Page 1

•

SERVICE

MANUAL

FOR

V SERIES

OVERLO

EF4-V41 •

EF4-V71 •

EF4-V72 • V82 • MA4

CK

SEWING

V51

V81

• MA4-

• MA4-

MACHINE

V61

V91

-V

92

Page 2

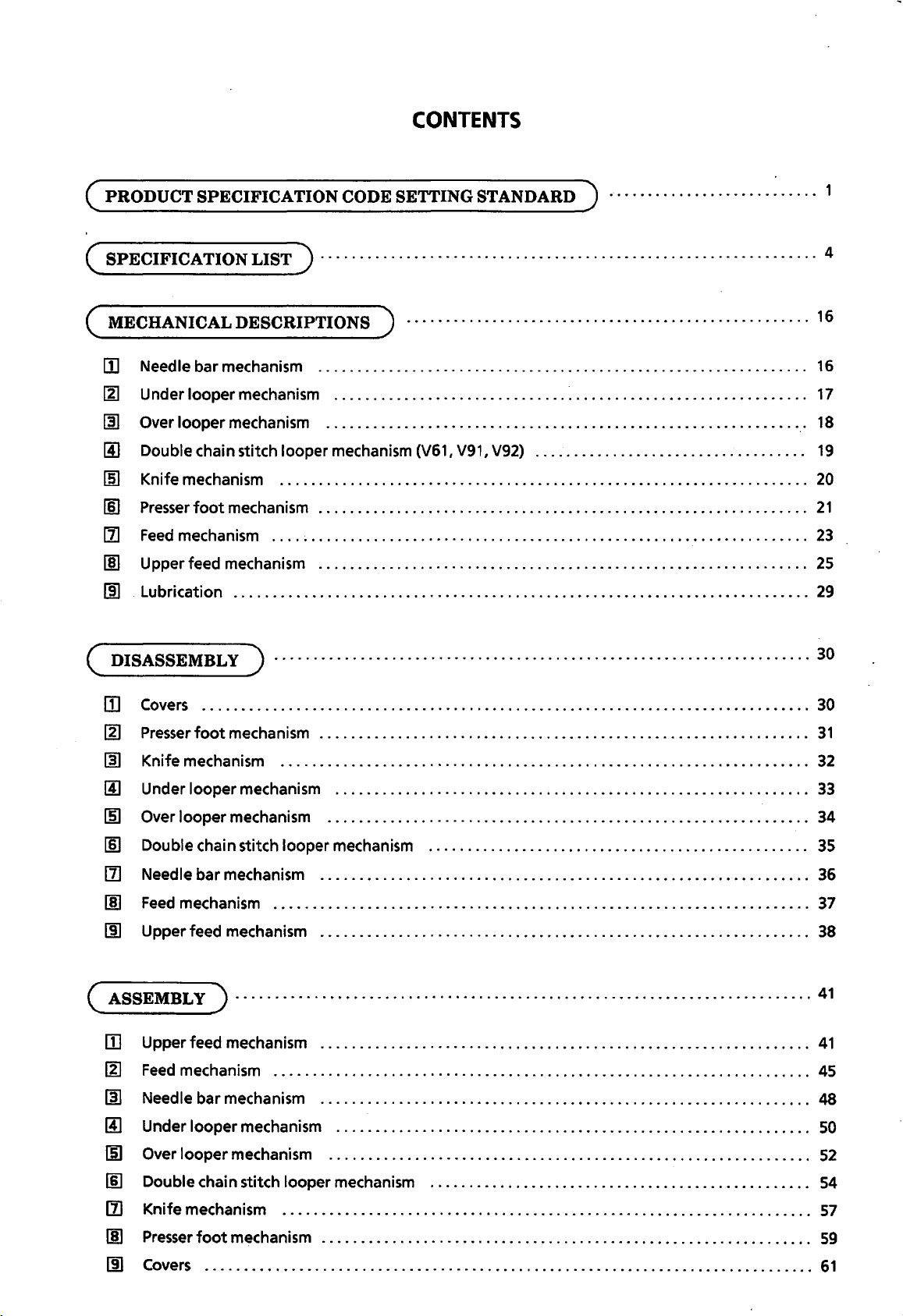

(

PRODUCT

(

SPECIFICATION

SPECIFICATION

LIST

CONTENTS

CODE SETTING STANDARD ) · · · · · · · · · · · · · · · · · · · · · · · · · · ·

) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 4

( MECHANICAL DESCRIPTIONS )

III Needle

1Z1

Under

00

Over

1!1

Double

liD

Knife

[§]

Presser

[1] Feed mechanism

[I]

Upper

00

.

Lubrication

bar

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

looper

looper

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

feed mechanism

mechanism

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

chain

stitch

looper

foot

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.... ~ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

..............................

mechanism (V61, V91, V92)

...............................................................

· · · · · · · · ·

( DISASSEMBLY ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

··

· · · · · · · ·

··

· · · · · · · · ·

~

..............................

...................................

··

· · · · · · · · · · · · · · · · · · · ·

··

· · · · · · · · · · ·

··

· · · · · · · · 30

III Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IZ1

00

Presser

Knife

foot

mechanism

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

...............................................................

..

. 18

16

16

17

19

21

25

30

31

1!1

Under

liD

Over

[§]

Double

[1]

Needle

[I]

Feed mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

II]

Upper

looper

looper

feed mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

mechanism

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

chain

stitch

looper

bar

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

.............................................................

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

( ASSEMBLY ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

III

Upper

IZ1

Feed mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

00

Needle

1!1

Under

[§] Over

00

[1]

[I]

feed

mechanism

bar

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

looper

looper

Double

Knife

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Presser

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

chain stitch

foot

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...............................................................

looper

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

. . . . . . . . . . . . . . . . . . . 54

33

41

41

SO

59

00

Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61

Page 3

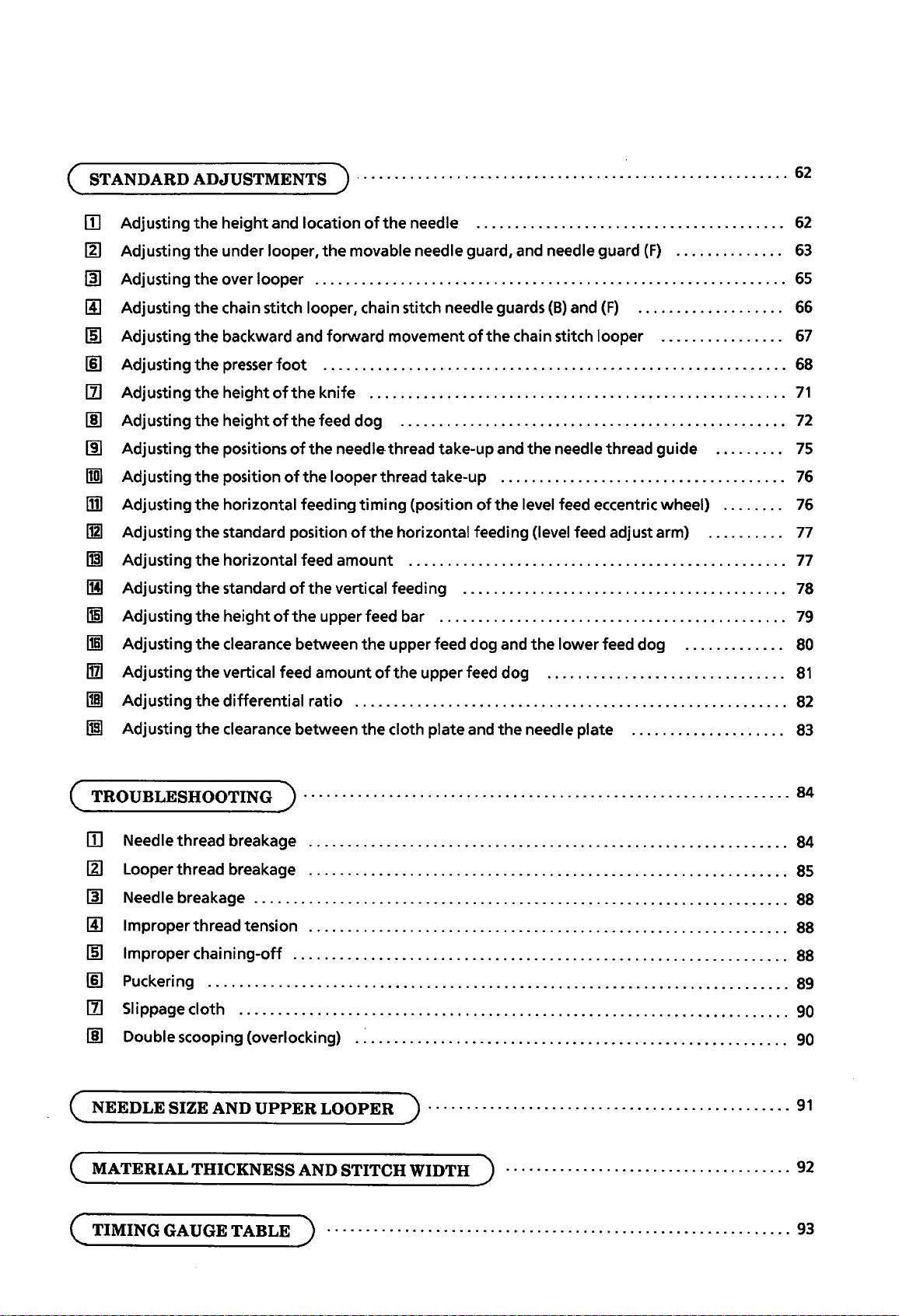

( STANDARD

[I]

Adjusting

lZ1

Adjusting

rn1

Adjusting

1!1

Adjusting

[§]

Adjusting

[§]

Adjusting

11]

Adjusting

00

Adjusting

00

Adjusting

1m!

Adjusting

Ill]

Adjusting

H2l

Adjusting

111

Adjusting

Ml

Adjusting

1m

Adjusting

ADJUSTMENTS ) ·······

the

height

the

under

the

over

the

chain stitch looper, chain stitch needle guards

the

backward and

the

presser

the

height

the

height

the

positions

the

position

the

horizontal feeding

the

standard position

the

horizontal feed

the

standard

the

height

and location

looper,

looper

of

of

of

the

.............................................................

foot

............................................................

the

knife

the

feed

of

the

of

the

of

the

the

upper feed bar

movable needle guard, and needle guard

forward

dog

needle-thread take-up and

looper

timing

of

amount

vertical feeding

· · · · · · ·

of

the

needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

movement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

thread take-up

(position

the

horizontal feeding (level feed adjust arm) . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

··········································

of

of

..

..

.............................................

(F)

. . . . . . . . . . . . . .

(B)

and

(F)

. . . . . . . . . . . . . . . . . . . 66

the

chain stitch

the

.....................................

the

level feed eccentric wheel) . . . . . . . . 76

. . .

.. . ..

looper

needle thread

.. . ..

.. ..

..

.. .. . .. . ..

. . . . . . . . . . . . . . . .

guide . ..

..

. . . . . . 75

..

. . .

..

62

62

63

65

67

68

71

72

76

77

77

78

79

11§)

Adjusting

lll1

Adjusting

1m]

Adjusting

Iii

Adjusting

(

TROUBLESHOOTING

[1]

Needle

lZ1

Looper

rn1

Needle breakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

1!1

Improper

1m

Improper

[§] Puckering

11]

Slippage

00

Double scooping (overlocking) . :

the

the

the

the

thread

thread

thread

chaining-off

...........................................................................

cloth

clearance between

vertical feed

differential

clearance

ratio

between

the

upper feed

amount

of

the

upper feed

........................................................

the

cloth plate and

dog

and

the

dog

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

needle plate . . . . . . . . . . . . . . . . . . . . 83

lower

feed

dog

. . . . . . . . . . . . . 80

) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 84

breakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

breakage

tension

.......................................................................

..............................................................

..............................................................

................................................................

......................................................

81

82

85

88

88

89

90

90

(

NEEDLE

(

MATERIALTHICKNESSANDSTITCHWIDTH

TIMINGGAUGETABLE

(

SIZE

AND

UPPER

)

LOOPER

) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

·································

) · · · · · · · ·

··

· · · · · · · · · · · · · · · · · · · ·

···························

···

91

· · · · 92

93

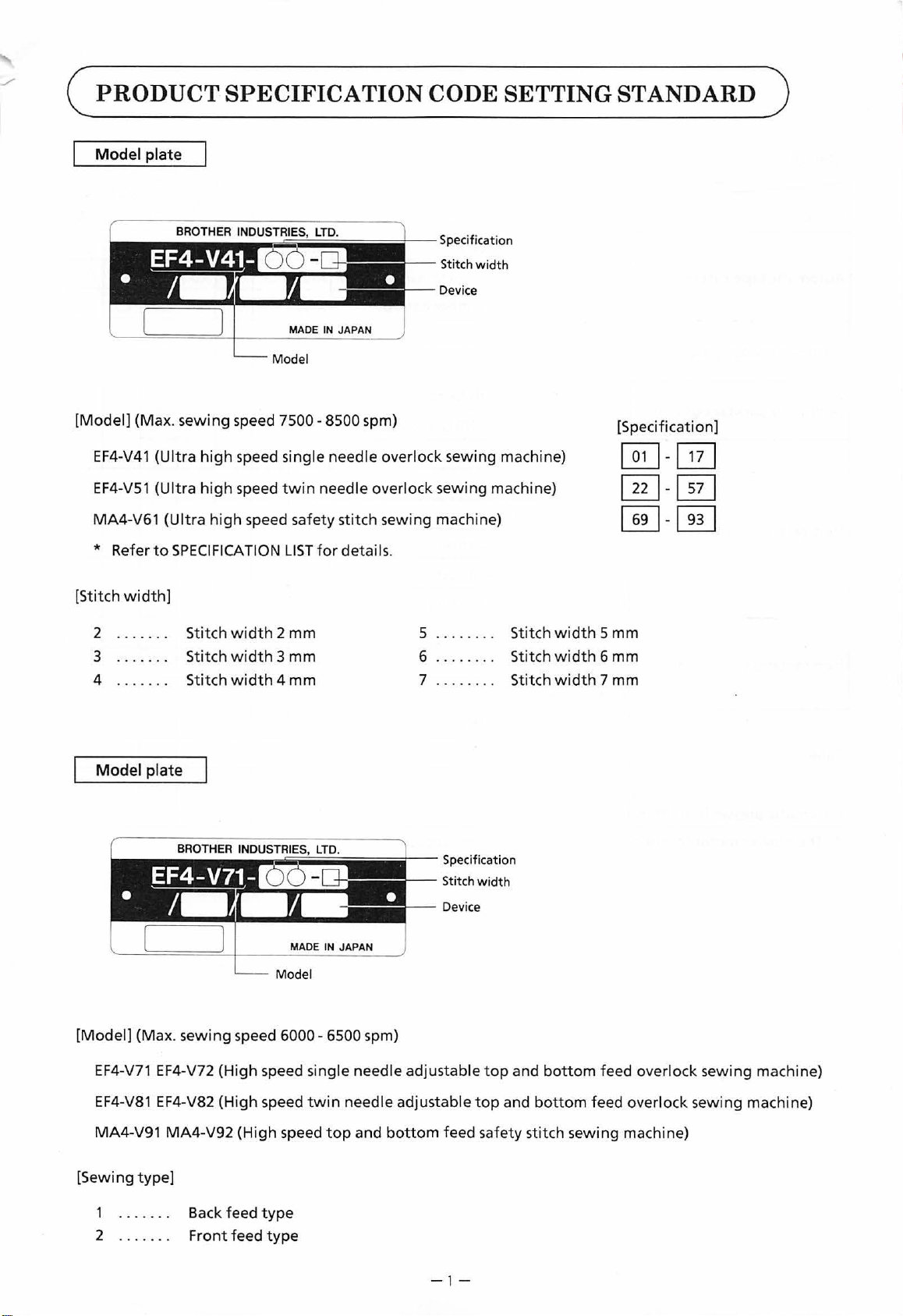

Page 4

PRODUCT

SPECIFICATION

CODE SETTING STANDARD

Model

[Model]

EF4-V41

EF4-V51

MA4-V61

* Refer

[Stit

ch

plate

(Max. sewing speed

(Ultra

high

speed single needle

(Ultra

high

speed

(Ultra

high

to

SPECIFICATION

width]

Specification

Stitch

width

Device

MADE IN JAPAN

7500-8500

twin

speed safety stitch sewing machine)

LIST

spm)

over

lock sewing machine)

needle overlock sewing machine)

for

details.

[Specification]

~-0

[ill-

[E)

@]-[ill

2 ......

3

4

......

Model

[Model]

EF4-

.

Stitch wid

Stitch

.

Stitch

plate

(Max. sewing speed

V71

EF4-V72 (High speed single needle adjustable

th 2 mm

width 3 mm

width

4 mm

~~ii;;;i~iiiiiiiiiiiiil

MADE IN JAPAN

6000-6500

--

spm)

.......

5

6

7

.......

Specification

Stitch

Device

.

.

width

top

Stitch widt

width

Stitch

width

Stitch

and

bottom

h 5 mm

6 mm

7 mm

feed overlock sewing machine)

EF4-V81

MA4-V91 MA4-V92

[Sewing

2

type]

......

EF4-V82 (Hi

Back feed

.

Front feed

gh

speed

(High

type

type

twin

speed

needle adjustable

top

and

bottom

top

and

bottom

feed safety stitch sewing machine)

- 1-

feed ove rlock sewing machin

e)

Page 5

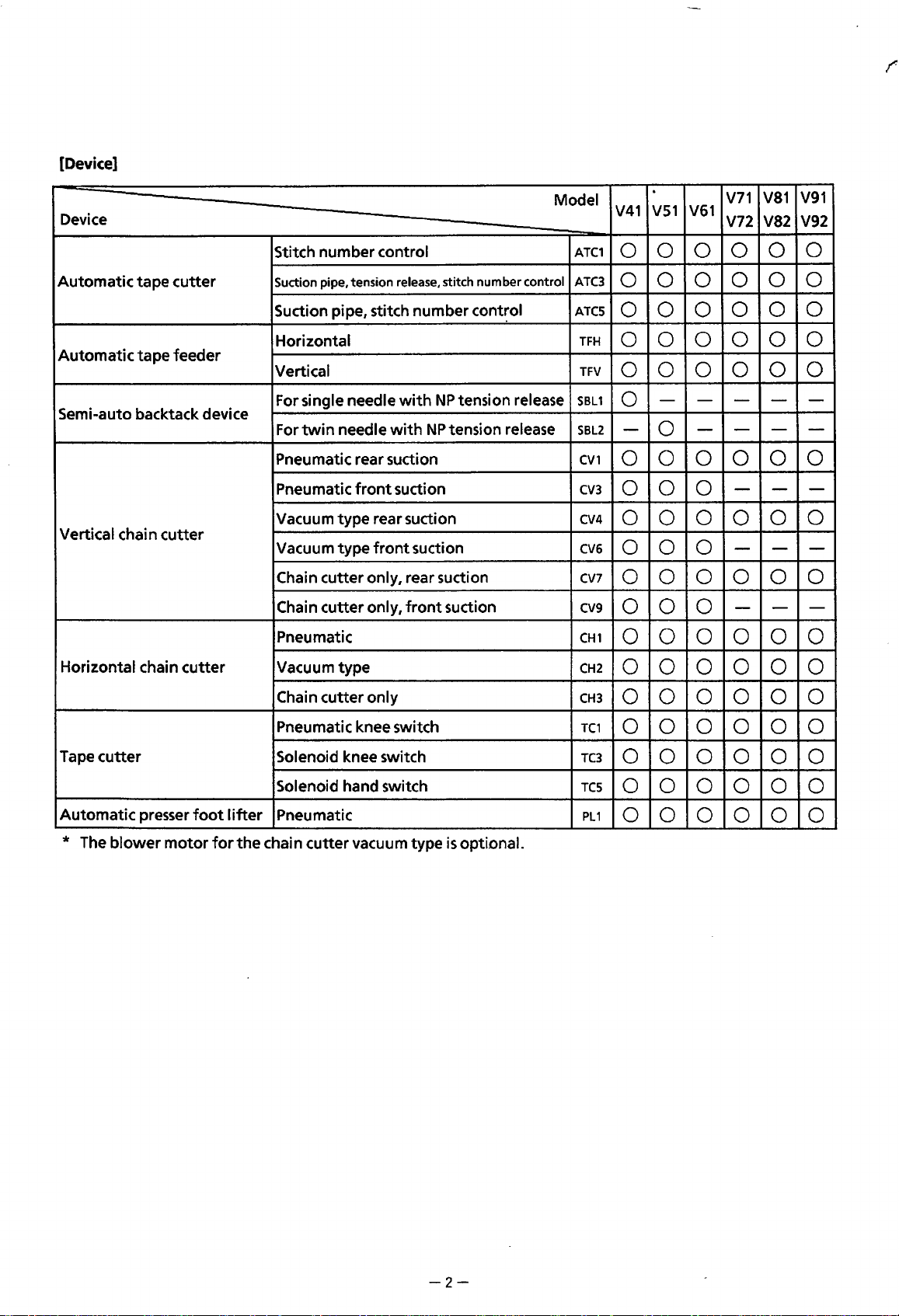

[Device]

Device

Model

V41

.

V51

V61

V71

V72

V81

V91

V82 V92

Automatic

Automatic

Semi-auto backtack device

Vertical chain

Horizontal chain

tape

tape

cutter

cutter

feeder

cutter

Stitch number control

Suction pipe, tension release, stitch number control

Suction pipe, stitch number

Horizontal

Vertical

For single needle

For

twin

needle

Pneumatic rear suction

Pneumatic

Vacuum type rear suction

Vacuum

Chain cutter only, rear suction

Chain

Pneumatic

Vacuum type

Chain cutter only

type

cutter

front

front

only,

with

with

suction

suction

front

cont~ol

NP

tension release

NP

tension release

suction

ATC1

0 0 0 0 0

ATC3

0 0 0

ATCS

0 0 0

TFH

0 0 0 0 0 0

TFV

0 0 0 0 0 0

SBL1

SBL2

CV1

CV3

CV4

CV6

CV7

CV9

CH1

CH2

CH3

-

0

-

-

0 -

0 0 0 0 0 0

0 0 0

0

0

0

0 0 0

0 0 0 0 0 0

0 0 0

0 0 0 0 0 0

0 0 0 0 0 0

0 0 0 0 0 0

0 0

0

0 0

- - -

-

-

-

-

0

0

- -

-

-

-

0

0

-

-

0

-

Tape

cutter

Automatic presser

* The

blower

motor

foot I ifter

for

the

Pneumatic knee switch

Solenoid knee switch

Solenoid hand switch

Pneumatic

chain cutter vacuum type

is

optional.

TC1

0 0 0 0

TC3

0

TCS

0 0

PL

1

0 0

0

0

0 0 0 0 0

0 0 0 0

0 0 0 0

-2-

Page 6

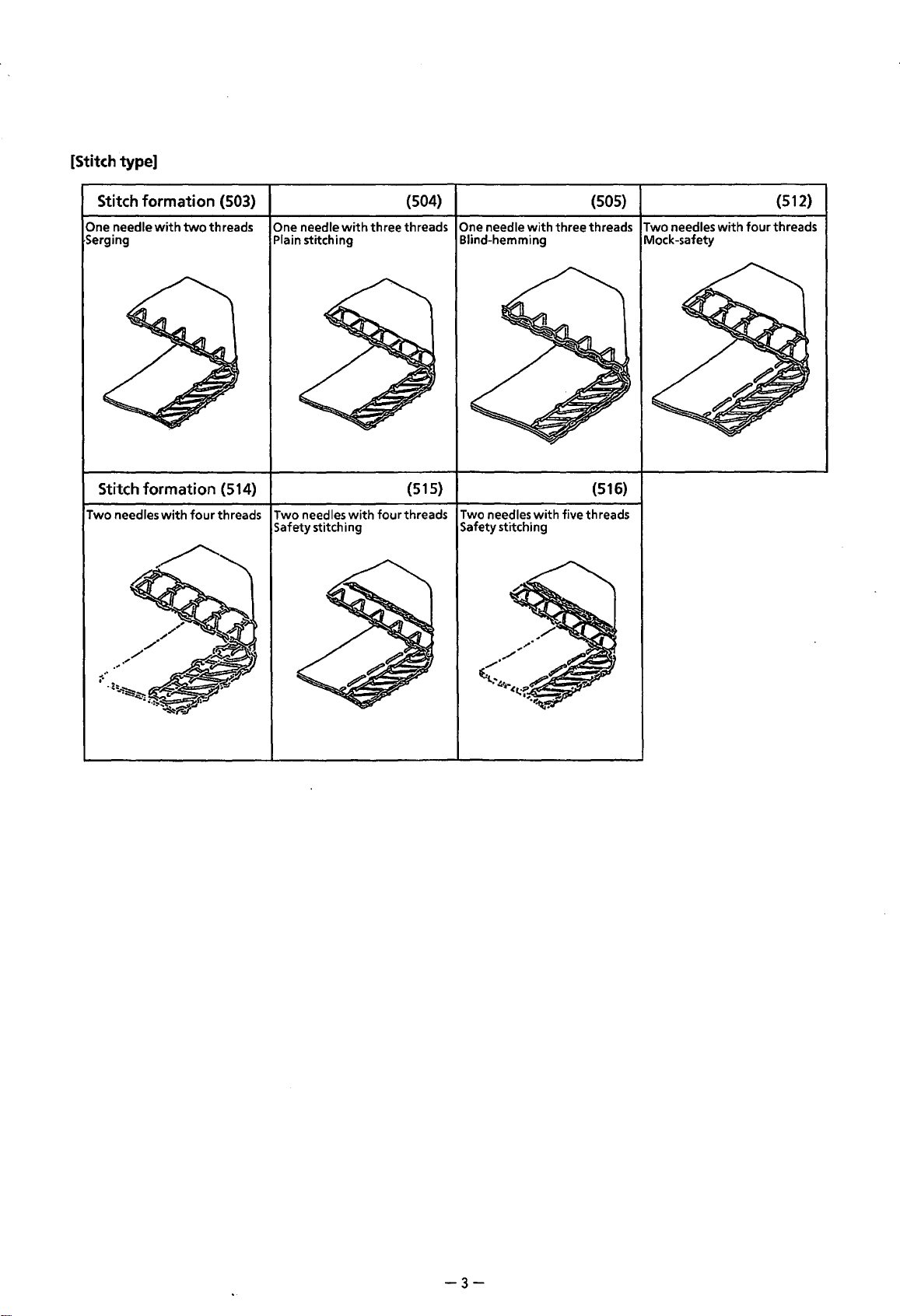

[Stitch type]

Stitch

formation

One needle

Serging Plain stitching Blind-hemming Mock-safety

Stitch

Two needles

with

formation

with

(503)

two

threads One needle

(514)

four

threads Two needles

Safety stitching Safety stitching

with

with

(504)

three threads

One

needle

(515)

four threads Two needles

with

with

(505)

three threads Two needles

(516)

five threads

with

four threads

(512)

-3-

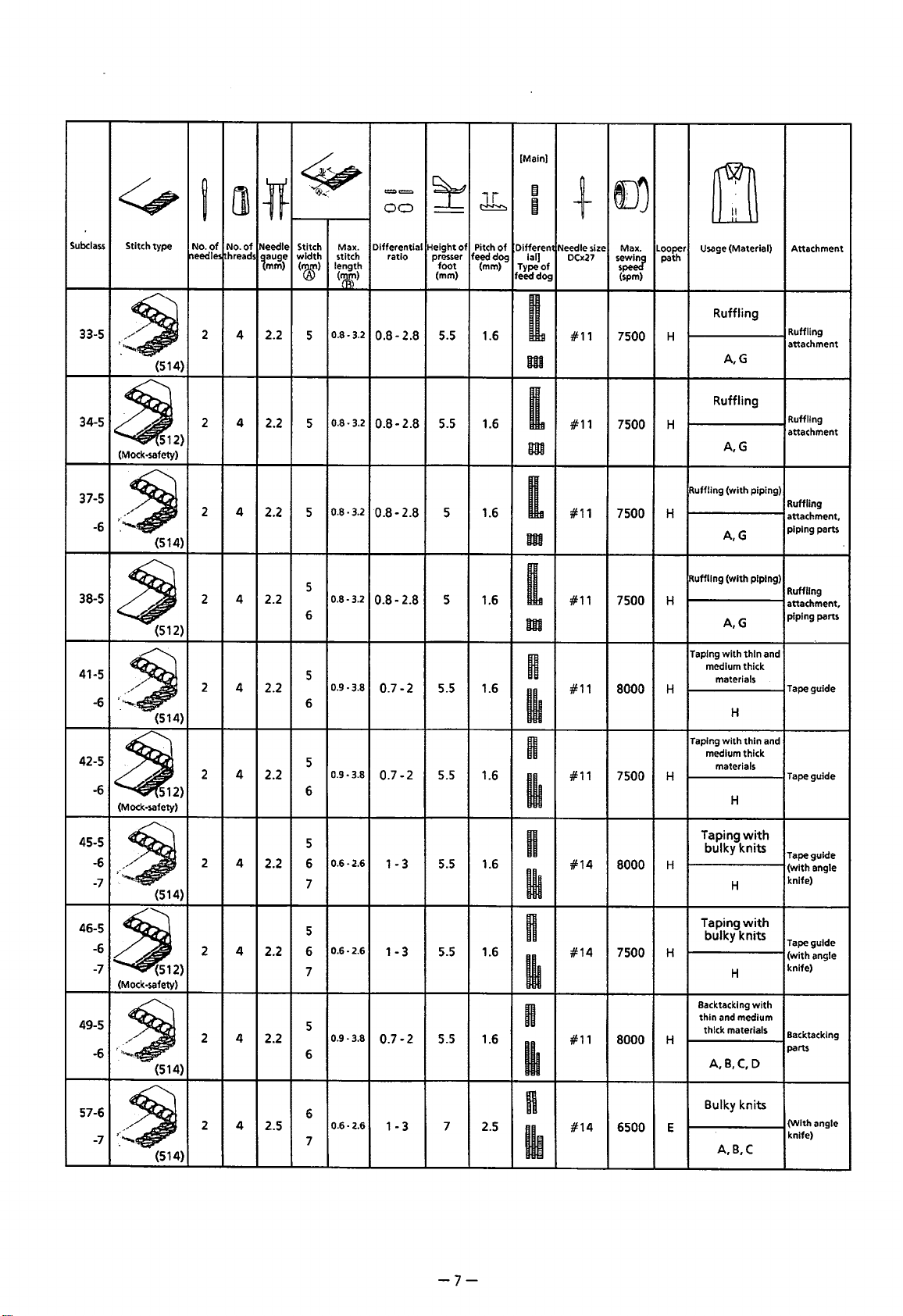

Page 7

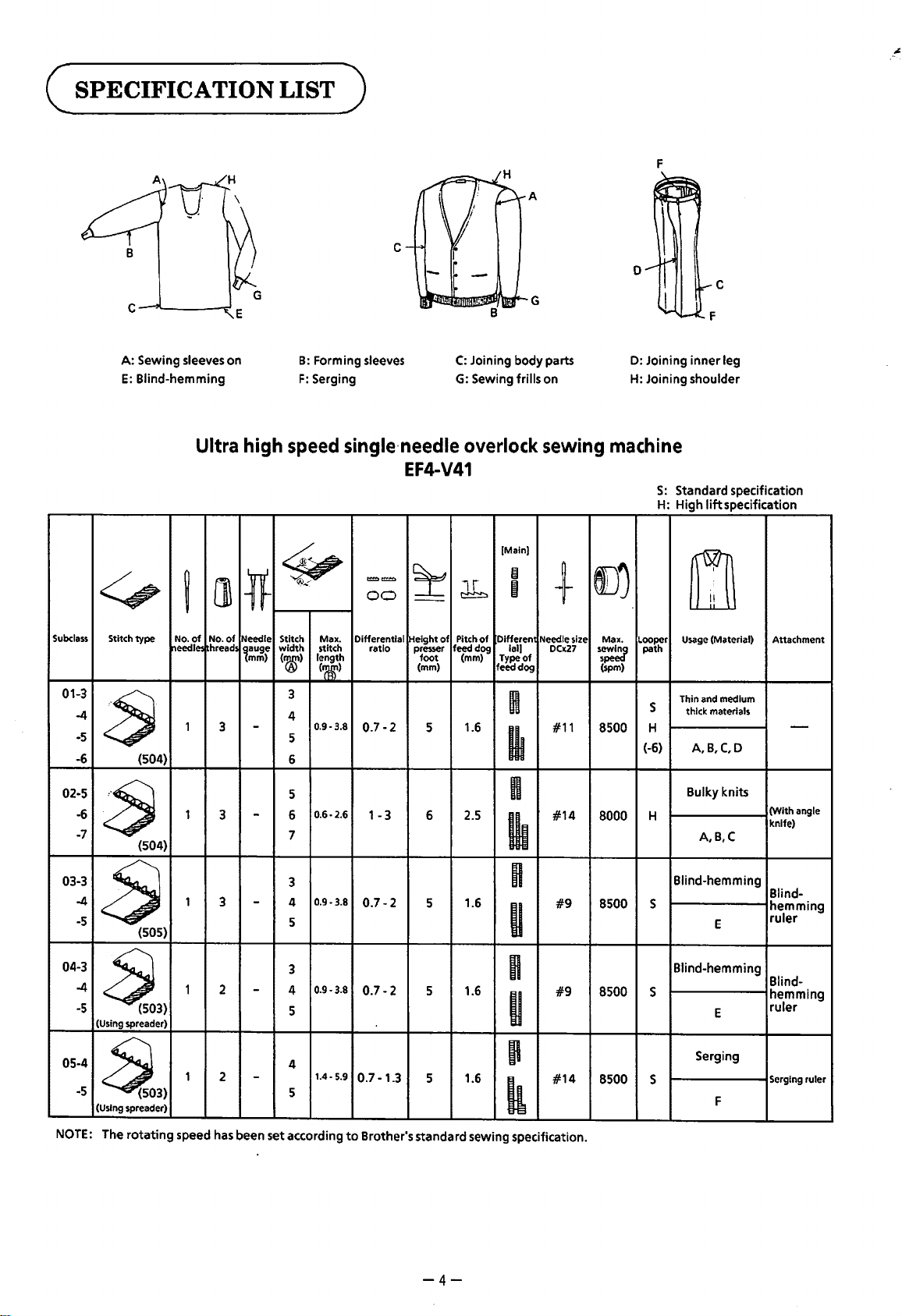

c

SPECIFICATION

A:

Sewing sleeves on

E:

Blind-hemming

LIST )

B:

Forming sleeves

F:

Serging

F

c

0

C:

Joining body parts

G:

Sewing frills on

0:

Joining

inner

leg

H: Joining shoulder

Subclass

01-3

-4

-5

-6

02-5

-6

-7

03-3

-4

-5

~

Stitch

type

needle=

a

(504)

a

(504)

8

(505)

Ultra

[]

~

No.

of

No.

of

Needle

hread5

1

3

1

3

1

3

high

speed

4;,

~.<

*

Stitch

width

~auge

mm)

(®)

3

4

-

5

6

5

6

-

7

3

4

-

5

single·needle

EF4-V41

==

:t

00

--

Max. Differential Height

stitch

length

(~)

0.9-3.8

0.6-2.6

0.9-3.8

ratio

0.7-2

1-3

0.7-2

presser feed dog

foot

(mm)

5

6

5

overlock

lr

~

of

Pitch

of

(mm)

1.6

2.5

1.6

[Main)

m

I

Dlfferen

Ia

I)

Type

of

feed

dog

H

Ill

n

Ill

n

II

sewing

+

Needle size

0007

#11

#14

#9

machine

l)j

Max.

Looper Usage (Material)

(spm)

8500

8000

8500

path

s

H

(-6)

H

s

s=

S:

Standard specification

H: High

lift

specification

m

Thin and medium

thick materials

A, B,C, D

Bulky knits

A,B,C

Blind-hemming

E

Attachment

-

(With

angle

knife)

Blindhemming

ruler

04-3

-4

-5

~3)

(Using spreader)

05-4

-5

~3)

(Using spreader)

NOTE:

The

rotating

1 2

1

2

speed has been set according

3

0.9

·3.8

4

-

5

4

-

5

0.7-2

1.4·5.9

0.7-1.3

to

Brother's standard sewing specification.

5 1.6

5 1.6

-4-

m

II

'

k

#9

#14

8500

8500

Blind-hemming

s

Serging

s

Blindhemming

E

F

ruler

Serging ruler

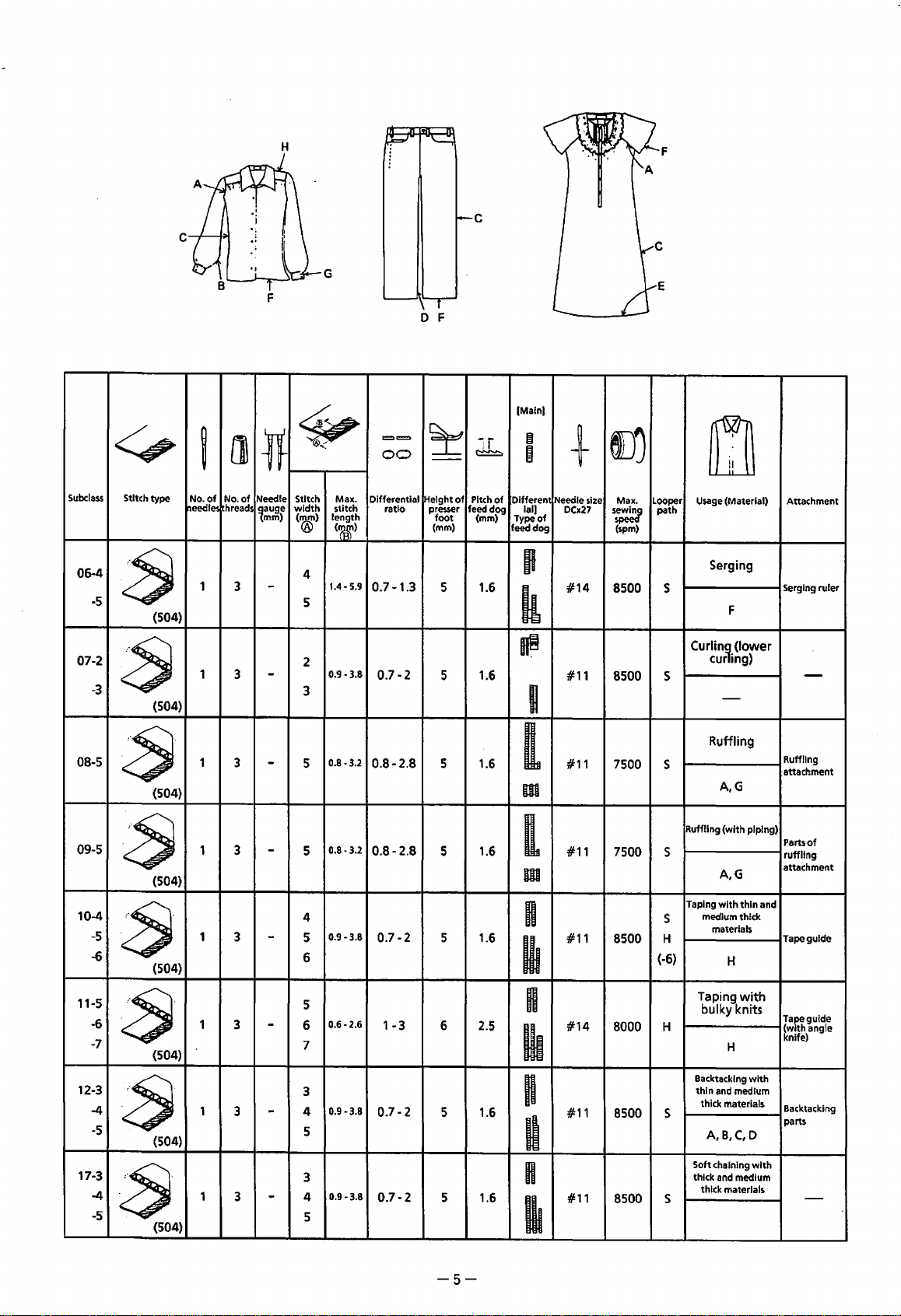

Page 8

H

-~

F

r

t-C

c

Subclass

06--4

-5

07-2

-3

<,

Stitch type

ij

No.

of

t~eedle!

1

~

(504)

1

~

(504)

F

l]

lf

No.

of

Needle Stitch Max.

hreads

~auge

mm)

3

-

3

-

G

~

width

stitch

length

(®)

(~~)

4

1.4-5.9

5

2

0.9-3.8

3

==

00

Differential

ratio presser

0.7-1.3

0.7-2

r

0 F

~

--

~eight

of

Pitch

feedd99

foot

(mm)

5 1.6

5 1.6

ir

~

(mm)

of

[Main)

~

I

Differen1

ial)

Type

of

feed dog

p

k

~

I

+

Neediesize

DCx27

#14

#11

E

~

Max. Looper

path

s=

(spm)

8500

8500 s

s

m

Usage

(Material)

Serging

Serging ruler

F

Curlin~

(lower

curing)

-

Attachment

-

08-5

~

09-5

~

10-4

-5

~

-6

11-5

~·

-6

-7

12-3

~·

-4

-5

17-3

~·

-4

-5

(504)

(504)

(504)

(504)

(504)

(504)

1 3

1 3

1 3

1

1

1

Ruffling

s

A,G

Ruffling (with piping)

s

A,G

Taping

with

medium thick

s

H

s

materials

Taping

bulky knits

Backtacking

thin

and medium

thick materials

A,B,C,D

Soft chaining

thick

and

thick materials

thin and

H

with

H

medium

with

with

Ruffling

attachment

Parts

of

ruffling

attachment

Tape guide

Tape guide

(with angle

knife)

Backtacking

parts

-

0.8-3.2

5

-

0.8-2.8

5

1.6

[

#11

7500

m

0.8-3.2

5

-

0.8-2.8

5 1.6

[

#11

7500

m

4

0.9-3.8

5

-

6

5

3

-

3

-

0.6-2.6

6

7

3

0.9

4

5

·3.8

0.7-2

1-3

0.7-2

5 1.6

6 2.5

5 1.6

n

#11

~

H

#14

Ill

n

#11

8500

(-6)

8000 H

8500

D

3

3

-

0.9-3.8

4

5

0.7-2

5 1.6

n

#11

~

8500 s

-5-

Page 9

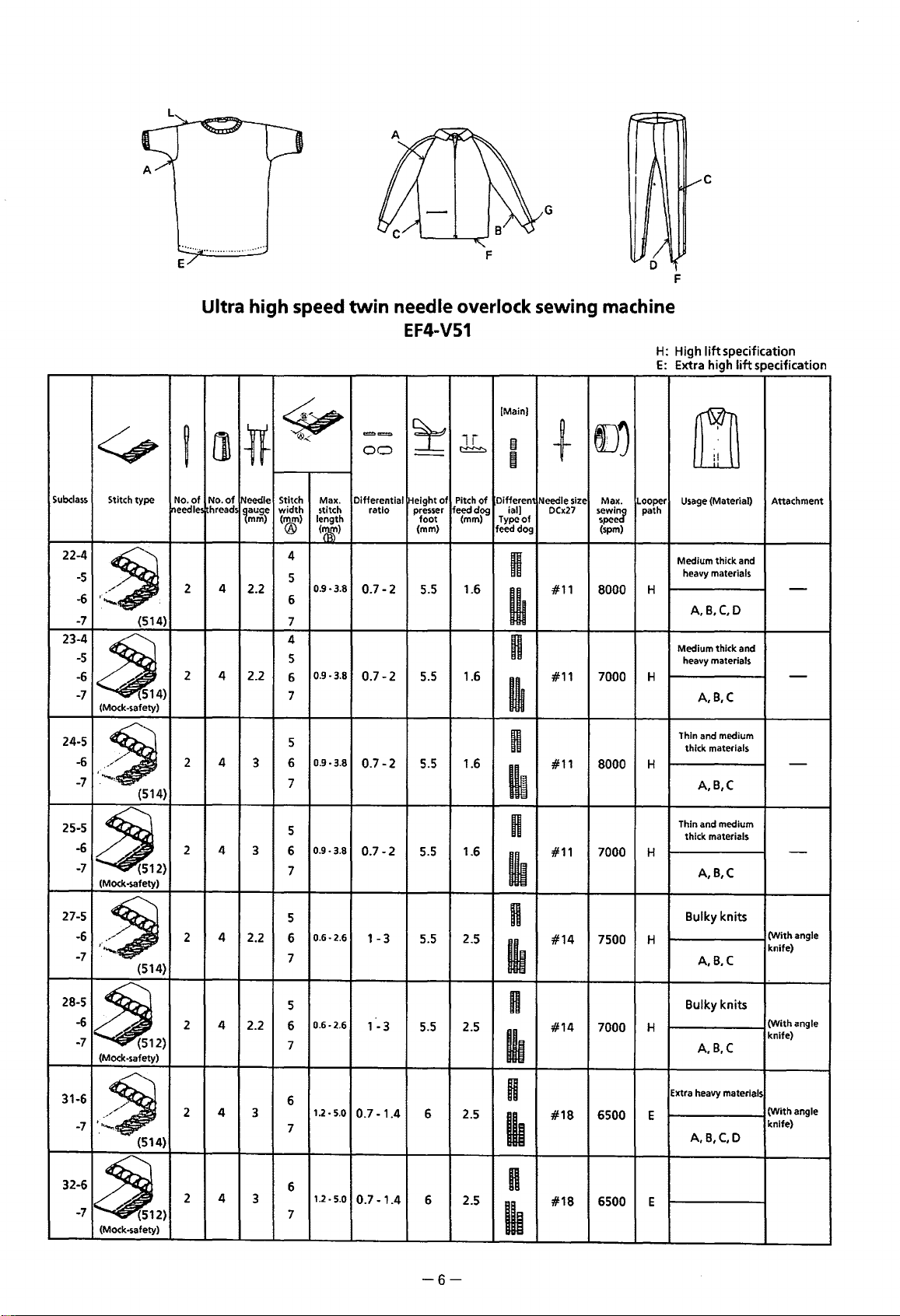

G

F

<:,

Subclass

Stitch

22-4

-5

··,

-6

-~

.

--...

-7

23-4

-5

-6

a.

-7

(Mock-safety)

24-5

-6

•'

,·,"'-

-7

Ultra high speed

[]

~

type

No.

of

No.

hreads

reedle

4

2

:

{514)

2

4 2.2

(5

4)

,

~

(514)

4

2

'ff

of

Needle Stitch

~auge

mm)

2.2

3 6

~

~<

Max. Differential

width

stitch ratio

length

(®)

(~)

4

5

0.9·3.8

6

7

4

5

0.9

·3.8

6

7

5

0.9·3.8

7

twin

needle overlock sewing machine

EF4-V51

(Main}

==

00

~

--

!Height

presser

foot

(mm}

lr

!:::!::!:::!::>

Pitch

of

feedd~

(mm)

0

+

e

of

Oifferen

Needle size

Ia

I]

DCx27

of

Type

feed dog (spm)

H

0.7-2

5.5

1.6

#11

I

H

0.7-2

0.7-2

5.5

5.5

1.6

1.6

#11 7000 H

lit

n

#11

Ill

eD)

Max. Looper

path

sewlnJ'

spee

8000

8000

H:

High

E:

lift

Extra high

m

Usage

(Material)

Medium thick and

heavy materials

H

A,B,C,D

Medium thick and

heavy materials

A,B,C

Thin and medium

thick materials

H

A,B,C

specification

lift

specification

Attachment

-

-

-

25-5

-6

~

-7

(Mock-safety)

27-5

-6

-~

·:·--..

-7

28-5

-6

~

-7

31-6

-7

32-6

-7

{512)

(Mock-safety)

-~

{514)

~2)

(Mock-safety)

{512)

(514)

2

4

3

4

2

2

2

2

2.2

4

2.2

4

3

4

3

5

0.9·3.8

6

7

5

0.6·2.6

6

7

5

0.6·2.6

6

7

6

1.2·

7

5.0

0.7-2

1-3

1-3

0.7-1.4

1.6

5.5

2.5

5.5

5.5 2.5

6 2.5

n

#11 7000 H

Ill

n

#14

lh

H

#14

•

H

#18

7500 H

7000 H

6500

Thin and medium

thick materials

A,B,C

Bulky knits

A,B,C

Bulky knits

A,B,C

Extra heavy materials

E

A,B,C,D

(With

knife)

(With

knife)

(With

knife)

-

angle

angle

angle

•

6

1.2.

5.0

7

0.7-1.4

6

2.5

H

lh

#18

6500 E

-6-

Page 10

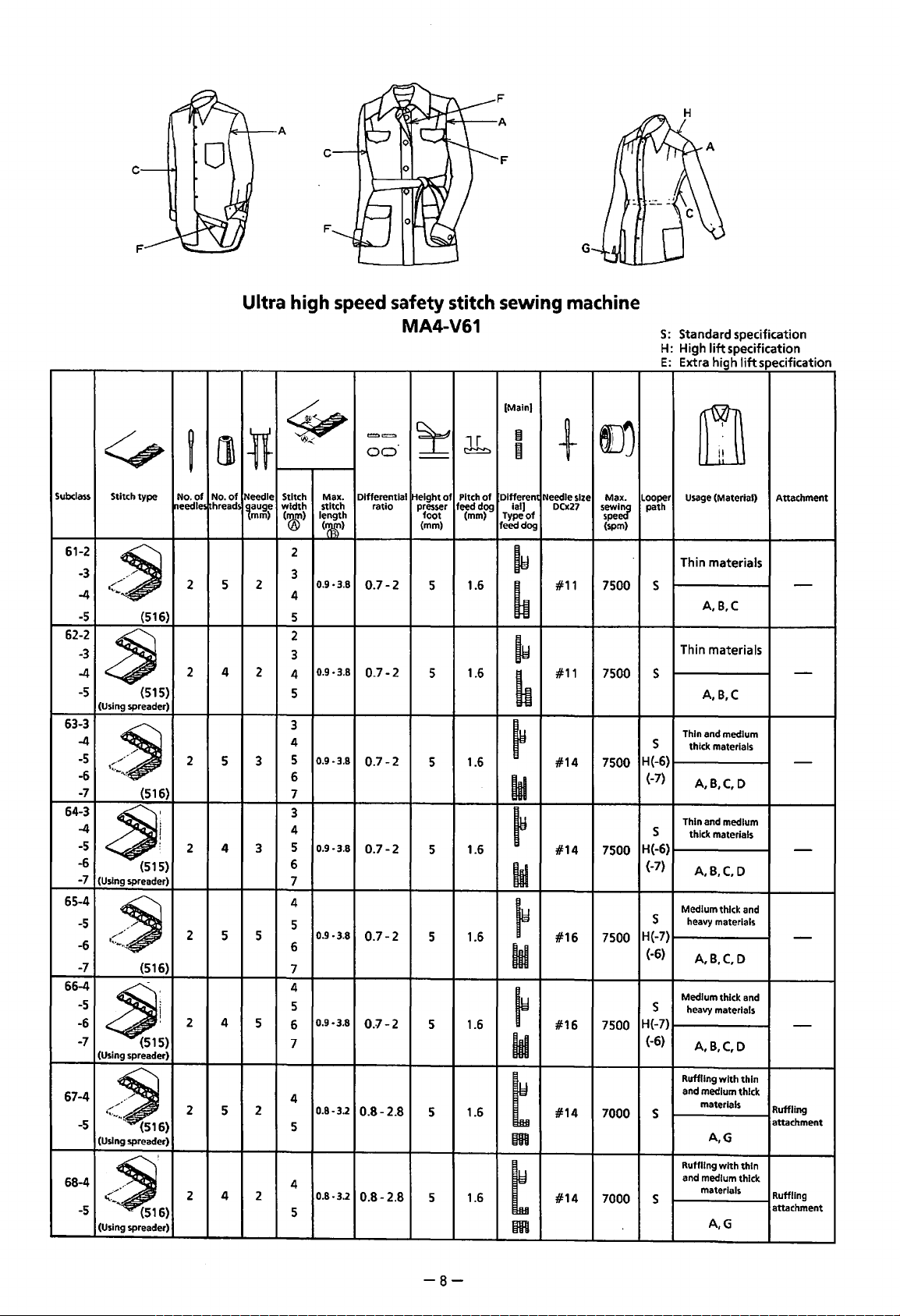

Subclass

33-5

<f;,

Stitch

width

('(&')

5

~<

[]

(514)

j

No.

of

No.

of

hreads

t~eedle!

2 4 2.2

~

Needle

~auge

mm)

~

Stitch type

.·~

·

.........

==

00

MalC.

Differential Height

stitch ratio presser

length

(~)

0.8-3.2

0.8-2.8

~

--

foot

(mm)

5.5 1.6

of

Pitch

feed

lr

~

(mm)

(Main)

of

Differen1

dog ial)

Type

feed dog

I

m

~

I

of

+

Needle size

DClC27

#11

f)j

MalC.

Looper

sew~

spe

(spm)

7500 H

path

m

Usage

(Material) Attachment

Ruffling

Ruffling

A,G

attachment

34-5

2 4

2.2

~2)

(Mock-safety)

37-5

--~

·:·-.....

-6

38-5

~

41-5

.,~

-6

42-5

-6

~2)

(Mock-safety)

45-5

-6

,·,

-~

._

........

-7

(514)

(512)

(514)

(514)

2 4

2 4

2

2 4

2

2.2 5

2.2

4 2.2

2.2

4

2.2 6

0.8-3.2

5

0.8-2.8

5.5 1.6

[

#11

7500 H

m

0.8-3.2

0.8-2.8

5

1.6

[

#11

7500 H

m

5

0.8-3.2

0.9-3.8

0.8-2.8

0.7-2

6

5

6

5 1.6

5.5

1.6

[

#11

m

n

#11 8000 H

7500 H

Ill

5

0.9·3.8

6

5

0.6-2.6

7

0.7-2

1-3

5.5

5.5 1.6

1.6

H

Ill

H

HI

#11 7500

#14

8000

Ruffling

A,G

Ruffling

(with

A,G

Ruffling (with piping)

A,G

Taping

with

medium thick

materials

Taping

with

medium thick

H

H

materials

Taping

bulky knits

H

H

H

piping)

thin

thin

with

and

and

Ruffling

attachment

Ruffling

attachment,

piping parts

Ruffling

attachment,

piping parts

Tape guide

Tape guide

Tape guide

(with

angle

knife)

46-5

-6

-7

~2)

(Mock-safety)

49-5

~~~~.

-6

~

57-6

.~

-7

2 4

2 4

(514)

2 4

(514)

2.2

2.2

2.5

5

0.6-2.6

6

7

5

0.9-3.8

6

1-3

0.7-2

5.5 1.6

5.5 1.6

H

Ill

H

Ill

6

0.6-2.6

7

1-3

7

n

2.5

Ill

-7-

#14

#11

#14

7500 H

8000 H

6500 E

Taping

with

bulky knits

H

Backtacking

thin and medium

thick materials

Bulky knits

with

A,B,C,D

A,B,C

Tape guide

(with

angle

knife)

Backtacklng

parts

(With angle

knife)

Page 11

c

F

G

Subclass

61-2

-3

-4

-5

62-2

-3

-4

-5

63-3

-4

-5

-6

-7

64-3

-4

-5

-6

-7

65-4

-5

-6

-7

66-4

-5

-6

-7

67-4

-5

68-4

-5

Ultra

<,

Stitch

type

~.

<'~

(516)

~

{515)

(Using spreader)

*r""··

·~·

-~

{516)

~~

(515)

(Using spreader)

·'-.·

..

>~

{516)

~~)

(Using spreader)

[l\

~

No.

of

No.

of

hread

~eedle!

2 5 2

2 4 2

2

5

2 4

2

5 5

2 4

2

5

Needle

<~6)

(Using spreader)

<~,6)

(Using spreader)

2 4 2

high

~

~

Stitch Max. Differential

width

(®)

2

3

4

5

2

3

4

5

3

4

5

6

7

3

4

5

6

7

4

5

6

7

4

5

6

7

4

5

4

5

stitch ratio

length

<mr>

0.9·3.8

0.9·3.8

0.9-3.8

0.9-3.8

0.9

0.9-3.8

0.8-3.2

0.8-3.2

lauge

mm)

3

3

5

2

speed

==

00

0.7-2

0.7-2

0.7-2

0.7-2

·3.8

0.7-2

0.7-2

0.8-2.8

0.8-2.8

safety

MA4-V61

~

--

[Height

of

presser

foot

(mm)

5

5

5 1.6

5

5 1.6

5 1.6

5 1.6

5 1.6

stitch

lr

~

Pitch

of

feedd!>Q

(mm)

1.6

1.6

1.6

sewing

[Main]

~

I

Differen

ial]

Type

feed dog (spm)

machine

+

Needle size Max.

DCx27

of

f)j

sew~

spe

~

#11 7500

~

IY

#11

7500 s

~

~

#14

7500

hi

~

#14

7500

ld

~

#16

7500

ld

~

#16

7500

ld

t

m

t

m

#14

#14

7000

7000

S:

Standard specification

H: High

E·

lift

Extra high

m

Looper

Usage

path

s

s

H(-6)

{-7)

s

H{-6)

{-7)

s

H{-7)

(-6)

s

H(-7)

(-6)

s

s

(Material)

Thin materials

A,B,C

materials

Thin

A,B,C

Thin and medium

thick materials

A,B,C,D

Thin and medium

thick materials

A,B,C,D

Medium thick and

heavy materials

A,B,C,D

Medium thick and

heavy materials

A,B,C,D

Ruffling

with

and medium thick

materials

A,G

Ruffling

with

and medium thick

materials

A,G

specification

lift

specification

Attachment

thin

Ruffling

attachment

thin

Ruffling

attachment

-

-

-

-

-

-

-8-

Page 12

A

F

c

[Main)

Subclass

69-4

-5

70-4

-5

71-5

-6

72-5

-6

75-5

76-5

77-5

-6

78-5

-6

<::,

Stitch

type

<.

....

.

~

(516)

[]

ij

No.

of

No.

~eedle!

hreads

2

5

2

4

of

~5)

(Using spreader)

(516)

2

2 4

5 5

t..,.,.

/~

~5)

(Using spreader)

(516)

2 5

2

4

"-·

...

-~

~

~

Stitch

Needle

width

lauge

mm)

('®)

4

3

5

4

3

5

5

6

5

5

6

3

5

3

5

Max.

stitch

length

(~)

0.8-3.2

0.8-3.2

0.8-3.2

0.8-3.2

0.8-3.2

0.8-3.2

~5)

(Using spreader)

5

2

5

<~

(516)

2 4

5

5

~5)

(Using spreader)

0.9-3.8

6

5

0.8-3.2

6

=..,..

00

Differential Height

0.8-2.8

0.8-2.8

0.8-2.8

0.8-2.8

0.8-2.8

0.8-2.8

0.8-2.8

0.8-2.8

~

--

ratio presser

foot

(mm)

5 1.6

5 1.6

5

5

5 1.6

5

5

5 1.6

db

of

Pitch

of

feed dog ial)

(mm)

1.6

1.6

1.6

1.6

0

a

l)j

+

Differen1

Needle size Max.

DCx27

#14

#14

#14

#14

#14

#14

#14

#14

5~~~

7000

7000

7000

7000

7000

7000

7000

7000

Type

of

feed dog (spm)

t

m

t

m

t

m

t

m

t

m

t

m

t

m

t

m

Looper

Usage

path

Ruffling

and medium thick

s

Ruffling

and medium thick

s

medium thick and

s

H

(-6)

medium thick and

s

H

(-6)

Ruffling (and piping)

s

Ruffling (and piping)

s

Ruffling (and piping)

with

s

and heavy materials

H(-6)

Ruffling (and piping)

with

s

and heavy materials

H(-6)

m

(Material)

with

materials

A,G

with

materials

A,G

Ruffling

heavy materials

A,G

Ruffling

heavy materials

A,G

with

thin

medium thick

materials

A,G

with

thin and

medium thick

materiaio;.

A,G

medium thick

A,G

medium thick

A,G

with

with

and

thin

thin

Attachment

Ruffling

attachment

Ruffling

attachment

Ruffling

attachment

Ruffling

attachment

Ruffling

attachment,

piping parts

Ruffling

attachment,

piping parts

Ruffling

attachment,

piping parts

Ruffling

attachment.

piping parts

-9-

Page 13

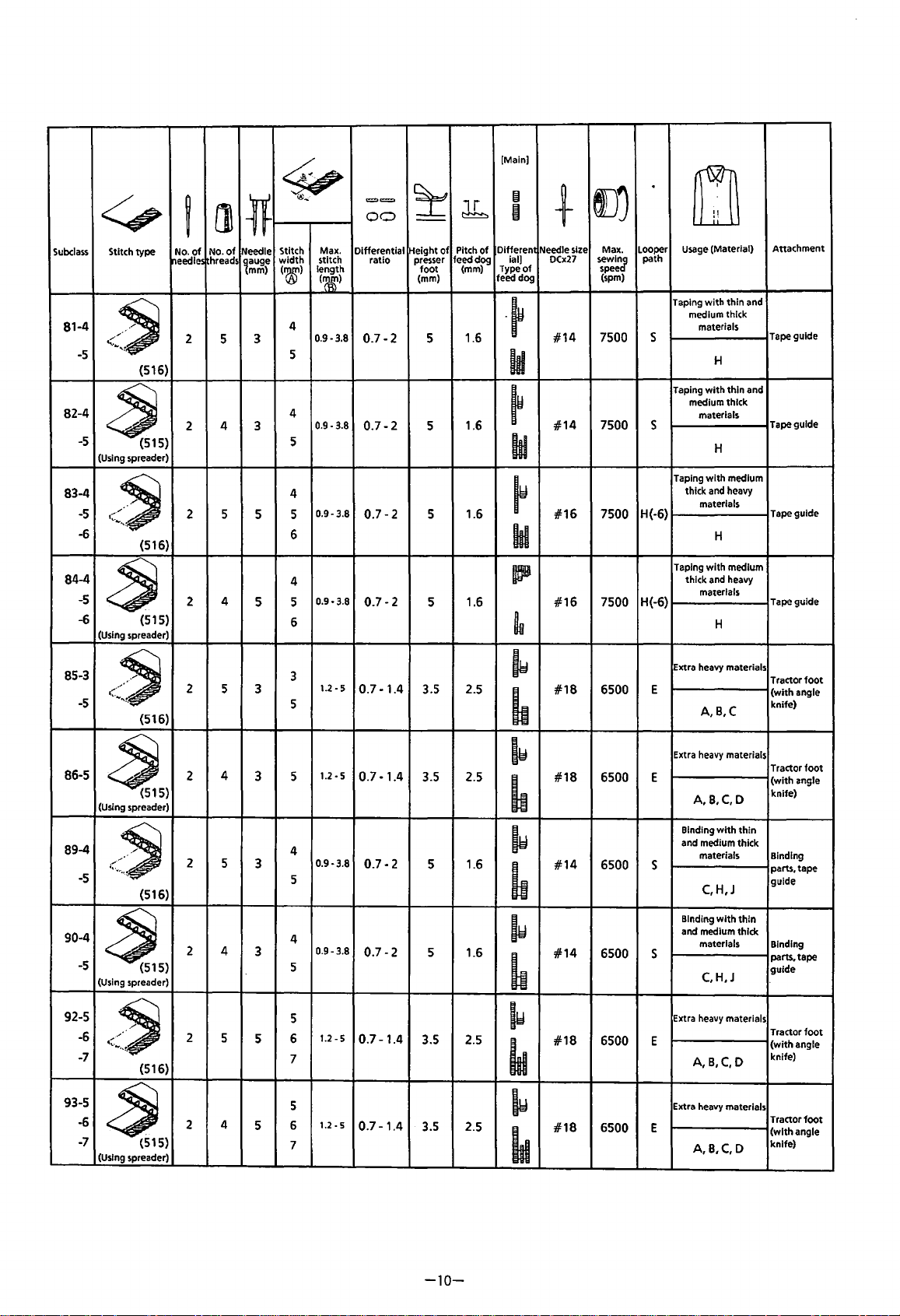

<::.,

Subcla$$

Stitch

type

81-4

<~

-5 5

82-4

-5

83-4

-5

-6

84-4

-5

-6 (515)

{516)

~

{515)

(Using spreader)

/~

t.._ • .,.._"·

{516)

~

(Using spreader)

ij

No.

of

reedles

2

2

2 5

2

l]

No.

of

hreads

5 3

4

4

lf

Needle

~auge

mm)

3

5

5

~

@..;

Max.

Stitch

stitch

width

length

('&)

~~

4

0.9-3.8

4

0.9-3.8

5

4

0.9-3.8

5

6

4

0.9-3.8

5

6

==

00

Differential

ratio

0.7-2

0.7-2

0.7-2

0.7-2

~

--

Pitch

of

Height

feed dog

presser

foot

(mm)

5

5

5

5

[Main)

lr

~

Differen

of

(mm) Type

ial)

feed dog

-~

1.6

hi

1.6

1.6

1.6

~

II

+

Needle size Max.

0Cx27

of

#14

~

#14

hi

~

#16

ld

ICB

#16

~

l)j

sewincr

spee

(spm)

7500 s

7500 s

7500

7500

.

Looper

path

H(-6)

H(-6)

m

Usage

(Material)

Taping

with

thin

with

with

with

H

thin

H

medium

H

medium

H

and

and

medium thick

materials

Taping

medium thick

materials

Taping

thick and heavy

materials

Taping

thick and heavy

materials

Attachment

Tape guide

Tape guide

Tape guide

Tape guide

85-3

l~,._

•

.,..

/~

-5

86-5

(516)

2

5 3

4

2

3

~5)

(Using spreader)

89-4

{~

....

<~

-5

90-4

-5

~5)

(Using spreader)

92-5

-6

<~

-7

93-5

-6

~

-7

(Using spreader)

(516)

{516)

{515)

2 5

2 4

2

2

3

3

5

5

4

5

3

1.2-5

5

0.7-1.4

3.5

2.5

~

#18

6500

~

1.2-5

5

0.7-1.4

3.5 2.5

~

#18

6500

~

4

0.9-3.8

5

0.7-2

5

1.6

lw

#14

6500

~

4

0.9-3.8

5

0.7-2

5 1.6

~

#14

6500

~

5

1.2-5

1.2-5

0.7-1.4

0.7-1.4

3.5

3.5 2.5

6

7

5

6

7

2.5

~

#18

~

~

#18

6500 E

6500 E

~

Extra heavy materials

E

A,B,C

Extra heavy materials

E

A,B,C,D

Binding

and medium thick

s

s

materials

C,H,J

Binding

and medium thick

materials

C,H,J

Extra heavy materials

A,B,C,D

Extra heavy materials

A,B,C,D

with

with

thin

thin

Tractor

foot

(with

angle

knife)

Tractor

foot

(with

angle

knife)

Binding

parts. tape

guide

Binding

parts. tape

guide

Tractor

foot

(with

angle

knife)

Tractor

foot

(with

angle

knife)

-10-

Page 14

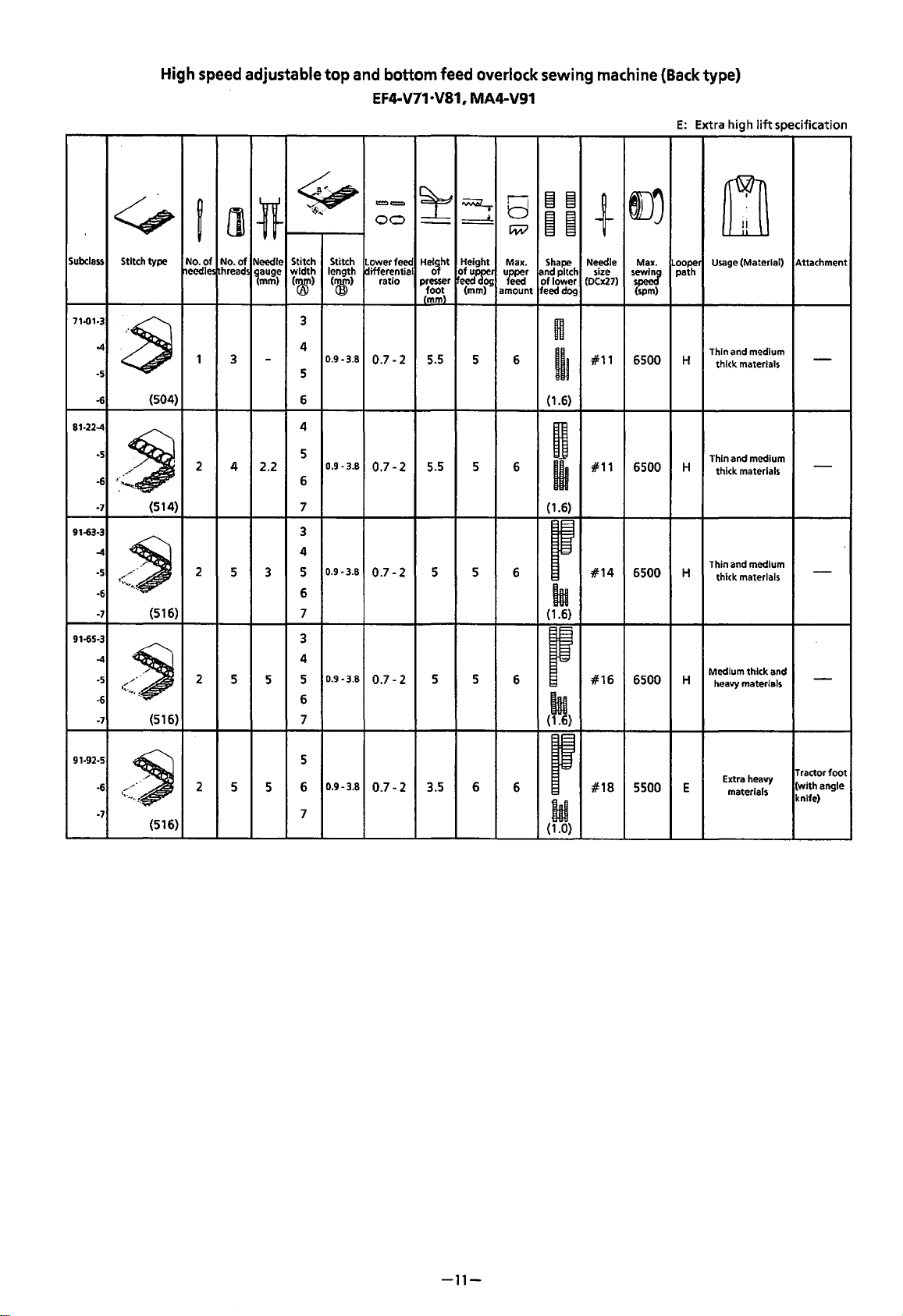

High

speed

adjustable

top

and

bottom

EF4-V71·V81, MA4-V91

feed

Overlock

sewing

machine

(Back

E:

Extra high

type)

lift

specification

<:::,

Subclass

71..01-3

81·22-4 4

91-63·3

91-65·3

Stitch

type

-4

~

·5

-6

·5

-6

-7

-4

·5

·6 6

-7

-4

-5

-6

-7

(504)

-~

:-

........

~.

(514)

1\.•q.

-~

{516)

r.

.•.

/~

{516)

l]

~

No.

of

No. of

hreads

~eedles

1

3

2

4 2.2

2

5

2

5

Stitch Stitch

Needle

*

width

~auge

mm)

-

3 5

5

~

length

('&)

(®)

3

4

0.9-3.8

5

6

5

0.9-3.8

6

7

3

4

0.9-3.8

7

3

4

0.9-3.8

5

6

7

t==

00

Lower feed

differential

ratio

0.7-2

0.7-2

0.7-2

0.7-2

~

~

~

--

Height

He~~ht

ofupJ:r

presser

eed

(mm)

(~~\

5.5

5 6

5.5

5

5 5

5 5

og

a

c;;;:v

Max.

uffe:I

amount

6

6

6

1§1 1§1

i i

Shape

[and

pitch

of

lower

feed dog

H

Ill

{1.6)

H

~

(1.6)

p

hi

(1.6)

p

hi

(1.6)

+

Needle

size

(0Cx27)

#11

#11

#14

#16

l)j

Max.

s;=

(spm)

6500

6500

6500

6500

Looper

path

H

H

H

H

m

Usage

(Material)

Thin and medium

thick materials

Thin and medium

thick materials

Thin and medium

thick materials

Medium thick and

heavy materials

Attachment

-

-

-

-

91-92-5

·6

t ...

/~

-7

2

(516)

5

0.9-3.8

5

6

5

7

0.7-2

3.5 6

6

p

#18

ld

{1.0)

5500 E

Extra heavy

materials

Tractor

(with

knife)

foot

angle

-11-

Page 15

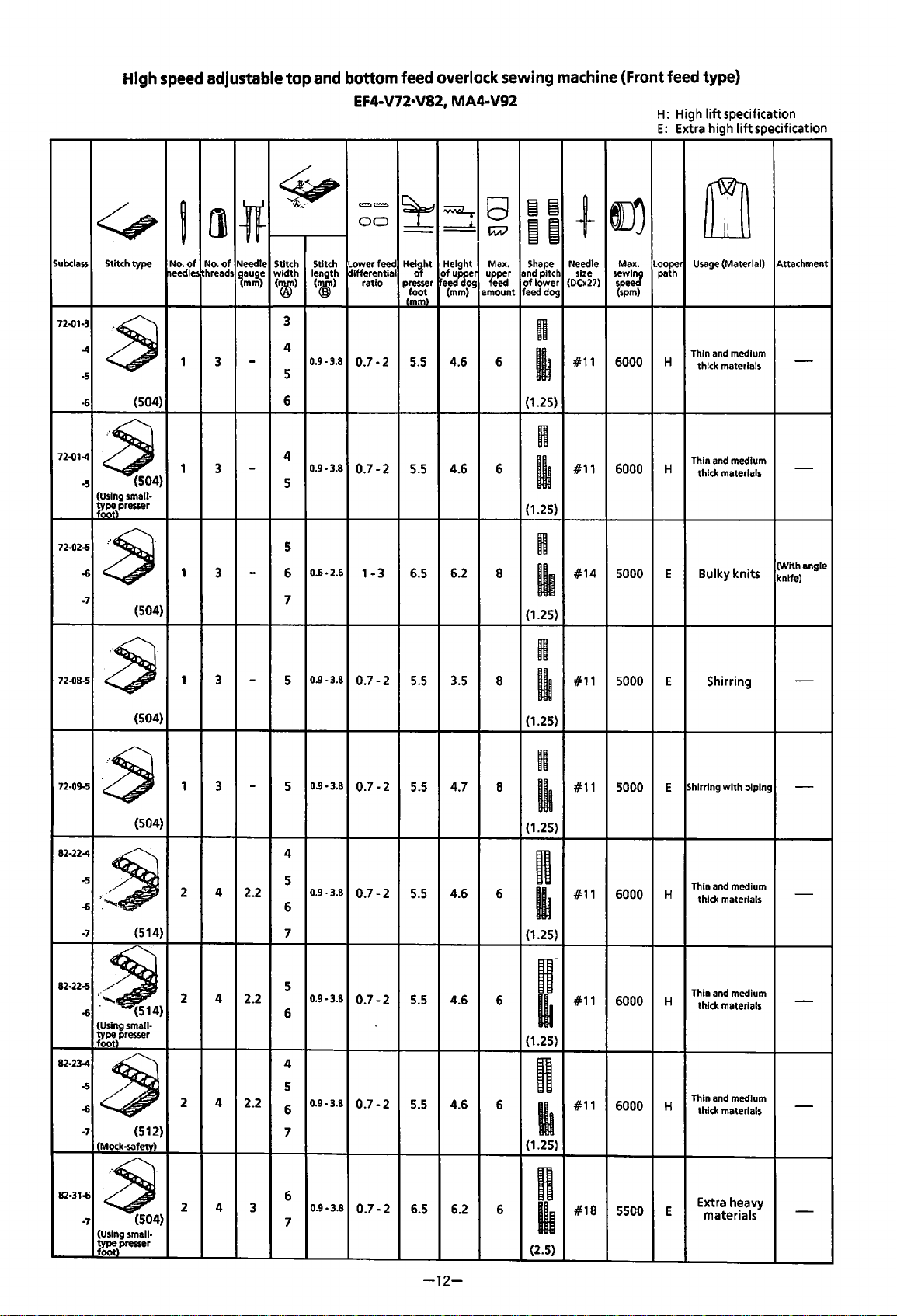

Subclass

72.01·3

-4

·5

·6

High

speed

.::::,

Stitch

type

a

(504)

~

No.

needles hreads

1

adjustable

(l\

of

No.

of

3

top

and

bottom

EF4-V72•V82,

<£;,

®.;

==

00

lf

Needle Stitch Stitch Lower feed

width

~auge

mm)

-

length differential

(roo')

(~)

3

4

0.9-3.8

5

6

ratio presser eed og

0.7-2

feed

overlock

MA4-V92

~

~

==:!:

Height Max.

He~~ht

of

ur3cer

(mm)

(~~\

5.5 4.6

sewing

8

!NV

ureper

eed

amount

machine

~~

iii

Shape

and pitch size

of

lower

feed dog

H

6 #11

~

(1.25)

(Front

em

+

Needle Max.

sew~

(DCx27)

spe

(spm)

6000

feed

H:

High

E:

Extra high

Looper

path

H

type)

lift

specification

lift

specification

m

Usage

(Material) Attachment

Thin and medium

thick materials

-

72.01-4

~4)

·5

(Using small·

%:)presser

72.02·5

·6

a

·1 7

72.08·5

a

{504)

72-09·5

~

82·22-4

·~

1~

'"'-~.

·6

·7

(504)

{504)

(514}

1

1

1 3

1

2

3

-

3

-

-

3

-

4 2.2

4

0.9·3.8

0.6·2.6

0.7-2

1-3

5

5

6

5.5

6.5

4.6

6.2

6 #11

~

(1.25)

n

8

#14

6000

5000 E Bulky knits

Thin and medium

H

thick materials

-

(With angle

knife)

lh

(1.25}

H

0.9·3.8

n

0.9-3.8

0.9-3.8

0.7-2

0.7-2

0.7-2

5.5 3.5

5.5 4.7

5.5 4.6

8

8

6

~

{1.25)

n

~

(1.25)

n ·5

I

(1.25)

#11 5000 E

#11 5000 E

#11

6000

H

Shirring

Shirring

with

piping

Thin and medium

thick materials

-

-

-

5

5

4

5

6

7

82-22·5

.•

~)

·6

(Using small·

%:resser

82·23-4

·5

·6

~

·7

(Mock-safety)

82·31·6

a

·7

(Using small·

%:\presser

{512}

{504)

2 4

2 4

2

5

2.2

2.2

4

3

0.9·3.8

0.9·3.8

0.9

·3.8

0.7-2

0.7-2

0.7-2

6

4

5

6

7

6 n

7

5.5 4.6

5.5 4.6

6.5

6.2

-12-

u-

6

I

(1.25)

n

6

~

{1.25)

6

lh

{2.5)

#11

#11

#18

6000 H

6000

5500 E

Thin and medium

thick materials

Thin and medium

H

thick materials

Extra heavy

materials

-

-

-

Page 16

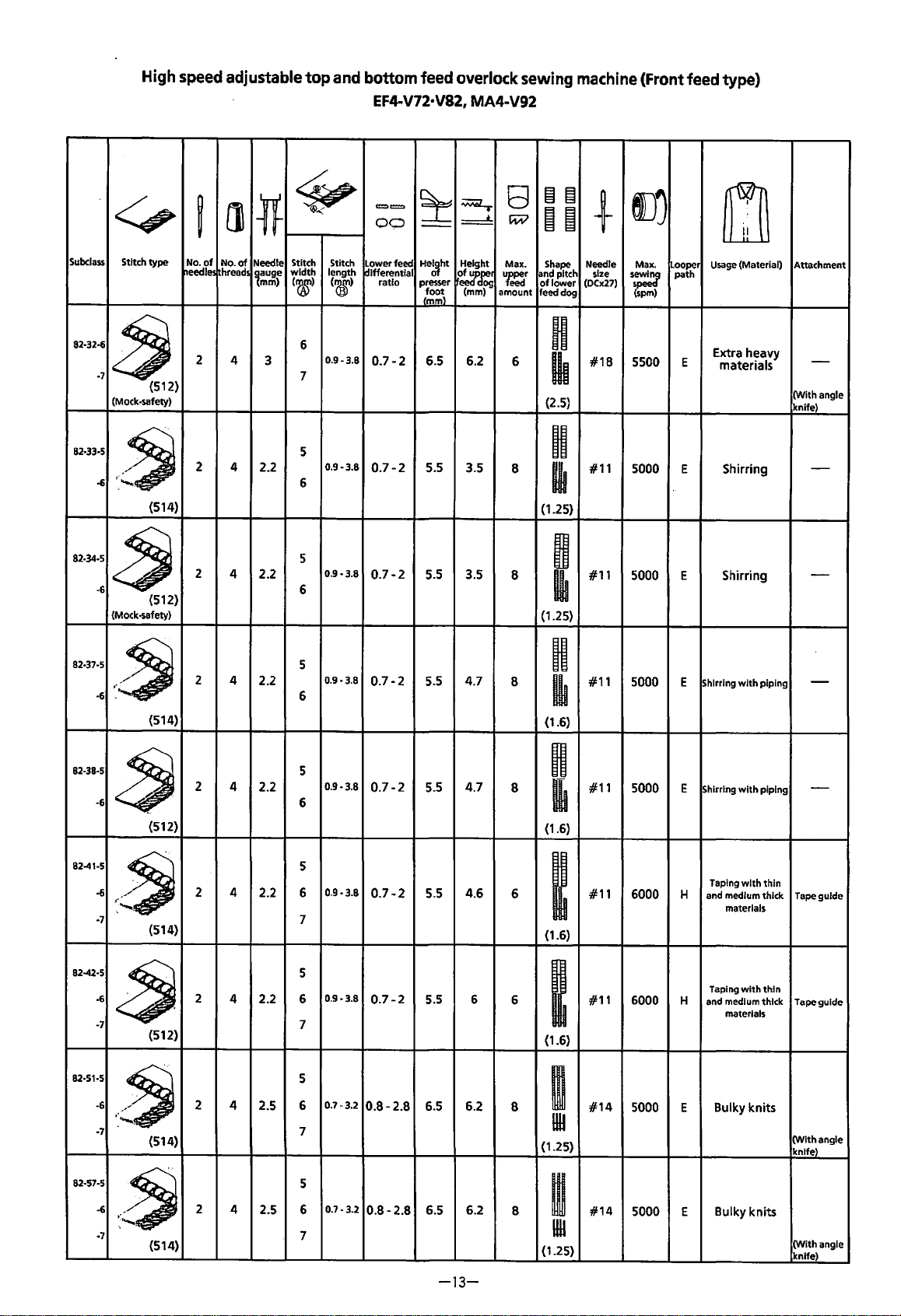

Subclass

High

speed

<:.,

Stitch

type

needles

adjustable

[]

~

No.

of

No.

of

hreads

top

and

~

~

Needle Stitch Stitch

width

('00')

length

(aD)

1auge

mm)

bottom

EF4-V72•V82,

Lower feed

~Jfferential

c=:.=

00

ratio

feed

overlock

MA4·V92

~

~

~

Height

He~~ht

presser

~~~

(mm)

~~~\

sewing

8

c:;;v

Max.

'feper

eecl

amount

§I §I

B

~

Shape

and pitch

of

lower

feed

dog

machine

I))

+

Needle

size

sew~

(0Cx27)

spe

(Front

Max.

(spm)

feed

type)

rn

Usage (Material)

ooper

path

Attachment

82·32·6

·1

~

(512)

(Mock-safety)

82·33·5

.~

·6

(514)

82·34·5

~

-6

82-37·5

·6

82·38·5

-6

(512)

(Mock-safety)

:~

(514)

~

(512)

2

2 4

2

2

2

4

3

2.2

4 2.2

4 2.2

4

2.2

6

0.9-3.8

7

5

0.9-3.8

6

5

0.9

6

5

0.9·3.8

6

5

0.9-3.8

6

·3.8

0.7-2

0.7-2

0.7-2

0.7-2

0.7-2

6.5

6.2

5.5 3.5

5.5 3.5

5.5 4.7

4.7

5.5

n

6

#18

5500 E

Extra heavy

materials

-

lh

(With

(2.5)

angle

knife)

H

8

#11

5000 E Shirring

-

I

(1.25)

9

8

#11

5000

E

Shirring

-

I

(1.25)

n

8

Ill

(1.6)

#11

5000 E Shirring

with

piping

-

n

8

#11

5000 E Shirring

with

piping

IIi

(1.6)

-

82-41-5

-6

-~

·:...-.,.

·1

82-42·5

·6

~

-7

82·51·5

·6

':·"'--.

~

·1

82·57·5

-6

·:~

·1

(514)

(512)

(514)

(514)

2

2

2

2

4

4 2.2

4

4

2.2

2.5 6

2.5 6

5

0.9

·3.8

6

7

5

6

7

5

7

5

7

0.9·3.8

0.7-3.2

0.7

·3.2

0.7-2

0.7-2

0.8-2.8

0.8-2.8

5.5 4.6

5.5 6

6.5 6.2

6.5 6.2

-13-

6

I

(1.6)

6 #11

I

(1.6)

m

8

1111

(1.25)

w

8

uu

(1.25)

#11

6000 H

6000 H

#14

5000 E Bulky knits

#14

5000 E Bulky knits

Taping

with

and medium

materials

Taping

with

and medium

materials

thin

thick

thin

thick

Tape

guide

Tape

guide

(Wlthangle

knife)

(With

angle

knife)

Page 17

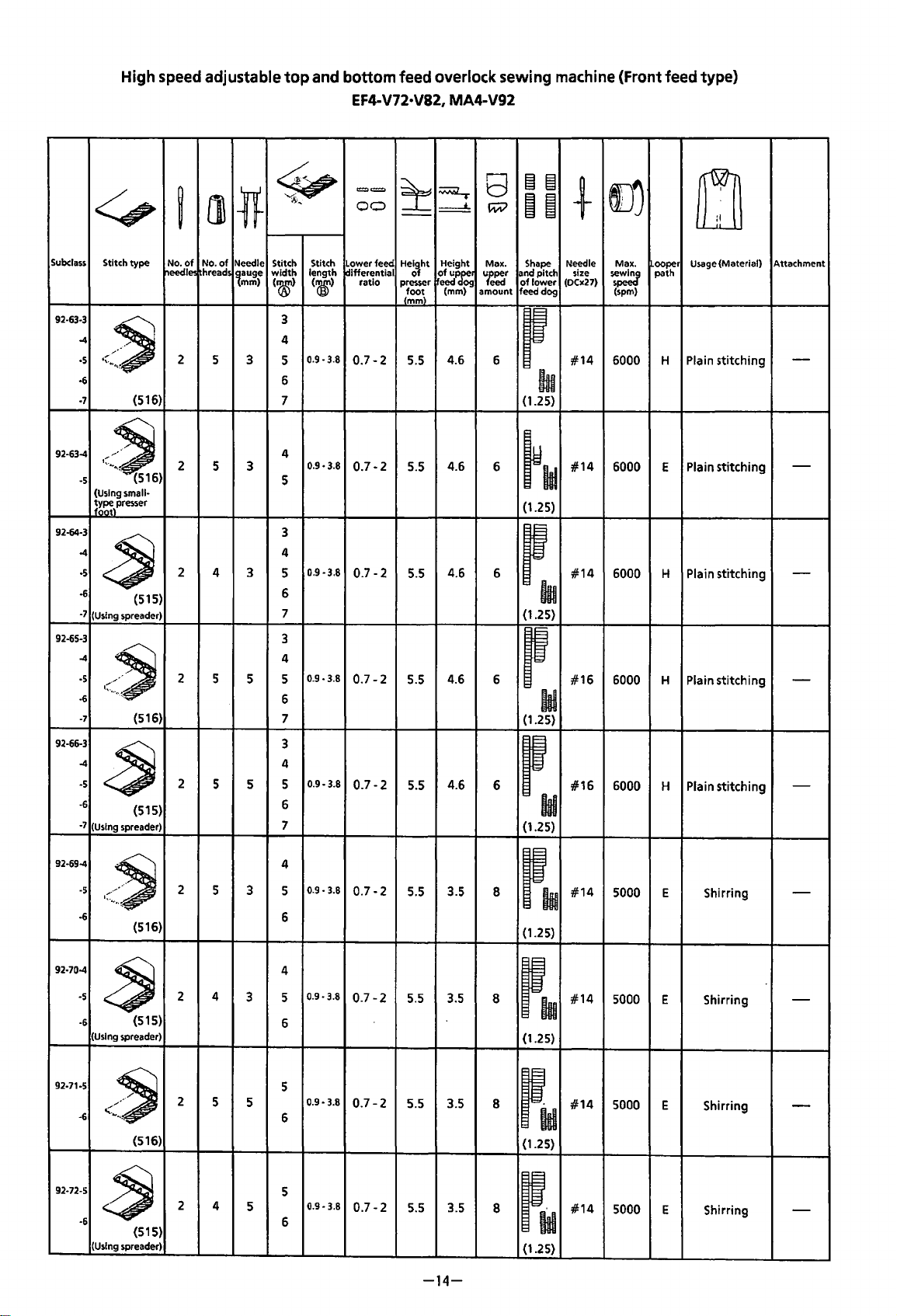

High

<,

speed

adjustable

[]

~

top

~

~

and

bottom

EF4-V72·V82, MA4-V92

==

00

feed

j:

overlock

~

__j_

8

[;WI

sewing

I§

ti

machine

~

i

+

(Front

()j

feed

type)

m

Subclass Stitch

92·63·3

-4

·5

·6

·7

92-63-4

·5

92·64·3

-4

·5

·6

·7 (Using spreader)

92-65·3

-4

·5

·6

·1

92-66-3

-4

·5

-6

-7

type

<.~

(516)

.-~

··~'<..

(516)

(Using small-

I

~~~~\presser

~

(515)

l,

...

,

-~

(516)

~

(515)

(Using spreader)

No.

of

No.

of

hreads

~eedle!

2

5 3

2

5 3

2

4 3

2

5

2

5 5

Needle Stitch Stitch Lower feed

~auge

mm)

5

length

width

(COO')

3

4

5

6

7 (1.25)

4

5

3

4

5

6

7

3

4

5

6

7

3

4

5

6

7

~ifferential

·3.8

·3.8

ratio

0.7-2

0.7-2

0.7-2

0.7-2

0.7-2

(®)

0.9-3.8

0.9

0.9

0.9·3.8

0.9-3.8

Height Max. Shape Needle Max.

Height

of

ofu'fo:

eeclog

presser

(mm)

c~\

4.6

5.5

4.6

5.5

4.6

5.5

4.6

5.5

4.6

5.5

and pitch size

uf:Jr

amount

6

of

lower

feed dog

f

(DCx27)

#14

Ill

6

#14

h~

(1.25)

6

#14

flu

(1.25)

6

f

(1.25)

6

#16

Ill

#16

fld

(1.25)

Usage (Material)

Looper

path

s;~

(spm)

6000 H Plain stitching

6000 E Plain stitching

6000 H Plain stitching

6000 H

6000

Plain stitching

H

Plain stitching

Attachment

-

-

-

-

-

92-69-4

·5

·6

92-70-4

·5

·6

92-71-5

·6

92-72-5

·6

2

2 4

2

2

5

5

4

·\·

....

-~

(516)

:}J

(515)

(Using spreader)

..........

--~

(516)

~

(515)

(Using spreader)

4

0.9.

3

5

3.8

0.7-2

5.5 3.5

8

f~u

6

4

3

5

5

0.9·3.8

5

6

5

0.9.

6

5

0.9-3.8

6

3.8

0.7-2

0.7-2

0.7-2

3.5

5.5

5.5 3.5

5.5 3.5

-14-

(1.25)

8

f~u

(1.25)

8

fid

(1.25)

8

fld

(1.25}

#14

#14

#14

#14

5000 E

5000 E

5000

5000

Shirring

Shirring

E

Shirring

E Shirring

-

-

-

-

Page 18

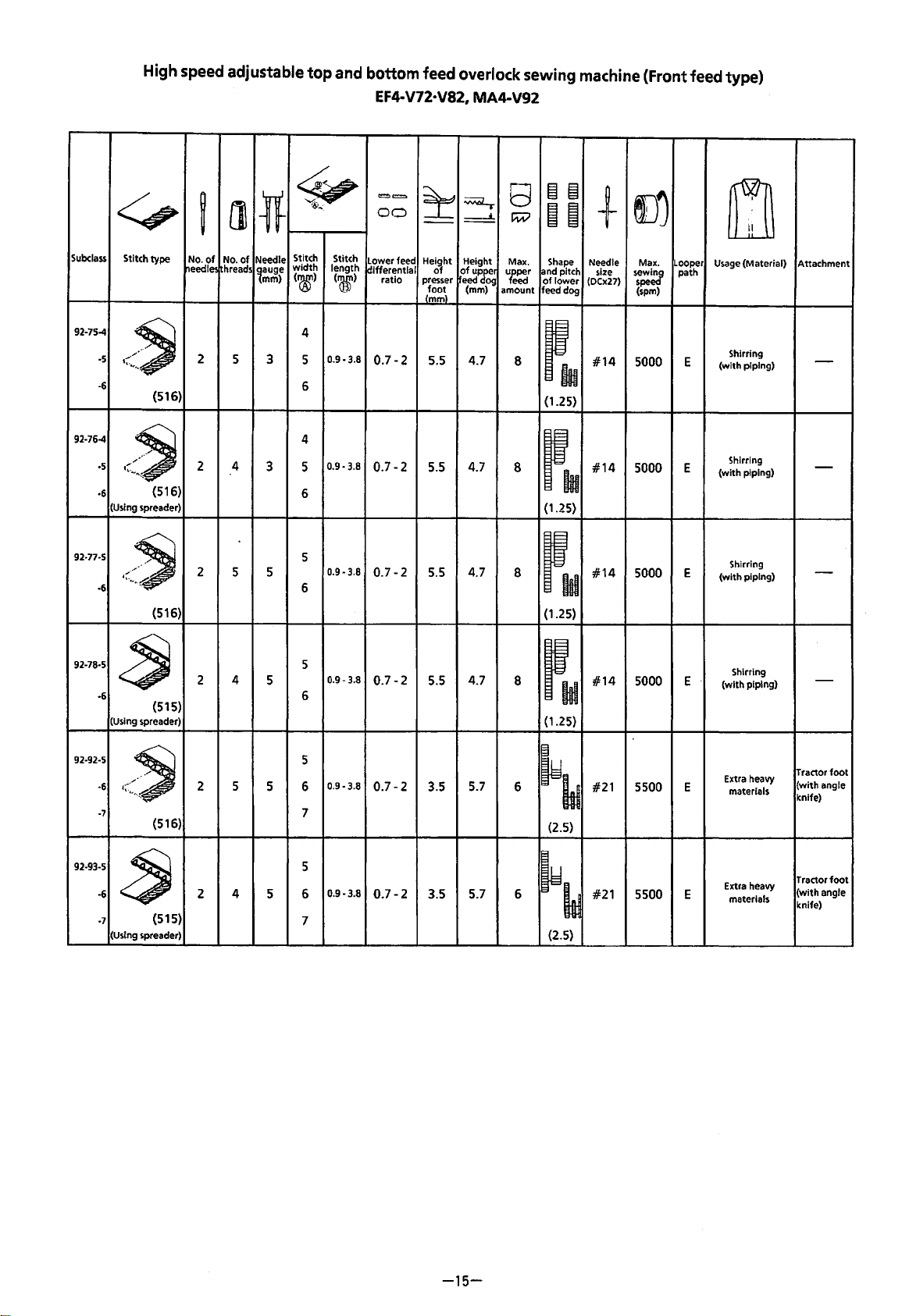

Subclass

High

<,

Stitch

type

speed

adjustable

[}1

~

No.

of

No.

hreads

reedles

:rr

of

Needle

lauge

mm)

top

and

1f?

Stitch

Stitch

width

length

(®)

(®)

bottom

EF4-V72·V82, MA4·V92

Lower feed

~ifferential

~=

00

ratio

feed

overlock

~

~

===:!:

--

Height

Height

of

ofu':cer

presser

~eed

foot

(mm)

Cmml

og

8

wv

Max.

u~r

amount

sewing

(§

~

~I

Shape

and pitch

of

lower

feed dog

machine

()j

+

Needle

size

(DCx27)

s:=

(Front

Max.

(spm)

feed

Looper

path

type)

m

Usage

(Material)

Attachment

92-75-4

-5

'\·

...

-~

-6

92-76-4

-5

•~...

.....

-~

·6

(Using spreader)

92·77·5

''··~

-~

·6

92-78·5

~

-6

(Using spreader)

92-92-5

(:

·6

..

·~~

·1

..

~

{516)

(516)

(516)

(515)

(516)

2

2 4

2

2 4

2

5 3

3

5 5

5

5 5 6

4

E

E

E -

E

Shirring

(with piping)

Shirring

(with

piping)

Shirring

(with

piping)

Shirring

(with

piping)

Extra heavy

materials

-

-

-

-

Tractor

(with

knife)

foot

angle

0.9-3.8

·3.8

0.9

·3.8

0.9·3.8

0.9

·3.8

0.7-2

0.7-2

0.7-2

0.7-2

0.7-2

5.5

5.5

5.5

5.5

3.5

4.7

4.7

4.7

4.7

5.7

8

#14

5000 E

P~u

(1.25)

8

P~~

(1.25)

8

pld

(1.25)

8

pld

(1.25}

6

~~.~

(2.5)

#14

#14

#14

#21

5000

5000

5000

5500

5

6

4

0.9

5

6

5

6

5

6

5

7

92-93·5

-6

~

·1

(Using spreader)

2 4

(515)

5 6

5

0.9·3.8

0.7-2

7

3.5

-15-

5.7

6

~~

(2.5)

#21

5500 E

Extra heavy

materials

Tractor

(with

knife)

foot

angle

Page 19

c MECHANICAL

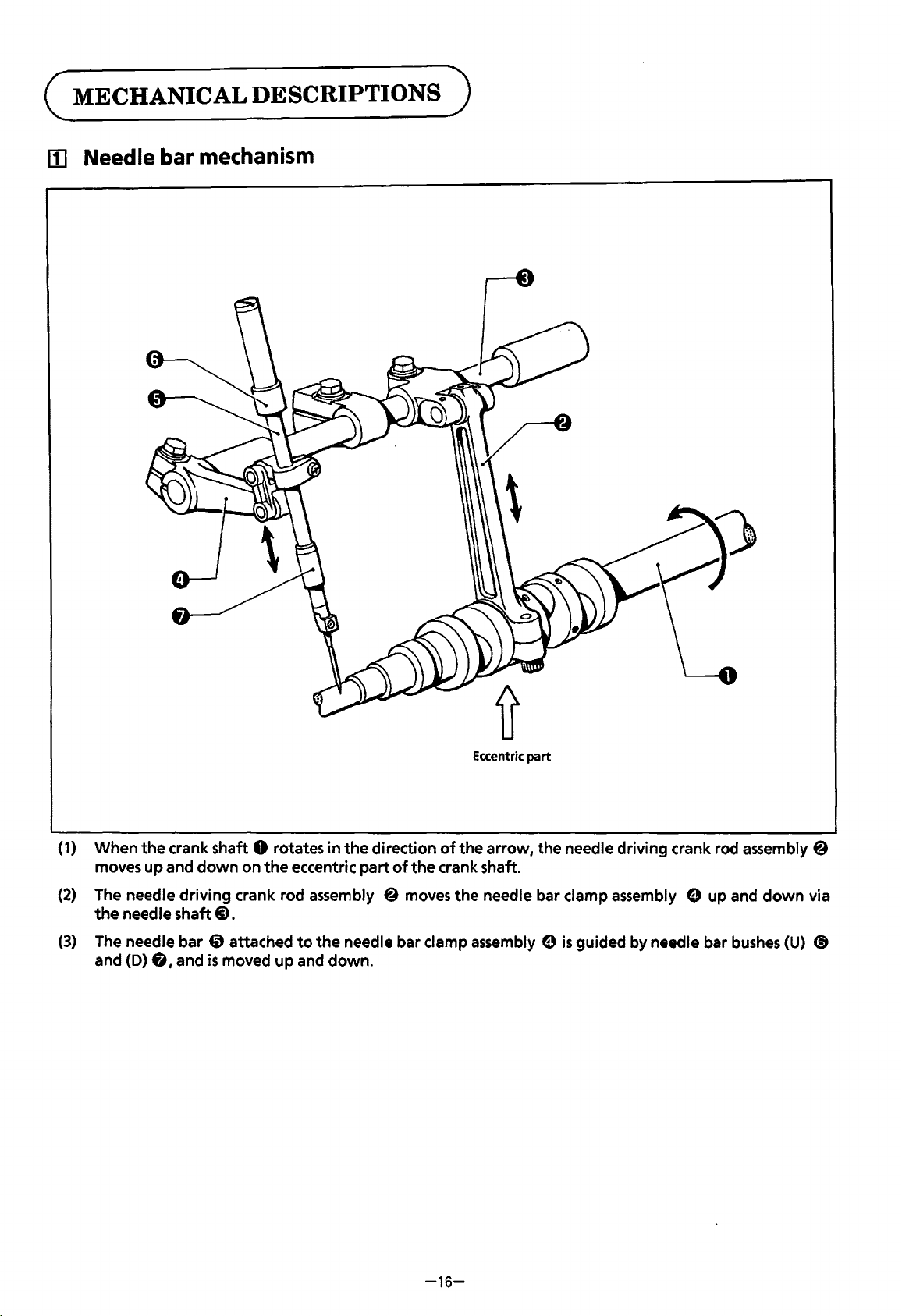

[!]

Needle bar

mechanism

DESCRIPTIONS

)

(1) When

moves up and

(2)

The needle

the

needle shaft@).

(3)

The needle bar

and (D)

the

crank shaft 0 rotates

down

on

6,

driving

and

crank rod assembly @ moves

@)

attached

is

moved

the

eccentric

up

to

and

Eccentric

in

the

direction

part

of

the

needle bar clamp assembly e

down.

of

the

crank shaft.

the

the

arrow,

needle bar clamp assembly e up and

part

the

needle driving crank rod assembly @

is

guided by needle bar bushes (U)

down

via

<9

-16-

Page 20

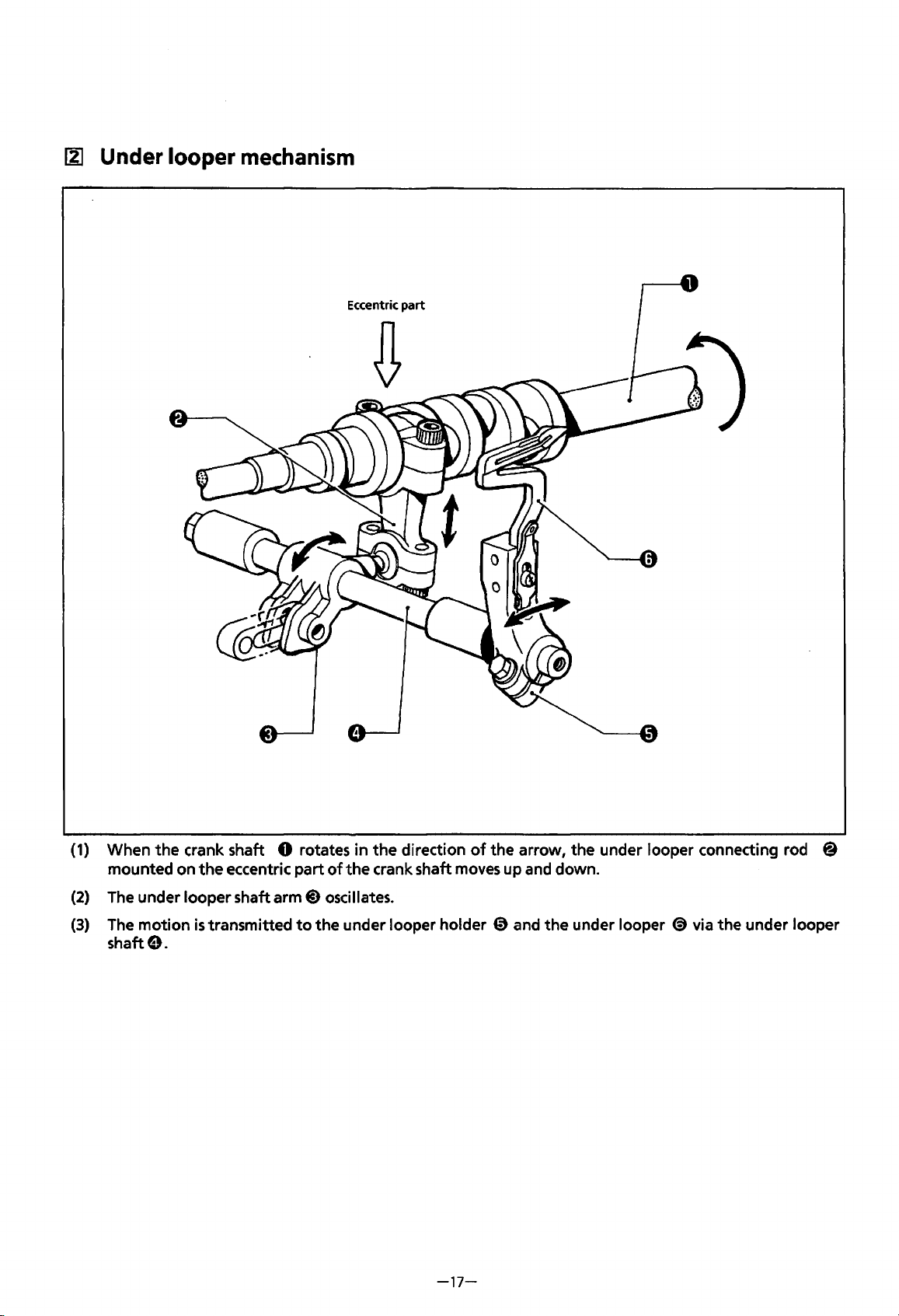

[2]

Under looper

mechanism

Eccentric

part

(1)

When

(2)

(3)

the

crank shaft 0 rotates in

mounted on

The

under looper shaft

The

motion

shaft e.

the

is

eccentric part

arm@)

transmitted

the

direction

of

the

crank shaft

oscillates.

to

the under looper holder 0 and

moves

-17-

of

the arrow, the under looper connecting rod @

up and down.

the

under looper

@}

via the under looper

Page 21

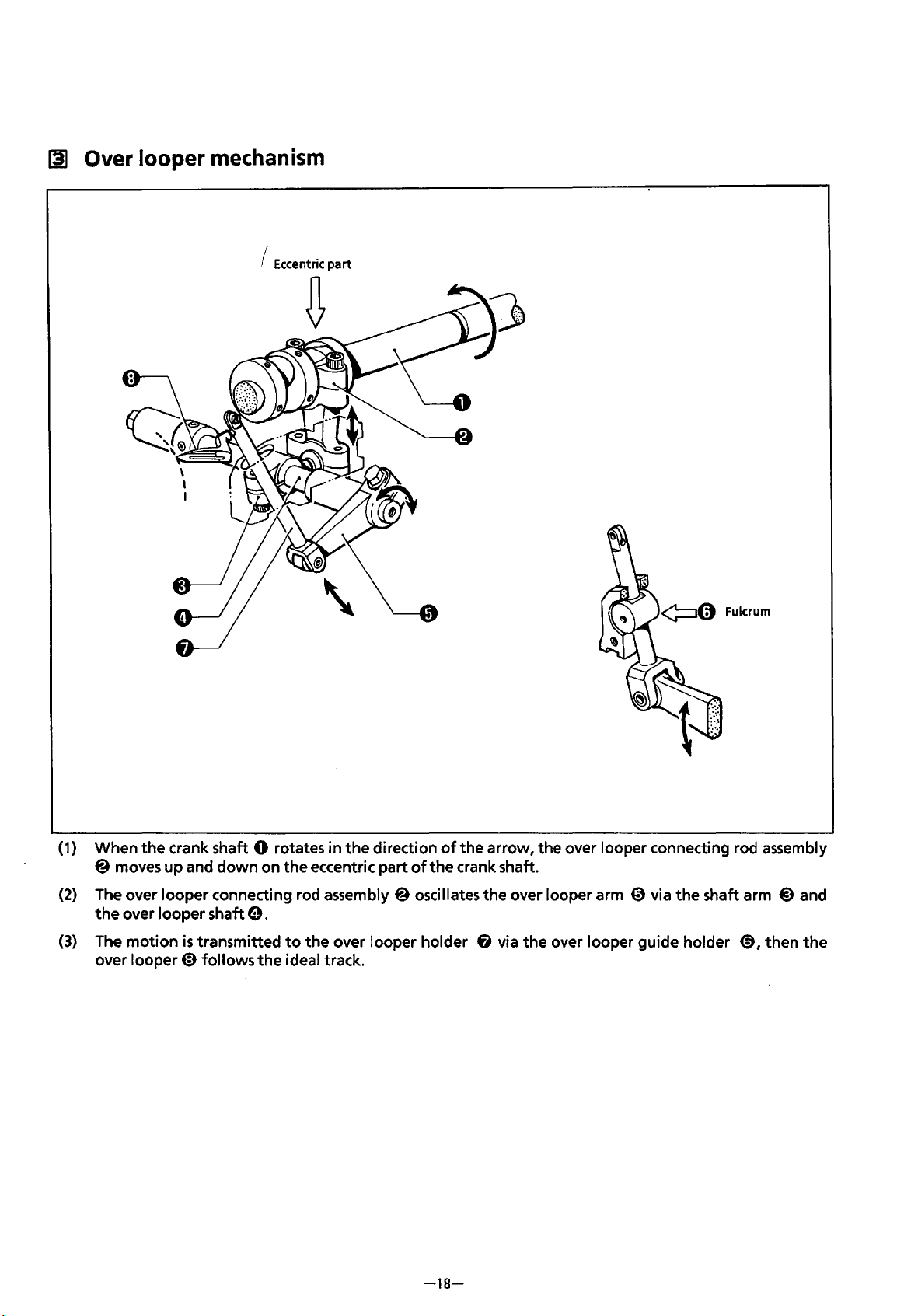

~

Over looper mechanism

(

Eccentric

~

part

(1)

When the crank shaft 0 rotates in the direction

@ moves up and down on

(2)

The

over looper connecting rod assembly @ oscillates the over looper arm 0 via the shaft arm

the

over looper shaft

(3)

The motion

over looper@) follows

is

transmitted

0.

the

the

eccentric part

to

the over looper holder 6 via

ideal track.

of

of

the arrow, the over looper connecting rod assembly

the

crank shaft.

the

over looper guide holder

-18-

@,

@)

then

and

the

Page 22

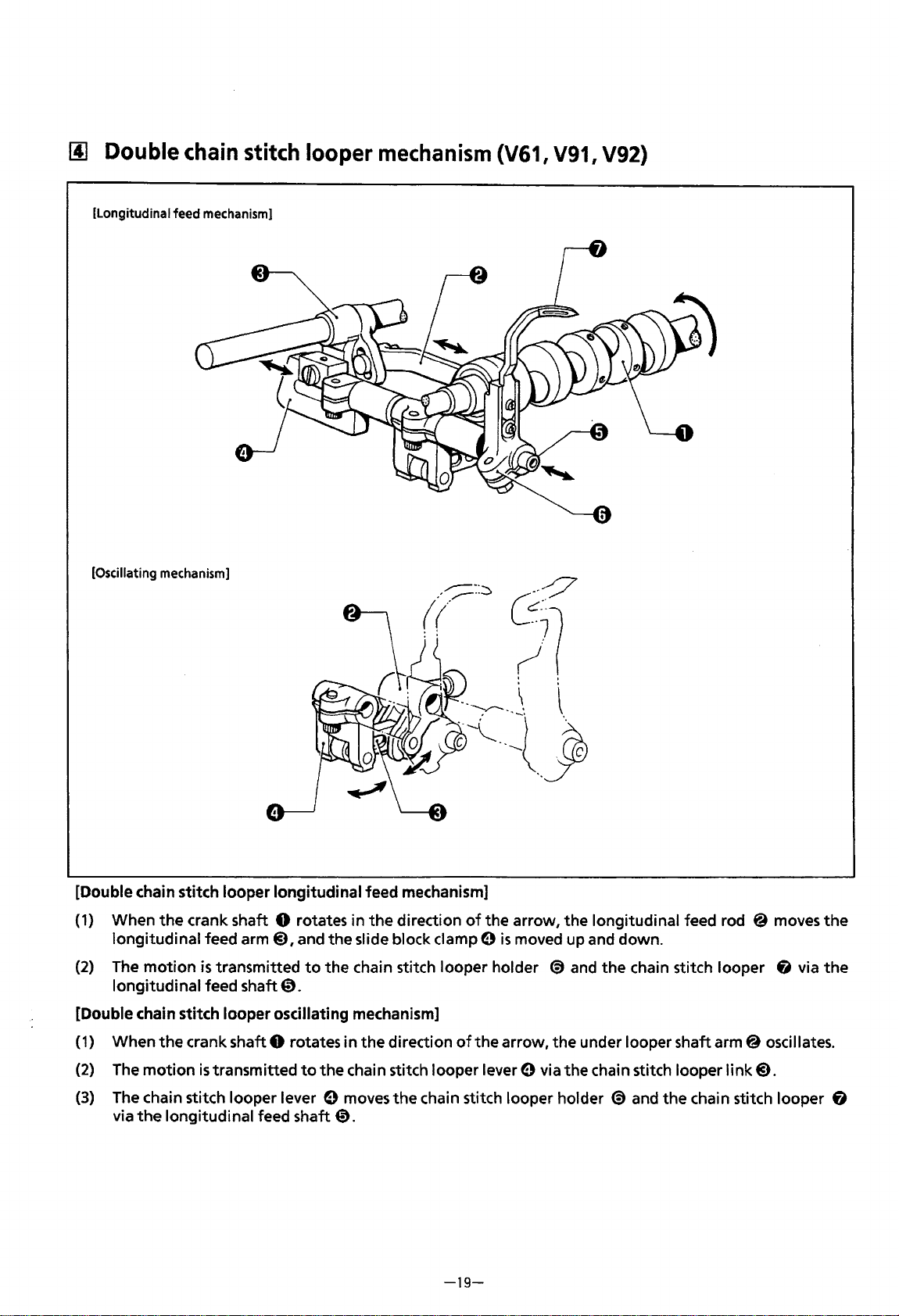

[!]

Double

[Longitudinal feed mechanism]

[Oscillating mechanism]

chain

stitch

looper

mechanism

(V61,

V91,

V92)

[Double chain stitch looper longitudinal feed mechanism]

{1)

When

longitudinal feed

{2)

The motion

longitudinal feed shaft@).

[Double chain stitch looper oscillating mechanism]

(1)

When the crank shaft 0 rotates in the direction

{2)

The

(3)

The chain stitch looper lever 0 moves the chain stitch looper holder @)and the chain stitch looper &

via

the

crank shaft 0 rotates in

arm@), and the slide block clamp 0

is

transmitted

motion

the

is

transmitted

longitudinal feed shaft@).

the

direction

to

the chain stitch looper holder

to

the chain stitch looper lever 0 via the chain stitch looper link@).

of

the arrow, the longitudinal feed rod @ moves the

is

moved up and down.

@)

of

the arrow, the under looper shaft arm@ oscillates.

-19-

and

the chain stitch looper & via

the

Page 23

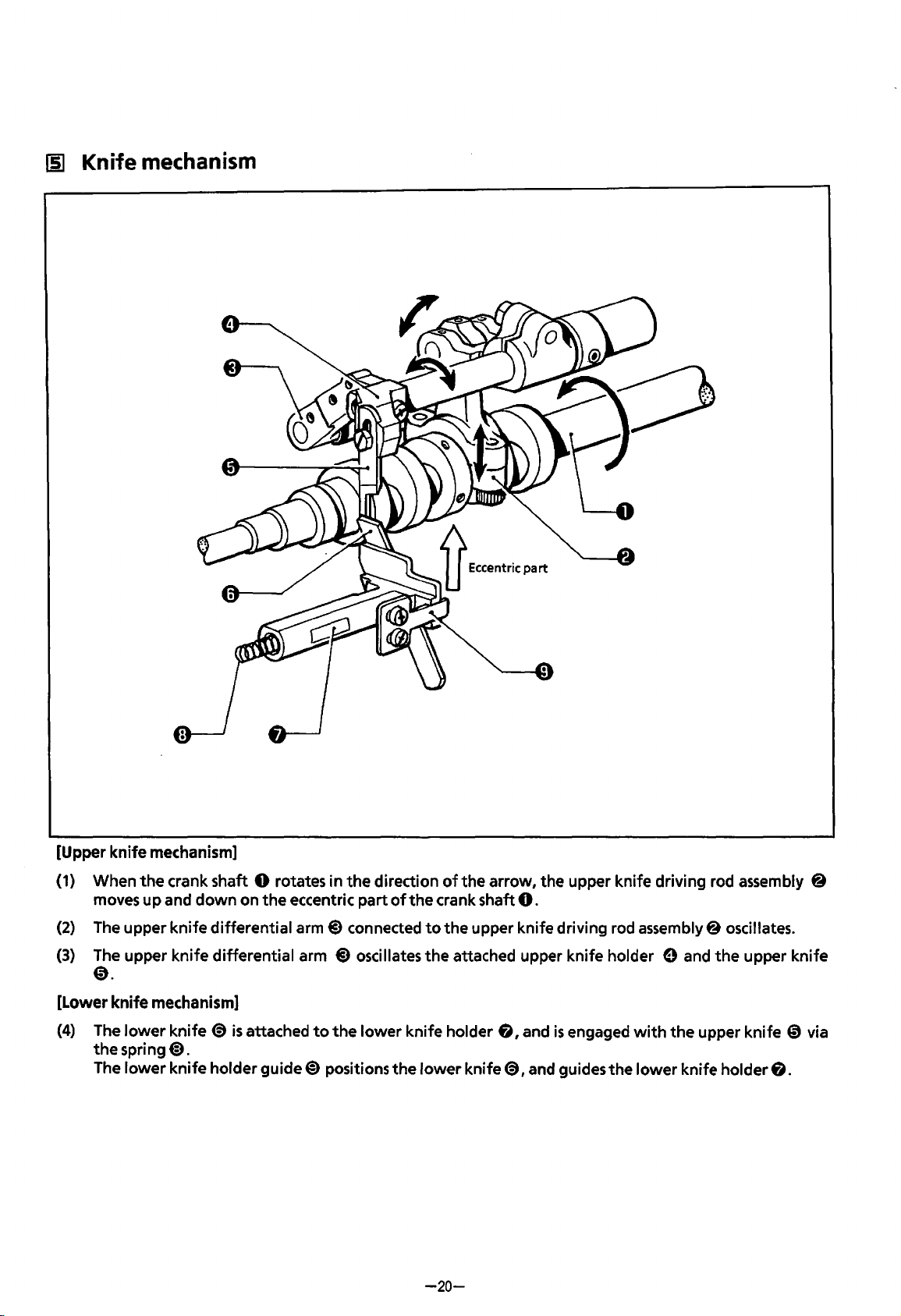

[51

Knife

mechanism

[Upper knife mechanism]

(1)

When

the

crank shaft 0 rotates in

moves up and

(2)

The upper knife differential

(3)

The upper knife differential arm

down

on

the

eccentric part

arm@)

the

direction

connected

@)

oscillates

of

the

of

the arrow,

crank shaft

to

the

upper knife driving rod assembly 8 oscillates.

the

attached upper knife holder 9 and

the

0.

@).

[Lower knife mechanism]

(4)

The

lower

knife

(9

is

the

The

spring

lower

attached

@).

knife holder guide@) positions

to

the

lower

the

knife holder

lower

knife

-20-

6,

and

is

<a,

and guides the lower knife holder

upper knife driving rod assembly @

the

upper knife

engaged

with

the

upper knife 0 via

6.

Page 24

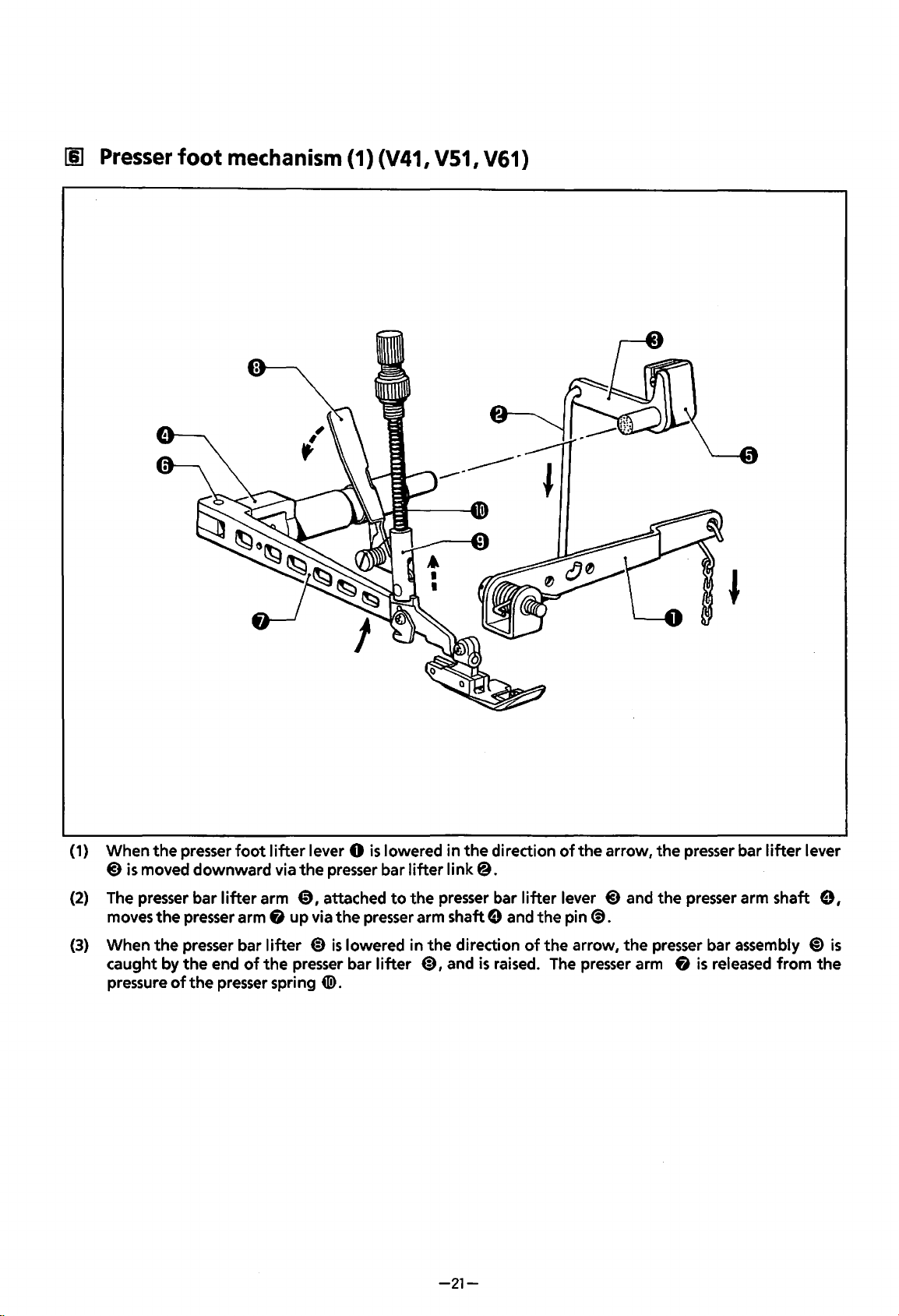

[§]

Presser

foot

mechanism (1) (V41, V51, V61)

(1) When

(2) The presser bar

(3) When

the

presser

@}is moved

moves

caught by

pressure

the

the

of

foot

downward

lifter

presser arm

presser bar

the

end

of

the

presser spring

lifter

via

the

arm

0,

fi

up

lifter

the

presser bar

lever 0

presser bar

attached

via

the

@)

is

lowered in

en>.

is

lowered

to

presser arm shaft e and

lifter

in

lifter

link@.

the

presser bar

the

@),

and

-21-

the

direction

lifter

direction

is

raised. The presser arm

of

the

the

of

lever

pin(!).

the

arrow,

@)

arrow,

the

presser bar

and

the

presser arm shaft

the

presser bar assembly

fi

is

released

lifter

from

lever

9,

@)

is

the

Page 25

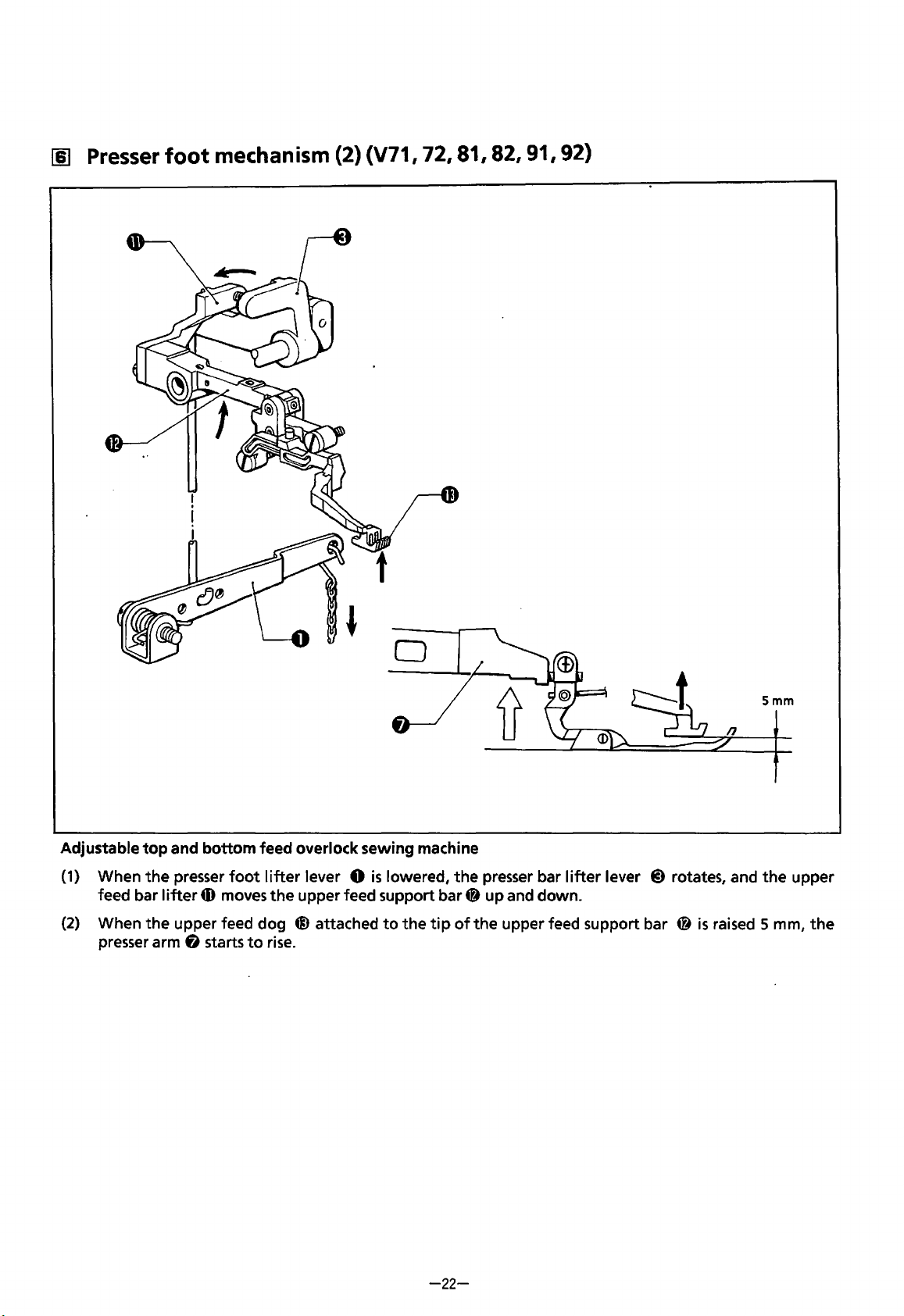

[I) Presser

foot

mechanism (2) (V71, 72, 81, 82, 91, 92)

Adjustable

(1)

(2)

top

When

the

feed bar

When

the

presser arm & starts

and

bottom

presser

lifter

upper feed dog

foot

m moves

to

feed overlock sewing machine

lifter

lever 0

the

upper feed support bar

@attached

rise.

is

lowered, the presser bar

4)

to

the

tip

of

lifter

lever

@)

rotates, and

up and down.

the upper feed support bar @

Smm

the

is

raised 5 mm,

upper

the

-22-

Page 26

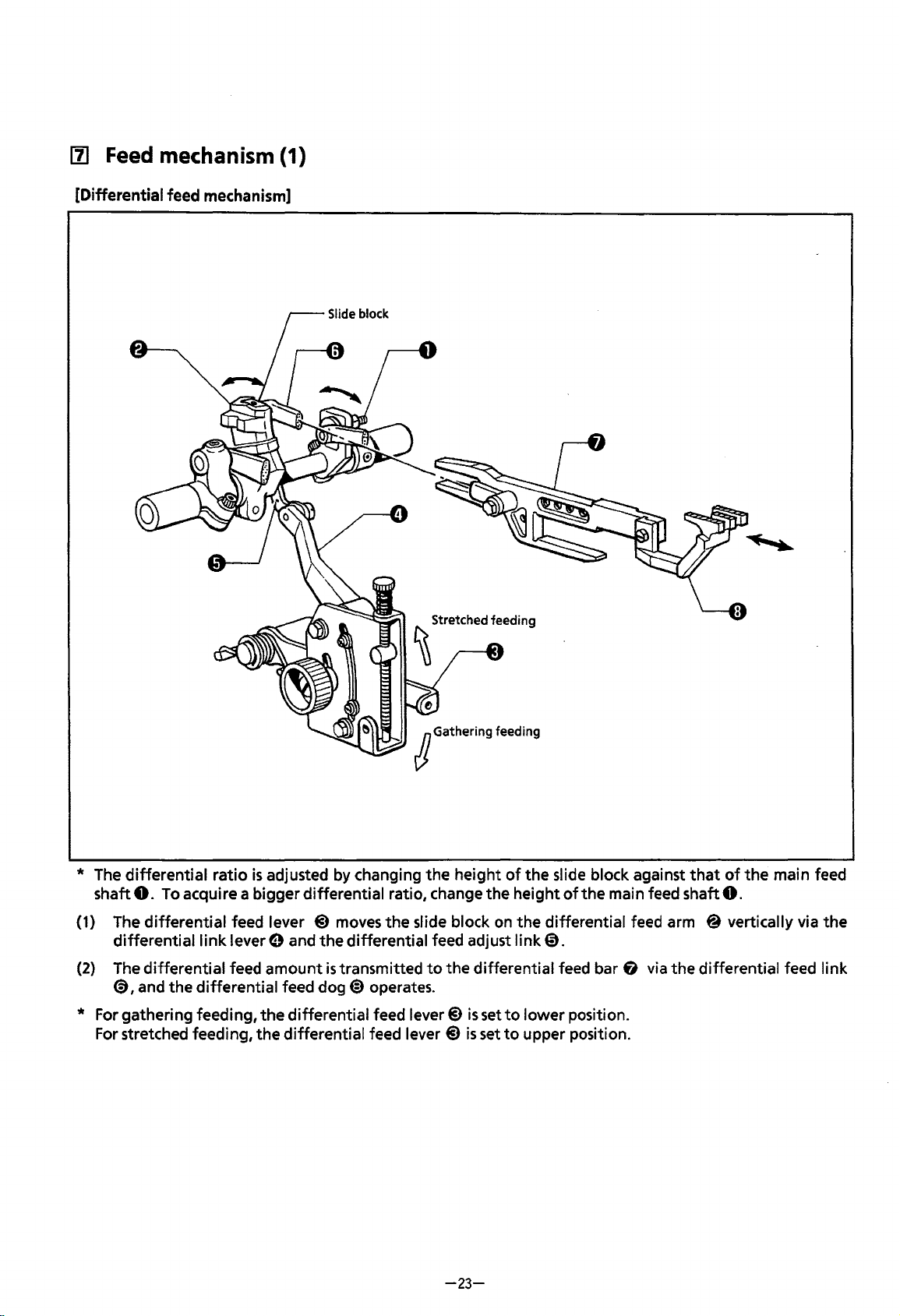

111

Feed

[Differential feed mechanism]

mechanism

(1)

Slide

block

* The

(1) The

(2)

differential

shaft

0.

differential

differential

The

differential

@),

and

ratio

To acquire a bigger

feed lever

link

lever e and

feed

the

differential

* For gathering feeding,

For stretched feeding,

is

adjusted by changing

differential

@)

moves

the

differential

amount

the

the

is

transmitted

feed dog

differential

differential

@)

operates.

feed lever@)

feed lever

JGathering

the

height

ratio, change

the

slide block on

feed adjust

to

the

@)

feeding

of

the

slide block against

the

height

the

link@.

differential feed bar

is

set

to

is

set

to

of

the

differential feed arm @ vertically via

lower

position.

upper position.

that

main feed shaft

fi

via

the

differential feed

of

0.

the

main feed

the

link

-23-

Page 27

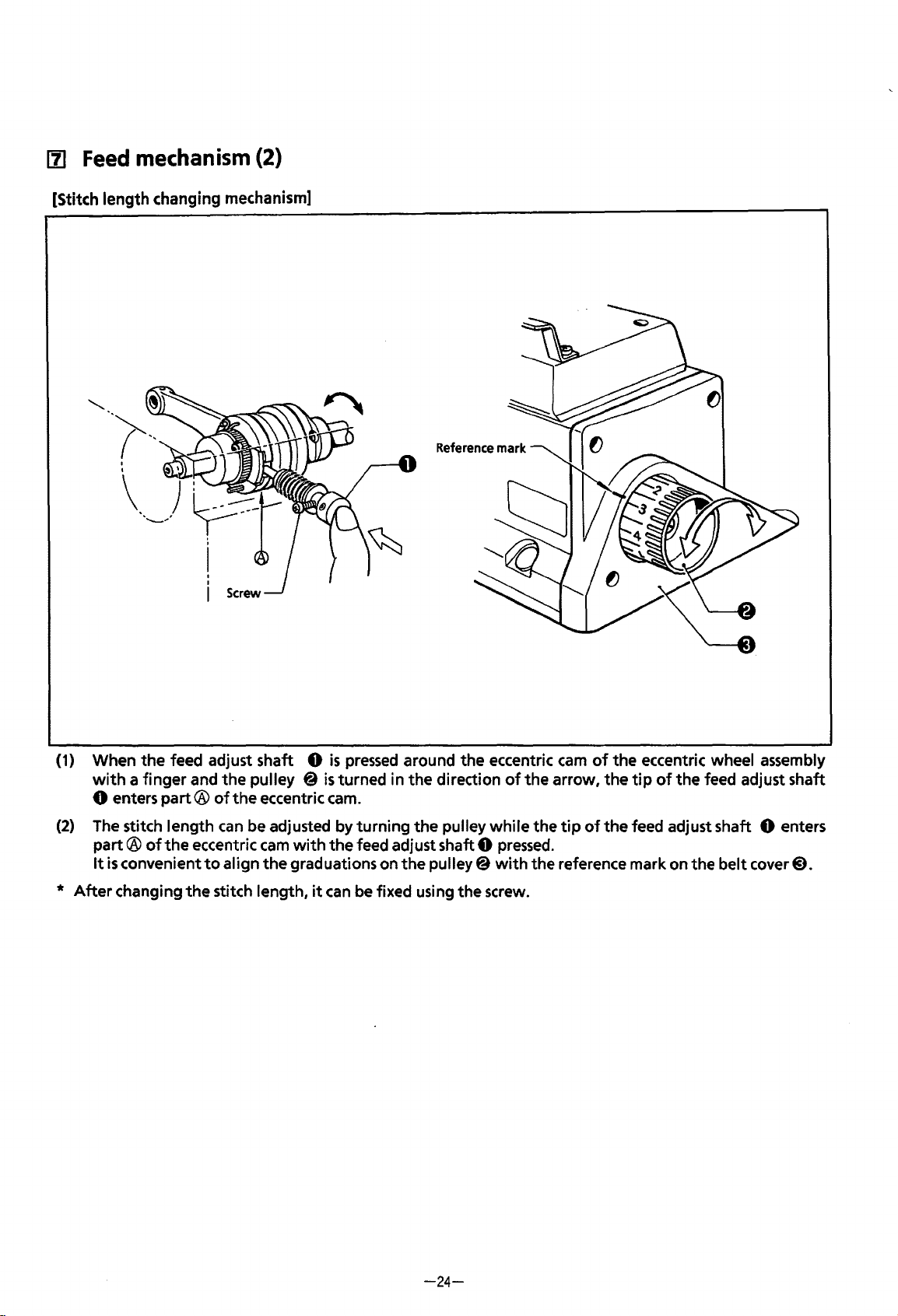

111

Feed

mechanism

(2)

[Stitch length changing mechanism]

(1) When

with

a finger and

0 enters

(2)

The stitch length

part®

It

is

convenient

*

After

changing

the

feed adjust shaft 0

the

pulley @

part®

of

the

of

the

can

eccentric

to

align

the

stitch length,

be adjusted by turning

is

pressed

is

turned in

eccentric cam.

cam

with

the

the

graduations on

it

can

Reference

around the eccentric

the

direction

the

pulley

feed adjust shaft 0

the

pulley@

be fixed using

the

mark

cam

of

the eccentric wheel assembly

of

the

arrow,

while

the

pressed.

with

the reference mark on the

screw.

tip

of

the

the

tip

of

the

feed adjust shaft

feed adjust shaft 0 enters

belt

cover@).

-24-

Page 28

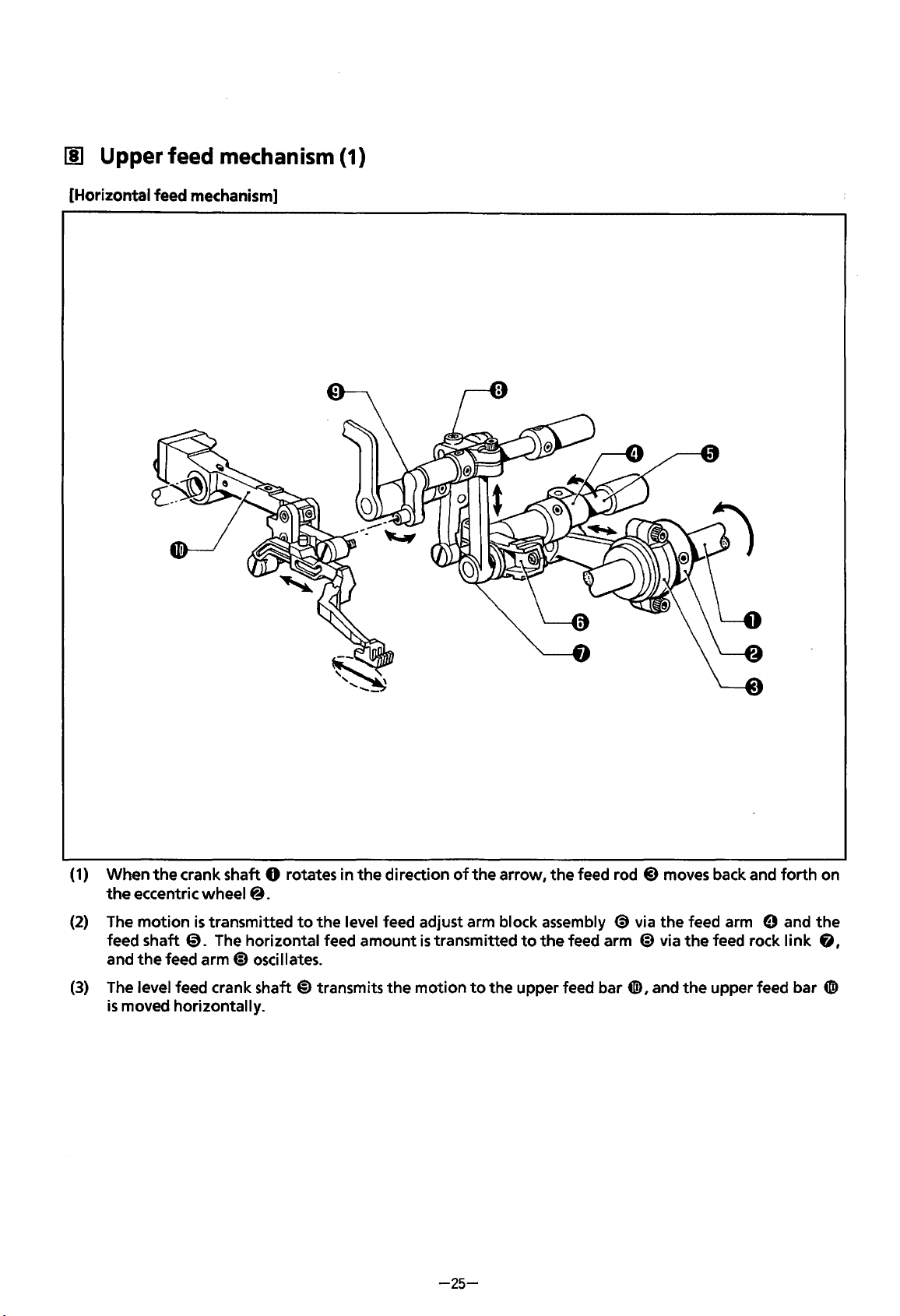

1!1

Upper feed

[Horizontal feed mechanism]

mechanism

(1)

(1)

When

the

crank shaft 0 rotates in

the

eccentric wheel

(2)

The

motion

feed shaft

and

the

(3)

The level feed crank shaft

is

moved horizontally.

is

0.

feed

transmitted

arm@

@.

to

The horizontal feed

oscillates.

@)

the

direction

the

level feed adjust arm block assembly

amount

transmits

the

of

the

is

transmitted

motion

to

-25-

arrow, the feed rod

to

the upper feed bar

the

@)

moves back and

(9

via the feed arm e and

feed arm @ via

G!>,

and

the

feed rock I

the

upper feed bar

forth

ink

on

the

fj,

G!>

Page 29

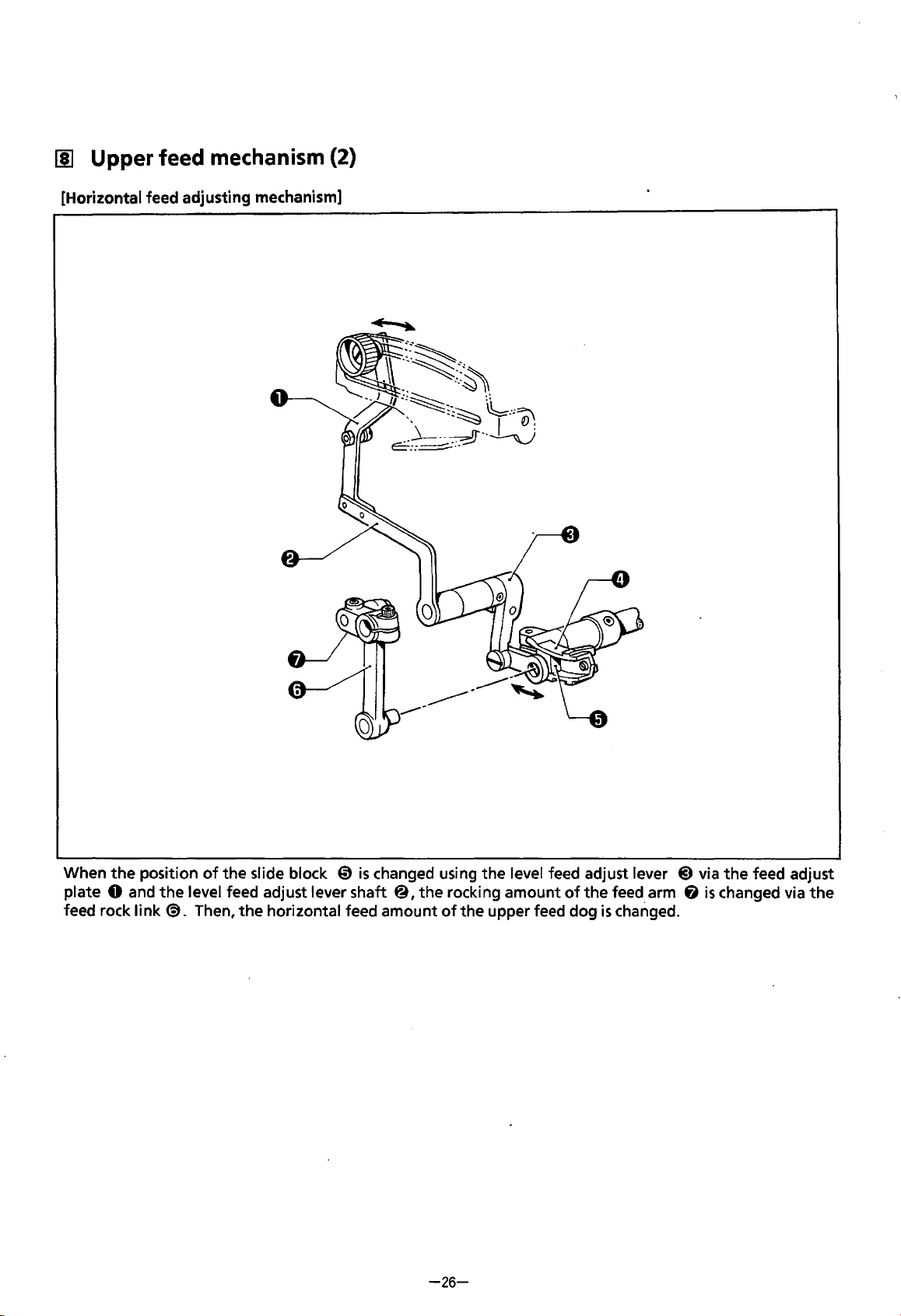

[I]

Upper feed mechanism (2)

[Horizontal feed adjusting mechanism]

the

When

plate

0 and

feed rock

position

link@.

of

the

slide block 0

the

level feed adjust lever shaft

Then,

the

horizontal feed amount

is

changed using

@,the

-26-

the

level feed adjust lever

rocking amount

of

the

upper feed dog

of

the

feed arm 6

is

changed.

@)

via

is

the

feed adjust

changed via

the

Page 30

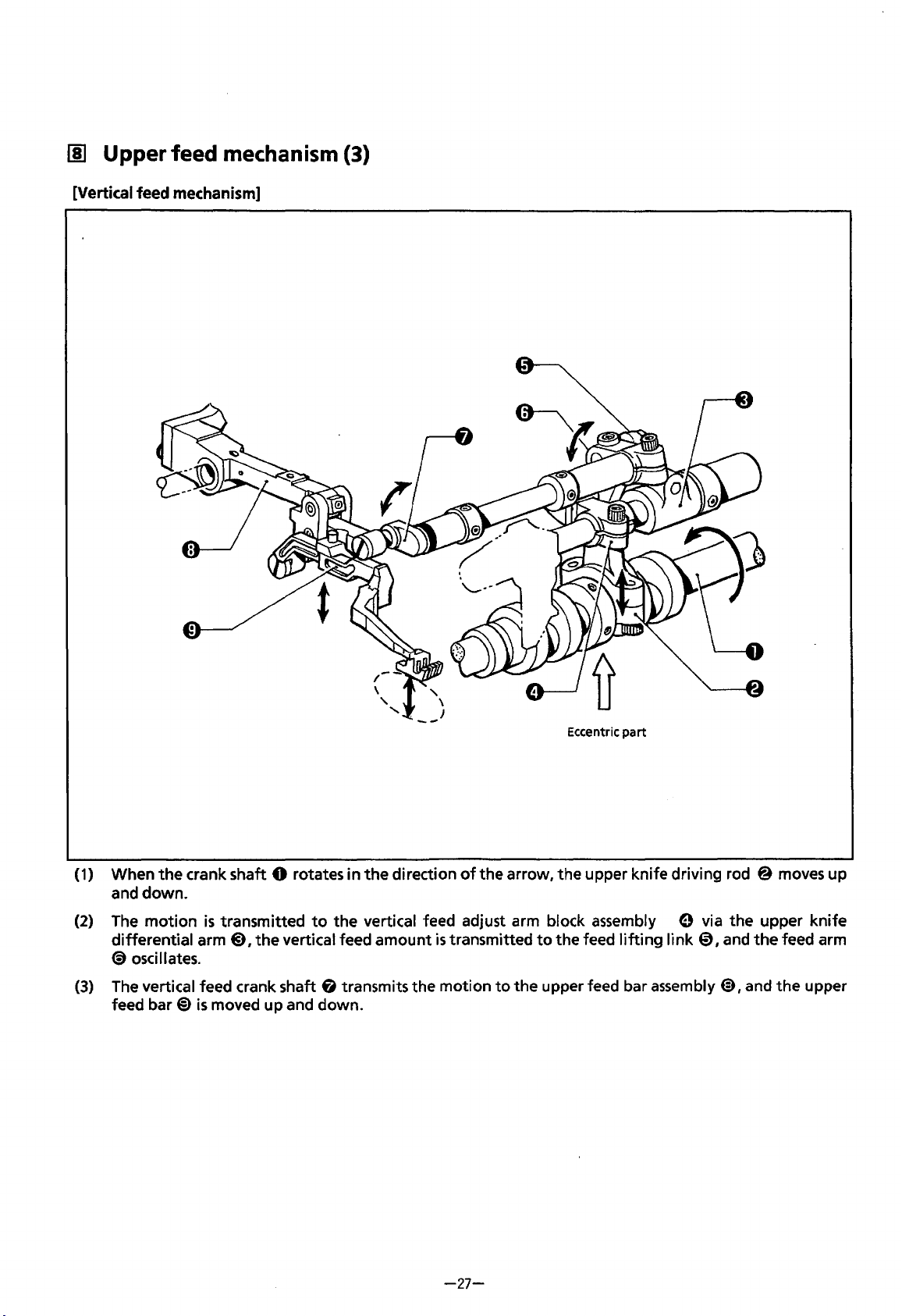

00

Upper feed mechanism {3)

[Vertical feed mechanism]

(1)

When

and down.

(2)

The

differential

<9

(3)

The

feed

the

crank shaft 0 rotates in

motion

osci

vertical feed crank shaft G transmits the motion

bar@)

II

ates.

is

transmitted

arm@) I

is

the

moved up and down.

to

vertical feed amount

the

direction

the vertical feed adjust arm block assembly 0 via the upper knife

of

is

transmitted

Eccentric

the arrow, the upper knife driving rod @ moves up

to

the feed

to

the upper feed bar assembly @),and

part

lifting

link@) I and

the

the

feed arm

upper

-27-

Page 31

[I]

Upper feed

[Vertical feed adjusting mechanism]

mechanism

{4)

the

(UL)

position

0,

When

shaft

horizontal feed

of

the

rocking

amount

the

slide block 0

amount

of

the

is

changed using

of

the

feed arm (§}is changed via

upper feed dog

is

changed.

the

vertical feed adjust lever @ via adjust lever

the

feed

lifting

link

0.

Then,

the

-28-

Page 32

[II

Lubrication

-29-

Page 33

c

DISASSEMBLY)

[II Covers

NOTE:

Drain

the

oil

from

the

pump by

turning

the

pulley a

I

®

I

few

times before

remo-ooing

--~

the

cover.

(

1)

Remove

(2)

Remove

(3)

Remove

(4)

Loosen

(5)

Remove

(6)

Loosen

(7)

Remove

(8)

Remove

(9)

Remove

(1

0)

Remove

(11) Remove

(12)

Remove

(13) Remove

(14) Remove

the

three screws and

the

four

bolts and

the

four

screws and

the

two

screws, and remove

the

presser arm assembly 0 from

the

set screw, and remove

the

two

screws, and

the

two

screws and

the

six screws,

the

two

screws, and

the

four

screws, and

the

two

screws, and

the

three

screws, and

the

six screws,

the

the

the

the

the

the

feed bar cover@), and

the

the

the

the

the

cover

belt

cover

0.

oi I reservoir@.

top

cover@).

the

face plate cover e by sliding

the

needle plate.

the

cloth plate along

cloth guide

cloth guide set plate@).

eccentric wheel cover

frame side cover G).

front

front

for

feed mechanism

cover

cover

6.

the

(L)

guide~.

(L)

assembly@) by sliding

-30-

with

the

packing.

4Il>.

(B)

4D,

and

cloth plate (lower)@).

the

it

to

the

it

to

the

packing.

front.

front.

Page 34

~

Presser

foot

mechanism

(V61

(V711

I

V91

V721

I V92)

V81

V821 V91

1

1

V92)

(

1)

(2)

Loosen

Remove

the

screw, and remove

the

screw, and

the

the

upper feed dog

presser

foot

0.

@.

(This

step

is

for

overlock sewing machine.)

(3)

Loosen

(4)

Remove

remove the presser bar

(5)

Remove

(6)

Remove

the

bolt

for

the

presser bar I

the stud screw, and

lifter

the

two

screws, and

the

screws, the thread guide pipe G, and the looper thread guide

ifter

arm

the

presser bar

lever@).

the

lever adjust plate@.

@),

and remove the

lifter

link from the

sewing machine only).

-31-

only adjustable

presser

arm shaft·

presser

foot

top

and bottom feed

0.

lifter

lever

€l

(for

the safety stitch

@).

Then,

Page 35

~

Knife

mechanism

(1)

(2)

(3)

(4)

Remove

Remove

Remove

Loosen

the

screw and

the

screw,

the

bolt, the lower

the

screw, and remove

the

the

upper knife

upper knife holder@, and the nut.

knife@

the

0.

I and the

lower knife holder (D and

lower

-32-

knife

presser

the

e.

spring

@).

Page 36

III Under looper

mechanism

(1)

Loosen

(2) Remove

(3)

Remove

(4) Remove

(5)

Loosen

from

the

(6)

Remove

the

set screws

the

two

the

screw, under looper thread guide

the

screw and looper thread take-up

the

screw

under looper shaft & .

the

movable needle guard from

of

the

screws and

of

the

movable needle guard, and

needle clamp

the

needle plate@).

0,

and remove

(L)

e I and

(L)

<9.

the

under looper holder@).

the

the

the

bolt, and remove

needles@.

under looper

0.

the

under looper holder

@)

-33-

Page 37

~

Over

looper

mechanism

(1)

Remove

(2)

Loosen

looper

(3)

Remove

(4)

Loosen

(5)

(6)

Remove

NOTE:

Loosen

the

three screws and the thread guide bracket

the

screw, and remove over looper thread take-up

thread take-up

the

five screws,

the

screw, and remove

the

bolt

for

the

two

The guide bush positioning plate

unless

it

is

necessary.

(R) 0 will

the

the

over looper arm

screws,

the

come off.)

inside cover@), and

the

over looper@) from

over looper mechanism assembly

{I)

0.

(R)

@)

from

the

looper thread guide

the

over looper holder & .

@).

4Ii>

from

has

already been adjusted before shipping.

-34-

the

over looper shaft @. (Under

(9.

the

over looper shaft@.

Do

not

remove

it

Page 38

(§]

Double

chain

stitch

looper

mechanism

(V61,

V91,

V92)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Remove

Remove

Remove

Remove

(F)@).

Loosen

Remove

Loosen

the

bolt,

the

main feed dog

the

screw,

the

screw and

the

screw, chain stitch needle guard

the

bolt, and remove the chain stitch looper holder 0 from the longitudinal feed shaft@).

the

stud screw and the thread handler

the

two

set

the

chain stitch looper@ from the chain stitch looper holder

the

felt

screws,

and remove the thread take-up assembly

0,

and the differential feed

support assembly@.

(B)

@,needle guard

bracket~.

-35-

dog@.

(F)

6,

tD.

e.

and chain stitch needle guard

Page 39

11]

Needle

bar

mechanism

(1)

Remove

(2)

Loosen

(3)

Remove

(4)

Remove

lifting

(5) Loosen

needle bar clamp assembly

the

needle

the

set screw, and remove

the

screw 0

the

oil cap

it

from above.

the

bolts

bar@

<9,

for

by

turning

the

of

needle bar bush (U)

and loosen

the

needle balance

4D

along

the

needle clamp 0 in the direction

needle thread holder@) from the needle

9.

the

screw

of

@)

and

with

the needle shaft

the needle bar clamp

the

needle driving crank rod assembly

4D).

fj.

of

the arrow.

bar@.

Remove

the

needle bar @ by

@).

Remove

the

-36-

Page 40

[II

Feed

mechanism

I

)

®'

~

(1)

Loosen

(2)

Remove

(3)

Tilt

of

(4)

Return

machine head, and

(5)

Remove

only).

(6)

Loosen

(7)

Tilt

shafteD.

*

the

set screw

the

two

the

machine head until

the

set collar@.

the

machine head

the

two

the

bolts

the

machine head until

After

the

feed shaft

0,

and remove the set screw knob@.

bolts, and

Remove

the

oil

screws

for

and the longitudinal feed arm stopper@) (for the safety stitch sewing machine

the

feed arm assembly

CD

the

differential stitch control plate@).

it

stops.

the differential feed adjust lever(!).

to

cap@}

it

is

removed, return the machine head

Loosen

its original position.

on the machine side.

stops.

4!0,

Loosen

the

the

-37-

bolt

the

set

of

the differential link lever

Remove

differential feed arm

screw

of

the oil

the set collar

to

cap

& on the rear side

4D,

and

its original position.

e,

and

the

main feed arm

@,

and

the

set

screws

of

the

4).

remove the feed

Page 41

[I] Upper feed mechanism (1)

[Horizontal feed]

~

-~

"'

---"', .

Jf!f:::r~d~r

Stud screw J assembly

(

1)

Remove

(2)

Loosen

(3)

Remove

(4)

Remove the

(5)

Loosen

(6)

Remove

(7)

Loosen

the

Remove

the

the

set screw

the

the

set screw, and remove upper feed bar guide

the

the

feed arm

the

spring

two

two

stud screw

set screws

level

0.

screws and

screws and

@).

fee~

knob@,

the

the

of

the

for

the

crank shaft

and remove the set

level feed length control plate@).

feed adjust plate e from

level feed crank shaft@). (The upper feed bar assembly

two

set collars attached

@).

screw@)

(L)

to

from

the

feed adjust plate

the

level feed adjust lever shaft@).

6.

the

level feed crank shaft @),and

e.

will

come

the

off.)

bolt

of

-38-

Page 42

[j] Upper feed mechanism (2)

[Vertical feed]

(

1)

Loosen

(2)

Remove

(3)

Loosen

vertical feed adjust lever(!). Remove adjust lever shaft

(4)

Loosen

(5)

Remove

{6)

Loosen

the

set screw

the

two

the

set screw

the

adjust screw

the

screw and silicone

the

set screw, and remove upper feed bar guide

0,

and remove

screws and

for

the

6,

the

set screw

the

vertical feed length control plate@.

set collar 0 attached

and remove

tank

it

along

assembly

with

(U)

knob@.

to

(U

the

~.

Setscrew

adjust lever shaft

L)

0.

spring.

(R)@).

(U