Brother Embroidery Operation Manual

Operation Manual

Be sure to read this manual before using the machine.

We recommend that you keep this document nearby for future reference.

Embroidery

Embroidery and Sewing Machine

Product Code: 882-W30

Be sure to read this manual before using the machine.

Be sure to read this manual before using the machine.

We recommend that you keep this document nearby for future reference.

We recommend that you keep this document nearby for future reference.

HOW TO USE THIS MANUAL

The Operation Manuals for this machine consist of the Operation Manual (Sewing) and the Operation

Manual (Embroidery). Refer to the appropriate Operation Manual according to your needs. For basic

information about, for example, the included accessories or the settings screen, refer to chapter 1 of the

Operation Manual (Sewing).

In the screens appearing in the step-by-step instructions, the parts referred to in the operations are marked

with . Compare the screen in the directions with the actual screen, and carry out the operation.

If, while using the machine, you experience something you do not understand, or there is a function you

would like to know more about, refer to the index at the back of the Operation Manual in conjunction

with the table of contents to find the section of the manual you should refer to.

1

CONTENTS

CONTENTS

HOW TO USE THIS MANUAL ............................. 1

Chapter 1 Embroidery Step by Step 5

BEFORE EMBROIDERING .................................... 6

Using the Machine Setting Mode Key.................................... 7

Embroidery settings................................................................ 7

CHANGING THE PRESSER FOOT ........................ 9

Removing the Presser Foot ..................................................... 9

Attaching Embroidery Foot “W” ........................................... 10

CHANGING THE NEEDLE.................................. 11

ATTACHING THE EMBROIDERY UNIT ............. 13

About the Embroidery Unit................................................... 13

Removing the Embroidery Unit ............................................ 14

LOWER THREADING ......................................... 15

Winding the Bobbin ............................................................. 15

Setting the Bobbin ................................................................ 20

UPPER THREADING........................................... 22

Upper Threading.................................................................. 22

Using the Spool Stand .......................................................... 25

Using Threads that Unwind Quickly .................................... 27

PREPARING THE FABRIC ................................... 28

Attaching Iron-on Stabilizers (Backing) to the Fabric............. 28

Hooping the Fabric in the Embroidery Frame ....................... 29

Embroidering Small Fabrics or Fabric Edges ......................... 33

ATTACHING THE EMBROIDERY FRAME........... 34

EMBROIDERY SCREENS ..................................... 36

KEY FUNCTIONS ............................................... 38

Editing Patterns..................................................................... 38

Editing Letters....................................................................... 40

Embroidery Screen ............................................................... 41

SELECTING PATTERNS....................................... 43

Selecting Embroidery Patterns/Decorative Alphabet Patterns/

Utility Embroidery Patterns................................................... 43

Selecting Frame Patterns....................................................... 45

CONFIRMING THE PATTERN POSITION .......... 46

Checking the Embroidery Pattern with the Projector ............. 46

Checking the Needle Drop Point With the Projector ............ 47

Aligning the Embroidering Position Using the Built-In Camera

Using the Embroidery Position Sticker to Align the Embroidering

Position................................................................................ 49

Checking the Pattern Position............................................... 52

... 47

EMBROIDERING A PATTERN ............................ 53

Embroidering Attractive Finishes .......................................... 53

Embroidering Patterns .......................................................... 54

ADJUSTMENTS DURING THE EMBROIDERY

PROCESS.............................................................. 56

If the Bobbin Runs Out of Thread ......................................... 56

If the Thread Breaks During Embroidering............................ 57

Restarting from the Beginning............................................... 58

Resuming Embroidery After Turning Off the Power .............. 58

Chapter 2 Basic Editing 61

BASIC EDITING.................................................. 62

Previewing the Pattern.......................................................... 62

Moving the Pattern............................................................... 63

Rotating the Pattern.............................................................. 63

Changing the Size of the Pattern........................................... 64

Changing the Density........................................................... 66

Creating a Horizontal Mirror Image...................................... 67

Designing Repeated Patterns ................................................ 67

Embroidering the Pattern Repeatedly.................................... 70

Duplicating a Pattern............................................................ 73

Deleting the Pattern.............................................................. 73

Displaying Patterns in the Screen Magnified ......................... 73

EDITING LETTERS .............................................. 75

Selecting Alphabet Character Patterns .................................. 75

Character Alignment............................................................ 76

Changing Font Type............................................................. 76

Changing Letter Size............................................................ 77

Changing the Configuration of Alphabet Character Patterns

Changing Alphabet Character Spacing................................. 79

Re-editing Character Patterns............................................... 80

... 78

EDITING COLORS............................................. 81

Changing the Thread Color.................................................. 81

Find New Color Schemes With the Color Shuffling Function

Thread Color Sorting............................................................ 84

... 81

COMBINING PATTERNS ................................... 85

Editing Combined Patterns................................................... 85

Selecting Multiple Patterns at the Same Time....................... 87

Grouping Multiple Selected Patterns .................................... 88

Aligning the Embroidery Patterns......................................... 89

Embroidering Combined Patterns......................................... 90

Chapter 3 Advanced Editing 91

VARIOUS EMBROIDERING FUNCTIONS ......... 92

Uninterrupted Embroidering (Using a Single Color :

Monochrome) ...................................................................... 92

Display the Fabric While Aligning the Embroidering Position

Basting Embroidery.............................................................. 96

... 92

PRINT AND STITCH (COMBINING EMBROIDERY

PATTERNS AND PRINTED DESIGNS)................ 97

Selecting a Pattern............................................................... 98

Exporting the Background Image and Positioning Image ...... 98

Printing the Background and Embroidery Position Sheet ...... 99

Embroidering Patterns........................................................ 100

MAKING EMBROIDERY ADJUSTMENTS......... 102

Adjusting Thread Tension .................................................. 102

Adjusting the Alternate Bobbin Case (with No Color on the

Adjusting Screw)................................................................ 104

Using the Automatic Thread Cutting Function (End Color Trim)

Using the Thread Trimming Function (Jump Stitch Trim) .... 106

Adjusting the Embroidery Speed........................................ 107

Changing the Thread Color Display ................................... 107

Changing the Embroidery Frame Display........................... 108

Aligning the Pattern and the Needle .................................. 108

Embroidering Linked Characters ........................................ 109

... 105

USING THE MEMORY FUNCTION ................. 112

Embroidery Data Precautions............................................. 112

Saving Embroidery Patterns in the Machine’s Memory ....... 114

Retrieving Patterns from the Machine’s Memory................ 115

Saving Embroidery Patterns to USB Media/SD Card ........... 116

Recalling from USB Media/SD card ................................... 117

Saving/Deleting Multiple Patterns ...................................... 119

Transferring Embroidery Patterns ....................................... 119

Receiving Embroidery Patterns on the Machine ................. 120

EMBROIDERY APPLICATIONS ........................ 121

Creating an Appliqué Piece ............................................... 121

Using Appliqués ................................................................ 126

Using a Frame Pattern to Make an Appliqué (1) ................. 129

Using a Frame Pattern to Make an Appliqué (2) ................. 130

Creating Stippling or Echo Patterns Automatically .............. 131

Embroidering Quilting Border Patterns............................... 132

Embroidering Split Embroidery Patterns ............................. 134

USING THE CAMERA TO CONNECT PATTERNS

Connecting Three Patterns ................................................. 136

Changing the Position of a Sticker...................................... 142

Connecting Large-Size Split Embroidery Patterns ............... 144

Resume Feature ................................................................. 145

... 136

Chapter 4 My Design Center 147

ABOUT MY DESIGN CENTER.......................... 148

PATTERN DRAWING SCREEN......................... 149

Before Creating Designs..................................................... 151

2

Drawing Lines.................................................................... 151

Drawing Regions ............................................................... 153

Using the Stamp Key.......................................................... 154

Using the Erase Key ........................................................... 155

Using the Select Key .......................................................... 156

STITCH SETTINGS SCREEN .............................. 157

Specifying Individual Stitch Settings ................................... 157

Specifying Global Stitch Settings........................................ 159

MY DESIGN CENTER WITH SCAN .................. 160

Using the Scanning Frame ................................................. 160

Scanning to Trace Background Image ................................ 161

LINE SCAN ....................................................... 165

Using the Scanning Frame to Create a Pattern with Line Scan

ILLUSTRATION SCAN...................................... 168

Using the Scanning Frame to Create a Pattern with Illustration

Scan................................................................................... 168

STIPPLING ....................................................... 171

Basic Stippling with My Design Center .............................. 171

Scanning Drawing to Create Stippling Pattern.................... 173

Scanning Fabric and Stippling............................................ 177

Decorative Stitching Around a Pattern in Embroidery (a Quilting

Function) ........................................................................... 181

Chapter 5 Appendix 185

TROUBLESHOOTING ...................................... 186

List of Symptoms................................................................ 186

ERROR MESSAGES ........................................... 192

INDEX .............................................................. 197

... 165

CONTENTS

1

2

3

4

5

3

CONTENTS

4

Chapter 1

Embroidery Step by Step

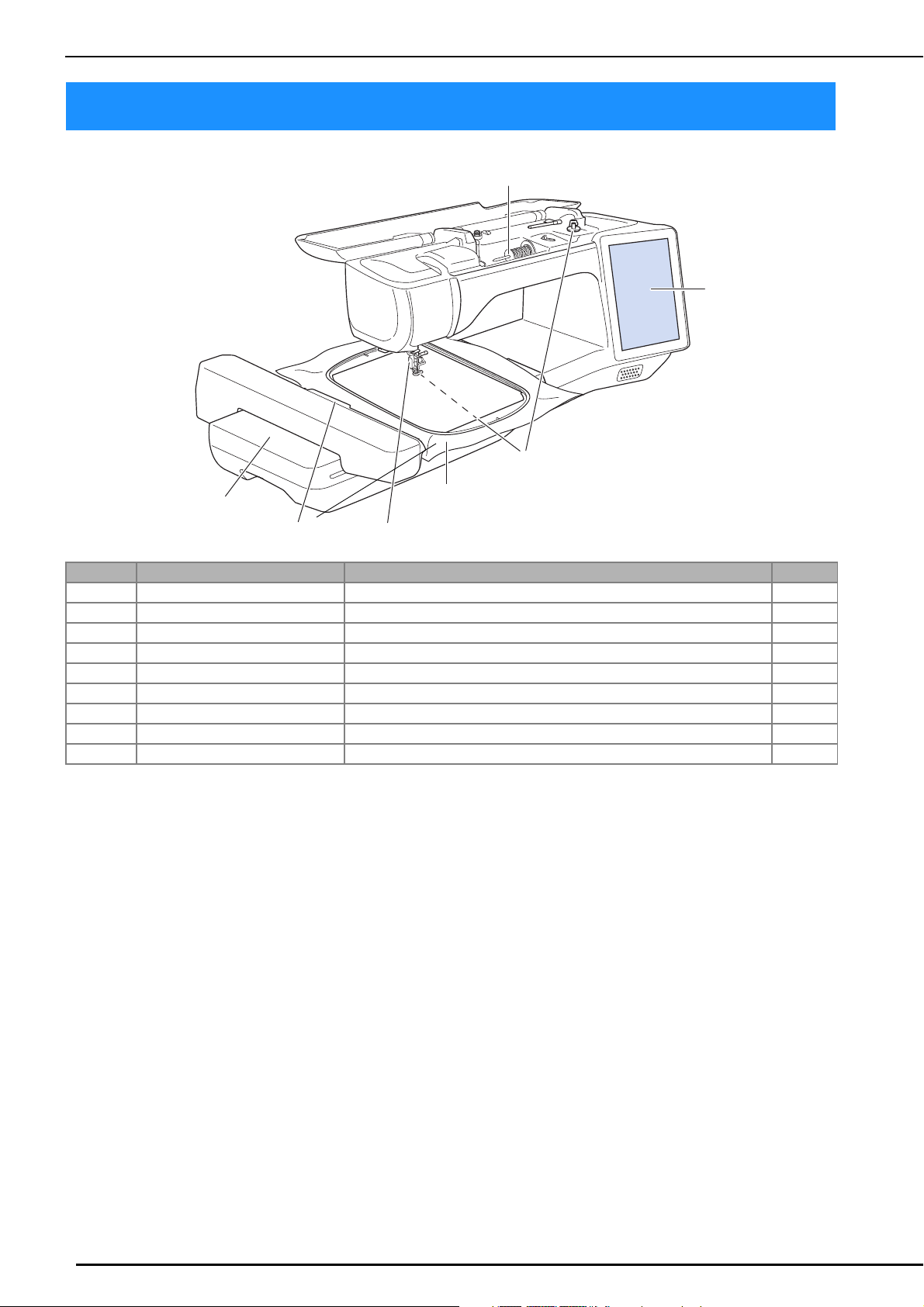

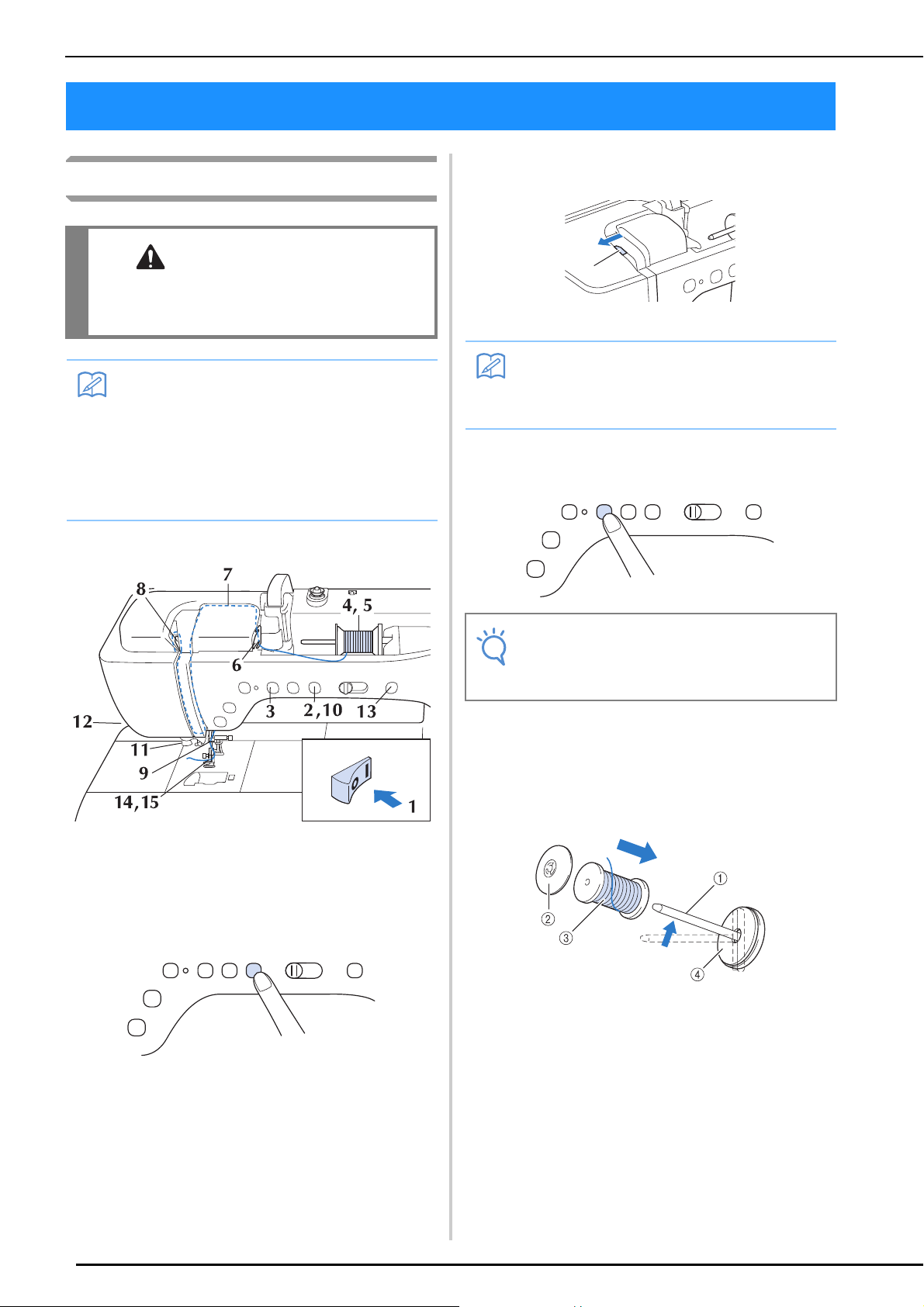

BEFORE EMBROIDERING

Step 3

Step 1, 2

Step 7

Step 5

Step 4

Step 6, 8

Step 9

BEFORE EMBROIDERING

Follow the steps below to prepare the machine for embroidery.

Step # Aim Action Page

1 Presser foot attachment Attach embroidery foot “W”. 9

2 Checking the needle Use needle 75/11 for embroidery. * —

3 Embroidery unit attachment Attach the embroidery unit. 13

4 Bobbin thread setup For the bobbin thread, wind embroidery bobbin thread and set it in place. 15

5 Fabric preparation Attach a stabilizer material to the fabric, and hoop it in the embroidery frame. 28

6 Pattern selection Turn the main power to ON, and select an embroidery pattern. 36

7 Embroidery frame attachment Attach the embroidery frame to the embroidery unit. 34

8 Checking the layout Check and adjust the size and position of the embroidery. 46

9 Embroidery thread setup Set up embroidery thread according to the pattern. 22

* It is recommended that a 90/14 needle should be used when embroidering on heavy weight fabrics or stabilizing products (for example;

denim, puffy foam, etc.). Ball point needle (golden colored) 90/14 is not recommended for embroidery.

6

BEFORE EMBROIDERING

Memo

a

d

e

f

b

c

k

l

g

h

j

m

i

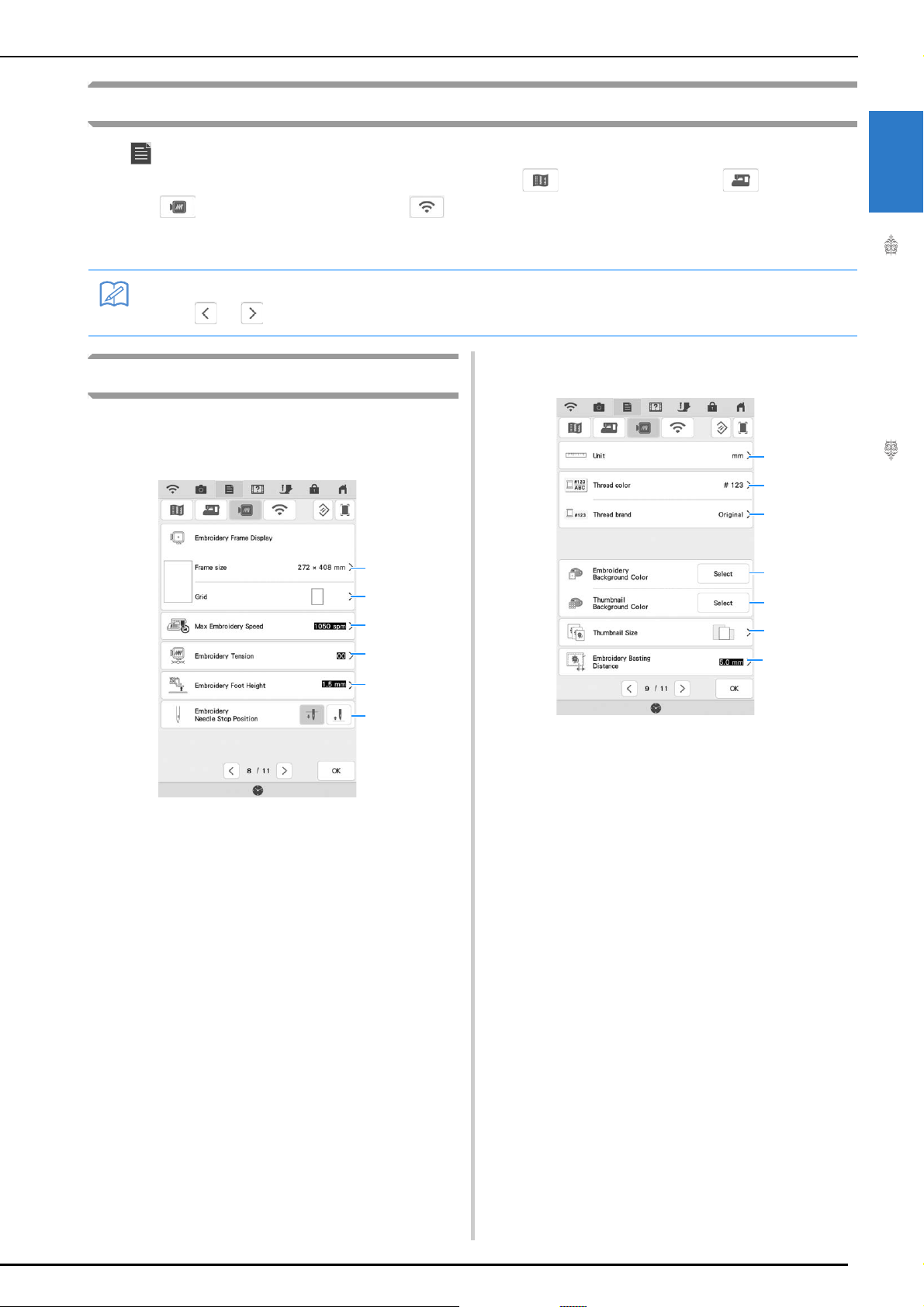

Using the Machine Setting Mode Key

Press to change the default machine settings (needle stop position, embroidery speed, opening

display, etc.). To display the different settings screens, press for “Sewing settings”, for “General

settings”, for “Embroidery settings” or for “Wireless LAN settings”. For details on settings for

sewing utility stitches, on common settings and on wireless settings, refer to the Operation Manual

(Sewing).

• Press or to display a different settings screen.

■ Page 9

Embroidery settings

■ Page 8

1

Embroidery Step by Step

a Select from among 12 embroidery frame displays

(page 108).

b Change the center point marker or grid lines

(page 108).

c Adjust the maximum embroidery speed setting

(page 107).

d Adjust the upper thread tension for embroidering

(page 103).

e Select the height of the embroidery foot during

embroidering.

f Adjust the needle position for embroidering.

g Change the display units (mm/inch).

h Change the thread color display on the

“Embroidery” screen; thread number, color name

(page 107).

i Select the thread brand used to display a pattern

when it is opened (page 107).

j Change the color of the background for the

embroidery display area.

k Change the color of the background for the

thumbnail area.

l Press to specify the size of pattern thumbnails.

m Adjust the distance between the pattern and the

basting stitching (page 96).

7

BEFORE EMBROIDERING

n

o

p

q

■ Page 10

n Select the quality for displaying the fabric in the

screen (page 94).

o Erase the scanned image (page 94).

p Set to “ON” when positioning the pattern on the

thick fabric using the built-in camera (page 95).

q Adjust the position and brightness of the

embroidery foot “W+” with LED pointer (sold

separately). (These settings are not available

unless embroidery foot “W+” with LED pointer is

installed on the machine.)

8

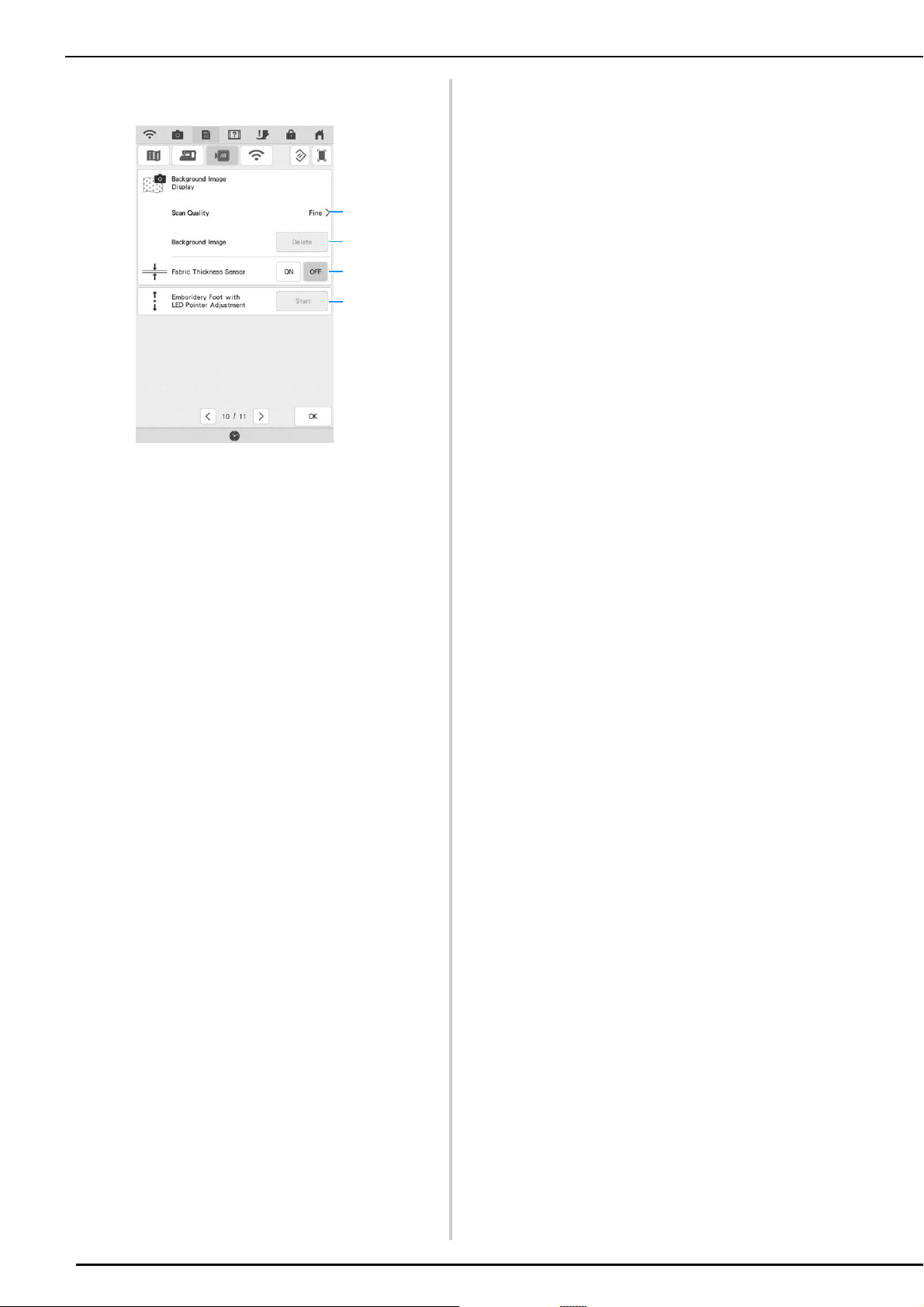

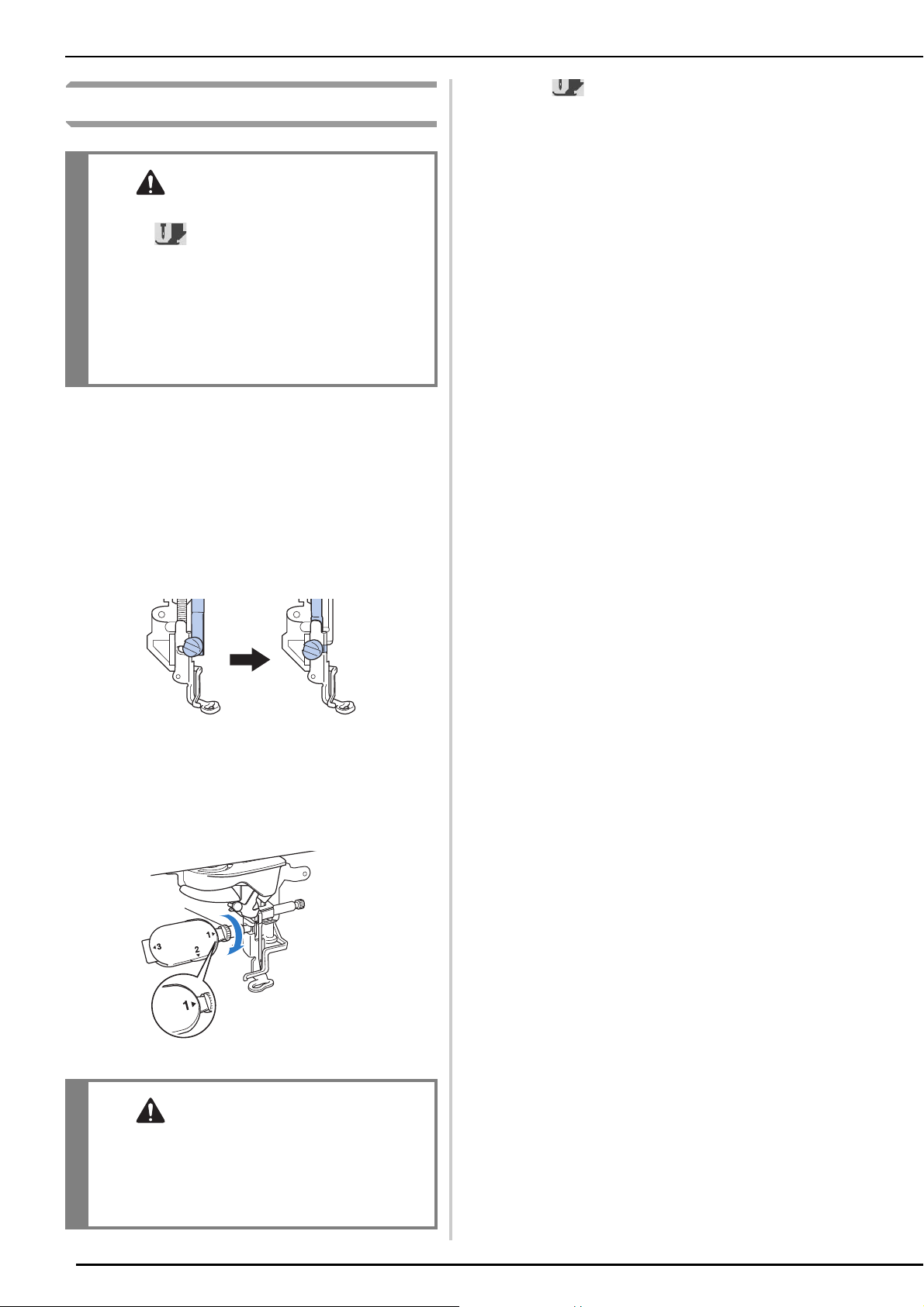

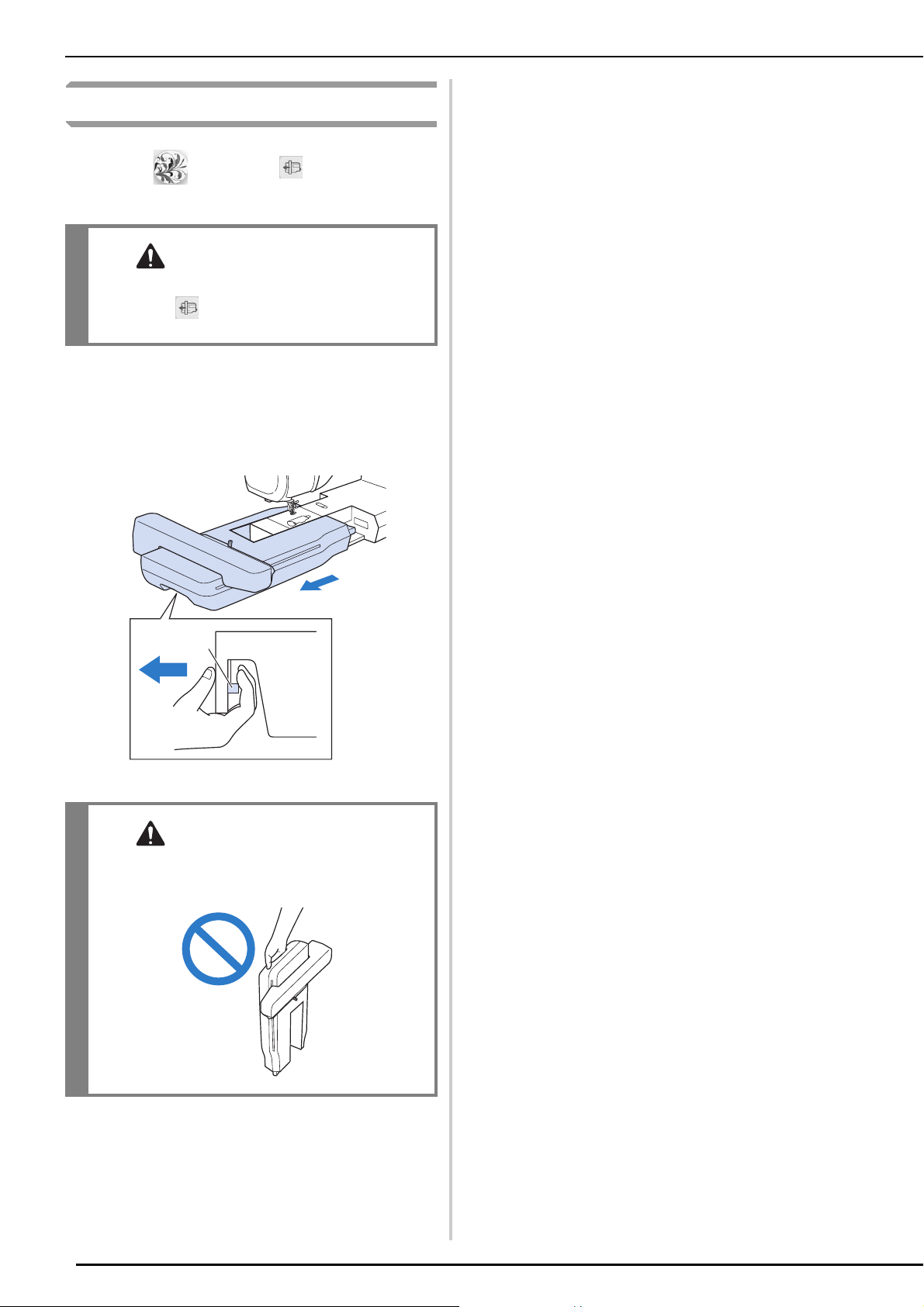

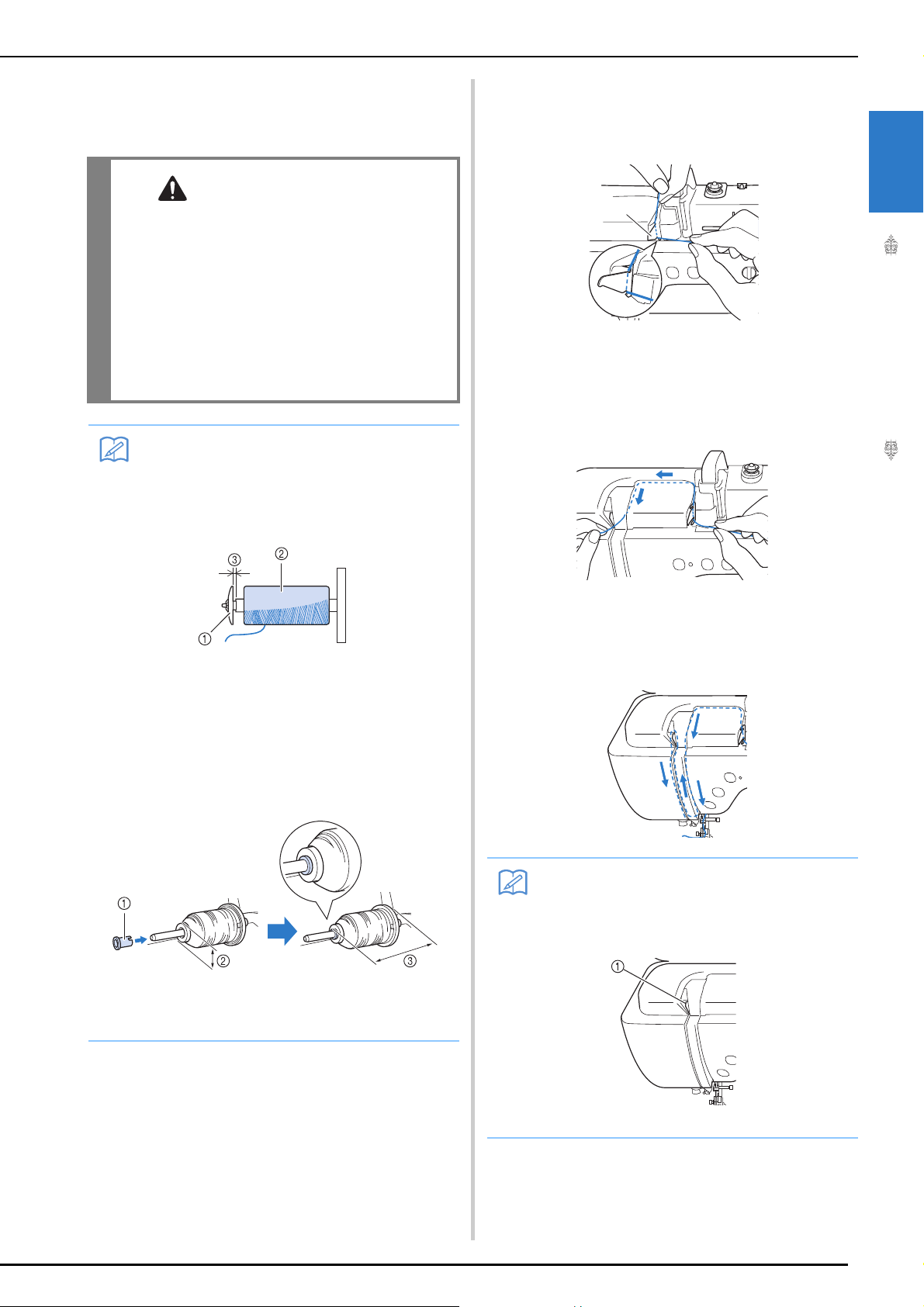

CHANGING THE PRESSER FOOT

CAUTION

b

a

CHANGING THE PRESSER FOOT

• Always press on the screen to lock all keys and buttons before changing the presser foot. If is

not pressed and the “Start/Stop” button or another button is pressed, the machine will start and may

cause injury.

• Only use presser feet made for this machine. Using other presser feet may lead to accident or injury.

Loosen the screw of the presser foot holder

Removing the Presser Foot

Press the “Needle Position” button to raise

a

the needle.

e

to remove the presser foot holder.

1

Embroidery Step by Step

Press to lock all keys and buttons.

b

* If the message “OK to automatically lower the

presser foot?” appears on the LCD screen, press

to continue.

Raise the presser foot lever.

c

Press the black button on the presser foot

d

holder and remove the presser foot.

a Multi-purpose screwdriver

b Presser foot holder screw

c Presser foot holder

Remove the screw of the presser foot

f

completely from the presser foot shaft.

a Black button

b Presser foot holder

9

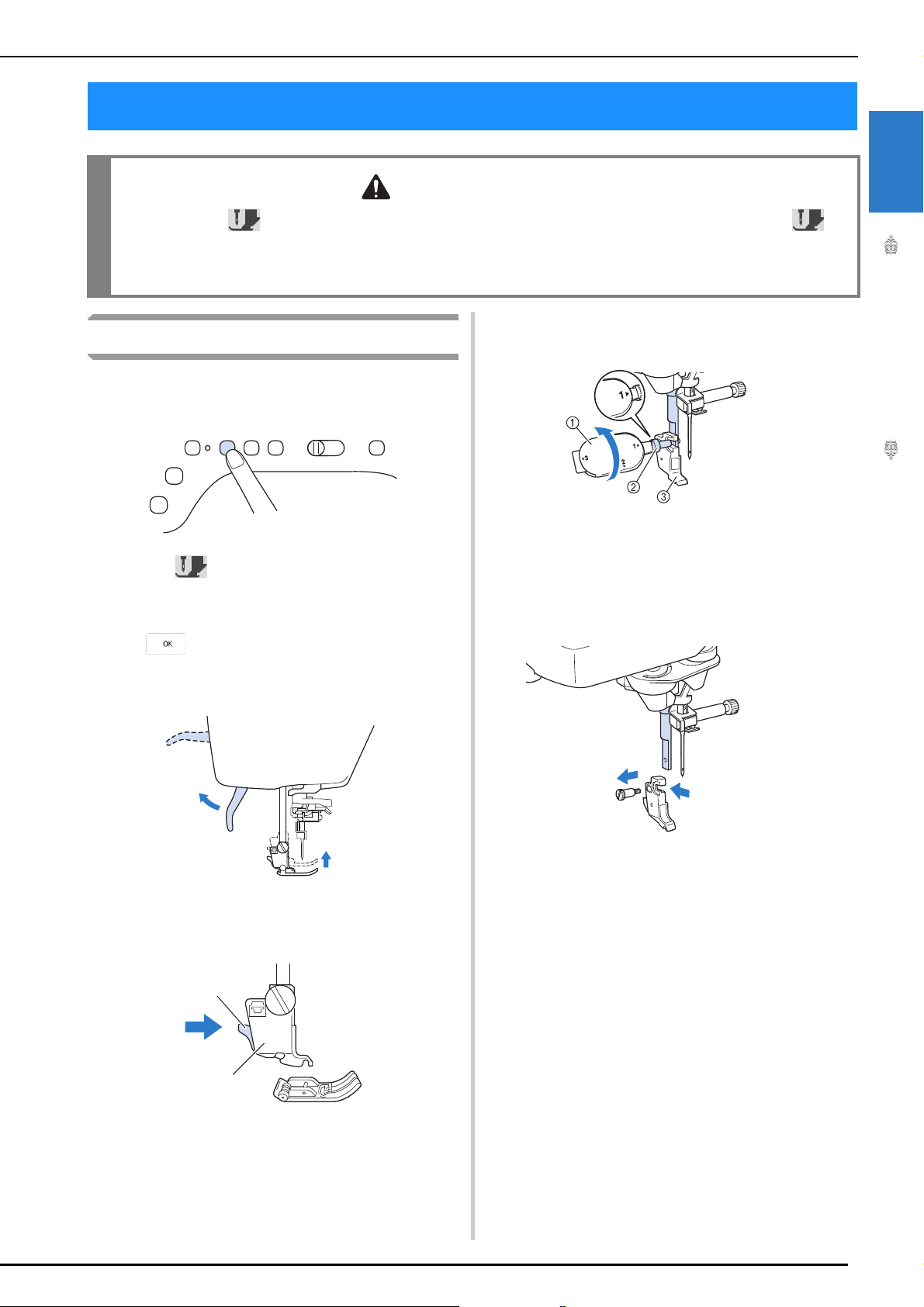

CHANGING THE PRESSER FOOT

CAUTION

CAUTION

a

Attaching Embroidery Foot “W”

• When attaching an embroidery foot, always

press on the screen. You may

accidentally press the “Start/Stop” button and

possibly cause injury.

• Be sure to use embroidery foot “W” when

doing embroidery. Using another embroidery

foot may cause the needle to strike the

embroidery foot, causing the needle to bend or

break and possibly cause injury.

Remove the presser foot and presser foot

a

holder. For details, refer to “Removing the

Presser Foot” on page 9.

Press to unlock all keys and buttons.

d

All keys and operation buttons are unlocked, and

the previous screen is displayed.

Position the embroidery foot “W” on the

b

presser foot bar by aligning the notch of the

presser foot to the large screw.

Side view

Hold the embroidery foot in place with

c

your right hand, and then use the included

multi-purpose screwdriver to securely

tighten the presser foot holder screw.

10

a Presser foot holder screw

• Use the included multi-purpose screwdriver to

firmly tighten the screw of the presser foot

holder. If the screw is loose, the needle may

strike the embroidery foot and possibly cause

injury.

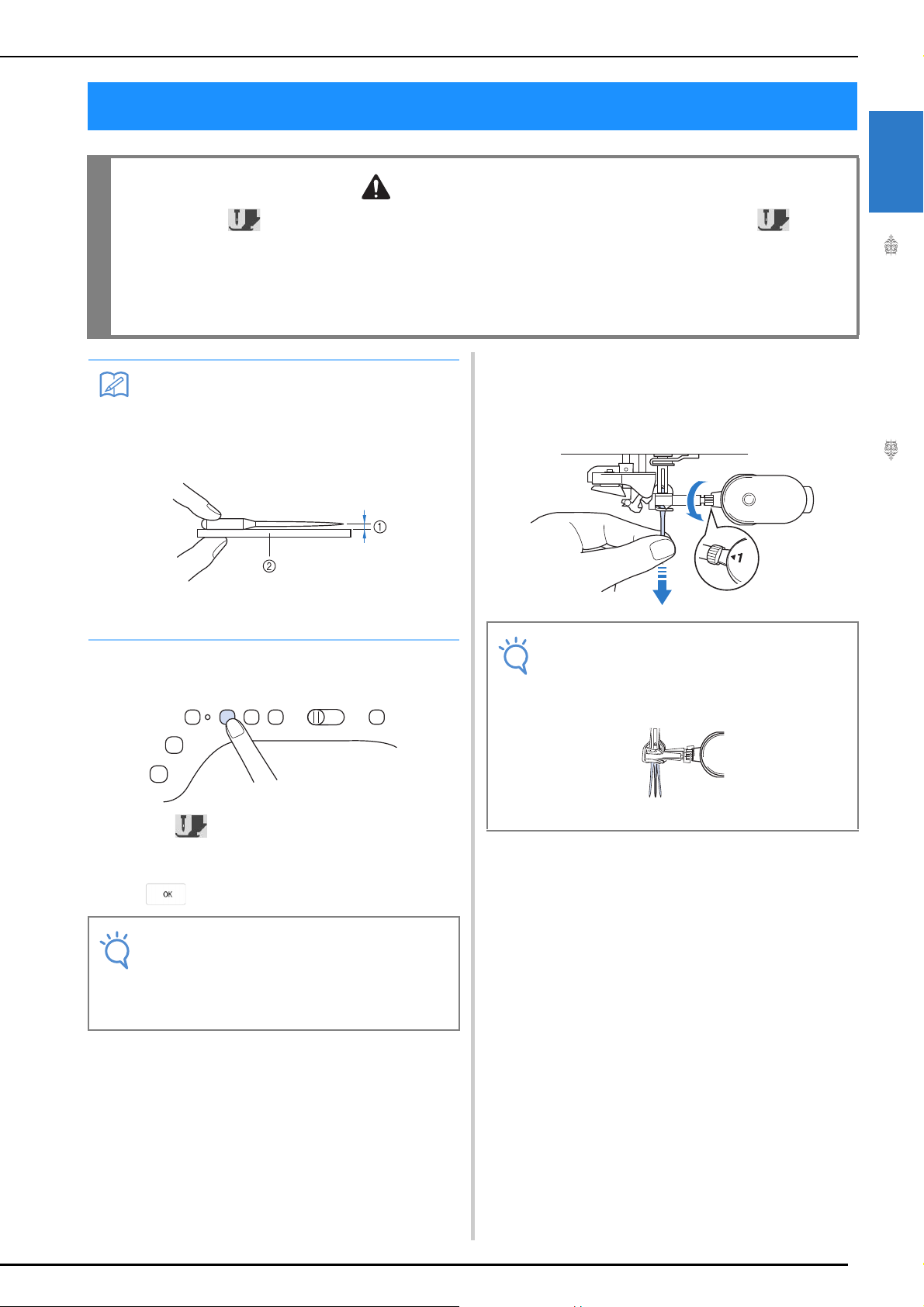

CHANGING THE NEEDLE

CAUTION

Memo

Note

Note

CHANGING THE NEEDLE

• Always press on the screen to lock all keys and buttons before changing the needle. If is not

pressed and the “Start/Stop” button or another operation button is pressed accidentally, the machine will

start and injury may result.

• Use only home sewing machine needles made for home use. Other needles may bend or break and may

cause injury.

• Never embroider with a bent needle. A bent needle will easily break and may cause injury.

Use the screwdriver to turn the needle

c

clamp screw toward the front of the

• To check the needle correctly, place the flat

side of the needle on a flat surface. Check

the needle from the top and the sides.

Throw away any bent needles.

machine and loosen the screw. Remove the

needle.

1

Embroidery Step by Step

a Parallel space

b Level surface (bobbin cover, glass, etc.)

Press the “Needle Position” button to raise

a

the needle.

Press to lock all keys and buttons.

b

* If the message “OK to automatically lower the

presser foot?” appears on the LCD screen, press

to continue.

• Before replacing the needle, cover the hole

in the needle plate with fabric or paper to

prevent the needle from falling into the

machine.

• Do not apply pressure to the needle clamp

screw. Doing so may damage the needle or

machine.

11

CHANGING THE NEEDLE

CAUTION

a

b

c

With the flat side of the needle facing the

d

back, insert the new needle all the way to

the top of the needle stopper (viewing

window) in the needle clamp. Use a

screwdriver to securely tighten the needle

clamp screw.

a Needle stopper

b Hole for setting the needle

c Flat side of needle

• Be sure to push in the needle until it touches

the stopper, and securely tighten the needle

clamp screw with a screwdriver. If the needle

is not completely inserted or the needle clamp

screw is loose, the needle may break or the

machine may be damaged.

Press to unlock all keys and buttons.

e

12

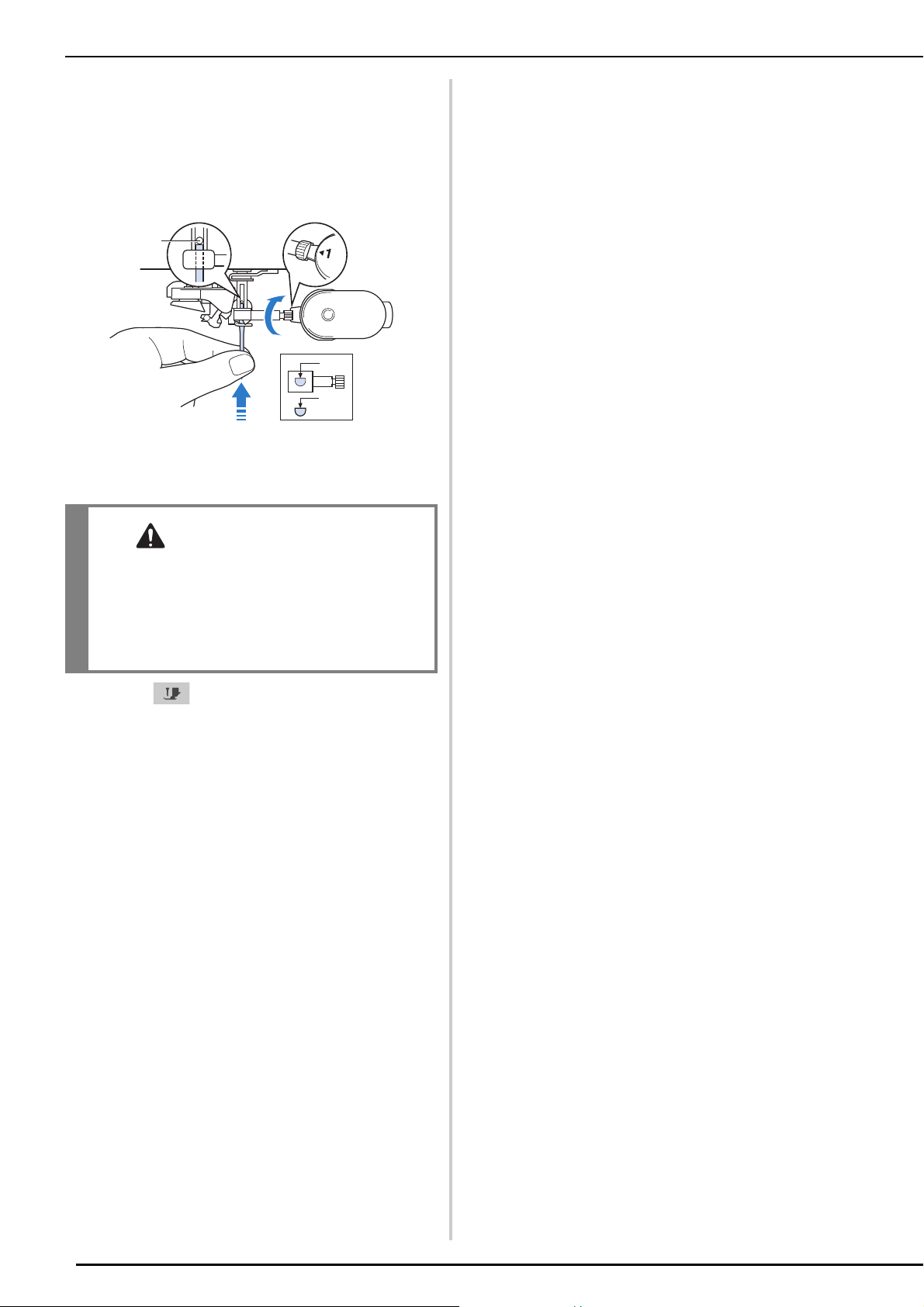

ATTACHING THE EMBROIDERY UNIT

CAUTION

Note

Note

ATTACHING THE EMBROIDERY UNIT

Insert the embroidery unit connection into

About the Embroidery Unit

• Do not move the machine with the embroidery

unit attached. The embroidery unit could fall

off and cause injury.

• Keep your hands and foreign objects away

from the embroidery carriage and frame when

the machine is embroidering. Otherwise,

injuries or damage may result.

• To avoid distorting your embroidery design, do

not touch the embroidery carriage and frame

when the machine is embroidering.

• Be sure to turn off the power before installing

the embroidery unit. Otherwise, the machine

may be damaged.

• Do not touch the inner connector of the

embroidery unit. The pins on the embroidery

unit connection may be damaged.

• Do not apply strong force to the embroidery

unit carriage or pick up the unit by the

carriage. Otherwise, the embroidery unit may

be damaged.

• Store the embroidery unit in a safe place to

prevent damage to the unit.

• Do not push on the carriage when installing

the embroidery unit onto the machine. Moving

the carriage may damage the embroidery unit.

• Allow sufficient space around the embroidery

unit. Otherwise, the embroidery unit could fall

off foreign object, and may cause injury.

• Do not touch the embroidery carriage until the

initialization finishes.

b

the machine connection port. Push lightly

on the connection port cover until the unit

clicks into place.

a Embroidery unit connection

b Machine connection port

• Be sure there is no gap between the

embroidery unit and the machine. If there is

a gap, the embroidery patterns will not

embroider with the correct registration.

Turn the main power to ON.

c

Press .

d

The carriage will move to the initialization position.

a

1

Embroidery Step by Step

b

• You can also sew utility/decorative stitches

with the embroidery unit attached. Touch

and . The feed dog will

automatically raise for utility and decorative

stitching.

Turn the main power to OFF, and remove

a

the flat bed attachment.

13

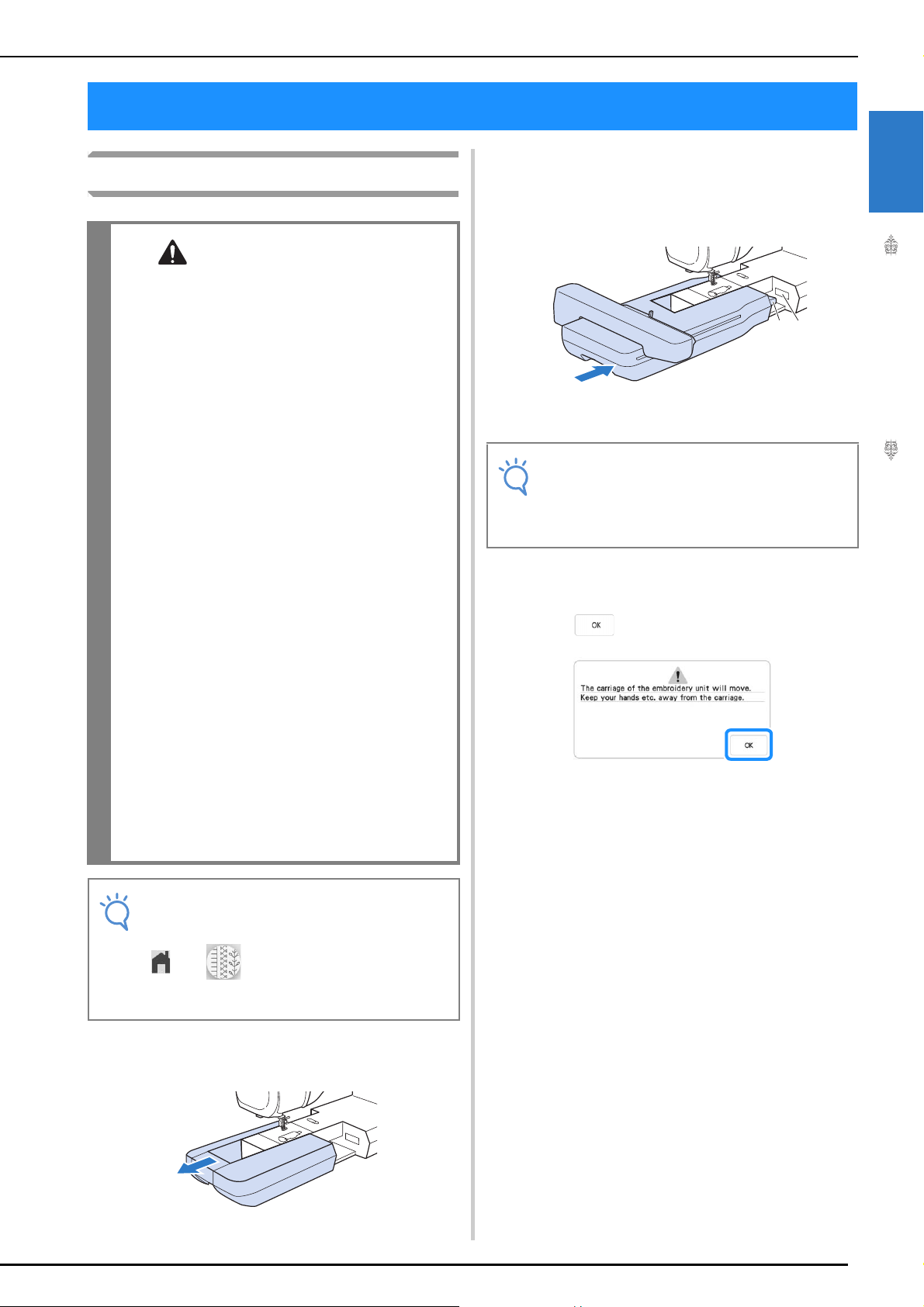

ATTACHING THE EMBROIDERY UNIT

CAUTION

CAUTION

a

Removing the Embroidery Unit

Press , then press .

a

The carriage will move to the removal position.

• Always remove the embroidery frame before

pressing . Otherwise, the frame may strike

the embroidery foot, and possibly cause injury.

Turn the main power to OFF.

b

Press the release button, and pull the

c

embroidery unit away from the machine.

a Release button

• Do not carry the embroidery unit by holding

the release button compartment.

14

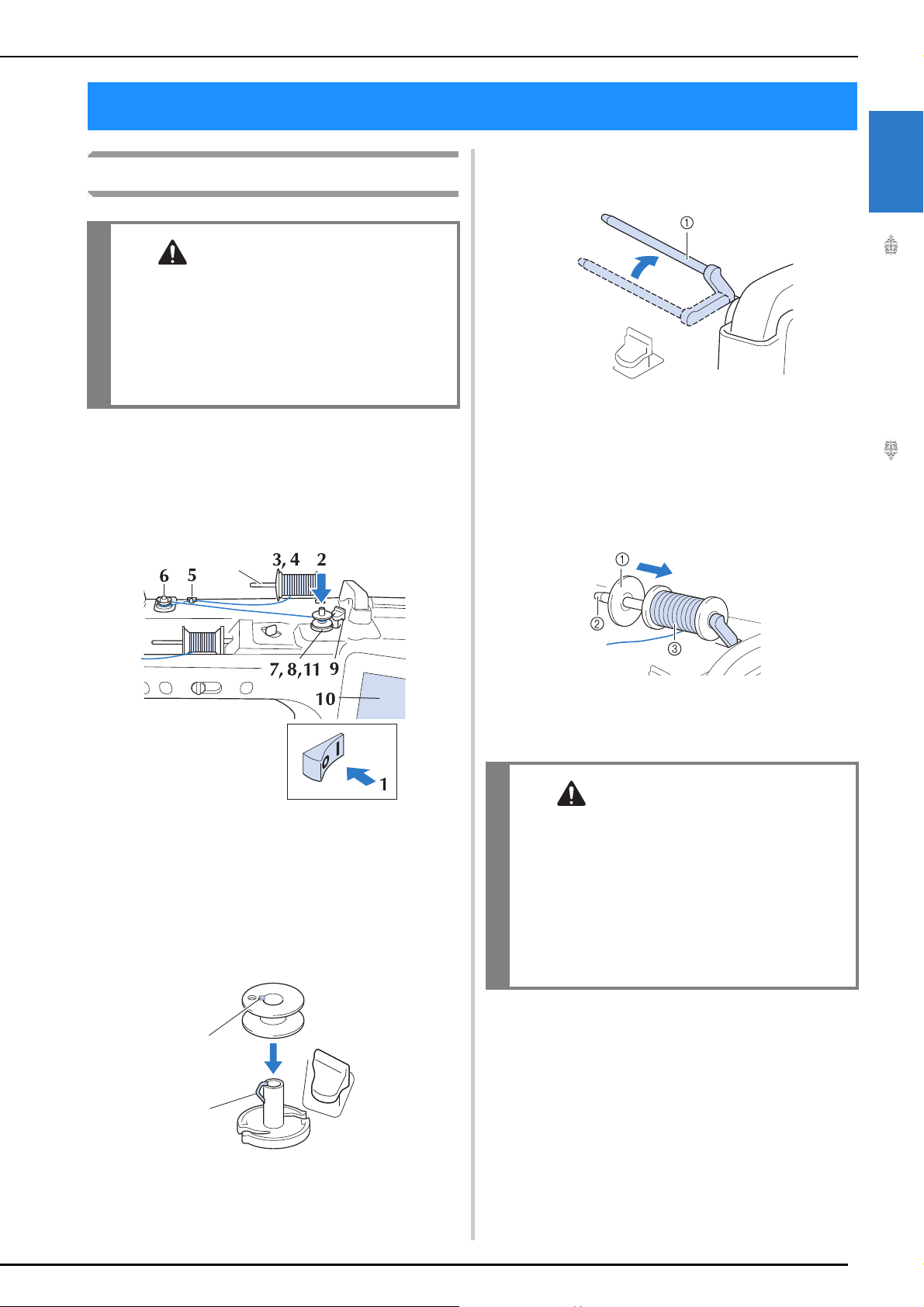

LOWER THREADING

CAUTION

a

CAUTION

Winding the Bobbin

• The included bobbin was designed specifically

for this machine. If bobbins from other models

are used, the machine will not operate

correctly. Use only the included bobbin or

bobbins of the same type (part code: SA156,

(SFB: XA5539-151 / 115J05E0001)). SA156 is

Class 15 type bobbin.

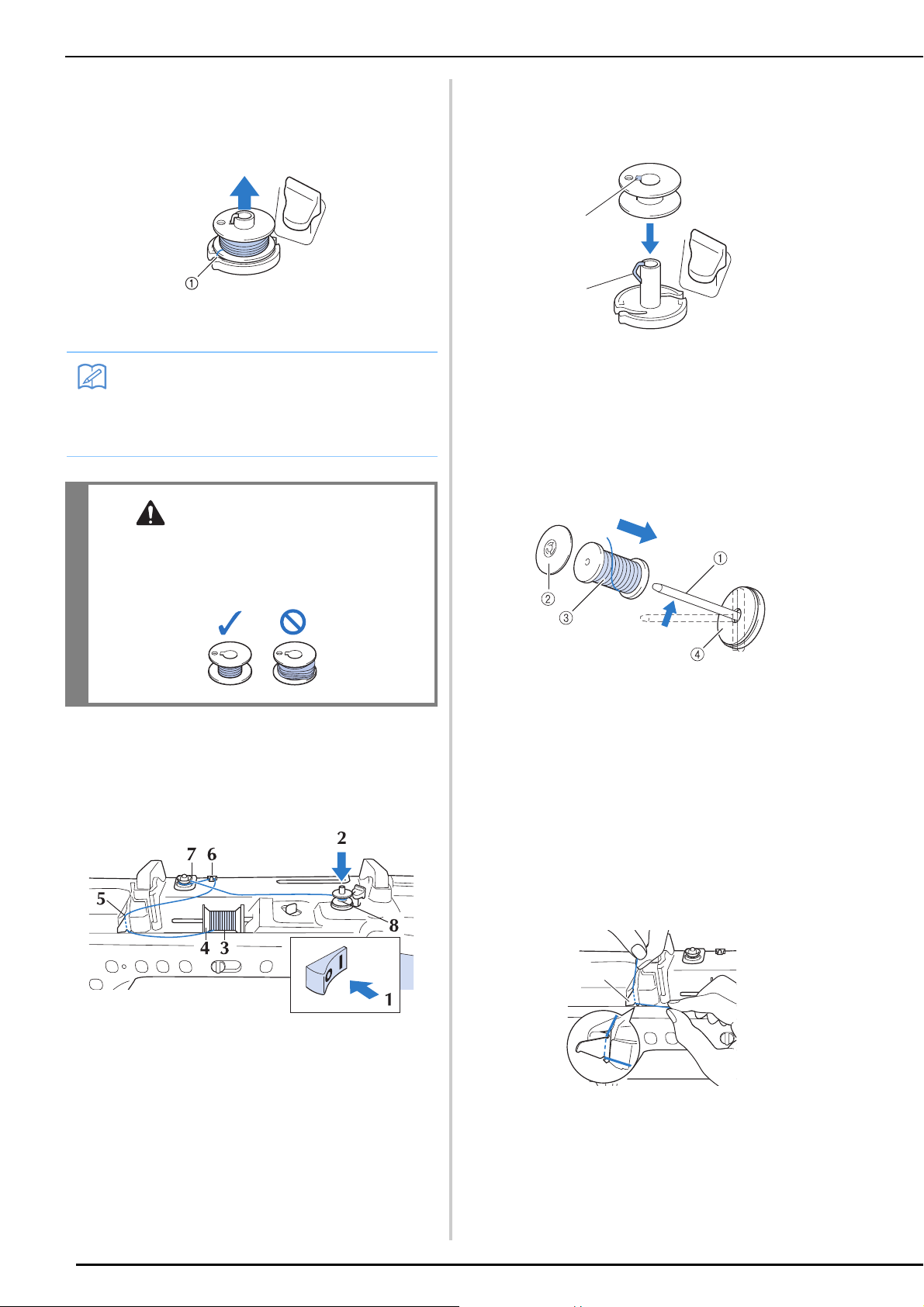

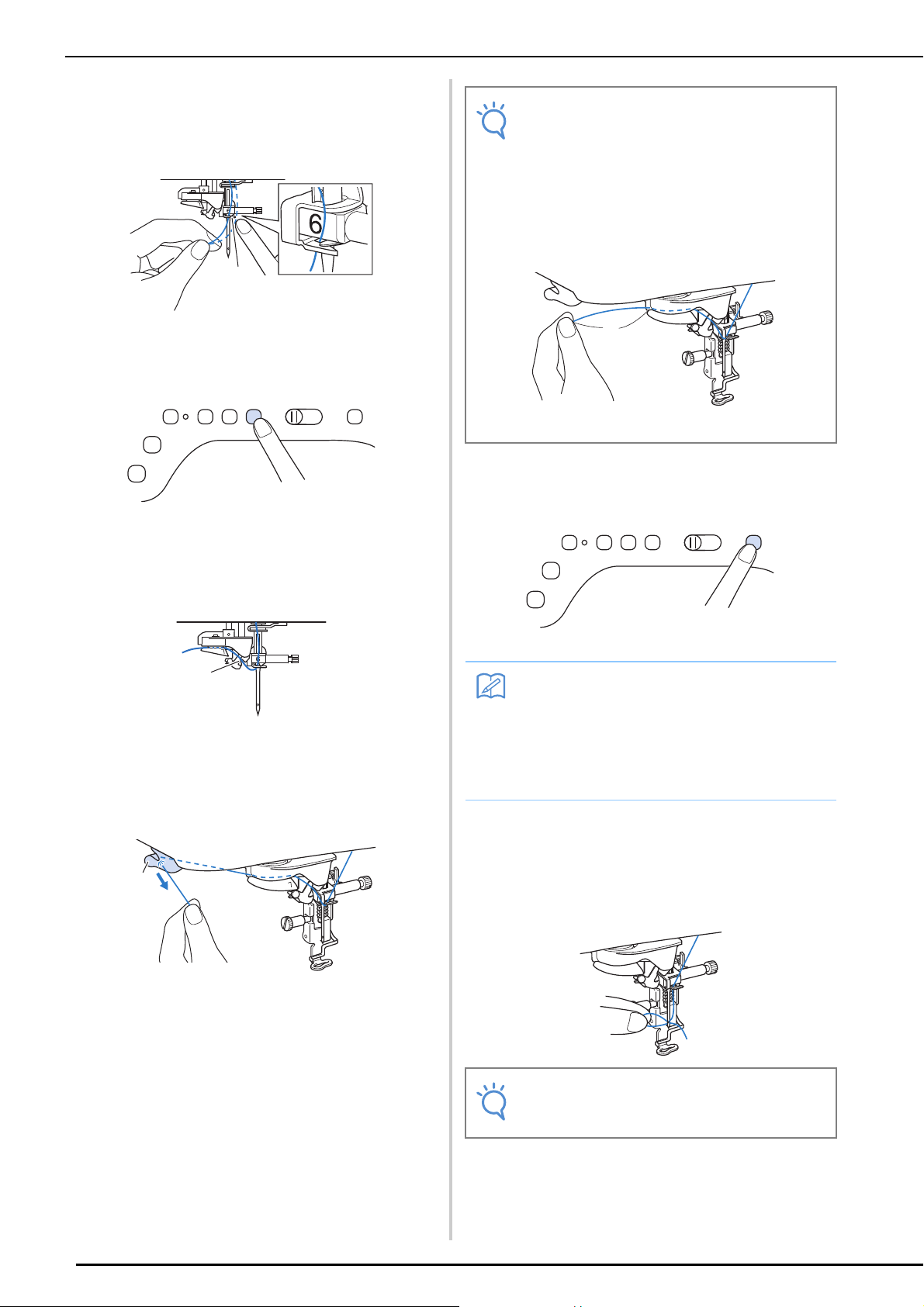

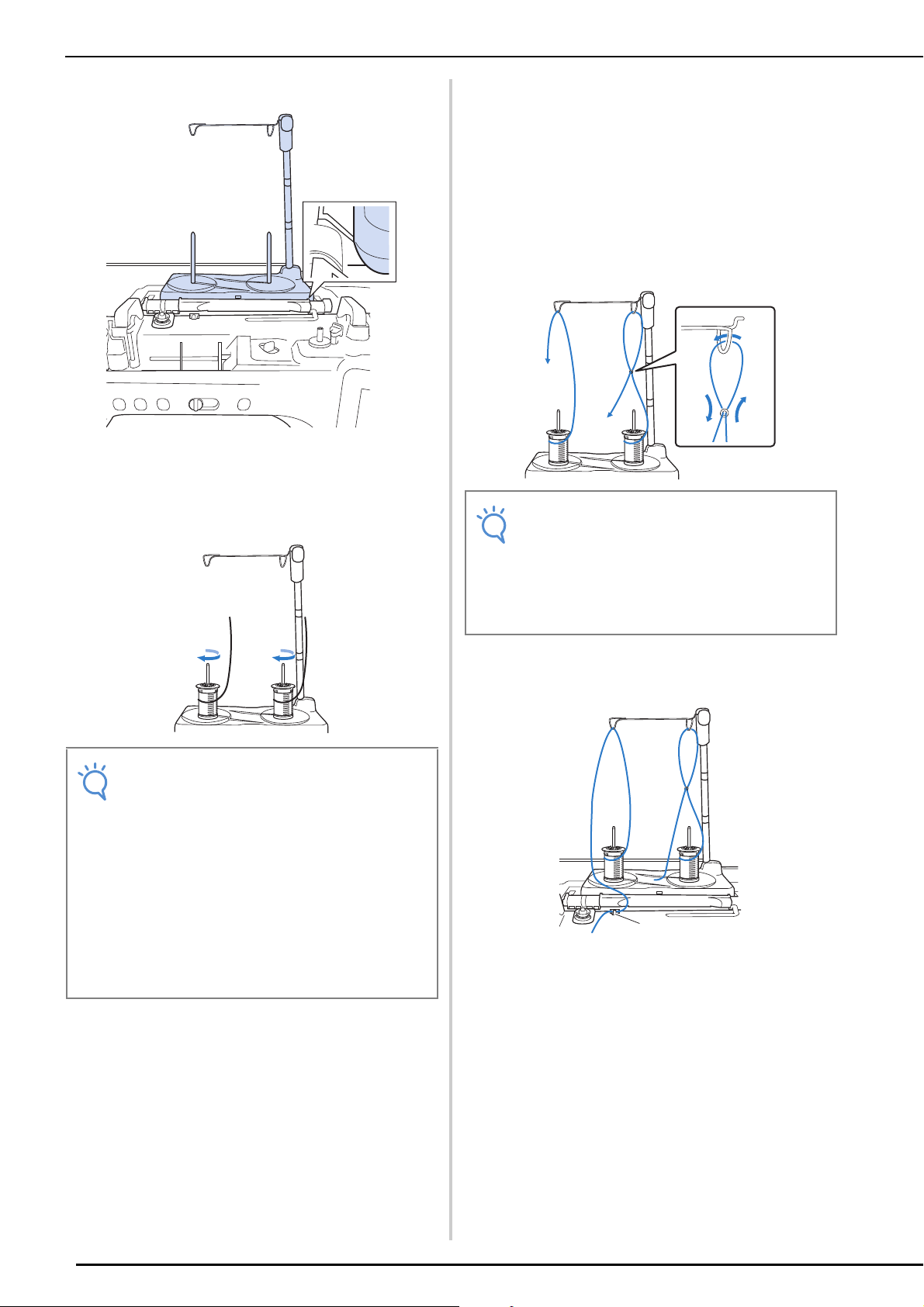

■ Using the Supplemental Spool Pin

With this machine, you can wind the bobbin during

embroidering. While the main spool pin is being

used for embroidering, you can wind a bobbin by

using the supplemental spool pin.

LOWER THREADING

Set the supplemental spool pin in the “up”

c

position.

a Supplemental spool pin

Place the spool of thread on the

d

supplemental spool pin, so that thread

unrolls from the front. Push the spool cap

onto the spool pin as far as possible to

secure the thread spool.

1

Embroidery Step by Step

a Supplemental spool pin

Turn the main power to ON and open the

a

top cover.

Align the groove in the bobbin with the

b

spring on the bobbin winder shaft, and set

the bobbin on the shaft.

a

b

a Spool cap

b Spool pin

c Thread spool

• If the thread spool and/or spool cap are set

incorrectly, the thread may tangle on the spool

pin and cause the needle to break.

• Use the spool cap (large, medium or small)

that is closest in size to the thread spool. If a

spool cap smaller than the thread spool is

used, the thread may become caught in the slit

on the end of the spool and cause the needle

to break.

a Groove in the bobbin

b Spring on the shaft

15

LOWER THREADING

Memo

• When embroidering with fine, cross-wound

thread, use the small spool cap, and leave a

small space between the cap and the

thread spool.

a Spool cap (small)

b Thread spool (cross-wound thread)

c Space

• If a spool of thread whose core is 12 mm (1/

2 inch) in diameter and 75 mm (3 inches)

high is inserted onto the spool pin, use the

mini spool cap.

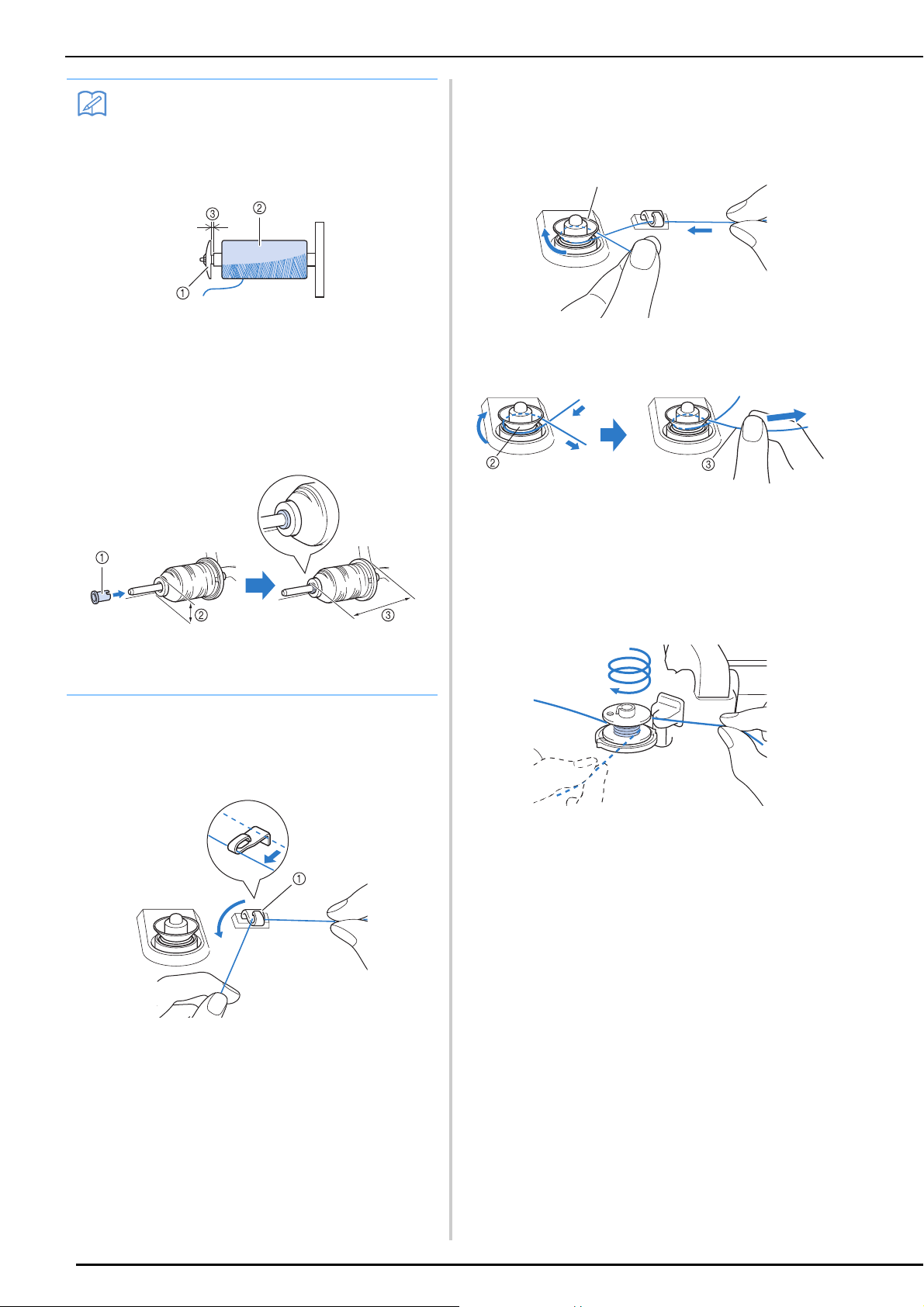

Pass the thread around the pretension disk

f

making sure that the thread is under the

pretension disk.

a

a Pretension disk

Make sure that the thread passes under the

pretension disk.

a Spool cap (mini king thread spool)

b 12 mm (1/2 inch)

c 75 mm (3 inches)

With your right hand, hold the thread near

e

the thread spool. With your left hand, hold

the end of the thread, and use both hands to

pass the thread through the thread guide.

b Pretension disk

c Pull it in as far as possible.

Check to make sure thread is securely set between

pretension disks.

Wind the thread clockwise around the

g

bobbin 5-6 times.

16

a Thread guide

Pass the end of the thread through the guide

CAUTION

Memo

a

b

c

Note

Note

Memo

h

slit in the bobbin winder seat, and pull the

thread to the right to cut the thread with

the cutter.

a Guide slit (with built-in cutter)

b Bobbin winder seat

• Be sure to follow the process described. If the

thread is not cut with the cutter, and the

bobbin is wound, when the thread runs low it

may tangle around the bobbin and cause the

needle to break.

LOWER THREADING

• When winding transparent nylon thread on

the bobbin, stop bobbin winding when the

bobbin is 1/2 to 2/3 full. If the bobbin was

fully wound with transparent nylon thread, it

may not be wound neatly.

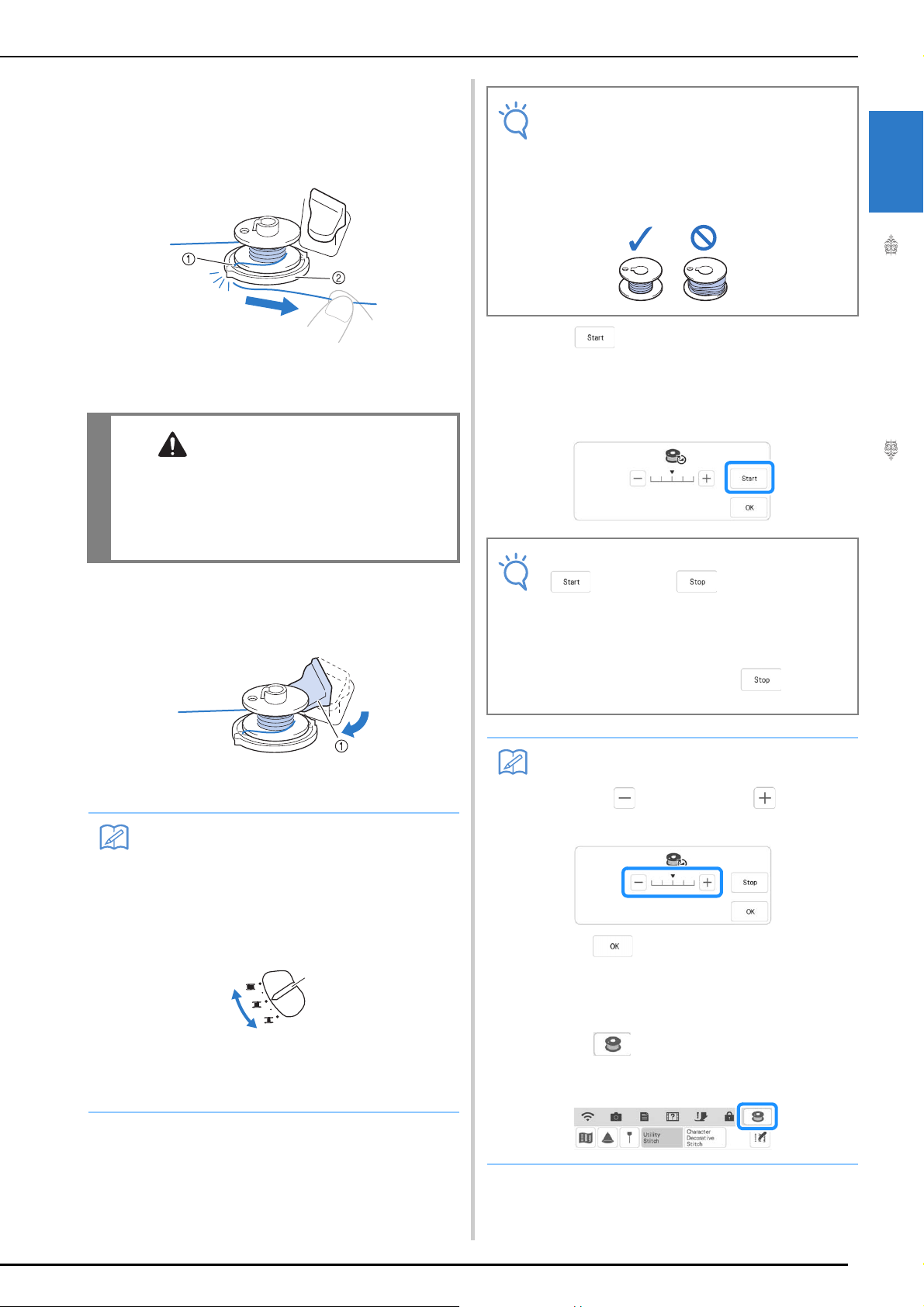

Press .

j

Bobbin winding starts. The bobbin stops rotating

when bobbin winding is completed. The bobbin

winding switch will automatically return to its

original position.

1

Embroidery Step by Step

Set the bobbin winding switch to the left,

i

until it clicks into place.

a Bobbin winding switch

• Sliding the bobbin winding switch to the left

switches the machine into bobbin winding

mode.

• Use the bobbin winding slider to adjust the

amount of thread wound onto the bobbin to

one of five levels.

• changes to while the bobbin is

winding.

• Stay near the machine while winding the

bobbin to make sure the bobbin thread is

being wound correctly. If the bobbin thread

is wound incorrectly, press

immediately to stop the bobbin winding.

• You can change the winding speed by

pressing (to decrease) or (to

increase) in the bobbin winding window.

• Press to minimize the bobbin winding

window. Then, you can perform other

operations, such as selecting a stitch or

adjusting the thread tension, while the

bobbin is being wound.

a Bobbin winding slider

b More

c Less

The bobbin winding window appears.

• Press (in top right of the LCD screen)

to display the bobbin winding window

again.

17

LOWER THREADING

Memo

CAUTION

a

b

a

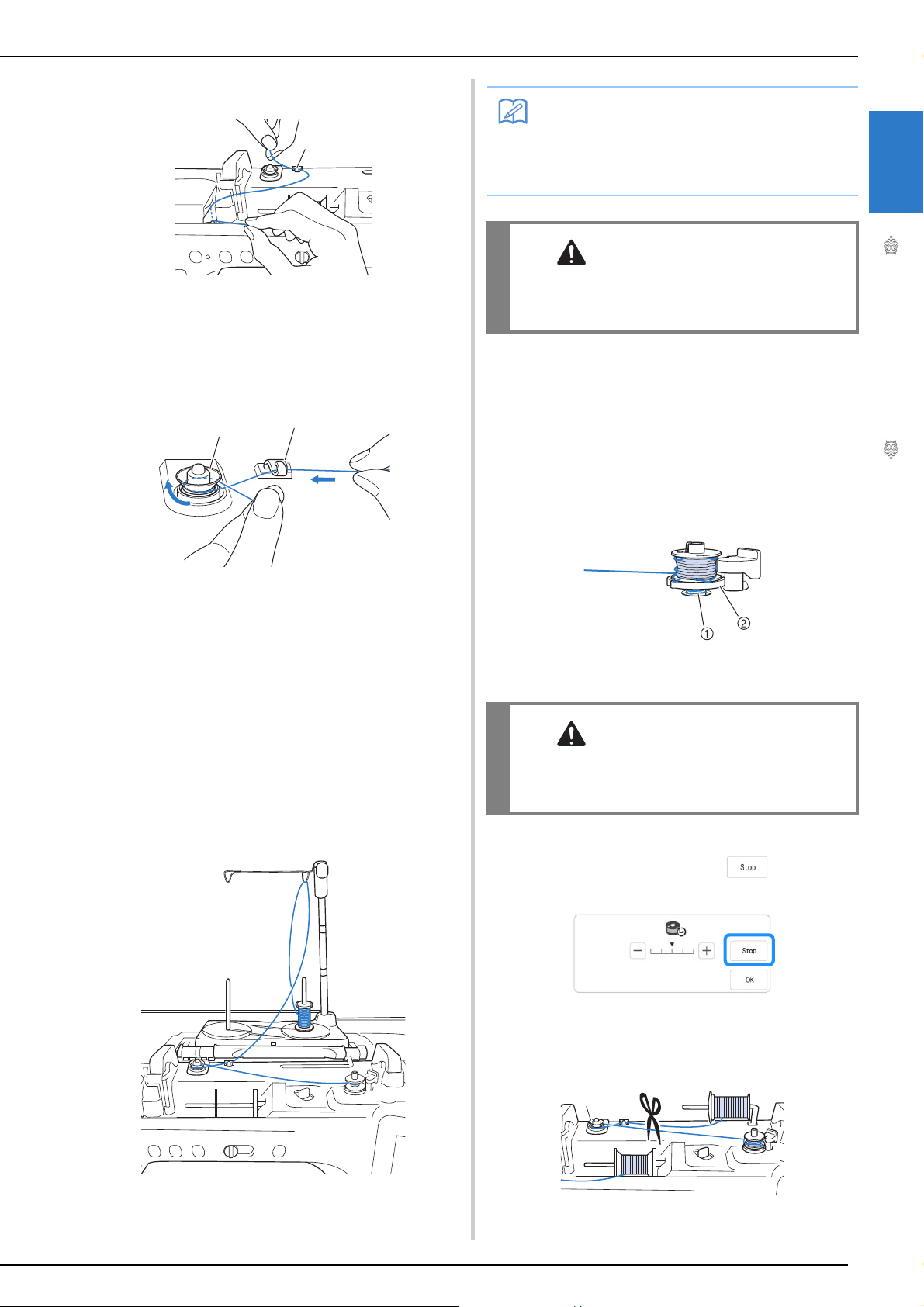

Cut the thread with cutter and remove the

k

bobbin.

a Cutter

• When removing the bobbin, do not pull on

the bobbin winder seat. Doing so could

loosen or remove the bobbin winder seat,

and could result in damage to the machine.

Align the groove in the bobbin with the

b

spring on the bobbin winder shaft, and set

the bobbin on the shaft.

a Groove in the bobbin

b Spring on the shaft

Pivot the spool pin so that it angles upward.

c

Set the thread spool on the spool pin so that

the thread unwinds from the front of the

spool.

• Setting the bobbin improperly may cause the

thread tension to loosen, breaking the needle

and possibly resulting in injury.

■ Using the Spool Pin

You can use the main spool pin to wind the bobbin

before embroidering. You cannot use this spool pin

to wind the bobbin while embroidering.

a Spool pin

b Spool cap

c Thread spool

d Spool felt

Push the spool cap onto the spool pin as far

d

as possible, then return the spool pin to its

original position.

While holding the thread with both hands,

e

pull the thread up from under the thread

guide plate.

18

Turn the main power to ON and open the

a

top cover.

a Thread guide plate

Pass the thread through the thread guide.

a

b

Memo

CAUTION

CAUTION

a

f

a

a Thread guide

Pass the thread around the pretension disk

g

making sure that the thread is under the

pretension disk.

LOWER THREADING

• Refer to the Operation Manual (Sewing) to

assemble the spool stand.

• Refer to page 25 to thread the machine

using the spool stand.

• When winding thread on the bobbin, do not

cross the bobbin winding thread with the

upper thread in the thread guides.

■ Untangling Thread from Beneath the

Bobbin Winder Seat

If the bobbin winding starts when the thread is not

passed through the pretension disk correctly, the

thread may become tangled beneath the bobbin

winder seat.

Wind off the thread according to the following

procedure.

1

Embroidery Step by Step

a Thread guide

b Pretension disk

Follow steps g through k on page 16

h

through 18.

■ Using the Spool Stand

To wind thread on the bobbin while the spool stand

is installed, pass the thread from the spool through

the thread guide on the telescopic thread guide, and

then wind the bobbin according to steps

k of “Using the Supplemental Spool Pin”on

page 16 to page 18.

e through

a Thread

b Bobbin winder seat

• Do not remove the bobbin winder seat even if

the thread becomes tangled under the bobbin

winder seat. It may result in injuries.

If the thread becomes tangled under the

a

bobbin winder seat, press once to

stop the bobbin winding.

Cut the thread with scissors near the

b

pretension disk.

a Pretension disk

19

LOWER THREADING

Note

CAUTION

a

b

Push the bobbin winder switch to the right,

c

and then raise the bobbin at least 100 mm

(4 inches) from the shaft.

Cut the thread near the bobbin and hold the

d

thread end of the spool with your left hand.

Unwind the thread clockwise near the

bobbin winder seat with your right hand as

shown below.

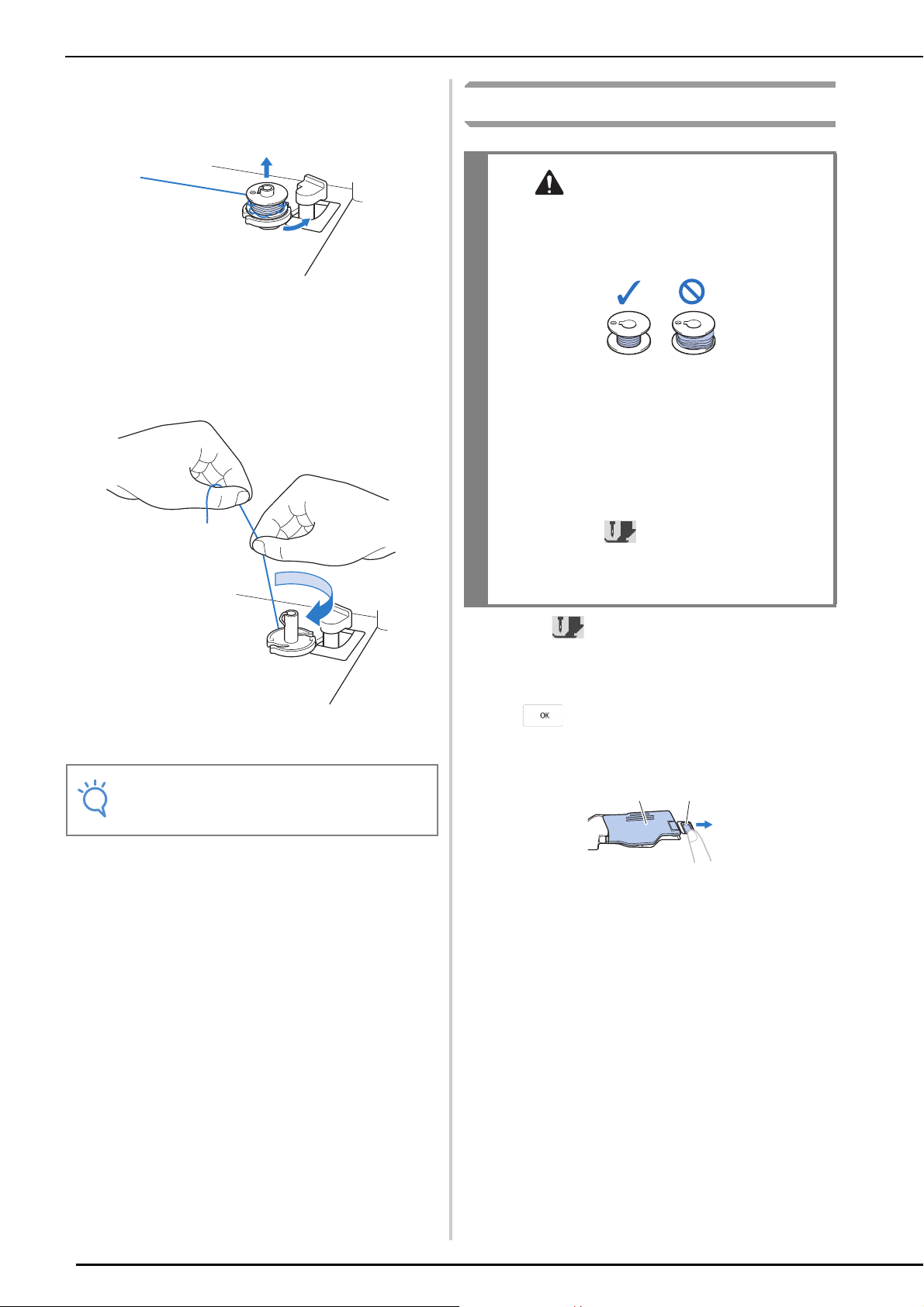

Setting the Bobbin

• Use a bobbin thread that has been correctly

wound. Otherwise, the needle may break or

the thread tension will be incorrect.

• The included bobbin was designed specifically

for this machine. If bobbins from other models

are used, the machine will not operate

correctly. Use only the included bobbin or

bobbins of the same type (part code: SA156,

(SFB: XA5539-151 / 115J05E0001)). SA156 is

Class 15 type bobbin.

• Before inserting or changing the bobbin, be

sure to press in the LCD to lock all keys

and buttons, otherwise injuries may occur if

the “Start/Stop” button or any other button is

pressed and the machine starts embroidering.

Wind the bobbin again.

e

• Make sure that the thread passes through

the pretension disk correctly (page 16).

Press to lock all keys and buttons and

a

raise the embroidery foot.

* If the message “OK to automatically lower the

presser foot?” appears on the LCD screen, press

to continue.

Slide the bobbin cover latch to the right.

b

a Bobbin cover

b Latch

The bobbin cover opens.

20

Remove the bobbin cover.

Note

CAUTION

c

Hold the bobbin with your right hand and

d

hold the end of the thread with your left

hand.

Set the bobbin in the bobbin case so that

e

the thread unwinds to the left.

LOWER THREADING

• If the thread is not correctly inserted

through the tension spring of the bobbin

case, it may cause incorrect thread tension.

(page 102)

a

a Tension spring

1

Embroidery Step by Step

Hold the bobbin lightly with your right

f

hand, and then guide the thread with your

left hand.

Pass the thread through the guide, and then

g

pull the thread out toward the front.

a Cutter

The cutter cuts the thread.

• Be sure to hold down the bobbin with your

finger and unwind the bobbin thread

correctly. Otherwise, the thread may break or

the thread tension will be incorrect.

Insert the tab in the lower-left corner of the

h

bobbin cover (1), and then lightly press

down on the right side to close the cover

(2).

Press to unlock all keys and buttons.

i

21

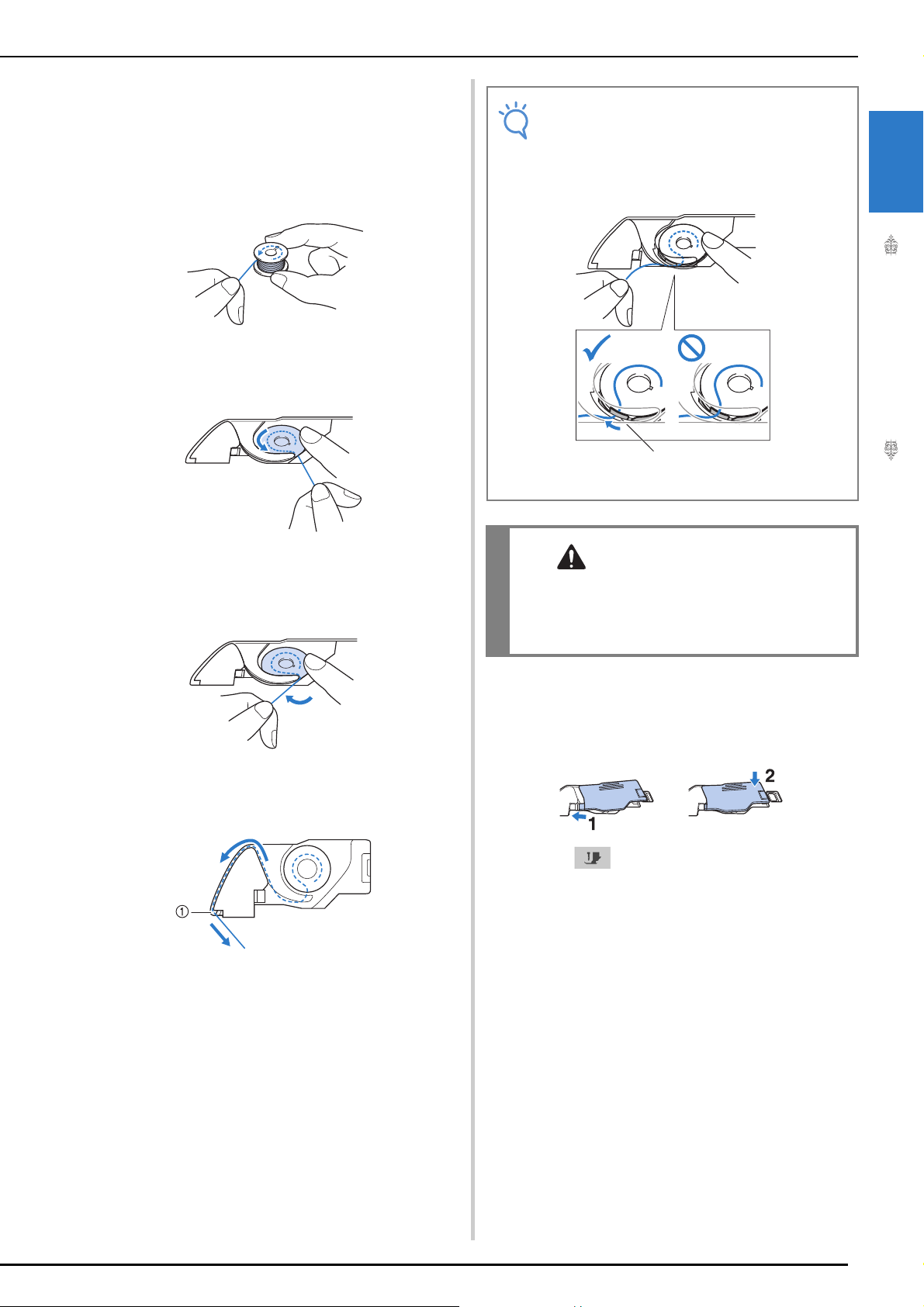

UPPER THREADING

CAUTION

Memo

Memo

Note

UPPER THREADING

Upper Threading

The upper thread shutter opens so the machine can

be threaded.

• Be sure to thread the machine properly.

Improper threading can cause the thread to

tangle and break the needle, leading to injury.

• The automatic threading function can be

used with home sewing machine needle

sizes 75/11 through 100/16.

• When threads such as transparent nylon

monofilament or speciality threads are used

it is not recommended to use the needle

threader.

a

a Upper thread shutter

• This machine is equipped with an upper

thread shutter, allowing you to check that

the upper threading is performed correctly.

Press the “Needle Position” button to raise

c

the needle.

• If you try to thread the needle automatically

without raising the needle, the thread may

not thread correctly.

Turn the main power to ON.

a

Press the “Presser Foot Lifter” button to

b

raise the embroidery foot.

Pivot the spool pin so that it angles upward.

d

Set the thread spool on the spool pin so that

the thread unwinds from the front of the

spool.

a Spool pin

b Spool cap

c Thread spool

d Spool felt

22

UPPER THREADING

CAUTION

Memo

Memo

a

Push the spool cap onto the spool pin as far

e

as possible, then return the spool pin to its

original position.

• If the thread spool and/or spool cap are set

incorrectly, the thread may tangle on the spool

pin and cause the needle to break.

• Use the spool cap (large or medium) or the

thread spool insert (mini king thread spool)

that is closest in size to the thread spool. If a

spool cap smaller than the thread spool is

used, the thread may become caught in the slit

on the end of the spool and cause the needle

to break.

• When embroidering with fine, cross-wound

thread, use the small spool cap, and leave a

small space between the cap and the

thread spool.

While holding the thread with both hands,

f

pull the thread up from under the thread

guide plate.

a Thread guide plate

While holding the thread in your right

g

hand, pass the thread through the thread

guide in the direction indicated.

1

Embroidery Step by Step

a Spool cap (small)

b Thread spool (cross-wound thread)

c Space

• If a spool of thread whose core is 12 mm (1/

2 inch) in diameter and 75 mm (3 inches)

high is inserted onto the spool pin, use the

thread spool insert (mini king thread spool).

a Thread spool insert (mini king thread spool)

b 12 mm (1/2 inch)

c 75 mm (3 inches)

Guide the thread down, up, then down

h

through the groove, as shown in the

illustration.

• Look in the upper groove area to check if

the thread catches on the thread take-up

lever visible inside the upper groove area.

a Look in the upper groove area

23

UPPER THREADING

a

a

a

Note

Memo

Note

a

Pass the thread through the needle bar

i

thread guide (marked “6”) by holding the

thread with both hands and guiding it as

shown in the illustration.

a Needle bar thread guide

Press the “Presser Foot Lifter” button to

j

lower embroidery foot.

Pass the thread through the thread guide

k

disks (marked “7”). Make sure that the

thread passes through the groove in the

thread guide.

• When using thread that quickly winds off

the spool, such as metallic thread, it may be

difficult to thread the needle if the thread is

cut.

Therefore, instead of using the thread

cutter, pull out about 80 mm (approx. 3

inches) of thread after passing it through the

thread guide disks (marked “7”).

a 80 mm (approx. 3 inches) or more

Press the “Automatic Threading” button to

m

have the machine automatically thread the

needle.

a Groove in thread guide

Pull the thread up through the thread cutter

l

to cut the thread, as shown in the

illustration.

a Thread cutter

The thread passes through the eye of the needle.

• When the “Automatic Threading” button is

pressed, the embroidery foot will be

automatically lowered. After threading is

finished, the embroidery foot moves back to

the position before the “Automatic

Threading” button was pressed.

Carefully pull the end of the thread that was

n

passed through the eye of the needle.

* If a loop was formed in the thread passed through

the eye of the needle, carefully pull on the loop of

thread through to the back of the needle.

24

• Pulling the loop of thread gently will avoid

needle breakage.

UPPER THREADING

Memo

Note

Memo

a

b

Pull out about 100-150 mm (approx. 4-6

o

inches) of the thread, and then pass it under

the embroidery foot toward the rear of the

machine.

Raise the presser foot lever if the embroidery foot is

lowered.

a

a About 100-150 mm (approx. 4-6 inches)

• If the needle could not be threaded or the

thread was not passed through the needle

bar thread guides, perform the procedure

again starting from step

Then, pass the thread through the eye of

the needle after step

c.

i.

larger than the spool, the thread may catch and

embroidering performance may suffer.

1

Embroidery Step by Step

• When using thread on a thin spool, place the

included spool felt on the spool pin, place the

thread spool on the spool pin so that the center

of the spool is aligned with the hole at the center

of the spool felt, and then insert the spool cap

onto the spool pin.

• Some needles cannot be threaded with the

needle threader. In this case, instead of

using the needle threader after passing the

thread through the needle bar thread guide

(marked “6”), manually pass the thread

through the eye of the needle from the front.

Using the Spool Stand

The included spool stand is useful when using

thread on spools with a large diameter (crosswound thread). This spool stand can hold two

spools of thread.

• Refer to the Operation Manual (Sewing) to

assemble the spool stand.

• Refer to page 19 to wind the bobbin when

using the spool stand.

a Spool felt

• When using thread on a cone spool, use the

spool holder. When using cone shaped thread

spool with other than cotton thread, it is not

necessary to use spool caps.

a Spool holder

• Depending on the size of spool or the amount of

thread remaining, choose the appropriate sized

spool cap (large or medium). Spool cap (small)

cannot be used with the spool cap base.

■ Using the Spool Stand

• Be sure to use a spool cap that is slightly larger

than the spool.

If the spool cap that is used is smaller or much

a Spool cap

b Spool cap base

25

UPPER THREADING

Note

Note

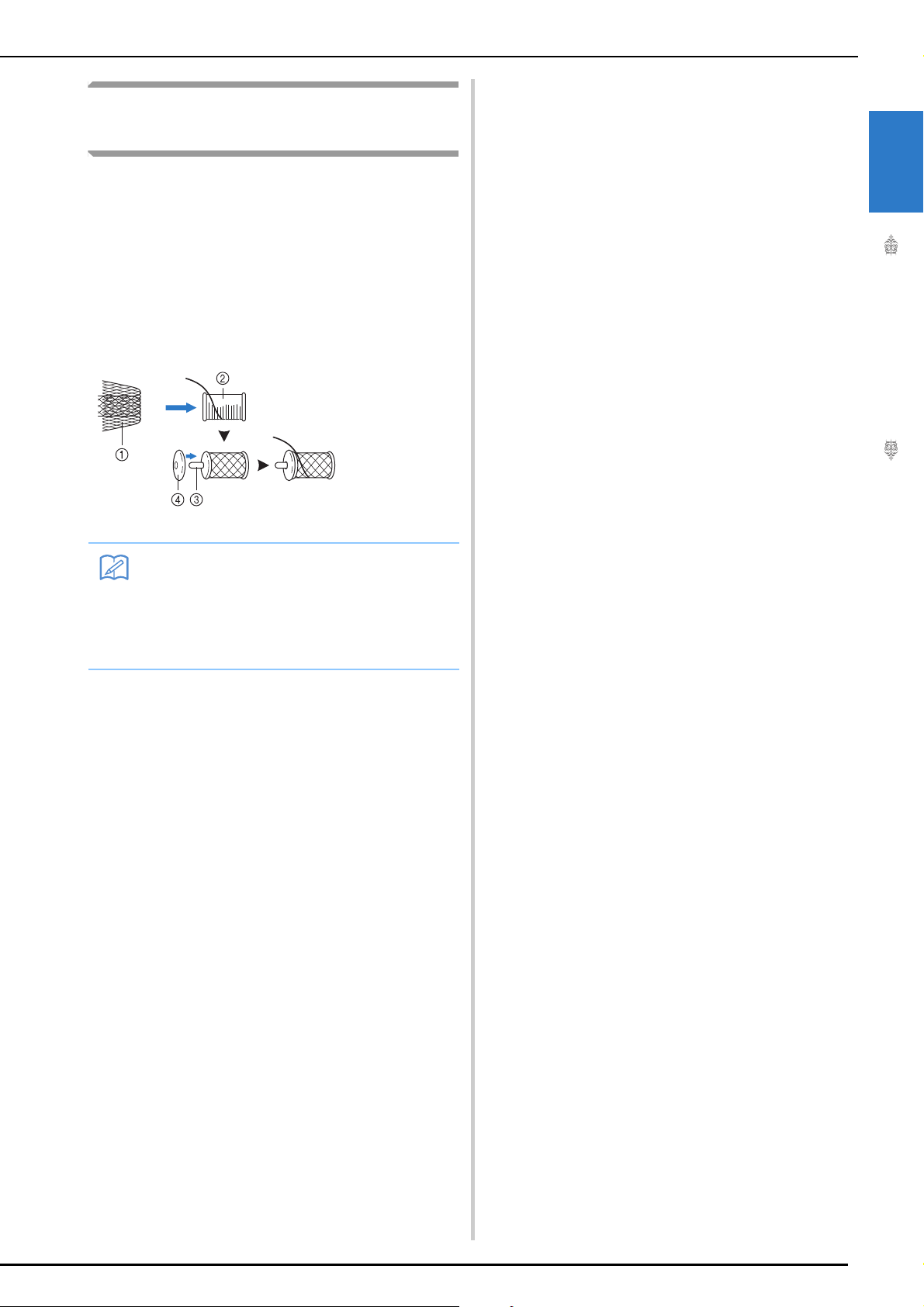

Attach the spool stand to the machine.

a

Place the spool of thread on the spool pin

b

so that the thread feeds off the spool

clockwise. Firmly insert the spool cap onto

the spool pin.

Pull the thread off the spool. Pass the thread

c

from the back to the front through the

thread guides at the top.

When using thread that quickly feeds off the spool,

such as metallic thread, use the enclosed ring to

prevent the thread from becoming entangled.

Threading sequence; Pull the thread from the spool,

place the thread through the ring from the bottom up

(1), into the thread guide (2) and through the ring

from the top down (3). When using the ring, do not

use the spool cap base.

• Guide the thread so that it does not become

entangled with the other thread.

• After feeding the thread as instructed, wind

any excess thread back onto the spool,

otherwise the excess thread will become

tangled.

2

13

• When using 2 spools of thread, make sure

that both spools are feeding in the same

direction.

• Make sure that the spools do not touch

each other, otherwise the thread will not

feed off smoothly, the needle may break, or

the thread may break or become tangled. In

addition, make sure that the spools do not

touch the telescopic thread guide at the

center.

• Make sure that the thread is not caught

under the spool.

Pass the thread through the machine’s

d

thread guide from the right to the left.

a

a Thread guide

Thread the machine according to the steps

e

f to o of “Upper Threading” on page 22.

26

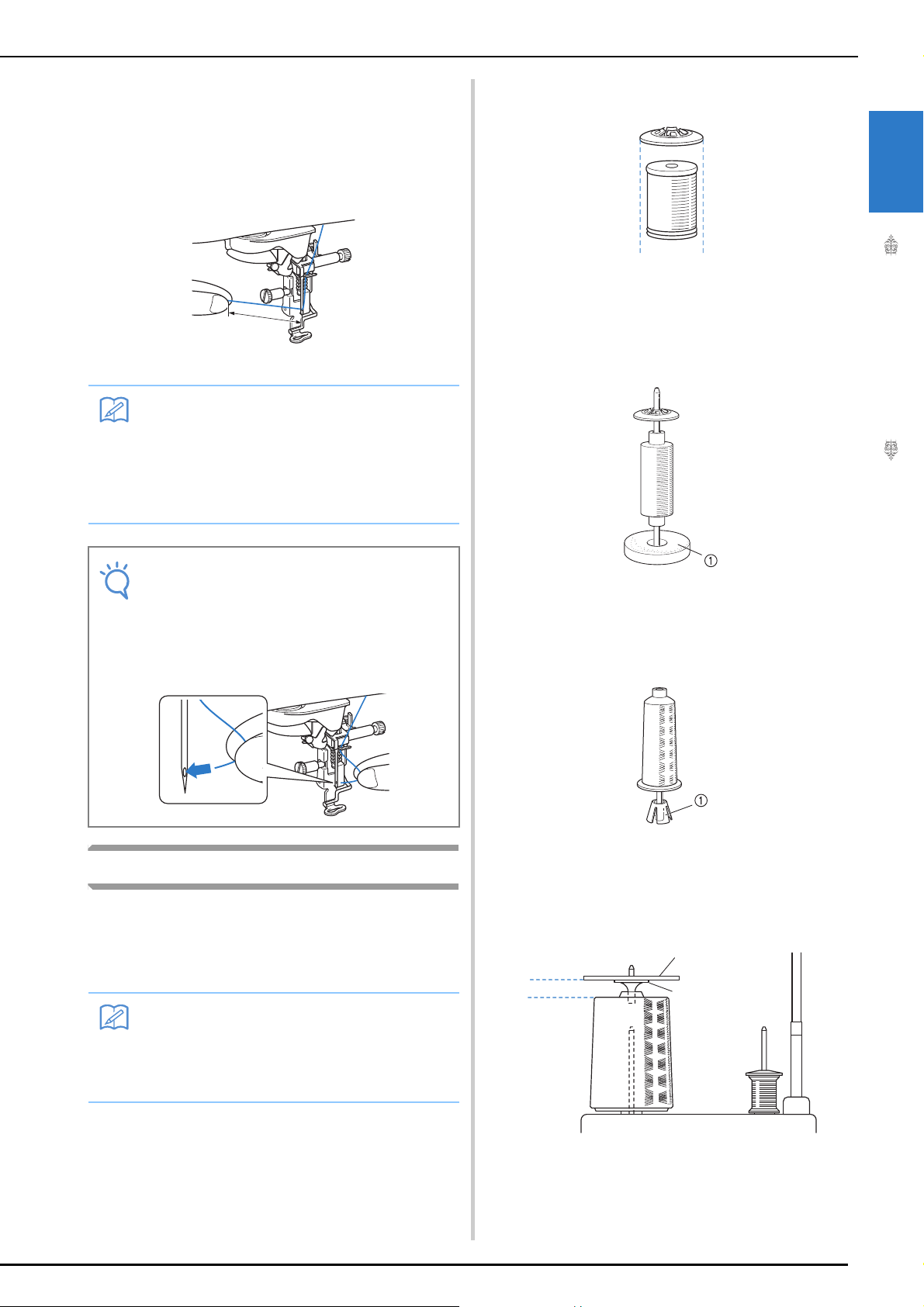

Using Threads that Unwind

Memo

Quickly

■ Using the Spool Net

If using transparent nylon monofilament thread,

metallic thread, or other strong thread, place the

included spool net over the spool before using it.

When using specialty threads, threading must be

done manually.

If the spool net is too long, fold it once to match it to

the spool size before placing it over the spool.

a Spool net

b Thread spool

c Spool pin

d Spool cap

UPPER THREADING

1

Embroidery Step by Step

• When threading the spool with the spool net

on, make sure that 50-60 mm (approx. 2 2-1/2 inches) of thread are pulled out.

• It may be necessary to adjust the thread

tension when using the spool net.

27

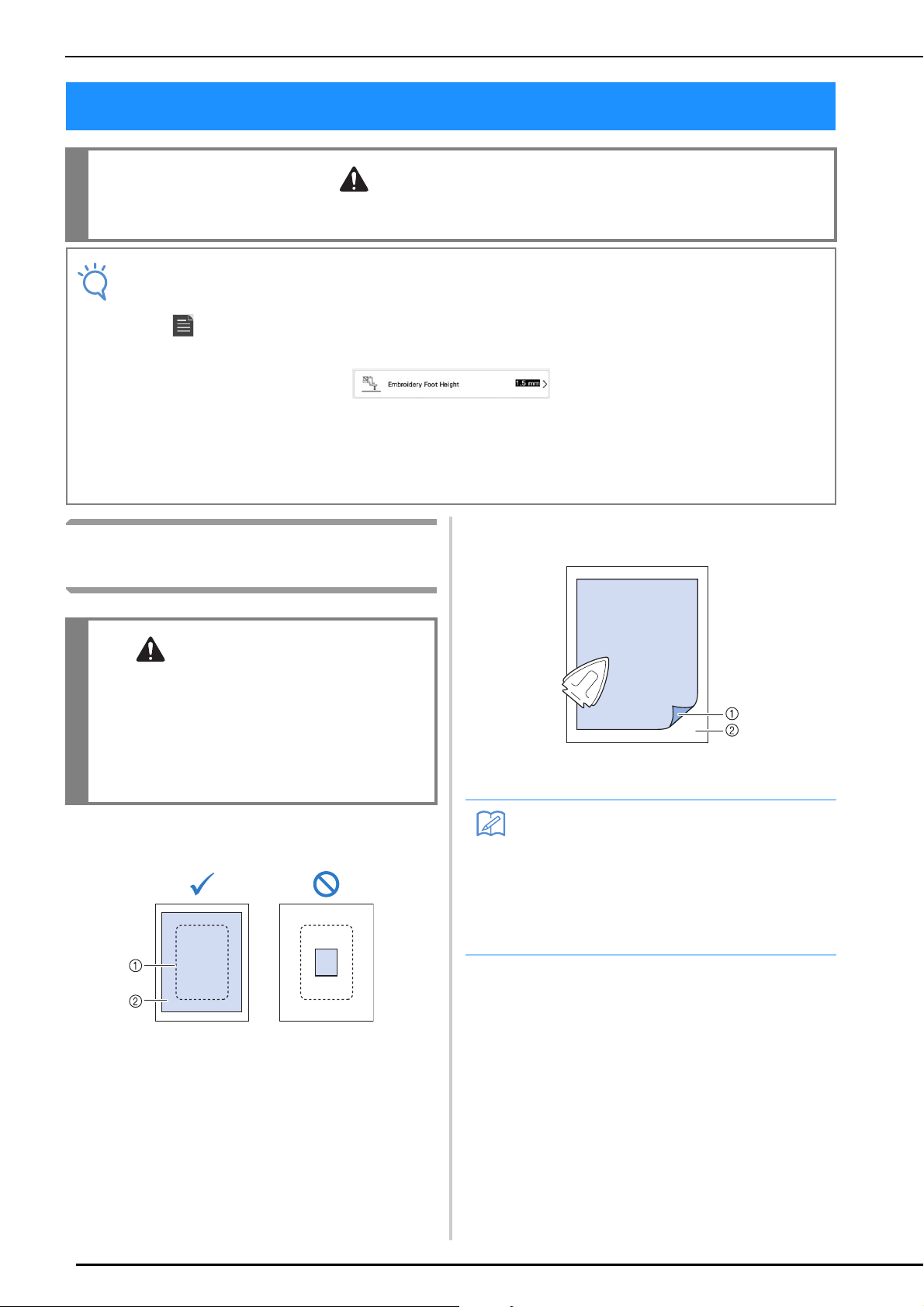

PREPARING THE FABRIC

CAUTION

Note

CAUTION

Memo

PREPARING THE FABRIC

• Use fabrics with a thickness of less than 3 mm (approx. 1/8 inch). Using fabrics thicker than 3 mm

(approx. 1/8 inch) may cause the needle to break.

• When embroidering fabric layers filled with thick batting, for example, a better result can be achieved

by adjusting the embroidery foot height in the embroidery settings screen.

Press , and select page 8. Touch the number beside “Embroidery Foot Height” in the embroidery

settings screen. Adjust the embroidery foot height for thick or puffy fabrics.

• To increase the space between the embroidery foot and the needle plate, set the “Embroidery Foot

Height” to a larger number.

• In the case of thick terry cloth towels we recommend that you place a piece of water soluble stabilizer

on the top surface of the towel. This will help to reduce the nap of the toweling and result in more

attractive embroidery.

Attaching Iron-on Stabilizers

(Backing) to the Fabric

• Always use a stabilizer material for embroidery

when embroidering stretch fabrics, lightweight

fabrics, fabrics with a coarse weave, or fabrics

which cause pattern shrinkage. Otherwise, the

needle may break and cause injury. Not using

a stabilizer material may result in a poor finish

to your project.

Use a piece of stabilizer which is larger

a

than the embroidery frame being used.

Iron the iron-on stabilizer material to the

b

wrong side of the fabric.

a Fusible side of stabilizer

b Fabric (wrong side)

• When embroidering on thin fabrics such as

organdy or lawn, or on napped fabrics such

as towel or corduroy, use water soluble

stabilizer (sold separately) for best results.

The water soluble stabilizer material will

dissolve completely in water, giving the

project a more attractive finish.

28

a Size of the embroidery frame

b Iron-on stabilizer (backing)

Loading...

Loading...