Page 1

FACSIMILE EQUIPMENT

SERVICE MANUAL

MODEL: FAX100/570/615/625/635/675

FAX575M/715M/725M

FAX590DT/590MC/825MC/875MC

Page 2

© Copyright Brother 1995

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

Page 3

PREFACE

This publication is a Service Manual covering the specifications, construction, theory of operation, and maintenance of the Brother facsimile equipment. It includes information required for

field troubleshooting and repair—disassembly, reassembly, and adjustment—so that service

personnel will be able to understand equipment function, to rapidly repair the equipment and

order any necessary spare parts.

T o perform appropriate maintenance so that the facsimile equipment is always in best condition

for the customer, the service personnel must adequately understand and apply this manual.

This manual is made up of five chapters and appendices.

CHAPTER I

CHAPTER II

CHAPTER III. THEORY OF OPERATION

CHAPTER IV. INDICATION AND INFORMATION PRINTOUT OF ERROR

CHAPTER V. MAINTENANCE

APPENDICES Circuit Diagrams

.

GENERAL DESCRIPTION

.

INSTALLATION

This manual describes the model and its versions to be destined for major countries. The specifications

and functions are subject to change depending upon each destination.

Page 4

CHAPTER I.

GENERAL DESCRIPTION

Page 5

CONTENTS

1. EQUIPMENT OUTLINE................................................................................. I-1

1.1External Appearance.............................................................................. I-1

1.2Components............................................................................................I-1

2. SPECIFICATIONS..........................................................................................I-2

Page 6

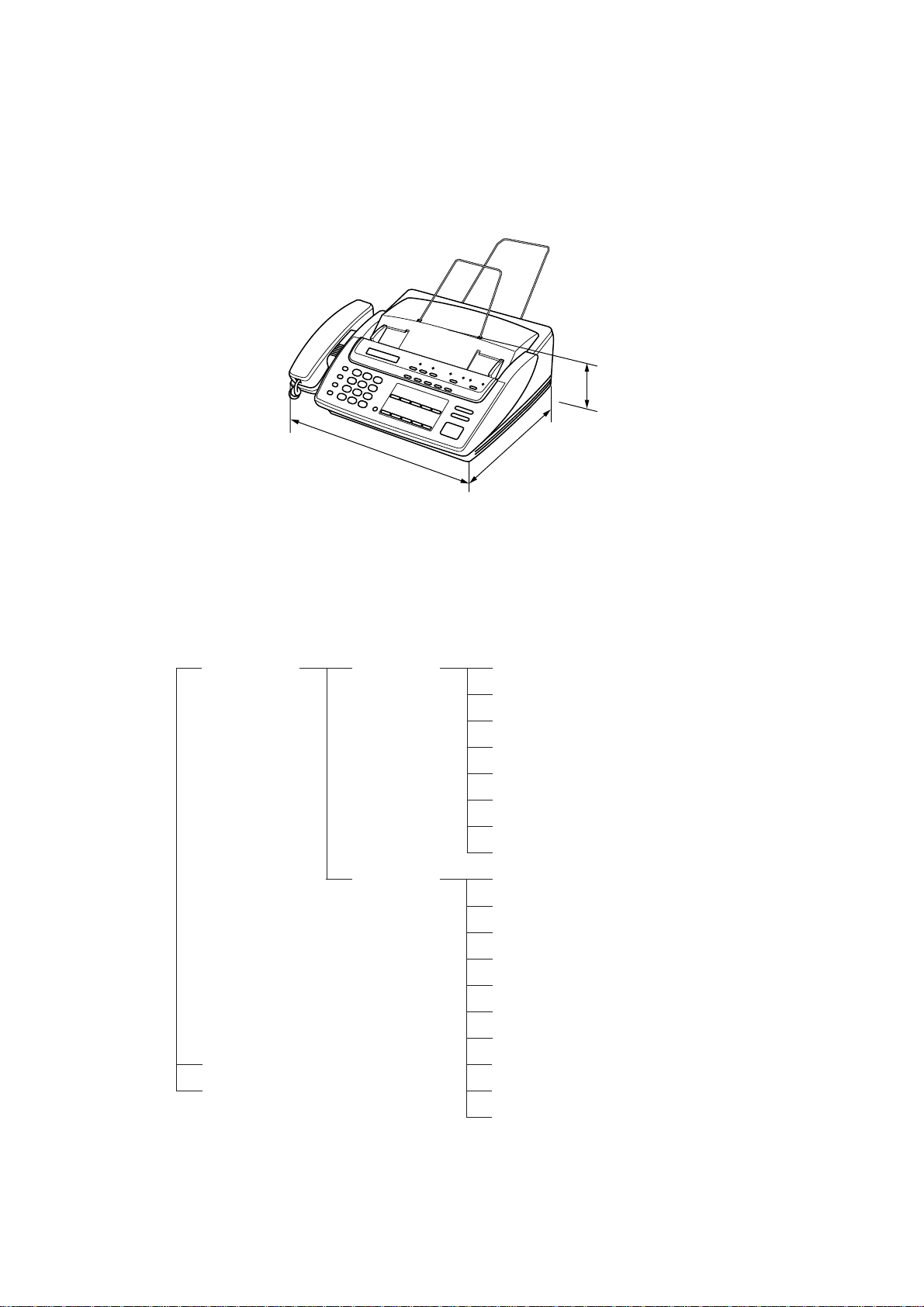

1. EQUIPMENT OUTLINE

1.1 External Appearance

The figure below shows the equipment appearance and approximate dimensions.

121 (H)

1.2 Components

The equipment has the following components:

Facsimile

Equipment

377 (W)

Electronic/

Electrical/

Section

Mechanical

Section

304 (D)

(Unit: mm)

Main PCB

NCU PCB

Control Panel PCB

Recording Head Unit

LED Array (for illuminating documents)

Charge Coupled Device (CCD) Unit

Sensors

Power Supply PCB

Recorder & Cutter Unit

CCD Unit

Drive Motor

Clutch Solenoid

(for paper & document feed and for cutter drive)

Package

Accessories

Drive Gears

Control Panel Unit

Covers

Automatic Document Feeder (ADF)

Handset

Frame and Miscellaneous Parts

I – 1

Page 7

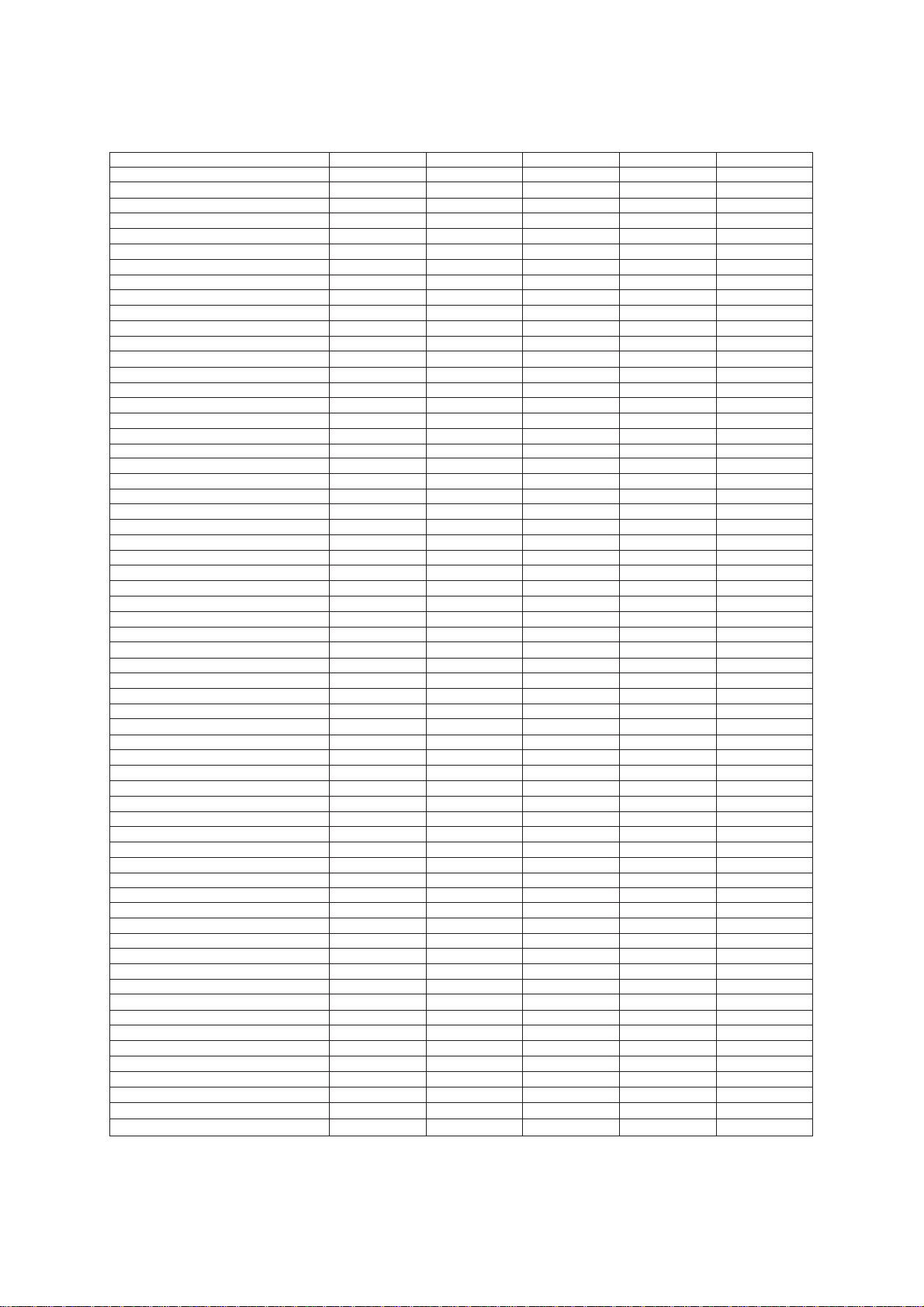

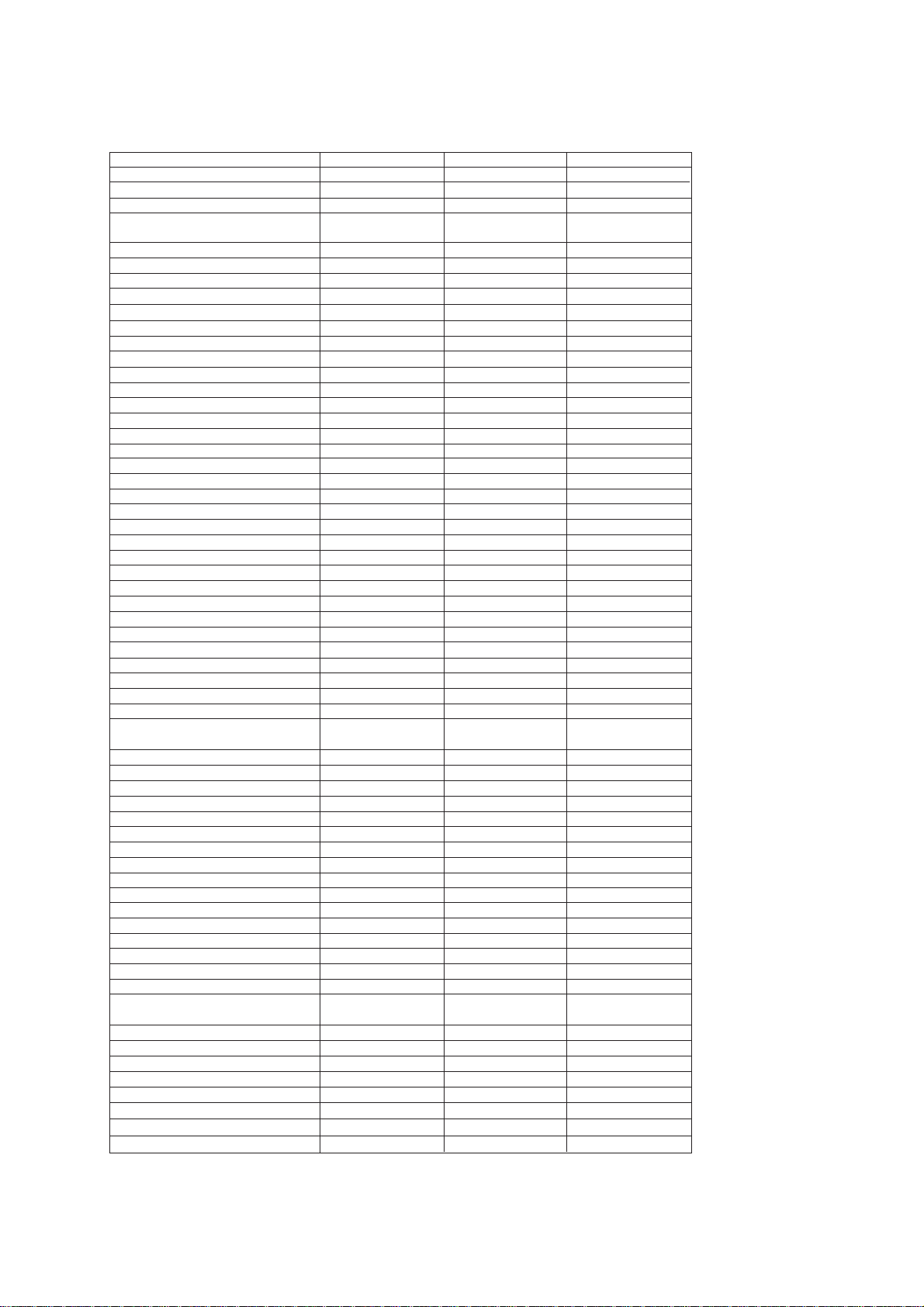

2. SPECIFICATIONS

Model FAX100 FAX615 FAX625 FAX635 FAX675

Color 1138 BN4 BN2 BN4 BN2

Modem Speed 9600 bps 9600 bps 9600 bps 9600 bps 9600 bps

Coding Method MH MH MH MH MH

Transmission Speed 15 sec 15 sec 15 sec 15 sec 15 sec

CCITT Group G3 G3 G3 G3 G3

Input/Output Width 8.5"/8.5" 8.5"/8.5" 8.5"/8.5" 8.5"/8.5" 8.5"/8.5"

Auto Cutter Yes Yes Yes Yes Yes

ADF Capacity (pages) 15 15 15 15 15

Anti-curl System Yes Yes Yes Yes Yes

Paper Size

LCD Size 16 x 1 16 x 1 16 x 1 16 x 1 16 x 1

On-screen Programming Yes Yes Yes Yes Yes

Super Fine Yes Yes Yes Yes Yes

Smoothing Yes Yes Yes Yes Yes

Gray Scale 32 32 32 64 64

One-touch Dialing 10x2 10 10x2 10x2 10x2

Speed Dialing 20 30 20 30 40

Group Dialing No No No No No

Telephone Index No No No No No

Speakerphone Monitor Monitor Monitor Monitor Monitor

Fax/Tel Switch Yes Yes Yes Yes Yes

TAD Interface Yes Yes Yes Yes Yes

Enhanced Remote Activation Yes Yes Yes Yes Yes

Distinctive Ringing Yes Yes Yes Yes Yes

Next-Fax Reservation Yes No Yes Yes Yes

Help Yes Yes Yes Yes Yes

Caller ID No No No No Yes

Automatic Redialing Yes Yes Yes Yes Yes

Multi-Resolution Transmission Yes Y es Yes Yes Yes

Polling Std/Sec/Del Std/Sec/Del Std/Sec/Del Std/Sec/Del Std/Sec/Del

Delayed Transmission Yes, 1 timer Yes, 1 timer Yes, 1 timer Yes, 1 timer Yes, 1 timer

Coverpage Yes Yes Yes Yes Yes

Call Reservation Yes Yes Yes Yes Yes

Call Back Message Yes Yes Yes Yes Yes

Activity Report Yes Yes Yes Yes Yes

Transmission Verification Report Yes Yes Yes Yes Yes

Page Memory No No No No No

ECM No No No No No

Broadcasting No No No No No

Quick Scanning No No No No No

Out-of-Paper Reception No No No No No

Multi Copy No No No No No

Multi Transmission No No No No No

TAD T ype No No No No No

ICM Recording Time No No No No No

Remote Control No No No No No

Paging No No No No No

Toll Saver No No No No No

Memo/2-Way Recording No No No No No

Time/Date Stamp No No No No No

Message Center No No No No No

OGM No No No No No

FAX Forwarding No No No No No

FAX Retrieval No No No No No

PCI (Missing link)

Password No No No No No

Paper Save No No No No No

Day-Night Mode No No No No No

Elec. Vol. Control No No No No No

FAX-on-demand No No No No No

Voice-on-demand No No No No No

Fax Mail Box No No No No No

Voice Mail Box No No No No No

(Standard thermal/Therma PLUS)

(* : w/o PC FAX RX)

164'/164' 164'/164' 164'/164' 164'/164' 164'/164'

No (Note 1) (Note 1) Option* Option*

(Note 1) No: Asia and Taiwan

Option*: Gulf, China, and Saudi Arabia

I – 2

Page 8

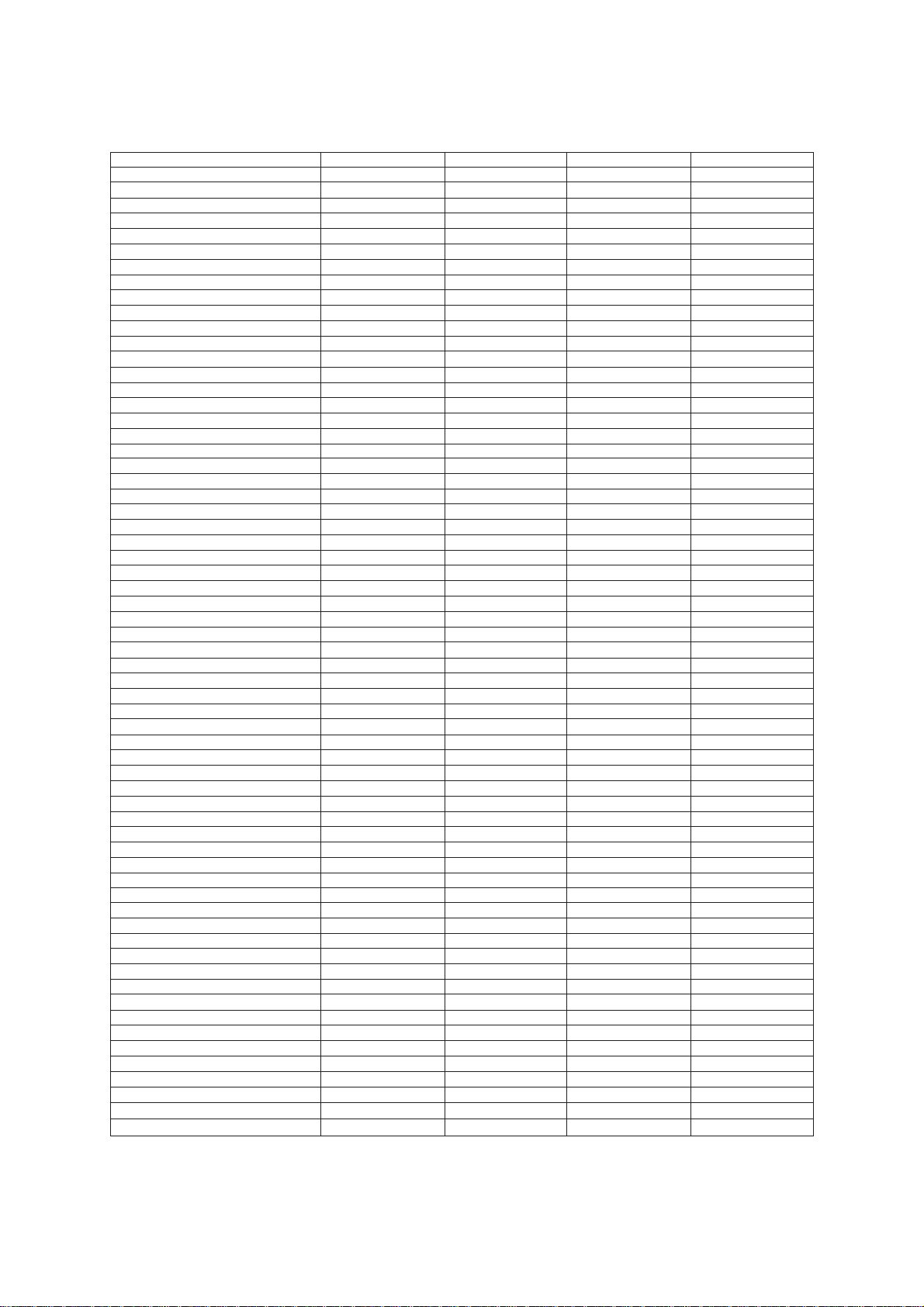

Model FAX715M FAX725M FAX825MC FAX875MC

Color BN2 BN4 BN2 BN2

Modem Speed 9600 bps 14400 bps 14400 bps 14400 bps

Coding Method MH MH MH MH

Transmission Speed 15 sec 9 sec 9 sec 9 sec

CCITT Group G3 G3 G3 G3

Input/Output Width 8.5"/8.5" 8.5"/8.5" 8.5"/8.5" 8.5"/8.5"

Auto Cutter Yes Yes Yes Yes

ADF Capacity (pages) 15 15 15 15

Anti-curl System Yes Yes Yes Yes

Paper Size

LCD Size 16 x 1 16 x 1 16 x 1 16 x 1

On-screen Programming Yes Yes Yes Yes

Super Fine Yes Yes Yes Yes

Smoothing Yes Yes Yes Yes

Gray Scale 64 64 64 64

One-touch Dialing 10x2 10x2 10x2 10x2

Speed Dialing 40 40 40 80

Group Dialing 6 6 6 6

Telephone Index Yes Yes Yes Yes

Speakerphone Monitor Monitor Monitor Monitor

Fax/Tel Switch Yes Yes Yes Yes

TAD Interface Yes Yes Yes Yes

Enhanced Remote Activation Yes Yes Yes Yes

Distinctive Ringing Yes (Note 2) Yes (Note 3)

Next-Fax Reservation Yes Yes Yes Yes

Help Yes Yes Yes Yes

Caller ID Yes (Note 2) Yes (Note 3)

Automatic Redialing Yes Yes Yes Yes

Multi-Resolution Transmission Yes Yes Yes Yes

Polling Std/Sec/Del Std/Sec/Del Std/Sec/Del/Seq Std/Sec/Del/Seq

Delayed Transmission Yes, 3 timers Yes, 3 timers Yes, 3 timers Yes, 3 timers

Coverpage Yes Yes Yes Yes

Call Reservation Yes Yes Yes Yes

Call Back Message Yes Yes Yes Yes

Activity Report Yes Yes Yes Yes

Transmission Verification Report Yes Yes Yes Yes

Page Memory 10 pages 10 pages 50 pages 50 pages

ECM Yes Yes Yes Yes

Broadcasting Yes Yes Yes Yes

Quick Scanning Yes Yes Yes Yes

Out-of-Paper Reception Yes Yes Yes Yes

Multi Copy Yes, w/sort Yes, w/sort Yes, w/sort Yes, w/sort

Multi Transmission Yes Yes Yes Yes

TAD Type No No IC Digital IC Digital

ICM Recording Time No No (18 min) (18 min)

Remote Control No No Full Full

Paging No No Yes Yes

Toll Saver No No Yes Yes

Memo/2-Way Recording No No Yes Yes

Time/Date Stamp No No Yes Yes

Message Center No No Yes Yes

OGM No No Yes Yes

FAX Forwarding No No Yes Yes

FAX Retrieval No No Yes Yes

PCI (Missing link)

Password No No No No

Paper Save No No No No

Day-Night Mode No No No No

Elec. Vol. Control No No No No

FAX-on-demand Yes Yes

Voice-on-demand No No Yes Yes

Fax Mail Box No No Yes, 5 Yes, 5

Voice Mail Box No No Yes, 5 Yes, 5

(Standard thermal/Therma PLUS)

(* : w/o PC FAX RX)

164'/164' 164'/164' 164'/164' 164'/164'

Option Option Option Option

(Note 2) No: Taiwan

Yes: Other countries

(Note 3) No: Asia, Gulf, China, and Saudi Arabia

Yes: Other countries

I – 3

Page 9

Model FAX570 FAX575M FAX590DT/590MC

Color 1138/1293 (Note 4) 1138/1293 (Note 4) 1138/1293 (Note 4)

Modem Speed 9600 bps 9600 bps 14400 bps

Coding Method MH MH MH

Transmission Speed

CCITT Group G3 G3 G3

Input/Output Width A4/A4 A4/A4 A4/A4

Auto Cutter Yes Yes Yes

ADF Capacity (pages) 15 15 15

Anti-curl System Yes Yes Yes

Paper Size

LCD Size 16 x 1 16 x 1 16 x 1

On-screen Programming Yes Yes Yes

Super Fine Yes Yes Yes

Smoothing Yes Yes Yes

Gray Scale 32 64 64

One-touch Dialing 10x2 10x2 10x2

Speed Dialing 40 40 40

Group Dialing None 6 6

Telephone Index No Yes Yes

Speakerphone No No No

Fax/Tel Switch Yes Yes Yes

TAD Interface Yes Yes Yes

Enhanced Remote Activation Yes Yes Yes

Next-Fax Reservation Yes Yes Yes

Help Yes Yes Yes

Caller ID UK/Holland/Sweden UK UK/Holland/Sweden

Automatic Redialing Yes Yes Yes

Multi-Resolution Transmission Yes Yes Yes

Polling Std/Sec/Del Std/Sec/Del Std/Sec/Del/Seq

Delayed Transmission Yes, 1 timer Yes, 3 timers Yes, 3 timers

Coverpage Yes Yes Yes

Call Reservation Yes Yes Yes

Call Back Message Yes Yes Yes

Journal Report (Activity Report) Yes Yes Yes

Transmission Verification Report Yes Yes Yes

Page Memory (Brother chart) No 10 pages 55 pages

ECM No Yes Yes

Broadcasting No 60 60

Quick Scanning No No No

Out-of-Paper Reception No Yes Yes

Multi Copy No Yes, w/stack & sort Yes, w/stack & sort

Multi Transmission No Yes Yes

TAD Type No No IC Digital

ICM Recording Time No No 13 min

Remote Control No No Yes

Paging No No Yes

Toll Saver No No Yes

Time/Date Stamp No No Yes

Message Center No No Yes

OGM No No Yes

FAX Forwarding No No Yes

FAX Retrieval No No Yes

Connect 5000 Connectivity

(PCI or Missing link)

Backup for Voice No No 6 hours

Backup for Page Memory No No 6 hours

Backup for Clock 15 hours 15 hours 15 hours

Password No No No

FAX-on-demand No No Up to 50 messages

Voice-on-demand No No Up to 50 messages

Fax Mail Box No No Yes, 5

Voice Mail Box No No Yes, 5

(Standard thermal/Therma PLUS)

(Brother chart)

(ITU-T No. 1 chart)

(CCITT No. 1 chart) No 9 pages 49 pages

(* : w/o PC FAX RX)

15 sec 13 sec 9 sec

19 sec 15 sec 10 sec

50 m/50 m 50 m/50 m 50 m/50 m

No Yes Yes

(Note 4) 1293: German and UK versions

1138: Other versions

I – 4

Page 10

CHAPTER II.

INSTALLATION

Page 11

CHAPTER III.

THEORY OF OPERATION

Page 12

CONTENTS

1. OVERVIEW.....................................................................................................III-1

1.1Mechanical Layout................................................................................. III-1

1.2Functional Block Diagram...................................................................... III-1

2. MECHANISMS................................................................................................III-2

2.1Transmitting Mechanism (Feeding and Scanning Documents).............. III-2

2.1.1Automatic document feeder (ADF).................................................. III-2

2.1.2Scanner...........................................................................................III-2

2.2Receiving Mechanism (Feeding Recording Paper & Recording Data)... III-3

2.2.1Anti-curl system (ACS).................................................................... III-3

2.2.2Automatic cutter.............................................................................. III-3

2.3Sensors...................................................................................................III-4

2.4Power Transmission Shift by the Planetary Gear Train and

Clutch Solenoid.......................................................................................III-6

2.4.1Description of planetary gear train.................................................. III-6

2.4.2Power transmission for four operation modes................................. III-7

[ 1 ]Recording mode (Solenoid: OFF, Motor rotation: Forward)........ III-7

[ 2 ]Scanning mode (Solenoid: OFF, Motor rotation: Reverse).......... III-8

[ 3 ]Copying mode (Solenoid: ON ➞ OFF, Motor rotation: Forward). III-8

[ 4 ]Cutter driving mode (Solenoid: ON, Motor rotation: Reverse)..... III-9

2.4.3Power transmission route............................................................... III-10

3. CONTROL ELECTRONICS........................................................................... III-11

3.1Configuration...........................................................................................III-11

3.2Main PCB................................................................................................III-11

3.2.1FAX100/570/615/625/635/675/575M/715M.................................... III-12

[ 1 ]Primary function group................................................................ III-12

[ 2 ]ROM and DRAM group............................................................... III-13

[ 3 ]Image processing group............................................................. III-14

[ 4 ]Analog signal processing group.................................................. III-15

3.2.2FAX725M/590DT/590MC/825MC/875MC....................................... III-16

[ 1 ]Primary function group................................................................ III-16

[ 2 ]DRAM group............................................................................... III-17

Page 13

[ 3 ]Image processing group............................................................. III-18

[ 4 ]Analog signal processing group.................................................. III-19

[ 5 ]MODEM.......................................................................................III-20

3.3NCU PCB................................................................................................III-21

3.4Control Panel PCB................................................................................. III-23

3.5Power Supply..........................................................................................III-24

Page 14

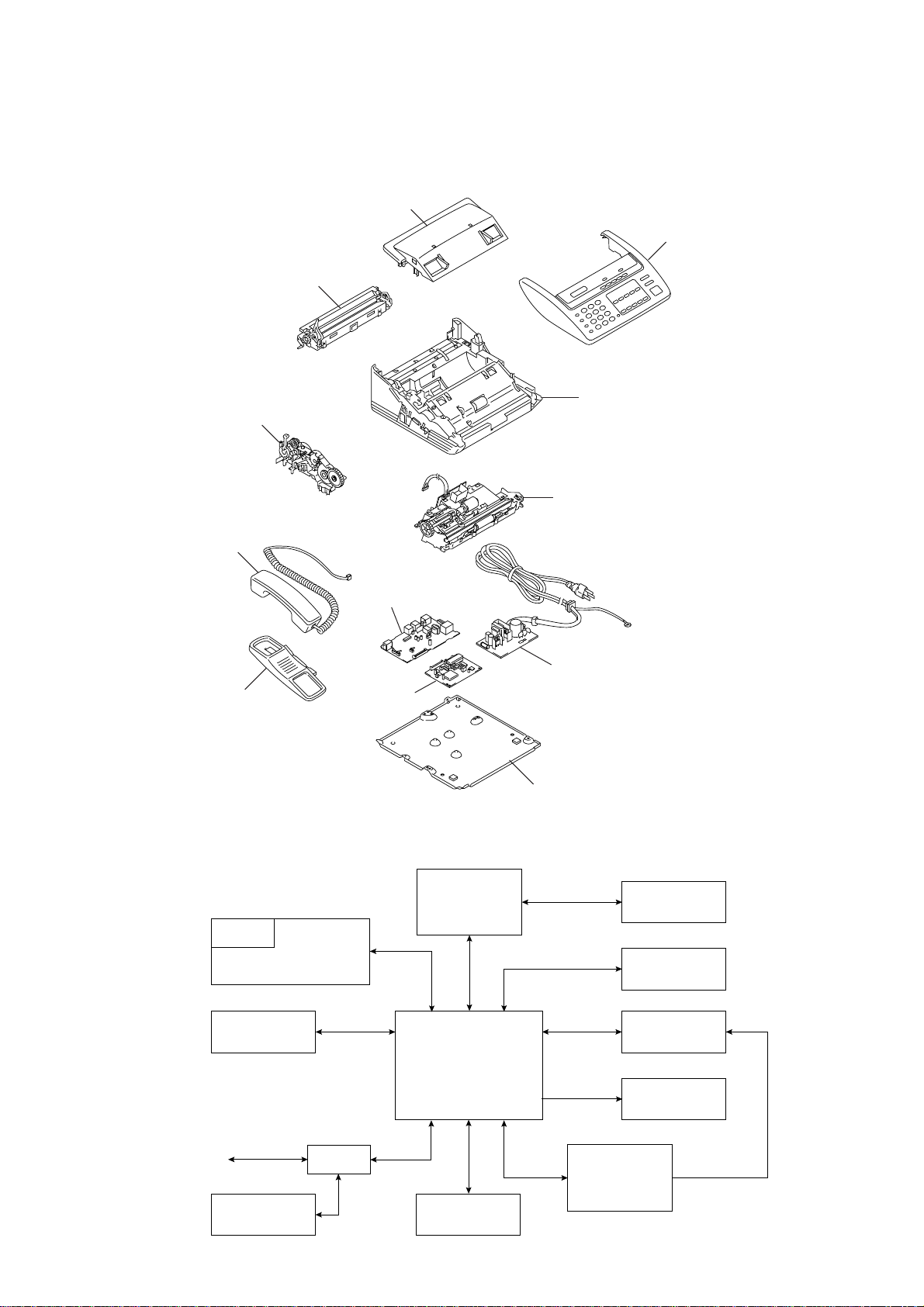

1. OVERVIEW

1.1 Mechanical Layout

Recording paper cover

Recorder & cutter unit

Drive unit

Handset

Panel cover ASSY

Main frame

Scanner frame ASSY

Handset mount

Main PCB

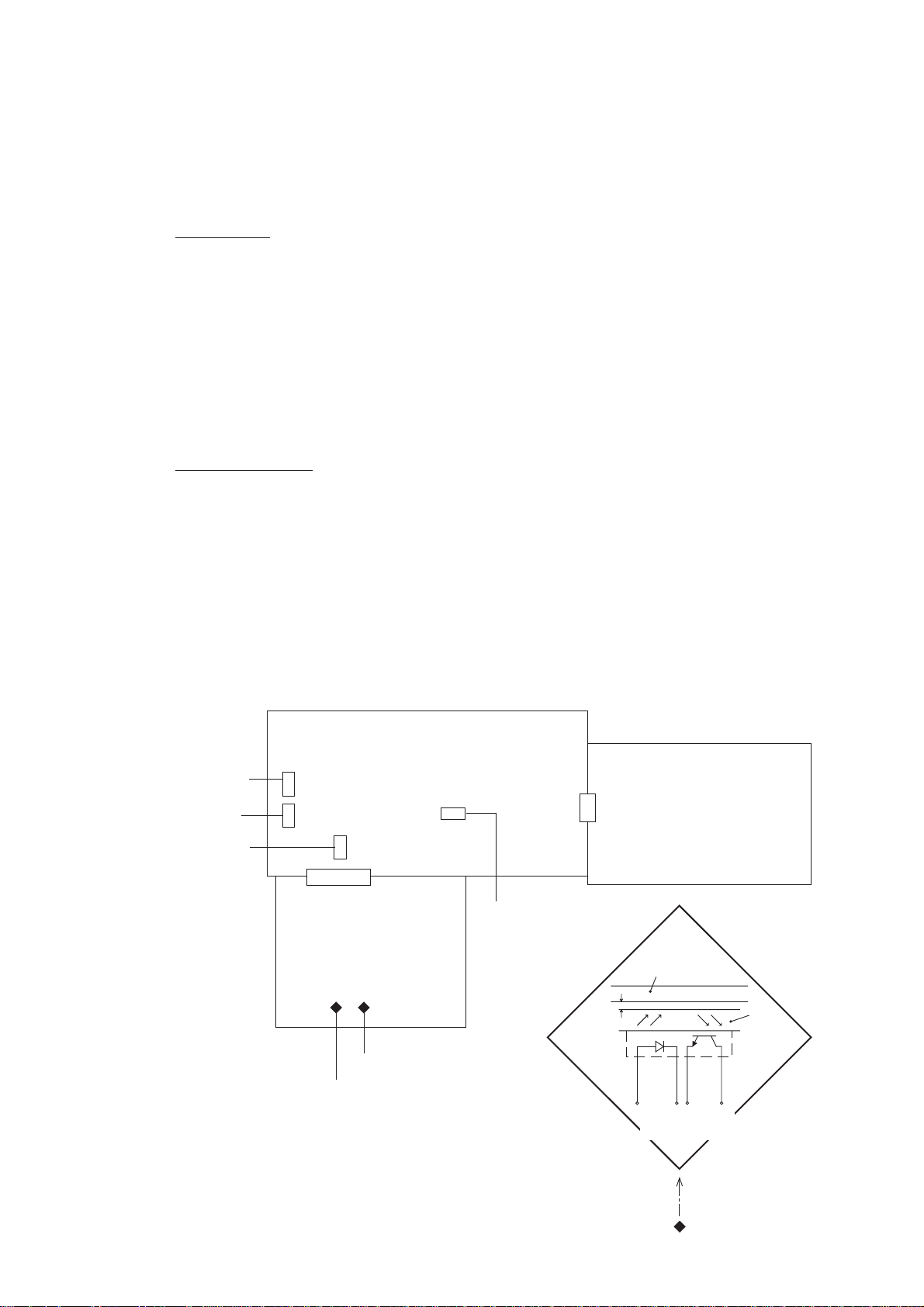

1.2 Functional Block Diagram

LCD

Control panel

Scanner

NCU PCB

(Missing link)

PCI

Power supply PCB

Bottom plate

PC

Automatic

cutter

Recorder

Line NCU

Telephone

Controller

Drive unit

Power supply

Speaker

III – 1

Page 15

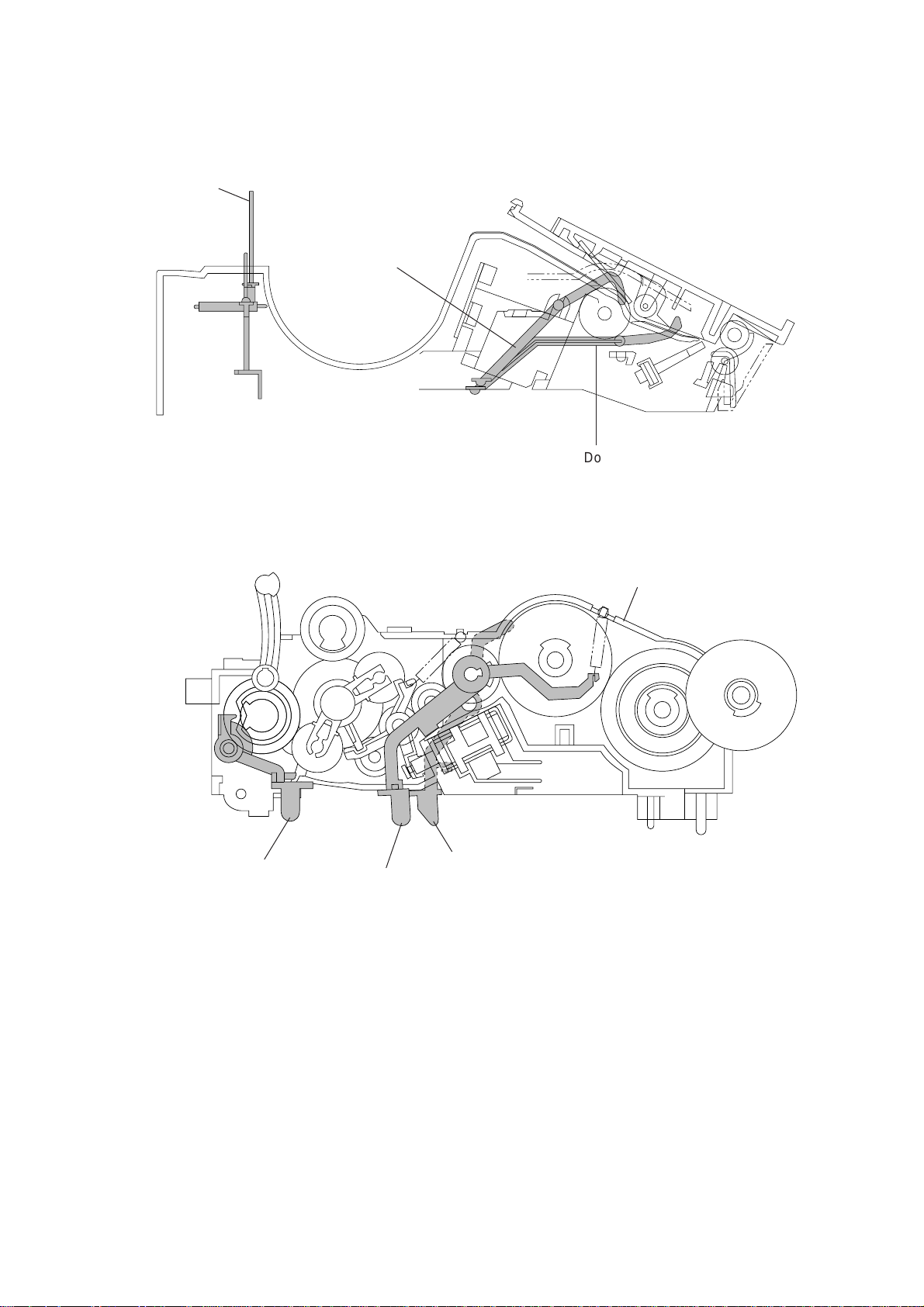

2. MECHANISMS

,

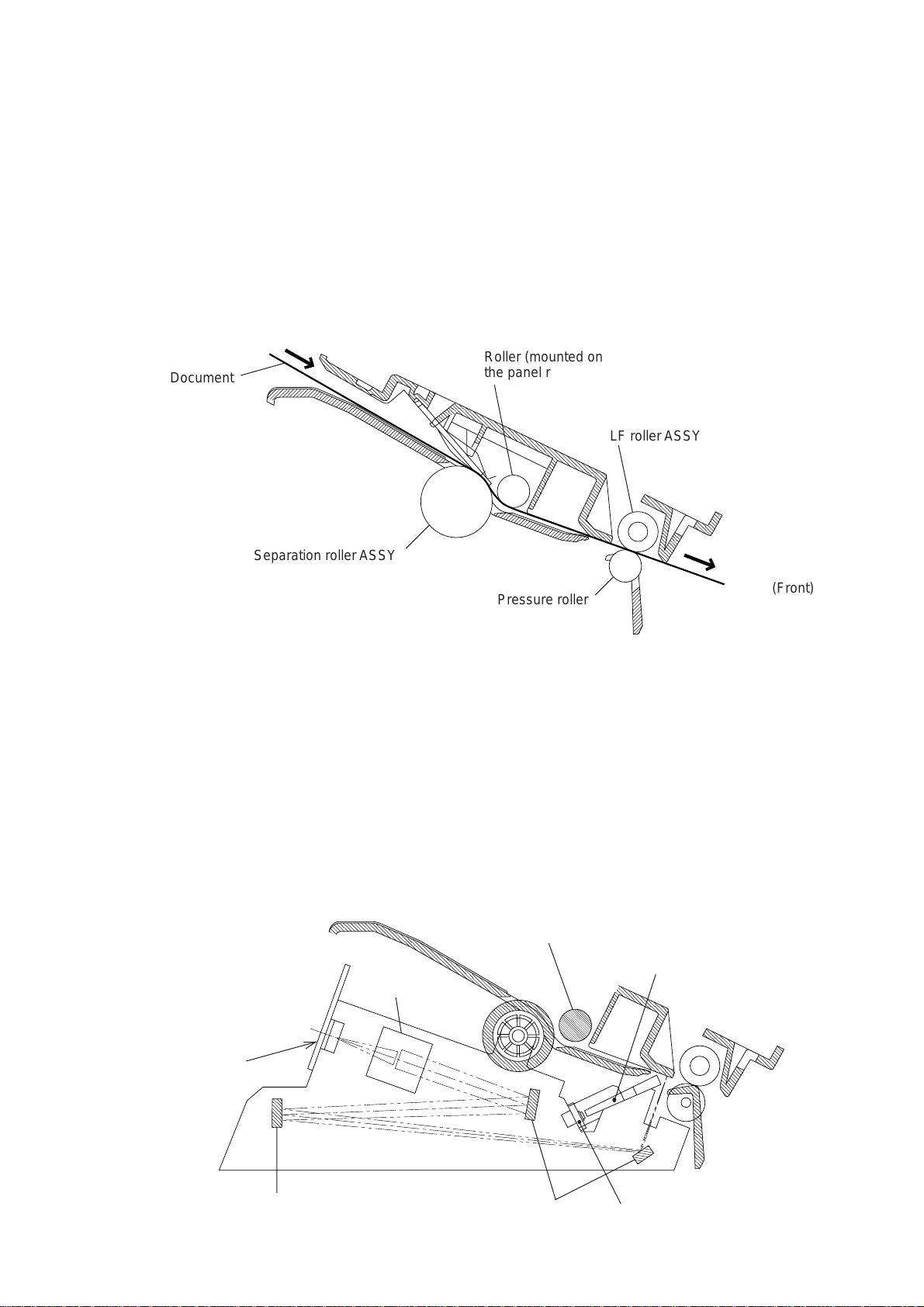

2.1 Transmitting Mechanism (Feeding and Scanning Documents)

The transmitting mechanism consists of the document stacker, automatic document feeder

(ADF), document feeding related rollers, scanner, and document sensors. (For details about

the sensors, refer to Section 2.3.)

If the operator sets documents on the stacker and starts the sending operation, the ADF

feeds those documents into the equipment, page by page. Each document advances with

the separation roller to the scanner, and then it is fed out of the equipment with the LF roller.

For the drive power source, refer to Section 2.4.

Roller (mounted on

Document

Separation roller ASSY

the panel rear cover)

LF roller ASSY

2.1.1 Automatic document feeder (ADF)

The ADF, which consists of the separation roller and separator, feeds documents set on the

document stacker, starting from the bottom sheet to the top, page by page, due to the frictional difference among the separation roller, the documents, and the separator.

2.1.2 Scanner

The scanner uses a charge coupled device (CCD) image sensor.

As shown below, the LED array illuminates a document and the reflected light of the scanned

image data is transmitted via the mirrors into the lens which reduces the scanned data so as

to form the image on the CCD.

Lens

Pressure roller

Separation roller ASSY

(Front)

Bar lens

CCD PCB

Mirror

(Front)

Mirrors LED array

III – 2

Page 16

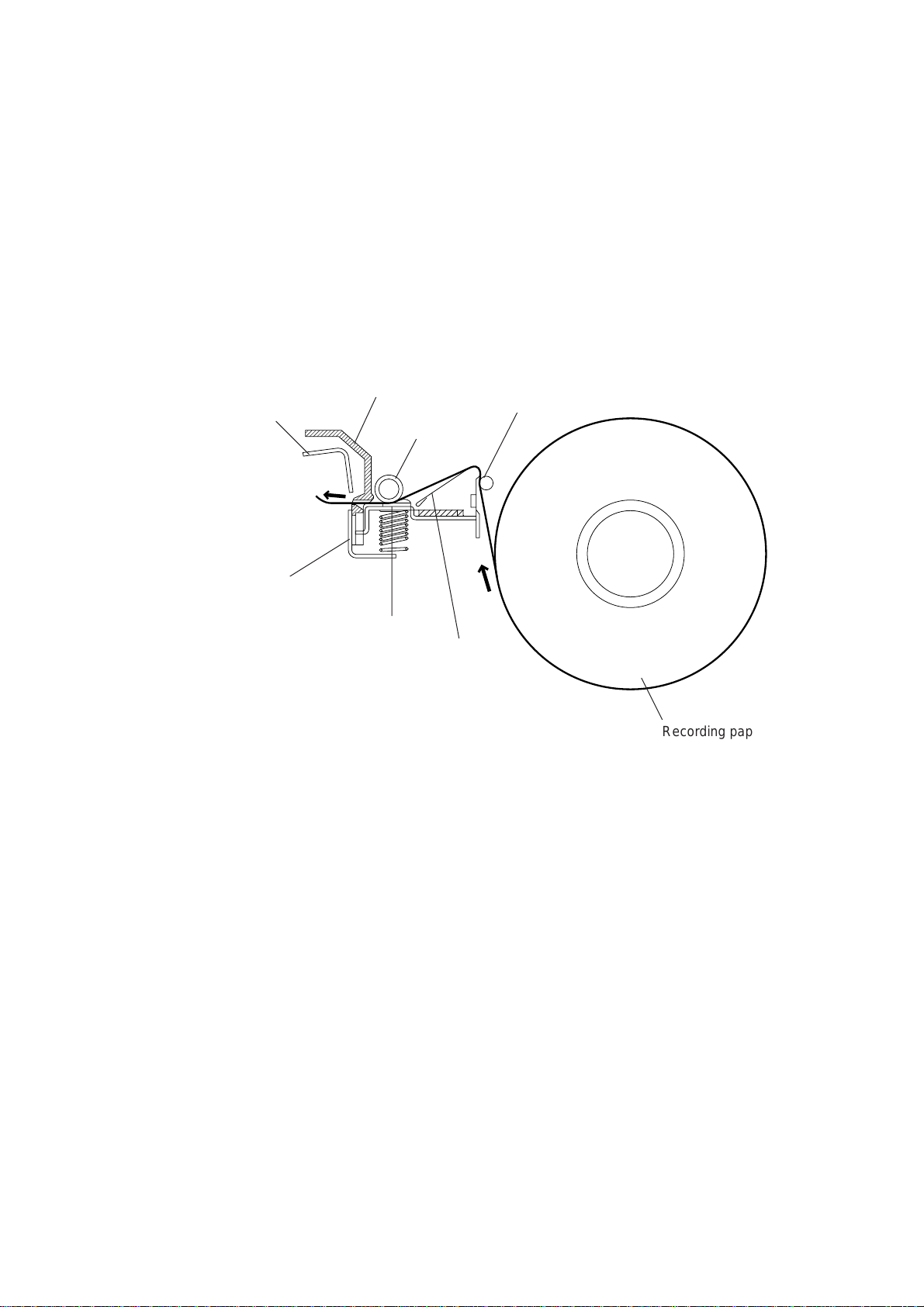

2.2 Receiving Mechanism (Feeding Recording Paper & Recording Data)

The receiving mechanism consists of the recording paper roll holder, anti-curl system (ACS),

platen, thermal recording head, automatic cutter, and sensors. (For details about the sensors, refer to Section 2.3.)

The recording paper is routed through the ACS to the recording head which prints onto the

heat-sensitive recording paper pressed by the platen according to received image signals.

The printed paper is further fed through the cutter chute and cut by the automatic cutter page

by page.

For the drive power source, refer to Section 2.4.

Upper blade

Lower blade

(Rear)

2.2.1 Anti-curl system (ACS)

The ACS eliminates curl peculiar to the rolled recording paper by curving the paper towards

the opposite side of the curl with the ACS rod and the ACS plate.

Cutter chute

Platen

Recording

head

ACS rod

ACS plate

Recording paper roll

2.2.2 Automatic cutter

The automatic paper cutter consists of an upper blade (rotary) and a lower blade (stationary). As the upper blade rotates around the left end as a support, the recording paper will be

cut. Upon completion of cutting operation, the upper blade returns to the home position

which is detected by the cutter sensor.

III – 3

Page 17

2.3 Sensors

This equipment has two photosensors and four mechanical sensors as described below.

Photosensors

• Document front sensor which detects a presence of documents.

• Document rear sensor which detects the leading and trailing edges of pages to tell the

control circuitry when the leading edge of a new page has reached the starting position

and when the scan for that page is over.

These two photosensors are located on the main PCB. They are of a reflection type consisting of a light-emitting diode and a light-receiving transistor. Each of them has an actuator

separately arranged (see the next page). If an actuator is activated, its white end will come

to the path of light issued from the light-emitting diode and reflect its light. The moment the

reflected light enters the light-receiving transistor, the sensor signals the detection.

Mechanical sensors

• PE (paper empty) sensor which detects whether the recording paper is present.

• Cover sensor which detects whether the recording paper cover is closed.

• Cutter sensor which detects the home position of the upper rotary blade of the automatic

cutter.

• Hook switch sensor which detects whether the handset is placed on the handset mount.

These four sensors are located on the NCU PCB. Each of them has an actuator separately

arranged (see the next page). If an actuator is activated, its lower end pushes down the lever provided on the corresponding sensor so that the sensor signals the detection.

(Rear)

NCU PCB

Cutter sensor

Hook switch

sensor

Cover sensor

SW3

SW4

SW2

PH1 PH2

Main PCB

SW1

PE sensor

Approx.

0.7 mm

Power supply PCB

Path of

actuator's end

Glass

Document rear sensor

Document front sensor

III – 4

Lightemitting

diode

Lightreceiving

transistor

Page 18

PE sensor

actuator

Document front

sensor actuator

(Front)

Document rear sensor actuator

Drive unit

Cutter sensor

actuator

(Front)

Cover sensor actuator

Hook switch

sensor actuator

Location of Sensor Actuators

III – 5

Page 19

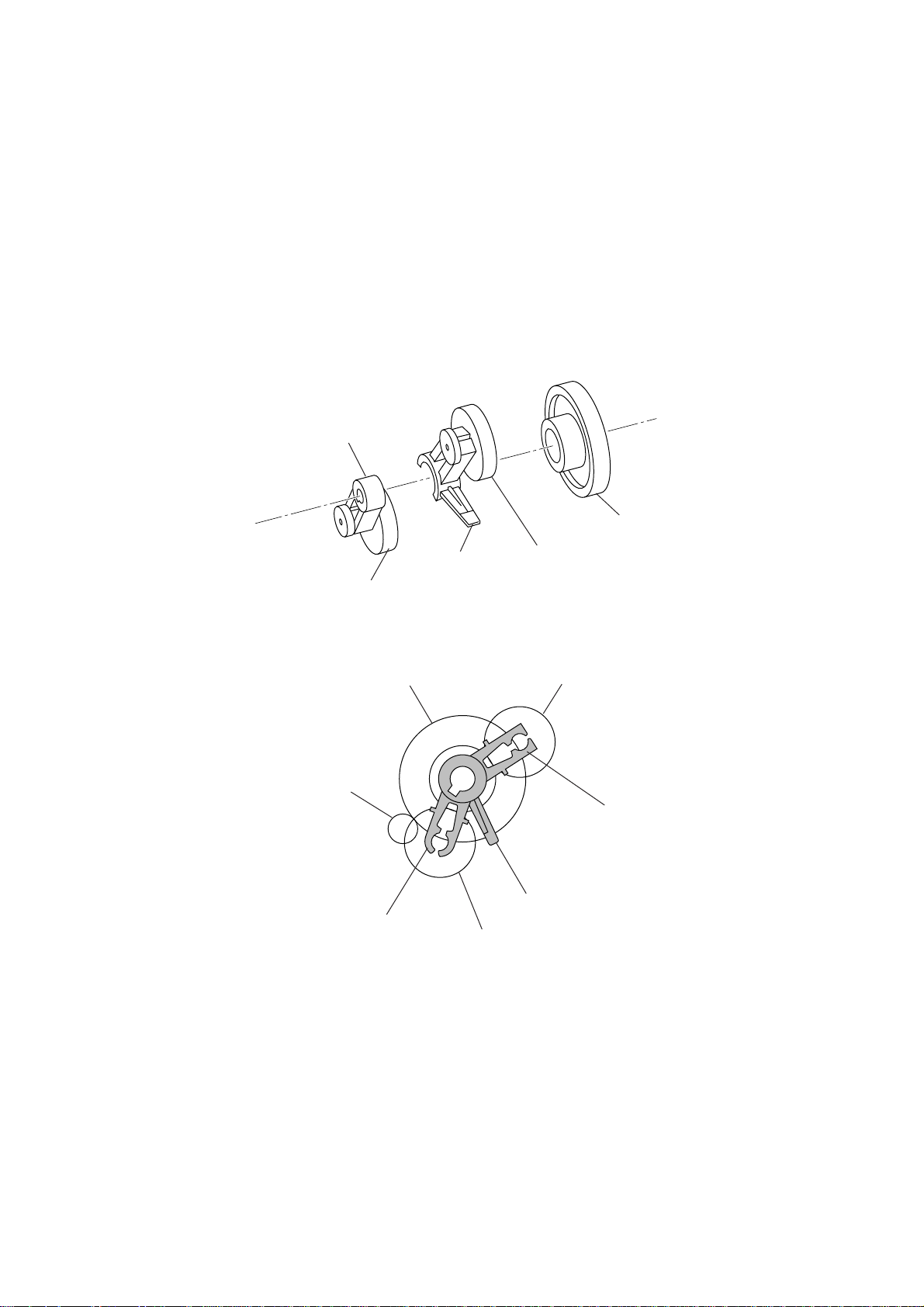

2.4 Power Transmission Shift by the Planetary Gear Train and Clutch Solenoid

The equipment has a single drive motor whose power transmission route can be switched by

the planetary gear train and the clutch solenoid. Accordingly, the equipment mechanism can

function in four operation modes (recording, scanning, copying, and cutter driving modes).

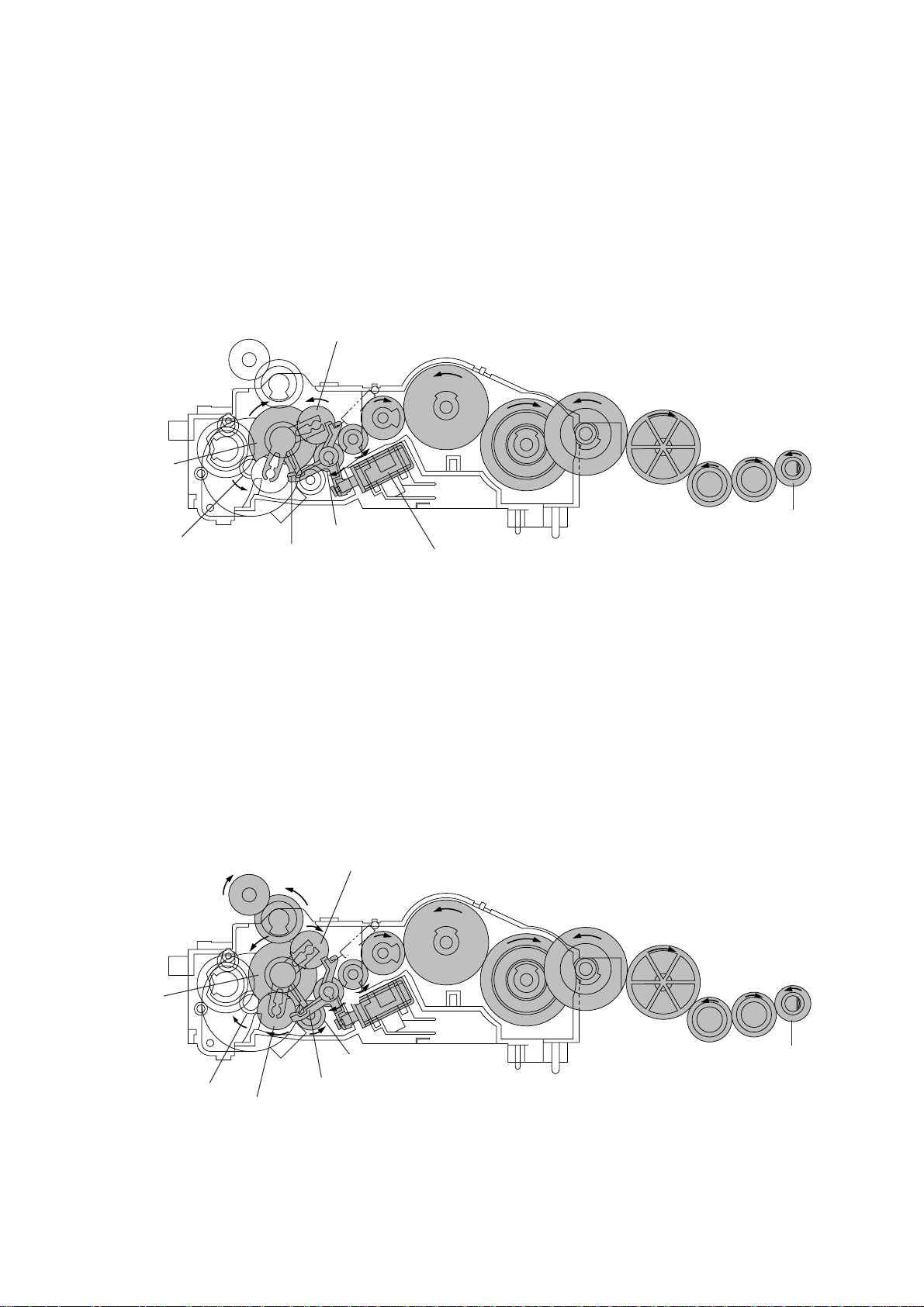

2.4.1 Description of planetary gear train

The planetary gear train consists of the sun gear 18/73, two planet gears 20, arm A, and arm

B, as shown below.

Arm B

Sun gear 18/73

Arm A

Planet gear 20B

Sun gear 18/73

Motor gear

Arm A

Planet gear 20A

Planet gear 20A

Planet gear 20B

Arm B

Stopper of arm A

If the motor rotates, the sun gear 18/73 rotates so that the rotational force is transmitted to

the engagement between the sun gear and the planet gears 20. Since the arms and planet

gears are so designed that the moment of the arms is less than that of the planet gears, the

arms turn around the center shaft in the same direction as the sun gear 18/73.

If the planet gear(s) becomes engaged with any other gear so that the arm cannot turn furthermore, the rotational force of the sun gear 18/73 is transmitted to that planet gear. Accordingly, the planet gear starts rotation in the opposite direction of the sun gear 18/73.

III – 6

Page 20

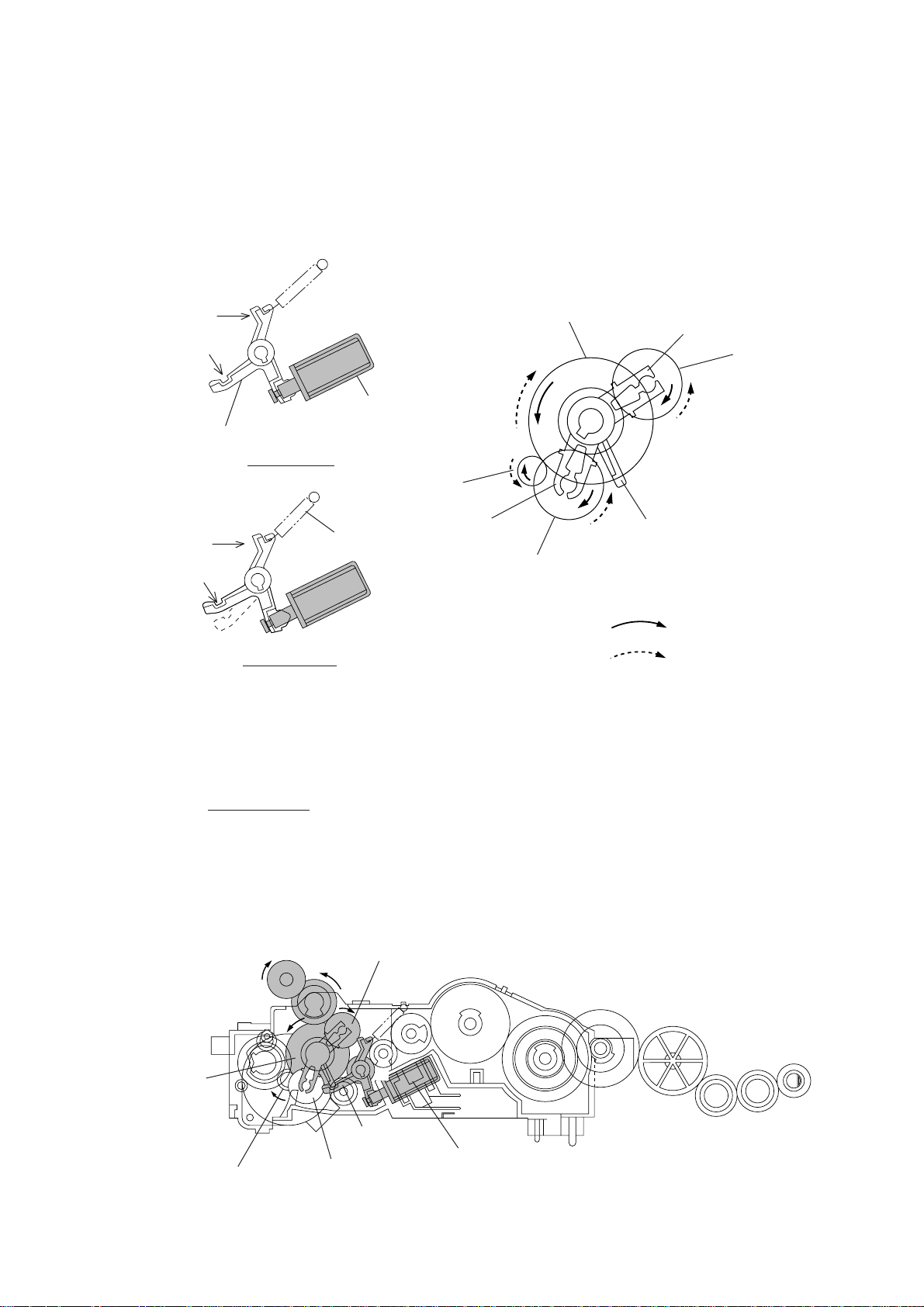

2.4.2 Power transmission for four operation modes

Depending upon the clutch solenoid ON/OFF state and the motor rotation direction, the planetary gear train switches the power transmission route for the four operation modes.

Section Y

Cutout X

Clutch lever

Section Y

Cutout X

(engaged

with stopper

of arm A)

[ 1 ] Recording mode (Solenoid: OFF, Motor rotation: Forward)

Solenoid: ON

Solenoid: OFF

Spring

Solenoid

Motor gear

Arm A

Sun gear 18/73

Arm B

Planet gear

20B

Stopper of arm A

Planet gear 20A

Forward

Reverse

In the recording mode, the control system deactivates the clutch solenoid (see the above figure, Solenoid: OFF). Therefore, when the motor rotates in the forward direction, the clutch

lever turns clockwise with the spring and its cutout X becomes engaged with the stopper of

arm A. Once arm A is locked, the planet gear 20A (C2) will not be engaged with any other

gear but simply idle.

The motor rotation turns the sun gear 18/73 (B) counterclockwise so that the planet gear 20B

(C1) transmits the rotation to the platen gear (E) via the gear D.

B (Sun gear

18/73)

E (Platen gear)

A (Motor gear)

C1 (Planet gear 20B)

D

F

Cutout X of

clutch lever

C2 (Planet

gear 20A)

(Front)

Clutch

solenoid

III – 7

Page 21

[ 2 ] Scanning mode (Solenoid: OFF, Motor rotation: Reverse)

Just as in the recording mode, the control system deactivates the clutch solenoid in the

scanning mode to lock arm A.

The motor rotates in the reverse direction and the sun gear 18/73 (B) rotates clockwise so

that the planet gear 20A (C2) transmits the rotation to the separation roller gear (L) and LF

roller gear (O) via the several gears.

C2 (Planet

gear 20A)

I

B (Sun gear

18/73)

A (Motor gear)

[ 3 ] Copying mode (Solenoid: ON ➞ OFF, Motor rotation: Forward)

F

Cutout X of

clutch lever

H

J

G

Clutch solenoid

K

L (Separation

roller gear)

M

(Front)

N

O (LF roller

gear)

The control system at first activates the clutch solenoid to release the stopper of arm A from

coutout X of the clutch lever while rotating the motor in the forward direction. Accordingly,

the sun gear 18/73 (B) rotates counterclockwise so that both the planet gears 20B (C1) and

20A (C2) transmit the rotation to the platen gear (E) and the roller gears (separation roller

gear and LF roller gear), respectively.

Once the planet gear 20A becomes engaged with the gear P, the control system deactivates

the clutch solenoid.

B (Sun gear

18/73)

A (Motor gear)

E (Platen gear)

C2 (Planet gear 20A)

C1 (Planet gear 20B)

D

H

G

F

P

Clutch lever

I

III – 8

K

J

L (Separation

roller gear)

M

(Front)

N

O (LF roller

gear)

Page 22

[ 4 ] Cutter driving mode (Solenoid: ON, Motor rotation: Reverse)

B (Sun gear

18/73)

Q (Cutter

gear)

The control system activates the clutch solenoid to release the stopper of arm A from cutout

X of the clutch lever. When the motor rotates in the reverse direction, the sun gear 18/73

(B) rotates clockwise so that the planet gear 20A (C2) transmits the rotation to the cutter

gear (Q).

Since the planet gear 20B (C1) is blocked by section Y of the clutch lever, it remains idling

without engaging with any other gear.

C1 (Planet gear 20B)

Section Y of clutch lever

(Front)

C2 (Planet gear 20A)

III – 9

Page 23

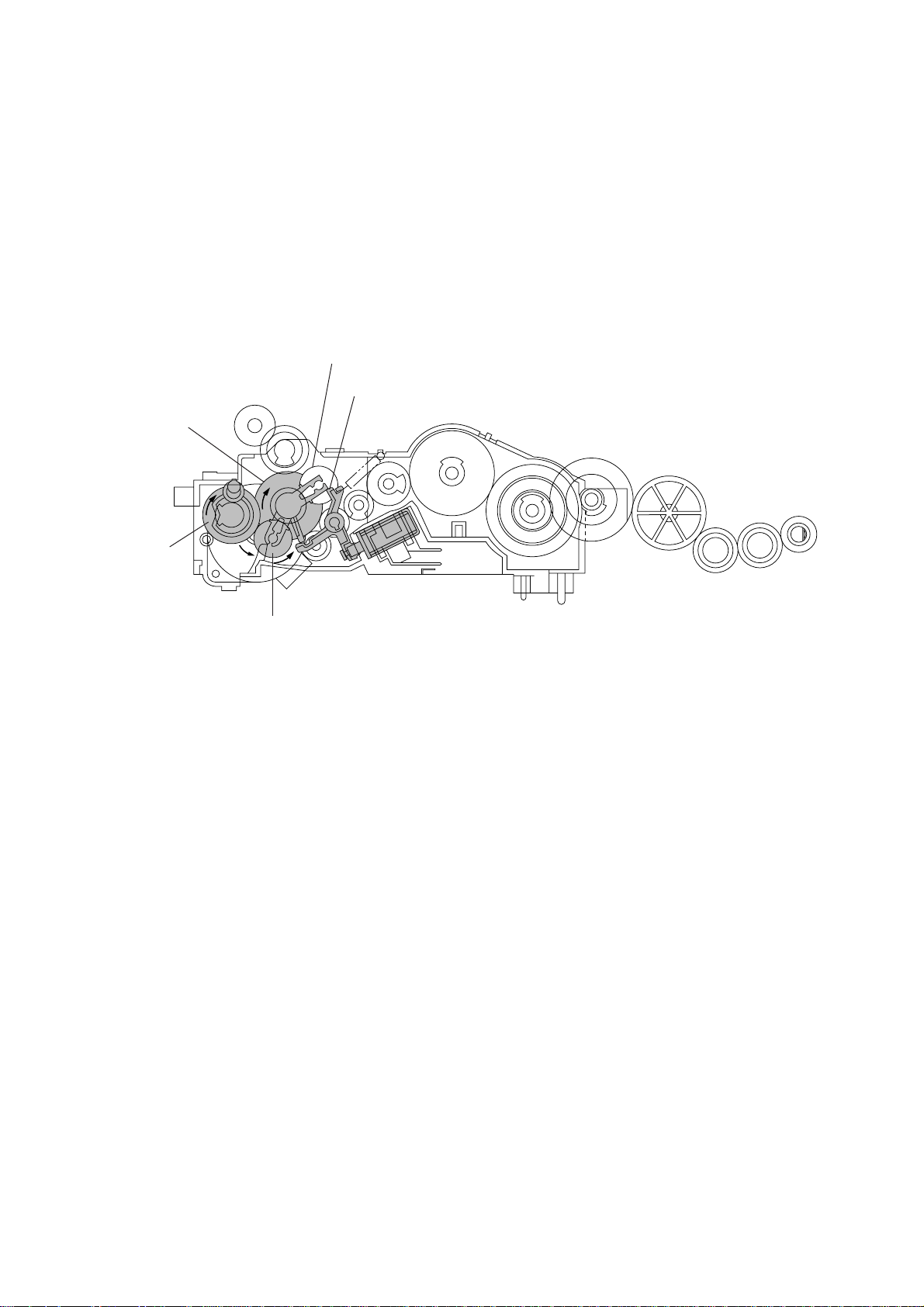

2.4.3 Power transmission route

Rotation of the motor gear is transmitted as shown below.

E

D

B

Q

A

C2

A: Motor gear

B: Sun gear 18/73

C1: Planet gear 20B

C2: Planet gear 20A

D: Gear 18/26

E: Platen gear

F: Gear 16A

G: Gear 16B

H: Gear 24

C1

H

G

F

P

I

J

K

L

O

M

N

I: Gear 44A

J: Gear 21/50

K: Gear 44B

L: Separation roller gear

M: Idle gear 24A

N: Idle gear 24B

O: LF roller gear

P: Gear 16C

Q: Cutter gear

[ 1 ] Recording Mode (Solenoid: OFF, Motor rotation: forward)

C1 ➔ D ➔ E

A ➔ B

C2 (idling)

[ 2 ] Scanning Mode (Solenoid: OFF, Motor rotation: reverse)

C1 (idling)

A ➔ B

C2 ➔ F ➔ G ➔ H ➔ I ➔ J ➔ K ➔ L ➔ M ➔ N ➔ O

[ 3 ] Copying Mode (Solenoid: ON ➔ OFF, Motor rotation: forward)

C1 ➔ D ➔ E

A ➔ B

C2 ➔ P ➔ F ➔ G ➔ H ➔ I ➔ J ➔ K ➔ L ➔ M ➔ N ➔ O

[ 4 ] Cutter Driving Mode (Solenoid: ON, Motor rotation: reverse)

C1 (idling)

A ➔ B

C2 ➔ Q

III – 10

Page 24

3. CONTROL ELECTRONICS

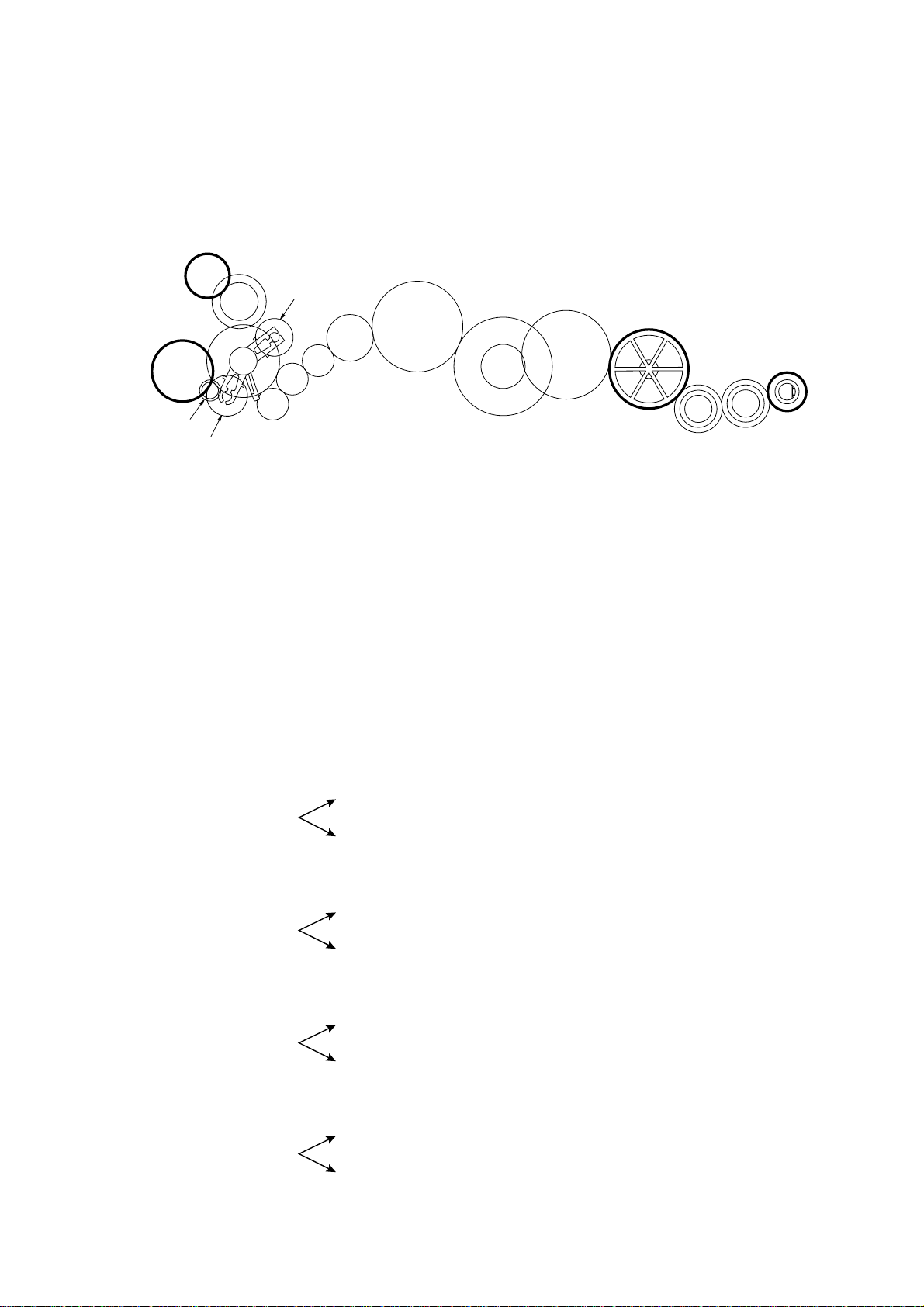

3.1 Configuration

The hardware configuration of the facsimile equipment is shown below.

Speaker

Motor

Handset

Solenoid

Line

2-pin 8-pin

2-pin

4-pin

NCU PCB

(See NOTE

below.)

Main PCB

2-pin

6-pin

2-pin

12-pin

2-pin

26-pin

FAX

engine

LED array

Thermal recording head

NOTE: The FAX engine includes a CPU and gate array. In the FAX100/570/

615/625/635/675/575M/715M, it also includes a MODEM.

*1 On the NCU PCB are the

following switches:

PC

• PE sensor (SW1)

• Cover sensor (SW2)

• Cutter sensor (SW3)

• Hook switch sensor (SW4)

*

Power

8-pin

supply

PCB

*1

2 On the main PCB are the

following photosensors:

• Document front sensor

(PH1)

• Document rear sensor (PH2)

14-pin

5-pin

LCD

LEDs

*2

10-pin

CCD

PCB

13-pin

FPC key

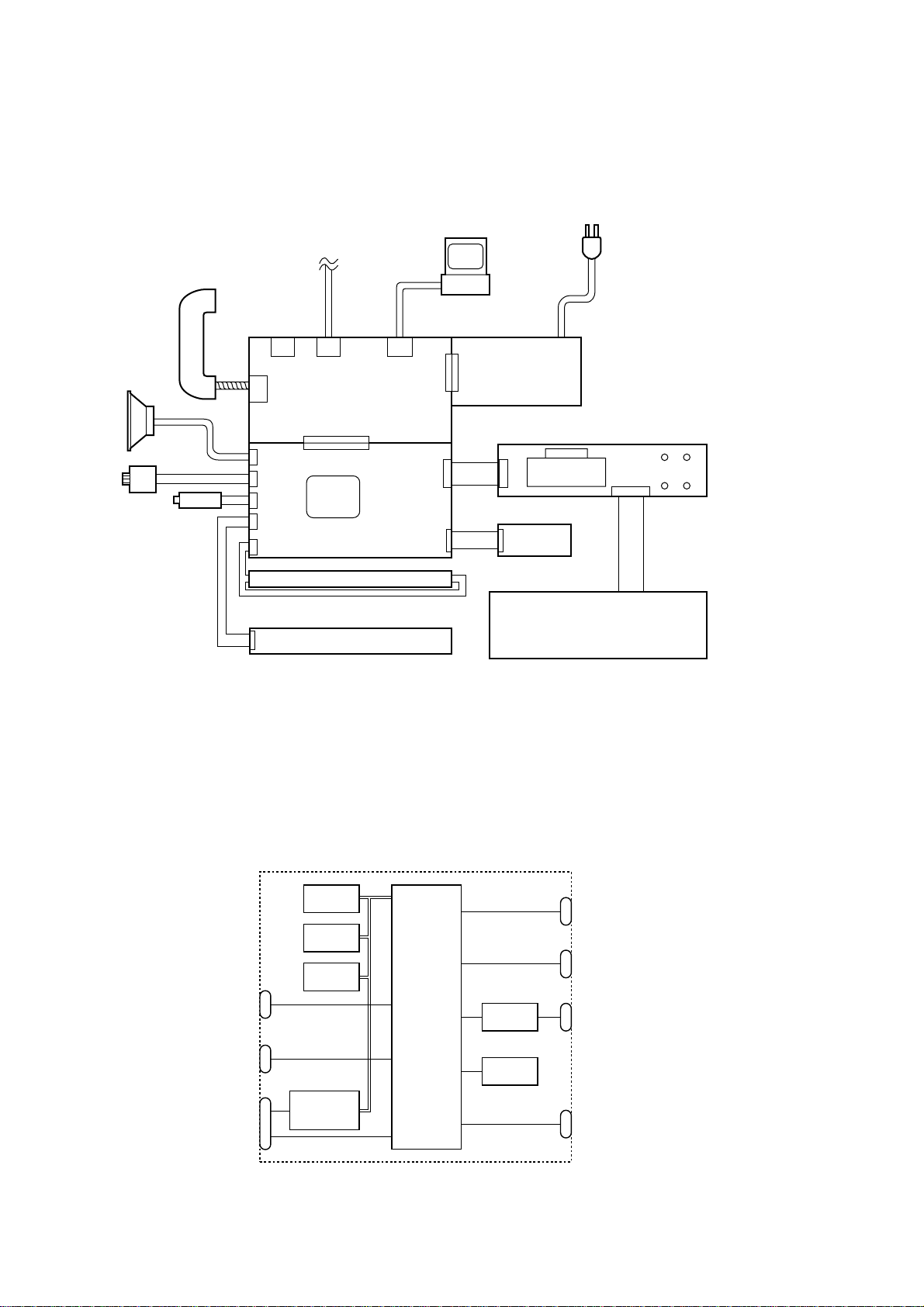

3.2 Main PCB

The main PCB, which is the nucleus controlling the entire operation of the equipment, consists of a FAX engine (ASIC), memories, MODEM (except for FAX100/570/615/625/635/675/

575M/715M)

recording, and power transmission switching.

NCU and

Power supply

Speaker

LED array and

CCD PCB

Configuration of Facsimile Equipment

, motor drive circuitry, sensor detection circuitry, and analog circuits for scanning,

ROM

E2PROM

DRAM

Image

processor

FAX

engine

(ASIC)

Motor

driver

Sensors

Control panel

Recording head

Motor

PCI

E2PROM: Electrically Erasable Programmable Read-only Memory

DRAM: Dynamic Random Access Memory

Block Diagram of Main PCB

III – 11

Page 25

3.2.1 FAX100/570/615/625/635/675/575M/715M

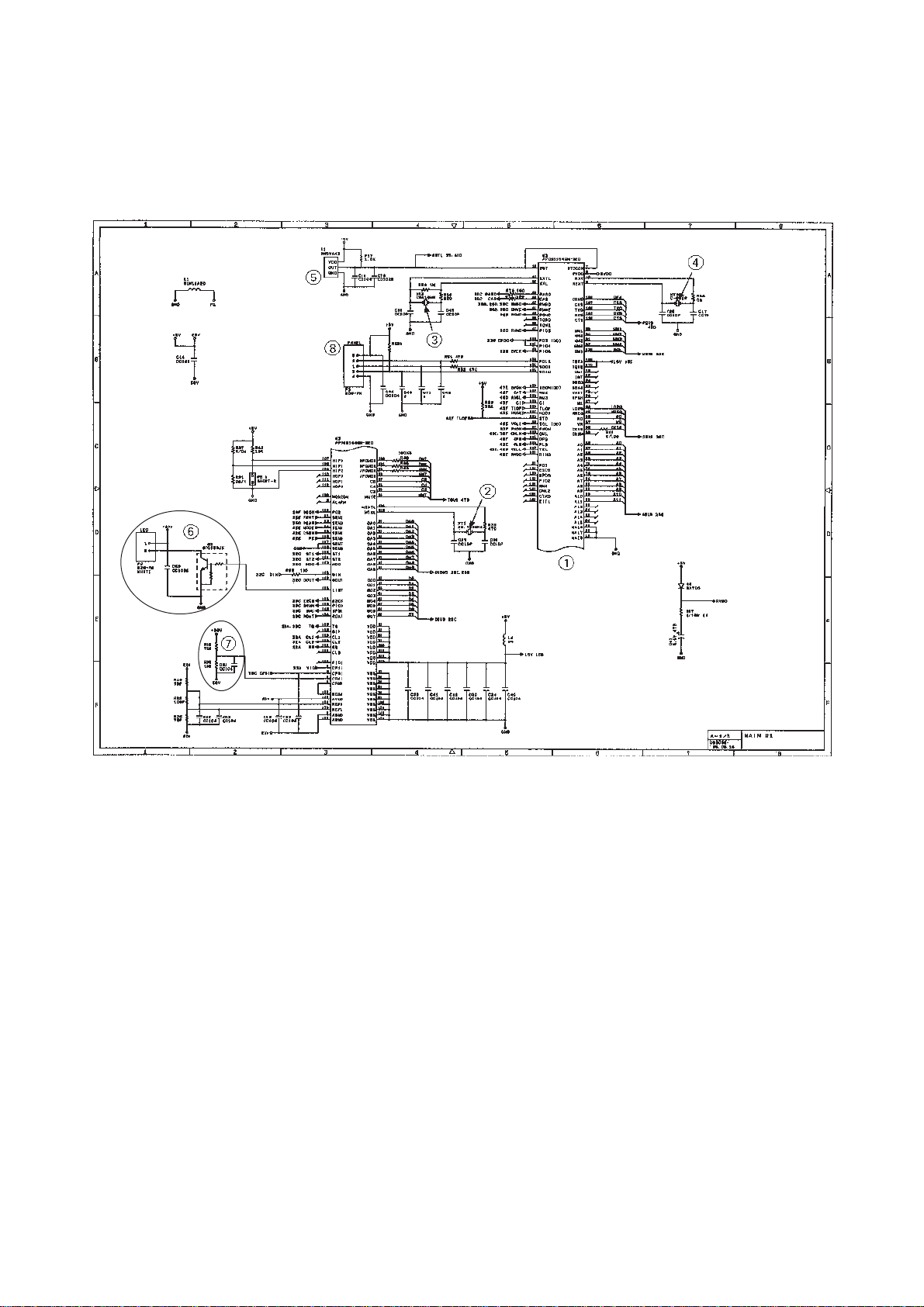

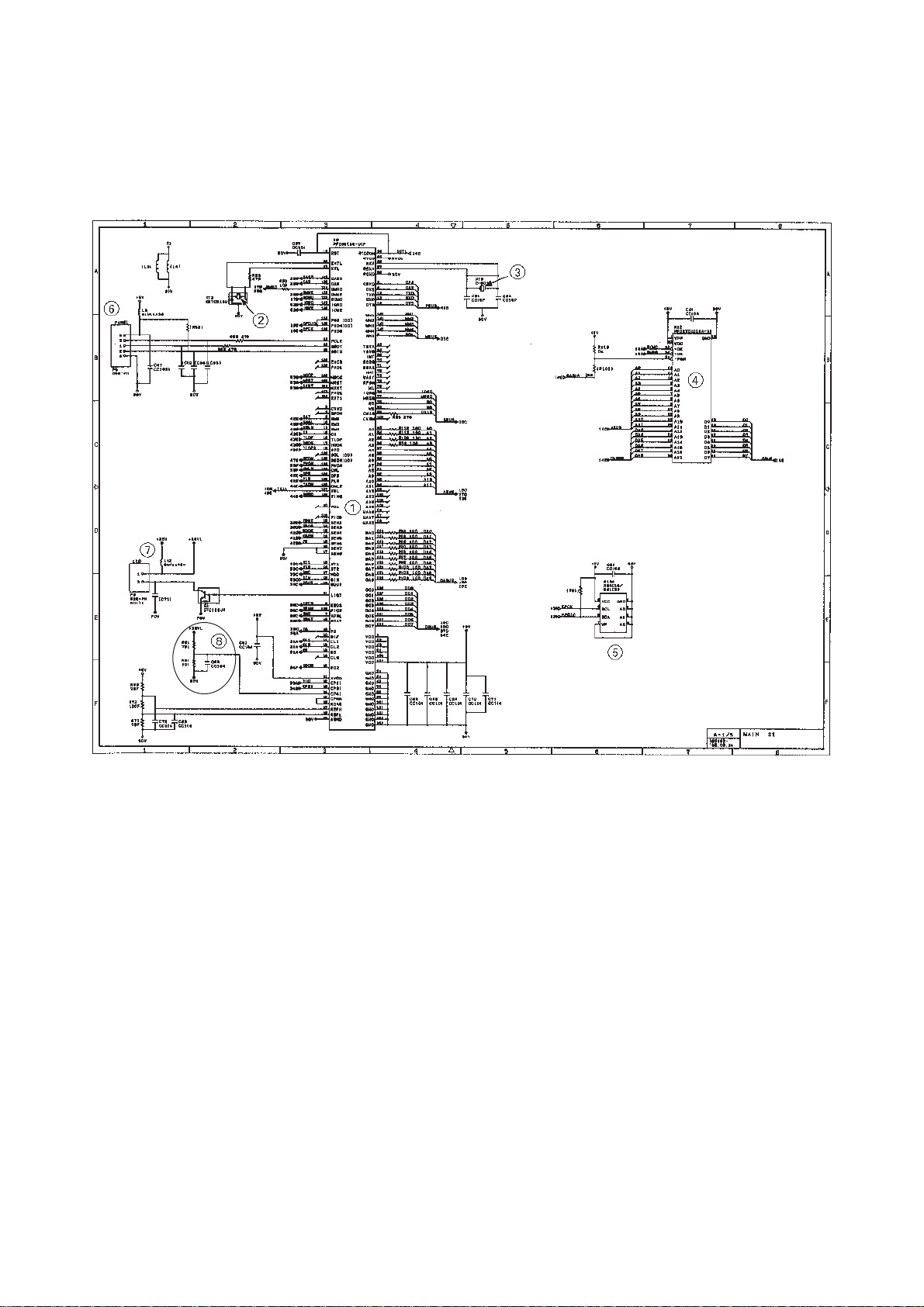

[ 1 ] Primary function group

Main PCB Circuit Diagram 1/4

1 FAX engine (ASIC) which integrates a CPU, MODEM and gate array

2 Clock for MODEM

3 Clock for CPU

4 Clock for calendar clock

5 Reset IC

6 LED array light intensity control circuit and connector

7 Recording head drive voltage detector

8 Control panel connector

III – 12

Page 26

[ 2 ] ROM and DRAM group

Main PCB Circuit Diagram 2/4

1 ROM (2-megabit. Note that the sample machines for demonstration have a 4-

megabit ROM.)

2 E2PROM (16-kilobit)

3 DRAM (256-kilobit) for the FAX100/570/615/625/635/675

4 DRAMs (256-kilobit) for the FAX575M/715M

III – 13

Page 27

[ 3 ] Image processing group

Main PCB Circuit Diagram 3/4

1 Image processor (Image processing IC)

2 Connector for the CCD PCB

3 Recording head temperature detector and head connector

4 Motor driver and connector

5 Clutch solenoid connector

6 Document front sensor (photosensor)

7 Document rear sensor (photosensor)

III – 14

Page 28

[ 4 ] Analog signal processing group

Main PCB Circuit Diagram 4/4

1 Analog front end IC

Processes the analog I/O signals from/to the MODEM.

2 Main-NCU connector

3 Analog signal selectors

3-1: Selects either RL1 or RL2 signals inputted from the communications net-

work.

3-2: Selects either input signals from the handset or those from the MODEM.

3-3: Selects either sound signals (e.g. alarm beeps, key clicks and ringer sounds)

generated by the FAX engine or signals selected by 3-1.

4 Amplifier circuit for signals outputted from the MODEM

5 Amplifier & shaper circuit for signals inputted from the communications network

6 Speaker amplifier circuit

Amplifies sounds issued from the above analog signal selector (3) and feeds them

to the speaker.

7 Speaker connector

III – 15

Page 29

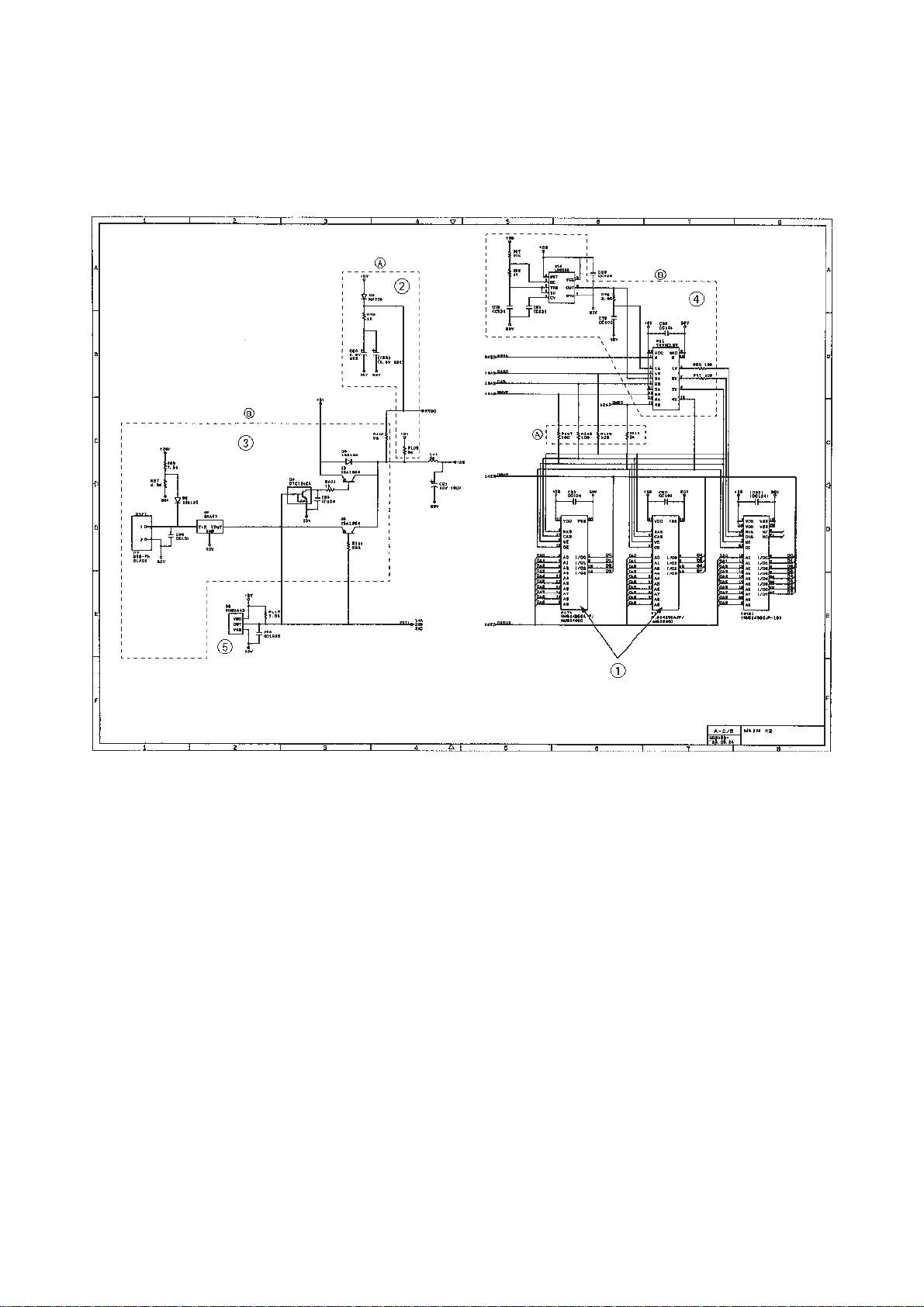

3.2.2 FAX725M/590DT/590MC/825MC/875MC

[ 1 ] Primary function group

Main PCB Circuit Diagram 1/5

1 FAX engine (ASIC) which integrates a CPU and gate array.

2 Clock for CPU

3 Clock for calendar clock

4 ROM (2-megabit. Note that the sample machines for demonstration have a 4-

megabit ROM.)

5 E2PROM (16-kilobit in the FAX725M/590DT/590MC/825MC, 32-kilobit in the

FAX875MC)

6 Control panel connector

7 LED array light intensity control circuit and connector

8 Recording head drive voltage detector

III – 16

Page 30

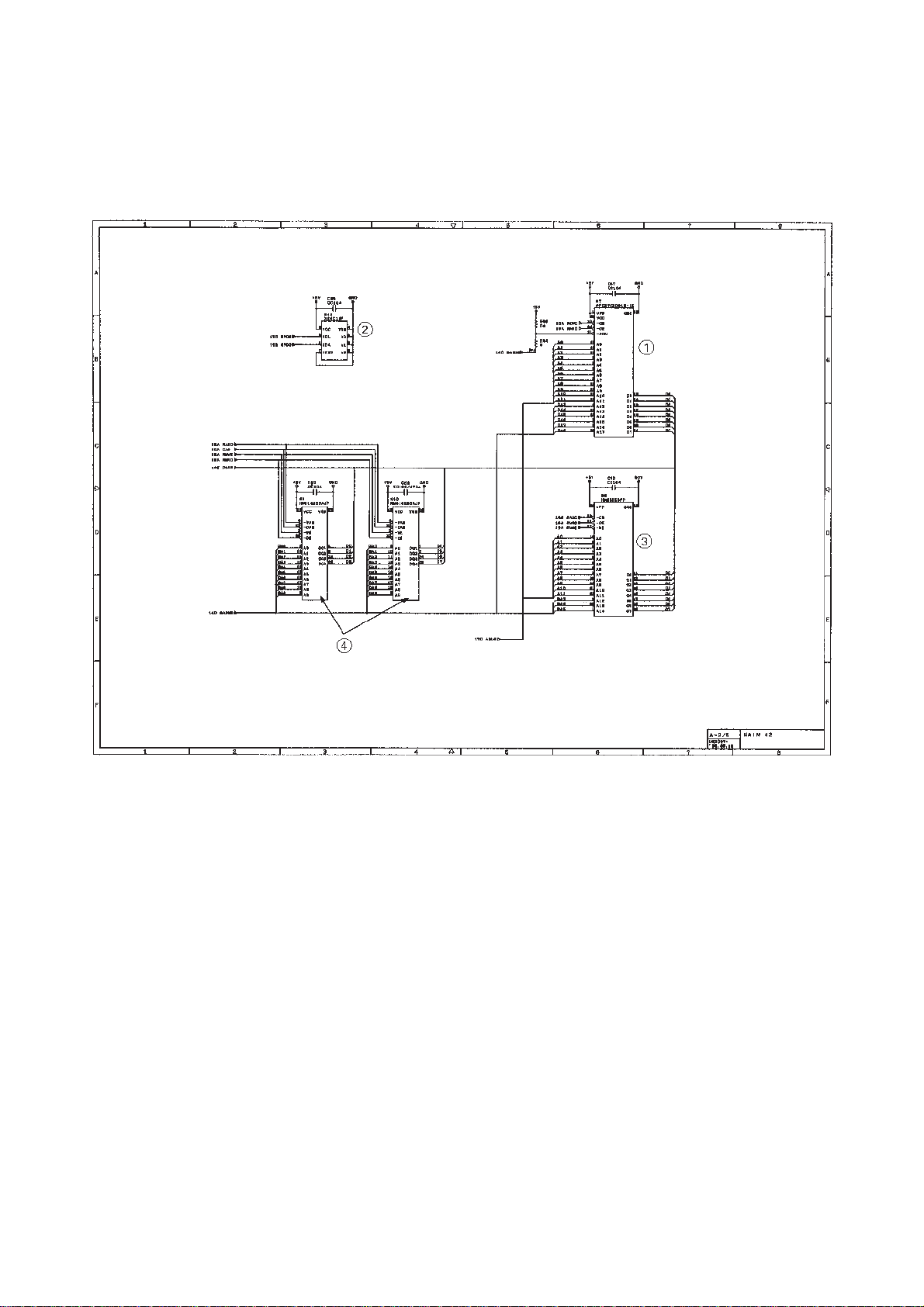

[ 2 ] DRAM group

Main PCB Circuit Diagram 2/5

1 DRAMs

FAX725M: Two 256-kilobyte DRAMs

FAX590DT/590MC/825MC/875MC: Two 512-kilobyte DRAMs

2 Calendar clock backup circuit (for the FAX725M)

3 DRAM backup circuit and nickel-hydrogen battery connector (for the FAX590DT/

590MC/825MC/875MC)

4 DRAM refresh circuit (for the FAX590DT/590MC/825MC/875MC)

5 Reset IC

III – 17

Page 31

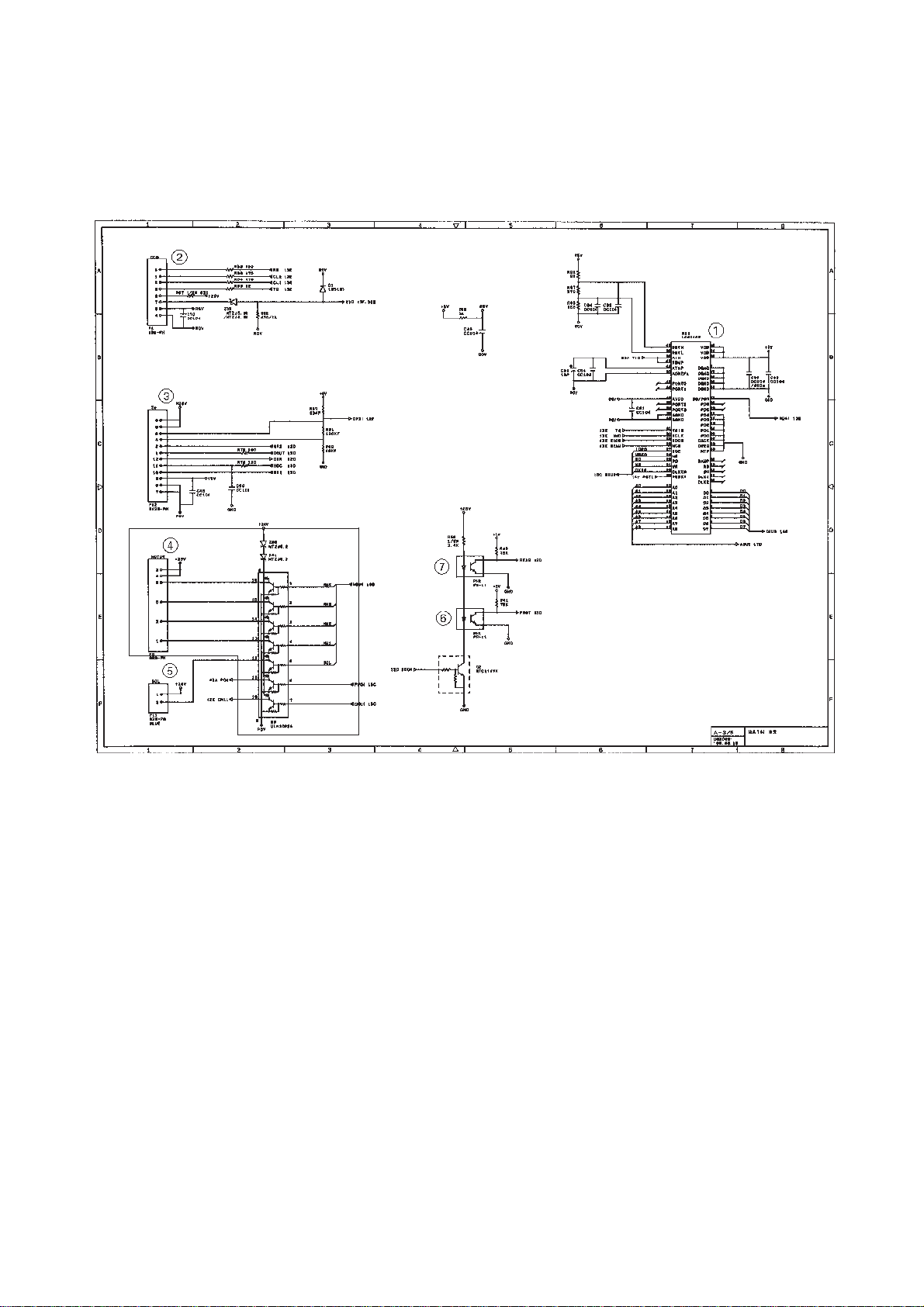

[ 3 ] Image processing group

Main PCB Circuit Diagram 3/5

1 Image processor (Image processing IC)

2 Connector for the CCD PCB

3 Recording head temperature detector and head connector

4 Motor driver and connector

5 Clutch solenoid connector

6 Document front sensor (photosensor)

7 Document rear sensor (photosensor)

III – 18

Page 32

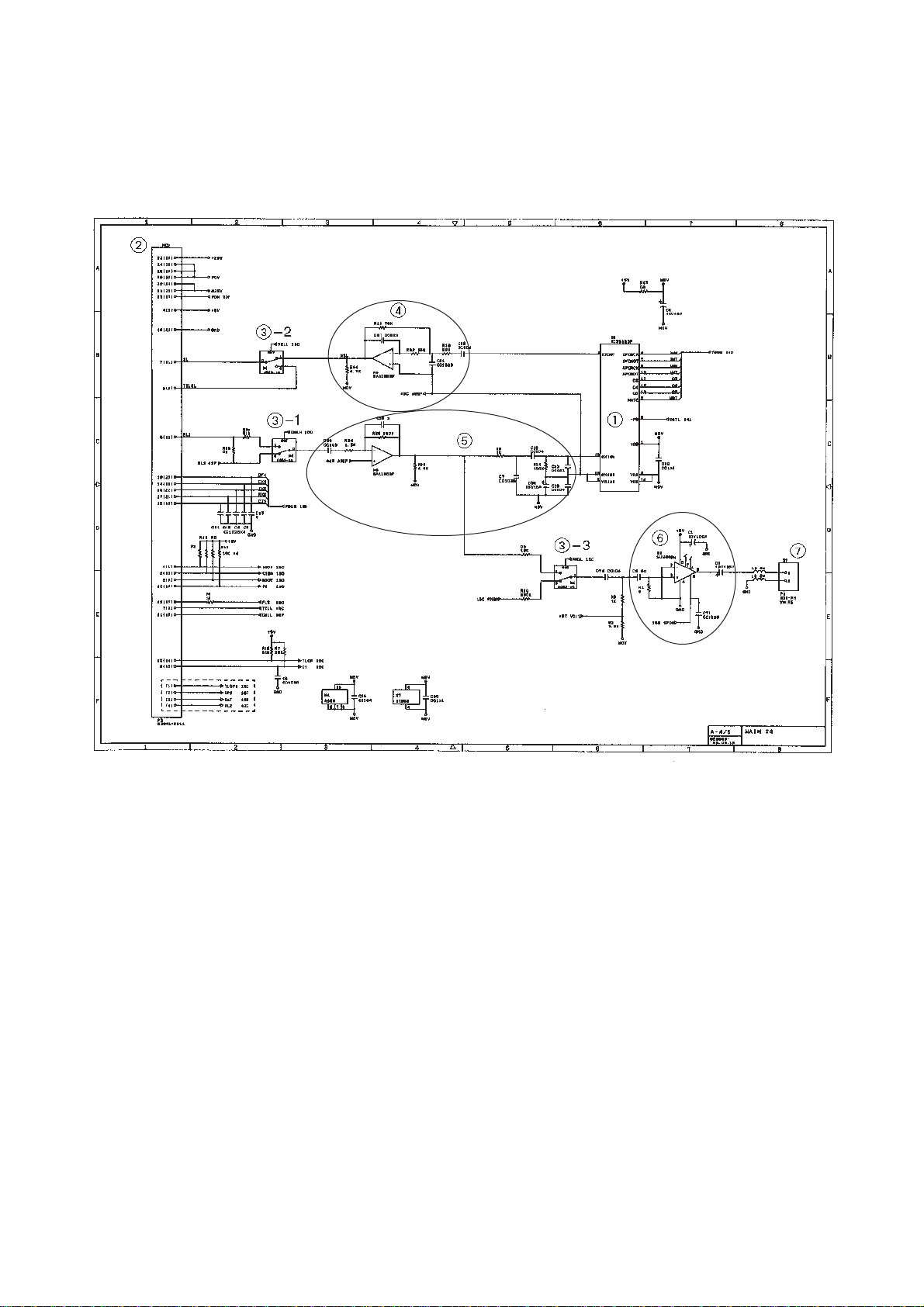

[ 4 ] Analog signal processing group

Main PCB Circuit Diagram 4/5

1 Main-NCU connector

2 Analog signal selectors

2-1: Selects either RL1 or RL2 signals inputted from the communications net-

work.

2-2: Selects either input signals from the handset or those from the MODEM.

2-3: Selects either sound signals (e.g. alarm beeps, key clicks and ringer sounds)

generated by the FAX engine or signals selected by 2-1.

3 Voice switching analog selectors

3-1: Selects either input signals from the communications network or those from

the MODEM, then feeds them to the speaker.

3-2: Selects either signals inputted from the communications network or recorded

voice signals inputted from the microphone or handset, then feeds them to

the MODEM.

4 Speaker output circuit and connector

5 Microphone connector and voice signal amplifier circuit

The voice signal amplifier circuit is applicable in those countries where telephones

can be used to call even during power failures.

III – 19

Page 33

[ 5 ] MODEM

1 MODEM

2 Clock for MODEM

Main PCB Circuit Diagram 5/5

III – 20

Page 34

3.3 NCU PCB

The NCU PCB switches the communications line to telephone or built-in MODEM, under

control of the main PCB. Also, it works as a power supply interface from the power supply

unit to the main PCB and the recording head.

As shown in the circuit diagrams on the next page, the NCU PCB consists of the components listed below:

1 Surge absorber 7 Calling signal detector

2 Noise filter 8 Loop current detector

3 Line relay (CML relay) 9 Dial pulse generator

4 Line transformer : Telephone circuit

5 Circuit related to line transformer a Recording head interface

6 High-impedance transformer circuit

• The primary function of the NCU which is shared by facsimile and telephone units is to

switch a line to the facsimile unit or to the telephone, which is carried out by the line relay.

• Since the direct connection of a facsimile equipment to the line is not allowed for protecting the line, it is essential to insert a line transformer between the line and the facsimile

equipment to insulate them each other in direct current band.

The above two components, a line relay and a line transformer, are the minimum requirements for the NCU of the facsimile equipment.

• If an external telephone is attached to the facsimile equipment, the NCU should have a

loop current detector to identify the hook state by detecting loop current.

• If the facsimile equipment has an automatic answering facility, the NCU should be

equipped with a calling signal detector which detects a calling signal and tells it to the

CPU in the FAX engine.

• The circuit related to a line transformer allows the line transformer to be invariant by selecting the constants of the parts in this circuit so as to conform to the communications

regulations or codes of each country.

In addition to the above basic components of the NCU, the following components are also

required depending upon additional functions of the facsimile equipment:

• The dial pulse generator generates dial pulses within the facsimile equipment.

• The surge absorber is a protection circuit which absorbs lightning surge.

• The noise filter eliminates noise including radiation noise to prevent them from flowing out

onto the communications line.

• The high-impedance transformer circuit detects the remote activation, and F/T switching

sent from the line in ON-HOOK state without any interference to the line.

• The telephone circuit includes two amplifiers; one for amplifying the output signals of the

handset microphone and the other for amplifying the receive signals from the communications lines to sound the handset receiver.

III – 21

Page 35

5

a

6

3

2

4

:

7

8

9

1

2

NCU Circuit Diagram

III – 22

Page 36

3.4 Control Panel PCB

The control panel PCB and the main PCB communicate with each other by serially transmitting commands and data.

The control panel unit consists of a gate array, an LCD, and LEDs, which are controlled according to commands issued from the FAX engine on the main PCB.

The calendar clock is backed up by the backup circuit on the main PCB.

The panel FPC is a flexible keyboard PCB which integrates the key matrix having rubber

keytops.

FAX

Engine

RESET

Backup

Circuit

Main PCB

SIDN

SDOUT

PCLK

+5V

Reset

Circuit

Control Panel PCB

+5V

Control Panel PCB and its Related Circuit

Serial

Communications

Ports

Gate Array

I/O Ports

POWER

RESET

LCD

Panel FPC

(Key Matrix)

LED

S

III – 23

Page 37

3.5 Power Supply

The power supply uses the switching regulation system to generate the required DC power

(+5V and +26.6V) from the commercial AC power supply.

The 26.6V power source is fed to the NCU PCB where the +26.6VH source is generated.

The 26.6VH power source, which drives the recording head, outputs 26.6 VDC only when

the 26.6V ON/OFF control signal sent from the main PCB turns High.

The 26.6V power source mainly drives the motor for feeding documents and recording pa-

per.

Signals other than +26.6VH are connected to the main PCB through the NCU PCB and

+26.6VH is fed to the recording head.

Commercial

AC Power Line

Fuse

Lightning

Surge

Absorption

Circuit

Oscillator

Circuit

Link

Filter

Output Feedback

Power Supply Circuit

Rectifier

Circuit

26.6 V

Output

Circuit

5 V

Output

Circuit

NCU PCB

26.6 VH

Output

Circuit

26.6 V ON/OFF

Control Signal

26.6 VH

26.6 V

5 V

III – 24

Page 38

CHAPTER IV.

INDICATION AND INFORMATION

PRINTOUT OF ERROR

Page 39

CONTENTS

1. INDICATION AND PRINTOUT OF ERROR................................................... IV-1

2. EQUIPMENT ERROR.................................................................................... IV-1

2.1Error Messages on the LCD................................................................... IV-1

2.2Error Codes Shown in the “MACHINE ERROR xx” message................ IV-2

3. COMMUNICATIONS ERROR........................................................................ IV-4

3.1Definition of Error Codes on the Communications List........................... IV-5

Page 40

1. INDICATION AND PRINTOUT OF ERROR

To help the user or the service personnel promptly locate the cause of a problem (if any), the

facsimile equipment incorporates the self-diagnostic functions which display error messages

for equipment errors and communications errors.

For the communications errors, the equipment also prints out the transmission verification report and the communications list.

2. EQUIPMENT ERROR

If an equipment error occurs, the facsimile equipment emits an audible alarm (continuous beeping) for approximately 4 seconds and shows the error message on the LCD. For the error

messages, see Section 2.1. As one of the error messages, “MACHINE ERROR xx” includes

an error code which indicates the detailed error causes listed in Section 2.2. T o display an error

code for other latest error message, make the equipment enter the maintenance mode and

press 8 and 2 keys (for details, refer to Chapter V, Subsection 3.3.9).

2.1 Error Messages on the LCD

Messages on the LCD Probable Cause

PAPER ROLL EMPTY The paper empty (PE) sensor detects that no recording paper

is present.

PRINTER JAM The recording paper failed to return to the printing position after

it had been cut.

COVER OPEN The cover sensor detects that the the recording paper cover is

not closed.

DOCUMENT JAM ■ Document jam

(1) The document length exceeds the limitation (400 or 90 cm)

registered by firmware switch WSW16. (Refer to Chapter

V , Subsection 3.3.5.)

(Both the document front and rear sensors stay ON after

the document has been fed by the registered length.)

(2) The document rear sensor detects no trailing edge of a

document after the document has been fed by 400 cm.

(The document rear sensor stays ON even after the

document has been fed when the document front and rear

sensors were OFF and ON, respectively.)

IV – 1

Page 41

Messages on the LCD Probable Cause

DOCUMENT JAM ■ Document loading error

(1) The document rear sensor detects no leading edge of a

document within 10 seconds from the start of document

loading operation.

(The document rear sensor stays OFF even after the

document has been fed when the document front sensor

was ON.)

(2) The loaded document is too short.

(Since the document is shorter than the distance between

the document front and rear sensors, the document front

sensor is turned OFF before the document rear sensor is

turned ON.)

CUTTER JAM The upper rotary blade of the automatic cutter failed to return to

the home position within the specified time after cutting the

recording paper.

CLEAN UP SCANNER In the scanning compensation data list printed by the mainte-

nance-mode function No. 05, less than fifty percent of the white

level data is faulty.

SCANNER ERROR In the scanning compensation data list printed by the mainte-

nance-mode function No. 05, fifty percent or more of the white

level data is faulty.

PRINTER FAULT

The thermistor in the recording head caused a heat error.

MACHINE ERROR xx “xx” indicates an error code. Refer to Section 2.2.

If only an alarm beep is heard without any message on the LCD when the equipment is powered up, the ROM or RAM will be defective.

2.2 Error Codes Shown in the “MACHINE ERROR xx” message

Error Code

xx

(Hex.)

82 Recording paper feeding error.

87 Fails to complete the sequence of recording operation.

( 89 Cutter jam. )

8A Wrong or weak contact of the recording head connectors.

( 8B Recording head overheat. )

( A1 Recording paper cover opened. )

( A2 Document too long to scan. )

( A3 Document not detected by the document rear sensor. )

Error factor

( A4 50% or more faulty of white level data. )

Error codes in parentheses do not appear in the “MACHINE ERROR xx”, since those errors are displayed as

messages described in Section 2.1. Those error codes appear in the communications error list if an equipment error occurs

during communications. Refer to Section 3.1, (13).

IV – 2

Page 42

Error Code

xx

Error factor

(Hex.)

A5 Faulty operation of DMA0 during scanning.

A6 Faulty operation of DMA1 during scanning.

A7 One-line feeding time-out error.

A8 One-line scanning time-out error.

A9 Abnormal scanning reference voltage.

AB Document feed-in amount measuring error.

AC Less than 50% faulty of white level data.

B1 CODEC LSI error.

( B8 Amplifier gain error. )

( B9 Light emission intensity error of the LED array. )

( BA Scanning error: The left-hand black reference line which is marked on

the document pressure bar for scanning width setting is not detected.)

( BB Scanning error: The right-hand black reference line which is marked on

the document pressure bar for scanning width setting is not detected.)

( BC Scanning error: Reduction miss)

( BD Scanning error: Enlargement miss)

D1 The MODEM setup bit sticks to High.

D2 CTS stays OFF or ON if the MODEM RTS is turned ON or OFF, re-

spectively.

D3 Bit B1A of the MODEM stays OFF.

D4 Bit RX of the MODEM stays OFF.

D5 The MODEM fails to complete the command transmission sequence.

D6 No MODEM interrupt for 60 seconds.

E1 Microprocessor (MPU) error on the control panel PCB.

( E4 Out of recording paper. )

( E5 Recording paper set error. )

E6 Write error in E2PROM.

E8 Data scanning error during transmission.

( EA Document removed at phase B.)

F3 Voice message recording or playing-back not started.

F5 EOL not found in page memory transmission mode.

FF Interface error of page memory command.

Error codes in parentheses do not appear in the “MACHINE ERROR xx”, since those errors are displayed as

messages described in Section 2.1. Those error codes appear in the communications list if an equipment

error occurs

during communications. Refer to Section 3.1, (13).

IV – 3

Page 43

3. COMMUNICATIONS ERROR

If a communications error occurs, the facsimile equipment

(1) emits an audible alarm (intermittent beeping) for approximately 4 seconds,

(2) displays the corresponding error message, and

(3) prints out the transmission verification report if the equipment is in sending operation.

Transmission Verification Report Sample

IV – 4

Page 44

3.1 Definition of Error Codes on the Communications List

(1) Calling

Code 1 Code 2 Causes

10 08 Wrong number called.

11 01 No dial tone detected before start of dialing.

11 02 Busy tone detected before dialing.

11 03 2nd dial tone not detected.

11 05 No loop current detected. *

11 06 Busy tone detected after dialing or called.

11 07 No response from the remote station in sending.

11 10 No tone detected after dialing.

17 07 No response from the remote station in receiving.

(2) Command reception

Code 1 Code 2 Causes

20 01 Unable to detect a flag field.

20 02 Carrier was OFF for 200 ms or longer.

20 03 Abort detected (“1” in succession for 7 bits or more).

20 04 Overrun detected.

20 05 A frame for 3 seconds or more received.

20 06 CRC error in answer back.

20 07 Undefined command received.

20 08 Invalid command received.

20 09 Command ignored once for document setting or for dump-

20 0A T5 time-out error

* Available in Germany and Austria only.

ing-out at turn-around transmission.

20 0B CRP received.

20 0C EOR and NULL received.

IV – 5

Page 45

(3) Compatibility [checking the NSF and DIS]

Code 1 Code 2 Causes

32 01 Remote terminal only with V.29 capability in 2400 or 4800

bps transmission.

32 02 Remote terminal not ready for polling

32 10 Remote terminal not equipped with password function or

its password switch OFF.

32 11 Remote terminal not equipped with or not ready for confi-

dential mail box function.

32 12 Remote terminal not equipped with or not ready for relay

broadcasting function.

32 13 No confidential mail in the remote terminal.

32 14 The available memory space of the remote terminal is less

than that required for reception of the confidential or relay

broadcasting instruction.

IV – 6

Page 46

(4) Instructions received from the remote terminal [checking the NSC, DTC, NSS, and DCS]

Code 1 Code 2 Causes

40 02 Illegal coding system requested.

40 03 Illegal recording width requested.

40 05 ECM requested although not allowed.

40 06 Polled while not ready.

40 07 No document to send when polled.

40 10 Nation code or manufacturer code not coincident.

40 11 Unregistered group code entered for relay broadcasting

function, or the specified number of broadcasting subscrib-

ers exceeding the limit.

40 12 Retrieval when not ready for retrieval.

40 13 Polled by any other manufacturers’ terminal while waiting

for secure polling.

40 17 Invalid resolution selected.

(5) Command reception [checking the NSF and DIS after transmission of NSS and DCS]

Code 1 Code 2 Causes

50 01 Vertical resolution capability changed after compensation

of background color.

IV – 7

Page 47

(6) ID checking

Code 1 Code 2 Causes

63 01 Password plus (lower 4 digits of telephone number) not

63 02 Password not coincident.

63 03 Polling ID coincident.

63 04 Entered confidential mail box ID uncoincident with the mail

63 05 Relay broadcasting ID not coincident.

63 06 Entered retrieval ID uncoincident with that of the mail box

(7) DCN reception

coincident.

box ID.

ID.

Code 1 Code 2 Causes

74 DCN received.

(8) TCF transmission/reception

Code 1 Code 2 Causes

80 01 Fallback impossible.

IV – 8

Page 48

(9) Signal isolation

Code 1 Code 2 Causes

90 01 Unable to detect video signals and commands within 6

90 02 Received PPS containing invalid page count or block

(10) Video signal reception

Code 1 Code 2 Causes

A0 03 Error correction sequence not terminated even at the final

A0 11 Receive buffer empty. (5-second time-out)

A0 12 Receive buffer full during operation except receiving into

seconds after CFR is transmitted.

count.

transmission speed for fallback.

memory.

A0 13 Decoding error continued on 500 lines.

A0 14 Decoding error continued for 10 seconds.

A0 15 Time-out: Five seconds or more for one-line transmission.

A0 16 RTC not found and carrier OFF signal detected for 6

A0 17 RTC found and command detected for 60 seconds.

A8 01 RTN, PIN, or ERR received at the calling terminal. *

A9 01 RTN, PIN, or ERR received at the called terminal. *

AA 18 Receive buffer full during receiving into memory.

(11) General communications-related

Code 1 Code 2 Causes

B0 01 Polarity inversion detected.

B0 02 Unable to receive the next-page data.

seconds.

* Available in Germany and Austria only.

B0 03 Unable to receive polling even during turn-around trans-

mission due to call reservation.

B0 04 PC interface error.

IV – 9

Page 49

(12) Maintenance mode

Code 1 Code 2 Causes

E0 01 Failed to detect 1300 Hz signal in burn-in operation.

E0 02 Failed to detect PB signals in burn-in operation.

E0 03 Failed to detect any command from the RS-232C interface

(13) Equipment error

Code 1 Code 2 Causes

FF xx Equipment error (For xx, refer to Section 2.2.)

in burn-in operation.

IV – 10

Page 50

CHAPTER V.

MAINTENANCE

Page 51

CONTENTS

1. DISASSEMBLY, REASSEMBLY, AND LUBRICATION................................. V-1

■Safety Precautions.................................................................................... V-1

■Preparation................................................................................................V-2

■How to Access the Object Component...................................................... V-2

■Disassembly Order Flow........................................................................... V-3

1.1 ROM Cover............................................................................................V-4

1.2 Recording Paper Cover........................................................................ V-4

1.3 Panel Cover ASSY................................................................................ V-5

1.4 Panel Rear Cover and Control Panel.................................................... V-6

1.5 Recorder & Cutter Unit.......................................................................... V-7

1.6 LF Roller ASSY......................................................................................V-9

1.7 Bottom Plate..........................................................................................V-10

1.8 Main PCB, NCU PCB, and Power Supply PCB.................................... V-11

1.9 Scanner Frame ASSY........................................................................... V-13

1.10Drive Unit...............................................................................................V-14

1.11Handset Mount and Speaker................................................................ V-15

■Lubrication.................................................................................................V-16

2. TROUBLESHOOTING................................................................................... V-17

2.1Introduction.............................................................................................V-17

2.2Precautions.............................................................................................V-17

2.3Checking prior to Troubleshooting......................................................... V-17

3. MAINTENANCE MODE................................................................................. V-23

3.1Entry into the Maintenance Mode.......................................................... V-23

3.2List of Maintenance-mode Functions..................................................... V-23

3.3Detailed Description of Maintenance-mode Functions........................... V-25

3.3.1E2PROM parameter initialization..................................................... V-25

3.3.2Printout of scanning compensation data......................................... V-26

3.3.3ADF performance test..................................................................... V-27

3.3.4Test pattern 1.................................................................................. V-27

Page 52

3.3.5Firmware switch setting and printout............................................... V-28

3.3.6Operational check of control panel PCB......................................... V-66

3.3.7Sensor operational check............................................................... V-69

3.3.8CCD scanner area setting............................................................... V-69

3.3.9Equipment error code indication..................................................... V-70

Page 53

1. DISASSEMBLY AND REASSEMBLY

■ Safety Precautions

To prevent the creation of secondary problems by mishandling, observe the following precautions during maintenance work.

(1) Always turn off the power before replacing parts or units. When having access to the

power supply, be sure to unplug the power cord from the power outlet.

(2) Be careful not to lose screws, washers, or other parts removed for parts replacement.

(3) When using soldering irons and other heat-generating tools, take care not to damage

the resin parts such as wires, PCBs, and covers.

(4) Before handling the PCBs, touch a metal portion of the equipment to discharge static

electricity, or the electronic parts may be damaged due to the electricity charged in your

body.

(5) When transporting PCBs, be sure to wrap them in conductive sheets such as aluminum

foil.

(6) Be sure to reinsert self-tapping screws correctly, if removed.

(7) Unless otherwise specified, tighten screws to the torque values listed below.

• Tapping screws

M2.6 : 3.5 kgf•cm

M3 x 8 : 5 kgf•cm

M3 x 10 : 7 kgf•cm

• Sems screws M3 : 7 kgf•cm

(Screws with washer)

• Stepped screws : 7 kgf•cm

(8) When connecting or disconnecting cable connectors, hold the connector bodies not the

cables. If the connector has a lock, always slide the connector lock to unlock it.

(9) After repairs, check not only the repaired portion but also that the connectors and other

related portions function properly before operation checks.

V – 1

Page 54

■ Preparation

Prior to proceeding to the disassembly procedure,

(1) Unplug the modular jack of the telephone line.

(2) Unplug modular jacks of external telephone sets if mounted.

(3) Unplug the modular jack of the curled cord and remove the handset. (See below.)

(4) Remove the recording paper roll, the document wire-extension, and the receive wire-

Document wire-extension

extension. (See below.)

Receive wire-extension

Recording paper roll

Curled cord

Handset

■ How to Access the Object Component

• On the next page is a disassembly order flow which helps you access the object compo-

nent. To remove the scanner frame ASSY, for example, first find it on the flow and learn

its number (9 in this case). You should remove parts numbered 6 through 8 so as to

access the scanner frame ASSY.

• Unless otherwise specified, the disassembled parts or components should be reas-

sembled in the reverse order of removal.

V – 2

Page 55

■ Disassembly Order Flow

Panel cover ASSY

3

Panel rear cover

- ADF parts

Control panel

- Control panel

PCB

- FPC key

4

Recorder &

cutter unit

5

ROM cover

1

Recording

paper cover

2

8

Bottom plate

7

8

8

NCU PCB**

Power supply

PCB

Main PCB*

9

LF roller ASSY

6

Scanner frame ASSY

- Separation roller ASSY

- Document front sensor

actuator

- Document rear sensor

actuator

PE sensor

actuator

Handset mount

Speaker

11

* On the main PCB are the following photoelectric sensors:

• Document front sensor (PH1)

• Document rear sensor (PH2)

** On the NCU PCB are the following mechanical switches:

• PE sensor (SW1)

• Cover sensor (SW2)

• Cutter sensor (SW3)

• Hook switch sensor (SW4)

10

Drive unit

- Motor

- Gears

- Cover sensor actuator

- Cutter sensor actuator

- Hook switch sensor

actuator

Main frame

V – 3

Page 56

1

2

1.1 ROM Cover

(1) Open the recording paper cover.

(2) Turn up the head release lever.

(3) Insert the tip of a flat screwdriver into slot “A” to release two pawls of the ROM cover

from the main frame.

(4) Lift up the ROM cover.

Flat screwdriver

Pawls

Slot “A”

Head release lever

Main frame

1.2 Recording Paper Cover

(1) Open the recording paper cover.

(2) As shown below, press section “B” with your thumb to release the recording paper

cover from the bosses provided on the main frame.

ROM cover

Recording paper cover

2

1

Recording paper

cover

Main frame

Boss

“B”

V – 4

Page 57

1.3 Panel Cover ASSY

(1) Disconnect the main-panel harness from the main PCB.

(2) Slightly open the panel cover ASSY.

(3) Push the right and left arms of the panel cover ASSY outwards with you thumbs as

shown below to unhook them from the bosses provided on the main frame, then open

the panel cover ASSY further.

Main PCB

Main-panel harness

Arm

1

Panel cover ASSY

2

3

Panel cover ASSY

Routing the harness

Main-panel harness

Main PCB

V – 5

Page 58

1.4 Panel Rear Cover and Control Panel

(1) Place the panel cover ASSY upside down.

(2) Remove the ADF parts from the panel rear cover.

(3) Remove the two screws.

(4) Insert the tip of a flat screwdriver into the slot between the panel rear cover and control

panel as shown below and unhook the panel rear cover from the 15 “x” pawls provided

on the control panel.

(5) To remove the control panel PCB, FPC key and LCD, unhook the PCB from the four “y”

pawls provided on the control panel.

14243

ADF parts

Panel rear cover

LCD

Control panel PCB

FPC key

4 “y” pawls

(Rear)

15 “x” pawls

Control panel

(Front)

■ Reassembling Notes

• When installing the panel rear cover to the control panel, first fit the rear edge into

place and then snap in the panel rear cover.

V – 6

Page 59

1.5 Recorder & Cutter Unit

(1) Disconnect the main-head harness from the main PCB.

(2) Remove the screw from the recorder & cutter unit.

(3) Release the lock of the cutter link and pull out the upper blade shaft from it.

(4) Pull up the recorder & cutter unit which is attached to the main frame with double-sided

adhesive tape, then remove it in the direction of the arrow shown below.

Lock

Main-head

harness

Ratchet

Upper blade shaft

Recorder & cutter unit

Cutter

link

Main PCB

■ Disassembly of recorder & cutter unit

1) Disconnect the main-head harness from the recorder PCB.

2) Remove the ratchet from the upper blade shaft, taking care not to deform it.

3) Slide the ACS plate upwards while pulling sections “a” towards you.

4) Unlock the two latches “b” of the cutter chute from the cutter chassis and pull up

the cutter chute.

Cutter chute (removed)

Latch “b”

"x"

ACS plate

Latch “b”

Cutter chute

(mounted)

“a”

Ratchet

Upper blade shaft

Slightly pull section “x” to the

left and turn the ratchet as

shown above.

Main-head harness

“a”

V – 7

Page 60

5) Turn down the left release lever.

6) Slide the left ACS catch towards you while pulling the lock “c” outwards.

In the same way, remove the right ACS catch.

ACS catch (R)

1

Release lever (L)

ACS catch (L)

2

3

“c”

7) Remove the right bushing from the platen ASSY while releasing the two pawls “d.”

Then, remove the platen ASSY.

8) Push down the recorder PCB and pull it towards you slightly to release the two tabs

“e” from the cutter chassis, taking care not to lose three springs.

9) Remove the right and left release levers from the release shaft.

Recorder PCB

Tab “e”

Tab “e”

Release lever (R)

Release shaft

Spring

Release lever (L)

Cutter chassis

Pawls “d”

Bushing (R)

V – 8

Platen ASSY

Page 61

■ Reassembly of recorder & cutter unit

• When installing the platen ASSY to the cutter chassis, orient the left bushing as

shown below. Then, fit the bushing into the cutter chassis from the left side while

pressing down the platen and the recorder PCB.

Platen

1.6 LF Roller ASSY

(1) Push down the lock arm on the scanner frame ASSY and pull out the LF roller ASSY in

the direction of the arrow shown below.

Platen ASSY

Bushing (L)

Cutter chassis

Right side view

Lock arm

1

Scanner frame

V – 9

2

LF roller ASSY

Page 62

1.7 Bottom Plate

(1) Place the machine upside down.

(2) Remove the five screws.

(3) Remove the bottom plate.

Inside of the bottom plate

Grounding terminal

Bottom plate

V – 10

Page 63

1.8 Main PCB, NCU PCB, and Power Supply PCB

(1) Disconnect the following seven harnesses from the main PCB as shown below:

• Main-head harness (12-pin)

• Main-panel harness (5-pin)

• CCD harness (10-pin)

• Speaker harness (2-pin)

• Motor harness (6-pin)

• Solenoid harness (2-pin)

• LED harness (2-pin)

FAX100/570/615/625/635/

675/575M/715M

Speaker

connector

CCD harness

Solenoid connector

Motor connector

Main-head connector

Main-panel

connector

CCD connector

LED connector

LED

harness

Mainpanel

harness

Solenoid

harness

Speaker

harness

Motor harness

Main-head harness

NCU PCB

FAX725M/590DT/590MC/

825MC/875MC

Speaker

connector

Main PCB

Main-panel connector

Nickel-hydrogen

battery connector

Power supply PCB

Main-head

connector

Solenoid

connector

Motor

connector

LED connector

CCD connector

V – 11

Page 64

(2) Take off the AC cord bushing from the main frame.

(3) Take out the main PCB, NCU PCB and power supply PCB.

AC cord

bushing

(4) Disconnect the main PCB and power supply PCB from the NCU PCB.

NCU PCB

SW1 (PE sensor)

Main PCB

SW3 (Cutter sensor)

SW4 (Hook switch sensor)

Grounding

plate

Power supply PCB

SW2 (Cover sensor)

PH2 (Document rear sensor)

PH1 (Document front sensor)

V – 12

Page 65

1.9 Scanner Frame ASSY

(1) Remove the two screws.

(2) Unhook the scanner frame ASSY from the two pawls provided on the main frame.

(3) Lift up the scanner frame ASSY.

NOTE: Never remove or replace the CCD PCB, CCD lens, mirrors, LED array or bar

lens.

Main frame placed

upside down

Scanner frame ASSY

Mirrors

CCD lens

Pawls

(4) To remove the separation roller ASSY, document front and rear sensor actuators, press

the a, b, and c locking pawls shown below with the tip of a flat screwdriver, respectively, and move the component to be removed to the left.

Separation roller

ASSY

CCD PCB

Document front

sensor actuator

b

a

c

Scanner frame

ASSY

LED array

Bar lens

V – 13

Document rear

sensor actuator

Page 66

NOTE: When accessing these components, take care not to scratch the mirrors, CCD

1.10 Drive Unit

(1) Remove the two screws.

(2) Lift up the drive unit.

(3) To remove the motor, press the lock and turn the motor in the direction of the arrow as

shown below.

lens, or bar lens.

Mirrors

Drive unit

Motor

Lock

Drive unit

Cutter sensor

actuator

Hook switch

sensor actuator

(Front)

Cover sensor actuator

V – 14

Page 67

1.11 Handset Mount and Speaker

(1) Insert the tip of a 0.5-mm-wide ruler into the slots between the handset mount and the

main frame and unhook the handset mount from the pawls provided on the main frame.

(2) Slightly lift up the handset mount slightly and take it off to the left.

Speaker

harness

Pawl

2

1

Speaker harness

3

Handset mount

(3) To remove the speaker or the hook switch, unhook the locks with a small-blade flat

screwdriver to disassemble the handset mount.

(4) Slide the speaker to the right.

Main PCB

Locks

Handset mount placed

upside down

1

Hook switch

Speaker

3

2

V – 15

Page 68

■ Lubrication

Apply two grains of grease (Molicoat EM-30) to each of the following lubrication points:

(1) LF roller ASSY and grounding plates

Grounding

plate

3

(2) Separation roller ASSY

LF roller ASSY

Scanner frame ASSY

V – 16

Separation roller ASSY

Page 69

2. TROUBLESHOOTING

2.1 Introduction

This chapter gives the service personnel some of the troubleshooting procedures to be followed if an error or malfunction occurs with the facsimile equipment. It is impossible to anticipate all of the possible troubles which may occur in future and determine the troubleshooting procedures, so this chapter covers some sample troubles. However, those samples will

help service personnel pinpoint and repair other defective elements if he/she analyzes and

examines them well.

Prior to proceeding to the troubleshooting, read CHAPTER IV, INDICATION AND INFORMATION PRINTOUT OF ERROR.

2.2 Precautions

Be sure to observe the following to prevent the secondary troubles from happening:

(1) Always unplug the AC power cord from the outlet when removing the covers and PCBs,

adjusting the mechanisms, or conducting continuity testing with a circuit tester.

(2) When disconnecting the connectors, do not pull the lead wires but hold the connector

housings.

(3) ● Before handling the PCBs, touch a metal portion of the machine to discharge static

electricity charged in your body.

● When repairing the PCBs, handle them with extra care.

● When removing the electronic devices with a soldering iron, do not leave solder chips

or lead wires inside the machine.

After repairing the defective section, be sure to check again if the repaired section works correctly. Also record the troubleshooting procedure so that it would be of use for future trouble

occurrence.

2.3 Checking prior to Troubleshooting

Prior to proceeding to the troubleshooting flowcharts, check that:

(1) Each voltage level on AC input lines and DC lines is correct.

(2) All cables and harnesses are firmly connected.

(3) None of the fuses are blown.

V – 17

Page 70

■ Control panel related

Trouble Action to be taken

(1) LCD shows nothing. • Check the main-panel harness between the main PCB and the

control panel.

• Check the interfaces between the main PCB, NCU PCB and

power supply PCB.

• Check the control panel PCB.

• Check the power supply PCB.

• Check the main PCB.

(2) Control panel

inoperative.

■ Telephone related

Trouble Action to be taken

(1) No phone call can be

made.

• Check the main-panel harness between the main PCB and the

control panel.

• Check the interfaces between the main PCB, NCU PCB, and

power supply PCB.

• Check the control panel PCB.

• Check the FPC key.

• Check the main PCB.

• Check the FPC key.

• Check the control panel PCB:

- Use the maintenance-mode function No. 13. (Refer to

Section 3.) If any defective keys are found, replace them.

• Check the NCU PCB.

• Check the main PCB.

(2) Speed dialing or one-

touch dialing will not

work.

• Check whether the ordinary dialing function (other than the

speed and one-touch dialing) works correctly or not.

- If yes, check the main PCB.

- If not, refer to item (1) above.

V – 18

Page 71

Trouble Action to be taken

(3) Speaker silent during

on-hook dialing.

(4) Dial does not switch

between tone and pulse.

(5) Telephone does not

ring.

■ Communications related

• Check whether the ordinary dialing function (other than the onhook dialing with the hook key) works correctly or not.

- If yes, proceed to the following checks:

- If not, refer to item (1) above.

• Check the speaker.

• Check the NCU PCB.

• Check the main PCB.

• Check the main PCB.

• Check the speaker.

• Check the NCU PCB.

• Check the main PCB.

Trouble Action to be taken

(1) No tone is transmitted. • Check the main PCB.

• Check the NCU PCB.

V – 19

Page 72

■ Image related

If the received or sent image has any trouble, first make a copy with the facsimile equipment.

If the copied image is normal, the remote terminal is defective. If it is abnormal, proceed to

the troubleshooting list given below:

Trouble

(1) All white images.

[At scanning side]

[At recording side]

(2) Image has white

vertical streaks.

[At scanning side]

Action to be taken

• Check the harnesses between the main PCB and CCD & lens

holder ASSY.

• Check the main PCB.

• Check the main-head harness between the main PCB and the

recording head.

• Check the NCU-head harness between the NCU PCB and the

recording head.

• Check that the compression springs beneath the recording head

are set in place.

• Check the main PCB.

• Check the recording head.

• Check the CCD & lens holder ASSY.

[At recording side]

(3) All black images.

[At scanning side] • Check the interfaces between the main PCB, NCU PCB, and

[At recording side]

(4) Image has black

vertical streaks.

[At scanning side]

[At recording side]

• Check the recording head.

CCD & lens holder ASSY.

• Check the LED harness.

• Check the LED array.

• Check the main PCB.

• Check the main PCB.

• Check the recording head.

• Check the CCD & lens holder ASSY.

• Check the recording head.

V – 20

Page 73

Trouble Action to be taken

(5) Faint/dark image.

[At scanning side] • Check the LED array.

• Check the main PCB.

[At recording side]

(6) Improper image align-

ment.

[In communications]

[At scanning side]

[At recording side]

(7) Stretched-out image or

compressed image.

[In communications]

• Check that the compression springs beneath the recording

head are set in place.

• Check the displayed error code. (Refer to Chap. IV.)

• Check the connection between the main PCB and the NCU

PCB.

• Check the interfaces between the main PCB, NCU PCB, and

CCD & lens holder ASSY.

• Check the main PCB.

• Check the main-head harness between the main PCB and the

recording head.

• Check the main PCB.

• Check the displayed error code. (Refer to Chap. IV.)

[At scanning side]

[At recording side]

• Check the separator and its related section.

• Check the document feed rollers and their related gears.

• Check the solenoid and the planetary gear train.

• Check the drive motor and its harness.

• Check that the compression springs beneath the recording

head are set in place.

• Check the platen and its gear.

• Check the solenoid and the planetary gear train.

• Check the drive motor and its harness.

V – 21

Page 74

■ Paper feeding related

Trouble Action to be taken

(1) Neither “COPY:

PRESS COPY” nor

“FAX: NO. & START”

message appears

although documents

are set.

(2) Document not fed. • Check the drive motor and its harness.

(3) Recording paper not

fed.

(4) The “CUTTER JAM”

message cannot be

removed.

• Check the document sensors according to the maintenancemode function No. 32. (Refer to Section 3.)

• Check the document feed rollers and their related gears.

• Check the main PCB.

• Check the solenoid and the planetary gear train.

• Check the drive motor and its harness.

• Check the ADF and its related section.

• Check the drive motor and its harness.

• Check the recording paper feed rollers and their related gears.

• Check the solenoid and the planetary gear train.

• Check the main PCB.

• Check the drive motor and its harness.

• Check the cutter sensor and its position.

• Check the cutter gear.

• Check the solenoid and the planetary gear train.

• Check the main PCB.

V – 22

Page 75

3. MAINTENANCE MODE

3.1 Entry into the Maintenance Mode

To make the facsimile equipment enter the maintenance mode, press the FUNCTION ,

* , 2 , 8 , 6 , and 4 keys in this order.

Within 2 seconds

The equipment beeps for approx. 3 seconds and displays "MAINTENANCE" on the LCD, in-

dicating that it is placed in the initial maintenance mode, a mode in which the equipment is

ready to accept entry from the keys.

To select one of the maintenance-mode functions listed in the table below, enter the corresponding 2-digit function code with the numerical keys on the control panel. (The details of

each maintenance-mode function are described in Section 3.3.)

NOTES: • Pressing the 9 key twice in the initial maintenance mode restores the equip-

ment to the standby state.

• Pressing the STOP button after entering only one digit restores the equipment to the initial maintenance mode.

• If an invalid function code is entered, the equipment resumes the initial maintenance mode.

3.2 List of Maintenance-mode Functions

Maintenance-mode Functions (1)

Function

Code

01 E2PROM Parameter Initialization 3.3.1

02

03

04

05

06

07

08

09

10

11

12

13

Printout of Scanning Compensation Data

ADF* Performance Test