Page 1

e

..

-~·~

.a:.~-'...L=

......

.

Page 2

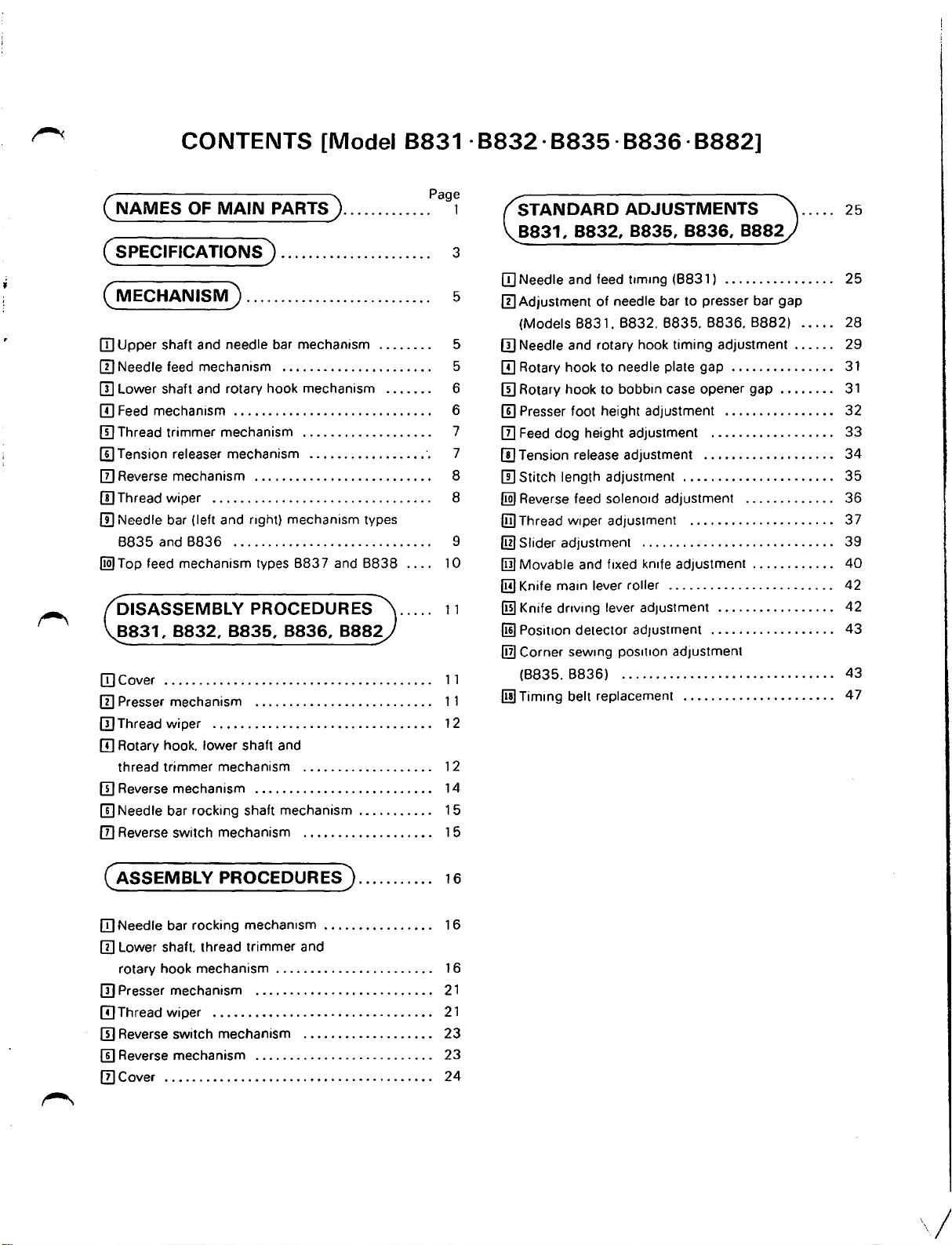

CONTENTS

[Model

8831 · 8832 · 8835 · 8836 · 8882]

NAMES

C

(SPECIFICATIONS)

OF

MAIN

PARTS).............

. . . . . . . . . . . . . . . . . . . . . . 3

(MECHANISM)...........................

[]Upper

[!)Needle

[!]

[!]

III

[I) Tension releaser mechanism

[II

(!]Thread

[!J

@)Top feed mechanism types

shaft and needle bar mechanism . . . . . . . • 5

feed mechanism . . . . . . . . • . . . . . . . . . . . • . 5

Lower shaft and rotary hook mechanism . . . . . . . 6

Feed

mechanism . . . . . • . . . . . . • • . . . . . . . . . . . . . . . 6

Thread trimmer mechanism . . • • . . . . • . . . . . . • • . . 7

...............•

Reverse mechanism . . . . . . . . . . • . . . . . . • . . . . . . • . 8

wiper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Needle bar (left and right) mechanism types

8835

and

8836 . .. . ..

..

..

.. . .. ..

883

7 and

..

8838

. .

.. . .. . ..

DISASSEMBLY PROCEDURES 11

B831,B832,B835,B836,8882

[]Cover

[1]

[!]Thread

[!]Rotary

III

[!]Needle

[II

. • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Presser mechanism . . . . . . . . . . . . . . . . . . . . . . . . . .

wiper . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . • 12

hook. lower shaft and

thread trimmer mechanism .

Reverse mechanism . . . . . • . . . . . . • . . . . . . . . . . . . •

bar rocking shaft mechanism . . . . . . . . . . .

Reverse switch mechanism . . . . . . . . . . . . . . . . . • . 1 5

• . . . . . . . . . . . . • • . . . 12

Page

;.

10

11

11

14

15

1

STANDARD

ADJUSTMENTS . . . . .

25

B831,B832,B835,B836,B882

lil

Needle and feed

5

7

(1]

Adjustment

(Models

[!]Needle

[!]

Rotary hook to needle plate gap . • . . . . . . . . . . . . .

II]

Rotary hook to bobbin case opener gap . • • . . . . .

[!]Presser foot height adjustment . . . . . • . . . . • • . . . .

[II

Feed

(!]Tension

[!]Stitch

(!ID

Reverse feed soleno1d adjustment . . . . . . . . . . . . .

8831.

and rotary hook timing adjustment • . . . . .

dog height adjustment

release adjustment . • . . • . . . . . . • • . . . . . .

length adjustment . . . . . . . . . • • . . . . . . . . . • .

[ill Thread wiper adjustment . . . . . . . . . . . . . . . . . . . . .

9

lliJ

Slider adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[!!]Movable and fixed

IE)

Knife mam lever roller . . . . . . . . . • . . . . . . . . . . . . . .

ffi)

Knife drcving lever adjuStment . . . . . . . . . . . . . . . . .

@]

Position detector adjustment . . . . . . . . . . . . . . . . . . 43

ill)

Corner sewmg

(8835.

[!!]

Timmg belt replacement • . . . . . . . . . . . . . . . . . . . . . 4 7

8836)

t1mmg

(8831)

of

needle bar to presser bar gap

8832.

8835.

kn1fe

adjustment . . . . . . . . . . . .

pos1t10n

.. . ..

adjustment

. . .

.. . .. .. ..

. . . . . . . . . . . . . . . .

8836.

8882)

..

..

. . • • . •

..

. . .

. . . . .

..

. . . .

..

.. . .. .. ..

25

28

29

31

31

32

33

34

35

36

37

39

40

42

42

43

(ASSEMBLY

[]Needle

[1]

Lower shaft. thread trimmer and

rotary hook mechanism . . . . . . . . . . . . . . . . . . . . .

[!]

Presser mechanism . . . . . . . . • . . . . • . . . . . . . . . . . •

[!]Thread

(1]

Reverse switch mechanism . . . . • . . . . . . . . . . . . . .

[!]Reverse mechanism . . . . . . . . . • . . . . . . . . . . . . . • . .

[II

Cover • . . . . . . . . . • . . . . . . • . . . • . . . . . . . . . . . . . . . . .

bar rocking mechanism . • . . . • . . . . . . . • . . 16

wiper

PROCEDURES)

.......••.....................••

...........

• .

16

16

21

21

23

23

24

\/

Page 3

CONTENTS [Model

8837 · 8838]

DISASSEMBLY PROCEDURES

......

B837,B838

[I) Cover . . . . . . . . . . • . . • . • • . . . . . . . . . . . . . . . . . . . . . .

[!]Tension

[II

Presser foot and walking bar . . . . . . . • . • . . . . . . . .

fl]

Needle bar and needle thread take-up . . . . . . . . .

[I]

Feed

(ASSEMBLY

[I)

Feed

[!]Needle

[II

Walking bar and presser foot . . . • . . . . . . . . . . . . . 53

fl]Tension

[!]Cover

STANDARD

release lever . . . . . . . . . . . . . . . . . . . . . . . . .

assembly . .

assembly . . . . . . . .

bar . . . . . . . . . . • . . . . . . . . • . • . • . . • . . . . . • • 52

release lever

.•...•....•..•...•.•..•••..............

..

. . . . . . • •

PROCEDURES)

..

. .

.. ..

. .

..

...........

..

. . . . . . • . . . . . . . . . . . . . . 52

.........................

ADJUSTMENTS ..

. . .

..

.. ..

. . ..

B837,B838

Page

48

48

49

49

51

51

52

57

58

59

GAUGE PARTS LIST

DOUBLE NEEDLE

FOR

LOCK

STITCH

SEWING MACHINES

(OTHERS).................................

[I) Top cover thread guide

[!]Adjusting

[II

Anti-spinning spring

fl]8obbin

ITlTo thread bobbin cases (8835.

upper thread length • . . . . . . . . . . . . . . . • 75

......................•......•........

(TROUBLESHOOTING

.. • .. .. .. • .. .. ..

.. . .. . ..

..

..

8836)

GUIDE)

• . .

..

_,

.....

.. . ..

. . .

.. . ..

........•

.........

..

. 76

67

75

75

76

76

77

[I) Needle and feed timing adjustment (standard) . . 59

[!]Feed

[II

fl]

11]

[!] Presser foot height adjustment . • . . . . • • . . . . . . . .

II]

II]

1IJ

[!ID

dog adjustment m back and forth

directions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Needle and rotary hook timmg adjustment . . . . . .

Clearance between rotary hook and

needle plate . . • . • . . . . . • . . . . . . . . . . . . . . . . . . . . . .

Clearance between rotary hook and

bobbin .case opener . . . . . .

Feed

dog height adjustment . . . . . . . . . . . • . . . . . .

Vibrating presser foot and lifting presser foot

and

needle timing adjustment . . . . . . . . . • . . . . . . •

Upper feed adjustment

Vibrating presser foot and lifting presser foot

vertical stroke adjustment . . . . . . . . . . . . . . . . . . . . .

• . . . . . . . . . . . . . . . . . . . 62

..

. • •

..

. .

.. .. . ..

. . . .

.. . 65

60

61

62

63

64

65

66

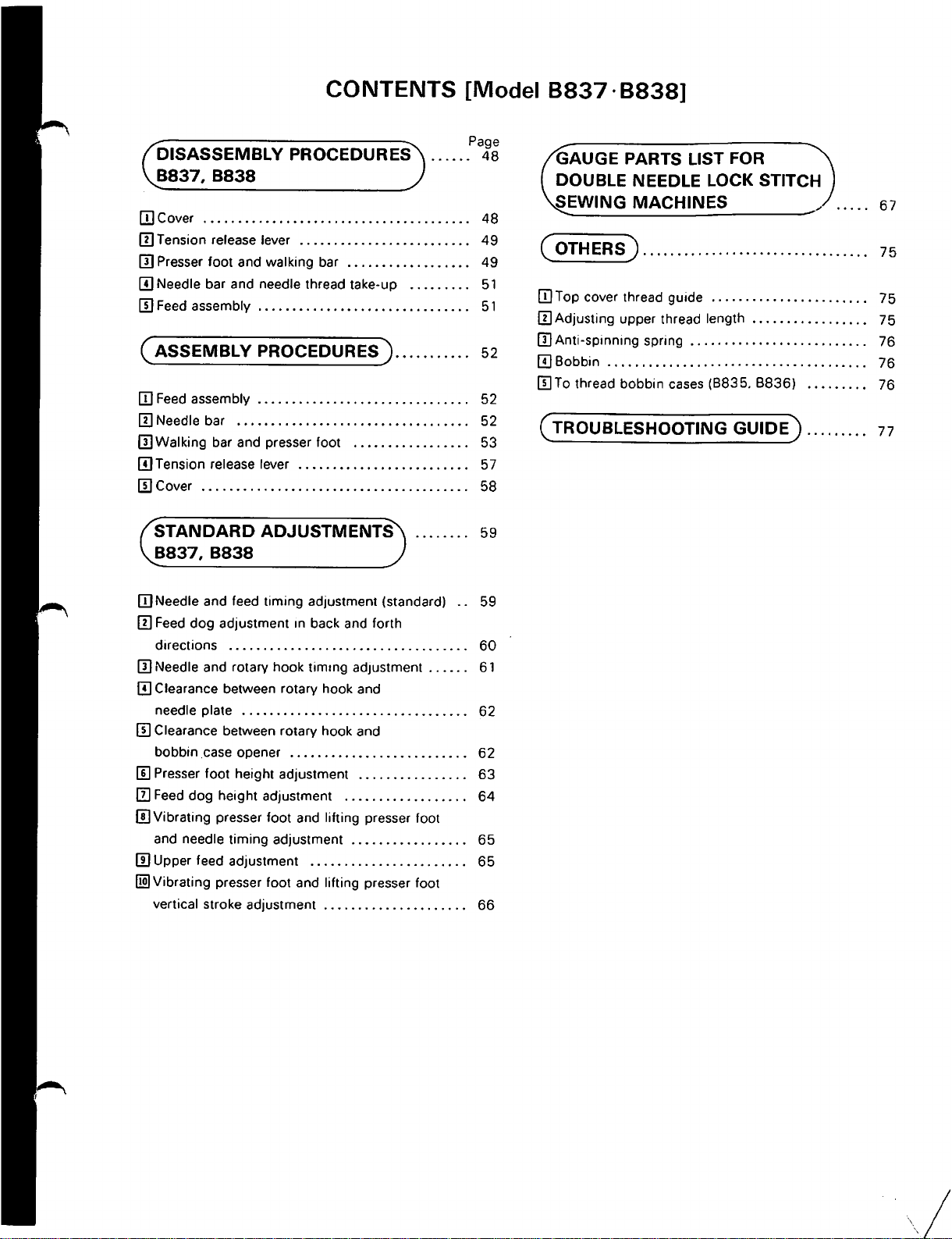

Page 4

( NAMES

OF

MAIN PARTS )

< M odel LT2-B831 >

Mod

el

<

LT2-B832

Ll2B831

Use

Sew1ng

speed

Sutch length

Presser foot

he1ght

Feed

dog he1ght

Needles

>

LT2-B832

Us

e

Sew1ng

speed

Stitch length

Presser

fo

he1ght

f---

reed dog

Presser foot

lifter

ot

Knee lifter 7 mm

he1ght

- 1

for

thon

matenals

4000

-1

For th1n

matenals

For

med1um-

th

matenals

spm

0-4

mm

7 mm

1

DP X 5

For med1

matenals

4000 spm

0-4

mm

7

1 mm

3

iCk

mm

- 3

thi

Ck

mm

um-

-5

For

th1ck

matenals

3000

spm

0-5

mm

-5

For t

h1ck

matenals

3000

spm

0-5

mm

<

Model

LT2-B882

es

Needl

>

Use

Sew1ng speed

St1tch length

Pre

foot

he1ght

Feed

Needles

DP x 5

LT2

-8882

Presser foot

sser

l1fter

Knee lifter 12 7 mm

dog

he1gh

t

DP x 5

DPx5 # 1 1 DPx5 li

-3 -5

med1um-t

For

matenals matenals

Q-7

mm

DPx

51i

14

DPx5

h1ck

3000

(Spec1al order 8mm)

7

10

14

spm

mm

mm

Fo

r t

h1ck

DP X 5fj 22

li22

_, _

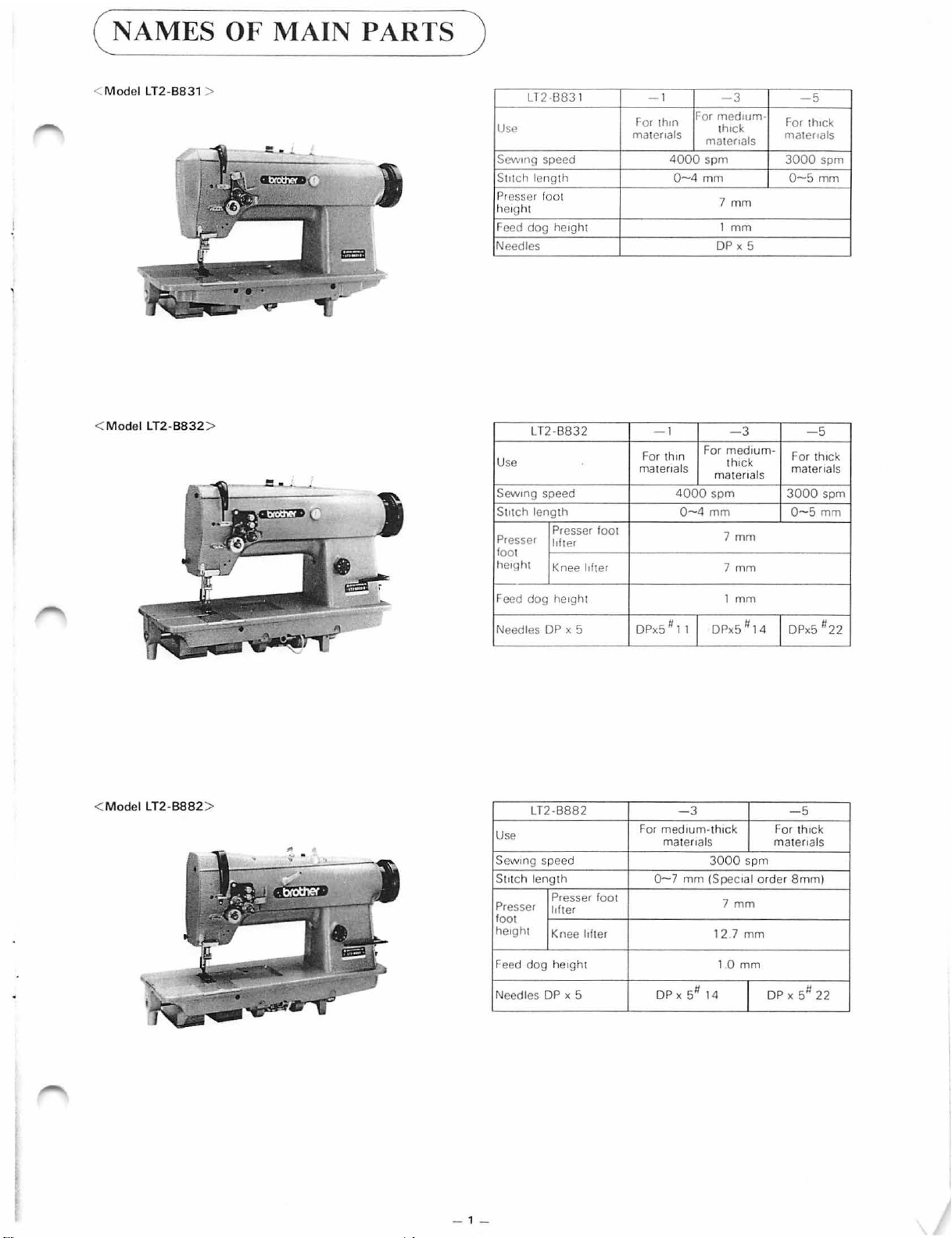

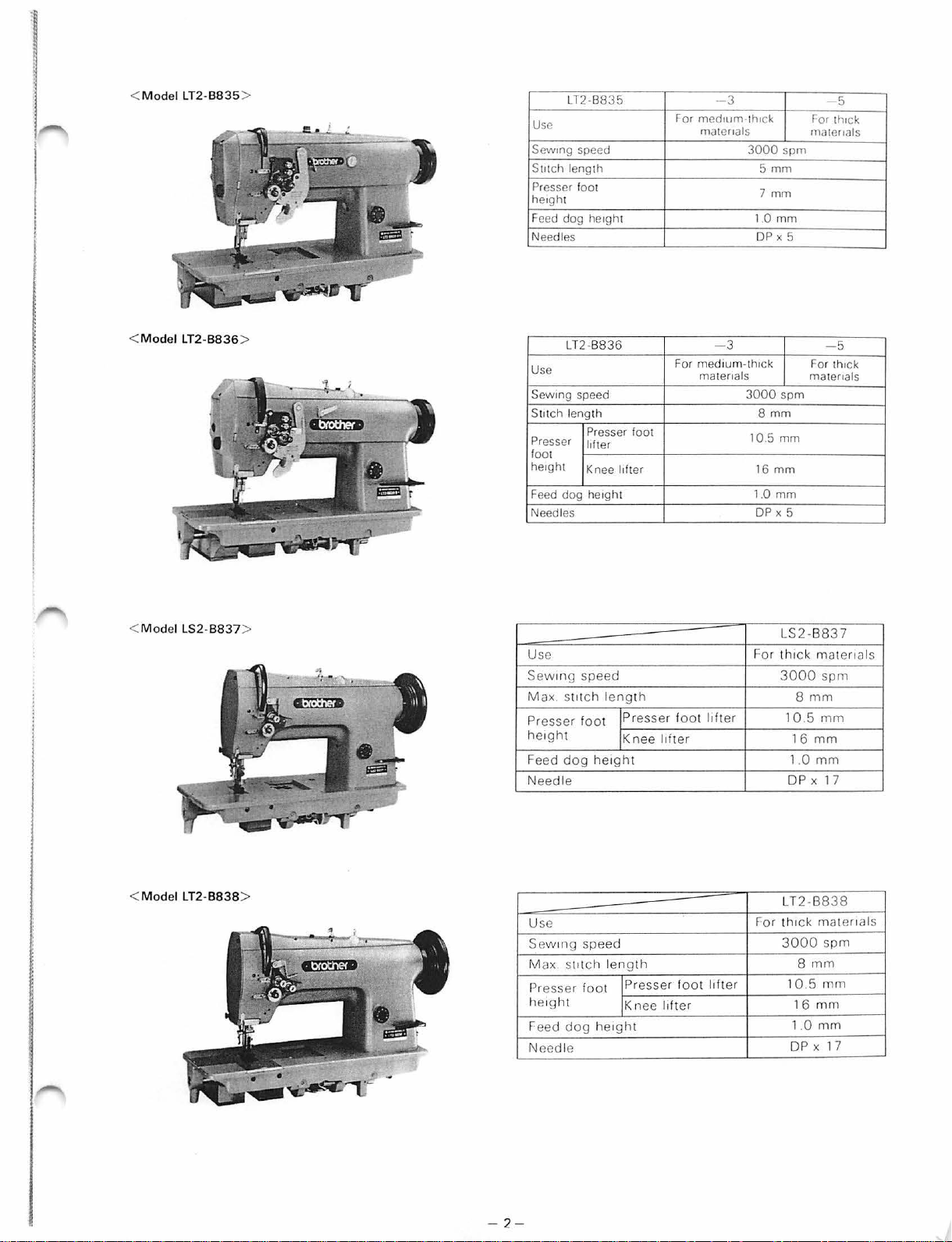

Page 5

<

<

Mod

Mod

el LT2-

el LT2-

B835

B836

>

>

LT2-B835

Use

speed

Sewtng

Stnch

length

Presser foot

hetght

Feed dog hetght 1.0

Needl

es

LT2-

B836

Us

e

Sewtng

speed

Sutch length

Presser

Presser

foot

hetght

Feed d

Needles

og

foot

lifter

Knee lifter 16

hetght

medtum-lh

For

matenals

med

For

matena

- 3

3000

- 3

turn-thtck

ls

3000

105

DP X 5

1.0

DP

tck

5 rnm

7 rnrn

mm

8

mm

mm

mm

X 5

spm

spm

mm

5

ro

r thtck

matenals

- 5

For thtck

matenals

<

Mod

<

Model

el LS2-B837

LT2-B838

>

U

se

Sewmg

Max. stttch l

Presser

he1ght

Feed

dog

speed

ength

foot

he1ght

!Presse r

!

Knee

lifter

foot

l1f

ter

Needle

>

Use

w111

g speed

S e

Max .

StitCh

length

l

ift

Pr

esser

he1ght

Feed d

N

eedle

foot lPresser

IK

nee l1fter

og

he1ght

foot

er 10

LS2 -

For th1

3000

10

DP X 17

L

th1

For

3000

B837

ck

mat

spm

8

mm

.5

mm

16

mm

1.0

mm

T2-B838

ck

mater

spm

8

mm

.5

mm

16

mm

1.0

mm

DP X 17

ena

ls

1als

- 2 -

Page 6

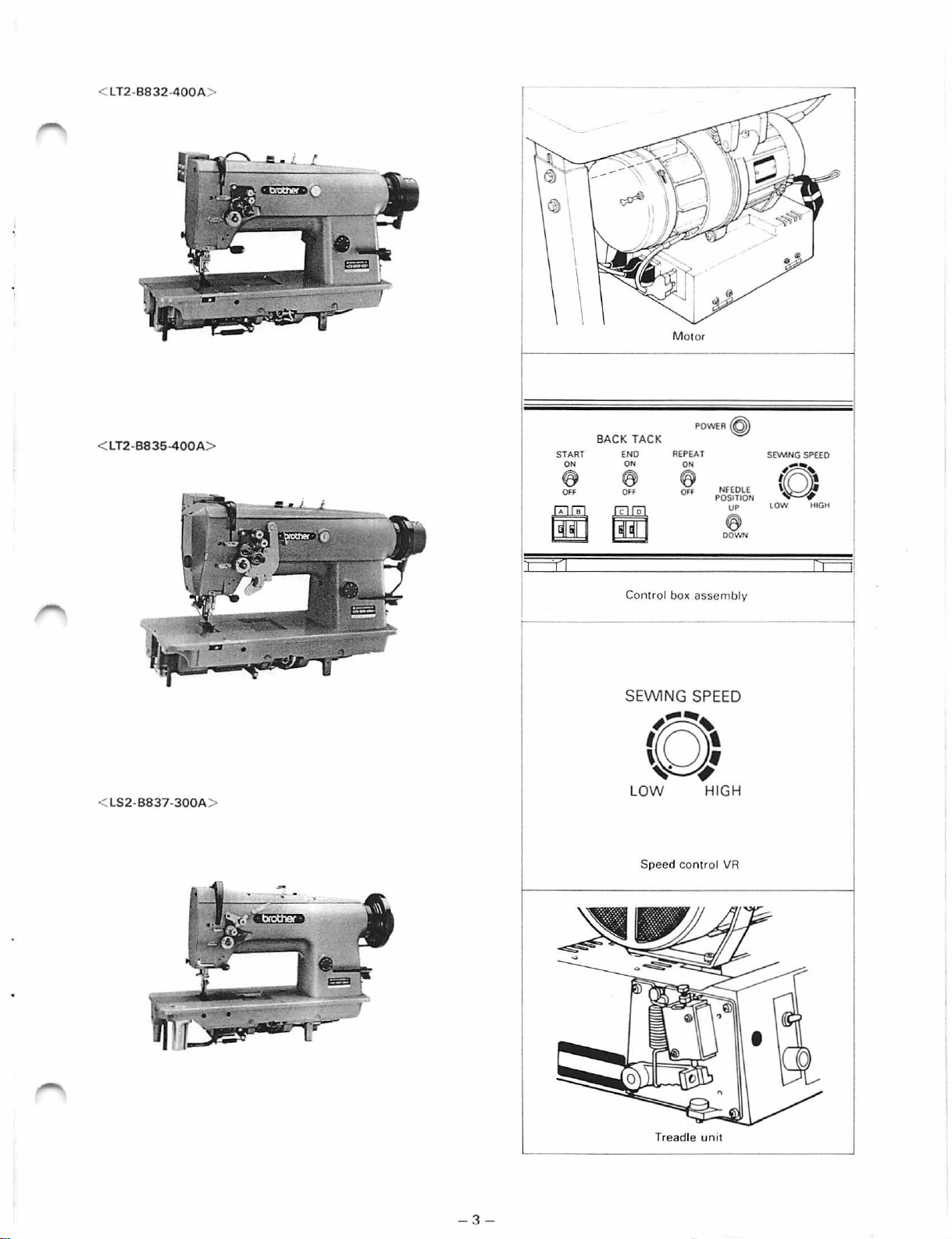

< LT2-B832-

<

LT2-BB35-400A

400A

>

M

otor

POWI:R

B

ACK

>

START

ON ON

@ @

OFF OFF

TACK

END

REPEAT

ON

@

OFF

~

NFEOLE

POSITION

UP

@

OOWN

S

E'MNG

SPEED

,.

....

~

(~'

~

lOW

HIGH

S2-B837-300A

< L

I

r--"YI

Control box assembly

'Ej

SEWING SPEED

~----~

(M:

L

>

OW

Speed c

ontr

HIGH

ol

VR

-3-

Treadle

unit

Page 7

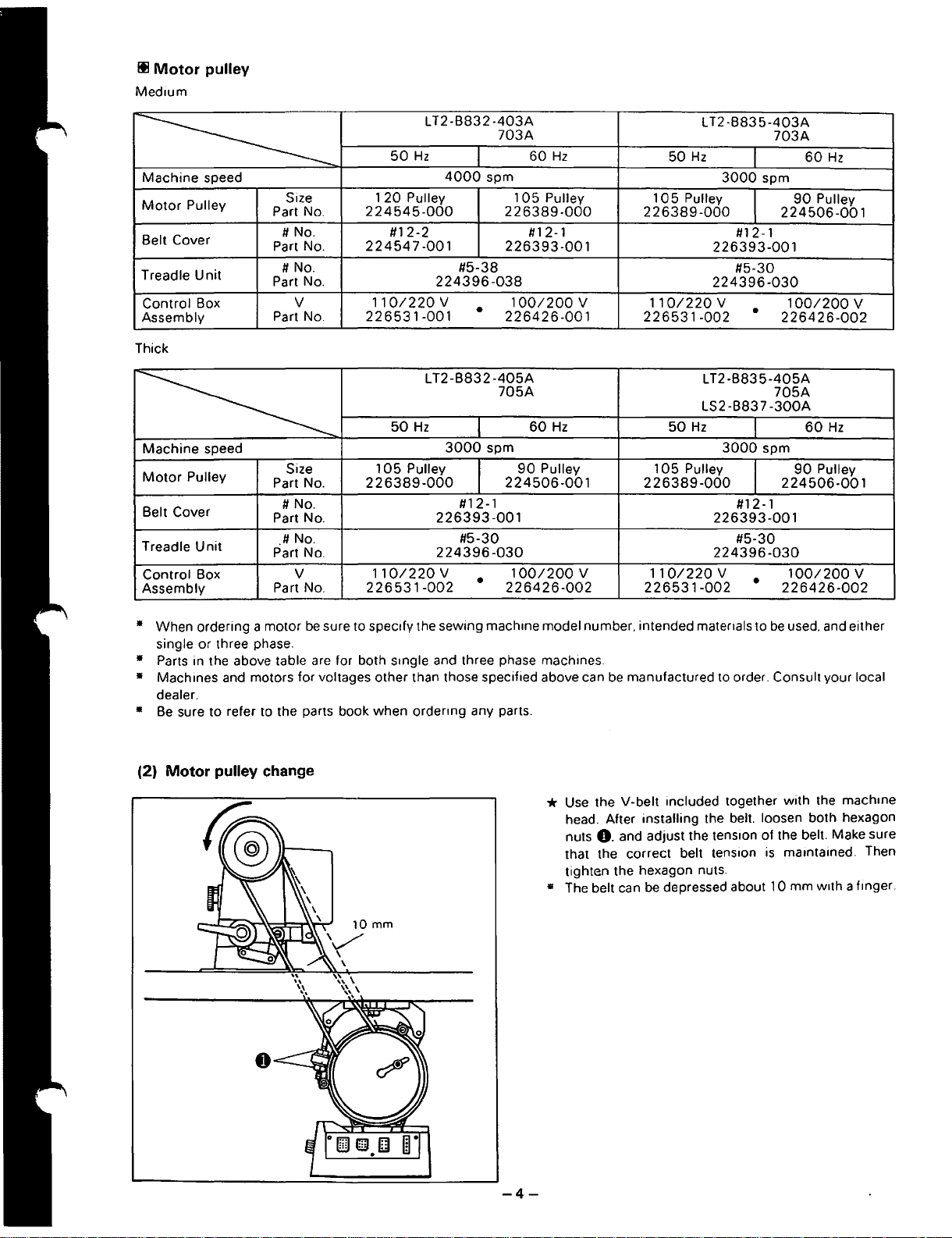

Ill

Motor

Med1um

Machine

---------------

Motor

Belt Cover

Treadle

Control Box

Assembly

Thick

pulley

speed

Pulley

Unit

Size

Part No.

#No.

Part No.

#No.

Part No.

v

Part No.

LT2

50

Hz

1

20

Pulley

224545-000

#12-2

22454

7-001

224396-038

110/220V

226531-001

-B832

4000

#5-38

-403A

703A

spm

105

226389-000

226393-001

100/200

•

226426-001

60Hz

Pulley

#1

2-1

v

L

T2

50

Hz

105

Pulley

226389-000

226393-001

224396-030

110/220

226531

-002

-B83

3000

v

5-403A

I

spm

l

#12-1

#5-30

•

703A

60Hz

90

Pulley

224506-001

100/200

226426-002

v

LT2-B832-405A

50

Hz

Machine

----------

Motor

Belt Cover

Treadle

Control Box

Assembly

• When ordering a motor

single or three phase.

• Parts in the above table

• Machines

dealer.

•

Be

(2)

speed

Pulley

Unit

Size

Part No.

#No.

Part No.

.#No.

Part No.

v

Part No.

be

sure to specify the sewing

are

and

motors for voltages other than those specified above can

sure to refer to the parts book when ordermg any parts.

Motor

pulley change

105

226389-000

110/220

226531-002

for both smgle and three phase machines.

3000

Pulley

226393-001

224396-030

v

I

spm

I

#1

2-1

#5-30

•

mach1ne

705A

60Hz

90

Pulley

224506-001

100/200

226426-002

v

model number. intended matenals to

be

*

Use

the V-belt included together with the machme

head. After installing the belt. loosen both hexagon

nuts

0.

and adjust the

that the correct

tighten the hexagon nuts.

• The belt can

50

105

226389-000

110/220

226531-002

manufactured

be

depressed about 10 mm

LT2-B835-405A

LS2-B837

Hz

Pulley

I

3000

I

#12-1

226393-001

#5-30

224396-030

v

•

to

order. Consult your local

tens1on

belt tension

705A

-300A

60Hz

spm

90

Pulley

224506-001

100/200

226426-002

be

used. and either

of the belt. Make sure

is

mamtained. Then

v

w1th a f1nger.

-4-

Page 8

""- 1

l'

J.

.c,

~

J-.

J-\. 1

''U,::,

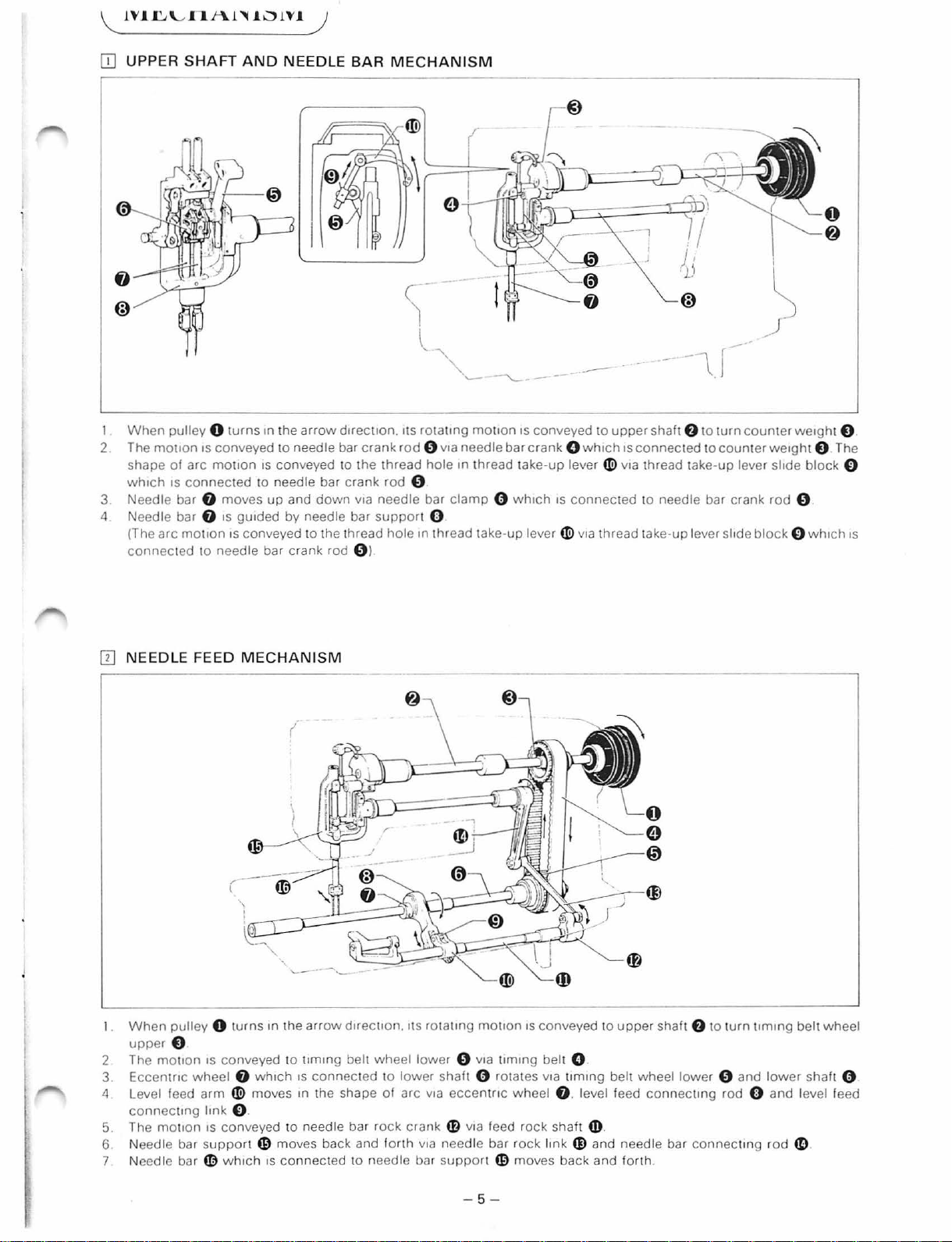

[I]

UPPER

I

When

2 The

shape

wh1ch

SHAFT

pulley 0 t

motion

of

1s

connec

arc

1S

motion

AND

urns

conveyed

ted to need

3 Needle bar 0 moves

4 Needle bar 0

(The

arc

connec

ted

motion

to

needle bar

IS

gu1ded by needle bar

1s

conveyed

rn

)

NEEDLE

m the

arrow

to

needle bar

1s

conveyed to the thread

le

up

and

crank

BAR

d1rect1on. Its rotatm g

crank

bar

crank

rod

down

v1a

needle

support

to

the thread

rod 0 l

MECHANISM

rod 8v1a

hole

needle bar

1n

0

bar

clamp

0

hole

m thread take-

motion

thread tak

IS

0 wh1ch

up

--

conveyed to

crank

O wh1ch

e-up

lever ~ v1a

IS

connected

lever ~ v1a

---

--~.r

upper

shaft

f)

to

1s

connected

thread take-up lever sl1de

to

needle bar crank

thread take-

up

lever slide

turn

to

counter

----

counter

we1ght 0 The

rod

block

0

@

we1ght 0 .

block

0

0

0 wh1ch

1s

[I) NEEDLE FEED

When

pulley

0 t

upper

0

2 The

3 Eccent

4 Level feed

5 The moti

6 Needle bar su

7 Needle bar

mouon

connec

IS

conveyed to

r1c

whee

arm ~ moves m the shape ol arc v

tmg

link

on

IS

conveyed

pport

fD

wh1ch

MECHANISM

urns

1n

the

l 0 wh1ch

O.

to

G)

mo

ves back and

IS

connec

arrow

d1rect10n. ItS

t1m1ng

belt

wheel lower

1s

connec

ted

needle bar

ted to needle bar s

rock

to

lower

forth

rotating

0 v1a

shaft 0 rotates v

1a

eccen

cran k

41)

VIa feed ro

VIa

needle bar rock

upp

motion

tlmmg

triC

ort

G)

IS

conveyed

belt 0

wheel

ck shaft

moves

to

1a

t1m1ng

belt wheel

0 . level feed

m.

lmk m and

back

and

upper

shaft

connectmg

needle bar

forth

.

f)

to t

urn

lower 0 and

rod 0 and

connec

ting

t1m1ng

lower

rod

belt

wheel

shaft 0

level feed

4D

- 5 -

Page 9

[I]

LOWER

SHAFT

AND

ROTARY

HOOK

MECHANISM

1.

When

upper

2. The

3. As

4. Rotary

(Opener)

1. Open

2. Op

IT]

moti

lower shaft 0 which

ener

• The

FEED

pu

lley 0 turns in

0 .

on

is conveyed

h

ook

~

rotates via pini

er

crank

41)

move

4D

which

LS2-B837

MECHANISM

s in the

is conn

sewing

th

e ar

to

tim

is

connec

ected

machine

______=::~~

row

direc

tion. its r

ing

belt

wheel

ted to

on

gear 0 which

shape

of

to

opener crank

does not contain a left side

----

ota

lower

tim

ing

belt

an arc via

41)

is

----~

ting

mot

0 via t

wheel l

connec

rota

ry

moves

---~

ion

is

conveyed

imi

ng

belt

ower 0 rotat

ted to rotary h

hook ~ and

in

the

shape

rotary

i

to

upper

sha

ft

f)

to

turn

timing

0 .

es. spiral

ook

ope

ner

of

an ar

hook. etc. because of the one needle.

gear

base O.

link

$ .

c.

8 is turn

ed

.

belt

whee

l

1.

When

pu lley 0 t

upper

O.

2. The motion IS conv

3. Eccentric

4. Level feed

connect

5. Feed bar

6. Feed bar fork

7.

The moveme

ing link 0 .

ur

ns in the

eyed

wheel 8 whi

arm

«!)

moves in the sh

41)

moves b

4D

moves

nt

of feed

to timmg

ch is con

ack

and

up

dog

arrow

directio

belt

nec

ape

forth via

and down

1s f1xed

by the comb

n.

its

rotating

wheel lowe

ted to

lower shaft 0 rot

of

an

arc

feed ro

ck

by vertical feed

r 0 via t

via

eccentric

shaft

inati

on

motio

tD

.

ecce

of

n IS

imi

ng bel t 0 .

ates via t

wheel

ntri

C w heel m whi

move

ments in

- 6 -

conveyed

imi

ng belt wheel lower 0 a

8 . level feed

to upper sh

Ch

IS

1tem

5 and 1tem 6.

aft

connec

connec

f)

ting r

ted

to t

urn timi

nd

od

0 and level feed

to

lower

ng

belt

wheel

lower shaft

shaft o.

0 .

Page 10

i

l

l

r

I

I

r

!

i

!

~.

~

IT]

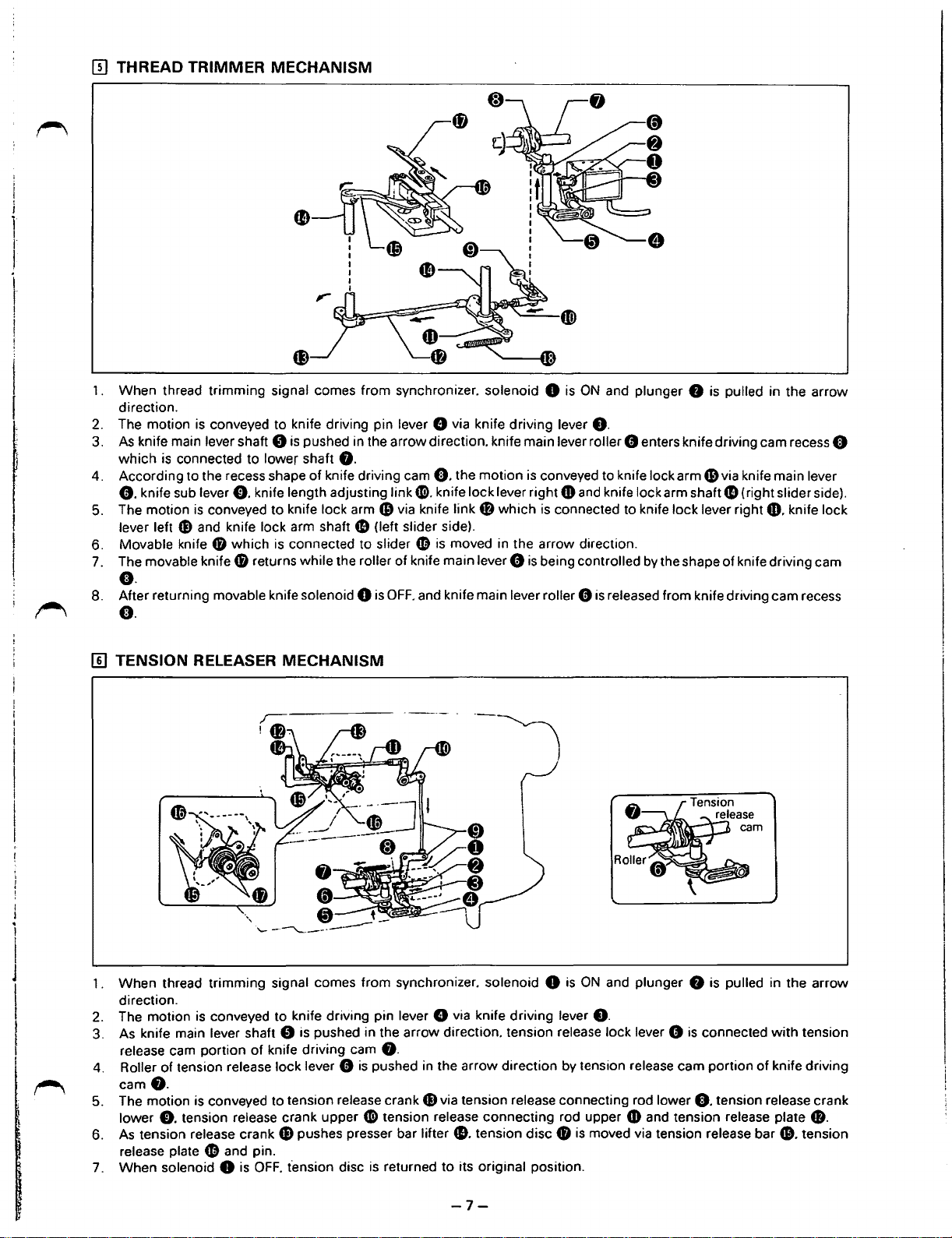

THREAD TRIMMER MECHANISM

1.

When thread trimming signal comes from synchronizer. solenoid 8

direction.

2.

The motion

3.

As

knife main lever shaft 8

which

According to the recess shape of knife driving cam

4.

8.

knife sub lever

The motion

5.

lever left

Movable knife

6.

The movable knife

7.

is

conveyed to knife driving pin lever 8 via knife driving lever

is

pushed in the arrow direction. knife main lever roller 8 enters knife driving cam recess e

is

connected to lower shaft

0.

knife length adjusting link

is

conveyed to knife lock arm

G)

and knife lock arm shaft

0 which

is

connected to slider

8.

6)

G)

(left slider side).

e.

the motion

CD.

knife lock lever right

via knife link

fD

is

moved in the arrow direction.

4B

0 returns while the roller of knife main lever 8

e.

After returning movable knife solenoid 8

8.

is

OFF.

and knife main lever roller G

e.

is

ON

and plunger 8

8.

is

conveyed to knife lock arm

4D

and knife lock arm shaft

which

is

connected to knife lock lever right

is

being controlled

is

released from knife driving cam recess

is

pulled in the arrow

6)

via knife main lever

G)

(right slider side).

49.

knife lock

by

the shape of knife driving cam

I

I

.

I

l

J

I

I

~

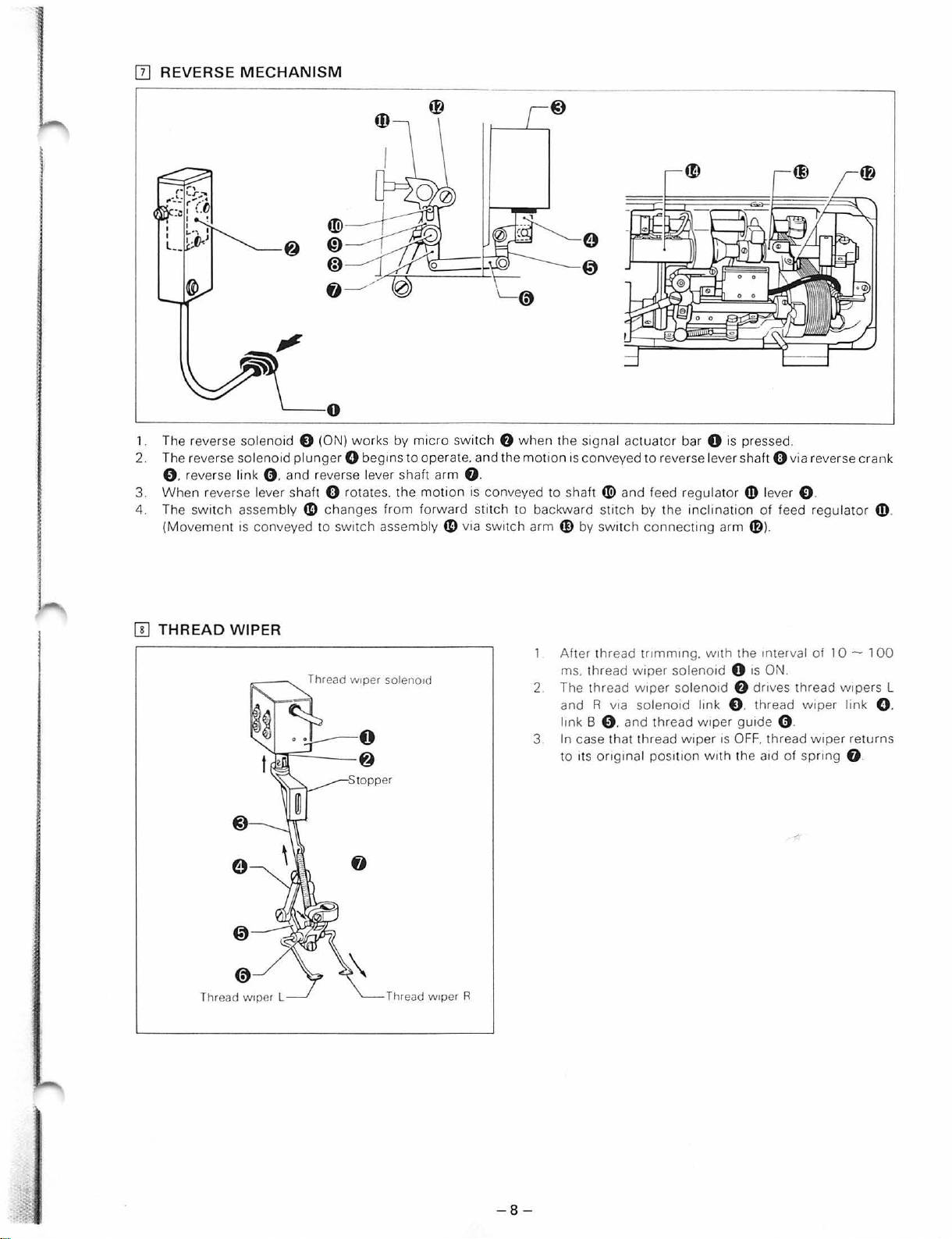

[[]

TENSION RELEASER MECHANISM

When thread trimming signal comes from synchronizer. solenoid 8

1 .

direction.

The motion

2.

As knife main lever shaft 8 is pushed in the arrow direction. tension release lock lever 0

3.

release cam portion of knife driving cam

Roller of tension release lock lever 8

4.

cam8.

The motion is conveyed to tension release crank

5.

lower

As

tension release crank

6.

release plate

When solenoid

7.

is

conveyed to knife driving pin lever 8 via knife driving lever

0.

tension release crank upper

G)

pushes presser bar lifter

fD

and pin.

8

is

OFF.

t'ension disc

8.

is

pushed in the arrow direction by tension release cam portion

G)

via tension release connecting rod lower

CD

tension release connecting rod upper

41).

tension disc 0 is moved via tension release bar

is

returned to its original position.

is

ON

and plunger 8 is pulled in the arrow

0.

is

connected

of

e.

tension release crank

4D

and tension release plate

with

tension

knife driving

8.

41.

tension

-7-

Page 11

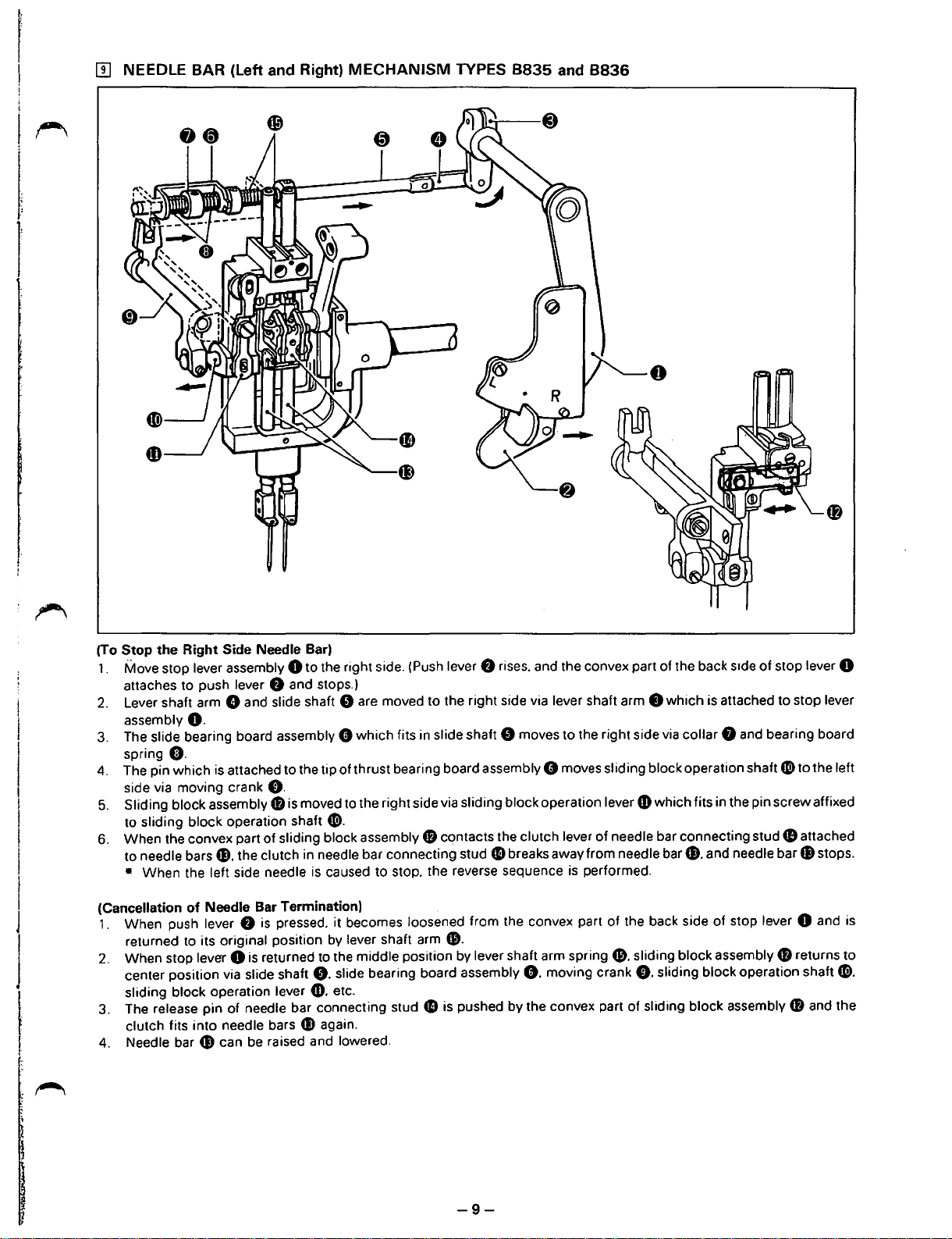

[I]

REVERSE MEC

HANISM

~0

1. The reverse solenoid 0 (ON) works by

2. The reverse

solenoid

plunger

0 begins

micro

to

0 . reverse link 0 . and reverse lever shaft arm G.

3.

Wh

en reverse lever shaft 0 rota tes. the

4. The

[!]

switch

(Movement

THREAD

assembly

is

conveyed to switch assembly

«)

changes from forward

WIPER

Thread w1per soleno1d

switch 0

operate. and the

motion

is

conveyed to shaft

stitch

«)

via Switch arm

when

the signal actuat

mot

ton

is

conveyed to reverse lever shaft 0 via reverse crank

«!>

to backward stitch by the inclination

4f}

by

SWitCh

Afte r thread trtmmtng. w

ms. thread w1per solenotd 0

2 The thr ead w1per solenotd

1ts

v1a

orig

and R

ltnk B 0 . and

3 In case th

to

or

bar 0 is pressed.

and feed regulat

connec

solenotd lmk 0 . thread wiper li

thr

ead

at

thread

tnal posttt

ting

w1per

wipe

on

or

arm

1th

the mterval of 1 0 - 1

f)

guide 0 .

r 1s

OFF.

wtth the

4D

lever 0 .

of

feed regulator

fD

).

1s

ON.

dr1ves

thread w1pers L

thread wiper returns

a1d

of

spnng

nk

G.

4!)

00

0 .

.

Thread

Thread w1per L

w1per R

-8-

Page 12

l

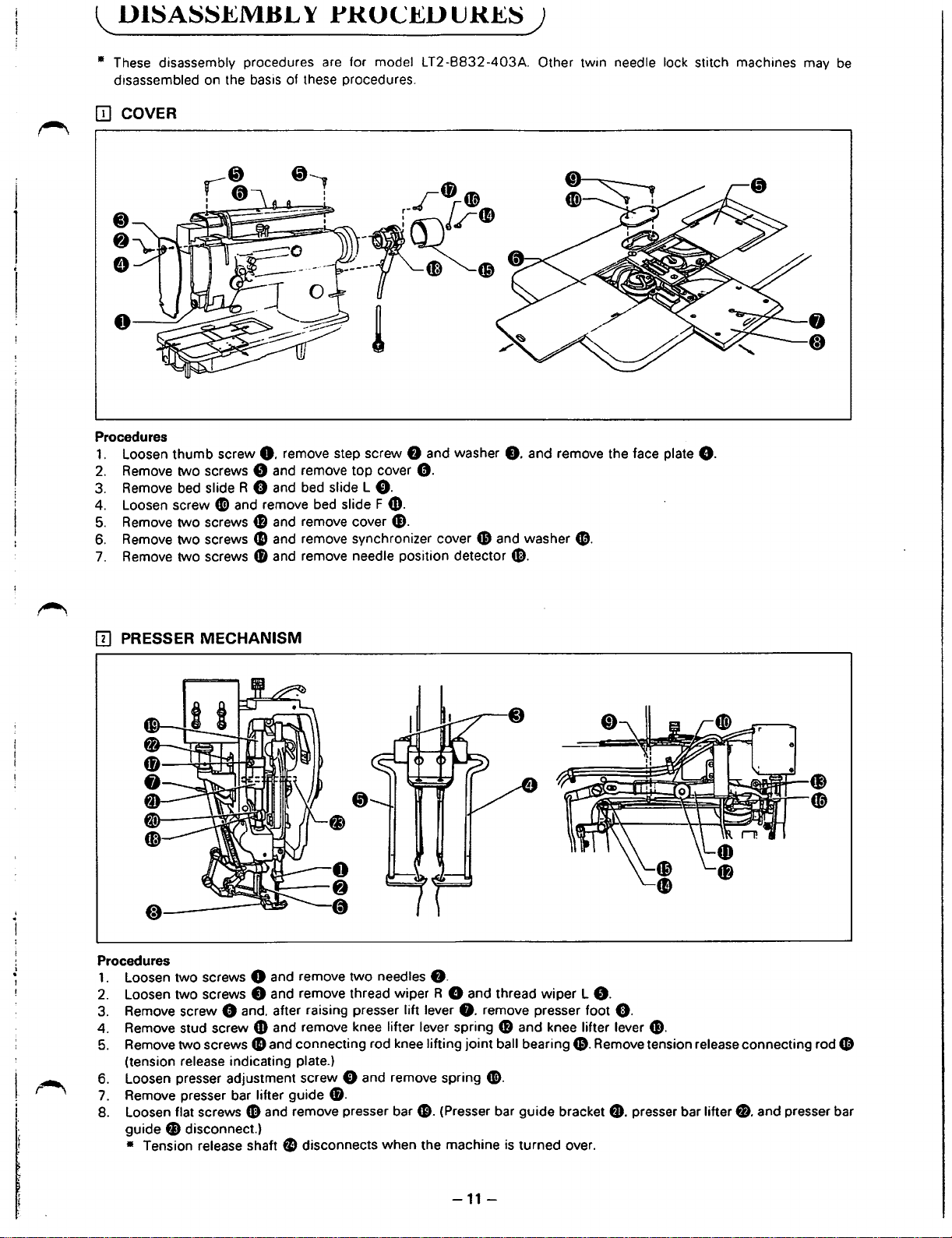

[[]

NEEDLE BAR

(left

and Right)

MECHANISM

TYPES

8835

and

8836

I

I

J

J

I

I

(To Stop the Right Side Needle Bar)

1.

Move stop lever assembly 0 to the right side. (Push lever

attaches to push lever

2.

Lever shaft arm 8 and slide shaft 0 are moved to the right side via lever shaft arm 8 which is attached to stop lever

assembly

3.

The slide bearing board assembly 8 which fits in slide shaft 0 moves to the right side via collar 8 and bearing board

spring

4. The pin which is attached to the tip of thrust bearing board assembly 8 moves sliding block operation shaft

side via moving crank

5.

Sliding block assembly

to sliding block operation shaft

6.

When the convex part

to needle bars

• When the left side needle

(Cancellation

1. When push lever

returned to its original position

2.

When stop lever 0 is returned to the middle position by lever shaft arm

center position via slide shaft

sliding block operation lever

3. The

clutch fits into needle bars fl) again.

4. Needle bar G) can

O.

0.

fl). the clutch in needle bar connecting stud

of

Needle Bar Termination)

release pin of needle bar connecting stud

f)

and stops.)

0.

48

is moved to the right side via sliding block operation lever

G).

of

sliding block assembly

is

caused to stop. the reverse sequence

f)

is

pressed. it becomes loosened from the convex part

by

lever shaft arm

0.

slide bearing board assembly

CD.

etc.

fB

41

be

raised and lowered.

f)

rises. and the convex part of the back

CD

which fits in the pin screw affixed

contacts the clutch lever of needle bar connecting stud

41

breaks away from needle

is

performed.

of

bar~.

the back side

s1de

of stop lever 0

and needle bar fl) stops.

of

stop lever 0 and is

CD.

spring&.

0.

moving crank

is

pushed by the convex part of sliding block assembly

sliding block assembly

0.

sliding block operation shaft

G)

41

fB

CD

to the left

attached

returns

G>.

and the

to

-9-

Page 13

.,

[@]

TOP

FEED

MECHANISM

TYPES

8837

AND

8838

1.

When

mach i

ne

pulley 0

of

rotation

2. The top feed eccentric wh

3. Motion

4. Bell crank link

5.

Th

e top feed presser link 0 is

feed presser bar

6.

Middle

By

loosening

7.

crank 0 is changed and alterati

top feed eccentric wheel 0 .

is conv

presser @ affixed to top feed presser bar

eyed to bell cra nk

f)

causes the up-

Q)

.

wing

nut

turn

s in the direction of the arrow. the rotation is conveyed to

ee

l crank 0 is moved in an arc by

f)

via

top feed shaft 0 which is affixed to t

down mot

gu

1ded by the

CD

and adjusting the

on

of the

10n

of

groove

position

amount

top feed presser link 0 via bell crank 0 .

Q)

of up-

top

feed eccen tric wheel 0 . via t

(oval) of middle presser gu1de

IS caused to move

of

hinge screw m. the

down

motion

of

up

and

middle

amount

upper

shaft 0 and causes the

op

feed con necting rod 0 .

op feed ecce

plate

down

presser @ becomes possible.

ntri

c wheel crank 0 .

~

and conveys mot1on to t

.

of

motion

of

top feed eccentriC

op

-

10-

Page 14

~

UISASS.EMHL

Y .PKUC.EU

lJK.ES)

• These disassembly procedures are for model l

disassembled on the basis of these procedures.

ITJ

COVER

Procedures

1.

Loosen thumb screw

2.

Remove two screws 8 and remove

3.

Remove bed

4. Loosen screw

5.

Remove two screws

6.

Remove two screws

7.

Remove two screws

slideR

0.

remove step screw 8 and washer

G and bed slide L

Cl)

and remove bed slide F

4B

and remove cover

CD

and remove synchronizer cover

41

and remove needle position detector G).

top

cover

0.

4]).

G).

0.

T2

-8832

-403A. Other twin needle lock stitch machines may

8.

49

and washer

and remove the face plate

(D.

8.

be

[]]

PRESSER MECHANISM

Procedures

1.

Loosen two screws 0 and remove two needles

2.

Loosen two screws 8 and remove thread wiper R 8 and thread

3.

Remove screw 0 and. after raising presser lift lever

4. Remove stud screw

5.

Remove two screws

(tension release indicating plate.)

6. Loosen presser adjustment screw

7.

Remove presser bar lifter guide

8.

Loosen flat screws G) and remove presser bar

fJ)

guide

• Tension release shaft e disconnects when the machine

disconnect.)

CD

and remove knee lifter lever spring

48

and connecting rod knee lifting

0 and remove spring

8.

f).

8.

joint

G).

(Presser bar guide bracket

wiper

L

8.

remove presser foot

CD

and knee lifter lever

ball bearing

Cl).

is

turned over.

8.

Remove tension release connecting rod

0.

G).

fD.

presser bar lifter fl. and presser bar

CD

-11-

Page 15

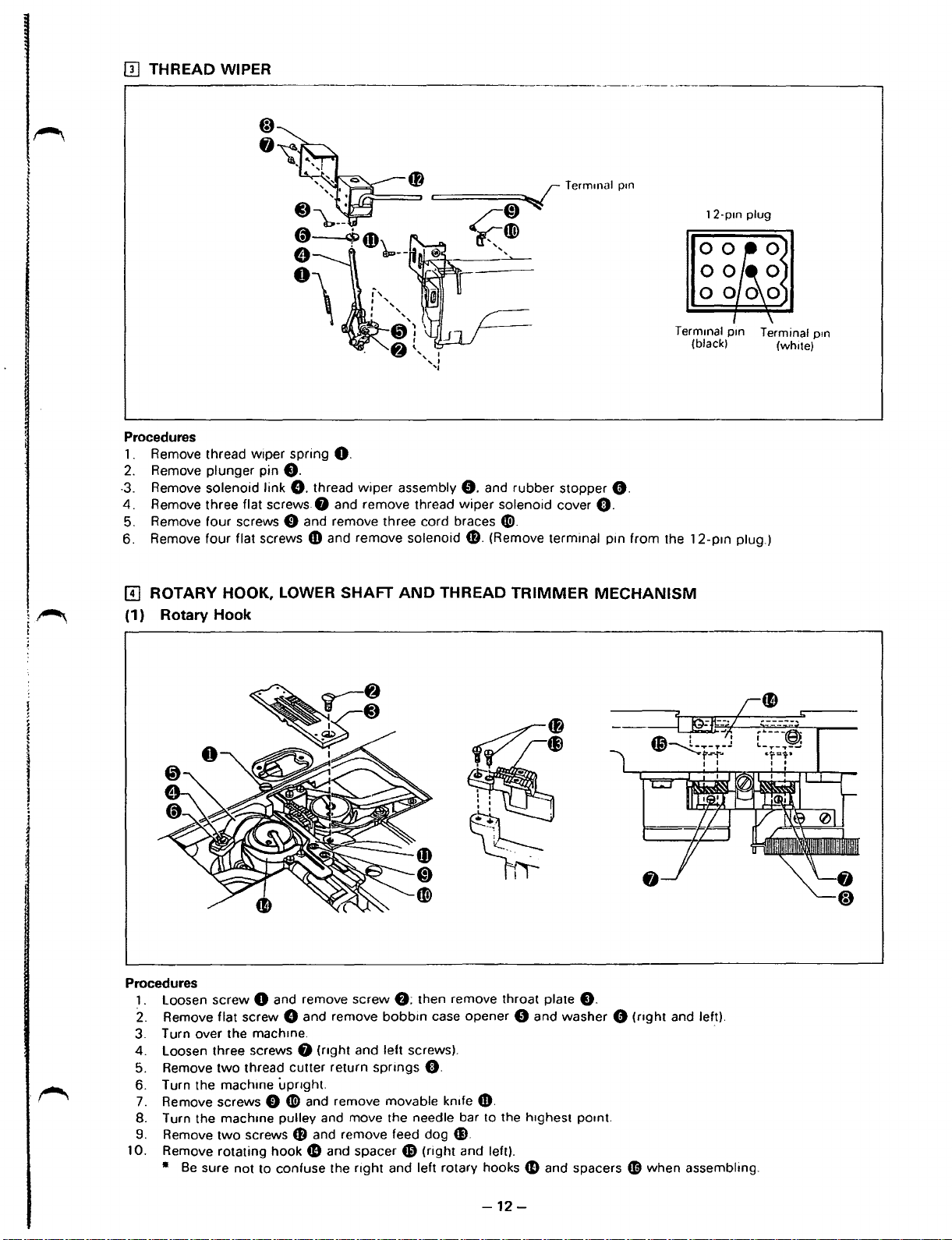

[!]

THREAD WIPER

trri-==f)~

c:====~~

.reD

c(~a.>

Procedures

1.

Remove thread wiper spring

2.

Remove plunger pin

-3.

Remove solenoid link

4.

Remove three flat screws 8 and remove thread

5. Remove four screws 0 and remove three cord braces

6. Remove

ffi

ROTARY HOOK, LOWER SHAFT

four

flat screws

O.

(1) Rotary Hook

O.

0.

thread

wiper

CD

and remove solenoid

assembly

AND

THREAD

0.

wiper

f).

Termrnal

.........

and rubber stopper

solenoid cover

0.

0.

(Remove terminal pm

TRIMMER

MECHANISM

prn

0.

12-prn

Termmal prn Terminal

(black) (white)

from

the 12-p1n plug.)

plug

p1n

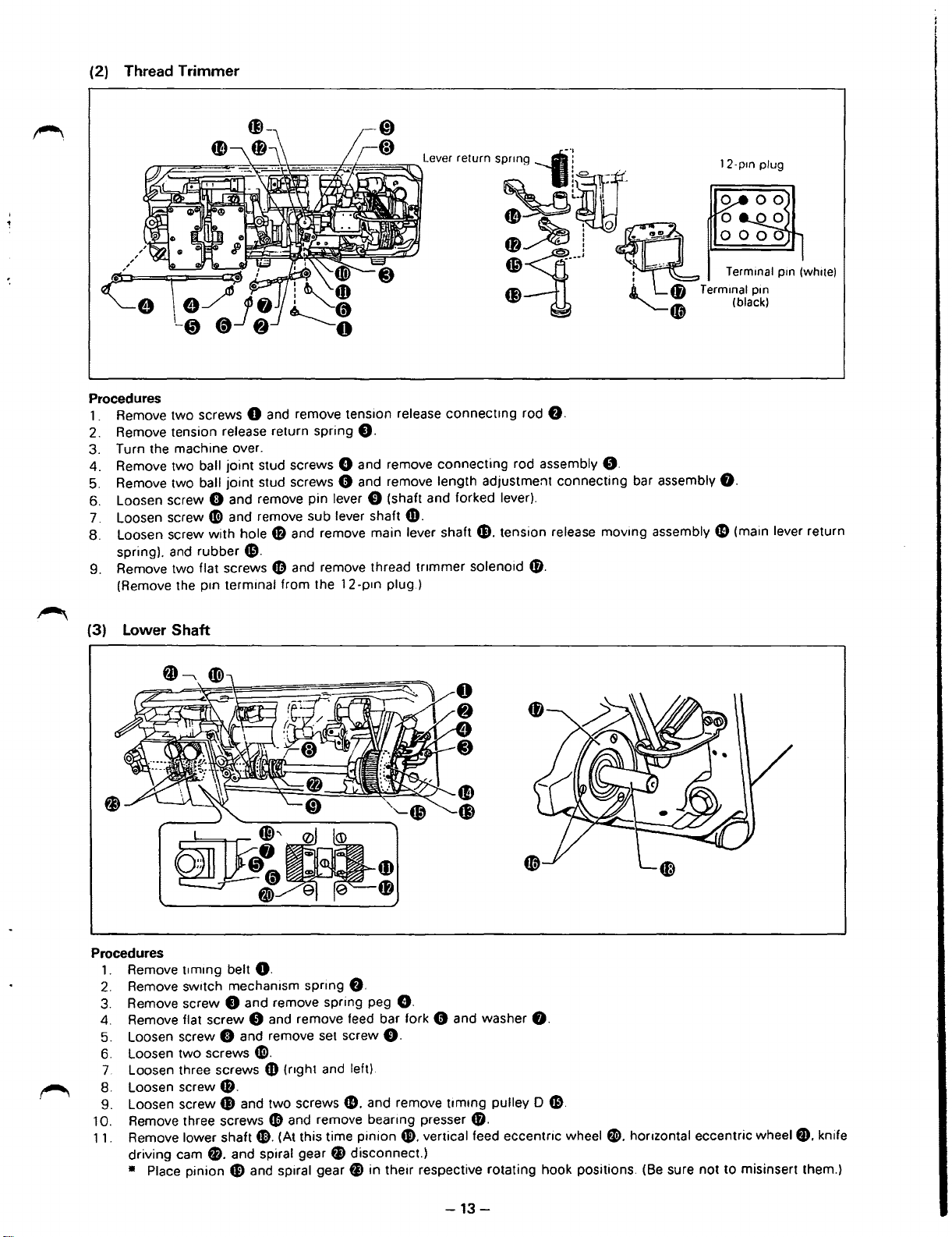

Procedures

1.

loosen

2.

Remove flat screw 0 and remove

3. Turn over the mach1ne.

4.

loosen

5.

Remove

6. Turn the mach1ne

7.

Remove screws 0 0 and remove movable

8. Turn the machme pulley and move the needle bar to the h1ghest pomt.

9.

Remove

10. Remove rotating hook

•

screw 0 and remove screw

three screws 8

two

thread cutter return

two

screws

(nght

upnght.

CD

and remove feed dog

fD

Be

sure not to confuse the

bobbin

and left screws).

spnngs

and spacer

right

and left rotary hooks

f);

then remove throat plate

case opener 0 and washer 0

0.

kn1fe

CD.

CD.

CD

(right and left).

fD

and spacers

-12-

0.

(nght

and

lef_t).

CD

when assembling.

Page 16

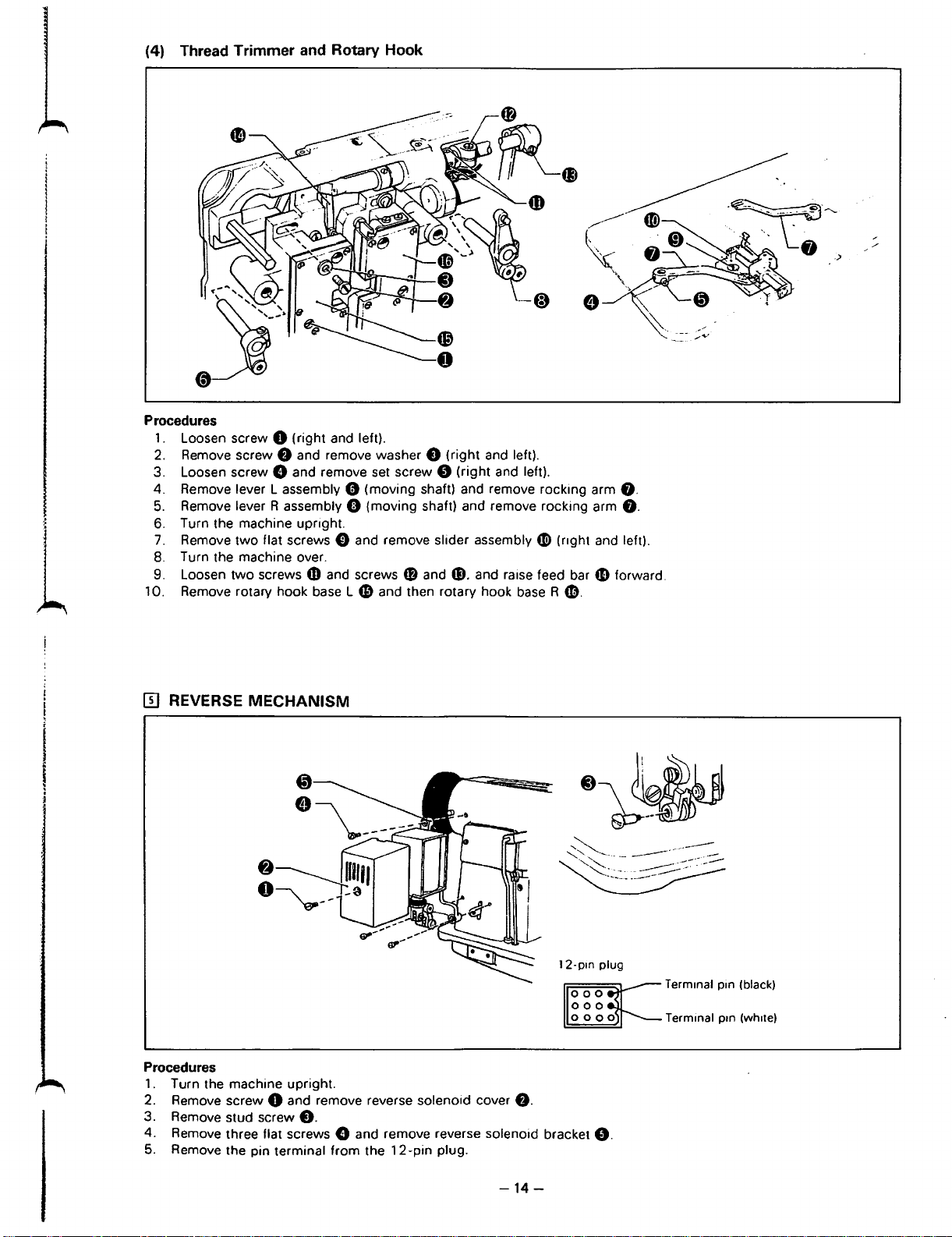

(2) Thread Trimmer

lever

relurn

s~l~lf

-~~~~

fB~!

~~---•

C) A L

Procedures

1 . Remove two screws 0 and remove tension release connectmg rod

2. Remove tension release return spring

3. Turn the machine over.

ball

joint

4. Remove two

5. Remove two ball joint stud screws 0 and remove length adjustment connecting bar assembly

6. Loosen screw 8 and remove pin lever 0 (shaft and forked lever).

7. Loosen screw

8. Loosen screw

spring). and rubber

9. Remove two flat screws

(Remove the prn terminal from the 12-prn plug.)

41)

with

stud screws 0 and remove connecting rod assembly

and remove sub lever shaft

hole$

and remove main lever shaft fl. tension release moving assembly e (main lever return

Gl.

4D

and remove thread tnmmer solenoid

0.

fD.

8.

(D.

0.

.

-~

:

-~

fB

~(@

T ermrnal prn

12-prn plug

T ermmal pm (whrte)

(black)

8.

(3) Lower Shaft

Procedures

1.

Remove

2.

Remove switch mechanism sprrng

3.

Remove screw 0 and remove spring peg

4.

Remove flat screw 0 and remove feed bar fork 0 and washer

5. Loosen screw 8 and remove set screw

6. Loosen two screws

7.

Loosen three screws

8. Loosen screw

9. Loosen screw G) and two screws

10. Remove three screws

11. Remove lower shaft 1). (At this time pinion

driving cam

• Place pinion G) and spiral gear

t1mrng

belt

8.

41).

fD

8.

fl. and spiral gear

G.

O.

f).

(nght and left)

e.

and remove timrng pulley 0

fD

and remove beanng presser

G>.

f1

disconnect.)

fi

in therr respective rotating hook positions.

vertical feed eccentric wheel fl. horrzontal eccentric wheel

fD.

8.

Gl.

(Be

sure not to misinsert them.)

fD.

knife

-13-

Page 17

L

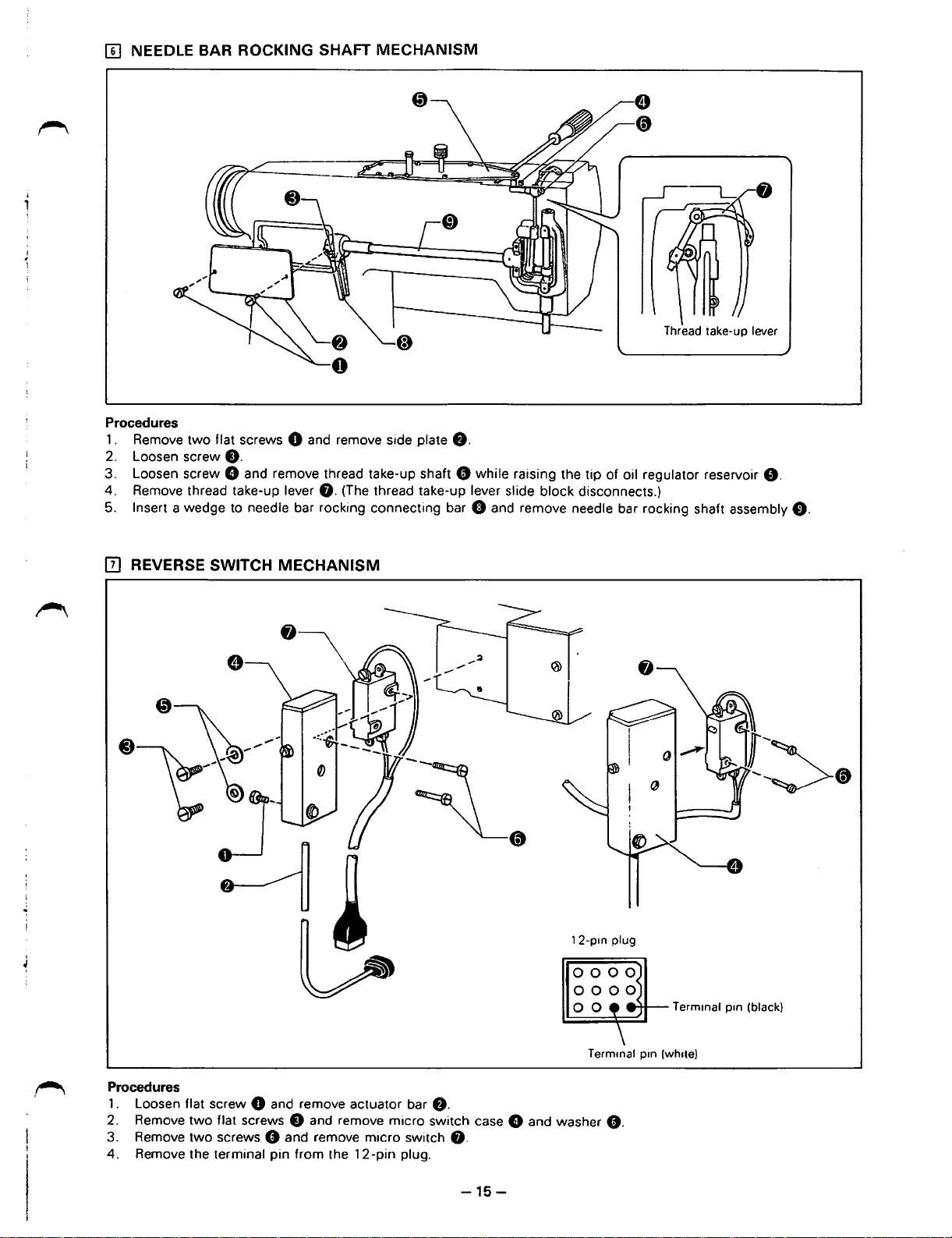

(4) Thread Trimmer and Rotary Hook

Procedures

1.

Loosen screw 0 (right and left).

2.

Remove screw

3. Loosen screw 8 and remove set screw 8 (right and left).

4. Remove lever L assembly 0 (moving shaft) and remove rocking arm

5.

Remove lever R assembly 0 (moving shaft) and remove rocking arm

6. Turn the machine upright.

7.

Remove two flat screws 0 and remove slider assembly

8.

Turn the machine over.

9. Loosen two screws

10. Remove rotary hook

f)

and remove washer 0 (right and left).

4D

and screws

baseL

fD

and ~-and raise feed bar G) forward.

49

and then rotary hook

4D

(nght and left).

base

R

CD.

8.

f).

[[]

REVERSE MECHANISM

12-pm

Procedures

1.

Turn the machine upright.

2. Remove screw

3. Remove stud screw

4. Remove three flat screws 8 and remove reverse solenoid bracket

5.

Remove the pin terminal from the

0 and remove reverse solenoid cover

0.

12-pin

plug.

f).

plug

8.

Term1nal

Terminal

pm

pm

(black)

(wh1te)

-14-

Page 18

[II

NEEDLE BAR ROCKING SHAFT

Procedures

1. Remove

2. Loosen screw

3. Loosen screw 8 and remove thread take-up shaft 0 while raising the tip of oil regulator reservoir

4. Remove thread take-up lever

Insert a wedge to needle bar rocking connecting bar 0 and remove needle bar rocking shaft assembly

5.

two

flat screws 8 and remove side plate

f).

8.

MECHANISM

Thread take-up lever

f).

(The thread take-up lever slide block disconnects.)

0.

0.

[I] REVERSE SWITCH

MECHANISM

Term1nal pin (black)

Procedures

1 . Loosen flat screw 8 and remove actuator bar

2. Remove

3. Remove two screws 0 and remove micro switch

4. Remove the terminal pin from the

two

flat screws 8 and remove micro switch case 8 and washer

12-pin

f).

f).

plug.

-15-

T ermmal pin

0.

(wh1te)

Page 19

l ASSEMBLY PROCEDURES)

OJ

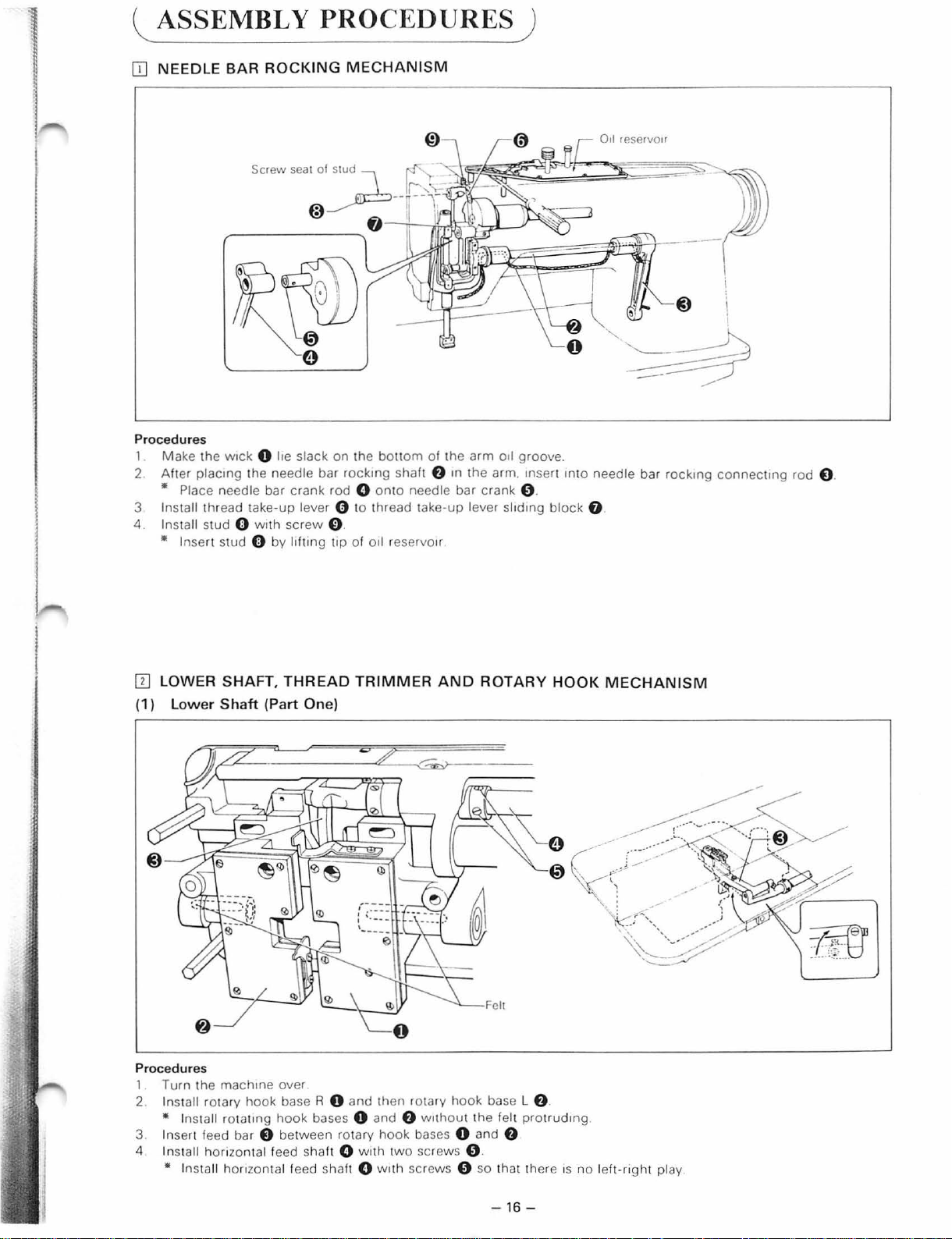

NEEDLE BAR

Procedures

1 Make

2

the

Alter

placmg

• Place needle bar

3 Install thread take-up lever 0 to thread take-

4. Install

stud 0 wnh

• Insert stud 0 by l1ftmg

ROCKING

w1ck

0 he slack

the needle bar

crank

screw

MECHANISM

on

the

bottom

rockmg

rod 0 onto

shaft

0 .

t1p

of

oil

reservo1r

of

the

f)

m

the

needle bar

up

arm

oil groove.

arm. 1nsert mto needle bar

crank

0 .

lever slidmg

block

0 .

rockmg

connectmg

rod

O.

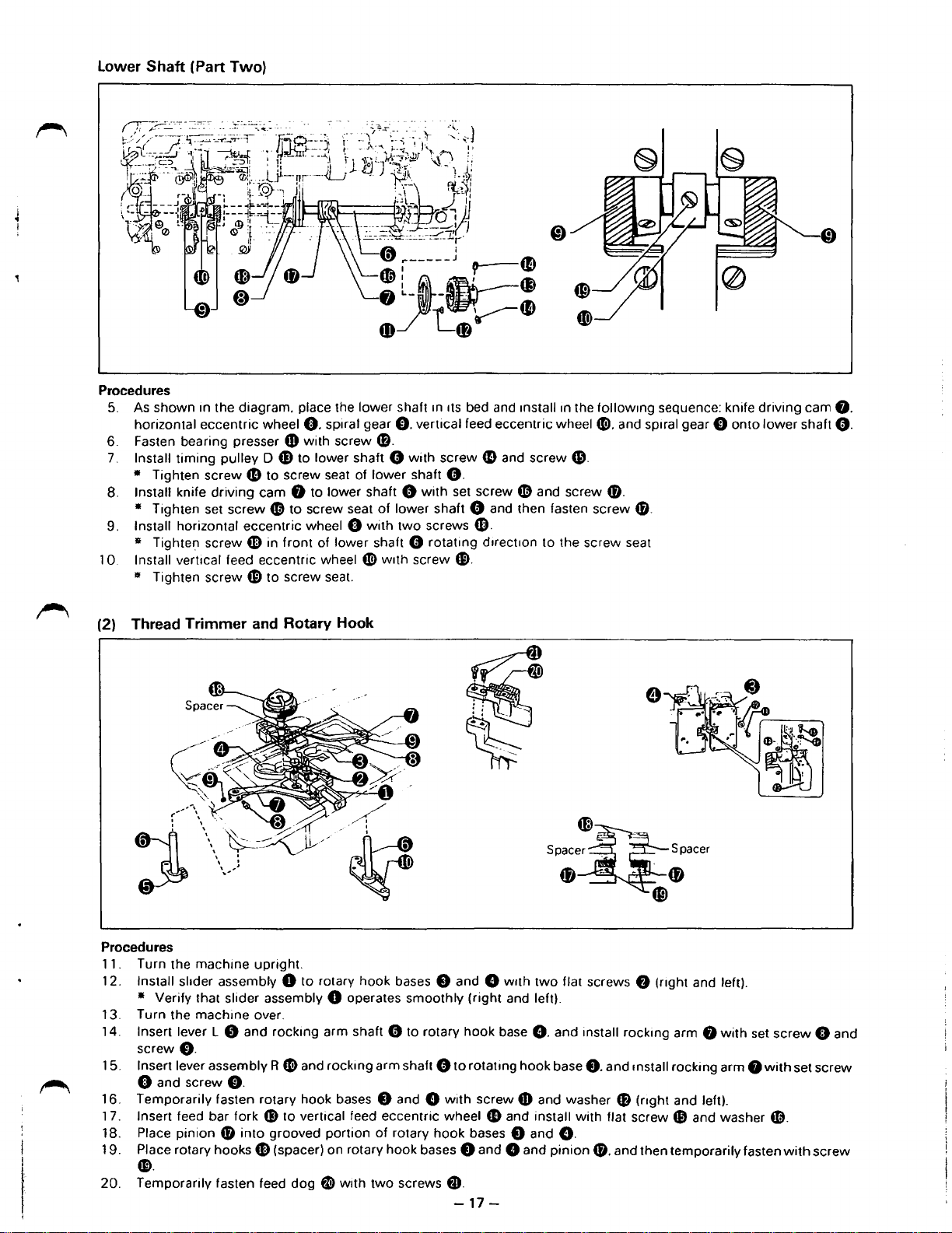

ITJ

LOWER SHAFT,

(1)

Lower

Proc

edu

1. Turn the

2.

Install rotary

• Install ro t

3 Insert feed bar 0 between rotary

4 Install honzontal teed

• Install

Shaft

res

machme

homon

(Part

hook

at1ng

tal feed sha

THREAD

One)

over

base R 0

hook

and

bases 0

shalt 0 w1th two

lt 0 w1t

TRIMMER

then rotary

and

f)

w1thout t

hook

bases 0

screws 0 .

h screws 0

AND

hook

ROTARY

base L

he

felt prot

and

f)

so

that there 1s

HOOK

f)

.

rudmg

MECHANISM

.

no

lelt-nght

play.

-16-

Page 20

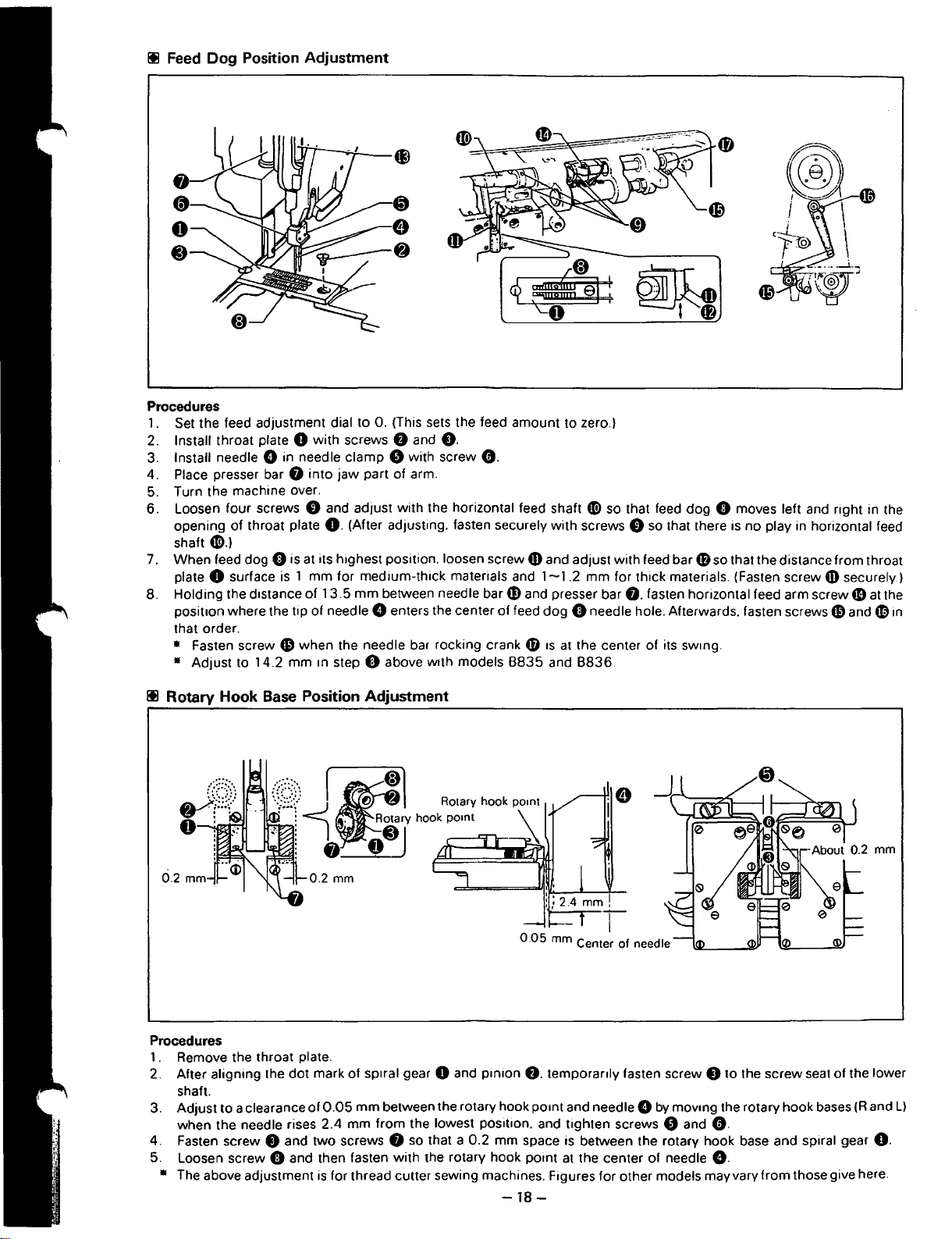

Lower Shaft (Part Two)

Procedures

5.

As

shown

1n

the diagram. place the lower shaft m

horizontal eccentric wheel

6. Fasten bearing presser

7.

Install

timing

pulley 0

• Tighten screw

8.

Install knife driving cam

• Tighten set screw ~ to screw seat

9. Install horizontal eccentric wheel 0

• Tighten screw

1 0. Install vertical feed eccentric wheel

• Tighten screw

G)

41

CB

Cl).

spiral gear

4D

with screw

f»

to lower shaft 0 with screw

to screw seat of lower shaft O.

f)

to lower shaft 0

in front of lower shaft 0 rotating

to screw seat.

1ts

bed and 1nstall

C).

vertical feed eccentric wheel«!). and Spiral gear

1n

the followmg sequence: knife driving cam

0.

G)

and

screw$.

with

set screw

of

lower shaft 0 and then fasten screw 0).

with

two

screws

«!>

w1th

screw

CB.

Cl).

d1rect1on

4D

and screw 0).

to the screw seat

C)

onto

lower shaft

f).

0.

~

(2) Thread Trimmer

Procedures

11

.

Turn the machine upright.

12.

Install slider assembly 0 to rotary hook bases e and 8 With

• Verify that slider assembly 0 operates smoothly (right and left).

13.

Turn the machine over.

14.

Insert lever L 0 and rockmg arm shaft 0 to rotary hook base

0.

screw

15.

Insert lever assembly R «!)and rockmg arm shaft 0

0 and screw

16.

Temporarily fasten rotary hook bases 8 and 8

17.

Insert feed bar fork

18.

Place pinion

19.

Place rotary hooks G) (spacer) on rotary hook bases 8 and 8 and

0)

and

f).

G)

into

grooved portion

Rotary Hook

to

rotatmg hook base

with

to vertical feed eccentric wheel

of

rotary hook bases 8 and

fD

spacen~

fJ)

two

flat screws • (nght and left).

8.

and install rockmg arm

screw 0 and washer 0 (nght and left).

G)

and install with flat screw

0.

pinion

-

..

spacer

~

Cfj

f)

f)

8.

and mstall rocking arm

41

and washer

0). and then temporarily fasten

with

set

f)

screw

with

~.

with

0 and

set screw

screw

••

Temporarily fasten feed

20.

dog

~with

two

screws

f».

-17-

Page 21

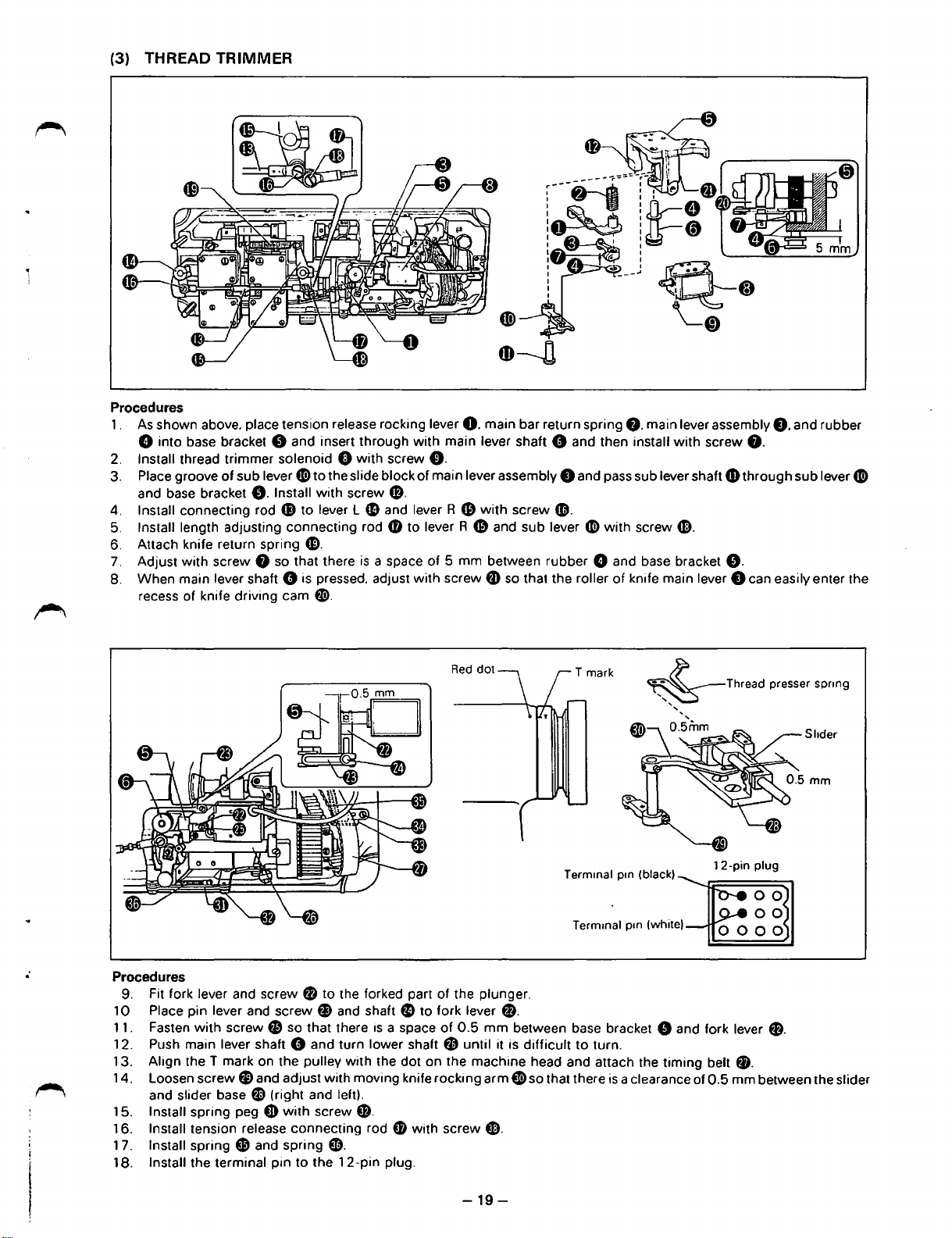

Ill

Feed

Dog Position Adjustment

Procedures

1. Set the feed adjustment dial to 0. (This sets the feed amount to zero.)

Install throat plate 0 with screws 8 and

2.

3. Install needle Gin needle clamp 0 with screw

4. Place presser bar 8

5. Turn the machine over.

6. Loosen four screws

opening of throat plate

tii).)

shaft

7. When feed dog 0 is at its highest position. loosen screw

0 surface is 1 mm for medium-thick materials and

plate

8. Holding the distance of

posit1on where the tip of needle 0 enters the center of feed

that order.

• Fasten screw

Adjust to 14.2 mm m step 0 above

•

into

jaw

part of arm.

0 and adjust with the horizontal feed shaft

0.

(After adjusting. fasten securely with screws 0

13.5

mm

between needle

fl

when the needle bar rocking crank 0

8.

w1th

G.

bare

models

tii>

fD

and adjust with feed bar

1-1

.2

mm for thick materials. (Fasten screw

and presser bar

dog

0 needle hole. Afterwards. fasten screws

1s

at

the center of its swmg.

8835

and

8836.

so that feed dog 0 moves left and right in the

so

that there is no play in horizontal feed

48

so that the distance from throat

fD

securely.)

8.

fasten horizontal feed arm

screw.

CD

and

at the

4D

in

Ill Rotary Hook

Procedures

1 . Remove the throat plate.

2. After aligning the

shaft.

3. Adjust

when the needle rises

4. Fasten screw 8 and two screws 8 so that a

5. Loosen screw 0 and then fasten with the rotary hook point

• The above adjustment

Base

to

a clearance

Position Adjustment

dot

mark of

of

is

sp1ral

gear 0 and pinion

0.05

mm between the rotary hook pomt and needle 0

2.4

mm from the lowest positiOn. and tighten screws 0 and

0.2

for thread cutter sewing machines. Figures for other models may vary from those give here.

8.

mm space is between the rotary hook base and spiral gear

-18-

temporanly fasten screw 8 to the screw seat of the lower

by

movmg the rotary hook bases (Rand

L)

0.

O.

at

the center of needle

8.

Page 22

(3)

THREAD TRIMMER

~!l

~

Procedures

1 .

As

shown above. place tension release rocking lever

8 into base bracket 8 and insert through

2.

Install thread trimmer solenoid 8 with screw

3. Place groove

and base bracket

4. Install connecting rod G)

5. Install length adjusting connecting rod

6. Attach knife return spring

7.

Adjust

8. When main lever shaft 0 is pressed. adjust with screw

recess of knife driving cam

of

sub lever G) to the slide block of main lever assembly 8 and pass sub lever shaft

0.

Install

with

screw 8 so that there

to

G).

e.

with

lever l

screw

CD

is

with

$.

and lever R

4J)

to lever R

a space of 5 mm between rubber 8 and base bracket

0.

main lever shaft 0 and then install

0.

CD

main bar return spring

with

screw

4D.

CD

and sub lever 0 with screw

tD

so

that the roller

of

8.

main lever assembly

with

screw

8.

and rubber

8.

CD

through sub lever G)

CD.

8.

knife main lever 8 can easily enter the

..

Red

dot

·

Procedures

9. Fit fork lever and screw 0 to the forked part of the plunger.

0 Place pin lever and screw

1

1 1 . Fasten

12. Push main lever shaft 0 and turn lower shaft

13. Align the T mark on the

14.

15.

16. Install tension release connecting rod G with screw

1

7.

18. Install the terminal pin

with

screw

f1'

loosen

Install spring peg

Install spring G and spring (b.

screw

and slider base

tl

and adjust with moving knife rocking arm e so that there

8 (right and left).

fD

f»

and shaft

so that there

pulley with the dot on the machine head and attach the timing belt

with

screw G.

to

the

12-pin

is

a space

plug.

f)

to fork lever

of

fJ

0.

0.5

mm

until it is difficult

G).

between base bracket 8 and fork lever

T mark

Termmal

Termrnal pm (white)

to

turn.

o/

prn (black)

is

a clearance of

o.5mm

0.5

Thread presser spnng

Shder

12-pin

plug

00

0.

f).

mm between the slider

-19-

Page 23

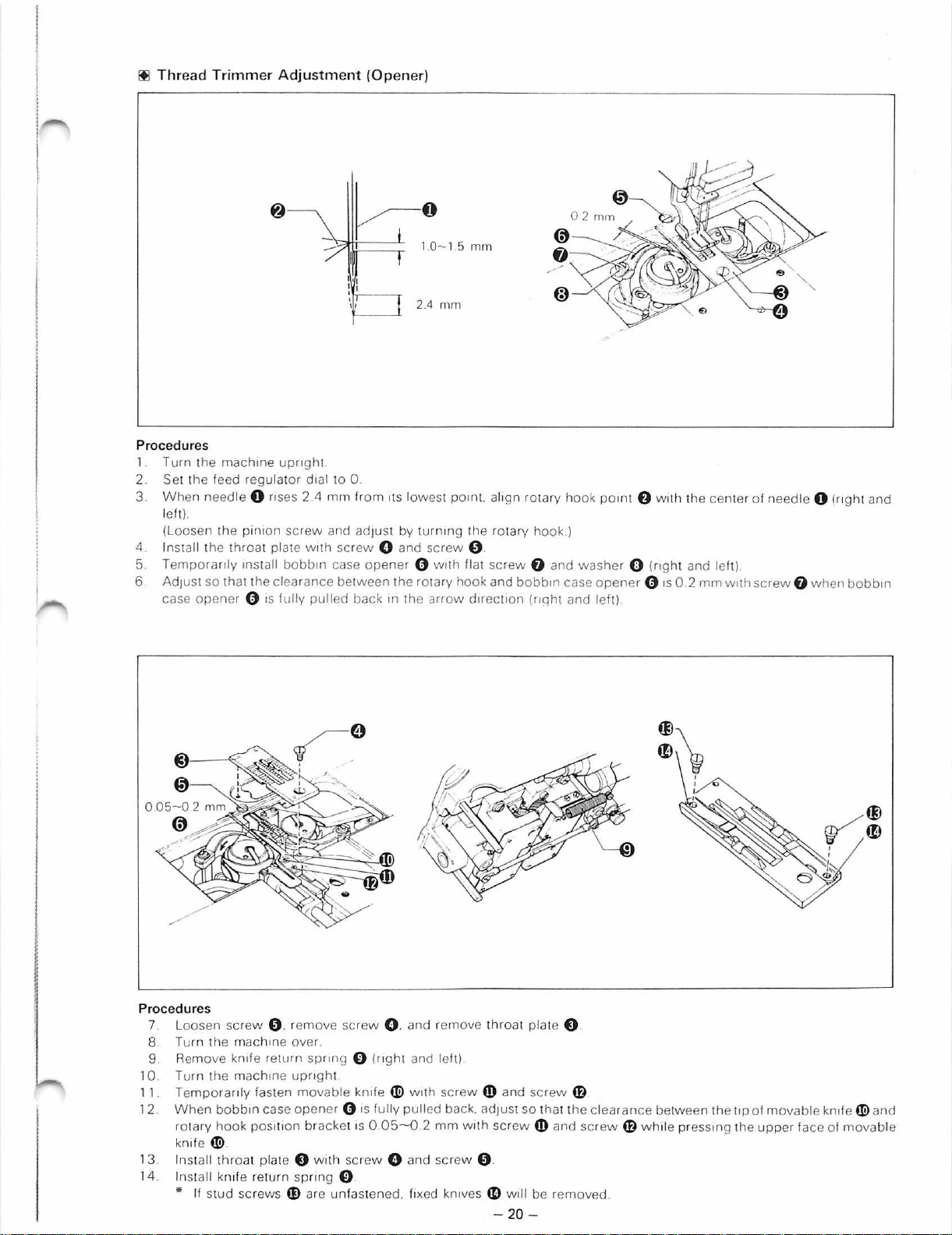

ltl

Thr

ead

Trimm

er

Adjustment (Op

ener)

Procedur

1. Turn

2. Set the feed regulat

3.

4

5.

6

es

th

e mach1ne

Wh

en

needle

left).

(L

oosen

th e

Insta

ll the

Temporarily

Adju

St

so

that the

case

opener 0 IS

0 nses 2.4 mm fr

pin1

on screw and

throat plate

1nstall bobb1n case

upnght.

or

d1al

to 0.

w1th screw

clearance bet

fully

pulled

~

om

adjus

0

1.0

2.4

1ts

low

t by t

urnmg

0 and

opener 0 wllh

ween

the

rotary

back

1n

the

-1.5

mm

est

pom

screw

arrow

mm

t.

al1gn

th e

9 .

flat

screw

hook

and

d1rect1on

rotary hook

rotary

hook

0 and

bobb1n case

(nqht and

pomt

f)

.)

washer 0 (nght

opene

r 0

left).

w

llh

1s

the

and left)

0 2

mm

center

wllh

of

needle 0

screw 0 when

(r1ght

bobbm

and

Procedur

7. Loosen

8. Turn

9 Remove

10. Turn t

1 1.

1 2

13 . In stall

1 4. Install knife re

es

sc

rew 9 . r

the mac

he

Temporan

Wh

en

rotary hook

kn1f

e W.

'" If stud sc rews

hme over.

kn1

fe return

machme upngh

ly fasten

bobb

1n

case

pOSitiOn

thr

oa t plate 0 w1th sc

turn

emove

opene

spn

CD

screw 0 . and remove t

spnng 0 (ngh

t

movable

bracket IS 0 .

are unfastened. f1xed

knife w Wi

r 0 IS fully

rew

ng

0 .

05-0 2 mm

0 and screw 9 .

t and left)

th

screw

pulled

back. adj

kn1ves

hro

at plate 0 .

m and

uSt

With screw

4D

will

- 20 -

screw

so

th at t

41)

and

be removed.

=

~

I

I

I

I

4D

he

clearance between the lip

SCrew

4!)

while

pressmg

of

movable knife W and

the

upper

face of

movab

le

Page 24

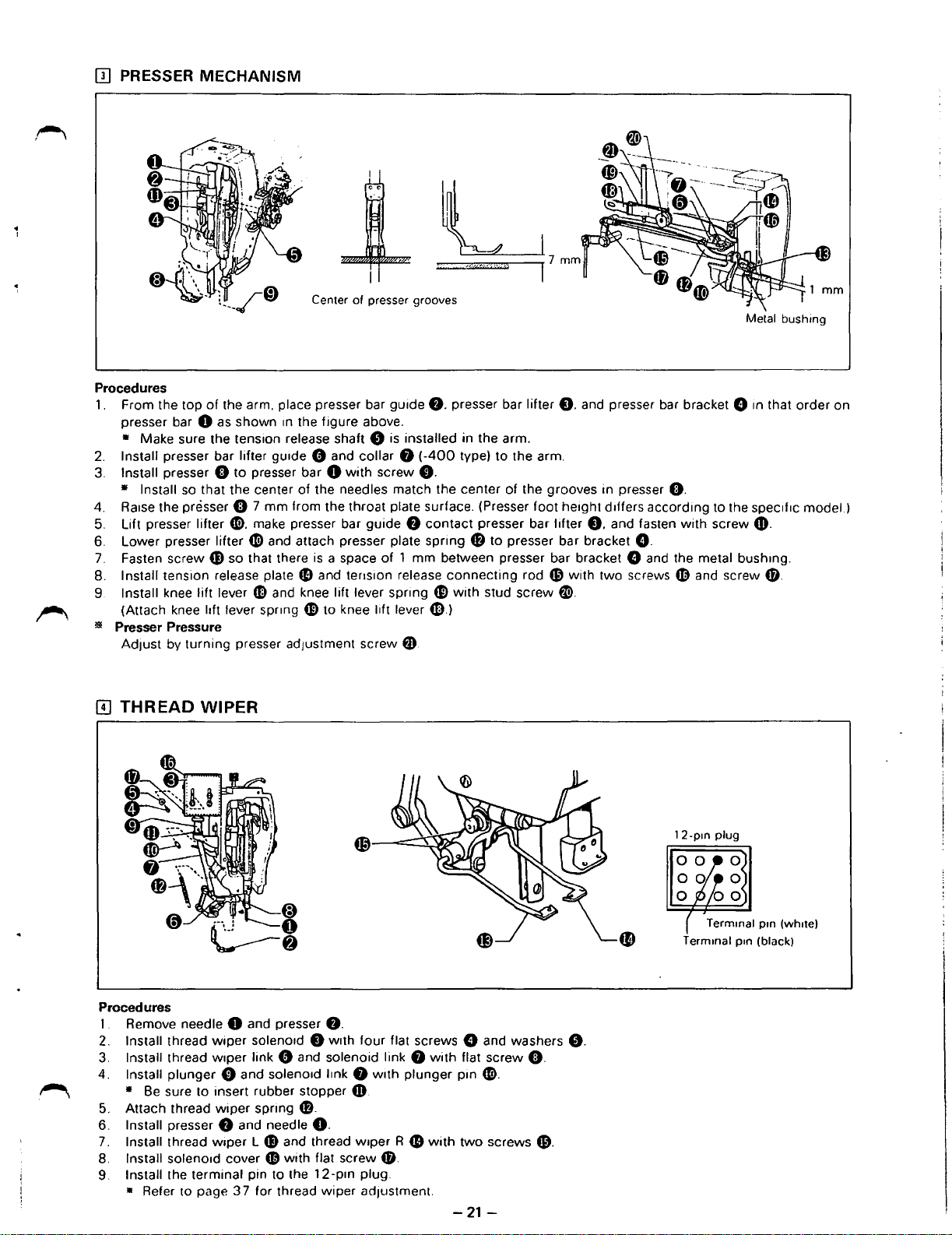

[I]

PRESSER MECHANISM

Center

of

presser grooves

Procedures

1.

From the top

presser bar

• Make sure the tens1on release shaft 0

2.

Install presser bar lifter gUide 0 and

3.

Install presser 0

• Install so that the center

4. Raise the presser 0 7

5.

Lift presser lifter

6.

Lower presser lifter (!) and attach presser plate spring

7.

Fasten screw

8. Install tension release plate

9 Install knee lift lever

(Attach knee lift lever

!11!

Presser Pressure

AdJUSt

of

the arm. place presser bar guide

0 as shown in the figure above.

collar 8 (-400

to

presser bar 0

of

mm

from the throat plate surface. (Presser foot he1ght d1ffers according to the

0.

make presser bar

G)

so that there

fB

CD

and knee lift lever spring

spr1ng

by turning presser adJustment screw

with

screw

the needles match the center of the grooves in presser

guide 8 contact

is

a space

and tension release

fD

to

of

knee lift lever

is

1 mm between presser bar bracket 8 and the metal bushmg.

0.

presser bar lifter

installed in the arm.

type) to the arm.

0.

presser bar lifter

fB

to

presser bar bracket

connecting

fD

with

stud screw

.:D.)

tD.

0.

and presser bar bracket 8

rod (D with

fli).

0.

and fasten

two

G.

screws

0.

with

4D

and screw

screw

Metal

bushmg

1n

that order on

spec1f1c

CD.

fD_

model.)

II)

~

THREAD

Procedures

1 . Remove needle 0 and presser

2.

Install thread

3.

Install thread

4. Install plunger 0 and soleno1d

• Be sure to insert rubber stopper &.

5.

Attach thread

6. Install presser

7.

Install thread

8. Install solenoid cover

9. Install the terminal pin to the

• Refer to page 3 7 for thread

WIPER

wiper

wiper

wiper

f)

and needle

wiper

f).

soleno1d 8

link 0 and solenoid link 8

spring

CD.

w1th

four

flat screws 8 and washers

l1nk

f)

With plunger pin (!).

0.

L

G)

and thread w1per R

4D

with flat screw

12-pm

wiper

plug.

adJUStment.

4D

0.

with

with

flat screw

two

screws

0.

(D.

-21-

8.

Page 25

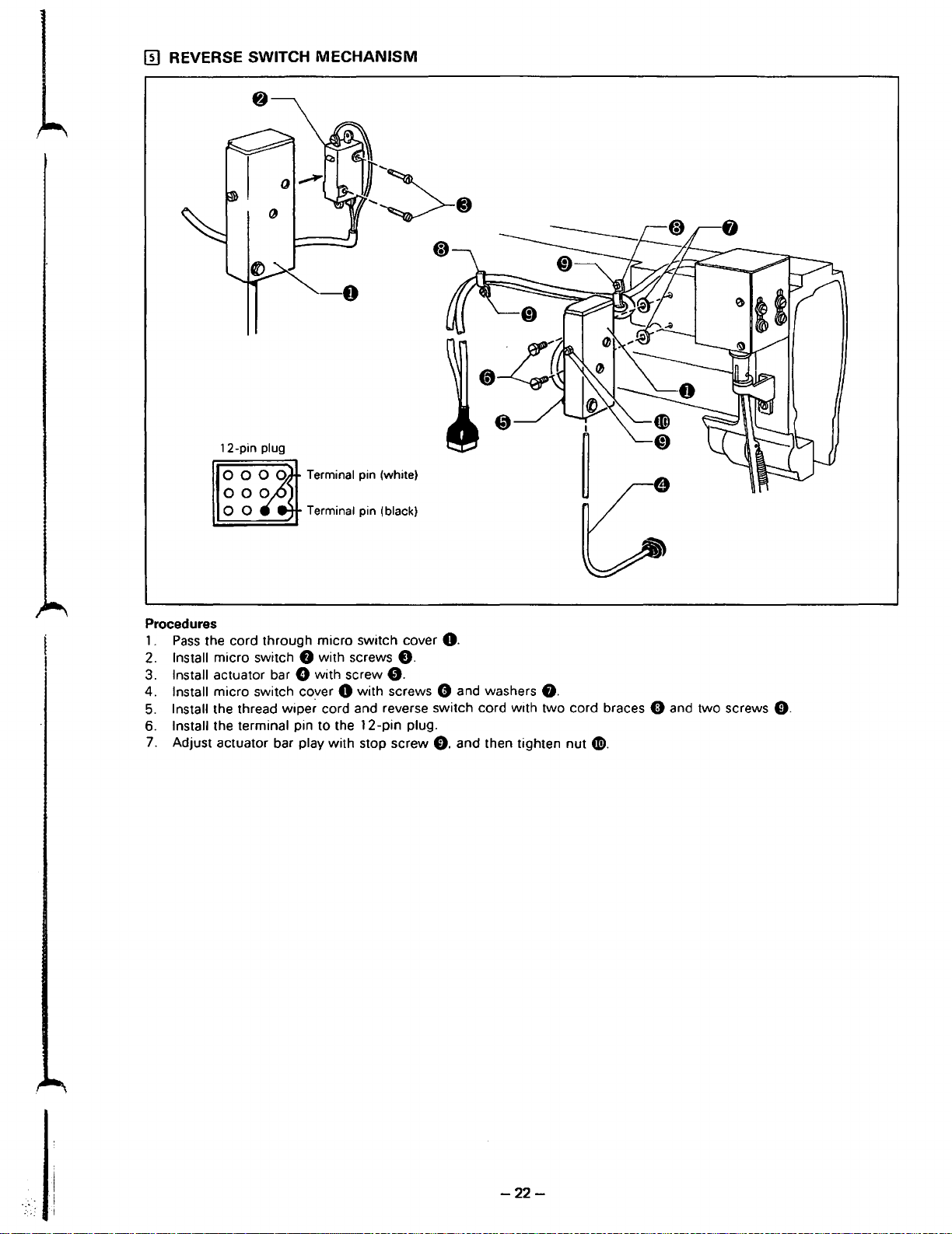

II]

REVERSE SWITCH

12-pin

MECHANISM

-0

plug

Terminal pin (white)

Procedures

1 .

Pass

the cord through micro switch cover

2. Install micro switch

3. Install actuator bar 0 with screw

4. Install micro switch cover 0 with screws 0 and washers

5. Install the thread

6. Install the terminal pin

7. Adjust actuator bar play with stop screw

f)

with screws

4:).

wipe~

cord and reverse switch cord with two cord braces 0 and two screws

to

the

12-pin

0.

plug.

0.

0.

and then tighten nut

8.

0.

~.

-22-

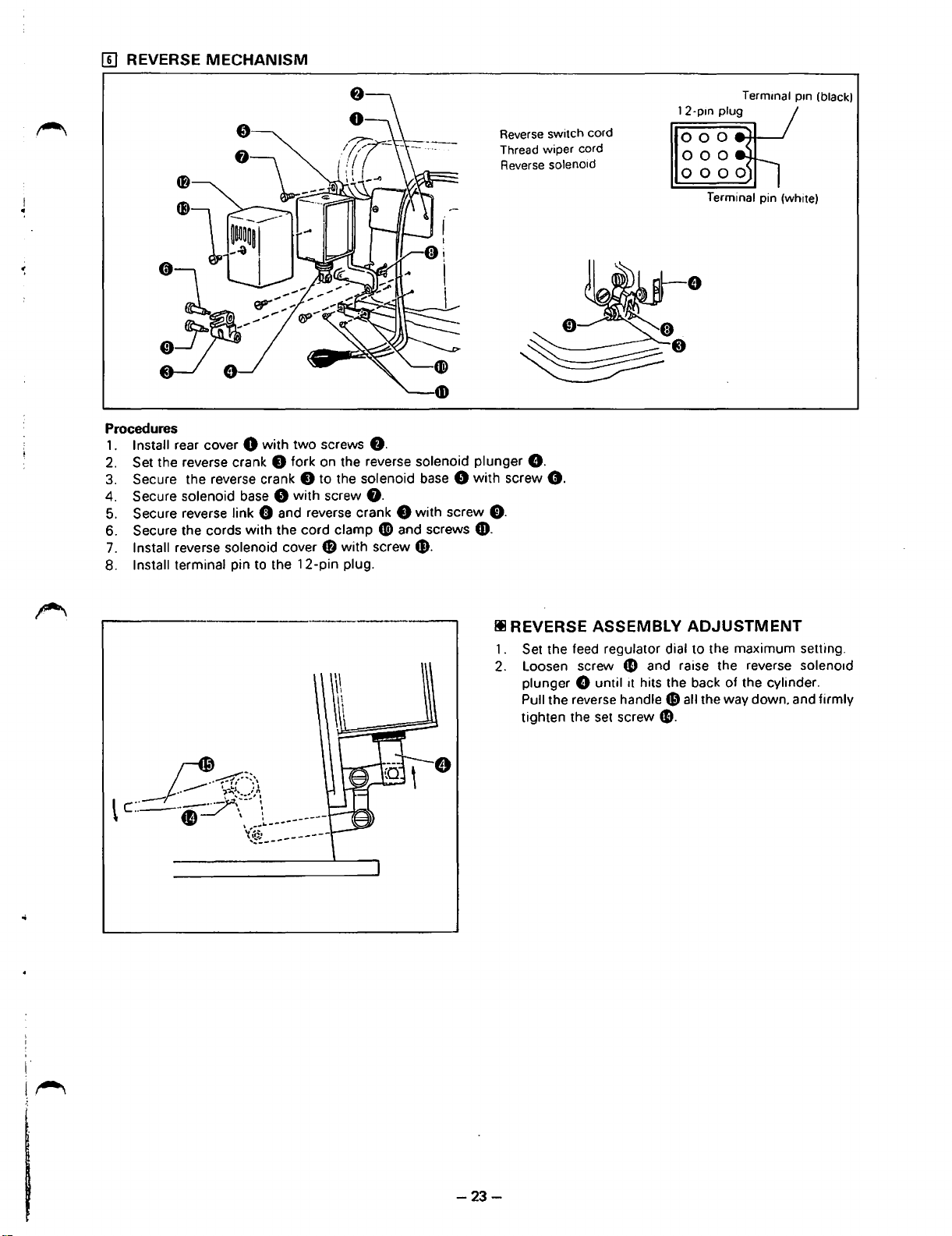

Page 26

[!]

REVERSE MECHANISM

Procedures

1.

Install rear cover 0 with two screws

2.

Set the reverse crank 0 fork on the reverse solenoid plunger

3.

Secure the reverse crank 0 to the solenoid

4. Secure solenoid base 8 with screw

5.

Secure reverse link 0 and reverse crank 0 with screw

6. Secure the cords

7.

Install reverse solenoid cover

8. Install terminal pin to the 12-pin plug.

with

the cord clamp

f)

with

8.

f).

Gi)

and screws

screw$.

base 8 with

Reverse switch cord

Thread wiper cord

Reverse solenoid

8.

screw

f).

0.

CD.

12-pm

Termmal pm (black)

plug

Terminal

pin (white)

Ill REVERSE ASSEMBLY

1.

Set the feed regulator dial to the maximum setting.

2.

Loosen screw

plunger

Pull the reverse handle

tighten the

G until

set

fD

1t

screw

ADJUSTMENT

and raise the reverse soleno1d

hits the back of the cylinder.

49

all the way down. and firmly

e.

-23-

Page 27

[I] COVER

Procedures

1.

Install needle position detector 0 with two screws

2. Install synchronizer cover 0 with two screws G (and washers).

Install top cover 8 with screws 0 and

3.

4. Install face plate 0

5.

Install cover

6. Install slide plate R fl) and slide plate L

7.

Install slide plate F assembly & and stop with screw

with

4D

with two screws

stud screw 0 (and washer) screw

f).

f).

e.

8.

CD.

fD.

Page 28

(

sTANDARD

OJ

NEEDLE

AND

FEED

ADJ USTMENT (B831, B832, B835, B836, B882))

TIMING

(88

31 )

1. Remove

2.

T11t

the

machme

3.

Align

pos1110n 4 on

Hold the arm shaft

4.

t1mmg belt 0

5. R1ght the

!tl

Needle

and

the

needles.

on

machme

Feed

head. and remove

the

machme

f1rm

. align the

the

pulley

.

head and mstall the needles.

Timing

pulley

(Stand

the

arrow

ard

t1m1ng

with

on the

mod

belt 0 .

the red dot.

lower

be

el

8832, 8835,

lt 9 w

ith

the r

8882)

eference

line

on

the arm bed and

mount th

e

1 . Remove the needles.

2. Tilt the

3.

Turn the machme pull

4.

Whil

the arm

5. Return the

machme head back and

ey

e holding the

bed. and attach the

upp

mach

me head to its

er shaft so that

remov

until the ··A·

11mm

g belt 0

ongmal pOSi

e the

t1m1n

mark

1s

aligned w1th

11

won·t move. al

tion.

g belt 0 .

the red dot.

ign the

arrow

and

mstall the need les

on th e

low

er belt pulley 9

with

the referen

ce

line on

Page 29

Ill Thread Cutter Timing

(8832/

8835

with Thread Cutter)

~essthan

II

H

I~

@Thread Cutter Timing

1.

Remove the needles and tilt the head

2.

With main lever shaft 0 depressed. turn the machine pulley in its normal rotating direction unitl it gets hard to turn.

3. The T mark on the machine

(The

permissible deviation of the upper

pulley scale must

back.

be

in line with the red

and

lower shaft timing T mark from the center of the red

dot

on the machine head.

dot

is

2 mm.)

mm

@Upper and Lower

1 . Remove riming belt

2.

Turn the machine pulley until upper and lower shaft timing T mark

With

3.

4. Keep the machine

5.

main lever shaft 0 depressed. turn lower belt wheel

Recheck the upper and lower shaft timing T mark on the machine pulley.

•

Refer to the next page if the lower belt wheel

Shaft

Timing

O.

pulley and lower belt wheel

f)

in the arrow direction until it gets hard to turn.

f)

still. and put timing belt 0 on.

f)

is

improperly adjusted.

is

in lme with the red dot.

-26-

Page 30

rll

Lower Belt Wheel Position

'

-

(8832,

Reference screw hole

8835,

8837

Red

with. Thread Cutter)

mark

T mark

•

Deviation

±6°

-6"

1. Align the reference screw hole of timing belt wheel lower 0 with theV-groovescrewseatof lower shaft

to lower shaft

(The reference screw hole

2. Push main lever shaft

in its normal rotating direction until it gets hard to turn (where the movable knife begins to move).

3. Align the T mark with the red dot.

4. Hold the

(Put the belt around the upper wheel first.)

5.

Push main lever shaft

• Check that at this point the

• Allowable deviation:

• If deviation

Select one. retighten reference screw

0 with reference screw

is

red.)

8.

0 so the main lever roller enters the cutter drive cam groove. and turn timing belt wheel lower

pulley and timing belt wheel lower

8.

and turn the pulley to a

red

dot is in line

±2.0

mm

is

greater than 2.0 mm. remove the timing belt. Additional positions

8.

f)

in place. and mount the timing belt

point

where

it

is hard to turn.

with

the T mark.

remount the timing belt

as

in steps

0.

are

provided at +6°, +3°. and -6°.

2.

3.

and 4. and recheck.

Thread Cutting Timing

O.

and screw it

f)

rll

Thread cutting timing too early

• Needle thread may pull

• Thread cutter will not function properly.

• Top right thread catcher will not function properly with cotton threads.

out

Ill Thread cutting timing too late

• Needle and thread wiper will strike.

• Improper thread cutting.

-27-

of needle hole.

Page 31

[TI

ADJUSTMENT

OF NEEDLE BAR

TO

PRESSER BAR GAP (Models

:m-s

cry

II®

1.

Set the feed regulator dial to 0.

2.

The required gap between the needle bar 0 and

f)

is

presser bar

If necessary. adjust

1 ) Loosen screws 0 and

2) Turn the needle bar vibrat1ng crank 0 until the

reqUired gap (dimension

needle bar

3) Make sure the needle comes to the center of the

needle hole 0 in the feed dog

0 if necessary.)

dog

Turn the feed

position (so the needle enters the center of the needle

hole).

dimension

as

below.

0 and presser bar

dnvmg shaft 0 to adjuSt the feed dog 0

A.

G.

A)

IS

obtamed between the

f).

0.

(Adjust the feed

II

II

8831

·8832·8882

8835·8836

B831,

Model

B832,

8835,

8836,

A

13.5 mm

14.2

mm

8882)

Gap

too

D1mens1on

small

A

Ill When dimension A

• The feed dog will strike the needle plate when the feed

control dial is set to maximum.

•.

Skipped stitches and needle breakage will occur.

Ill When dimension A

• The feed dog will strike the needle plate when the feed

control dial is set to maximum.

• This will cause skipped stiches and needle breakage.

Gap

too

large

-28-

is

too large (feed dog):

is

too small:

Page 32

0 NEEDLE

• Be sure to check the

1 . Needle to rotary hook point

AND

ROTARY HOOK

pos1t1on

TIMING

detector adJustment (p.43) after the needle and rotary hook

gap

ADJUSTMENT

t1m1ng

1s

adJuSted.

Rotary hook pomt

1. Loosen the

needles and rotary-hook

2. Adjust the engagement

and the end face

•

Tighten the screws

• The needle

guard position

2.

Needle bar

screws@.®

of

the

©for

guard

on the rotary hook

when

the rotary hook

rise

and height

and©.

t1ps

are about

of

the spiral gear

sp1ral

gear

the

sp1ral

* Needle bar rise spectf1cat1ons vary

reference marks is 2.4 mm.

Needle

Needle guard

0-0.15

and move the rotary-hook base 0 to the

0.05

mm.

f)

by adjusting the clearance between the inner side

f)

to about

gear

is

to prevent needle to rotary hook

is

replaced.

w1th

d1fferent models. Use the followmg table to

0.2

f)

in such a way

mm

by moving the spiral gear

as

mm

not

to

change the contact.

right

or

left until the clearances between the

of

the rotary-hook base 0

f)

to the

nght

or

left.

point

contact. Be sure to readjust the needle

adJUSt

the

r1se.

The gap between

Models-8831 ·

Model

118-831

118-832

118-835

836

118-882

Needle bar nse should be set

•

When

•

machine

8832 · 8835 · 8836 · 8882

Application

Thin materials

Regular materials

Th1ck materials

Thin materials

Regular materials

Thick

materials

Regular materials

Regular

adjusting the walking bar feed regulator dial on model

matenals

pulley scale

Standard

SynthetiC threads 2.6

Synthetic threads 2 6

to

2.4 mm on machmes

with

the red dot.

2.4

2 4

2.4

2.4

2.4

2.4

mm

mm

mm

mm

mm

mm

mm

mm

R1se

Thread cutter Standard

----

--

-

2.4

-

2.4

2.4

--

with

wh1ch a thread cutter

B831.

Feed dial

Thread cutter

----

-------

mm

mm

mm

2

2

3

2

2

3 0

3

3

~

~

--------.___

--------

0

0

~

--

1s

used .

press the feed regulator button and align the

-29-

Page 33

Ill

Needle

Needle

bar

bar

down

rise

pos1110n

@

and

Wh

needle

en ra1sed

bar

height

Needle bar

2 4

mm

down

POS

iti

On

e

Needle bar

down

posH10n

(

Mod

el LT2-

B832-400A

8831 . 8832. 8882

( 1)

When

the needle bar e

with the bottom

line

.. a ..

of

the needle

(2)

When

the needle bar E) IS 2 4

•

aligned

needle

Loosen the

When

and

with

center

the rotary h

rot

ary

hook

ll I

[Mod

el LT2-

]

IS

In

ItS

lowest

pOSitOin.

edge

of the needle bar

bar with

the bott

thr

om

.

ee set screws 0 . and al1gn the rotary h

ook

pomt1s

po~nt

IS

the

bottom

mm

above liS lowes t

edge

of the need le bar bush1ng 0 .

aligned

1 - 1 .5

mm

with

.

B835-400A

the

bushmg

edge

the

needle center.

• Slide t

needle

he

]

POS

all t

iti

needle

he

On

clamp

1nt0 the needle

bar

0 Loosen the set

of the needle bar

POSitiOn.

needle pOSitiOn refer

Atth

1s lime. the rotary

ook

pomt

conf1rm that the

Rotary

way

reference I

screw

0 . and

bushmg

with

the needle

hook

me

0 .

spacer

po1nt

.. a ..

of

the

needle

align

the needle

ence

line

hook po1nt

center

between the top

~

•''

<I

~P.-,---'-

bar

must

pos1110n

.. b ..

Of

the needle bar

mus

t be al1gned w1th the

of

N"d

lo

t- t 5

be aligned

reference

the

needle eye

""'"

mm

IS

8835·8836

(

1)

Wh

en the needle bar E)

the bottom

(2)

Wh

en

the

aligned w1th the

needle cente r.

Loosen t

(3)

When the

hook

po~nt

Remove the set

po1nt and the

• One full revolut1on

edge

of

needle bar E)

bott

he

thr

ee set

rotary

hook

mus

t be 1 - 1 5

screw

top

of the needl e eye

IS Ill

liS l

owest pOSitiOn. the needle

the

needle bar bush1ng O.

IS

2.4

mm

above liS lowest

om edge

scre

ws

po~n

t

IS

0 . turn t

of set sc

of the

needle bar bush1ng 0

0.

and

align the rotary

aligned

mm.

w1th

he

needle

1S

rew 0 will

the needle

clampset

1 - 1 .5

ra1se

screw

mm

.

or lowe

POS

iti

POSitiOn.

hook

cen

needle

At

th1s

po1nt

ter. t

he

0 .

and

r the needle cla

On

reference line

pOSit

iOn

lime. the rotary

with

the

needle center.

space bet

adJUSt

ween

so that the

mp

.. a ..

Of the needle

reference line

hook

po1nt

the top

space betwe

app rox. 0.6

bar

IS

al1

.. b ..

of the ne

must

be

aligned

of the needle eye

en

the

mm

gned

edle bar

w1th the

and

rotary

rotary

with

hoo

IS

k

Page 34

[I] ROTARY HOOK TO NEEDLE PLATE GAP

0.6-0.9

mm

Ill Standard models

* The rotary hook 0

0 position

to

needle plate 8 gap should be

to

adjust the gap.

Ill Thread cutter models

* The rotary hook 0 to needle plate 8 gap

*

When

replacing the rotary hook. loosen screw

• Somet1mes

(I]

ROTARY HOOK TO BOBBIN CASE OPENER GAP

two

spacers 0 are required. Both should

is

set to 1

0.

and remove the rotary hook

0.6

to

0.9

mm. Loosen screw 0 and adjust the vertical rotary hook

.3

mm

with

a spacer

be

inserted under the rotary hook.

0.

0.

being careful not to lose the spacer

* The rotary hook 0 to bobb1n case opener 8 gap should

be 0.2 mm when the bobbin case opener is pulled all

the way m the direction of the arrow. Loosen screw 0

and move the bobbin

adjust.

r:ase

opener 8 right

or

O.

left to

1.

Needle

2. Needle bar rise. height

Rotary hook to needle plate gap

3.

4. Rotary hook to

•

Be

to

rotary hook point gap . . . . . . . . . . . .

....................

bobbm case opener gap

sure

to

readjust rotary hook lubrication after replacing the rotary hook.

•Improper

needle stitch1ng.

broken

•Improper

.

needle

• Excessive gap: Shuttle body may

•Insufficient

• Excessive gap: Loose stitches.

•I

nsuff1c1ent gap: Damage to shuttle body

adjustment may result in improper

needles.

adjustment may result in improper

stitching. skipped stitches. thread breakage.

gap: Improper stitch tightness

right

and left

skipped stitches. thread breakage.

right

and left

not

be

properly

positioned near the needle plate.

ing

improper

..

..

-----·---~·-·

st1tch tighten-

_____

___,

Page 35

[I]

PRESSER FOOT

HEIGHT

ADJUSTMENT

1. Loosen

(Remove the face plate on model 8835

Refer

2. The presser foot 9 bott om should be 7 mm from the needle plate top. Loosen screw 0 . and vertiCally adjust the presser

bar

(F1rmly re

•

• Use a presser foot

sc

rew 0 . open the face plate 0 . and

to

the table

below

for the requ1red presser foot he

0 to adjust the he1ght.

tigh

ten

screw

0 after adjustment

Be

careful

with

Refer

not

to

turn

presser bar 0

w1th

no

front

thm and standard matenals

to

page 6 7 for presser foot types.

Subclassif

~

Presser

• The presser bar lifter lever should be adjusted to 5

foot

Presser

Knee l1fter

bar

height .............

lifter

gap

to prevent

icati

on

Model

lever

ra1se

the presser bar

·8836

.)

1ght.

IS

completed

Sti

8831 I 88321 8835

tch

sk1pp1ng

7

mm

10

)

mm

l1

fter lever O.

or

thread cast-off at the start of sew1ng

Standard

8836 I 8882

8

mm

12

.7

mm

mm

for thm matenals.

when

Thread

B83

2-400A I B835-400A

7

10

Cutte

mm

mm

work1ng

r

900

A

-

32-

Page 36

[II

FEED DOG HEIGHT

ADJUSTMENT

•

0

1.

Turn the pulley and set the feed dog 0 to the up position.

2.

The feed dog 0 should be 1.0 mm above the needle plate. Loosen screw 8 and vertically adjust the feed bar 0 to

adjust the height.

11

The back

Frrmly tighen screw 8 after adjusting the height.

llllf

the feed dog

lll

If

the feed dog

7

of

the feed dog needle hole should be smooth to enable free thread passage.

is

too high: . . . •

is

too low: . . . . • Stitches will be shorter than indicated by the feed regulator dial.

The

feed dog will strrke the needle plate.

• Stitches will be longer than indicated by the feed regulator dial.

-33-

Page 37

[!]

TENSION RELEASE ADJUSTMENT

Tens

ion

discs are closed

0

Approx. 0.5 mm

Greater than 0.8 mm

1 • When the presser

1) Check the presser

2) Check that the thread tension disc 8 is open

0.

lever

3) Turn the tension release lever 0 to adjust the tension disc gap

2. During thread cutting

1) The tension release crank 0 to presser bar lifter 8 gap should be 1.5 mm when the tension release is not operating.

2) Loosen nut

Ill

Insufficient

• The thread will

Ill

Excessive

• Improper stitch tightening

• Loose stitches will appear

foot

foot

0.

remove screw

tenison

be

tension

is raised

height. Refer to page

held too tightly and will not pass smoothly

disc

disc

with

the presser bar

f).

and adjust

gap

gap

at

the corners

lifter

lever

32.

0.8

mm when the presser

with

the link

with

thread cutter sewing machines.

0.

8.

through

foot

is raised 7

the disc.

mm

with the presser bar lifter

-34-

Page 38

[I]

STITCH LENGTH

f)__,_

__

-

@)=::r-------~~-~

1 . Forward feed adjustment

(1) Set the feed regulator dial 0 to the maximum position.

(2)

Sew.

(3) Measure the stitch length.

ADJUSTMENT

_

~.

To increase stitch length

( 1 ) Loosen screw

(2) Tighten screw

To decrease stitch length

(

1)

Turn the feed regulator dial 0 all the way counterclockwise.

(2) Loosen screw

(3) Tighten screw

2.

Reverse feed sewing

*Reverse

3.

Aligning forward/reverse feed stitch lengths

( 1 ) Adjust the forward feed stitch length.

(2) Sew. Stop the machine with the needle below the top of the needle plate.

(3)

(4) Adjust the reverse feed stitch length by adjusting the position

feed stitch length

Drop

the reverse lever 8 (reverse feed switch) all the way down to sew in reverse.

stitch length

• Readjust the stopper 0 position when the forward feed stitch length

8.

and turn the feed regulator dial 0 counterclockwise.

8.

and turn the feed regulator dial 0 clockwise.

8.

and turn the feed regulator dial 0 clockwise.

8.

is

determined by the forward feed stitch length.

will decrease

as

the stopper 0 is raised.

of

the stopper 0 on the reverse lever

is

changed.

0.

Reverse feed

-35-

Page 39

[@]

REVERSE FEED SOLENOID

ADJUSTMENT

1 . Loosen screw

2. Turn the feed regulator dial

Raise

3.

4. Completely lower the reverse lever

5. Tighten screw

the reverse feed solenoid plunger

O.

0.

to

the maximum stitch length setting.

r

il

An

excessive gap between the soleno1d base and reverse feed solenoid

strength of the magnet and may prevent reverse sewing.

Ill Reverse switch adjustment

r--~----·

~

I

I

G.

f)

until it meets the back of the solenoid

1 . Loosen screw

it is easy to reach.

Firmly tighten the screw

2.

3. Loosen nut 8 and turn screw 8 to