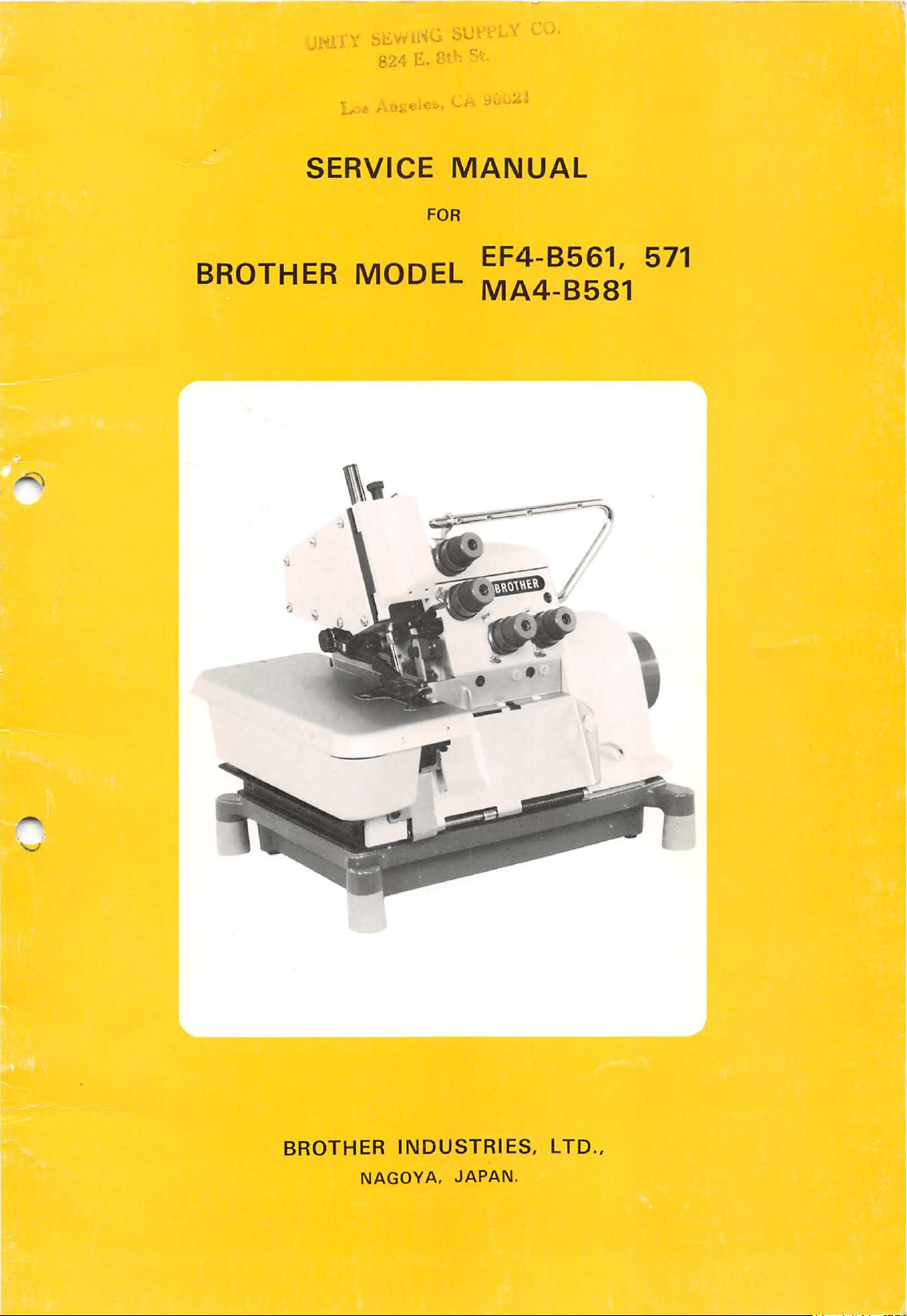

SERVICE

FOR

MANUAL

BROTHER

MODEL

4-8561

EF

,

MA4-B581

571

BROTHER

INDUSTRIES, LTD.,

NAGOYA. JAPAN

.

CONTENTS

Page

1.

FEATURES

2. SPECIFICATIONS I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

I·

.................................................. .

DESCRIPTION OF

3.

[!]

Needle bar mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 9

[g)

Under looper mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 9

[a]

Over looper mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 9

MECHANISM

I·

..................................... 9

III Double chain stitch looper mechanism· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

00

Knives mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

liD

Feed mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

[1]

Presser foot mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

4. DISASSEMBLING PROCEDURES

[l]

Cover · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

[g)

Presser foot and feed mechanism· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

~

Knives mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

I·

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III Under looper mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 14

00

Over looper mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · : · · · · · · · · 14

liD

Double chain stitch looper mechanism· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

[1]

Needle bar mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

5. ASSEMBLING

[!]

Needle bar mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

00

Under looper mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 18

[a]

Over looper mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

AND

ADJUSTMENT PROCEDURES

I·

........................

III Double chain stitch looper mechanism· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 20

I]]

Knives mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

liD

Feed and presser foot mechanism · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 23

[1]

Looper thread take-up and thread· guide mechanism · · · · · · · · · · · · · · · · · · · · · · · · 24

[ID

Double chain stitch looper thread take-up and thread guide mechanism · · · · · · · · · · 25

[ID

Cover · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 26

10

10

11

12

12

12

13

13

15

15

16

16

19

21

.~"""..

6. STITCH LENGTH

7.

SEWING

[!]

00

[a]

III Twin needle

8. TROUBLE SHOOTING

[!]

[g)

[a]

III Needle breakage · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 36

[§]

liD

[1]

[ID

AND

DIFFERENTIAL FEED ADJUSTMENT

INSTRUCTION

Single needle two thread · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 28

Single needle three thread · · · · · · • · · · · · · · · · · · · · · · ·. · · · · · · · · · · · · · · · · · · · 29

Twin needle four thread · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

five

Thread breakage (Overlock Stitch Needle) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 32

Thread breakage (Looper Thread) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 33

Skip stitching (Overlock Stitch) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

Improper thread tension · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 36

Wrong chaining-off (Overlock Stitch) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 36

Excessive wrinkles . . . . · · · · . · · · · · · . · · · · · · · · · · · · · · · . . · · · · · · · · · · · · · · · 3 7

Slipage

of

cloth

I·

........................................... 28

thread · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

I·

............................................ 32

.....

· · . ·

...

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 37

I·

............... 27

31

31

34

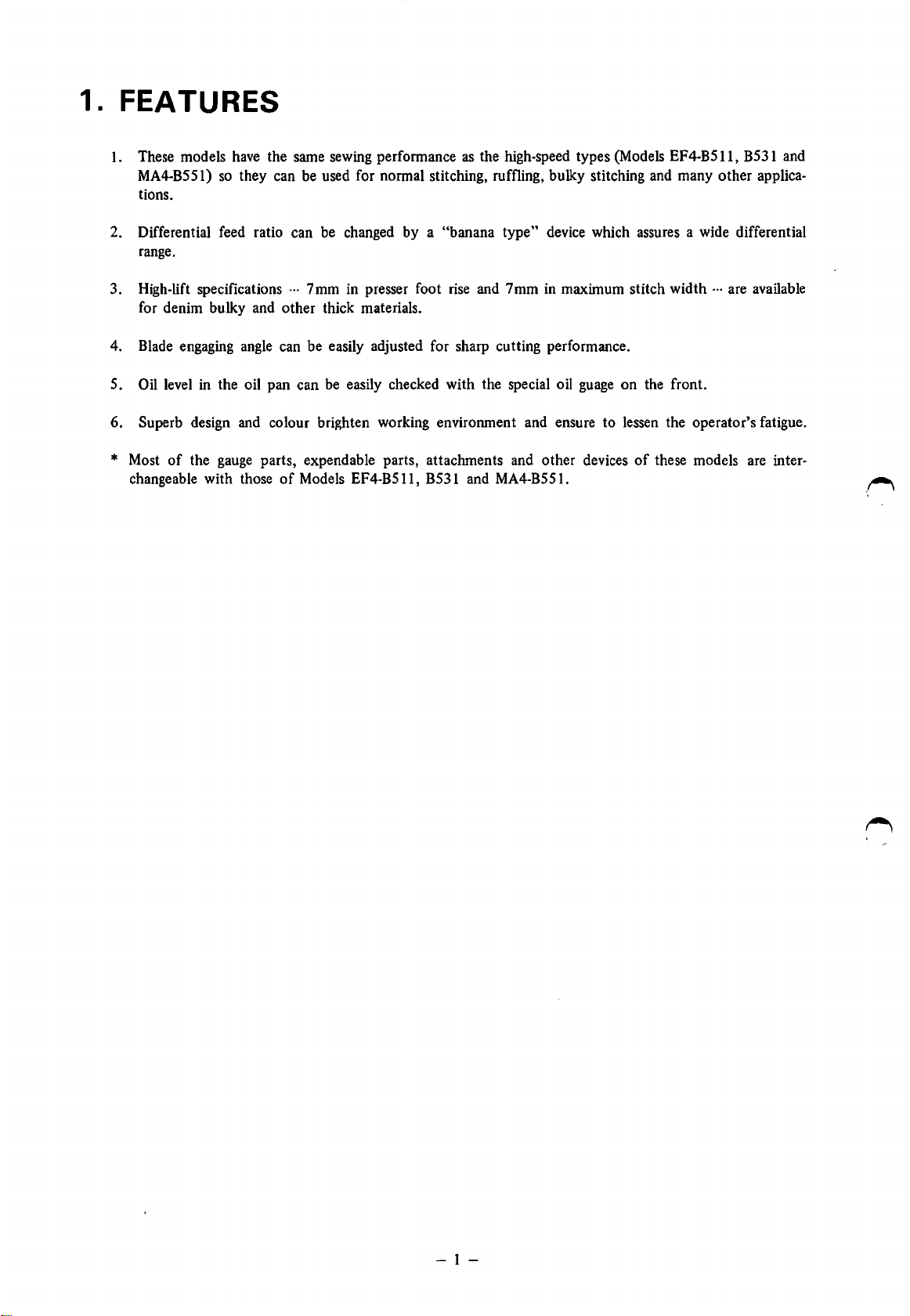

1. FEATURES

1.

These models have the same sewing performance

MA4-B551)

tions.

so

they can be used for normal stitching, ruffling, bulky stitching and many other applica-

as

the high-speed types (Models EF4-BS11, B531 and

2. Differential feed ratio can be changed by a

range.

···

7mm

3. High-lift specifications

for denim bulky and other thick materials.

4. Blade engaging angle can be easily adjusted for sharp cutting performance.

5.

Oil level in the oil pan can be easily checked with the special oil guage on the front.

Superb design and colour brighten working environment and ensure to lessen the operator's fatigue.

6.

* Most

of

the gauge parts, expendable parts, attachments and other devices

changeable with those

of

in presser foot rise and

Models EF4-B511, B531 and MA4-B551.

"banana

type"

device which assures a wide differential

7mm

in maximum stitch width

of

these models are inter-

···

are available

-~

-

1-

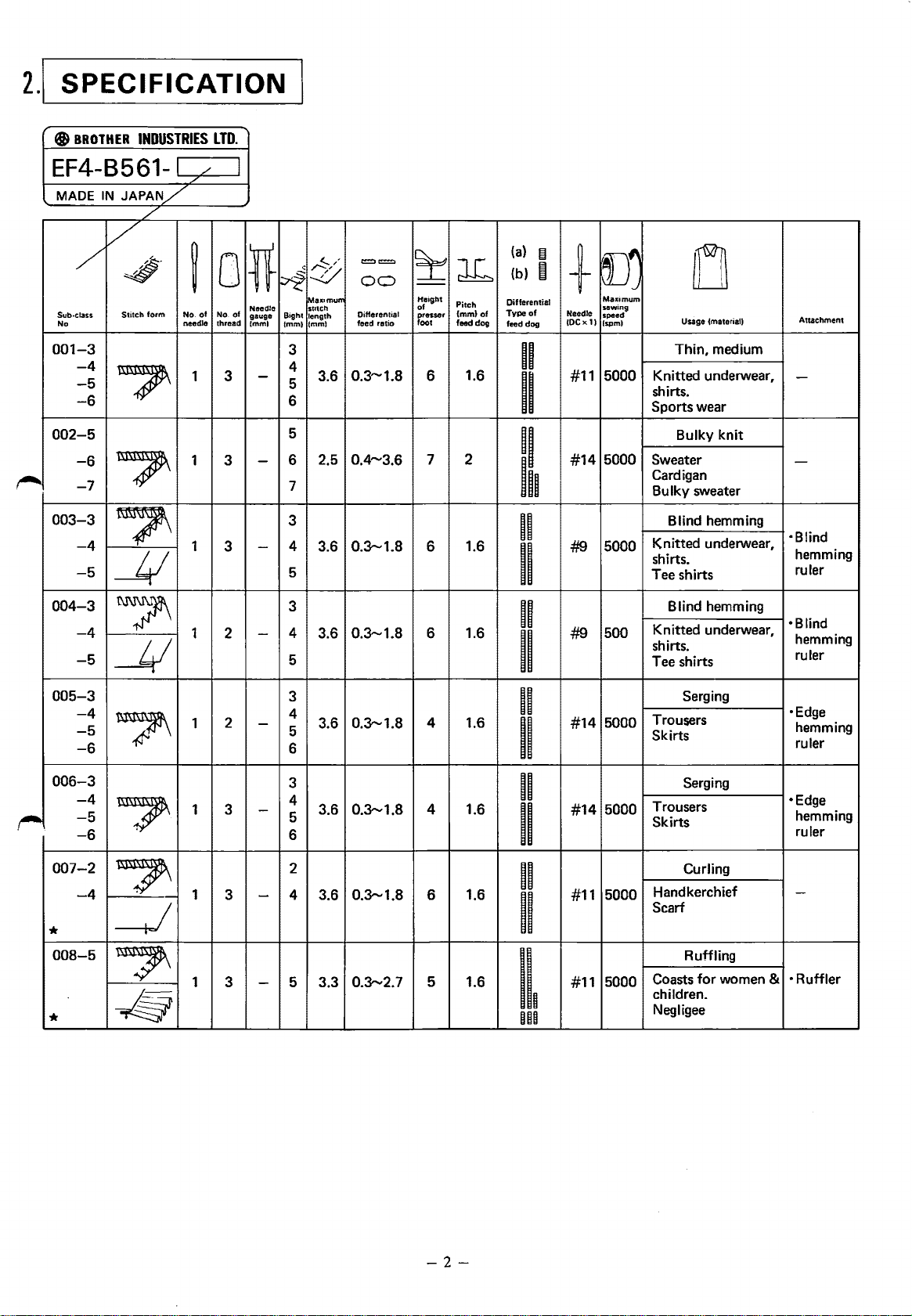

2.\

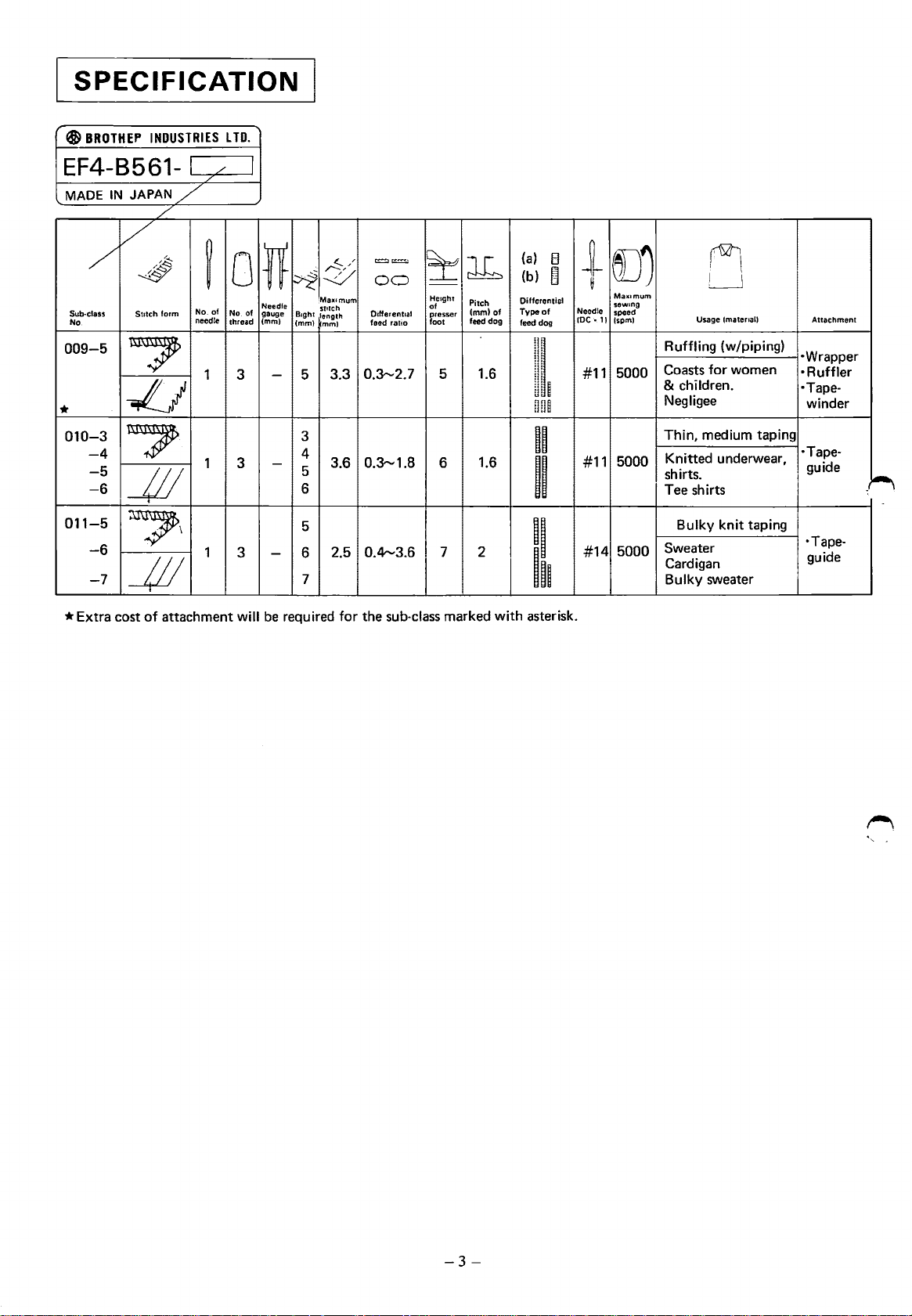

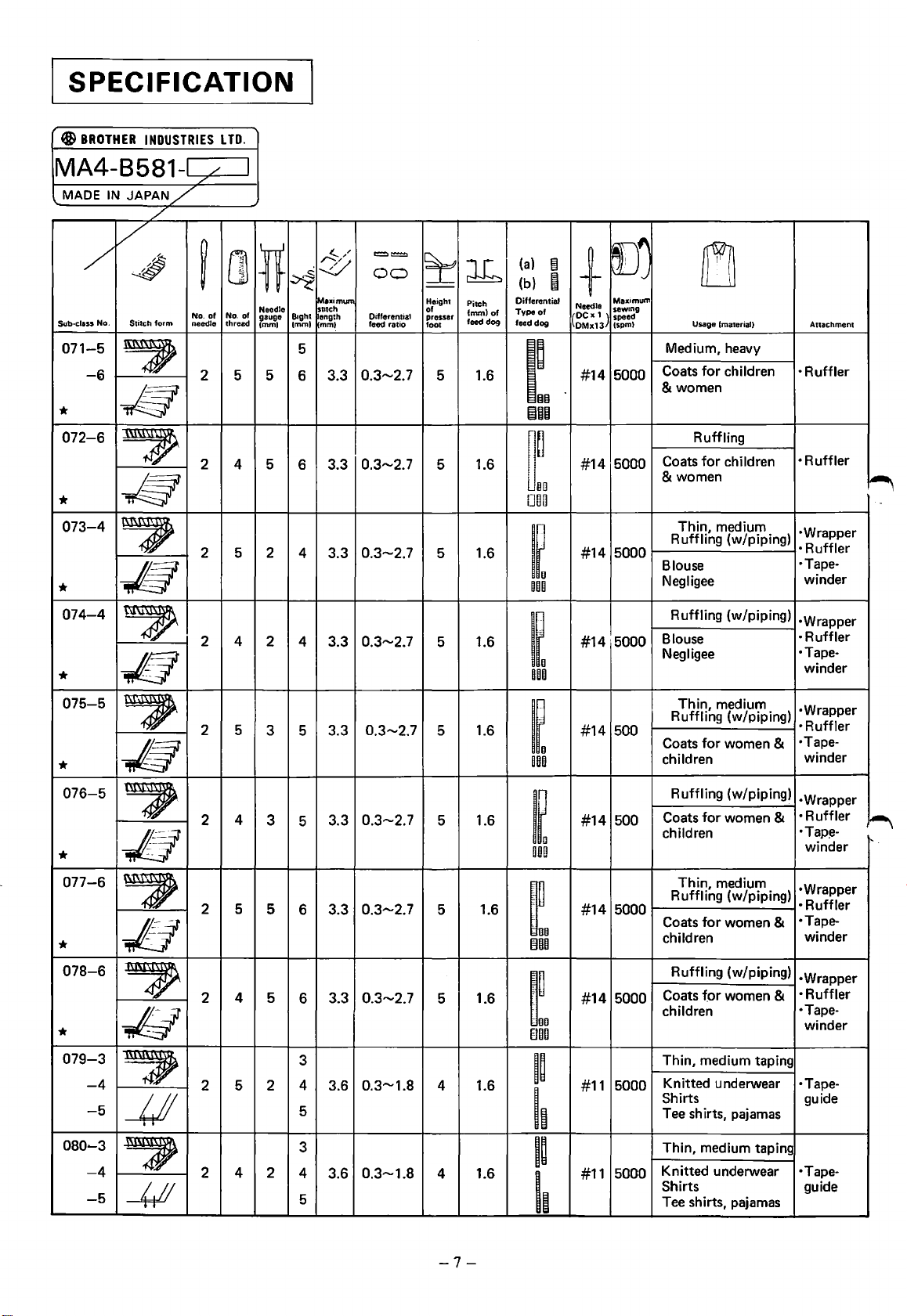

SPECIFICATION

$

BROTHER

INDUSTRIES

LTD.

EF4-B561-

MADE IN

/

Sub-class

No

001-3

-4

-5

-6

002-5

-6

~

-7

003-3

-4

-5

004-3

-4

-5

JAPAN/

/

v

41'

Stitch

form

?

?

?

_LV

?

_1/

/ I

/

0

No.

of

3

lf

Needle

gauge

(mml

-

-

-

-

~

No.

of

needle thread

1 3

1 3

1

1 2

c

~

~

Maoumum

stotch

Bight

length

(mm) feed ratio

(mml

3

4

3.6

5

6

5

2.5

6

7

3

4

3.6

5

3

4

3.6

5

==

00

Differential

0.3"'1.8

0.4"'3.6

O.J......1.8

0.3

......

1.8

~

l6

Height

Pitch

of

(mm)of

presser

foot

feed dog

6

7

6

6

1.6

2

1.6

1.6

(a)

(b)

Differential

Type

of

feed dog

II

II

II

hi

II

II

II

II

~

i

+

Needle

IDCx1)

#11

#14

#9

#9

[)j

Maxomum

sewing

speed

(spm)

5000

5000 Sweater

5000

500

Usage (material)

Thin, medium

Knitted underwear,

shirts.

Sportswear

Bulky

Cardigan

Bulky

Blind hemming

Knitted underwear,

shirts.

Tee shirts

Blind hemming

Knitted underwear,

shirts.

Tee shirts

n

Attachment

-

knit

-

sweater

·Blind

hemming

ruler

·Blind

hemming

ruler

~

005-3

-4

-5

-6

006-3

-4

-5

-6

007-2

-4

*

008-5

*

?

?

?

_J

?

-lfjJr

1

1 3

1 3

1

3

2

4

-

5

6

3

4

-

5

6

2

4

-

3.6

3.6

3.6

O.J......1.8

O.J......1.8

O.J......1.8

4 1.6

1.6

4

1.6

6

II

II

II

II

II

#14

#14

#11

5000

5000

5000

Serging

Trousers

Skirts

Serging

Trousers

Skirts

Curling

Handkerchief

Scarf

•Edge

hemming

ruler

•Edge

hemming

ruler

-

II

Ruffling

Coasts

for

3

-

5 3.3

O.J......2.7

5 1.6

II~

on

#11

5000

children.

Negligee

women &

• Ruffler

-2-

SPECIFICATION

~

BROTHEP

INDUSTRIES L TO.

EF4-8561-

MADE

IN

JAPAN/

/

v

/

Sub-class

No

009-5

~

Stotch

/~

form

7

-4

-5

-6

-6

-7

J__j

7

_jjj

?\

_jjj

cost

of

*

010-3

011-5

*Extra

/ I

/

~

No.

of

needle

1 3

1 3 -

1

attachment

0

No

of

thread

3

will

l1

~

Needle

gauge

Boght

(mml

(mm)

-

5

3

4

5

6

5

- 6

7

be

required

~/

~

Maxomum

stotch

length

mml

==

00

Oifferentoal

feed ratio

0.3--2.7 5

3.3

0.3--1.8 6

3.6

0.4--3.6

2.5

for

the sub-class marked

~

~

--

Height

Pitch

of

lmmlof

presser

feed dog

foot

7 2

1.6

1.6

(a)

El

(b)

~

Differential

Type

of

feed

dog

~~~

u

n~

n

II

II

hi

with

asterisk.

t

Needle

IDC·ll

#11

#11

#14

eJJ)

Maxomum

sewong

speed

(spml

Ruffling (w/piping)

5000

5000

5000

Coasts

& children.

Negligee

Thin,

Knitted

shirts.

Tee shirts

Sweater

Cardigan

Bulky

Bulky

LJ

tmateroall

Usage

for

women

medium taping

underwear,

knit

taping

sweater

Attachment

·Wrapper

•

Ruffler

·Tapewinder

·Tapeguide

·Tapeguide

~~

-

-3-

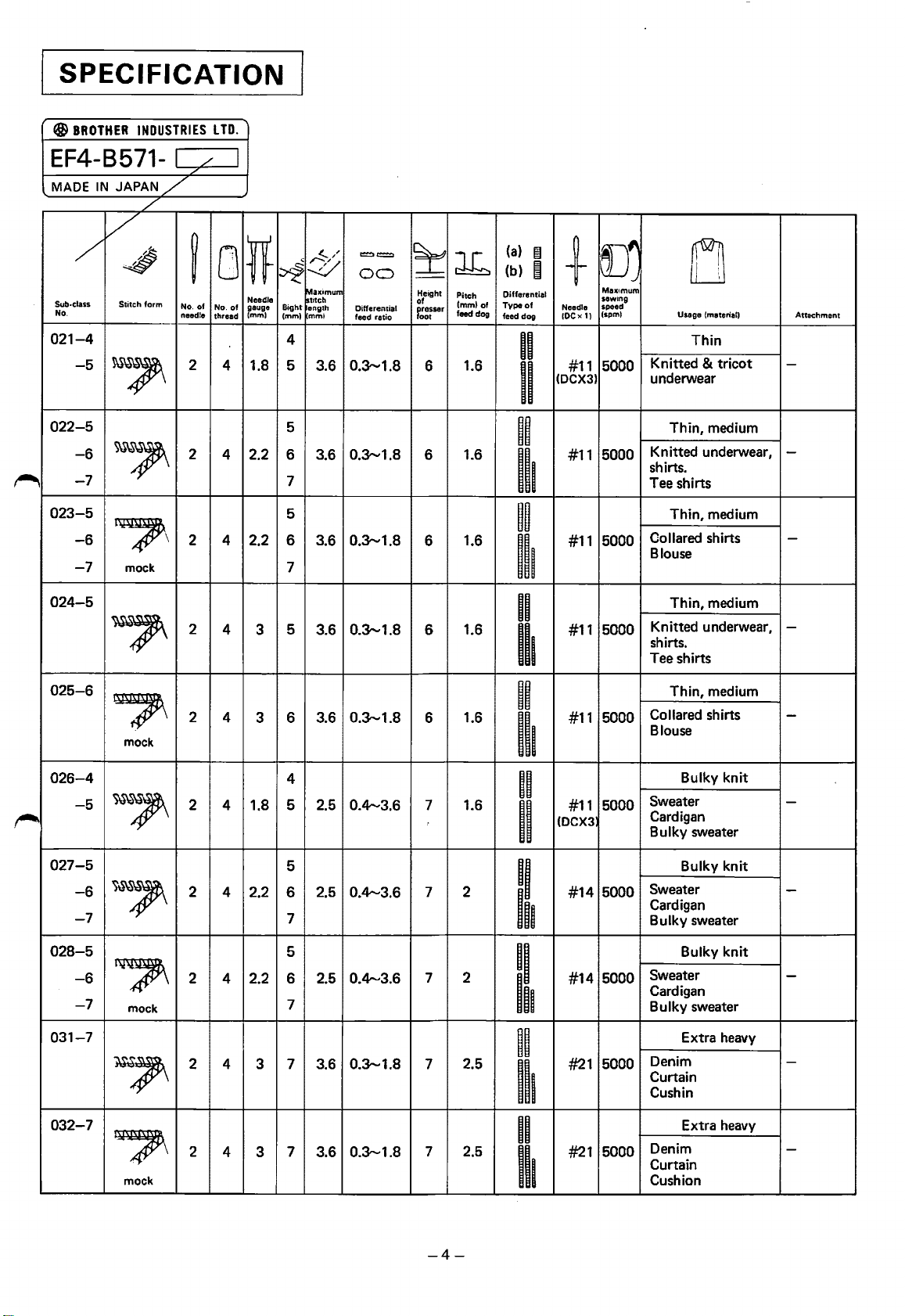

SPECIFICATION

fa&

BROTHER

EF4-B571-

MADE

INDUSTRIES L TO.

IN

JAPAN_/

/

/_

J

/

v

/

Sub-class

No.

021-4

-5

~

Stitch

?

form

No.

noodle

0

~

of

2

lf

Needle stitch

No.

of

p.auge

mml

thread

4 1.8 5

,.!::-/

:y

~

Ma>cimum

Bight

ength

(mm)

mmt

4

3.6

==

00

Differential

feed

ratio

0.3-1.8

~

lb

Height

Pitch

of

lmm)of

rcresser

feed dog

001

6

1.6

(a)

~

(b) e

Difforential

Type

of

dog

feed

II

II

[J'

Max1mum

+

SOWing

speed

Noodle

(spml

(0Cx1)

5000

#11

(DCX3)

J

0

Usage (material)

Thin

Knitted & tricot underwear

Attachment

~

r---

022-5

-6

-7

023-5

-6

-7

024-5

025-6

026-4

-5

027-5

-6

-7

?

?

mock

?

?

mock

?

?

5

2

4 2.2 6

7

5

2 4 2.2 6

7

2

4 3

2

4

2 4 1.8 5 2.5 0.4--3.6 7 1.6

2 4

5

3 6 3.6

4

5

2.2 6

7

3.6

3.6

3.6

2.5

0.3-1.8

0.3-1.8

0.3-1.8

0.3-1.8

0.4-3.6

6

6

6

6

7 2

1.6

1.6

1.6

1.6

~~

#11

Ill

~~

ll1

II

ll1

II

ll1

n

II

II

IIi

#11

#11

#11

#11

(DCX3

#14

5000

5000

5000

5000

5000

5000

Thin,

medium

Knitted underwear,

shirts.

Tee shirts

Thin, medium

Collared shirts

Blouse

Thin, medium

Knitted underwear,

shirts.

Tee shirts

Thin, medium

Collared shirts

Blouse

Bulky knit

Sweater Cardigan

Bulky sweater

Bulky knit

Sweater

Cardigan

Bulky sweater

-

-

-

-

-

028-5

-6

-7

031-7

?

mock

~~

2

4

2 4 3 7

2.2

5

2.5

3.6

0.4-3.6

0.3-1.8

6

7

7 2

7

2.5

II

hi

~~

ll1

032-7

?

mock

2

4 3

7

3.6

0.3-1.8

7 2.5

-4-

II

ll1

#14

#21

#21

5000

5000

5000

Bulky knit

Sweater

Cardigan

Bulky sweater

Extra heavy

Denim

Curtain

Cushin

Extra heavy

Denim

Curtain

Cushion

-

-

-

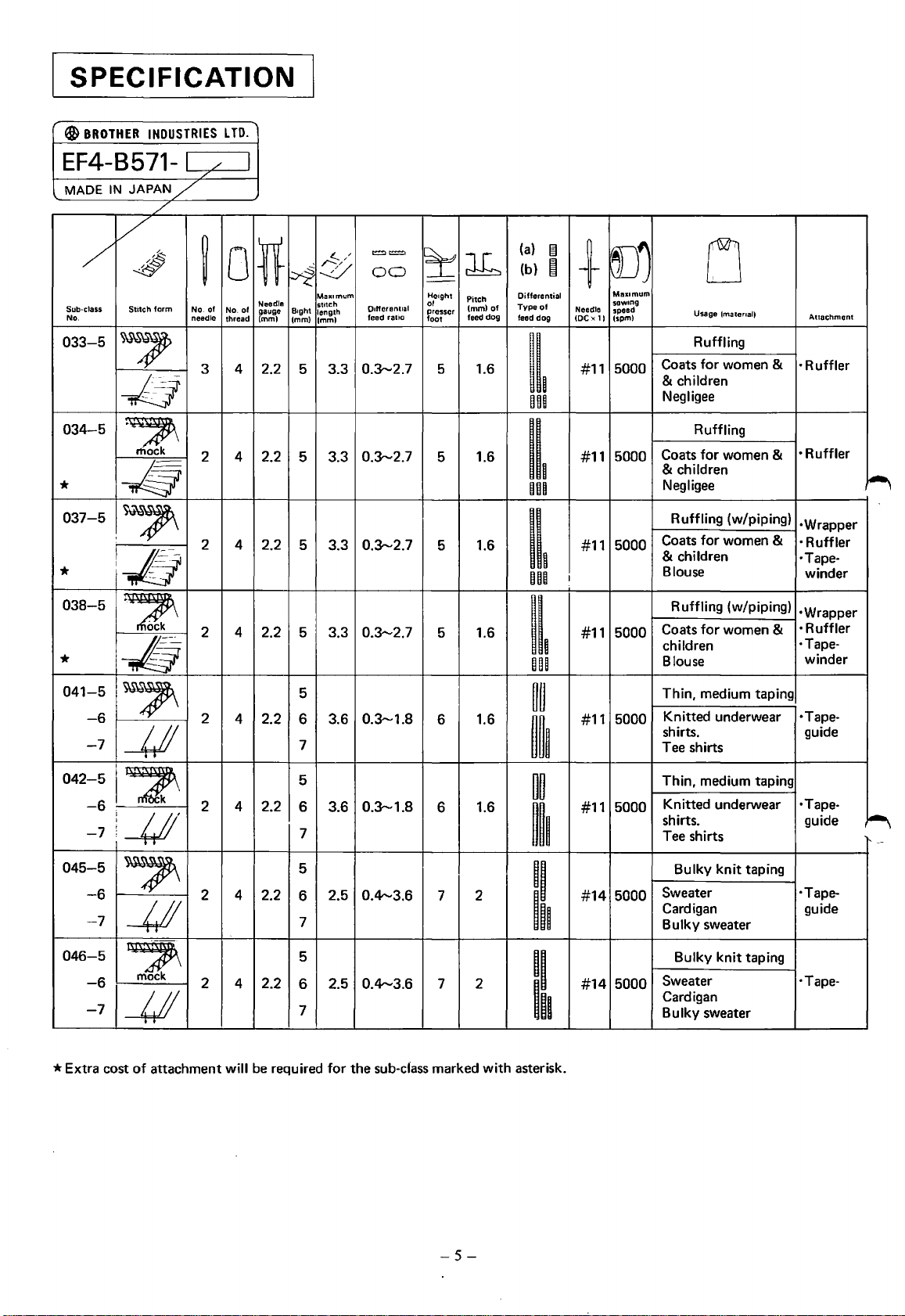

SPECIFICATION

~BROTHER

INDUSTRIES l TO.

EF4-B571-

MADE

IN

JAPAN/

/

v

/

Sub-class

No.

033-5

034-5

*

037-5

*

038-5

~

Stitch

form

7

-

-/f!J

~

mock

~

I?

J!j

-

7

*

041-5

042-5

045-5

-Jj

?

-6

-7

_jj/

~

-6

~~~

-7

?

-6

-7

-U

/ I

/

0

~

No.

of

needle

3 4 2.2

2 4 2.2

2 4 2.2

2 4 2.2

2

2 4 2.2

2 4 2.2

lf

Needle

No.

of

gauge

thread (mml

4 2.2

/::-/

~

~

Maxtmum Height

stitch

Bight

length

lmml

lmml

5 3.3

5 3.3

5

5 3.3

5

6 3.6

7

5

6

7

5

6

7

==

00

Otfferent•al

feed rat•o

0.3--2.7 5 1.6

0.3--2.7

0.3--2.7

3.3

0.3--2.7

0.3--1.8

0.3--1.8

3.6

2.5

0.4--3.6 7 2

~

~

--

Pitch

of

(mm)of

prosser

feed dog

foot

5

5 1.6

5 1.6

6 1.6

6

1.6

1.6

(a)

~

(b) ;

Differential

Type

of

feed dog

ij~l

HH~

It

no

It

no

ijt

n~

~~

~~I

~~

~~~

II

hi

eD)

Mu•mum

+

sewtng

Needle

speed

(spml

IOCx

11

5000

#11

5000

#11

5000

#11

I

5000

#11

5000

#11

5000

#11

#14

5000

Coats

& children

Negligee

Coats

& children

Negligee

Ruffling (w/piping)

Coats

& children

Blouse

Ruffling (w/piping)

Coats

children

Blouse

Thin, medium taping

Knitted underwear ·Tapeshirts. guide

Tee shirts

Thin,

Knitted underwear

shirts. guide

Tee

Bulky

Sweater

Cardigan guide

Bulky

I

I

u

Usage lmatonall

Ruffling

for

women &

Ruffling

for

women &

for

women &

for

women &

medium taping

shirts

knit

taping

sweater

Anachment

·Ruffler

• Ruffler

~

·Wrapper

• Ruffler

·Tapewinder

•Wrapper

• Ruffler

•Tapewinder

•Tape-

~

--

·Tape-

046-5

-6

-7

*Extra

AA

_jj/

cost

of

mock

attachment

2

4

will

be

2.2

required

5

2.5

6

7

0.4--3.6 7 2

for

the sub-dass marked

with

-5-

II

hi

asterisk.

#14

5000

Bulky

Sweater

Cardigan

Bulky

sweater

knit

taping

·Tape-

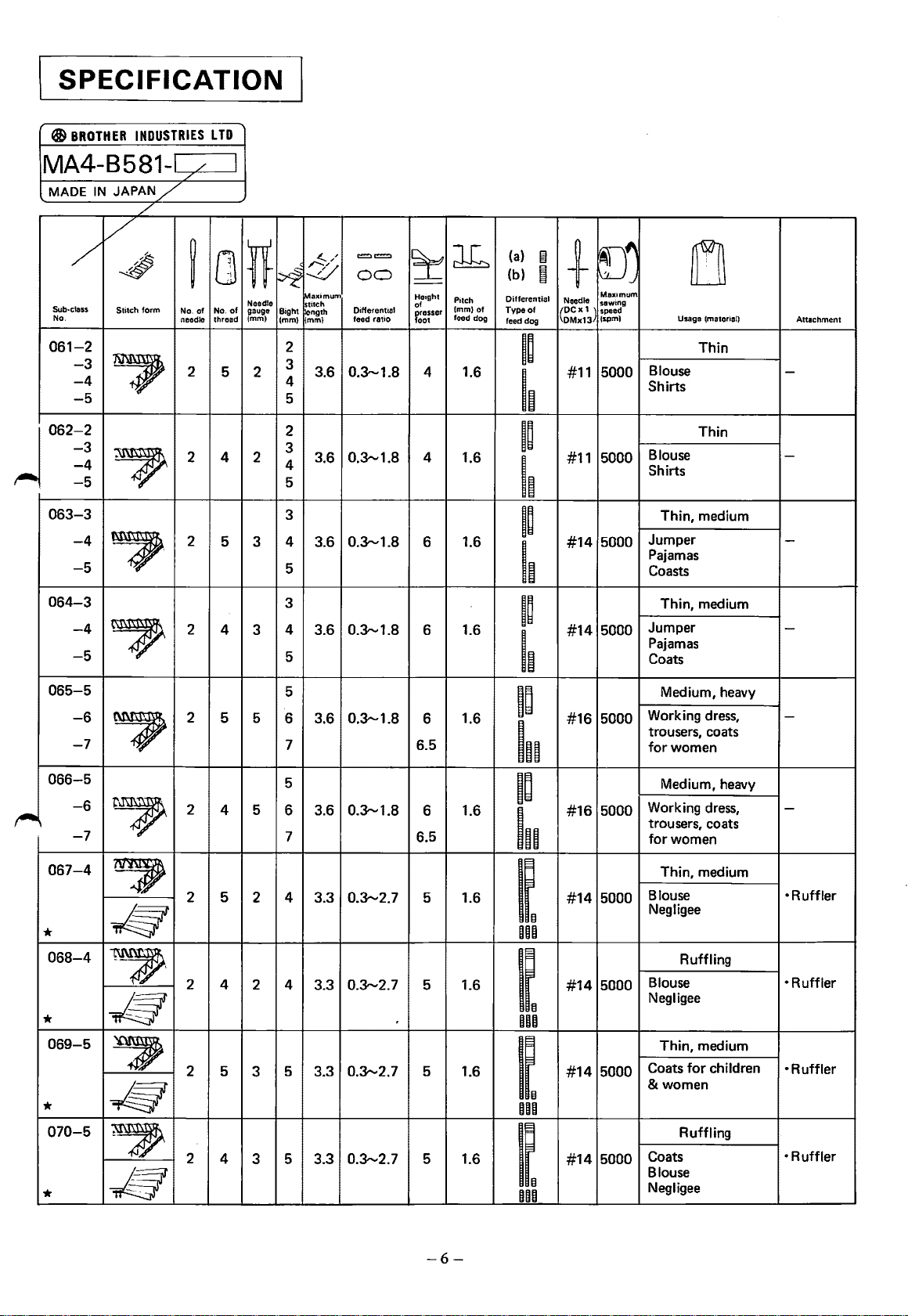

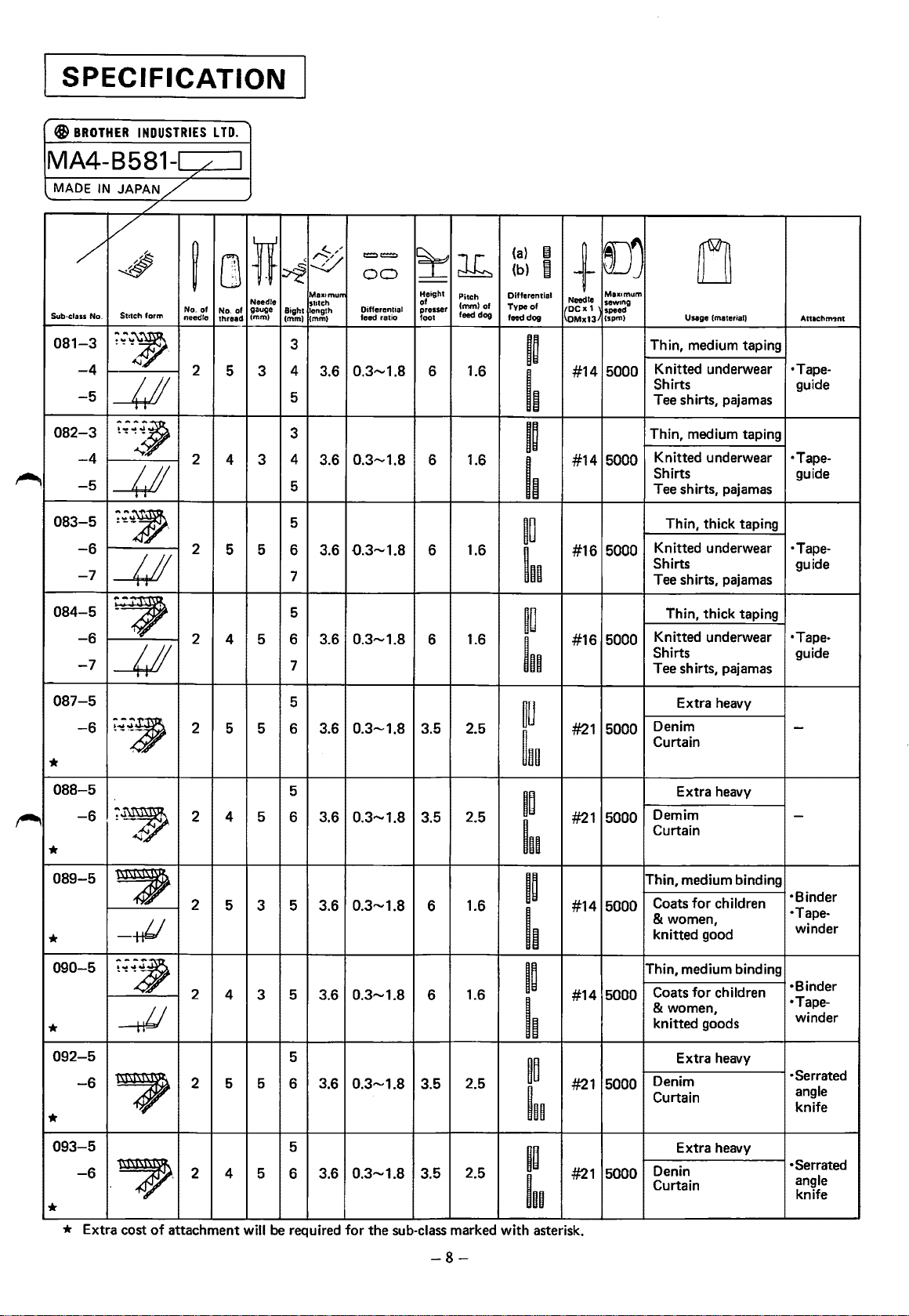

SPECIFICATION

@)BROTHER

INDUSTRIES

MA4-B581- /

MADE

IN

JAPAN/

/

v

~

I"-

Sub-class

No.

061-2

062-2

063-3

064-3

065-5

066-5

067-4

*

068-4

*

069-5

*

070-5

*

/

~

Stitch

-3

-4

?

-5

-3

-4

-5

7

-4

7

-5

-4

?>

-5

-6

-7

?

-6

?

-7

,

~

~

./!#}'

,

-~iff~

,

./tfJ

form

-

LTD

/

No.

needle

2 4

2 5

2

I

[]

~

of

2

2

2

2

2

2

2

lf

Needle

No.

of

gauge

(mm)

thread

5

2

4 2

5

3

4

3

5 5

5

4

5 2 4

2

3

4

3

~/

~

~

~aJ:imum

stitch

Bight

length

(mm)

(mmJ

2

3

4

5

2

3

4

5

3

4

5

3

4

5

5

6

7 6.5

5

6 3.6

7

4

5

5 3.3

==

00

Differential

feed ratio

3.6

0.3--1.8

0.3-1.8

3.6

0.3-1.8

3.6

0.3--1.8

3.6

0.3--1.8

3.6

0.3--1.8

3.3

0.3--2.7 5

0.3--2.7 5 1.6

3.3

3.3

0.3--2.7

0.3--2.7 5 1.6

:t=

-

Height

of

~rosser

oot

4

4

6

6 1.6

6

6

6.5

5

db

Pitch

(mm)of

feed dog

1.6

1.6

1.6

1.6

1.6

1.6

1.6

(a)

1§1

(b)

I

Differential

Type

of

feed dog

~~

~~

+

Maxomum

Noodle

sewing

speed

(DCK

1)

(spmJ

DMx13

5000

#11

Blouse

Shirts

I~

~~

#11

5000

Blouse

Shirts

I~

~~

#14

5000

I~

~~

#14

5000

I~

~~

#16

5000

In

~~

In

#16

#14

5000

5000

~~

no

#14

5000

~~

no

5000

#14

~~

no

5000

#14

~~

no

Thin, medium

Jumper

Pajamas

Coasts

Thin, medium

Jumper

Pajamas

Coats

Medium, heavy

Working

trousers, coats

for

women

Medium, heavy

Working

trousers, coats

for

women

Thin, medium

Blouse

Negligee

Blouse

Negligee

Thin,

Coats

& women

Coats

Blouse

Negligee

~

Usage (material)

Thin

Thin

dress,

dress,

Ruffling

medium

for

children

Ruffling

Attachment

-

-

-

-

-

-

•

Ruffler

• Ruffler

·Ruffler

• Ruffler

-6-

SPECIFICATION

0

BROTHER

INDUSTRIES L TO.

MA4-B581-

MADE IN

JAPAN/

/

v

/

Sub-class

071-5

*

072-6

*

073-4

*

074-4

*

075-5

*

076-5

*

077-6

*

078-6

*

079-3

080

No.

-5

-/@

?

-./@

?

.n

.n

n

-£1

H

-IY

-4

-5

......

3

-4

-5

~

Stitch form

~

~

,

,

-

~

-

~

~

-U

~

~

/ I

/

.

[]

~

No.

of

needle

2 5 5

2 4 5

2 5 2

2 4

2 5

2

2 5

2 4 5

2 5 2

2

No. of

thread

4

4 2

ll

Neodlo

gauge

(mml

2 4 3.3

3

3

5

==

0

~

Maximum

StitCh

Bight

length

(mm)

(mml

5

6

6

4 3.3

5

5

6

6

3

4

5

3

4

5

00

Differential

feed ratio

0.3--2.7 5 1.6

3.3

0.3--2.7 5 1.6

3.3

0.3--2.7

0.3--2.7

3.3

0.3--2.7 5 1.6

3.3 0.3--2.7 5 1.6

0.3--2.7 5

3.3

3.3

0.3--2.7

0.3--1.8 4 1.6

3.6

0.3--1.8 4 1.6

3.6

~

~

--

Height

Pitch

of

(mmlof

presser

feed dog

foot

5 1.6

5 1.6

5

1.6

1.6

(a)

~

(b)

e

Differential

Type

of

feed dog

~~0

~00

~~u

000

~~

no

~~

000

~~

000

~~

000

~~

gg

(j00

~~

oo

[100

~~

I~

~~

I~

()j

+

Maximum

Nndle

sew•ng

speed

(spml

(~~=,~)

Medium, heavy

#14

#14

#14

#14

#14

#14

#14

#14

#11

#11

5000

5000

5000

5000

500

500

5000

5000

5000

5000

Coats

& women

Coats

& women

Thin, medium

Ruffling (w/piping)

Blouse

Negligee

Ruffling (w/piping)

Blouse

Negligee

Thin,

Ruffling (w/piping)

Coats

children

Ruffling

Coats

children

Thin,

Ruffling

Coats

children

Ruffling (w/piping)

Coats f.or women &

children

Thin, medium taping

Knitted underwear

Shirts guide

Tee

Thin, medium taping

Knitted

Shirts

Tee

m

(material)

Usage

for

children

Ruffling

for

children

medium

for

women &

(w/piping)

for

women &

medium

(w/piping)

for

women &

shirts, pajamas

underwear

shirts, pajamas

Anachment

•

Ruffler

•

Ruffler

·Wrapper

•

Ruffler

·Tapewinder

·Wrapper

•

Ruffler

·Tapewinder

•Wrapper

•

Ruffler

·Tapewinder

•Wrapper

•

Ruffler

·Tap~-

winder

·Wrapper

• Ruffler

·Tapewinder

•Wrapper

•

Ruffler

•Tapewinder

·Tape-

·Tapeguide

~

-7-

SPECIFICATION

~BROTHER

INDUSTRIES L TO.

MA4-B581-

MADE

IN

JAPAN/

/

v

/

~

form

7;~

-4

-5

_IJ

A--~

-4

_Jj/

-5

~~7,

-6

-7

-U

Stitch

t~~~

~

Sub-class No.

081-3

082-3

083-5

/ I

/

ij

No.

of

needle

2

2

2

[]

.

No.

of

thread

5

4 3

5 5

~

ll

Needle

gauge

Bight

(mm)

(mm)

3

~/

~

MaKimurT

slltch

length

(mml

3

4 0.3

5

3

4

5

5

6 3.6

7

==

00

Differential

feed ratio

3.6 6

0.3

3.6

.0.3

.....

.....

.....

1.8

1.8

1.8

~

~

--

Haight

Pitch

of

lmml

prosser

feed

foot

6 1.6

6

dog

1.6

1.6

(a)

~

(b)

I

Differential

of

Type

of

foeddog

~~

I~

~~

I~

~~

I

me

[)j

+

Needle

sewong

speed

(ocx1

(spm)

0Mx131

#14

#14

#16

Ma~tomum

Thin, medium taping

5000

5000

5000

Knitted underwear

Shirts guide

Tee

shirts, pajamas

Thin,

Knitted

Shirts

Tee

shirts, pajamas

Thin,

Knitted

Shirts

Tee

shirts, pajamas

~

Usage (material)

medium taping

underwear

thick

taping

underwear

Anachm"Jnl

·Tape-

·Tapeguide

·Tape-

guide

084-5

087-5

*

088-5

*

089-5

*

090-5

*

092-5

*

093-5

*

*

'?

-6

-7

_IJ

-6

A-~

~~~

7,

-6

,

_,tf

~~"!~

--~

-riJ

-6

?

-6

·~

Extra

cost

2

2

.

2

2

2

2 5 5

2 4

of

attachment

5

4 5

5

4 5

5

4 3 5 3.6

6 3.6

7

5

5 6 3.6

5

3.6

6

3 5 3.6

5

6 3.6

5

5

will be required

3.6

6

0.3

.....

0.3

.....

0.3

.....

0.3

.....

0.3

.....

0.3

.....

0.3-1.8

for

the

1.8

1.8

1.8

1.8

1.8

1.8

3.5

3.5

sub-class marked

1.6

6

3.5 2.5

2.5

3.5

1.6

6

1.6

6

2.5

2.5

~~

#16

5000

In

~u

~80

~~

#21

#21

5000

5000

In

~~

#14

5000

I~

~~

#14

5000

I~

~~

~~~

IC

iou

with

asterisk.

#21

#21

5000

5000

Thin,

thick

taping

Knitted

Shirts guide

Tee

Denim

Curtain

Demim

Curtain

Thin,

Coats

&

knitted

Thin,

Coats

&

knitted

Denim

Curtain

Den

Curtain

underwear

shirts, pajamas

Extra

heavy

Extra

heavy

medium

women,

medium

women,

Extra

Extra

in

for

good

for

goods

binding

children

binding

children

heavy

heavy

·Tape-

-

-

•Binder

·Tape-

winder

•Binder

•Tapewinder

·Serrated

angle

knife

•Serrated

angle

knife

-8-

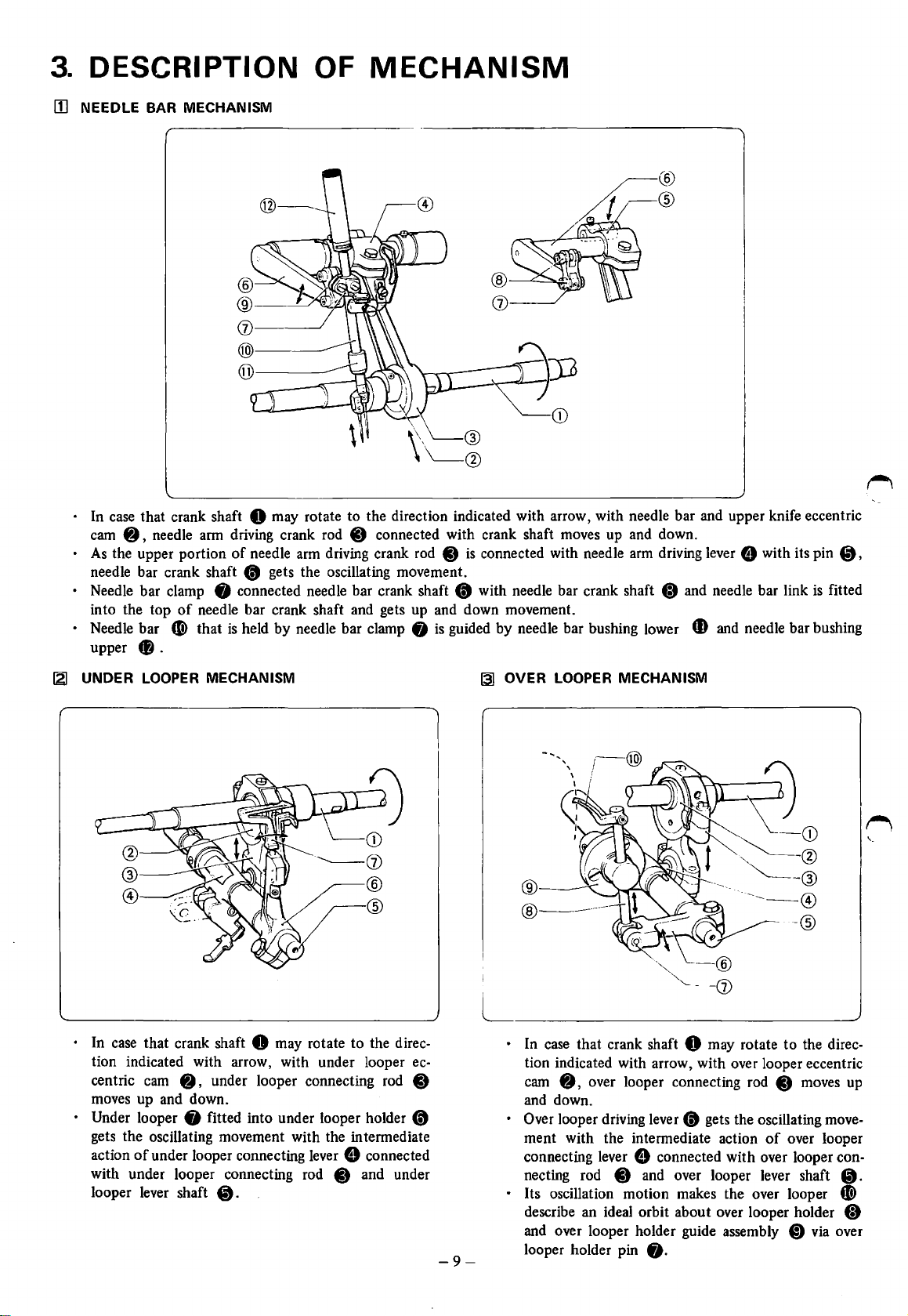

3.

DESCRIPTION

[j]

NEEDLE

BAR

MECHANISM

®

®-~-"

(j)------/

(@--

@------

OF

MECHANISM

CD

• In case that crank shaft 0 may rotate

8 , needle arm driving crank rod 0 connected with crank shaft moves up and down.

cam

•

As

the upper portion

needle bar crank shaft

• Needle bar clamp • connected needle bar crank shaft

into the top

• Needle bar C) that

upper

12J

UNDER

of

f).

LOOPER

of

needle arm driving crank rod

(t

gets the oscillating movement.

needle bar crank shaft and gets up and down movement.

is

held by needle bar clamp

MECHANISM

to

the direction indicated with arrow, with needle bar and upper knife eccentric

Ct

is

connected with needle

(t

with needle bar crank shaft (;) and needle bar link

fj

is

guided by needle bar bushing lower

13]

OVER

LOOPER

®

@---

arm

driving lever 8 with its pin

CD

and needle bar bushing

MECHANISM

~@

-CD

~®

-----@)

-®

is

~,

fitted

L

_____

• In case that crank shaft 0 may rotate to the direc-

tion indicated with arrow, with under looper ec-

8,

centric cam

moves up and down.

• Under looper 8 fitted into under looper holder

gets the oscillating movement with the intermediate

action

of

under looper connecting lever 8 connected

with under looper connecting rod

looper lever shaft

under looper connecting rod C)

(t

Ct

and under

•.

-9-

• In

case

tion indicated with arrow, with over looper eccentric

cam

8,

and down.

Over looper driving lever

•

ment with the intermediate action

connecting lever

necting rod

• Its oscillation motion makes the over looper

describe an ideal orbit about over looper holder

and over looper holder guide assembly

looper holder pin

that crank shaft 0 may rotate

over looper connecting rod

(t

gets the oscillating move-

of

8 connected with over looper con-

C) and over looper lever shaft

fj.

____,

to

the direc-

Ct

moves up

over looper

CD

via over

•.

"'

(;)

~

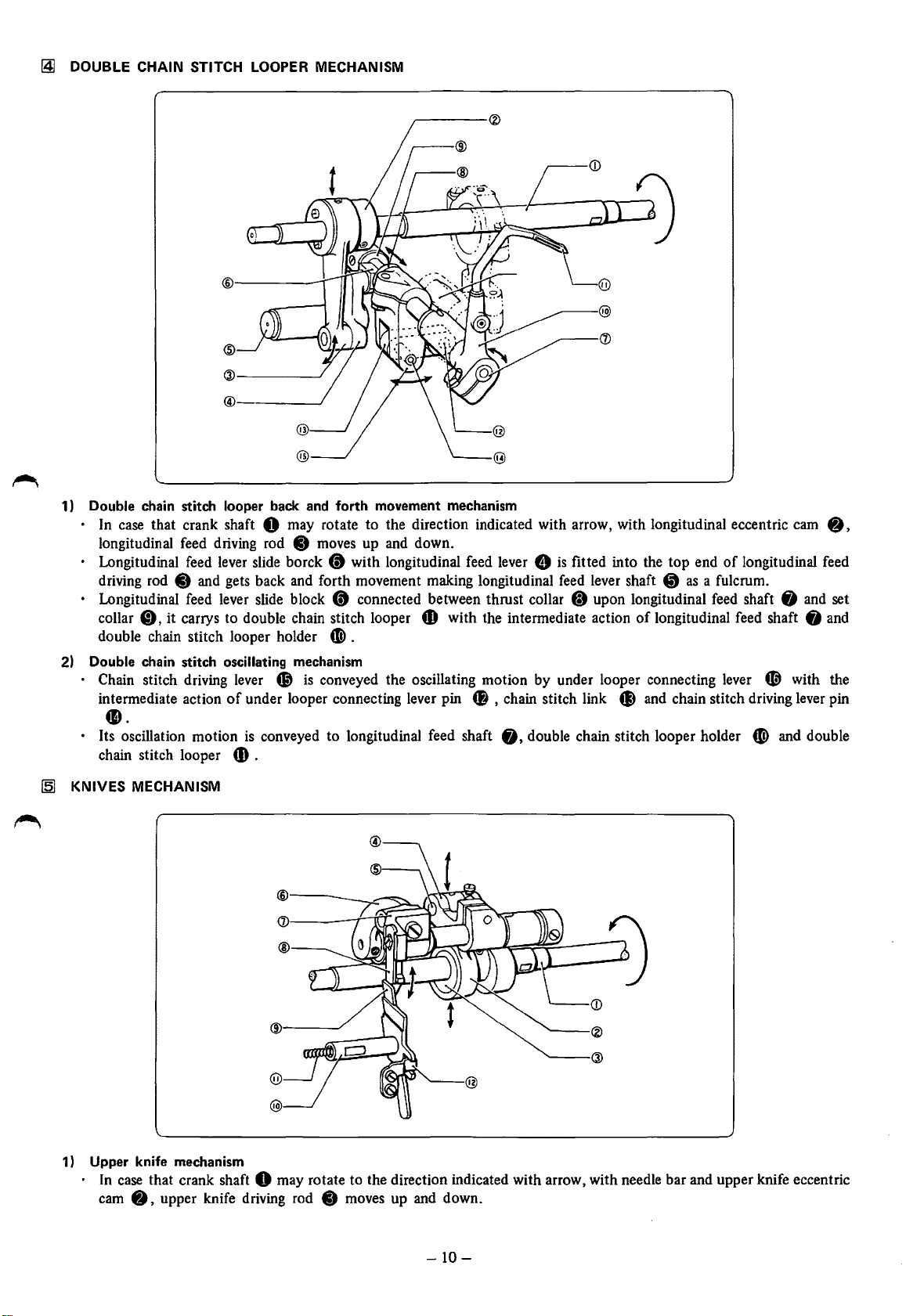

DOUBLE CHAIN STITCH LOOPER MECHANISM

1) Double chain stitch looper back and

• In case that crank shaft 0 may rotate to the direction indicated with arrow, with longitudinal eccentric cam

longitudinal feed driving rod • moves up and down.

• Longitudinal feed lever slide borck • with longitudinal feed lever e

driving rod

• Longitudinal feed lever slide block • connected between thrust collar

collar

double chain stitch looper holder

2) Double chain stitch oscillating mechanism

• Chain stitch driving lever

intermediate action

••

• Its oscillation motion

chain stitch looper

~

KNIVES MECHANISM

• and gets back and forth movement making longitudinal feed lever shaft •

• ' it carrys to double chain stitch looper m

~

of

under looper connecting lever pin

is

conveyed to longitudinal feed shaft

m .

forth

movement mechanism

with

the intermediate action

(0

.

is

conveyed the oscillating motion

f)

is

fitted into the

(;)

upon longitudinal feed shaft

by

under looper connecting lever

, chain stitch link

fj,

double chain stitch looper holder C) and double

41

top

end

of

as

a fulcrum.

of

longitudinal feed shaft • and

and chain stitch driving lever pin

8,

longitudinal feed

fj

and set

41

with the

1) Upper knife mechanism

· In case

cam

that

crank shaft 0 may rotate to the direction indicated with arrow, with needle bar and upper knife eccentric

8,

upper knife driving rod • moves up and down.

-10-

• The top end

knife driving lever

• Upper knife

knife driving lever 8 and upper knife driving arm

2) Lower knife mechanism

• Lower knife

knife holder spring

plays role

12J

FEED MECHANISM

of

tD

CD

of

positioning

upper knife driving rod 8

e gets oscillating movement.

is

connected upper knife holder

is

fixed with lower knife holder

fD

plays a role

of

lower knife

of

edge trimming with upper knife

CD

is

connected with upper knife driving lever 8 with pin

8,

gets oscillating movement with the intermediate action

(3.

f)

and guide

and being pushed to upper knife

tD.

of

lower knife holder

f).

tD

with the pressure

And lower knife holder guide

8,

then upper

of

of

upper

lower

fB

@)

@

~

•.

I :

~:v'

:

---

®

(j)- ®

@

@)

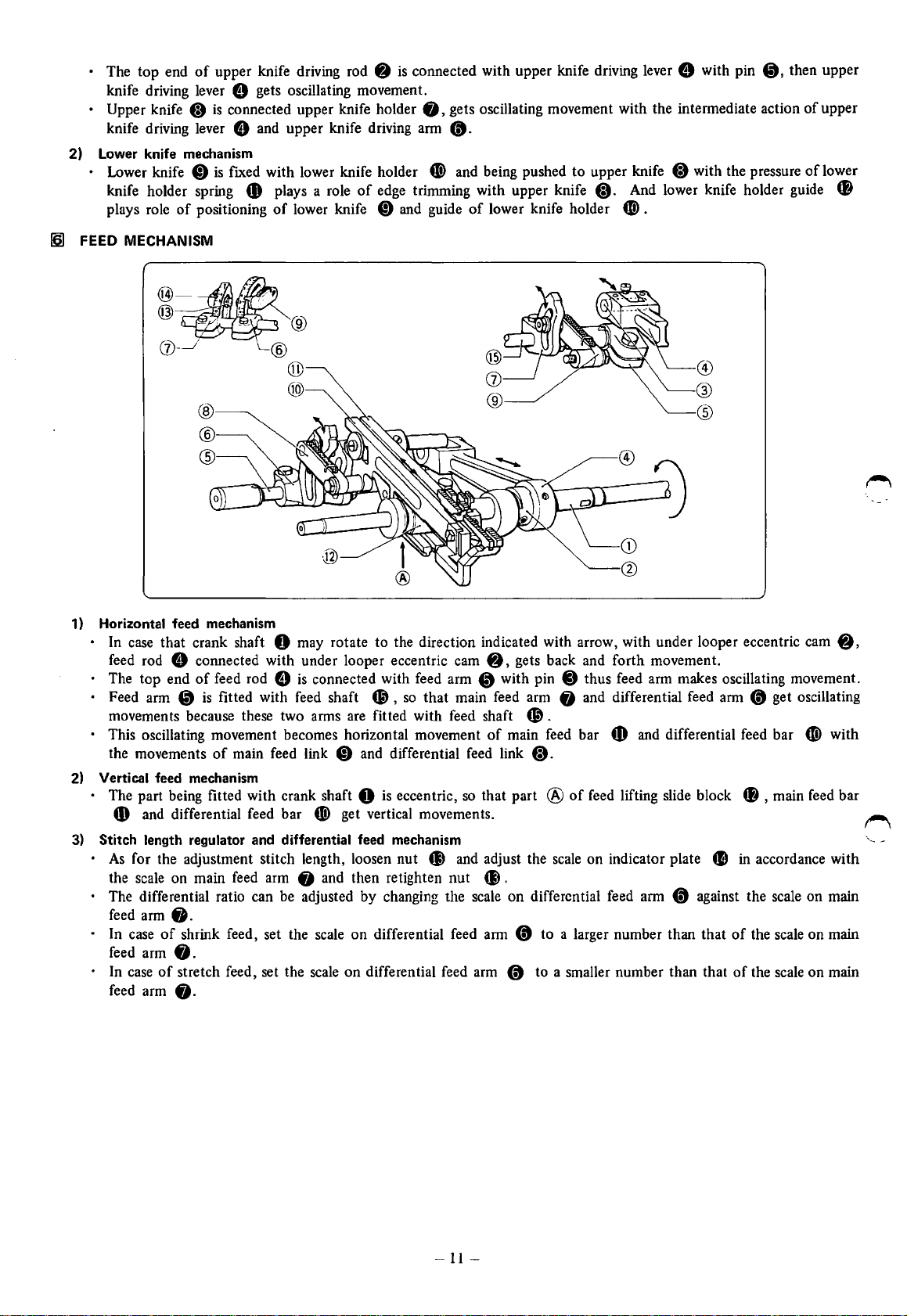

1) Horizontal feed mechanism

• In case that crank shaft 0 may rotate to the direction indicated with arrow, with under looper eccentric cam

feed rod e connected with under looper eccentric cam • ' gets back and forth movement.

• The top end

• Feed arm

movements because these two arms are fitted with feed shaft

• This oscillating movement becomes horizontal movement

the movements

2)

Vertical feed mechanism

• The part being fitted with crank shaft 0

4)

and differential feed bar

3)

Stitch length regulator and differential feed mechanism

•

As

for the adjustment stitch length, loosen nut

the scale on main feed arm

• The differential ratio can be adjusted by changing the scale on differential feed arm

feed arm

• In case

feed arm

• In case

feed arm

of

feed rod 8

CD

is

fitted with feed shaft

of

main feed link

fj.

of

shrink feed, set the scale

8.

of

stretch feed, set the scale

fj.

is

connected with feed arm

69,

so

that main feed arm

CD

and differential feed link

is

eccentric,

f)

get vertical movements.

ell

fj

and then retighten

on

differential feed arm

on

differential feed arm

4D

with pin C) thus feed arm makes oscillating movement.

fj

and differential feed arm

69.

of

main feed bar

fD

and differential feed bar

tD.

so

that part @

and adjust the scale on indicator plate

nut

Cl).

(t

(t

of

feed lifting slide block

to a larger number than that

to a smaller number than that

®

®

@

(t

get oscillating

f)

, main feed bar

CD

in

accordance with

(t

against the scale on main

of

the scale on main

of

the scale on main

CD>

8,

with

\

..

_.

__

-

11-

iZJ

PRESSER FOOT

MECHANISM

• In case that presser foot lifter lever 0

•

Main

presser arm connected with pin 8

•

If

presser bar lifter 8

arm roller

presser arm

4.

DISASSEMBLING

[I] COVER

\\

~

~

®

Procedures

Turn the pulley until the needle bar

the highest position, and then turn out presser

foot

2 Remove needles

3 Remove cloth plate

4 Remove cloth guide (L)

bill

0 above needle plate.

is

depressed down

fD

are raised with roller

CD

is

released from the pressure

®

DCX I

CXI3

8.

• . 2

8.

is

depressed down, presser foot supporter 0

is

raised with presser foot supporter

as

per above figure, presser bar lever

fD

knocked into presser bar lever

of

presser bar spring e.

PROCEDURES

Q'ty

of

screw

is

raised to

2

2

is

lowered with spring hook

•.

8,

presser arm roller shaft

as

a fulcrum presser bar lever shaft

5 Open feed mechanism cover (B)

feed mechanism cover

6 Remove front cover guide

7 Remove front cover

8 Remove front cover supporter

(t.

fj.

@).

CD

and remove

Ci).

f)

and presser

t),

thus main

®

®

Q'ty

screw

8.

of

4

2

2

2

-12-

!2]

PRESSER

Procedures

Remove presser foot

(In case

remove presser foot 0

2 Turn the pulley until the needle bar

the highest position.

131

KNIVES MECHANISM

FOOT AND FEED MECHANISM

0 .

of

safety stitch, after pull

.)

out

is

raised to

pin

8,

Q'ty

screw

of

1

3 Remove needle plate

4 Remove differential feed dog

5 Turn the pulley until the under looper

mostly and remove main feed dog

6 Remove chain feed dog.

0 . 2

8.

to

the left

t).

(0

Q'ty

screw

of

~--

~f.:.#---@

~Wr.;..ll...\'01

• Q'ty

Procedures

nut

0 and

8.

Loosen screw

to

the left direction, then tighten it.

2 Remove upper knife

3 Remove upper knife holder C) .

4 Remove

5 Remove lower knife

turn

lower knife holder 8

8.

t)

as

holding it

by

screw

hand.

uu--(j)

--

of

®

...

~.

~

®

6 Remove lower knife holder guide

7 Remove lower knife holder 8

hand. (Pull

8 also.)

8 Remove lower knife holder. supporter

(At

first loosen bolt

support bracket

out

spring for lower knife holder 1

Q)

under the needle plate

CD>

.)

e.

as

holding it by

~.

Q'ty

screw

·~

-

..

of

2

~

2

-13-

~

UNDER

Procedures

Turn the pulley until under looper

left mostly, and the remove movable needle

guard

2 Set under looper 8 at the center position

~

the operation range, and then remove under 1

looper

LOOPER

8.

8.

MECHANISM

8 to the

in

Q'ty

screw

2

of

®

G)

Procedures

3 Remove looper thread take up (L)

4 Remove under looper holder

5 Remove over looper thread take-up (R)

under looper thread take-up (R)

6 Remove under looper thread guide

8.

(D

8.

@).

@)

and

Q'ty

screw

of

~

OVER

Procedures

Remove inside cover 0 .

(Set over looper 8 to the left mostly.)

2 Remove over looper

LOOPER

MECHANISM

8.

Q'ty

screw

2

of

Procedures

3 Remove over looper driving lever

looper holder guide assembly

time.

@)

and over

8 at the same

Q'ty

screw

1·3

of

-14-

12]

DOUBLE CHAIN STITCH

Procedures

1 Remove needle guard

(B)

LOOPER

0 .

MECHANISM

2 Remove needle guard (F) 8 from needle guide

(B)

0.

3 Remove double chain stitch-looper O. 1

4 Remove double chain stitch looper holder

5 Remove thread guide

(R)

{it

and (L)

8.

8.

Q'ty

screw

1

1

Q'ty

t).

of

screw

1

2

2

of

1

1

Procedures

6 Remove thread handler

7 Remove thread take-up bracket

(Put screw driver into the hole

stitch looper take-up and loosen set screw.)

8 Remove double chain stitch looper take-up

fj.

~.

of

double chain

7 NEEDLE

BAR

MECHANISM

@

®

Procedures

1 Remove needle thread take-up 0 .

2 Remove needle thread guide (A)

3 Remove needle thread take-up supporter

4 Remove chain stitch needle thread guide 8

(B581).

5 Remove face plate

(Stopper spring

out.)

{it

8.

is

naturally

8.

to

be removed

t)

.

Q'ty

screw

1

1

1

4

3(B581)

of

Procedures

6 Remove needle mechanism cover

not

to

spoil the packing. 7

(Put

feed mechanism cover

body.)

7 Loosen screw for needle bar clamp

out

needle

bar~

lower.

«;>

8,

on

®

®

the

fj

taking care

machine

and pull-

Q'ty

screw

of

~

-15-

,-......

5.

ASSEMBLING

[]]

NEEDLE BAR MECHANISM

Procedures

1 Insert needle bar 0 into needle bar clamp 8 .

2 Turn the pulley until the needle bar clamp 8 is raised

fasten the needle bar

lower

e.

3 Install face plate 8 to the machine body.

(Install stopper spring

cranky.)

4 Install needle mechanism cover 8

take care

5 Install needle thread take-up supporter 0

6 Install needle thread guide (A)

7 Install needle thread take-up

take-up supporter

• Normally, it should be fastened in the center

adjustable range.

Lower its position

sion.

Raise its position to decrease the needle thread

sion.

not

make any clearance.

0 at a height where the needle clamp 0 is barely hidden in needle bar bushing

..

0 .

to

increase the needle thread ten-

ADJUSTMENT

at the same time, and adjust it when face plate cover 8 is closed without

to

the machine body firmly putting

to

needle bar clamp

0)

to

face plate

f.D)

to needle thread

of

8.

its

ten-

PROCEDURES

to

the highest position, and then temporarily

of

Q'ty

screw

face plate

8.

of

CD

@)

@

lightly, then

~

(B571)

Q'ty

of

3 (B581)

screw

4

7

I Safety Stitch I Install chain stitch thread guide m

face plate

• Normally, it should be fastened in the center

adjustable range.

Raise its position

around the looper.

Also raise its position to increase the needle thread

tension.

Lower its position to decrease the needle thread tension.

CD.

if

the needle thread winds itself

of

to

its

-16-

Procedures

Q'ty

screw

of

8 Insert needles all the way into needle clamp

tighten screws.

9 Install needle plate

10 Check part ®

whether the machine

use (H).

11

Standard needle for adjustment

• In case

• In case

Ill

The below items

taken simultaneously.

12 In case

specifications, adjust the distance between the needle

point and the

the needle

high-lift specifications must be adjusted

of

of

the

of

the

of

sewing machines made

is

up

11.5 mm between them.

~

.

on

the

over looper driving lever and see

is

for standard use (S)

is

as

follows.

twin-needle, use the left needle.

safety stitch, use the hemming needle.

of

f)

and \Safety Stitch\ should be

top

of

needle plate

highest. The sewing machines

to

to

or

the

11

mm

to

a distance

0 and

high-lift

standard

when

of

the

2

I Safety

Stitch

I Turn

13 In case

with screw.

In case

bar clamp with screw.

In case

should be in the center

needle bar clamp with screw.

of

the

of

the twin-needle, temporarily fasten needle

of

the

the

slightly into needle plate and adjust it

so

needles will be in the center

plate slot,

single needle, tighten needle

safety stitch; after make sure needle

pulley slowly, lower needle

of

needle

by

turning needle bar.

bar

clamp

of

needle plate slot, tighten

Safety stitch (B581)

-17-

~

UNDER LOOPER MECHANISM

CD

Procedures

I Remove needles and needle plate.

0

on

under

is

under

looper

bottom,

in

2 Temporarily fasten under looper holder

looper lever shaft

3 Insert under looper 0

holder

4 Measure under looper 8 tilt

adjust it until the measurement difference

range

with screw (D.

5 Install the standard needle for adjustment into needle

clamp.

O.

of 1 to

8 .

all

1.5 mm, and

the way into

at

its point and

then

fasten under looper 8

the

Q'ty

screw

of

Scale

Ill The below items

simultaneously.

6 In case

specifications, adjust the distance between the under

looper point and the needle center to 4.5

under looper

machine

to

positioning)

of

of

the high-lift specifications must be adjusted

a distance

I Safety Stitch I In case

7 With the point

of

needle, make an adjustment

under looper will push needle 0.01

slightly contact needle) in the upward travel

However,

adjusted to

(Longitudinal positioning)

* 0.05

in case

touch

to

0.07mm

for chemical fabrics.

of

8 and

sewing machines made to the standard

is

at

the left most position. The sewing

of

2.2mm

of

distance

In case

distance

is

4.7mm.

of

is

2.2mm.

of

under looper in line with the center

of

sewing for thick materials, must be

about 0

for

cotton

fj

should be taken

mm

when the

between them. (Sidewise

standard specifications,

high-lift specifications,

so

that

the point

"'0.05mm

of

needle.

to

0.05 mm between them.

fabrics; 0.08 to O.l·mm

that

that

of

{i.e.,

I Twin Needles I Iqstall the right needle into needle clamp,

loosen screw for needle bar clamp,

the needle bar until the under looper

both

depth

needles

or

then

point hits

the same

deeper, and

needle bar clamp. Also check the height

of

needle bar at the same time.

(See the figure at right.) -

by

approximately

the right needle slightly

retighten screw for

turn

slightly contact needle

18-

Procedures

8 Turn the pulley until under looper to the left mostly,

and then temporarily fasten movable needle guard

to under looper holder

9 Match the under looper point with the needle center

on the needle's upward travel, move movable needle

guard

e until it contacts needle, adjust the clearance

between the under looper point and needle to

0.05mm, and fasten movable needle guard

* 0.02 to 0.05mm for cotton fabrics; 0

for chemical fabrics.

131

OVER

LOOPER

0.

MECHANISM

8.

to

0.03mm

0 to

e

Q'ty

screw

of

2

Procedures

1 Fit over looper holder guide assembly

looper lever shaft

2 Temporarily fasten over looper holder guide assembly

3

Move

the over looper driving lever

driving lever

(Tum the pulley,

4 Insert over looper • all the way into over looper holder 8 , and temporarily fasten it.

(Tum the pulley in order

5 Install needle plate. 2

Select the correct distance A and B from the table below according to your machine specifications,

6

make an adjustment by moving the over looper holder guide assembly

A measurement),

then fasten them securely.

e at the same time.

•

is

in alignment with over looper lever shaft e' and then temporarily fasten it.

make sure that the machine smoothly.)

to

make sure that the machine runs smoothly. )

by

moving over looper driving lever

0 onto flame e and over looper driving lever 8 onto over

0.

f}

up

or

down until there

f}

to up or down (decide B measurement), and

is

the least resistance

0

to

the right or left, (decide

so

over looper

Q'ty

* When changing your machine from the standard specifications to the high-lift specifications, replace

over looper and over looper holder assembly, and make an adjustment.

e

~

A

B

Standard

7.2 8.2

5.6

Single needle

High-lift

5.6

Twin needles

(four threads)

Standard High-lift

7.2

5.6

8.2 7.2

5.6 5.6

Twin needles

(mock safety)

Standard

High-lift

8.2 7.2

5.6 5

Standard High-lift

(Unit: mm)

Safety stitch

8.2

5

of

screw

3

~

.

-19-

Procedures

~

Meeting

I

Single

Twin

needles (mock safety) I

I

7

Remove

8

Make

«;),

the point

looper about

point

B A

needle (two threads) I

needle plate.

sure

that, when

0.1

over

looper

of

over looper

mm

below its projected part.

Over

spreader

able. Its meeting distance

that

of

Replace

stitch over looper.

CD

will

pass

fj

for two threads

over

looper.

over

looper with mock safety

meets under looper

clear

of

under

is

Q'ty

A:

Distance between over looper point and needle

when over looper point

B:

Distance between

over

when

is

abail-

the

same

as

of

screw_,.-------------------..

2

looper

Meeting

is

at needle plate top.

over

looper point

is

at left extremity.

point

~!

~

and

needle center

~enter

~

In

case

of

9

tion ®

forth, direction

or down,

* If there

tion ®, stitches may

ing

in direction

less

Install inside cover to flame. 2

10

DOUBLE CHAIN STITCH LOOPER MECHANISM

~

above-mentioned measurement

in

the

figure

at right,

@

move

and

fasten them.

is

a clearance

loops.

Even

if there

@,

loops

clearance between needle and over looper.

move

over looper driving

of

more than

skip

due to the failure

is

a clearance

can

be picked up, but there

is

wrong, direc-

over

looper back or

0.1

mm

of

0.1

lever

in

of

catch-

to 1 mm

up

direc-

is

2

Thread

a

-20-

Procedures

Temporarily fasten double chain stitch looper holder 0

on longitudinal feed shaft 8

2 Install double chain stitch looper 0 by inserting it

the way into double chain stitch looper holder

of

inclination

I~stall

3

double chain stitch needle into needle clamp.

the looper depends on the screw recess.

0.

all

The

Q'ty

screw

of

1

Ill The below items

taneously.

4

In

case

of

so

that the distance between the looper point and the

center

looper comes to the leftmost position. In

lift specifications, that distance

(Sidewise potioning)

5 Position the looper

line with the needle center on the needle's upward travel,

the looper point will

needle, and then fasten double chain stitch looper holder.

(Longitudinal positioning)

*

6 Install double chain stitch needle guard (F) 8 to that

of

O.Smm.

7 Temporarily fasten double chain stitch needle guard (B)

to needle plate support bracket.

of

When

stitch-skips occur, adjust it that the looper point

will hit needle about

(B) (i) in order to make clearance about 0.3 to

of

8

and

(i) should be taken simul-

standard specifications, make

needle

is

1.5mm when double chain stitch

is

1.3

so

that, when the looper point

be

at about 0 to 0.05 mm from

0.05 to 0.1

mm

mm.

an

adjustment

case

deep.

of

high-

is

in

8 Match the looper point with the needle center on the

needle's upward travel, hold double chain stitch needle

guard (B) in contact with the needle, adjust the clearance

between the looper point and the needle

and fasten double chain stitch needle guard

~

KNIVES MECHANISM

to 0 to

(B)

0.05 mm,

securely.

®

L__®

-21-

Procedures

2

3 Insert spring

4

5

Ill

6

7

~

Temporarily fasten lower knife holder support

needle plate support bracket

Temporarily fasten lower knife holder guide 0

plate support bracket

Ci)

into lower knife holder

knife holder into lower knife holder support

8

tighten screw

sliding

Temporarily fasten lower knife

holder

Install needle plate

The below items 8 and 8 should be taken simul-

taneously.

Loosen screws for lower knife holder guide

lower the tip

out

e.

just

(but

not

on

of

lower knife holder guide

8.

8.

tight enough to keep it from

securely).

(t

on the lower knife

needle plate support bracket

so

0

on

needle

8,

fit lower

0,

0,

raise

lower knife

on

and

8.

or

8 will be longitudinally equi-distant in the needle plate

slot for lower knife, and temporarily fasten it.

or

Raise

is

securely.

lower lower knife

level with the needle plate

(t

until

the

top

of

top,

and fasten lower knife

lower knife

Q'ty

screw

of

"

2

2

~

2

2

1

"

Top

Top

Needle plate

of

lower knife

oflower

knife

8 Remove needle.

9 Turn the pulley until needle bar is raised

position, fit

10 Temporarily fasten upper knife

••

11

Temporarily fasten upper knife holder

knife driving arm

(Toutch upper knife

12 Loosen screw and

so

as

temporarily tighten it.

13

Lower upper knife

upper knife will engage lower knife

~

14 When upper and lower knives are engaged, adjust

angle

of

knife will match the upper left angle

and fix it securely.

15

For

adjusting the engagement

loosen the screw and

turn the lower knife holder about the

is

a clearance corresponding

0.01 mm, then retighten the screw and bolt.

(As per figure

nut

• on upper knife driving arm Q).

CD

in upper knife holder

fD

Q).

to

lower knife lightly.)

bolt

for lower knife holder support 0

to fit lower knife face and upper knife face and

f)

all

the

way, and adjust

0.5-

lower knife so

next

that

the lower left angle

of

upper and lower knife,

bolt

which fasten lower knife holder,

to

the thickness

page.)

to

the highest

on

the upper

1

mm

deep.

of

lower knife,

bolt

until there

so

that

the

of

upper

of 0 to

2

2

2

{

®

-22-

Procedures

0

-O.Oimm

0

(Note)

This adjustment

it

is

not

do it very carefully.

16

Make

sure it that upper and lower knives are engaged

and lower knife

and then fasten lower knife holder.

17

Place the thread between upper and lower knives in the

fore and rear parts, and

sharply cut.

1§1

FEED AND

is

necessary

is

PRESSER

carefully done before shipment

to

pressed against upper knife

X

do it. However,

see

that the thread can be

FOOT MECHANISM

if

X

it

by

so

is

needed,

spring

that

Thread

Procedures

1 Remove needle plate.

2 Adjust chain feed dog

case

of

(In

a height

3 Turn the pulley until under looper to the left mostly, temporarily fasten main feed dog

bar

O.

4 Temporarily fasten differential feed dog 8 on differential feed bar C).

5 Install needle plate on needle plate support bracket.

6 Turn the pulley until feed dogs are raised to the highest position, and adjust them to the following height

above the top

However,

thicker thread and knitting wool and/or chaining-off hardly come out, adjust chain feed dog to

of

0.3

"'0.5mm

of

l.Omm for thin materials

1.3

mm for medium materials

1.5

mm for thick materials

in

case

0 at the same level

below main feed dog.)

needle plate.

of

denim specification

as

main feed dog.

of

safety stitch, its height

is

1.3mm.

-23-

• on main feed

Q'ty

of

2

2

screw

1

Procedures

,-------------------------------------------------------~

I Safety Stitch I

Note:

~

1

.z::wmmm

GJ$~~~~~~~~~w~w~wi="

.

~

CD

When

sewing safety stitches, make sure

each other. Otherwise, chaining-off cannot be sewn.

Use

a scale

In case

piping ruffler specifications only), install needle plate

prevent from slipping

as

shown below to check their levelness.

of

needle gauge 2mm and Smm (as for needle gauge Smm, it

out

1

==1.=i0tmm

of

chaining-off stitches.

for thin

1.3 mm for medium materials

1.5 mm for. thick materials

materJs

that

main and differential feed dogs are level with

l

mm~,....-4-~-~-z-L-L-L

Q'ty

of

screw

J 0.3-0.SIIIID

.ru;gi~~)&d?ff&

is

available for ruffler and

in

light toutch with feed dog

Needle gauge 2 mm Needle gauge 5 mm

in

order to

7 Install presser foot

(In case

1ZJ

LOOPER

Procedures

1 Install looper thread take-up (L) 0

2 Install over looper thread take-up (R) C) and under looper thread take-up (R) 8 to over looper lever

shaft

3 Install under looper thread guide

4 Adjust each thread take-up and thread guide to their standard positions

needle up highest.

of

safety stitch, install presser foot 0 to presser foot supporter

THREAD TAKE-UP AND THREAD GUIDE MECHANISM

•.

* When looper thread take-up (R)

thread will be delivered. When under loooer thread guide

delivered.

When

(t

on main presser arm

to

(t

is

it

is

moved leftward, more thread will be delivered.

•.

under looper lever shaft

to thread guide support

raised, less thread will be delivered. When it

0)

8.

•.

as

shown above after raising the

is

moved to the rieht,

with pin ~ .)

is

lowered, more

less

thread will be

Q'ty

of

screw

1

1

-24-

lal

DOUBLE CHAIN STITCH

Procedures

Fit double chain stitch thread take-up 0

shaft.

2 Install thread handler

parallel to it.

3 Install thread take-up

(Insert thread handler 8 onto double chain stitch thread

take-up

stitch thread take-up.)

0

in

accordance with the slot

* Thread consumption and timing

adjusted by moving thread handler

(When the top

thread tension decreases, and when it

looper thread increases.)

4 Turn the pulley until needle bar

position.

of

LOOPER

THREAD TAKE-UP AND THREAD GUIDE MECHANISM

onto

8 to thread take-up bracket

bracket@) to machine body.

of

double chain

of

thread release are

8.

thread handler

is

raised, the looper

is

lowered, the

is

raised to the highest

crank

@)

Q'ty

screw

2

of

Unclockwise

Loosen

Clockwise

Tighten

~

The below items

taneously.

5 Set double chain stitch thread take-up O

where thread handler

6 Adjust the distance between the top end

chain stitch thread take-up

@)

to

6mm,

* When double chain stitch thread take-up

(counterclockwise), the looper thread tension

creases; and when it

looper thread tension decreases.

7 Install thread guide (R)

up bracket @), making sure that they are equi-distant

from the reference line on thread take-up holder

thread slot.

C)

and

8

is

and fasten it.

is

8 and (L)

(3

should be taken simul-

at

in the center

of

the slot.

of

0 and thread take-up bracket

is

advanced

moved back (clockwise), the

C)

on

thread take- 2

a point

double 2

in-

in

the

-25-

191

COVER

Procedures

1 Temporarily fasten front cover supporter 0 on machine body.

2 Temporarily fasten front cover

3 Temporarily fasten front cover guide

*

Make

an

in

place

~Ill

The following items from 8 to

4 Adjust front cover

Overlock Stitch

adjustment

as

before.

I

8

so

so

8 on oil reservoir. (Close front cover)

• parallel to machine body.

that, when front cover 8 comes

fj

must be made while checking.

it

is

parallel to machine body and has a clearance about O.Smm.

off

front cover guide

I Safety Stitch I

Parallel

.,,

it can be put back

about

Q'ty

0.5

of

2

2

2

mm

screw

5

Make

an adjustment

is

down lowest, there

between front cover 8 and upper knife e.

6 Adjust the clearance between front cover 8 and

front cover guide

so

that, when upper knife 8

is

0

to

a clearance

0.5 to 1 mm.

of

0.5-1

about O.Smm

mm

-26-

Make

an adjustment

upper knife e and double chain stitch looper • and

their clearance will be

7 Front cover 8

porter

0 and stopper spring

so

that front cover will be between

as

shown above.

CD

is

held securely by front cover sup-

8.

6.

STITCH LENGTH

AND

DIFFERENTIAL

FEED

ADJUSTMENTS

[i] STITCH LENGTH ADJUSTMENT

A desired stitch length can be selected by means

main feed arm 0 and differential feed arm 8 indicate stitch length in millimeters, but actual stitch length varies with

of

the kind and thickness

Procedures

1 Pull and open feed mechanism cover (B) 8 on the back

2 Loosen nut

3

Move

desired stitch length.

4 Retighten nut

e.

feed ling indicator plate

8 securely.

the material and the differential fedd.

fit

until its red mark

of

the

scale

on main feed arm 0 and the numerals on the scales

of

the machine.

is

in line with that number on the

scale

which represents your

of

12J

DIFFERENTIAL

Differential ratio produced

stretching and shirring.

Calculation method

Differential ratio

* In

case

of

FEED ADJUSTMENT

by

the movement

of

differential ratio:

= The scale on differential feed arm

The scale on main feed arm

the maximum stitch length in normal stitching refer below.

of

differential feed arm

2 In case

is

In case

Set the scale on differential feed arm 0

way

Set the scale on differential feed arm 8 to a smaller

number than that

of

as

the scale on main feed arm

of

to

be dicided depending on normal stitching,

normal stitching

in

the

0.

stretching

of

the scale on main feed

arm

same~

0 .

-27-

*

Even

in case you adjust stitch length by changing the movement

ratio unchanged

Note:

If

ferential feed arm 8 are set

scale value greater than those shown

at right, the feed dogs will hit the

edges

as

before without fail.

the main feed arm 0 and dif-

to

any

of

the slots in needle plate.

·3

In case

Set

number than

of

of

slwrring

the scale

main feed arm

-

s

~

Normal stitching

Denim

Ruffler

Bulky

on

differential feed arm 8

that

of

the scale

0,

make sure

Main

on

to

feed arm

3.6mm

3.3mm

2.5mm

to

a larger

main feed arm O.

remain differential

Differential

feed arm

6.5mm

9.0mm

9.0mm

7.

SEWING INSTRUCTION

[I]

SINGLE-NEELDE, TWO-THREAD

* Thread tension means the tension

No.

1

2 medium-thick

3

Note

Edges tend to curl when sewing thin materials. So decrease the

hemming width

to such an extent

Better stitches can be obtained

a little above the normal level.

Note on Item 2:

Edges will not curl when sewing medium materials. Hemming width may be increased up

to 3.6mm.

Cloth

Wool, polyester,

thin trouser fabrics

Wool, polyester,

trouser fabrics

Knit fabrics,jersey

on

Item

1:

(to

that

Thread Needle

Cotton

Wooly nylon

about 3

to

the stitches will not be

of

the thread pulled in the running direction after the tension disc.

of

shape.

Differential

1--

size

#60/2

"

#11

"

"

4mm)

and reduce the thread tensions

out

by

increasing the over looper tension

ratio

1

"

1.5

Stitch length

3--

2--3

"

3.6

Needle thread Looper thread

tension tension

18--

28

"

10--20

~

to

6mm,

8--

18

"

15--

25

Looper thread

Needle thread

and stitch length up

Note

on

Item 3:

It wooly nylon thread is used for

neatly.

The smaller the stitch length the better will be the finished stitches.

Needle thread: Synthetic thread

(

Looper thread: Wooly nylon thread

both

the needle and the loopers, or only for the loopers, cloth edges

Needle thread: Wooly nylon thread

(

Looper thread: Wooly nylon thread

-28-

~Looper

thread

C Looper thread

Even if wooly nylon thread

stitches because the thread tension

~

SINGLE-NEEDLE, THREE-THREAD

No.

1

2

3 Thin knit fabrics Synthetic

4

5

6

7

Notes

Cloth

Knit under wear

material

"

"

Thick knit fabrics

Knit underwear

material

(Blind hemming)

"

on

Items I to 3:

Thread

Cotton

Synthetic

Wooly nylon

Needle:

Looper: Woolen

Cotton

Wooly nylon

~Needle

Needle

#60/2

#60

#60

Synthetic

#60

#60/2

is

#9

#11

"

#14

#9

"

"

thread

used

size

as

needle thread, there will be no skipped

is

small.

Differential

ratio tension

1

"'

Stitch length

1.5

"

1-2

"

2-3

1

"'

2.2"'2.8

1.5

"

Stitches will change when the over looper thread take-up (R) is raised or lowered

Be

careful not

to

lower the thread take-up

so

much because stitches at high speed will become different at low speed

or vice versa.

2"'

2.5

"

2-25

"

2"'2.5

"

Needle thread

"'73

43

40-70

40-70

30

"'50

so--so

15-25

10--20

as

shown below.

~Needle

Over looper

thread tension thread tension

6

"'22

4-18

4--18

4-15 4-15

4-15

8"'

15

2

"'10

thread

Under looper

6"'22

4-18

4-18

4

"'15

22

.....

32

6-18

Raise when thread

©

If

the work becomes damaged:

1)

Decrease the presser pressure

A smaller pressure

2) Make the angle

is

of

feed dogs less sharp.

effective for preventing work slipping in ordinary sewing, too.

to

2 to 3kg,

When buffing the feed dogs, hold them horizontally.

Remember not to

buff

them too much because excessive

buffing will lower feed efficiency.

©

If

fiber breaks

I)

Cool the needle thread.

2)

Use

a smaller needle (selecting one in the range

#7

to

3)

Use

a well-shaped light ball point (Schmetz), S-point

{Organ), or knit needle

#9).

by

needle:

KN

(Organ).

is

tense. Lower when thread

or

by about

of

I2

to

IS screw threads.

~Smooth

of

comers

is

loose.

~

-29-

Note on Item

When using wooly nylon thread for the needle,

crease the thread tension especially low. Stitch

skipping

avoided

4:

is

liable to occur,

by

using a

DC

X27 needle.

but

can be effectively

de-

xo

~-Under

r harldy enter.

DC

XI

Note on Item

Stitches tend

rubber-interlaced parts. In

ment by lower the over looper and under looper

thread take-up (R).

looper

can

f

5:

to

become loose on thick knitwork or

that

case, make an adjust-

fn

Lower

Under looper can

easily enter.

OCX27

6~

'\

/

Pass the thread through the two holes

without winding.

©

If

stitches skip (Needle and under looper):

1)

Use a DC

Make

2)

needle.

X27 needle.

an adjustment by only slightly bending the

-

Make

under looper contact

0.1 to 0.15

needle

deep.

mm

Pull out needle guard and

adjust clearance between

needle and under looper

0 to 0.03mm.

to

in

the thread guide

Note on Item

1}

Sew

2) Do not pull the work with

stitches will be made away from the desired line.)

3}

Push a thicker part

hand.

Machine adjustments:

1}

Adjust the presser pressure to 2 to 3kg,

threads.

2}

Adjust the clearance between the presser foot and the blind hemming

ruler so that the work will easily pass.

3) Adjust the clearance between the blind hemming ruler. An assembly's

tip and the blind hemming ruler so that the work will easily pass.

4}

Adjust hemming width by turning the blind hemming ruler adjusting

screw.

Note

on

If

wooly nylon

the needle thread tension

in

the thread guide without winding.

6:

Precautions on blind hemming

at constant speed.

Item 7:

is

used for blind hemming, stitches will not skip because

your right hand.

of

material under the presser foot with your left

is

small. Pass the thread through the two holes

(If

or

by about 12

the work

to

is

15

pulled,

screw

Q Blind Hemming ruler

Clearance

Clearance

-30-

13]

DOUBLE-NEEDLE, FOUR THREADS

No.

Double-needle

four threads

Mock safety

No.

Double-needle

four threads

Mock safety

Qoth

Knit underwear

1

material

Thin knitwork

2

Bulky material

3

Broadcloth Cotton #SO

4

Jersey

5

Left needle Right needle

thread tension thread tension

60-SO

1

40--60

2

70--90

3

4

so

--so

s

so"'

70

Cotton

Synthetic

Needle: Synthetic

Looper: Woolen

Polyester

30--

2S-4S

35-SS

4S

2S-SO

Thread

51)

--70

#60/2

#60

#60

#50

Over looper Under looper

thread tension thread tension

6

--1S

4-16

3--10

s

10--20

Needle size

--1S

Note on Item I:

Cotton threads in the range

thread tension must be reduced

thread tends