User’s Guide

Barcode Print +

ENG

Version 0

i

Copyright

Copyright © 2019 Brother Industries, Ltd. All rights reserved.

Information in this document is subject to change without notice. The software described in this document is

furnished under licence agreements. The software may be used or copied only in accordance with the terms

of those agreements. No part of this publication can be reproduced in any form or by any means without

prior written permission of Brother Industries, Ltd.

Trademarks

Brother is the trademark of Brother Industries, Ltd.

BarDIMM is a registered trademark of Jetmobile SAS.

QRCode is a trademark of DENSO WAVE INCORPORATED.

Other products and company names herein may be the trademarks of their respective owners.

Any trade names and product names of companies appearing on Brother products, related documents and

any other materials are all trademarks or registered trademarks of those respective companies.

ii

Table of Contents

1

Background 3

1.1 Overview ................................................................................................................................................. 3

1.2 Supported Brother Machines .................................................................................................................. 4

1.3 Supported Barcodes ............................................................................................................................... 4

2

Activation 5

3

Breakdown of Control Codes 6

3.1 1-D Barcodes .......................................................................................................................................... 6

3.2 PDF417 ................................................................................................................................................... 9

3.3 QRCode ................................................................................................................................................ 12

4

Overview of Barcode Types 14

3

1

1 Background

1.1 Overview

The Brother Barcode Print + software solution extends the barcode printing capability of Brother printers.

Features

• Uses the same BarDIMM commands as other printer vendors.

• Requires no additional hardware, such as a USB memory stick, compact flash card, or DIMM.

• Supports both 1D and 2D barcodes.

4

1

1.2 Supported Brother Machines

For a comprehensive list of all Brother machines compatible with Brother Barcode Print +, visit your local

Brother website.

1.3 Supported Barcodes

Brother Barcode Print + supports many popular 1D and 2D barcodes.

Barcode category

Details

CODABAR

CODABAR

Code 128

Code 128 A, B, C

Code 128

Code 128 with Auto-Switch

Code 25 (2 of 5)

Code 25 Interleaved

Code 39 (3 of 9)

Code 39

Code 39 (3 of 9)

Code 39 + Chk Encode Space Before Data

Code 39 (3 of 9)

Code 39 + Mod 43Chk

Code 39 (3 of 9)

Code 39 Encode Space Before Data

Code 93

Code 93

Code 93

Code 93 Extended

EAN/JAN

EAN/JAN-13, EAN/JAN-13 +2

EAN/JAN

EAN/JAN-13 +5

EAN/JAN

EAN/JAN-8, EAN/JAN-8 +2

EAN/JAN

EAN/JAN-8 +5

EAN/JAN

GS1-128 (UCC/EAN 128)

GS1 DataBar

Standard, Limited, Expanded, Truncated, and Stacked

Interleave 25 (2 of 5)

Interleave 25 + Chk

MSI Plessey

MSI Plessey + Chk 10 and Chk 11

PDF-417

PDF-417 and Macro PDF-417

PostNet

PostNet 9 and PostNet 5

QR Code

QR Code

QR Code

Model 1

QR Code

Model 2

Swiss QR Code

Swiss QR Code

UPC

UPC-A, UPC-A +2, and UPC-A +5

UPC

UPC-E (UPC-E0 and UPC-E1)

UPC

UPC-E +2 and UPC-E +5

USPS

ZIP+4 PostNet 11

For a comprehensive list of all the barcodes compatible with Brother Barcode Print +, visit your local Brother

website.

5

2

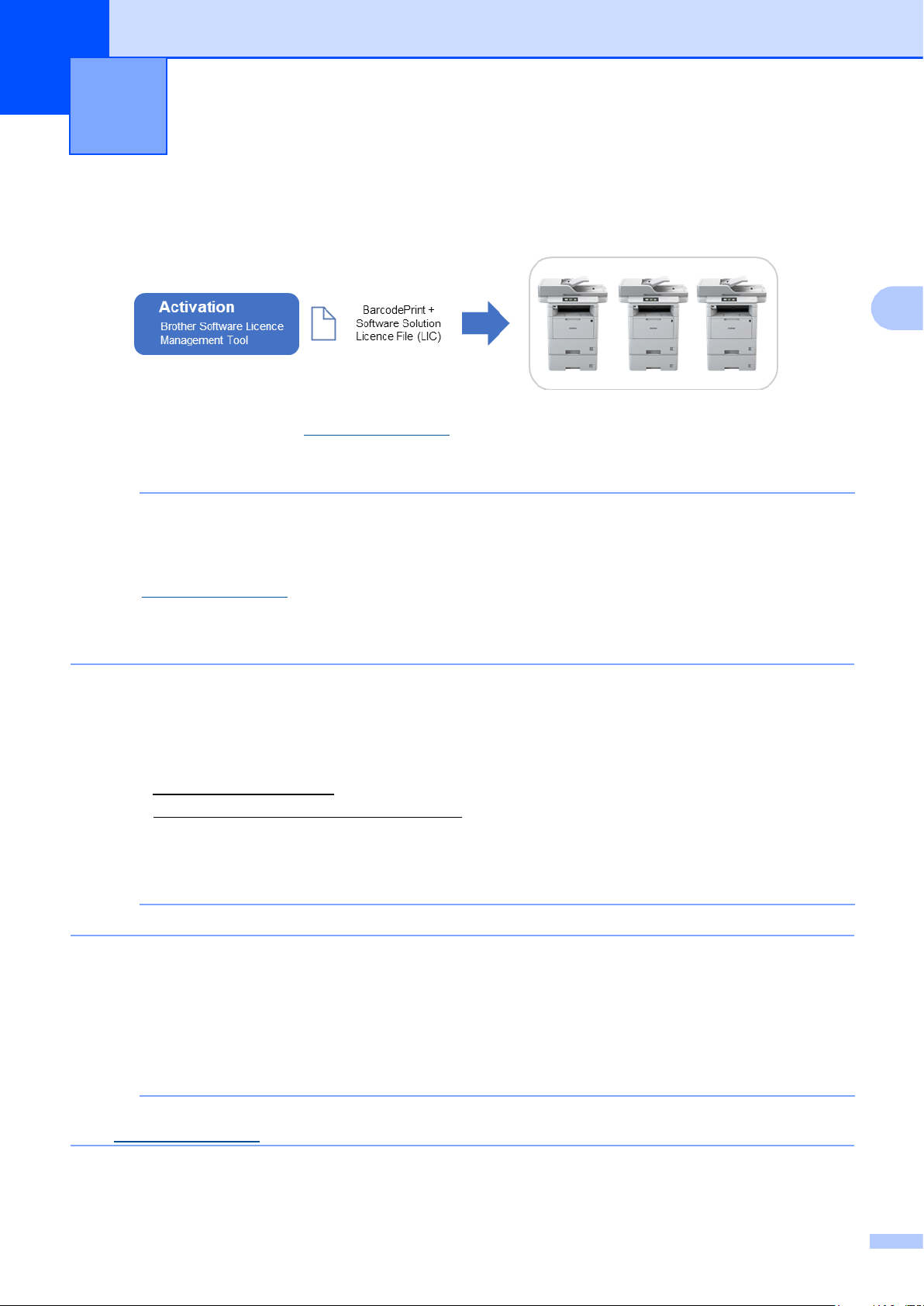

2 Activation

To activate the Barcode Print + solution, send a valid licence file to the target machine using the Brother

Software Licence Management Tool. If you do not have a valid licence file (in LIC format), contact your local

Brother office.

You can download the tool from support.brother.com.

NOTE

To successfully send licence files to the target machines, make sure that:

• The target machines are correctly set up, connected to a local network, and available.

• The target machines have the latest firmware installed. To update your machine’s firmware, go to

support.brother.com and download the Firmware Update Tool.

• You know the target machines’ passwords. You can activate more than one machine using the

same software solution if the target machines have a common password, or if they are not

password-protected.

1. Run the Brother Software Licence Management Tool.

2. The tool lists the Brother machines on your network. Double-click the machines you want to select for

activation, and then click the Activate button.

• If no machines are listed: Click the Search button to update the list.

• If the machines you want are not in the list: Go to Search > Add Machine.

3. The Licence Selection window appears. Select the correct software solution licence file (LIC file) for

your target machines.

NOTE

If you were provided with 20-digit licence codes, you can use them instead of the LIC file.

4. If the machines are password-protected, enter the password, and then click OK.

5. Make sure the information in the Confirmation dialog box is correct, and then click the Activate button.

When the activation is complete, the newly activated machines will be rebooted, and the log file will be

saved in the tool’s folder.

NOTE

For more information, see the Brother Software Licence Management Tool User’s Guide at

support.brother.com.

6

3

3 Breakdown of Control Codes

3.1 1-D Barcodes

Each barcode comprises a sequence of PCL commands and control codes. Control code parameters can be

customised to change the code’s size, shape, and content.

Example

1 2 3 4 5 6 7 8

ESC(s

0p

30v

,,,b

,,,s

h

24600T

123456789123

Barcode Print PCL Command

Barcode Data

#

Name

Parameter

Comments

1

Escape code

ESC(s

ESC is ASCII value 27

2

Human-readable information

#p

Default value = 0p

3

Barcode height

#v

Default value = 0v

4

Barcode width

#b

Default value = ,,,b

5

Barcode space width

#s

Default value = ,,,s

6

Human-readable text font

#h

Default value = h

7

Barcode name

PCL_BARCODE_NAMET

See Overview of Barcode Types

8

Barcode data

N/A

User-defined information

NOTE

• To ensure good readability, each barcode must be programmed correctly.

• If the “b” and “s” parameters are identical, the “s” parameter does not need to be specified.

• Do not use decimal values (e.g. “1.5”).

3.1.2 Human-readable information (“p”)

Specifies if a caption is printed with the barcode.

ESC(s0p

30v,,,b,,,sh24600T123456789123

Value

Description

0

Default (print)

1

Do not print human-readable text

2

Embed human-readable text

3

Half-embed human-readable text

4

Print human-readable text under the code

7

3

3.1.3 Barcode height (“v”)

Specifies the barcode height in 1/60th of an inch.

ESC(s0p

30v,,,b,,,sh24600T123456789123

In this example, 30/60th means that the barcode height will be 0.5 in. (12.7 mm).

3.1.4 Barcode width (“b”)

Specifies the width of barcode bars.

ESC(s0p

30v,,,b,,,sh24600T123456789123

This setting affects the total barcode width. To print smaller barcodes, specify smaller values.

For 1D codes, four values need to be specified in 1/600th of an inch:

1. First (thin) bar width

2. Second bar width

3. Third bar width

4. Fourth bar width

Alternatively, default values (“,,,”) can be used. The “ESC(s0p30v,,,b…” sequence will then give the

same output as “ESC(s0p30v8,16,24,32b…”.

Example

For UPC-A barcodes to be printed correctly, four different bar thicknesses are required.

The output will vary depending on the specified values:

Greater Values

Smaller Values

NOTE

Not all barcode readers may be able to read small barcodes.

3.1.5 Barcode space width (“s”)

Specifies the width of the spaces between bars in a barcode.

ESC(s0p

30v,,,b,,,sh24600T123456789123

For 1D codes, four values need to be specified in 1/600th of an inch:

1. First (thin) space width

2. Second space width

3. Third space width

4. Fourth space width

8

3

3.1.6 Human-readable text font (“h”)

Specifies the font used for barcode captions.

ESC(s0p

30v,,,b,,,sh24600T123456789123

Value

Description

0 (or no value)

Default (Courier)

1

Letter gothic

2

Universe

3

Universe condensed

5

OCR-B

3.1.7 Barcode type (“T”)

Specifies the barcode type.

ESC(s0p

30v,,,b,,,sh24600T123456789123

For more information, see Overview of Barcode Types.

3.1.8 Barcode data

The actual user-defined information.

ESC(s0p

30v,,,b,,,sh24600T123456789123

ASCII control code characters (ASCII code 0–30) can be specified for Code93 Extended, Code128A, and

Code128 With-AutoSwitch as follows:

ESC

&p#X

<00>

Where:

# is the number of control code characters

<00> is an example control code character

Example

To specify two ASCII control code characters “0” and “1” with Code 128A, use: 24850TESC&p2X<00><01>

9

3

3.2 PDF417

3.2.1 Barcode composition

Each barcode comprises a sequence of PCL commands and control codes. Control code parameters can be

customised to change the code’s size, shape, and content. Each PDF417 barcode (also called “symbol”) can

consist of several modules.

Example

1 2 3 4 5 6 7

ESC(s

0p

,,,v

,,,b

,,,s

24850T

123456789123

Barcode Print PCL Command

Barcode Data

#

Name

Parameter

Comments

1

Escape command

ESC(s

ESC is ASCII value 27

2

Error correction

#p

Default value = 0p

3

Barcode height

#v

Default value = ,,,v

4

Barcode (symbol) size

#b

Default value = ,,,b

5

Module size

#s

Default value = ,,,s

6

Barcode name

PCL_BARCODE_NAMET

▪ PDF417:

24850

▪ MacroPDF417:

24855

7

Barcode data

N/A

User-defined information

NOTE

• To ensure good readability, each barcode must be programmed correctly.

• Do not use decimal values (e.g. “1.5”).

10

3

3.2.2 Error Correction (“p”)

Specifies the error correction level or ratio against the data size.

ESC(s0p

,,,v,,,b,,,s24850T123456789123

Error Correction Level

Error Correction Data Code

0 2 1 4 2 8 3

16 4 32 5 64 6 128

7

256

8

512

You can also choose a value between 1000 and 1400 to define the error correction level in percent (0–

400%), based on the ratio between the size of the codeword and the data size.

3.2.3 Barcode height (“v”)

Specifies the barcode height.

ESC(s0p

,,,v,,,b,,,s24850T123456789123

1. (MacroPDF417 only) The number of blocks displayed as one column (default: 1)

Example

2v: If the number of blocks is three, the first column will show the first and second block, and the

second column will show the third block.

2. (MacroPDF417 only) Unused

3. Maximum block width (unit: 1/600th of an inch)

4. Maximum block height (unit: 1/600th of an inch)

3.2.4 Symbol size (“b”)

Specifies the PDF symbol size.

ESC(s0p

,,,v,,,b,,,s24850T123456789123

1. Maximum number of rows for the PDF symbol

2. Maximum number of columns for the PDF symbol

3. PDF symbol size control:

• 0: The size specified in 1 and 2 is set as the maximum for rows and columns (default)

• 1: The size specified in 1 and 2 is set as the mandatory values for rows and columns

4. PDF symbol content control:

• 0: The code is displayed with the stop pattern (default)

• 1: The code is displayed without the stop pattern

11

3

Display with the stop pattern

Display without the stop pattern

3.2.5 Module size (“s”)

Specifies the module size.

ESC(s0p

,,,v,,,b,,,s24850T123456789123

1. Module height to width ratio (1–10, default: 3)

2. Symbol length in the length to width ratio (default: 2)

3. Symbol width in the length to width ratio (default: 3)

4. Minimum module width (1–100, default: 10, unit: 1/100 of an inch)

Example

1,3,2,5s

(Module: square; Symbol length: 1.5 x width; Module width: 0.05 in.)

3.2.6 Barcode type (“T”)

Specifies the barcode type.

ESC(s0p

,,,v,,,b,,,s24850T123456789123

Value

Code Type

24850

PDF417

24855

MacroPDF417

3.2.7 Barcode data

The actual user-defined information:

ESC(s0p

,,,v,,,b,,,s24850T123456789123

ASCII control code characters (ASCII code 0–31) can be specified for PDF417 as follows:

ESC

&p#X

<00>

Where:

# is the number of control code characters

<00> is an example control code character

Example

To specify two ASCII code characters “0” and “1” with PDF417, use: 24850TESC&p2X<00><01>

12

3

3.3 QRCode

3.3.1 Barcode composition

Each barcode comprises a sequence of PCL commands and control codes. Control code parameters can be

customised to change the code’s size, shape, and content.

Example

1 2 3 4 5 6

ESC(s

0p

b

0s

24860T

123456789123

Barcode Print PCL Command

Barcode Data

#

Name

Parameter

Comments

1

Escape command

ESC(s

ESC is ASCII value 27

2

Error correction

#p

Default value = 0p

3

Barcode height

#b

Default value = b

4

Data type

#s

Default value = 0s

5

Barcode name

PCL_BARCODE_NAMET

▪ QRCode Model 1:

24860

▪ QRCode Model 2:

24861

▪ Swiss QRCode:

24862

6

Barcode data

N/A

User-defined information

NOTE

• To ensure good readability, each barcode must be programmed correctly.

• Do not use decimal values (e.g. “1.5”).

3.3.2 Error Correction (“p”)

Specifies the error correction level.

ESC(s0p

b0s24860T123456789123

Error Correction Level

Correction Ratio Against All Code Words

0 (Default)

M (~15%)

1

L (~7%)

2

M (~15%)

3

Q (~25%)

4

H (~30%)

13

3

3.3.3 Barcode height (“b”)

Specifies the maximum height of the small module (unit: 1/600th in.).

ESC(s0p

b0s24860T123456789123

3.3.4 Data type (“s”)

Specifies the barcode data type.

ESC(s0p

b0s24860T123456789123

Parameter

Barcode Data Type

0 (default)

Automatic (JIS/ShiftJIS)

1

Numerical (0–9)

2

Alphanumeric (0–9, uppercase A to Z, space $%*+-. /: )

3

Binary 8-bits/byte data (JIS 8-bit character set)

4

Kanji (Shift JIS values 8140h – 9FFCh and E040h – EAA4h)

Example

2s (Alphanumeric data)

3.2.5 Barcode type (“T”)

Specifies the barcode type.

ESC(s0p

b0s24860T123456789123

Value

Code Type

24860

QRCode Model1

24861

QRCode Model2

24862

Swiss QRCode

3.2.7 Barcode data

The actual user-defined information:

ESC(s0p

b0s24860T123456789123

ASCII control code characters (ASCII code 0–30) can be specified for QRCode as follows:

ESC

&p#X

<00>

Where:

# is the number of control code characters

<00> is an example control code character

Example

To specify two ASCII code characters “0” and “1” with QRCode, use: 24850TESC&p2X<00><01>

14

4

4 Overview of Barcode Types

Barcode Type

PCL

Barcode

Name

Barcode Sample

BOI:GTIN12-UPC-A

24600

B02:UPC-A +2

24601

B03:UPC-A +5

24602

B04:GTIN12-UPC-E

24610

B05:UPC-E +2

24611

B06:UPC-E +5

24612

B07:GTIN/EAN/JAN-8

24620

B08:EAN/JAN-8 +2

24621

B09:EAN/JAN-8 +5

24622

B10:GTIN/EAN/JAN-13

24630

B11:EAN/JAN-13 +2

24631

B12:EAN/JAN-13 +5

24632

15

4

Barcode Type

PCL

Barcode

Name

Barcode Sample

B13:25 (2 of 5)

Interleaved

24640

B14:25 Interleaved +

CHK

24641

B15:39 (3 of 9)

24670

B16:39 + CHK

24671

B17:39 (3of9) Encode

Space

24672

B18:39 + CHK Encode

Space

24673

B19:93

24690

B20:93 Extended

24691

B21:128 Autoswitch

24700

B22:128 A

24701

B23:128 B

24702

B24:128 C

24704

B25:GS1-128/EAN-UCC128

24720

16

4

Barcode Type

PCL

Barcode

Name

Barcode Sample

B26:CODABAR

24750

B27:CODABAR

+CHKmod16

24751

B28:MSI

24760

B29:MSI +CHK10

24761

B30:MSI+CHK10

+CHK10

24762

B31:MSI+CHK11+CHK10

24763

B32:ZIP+4 POSTNET 5

24770

B33:ZIP+4 POSTNET 9

24771

B34:ZIP+4 POSTNET 11

24772

B35:GS1 DataBar14/RSS-14

24810

B36:GS1 DataBar14/RSS Tru

24811

B37:GS1 DataBar14/RSS Sta

24812

B38:GS1 DataBar14/RSS Limited

24814

17

4

Barcode Type

PCL

Barcode

Name

Barcode Sample

B39:GS1 DataBar14/RSS Exp

24815

PDF417

24850

Macro PDF417

24855

B01:QRCode Model 1

24860

B02:QRCode Model 2

24861

B03:Swiss QR Code

24862

Loading...

Loading...