Brother BAS-760 Instruction Manual

AUTOMATIC POCKET SETTER

brother:

INSTRUCTION

MANUAL

Ir

f

(

NAMES

(

NOTES

OF

ON

THE

PART^

THE

CONTROL

BOX

AND

CONTENTS

THE

FOOT-SWITCHE^^

^

^

(

INSTALLATION

Q] Installationofthe

[U

Removalofthe

[H Installationof

S Installationofthe

[S]

Connectionofthe

H]

Connection

[2l Positioning of

m Installation

(

LUBRICATION

(

CORRECTOPERATIoIT)

Q]

Needle

[H Upperthreading 10

[U

Bobbin

S Bobbinthreadwinding

[U

Thread

attachment

casethreading

tension

)

machine

fixing

the

spoolstand 6

control

foot-switch

ofthe

air

the

front supporter 7

ofthe

folding group assembly 8

table

boltsfrom

box

hose

the

machine 5

connector

) ®

5

5

6

6

7

10

11

11

12

(

SEWING

Q] Preparationfor sewing 13

[2]

m Emergencystop 22

[4]

(

OPERATION

[II

[H

m Programmerconnection 25

)

Sewing 16

Testoperation 23

OF

THE

Key

switchesand

Command

PROGRAMMER

the

displays 24

list 25

^

24

(

PROGRAMMING

D] Preliminaryprocedure 26

[2]

Programming a pattern one stitchata time 27

[U Programming a pattern containing numerous straight lines 27

(U Programming a skipped startsewing 29

[H Programming a pattern byemploying

[H Programming a pattern bytracing

[7]

Programming bar tacking 33

m Partial low speed 34

HI Exampleof program 35

Go]

Noteswhen programming 37

03 Erroneouscommand keyoperation 37

011

Datastorage on a floppy disk 38

(

PROGRAM

PROCEDURES

MODIFICATION

^

)

the

smoothing operation 30

the

design 32

^6

39

G] Partiallyrevising a pattern due to a design change:

[D Cancelling

HI

Cancelling the initialsewingstitchina programmedstitch pattern and reprogramming a new

initial

(U Adding a sewing operation before an initial sewing stitch

in a

programmed

Hi Reprogramming a shunting point before

in a

programmed

m Shiftinga shunting point from point Ato

G] Cancellingshunting pointA 42

m Parallel-shifting a programmed stitch pattern 43

[D Cancellingpoints7and 8 after locating an error 44

(

STANDARD

D] Needle-bar heightadjustment 45

m Needleand rotary hook timing 45

[D Presserfoot height adjustment 46

Si

Removalofthe

[5]

Stacker position adjustment 47

m Stacker roller adjustment 48

[7]

Sewing clamp assembly number selection 49

the

initialsewingstitchina programmedstitch pattern 40

sewing

stitch

stitch

stitch

pattern

pattern

ADJUSTMENTS}

fixed

knife

and

the

the

points

movable

knife 46

5,6

and 7to

initialsewing stitch

5',6'and

7'

39

40

41

41

42

(

USING

FLOPPY

THE

DISK

DIP

SWITCHES

USE

AND

)

CARE

)

50

52

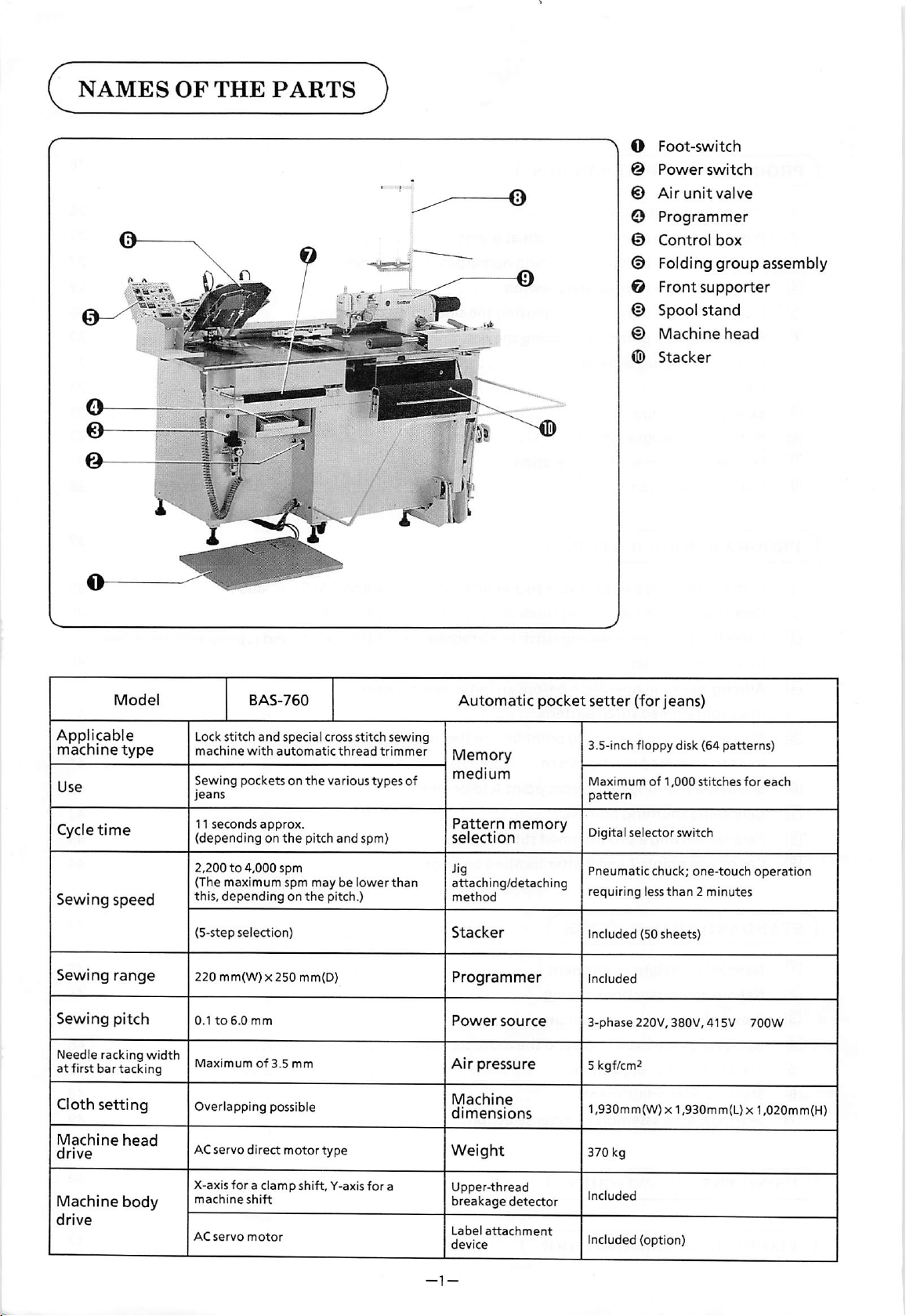

NAMES

OF

THE

PARTS

O

Foot-switch

@

Power

©

Air

O

Programmer

©

Control

unit

switch

valve

box

© Folding group assembly

© Front

supporter

© Spool stand

©

©

Machine

Stacker

head

Model

Applicable

machine

Use

Cycle

Sewing

Sewing

Sewing

Needle

at

first

Cloth

Machine

drive

type

time

speed

range

pitch

racking

bar

tacking

setting

head

width

BAS-760

H

Lockstitch

and

special cross stitchsewing

machine with automatic thread trimmer '

Sewing pockets on

jeans

11

seconds

(depending on

2,200

to4,000

(The maximum spm may be

this,

dependingonthe

(5-step

selection)

220

mm(W)x250

0.1to6.0

Maximumof3.5

Overlapping possible

AC

servo

mm

direct

approx.

the

spm

motor

the

various

pitch and spm)

pitch.)

mm{D)

mm

type

types

lowerthan

Automatic

1

Memory

of

medium

Pattern

selection

Jig

attaching/detaching

method

Stacker

Programmer

Power

Air

Machine

dimensions

Weight

memory

source

pressure

pocket

setter

(for

jeans)

3.5-inch

floppy

^

Maximumof1,000

pattern

Digital selectorswitch

Pneumatic chuck;

requiring less

Included

Included

3-phase

5 kgf/cm2

1,930mm(W)x1,930mm(L)x1,020mm(H)

370

kg

disk (64

than2minutes

(50

sheets)

220V, 380V, 415V

patterns)

stitches

one-touch

for

each

operation

700W

Machine

drive

body

X-axis for a

machine

AC

servo

shift

motor

clamp

shift. Y-axis for a

upper-thread

breakage

Label

attachment

device

detector

Included

Included

(option)

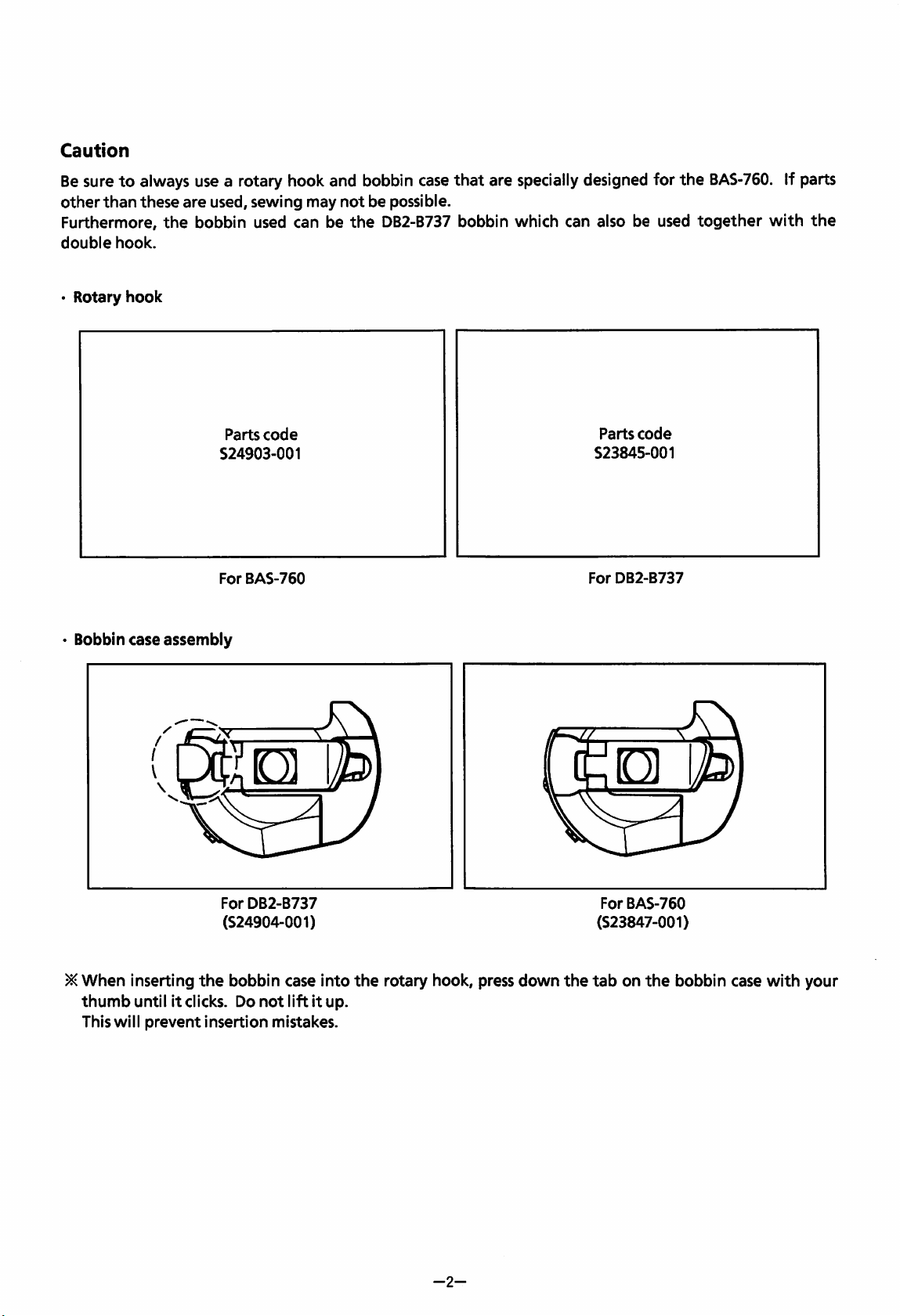

Caution

Besure to always use a rotary hook and bobbin case

other

than

these

are

used,

Furthermore,

double

Rotary

hook.

hook

sewing

the

bobbin used can be

Parts

S24903-001

For

BAS-760

code

may

not

be possible.

the

DB2-B737

that

are speciallydesigned for

bobbin which can also be used

Parts

code

S23845-001

For

DB2-B737

the

BAS-760.

together

If parts

with

the

Bobbin

^

When

thumb

This will

case

assembly

For

(S24904-001)

inserting

the

bobbin case

until it clicks. Do

prevent

insertion

DB2-B737

not

lift it up.

mistakes.

into

the

rotary hook, press

down

the tabonthe

For

BAS-760

(S23847-001)

bobbin case

with

your

-2-

NOTES

ON

THE

CONTROL

BOX

AND

THE

Q e Q 0

FOOT-SWITCHES

&

&

&

brother

€-K

MODE

AUT02

MANUAL

AUTOr—^LABa

STEP

FOLDER

ON'OFF

RESET

STACKER

PROG

RAM

:7a'yf-

FLOPPY

T^ktioys)-

BOBBIN

COUNTER

SET

READ

NO

S-^^BO

THR iAD MONITO I

t)oys-}

COUNTER

^!tZ57-

FOOT

DEC

PIECE

BOBBIN

ALARM

COUNTER

SPEED

FAST

CODE

CHANGE

POW

Z2±:

TEST

START

7.=t-^7IV.>0

STEP

BACK

EM-STOR

ER

4D

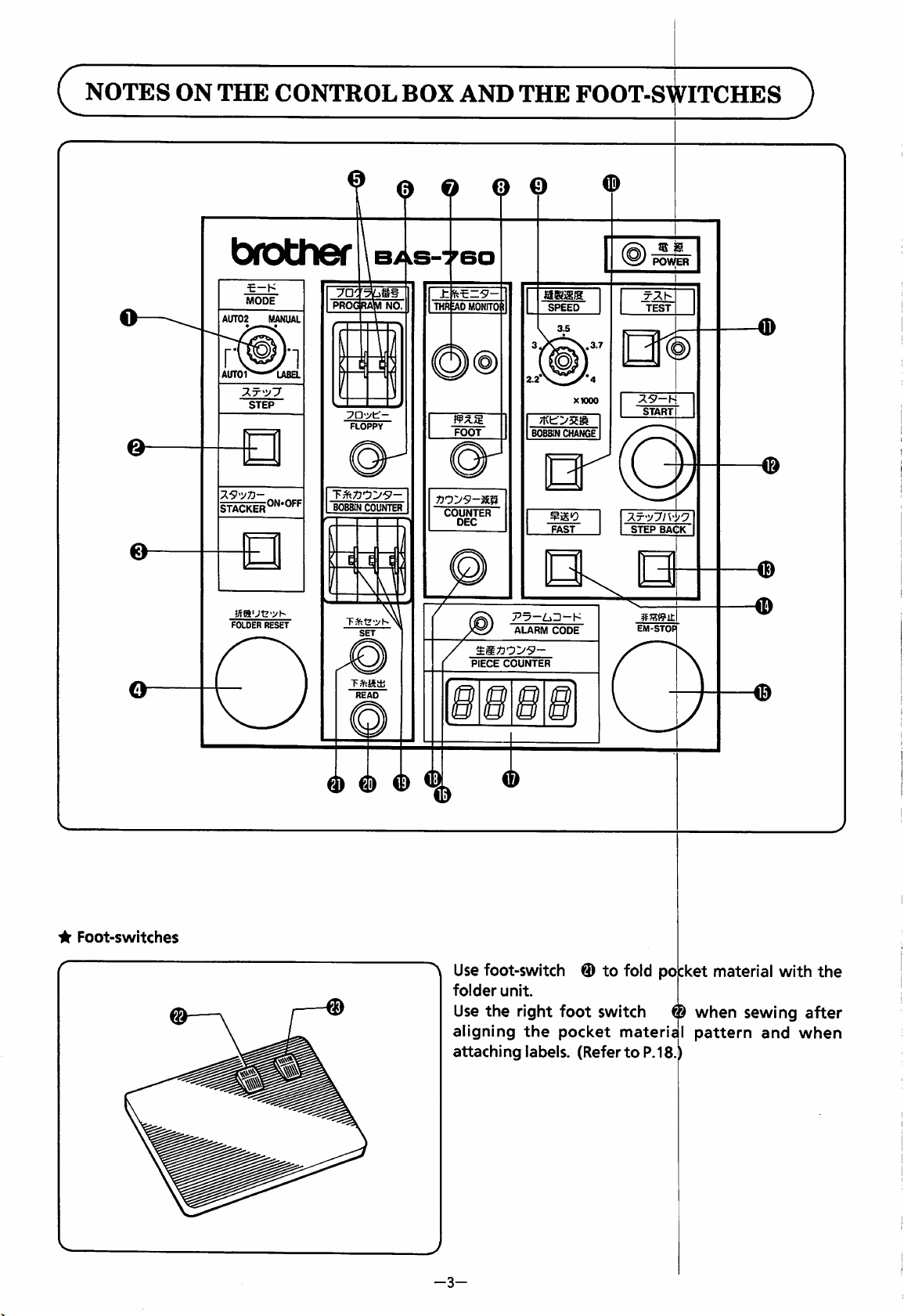

★

Foot-switches

/

® ® ® ^

Use

foot-switch

folder

aligning

Use

unit.

the

right

the

® to

foot

pocket

fold

switch

materiel

po|cket

attaching labels. (RefertoP.18.)

material with the

when

pattern

sewing

and

after

when

J

-3-

O

MODE

LABEL

MANUAL

AUT01

AUT02 The first pressonthe

@

STEP

©

STACKER

©

FOLDER

©

PROGRAM

©

FLOPPY

©

THREAD

©

FOOT

©

SPEED

©

BOBBIN

©

TEST

©

START

ON-

OFF

RESET

NO For calling a program number correspondingtothe

MONITOR

CHANGE

Pressing

foot

By

always

canbeselected.

The

monitored.

One

second presson

When

stepofthe

Press

turnitoff

By

changed

the

(for

For resetting

program

the

switch is pressed once, folding starts.

changing

attachedorthe

automatic

press on

the

MANUAL

folding actions can be monitored.

the

buttontoturn

whenastackerisnot

changing

from

mode

whereby

both

pockets).

number

Forwriting and reading programs.

Press thistolight

thread

breakage.

Forliftingand lowering the presserfoot.

The spm of

4,000

spm.

Press this buttontomove

bobbin. (U99 flash on

button

standby

and

position.

Press this buttontosee

(except during feeding). To restart sewing, repress this

light.

Pressthistorestartsewing.

(For restarting,

©

STEP

©

FAST

©

EM

©

ALARM

©

ALARM

PIECE

©

COUNTER

©

BOBBIN

©

SET

®

READ

BACK

STOP

lamp

CODE

COUNTER

COUNTER

DEC

checking

For

the

Faster feeding is available if this button is pressed in

feed

Ifthe emergencystop button ispressed, all machineactionswillstop.

This

stop

and

Necessary

number

displayed.

Each

one.

Inputthenumberof

Press

number.

Press

causes).

continuing stitches after thread breakage (reverse step-feeding while

button

while

lamp

button

is pressed).

the

will

will

time this is

to enter

(From 0to399

this button to

right

foot

the

settingofDIP

folding action

(The

procedure

the

left

foot-switch starts folding (plain

the

left

mode is selected, each time

the

setting

the

mode

the

the

foldertoset

switch

mode

right

foot-switch startsfolding.

roller movestothe

twice

switch 2-1,

where

order

order

willbethat

foot-switch

it on

when

used.

of

DIP switch 2-1,

whereby

the

new

pocket material.

enables

labels

starting

using a stacker

roller always movestothe

label

the

are

attachedinalternating

from

for

enables

the

rightoneach

setting,

mode

pocket

label

pattern

pattern

the

roller

where

attachment.)

alignment

button

after

operation

andifthe

labels

folding

material).

and

is pressed

sewing, and

right

alternating

folder. For setting a

when

writing programs.

the

lamp and

the

sewing machine can be settoupto5 stages, from 2,200

the

press

the

START

the

when

U51, US2,

button

is pressed).

the

machine will stop automaticallyata

the

machine towards you when c-hanging a

display.) After cjanging a bobbin, repress

button.

needle action when

The

machine

US3,

U60 or U99 has been displayed

will

move

the

machine is idling

buttontoout

the

backtothe

test mode (fast

come on in the case of abnormality or when the emergency

has

been

pressed.

information,

be

displayed.

presseditwill

such as

Normally

error

messagesora

the

production

production

piece

amount

decreasethe production piece counter by

piecestobe sewn into this counter.

the

piece number setatthe bobbin counter to store

canbeset.)

display

the numberof

pieces

to be sewn.

can

can

left

are

steps

be

the

one

to

be

to

step

to

this

the

after

piece

is

the

-4-

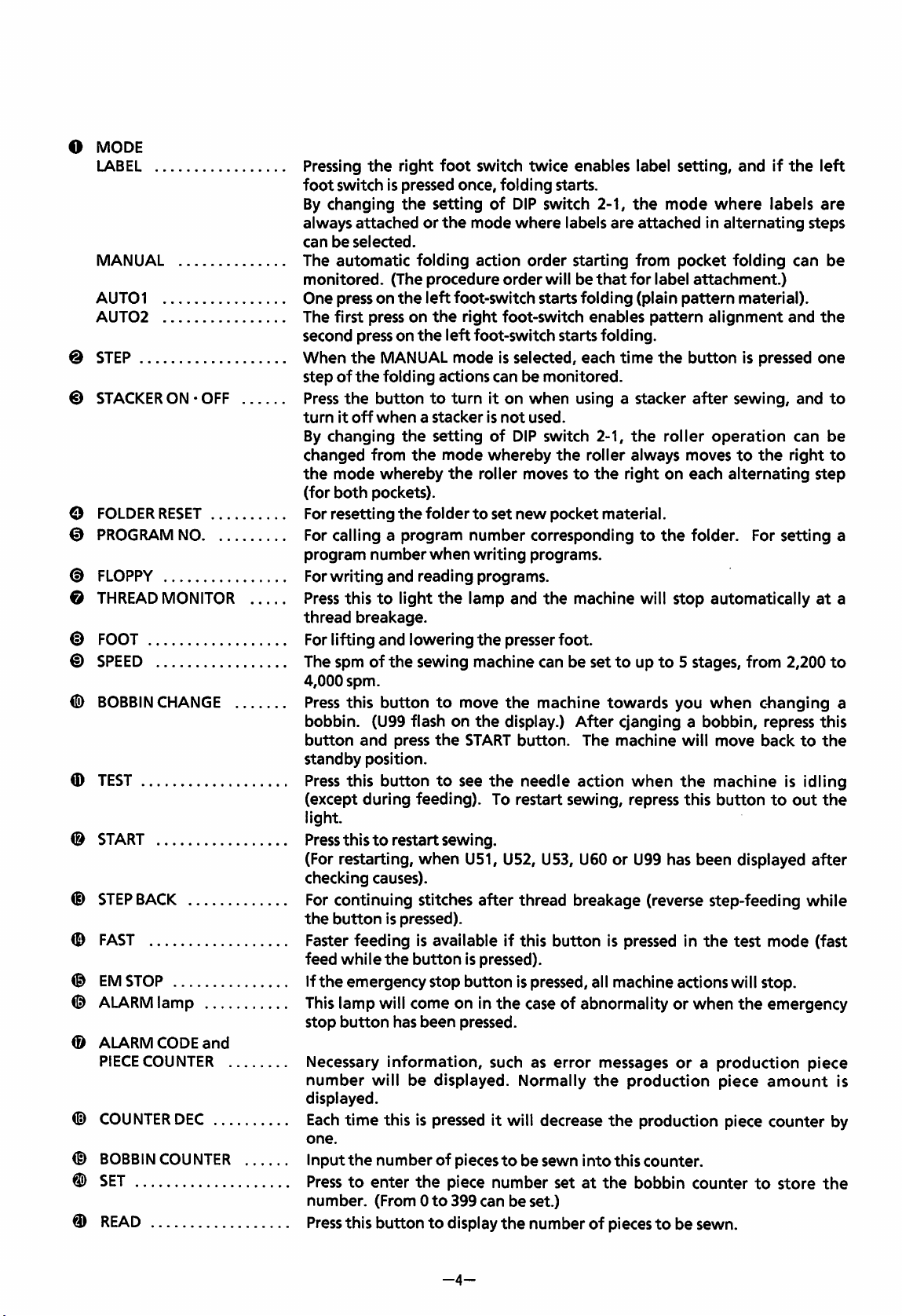

INSTALLATION

★

Supply power directly from a receptacle for

^ Be

suretopower

Q]

Installation

off

of

when

the

J

installating.

machine

the

table

machine'sexclusiveuse,

r

/A

!

/—©

\

1. Secure

2. The

To move

the

the

leveladjusters O so

remain

does

adjusters Otolevel

adjusting

casters©.

level.

table

has

eight

not

sit

well,

points.)

the

machine,

table

can be moved on its

level adjusters. If

loosen

nuts@and

the

table. (There

turn

up adjusters

that

the

turn

machine

table

the

the

are

O,

body

top

table

level

eight

and

—0

\—0

j

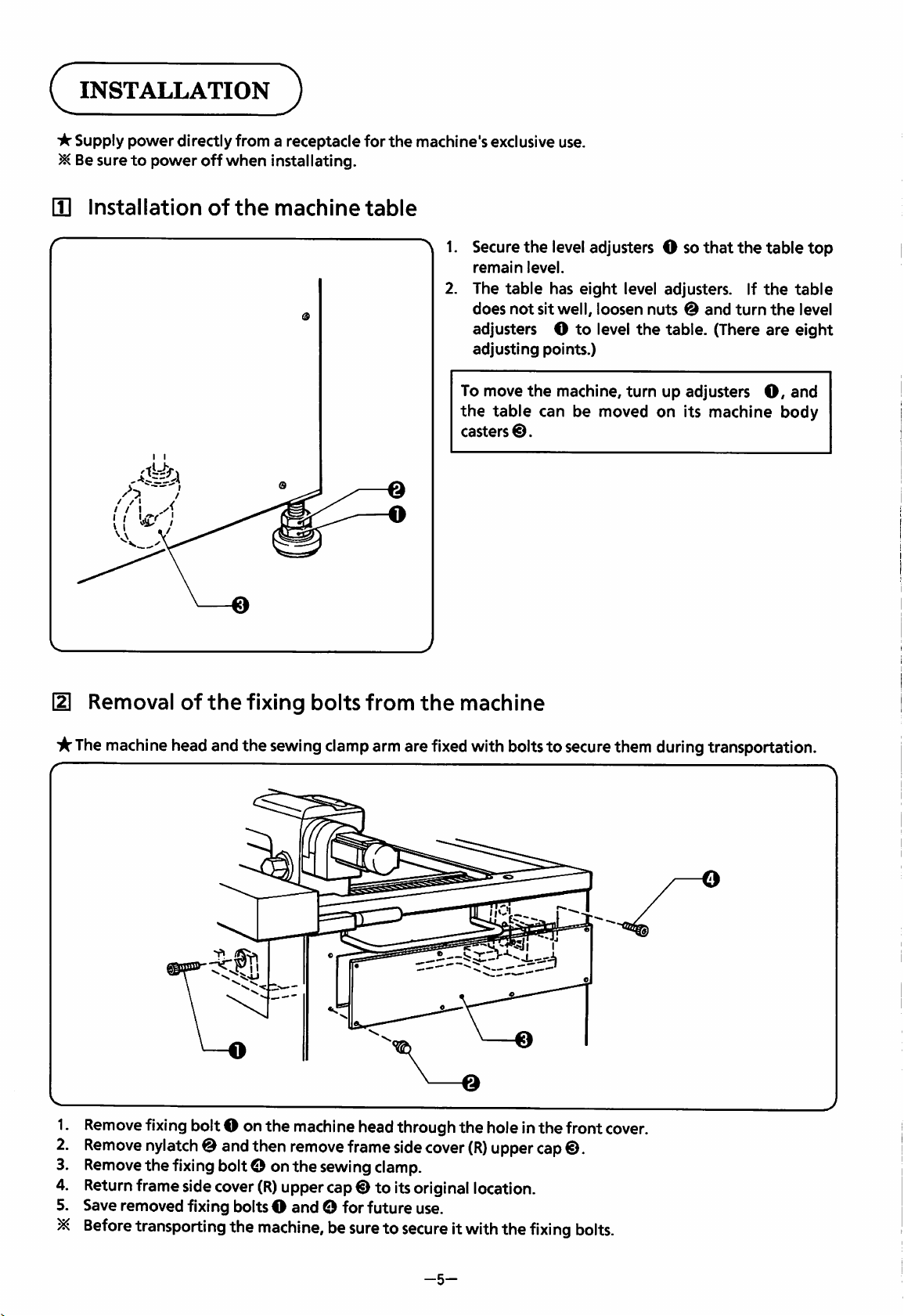

HI

Removal

★

The

machine

1.

Remove

2.

Remove

3.

Remove

4. Returnframe sidecover

5. Save removed fixing boltsO

Before

of

the

headandthe

fixing bolt O on

nylatch

the

© andthen

fixing bolt © on

transporting the

fixing

(R)

machine,besuretosecureitwith

bolts

sewing

the

machine head through the hole in

remove

the

from

clamp

sewing clamp.

arm

are

framesidecover

the

fixed

machine

with

(R)

uppercap©.

upper cap © to itsoriginal location.

and0IPor

future

use.

boltstosecure

the

front cover.

the

fixing

bolts.

them

during

transportation.

-5-

Installation

15

Installation

of

of

the

the

spool

control

stand

box

"N

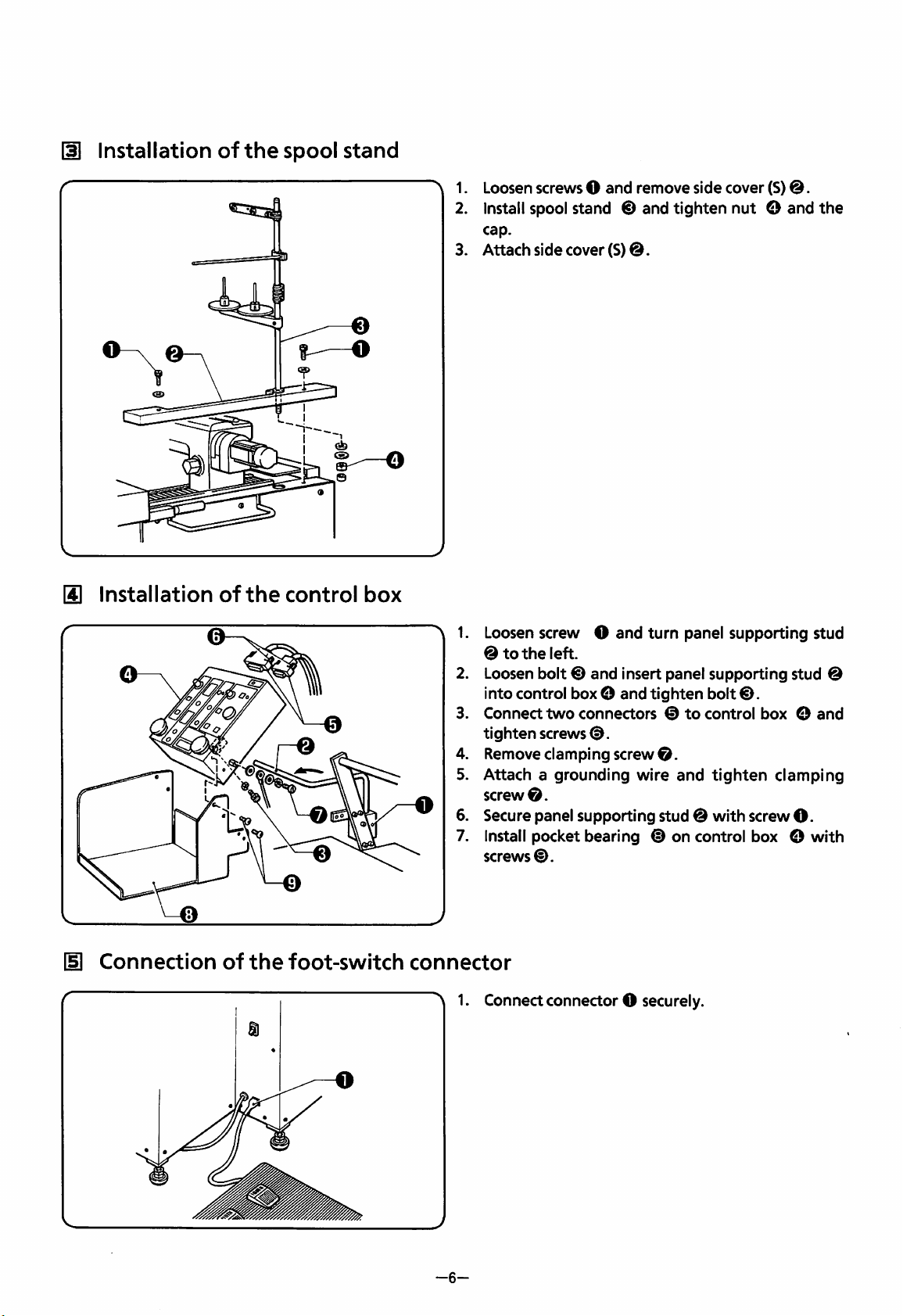

1. Loosen

screwsOand

remove

2. Installspool stand © and tighten

cap.

3.

Attach

side

cover

(S)@.

side

cover

nut

(S)

@.

O and

the

Connection

r

of

the

foot-switch

%

1. Loosenscrew O and turn panel supporting stud

2. Loosen

3.

4. Remove clamping

5. Attach a grounding wire

6. Secure panel supportingstud © with screw

7. Install pocket bearing © on control box ©

connector

@tothe

left.

bolt€)and

intocontrol box O

Connect

tighten

screw©.

screws®.

two

connectors

screws®.

insert panel supporting stud 0

and

tighten

bolt

©tocontrol

®.

box

©and

screw©.

and

tighten

clamping

O.

with

•

%

V

-6-

Connection

of

the

air

hose

I

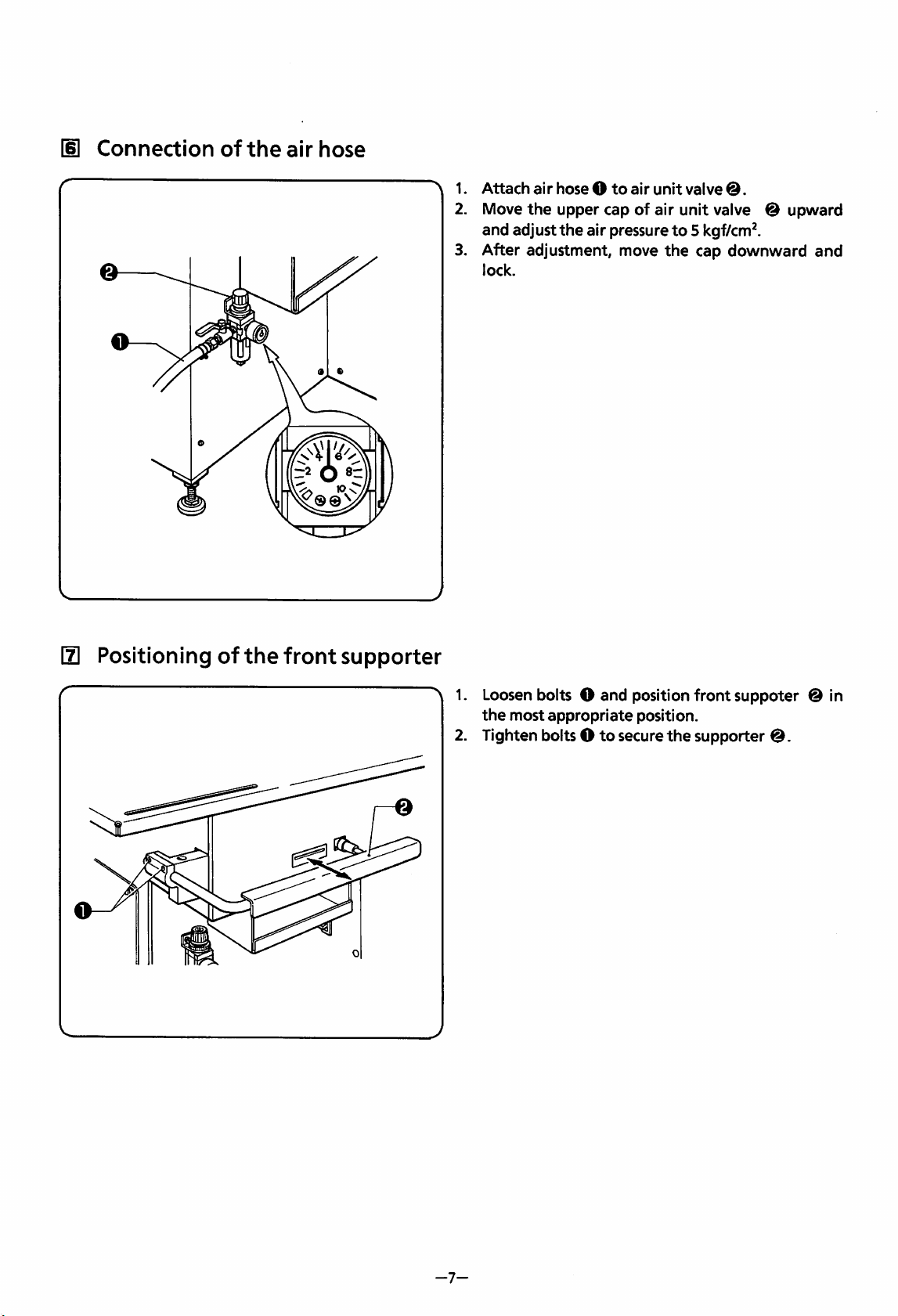

1.

Attach

2. Move

and adjust

3. After adjustment, move

lock.

air

the

hoseOto

upper

the

air

capofair

air pressureto5 kgf/cm^.

unit

valve

unit

the

cap downward

0.

valve @

upward

and

[3

Positioning

of

the

front

supporter

1. Loosen bolts O and position front suppoter @ in

the

most

appropriate

2. Tighten bolts Otosecure

position.

the

supporter @.

-7-

11

Installation

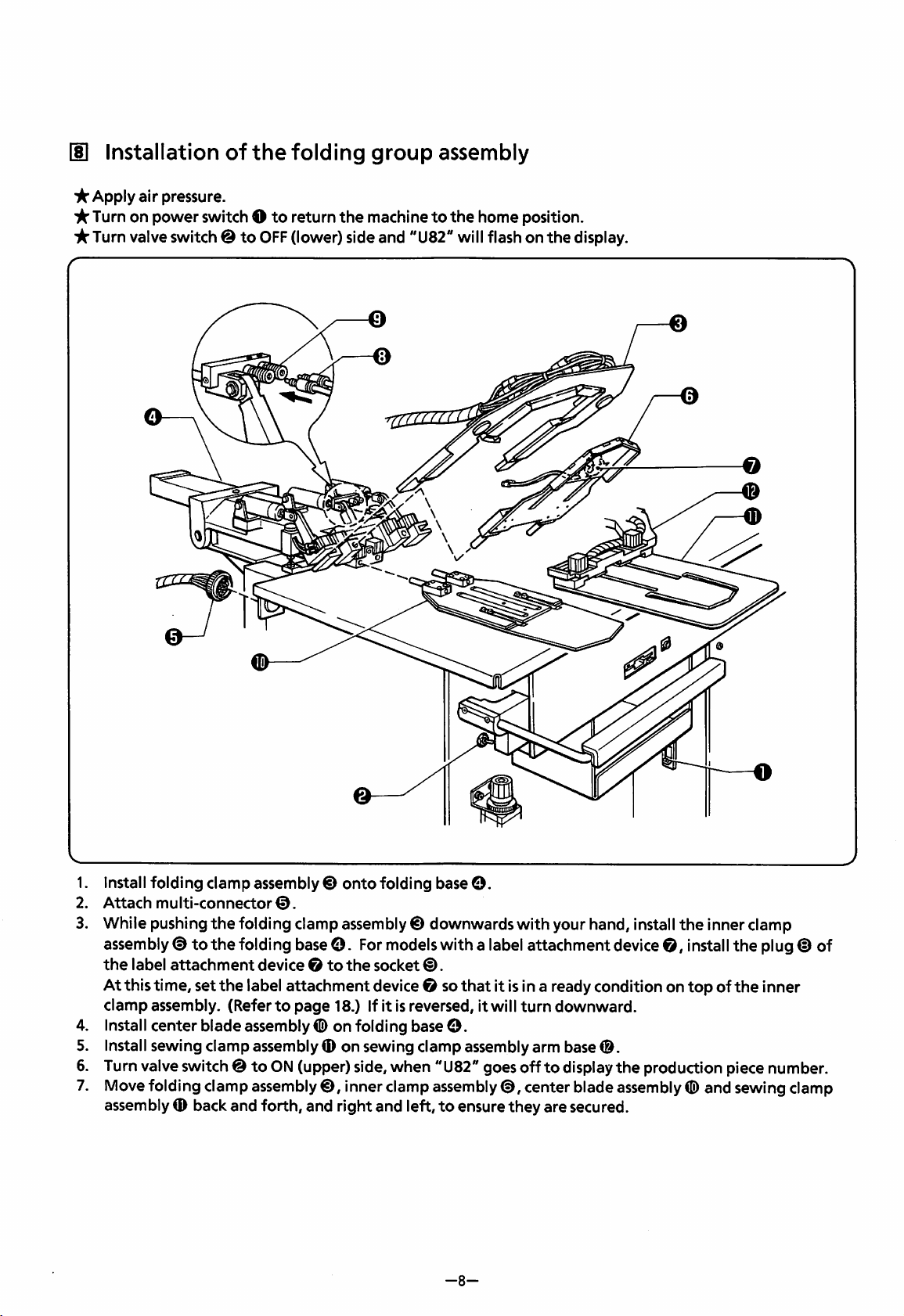

★

Applyair pressure.

★

Turnon power switchO to return

★

Turnvalveswitch @ to

of

the

OFF

folding

group

the

machineto the home position.

assembly

(lower)sideand "U82"willflashon the display.

1. Install folding clamp

2.

Attach

multi-connector©.

3. While pushing

assembly®tothe

the

label

attachment

Atthis time, set

clamp

4. Install center bladeassembly © on folding base

5. Install sewing clampassembly © on sewing clamp assembly arm base

assembly. (Refertopage

6. Turnvalveswitch ©toON

assembly©

the

folding clampassembly© downwards with your hand, install

onto

folding base

O.

folding base©. Formodelswith a labelattachment device©, install the plug© of

device©to

the

label attachmentdevice © so

(upper) side, when "U82" goes offtodisplay

the

socket

18.) If it isreversed, it will

©.

©.

that

it isina ready condition on

turn

downward.

©.

the

production piece number.

7. Movefolding clamp assembly©,inner clamp assembly®,center blade assembly® and sewing clamp

assembly © back and forth, and right and left,toensuretheyare secured.

-8-

the

innerclamp

topofthe

inner

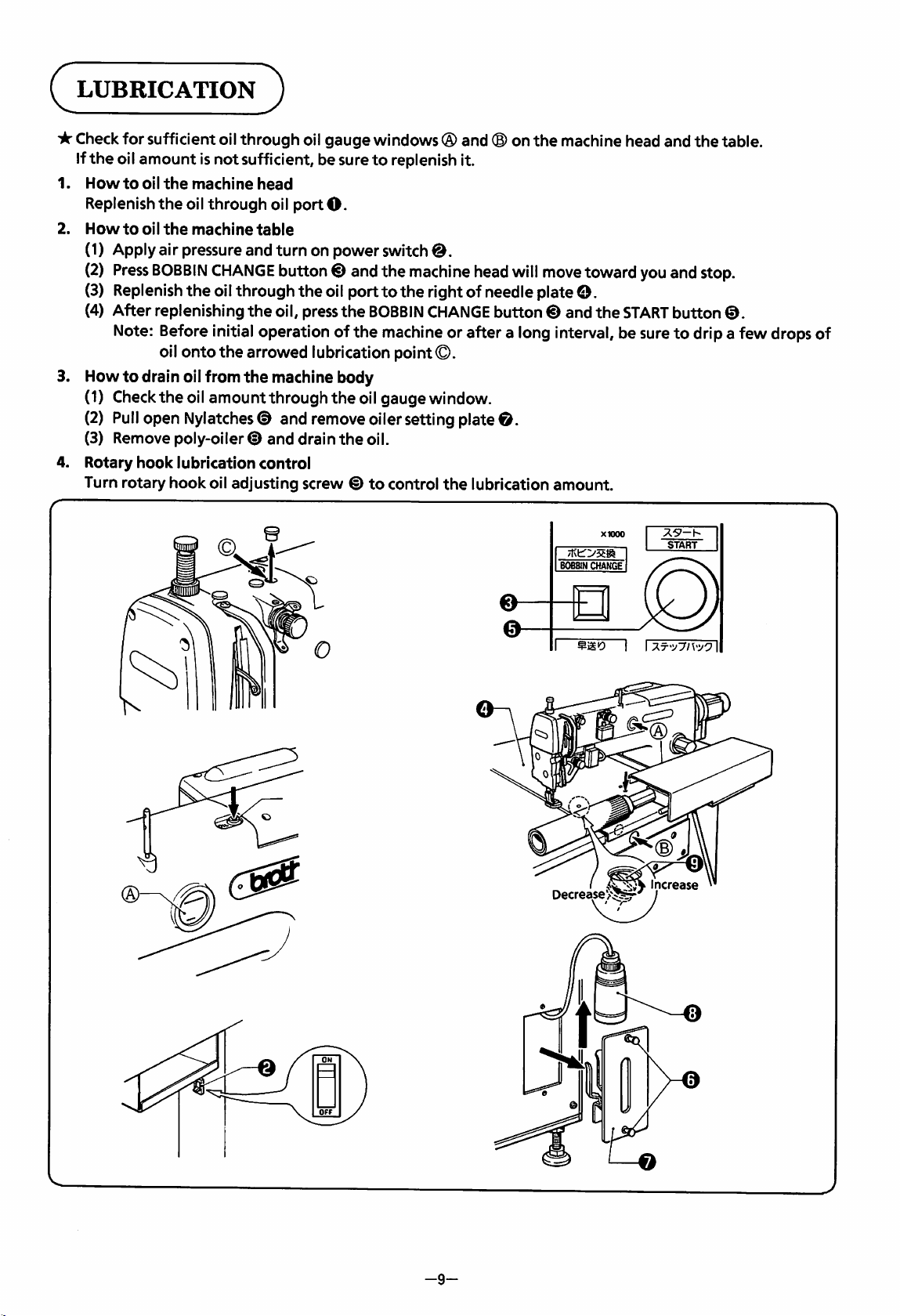

LUBRICATION

★

Checkfor sufficientoil through oil gaugewindows ® and (Don

If

the

oil

amountisnot

1.

Howtooil

Replenish

2.

Howtooil

the

the

the

machine

oil

through

machine

)

sufficient, be suretoreplenish it.

head

oil

port

O.

table

(1) Applyair pressure and turn on powerswitch

(2)

Press

BOBBIN

(3) Replenish

(4) After replenishing

CHANGE

the

oilthrough

button €) andthe machine head

the

oil porttothe right of needle plate

the

oil, press

the

BOBBIN

CHANGE

Note: Beforeinitial operation of the machine or after a long interval, be sureto drip a few drops of

oil

onto

the

3. Howtodrain oil from

(1) Check

(2)

(3) Remove poly-oiler ®

Rotary

4.

Turn

the

oilamountthroughtheoil gauge window.

Pull

open Nylatches® and remove oilersetting

hook

lubrication

rotary

hook

oil

arrowed lubrication

the

machine body

and

drain

the

control

adjusting

screw©to

oil.

point©.

control

plate©.

the

lubrication

the

machine head and

will

move

©.

button®and

amount.

toward

the

START

you

the

table.

andstop.

button

@.

BOBBIN

Decrease

xwoo

CHANGE

START

Increase

-9-

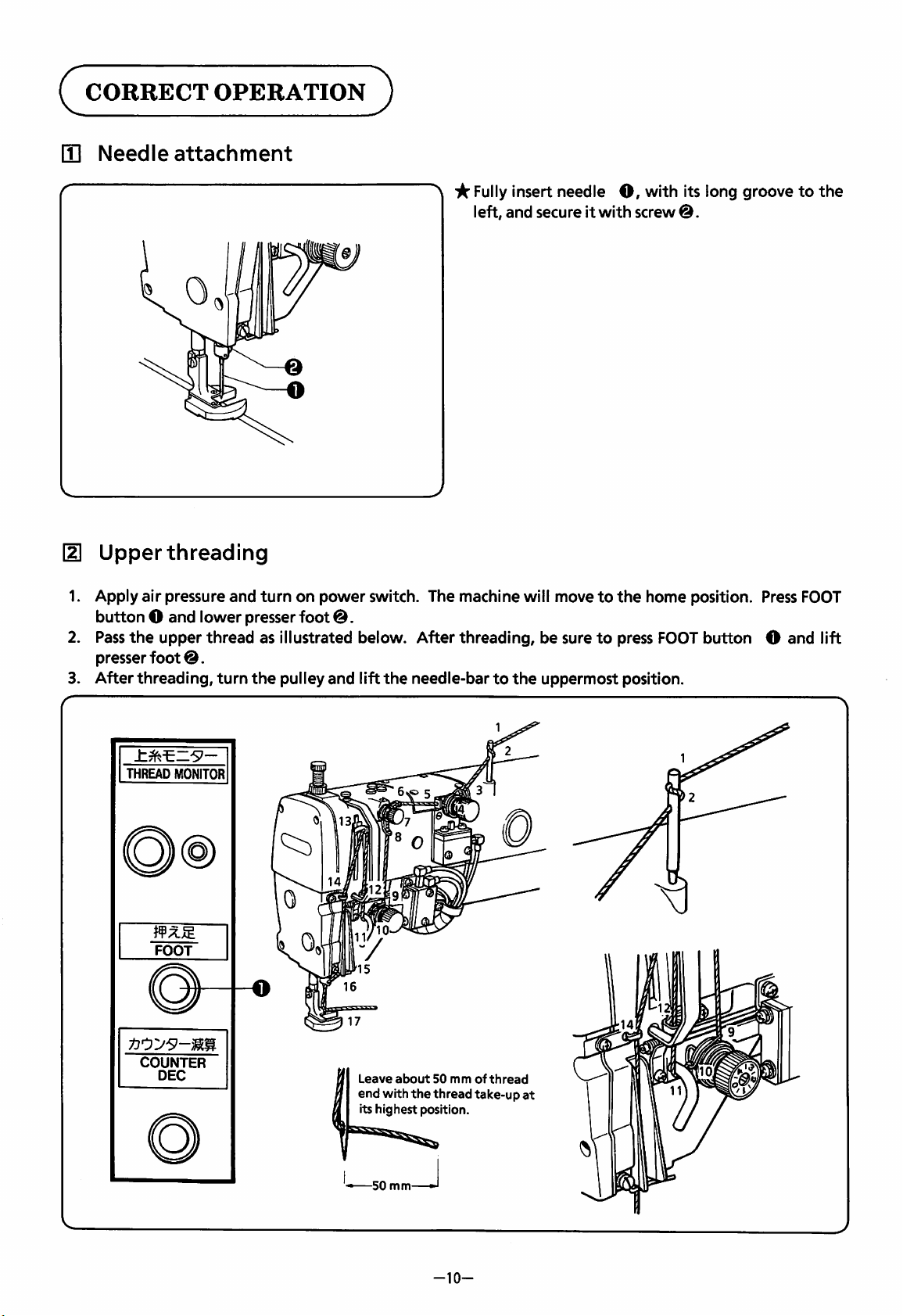

CORRECT

Q]

Needle

OPERATION

attachment

0

if

Fully

insert needle

left,

and

secureitwith

O,

with its long groove to

screw

the

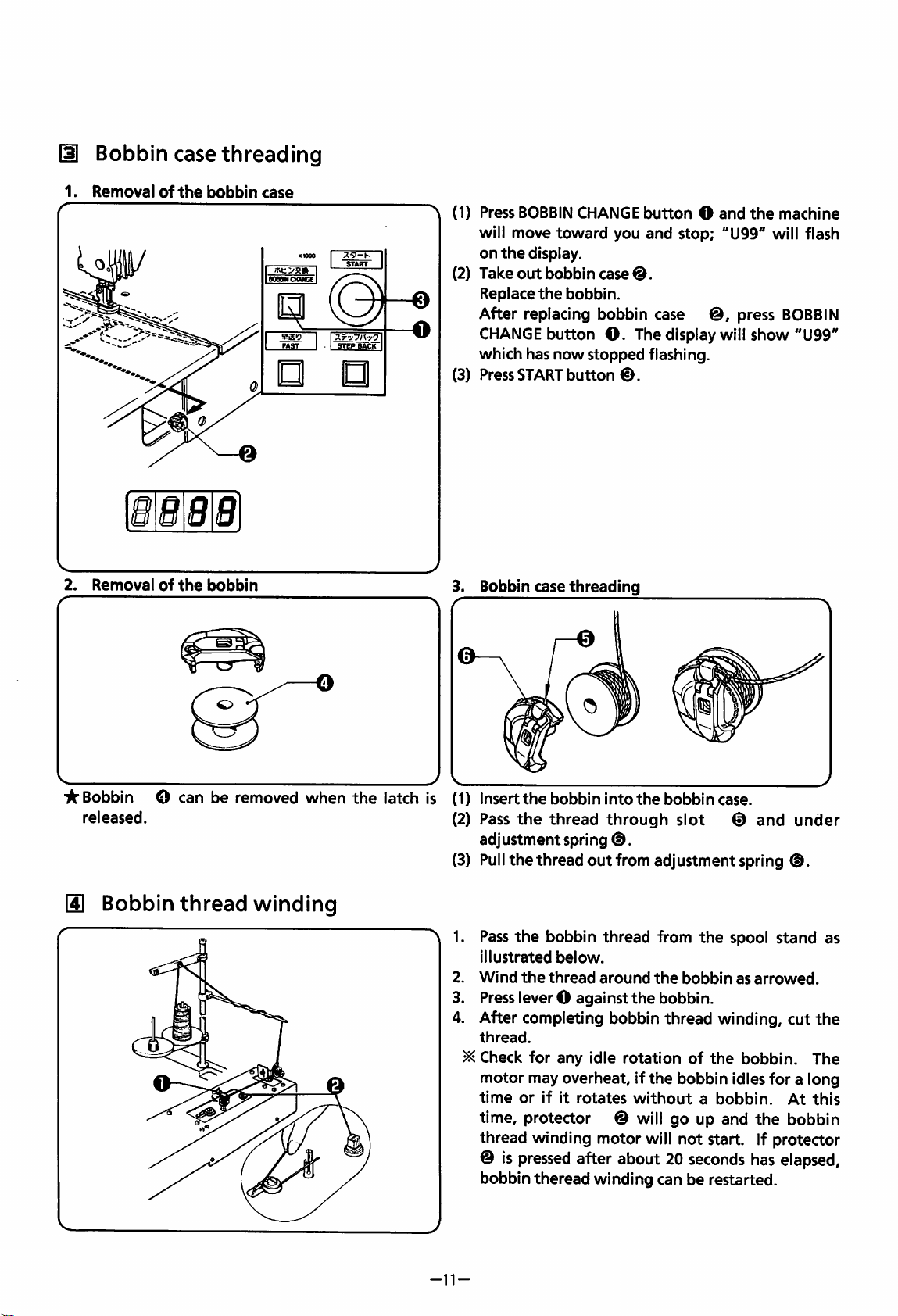

Upper

threading

1. Apply air pressure and

button

2. Pass

presser

3. After

O and lowerpresser

the

upper

thread

foot®.

threading,

THREAD

FOOT

turn

MONITOR

turn

on power switch. The machine will movetothe

foot

as illustrated below. After threading, be suretopress

the

pulley

and

lift

the

needle-bartothe

uppermost position.

home position. Press

FOOT

button

O

FOOT

and

lift

tioys-l

COUNTER

DEC

Leave

about50mmofthread

end with

its

highest

-50

mm

the

thread

position.

-10-

take-up

at

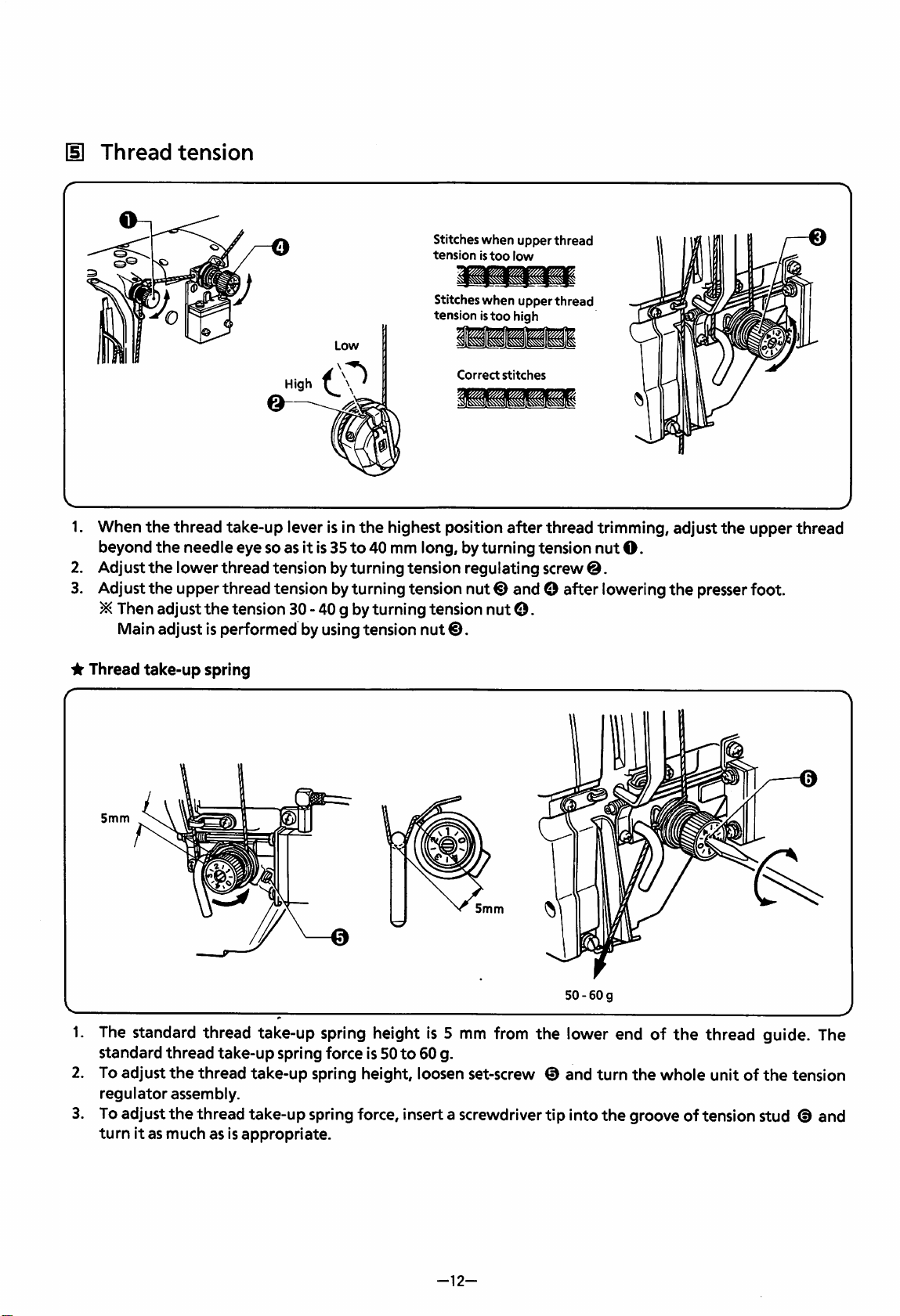

Bobbin case

1.

Removalofthe

2.

Removal

r

bobbin

B B 9 9

of

the

bobbin

threading

case

gjgO

FAST

(1) Press BOBBINCHANGE

will move

on

(2)

Take

Replace

the

display.

out

bobbin

the

toward

bobbin.

After replacing bobbin case press

I

STEP

BACK

CHANGE

which has

(3) PressSTART

3. Bobbin case

A

button

now

button

threading

stopped

button

you

and

case

@.

O.

The display will show "U99"

O

and

the

stop; "U99" will flash

flashing.

€).

machine

BOBBIN

★

Bobbin

released.

O

SI Bobbin

C ^ j

can

be

thread

—o

removed

winding

when

the

latch

V

is

(1)

Insert

the

(2) Pass

the

adjustmentspring

(3)

Pull

the

thread

Pass

the

illustrated

Wind

the

Press leverO

bobbin

thread

bobbin

below.

thread

into

the

bobbin

through

slot

©.

out

from adjustment spring

thread

around

against

the

from

the

bobbinasarrowed.

bobbin.

the

case.

@

spool

and

After completing bobbin thread winding, cut

thread.

^ Check

motor may overheat, if

time

time, protector @ will go up and

or

for

if it

any

idle

rotationofthe

rotates

the

bobbin idles for a long

without

a

bobbin.

bobbin.

the

thread winding motor will not start. If protector

© is

pressed

bobbin

after about 20

theread

seconds

haselapsed,

winding can be restarted.

under

©.

stand

At

bobbin

as

the

The

this

-11-

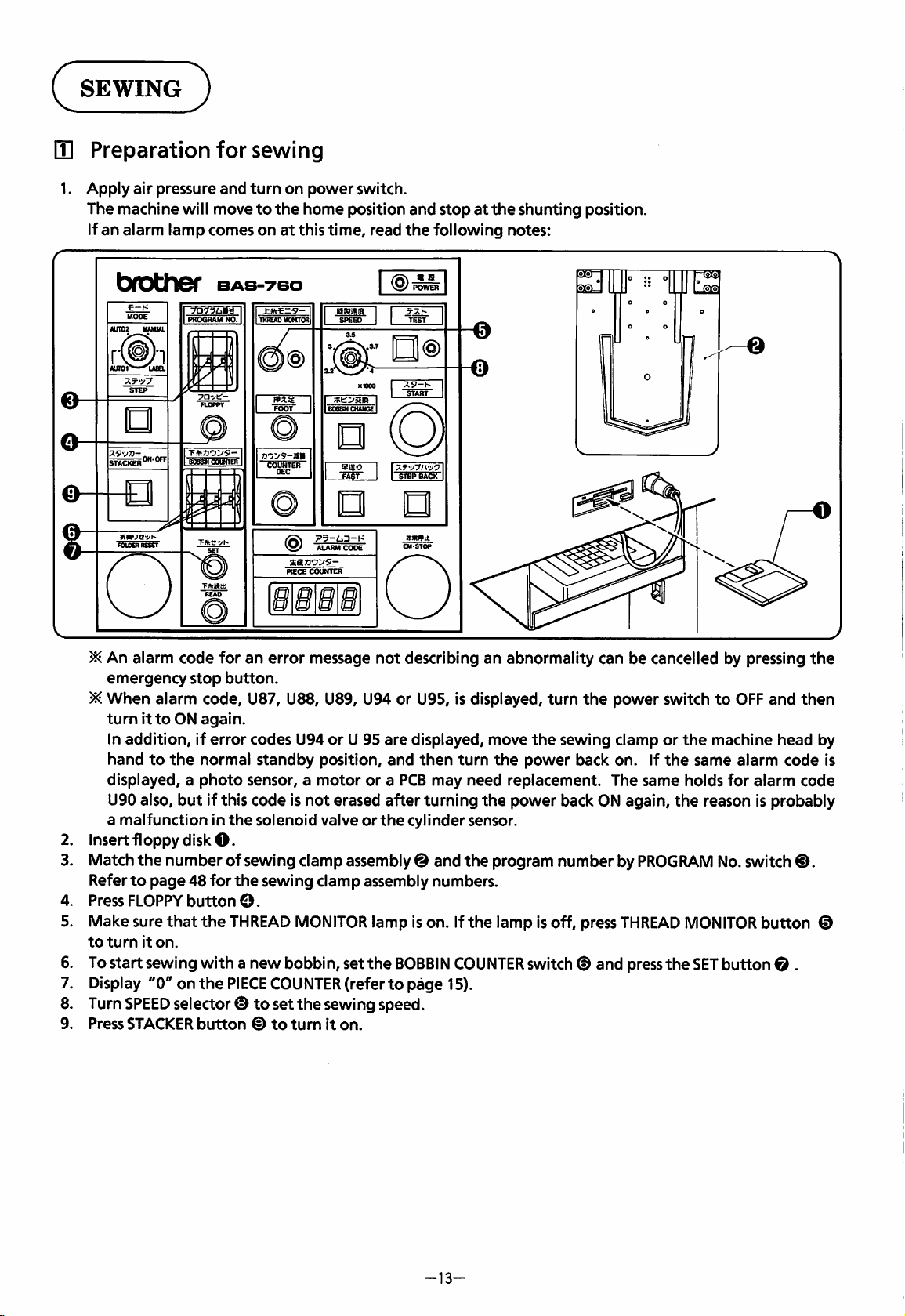

Thread

tension

1. When

2. Adjust

3. Adjust

beyond

the

thread

the

needle

the

lower

the

upperthread

^ Then adjust

Main adjust isperformed by using tension

it

Thread take-up spring

take-up lever Isin

eye

so as it is35to40 mm long, by

thread

tension by

the

highest position

turning

tension regulating

tension byturning tension

the

tension 30 - 40 g byturning tension

Stitches

tensionistoo

Stitches

tension is

Correct

nut®

nut

®.

when

upperthread

low

when

upperthread

too

high

stitches

after

thread trimming, adjust

turning

tension

screw®.

and O after lowering

nut

O.

nut

O.

the

presser foot.

the

upper

thread

50 - 60 9

1. The standard thread take-up spring height is 5 mm from the lower end of

standard

2. To

regulator

3. Toadjust

turn

adjust

it as

thread

the

the

much

take-up

thread

assembly.

spring force is50to60 g.

take-up

spring

height,

loosen set-screw ®

thread take-up spring force, insert a screwdriver tip into

as is

appropriate.

-12-

and

turn

the

the

groove of tension stud ® and

the

thread guide. The

whole

unitofthe

a

tension

SEWING

[B

Preparation

)

for

sewing

1. Apply

air

pressure

and

The machine will movetothe

Ifanalarm

STACKER

e-K

MODE

ON'OFF

lamp

PROGRAM

TMg-vK

comesonat

NO.

SET

READ

turnonpower

home

this

time,

TKREADMOMTOn

@

B06BM

COUNTER

DEC

ALARM

@

PtECE

COUNTER

switch.

position

read

SPEED

CHANGE

COOE

and

stopatthe

the

following notes:

@

STEP

BACK

shunting position.

^ An alarm

emergency

^

When

turnitto

code

stop

alarm code, U87, U88, U89, U94 or U95, is displayed,

ON

In addition, if

handtothe

displayed, a

U90also,

a

malfunctioninthe

but

2. Insert floppy disk

3. Match

the

numberof sewing clamp assembly @ and

Refertopage48for

4.

Press

FLOPPY

5. Make sure

to

turniton.

6. To

start

button

that

sewing with a new bobbin,

7. Display "0" on

8. Turn

9.

Press

SPEED

STACKER

selector©toset

for an error message

button.

again.

error

codes U94orU95

normal

photo

if this

standby

sensor, a

codeisnot

solenoid

O.

the

sewing

©.

the

the

THREAD

PIECE

MONITOR

COUNTER

the

button

©toturniton.

not

describing an abnormality can be cancelled by pressing

are

displayed, move

position,

motorora PCS

erased

valveorthe

and

then

may

after

turning

cylindersensor.

turn

need

the

the

clampassembly numbers.

lamp is on. If

set

the

BOBBIN

(refertopage

the

COUNTER

15).

sewing speed.

turn

the

power

the

sewing clamp or

the

power

replacement.

back

on.Ifthe

The

power back ON again,

program number by

lamp isoff, press

switch©

THREAD

and press

switchtoOFF

the

same

same

holds

the

reason is probably

PROGRAM

MONITOR

the

SET

machine

alarm

for

alarm

No.switch

button @

button©

and

head

then

code

code

®.

.

the

by

is

-13-

Alarm

code

U51

Needle-bar

the

needle-bar

Error

drop->Turn

message

the

machine pulleytoraise

Alarm

code

U82

No

air

pressureorair

Error

zipper

message

has

been

turned

off

U52

U53

U54

U55

U56

U58

U60

U61

U62

U70

U71

U72

U73

U74

Upper

thread

breakage-»Pass

Discrepancy

Machinesynchronism

malfunction

Needle

Presser

between

lift

sensor

foot

cylinder malfunction or sensorwire break

the

sensor

folder

wire

the

and

upper

the

break

thread

program

or

Needle zigzag cylinder malfunction or sensorwire

break

No

data

Check

the

floppydisk

Sensor

connector

Pattern

number

Try

again

No

data

available from designated program

No

diskinthe

Write

protected

Designated

connection

check

-> Floppy disk

FDD

^Change

number

unavailable

alarm

fault

the

check

disk

alarm

window

U83

U84

U85

U86

U87

U88

U89

U90

U91

U92

U93

U94

U95

U96

X-rightover-travel switch has

X-leftover-travel switch has

Y-above over-travel switch

Y-underover-travelswitch has

X-axis

motor

system

fault

Y-axis

motor

system

fault

Machine

Folder

X-axis positioning

Y-axis positioning

fault

motor

system

error

error

fault

been

has

been

been

been

operated

operated

operated

operated

Over-area during programming operation

X-originswitchfault, or

turnedonwhen

Yorigin switch fault or

turnedonwhen

Xorigin switch has

the

the

the

Xorigin switch has been

power

switch

the

Yorigin switch has

power

switch

been

turned

on

was

was

turned

turned

on

been

on

U78

U80

Keyword

Emergency

error

stop

button

has

been

pressed

U97

U99

Sewing

clamp

Bobbinchangeon-going isbeing displayed

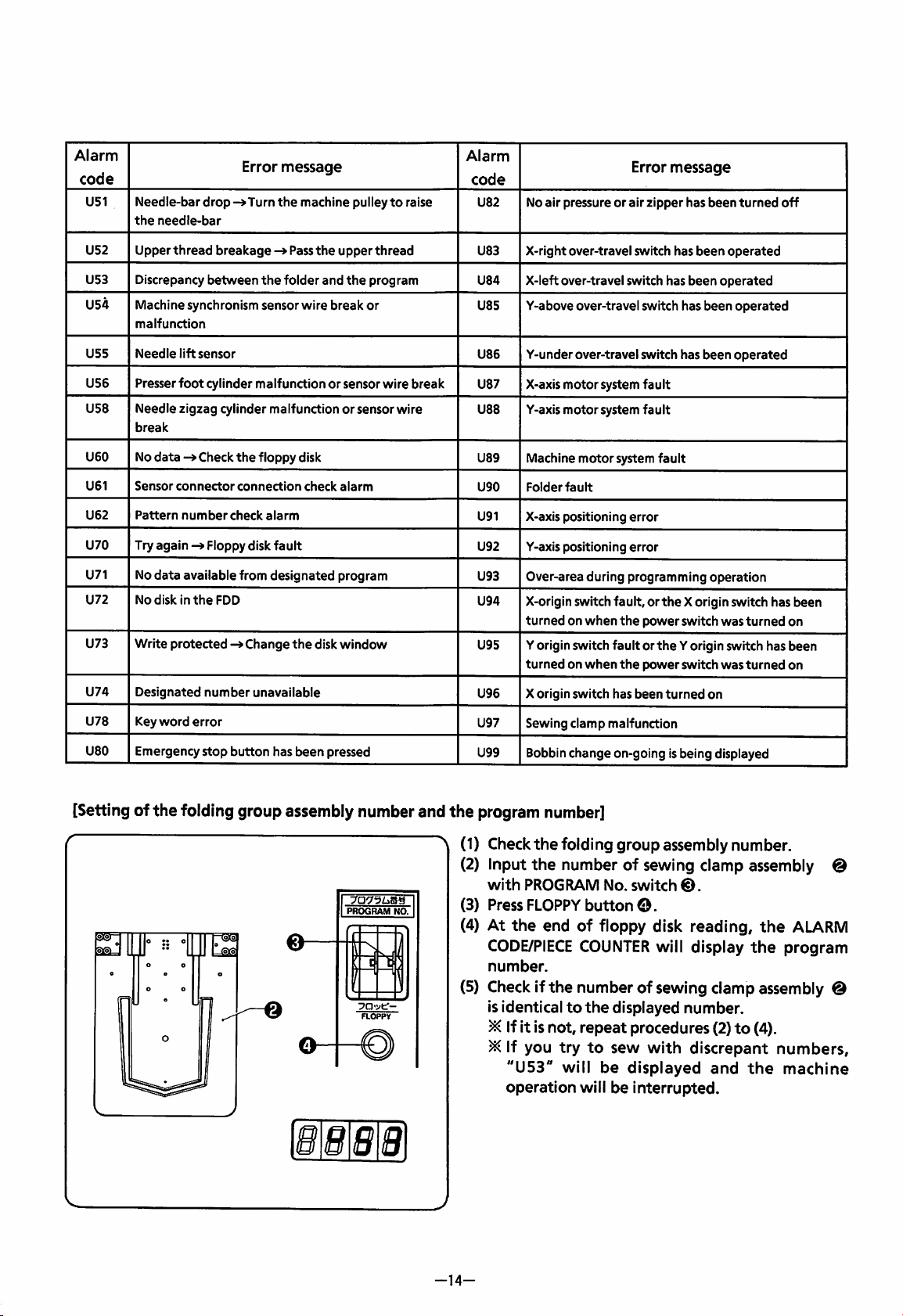

[Setting of thefolding group assembly number and the program number]

&

PROGRAM

NO.

^ (1) Check

(2)

(3)

(4) At

the

folding group assembly number.

Input the number of sewing clamp assembly ®

with

PROGRAM No.

Press

FLOPPY

the

CODE/PIECE

number.

button©.

end of floppy disk reading,

COUNTER

(5) Checkif the number of sewing clamp assembly @

n

isidenticaltothe

^ Ifit is not,

repeat

^ If you trytosew with discrepant numbers,

"U53" will

B

B

operation

8 a

will be

malfunction

switch

©.

wiil display

displayed number.

procedures(2)to(4).

be

displayed

interrupted.

and

the

the

the

ALARM

program

machine

-14-

Loading...

Loading...