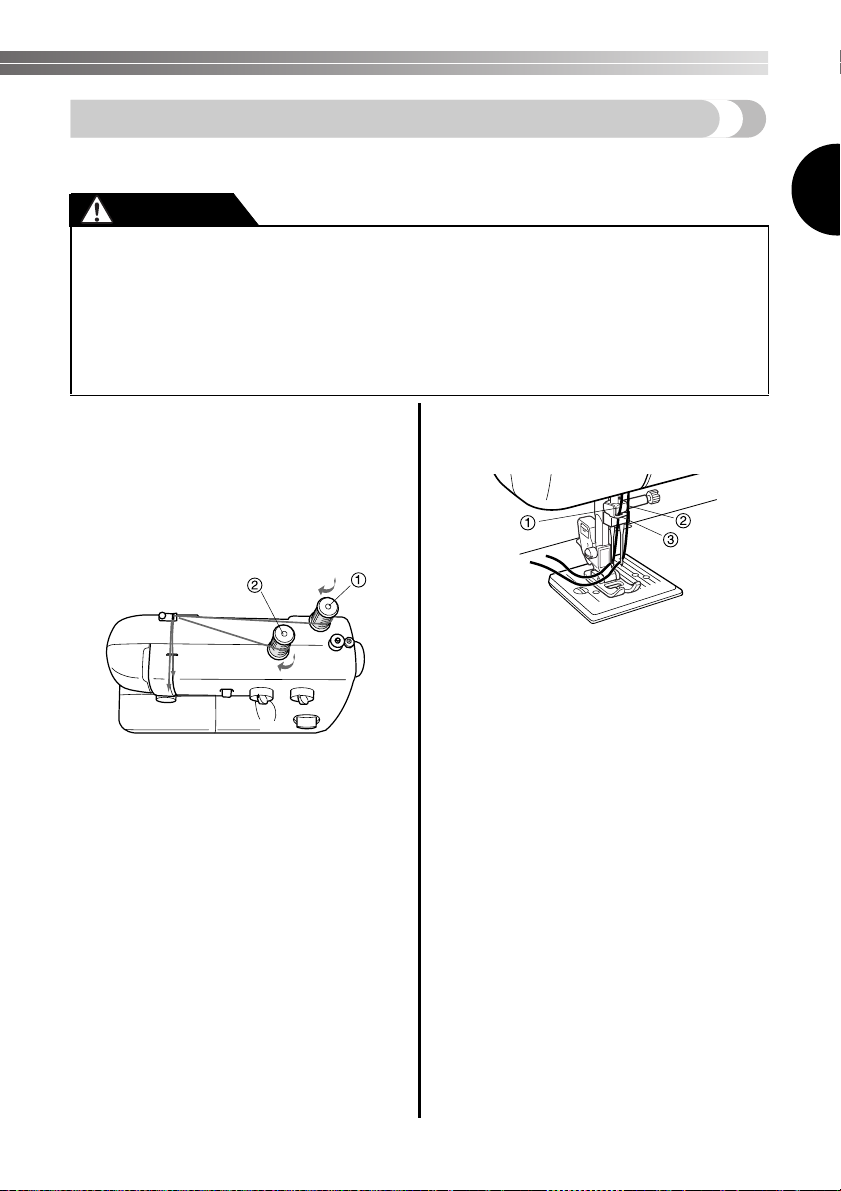

Power supply

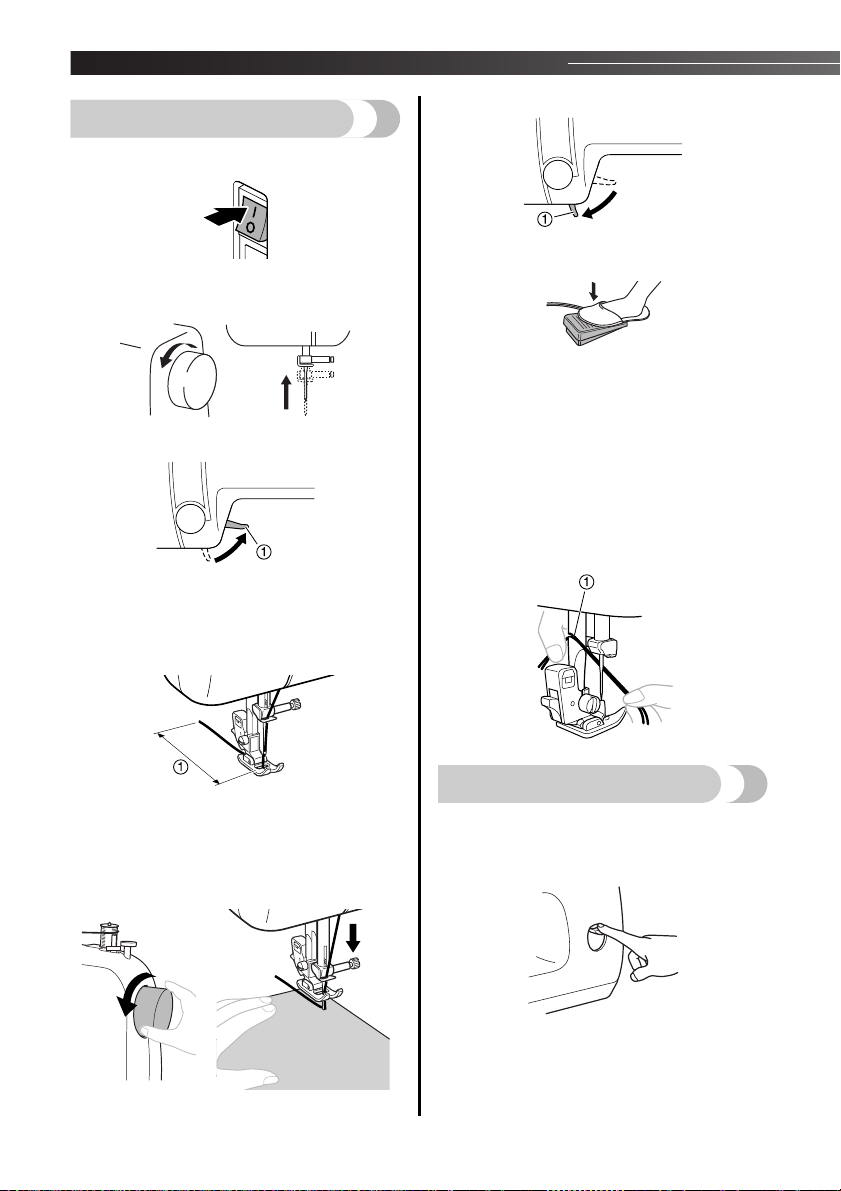

1

Insert the foot controller plug, located

a

between the foot controller and the power

supply plug on the cord, into the jack on the

machine. Then, insert the power supply plug

into a wall outlet.

1

a Foot controller plug

8

Page 10

KNOWING YOUR SEWING MACHINE ————————————————————————————————————————

—

Note

CAUTION

Slower

Faster

CAUTION

Set the main power switch to “I”.

b

X The sewing lamp comes on when the

machine is turned on.

To turn off the machine, set the main power

c

switch to “

{”.

X The sewing lamp goes off when the

machine is turned off.

● If a power outage occurs while the sewing

machine is being operated, turn off the

sewing machine and unplug the power

supply cord. When restarting the sewing

machine, follow the necessary procedure to

correctly operate the machine.

(For U.S.A. only)

● This appliance has a polarized plug (one

blade wider than the other). To reduce the

risk of electric shock, this plug is intended

to fit in a polarized outlet only one way. If

the plug does not fit fully in the outlet,

reverse the plug.

If it still does not fit, contact a qualified

electrician to install the proper outlet. Do

not modify the plug in any way.

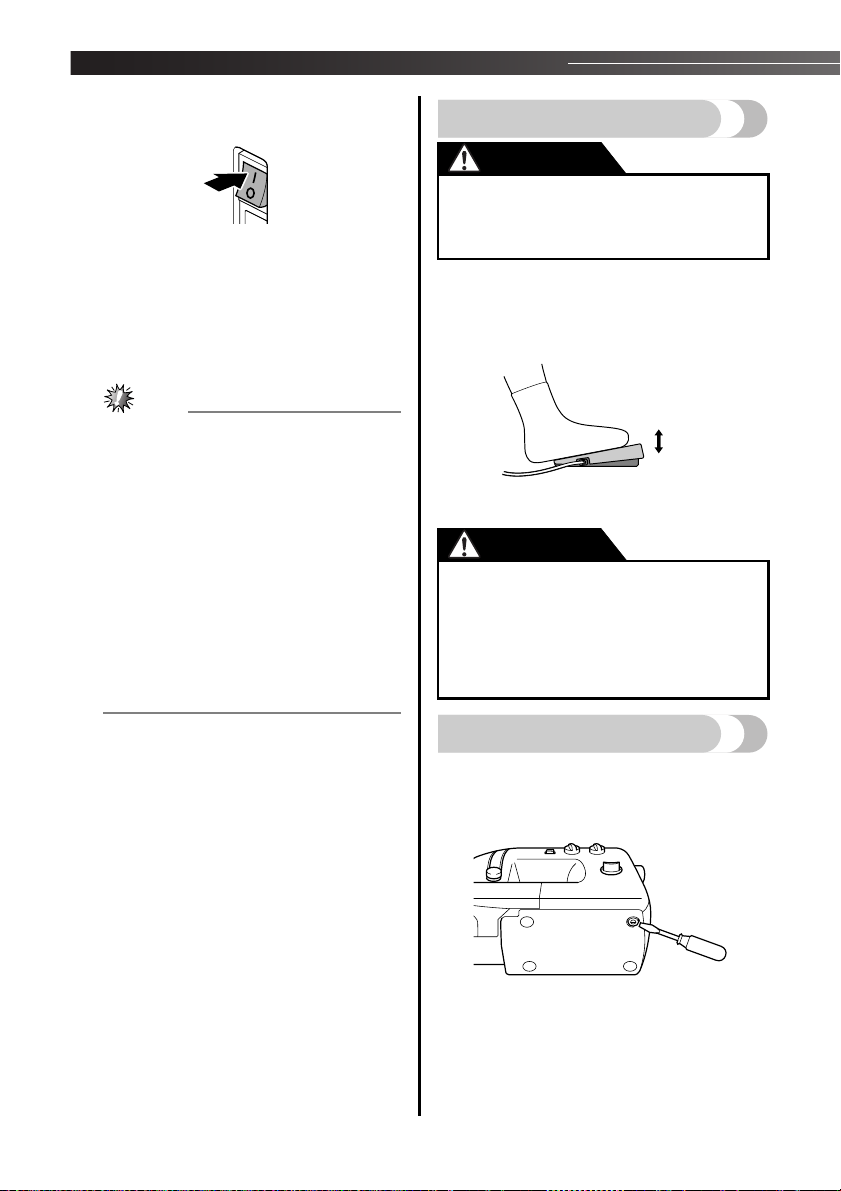

Foot controller

● When connecting the foot controller, be sure

to turn off the sewing machine in order to

prevent the machine from accidentally being

started.

When you press the foot controller down lightly, the

machine will run at a low speed. When you press

harder, the machine’s speed will increase. When you

take your foot off the foot controller, the machine

will stop.

You should make sure that nothing is placed on the

foot controller when the machine is not in use.

● Do not allow pieces of cloth and dust to build

up on the foot controller. Doing so could

cause a fire or an electric shock.

● A new sewing machine or one that has not

been in use for a long period of time should

be oiled as described on page 38. After oiling,

be sure to wipe off any excess oil.

9

Steadying the machine

If the sewing machine has been placed on an uneven

surface, turn the rubber cushion in the right-front

corner of the base plate to adjust its height until the

sewing machine is stable.

Page 11

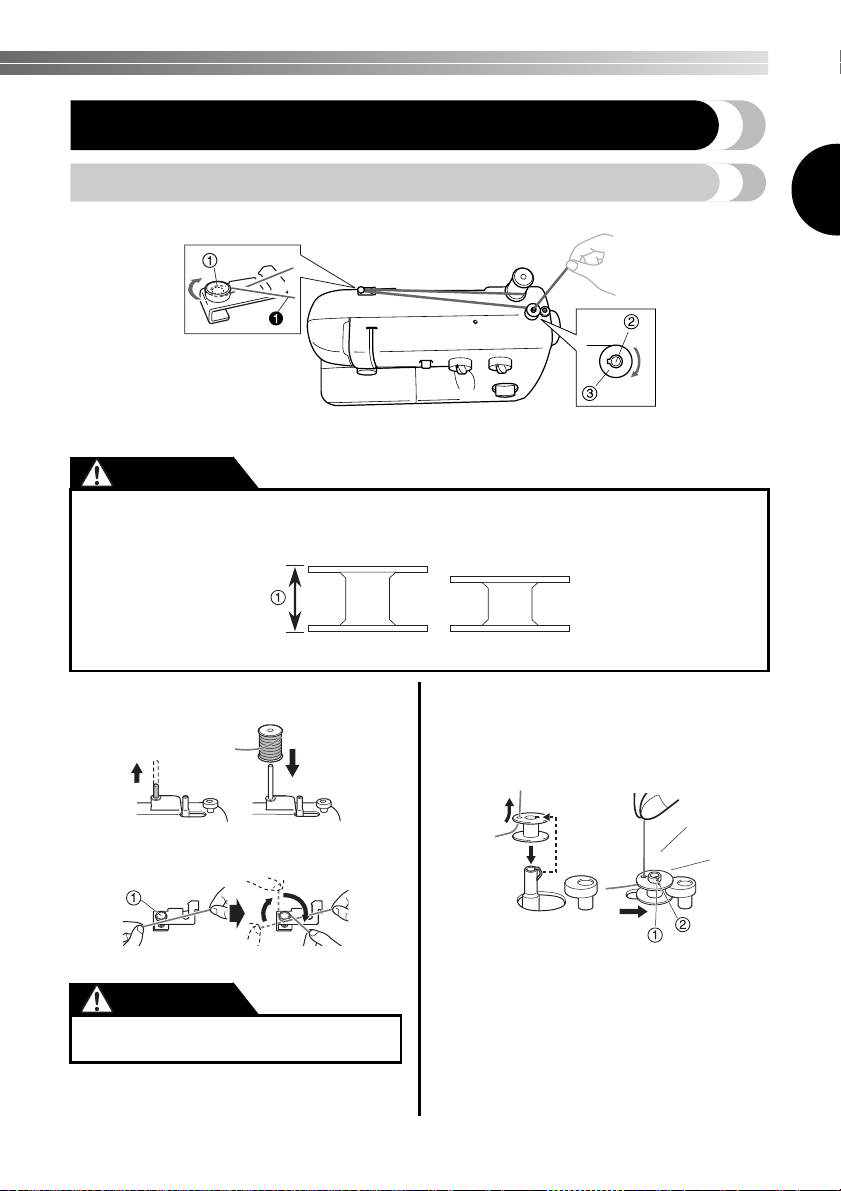

THREADING THE MACHINE

1 Pulling it in as

far as possible.

CAUTION

Actual size

This model Other models

CAUTION

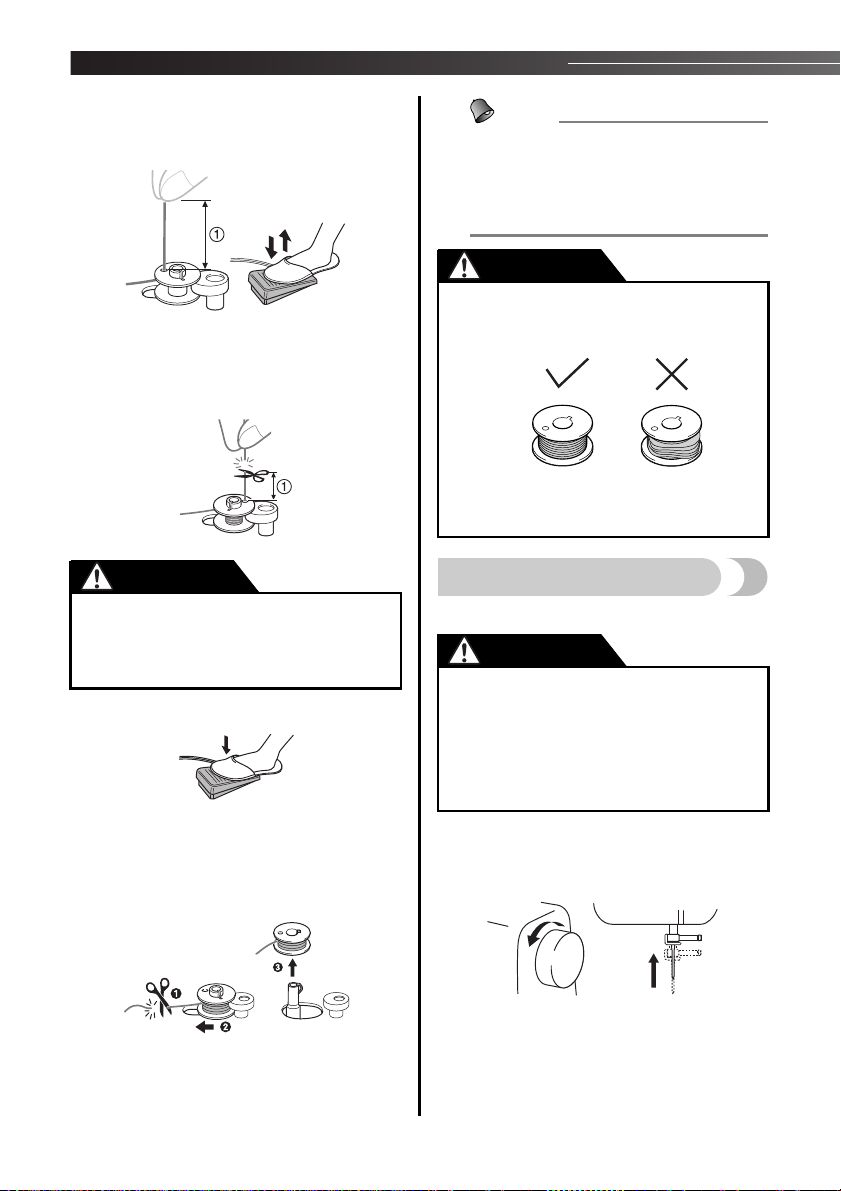

Winding the bobbin

This section describes how to wind the thread onto the bobbin.

a Pre-tension disk

b Bobbin winder shaft

c Bobbin

● We designed the bobbin that comes with this machine. If you use bobbins from other models, the

machine will not work properly. Only use the bobbin that comes with this machine or bobbins of the

same type (part code: SA156, SABOBBIN, SFB: XA5539-151).

a 11.5 mm (7/16 inches)

Pull up the spool pin as far as possible, and

a

then put a spool of thread on this pin.

Put the bobbin onto the bobbin winder shaft and

d

slide the bobbin winder shaft to the right. Turn

the bobbin clockwise, by hand, until the spring

on the shaft slides into the groove of the bobbin.

• Align the notch on bobbin to the spring on

the shaft.

1

Pass the thread around the pre-tension disk.

b

a Pre-tension disk

● If the spool of thread is not in the right place,

the thread may tangle on the spool pin.

Pass the end of the thread through the hole on

c

the bobbin from the inside of the bobbin.

a Spring on the shaft

b Groove of the bobbin

Turn on the sewing machine.

e

Click!

10

Page 12

KNOWING YOUR SEWING MACHINE ————————————————————————————————————————

—

Memo

CAUTION

CAUTION

1

2

CAUTION

While holding the end of the thread, gently press

f

the foot controller to wind the thread around the

bobbin a few times. Then stop the machine.

a 7-10 cm (3-4 inches)

Trim the excess thread above the bobbin.

g

• Leave 1 cm (1/2 inch) of thread from the

hole on the bobbin.

a 1 cm (1/2 inch)

●

When the sewing machine is started or the

handwheel is turned after winding the thread

around the bobbin, the machine will make a

clicking sound; this is not a malfunction.

● The needle bar does not move when you

slide the bobbin winding shaft to the right.

● Winding the bobbin improperly may cause

the thread tension to loosen, breaking the

needle and resulting in injury.

a Wound evenly

b Wound poorly

Lower threading

● Make sure you follow the instructions

carefully. If you do not cut the thread

completely, and the bobbin is wound, when

the thread runs low it may tangle around the

bobbin and cause the needle to break.

Press the foot controller to start.

h

When the bobbin seems full and begins

i

spinning slowly, take your foot off the foot

controller.

Cut the thread, slide the bobbin winder shaft

j

to the left and remove the bobbin.

Install the bobbin wound with thread.

● Make sure you turn the power off while

threading the machine. If you accidentally

step on the foot controller and the machine

starts to sew, you could be injured.

● -“ Moving parts - To reduce the risk of injury.

Disconnect from supply circuit before

servicing. Remove cover.”

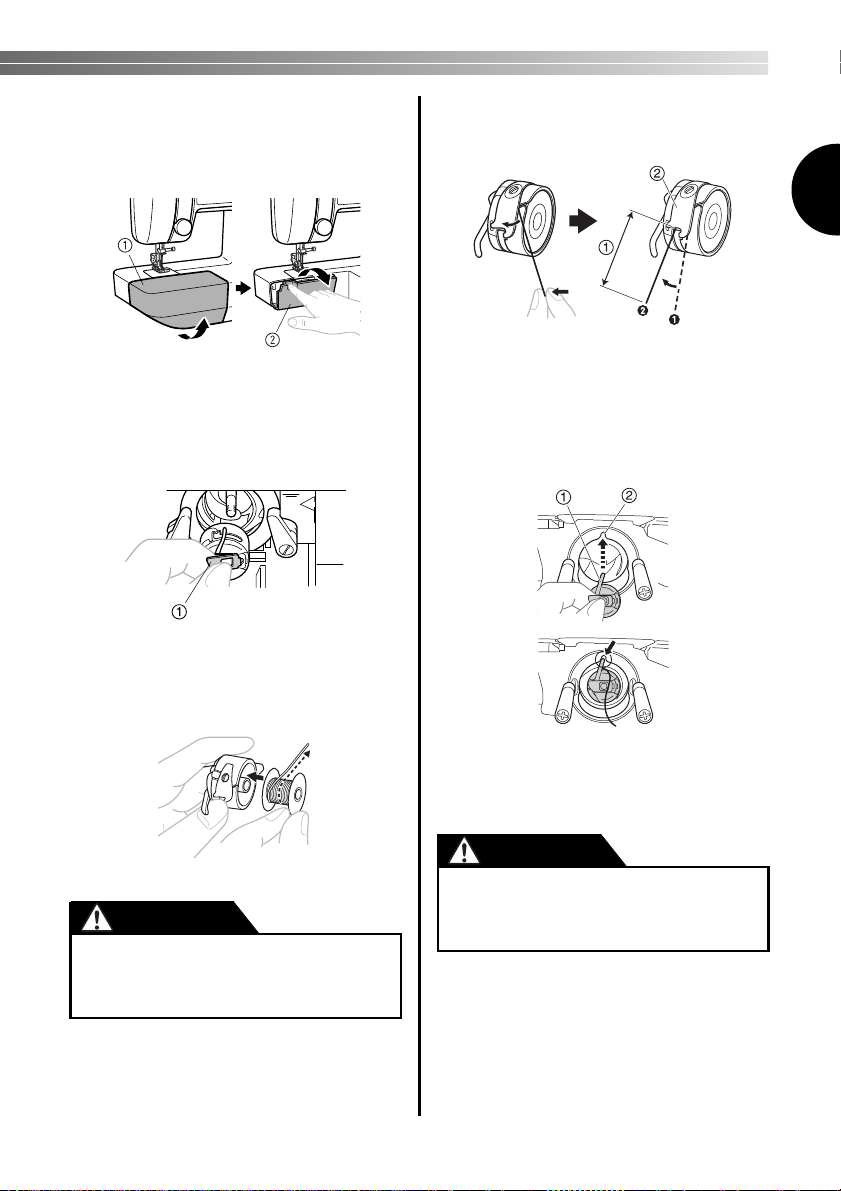

Raise the needle to its highest position by turning

a

the handwheel toward you (counterclockwise)

and raise the presser foot lever.

11

Page 13

Turn off the sewing machine.

CAUTION

CAUTION

b

Open the shuttle cover behind the flat bed

c

attachment at the front of the machine.

a Flat bed attachment

b Shuttle cover

Remove the bobbin case by pulling its latch

d

toward you and pulling it out from the shuttle

race.

a Bobbin case latch

Unwind about 5 cm (2 inches) of thread from

e

a full bobbin, and then insert the bobbin into

the bobbin case.

Pull the trailing thread through the slot, down

f

and to the left, as shown below, until it enters

the delivery eye under the tension spring.

a Tension spring

b 5 cm (2 inches)

Hold the bobbin case by the latch, fully insert

g

the bobbin case into the shuttle race, and then

release the latch.

• Make sure the bobbin case finger fits into the

notch at the top of the shuttle race.

1

• Only use bobbins that were designed to be

used with this machine.

● Make sure you set the bobbin so the thread

unrolls in the right direction. If the thread unrolls

in the wrong direction, it may cause the thread

tension to be incorrect or break the needle.

a Bobbin case finger

b Notch

Close the shuttle cover.

h

● Make sure that the bobbin case is properly

placed back into the machine. If it is incorrectly

installed, it will fall out from the shuttle when the

machine starts to sew.

12

Page 14

KNOWING YOUR SEWING MACHINE ————————————————————————————————————————

—

CAUTION

CAUTION

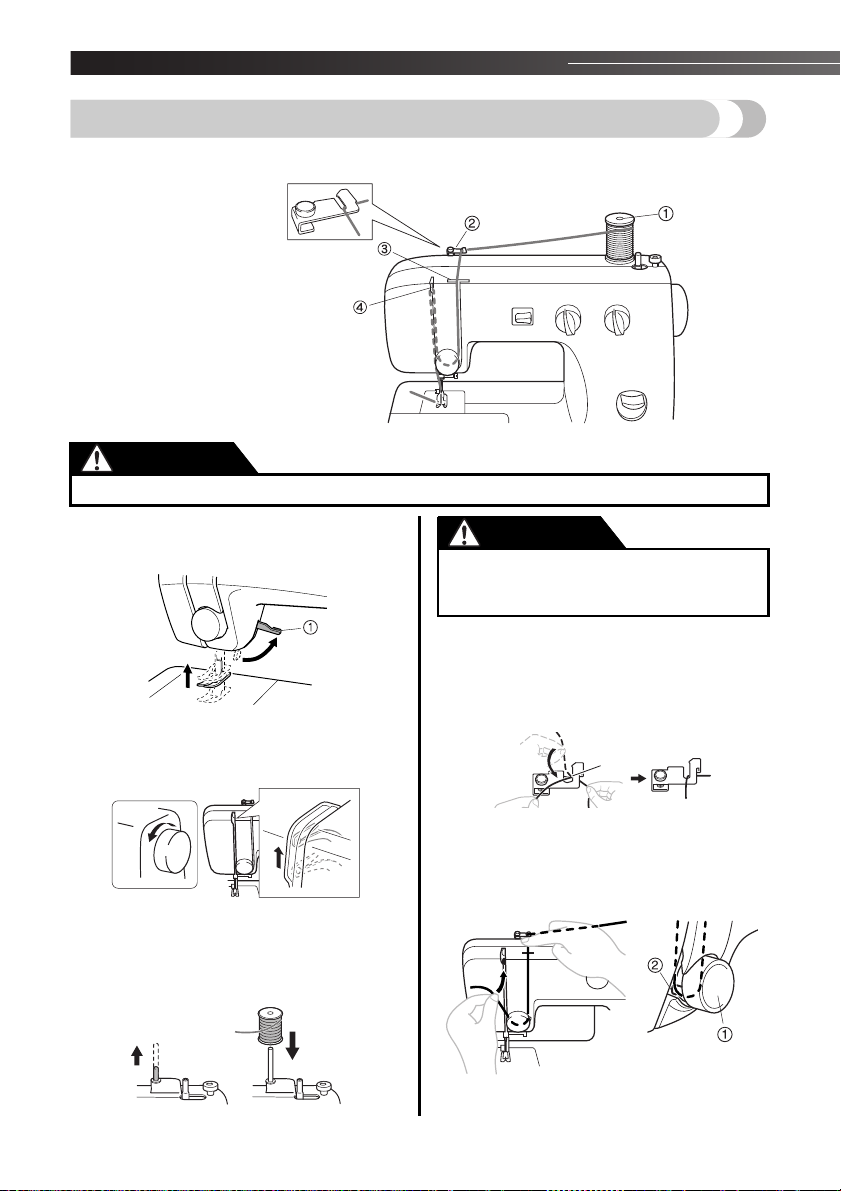

Upper threading

Set the upper thread and thread the needle.

a Spool pin

b Thread guide (rear)

c Thread guide (front)

d Thread take-up lever

● Make sure you thread the machine properly. Otherwise, the thread could tangle and break the needle.

Turn off the sewing machine.

a

Raise the presser foot using the presser foot lever.

b

a Presser foot lever

Raise the needle by turning the handwheel

c

toward you (counterclockwise) to raise the

thread take-up lever to its highest position.

● If the spool of thread is in the wrong place, or

is set incorrectly, the thread may tangle on

the spool pin and cause the needle to break.

While holding the thread from the spool with

e

your right hand, pass the thread toward you,

in the groove on the thread guide.

• Make sure that the spring in the groove

catches the thread

1

• If the needle is not correctly raised, the sewing

Pull up the spool pin as far as possible, and

d

then put a spool of thread on this pin.

13

machine can not be threaded. Be sure to turn the

handwheel before threading the sewing machine.

a Spring

Pull the thread down and around the upper

f

tension control dial from the right to the left so

the thread picks up the thread check spring.

a Upper tension control dial

b Thread check spring

Page 15

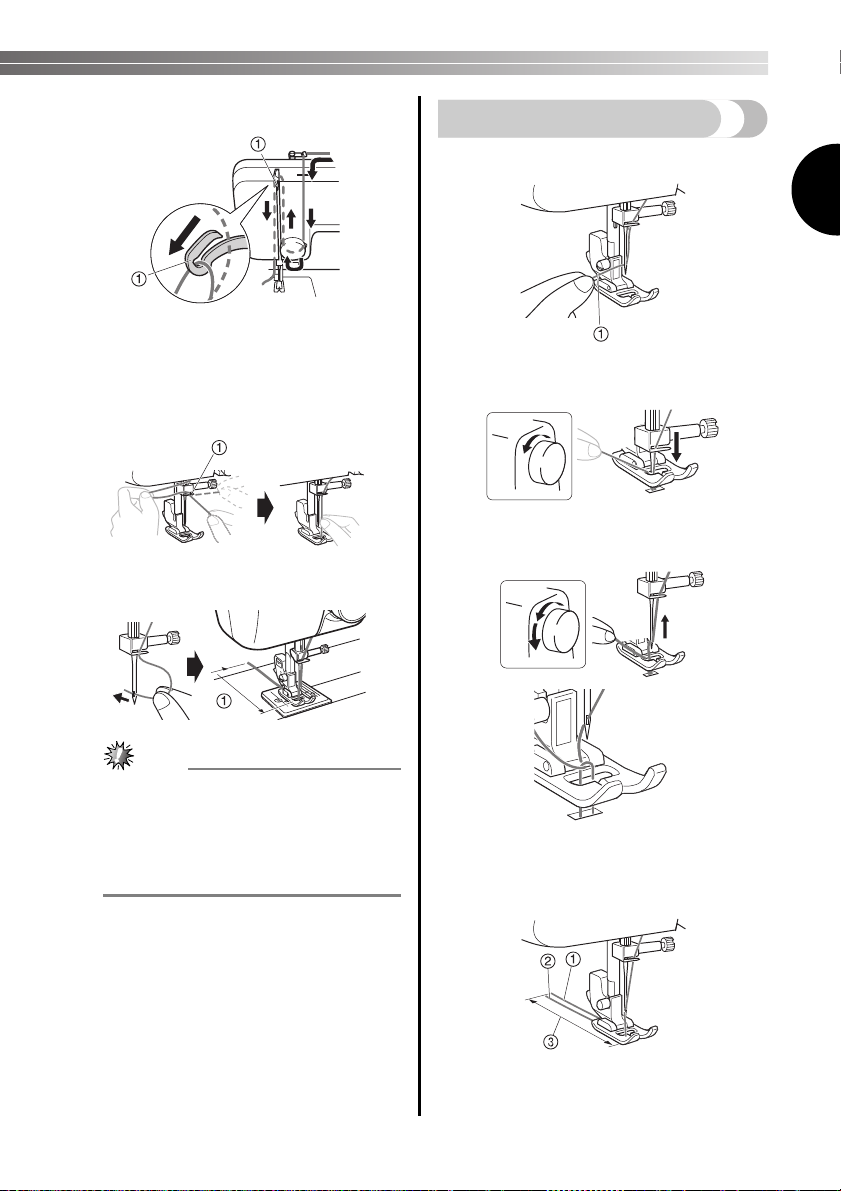

Guide the thread through the thread take-up

Note

g

lever from right to left.

a Thread take-up lever

Put the thread behind the needle bar thread

h

guide above the needle.

The thread can easily be passed behind the

needle bar thread guide by holding the thread

in your left hand, then feeding the thread with

your right hand.

a Needle bar thread guide

Thread the needle from front to back and pull

i

out about 5 cm (2 inches) of thread.

Drawing up the lower thread

Lightly hold the end of the upper thread.

a

a Upper thread

Turn the handwheel toward you

b

(counterclockwise) to lower the needle.

Turn the handwheel toward you

c

(counterclockwise) to raise the needle, pulling on

the upper thread to draw up the lower thread.

1

a 5 cm (2 inches)

● If the thread take-up lever is lowered, the

upper thread cannot be wrapped around the

thread take-up lever. Make sure you raise

the presser foot lever and the thread take-up

lever before you feed the upper thread.

● If you incorrectly feed the thread you may

cause sewing problems.

• Pull thread loop to finish threading process.

Pull out about 5 cm (2 inches) of both threads

d

and pull them toward the back of the machine

under the presser foot.

a Upper thread

b Lower thread

c 5cm (2 inches)

14

Page 16

KNOWING YOUR SEWING MACHINE ————————————————————————————————————————

—

Memo

CAUTION

REPLACING THE NEEDLE

This section provides information on sewing machine needles.

Needle precautions

Be sure to observe the following precautions concerning the handling of the needle. Failure to observe these

precautions is extremely dangerous. Be sure to read and carefully follow the instructions below.

● Only use home sewing machine needles. Use of any other needle may bend the needle or damage the

machine.

● Never use bent needles. Bent needles can easily break, possibly resulting in injury.

Selecting the needle depending on the thread and fabric types

The sewing machine needle that should be used depends on the fabric and thread thickness. Refer to the

following table when choosing the thread and needle appropriate for the fabric that you wish to sew.

Use the same size thread for the upper (spool) and lower (bobbin) threads.

Sewing fabrics Needle sizes Thread sizes

Cotton: 80

Synthetic/ Polyester Long

Fiber

Fine Mercerized Cotton

Cotton: 60-80

Silk: “A”

Synthetic/ Polyester Long

Fiber

Mercerized 50

Cotton: 50-60

Silk: “A”

Synthetic/ Polyester Long

Fiber

Mercerized 50-60

Cotton: 40-50

Mercerized Heavy Duty

Polyester Long Fiber

Cotton Wrapped

Polyester

Polyester Long Fiber

Very thin

Lightweight

Medium weight

Heavyweight

Knits

Fine tricot, Fine lace,

Thin linen, Silk,

Organza, Chiffon

Voile, Taffeta,

Synthetics, Silk, Batiste

Cotton, Gingham,

Poplin, Percale, Pique,

Satin, Velvet,

Lightweight wool,

Fine corduroy, Suitings,

Linen, Muslin

Denim, Gabardine,

Tweed, Corduroy,

Canvas, Duck

Single knit, Double knit,

Jersey, Tricot

65/9

75/11

90/14 (Supplied with

your machine.)

100/16

90/14 (Ball point)

● The smaller the thread number, the thicker the thread; and the larger the needle number, the thicker the

● Use the ball point needle when sewing on stretch fabrics or fabrics where skipped stitches easily occur.

● Use a 90/14 to 100/16 needle with transparent nylon threads, regardless of the fabric being sewn.

15

needle.

Page 17

● The appropriate fabric, thread and needle

CAUTION

1

2

1

1

CAUTION

combinations are shown in the table on the

previous page. If the combination of the

fabric, thread and needle is not correct,

particularly when sewing thick fabrics (such

as denim) with thin needles (such as 65/9 to

75/11), the needle may bend or break. In

addition, the stitching may be uneven or

puckered or there may be skipped stitches.

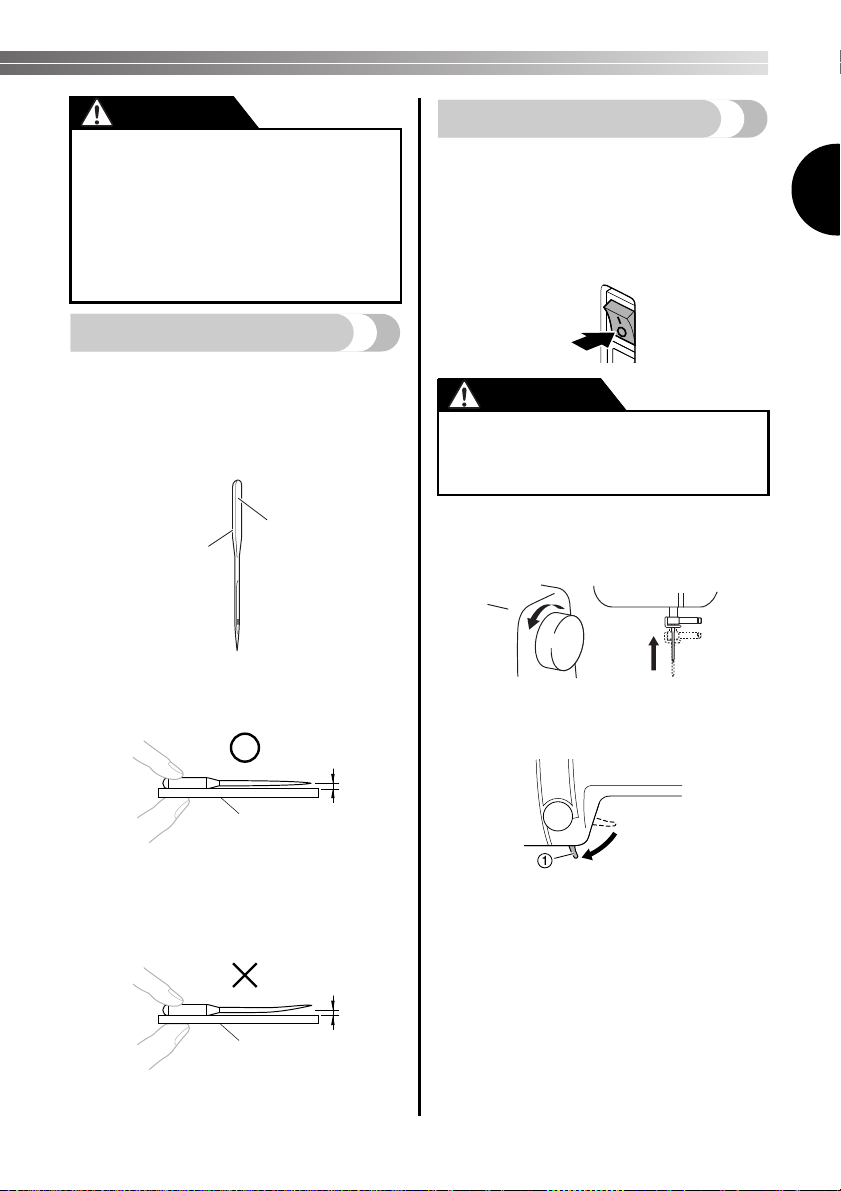

Checking the needle

Sewing with a bent needle is extremely dangerous

since the needle may break while the machine is

being operated.

Before using the needle, place the flat side of the

needle on a flat surface and check that the distance

between the needle and the flat surface is even.

a Flat side

b Needle type marking

■ Correct needle

Replacing the needle

Replace the needle as described below. Use a coin

and a needle that has been determined to be straight

according to the instructions in “Checking the

needle” .

Turn off the sewing machine.

a

● Before replacing the needle, be sure to turn

off the sewing machine, otherwise injuries

may occur if the foot controller is accidentally

pressed and the machine starts sewing.

Raise the needle to its highest position by

b

turning the handwheel toward you

(counterclockwise).

Lower the presser foot lever.

c

1

a Flat surface

■ Incorrect needle

If the distance between the needle and the flat

surface is not even, the needle is bent. Do not use

a bent needle.

a Flat surface

a Presser foot lever

16

Page 18

KNOWING YOUR SEWING MACHINE ————————————————————————————————————————

—

Note

CAUTION

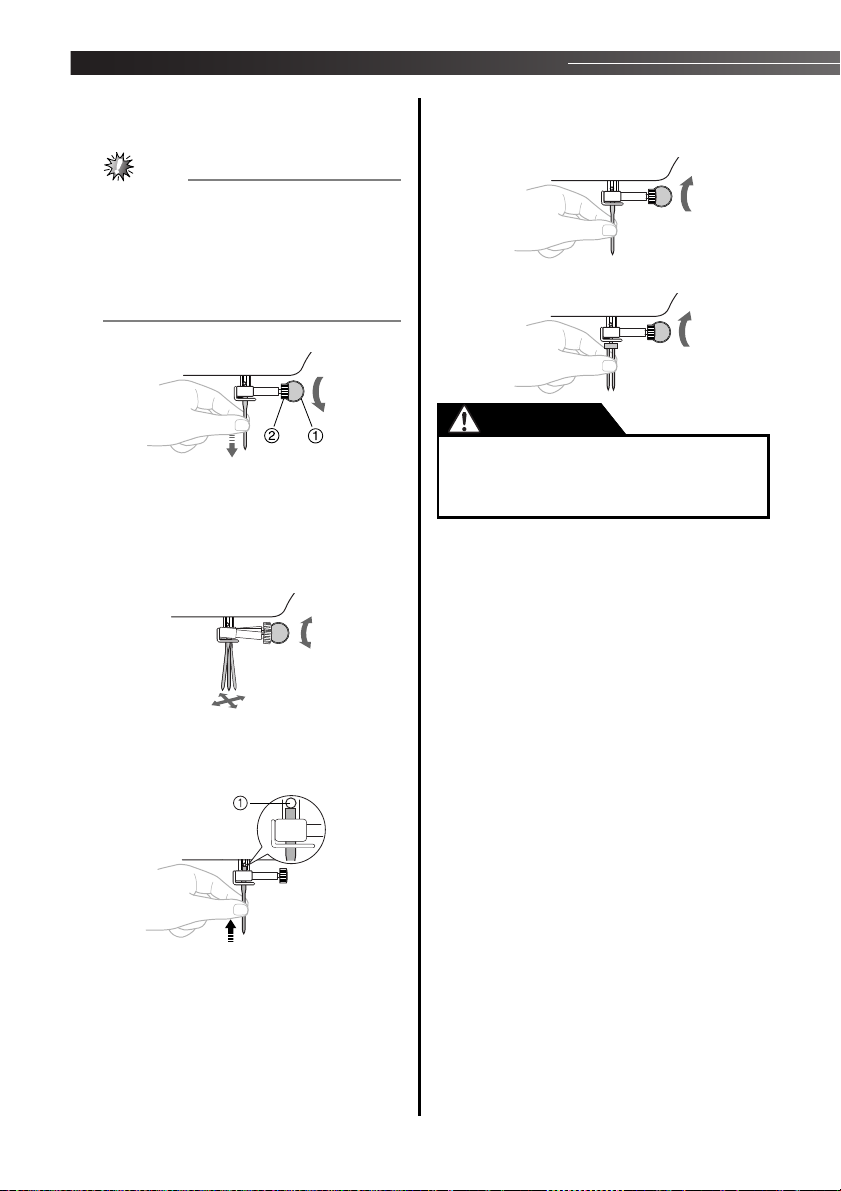

Hold the needle with your left hand, and then

d

use a coin to turn the needle clamp screw

counterclockwise to remove the needle.

● The needle can be removed by simply

loosening the needle clamp screw about

one turn. (If the needle clamp screw is

loosened too much, the needle clamp

(which holds the needle) may fall off.

Therefore, do not loosen the needle clamp

screw too much.)

a Coin

b Needle clamp screw

• Do not apply strong force when loosening or

tightening the needle clamp screw,

otherwise certain parts of the sewing

machine may be damaged.

While holding the needle with your left hand,

f

use the coin to tighten the needle clamp screw

by turning it clockwise.

Install the twin needle in the same way.

● Be sure to insert the needle until it touches

the needle stopper and securely tighten the

needle clamp screw with a coin, otherwise

the needle may break or damage may result.

With the flat side of the needle toward the

e

rear of the machine, insert the needle until it

touches the needle stopper.

a Needle stopper

17

Page 19

Sewing with a twin needle (Option)

CAUTION

We have designed your machine so you can sew with the optional twin needle and two top threads. You can

use the same color or two different colors of thread for making decorative stitches.

● Use only twin needles that have been made for this machine (part code: 131096-121). Other needles

could break, and damage the machine.

● Do not sew with bent needles. The needle could break and injure you.

● Use the zigzag presser foot.

● Use a setting of less than 3 on the stitch width knob.

● Set the needle position selector to M.

● Slowly turn the handwheel toward you (counterclockwise) and check that the needle does not touch the

presser foot. If the needle hits the presser foot, the needle may bend or break.

● When changing the sewing direction, be sure to raise the needle before turning the fabric. If the fabric is

turned while the needle is lowered, the needle may bend or break.

■ Twin needle threading

Attach the twin needle.

a

Attach the twin needle in the same way as a

single needle (page 16).

Attach the optional extra spool pin.

b

Put the extra spool pin in the hole on the top of

the machine. Put the second spool of thread

onto the extra spool pin.

Thread the right needle from front to back.

f

Do not pass the thread behind the needle bar

thread guide.

a Left needle thread passes through the needle bar

thread guide.

b Right needle thread passes in front of the needle

bar thread guide.

c Needle bar thread guide

1

a First spool

b Second spool

Use the thread from the first spool to thread

c

the machine to the needle bar thread guide.

The path for threading the machine to the

needle bar thread guide is the same as for

normally threading the machine (for a single

needle). See page 13 for more details.

Thread the left needle from front to back.

d

Use the thread from the second spool to thread

e

the machine to the thread take-up lever.

The path for threading the machine to the

thread take-up lever is the same as for normally

threading the machine (for a single needle).

See page 13 for more details.

18

Page 20

KNOWING YOUR SEWING MACHINE ————————————————————————————————————————

—

CAUTION

CAUTION

REPLACING THE PRESSER FOOT

● Always turn off the power before you change the presser foot. If you leave the power on and step on the

controller, the machine will start and you may be injured.

● Always use the correct presser foot for the stitch pattern you have chosen. If you use the wrong presser

foot, the needle may strike the presser foot and bend or break, and may cause injury.

● Only use presser feet that have been designed to be used with this machine. Using other any presser feet

may cause an accident or injury.

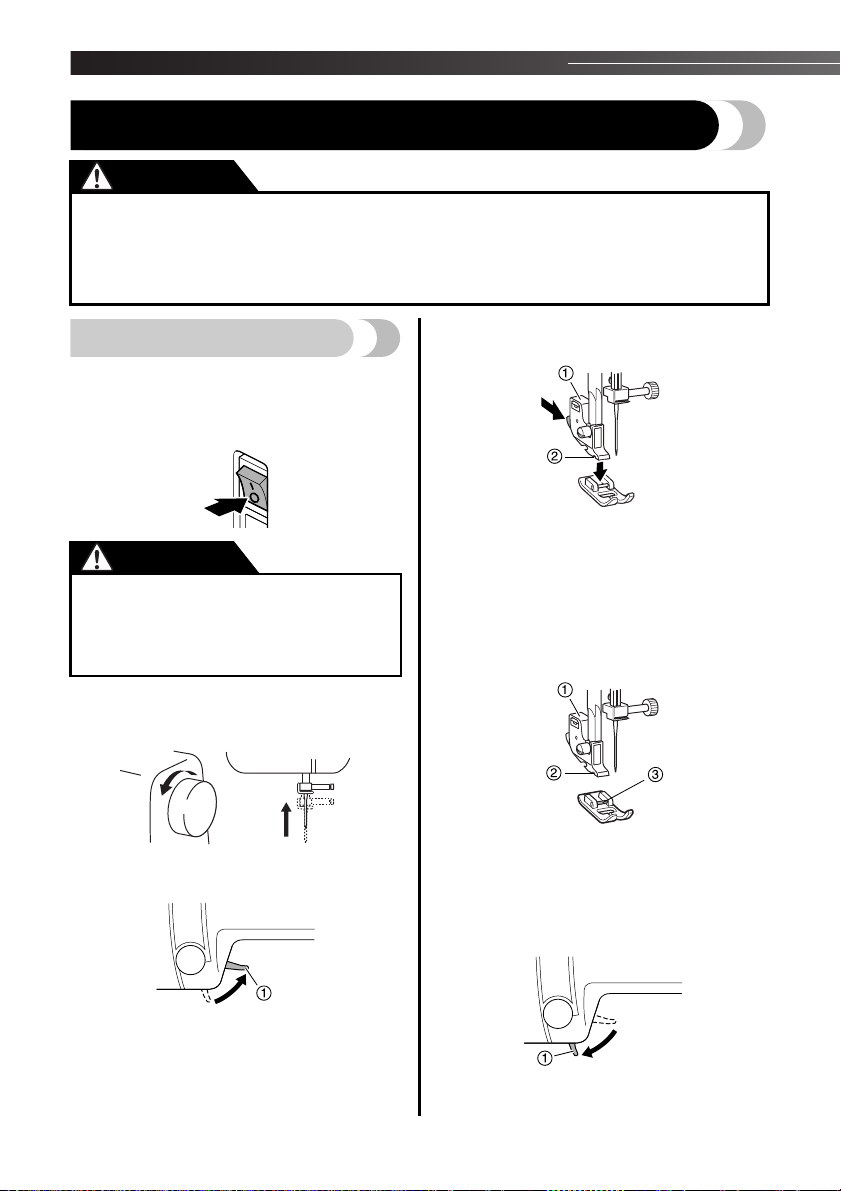

Press the black button at the back of the

d

Replacing the presser foot

Replace the presser foot as described below.

If the sewing machine has been turned on,

a

turn it off.

● Before replacing the presser foot, be sure to

turn off the sewing machine, otherwise

injuries may occur if the foot controller is

accidentally pressed and the machine starts

sewing.

Raise the needle to its highest position by

b

turning the handwheel toward you

(counterclockwise).

presser foot holder to release the presser foot.

a Black button

b Presser foot holder

Place a different presser foot below the holder

e

so that the presser foot pin is aligned with the

shank in the holder.

Position the presser foot so the letter indicating

the presser foot type (A, I, etc.) is positioned to

be read.

Raise the presser foot lever.

c

a Presser foot lever

19

a Presser foot holder

b Shank

c Pin

Slowly lower the presser foot lever so that the

f

presser foot pin snaps into the shank in the

presser foot holder.

a Presser foot lever

X The presser foot is attached.

Page 21

Raise the presser foot lever to check that the

Note

g

presser foot is securely attached.

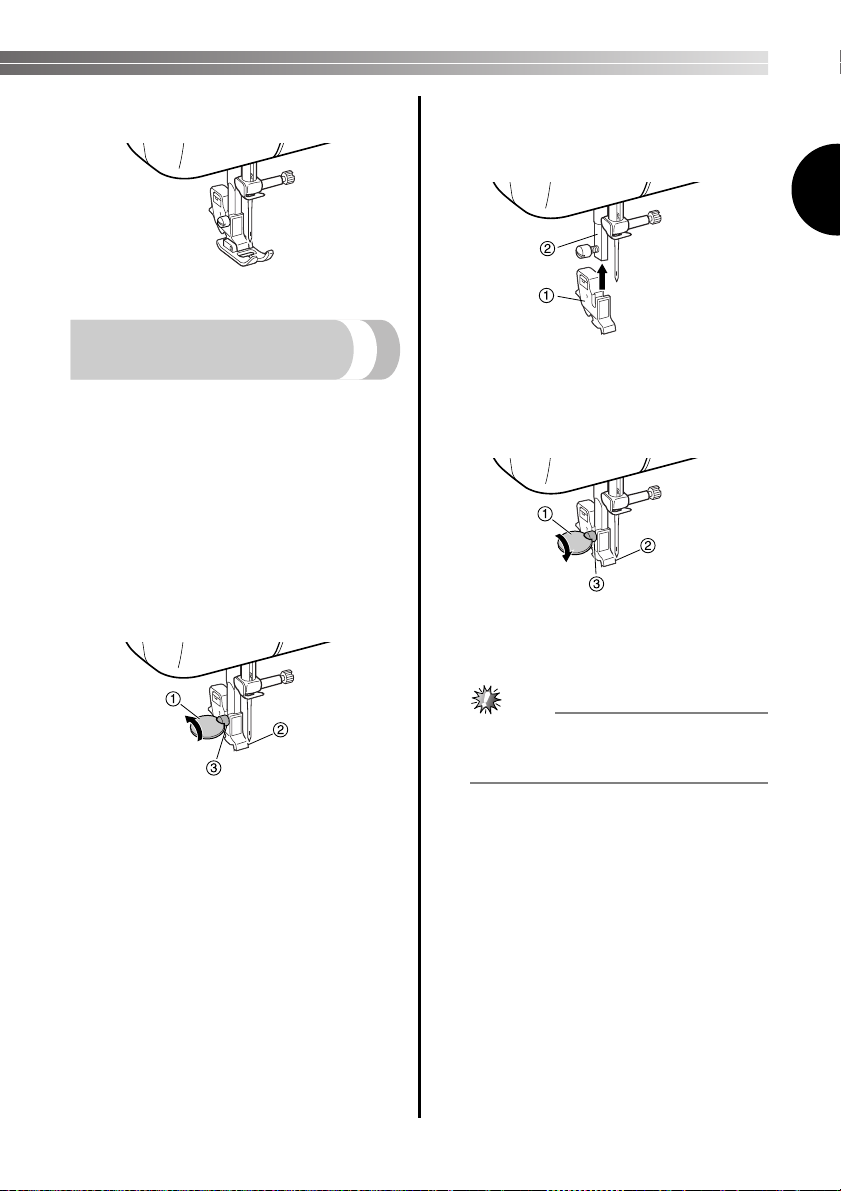

■ Attaching the presser foot holder

Align the presser foot holder with the lower-

a

left side of the presser bar.

1

Removing the presser foot

holder

Remove the presser foot holder when cleaning the

sewing machine or when installing a presser foot that

does not use the presser foot holder. Use a coin to

remove the presser foot holder.

■ Removing the presser foot holder

Remove the presser foot.

a

• For details, refer to “Replacing the presser

foot” (page 19).

Use a coin to loosen the presser foot holder

b

screw.

a Coin

b Presser foot holder

c Presser foot holder screw

a Presser foot holder

b Presser bar

Hold the presser foot holder in place with

b

your right hand, and then tighten the screw

using a coin in your left hand.

a Coin

b Presser foot holder

c Presser foot holder screw

● If the presser foot holder is not correctly

installed, the thread tension will be

incorrect.

20

Page 22

SEWING BASICS ——————————————————————————————————————————————————

—

CAUTION

2 SEWING BASICS

SEWING

Basic sewing operations are described below.

Before operating the sewing machine, read the following precautions.

● While the machine is in operation, pay special attention to the needle location. In addition, keep your

hands away from all moving parts such as the needle and handwheel, otherwise injuries may occur.

● Do not pull or push the fabric too hard while sewing, otherwise injuries may occur or the needle may

break.

● Never use bent needles. Bent needles can easily break, possibly resulting in injuries.

● Make sure that the needle does not strike basting pins, otherwise the needle may break or bend.

General sewing procedure

Follow the basic procedures below to sew.

1

2 Select the stitch.

3

4 Start sewing.

21

Turn on the

machine.

Attach the presser

foot.

Turn on the sewing machine.

For details on turning on the machine, refer to “Power supply” (page 8).

↓

Select the stitch appropriate for the area to be sewn.

For details on selecting a stitch, refer to “Stitch width knob” (page 22).

↓

Attach the presser foot appropriate for the stitch.

For details on replacing the presser foot, refer to “Replacing the presser

foot” (page 19).

↓

Position the fabric, and then start sewing. When sewing is finished, cut the

threads.

For details on starting to sew, refer to “Starting to sew” (page 23).

Page 23

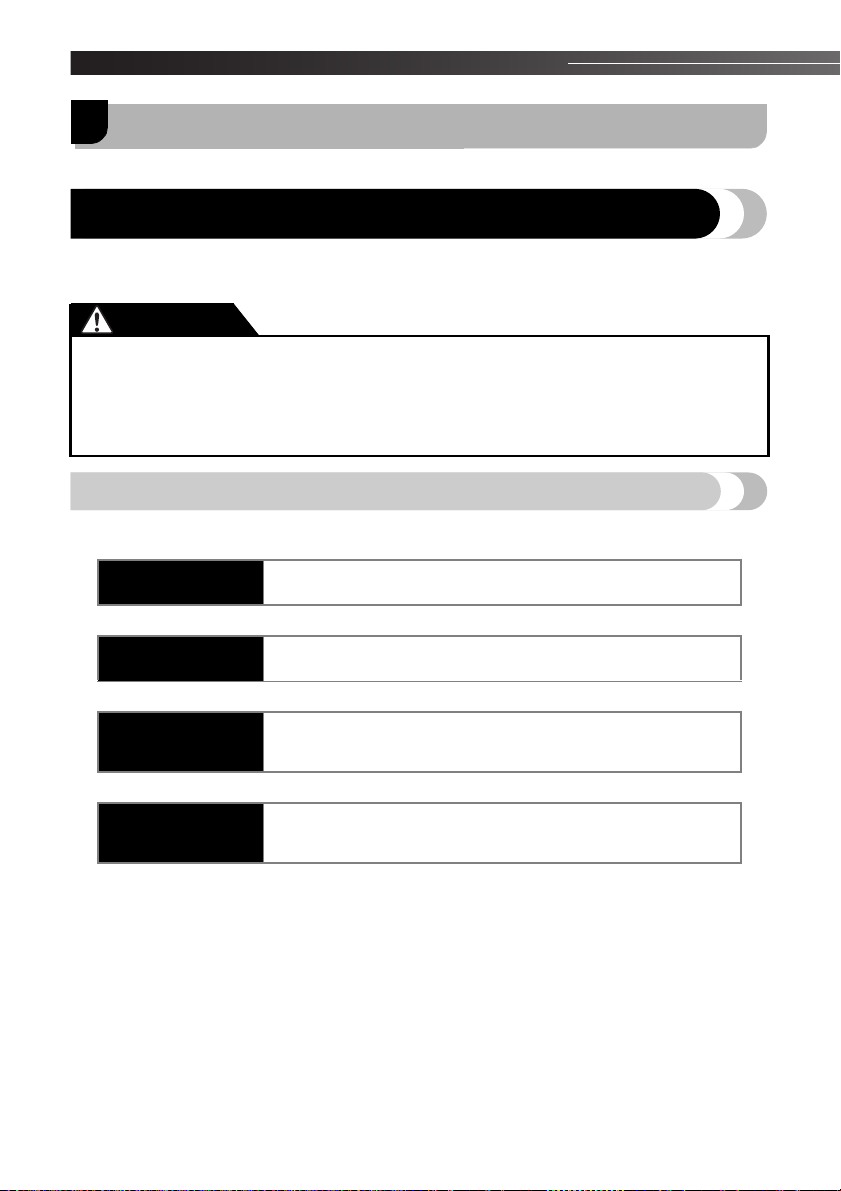

Stitch width knob

Note

Note

The width of the zigzag stitch is regulated by

operating the stitch width knob. The numbers above

the knob represent the stitch width in millimeters

(mm). The larger numbers set a wider stitch width.

When the knob is set at 0, a straight stitch is sewn.

a Stitch width knob

● Do not move the knob while the needle is

in the fabric.

● When using the twin needle, the knob

should always be set below 3.

Stitch length knob

The stitch length is regulated by turning this knob.

The numbers above the knob represent the stitch

length in millimeters (mm).

The larger numbers set a longer stitch length.

When the knob is set to 0, the fabric is not fed. This

setting is used for sewing on a button.

The F area is used for making a Satin Stitch (a close

zigzag stitch), which can be used in making

buttonholes and decorative stitches. The position

needed for making the Satin Stitch may need to be

adjusted according to the fabric and thread being

used. To determine the correct knob position, first

test the length settings on a fabric scrap.

a Stitch length knob

b Shorter

c Longer

Needle position selector

By shifting this lever to L (left), M (middle) or R

(right), you can sew straight and zigzag stitches on

the baseline.

When you sew close to the edge of the fabric, select

L or R so the fabric is fed more easily.

This selector should be set at M (middle) for almost

all stitches, but set it to other positions for the

following applications.

1. Buttonhole sewing (see “Buttonhole sewing” on

page 30.)

2. Button sewing (see “Button sewing” on page 31.)

3. Satin stitches (see “Satin stitches” on page 36.)

2

● Do not move the selector while the needle

is in the fabric.

● Always set the selector to M when using the

twin needle.

22

Page 24

SEWING BASICS ——————————————————————————————————————————————————

—

Lower the presser foot lever.

Starting to sew

Turn on the sewing machine.

a

Raise the needle to its highest position by

b

turning the handwheel toward you

f

a Presser foot lever

Slowly press down on the foot controller.

g

(counterclockwise).

X The machine starts sewing.

Take your foot off the foot controller.

h

X The machine stops sewing.

Raise the presser foot lever.

c

a Presser foot lever

Place the fabric under the presser foot, pass

d

the thread under the presser foot, and then

pull out about 5 cm (2 inches) of thread

toward the rear of the machine.

Raise the needle to its highest position by

i

turning the handwheel toward you

(counterclockwise).

Raise the presser foot lever.

j

Pull the fabric to the left side of the machine,

k

and then pass the threads through the thread

cutter on the back of the presser foot bar to

cut them.

a 5 cm (2 inches)

While holding the end of the thread and the

e

fabric with your left hand, turn the handwheel

toward you (counterclockwise) with your

right hand to lower the needle to the starting

point of the stitching.

23

a Thread cutter

Sewing in reverse

Reverse sewing is used to lock the threads at the end

of the seam or wherever reinforcement is needed.

Press and hold down the reverse sewing lever

a

while sewing.

To sew forward, release the reverse sewing

b

lever.

Page 25

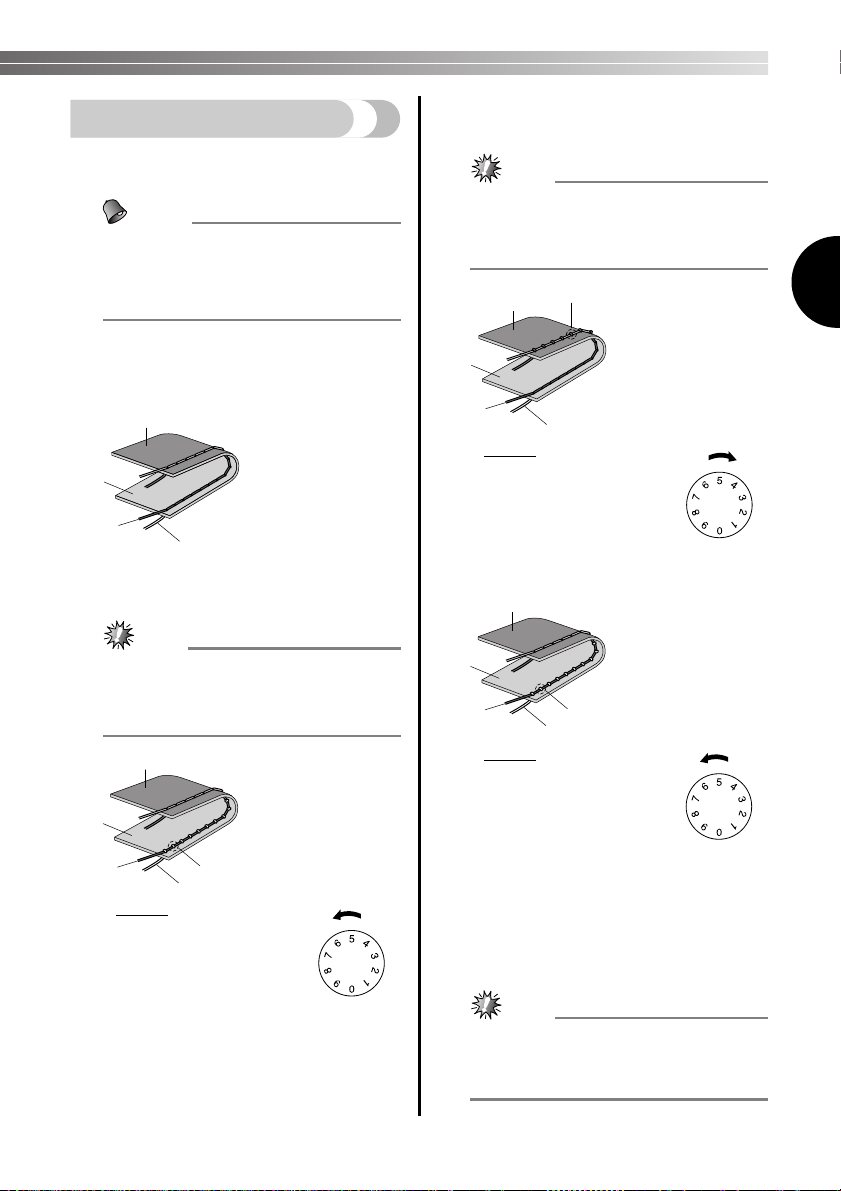

Thread tension

Memo

Note

Note

Note

1

2

3

4

a Wrong side

b Surface

c Upper thread

d Lower thread

1

2

3

4

5

a Wrong side

b Surface

c Upper thread

d Lower thread

e Loops appear on

surface of fabric

1

2

3

4

5

a Wrong side

b Surface

c Upper thread

d Lower thread

e Loops appear on

wrong side of

fabric

1

2

3

4

5

a Wrong side

b Surface

c Upper thread

d Lower thread

e Loops appear on

surface of fabric

The thread tension will affect the quality of your

stitches. You may need to adjust it when you change

fabric or thread.

● Before beginning to change tension

adjustments make sure the upper thread and

bobbin are inserted correctly.

● We recommend you do a test sample on a

scrap of fabric before you start to sew.

■ Correct tension

Correct tension is important as too much or too

little tension will weaken your seams or cause

puckers on your fabric.

■ Upper tension is too tight

Loops appear on the surface of the fabric.

● If the bobbin thread was incorrectly

inserted, the upper thread may be too tight.

In this case, refer to “Lower threading”

(page 11) and reinsert the bobbin.

■ Upper tension is too loose

Loops appear on the wrong side of the fabric.

● If the upper thread was incorrectly

threaded, the upper thread may be too

loose. In this case, refer to “Upper

threading” (page 13) and rethread.

2

Solution

Increase the tension by

turning the upper tensioncontrol dial to a higher

number.

■ Bobbin tension is too loose

Loops may appear on the surface of the fabric

when sewing thin fabric with thin thread.

Solution

Reduce the tension by

turning the upper tensioncontrol dial to a lower

number.

If the problem persists, increase the tension in

the bobbin by turning the screw clockwise

Solution

Reduce the tension by

turning the upper tensioncontrol dial to a lower

number.

with a screwdriver.

Be sure not to turn the screw more than one

full turn. In addition, be sure to return the

screw to its original position before the next

time that the machine is used.

● The bobbin thread tension has been

adjusted at the factory for general use. For

most sewing applications, no adjustment is

needed.

24

Page 26

SEWING BASICS ——————————————————————————————————————————————————

—

CAUTION

CAUTION

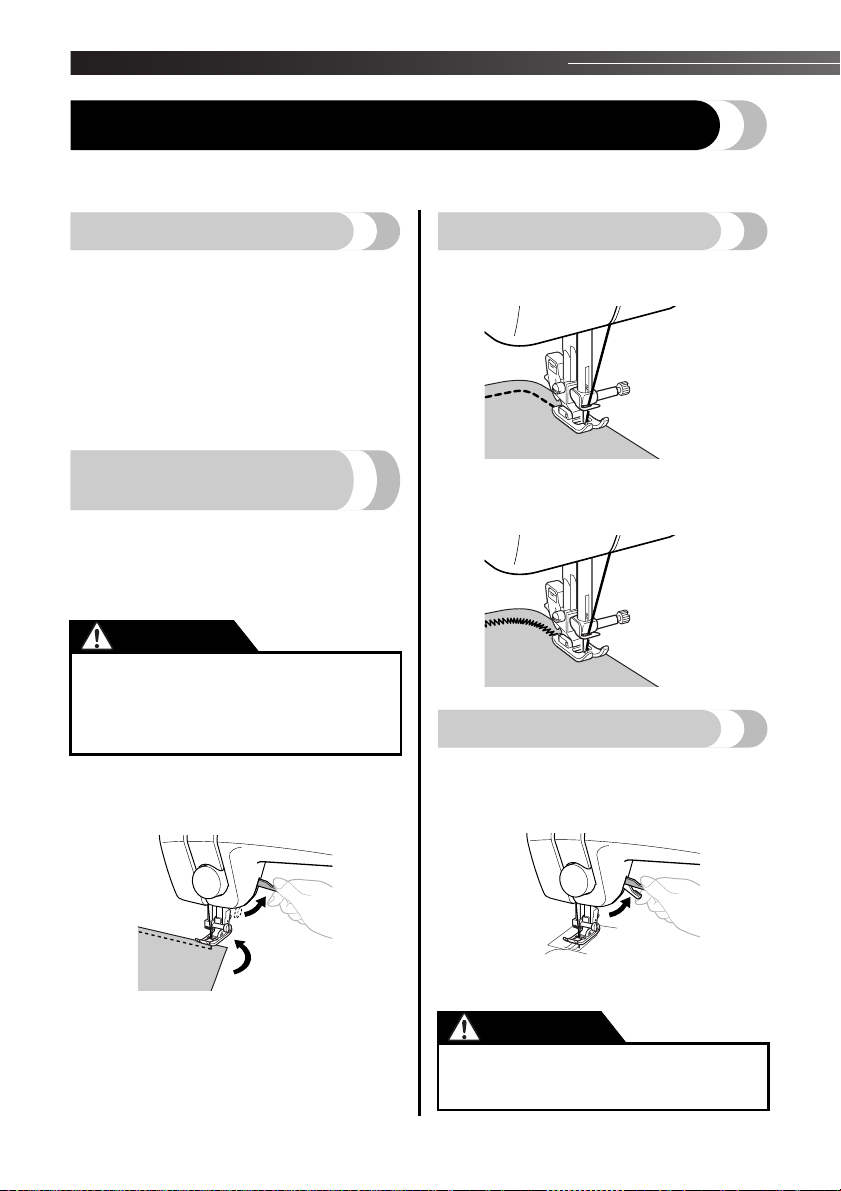

USEFUL SEWING TIPS

Various ways to achieve better results for your sewing projects are described below. Refer to these tips when

sewing your project.

Trial sewing

A trial piece of fabric should be sewn since, depending

on the type of fabric and stitching being sewn, the

desired results may not be achieved.

For the trial sewing, use a piece of fabric and thread

that are the same as those used for your project, and

check the thread tension and stitch length and width.

Since the results differ depending on the type of

stitching and the number of layers of fabric sewn,

perform the trial sewing under the same conditions

that will be used with your project.

Changing the sewing

direction

When the stitching reaches a corner, stop the

a

sewing machine.

Leave the needle lowered (in the fabric). If the

needle was raised, lower the needle by turning

the handwheel toward you (counterclockwise).

● When using the twin needle, be sure to raise

the needle before changing the sewing

direction. If the fabric is turned while the

needle is lowered, the needle may bend or

break.

Raise the presser foot lever, and then turn the

b

fabric.

Turn the fabric using the needle as a pivot.

Sewing curves

Stop sewing, and then slightly change the sewing

direction to sew around the curve.

When sewing along a curve while using a zigzag

stitch, select a shorter stitch length in order to obtain

a finer stitch.

Sewing thick fabrics

■ If the fabric does not fit under the presser foot

If the fabric does not fit easily under the presser

foot, raise the presser foot lever even higher to

bring the presser foot to its highest position.

Lower the presser foot lever and continue

c

sewing.

25

● If fabric more than 6 mm (15/64 inches) thick

is sewn or if the fabric is pushed with too

much force, the needle may bend or break.

Page 27

Sewing thin fabrics

When sewing thin fabrics, the stitching may become

misaligned or the fabric may not feed correctly. If

this occurs, place thin paper or stabilizer material

under the fabric and sew it together with the fabric.

When you have finished sewing, tear off any excess

paper.

a Stabilizer material or paper

Sewing stretch fabrics

First, baste the pieces of fabric together, and then

sew without stretching the fabric.

a Basting

2

Using a free-arm style

Free-arm sewing is convenient for sewing tubular

and hard-to-reach areas.

To change your machine to the free-arm style, lift the

bottom of the flat bed attachment toward you, and

then pull the flat bed attachment out to remove it.

a Flat bed attachment

26

Page 28

UTILITY STITCHES —————————————————————————————————————————————————

—

Memo

Note

CAUTION

3 UTILITY STITCHES

USEFUL STITCHES

When sewing is finished, cut the thread.

Zigzag stitches

You can use the zigzag stitches to join together

seams and finish them in one operation. They are

also useful for sewing stretch materials.

Stitch width

Stitch length 1-4 (For the Satin Stitch, set at F.)

Needle position

Presser foot Zigzag

Needle Single or Twin

■ Simple zigzag stitch

Set the stitch length between 1 and 4 for a simple

zigzag stitch.

Lower the needle into the fabric at the

a

beginning of the stitching.

Start sawing.

b

1-5 (For twin needle sewing,

always use a setting of less than 3.)

M, L, R (For twin needle sewing,

always set at M.)

c

• For details, refer to “Starting to sew”

(page 23).

● Slowly turn the handwheel toward you

(counterclockwise) and check that the needle

does not touch the presser foot. If the needle

hits the presser foot, the needle may bend or

break.

■ Satin stitch

When the stitch length is set in the F range and

the stitch width is set above 1, it produces a Satin

Stitch (a close zigzag stitch). The Satin Stitch can

be used for making buttonholes and decorative

stitches or edging.

● It is recommended that a test sample be

made on a fabric scrap before sewing on

your project.

• For details, refer to “Starting to sew”

● When sewing with a zigzag stitch, use

27

(page 23).

straight stitches at the beginning and end of

the zigzag stitch for reinforcement.

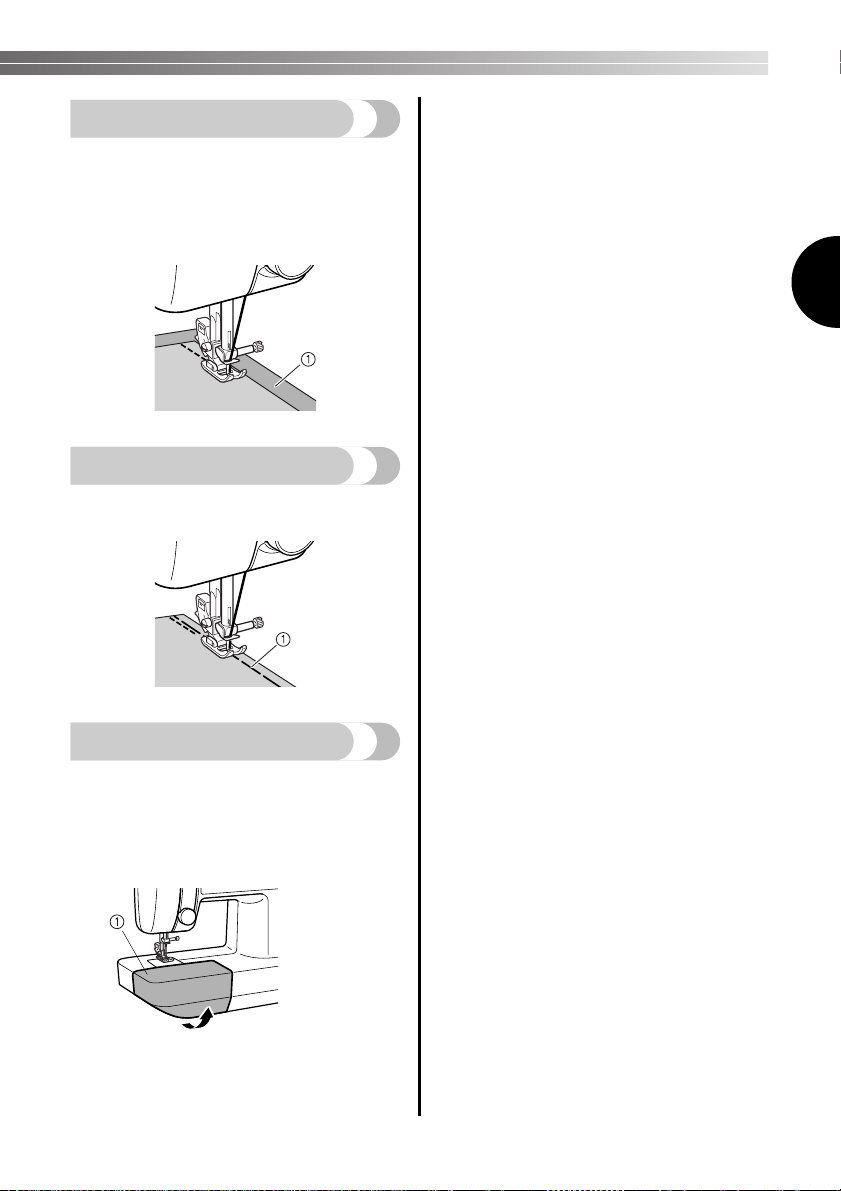

Basic stitching

Straight stitches are used for sewing plain seams.

Stitch width

Stitch length F-4

Needle position

Presser foot Zigzag

Needle Single or Twin

Baste or pin together the fabric pieces.

a

Lower the needle into the fabric at the

b

beginning of the stitching.

Start sewing.

c

• For details, refer to “Starting to sew”

(page 23).

0

M, L, R (For twin needle sewing,

always set at M.)

Page 29

When sewing is finished, cut the thread.

d

• For details, refer to “Starting to sew”

(page 23).

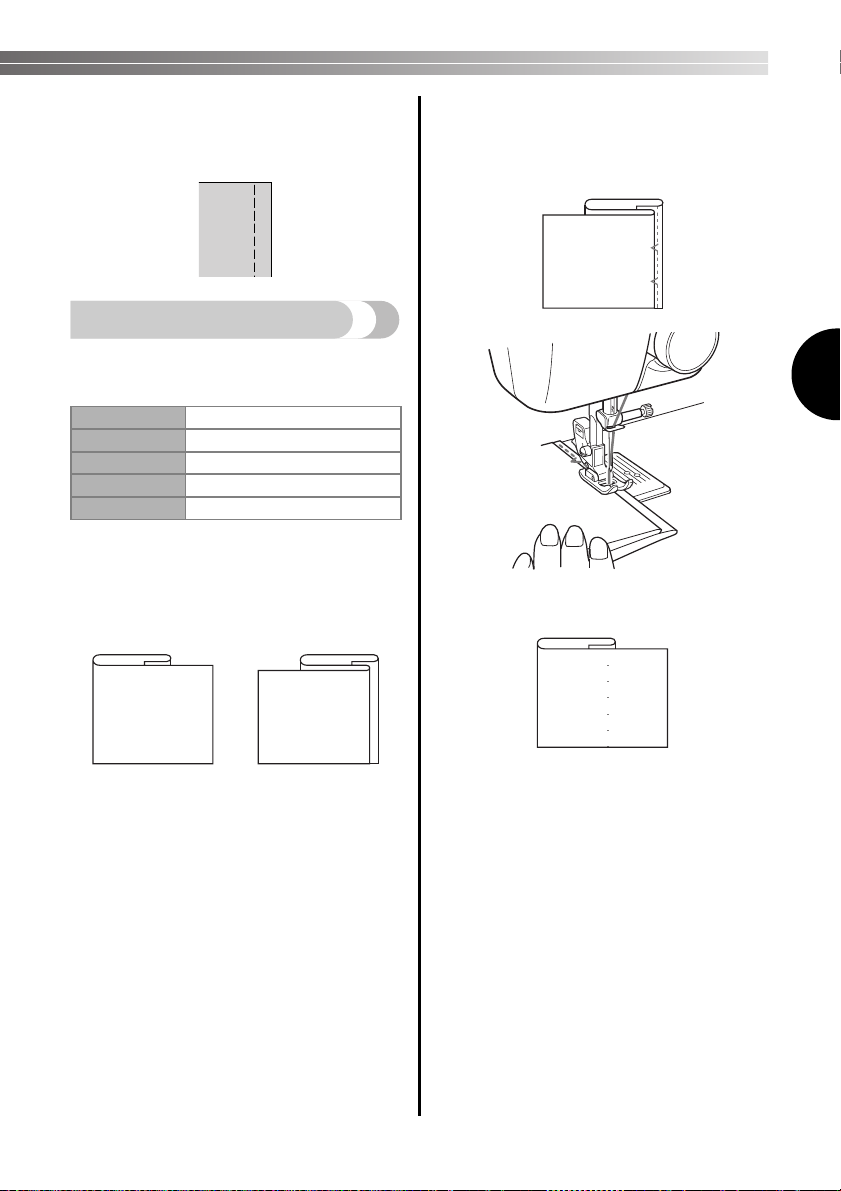

Blind hem stitching

You can use the Blind Hem Stitch to finish the edge

of a project, like the hem of a pair of trousers,

without the stitch showing.

Stitch width

Stitch length 2-3

Needle position R

Presser foot Zigzag

Needle Single

Both the upper and lower threads should be

a

the same color as the fabric.

Fold back the fabric to the desired location of

b

the hem (a). Then, fold the edge of the fabric

(b). Leave a 6 mm (1/4") overlap at the edge.

3-5

Sew 5-6 stitches on the fold using the R needle

c

position, a straight stitch (0 width) and stitch

length of 3-4. Quickly set the width to 2-3,

sew 1 stitch and set the width back to 0.

Repeat.

When the fabric is unfolded, you will have a

d

Blind Stitch hem.

3

ab

28

Page 30

UTILITY STITCHES —————————————————————————————————————————————————

—

Darning

Reinforce points that will be subject to strain.

Stitch width

Stitch length F-2

Needle position M

Presser foot None

Needle Single

Other Darning plate

Place the darning plate on the needle plate as

a

shown below, and then remove both the

presser foot and presser foot holder assembly.

Place the fabric to be darned under the

b

presser foot together with a fabric underlay

for reinforcement.

Start sewing while gently moving the fabric

c

with your hands, alternately drawing the

fabric away and pulling it toward you.

0

Over edge stitch

The Overlock Stitch is used to prevent the edge of

the fabric from fraying.

Stitch width

Stitch length

Needle position L

Presser foot Zigzag

Needle Single

Place the edge of the fabric under the presser foot so

the needle enters the fabric when the left side of the

zigzag stitch is sewn and misses the edge of the

fabric with the right side of the stitch. Sew with this

needle position along the edge of the fabric.

3-5

3-4

Stop sewing when the portion to be darned is

d

filled with parallel stitching.

29

Page 31

BUTTONHOLE SEWING/ BUTTON SEWING

Memo

A

D

Buttonholes can be sewn and buttons can be sewn on.

Buttonhole sewing

Stitch width

Stitch length

Needle position R (right position)

Presser foot Zigzag

Needle Single

■ Making a buttonhole

See the instructions below.

Set between 0 and 1 (F) for the

Satin Stitch.

Step C: Final Bar Tack

Set the stitch width to 5.

a

Sew 3-6 stitches.

b

Stop the machine when the needle is in the fabric

c

on the left side of the stitch (position C). (Turn

the handwheel counterclockwise if necessary.)

3

● It is recommended to practice making a

buttonhole on a scrap piece of fabric before

attempting it on your project.

● Using tailor’s chalk to mark the position and

length of the buttonhole on the fabric is also

recommended.

Step A: Bar Tack

Set the stitch length between 0 and 1 (F),

a

stitch width to 5 and the needle position to R.

Lower the presser foot over the top right corner

b

of the buttonhole mark and sew 3-6 stitches.

Stop the machine when the needle is in the fabric

c

on the right side of the stitch (position A). (Turn

the handwheel counterclockwise if necessary.)

Step B: Right Row

Set the stitch width to 2.

a

Sew the predetermined length of the

b

buttonhole to the other end.

Stop the machine when the needle is in the fabric

c

on the right side of the stitch (position B). (Turn

the handwheel counterclockwise if necessary.)

C

Step D: Left Row

Lift the presser foot.

a

Turn the fabric 180 degrees using the needle as

b

an axis and set the stitch width to 0. This will

move the fabric slightly. Lower the presser foot.

Turn the handwheel toward you

c

(counterclockwise) to sew one stitch.

This moves the needle from the left to the right.

Set the stitch width to 2.

d

Sew until the needle reaches the other bar tack.

e

Stop the machine with the needle in the fabric

on the right of the stitches (position D).

■ Securing the stitching and cutting the buttonhole

To secure the stitching, turn the fabric 90

a

degrees counterclockwise, set the stitch width

to 0, the stitch length to 1 and sew 5-6

Straight Stitches.

Raise the presser foot lever, remove the

b

B

fabric, and cut the thread.

30

Page 32

UTILITY STITCHES —————————————————————————————————————————————————

—

1

2

CAUTION

B

C

Insert a pin at the end of the buttonhole

c

stitching to prevent the stitching from being

cut, and then use a seam ripper to cut towards

the pin and open the buttonhole.

a Seam ripper

b Pin

● When opening the buttonhole with the seam

ripper, do not place your hands in the cutting

path, otherwise injuries may result if the seam

ripper slips. Do not use the seam ripper in any

other way than how it is intended.

■ Optional procedure for buttonholes

Step A: Bar Tack

Set the needle position at L, stitch width at 5

a

and stitch length at 0.

Lower the presser foot and sew 3 to 4 stitches.

b

Stop the machine when the needle is in the fabric

c

and at the left side of the stitches. (position A)

Stop the machine when the needle is in the fabric

c

and at the right side of the stitches. (position C)

Step D: Right Row

Set the needle position at R, stitch width at 2

a

and stitch length at F.

Sew until the needle reaches the other bar tack.

b

Stop the machine when the needle is in the fabric

c

and at the right side of the stitches. (position D)

D

Step E: Securing Buttonhole Stitch

To secure stitching, set the stitch width to 0.

a

Turn the fabric 90 degrees counterclockwise

and sew 5 - 6 straight stitches.

Step B: Left Row

Set the stitch width at 2 and stitch length at F.

a

Sew the desired length in reverse.

b

Stop the machine when the needle is in the

c

fabric at the left side of the stitches. (position B)

Step C: Final Bar Tack

Set the stitch width at 5 and stitch length at 0.

a

Sew 3 to 4 stitches.

b

31

Remove the fabric from the machine.

A

b

Button sewing

Buttons can be sewn on with the sewing machine.

Buttons with 2 or with 4 holes can be attached.

Stitch width

Stitch length 0

Needle position L or R

Presser foot Zigzag

Needle Single

Other Darning plate

Set according to the distance

between the holes.

Page 33

Measure the distance between the holes in the

CAUTION

a

button to be attached.

Place the darning plate on the needle plate as

b

shown below.

Pull the fabric to the left side of the machine,

g

and then cut the upper and lower threads,

leaving a length of 15 cm (6 inches).

Pull the upper thread at the end of the

h

stitching to the wrong side of the fabric, and

then tie it with the bobbin thread.

Use scissors to cut the upper thread and the

bobbin thread at the beginning of the stitching.

Place a button between the presser foot and

c

the fabric.

You will need to adjust the stitch width to

d

match the distance between the holes in the

button. Turning the width knob will narrow or

widen the “swing” of the stitch to

accommodate most buttons.

Turn the handwheel toward you

e

(counterclockwise) to check that the needle

correctly goes into the two holes of the button.

● When sewing, be sure that the needle does

not touch the button, otherwise the needle

may bend or break.

Start sewing.

f

• After sewing for about 10 seconds at a low

speed, press and hold down the reverse sewing

lever to sew a few reinforcement stitches.

■ Button fitting with thread shank

The thread shank of a button is often needed when

sewing on heavier fabric.

Place a button between the presser foot and

a

the fabric, adjust the stitch width according to

the distance between the holes in the button

and sew on the button as previously explained.

After sewing about 10 stitches, remove the

b

fabric from the machine leaving a longer

upper thread (about 15 cm (6")) in order to

form a thread shank.

Pull the upper thread through one of the holes

c

on the button until it is between the button

and the fabric and tightly wrap the thread

around the stitches.

With a normal sewing needle, pull the threads

d

to the back of the fabric and tie the ends

together to secure the button.

3

32

Page 34

UTILITY STITCHES —————————————————————————————————————————————————

—

CAUTION

CAUTION

ZIPPER INSERTION

You can use the zipper foot “I” to sew different types of zippers, and can easily position it to the right or left side

of the needle.

When sewing the right side of the zipper, attach the shank to the left pin of the zipper foot. When sewing the left

side of the zipper, attach the shank to the right pin of the zipper foot.

Stitch width

Stitch length

Needle position M

Presser foot Zipper foot

Needle Single

a Zipper foot “I”

b Right pin for sewing the left side of the zipper

c Left pin for sewing the right side of the zipper

Lower the presser foot lever and fix either the

a

left or right pin of the zipper foot onto the

shank.

Fold the edge of the fabric 2 cm (3/4 inches)

b

and place the zipper under the folded section.

Lower the needle into the notch located either

on the left or right side of the zipper foot.

0

2-3

Sew from the bottom of the zipper toward the

c

top on both sides. The needle should be

positioned on the zipper side of the foot for

best results.

To sew the opposite side of the zipper, release

d

the foot by pressing the button located at the

back of the presser foot, fit the zipper foot on

the other side of the zipper and continue

sewing using the other side notch.

● Make sure the needle does not hit the zipper

during sewing. If the needle hits the zipper,

the needle may break and you may be injured.

● Turn the handwheel by hand to make sure the

needle does not hit the presser foot before

you start sewing. If you choose a different

stitch, the needle will hit the presser foot and

break the needle. You may also be injured.

33

Page 35

APPLIQUÉ, MONOGRAMMING AND EMBROIDERING

Memo

CAUTION

Zigzag stitches can be used for sewing appliqués, monogramming and embroidering.

Appliqués

You can create an appliqué by cutting a different

piece of fabric into a shape and using it as a

decoration.

Stitch width

Stitch length

Needle position M

Presser foot Zigzag

Needle Single

Baste the cut design to the fabric.

a

Carefully sew around the edge of the design.

b

● Make reinforcing straight stitches at the

beginning and the end of stitching.

● Be careful that the needle does not hit a pin

during sewing, as the needle can break. You

may also be injured.

Cut away any fabric that is left outside the

c

stitching.

1-3

F-2

Monogramming and

embroidering

Stitch width

Stitch length

Needle position M

Presser foot None

Needle Single

Other Darning plate

Place the darning plate on the needle plate as

a

shown below, and then remove both the

presser foot and presser foot holder assembly.

Draw the lettering (for monogramming) or

b

design (for embroidering) on the surface of

the fabric.

Put the fabric in the embroidery hoop with

c

the surface of the fabric facing up inside the

well.

Place the project under the needle and lower

d

the presser bar.

Draw up the lower thread through the project

e

at the starting position by turning the

handwheel toward you (counterclockwise),

and then sew a few stitches to reinforce the

stitching.

0-5

Set at any position.

3

Remove the basting, if necessary.

d

34

Page 36

UTILITY STITCHES —————————————————————————————————————————————————

—

Memo

Memo

CAUTION

Grip the hoop with the thumbs and

f

forefingers of both hands while pressing the

fabric with the middle and third fingers, and

support the outside of the hoop with your

little fingers.

Start sewing.

g

● Be sure to keep your fingers away from

moving parts, especially needles.

■ Monogramming

Sew the lettering at a constant speed by

moving the hoop slowly.

■ Embroidering

Sew along the outline of the design by

moving the hoop slowly.

Then, sew to completely fill in the design

with stitches by alternately sewing from the

outline of the design to the inside and from

the inside to the outline.

Secure with a few straight stitches at the end

h

of the design.

● When the hoop is moved quickly, the

stitches are longer. When the hoop is

moved slowly, the stitches are shorter.

● Be sure to keep the stitches close together.

35

Page 37

DECORATIVE STITCHING

Note

Various decorative stitches can be sewn with this sewing machine.

Gathering

Stitch width

Stitch length

Needle position M

Presser foot Zigzag

Needle Single

Loosen the tension of the upper thread (to

a

about 2).

• For details, refer to “Thread tension”

(page 24).

Sew a single or multiple parallel rows of

b

stitches.

• Do not sew reverse stitches or cut the thread.

Pull the bobbin threads to create gathers.

c

Smooth the gathers by ironing them.

Needle

Single needle

Twin needle

Single needle

Twin needle

Single needle

Twin needle

0

4

Needle position

L

M

R

M

L

M

R

M

L

M

R

M

Pattern sewn Adjustment of the stitch width

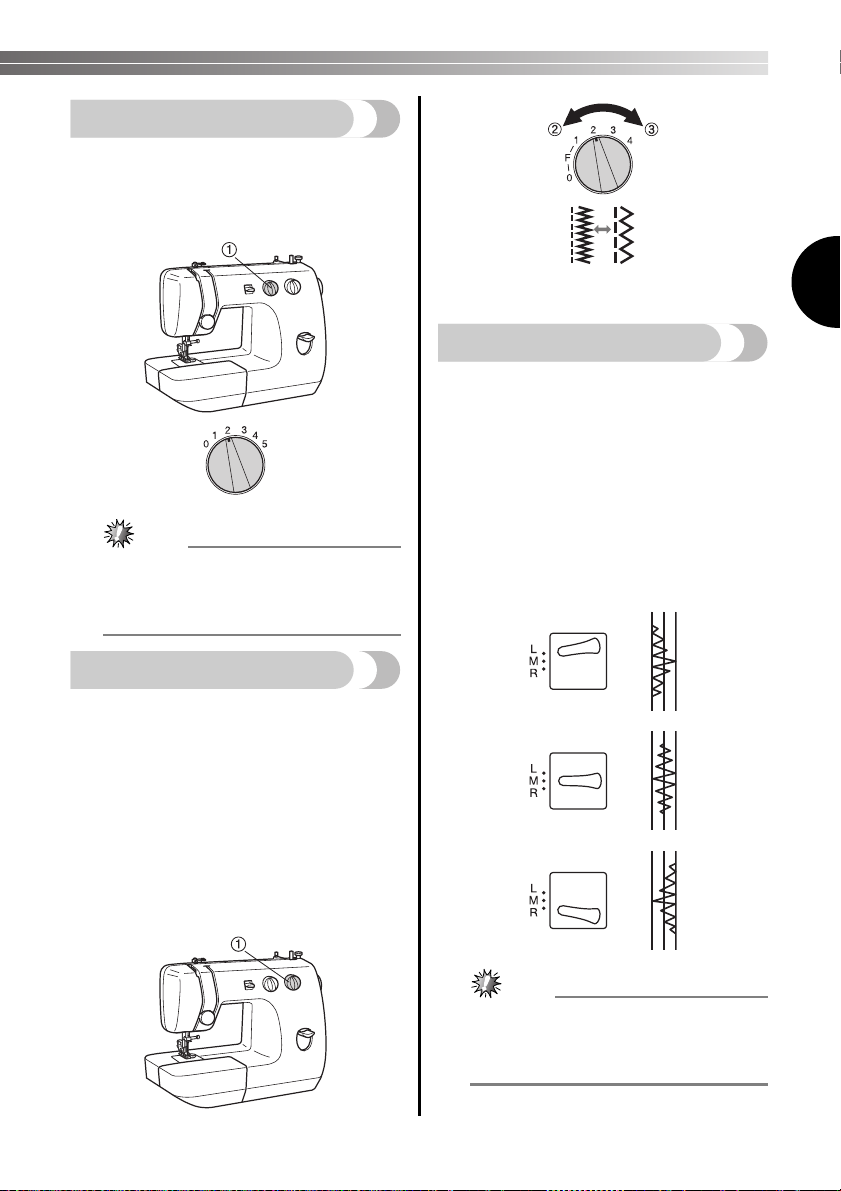

Satin stitches

Various decorative stitches can be obtained by

sewing with the Satin Stitch according to the

instructions on the following page.

Stitch width

Stitch length

Needle position

Presser foot Zigzag

Needle Single or Twin

● When using a twin needle, be sure to use a

stitch width of less than 3 and set the needle

position selector to M.

Repeatedly move the stitch width knob at an even speed

from 0 to 5, then from 5 to 0 while depressing the foot

control at an even speed.

NOTE:

For twin needle sewing, repeatedly move the stitch width

knob from 0 to 3, then from 3 to 0.

Repeatedly move the stitch width knob from 0 to 5, then from

5 to 0 more slowly than for the shape above to make round

patterns while depressing the foot control at an even speed.

NOTE:

For twin needle sewing, repeatedly move the stitch width

knob from 0 to 3, then from 3 to 0.

Repeatedly move the stitch width knob slowly from 0 to

5, then quickly back to 0 while depressing the foot

control at an even speed.

NOTE:

For twin needle sewing, repeatedly move the stitch width

knob from 0 to 3, then quickly back to 0.

See the table on this page.

Set between 0 and 1 (F) for the

Satin Stitch.

M, L, R (For twin needle sewing,

always set at M.)

3

36

Page 38

UTILITY STITCHES —————————————————————————————————————————————————

—

Note

Attaching the lace

Stitch width

Stitch length

Needle position M

Presser foot Zigzag

Needle Single

Place the lace under the fabric leaving a 5 mm

a

(1/4") overlap at the edge.

Place the overlapping edges under the presser

b

foot and sew.

● A decorative touch can be added by using

the Satin Stitch or a Decorative Stitch to

attach the lace.

0

2-4

Cording

Stitch width

Stitch length

Needle position M

Presser foot Zigzag

Needle Single

Set the stitch width knob so the needle will

a

just clear both sides of the cording.

Place the cord on the fabric in the position

b

where it will be sewn.

Lower the presser foot making sure the cord is

c

centered and sew using the zigzag stitch.

Guide the cord by hand along the path which

you wish to attach it.

Set according to the thickness of

the cord being used.

F-2

37

Page 39

4 APPENDIX

Note

Memo

CAUTION

MAINTENANCE

Simple sewing machine maintenance operations are described below.

Precautions on storing the

After oiling, run the machine for a short time

c

at a fast speed without thread.

machine

Do not store the machine in any of the locations

described below, otherwise damage to the machine

may result, for example, rust caused by condensation.

• Exposed to extremely high temperatures

• Exposed to extremely low temperatures

• Exposed to extreme temperature changes

• Exposed to high humidity or steam

• Near a flame, heater or air conditioner

• Outdoors or exposed to direct sunlight

• Exposed to extremely dusty or oily environments

● Make sure to oil the machine once a week if

● Sewing machine oil is available at your

● Do not apply too much oil as it may soil the

Changing the bulb

●