Page 1

i''.'

'••' -'i 04

i.'iuJii»»»frl*'.tUH

t*LV-»'W4i'

W- jiSS>i "'»Mi'Ji

ViVl«J-

*•

INSTRUCTION

BROTHER

MANUAL

EF4-B959

Twin

Needle

BROTHER

Overlock

Sewing

INDUSTRIES.

NAfiOYA

JAPAN

Machine

LTD.

Page 2

I •

CONTENTS.

Uroiher

Feature?

Installinpr

i'ulIcV? operatlni!

Overlook

fv

the

machine

Stitcher

direction

Model

EF4-B959

Breakin.tr-in

OilinK

Xeedie? -

Hcm-'vin^ the needle

Insitiliin.t:

>p'^:

Thneadrn^

I nrea:^.".!.' the

Thrcrtdin^r the underlooper t..... V.

Threadin.c

'i e.stir.a

Thrc'Tid

l're?>.r

Stitch

.•

•••.•.••.•

trio

needle

>ta:!d - :

v - - -

.overhioper

the

needle

uitheut

tensions

f.H.t

pitch

fabric"

prcs.-ure

and

differential

-vv"

feed

— :....^..

: o

..r...

."......•.

Streichint:

Stitch width

-Assembiinp

Needle

Reiniive

The I'per.itnvc distance-oi the loopers

Relative

Relative

Relative positions of the

Adiustinp the heipht and angle of the feed dogs

Adjusting

.Adjusting the height of the pre'sser foot :..26

Installing and removing'the lower knife — 30

Installing and removing the upper knife 31

Specifications

and adiustinp

hei.trht

and

position?

pusitiiin?

ptoitron.-i

the

feed

•••••

needie

bar

stroke

o: the

overlooper

of the

needle,

of the underlooper and needle

<»verlooper

dogsincross

and

underluoper

and

looper

and needle 2n

directions

- 30

•—•.

•••26

•'•••—.

21

26

25

2.5

26

27

i

-)

3

-

15

g

9

]„

in

jo

1-,

1^5

9 *

i.

I

Page 3

Brother

The EF4-B959 is an automatically lubricated high-speed straight two needle

overlock sewing machine of modern design.

unsurpassed performance in providing perfect and beautiful overlock -stitches

for

fabrics

etc. of cotton, wool. silk,

is it dependable and versatile,

inierchangcability.

Overlock

of all

kinds

and

rayon,

Stitcher

thicknesses,

nylon or

the

machine is

Model

The

new overlock stitcher boasts

stockinet,

suiting,

other

synthetic fibers.

guaranteedofcomplete

EF4-B959

brbadcloih.

Not

_ -

jersey,

only

parts

- 1 -

i.

*

--•K

Page 4

t . »

Features

I. Kasy adnistinK nf ItmpiT liniinv: :if<iiri's i-vc::

man

i>n.

U.

Fci'd piudi can

1

mm

;i. I

>ifl'ereiK:a!

according

•i.

I.iibriciitim; oil i> supplied by it powerfu!

iiiirts

for -imnoth

•t.

..Mock

sa!«'ty stitch I'im

i»

mm

feed can

to

bf

atliiisicd cptickly

by

meansofthe

tjie

kindpffabric.

operation

l>e

adiii,<ted

even

eitsii.v

and

.cradiialed

to stretchitjy ( r -hirrinj; its desired

<1;

hich

he obiiuiied

and

easily within a wide raniic nf-

main

and

pump

-o ail

sjieecis.

h;.

ci".r;:'.yine

loop;*:'. • • • - »

li.

ihtralnmin

the joopers

tetnperaiviie

Si>eeds.

7. The modern functional

and

Uesi.un

i.- used L" lessen lite ioad on the iooper i;!eci;ani.sn."s" :i;;:t

always

- • • i . ,

improve

operate

ri.-ieornoise

work

efficiency.

nice iind sinoth without itccoirtpanvini;

i*vei! wlu-n

desijzn

heli»s

the

r.iitchine

briKhten the workshop atmosphere

re^jistralion and utility model appiieil for.

ladfnrm

sub

slitch-fur-

tved

maior

the

runnin;,'alinei.

levers.

iiMviiu:

e-oer-

t::-.due

5. I

'St.*

Jisi

. s

.r.

•: *.

Page 5

•INSTALLING

3-

m-a.

N

^•^;A*'r,.

\\\

THE

MACHINE

f

CoVsi

oi ®

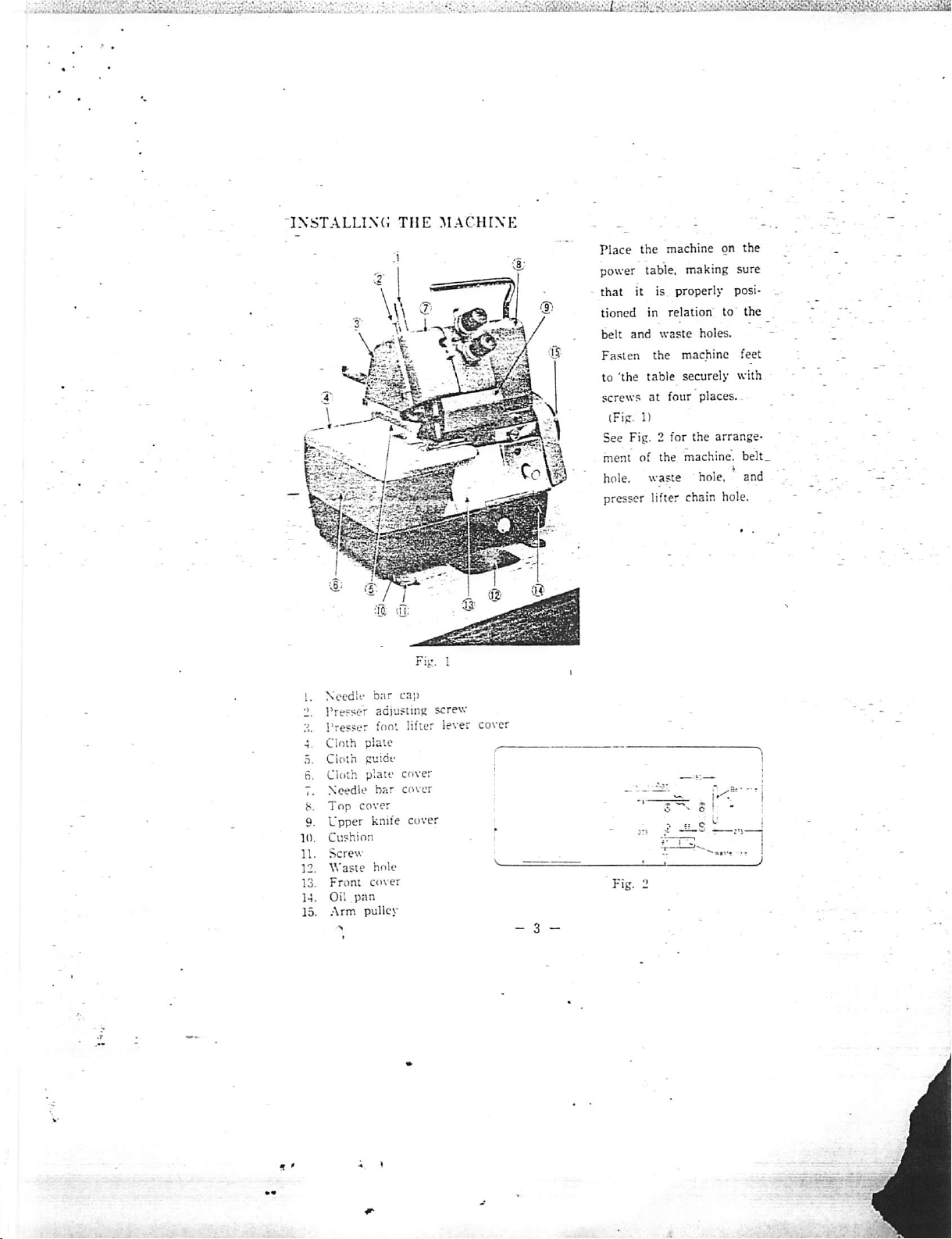

Place

the

machineonthe

power table, making sure

that

it is properly posi

tioned

in

relation

belt

and

waste

Fasten

to

screwsatfour

See

mentofthe

hole,

'the

(Fig.

Fig.2for

the

table

1)

waste

holes.

machine

securely

places..

the

machine,

hole, and

to

feet

with

arrange

the

belt,

presser lifter chain hole.

Needlf

rrevser

I'resser

Clnih

Cloth

Cloth

Needle

Top

bar

ad)u?tine

fon;

plate

puidv

plate

bar

cover

cap

lifter

cover

cover

Upper knife cover

Cushion

Screw

Waste

hole

Front

cover

Oil

pan

Arm

pulley

screw

lever

cover

j

,

;

[

rr^

. 1^-.

S 5 1 '

^ o P

—

Page 6

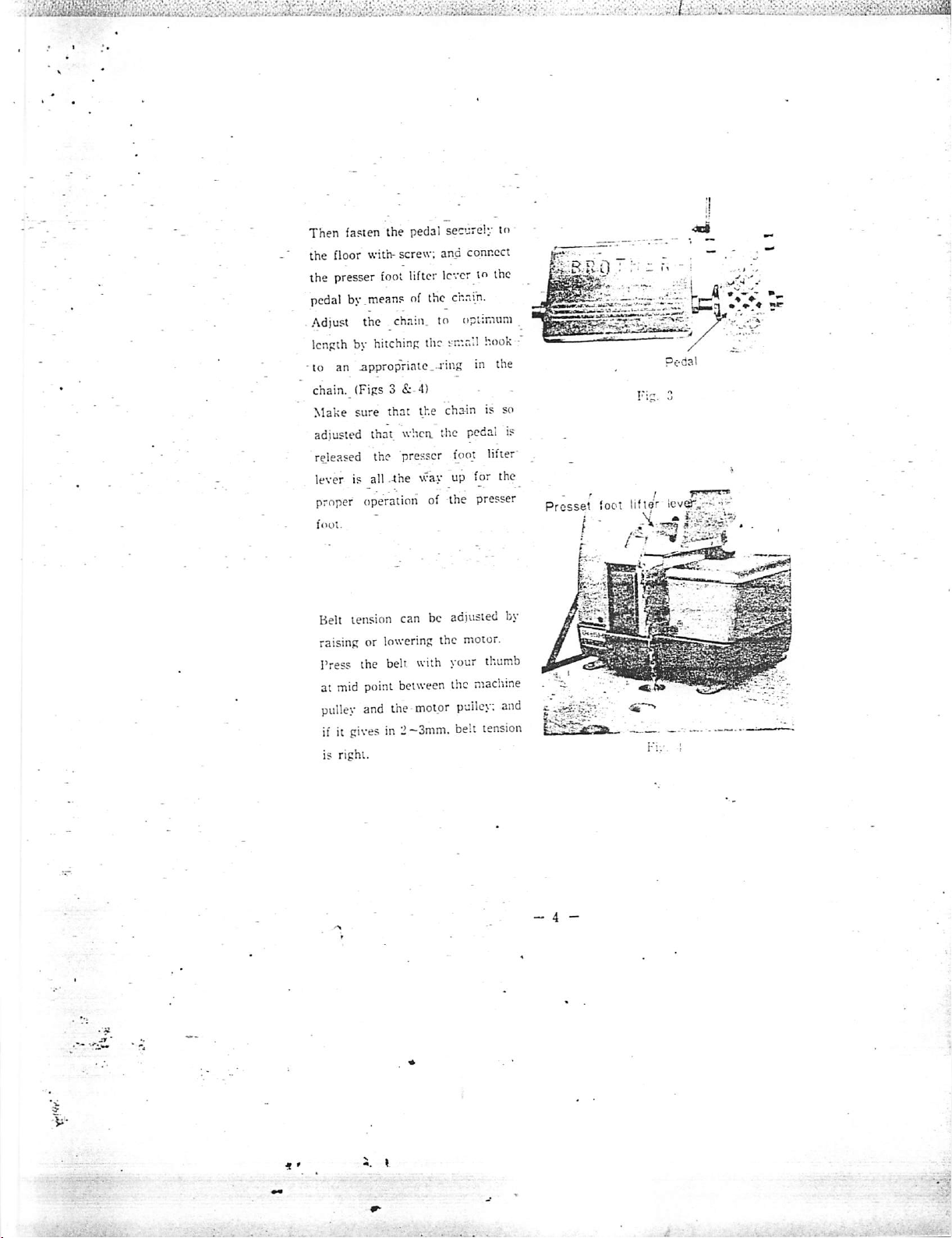

Then fasten ihe pedal securely tn

the

floor

with-

screw;

and

connect

the presser foot lifter lever to the

pedal by.means of the

Adjust

the

chain, to opf.ranni

Icnpthbyhitching

chnih.

the traatl

hook

"to an appropriate.-xing in the

chain. (Figs 3 S:--!)

Make

sure

that

the

chain

is so

adjusted that whea the pedal is

released the presser foot lifter"

lever is all .Xhe way up for the

proper operation of the presser

•

?

.*-

•• •!•VL'-J-

Presset

-.IK'irJi;•*"..

r / T

loot

- i-.

lifter

i>.r;>t,

!cv^

/

i.

Belt tension can be adjusted by

raising or lowering the motor.

I'ress the belt with your thumb

at

mid

point

between

pulley

and

the-moi.or

if it gives in 2~3mm. belt

is

right.

the

machine

pulley;

and

tension

>i»L

.r.

i, jc

Page 7

"•»''Vu'ii-Vf'^

;J

Wii.,

../it

.Vyi'*/*

i«VcUi(twlai/Jrj.iw>*L*it'.

0w

ITLLEVS

- 1

lie

ntirmal

from the pulley side.

OPERATING

iiperatiri};

direction

DIRECTION

of the

pulleyisclockw-iseasviewed

"

V-_"-:

BREAKING.IN . . • .

•

Althoush

minute,aspeed

the

first

will

the

normal

Following

have

ihis

-'machme

of

200

hours-(about

been

well

sewing

this practice

operatesatspeeds

about

3.800

one

run in by this

speed.

will

reduce

stitches

month).

time.

troubles

"up

fo

A200"s"titches

per

minuteisrecommended

Bearings,

and extend

Then

,

cranks

operate

machine

and

the

sliding

machine

life.

"per"

for

parts

at

r *. • •

-

Page 8

;^Uaine

Page 9

iV«lX6^£SU«

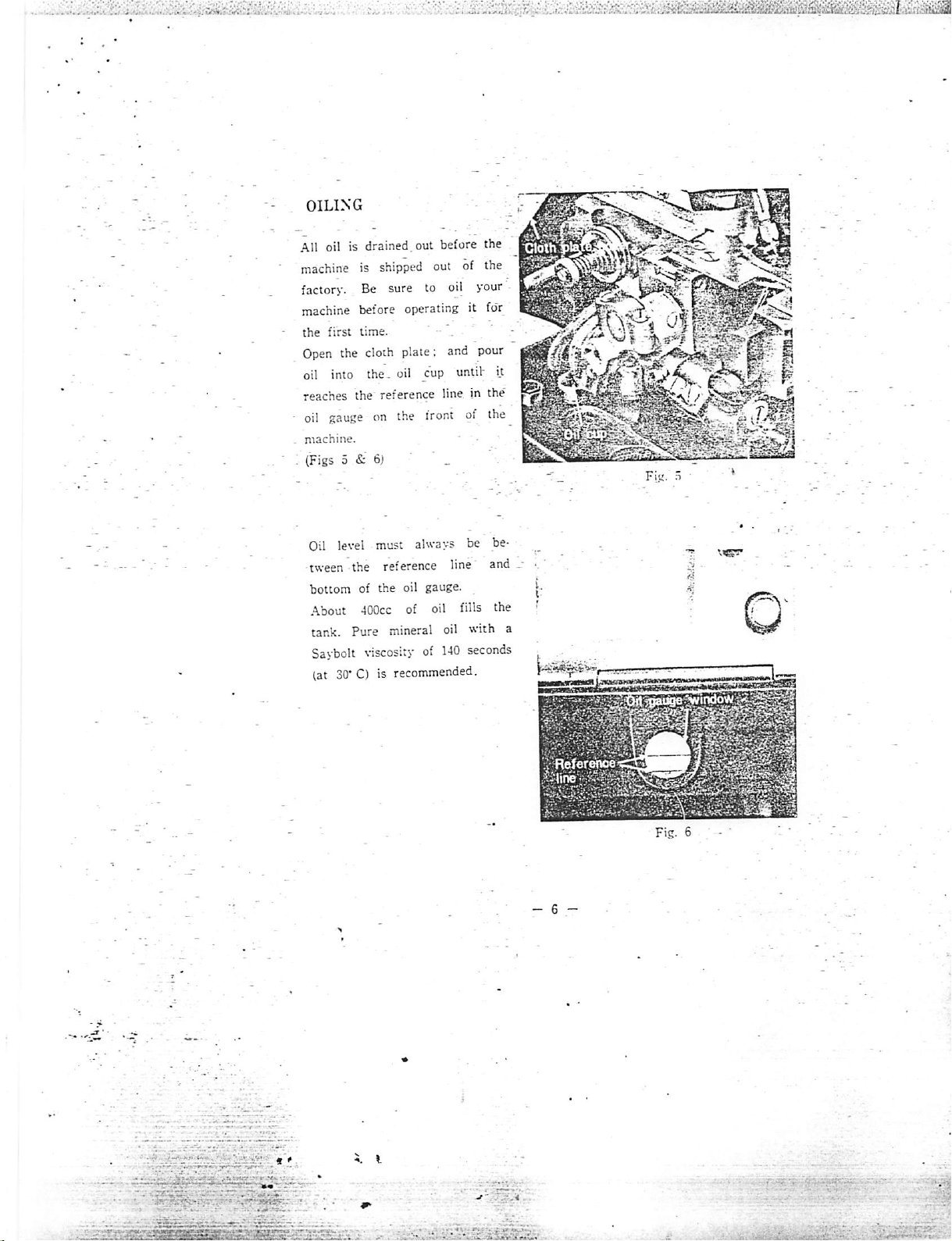

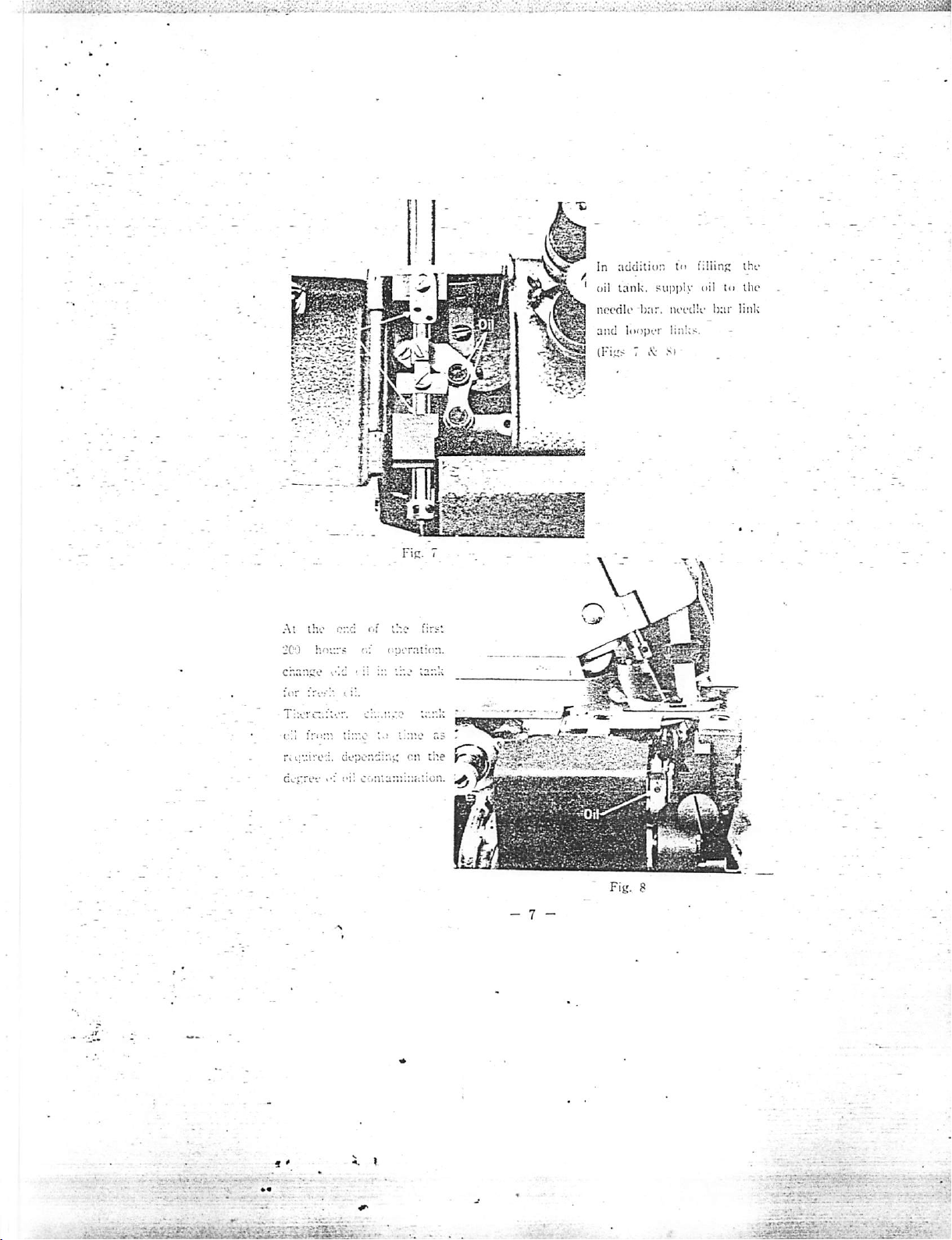

In

addiiiiin

oil liinlc.

1

nccdli'

and

loopi-r

"bnr,

t"

supply

iiouilk'

links.

filling

oil lo

Ixir

tho

tlic

link

Page 10

i--<-:.

Page 11

Wmm

«lanip-7&j

r,.':••.

Page 12

First,

Lead

from

the

thread

thread

discs,

the

tension

left

and

overloooer

open

the

the

jjass

guide

into

thread

ihe

over

spool

guide

i(

the

discs

th

Page 13

M

'

Over.-looper, .1

•-•-V-""

O^er!?o'f>er'uiread take-up

V>-

Page 14

ING

fr?Cr3w*^HIW^jSi*

T

t?j

I

Cbi^r(goper.;^hreac

ifc-'jS-sSS

^ake^:;u i

•fr

•f*-'^--

im:-

Jti-j

Page 15

K'"

Fig.

mr'

BririR

the

underlooper

its

left

extremity

16);

and

lead

the

into

the

hole

underlooper. See

about

5cm

of

fronvthe

16

underlooper.

"thread

in

thread

to

(Fig.

the

that

is

THREADING

NEEDLE

First,

open

bar

cover.

the

Turn

THE

needle

pulley until the needle

is up highest. Guide the

needle

thread

from

spool

stand

first to the

thread

guide;

then

into

the

upper

hole

of the

needle _ thread guide;

then

between

the

the

the

ten-

;edle thread 3"'"=

\ \ auidesty^—s

Needle

thncad

lake-upj'fYead

P -

;iiar

cover.,j

- \

c*

c-idc

Fig.

i

1,

17

Tensioit

dtsr.s

'."Tc-'''•'.•

•.'••^.y

Tir-r<sy—*7

--

••*•>'115,-

•

Page 16

sion

discs from

guide.

Pass the

thread

eye from your

5cmofthreadisout

guide; then through the needle Uircad guard; and into the needle

ripht

side

cn left; and into the loft

thread

through

toward

from,

the

the farther side of the table. See

the

needle

hole

in the

eye. (Fig. 17)

holeofthe

needle'lhrca<i-

needle

that

thread

take-up

about

TESTING

WITHOUT

F.4RRIC

Fig.

18

After

run_

slcwly. by'

the

thread

toward

sideofthe

(Fig.

Note; If the tensions of the four threads are iil-balanced,

"

may

not produce a, good chain.

the

the

treadle;

18)

th,e

threading.

machine

operating-

and

runs

the

farther

table.

machine

see

out

Page 17

THREAD

TENSIONS

Needle thread tension

The

Underlooper thread;

tension

adjuster

-

and

-justed

sion

tensions

looper

'by

adjustinR

of

the

threads

meansoffour

thumb

are

screws.

needle

('Fiji.-19)

Fig. 19

Tin-

iii'i-fiio

iluvad tension adjuster uses a strong-tension spring and .the •

(iwriooper and underlooper tension adjusters a -weak-tensfon spring.

Thread tension can he adjusted either to the .3-thread tight stitch (Fig.

in which the needle thread has strong tension and the overlooper and

underlooper

purl

on the

threads

edge

are lied

stitch

along

(Fig.

the

edge

R).inwhich

of a

the

cloth,

needle

or to the

thread

3-thread

has

weak

tension and eNtends to the edge of a cloth as it is tied with the overlooper

and underlooper threads

accomplished

"ny

aUmg

means of the

the

temsion

edge.

These-"adjustments •can easily be

thumb screws.

ad-

ten

.A),

Fig.

B

A I

Fig. A

-

15

-

•.v;»

Page 18

iSeBig^!^3;?Efjr^Sti2253iAe^

Page 19

^•*»Pi

:-KXis.>^i\:

CJ-:'J.1.'

Page 20

;^^Wih

.-^5i-'-:Jt>

'rfmd lever

!f;.i'jir Vs -.v-.v:l<

§V^V;.'«vc-^"

Page 21

Scl i!ic leversH)your desired differential

fabrics.

feed

according to_the kind

of..

STITCH

WIDTH

Slilcli widili can be changed by adjusting the

th.e stitch tongue of the

needle

gauge

is

2.2mm.

;

vj»

Twin

nceciic

iwerk'Ck

stitcr.

Mock

presser

safely

siitch

foot.

Standard

To

width,

holder

lower

screw

Turning

clockwise

"left

kniv^'

stitch

adjust-

sid_e

creases

culling width and

widthis5mm.-and

the

kni\tes'

loosen

set

"as"

the-lower

sctcv.-

and

Turn

knife-holder.adjiistftig

required."

the

(as

of

the

adjusting

"viewed

the

cutting

-

"frdm'-the

ma'chine) . in

width:

turningitcounter-clockwise

rows

it.

(Fig.

25)

Cutting

to

be

1.5mm

width

'the

edge

adjusted'within

to

5mm.

(from

of

cut

the

cloth)

a

range

cutting

knife

the

scr#w

and

nar

needle

can

of

•'

-e

I

Page 22

mr"

P

'^.

To

adjust the stitcH width, first

adjust

and

stitch,"

,

knife.

then

(Fig.

the

tongue

knives-

mount

26)'

the.

close

cutting

presser

to

the

width

.foot

upper

':

Stitch

rows

The

width

as

the

correct

.A

Fig.

26 .

widens

stitch

tongueismoved

stitch

tongue

.y^

~

as

the

stitch

position

tongueismoved

leftward.

varies

depending

rightward:

upon

the

anditnar

knives"

cut

ting width and the thickness and kind' of fabric.

The

Actually sew the fabric, to determine its correct-p"osition.

stitch tongue allows stitch width adjustment within a

range

standard

of 3mm to

Stitch tongue for 2.5mm stitch width is also available as an optional

accessory.

~

i-JUw.wW.iryjK

I-Sf?

r

Page 23

ASSEEMHLIN(;

To

adjust or replace ninchir.e, compoocni?. first open the cloth'

and

the

front cover: and li'icn remove the upper

lower knives: looper cover;

crank

cover:,

the

assemblyofpresser

upper

AND

cover;

lever

ADJI

presser

needle

cover

STING

knife

foot; needle plate; cloth guide; overlooper

bar

cap;

and

presser

needle

foot

bar

cover,inthe

cover;

adjusting

plate

upper,

screw;

order

cover"

and,

and-

men-

NEEDLE HEIGHT

Fig. 27

AND

NEEDLE BAR STROKE

Loosen, the sot .screw _(A)

(Fig. 27) for the needle bar

operating lever ball joint;

and

move

the

ball

joint

(IJl

(Fig. 27) inoroutsothat

needle

bar

stroke

is

25mm.

Rc-iighien the

wrench.

screw

with

-

-trTtm"

'r'l V » • « • - .•

• - • - •

>*•

IV

Page 24

.

SBKi-.'^-"-:i

mm

'-'-'if

,

tVIi

!-.-.-^v,"5y^.

~

Page 25

'.'fc

r*s\

^:*3J^.*:

Page 26

1hfdistance

of

tlif

needletodie

from

the

center

tipofthe

**-Jr-'

^

"am!

check

the

ovcrloiipcf

the

correct

needleasmentionedinpara.cfaph

hmin

move the ..veriooper cr;ink hall

i.s

iaryer than i'mm. move the same ball j.iini to the left.

1

lien

inspection memioned in par.a^raiih 'J.

If the

tarici-

it.- ric'htmo>i position shiuild be about

l"pi>n

looper

lever set screw lAi

_(.ij

Loosen

(b)

Loosen

clearance

loosen

the

as;ain

make

abo\e-meiilii>ned

iri'in

the

completion,

crank

hall

screw

screw

if it

has

with

the

ovorlooper

the

adiiisiment

crank

adinsimeius

centerofliu-

of the

adiiistmcuts.hesure to

joint

s.-i

screw

(I'ig.

JJl

(A)

and

adjust

(B)

and adjust ball joint.

•.

1'.

if the clearance is smaller than

ball

i<iinL

set

screw.

j.iiiii

to the

ri^du.c

mentionedinparagraph!Jand

have

been

made

needle

t<i

the lip of the

2t>.r>mm."

(15)

iFig.

3:il

securely.

ovcrlooper

levciv

Fig.

33_-

.?'S- ^_"

" . • -

ilS)

If'

properly,

vmderloojKT

re-lii;hum

:md

the

•

i»

_.

-,-v

(Fig.

fllb

ihe.

'clearfince

the

the"

otxTiuuper

3.0®^

and

the

di.-

over-

••

in

J

Page 27

KELATIVE

POSITIONS

OF THE

Turn the pulley by handJn the normal operat-

-

ing

direction.

When the underlocpcr •is

its

left

extremity,

between

looper

left

(FiB. M)

When the needle is 3.6mm up

from

lip of the underlooper must be

in

'

needleatthe

-

needle's

needle

line

and

its

with

depression.

llie tip of tiie

lowest

the

the

center

nut.s|

be

position.'

the

axis

centerofthe

(Fig.

distance

under-

of

3.5mm.

of

at

the'

the

the

3-1)

In case of making adjustment.

first . loosen the .overlooper .?

•.

crank

.screw (.A) (Fig. 35).

then adjust the overlooper

cranktothe

meansoftwo

proper

adjusting

angle

screws

and

by ' '

NEEDLE

^5^

J

l^'

•:•.

AND

Fig.

LOOPER

:

i ^

35

I!ELATI\E

Turn

There

looper

ever.

looper

underlooper

ments

turning

the

tip of

it

passes

ance

underlooper set screw

back

POSITIONSOFTHE

the pulley by

must be a clearance of about 0.1mm between the tip of the under

and

the

it is

desirable

be

slightly

be

canbeaccomplished

the

needle

the

the

between

as required. —25 —

handinthe

needles

that

smaller,

slightly

clamp

underlooper'

needles

the

needles

whenitpasses

the

larger,

as.required.

on its

and

(.A)

UNDERLOOPER

normal

operating

their

clearance

and

"the

than

by loosening

comes

return

underlooper

(Fig. 31) and lilting the underlooper

between

clearance

the

value

the

Turn

close

enoughtothe

sewing

from

canbeadjusted

direction.

depression. At

the

right

between

mentioned

needle

bar

the

pulley

its

right

AND

this

needle

the

left

above.

corraecting

further

needles'

extremity.

by

NEEDLE

instant,

and

needle

These

stud

and

see'that

shank

loosening

forward

how

under

and

adjust

and

when

Clear

the

or

Page 28

KliLATIVE

Turn

llio

inillry

When

t.he

-iraveh the overlenper nuiir.tains a clearance wiili the left

.

^

-

[I'm.

tniiches

operate

lever

justinent.

hole

holes

and

.in

are

.^(>1

the

tins

t!:u:htcn

the

level

Xeedle

POSITIONSOFTHE

l:y

ham!

in the

overlnoiHTV

riyhl

way!.

move

tip of

with

iJjrencl

needle

and

inoscr.

two

the

lever

ih.e

iwn

the

"tivcrlooperIsin

the

lower

holes

are

set

level

la.nnal

liule

bendsitsl:>;h:iy.•

set

«oes

screws

uicraliim

pa.-a

t.M

fnrwardorback

screws

"securely.

line

with

od;;eofthe

with

overlooijer's

OVEIiLOOPER

dirtvifuh.

l!ie

needlecm]ts

If the

C-i;:.

::Zt

ti.s

letiuired.

Aj^sn.

the

o\er!ooiier.

lower

everlueper

h-r

sec

left

needle.

ed.ice.

AND

Pic.

- ' -

needle,

the

(.verh.iipeF

After

thai

the'itWlle

NEEDLE

nn

Y'

riylilward

but

tines

niit

,thc-;id-

when

the-

'

""

'

ADJUSTING

Adjust the feed doffs so

(Flu.

liTi

shaft

as rctjuired.

THE

and

lurniuK the feed r-

HEIGHT

that

the

AND

ANGLEOFTHE

~ ~

e'tr.

•'/

FEED

DOGS'"

Page 29

EF4-S953-QIK

Page 30

Page 31

wm-]

•

.'s-

.W

4^jN2v^»A7^S*X

,•*^5^

A-.

•:'VxA-Vf,

'^2"''

Page 32

0

0

Page 33

V V

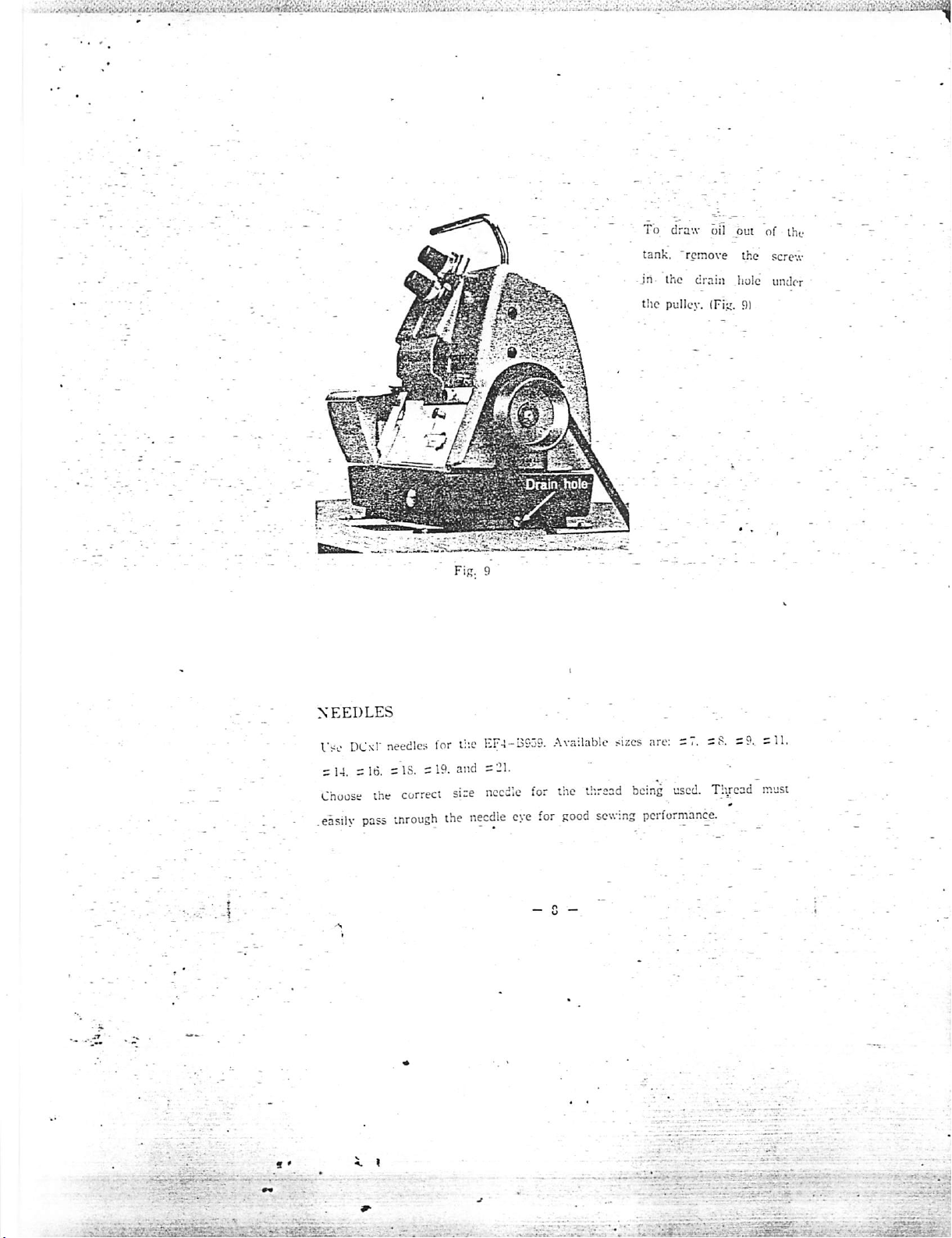

SPECIFICATIONS

Typeofslitch

Max.

sewing

speed

Sticch

i 1

1

length

Differential

feed

1

EF4-B959-01

Twin

4200

rpm

adju.stable

stretching

shirring

needle

overlook

Hj

miiiii

ft1fl

UTTi

to

-

1

or

.

EF4-B959-21

Mock

safety

4200

rpm"

-1mm —6mm (

adjustable

stretching

shirring

or

• j

. 1

to. - -|

- "

.|

. P

:

Presscr

:

Standard

:

width

:

Shapeoffeed

:

-

•

.

Needle

gauge

•

Cutting

Needle

Weightofhead

foot

stitch

width

height

dog

3.2iiim

3mm--5mm

. s _

2mm

adjustable

DC

XI

18.1kg

- 32 -

3.2mm

3mm

—5mm

^§§

2mm

adjustable

DCxl

18.1kg

!

'

«-

r.

n

«♦

5. «

i..

r->-

.. -7

irt'-

/

Loading...

Loading...