Brother LT2-B835-400, LT2-B835-500 Service Manual

SERVICE

MANUAL

FOR

BROTHER

MODEL

LT2-B835-400

BROTHER

INDUSTRIES,

NAGOYA,

LTD.

JAPAN

(D

@

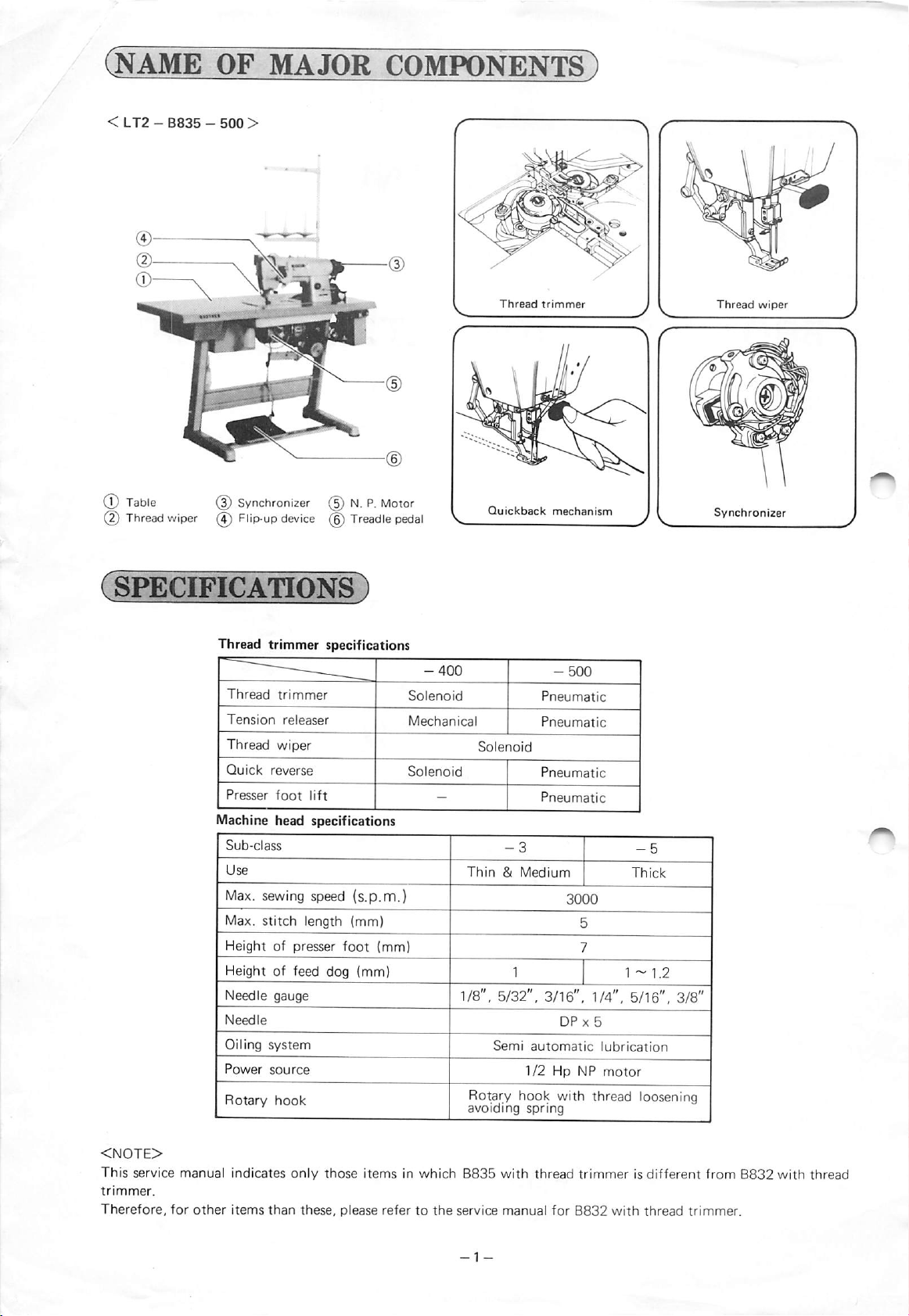

Table

Thread

wiper

@

Synchronizer

(4)

Flip-up

device

(5)N.P.

(6)

Treadle

Motor

pedal

Thread

Quickback

trimmBr

mechanism

Thread

wiper

Synchronizer

Thread

Thread

Tension

trimmer

trimmer

reieaser

specifications

Thread wiper

Quick

reverse

Presser

foot

lift

Machine head specifications

Sub-class

Use

Max.

sewing speed {s.p.m.)

Max.

stitch

length (mm)

Heightofpresser

foot

(mm)

Height of feed dog (mm)

Needle

Needle

Oiling

Power

Rotary

gauge

system

source

hook

-400

S

Solenoid

^

Mechanical

S

Solenoid

-500

Pneumatic

Pneumatic

Solenoid

Pneumatic

Pneumatic

Thin&Medium

1 1-

1.2

1/8". 5/32", 3/16", 1/4", 5/16", 3/8"

DP

X 5

Semi

automatic

1/2

Hp NP

Rotary hook with thread loosening

avoiding

spring

lubrication

motor

<NOTE>

This

service

trimmer.

Therefore,

manual

for

other

indicates

items

than

only

these,

those

itemsinwhich

please refertothe

B835

service

with

manual

thread

trimmerisdifferent

for

B832

with

thread

from

trimmer.

B832

with

thread

(ADJUSTING

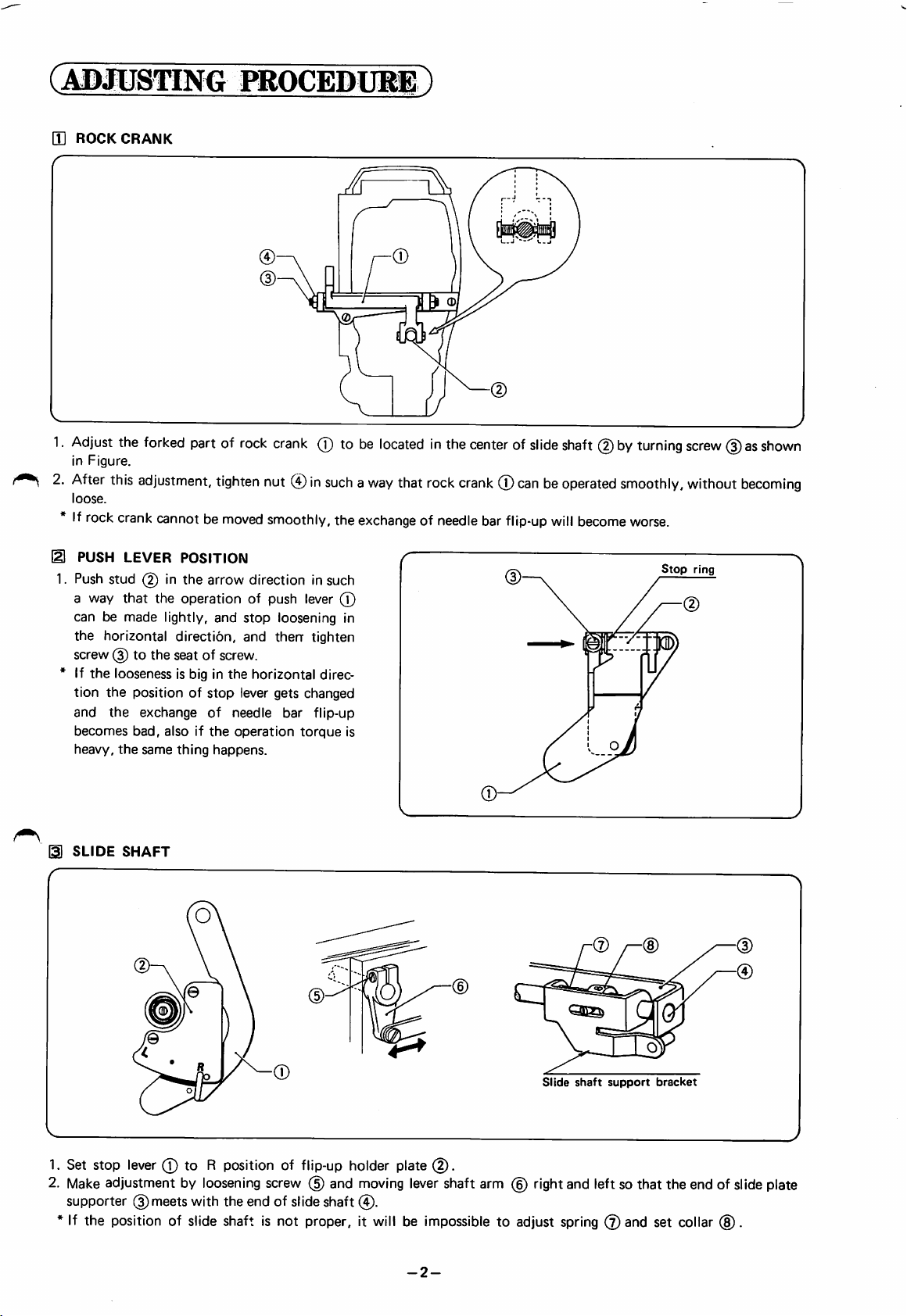

PROCEDU^

d ROCK

r

1.

Adjust

in

2.

After

loose.

If

11 PUSH LEVER POSITION

1.

a way

can be made lightly, and

the

screw

* If

tion

and

becomes

heavy,

CRANK

the

forked

Figure.

this

adjustment,

rock

crank

Push

stud

that

horizontal direction, and therr tighten

(3)tothe

the

looseness is big in

the

position of

the

exchange

bad,

the

same

partof

tighten

cannotbe

in

the operation of push lever (T)

seat

alsoifthe

the

thing

moved

arrow

of screw.

the

stop

of

needle

happens.

rock

crank

(T)tobe

nut

(4)insuchaway

smoothly,

directioninsuch

stop

loosening in

horizontal

lever gets changed

operation

bar

direc

flip-up

torque

locatedinthe

that

the

exchangeofneedle

is

rock

crank

centerofslide

(T)

canbeoperated

bar

flip-up

(D—\

shaft

will

become

(2)byturning

smoothly,

worse.

Stop

/

li

screw

without

ring

(3)asshown

becoming

V

SLIDE

1. Set stop

2. Make adjustment by loosening screw (5) and moving lever shaft arm (6) right and left so that the end of slide plate

supporter (3)meetswith the end of slideshaft

SHAFT

(D

lever

0 to R position of

(D

flip-up

holder plate

0.

0.

(6)

Slide

shaft

support

(3)

bracket

* If the position of slide shaft Is not proper, it will be impossible to adjust spring 0 and set collar (8).

y

-2-

Loading...

Loading...