Page 1

\yi

i VV'r.

11:

m

\-.r

^Hv-t

Si

UMll-,,

•.1?

•a

C

\m\

[t

Page 2

This

service

Trouhle

knowledgeonthe

be

acquainted

machine

any difficulties.

manualiscomposed

Shooting.

with

with

the

and

you

The

majorityofthe

instruction

this

parts

could

book

machine

catalogue,

solve

troublesifyou

PREFACE

of

three

chapters.

servicing

whichisincluded

perfecUy.

then

please

we

hope

problems

with

read

you

would

would

encounter

Mecharusn.

can

tins

machrne.Inord»

this

service

get

man^

full

know

any

problems

^e

^

to

caref^

wttho

BROTHER

INDUSTRIES.

LTD.

Page 3

CONTEISTTS

CHAPTER

1.

Upper

2.

Feed

3.

Thread

Thread

4.

5.

Work

6.

Clutch

7.

Safety

CHAPTER

1.

Adjustment

2.

Adjustment

3.

Adjustment

4.

Adjustment

5. Adjustment on

6.

Adjustment

7.

Adjustment

8.

Adjustment

9.

Adjustment

I

MECHANISM

shaft,

take-up

mechanism

trimming

nipper

clamp

lifting mechanism 7

mechanism

mechanism

11

ADJUSTMENT

on

on

on

on

on

on

on

on

lever, needle

bar

and

hook

mechanism

mechanism 4

mechanism

needle

bar

and

feed

clutch

work

thread

safety

thread

drive

bobbin

shuttle

mechanism

mechanian

clamp

mechanism

trimming mechanism 22

mechanian

nipper

mechanism

mechanism

winder

mechanism.

hook

mechanism

1

1

2

5

8

10

11

11

14

16

20

26

28

31

32

CHAPTER

1.

Thread

2.

Thread

3.

Clutch

4.

Feed

5.

Needle

ill

TROUBLE

tension

trimming

mechanism

mechanism

bar

and

SHOOTING

mechanism

mechanism

hook mechanism 36

33

33

34

35

36

Page 4

1.

Upper

shaft,

take-up

CHAPTER

I

lever, needle bar

MECHANISM

and

hook mechanism

DiroctiantofoUto

ui^

.Wit

Hign

speeo

puoey i417B3001

141781001

Oscillating rock shaft

141787001

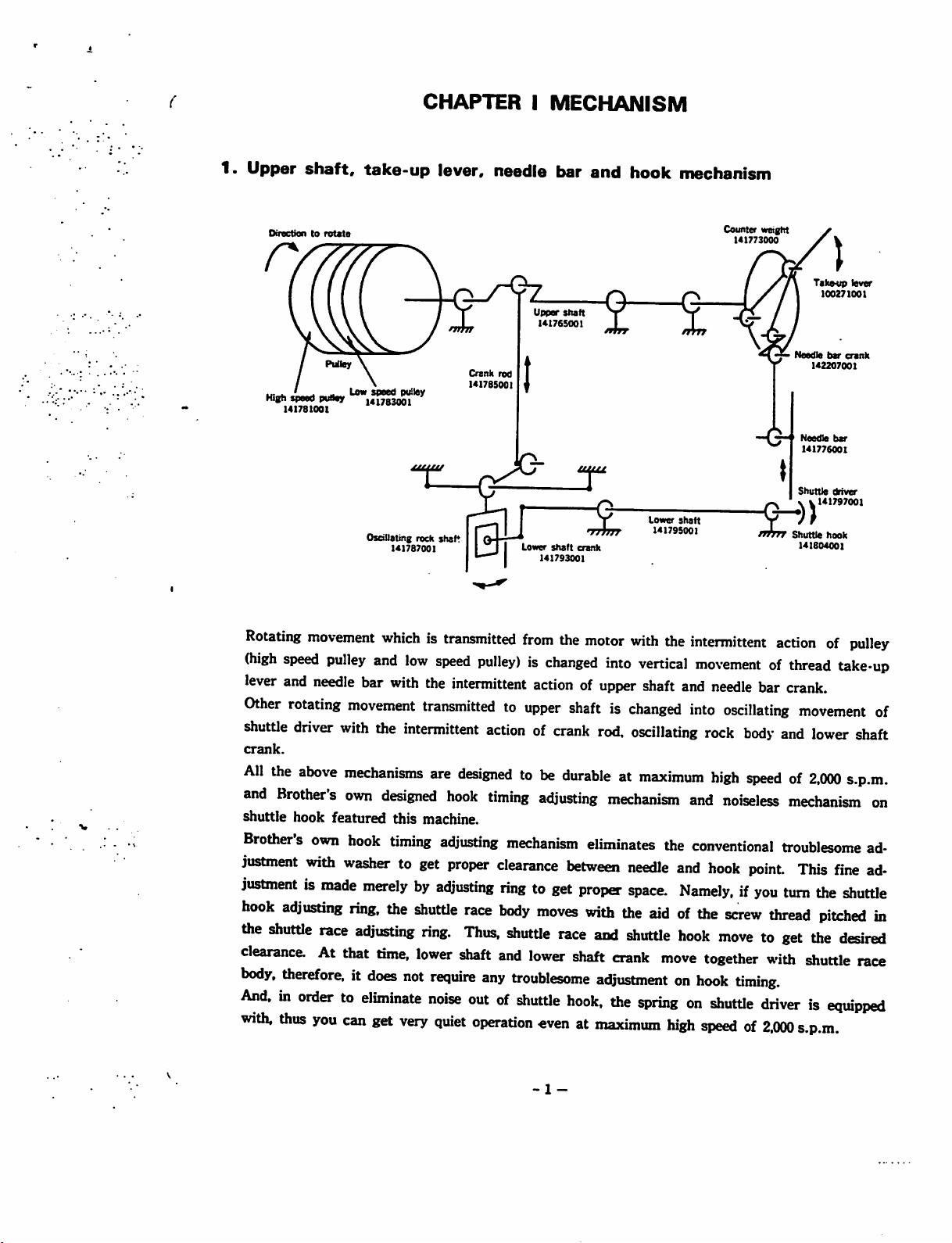

Rotating

(high

lever

Other

shuttle

crank.

All

and

shuttle

Brothersown

justment

justmentismade

hook

the

clearance.Atthat

body,

And,inordertoeliminate

wiUi,

movement

speed

pulley

and

needle

rotating

driver

the

above

Brother's

hook

bar

movement

with

mechanisms

own

featured

hook

with

washertoget

merelybyadjusting

adjusting

shuttle

race

ring,

adjusting

therefore,itdoes

thus

you

can

whichistransmitted

and

low

with

the

transmittedtoupper

the

intermittent

are

designed

this

machine.

timing

the

shuttle

ring.

time,

lower

not

require

noise

get

very

Crank

rod

1417BS001

speed

pulley)ischanged

intermittent

actionofcrank

designedtobe

hook

timing

adjusting

proper

mechanism

clearance

ringtoget

race

body

Thus,

shutUe

shaft

and

any

outofshutUe

quiet

operaUon

Upper

shaft

U176S001

Lower

sfiaft

crank

141793001

from

the

motor

into

actionofupper

shaftischanged

rod,

durableatmaximum

adjusting

mechanism

eliminates

between

proper

moves

lower

troublesome

with

the

race

and

shaft

crank

adjustmentonhook

hook,

the

«venatmaximum

Counter weight

I4I773000

Lower

shaft

141795001

with

the

intermittent

vertical

shaft

oscillating

movementofthread

and

needle

into

oscillating

rock

high

and

noiseless

the

conventional

needle

space.

shutUe

and

hook

Namely,ifyou

aidofthe

hook

move

together

screw

movetoget

timing.

springonshutUe

high

speedof2.000

Takotip

lever

100271001

Needle

t>ar

crank

142207001

—'

Needle

bar

141776001

Shuttle

driver

141797001

fftfTT

Shuttle hook

141804001

actionofpulley

take*up

bar

crank.

movement

body

and

lower

shaft

speedof2,(X)0

s.p.m.

mechanism

troublesome

point

This

turn

thread

with

fine

the

shuttle

pitched

the

desired

shuttle

race

driverisequipped

s.p.m.

of

on

ad

ad

in

-1

-

Page 5

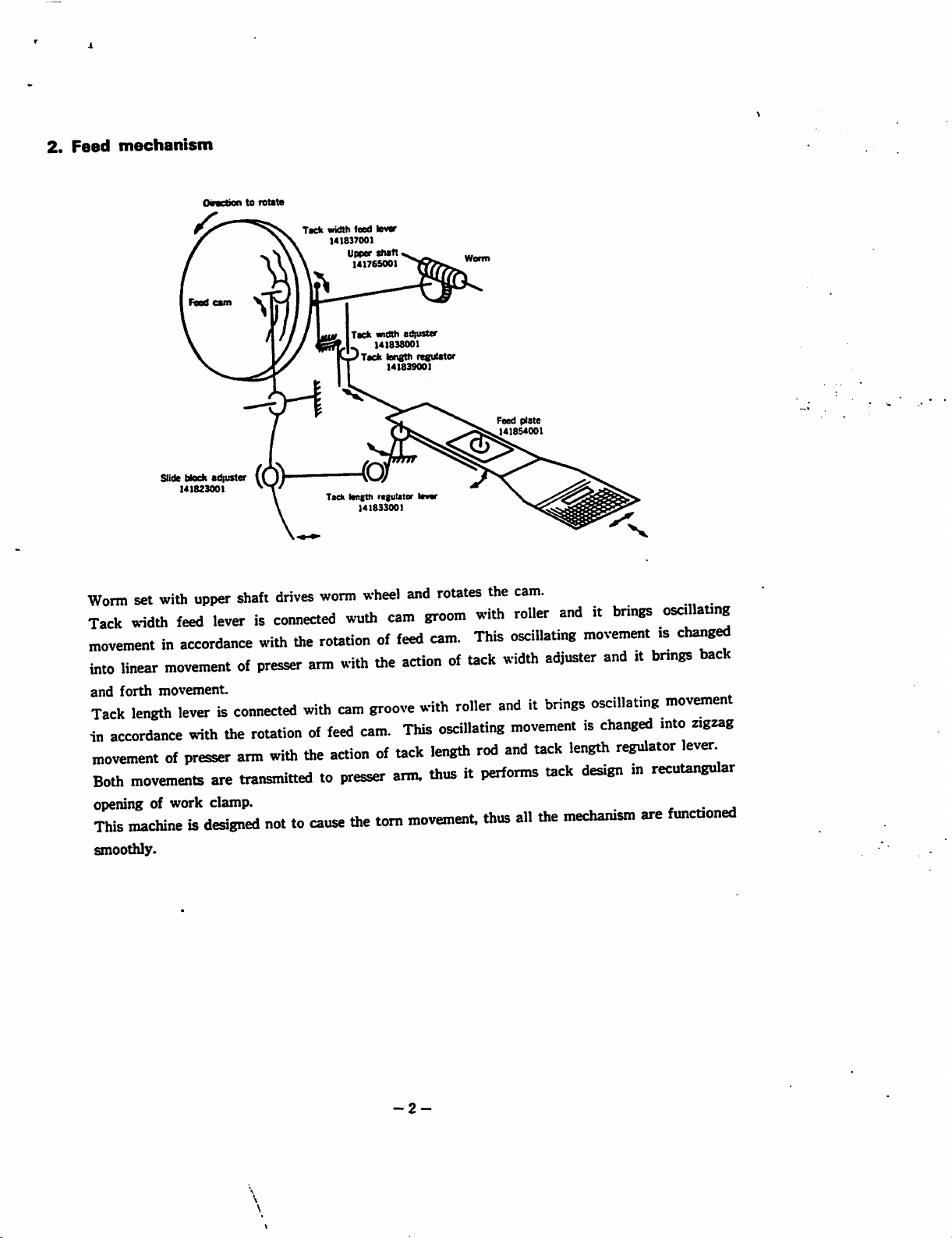

2.

Feed

mechanism

Oiractiontoretite

Tack

width

(^

141837001

teed

lever

141765001

Tack

width

141838001

K«_i<rTack

I

aQustar

lengthregulator

141839001

Feed

plate

141854001

Slide block

Worm

set

with

Tack

width

movementinaccordance

into

linear

movementofpresser

and

forth

movement.

Tack

length

in

accordance

movementofpresser

Both

movements

opening of work clamp. ^ ^

This

machineisdesigned

smoothly.

adjuster

14182300)

upper

shaft

drives

feed

leverisconnected

with

the

arm

leverisconnected

with

the

rotationoffeed

arm

are

transmittedtopresser

with

with

the

nottocause

Tack

length

regulator

141833001

worm

wheel

and

wuth

cam

groom

routionoffeed

with

the

actionofUck

cam

groove

cam.

actionoftack

the

with

This

arm.

torn

movement,

rotates

cam.

oscillating

length

thusitperforms

the

with

This

width

roller

anditbrings

rod

thus

cam.

roller

oscillating

adjuster

movementischanged

and

uck

uck

all

the

anditbrings

osallatjr®

movementischanged

anditbnngs

oscillating

length

regulator

designmrecutangular

mechanism

are

back

movement

mto

zigaag

ever.

functioned

-2-

Page 6

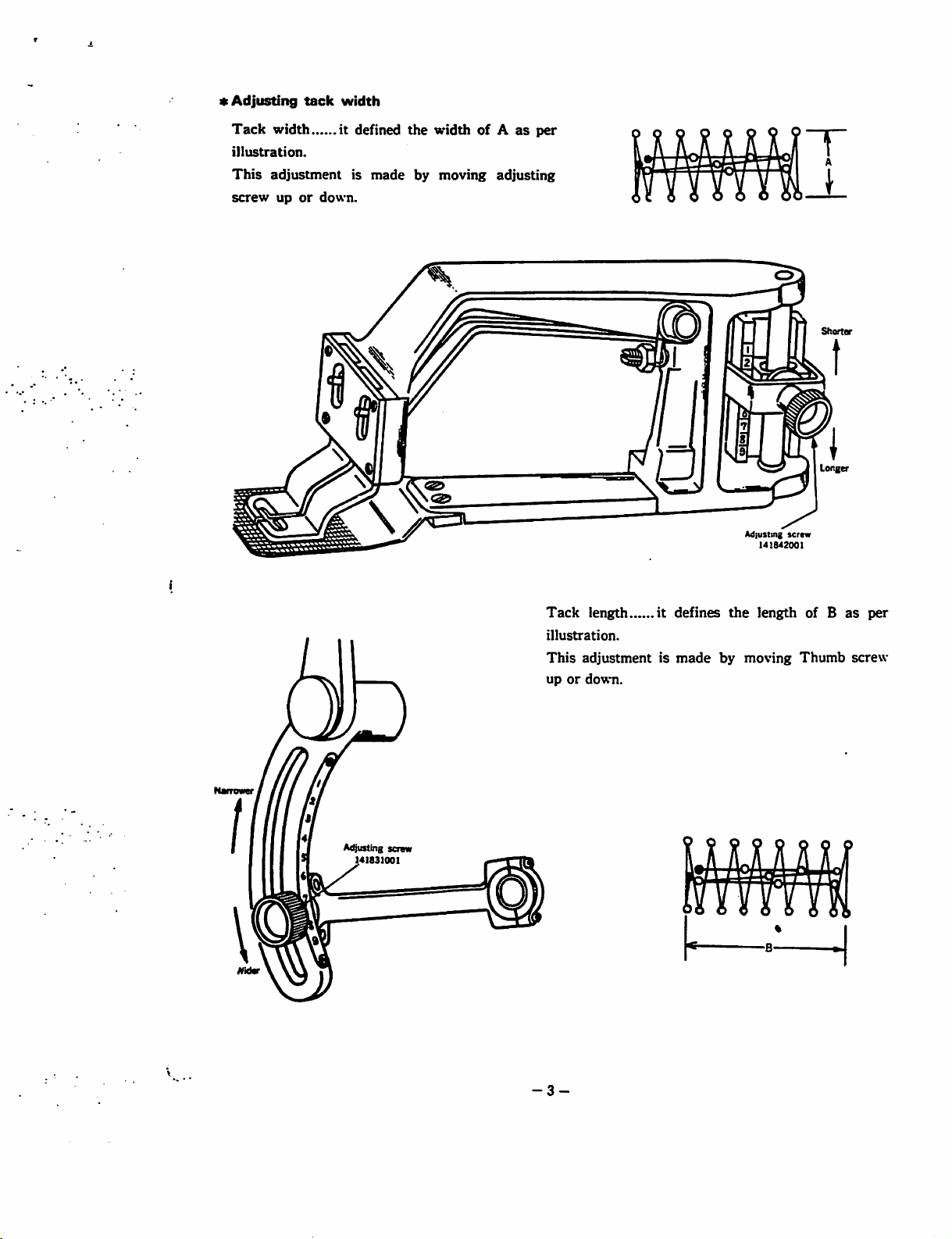

♦

Adjusting

Tack

illustration.

This

screw

tack

width

adjustment

upordown.

width

it

defined

is

made

the

widthofAasper

by

moving

adjusting

Shorter

Longer

\

Adjusting screw

Tack

length

illustration.

This

adjustmentismade

upordown.

it

defines

by

Adjusting

the

moving

141S42001

length

screw

Thumb

of B

as

screw

per

-3-

Page 7

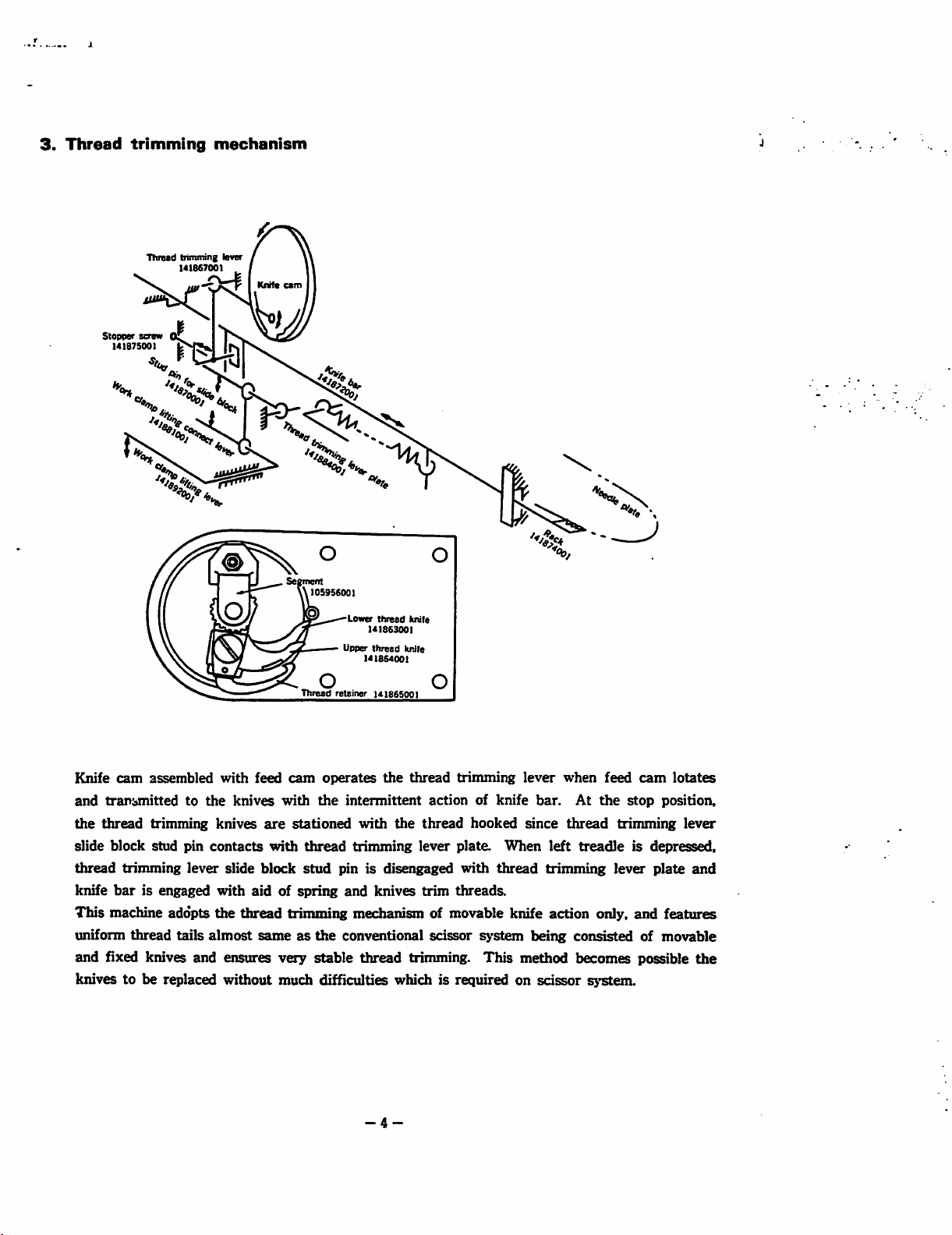

3.

Thread

trimming

Timed

trimffling lever

141867001

mechanism

Knift

ctm

105956001

Lower

Upper

o o

Thread

retainer

thread

141863001

thread

141864001

14186S001

kntle

knife

Knife

cam

assembled

and

transmitted

the

thread

trimming knives

slide block stud pin

thread

knife

This

uniform

trimming

barisengaged

machine adopts

thread

and fixed knives and ensures very stable thread trimming.

to

lever

tails

with

the

knives

contacts

slide

with

the

thread

almost

feed

cam

operates

with

the

are

stationed

with

thread

block

stud

aidofspring

the

thread

intermittent

with

trimming

actionofknife

the

thread

lever plate.

pin is disengaged

and

knives

trim

trimming

hooked since

When

with

thread

threads.

lever

bar.

trimming

left

when

At

thread

treadle

feed

the

stop

trimming

lever

trimming mechanism of movable knife action only, and features

sameasthe

conventional scissor

system

being

consisted of movable

This

method becomes possible

cam

is depressed,

knives to be replaced without much difficulties which is required on scissor system.

-4-

lotates

position,

lever

plate

and

the

Page 8

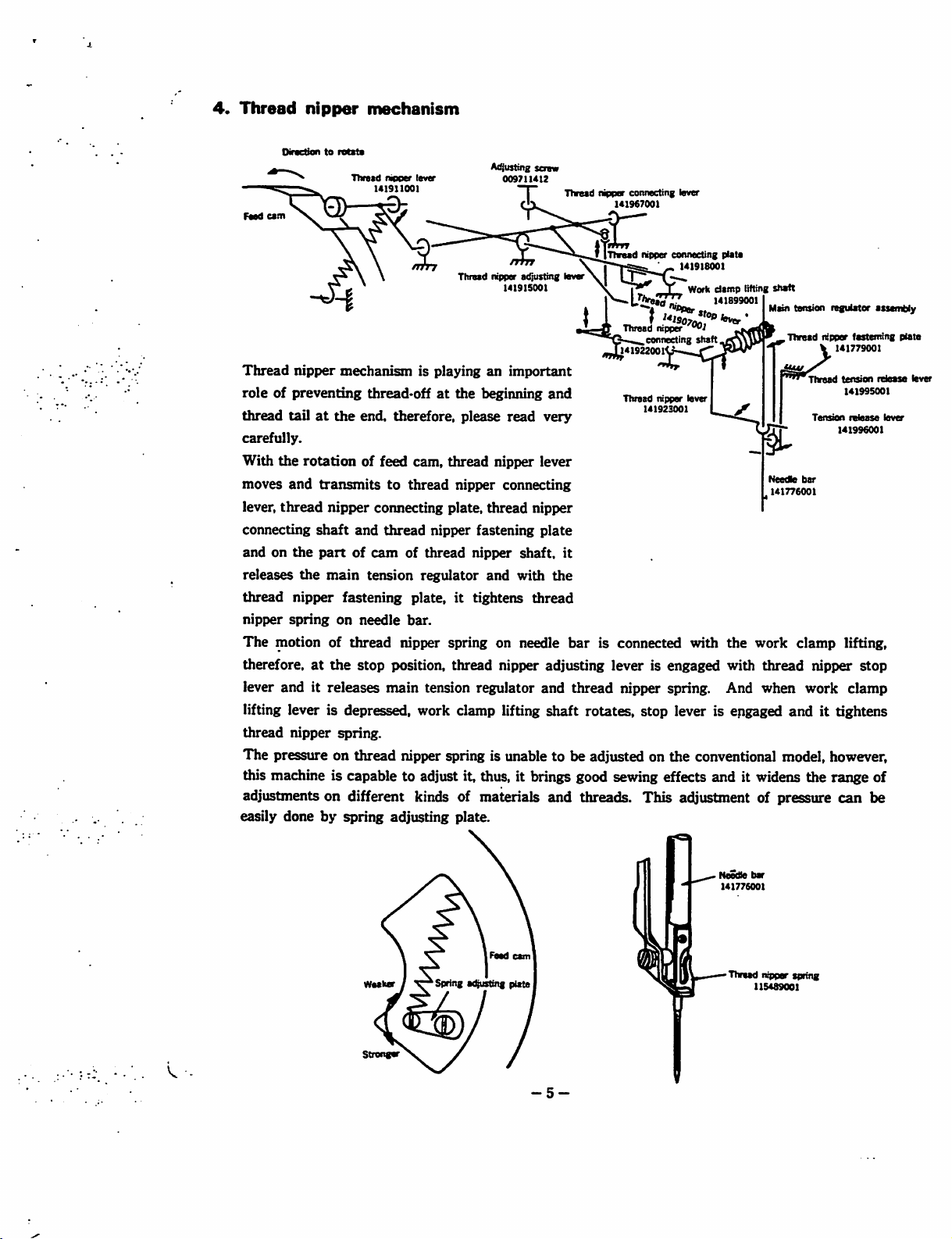

4.

Thread

nipper

mechanism

Oirvctiontoratita

Tlweed

Feed

cem

Thread

nipper

mechanismisplayinganimportant

roleofpreventing

thread

tailatthe

end. therefore, please

carefully.

With

the

moves

and

lever,

thread

connecting

andonthe

releases

thread

nipper

The

nipper

spring

motion of

therefore,

rotation

the

at

of feed cam,

transmitstothread

nipper

shaft

and

partofcamofthread

main

fastening

on

needle

thread

the

stop

lever and it releases

nipper

lever

141911001

thread>offatthe

connecting plate,

thread

nipper

tension

regulator

plate,ittightens

bar.

nipper spring on needle

position, thread nipper adjusting

main

tension regulator and thread nipper spring. And when work clamp

AcQusting

scraw

009711412

Tlwead nipper

adjusting

141915001

beginning

read

thread

nipper

lever

nipper connecting

thread

nipper

fastening

nipper

and

plate

shaft,

with

thread

and

very

the

connecting

141967001

Threed

lever

Thread

141922001

Thread

it

bar

is connected with

lever

lever

nipper connecting

O

..

nipper

connecting

nipper

141923001

141918001

Work

""l

shaft

lever

plate

damp

141899001

is engaged with

lifting

shaft

Maintension regulater assembly

Thread

Thread

Tension

Needte

bar

141776001

the

work

clamp

thread

nipper

nipper

141779001

fasteming

tension

141995001

relesse

141996001

lifting,

stop

lifting lever is depressed, work clamp lifting shaft rotates, stop lever is engaged and it tightens

thread

The

nipper

presstire on

spring.

thread

nipper spring is unable to be adjusted on

the

conventional model, however,

this machine is capable to adjust it, thus, it brings good sewing effects and it widens the range of

adjustments on different kinds of materials and threads. This adjustment of pressure can be

easily done by

spring

adjusting plate.

release

lever

plate

lever

rwd

cam

Spring

trusting

Waakar

Stnngir

plate

-5-

Needle

bar

141776001

Thraad njppar spring

115489001

Page 9

1

>Tt>wd

tonsion

141922001

Main

Pin

115599001

faradwt

tension

Thumb

117457001

regulator

screw

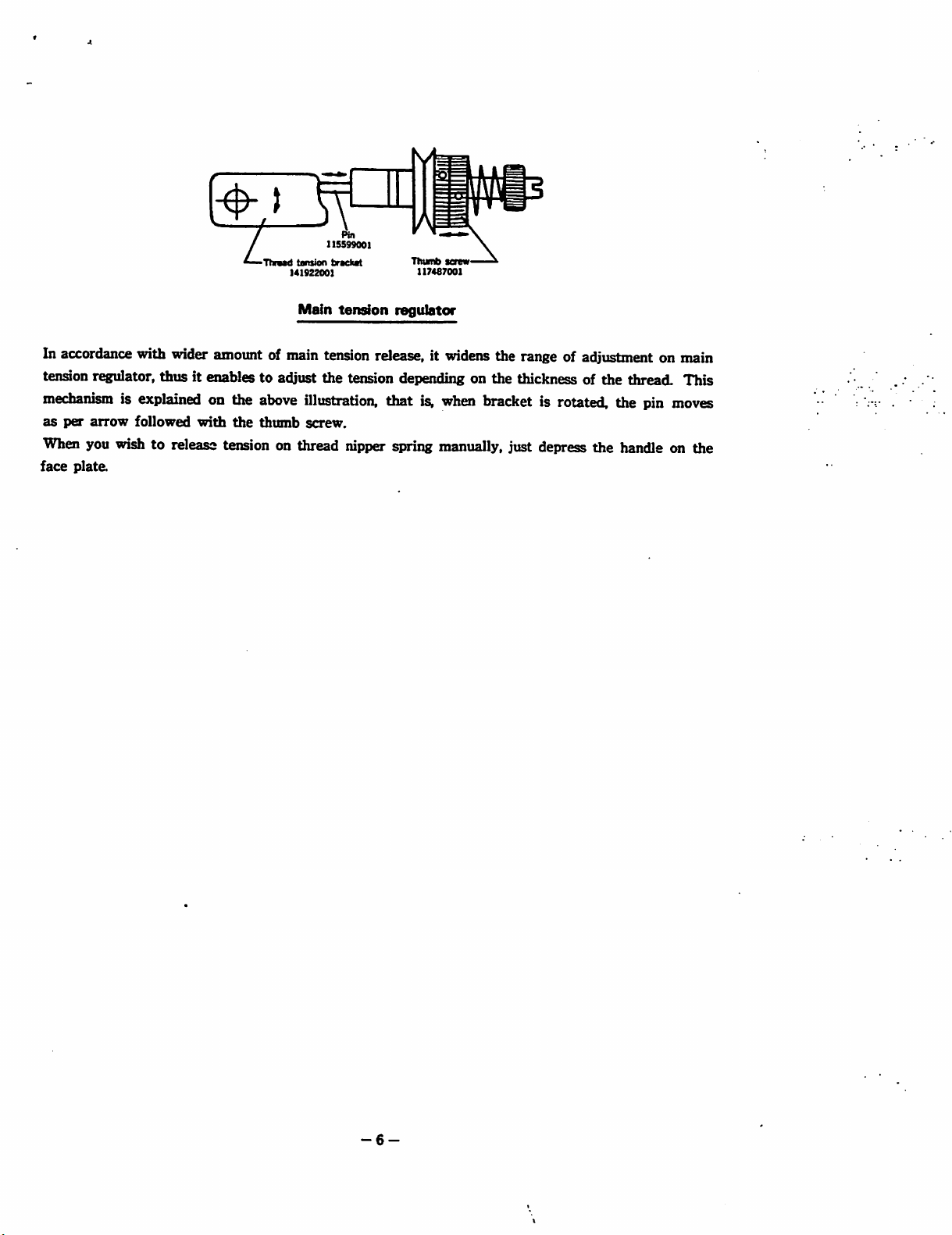

In accordance with wider amount of main

tension

mechanismisexplained

as

per

r^ulator,

arrow

followed

thus it enables to adjust the tension depending on the thickness of the thread. This

on the

with

the

above

thumb

tension

illustration,

screw.

release, it

that

is.

widens

when

the range of adjustment on main

bracketisrotated,

the

pin

moves

When you wish to release tension on thread nipper spring manually, just depress the handle on the

face

plate.

-6-

Page 10

'•

'<1881001

_

»

"^chanl

K ant)

'<1897001

(rufi

ism

*'•

tfaotp

J

J<190000,

sh«f»

ft

f'^ono

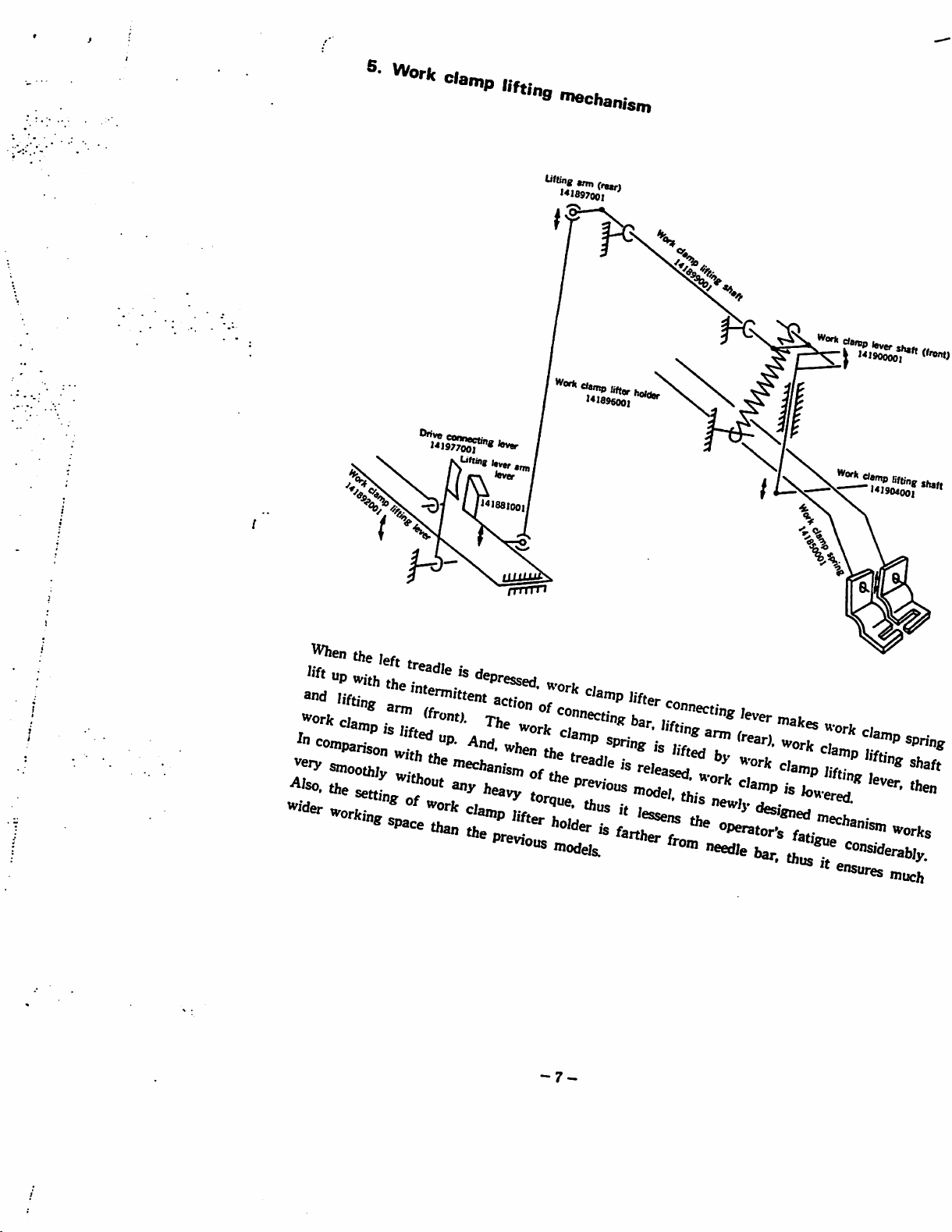

the /eft

h'ft

Up

Z'Z!

•"

smoothiv

®adleisdepresseri

h t/ie

fnfni

I..-

«,•

L ^ of

r>'

11''

^®cd,

to

n'orJc

fi,

/»!«

^

'

Z'™

^®'eased

ti

-"odr^.

ti""

*^'anip

' »

%

/jft;-

We?

't

ensi

-7-

Page 11

6.

Clutch

mechanism

Qutch

11S54S001

Brake

lever

141954001

stoppv

141782001

Ouch

144427001

lever

141783001

141962001

c

v-"^S^

Outch

tnppcng lever

141961001

Drive connecting lever

141977001

Food

cam

Clutch tripping dog lever

Outch

cam

[frrrr

141970001

lever

stopper

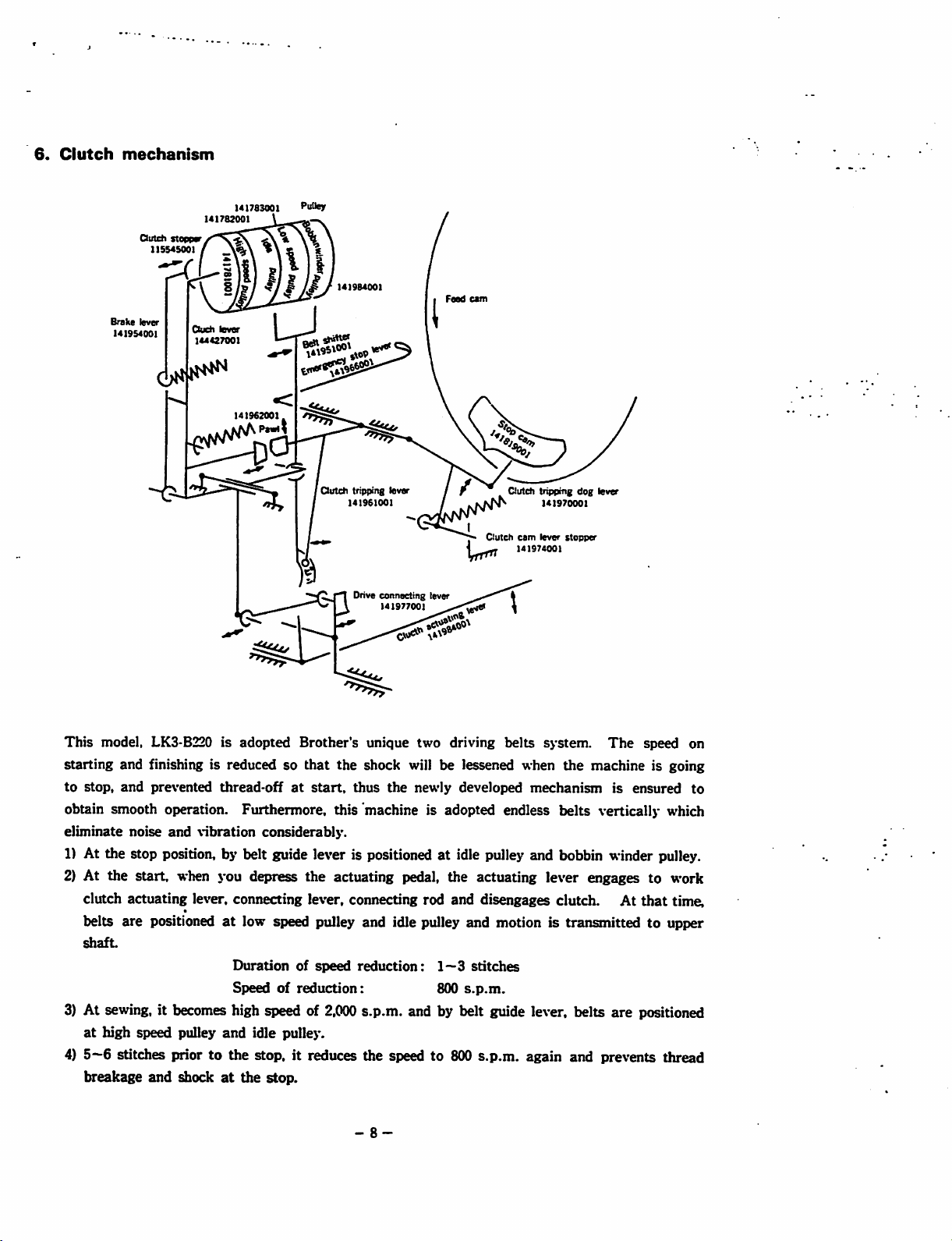

This

model, LK3-B220 is

starting and finishing is reduced so

to

stop,

and

prevented

adopted

Brother's

that

thread-offatstart,

unique two driving belts

the

shock will be lessened when

thus

the

newly developed

system.

the

mechanism

The

speed on

machine is going

is

ensured

obtain smooth operation. Furthermore, this machine is adopted endless belts vertically which

eliminate

noise

and

vibration

considerably.

1) At the stop position, by belt guide lever is positioned at idle pulley and bobbin winder pulley.

2) At the start, when \'ou depress the actuating pedal, the actuating lever engages to work

clutch actuating lever, connecting lever, connecting rod and disengages clutch. At

at

belts are positioned

shaft

3) At sewing, it becomes high speed of

at

high speed pulley

4)

5—6

stitches prior to the stop, it reduces the speed to 800 s.p.m. again and prevents thread

low speed pulley and idle pulley and motion is transmitted to upper

Durationofspeed

Speedofreduction:

and

idle pulley.

reduction;

2,000

s.p.m. and by belt guide lever, belts are positioned

1—3

800

stitches

s.p.m.

breakage and shockatthe stop.

-8-

that

time,

to

Page 12

(

before

the

endofone

cycleofsewing,

when

tripping

dogisover

the

stop

aun

sewi

Wing

cycleiscompleted

5)

Emergency

When

you

emergency

^

i""

stop lever

depressed

stop

emergency

lever

plaj«

and

machine

same

automatically

stop

lever

roleasmentioned

'='"^

pulley

down,

^tch.

thus

and

idle

puUeybybelt

stops.

tripping

above,

dog

thus

clutchisengaged.Atthat

guide

lever,

whichisassembled

machine

stops.

with

thus

I

-9-

Page 13

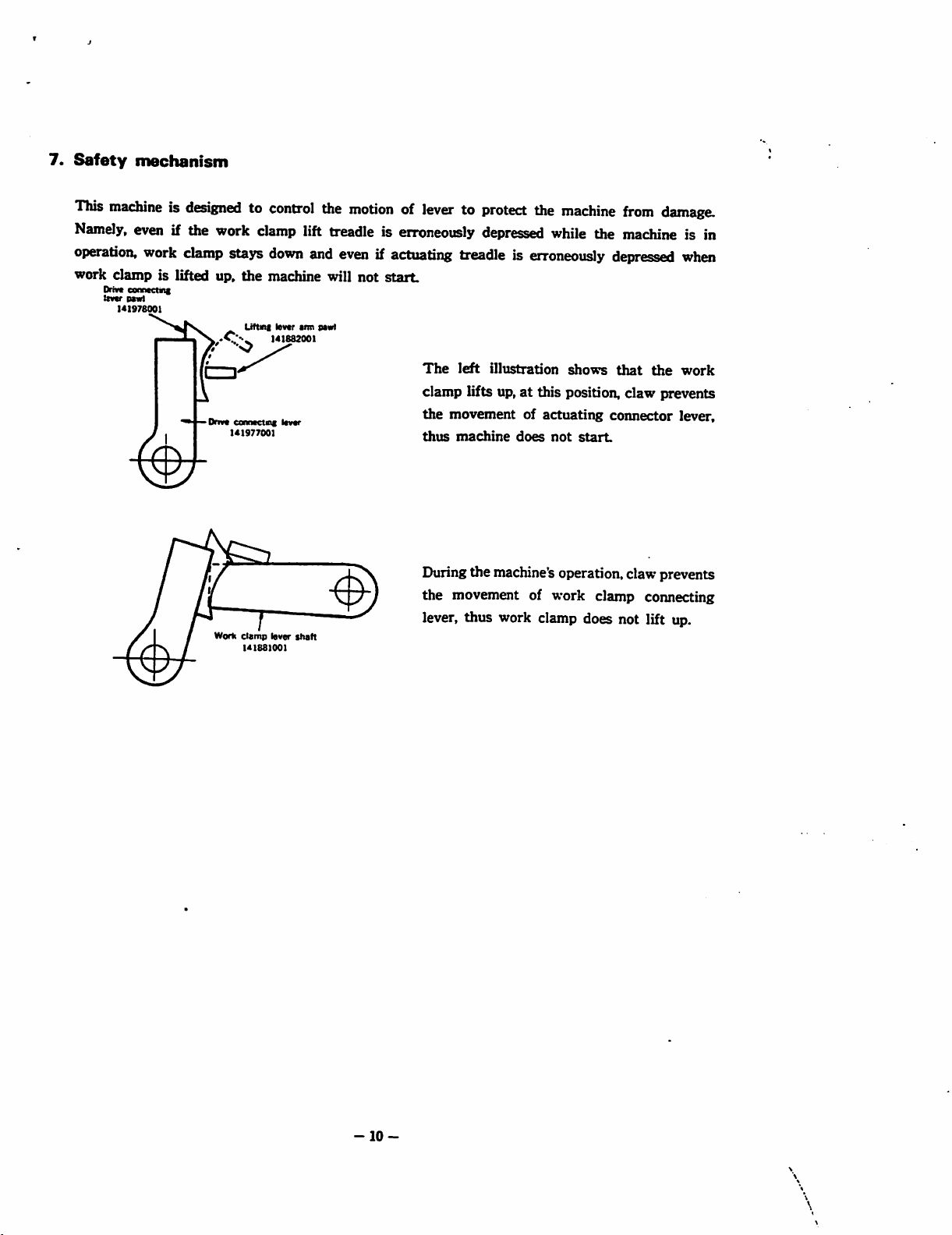

7.

Safety

This

Namely,

operation,

mechanism

machineisdesignedtocontrol

even

if the work

work

work clamp is lifted up.

Drive

conoKtinc

tmr

PMt

I4I976001

clamp

Dm*

.C''..,

Worli

clamp

stays

down

the

machine will not

Liftni

levtr

141882001

coimaetng

141977001

clamp

I4I88I001

iavar

lever

the

motionoflevertoprotect

lift treadle is

and

evenifactuating

aim

pawl

shaft

the

erroneously

treadleiserroneously

depressed

machine

while

from

the

machine

depressed

start.

The

left

illustration

shows

that

clamp lifts up.atthis position, claw prevents

the

movement of

thus

machine

does

actuating

not

start

connector

Duringthe machine'soperation, claw prevents

the movement of work clamp connecting

lever, thus work clamp does not lift up.

damage.

is in

when

the

work

lever,

-10-

Page 14

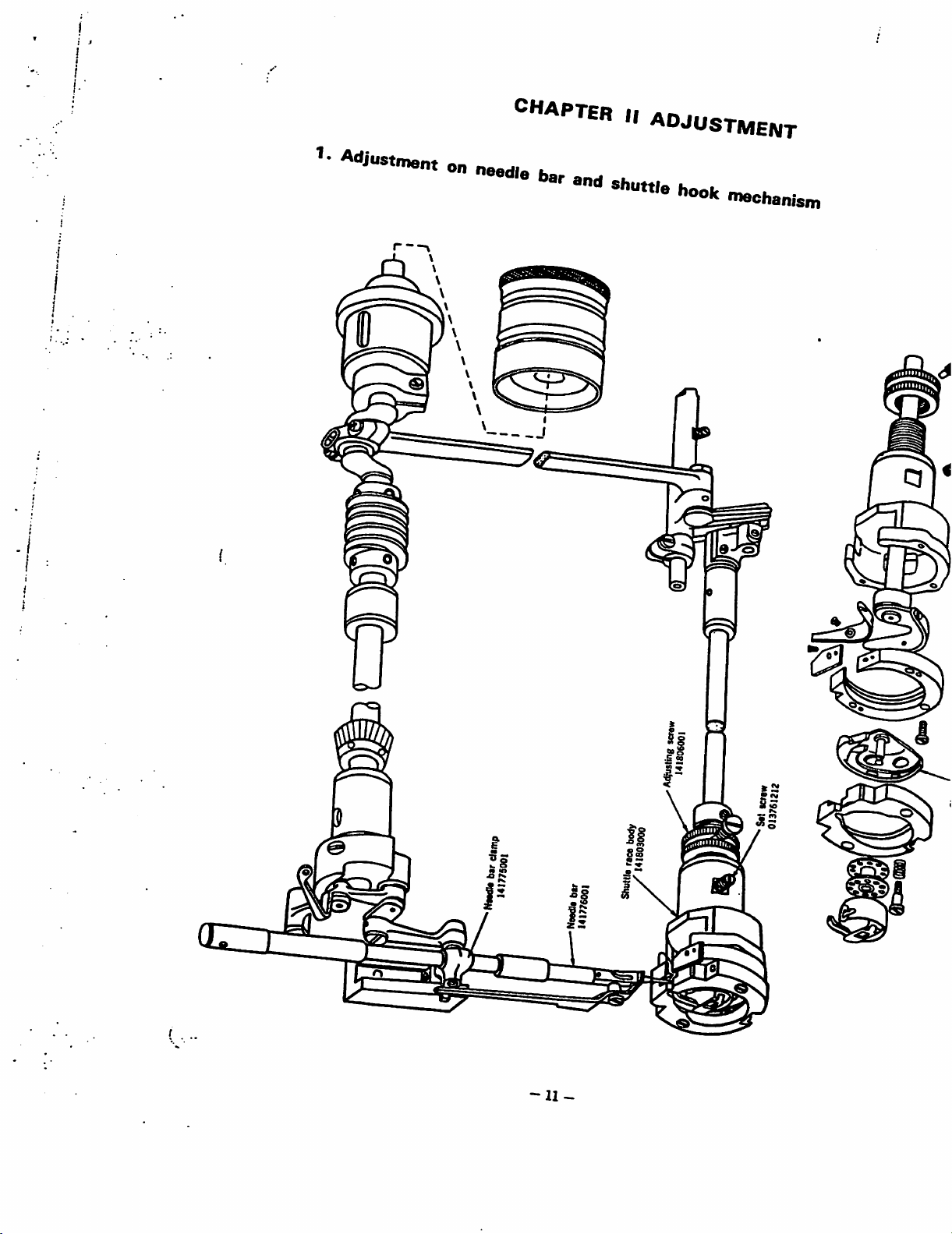

O

X

>

u

X

>

c

»

ra

I

O

3

3

O

o

a

cr

tt

•I

a

3

a

>

O

c.

C

CO

-I

3

m

X

H

«

3"

e

o

0

1

3

5.

»•

3

damp

b*r

MI775001

btr

•<1776001

Neada

'•CObody

141603000

scfow

141806001

^sting

teraw

013761212

'Sti

Page 15

MowupBnp

•nd loft ond rigfit

down,

Fostening

Shuttle

ract

Shuttle race body

(1) Setting shuttlo race body (clearance

between

When

the

three screws so

ween hook point and point of shuttle

driver spring may be 0.3-0.5mm both

up

setting

position

and

doiKm

hook

and

shuttle

shuttle

of shuttle race by

that

positions.

drive

spring)

race

body,

adjust

setting

the clearance bet

(NOTE)

Hook point

In this

This

body

Shuttle

case,

remove

assemblingisrigidly

except

hook

unavoidable

down

position

—-

needle

from

done

needle

when

bar.

shipping,

thusbesure

necessity.

sh«tle

hookupposition

U1798001

0.3-0.5

Shuttle

hook

0.3-0.5

Shuttle driver

(2) Adjusting lower shaft play

When

matching

setting

with

shuttle

the

driver,

grooveoflower

firstly

And, set collar not to have play of lower shaft

(NOTE)Inordertoadjust

holder

and

heightofneedle

easily

shaftiscorrespondenttothe

therefore,

instruction.

please

make

nottoremove

Press hook lightly and turn

high speed

and

between shuttle hook point

and shuttle driver spring.

141757001

pulley

check

fasten

shaft,

the

by hand,

the

clearance

the

then

positionofslide

bar, the

diameterofsilver

sure to

follow

shuttle

silver

black

race

screw

screw.

block

grooveoflower

screw,

the

above

-12-

Page 16

(

he,

®«

SCTBW

slight,^

,ia#

•*"''»

^

'®*ver

H7,e„

..

axfe

. neecfJe '«

fcoot.^..

orWJ"^

Pofat

"osiOon^

si,^^

"

"te

c/ea^

^^fter

^ompI^

'"'^o

^ion.

bet»a^

fasten

neeaie

®ecureK

«nd

SCr«vtr

^nd

and

hoofc

^ooJt

'"otate

POjfif

Ponit

adjusfj

b€

Page 17

fo

6

3

O

3

r*

O

3

Hi

O

O

a

e

3

3-

o

tt

3

5*

3,

Marking

cain

raad

levar

regulaler

141838001

width

Tack

levar

feed

width

141837001

009821612

Tack length feed

141827001

bracket

Tack

sr-ew

141839001

I4I82300I

screw

Thumb

wMth

regulator lever

141855001

Feedregulator post

I4I83800I

Tack widthadjuster

justing

141842001

I4IB4400I

Tack width teed iavar bracket

141829001

Tack taflfth rod

Tack length regulator lever

I4I833001

Tack length legulator lever

141846001

ami

Prtsser

_ ^^Ticfc

yms

Work clamp

1

screw

head

Rat

Feed plate

I4I85400I

V.

Page 18

to

to

esign

>n

regulatedbyfeed

centre

(1)

and

12)

Adjusting

f ^ ^ "

tack

length

e

outer

and

mustbemade

work

clamp

swings

Adjusting

Feeding

matenai

down

quired,

bolts

Turning

advances

beginsasthe

into

loosen

and

turn

feed

the

vice versa.

tack

and

Uck

width

mechanisms

inner

groovesoffeed

within

the

and

even

when

adjustment,

mustbeaiwajisatthe

timingofneedle

neeeie

and

finishes

the

materials.Ifadjustmentisre-

worm

feed

caminits

timingofneedle

width

before

wheel

cambydegrees.

rotating

movement

cam.

rectai«ular

their

swings

the

positionsoftheir

same

and

feed

raises

outofthe

needle

shaft

nut

direction,

and

feed

transmitted

with

The

tock

opening

are

point

cam

comes

and

set

it

cam

105844003

Set bolt

017782012

Fieed

ca

Adjusting

Make

adjustment

the

coirect

Firstofall.

1)Utthe

Match

loosen

3)

Loosen

tack

4)

Loosen

bracketsothat

then

5)

Loosen

festening

be

the

flat

adjusting

width

feed

tighten

tack

positioned

tack

width

and

firstlyontack

adjustment

adjusttoget

first

needle

openingonfeed

head

regulator

bracket,

fastening

width

screw.

exactlyatthe

was

correct

come

screwsonfeed

screw

lever

fastening

the

needle

screw.

lever

Again,

tack

ion,,.!.

width

movemenraLlT""^!li™'^'^^

made,nofur^^TI

position

down

plate

plate

and

raise

shaft

screw

hole

fastem„g

move

presser

beTwLrwrk

into

the

needle

and

work

and

vet

hingehiiTT!

and

tighten^adLV

^ ^

is

screw

and

arm

centreofwork

work

.

L''

hole

clampInc

'' "

in

u-

andZ

elamo

Clamp,

Z

then

""""

'''®

tighten

sensible

and

with

^

openings

^

of

work

fastening

screw.

precise

great

areindisordi

cauth

care.

clamp,

0

'

ar

"8^'®

-15-

Page 19

. I

"

hole

clutch

with

»-

he

consumed

machine's

'essened.

easeofadjustment

mstructions.

for

durahility

and

tn™

Uck

I

them,n-

j . .

1.

he

i

"'*^^0

*"*

pulley

by

"ej'

""^"on.

considerably

follow

or

the

-

r-

/

''

Clutch

^'^•-'hepos.t::::;t,'^««^«op.a.ch

end

lever

cateh

tte

minimum

clutch

stopperisalv,

Insert

T '

_.

distani

'^3hlX":r-^

enm

that-brake

Stop

cam

shTri^"^"®'"

rid,

^

""h

-erd

thete

from

-16-

Otrtch

1'5545007

eo

earn

stoppor

«0P

trtrt

'/1962001

HK

'♦J950001

ctcti

1^1207001

lever

Page 20

r

"«nove

"""""""e

"Mt

^°''

the

can,

of

">«

tte

"»e

Ptd/ej,

ad,

belt

6el,

ad

u""

'ace

"o"

'*'"

®«

at

1

H

^27^

ffi

'Clutet,

cam fcvw

'*'9'40oI

Page 21

Clutch

3»

Adjustliig

(1)

Timingofstop

and

Please

so

latch

"aches

Ctuctfi

r

levar

catch

'41959091

nop

clutch

stopper

adjust

that

clutch

may

disengage

three

stop

latch

141962001

o

position

cam

stop

cam

stop

"'c

Action

wheo

tri^

^th

clutch

lever

one

stitch

endofsewing

^'s

case,

'^t

clutch

'^nll

disengage

clutch

within

position

groove

tails

"»ove

lever

±30-

of stop

into

stop

h'Sh

where

line

cam

catch

before

please

stop

from

speti

the

cycle.

see

latch

with

catch

the

the

cam

with

leftornVht

or

pulloylyhoni.

In

clutch stopoer

f

ngijttoadiusL

ridh.to,«nt

-IS-

t»*

A.

^

a""toBet

an

screws

proper

'staniry

tuning

serB»

and

by

Page 22

®

PoMtiono,em.

^

«PPing

pos.«„„

adjustby|ooc«

sere.30r™""f

'^'ween

rfce^^""stance

•

'astening

®™ergencyst^'""'a

Imm.

is

about

"«

and

®/"p

few

><i96sa

Preasuna

Adjust

i°

permit

•^a'ii'ely

aamtostopthe™

«a®Of1.

fastening

angleofspr/e^

! ;

®'

Prossute

a'opper

.'^•^'-nn.

•a

Position.

"•

»n

'P"ngistoo

noodle

">®

materiale3~"''"P-n

going

the

impact

Machineatthe

increased

advetsoly

»« .

«'«ch

.1

tPst

clutch

it .ill

„t

clutch

into

the

sere,

^"-""aiing

of

«♦„

^'PPersMngA

spring

;

may

to

„

" at

other

c

stro

ev

and^•

0^^

^

"

"-is

leue,

leva-

.

"apnog

'"""8

sT'*'"

"""'"'"'aP

"enti,.

'°°aen

'''ange

plate.

"

P'nachino

Wrong

"""P®-

'®nsion,

on

the

"•

«'

the

so

115S5S001.

2

"195900^"®

M

fewer

sor<„

machine?"'Ability

tJ^""

^n^nuts

^"p«

adjusting"

<

stoppet^"^

pn

®

measured

from

„„r

®

"«

in

°~'2mm

Of

Shaft

at^usting

,5^0®

Page 23

*•

on

work

clamp

fnechanism

8

-20-

Page 24

4i(

"''enOie

®'"PPer,

P/ate

0 p.

^dj

fo be

ositi.

a«,as,

on

Of

the h •

J0~.

Pim

^

«et

"fenip

Oftn

scre».

ft..

^

^eed

«"<»

n

'®'8'ner

tbr*

ead

cba/

'"S^a

Peed;.

3;

^•Vuse,

Str,

"•eat

^®Qu/ret/

'•CQu/r

,-.

's

^iper

Oie

.„ . •"

thread

Case

aure

that it

dtjg

the .

<ng

and

^'"P

red

^

Pase

""-aad

that

thre

""•®a<'

"t^Oirr

cfoes

Ore

oo

,u.

is

^

fO

D/a

^c&'us

Z'"''®'"'®"!.

i», .

®atf.

„

Of

up

vtrortf

"'

Ah

ro/e

"Pt

Up

ead

Of

'^'«S00to|

a

(

Page 25

B.

Adjustment

on

thread

trimming

mechanism

bracket

" ^

3)MsoonasAe

4)

5)

6)

i)

and

are

operatedbythe

upper

threadtoprevent

Thread

needle

Upper

The

^en^left

bar

(NOTE)Inadjusting

Setting

retainer

hole of

thread

machine stops.

needle

knife

Pssition

treadleisdepressed,

and

connecting

installed

orderonknives

releases

upper

threadispulledupby

plate.

enters

after

rod

spring

the

correctly.

and

'Thread

141865001

power

the

upper

the

thread

moment,

into

the

catching

knives,

the

pulls

firstly

Then,

thread

retainer

retainer

,Upper thread knife

141864001

transmitted

thread

from

just

before

the

pointofupper

upper

loopinthe

connecting

the

knivestotrim

remove

make

adjustmentinthe

from

knife

slipping

the

thread

thread

precessofforming

rod

needle

ii)

outofthe

fifth

take-up

loop

while

adjuster

both

plate

Relative

retainer

cam

needle

stitchisformed

lever,

lower

thread

thread

knifeisjustinfrontofthe

the

hook

point

the

final

disengages

threads.

and

following

measurement

and

from

make

order.

knives

sure

eye.

knife

comestoits

stitch.

the

tipofknife

the

between

PWO"

stud

"tshss

catches

knives

are

thread

the

140023001

ii)

Relation

retainer

between

needle

Lower thread knife

141863001

hole

and

Upper thread knife

thread

reuiner

-22-

NeedeXhole

and

knives

Lower

thread

(D

knife

Page 26

II

Adiu«i„fl

When

b«.ee„

bl.. b«w«„

you

set

se^en.

needle

plate

,„d

O^nunby.u™i„g

backwanl.

(NOTE)Incaseoftight

be

smooth,

wrong

Threfore,

thusitcauses

thread

trimming.

adjust

meet

,33.^

bite

between

the

bitetoget

timm«

^J Tl I k

wy,.nt

that

slight

and

needle

hit"f

play.

'•«'

^

'»

n.ckispositionedateither

o

••

"""'f®

bar

"teiner or it

^dius.

*«

forward

"-n

will

causes

U.e

or

imt

thread

(1)

(2)

(i)

trimming

Setting

At

above

•e

of

ower

markofneedle

Knife cam a

Adjusting

ttree

n

positionofrack

thread

the

recess

the

second

thread

thread

timingofknife

Knife

cam A

Raise

clutch

band

and

rising

eck

needie

trimming

loop

will

trimming

trimming

get

km'ves

not

^aseofadjustment,

sorew

for

knife

bmingbymoving

(»)Atone

stitch

»™' «ta.in9

lever

roUerisjust

portionofknife

stitch,

andatthe

knives,

knifeispositionedatthe

plate.

camAand

and

turn

driving

roller

positionedateach

pointsofknife

Bill

not

touch

and

the

touch

with

loosen

camAand

leftorright

before

the

cam.

stop

position

the

point

Knife

cam B

B

pulley

camA.and

with

thread

upper

thread

kraves.

fastening

adjust

final

the

stitch,

In

of

that

of

red

by

fastening screws

Tinnng nwrk

•Wfe

bar

Knife

guide

tiar

plate

(A)

cTtartt

./

I \

-23-

frmn

screwisstepped

Page 27

Jfstf.

6

6j,^

^case

^

7C^<>"

^(ti

<*<>«%,

^"of

*^tntt

^'"Sd

or

'^«Ss

h

'^^<i°",''.^"'">-aS

'H

'^arj^

0/

^Oetfj

'""fa

'"V

,.

'^*'0.

«»<#

^oo^''"^"t

^"'Vos

Vr

°'^

^a/^e

es.

fte

ae</

ti,n

-

^**ses

«&e

A

a/icf

'^ajA

is

- "

^'^'tion

Of

i'G(f

^ ^

.

fo

•'asf

^

^ef

..

Of

tin,.

®%rr

evi

'eij^

^'ajr

'Set

eaj

«ft,

o«

''"

Poin^'^ci.

^es

^'es

« ^

fo?'

at

fA

®"'

irt\'.r.

/Sfe.'®V

'®'Oer

«'•or,V

«'t6,

'e/,

"«/ „

ess

a/tf

Oof

t6e

ii

Or

e«„.

"ot^"kl

0/

^

^^ore

«Ch

ew

'^osiy.

'Oft

'"^'ar- "'"a.

'^A.e.r'

afe

f6e

^earf

'-

^^^as.

> /e^r.

Oj-

eacj

tC tbr^

•<ea<y

iij

^

fii

ffta/

s«

•^e ^

23

6jr

°Oeti

^e

3

So

StOff

ce

«Ch

OfSi

en.

'a

St

"">

Page 28

0^

^en

bite

Art

'*9

''°''needfe

betM-

bv

t

biu,

segn,

•on

meet

•»«'

fScIt

'^rks

^bovQ

mar/

(t^OTE,

ax-ead

aier

i,

be

^'""'-ck

*n//e

®'"'®«>.th~

a-read

'ev,

/er

a«

&

We1""°"

'^x-een

'•'

=»>«as

*&n/j

'tg

Of

holler

IS

Jusf

s.oaT':»«

of

red

*'•'5

'•Sfl

6nf/)^

kn/-

»ves

*C»1»S

a,

^ead

eijt

of

retai

««"«»,

I

'

Or

<:.

««

its

f/;

c^sec,'

acreur

«„.

4/^

""e

^ben

^Shest

fftree

^ ^

cfceck

„

•*«

need/e

majiogj^

*17;

'"•A'cr««• ^ h

o/^'"'""®''atea

.,-„

not

„

eoac»

r

'»'"

iiUf.

aiient

i

'°°sen

movLT^a</^

a/tri.^'®aorri

befo..

SCTeur

rore

the

thn

®sa

tafc

ad,a«':i"'"'

stud

'

*«%

tc^

the

ftia/

the

cam 4

cam

tkrcad

^mVag

/V

«f;tch.

'evart.

on

23^

Cam

a

and

3

t''

/

4.

and

^ead

.

^

aie

is

Posjrt

of

Oiled

^oife ^ the w

^thi.

Of

^OlIU

Page 29

««)

,

kooks

Knife

At

downatthe

lower

cam

B '

the

final

first

recess

thread

stitch

nnr*-

adjust

h

knife

camB.Thisisthe

timi

^'""a-

s

thread

knife

fkn

(NOTE)

^asteniRff

«cr«w

3)

Positionofthraaii

'kt

the

stop

ootnws

n-insting

'o»er

and

screwsodm,

thread

When

roller

isT

in the rangp nt v

---

rangeof90-^135.'upper

-on

"tead

position,

adjust

knife

Of

km-fc^mT

m

tnmming

lever

loosen

J°T

'

plate

»

•"

-^0

k^fr^iTTt^r

(NOTE)

these

as

to caiieA * ®e

°

wachet set screw

-

o^dot:

that

you

cams

evenlyonth. t

unusual

(tavelling

thr^^T"

1fs:::

may

rotate

noise.

«"«'n»that

down

••"

second

knife

recess

cams

in

red

markonneedle

When

work

clampisHftg^

otopper

'™™'ing

about

0.3mm

cam. knife

At

this

"oedie

of

Plateispositioned

upper

scre^

lever

roller

from

moment,

thread

kmfe.

so

the

the

pla^

may

be

bo«

needui,i

at

tie

-24

®-3fiwi

-

•««f8nces

Page 30

/ '! •

-»

•aiistng

•o

work

loosen

Adju«i„9

katfe

^ m

<in»e

tewtonofkrtfa

bar

puHfeg

kni«s

some

breakage.

the

Often

extreme

fcmves,

B „„ ,k

thus

smoothly.Toa<Bust

set

left

screw

orright

,„s

fail

to^rT

cases

the

the

h.

•»'

PuBns

colivi

^ c

opriiv

J

^

«ension.

o<fiusting

Stopptf

Knifebar

Ming

spring

c.

-25-

Spring

adjusting

bgy

Page 31

§

I

3

O

3

O

at

3

«

o

•<

»

a

3

5*

3

(rear)

142433001

Jobrt

icraw

arm (rear)

0097II4I2

Lining

FaKenIng

141897001

patvi

arm

(ever

141882001

Lining

pawl

lever

141978001

connacllng

OHve

lever

I4I97700I

conneellng

Drive

141881001

Lining lever arm

bar

MI98300I

connecting

Drive

I

I

Page 32

tte

mach.„

.

njachin^

tten

wrorfc

fe

case

Of

.

«.

Se^tt^r

'®'

(

the

»

i. ^'nnifn» i stai^ h

cJa

«p.

tottow0^,.

-vet

ri

^

,etV^.

®"»"er

«,. .

a..

in„

tfcread

"ncwiipg

tobe,•

tP

,.

f"'^Ceo/^

""•"«>•««

"""

„/ ^

^

the

o,e^'

„ „

'eft

'""•

t,^,

to

«»

(41

r '^•>8

Just

befnm

oefore

hft/iig^

a^

the f„ .

''machine

C;'""

-"'^".ad

Shoe/

arm

ston«

"e

<C^

"""""'et.

, ^

'ever «, .

"•«

''"'ve

the

re^:,'^;

^27

-m

Page 33

C

(0

eO

3

I

e

a

9

9

a

a

V

3

9

O

a-

9

a

3

S'

roOar

lavar

141923001

nippar

Thread

Collar

HI90800I

0097II4I2

re^ustlng screw

lever

oparallng

I4I90700I

Nippar

lever

connecting

"'96T00>

""PP®"

O

t S

levar

7

adjusting

I4I91S00I

adjusling

nipper

nipper

Thread

pawl I4I9I000I

Thread

•ever

shalt

connecting

141922001

nipper

Thread

plate

fastening

I4I92300I

nipper

Thread

plate

faitanlni

Nippar

I

I

141779001

spring

nipper

115489001

Thread

Page 34

'"Pper

^alre

"*)

P

'ts

P

the

^eed

'^ast be

^n

cae

'••"e'e

"^aadnm_

need;.

n

'"eg.

/e/(

the

n,

to

"^'•n

'oop.

the

lipper

eye

and

ased

be^

and

nia/n

/s

'•e/e.

a<0'ustn,.

nnftfenof

the

«<>p

P0s,t/„

""I

bo

Of

""Oad

"^sition

Cam

the

O/:

"'PPer

bei

rd."'

"'•'"e'nient;*'^e

a^pper

•

'aosen

w""

"^«sion

'®

tfen

._

'^®'®ase(f

's

fie/i

''"er

roller

p .

trith-'^'"•nn

'•ed

niarh,

®Ofin,

®®""9tev8.

ovg^

or^

fa«. .

"nnJ

®Wtch,

'^'ned.

'n^.

^nion

ca^,

So

Pin

the

^

that

^PPer

'••nes

ers.

«,«

do^

n>re^

'fcrepd

the

®®Coin#

mt

frof

'ev(

4t

this

«n./evert

«aged.ad,

--Cr;'

the

n'feed

canj.

^ P,

osftio,

end

at

case of

®crenr

Poiti,

"<""n».d

the

atop

'ension

nipper

efeft

>•

®®®n-

On

''OSltf,

"'PPer

'On

(befi

'eve71""

'oosen

Pos,d„„

recess

eani

tb

Porti

hft

on

'n»

aiust

"•«

nfepe,

PQs/ti

o//.

ns

fever

ivorfc

"'nmp;.

be

Positii

CO,

n-nd/d,

, ..

On

eed

<^ni;.

oned

°a that

aipper

of

and

die

luting

\

njfBa

OOflfl

"'•1

(

^2!9^

Page 35

4)

Adjusting

main

tension

regulator

At the position of roller being over the

that

thumb screw so

recess portion of feed

5)

Position

At

off

nippar

the

positionofthread

pawl being disengaged

lever,

moving

spring on

6)

adjust

left

or

needle

thread

securely.

Adjusting coUar ffor

At

the

stop

position, when

depressed, adjust

nipper adjusting lever pawl

operating lever by positioning collar for nipper

operating

lever.

main tension will be tightened and at the position of roller being in the

r-am,

adjust it so that main tension will be loosened.

thread

rif^t

ffastanlng

nipper

bar

nipper

the

plate

nipper

adjusting

with

nipper operating

fastening

so

that

thread

may

catch

the

operating

the

left treadle is

bite between thread

and

reces^

lever

plate

nipper

upper

lever

nipper

a

••

portion of feed cam. adjust tension adjusting

Tension

dtet

108721001

CoOv for nipper operating lever

141908001

Set

screw

014770622

-30-

Page 36

t

"""«»

!v°C"

«i

Sr.-"

®S«

••SO

e*P/afned

adiust

etutet,

prevent

tt.

to set sr,

and

f„

due,0f

"'»«

.e,

''®®<"eisd

«««»,,

as

es„,

"Cn

°°®en

set

scr^

®

^'X'

.-t

causes

«.

/ I

""»-«

ievt"^

^

case

„r

'""•"siiw™

^"«ment,

"sventeTt

.*•

«>Bet? '

®f« ^

®

W)

Adi'

®'*<atnw

tten..

^®*^nein„

at

sto

I. 'Xsidon

..

'"

"teacces.

*a«e

oiitj

**^ssojy

-31^

in

1^

the

°'^

**««ine

/^fsSj^lOppar

tevtt.

Page 37

Ad,

Adi

In

'o'^Rr/i,

^I)

Put

Set

ont

ng

due

^

scre^, ,

On

c'otci,

"eit

^Oo

^ers.

cfr#

•"ecfca

•^fev,

/s

n,

Wsft,

'9r

®'"'esserf

tfce

.1 ^aus^.

<^onner^

<^ontu

ct

^'th

^«aa„,«-^

Set

Oie

er

'

screu,

niacft

5»»v

open

ii«e

'®°sa,

'oHrerfn

Out

»«oo;

^Md

®ir"'

"•Oust

^'asfB,

4/f-. ^ set

VPStfi

f/je

'^•«on

to

Cojjjnt

•"dtcii

"9

'".'"^«-tOB

^o/jjj»

®^eij(

feu,

er

®<"efrr

Of

«'aetoe^'^

^'•

acj/us^

Of

'13

®»Ciine

'ctua^a,

Screw

'••®SefrL'°'"®'nedin'^"^

ft;

tbe

•^'ust

^""".esiti

Oil.

ann

«s

eap,,.

... »

Set

/ever •

scre^r

ar^

'ever

nonne/

ajitf

i^'^.'^'-een

Set

screur

Set

"opper

/ever

o/otcA

t/ie

as

Screw

O'wfcft

^Oin

u,„

scn^

s^,

**W

'"«^ssr'

Out

set

Screw.

Page 38

Adjt/i

nt

Adi

b,

topper

««uatfn

4.

b)//<

"^'"P

(1)BeM.

®J=t,

Adfj

'^'e>s

^O//,

»>

Put

C2>

J?a•

Set

®^^«st

beef

and

•"«»»

^en

fasten

•^er

Con,

""*•"•

"-etto

tin

c,«^"f"^eacfle

tfte ,

Oi

,rf.

"tannc

'"^''

^ers.

/""^^sts,

aue

to

too

Uttch

s^,^^

®®

to

the

coQta/

-.1

"'''3'ned

®creT».

®®en

set

'^Ir.'"

®^eH^

C.2,-

'^"^"POver

Cfte

WU

oj

"" ""

<='>'tch

^<Uust

in

^^le

scTeur

"*

s_

scret^r

screur.

is

•niovi

,..

<^ve

iiietf

betvv»

as

**®PPer

'nj

tbe

'n/sin

'*'•<

/_

er

^bove.

and

^OtCh

•C|08,|

j7.

« fever

"•'^asooir

•'«£&»

bo> f

®'°few

O'-t/er

c»«,l''««ooi

*n»w

''eits

s//

''PP/

(S)

(3)

4i3ter

P'ain^

.

®baft

'•VVPH^^vvt

Out

Set

®creRr.

Set

(

-3J~

Oiitcft

««uafc

fever

'*i988oot^*l^

Page 39

9.

Adjustmentonbobbin

H

Adjusttng

In

caseofuneven

hsightofbobbin

Postnonofbobbin

2) Setting

presser

When

with

adjust

winder

endofspring

positioned

bobbin

positionofbobbin

bobbin

presser

bobbin

the

winder

positionofbobbin

paw]sothat

plate

at the

winder

centre

pawl.

winder

mechenism

windor

windingonbobbin,

winder

contacts

shaft,

the

top

may

be

of

tension

loosen

by

raisingorlowering

Bobtxn presser

Bobbin

winder

141755001

tension

*i«'ar

tansion

141756001

shaft

stud

collar

tension

guide.

Bobbin

winderpswl

11194S001

set

sZ

screw.

ZZ.

'Tensmt

stud

I18405002

, ^ .

coOsr

Spring piste

111942001

'

3)

gaged

pawl,

bobbin

rubber

pin

not

Sotting

prasser

When

and

have

positionofbobbin

stopper

spring

set the

presser

ring

with

may

bobbin

too

much

plateisdisen

bobbin

position

stopper

contact

presser

play.

wnder

of

sothat

with

may

presser

111950001

141752001

stopper

Builder ring

120448001

Pin

-32

-

Page 40

1.

Thread

1)

Thread-off

(1)

CAUSE:

ADJUSTMENT:

(2)

CAUSE:

ADJUSTMENT:

(3)

CAUSE:

ADJUSTMENT:

2)

Thread

tension

breakage

CHAPTER

mechanism

at

the

at

Hi

TROUBLE

beginning

In

caseofloose

tensiononthread

Refer7.Adjustmentonthread

Page

30.

In

caseofwrong

Set

thread

position

trimming

Page

22.

In

caseofshort

At

the

final

on

needle

the

machine's

of

mechanism.

bar,

positioning of

retainertocatch

thread

stitch,

retainerisreferred

thread

and

stop

end

set

the

functioningofknives.

SHOOTING

nipper

nipper mechanism.

thread

the

after

timingoftension

retainer.

upper

threadatthe

trimming.

springonneedle

to

5.

Adjustment

release,

theread

first

bar.

stitch.

on

nipper

The

thread

spring

CAUSE:

ADJUSTMENT:

3)

Untidy

lengthofthread

CAUSE: In

ADJUSTMENT:

4)

Loose

upper

tension

CAUSE: In

ADJUSTMENT:

5)

Upper

thread

jamming

CAUSE: In case of the upper thread not being

ADJUSTMENT: Adjust thread nipper spring on needle

In

caseofnot

Adjust

that

the

end

caseofthe

the

upper

Adjust

thread

case

Adjust

nipper

main

the

nipper

the

lever

being

loosenonmain

tension

proper

from

thread

knife

of loose

upper

rollerispositionedatcircumferenceoffeed

regulatorsoastobe

lengthofthreadispulledbyupper

needle

upper

thread

by

thread

timingsothat

springonneedle

main

thread

being

nipper

tension

being tightened by

tension

trimmed

spring

the

bar

tightens

regulator

on

knife

discs.

ti^tened

on

needle

baratthe

first

stitch.

barsothat

range of

the

needle being pulled out of needle hole untilatits highest

position. Loosened main tension discs will be

barisraisedupat

its

highest position.

regulatoratthe

loosenatthe

thread

final

knife.

final

stitch.

stitch

by knife before tightening

needle

willbeoperated

the

thumb

upper

bar.

thread.

screw

when

cam.

as

soon

thread

by thread nipper spring

it is tightened at the

Hghrpw»H

until the needle

so

as

c

-33-

Page 41

Th:

*0*1;

JJ,

^^VS£.

^Dju,

Off

^TAjp

Nt

•'

•Wecfca

t*»e

•61

p....

In

Case

'Cr

Wsm

•Mils

7

•

30

Of

^Oi

^ead

<3;

^^JVi

Arr-

'"BOflf

Offe

at

"I®

^dj

^oad

in

yust

in

sacf

case

/

/

/

"'"Ify

-'Ua

"PPet

L.

^toth

Arr

fhreaw®^ai/e

Oil

in

in

4t

t/)e

r=-

0/

M,

3fiie

22

case

0/

abort

bar

' atop

ttroo^""

*^^^Per

""ft,.

fr,

o*n

'^efib

the

^Pper

by

thft

f,;^

opting

On

thft

^

tt»0J

ea</

cad

^i<

J;»»«e

®iU

(•

VAer

C4t/se.

^jn

®rA££.

•X'T:.^."'^'

in

Case

an

^^Ust

aan^e

0/

thre

'Carf

Of th Sftw

'

is

^,

®®cned

the

uppg^

®t the Pot

„. ^"st

"eedle

i„.

"**

n, ^

^Xioi

33^

''a/w

lest

oej

«*•

o„

i>osif,-,

fja*

'e

^

0/

///

ose

On

thn

•

"^Of

to

""

o*snj.

tbre

""ead

ioni

he/j

«er

On

'^a/o

ator

®««''sn,.,.^'"osa,

Pu/;et/

tnnj.

aietf

that

^'Scs.

l^r

<Si*w'

"""nfcscn.

6a,

that/»-

aeoc^g

. ts

i»eft" ®

*«»td

o„

fens

on

the

untd

»

by

^

f'P/Jea-

»te

"'PBe,

"'Wn,

tferi

eacf

rerf

thft

"«>Per

the

PeetJie

®#IOo

^«niaa.

to

ator

at

at

the

hefi

Ore

as

•cad

^I'Aen

thft

at

tfc-

'est

at

4(fj

the

"sht

Soon

cad

tfie

fustn]

neatf

iina

enj

Page 42

2.

Thread

1)

trimming

Upper

thread

A

USE.

^

ADJUSTMENT:

mechanism

not

being

Wrong

Referto5.

tr&nmed

settingofupper

Adjustment

thread

on

knife

thread

trimming

mechanism.

Page

22.

AnTTTr-i-*

"•

(5)

CAUSE:

ADJUSTMENT:

2)

Lower

(3,

thread

not

being

^yUCTMTMx

^JUSTMENT-

rangeof90--135-

Wrong

.oosTng

Dull

Sharpen

positionofupper

:::reronr::

knife

edge.

knife

edgeorreplace.

trimmed

T""®

suuoISat

the

3. fte

first

of

final

sfitch.

thread

knife.

:=^i:z'z.r:z

rr.

recess

knife

'o"®"-

portionofknife

camAand

B.

cam

k-ife.

B

AriTT^e^

ADJUSTMENT:

(4)

CAUSE:

ADJUSTMENT:

3)

Needle

(1)

breakage

CAUSE:

ADJUSTMENT:

^JWTMENT-

JUbTMENT.

ADJUSTMENT:

weak

Adjust

Blunt

Sharpen

Wrong

bobbin

knife

the

settingofknifes.

RefertoS.

LT

Set

RefertoS.

T-

the

tunmg

tensiononlower

case

spring

edge.

knifeorreplace.

Adjustment

marks.

Adjustment

°°

(NOTE:

-34-

tension.

on

thread

on

thread

thread.

trimming

^

Make

sumonplay)

«

o"•'«"•-

trimming

mechanism.

and

mechanism.

position

if

Page 43

I f '

I

Clutch

1)

mechanism

Mal-functiononbelt

shift

Improper

ADJUSTMENT:

(2)

CAUSE:

ADJUSTMENT:

2)

Machine

does

ADJUSTMENT:

(2)

CAUSE:

3)

Machine

3)

M

)

Machine

^

ADJUSTMENT:

sj

irregular stop position

does

not

Sfrvntvx

JUSTMENT:

does

not

Proper

temporarily

Wroni?

Wrong

Adjust

and

Referto3.2)Adjusting

not

runettop

Change

Slippage

stop

r™"

Refertoa2)AdjusUng

runatlow

Wrong

Refer

lengthofbelt.

lengthofbeltis30-4ni«

between

•• ^

position of belt

the

positionofbelt

high

speed

pullevsoff

shiftPr

operations.

beit

speed

the

length

duetooil.

cotxectly

heightofclutch

speed

positionofbelt

to ^

aj-

3.2)Adjusting

shifter

belt

shifte

shifter.

on

Powl.

shifter.

i,

machine

the

upper

iever

Page

17.18.

head

and

Shaft

bushing

paw,.

length

the

motor.

(rear,

thatitsets

'»«'

(1)

CAUSE:

STMENT:

raCASUE-

ADJUSTMENT:

(3)

CAriQir.

adjustment

ADJUSTMENT:

6)

Abnonnal

noiseatstop

A^J^TMENT:

(2)

CAUSE:

adjustment:

(3)

CAUSE:

adjustment:

7)

MaMunctiononclutch

^11

^AUSE:

Wrong

Too

ReferTs.

Adjust

Tn«

Adjust

To« u .

cam

Wrnne*

positionofstop

1,

Tpr^e'of

belt

position.

t^ons

and

clutch

lever.

• •

shifter.

cam.

of

®

T •

Pressureofstopper

reduction.

stopper.

-35-

olwoh

spnng

A.

spthw

and

t

clearance

sto««r.

stopper

sprimi.

between

bulgeofstop

Page 44

(2)

CAUSE:

ADJUSTMENT:

(3)

CAUSE:

ADJUSTMENT:

8)

Belts

off

(1)

CAUSE:

ADJUSTMENT:

(2)

CAUSE:

ADJUSTMENT:

4.

Feed

mechanism

1) Needle breakage

Wrong

Referto8.1)

Wrong

Referto6.

Wrong

Adjust

Wrong

adjustmentonclutch

Adjusting

clutch

adjustmentondrive

Adjustmentonsafety

positionofclutch

position,

referto3.2)(2)

adjustmentofclutch

Referto8.1)Adjusting

actuating

actuating

connecting

cam

lever

actuating

clutch

actuating

lever.

lever.

bar.

mechanism.

stopper.

lever.

lever.

CAUSE:

ADJUSTMENT:

2)

Irregular

(1)

(2)

5. Needle bar and hook mechanism

1)

Needle

tack

CAUSE:

CAUSE:

ADJUSTMENT:

breakage

CAUSE:

ADJUSTMENT:

2)

Skip

stitch

(1)

CAUSE:

adjustment

(2)

CAUSE:

JUSTMENT:

Wrong

Referto2.1)Adjustmentonfeed

design

Wrong

Wrong

Referto2.

and

Needle

Adjust

adjusting ring.

Referto1.5)

Too

: Same as above.

Wrong

Adjust

line

as

Refer

timingoffeed

against

bending

work

centreoflength

centreofwidth

Adjustmentonfeed

hits

hook

clearancetobe

muchorless

timingofhook

heightofneedle

with

the

centre

standard

measurement.

to 1. 3) & 1. 4) Page

mechanism.

clamp

opening.

point.

0.03-0.05mm

clearance

point

barbyshuttle

axisofthe

feed

movement.

feed

movement.

between

and

12,13

mechanism.

mechanism.

between

hook

needle

and

driversothat

needle

when

needle

point

wrong

needle

and

bookbyturning

and

needle.

needle

the

bar

bar

hook

raisesup3.5mm

height

pointisin

3)

Thread

(1)

(2)

breakage

CAUSE:

ADJUSTMENT:

CAUSE:

adjustment

only

Scratchesonthread

Eliminate

Blxmt

: Replace.

oneortwo

thembysand

needle.

plysofthree

guides

and

paperorgrind

-36-

ply

hook,

thread.

etc.

stone.

Page 45

4)

Thread

(1)

jammhig

CAUSE

v-rtuon:

ADJUSTMENT:

(2)

CAUSE:

Adjustment:

Out

r •

A<(iu^

Wrone

M,

""die.

""

""d

thread.

I

(3)

CAUSE;

CAUSE:

ADJUSTMENT:

"

AtJ^

"PP"

du-ead

J"P

depending

„„

.^ZTZ

^"inteasure^ea,

spnng.

-37-

Loading...

Loading...