Brother LH4-B814-1, LH4-B814-2, LH4-B814-3 Instruction Manual

INSTRUCTION

FOR

MANUAL

BROTHER MODEL LH4-B814-1

,-2,-3

High

Speed

BROTHER

Buttonhole

NAGOYA,

Sewing

INDUSTRIES,

JAPAN.

Machine

LTD.

1 . F

eatures and Spec

1.

Ma

in

Spec

2.

Sti

tch

formation

3.

Features

Se

tti

2 .

3 . H

4.

5 . Trouble s hooting .... ..

6. Parts li

ng

1.

How

2.

Setting the

ow

1.

Cl

ean

2.

Nee

3. Sel

4.

Winding

5.

Thr

6.

Regu lati

7. Inserting

8. Runni

9.

Operati

10.

Emergen

II.

Operating

Adjustme nt.

1.

Regulating upper

2. R

egulati

3. Tim

4. Adju s

5.

Buttonho

6.

Nun1ber of s

7.

Setting pos

8.

Adj usting

9. Replac

10. Adjusting

l

1.

Releas

12. Re

13.

Adju

14.

The

15. Ins

1.

l ' hr

2.

Stitch skipping

3. Irregular stitch

4.

Threadi

5.

Irregular sti

....

up

and running .......................

to fix

to

us e t

ing up

dle

and

ect

ion

eading

ng

ng .................

ng knife

cy

...............

ng

ing

the hoo k and needle ......

ting

ing l

ing tension

leasing

sti

ng

cutter

ta

lling

ead brea

ng of. .....................

st

...................................................

ificatinos

ifi

cations

..............

the

machine head

he

machine

...........

its settin

of thread t

lower thr

bobbin case

lower

bobb

in

sto

p ....... ....

manual

the

thread

the width of

le sl

ot

titche

iti on of

uppe

r thread tri

owe

r thread

automat

tension on

oiling ....... .

falls on

the

tape

ks ...... ......

...........................

es

tch

..................

.................................................................

........ .

......................

...

........

................. ...................

motor ................................

on

........................

..... .

..................

g .. .. ............

hread

ing .........

ead

.........................................................

..............................................................................................

thread

case into

locki

..........

thread

and length

s ..........

ic th r

on main

...........................

...

at beg

tension

hook

... ......

...........

ng d

evice

.......................

feedi

ng

lever

...............................................................................................

ten

sion

tak

e-up s

button

........

.....................................................

cutter

.................

mmer

trimm

ead bre

tension regul

low

er tension regulator

.......................

the sci

sso

wind

er ............

.......................................................

........................................

........................ .. .......

inni

ng

.....

............

.......... ..

.........

table

top

... ................

................

.......

.........................................................................

...... .............

................. ............................................. .......

.........................................

....................................................................................

........................................................................

pring

.......

........

hole and positi

.... .........

.........

...... ............. ......

er

... .... ....

akage

...... .

rs ..

....................... ....................

...............

...

..............

..................

.................................................................

... ....

...........................

......................

...............

.............................

........... ..

........ ...........

.....

..................................

....

...

.......

.................................................... .

.... .

...........................................

... .......

......

.........................

...............

....................................................................

......

........ .... ............... ....... ....

perceiving dev

ator

.................................................

..............................................

.........................

....................................

....................

........

...

.............................

.........................................

...........

...............

............

....

..........................................................

... ..... .........

on

of

buttonhole

......... ........ ..

........

.................................

.....

..................

...................

.............

........ ....

.... ...

.........

.... ....... ....

... .

....... ..... ......... ... ............ ...

......

... .....

......

.....

ice ........ .

.... ........

....

.......................

.....

...............................

.............................

...... ...

......................

....................................

...

......................

................

..........

.....

...........

...

................

........................

.................................

...........................

......

..................................

..........

..............

........

................................

....

........................

...... ..

.............

......

.........................

................

.......... .

....... ...

..............................

...... .

................................

..... .

............

...........

.... 1

..... ..... .

......... ')

........ ..... 2

.......... 4

...... ... ... ......... ·I

.... ............. ......... 4

........

.............. 5

.... 5

........ .. 6

........

... . 6

..........

..... 6

.....

......... .

.....

.......

.....

........... 7

.. ...... ......... 8

._

.......... 8

: .... 8

.......... 9

................

.................... 12

......

... ...... .......

...................

...

..............

...

......

......

.....

........ 13

........ l3

............... l-1

.........

........

........

.......... .....

............

......

............

.......

....

... IS

... I

1

1

2

4

6

7

7

7

10

10

11

12

12

l-1

15

15

IS

15

IS

()

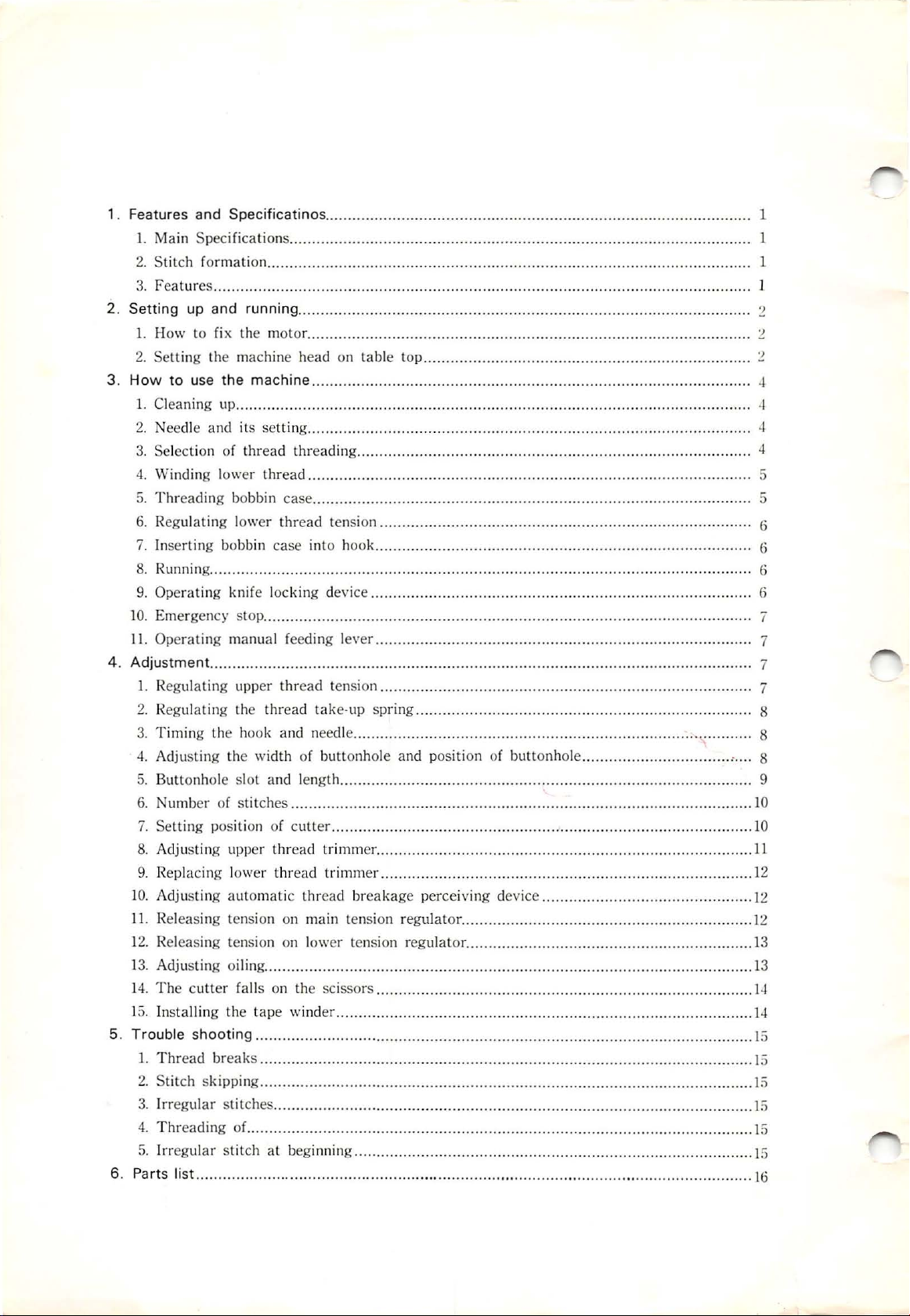

1. FEATURES AND SPECIFICATIONS

1. M a

in

Specifications

\l

ode

I

-class

Sub

Use

Max. se

Length of but

\\"idth of bu

Tape

wing

ttonhole

winding

spee

tonhole

Feeding mechanism

B

2.

uttonhole

I I e i

ght

Stit

ch formation

I) \\"hip s

of

upp

2)

Purl stitch

raised

Th

is

a ls.

with ,,-

stitch

of

presser foot

titch

.....

er

thread

.....

up

on the lo"·er

mod

el L! 14-8814 can

and

it

is

hip stitch

With this machine. if it is u

be clone

with ,,·hip s

As mentioned

It is

ver~·

easy

tension

on the

d

dc,·ice

es

same stitch

on

Stro

ng tension on

general!~

but

abO\·e. on

to

change

upper

general mater

6.-lmm-25mm

2mm- -lmm(

formation

lop

and

zigzag stit

thr

ead. This is

be done

·

used

,,·ith

tonhole

on

sed

tit

ch in

order to

the knitted

the stitch fo

thread

ten

- 1

(

%;"-\/'

t\il

upp

er

upp

er

either whip

purl

knitt

ed fabrics.

with

purl stit

fabrics and

sion

regulator.

Ll 1-1-B

Sl-1

single

needle

ials

1

"- 1 ") 6.-lmm-32mm(

•

1

) 2mm- 6mm(

general

3.

Equipped

upp

er &

60-%0

as

ordinar~

ch

of

thread

appli

stitch

be

able to get

rmati

·

lock

stitc

lower

thr

ead

appli

ed. thus.

ed for

buttonhole

stitch

or

buttonh

ch.

ole

both ends of

the

jers

eys

. it is r

on from purl s

purl stitch.

on shirt

lock s

titch

buttonhole

r

- 2 - 3

mate

300

s

pm

J,{

%;"

lo,,·er

stitc h

h zigzag

on

botto

the

\\·orks on shir

buttonho

beautiful

eco

tit

ch

to whip s

rials

''- I ),{" ) 6.-

1

-

~;n

es

formation.

m.

upper

dependi

s.

pyajamas and the like.

le.

and stable quali

mme

nded

knitted

lmm-32

2mm- 6mm(%;

upp

nam

thread

see

ts.

pyajamas

ng on,

porti

on

to

do

titch

o

nl~

Equipped

er & I

l 2.5mm(

ms

the

of

ty of

wi th

·

materal

mm(,l.{"- 1

''-').;';"

O\\·

Yz"

ely. z

igza

to

be straight

and

sewing

and use

bar

tacking can

butt

whip

by

changing

s

er

l

,g

sti

the

materi-

onh

stitch.

1

•1" )

)

lik

oles

the

tch

e.

d

.

3 . F

eat

ure s

1)

T his

mod

2) Aut

omat

:1)

It

can

rai

-

1)

\ride wor

;)

) A sp

ec

ially

61

.-\n

automatic knife

thread

7)

Specially designed sp

Hl

It

and

is ,·cry

bre

less ,-

of stitches and

9) Emergen

th

is

machi

!O

J Bobbi n \\'inding

II) The

1

applicable thic

21 This ma

direc

tion

el is ,-cry

ic

lubricatio

se

up

the pro

king spa

sel

ce can

ected

akage.

ibrat

ion ,,·or

easy

to change

amount

cy

instant s

ne

and also can

can

kne

chin e is equ

of back

fast to se,,· and can

n c

an

a,·oid

the oiling

ducti,

·ity as it ensures less

ens

ure

easy s

belt

mak

es

no fine

loc

king

de,·ice

enabl

eed reduction mechan

ks.

the length. wid th of bu

of

oil.

top lever ca

n gu

arantee

protect the bre

be

clo

ne eYen if

ss

of

the

material

ipped

\\'i

lh

adjustab

and fo

rth

or left

be

ewi

adjustment

es

akage of

machi

s is

ensureclup

le rul

and

right.

obta

ined

to

the

ng ope

to pre,·e

ism

ena

tto

the long

important

ne s

top

ers

good qual

machines

thread

ra

lion.

of belt

nt the

ble

s nois

nholes. nu

dura

bility

s.

to4.5- Smm.

either

it~

-

buttonhol

es with

in e \·ery morning.

breaks and thread off.

tensio

n.

mate

ele

rials from

ss

damage

mber

of

part

s.

to t

he

easy

in ca

adju

se

stments.

of

the

- 1 -

2. SETTING

1.

How

to

fix

UP

the

AND

motor

(Fig. 1)

RUNNING

1

357

As shown

me

nl

of

ning indu

(4 pole.

purchase

plea

induction

m

m

from o

follow

1.440/1,720 rpm, 250W).

se

use

ore

wattage

otor

mount ing br

ur Brot

the instruct

in

Fig

. 1,

it

is the m

the

location

ction motor, made

d this m

with the con stant running

motor

her motor,

of constant

by

Brothe

achine

and in this case, the

as head only.

of 4 pole. 250W

ack

et is

differ

thu

s, plea

ion below:

eas

If

ure·

run -

r.

you

or

ent

se

Fir

stly, put the two spe

the positi on

edge

of the

co

ndly,

Se

table top and m

The correct motor rota

the corr

2.

Setting

Put

2)

Put

3)

4)

Put

5) As s

Th

en, put the flat

apar

table top

put

ect rota tio

the mac

the hing

the tension pulley

the h

ead

how

n in Fig. 6,

~0

oW

(Fig.

ed pull

t 357

mm

to the end of pu lley as s

the mo

tor

oto

r mounting brack

tion is cou

n.

hine head on

(Fi

g. 4)

es

in

the

bed and pl

rest.

connect

belt between base pulley

I

2)

ey which is suppli ed

from the cen tre

to

table

top. Al that

et and

nter

clockw

table

ace

the m

as shown in Fig.

the oil tub

with

the m

of

the

machine. Set

hown in

time, please

faste

n securely with

ise

Fig 2. Drill the holes

\·i

ewed fro m the pulley side and if not. plea se gel

top

I) Set the

Put the base on the

b

elt

wit

diamete

-l

l ''s.

At the

wood

Unl

le

ach

5.

es

with

and

ba

se.

s as sho

h 42" for

r pulley. In the distri

pro

per

screw

s to

ess you

ssen th

e life of belts.

ine head

tube jo

int.

tension pulley as shown in Fig.

(Fig. 3)

ach

ine head to the motor shaft

the

position

make sure

set

bol ts.

tab

le lop as per Fi g. 4

wn

in Fig. 3. In the distri

larger

may

on

diam

eter pulley

ten

sion of t\\'O bells, fasten the ba se with

tab

le lop secur

put

the position correct

the base.

apart 107.5mm fr

at

to inse

ct

ely.

rt

of

60 H

the

correc

the was

ct

and

43" for

z,

ly, it cau

5.

hers betwee

of

use

and

om

t position.

and

put tw o

50 Hz,

smaller

wit

h both

ses

sel

the

n

use

lo

- 2 -

6)

Put

etwee

b

the bobbin

guide.

7)

Put

8)

Put

line

(Fig. 5)

the

bobbin wind er

n belt and pull

thread

the

belt cover with

the

flat belt

"·ith

indicat

s on

to the

or.

assem

ey.

bobbin

flat

machine

(Fig. 6)

bly

as

per

Fig.

7.

Thi

s is

becau

se

you

actually. The fine adjus

head screws.

pulley

and

push the tension lever

At

can

that

get

(Fig. 7 j

time, pl

the

tme

ease

make

sure

to be

eve

n bobbin win di

nt can be clone a t the po sition of thread

and

rel

ng

ease

whe

it

n you

at

right

the

position in

may

angle

wind

8)

(Fig.

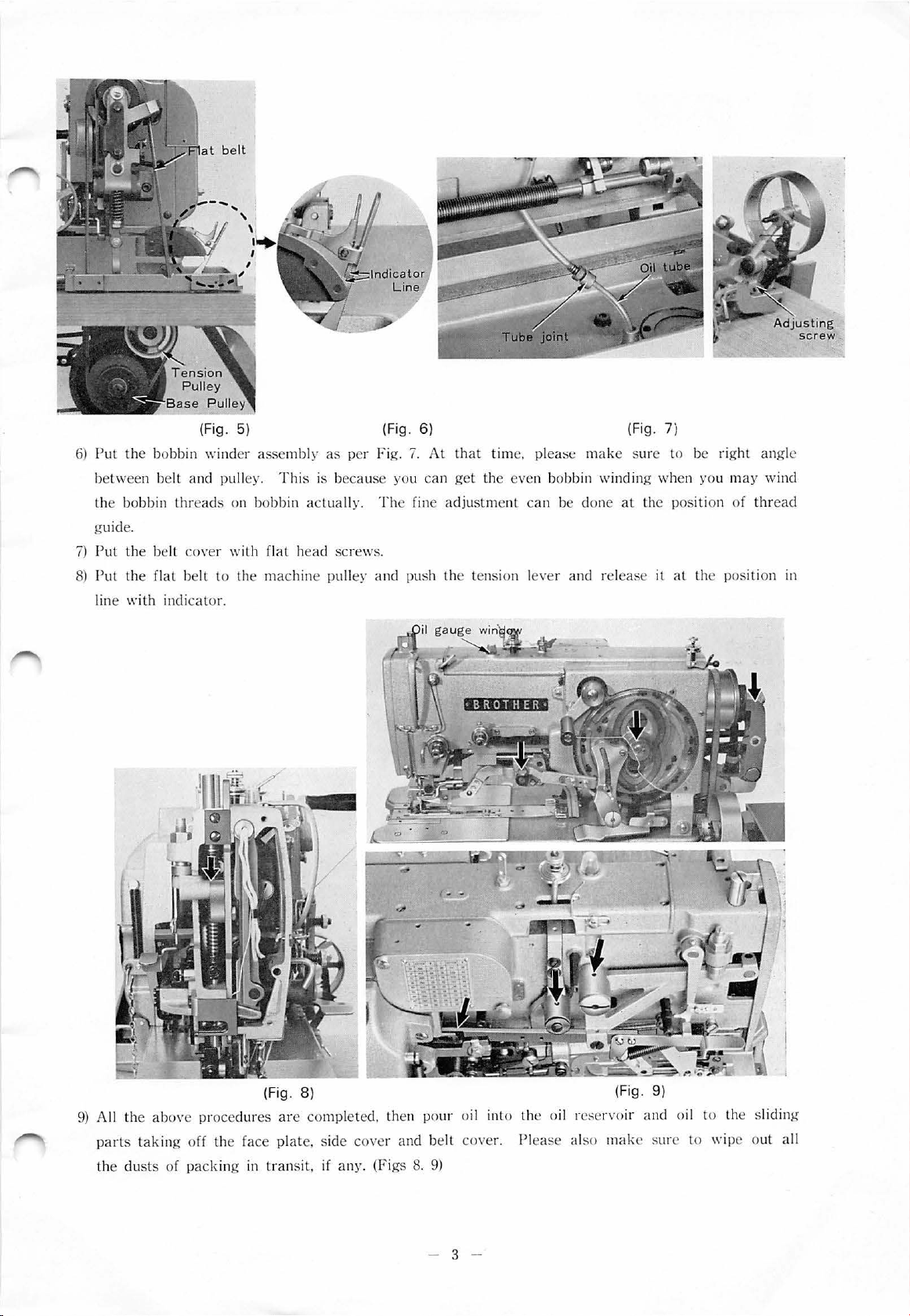

9) All

the

parts

the

taking

dust

above

s of

procedures

off the face

pac

king in

are completed . then

pla

tran

te, side

sit, if

any

cover

. (Fi

pour oil

and belt

gs

8.

9)

into the oil reservoir and o

cove

r.

Plea

se also mak

- 3 -

(Fig. 9)

il

e sure to \\·ipc

to

the sliding

out all

I I

L

ower

(Fig

(Fig

line

. 1 0)

. 11 )

1

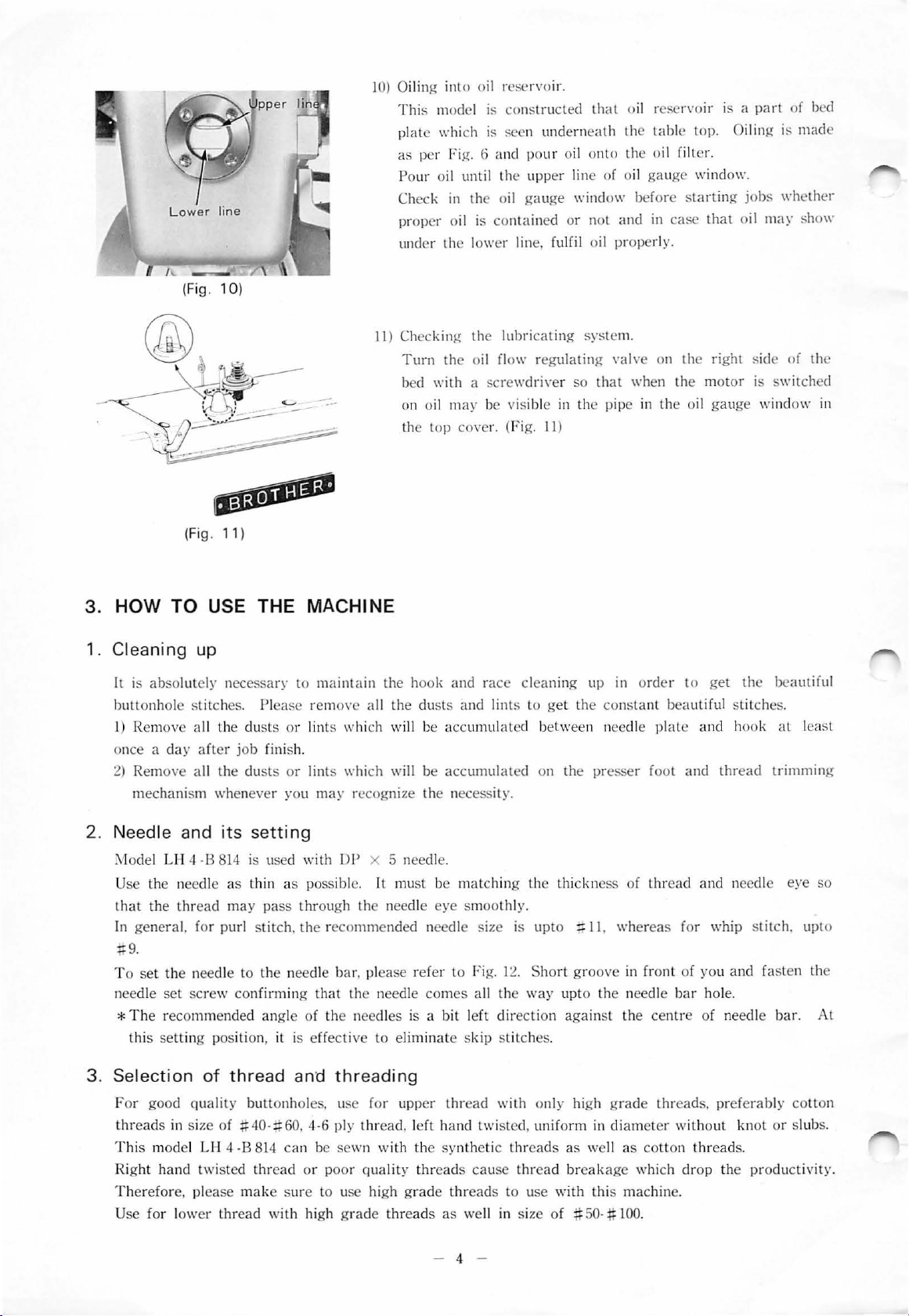

0)

Oili

n){

into o

mod

This

ate

pl

as

Pour oil until the

ec

Ch

proper

under the lower line,

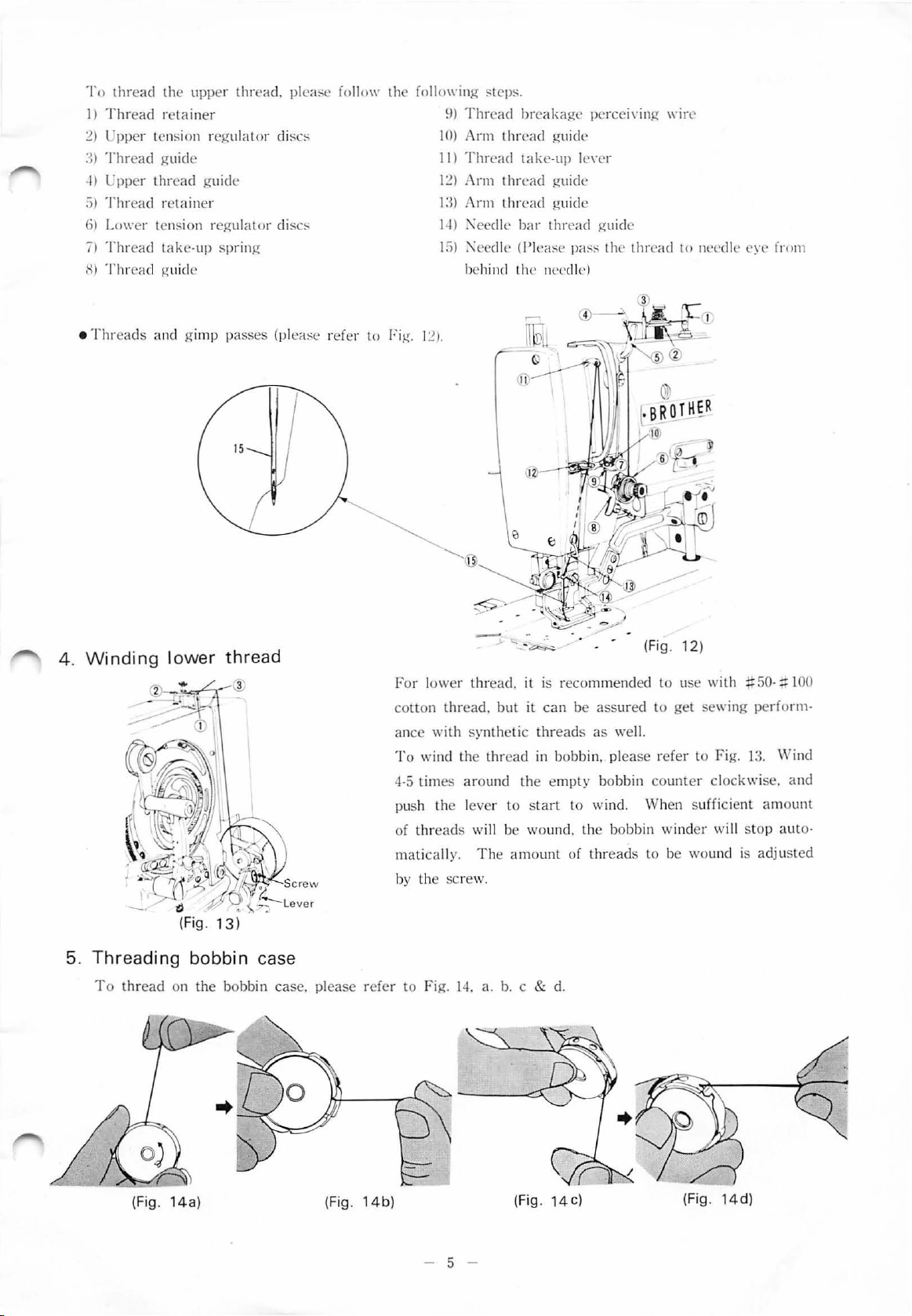

II)

Checking

Turn

bed \\'ith a

on oil

the l

el is constructed

which is seen

per Fig. 6 and po

k in the o

oil is

the

the

oil flo\\'

may

op

CO\·er.

il reservoi r.

that

oil r

underneath

ur oil

upper line of oil

il

gauge

contained

lubri

sc

rewdri\·er

be visible in the pipe in

(Fig.

\\'indo\\' bef

or

fulfil

cating

regulating

so

11

)

the tabl e top. Oili ng is

onto the oil

not

and

oil

prop

system.

\'ah·e

that

when the

ese

rvot r is a

filter.

gauge

windO\\'.

ore starting

in

case

erl

y.

on

the ri

motor

the oil gau

that

ght

part

job

s \\'hethcr

oil m

ay

side

is S\\'itched

ge

window

of bed

made

sho\\'

of

the

in

3 . HOW TO USE THE MACHINE

1. Cleaning up

It is abso

buttonhole

I) Remove a

on

ce a da

2) Remove all the du

2. Needle and

i\

lodel LH 4 -B 814 is used with

Use the n

th

at

In general. for purl stitch. the

;:9.

T o

needle

*The

this se tting position, it is effec tive to elimin

lutely nec

stitches. Plea

y after job finish.

mechanism whenever you may re

ee

dle

the

thr

ead

set

the need le to the needle

set scr

recommended angle

ll

ew

ess

ary

to

maintain

se

remove all the dusts and lints

the du

sts

or

lints which will be

sts

or

lints \\'hich will be

its

setting

as

thin

as

possible.

may

pass through th e needle

recomm

conf

irming

of

that

the

DP

bar

the needle com

the hook and race

cog

X 5 needle.

It

ended needle size is upto

, pl

ease

needles is a

nize

mu

the

st

refer

acc

umul

ated betwee

accumulated

necessit

be

eye smoothly.

to

es all

bit

ate skip sti

y.

matching

Fig. 12. Short

the

left

dir

ection agai nst the centre

tches.

clean

ing up in

to

get

the

on

the presser fo

the thickn

::II.

groove

way

upto the need le

order

lo

consta

nt

bea

utiful stit

n needle

ess

plat

e a

ol

and

of thr

ead

and

\\·hereas for whip stitc

in fr

ont

of

you and fasten

bar

hole.

of nee

get

the bea

nd

hook

thread

need le eye

dle bar.

ches

.

al least

trimming

h.

utiful

so

upt

o

the

Al

3.

Selection

For good

t

hread

Thi

s model LH 4

Right

refore, please

The

Use for l

of

thread

quality

s in si

xe

hand twisted th

ow

er

butt

of

~40-#60

-B

make sur

thread

and

onholes. u

814

can

read

wit

h high gr

threading

se

for upper

,

4-6 ply

or poor

e to use high g r

be s

thread,

ewn

with the synth

qua

lity thr

ade threa

thread

left h

and

eads cause

ade threads lo use with this

ds as well

- 4 -

with only high

twisted, uniform in di

etic threa

thr

ead

in size

ds as we

breakage

of

# 5

grade

ameter withou

ll

as cott

which

mac

0-#

100.

thr

eads.

on threa

hine.

preferably

t kn

ds.

drop the

cotton

ot

or

slubs.

productiv

ity.

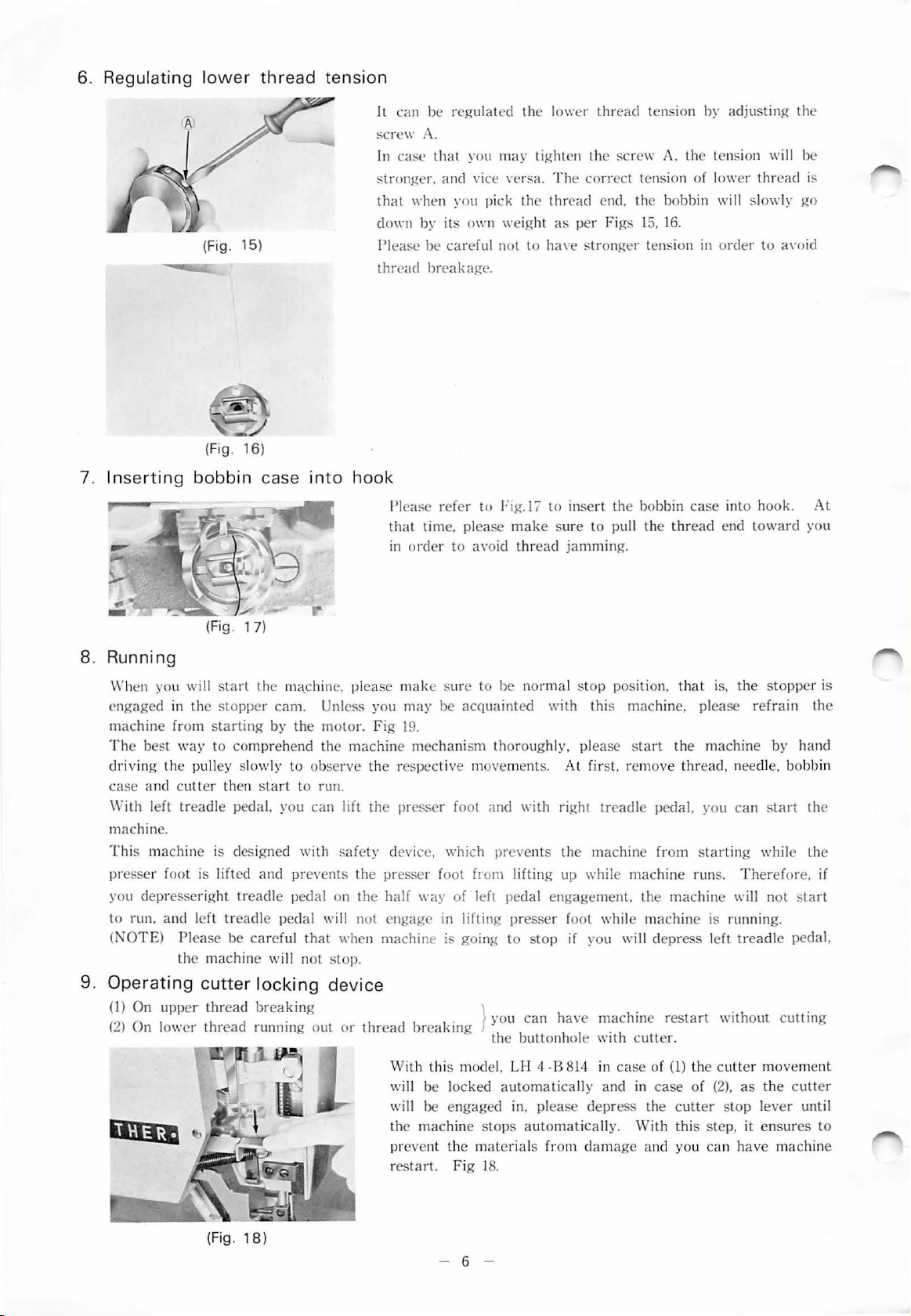

To

thread

1)

Thread

2) l.;pper te nsi

:~)

Thr

·ll t.;pper

5)

Thread reta

6J

Lower tension

7)

Thread

H)

Thread

ead

the

retainer

guide

thread

ta

guide

upper

thread.

on

regulator

guide

iner

regulator

ke·up spring

please follow the following steps.

9)

Thread

discs

disc~

I

0)

Arm

II)

Thr

12)

Ann

I:~)

1\rm

II)

:'\

eedle

L))

l\ceclle

behind the nccclle)

thread

ead

thread

thread

breakage

guide

take·

up l

guide

guide

bar

thread

(!'lease

percetnng

e,·er

guide

pass

the

thread

wire

to needle

c~·e

from

Thread

•

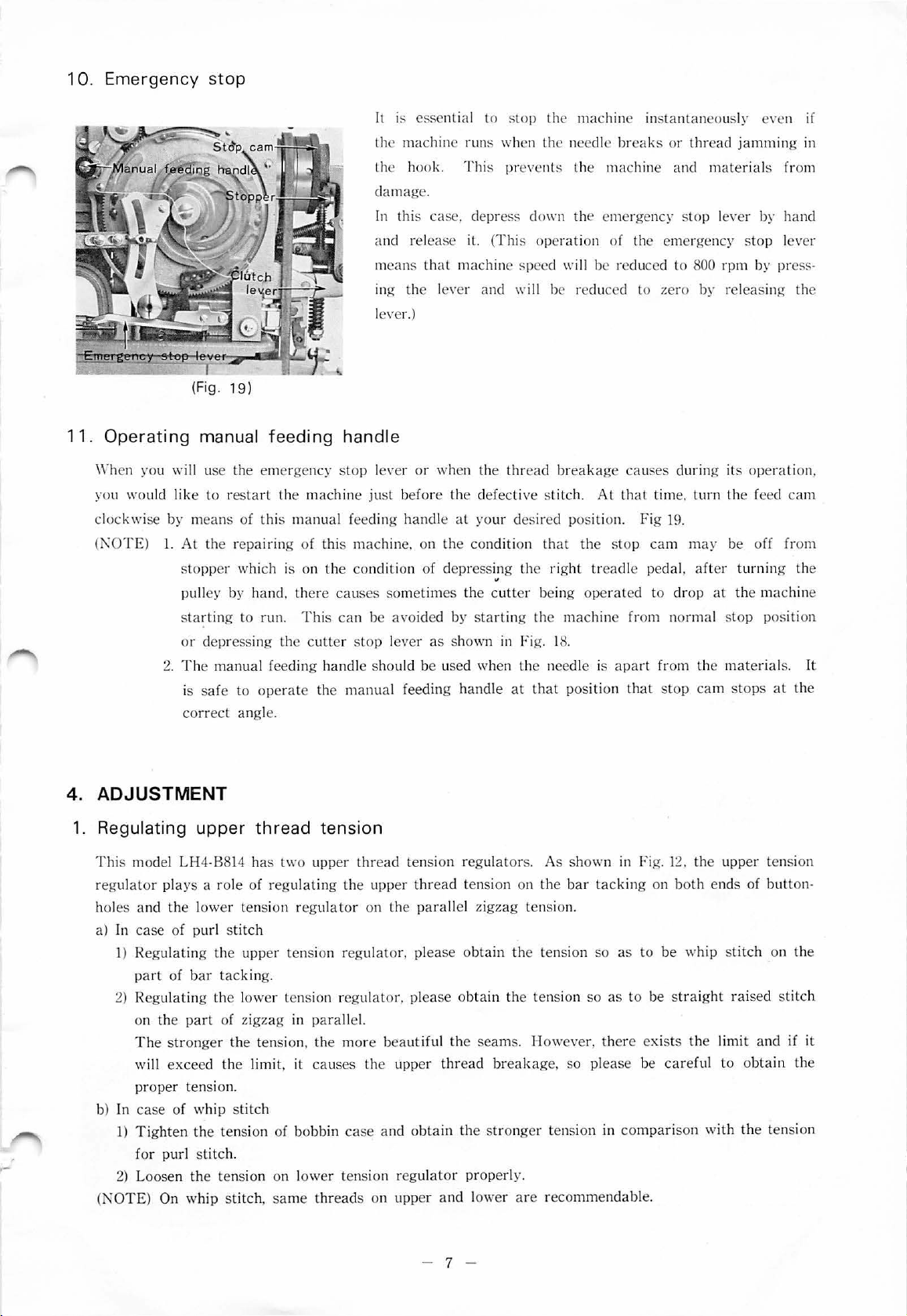

4.

Winding

s and

gimp passes (please r

lower

thr

ead

efer to Fig.

For

cotton

ance

To

4-5

push the l

of

matically.

by the screw.

1:!).

lower

thr

with

wind the

times

thread

s will

- - ->

t...

-

~

thread.

ead. but

synthet

it

it

ic

thread

around

the

ever to star

be

wound.

The

amou

.•

is r

ecom

can

be

assured

threads

as

in bobbin, pl

empty

(Fig. 12)

mended to use with

to

well.

ease

refer

bobbin

counter clockw

t to wind. When suffi

the

nt of

bobbin

threads

winder

to be wound is

get

sewing

to

Fig.

cient

will

±::

50·

::: I 00

perform·

13.

'vVind

ise.

amount

stop

auto-

adjusted

and

Thr

5.

To thread

eading

(Fig.

bobbin

on

the bobbin case.

14 a)

case

please

(F

ig. 1

refer

4b)

to

Fig. 1

4.

a.

b.

c & d.

(Fig . 14

- 5 -

C)

(Fig.

14d)

6. Regulati ng

7. In

serting

lower

(Fig.

15

(Fig. 16)

bobbin

thread

)

case in

tension

It

scr

In

st

that

down

!'l

thread breakage

to

hook

can

be regulated

ew

A.

case

that

~

·ou

ronger.

ease

Pl

that

in

and

,·i

ce ,·ersa. The correct

when you pick the

by

its

own

be

careful

.

ease

refer

to Fig.

time. please

order

to

a void

the l

may

,,·eight

not

to

I/

mak

thread

owe

r thread

tight

en

the screw A. the tension will be

thread

ha,·e stronger

to inse

e sure

as

per Fi

to

jamming.

encl

rt t

tension

tension

. th e bobbin will slowly

gs

15

.

tension

he

bobbin

pull the

by

adjusting

of

low

er

16.

in o

rder

case

into

thread end tow

thread

to

hook.

the

a\·oicl

ard

is

go

At

you

8. Runn

9.

ing

When you will

gaged

en

machine

The best

driving

case

\\"ith left treadle pedal.

ma

Th

presser foo

you

to run ,

(NO

Operating

(I ) On upper

(2)

· n ower t

in the

from

way

the pull

and cull

chin

e.

is machi

depresseright

TE) Please

0

ne

t is lifted

and left treadle

the

I h

cutter

0\I::Wie

slarl

the

stopper

starting

to comprehend

ey slow ly

er then

is designed

machin

cam. Unl

by

star

you

and prevents

treadle

pedal will

be careful

e wi

locking

thread brea

rea

runnmg

d

ma.

chine.

the motor.

the machine m

to

observe

t to run.

can

with safe

pedal on t

that

when machi ne is going

ll not

slop.

please

ess you

lift

mak

may

Fig

19.

the

respect

the

presser

ly

devi ce, ,,·hich

the

presser

he

hal

f w

not

engage

e s

be

ech

ani

ive movements.

foot fr om lifting up while

ay

in lifting

device

kin

g }

· h d b k.

out

or t

rea rea

With this mod el,

will be l

will

the

preve

esta

r

·mg

be

machin

nt

rt. Fig 1

ure

to be no

acquainted

sm

thoroughly,

foot

and

preven

of left

you

the buttonhole

oc

ked

engage

d in, pl

e slops

the

mate

8.

rmal sto

with

with

ts the

pedal engagement.

presser

to

slop

can

Ll-1

4 -B

automatically

ease

automatically.

rials from

p positio n, that is, t

this machine. pl

please s

At firs

t. r

right

treadle

machine from

foot while machine is running.

if you w ill

ha\·e

mach

with

814

in

case

and

depress

damag

he

stopper

ease

refrain

tart

the machine

emove

mach

cutte

e and you can have machine

thread, needle, b

pedal. you can

sta

rting while

ine runs.

the

machine

depress left tread

ine

restart

r.

of

(1

in

case

the

'vVith th

without

) the

cutter

of

(2).

cutter slop lever

is step, it ensur

The

will

as

by

start

refore. if

not

le pedal.

movem

the cu

the

hand

obb

the

the

start

culling

ent

tte

until

es

is

in

to

r

(Fig. 18)

- 6 -

1 0. Emergency s

(Fig.

top

19)

It

is

essent

ial to s

the ma chine run s when the needl e brea

lhc hook.

d

amag

In

this case, depress

and rel

m

ea

ns th

ing the leve r and

l

eve

r.)

This pr

e.

ease

il. (

at machine

lop the machine inst

events the machine and

dmm the

This opera

spee

d will be reduced to 800 rpm by press-

\\"ill

be reduce

emerge

tion of the emergency

d to ze ro by releasing

antan

eo us

ly

ks

or thread jamming

material

ncy sl

op leve

r by hand

stop

e\·en

s from

lever

the

if

in

11. Operating

\\"hen you wi

you wou

clockwi se by me

(l\O

TE)

manual feeding

ll

use the emergency

ld

like

to res

ans

1.

At

the

s

topper

ll

ey

pu

s

tartin

dep

or

2. The manual feeding handle shou

sa

fe to ope

is

orrect

c

4. ADJUSTMENT

1. Regulating

Thi

s model LH4-B814 has

ato

regul

holes and

ca

a) In

1)

Regulating the upper tension regulator, please

part

2) Regulati

on the part of zi

The stronger

will

proper

case

b) In

1)

Tighten

for purl s

2)

Loosen

(NOTE)

upper

r plays a role

the lower

se of purl stit

of

bar

tac

ng the l

exceed

ten

sion.

of whip s

the tension of bobbin case

tit

ch.

the

tension on l

On whip

handle

sto

tart

the machine just before the defecti ve stitc

of

this

man

ual feeding handle

repairing

which is on

by ha nd. th

g to run.

ressing the cutter

ang

of regulating the upper

tension regula

ch

king.

ower

gzag

the

the limit, it

tit

stitc

of this machine. on the condition

the

ere

cau

This can be

rate

the manual feeding

le.

thread

tension , the

ch

h, s

tension

t\\"O

upper

tor

tension regulator, please

in parall

more bea

causes the upper th

ower

tension regu l

ame

thread

p l

eve

r or when the thre

al your

condition of depressi.ng the right

ses

sometim

avoided by starting

stop lever

thread

on the

el.

and obtain the str

s on upper and

es

the

as

shown

ld

be use

d when the needle is

handle

tension regu l

thread

ut iful the seams. However, there exi

parall

ato

el zigzag

read

r properl

tension on the

obtain

obtain

lower

ad

breakage

desired position. Fig 1

that th

cutt

er being oper

the machine from normal

in

Fig. 1

8.

at that

ator

the

the tension so

breakage

onger

y.

are

position

s. As shown in Fig. 12. the up

tens

ion.

tension so

, so pl

tension in

recommendable.

h.

bar

causes

At

that

e stop

trea

dle pedal.

ated

apart

that

tack

ing on

as

as

to

ease

comparison with the

dur

time. turn the feed c

9.

cam

may

to

drop

from the

stop cam stops at the

both

to

be

whip stitch on the

be straight raised stit

sts

the limit

be

caref

ing its operation,

am

be off from

aft

er turning the

at the machine

sto

p position

mater

ial

s.

per

tension

ends

of

button-

ch

and if it

ul

to

obtain

the

tension

It

- 7 -

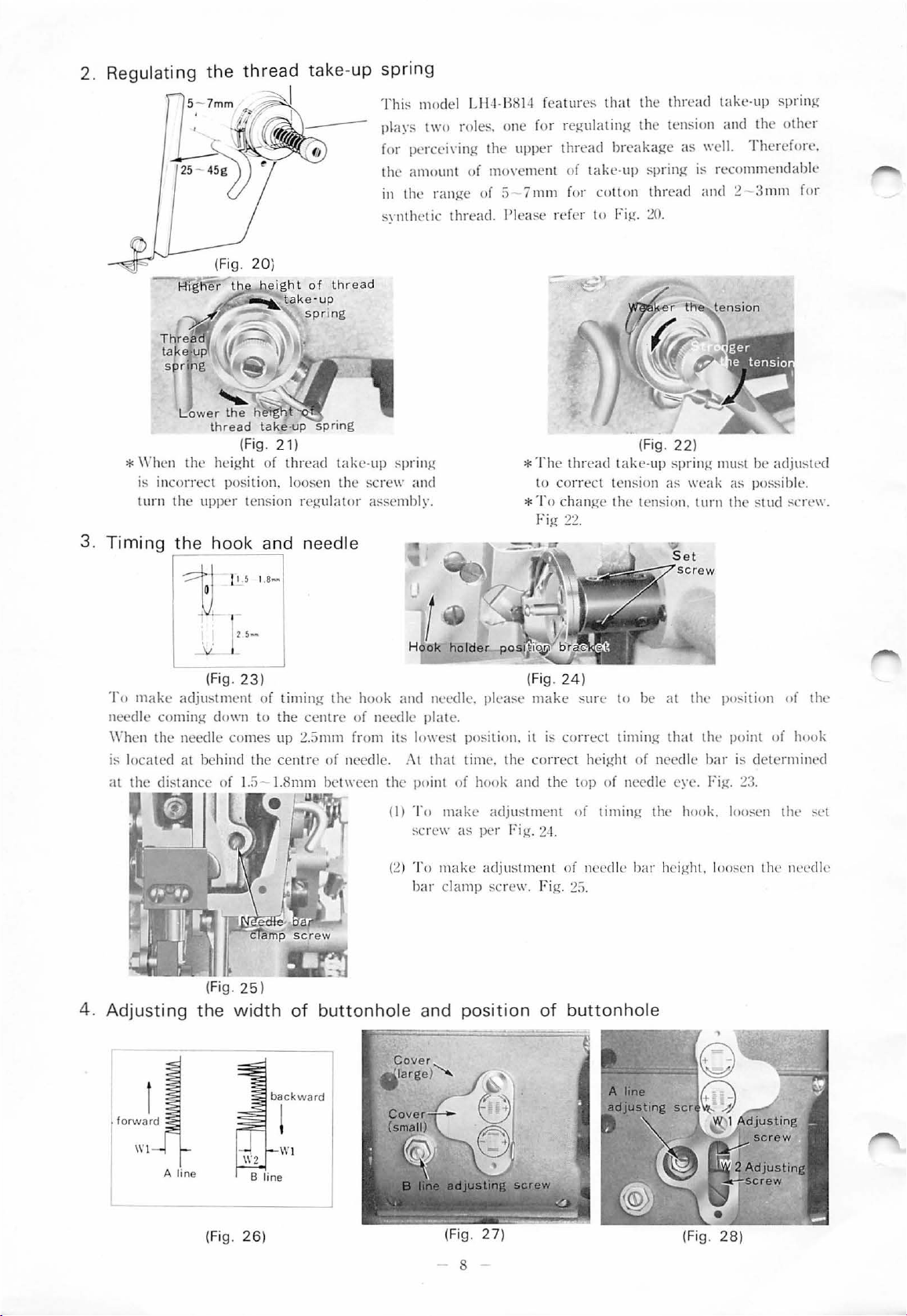

2. Regulating

the

thread

take -up

spring

3.

-

f';l(g~

Lower

thread tak

*\\"hen

turn the

Timing

the

height of thr

is incorrect position. l

upp

the

hook

I

"the

he

ight

of threa

,

..... .---"-ta

the

(Fig. 21 )

er tension regulator

ke· up

sp

ring

h

e-up

ead

oose

n the

and needle

take-

T

hi

~

model Ll l

p~ay~

two

roles. one for

for percei,·ing the

the

amount

in the

sy

nthetic

d

up s

pring

screw

and

assembl~·.

of

range

thread

-I·BH14

upp

movement

of;)

7mm

. !'l

ease

*The thr

* T o

f

eatu

r

e~

that

the

thr

ead

take-up sprin

regulating the tension and the oth

er

thread

ref

to corre

change the

Fig

n

breakage

of

tak

e-up s

for cotton

er

to

Fig. 20.

ead

take-up spring

ct

tension

pring

thread

(Fig.

22)

as \\·e

tension.

as well.

is r

ecommendab

and 2-3mm

must be adjustl

ak

as

turn

the stud screw.

Theref

pos

sible.

g

er

ore.

le

for

'd

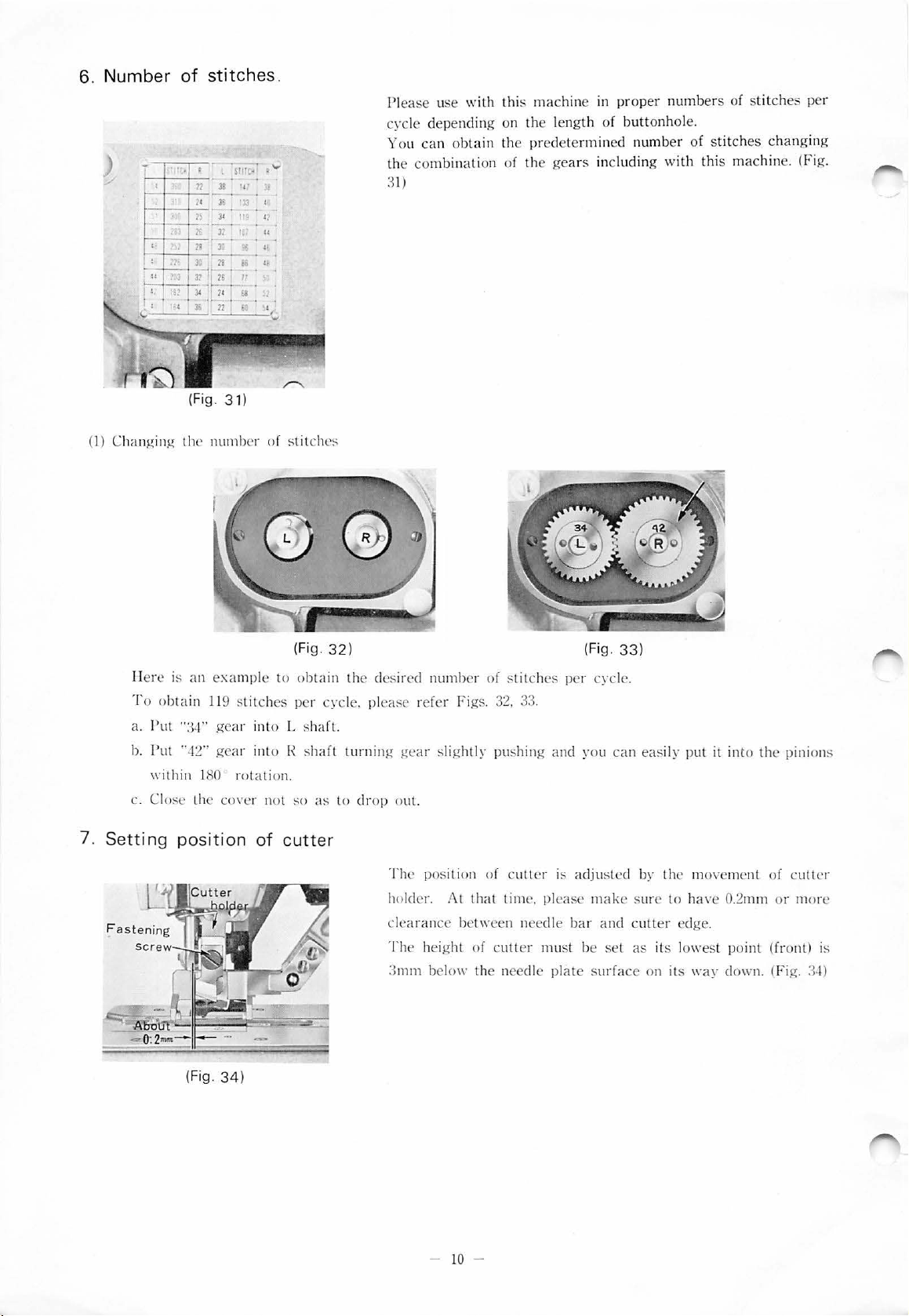

4.

1

L

To

make adjustment

needle

\\"hen

is

at

Adjust

coming

the

located

the

ing

needle

at

1.8-

"'

25-

-

\,,;

I

---'

(F

ig. 23) (Fig.

of

tJmm

.~~;

down

to

the cen

comes

behind the centr

(Fig. 25 )

the

1.:1

- l.Srnm

width

up

the hook

tre

2.5

mm

fr om its

e of needle. !

between the point of

of

buttonhole

of need

(I) T o

(2)

and

needle.

lc

plate.

lowest

\t

that

~cre

T o

bar clamp screw. Fig.

and posi

plea~c

position. it

tim

e.

hook

make

adjustme

w

as per Fig. 24.

mak

e adjustment of ne

tion

24

)

make sun:

i

~

correct timing

the correct hei

and the

top

nt

of timi ng the hook. lo

2:1.

of

buttonhole

to

be

at

the

pos

that

the

point

ght

of

needle

of needle eye. Fig. 23.

edle bar height.

bar

lo

is

osen the

o~e

iti

on

of

determin

n

th

e n

of

hook

eedle

the

ed

;:L't

backwa

rd

!

A line

B l

(Fig. 26)

ine

(Fi

g. 27)

8

(Fig. 28)

(!

l :\cecile

This machine

on bo

<2l

.Adjusting

th

e zigz

narrower. (Fig

The width

you

If

hole

. (3)

Adjust

\\"h en

t

he zigzag width

zi

gzag

portions.

(

:\OTE)

S\\·tng

th end

zigzag

ag

will

without

(Fig. 29)

ing proce

the cull

in

parallel. Aft

(I)

(2}

mg.

swings the n

s. Fi g.

width

of

loosen

By

will

fo re. pl

This machine

therefore. please

zi

lin

After

and

·s

26.

width

\\"I

will

be

s.

27

. 28}

zigzag

bar

er

gzag

es

ition

and

conside

taking.

dure

goes

do\\

of par

allel. Then. adjust

er compldi

means of needle bar

make

adjustment

ease

adjust the corr

width

on

both bac

turning the

et

the mac

ed

in

the stopper. Then. s

eed

le

from

right

a

nd

\\

.:?

.

\\"ith

\\·

ici

er.

and

turn

tackin

g c

an

be

adjusted

rablr

the

adjusting scre w

*

l

~efer

l

oosening

screw

Turning the scr

and

*

l~

eference

turning the screw. Turning

line ri

(See

·n.

after

adjusting

on

of

abovc·men

mo\·emenl

b~·

t

urning the pull

ect position \\·ith

is designed

make sure the needle

of

-lmm

l\\

rar

pulley

hine to the normal

the needle s \\·inging much more th

or

more

d and for

by

hand.

to

left

eith

er

\\"I

and

\\" 2

adjusting scre,,·s.

to

left (co

e n ce

the

\\'ith a sc

turning

ghtward: and

Fig. 29)

the :-\

the

B line

and press

on

bar

ward zigzag

plea

stop

tart the machine.

unt

br

the

for

bar

line

A c

an

nut

rcwclri,·er inserted

ew clock\\

it the other "·ar

line B can be

line

not

not

ti oned

adjustment.

ing

ey

br

actual

not

to

hit

Lacking

width

se

mak

e s

position. namely.

goi

ng forward

er·clo

ckw

isc). the

adjusting screws

lacking.

be

with

turnin

so

so

the

hand.

the

portions

ure

~·ou

adju

ste

d

the

accessory

·ise

moves

111oves

adjusted

it cl

ock,,·ise

g it the

as

as

to break the se\\·n thre

se,,·ing

presser

of

to

other ,,·ar mo,·cs

to

break

adju

materials with

it

causes

.

or

after the

parallel po

usc

or

backwa

turn

to

rig

zigzag

to

be

larger

c

an obtain

by

opening

tool.

through

st the

an the

foot when

the

the

the

the refe

ren

it

righ

t\\·arcl.

by

loosen

111o,·es

the

sewn thread. adjust

width

thr

a slig

ht

dif

slot

rou

rel11o\·al

rtions.

enH.'rgenc~·

stopper cam bei

rd.

for tacki

ht (cloc

width

or s

the

gimp

the

small

and turn

hole

in the

ce

line

leftward:

(See

ing the

the

refe

it leftward.

ad

of

bar

ead. when

ference.

of wo

rk

mar set

of

sl

op

ng

kwi

se).

will be

mall

er.

button·

cover.

ing the

tool.

Fig.

29}

nut

and

ren

ce

of right

tack

ing

rou

there·

clamp

the

position

le,

·er

ng

po·

5.

Buttonho

le s

lot

(Fig. 30)

and le

ngth

If you

and

set

arc corr

determine the

the

indicator

espondent

9

to

len

gth

to

the figures

the

cutler

of butt

lengt

onh ole.

of len

h.

(Fig.

choose

gth

proper cutler

feed. The figures

30)

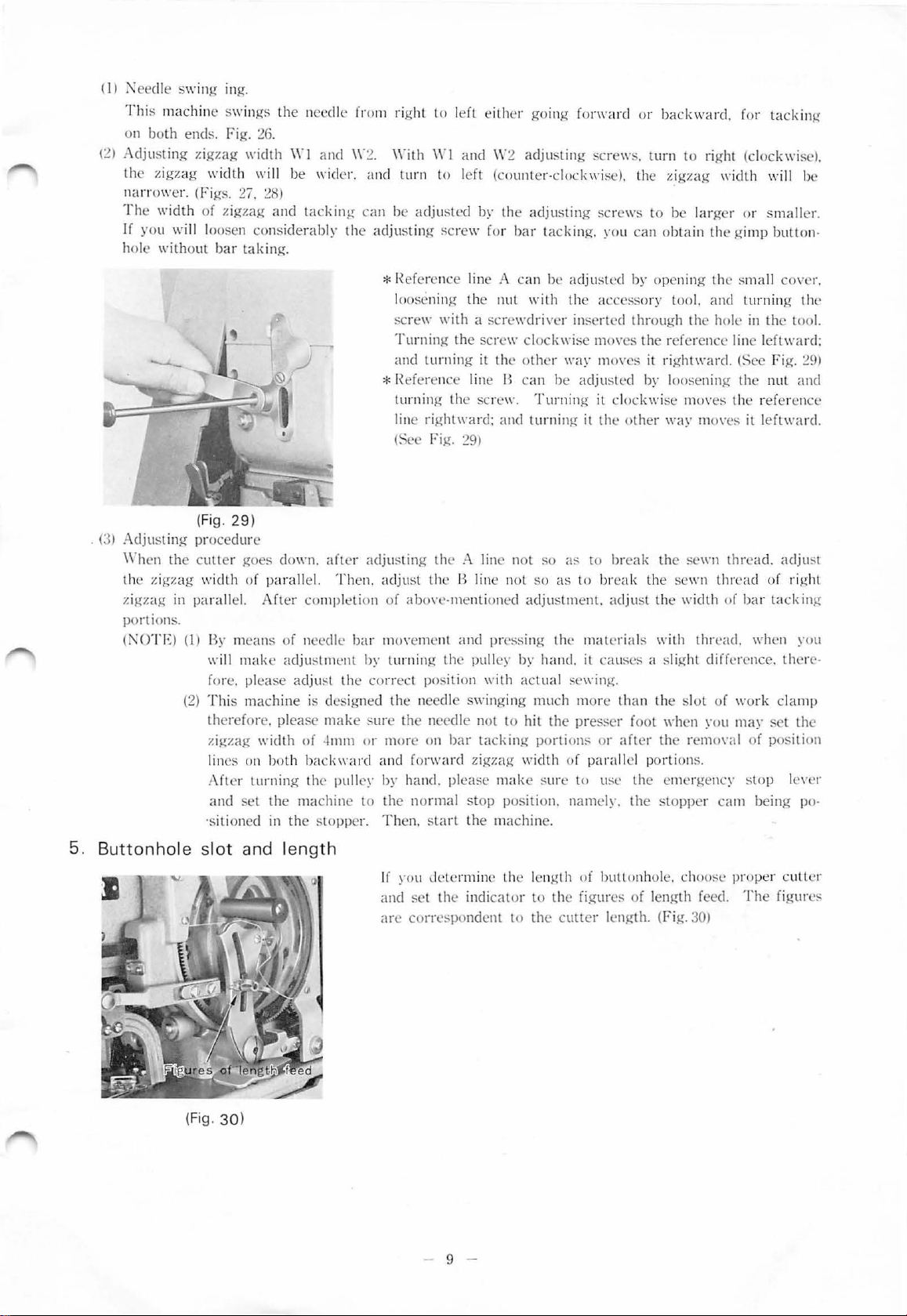

6. Number

)

-+--+t---+--+-"11-

(I)

Chang

ing th e n

of

stitches

. ~ "

..

(Fig. 31 )

~s,

t ... "

JB

'I

umber

.

'¥

. .

..

of stitches

Pl

ease

cycle d

an

You c

the comb

31)

use

epend

obta

inati on

with

this

ing on the

in the pr

of

machi

the

ne in proper

leng

th of

buttonhole.

edete

rmin

ed

numb

gea

rs in cluding with this

numb

er

of s

ers of s

titches cha

machin

titche

s per

ngi

ng

e. (Fig.

7.

Setting

ll

ere is

To obt

a.

Put

b.

l'ut

\\·ithin 180

c. Clo

se

an

ain

"3·1'

··

-12"

the c

pos

(Fig . 3

example

119

stitch

' ge

ar into L s

gea

r into

rotation

ove

iti

on

4)

(F

ig.

32)

to

obtain

es

per cycle. pl

haft.

I

~

shaft turning

.

r not so as to

of cut

ter

the desi red

ease refe

gea

drop

out.

Th

e posit ion of cutter is a

ho lder.

clearance

T he

:3

mm

numb

er of

r Figs.

r slightly

1\t

that

between nee

height

of c

belcl\\.

stitches

32

.

pushing

time. plea

utt

the nee

(Fi

per cycle.

3:3.

and

you

dju

se make sur

dle

bar

er must be s

dle

plate surfa

g.

33

)

can

easily put it into the pin i

sted

by

the moveme

e to ha\·e 0.2mm or more

and

cutter edge.

et

as

its l

owest

ce

on its \\

·ay clo\\'

nt

point

n.

of c

(front

(Fig.

utl

ons

er

) is

3-1)

10

-

Loading...

Loading...