Page 1

INSTRUCTION

FOR

MANUAL

BROTHER

LK3-B220,

221

High Speed Bar Tack Machine

BROTHER

NAGOYA,

INDUSTRIES,

JAPAN.

LTD.

Page 2

CONTENTS

1. FEATURES .............................

2.

SPECIFICATIONS ....................

3. OPERATION ............................................

1.

Name

of

major

component ............ .................. ...........................................

2.

Selling up . . . . ...... ...

3.

Oiling ............................................. ....................................... .. ........................................... 7

4.

Safety

5.

Needle

6.

Winding bobbin ............

7.

Threading

8.

Upper

9.

Thread

10.

Adjusting

11.

Adjusting

12.

Adjusting pressure of

13.

Cleaning shuttle .................................................................................................................

operation

and

thread

bobbin case

threading

tension ............... .......................................... ........................................... ...............

tack

tack

..

. . . .

......................................................................................... ....................... 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

.................................................................................................................

width

length ........................................................................................................ 12

...

...............................

...

..........................................................................................

..

.......

..

. . . . . . .....

..

.. . . . . .

..

...... .............. ..... ...... ....... ...... ......... ........ ... ... . . .......

....................................... ................................................................ 9

··········

·

·····

··

·················

work

clamp ..................................................................... ................ 12

............................................................ .

...

...............................

..

. ...

..

. . . . ..... ... . . .

·

····

·

····

~

~

....

........................................ 3

..

... ................. 3

..

. . . . ....

..

. . . . . . . . . . .

···

..:.:

························

..

..

..

... . . .

··

····

..

. . . .............

··

·····

..

... 11

..

... . .. . .... 9

10

11

·

··············

12

12

14

. Removing needle plate ......... .......................................... ....................................................

15.

Installing needle plate .......................................... ........................ ......................................

16

. Replacing needle hole

4.

ADJUSTMENT

11.

Adjusting needle

2.

Adjusting feed mechanism .......... ................................. .. .....................

3.

Adjusting

4.

Adjusting

5.

Adjusting clutch and

6.

Adjusting

7.

Adjusting

8.

Needle cooler mechanism (Opti

5.

PARTS

LIST

...................................................................................................................... 13

thread

thread

wor

k clamp lifter ............................................... .............

work

for

plate

.......................... .....................................................................

bar .............. ............................................................................................ 13

....

........................... 14

trimming mechanism ................................................... ............................

nipper ......................... ...

brak

e ......................... .......................................................................

clamp on B221·1 and -2

on)

.....................................................................................

LKJ-8220

...............................................................................................

....

.............. .........

............................................................................

........................ ...... ................ IS

.... .............. .............. ..

12

12

1:3

16

19

21

22

23

24

Page 3

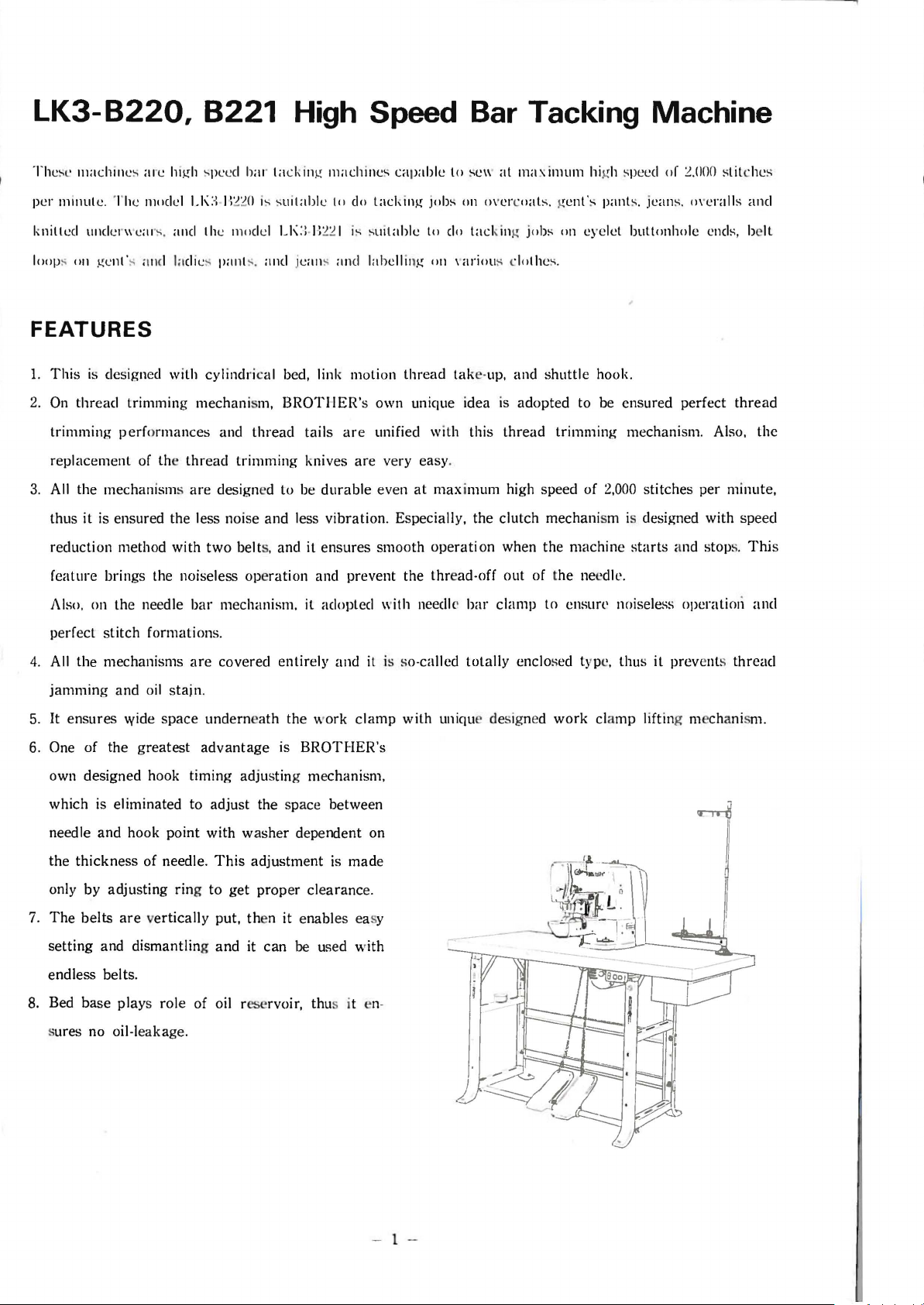

LK3-B220, 8221

The

~e mac hine~

are high

~

p ee

d

bar la cking machines capable to sew at

High

Speed

Bar

Tacking Machine

ma~imum hi~!h ~p

eed

of

2.

000

~!itches

per minut

knilled

loops on

e.

The model

unden\ear~

,l.(e

nl \ <llld ladies

Ll\

:~

ll220 b

.

and the model LI\::.J-:

pant

~uitable

~.

and jean: and Iabeii in.!.(

to do tacki ng jobs on overco

22

1

i~

suitable to do

tackin

on \ arious clothe

ats

. gent' s pants. jeans.

g

job~

on eye let buttonhole ends,

s.

m·e ra

l l

FEATURES

1.

This

is designed with cylindri cal bed, link motion

2.

On

thread

trimming

replacement of the

3.

All

the mechanisms

thus it is ensured the less noise and less vibration. Especially, the clutch mechanism is designed with speed

reduction method with

feature brings the noiseless ope

Also,

perfect

trimming mechanism,

perf

ormances and

thread

are

on the needle

stitch

formations.

BROTHER'

thread

trimming

designed to be

two

belts, and it ensures smooth

bar

mechanism, it adopted with needl e

tails are unified with this

knives

ration

are

durable

and prevent the

thread

s own unique idea is adopted to be ensured perfect

very easy .

even

take-up. and

at

max

imum high speed of

operation

thr

ead-off out of the needle.

bar

clamp

shuttle

thread

when the machine

to ensun• noiseless operaticni

hook.

trimming mechanism. Also,

2,000

stitches per minute,

starts

and stops.

~

and

belt

thread

the

Thi

and

s

4.

All

the mechanisms

jamming

5. It ensures

6. One of the

own designed hook timing adjustin g mechanism,

which is eliminated to adjust the space between

needle and hook point with wa

the

only by adjusting ring

7.

The

setting

endless belts.

8. Bed

sures no oil-leakage.

and oil stain.

wide

greatest

thickness

belts

are

and dismantling

base

plays role of oil reservoir, thu s it en·

are

covered entirely

space

underne

advantage

of needle.

to

vertically put, then it enables easy

ath

the work

is

BROTHER's

sher

dependent on

This

adjustment is made

get

proper

and

it

can

be

cle

used

aranc

and

it is so-called

clamp

e.

with

totally

with uniqu e designed

enclosed type, thus it prev ents

work

cla

mp

lifting mechanism.

thread

- 1 -

Page 4

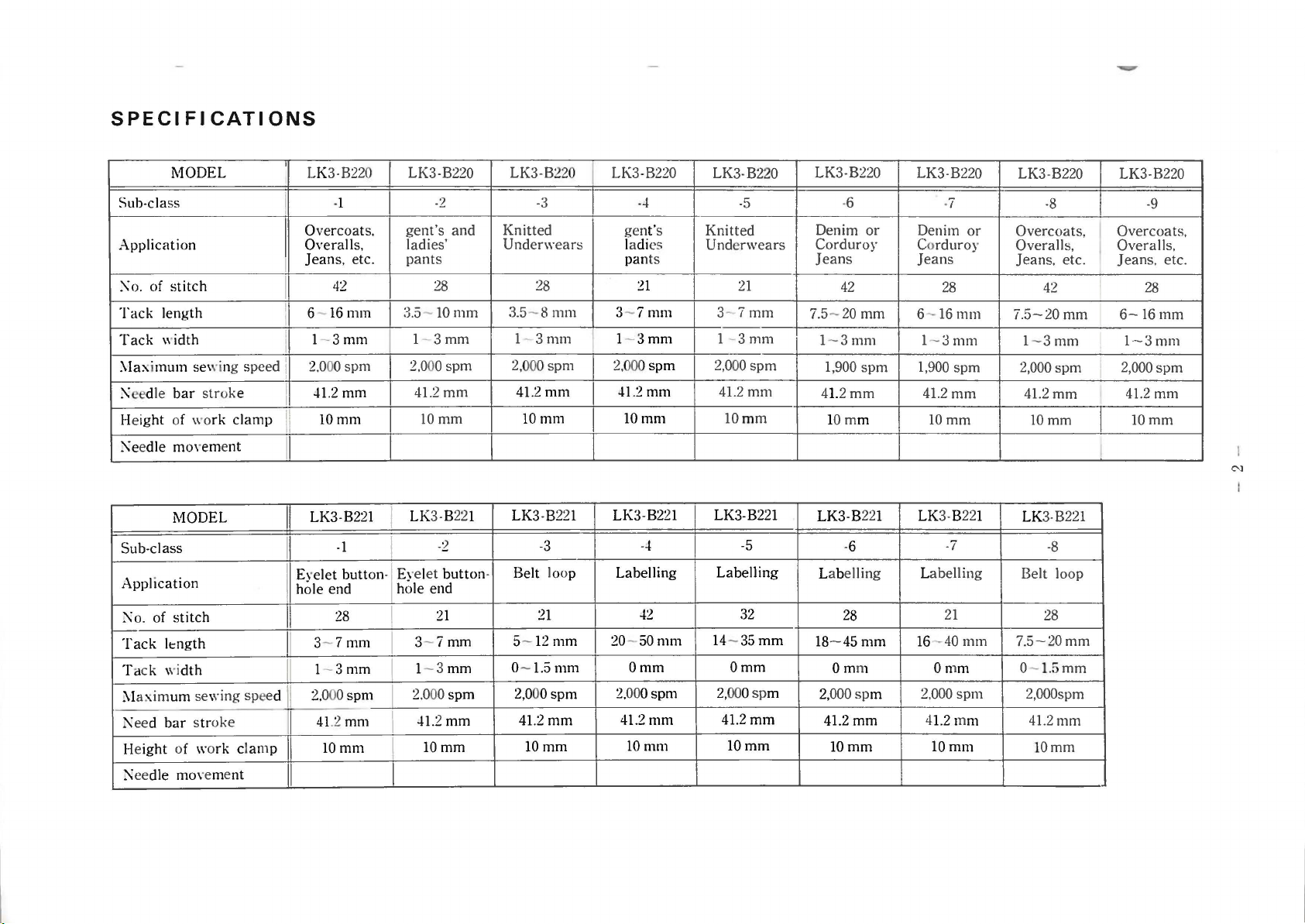

-

SPECI

MODEL LK3-B220 LK3-B220 LK3-B22 0

Sub-class

Application

;\

o.

of

stitch

Tack

length

Tack

\\'idth

:\Iaximu111

:1\eedle

Height of \\'o

;\e

Sub-class

Application

;\o.

Tack

Ta

1\I

l\

Height of wo

~eedle

edle

of

ck wi

axim

eed

bar

movem

MODEL

stitch

length

um

bar str

movement

Fl

CATIONS

sewing speed I

str

oke

rk

clamp

ent

dth

sewing speed

oke

rk

clamp

I

I

I

I

I

I

I

II

-1

Overcoats.

Overalls, ladies'

Jeans,

etc.

42

6-

16

111m

1-

3ml11

2.000 spm

-!1.2

mm

lOmm

gent's

pants

:3.5-10111m

1-

I

2,000

41.2

10mm

I

LK3-B221

I

-1

LK3-B221

I

I

I Eyelet button-! Eyel

hole end hole end

II

I

28

3-

7mm

1-

3mm

2.

000

41.2 ml11

lOmm

spm

I

I

I

I

I

I

3-

1- 3

2.000

-!1.2

-2

and

28 28

3mm

spm

mm

-2

et

button-

21

7mm

mm

spm

mm

lOmm

Knitted

Underwears

3.51-

2,000

41.2111111

LK3-B221

Belt loop Labelling

5-

0-

2,00

-3

8111111

3111111

spm

10mm

-3

21

12

1.5111111

0spm

41.2

mm

lOmm

mm

LK3-B220

I

gent's

ladi

pan

31-

I

2,000

-!1.2

10mm

LK3 -

20-50mm

Omm

2.

000spl11

41.2

10111111

--l

es

ts

21

7111111

3mm

spm

mm

B221

--l

-!2

111111

LK3-B220

-5

Knitted

Unde

rwears

21

3-

7mm

1 -

3mm

2,0

00

spm

41.2

mm

lO

mm

LK3-B221

-5

Labelling

32

14-35mm

Omm

2,

000spm

4L2mm

lOmm

LK3-B220

-6

Denim

Corduroy

Jeans

7.5-

LK3 -B

18-45

or

42

20

mm

1-

3mm

1,900

spm

4L

2mm

lO

mm

22

-6

Labelling Labelli

28

mm

Omm

2,

000sp

4L2mm

lOmm

1

m

LK3-B220

Denim

Co

rduroy

Jeans

6-

l -

1,900

4L2mm

10mm

LK

16-40111111

Omm

,000

2

4

1.2111111

10m111

-7

or

28

16111111

3mm

spm

3-B22

1

-7

ng

21

sp111

LK3-B220 LK3-B220

-8 -9

Overcoats,

Overalls, Overalls,

Jeans, etc.

42

7.5-20

7.5-20mm

mm

1-

3mm

2,000

spm

41.2

mm

lOmm

LK3-B221

-8

Belt loop

28

0-1.5mm

2,000spm

41.2111111

lOmm

Overcoats,

Jeans,

28

6-16111m

1-3ml11

2,000spm

41.2

10mm

I

etc.

mm

N

Page 5

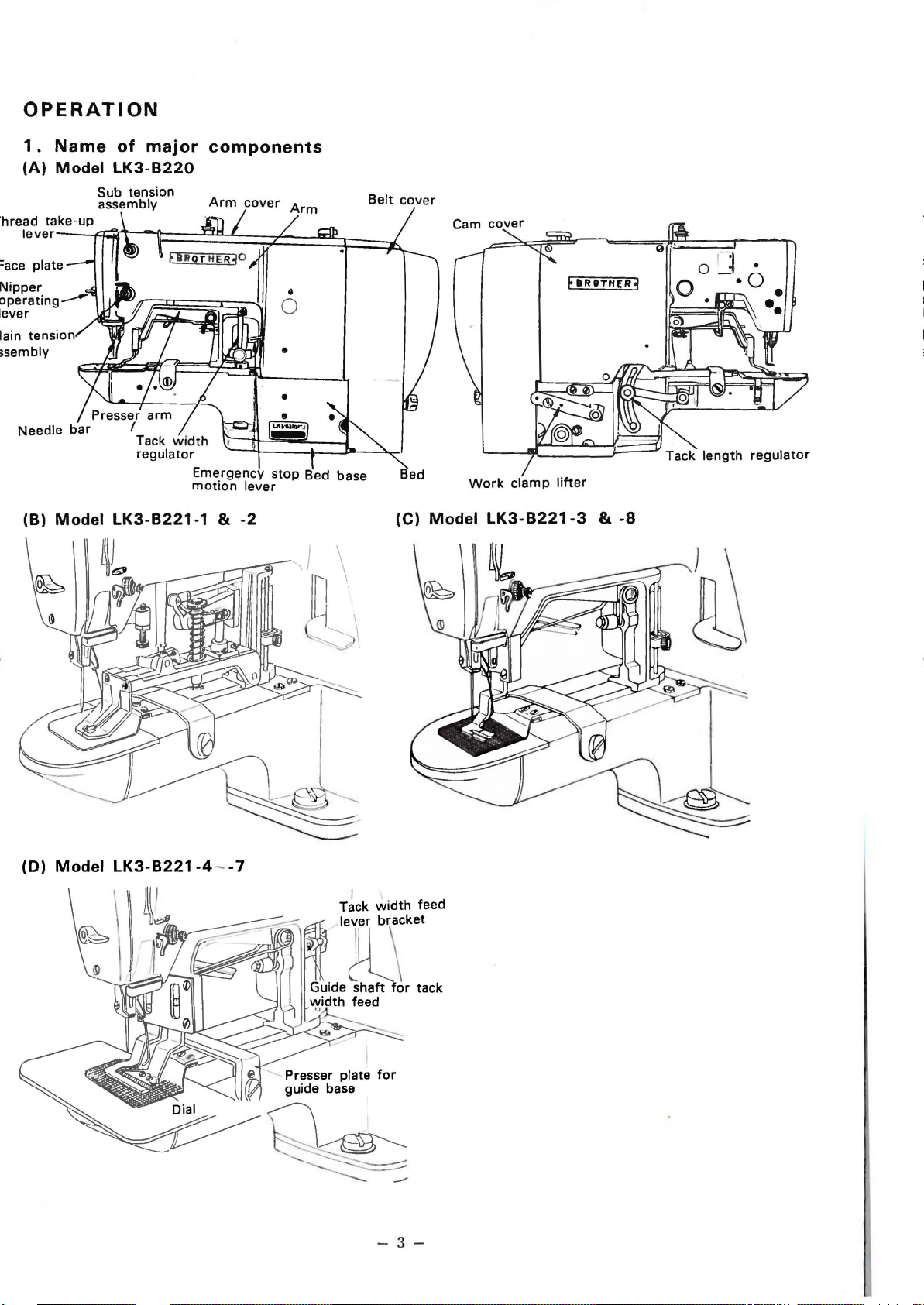

OPERATION

1.

Name

(A) Model

lever----ffff1~~====~~==~~==~~==~.(

plate

Nipper

tension

of

major

LK3-B220

Sub tension

assembly

components

Arm

cover

Belt

cover

Cam

cover

F

UDTHER3

Needle

bar

(B) Model

Presser

arm

I

Tack

regulator

LK3-B221-1

width

Emergency

motion

&

lever

-2

stop

Bed base

Bed

(C)

Work

Model

clamp

lifter

LK3-B221-3

&

-8

(D) Model

LK3-B221-4--7

-3-

Page 6

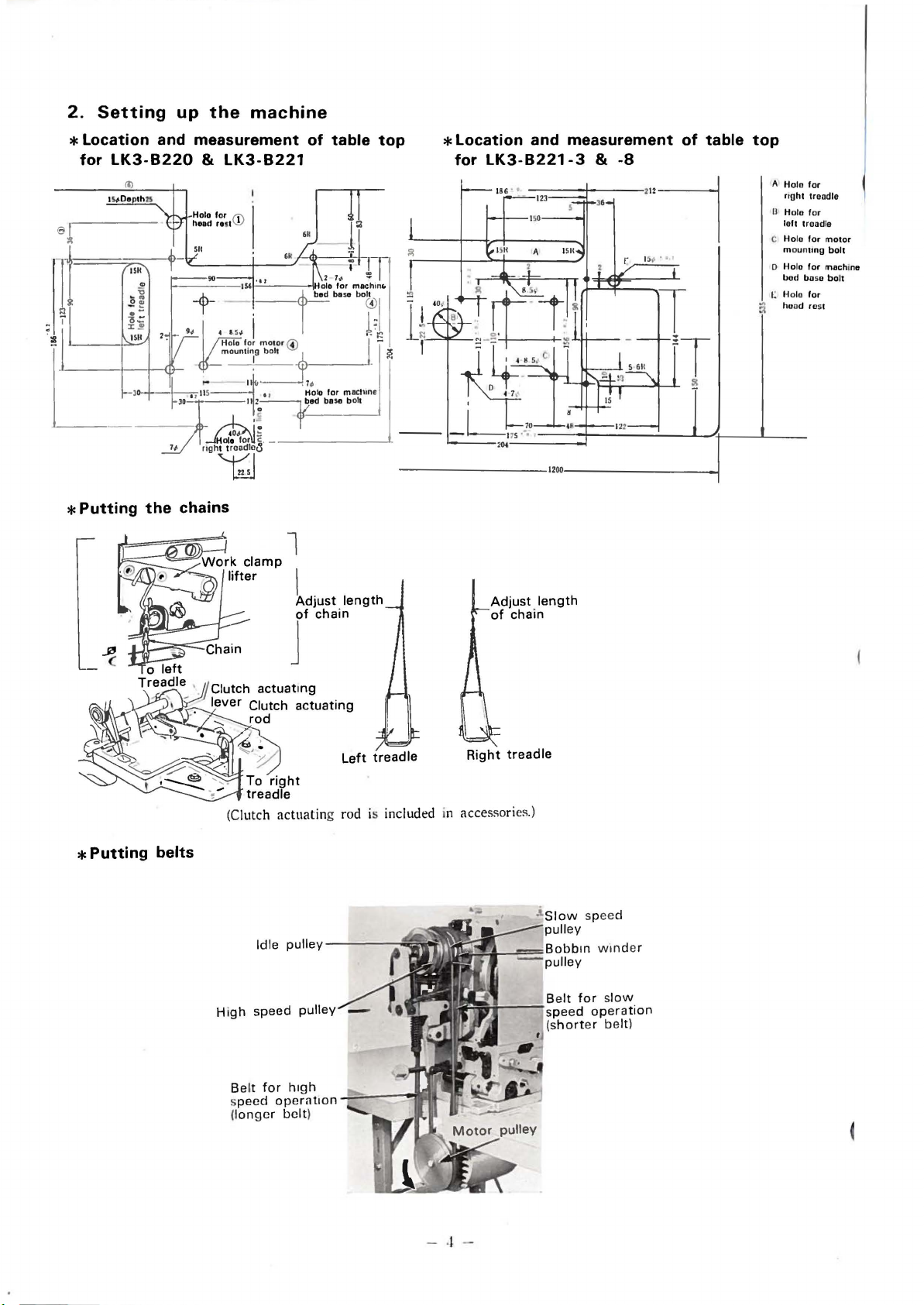

2.

Setting

up

the

machine

* Location and measurement

for

LK3-B220

*Putting

the

&

chains

Work

LK3-B221

l

clamp

lifter

of

l

Adjust

J'

oh•;"

table

length

top

* Location and measurement

for

LK3-B221-3

----------1200----------..j

Adjust

of

chain

length

&

-8

of

table

top

A Holo for

ng

ht troodle

U H

ofo

for

lo

ft

troodle

C Holo

lor

mounung

D Halo for machine

bod boso bolt

t:

Holo for

ho

nd rest

motor

bolt

*Putting

o

left

Trea~Je_

r-.~'""'-

'.§Clutch

, lever Clutch actuating

"'

.__,.

· ·

actuatmg

rod

(Clutch

actuatin

belts

Belt for h1gh

speed operat1o

(longe

r belt)

Right

Left

treadle

g rod is included in accessories.)

n

treadle

wmder

- ·l -

Page 7

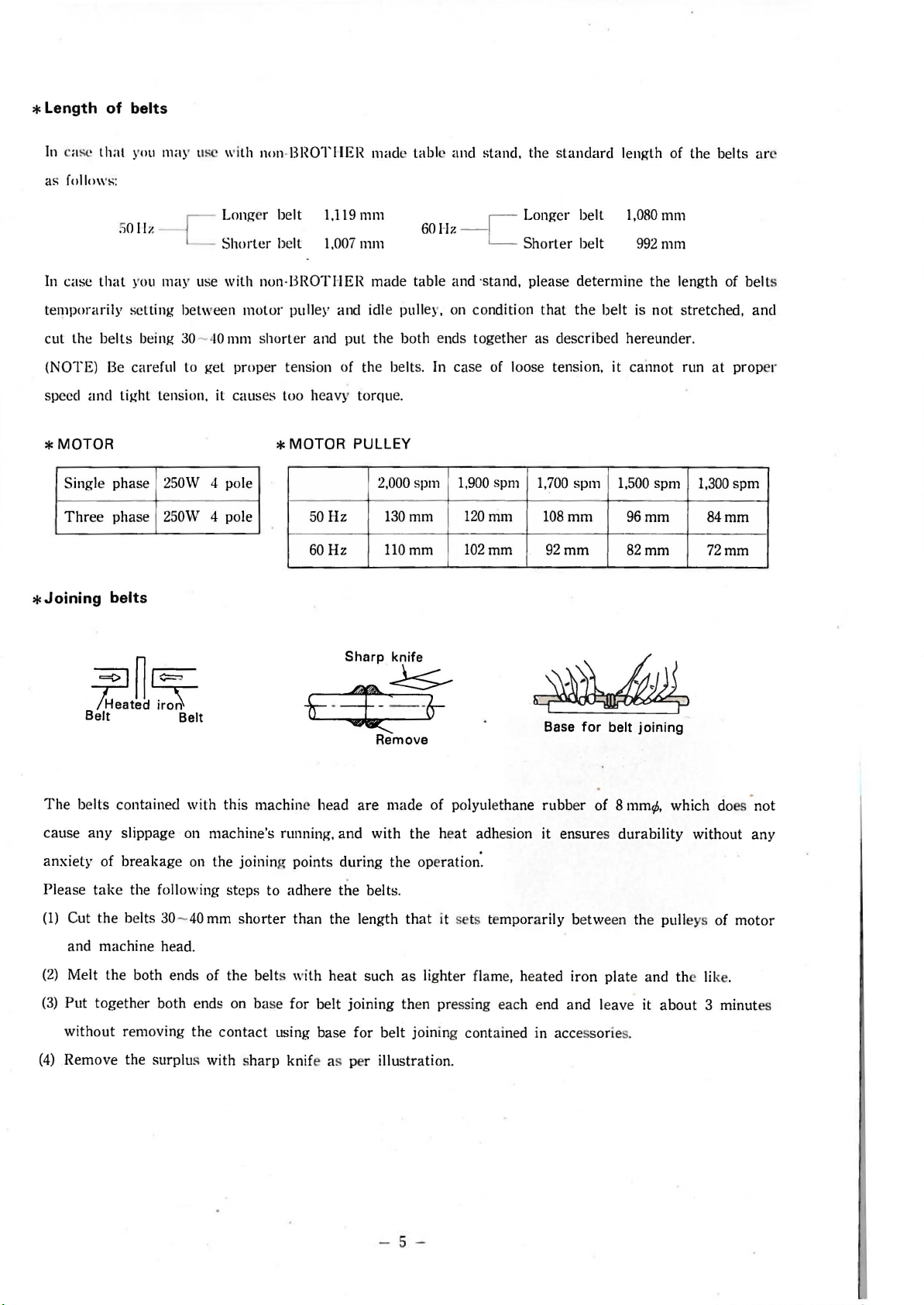

* Length

In

of

belts

·asc th at you may usc

\\'

ith non-

BROTHER

mad

e tabl e

and

stand, th e

standard

length of

the

belts arc

as follow

In

case

temporarily

cut

the

(NOTE)

speed

and

*MOTOR

Singl e

Three

*Joining

s:

50 liz

-c

that

you may use with non-

sett

ing between mo

belts

being 30- 40 mm s

Be careful to

tight

phase

phase

belts

get

tension, it

250W

250W

4 pole

4 pole

Longer belt

Short

er be

lt

BROTHER

tor

pull

hort

er

prop

er tension

caus

es

too heavy

*MOTOR

1,119mm

1,007

llllll

made

ey

and idle pulley, on condition

and

put

the both ends together

of

the belts. In case

torqu

60H

z

-c

table and ·stand, please

e.

PULLEY

1,900 spm

120

102mm

50

Hz

60Hz

2,000 spm

130mm

llOmm

Longer

Sho

of loose

trim

rter

that

as

descr

tension

1,700 s

108mm

92mm

belt

belt

determine

the

1,080

992mm

the

belt

is

not

ibed hereunder.

, it

cannot

pm

1,500

96mm

82mm

mm

length of

stretched, and

run

at

spm

1,300

84mm

72mm

belt

prop

spm

s

er

~~§:

/Heated~

Belt Belt

The

belts

cause

any

anxiety

Please

(1) Cut

(2)

(3)

(4)

of

take

the

and

machine

Melt

Put

together

without

Remove

contained

slippage on

breakage

the

following

belts 30 -

the

both

both ends on base

remov

the

surplu

head

ends

ing

with

this

machine's

on

the

40

mm

.

of

the

contact

s with s

machine head

running,

joining points

steps

to

adhere

shorter

the

belts w

using

harp

than

for

knif

Sharp

knife

~

t=-=-I;

and

during

the

the

ith

heat

belt

base

e as per

- -

6--

Remove

are

made

of

polyule

with

the heat

the

operation:

belts.

length

joining then pressing each end

for

that

it sets te

such

as lighter flame, heated

belt

joining cont ained in accessories.

illustration

.

Base

thane

rubb

adhesion it

mpor

arily between the pulleys

for

belt

er

of

Smm¢,

ensur

es

durability

iron

plate and the like.

and leav

e it

joining

which does

without

about 3 minut

of

not

any

motor

es

- 5 -

Page 8

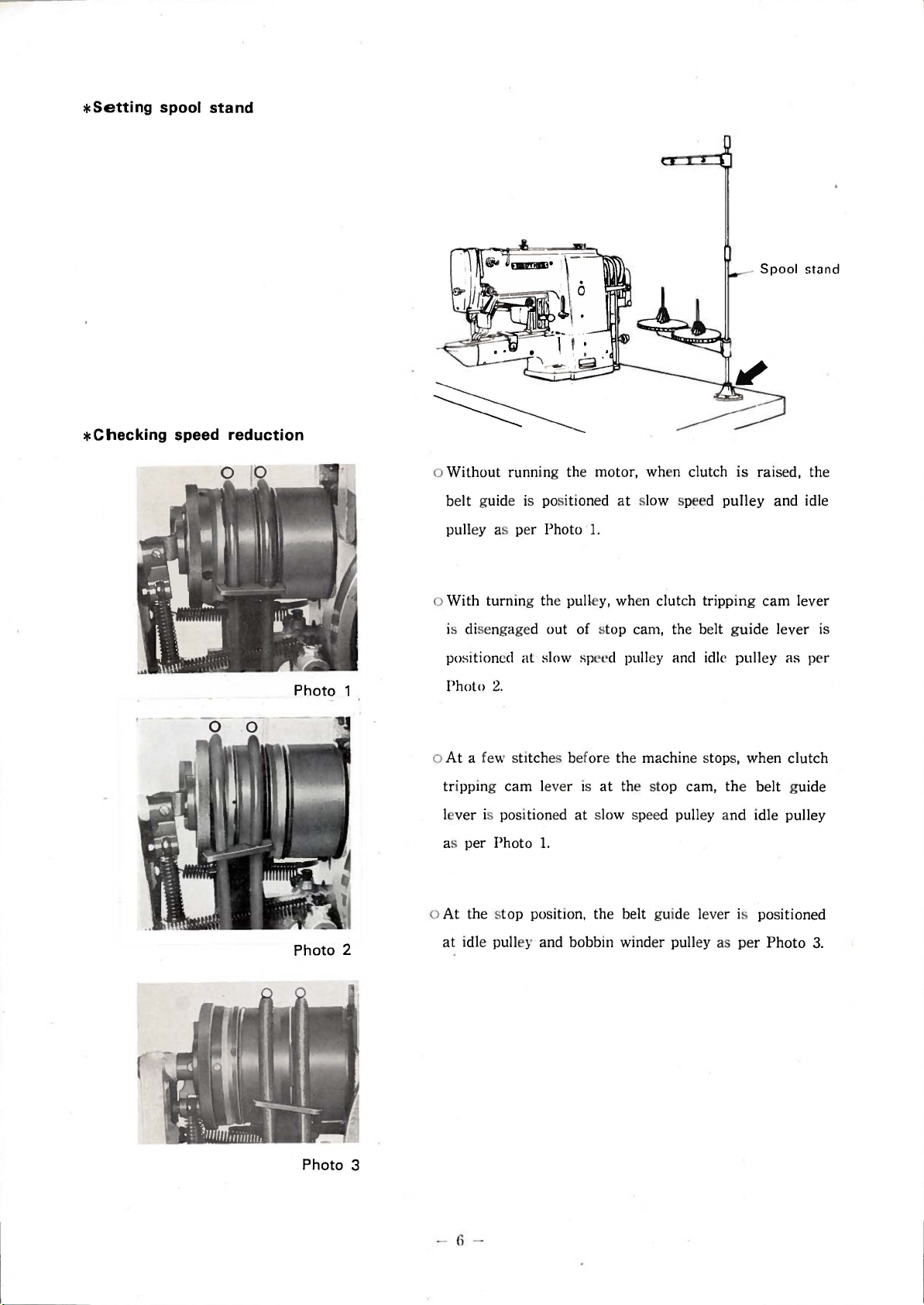

*Setting

spool stand

*Checking

speed reduction

Photo 1

o

Without

belt guide is positioned at slow speed

pulley as per

o

With

is disengaged out of s

positioned

Photo

o

At

tr

ipping

le

ver

as

running the motor, when clutch

Photo

1.

turn

ing the pulle

at

2.

a few sti

cam

is positioned

per

Photo

slow speed pulley and

tch

es before the machine stops, when

lever is

1.

y,

when clutch tripp

top cam, the belt g

at the stop cam, the

at

slow speed pulley a

is raised, the

pulley

ing

uide

idlt>

pulley

belt

nd

idle pulley

and

cam

lever is

as

clutch

guide

idle

lever

per

o

At

the stop position, the belt guide leve r is positioned

at

Photo 2

Photo 3

idle pulley and bobbin winder pulley as per

6

Photo

3.

Page 9

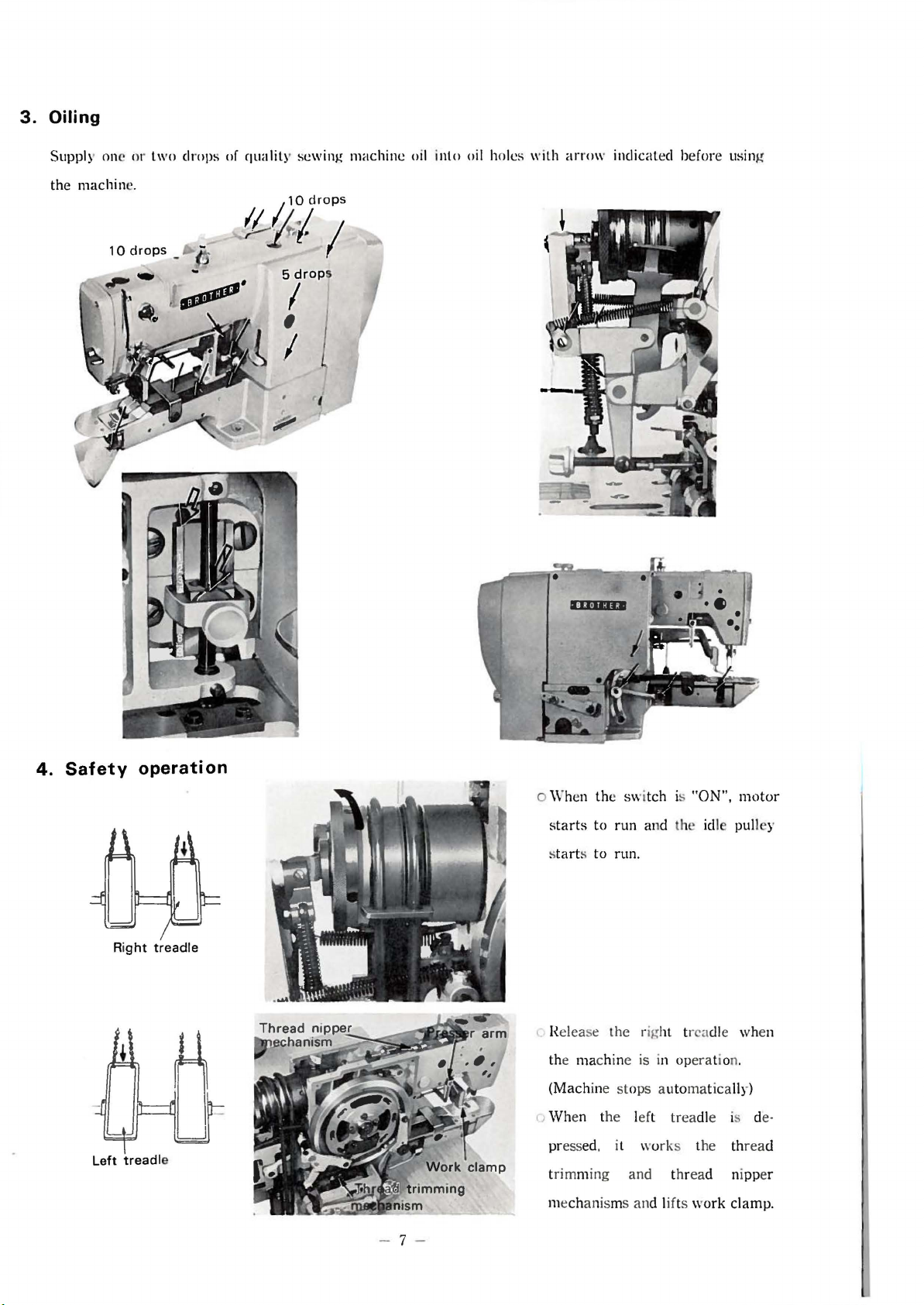

3.

Oiling

Supply one or two drops of quality sewing machine oil inlo oil holes with

the machin

e.

10drops

1

10

drops

!14

5

drop

I

s

(L-

I

'

I

' I

arrow

indicated before using

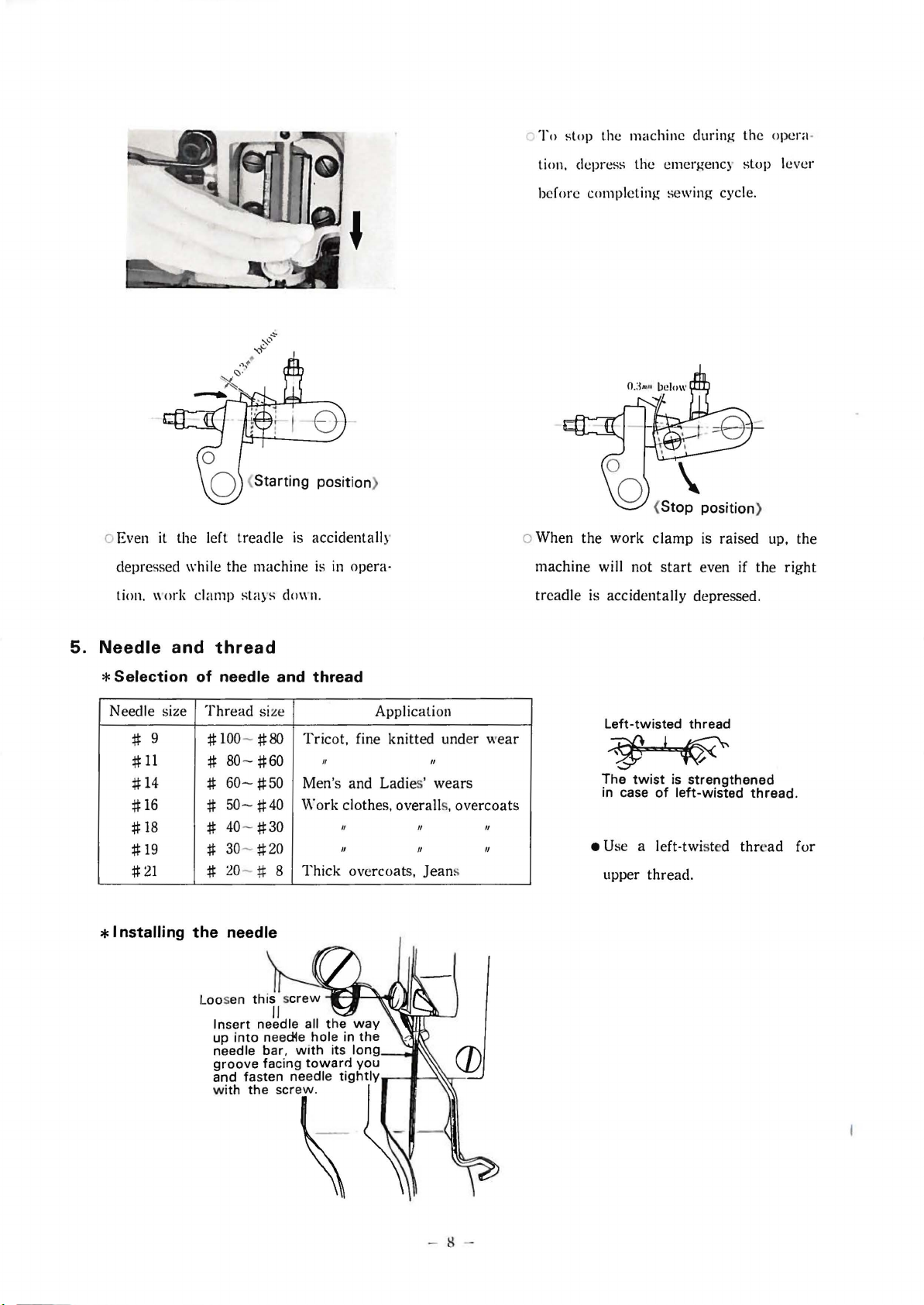

4.

Safety

Ri

Left

operation

ght

treadle

treadl

e

o When the switch is "ON",

s

tarts

to run and the idl pulley

s

tart

s to run.

l Release the right tr a

ma

the

(Machine

r;

When the left treadle is d

pressed, it works the th

trimming and thread nipper

mechanisms

chine is in op

st

ops automatically)

and li

era

fts work clamp.

motor

dl

e when

tion.

rea

e-

d

- 7 -

Page 10

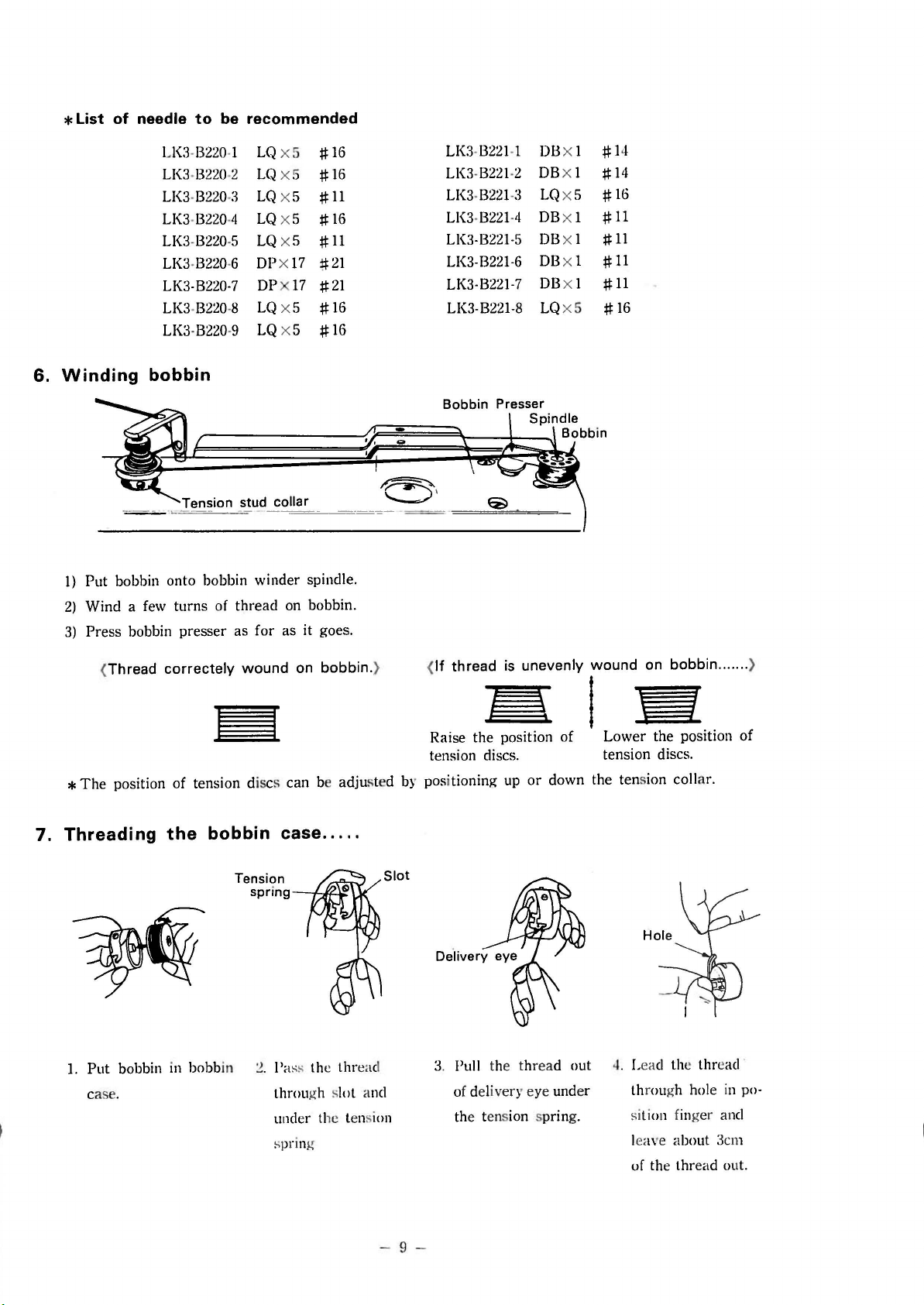

To

stop the machine during the opera -

tion. depress the emergency stop lever

o Even

it

depressed

the left treadle

while the machine

tion. \\'ork clamp

stays

is

accidentally

is

clown

.

in

opera·

before completing

o When the work

machine will not

is

treadle

accidentally depressed.

sewing cycle.

position)

clamp

is raised up, the

start

even if the right

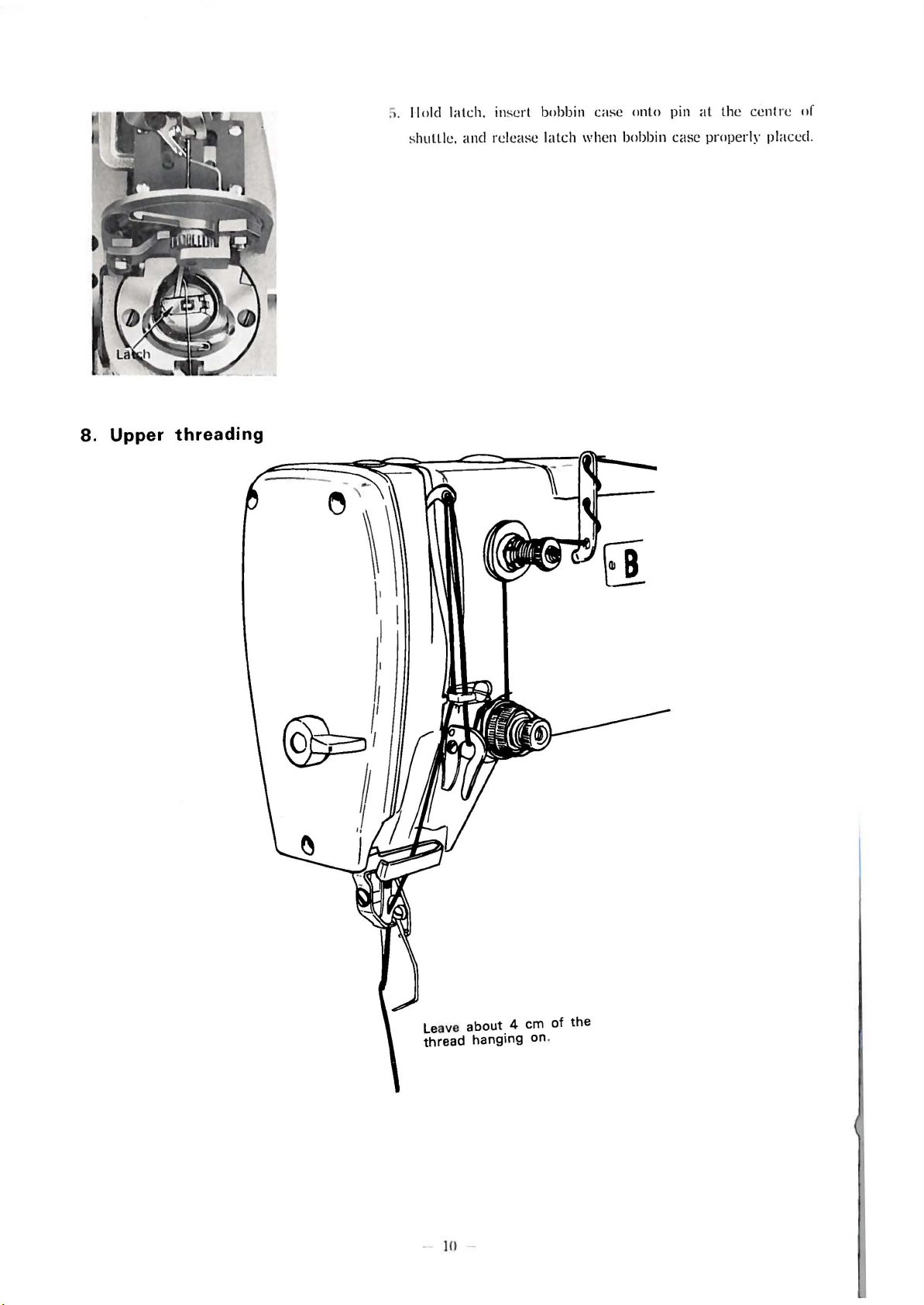

5.

Needle

*Selection

Needle

*Installing

#

#11

#

14

#

16

#

18

#

19

#21

9

and

size

thread

of

needle and thread

Thread

#

#

#

#

# 40-

# 30-

#

the

Loosen

up

needle bar,

groove

and fasten needle

with

size Application

100-#80

80-

#60

60-

#50

50-

#40

#30

#20

:W

- # 8

needle

this screw

needle all

into

the

II

need4e

facing

screw.

with

Insert

Tricot,

fine knitted under

II II

wear

Men's and Ladies' wears

Work clothes. overalls, overcoats

II

II

Thick

overcoats,

.,...;w~......:~

the

way

hole

in

the

its

toward

long _ ___,.,,,

you

tightiY--t

II II

II II

Jean

s

J--->...\.,

,........-J

Left-twisted

thread

~

The

twist

is

in case

• Use a left-twisted

upper thread.

strengthened

of

left-wisted

thread.

thr

ead for

Page 11

*List

of

needle

LK3-B220-1

LK3-B220-2

LK3-B220-3

LK3-B220-4

LK3-B220-5

LK3-B220-6

LK3-B220-7

LK3 -B220-8

LK3 -B220-9

to

recommended

be

LQ x s

LQ x s

LQ x s

LQ x s

LQ x s

DPX17

DP

17

LQ x 5

LQ x 5

#

16

#

16

#11

#

16

#11

;!:!:

21

#21

#

16

#

16

LK3-

B221

-l DB X 1

LK3-

B221

LK3-

B221

LK3-

B221

LK3-B221

LK3-B221-6

LK3-B221-7

LK3-B221-8 LQ x 5

-2

<3

·4

-5

DBx 1

LQ x s

DBx 1

DB x 1

DB x l

DB x 1

#1

#

14

#

16

#11

#11

#11

#11

#

4

16

Winding

6.

1)

2)

3)

*The

bobbin

Put bobbin onto bobbin winder spindle.

Wind a few turns of thread on bobbin.

Press bobbin presser as for as it goes.

(

If

(Thread correctely wound on bobbin. }

position of tension discs can be adjusted by positioning up

thread

Raise the position of

tension discs.

is

unevenly wound on bobbin ....... )

~l:e

Lower the position of

tension

or

down the tension colla

discs.

r.

7. Threading

1.

Put

bobbin in bobb

case. through slot and

the

bobbin case

in

.....

Tension

spring-~"'--10:

~

-

!'

ass the thread

under the tensi

spring

Slot

on

- 9 -

3. Pull the th

rea

d out 4. Lead the thread

of delivery eye under through ho

the tension spring.

sition finger and

leave about :km

of the thread out.

le

in po·

Page 12

8.

Upper

threading

S.

II

old

shuttle,

latch.

and

ins

ert

release

bobbin

latch

case

when

onto

bobbin

pin

case

at

the

properly

centre

placed

of

.

Le

ave

about

thread

-

10

hanging

-

4 em of

on.

the

Page 13

9.

Thread

tensions

*Lower

*Upper

thread tension

\

thread tension

Adjust the lower

pulling the

Me

asure the tens ion

After adjusting the lower

means of the main tension.

thread

thread

from the bobbin case.

tension so

by

the tension gauge as per the illustration.

that

you will feel a slight resistance

(15-30

thr

ead tension, adjust the upper thread tension by

gram

s for

#50

cotton thread)

in

* Main tension

This

adjustment is affected the sewing condition, therefore , adjust the tension to be following list

dependent on sub-class,

LK3-B220-1--5, -8LK3-

B220-6

LK3-B221-4

When the thread is trimmed

the upper

*Sub

Sub tension plays a role to prevent the upper

Adjust the sub tension

material

(40-50

*Thread

Thread--{]

guide ; :

thread

tension

when the machine stops.

gr

. for

take

Stroke Thread

>-.,.

'\~~r.~·

:)

should be left put of the needle eye.

B220-6--7; 5-25

up spring stroke and

..

~Ten©n

thread

- -7 ............ ...

- -7 ................

so

~

after

that

T .

eusron

gauge

and

materials

-9,

8221-1 -

...........................

..........................

the

main

the upper

gr. for all

its

Th

is adjustment is also affected much on the sewing condition.

LK3-B220

LK3-B221

LK3-B220

LK3-B22

.

Tension

-3,

-8

.......... 70- 80 gr.

150-200

50-

tension is released

thr

ead from loosening when the

thread

oth

tension

-1--5, -8-

-1-

-6- -7 .................................. 6- 8 mm

1-4- -7 ............................... 12.5- 13.5 mm

will be fairly taut betwee n the needle and the

er sub-classes)

-9

-3,

-8

gr.

60

gr.

at

}

························

Thread

Dacron

Cotton

Dacron

the final stitch, enough length

S

tro

3

#50

#50

#80

ke

mm

thr

ead is trimmed.

Tension

15- 20

220-300 gr.

15-220 gr.

of

gr

.

-

11

-

Page 14

10.

Adjusting

tack

width

11.

Adjusting

g

tack

length

Adjust by loosening adjusting screw and

1

2.

13.

moving hinge

Adjusting

Cleaning

bluci<

in

vertical direction.

pressure

shuttle

of

work

clamp

Adjust the work

than necef.sary

Adjust by loosening thumb screw and moving

along with the slot of the

clamp

so

that

to prevent the

tack

it

exerts

material

length

no more pressure

from slipping.

regulator.

it

1.

Remove shuttle

bobbin case. oil inside of shuttle race.

14.

Removing

R move four flat he

plate.

race

needle

ad scr

with

plate

ews and then needle

2. Remove shuttle.

15.

Match

- 12 -

Installing

markin

* After cleaning, put a

needle

g in assembling.

plate

drop

of

Page 15

~

Set

screw

Thread

Upper

Lower

1

6.

presser

thread

thread

__

knife

knife

Replacing needle

*Needle

(2.2mm

diameter) for ultra

hole plates are available

in

needle hole diamete

hole

plate

in

r)

for thick

hea vy materials.

Thread

Presser

*The

Upper

needle hole plate can be removed by loosening two

set screws and pushing it upward.

be

very smooth.

* Replace the needle hole plate

siderably damaged.

*When

putting a new needle hole plate

make sure the

groove

in

standard size (1.6mm

mat

erials , and another special size (4.0mm

thread

knife

Lower

if

thread

The

needle hole must

the needle hole IS con-

in

groove on its underside is

in

the needle plate .

in

needle hole diameter); and special size

in

knife

replacement,

line with the

needle hole

ADJUSTMENTS

1.

Adjusting

The

proper needle

the

lowest point to form the correct loop of the upper thread a

the loop.

needle bar

bar

rise and needle

bar

heig

ht are necessary for the needle in its upward trave l from

( 1 ) Needle bar rise

When the needle bar comes up from downmost to

mentioned measurement, the shuttle point must be in line

\\"

ith the centre axis of the needle. Adjustment can be

made by loosen

turn ing the shuttle

screw matching with the

black screw.

- 13 -

nd

for the shuttle point to properly hook

below-

in

g two shuttle driver set screws and

driver as required and fasten the silver

groove

of low

er

shaft a

nd

then

Page 16

Shuttle driver

(2)

Needle bar height

Shuttle Needle

p~~

ll

r-1

'l1T2

~·

Make

sure

Lhal

the shullle driv er is

of shuttle point.

LK3-

B220

-l - ·5, -H- -9 } ........ .

LK3-

B221

-l - -3, -8

LK3-B220

LK3-

(NOTE) LK3-

When

the

shuttle point is

distance between the lop of the needle eye and the shuttle point

If

adjustment

raise

or

is

required, loosen the needle

lower the needle bar.

LK3-

8220-1 - -

LK:~-

B221-l LK3-B220-6-

LK3-B221 -4- -7 ......

·6- -7 ...... ......

B221

-4- -7

.....................

B220

-6 & -7 for Denim. only one screw is sel.

in

line with the

5.

-8-

-9

) .

..

-3,

-H

-7

.....................

J

..........

.......

in

close

2.8

..........

...

..

2.5

2.5

centre

2.0

1.2mm ± 0.2mm

2.0mm ± 0.

axis

bar

111111

contact

111111

mm _ O.lmm

mm 0.2

connecting stud

± 0.

3mm

3mm

with lhe

±

0.2

111111

m111

of the needle, the

is

rear

as

follows.

scr

ew

side

correct

and

(3)

Clearance

Needle1C

2.

Adjusting

Bar

tacks

the

outer

The

tack

expanded by feed adjustment, its centre must always be at the same point.

between

- o.

~Shuttle

feed

will be made as the pow er is

and inner

design

the

os....

.

pomt

mechanism

groove

stays

within the re

needle and

s of the feed ca

ctan

the

shuttle point

transmitt

gul

ed to t

m.

ar

opening in the work clamp an d even when the swing ts

ack

length and tack width mechanisms through

Thl'

corr

ect

clearan

tween the centre

bein

).!

met with

po

int is

0.0:~-0.0Hmm

To

adjust the

loosen the s

s

et scr

adjusting screw

the s

et scr

completion.

huttle

ew and

ew tightly

ce be·

of needle

shuttle

.

clearance,

hook

rot

ate

the

and

fasten

after

(1)

Needle and feed cam

Feeding begins as soon as the needle rises out of the materia l and ends before needle comes down into

If

the material.

turn

the feed

Turnin

g the feed

(NOTE) LK3-B220-6

adjustm

cam

ent

by degrees.

cam

in its

is requ ired, loosen the wo

rotat

ing direction, it advances the feed Liming and vice versa.

rm

wheel shaft nut and the

& -7 for Denim. the Liming of feed cam should he advanced a h

- u -

hexag

onal bolt and

it

earlier.

Page 17

(2)

Adjusting

tack

width

motion

(Except

LK3-B221-4

- -

7)

Adjusti

justments

adjustment was mad e, no further adjustment

First of all, adjust to gel the correct posit ion between work clamp

fram e s

nM

tack width and lack length motions require very delicate and prec ise cautions.

firstly on

el

bolt.

the tack width mot ion and then tack length motion with

is

necessary

the needle hole will

then tighten the

4)

Loosen the

bl

hinge

Again , move the presse r arm and set the presser arm so

the needle hole will come

then

ock all the way down, then tighten th e fastening s

tighten the fastening screw.

unl

ess absolutely required.

come

fa

stenin g scre

tack

width lever fa : tening screw and lower th e

Make

great

care. Once the

and feed plate

I) Let the first needle come down

into the needle hole.

2) Loosen the adjusting screw and

raise the

block

hinge

tack

width regulator lever shaft,

tight en the adjusting

and

3) Loosen the feed bracket, fastening

screw. move the press

sel the

exa

ctly at the centre of work

w.

exactly at the

by

loosening

hinge block until the

is

in lev

el

er

po

sition of bracket so

centr

e of work clamp,

ad-

correct

clamp

with the

scre

w

arm

and

that

clamp

cre

w.

tha

t

,

(3)

Adjusting

tack

length

motion

1)

Raise the clutch and

needle comes down into the needle hole with tack length

regulator

2)

Loosen the feed

regu

of the ta

not so as to move the

:i)

Loosen ba

the ce

tighten the ball stud.

in

the marked position of the rim of the feed cam.

la

tor

rod brings to its fullest ext nt in the elongated hole

ck

length regula tor lever, set the position of

ll

stud and s

ntr

e of

work

turn

the driv

brack

et fastening screw, when the tack length

work

et

the po it ion of press

clamp will come to the nee dle hole, then

ing pulley by hand until

clamp.

er arm

so

tpe

bracket

that

- 1

5-

Page 18

(4)

Adjusting

I)

2)

3.

Adjusting

The

and

1)

2)

3)

4)

5)

*

motions

Adju~ting

( i) At the

be positioned

(ii)

Make

cycle.

Adjusting dial of labelling

The

When you

neath the dial to its

the pre-determined,

This

lack length motion

~top,

the tack length

In

case of adjustment. readjust the position of feed plate window.

dial plays a role to determine the position of label.

set the material by work

adjustment

thread

upper thread knife, lower thread knife and thread presser

are

oparated by the power

As the needle rises out of the needle hole

thread

The

As soon as the upper

the lower threarl. At this moment, the tip of the upper

The

po~ition

The

the tip of the knife

In

correctly. The

to prevent the thread from slipping out.

thread presser releases the

upper thread knife enters the upper thread loop while the

after

machine stops. When the left treadle is depressed, the connecting rod adjuster disengag

adjusting the knives, firstly remove the needle plate and

on

LK3-B221-4--7

mo

ve

pre~~er

at

the

exte

constant

is

made

trimming

thread

catching the loop in the process of forming the final stitch.

bar

and

n.

mak

e adjustments

plate for guide

centre

nt to fix the position, then you can get

of feed plate window.

at

maximum and

damp,

measurement on the materials.

by

moving the dial back and forth.

ba~e

back and forth

make

~ur

e

put the lab el

~o

that

that

the above position is kept during one

unci ·r·

Labels'~

mechaism

are

mounted to the pinion

transmitted

thread

is

pulled up by the

the connecting rod spring pulls the knives to trim both thread

from the knife

after

the first stitch, the

just before the fifth stitch is formed.

thread

in

the following steps.

cam

.

take

-up lever, the lower thread knife

thread

knife is just

shuttle

make

thread

point comes to its downmosl

sure the knives are installed

the needle hole plate may

presser catches the upper

in

front of the needle hole .

Fastening

~tud

s.

screw

brack

catches

es from

et

(1)

Thread

At

the recess portion of the kni

second stitch, and

trimming knives, the po int of low

is positioned at the red

trimming

the

thr

lever

ead trimming leve r roller is ju st above

at

roller and

fe

the stop position of

mark

of the needle plat

lower

cam,

that

er thread

thread knife

is the

thread

knife

e.

-

16

-

Thi

s adjustment is made by loosening the

a

nd movi

ng it back and forth.

rack

Page 19

(2) Timing

(3)

Lower

of

knife cam

Lo

oHen

the fastening screw for knife

timing so that the needle may not touch the thread trimming

knives and the upper thread loop

Adjust the thread trimming

so

that

the upp er thread knife ma y hook the upper

during hook point trav

at

the final stitch.

thread knife and thread trimming lever

elling

cam

(B)

downward

cam

(A)

and adjust

may

not touch the knives.

by loosening fastening

thread

with upper thread loop

At the stop position,·

loosen two screws

adjust the thread trimming adjusting screw

that

the point of

thread

sitioned

on the needle plate.

knife will be po·

at

the red

the

screw

loop

and

so

lower

mark

(4)

Adjusting thread

trimming

~hole

~pper

stopper

thread knife

screw

When work

so

that

0.

3mm

At

this moment, the needle hole is positioned

of upper thread knife.

clamp

thread

from the bottom of knife

is lifted up, adjust by stopper

trimming lever roller

cam

may

.

be

apart

at

the

screw

about

rear

- 17 -

Page 20

(5)

Tension

4.

Adjusting

As the needle begins to rise for the final stitch, the upper thread knife enters the upper thread loop.

And the main tension

When the left treadle

needle

Before the needle comes down for the second stitch, the thread nipper

is

tightened. Make adjustments, if necessary, in the following manner.

of

connecting rod spring

the

thread

is

released

is

depressed, it

bar

thread nipper

If

the connecting rod spring has too weak tension, the knives

often fail to trim the threads and in.some

break

. If.

with the needle causing to

has too strong tension

knives. thus the machine does not work smoothly .

spring

spring hook left

tension, loosen the spring hook set screw and move the

or

extra

right.

on

power will be needed to

extreme

the other hand, the spring

cases, collide

To

nipper

to

allow sufficient length of the thread for the knife.

works

is

lightly tightened to prevent the thread from slipping and being jammed.

the thread nipper mechanism and

is

released and the main tension

at

the first stitch, the

drive

the

adjust the

(2)

Adjusting timing

Adjusting

screw

----Ill

of

the

thread nipper

-.....~at-----Thread

\l!..--f"

--

nipper

lever

n;pp"

7>--+~

shaft

nipper

pawl

lever

(1)

At the stop position, adjust the roller position

so that

marking.

adjusting

Timing

•haft

0 Guide

its

line

f

centre

shaft

will be matched with the red

At the position of the

roller being over the

cess posit ion of the

the end of guide

must be positioned

upper line of the cam.

In case of adjustment,

loosen the fastening

and

rotate

nipper shaft.

the

re·

cam,

shaft

at

the

screw

thread

-

18

-

Page 21

(3)

At

the

stop

position (before lifting work clamp), the end of guide

of

cam

on the condition

In

case

of adjustment, loosen the

shaft

and adjust to bite the

lightly. (At

At

this position, when the

the bollom of the recess portion of the cam.

that

time, the roller position is

that

thread

the

thread

thread

thread

nipper

shaft

nipper stop lev

nipper adjusting lev

nipper adjusting lever pawl· and

2mm

slop lev

er

contact

apart

from recess portion of the cam).

er

is disengaged, adjust the roller to move smoothly

s the thread nipper adjusting lev

er

screw, fix the position of the

must be positioned

stop

lever, then fasten the

at

the lower line

er

thread

nipper

pawl.

screw

to

(4)

the

At

recess portion of the cam, adjust the tension

adjusting thumb screw so

will be light and

being

it

5.

Adjusting

Unless the clutch and

consumed for the machine's operation,

position of the roller being

at

the position of the roller

in

the recess portion of the cam,

so

that

the main tension will be loosened.

clutch

and brake

brake

that

the main tension

are

over

in order, the machine may not stop properl y,

(5)

the

At

the position of the lever pawl being

out of the stop lever, adjust the

adjust

or

machine's durability may be considerably lessened.

moving left and right so

guide

ma\' catch

the

thread

that

surely.

the needle

more

thread

bar

power

released

nipper

thread

may

be

In

case of adjustment, please follow the instruct ions.

(1) Clutch lever catch and clutch stop latch

Adjust the position

the clutch stopper is about 3 mm.

(2)

At

the position of trippi ng do g being ov

arc

at the idle pulley and th e slow speed puller.

of

the

clutch

stop

latch so

er

that

the

mm

imum distance between the stop

the stop cam. adjust the level of belt guide so

- 19

that

cam

and

the belts

Page 22

(3)

At the position of tripping dog being out the stop cam,

adjust the position of the stopper so

are

at

the idle pulley and the high speed pulley.

'

Bobbin

Idle pulley

winder

5~5mm

pulley

\1~

(

5)

Timing of stop cam and clutch stopper

Please adjust stop cam so

may disengage with clutch lever catch one stitch

before the end of sewing cycle.

please see

with clutch lever catch within

sition where the groove of stop cam falls into line

with clutch stopper. In case of adjustment, loosen

two set screws and move stop cam left or right to adjust. At

by turning high speed pulley by hand.

that

the belts

(4)

Adjusting height of trip-

ping dog

Please adjust the position

of lever so that clutch may

come into function when

tripping dog reaches three

quater position of stop cam.

that

clutch stop latch

In

that

clutch stop latch

that

time, make sure to get proper timing

will

±30·

from the po·

of

this case,

disengage

(6)

Pressure of

Adjust the clutch lever spring so

to permit the clutch stopper to fit positively into the groove of

the stop cam to

loosen the fastening screw and change the angle of the adjusting

plate

(7) Pressure of the stop spring

If

the

stop spring is too weak

down into the material as the machine is going to stop

machine may stop

stop spring is too strong

machine

adversely affect the durability of this machine. Adjust the stop

spring tension

-

the

clutch lever spring

that

it has just enough tension

stop

the machine gently.

.

in

tension, the needle

at

wrong position. If, on the other hand, the

in

tension, the impact exerted on the

at

the time of stopping will be increased and this will

by

turning the nut.

20

-

In

case of adjustment,

may

come

or

the

Page 23

(8)

Position

When tripping dog is

by

loosening fastening screw so that the distance between the

ann

hole and emergency stop lever

of

emergency stop lever

at

the highest position of stop cam, adjust

is

about 1 mm.

(9)

Clutch

lever

In

case that the right

treadle is depressed

strongly, it causes the

belts coming off out

of the pulleys due to

too much movement

of the clutch. In order

to avoid this, adjust

in

the following

manners.

*At

the starting, set the shaft by the fastening screw so that the actuating lever shaft contacts with the

of

lever pin and adjust to get the distance

the lever. After completion, take off the screw.

3mm between the bed and the clutch actuating lever by lowering

(1

0)

Clutch actuating lever stopper

In order to prevent the right treadle from going upward, the

clutch actuating lever stopper is limited the movement of the

clutch actuating lever. In case of adjustment, adjust in the

following manners.

1.

Be

the machine

2.

Fix the actuating lever shaft with set screw.

3.

Set the machine in normal position.

4.

Adjust the height of the stopper to be 1 mm by loosening

nut.

5.

After completion,

(Set screw

is

included

at

stop position.

take

out the set screw.

in

the accessory box)

actuating

Nut

6.

Adjusting

While the machine is

and also the knife bar remains inoperative. When the left treadle is depressed after the machine has

automatically stopped, the knife

clamp is raised

work

up.

clamp

in

lifter

operation, the work clamp stays down even if the right threadle is depressed

bar

tripping lever is actuated to operate the knives and then the work

-

21

-

Page 24

t:-. case of the adjustm ent. do m the following manner

(1)

At the stm.)

onnc

ctor

l:.tch

is

(2)

Fasten set screw for latch

connecting lever.

position, when the left treadle

I o o

i

erat

c with the clearance of less than 0.3 mm as the work clamp connecting lever

1

adjascent with the clutch actuatinR" connector lever stop.

at

the position

(3)

In

to be less than about 0.3 mm between clutch connector lever

stop and work clamp connector latch

(4)

When the left treadle is depressed

engage until the work clamp

(5)

(6)

(

7)

is

depressed, adjust the length of the clutch

that

the operation, adju st

make sure that the thread

the clutch actuating connector

the adjustment mentioned

When the left treadl e is depressed upto th e stopper, adjust the

height of the work clamp to be

Adjust the height of the presser arm to

the pres

At the stop position, when the tett

before the thread trimming rnechani

relation b tweem the

ser

s.

actuating

the lower portion of the latch meets work clamp

by

work clamp

trimming mechanism does not

con11eC.ting

lewr

in

step

arm and the presser

<:;top

lever

10

<>haft

lever the

as

per Page. 8.

after

the machine stopped,

lever latch is out of

step. if incomplete,

~)

a

nd

3)

.

mm

::~part

from the feed plate.

Le

2.5

--3.0mm between

<>priug

by set screw.

i-r

eadle is depressed,

o;;m 1s

Hnri

engaged, adjust the

the collar so

ueedle

1

:;

tightened.

bar

clearance

repeat

just

that

the

thread guide

7.

Adjusting

The

two presser feet

when the work clamp is depressed and

catch

the material up between the left a

In case

becomes very dirty.

In the adjustment,

(

1)

Amount of opening bet ween the feet can be adjusted by the nut (!).

(2)

In case

being d

guide towa rd you.

(3)

At

the stop position, in case that the feet wi

loosen nut

work

that

this action mar not work

that

the feet will not be closed when the right treadle pedal is

ep

re ed th right treadl e pedal, uns

clamp

a.-

e opened about 2 mm when th work clamp

do

iu the follow ing manners.

on

8221-1

actuat~d

nd

in

good condition, the sewing ref.l!lt on eyelet buttonhole

and

right.

crew

-2

1.

he ma chine by treadle peda

the fastening screw ® a

ll

not open when the left treadle pedal 1s depressed,

® and adjust th e he ight of stop lever adjusting screw.

-

22

-

are

lifted up. T he feet will be closed

l.

In this case,

dep~

essed,

at

nd

pull the feet closing

the stop po si tion,

the

feet

end

bar

Page 25

(4)

In case that the feet will

closed when the right

be

treadle pedal is depressed and

before the machine s

just

the length of the fed

closing conn 'clor bar.

8.

Needle

cooler

not

tart

s, ad-

mechanism

*This

machine can be used

with the needle cooler

vice

at

your option.

case

that

you may need,

please contact y

This

need le cooler device

is featured to

thread breakage with s

thtic

thr

mum high speed of

stitches

per

ad even

minute.

our

avoid the

at

de-

In

dealer.

yn-

maxi-

2,000

Needle

cooler

adJUS

'

oCock

you use th is machine with

\Vhen

vertically and if no

0

Thumb

Adjust oi I flow depending on the thi

th

o

If

o Sylicone o

Use ~ 1

rea

you

d.

screw

turn

thumb screw clock,vise, you

il

00 syl

t, close the cock .

icone oil which is avai lable

Oil ta

ter

syntht ic

ckne

nk

thread. open th c

ss of the

can

by

materia

get less

BROTHER.

oil

ock

ls and

flow.

-

23

-

Page 26

PARTS

LIST

for

LK3-B220

INDEX

l'nr

ta.

Nn. Wd . Nu ,

001401

.4·06

()(I!J.I02.0·1

~~~~~~~~8~1~·6~·1~2c-I-~A7.~7~3--

1

-

009670-5-

IM~J670

.6.12

t)()l;oi670

-7-l·l J .J

UO'JGH0

-6-12 A

i

--'

===

009680·7·13

009680·8·

009681

·2·

009681··1·1·1

~

0<W~~71~o~·7~·~·2c-l--~~~·~4

1

00~711·0·1

00~711·0·14

1~011~~~71~t~·2

:;-·~t2~1--~~~

009711

·4·12 A ·l

1

~009~~71~2~

·0~·~12

,.

009761

·0·12 C·

009761

·2· 12

009761·4·12

O<W771·0·12

009771·4·12

01~1781·4·12

,

__

009=."'112:::1c:·6::..>

,.

009822·0·12

013680·6·12

013710·5·

01~10·7·12

013711

'0·12

01376<1

·6·

Ol37f>ll

·7·

_0::.:I"'3.:.;76'CI"·<::..I·.:.:l2:.._ir~A;i..;;·6!~r,--t------l

1

1

~--------t---~~~.ss~,---+---------l----------1·---a;~·~.25~--·r---------

013761

·2·

013770·6·12

01~80·7·10

014680-6·

014760·6·

l------l

1

------f--..;F.;,;-

I-------+-~·~

Z·

40

2

11·3

14

1

1-53

A·57

:.:..

14

10

·

22

22

-:cl

-t--..;

!71.-::6:;.2--l

A

-71

I

·6fo

II

..

~;.

E·

2

1;

..

J ·I I 021

•.

~771---l·

11·

100

~-3

11·

I ·31 I

1

.:12

~r-~~~~·~~9

/19

F .u; A ·67 104212·0·

C·37 E·24 104450·0·

1·37

A·

C·

73

G·39 Z

C·7·1

11·9

11·37

11·:1

E·3!1

.:.:l2~r--F.;:;:-:;.28:;;--·t------t

F·38

11·45

C·78 025770 ·• 32 C ·53 106744·0·03 E·33 115593·0·

.7

1;

ll·H

1;.24 Ll·27 105812·

12

C·86

1·'1 E·32 105831·0·

ll·f.G

I ·6

C·70

12

1;.53

l2

I ·57

11·36

Z·21 G·49 1·18 I Z·

12

11·21

11·27

K.:llt C·67 106812·0·

11·51

Z·32 D·28 107038·0·01

11·23

8·22

8·57

11·6.<;

I ·70 Bl6302·0.00 C·62 C 49 117936·0·01

11·14

ll·33 Bl7502·2·42

K-73

C·83 047603·6·42

C·84

1>·6

~:.

-.-.;.zg;;;-:.":4~7--1

;·~3~5

G ·41 IJ.12

1; ·42

11

·5 081004-0·70 J ·2 108920·0·

11·67

II·!J.I

C·IO F·

~;.45

:::~5

017761

·6·

12

017771·4·12

017781·4·12 C·92 100062·0·03 F·IO 110191·0·01 J ·24 !41285·0·01 C·IS

1

--:o~t-=77=:8:::2~·0:-·1;.;2:--t-~~:;.

l---~---r--T.E~·30~-4------I

018102·0·20

11·27

1>·29

..

-=-=ss--:-4-----

C·68

C·R7

Wcmnrk

0

I ·

------·

r.

·------

1 IJ-I!f

1M

tt

l2

~r.

__

______ 1 ______

.

1

15

----------1~,~~2~t

4

17 I ·17

---+----------I

IS

Pnrtt, Nu .

0210(~)

02HX~I·I·O·I

I~'i'2~14~1~MI~·I~·';"

Ullf)K0

11

217

10·2·112

h ,.,,2,.1

7"'lil

'"'t"".

71

0·1·03

~7~~.2~·o~2~

0217M0·3·0~

11

21K

211

--'0~

2~1~H60~·

1125001·2·32

025060·

025080·1·32 t:·4 C·96 115548·0·

0251110·1·32

025680·2·32 G·56 105230·0·01 I ·5 115552·0·

--'

0257111·1·32

Ht'f

.1.02

·2-n

2"·'"''2' 1----;1;;., .

·2·

~·2~·1~12c-

2·3·1

. Nu.

A·

7.

.:lfl

;;-

I--~7.;

··~·1~1--I------I-~Il~MI~I3~6~·'~'·'~11~il---~~~·l;ll--------t-.I~

:l c;.12 J

C·

f:.&o

1 .:tu

.:;1~5--

ll·3l

~;.25

F·2'J

,;.s5

__

~·7~.7.2~1--r-----l-~

1

11·:!:1

11·35

1--~F.~:.7.~~~---r----------l-~to~l71t~8~·•'i-,

11

..

I ·26 10!531 ·0·

11·16

02

.f.Jf)

~;.3

l--~~~

·

~·~7a

A·H4

~··28

G·

Z

·~

.JS 104689·0·01

C·29 115549·0·01 C·33

C·40 105156-0·03

C·SO

F ·40 105333·0·01

G·lS

I

·44

~·~-·~-~--~c~.86~--4----------~~~~~77~1

C·94

~;.19

~;·41

(;.32

11·3'J

11·40

-''=

'28050·2·42

0281180·2

0~770·2·42

031311

Bl7301 ·8·42 I ·19 C 80

047603·2·42 F.·48

0.11!040·3·42

1

-t-----+-04

·--

--+------II

041!050.:1·42

041!070·3·42 C·47 107793·0 00 F

::.;:;

-"'~'4~K~

100013·0·Bl

100016·0·04 C·4 1·35

100032·0·01

t-====-

1()()()6j·O·OS

·~.ooo~~7~

·3·02 Z·26 C·39 A ·

K

::;.

IUO

::;;.:·~

I

I20~·1

~

•.

o~.~04

11·47

C·25 105969·0·01 G·3 117007·0·01 A·85

t;.t6

·42 11·58 106764·0·

C ·54 F ·30 117363·0·01 F ·39

C·93 Z 37

E·31 107053·0·

E·40 107149·0·01

11·38

11·44

C·9

C·79 !07779·0·01 Z·9 A·

1;.33

·7,4~7-,

-j---,~:7.-':.-1:71--j---·-

C·51

~

..

~

12'-f-~1~>·

7

11·31

11·70

C·45 109184·0·01

F·13

:;

:

~

G·l

--~F"'·"'I"-4

11

·92 11Bl95·0·03

~~-A~

·86~---

C·35

Wc~mnrk

611

26

-~----·---

------

18

__

-+----------l-~10~2~67~t;~

44

~I-T.t07~7!!0~0;;.0~1:-ilf---:7.~

1~-

·

------II-;;;:;:=·

12

----1-!"'1"'0""17'-!12

--+-·------ll-'t"I04::.":'367-".o"'.o"'t-f-~7.~·"'1

------·t-~11~0686~.~

l'nrt

a.

Nn,

l<c•(,

Nn.

ICXNIJlO

.o.

ot

,\

IIXIIOS.o.o.)

IIMII!II·II·II

l-====-l·-

HX124t

-o.u:t

l~ll;;;NI;:;25,;;1:;.H;;.I

·

:iO'i-l

IOU2Sl

·U-

CII

100253

·0·

01

IIM1388

·0·

111

IOOJ<J9.0·01

tOI~In.o.ot

·01~'~59~8~·'

:;-'·o~•c-

IOOil87·1J.III

IUHII

5·0·

01

.

,~~~c-i--~

10127

5·0·

01

01

101531·0·03 A·2ti

1017Uf.i.f).(H

10262fi-fHI

HI262'J

·0·

04

.

('i-1

·

1~12c-J~~7.~.

1033l7·

1J.II1

01

01

104525·0·

01

104649·0·01 I ·54 115546·0·

105183·0·01 1·41 115551·0·01 C·28

105343·0·01 Z ·5 115570·0·

.~o.

~t~t-t~~~~.~~J~.~z~.1=7~----------·l-71~tss~~~.o~~~~-t---+I~·S~t--~----------l

1~771-0·16

0·01

105828·0·

01

01

105832·0·00

105872·0·04 E·22 116715 ·0·01 Z-6

Hl5955·0·01 G·S 116828·0·

105965·

11·02

105970·0·01

·1--

i~~~.o~.o~z-+--~G~I~B~-+----------t~t~t7~t50~·0~~~~'-

01

01

01

107153·0·02 C 46 1!8768·0·01 A·8

• j 1'·46 118955·0·

101!721 0·01 i-_..;

_____ • _____

-;o-;;;;-

1088~·0·01

01

108960·0·03 1·59 A ·82

109986·0·01 1·16 140557·0·

110161·0·03 j ·25 140560·0·01

·0~·

0~2:.._1--~~7

.

o~.~o1~r---1~1~·4

1108~'0·0·01

.J2

11·11:1

.•

:I

""'"

--'-:

"'-·5

::,~.,.

A··H'

-f---7,tl""·2ti

ll·

lti

li

·IH

1·

14

1·52 114483·0·

±j

' 114486·0·

l

8

I A·78 I

z~

•.

7.~~--·!----------

~

;.u;

11

·!0

H·

2!'•

!t

B

-1:!

Z·:l 115404·0·

·~2~--~----------I

A·3U

A·

31

A·51 115489·0·01

1·11 115515·

I ·47 115544·0·01 C-2!

11·56

F·50

11·29

Z·37 1·38

G·37 115663·

11·32

11·89

11·88

F·25

G·IO 116968·0·00

G·2

11·43

0·34

F l

8·37

11·44

II

76

F

31

<•

29

•.

-::7~-

!I

1,.:;;2

J I

12

-fl---;1~50;---j------l

A

61

7.·16

C·ll

.

::::~:o---1-----+-::-':C!.:~=.·~:~!C:~~:'-

I ·36

11·93

7

l·l

Ht•mnrk

u;

•

_ -----·-·t-..:.1.:.:12..='•.:.1H::..·c:."·

;;:.~-!------l--;-lo:I2"'7"'51"'1·:;;-0

______

1

"----·----

--------·

'---t------t

s----t------t-~t4~1~4~~.o~.o~t~

Par-I

t'.

Z'\u

. 1

111~1:/.0.

0I ~·-~Ai'

II )9.)3.11.11

1 A·33 I

I I!'U~II·I~ A

lllV4tf·O·UI

IIIV511·1HI·

112751

112751

114240·0·

.1_.:.1.:..1·1~9.:.·1.:..•·~0

1150117

-

l-~~~~-l·---7u~.~~~~--ir---------

115157·0·

115316

115389·0·

·

~I~I~54~~~·0~·0~1-t--~ll~·~~~--!

1154-15·0·01

115488·0·01 G·

115547·0·01 C·27

115550·0·01 C·30

115558·

115599·0·00 I ·55

115958·0·01 I

116016·0·

116231·0·01 A ·

116827·0~1

11702!·0·00

117348·0~1

117~~·01

117487·0~1

117488·0~1

117671·0.02 0 ·

117934·0~1

118244·0~1

118404·0·01 I ·IS

118405·0·03 I ·13

1111872·0·01

1-

.;,

120034

=:7.'

t-~~~~~~s~.o~

1400'.!3·0·01

140392·0~!

!40399·0·

1412113·0·01

141284

t4t286·0·0I C ·l7

141289·0·01 C· l9

I A·

.::".:..l_

i A-39

I A·54

·

"'0<"'t-

·0·

01

·0·03 A·41

01

01

0t

·

~0.:..1_

__

1

·0·02 ll-2

111

·0·

01

02

01

0·01

01

01

01

11·01

01

01

0·01

01

01

[__~

~

01

.

~0~·"0"'

1

-!-

- ..!71

.70~1-r--A~.J6~--f------

01

01

f

-~~:::.

·0·00 C·

·

----:l~l.~~~--::---------

l<t

•L

!':u

. !

l<c

.-;iJ.I-;-'-1

·~

A

·25

27

!1-4

7 '

1·6:!

A·

46

Z·l4

z.~

-+.1~·~~3

____

Z·

20

11·32

Z·l2

1-61

U-13

E-17

11·9

G·48

47

11·11

11·40

C·24

C·32

C·31

C·38

I ·

34

I ·53

G·22

·3

Z·39

75

11·85

11·91

A·l8

27

C·20

G·l7

Z·38

1·49

I ·

48

25

A·3

l3

11·1

G·43

19

ll·

BU

G·3

A·

IO

'-!

.68

'7.-----J------1

Z ·

19

G·6

A·S

C-56

A·

24

11

·32

•umrk

~--=========

j

____

I

i-----

j------

__________

-----------

:

_

1

-

l

l

:7~3~-~-------

C·

l6

14

t

-

24

--

Page 27

Part

s.

Nh.

l~t

•f.

Nu

141·192·11·111

14149:1

u.

nt

14

1535·U-UI

141i36·fl·IJI

~-())

I4174·1·1HII

1417·15·1l·IJI

J.it746·11·UI

"!417~K·II·III

- l·U75J.fi.CII

l'.il75'"2

""

·n'"'.l;-;ll

-

1~175.1·11·111

1~17~'"'.,~

14175.>-:o.iii

"141756·11·01 A

-

1~1757·

141759C;-·I;;-I·iill;-'l

14176l·O·U1

141762·11·111

)4176.1'·1""1·""11'""1

J4i766.cHII

141771-11·111

141772·0·111

141773·0·1KI

141774·0·01

141775·0·01

141771i·IJ.III

~o~-~l-i-!.~2--l------l-~14~1;11\;~~l~·~0.7.11.;.1-I---7.11~-2!=5~--I!-------I-~17.4201~15~.~o.7.cx~I-~--7A~·7~1---I------I-

141778·1).111

14177!1·0·01

1417HIJ.IJ.III

•-cl~4

,-

1417K2·1J.III

1417li:J.II·OI

1417114·11·111

1417H6·U·tl1

1417H7·11·111

1417HK·II·III

!-;l;-;4-;.17;;9;;;2-;;·ll;-;·1;-;ll-f-;;ll-i.c;;O;;.,"_'-;,;c:;;;-!------l--i-1471;;;!JI~I';-I·~0-7,11.;.1-f----;;llc;·7;---f------l--7147,27,;2~17;-.~11·7,11.;-l-t-~F~.I;.i9;---J------·f

l-----cAc-·::"~K::--I

•.

~~~~,-I:-~,.;-,..;,~.;-,--~

-

ll·lll

-1--....:..;.I.::.N;::.._--f

-

l·-~z-".2!,0,,--l--

17~8~1~·0~·1~11-l-~c~··~K--I-----·I--i-14~1~K%~·~·1~1·;:-0I;-.I---1~1~-2=.2--I-----I-.;.1

7

. Hmmu·

II ·~·

•

11

·17

t;.r.!l

1\

.;.;1

A·ll

A·l-1

A·l7

A·!""tll

J\

..

J:J

,\

..

17

J\.14)

,\.~1

A·36

·2.1

A·~l

A·tjli I·IIKK2·0·UI

,\·77

lt.:l!l

11.:11

11·2H

11·2·1

11·63

11·15

11·5

II·K

11·7

11

..

1

t;.;;

t;.J

l:-2

B·!i~

11·5:!

11·54

1-,1~4"'17~9::;3-;;·11'"'·•;;11-1-'-,11·1•;

1

-;1~47,17;;9~5-;;·0;-;·I;.;II-!-~I~t·~i~~;--r------l--i-14.;:1~!JI~I:';-t·~O·.;;II.;.I-!----;;11~·4;----

,-

141796·11·111

!:::~14~1t799~d·ltJ.I~II~~==~jl~t-~7t7~~=~==========ii=~l~4~191;1;7.~11~·0ttl::~::::::~ltl-t13~===

,.

14181XI·IHII

141801·11·UI

141805·11·~11;...1

1·1181Ml-11:111

1·116011·11·111

141"'"J·IHII A·81

f-~14~1i81~2;-;·l~l.l;;illc-f----'A~·~~~~---+----------11~1~4~19~~~~.7.11~.o~l-t--~I-

1~1813·11·111

141814·11·01

11·78-HII

11·81

B·69

-!---7,B-;·8:,:4--I------I-,1~4~19:CI'::I-'·II;,;·O::;IC-t--:-1·.;2;...1--l--------1I-,1~4=,2225:;:;::-;·0:..:·0;.:IC-t---;1':,.·.,;4--1------l-

B·72

B·!l5

B<14

E-4t; 14192:t·ll·lll I ·43 142256·0·01 J

------

-

-----

l,

-

.;-l',.;a

';";

riO:•·;-:;-N;:"u;-l--l-!•;,•1..;.

I.JI

I(!'

~o~i.u.nl

1·11

1157·11111

1·118!"\li·U·nl

l·ltM62

·

1i.7.11TI

I·II~;.J.n.nt

l·ltHI).HI-111

141K65·11·111

141Hti7·1).(11

I·IU~(',H.tl.fll

Wll6!1·11·111

I·IIH7U·CI·411

I·IIK71·1J.HI

I·IIKn·ll·lll 1;.1:1

I·-71~~~~K7~4;-;·,-;-•·~11;-'I-!--~,~;-i.I~4--------I·-71~~~7.9115~'~·1-;-I·~O;-'I-!---1~1..;·2~2--

J.IIK75·11·01

-;-1·~11~K7;:";-;'''-;-I

·

I~ll;-l-----cl~;-;.l;;;!'

J.IIH77-IJ.III

141HKI·II·III

1·1111!1.1·11·111

l·llAA-I·U·Ill (;.51 Hl!1J5·0·01

I__,I;-;4,.;.IIVI!~'>-;·II;-;·,;;.;II-!----il

I·IIIIH6·11·0I

14111117·11-111

141868·11-111

J.ll889·0·01

1418911·11·01

14111\IJ.II·Ill

J.IIW.IJ.IJ.OI

141894·11-111

14III'J7·0·111

1418\IH·II·OI

1411199·11·01

14191XI·II·III

141!!112·11·111

1419114·11·111

141!!118·0·01

141909·11·01

141912·11·01

1-11914·11·111

141918·11·111

141922·11·111

;,:,

N_"

_·

-~-

F·2

F·22 l·

F·41 J.ll972·0·Hl C-77

-

f·--..,;~

..

1;.7 I·IHI74·11·1H

(;.K I·IHI7!i·O·III

C·9

C·~l

<;·21

c;.~ll

c;.3(1

c;.:H

c;.:u;

c;.:lll

11-41

11-4~

11·~1

7

;.~46;--!-----+-l;-;4,.;.1!!!;;;!16;;:,-;,o;-;.,;;.;ll,!--li-.766i;--!

c;.r>~

1;.52

11.:16

11-35

11-33

11·46

11·32

11-2H

11·26

11-18

11·19

l·'n

J.~t

11·11

1!-li 142214·0·01 C·44

11·111

11·2

11·14

11-12

1·20 142226·0·01

1·2'2 142'2'n·U·OI F·18

1·33

..

1-42 142255·0·01 A·20 144489·0·01 E·34-

~I--T.I'

1

fl

--jj------l--il7.11rf!l;.;7.'i''l·;;ll-;;·11:;-l-i·-~t;'O.\~II--

__ , _____

~

7.«~1--~----------1~1~4Z~~~3·7,11~·0~1-t--~A:..·5~9~--r---------+

I

;i'<r;..l

•

i;;

·

;-;

•

'>;";';;iu

.,-

f--l!'o

•

;,-

I . .;'

N

i;-

'-"

·-!--

l!-o·o

_n_nr_k_

-J--'I:..:'

u"r

::.:I

•

:.::

·

J.af067-:n.

ul

1

llll71111·111

1·11977·0·01

l·IHJ7K·U·OI

loii!J7!1·<1·01

1·119"'1-11·111

I·II!UU·CI·fll

1·11!111.1·1Hll

1·11911-1·0·111

I.JI9H6·11·111

l-.;.1·~117.91111~·1;;-l·~lll;-

J.II9W.I·II·III

1419!12·11·111

14l!t1J:l·II·Ul

1·119\1-1·11-111

1·11!!!17·1).01

1419\18·11-111

14201MI·O·OI

142001·0·01

14:.!(102-0·01

I421XI3·11·01

14:.!(KI6·11·01

14:.\(KI\f.IJ.III

~~:.!(

~118

..

~.9

..•

~.·1

1~.·1

0

1~1111

•""

~

1

2

1422111·11·01

142211·11·111

142219·11·111

•-.;.1~~2~2:.!(~1-I;;-I·~OI~I---~E·~35~'--+

,-

1422'21.11·111

142222·11·01

142223·11·111

14<!224·0·01

142221!-0·01

·2H

t;

.7;

,

jj------l-

t.:-95

C·KK

IJ·H

0·7

IJ·!i t4 :

11

..

1

ll·:i

p.ac;

11·2:1

------

11·2·1

__

...:1;-I·'=JI:;_I

__

------

1·1-

1·56

J.rJK

A·2 F·25

J.I)!J

-----

1·67 144427·0·01 l:·42

1·64 144429·0·01

A·OO

A·711

z.w

Z·2'J 144463·0·01 F-49

Z·24

Z·31 H

11·9

e-I-~A~-~~r,~-~3~7-·l

1·2.1-25

------l-

E·IK 144466·0·01

8-tH

11·6

E-S 144471-U·fll

G·31

-----I_c

E·JI!

E-37 H

8·34

E·46 4&-51

F·3

1;.42 144483·0·01 F·18

-19

..:N:..:•c:•~.--~~-;'

143-I·IS-o.

143-149-0-UI

;i'l~i-34;-;i51;;-I·;;II·;;O'i-l-t--':iA:_;·I!4;T--!------f

1-13539·0·01

143557·0·01 A-42

1.t3711G-0-()(J

l-13R52·0·01

t.HSM-0·01

1~31177·11·01

14:W.:Ni·O·OI

1~39~1·1HII

I~J981!.o.ol

I·-714~4~ll~o~·'-;-l·&~l~--~1~·4~-t------l

1441911·11·110

1 -

-+14;-;~;;226;;;..·'"'1·

144Z.1K·II·III

144~·0

14425S-Il-Ul

144256·0-01

+...c:..:=::-::...::..:~---if0.

144460·0·01 1'-18

14-1-161·0·01

144462·0·01 1'·3

7

14-i-4~4~~.;.·~0.7.0-i-l-r-~1'~·4~8-~-----l

l·l~4liS·O·OI

~~~c;;-;-f-~4~5--

14~~61!·0·01

144469·0·111

144473·11·01

144474·0·111

-

7;144475·0·01

144477·

11-111

l:.:4~44~7~8

~

·0cc·•~ll-

--

4479

1

~

'0'

-'

1:..:4-:-44:;1!0~·0~·0,;1

144481·0·01 F·4

14~-182·0·01

-

~17~~4~~~-~0~.o~l

144490·0

'

I:;_

.

uo

.

0~1;-W;;;,:IS

Ill E·

01

01

~N-'_'·-j--1!-c-·n_m_r_k

C· l

l:·

5

A·83

F-44

(;.28

Z·Z2

H-98

Z·23

A·52

t:·Z.1

D·21

8·86

:__

l;------1

8·5

21

F.:-22

Jo:.ZJ

..

;::26>--l------l

1;

.3

1'

·4

F· I -4

1'·34-42

1'·25-29

f-

..-'ll.;.·~~~

F·l-

-!

--~1',..·.:.5:..1

-t--

--71'~·4~5

II

-10

13-22

...:

5~1

-r------

~;.JS

G-8

~:·14

1'-24 I

1'·8 1

--

~l

4

-Ill

I

13-22

-+-----I

1'·3

~--~r---------

42

I

E·JS I

______

__

l

l

_

141KI9·11·111

I-1~4~1K~~~~;-;.;~,

141821·11-111

14182~·11·111

1418~'6·11·01

141112'1·11·01

141821C.U·III

--i-1471~~~.';-1·~11·7,11.;.1-i---'~E~.I~5~--r

1411133·11·111

l-,1~4~1~~~.o:-.,:::JIC-t--~1

1411!35·11·01

141836·0·01

1418.1K·O·OI

1411145·0·01

1~1846·0-01

1411!47·0·01

141114H·O·OI

I--1~4~1K~4~9.~o~.o

141Hr.O·O·OI

1411151·0·01

1411152·0·01

l-~14~~~~~1~·0~·1~11~----f~'·.:;l~5---t-----------1-7,14~1~~~·~0·~0

141KS4 0 01

J.IIHSS:O:Ill

E·42

.•

~~~e-!--~~~:.~~~--t----------l-~~~~-r---711~-c~ac----r----------l-~1~423~79~·~o~.o~l-+---7.u;-;.6~1~--,i-----------l

E·37

E-23 J ·16

~··26

I

E-26 141!r.!!IIIIJI

--~~"":.'='-n:;--,-------l

E-9-1:!

F·25

F·l-22

7

1-+---T.F~.z~--+l·---------l--':1

I

,----;,F,-:·21;::1--j------fi--714~1:.=.96607.

---------

E·5

I

7

7

J.~II

1----

---------

E-6 I 141936·0·01 J ·13

E·2

I 141939·0·01 J ·I

- 29 I

F·42

~-

F·7

F·4 141957·0·01 C·KI

F·:! I 141958.0·01

F

·K

1'·2:1

F·9

F·6

F·l8

141927·11·01

14192811·111

141931 0·01

1-11932·0·111

I-714~1~9.~D~·O~.~~~~~r-~7J~-17.K~~----------I--717.4~~'~'~.~~~.~071-1----7.E:..:.:~I7~---1~--------·f-71~~~0~

141934

·0·

I·-714~1~9JS~.o~.~~~~~·~--~J~·I;2-------------I·-TI4~~~;-;.o~.o~l~r-~~-==--~--------,--.;.l~~~.o~.o~I~----J~

141~·0.01

141941

·0.01 J

141953·0·01 C·48 142556·0·01 8 ·

7

41~9~~~.o~.~ol~~~c~·.;so~~

141960·0·01 C·61 14'.rl92·0·01 8 ·

141961·0·01

141962·0·01 l:·65 1·

14196.1·0·01

14196.'i·O-OI

·0~.07.-1

11·1

11·57

11-55

11·49

11·50

)·13-IH

01

J

·14

J

.J

·4

l:·58 142565·0·01 G·40 180504·0·01 B-62- 89

C·l!.'i

~----------

C·~

C·69 I 143190·0·01 IJ·I8 403865·0·01 F ·43

1-!----7.C:..:·8~2

7

+-

~--·~-----------

l:-72 143444·0·01 B·97

-7.l:

:

~.~C:.

'-

--jl·

------ll-;

142293·0·01 lt·59

142380·0·111

1423HI·O·OI