Brother LS2250PRW User Manual

USA customers only Únicamente clientes de Estados Unidos

!! IMPORTANT MESSAGE !!

Should you experience problems with your product, please read the Operation

Manual or the Quick Reference Guide fi rst, before returning your product to the

place of purchase. Brother International Corporation is committed to providing

the assistance necessary to ensure the Brother product you purchased meets your

expectations.

For assistance or to fi nd the address of your nearest Service Center, please call:

877-Brother (276-8437).

Further information is also available at our Brother Solutions Center site at

http://solutions.brother.com

To register your product online and enter for your chance to win $1,000, please

visit www.brother-usa.com/Registermybrother

¡¡ MENSAJE IMPORTANTE !!

Únicamente clientes de Estados Unidos

Si experimenta problemas con su producto, lea el Manual de operación o la

Referencia rápida antes de devolver su producto al lugar de adquisición. Brother

International Corporation se compromete a ofrecer la asistencia necesaria para

asegurar que el producto Brother adquirido satisfaga sus expectativas.

Para ayuda, o para encontrar la dirección del Centro de servicio más cercano,

llame a: 877-Brother (276-8437).

También podrá encontrar más información en nuestro Centro de soluciones

Brother, cuyo sitio es: http://solutions.brother.com

Para registrar en línea su producto y tener la posibilidad de ganar 1.000 dólares,

visite www.brother-usa.com/Registermybrother

Please retain this sheet for future use. We are here to help you.

Solution Center

To eliminate unnecessary repairs, listed below are common problems and possible

solutions. Please refer to your instruction manual for further instructions.

Needle Breaks

Needle is inserted incorrectly

Needle clamp screw is loose

Bent needle is being used

Upper threading is not correct

Upper thread tension is set too tight/high

Needle and/or thread for fabric being sewn is not correct

Material pulled and/or moved excessively during sewing

Upper Thread Breaks

Upper thread is not correct

Upper thread tension is set too high/tight

Upper thread is too large for the needle eye

Lower Thread Breaks

Lower thread may be entangled in shuttle

Lower thread tension is set too tight/high

Lower threading is not correct

Loops on Top or Bottom of Fabric Form During Sewing

Upper or lower thread tension not set correctly

Upper threading is not correct

Incorrect bobbin being used

Material Tends to Pucker During Sewing

Upper or lower thread tension is set too high/tight

Upper threading is not correct

Thread may be caught or is catching on something

Lower thread is unevenly wound on bobbin

Incorrect bobbin being used

Conserve esta hoja para uso futuro. Estamos aquí para ayudarle.

Quick Reference Guide

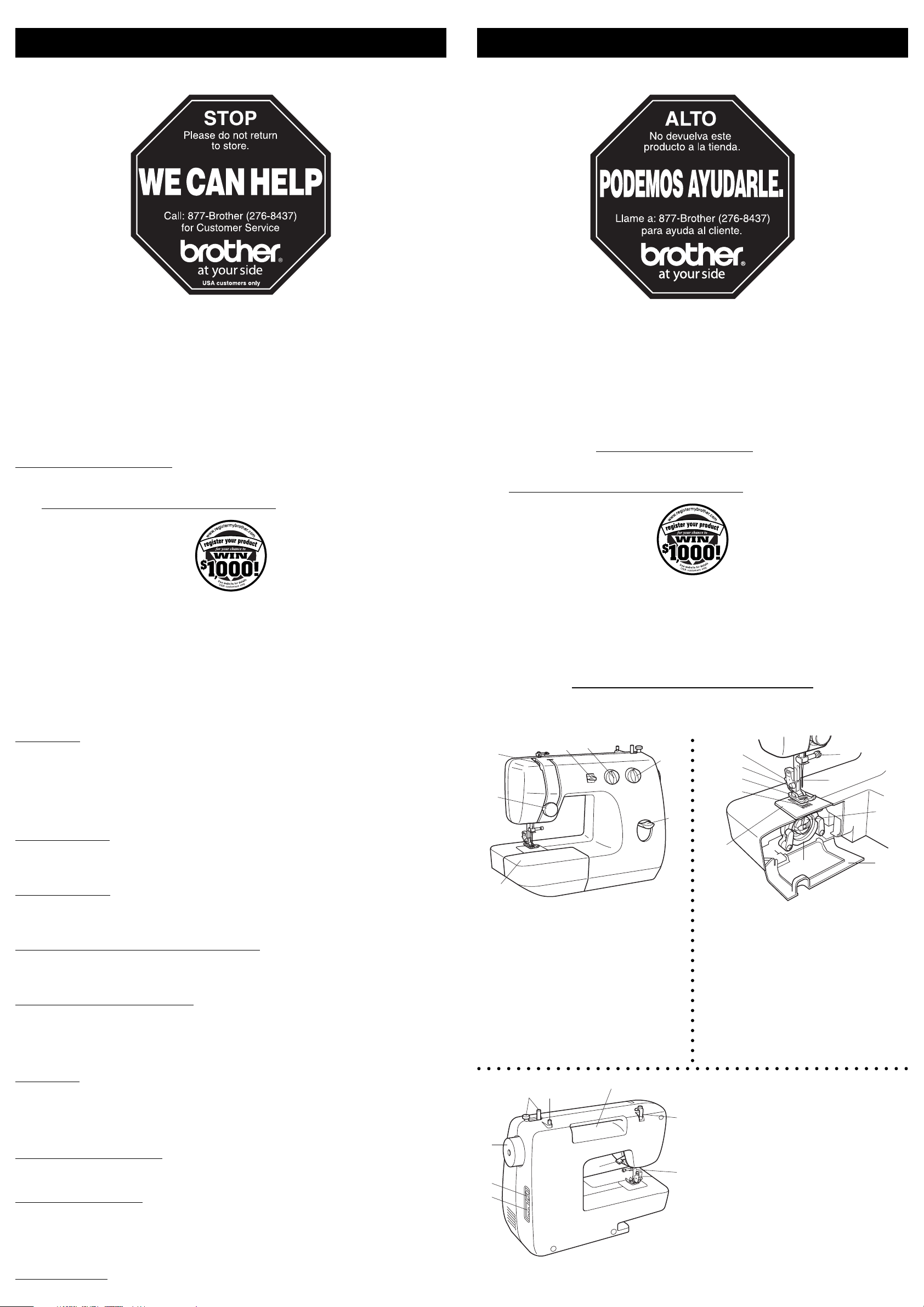

Knowing Your Sewing Machine

Name of Machine Parts and Their Functions

2

3

5

4

1 Needle position selector

Shift this lever to select needle position

2 Stitch width knob

Turn this knob to set the stitch width

3 Thread take-up lever

4 Flat bed attachment with accessory storage

5 Upper tension control dial

This controls the tension of the upper thread

6 Stitch length knob

Turn this knob to set the stitch length

7 Reverse sewing lever

Press and hold down the reverse sewing lever

to sew in the opposite direction

1

6

7

8

9

0

D

A

B

8 Presser Foot Holder Assembly

9 Presser Foot Screw

0 Presser Foot (Zigzag)

A Needle Plate

B Shuttle Hook

C Bobbin Case

D Feed Dogs

E Needle

F Needle Clamp Screw

G Shuttle Cover

XE7072-001

F

E

C

G

Skips Stitches

Needle is not sharp and/or straight

Needle is inserted incorrectly

Needle and/or thread for fabric being sewn is not correct

Upper threading is not correct

Lint and/or debris caught on underside of needle plate

Machine Runs Slow and/or Noisy

Machine may require cleaning or lubrication

Lint and/or debris may be caught in the shuttle and/or feed dog assemblies

Bobbin is Wound Incorrectly

Use a small pair of scissors to remove thread

Brother International Corporation recommends the use of genuine parts and supplies and proper maintenance

to keep your product running smoothly. Many of our resellers carry genuine Brother parts, accessories and

supplies. If you are unable to locate these items, please visit us online at

www.brothermall.com.

Toll Free Phone 877-276-8437

J

I

K

N

L

O

M

H Thread Cutter

I Spool Pin

Pull up on spool pin to level thread

J Bobbin Winder

P

H

Place unfi lled bobbin on winder

K Handwheel

Use for lower threading

L Foot Controller Jack

Insert plug in jack to operate foot controller

M Presser Foot Lever

Used to raise and lower the presser foot

N Main Power/Sewing Light Switch

Turns your machine/sewing light on

O Built-in Handle

Ideal for easy and effi cient transporting

P Thread Guide/Bobbin Winding Pre-tension

Disc

Used when winding the bobbin and then

threading the machine

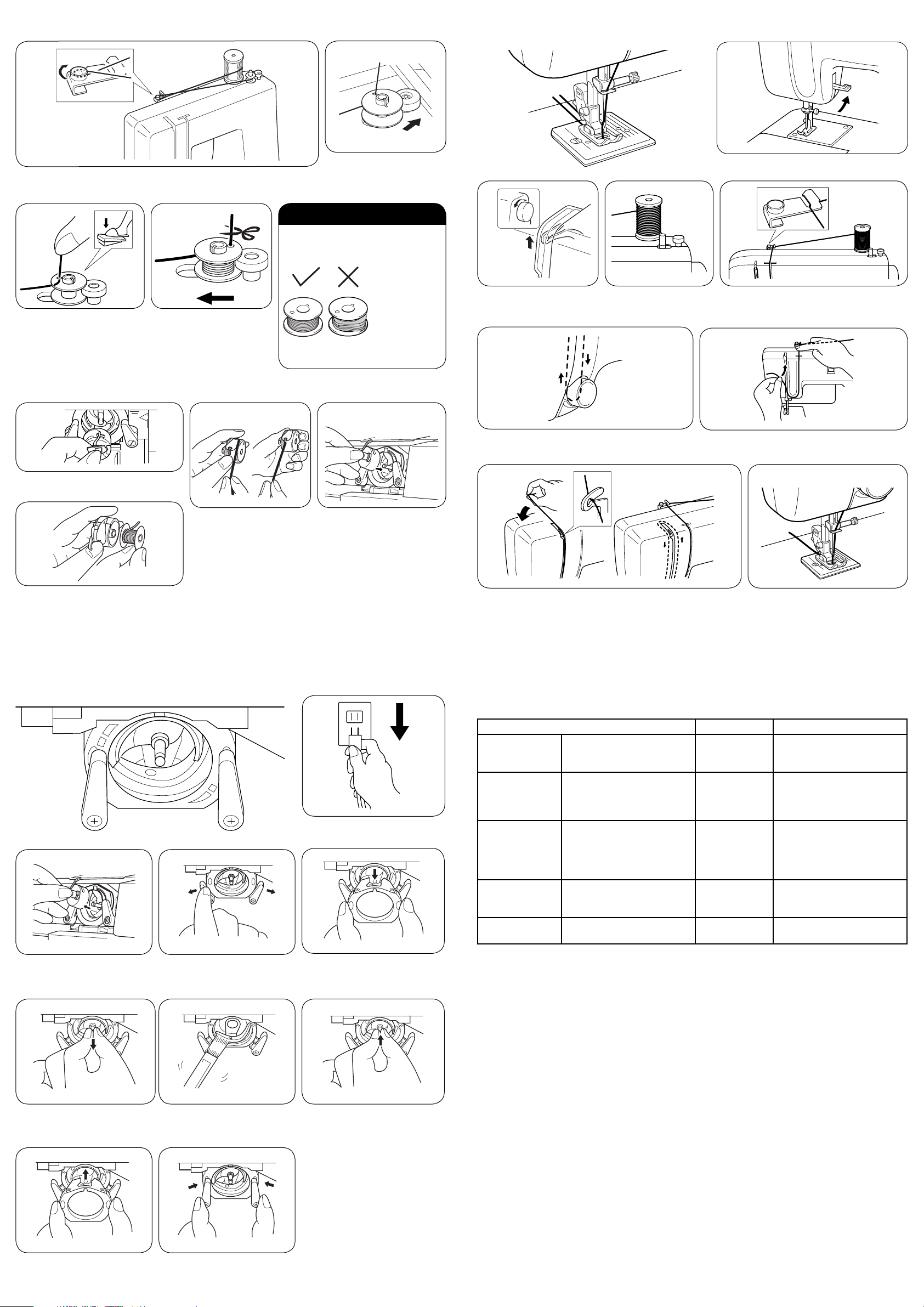

Winding the Bobbin

1

Threading the Needle

1

Pull up on the thread spool pin to lengthen the height. Place the thread spool on the pin

and pass the thread around the bobbin winder pre-tension disc.

34

Not winding the bobbin properly may

cause the thread tension to loosen, and

may break the needle.

While holding the end of the thread,

press the foot controller to begin

winding the thread. Cut the thread

from the top and proceed winding.

When the bobbin starts to spin

slowly and becomes full, release

the foot controller. Cut the thread,

slide the bobbin winding shaft to

the left and remove the bobbin.

2

Pass the thread through the hole

on the bobbin from inside. Use

upper hole, not both. Place on

bobbin shaft and slide to the right.

CAUTION

1 Wound evenly

2 Wound poorly

2

Raise the presser foot lifter.

23

Raise the thread take-up lever to

its highest position by turning the

handwheel.

5

Place the thread spool on the

spool pin.

(Don’t forget to pull up the pin)

6

1

4

Pass the thread through the thread guide and down the

right channel on the front of the machine.

Inserting the Bobbin

1

Raise the needle to its highest position and

remove the bobbin case by pulling the latch.

2

Hold the bobbin case as shown. Insert the

bobbin with the thread coming from the bottom

toward the top and the thread tail hanging out of

the bobbin case.

Cleaning the Bobbin Case

32

34

Pull the trailing thread through the

slot, down and to the left, until it

enters the delivery eye under the

tension spring. CAUTION:

sure you set the bobbin so the thread

unrolls in the right direction. If the

thread unrolls in the wrong direction,

it may cause the thread tension to be

incorrect or break the needle.

Make

Holding the bobbin case by the latch,

align your fi nger with the top opening

of the shuttle race, insert the case

into the shuttle race and release the

latch.

1

Remove the power plug from the outlet.

4

Pass the thread into the thread tension discs or behind the

thread tension dial from the right to the left.

Grasp the thread on both sides of the tension disc and pull to

ensure it is in place.

78

Guide the thread up the left channel, clear to the back of the opening around

the take-up lever and back down the left side of the channel to thread the

take-up lever.

Thread the needle from front to back and pull

out about 5 cm (2 inches) of thread.

Relative Chart of Sewing Fabrics,

Needles and Thread Combinations

Sewing Fabrics Needle Sizes Thread Sizes

Very Thin Fine tricot, Fine lace, Thin linen,

Silk, Organza, Chiffon

Lightweight Voile, Taffeta, Synthetics, Silk,

Batiste

Medium Weight Cotton, Gingham, Poplin,

Percale, Pique, Satin, Velvet,

Lightweight wool, Fine

corduroy, Suitings, Linen,

Muslin

Heavyweight Denim, Gabardine, Tweed,

Corduroy, Canvas, Duck

Knits Single knit, Double knit, Jersey,

Tricot

#65/9 Cotton: 80

Synthetic/Polyester Long Fiber

Fine Mercerized Cotton

#75/11 Cotton: 60-80

Silk: “A”

Synthetic/Polyester Long Fiber

Mercerized 50

#90/14

(Supplied with

your machine)

#100/16 Cotton: 40-50

#90/14

(Ball point)

Synthetic/Polyester Long Fiber

Cotton: 50-60

Silk: “A”

Mercerized 50-60

Mercerized Heavy Duty

Polyester Long Fiber

Cotton Wrapped Polyester

Polyester Long Fiber

Raise the needle to its highest position,

pull the latch and remove the bobbin

case.

5

Remove the hook by grasping the center

post and pulling out. Note its position

related to the driver.

Insert the retaining ring with the notch

up.

Slide the latch levers out from the

retaining ring.

Remove any accumulated lint and

thread with a brush.

98

Push the latch levers into their locked

position. Replace the bobbin case.

Remove the retaining ring.

76

Grasp the center post of the hook, match

the hook position opposite the driver and

insert.

Toll Free Phone 877-276-8437

Uses common replacement accessories:

Bobbin: Class 15

Needle: Standard sewing machine needles

Light Bulb: Small screw base sewing machine bulb

Utiliza accesorios comunes de remplazo:

Carretel: Clase 15

Agujas: Agujas estándares para máquina de coser.

Bombilla: Para máquina de coser con base roscada pequeña

Loading...

Loading...