Page 1

ML117VS-7-1A

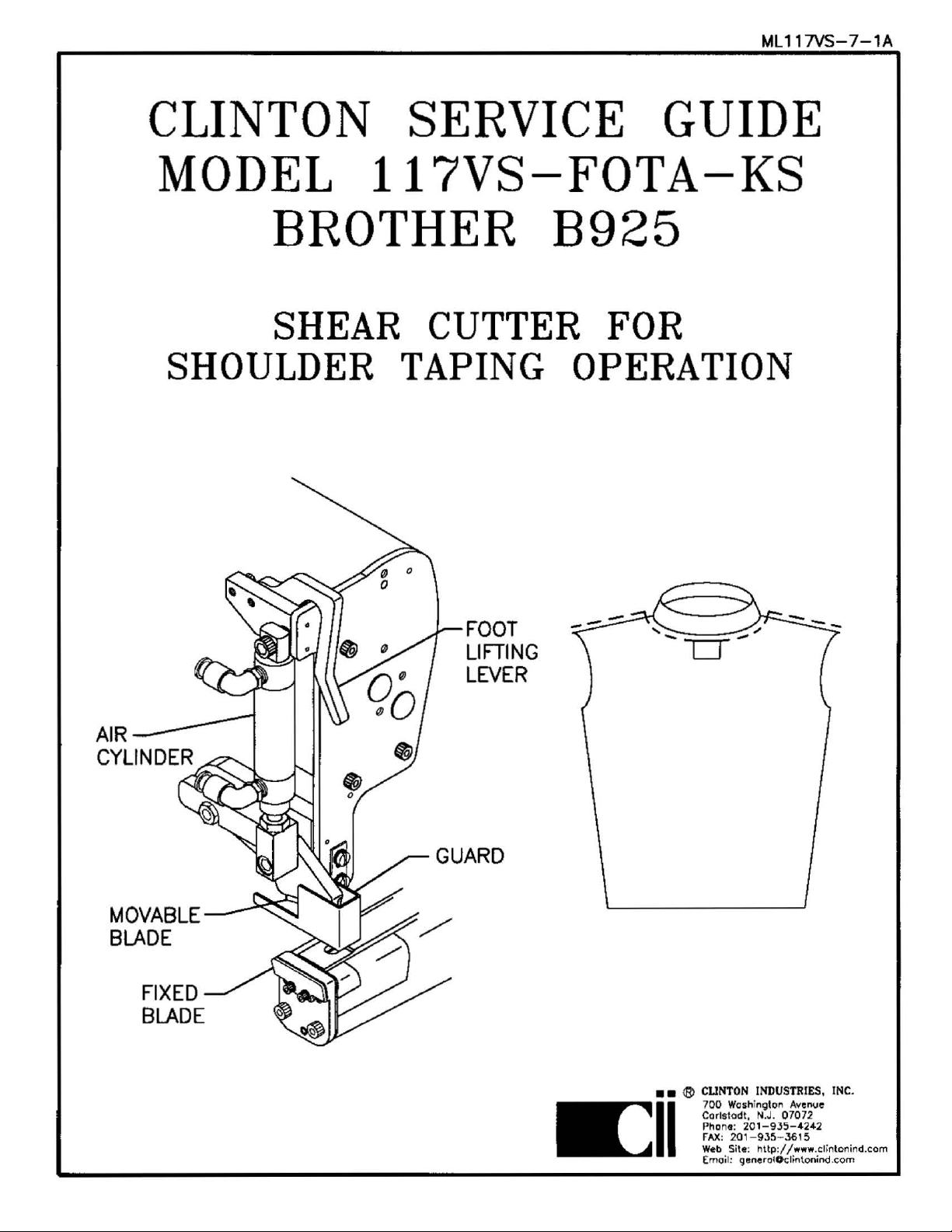

CLINTON

MODEL

117VS-FOTA-KS

BROTHER

SHEAR

SHOULDER

TAPING

SERVICE

B925

CUTTER

FOR

OPERATION

GUIDE

MOVABLE

BLADE

FOOT

LIFTING

LEVER

• • ®

CUNTON INDUSTRIES, INC

70

0 Washington Avenue

Co

rlstodt, N.J.

Ph

one:

201-935-4242

FAX: 201-935

Web

II

Site:

Email: gene

http

roiOcl

07072

- 361 5

:/ /

www.clinto

inlo

nind.co m

nind.com

.

Page 2

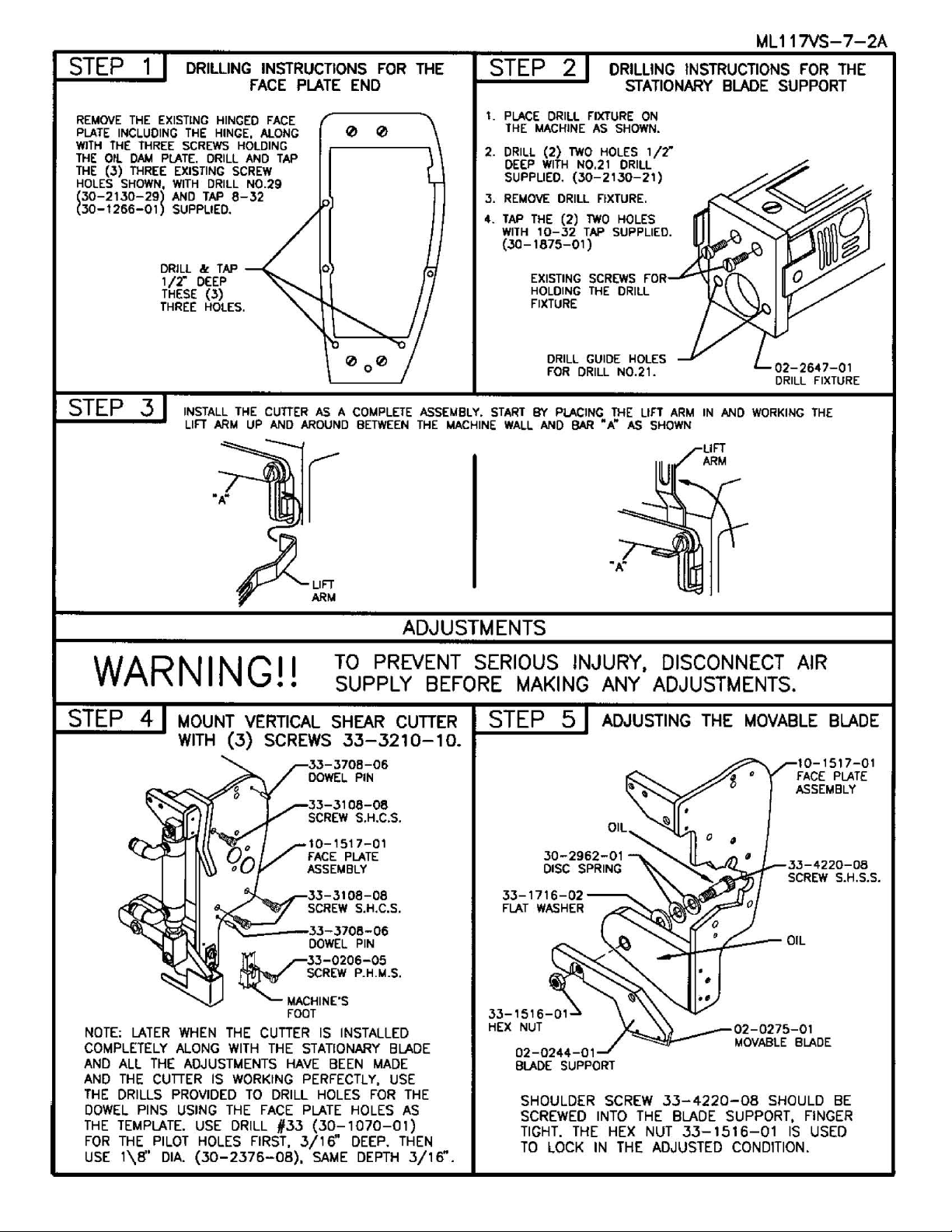

STEP

REMOVE

PLATE

WITH

THE

THE

HOLES

(30-2130-29)

(30-1256-01)

THE

INCLUDING

THE

OIL

DAM

(.3)

THREE

SHOWN,

DRILLING

1

EXISTING HINGED

THREE

THE

SCREWS

PLATE

. DRILL AND

EXISTING

WITH

AND

SUPPLIED.

DRILL

1/X'

DEEP

THESE

THREE

DRILL

TAP

& TAP

(.3)

HOLES.

INSTRUCTIONS

fACE

ALONG

HOLDING

SCREW

N0.29

8-32

FACE

HINGE,

PLATE

TAP

END

0 0

FOR

THE

STEP

1.

PLACE

THE

MACHINE

2. DRILL

DEEP

SUPPLIED.

3.

REMOVE

4.

TAP

THE

WITH

10-32

(30-1675-01)

EXISTING

HOLDING

FIXTURE

2

DRILL

FIXTURE

(2)

TWO

WITH

N0.21 DRILL

(.30-2130-21)

DRill

(2)

lWO

TAP

SCREWS

THE

DRILLING

STATIONARY

AS

ON

SHOWN

HOLES 1 /X'

FIXTURE.

HOLES

SUPPLIED.

FOR

DRILL

INSTRUCTIONS

BLADE

.

ML

117VS-7-2A

FOR

SUPPORT

THE

STEP

3 INSTALL

LIFT

ARM

THE

UP

~LIFT

~ARM

WARNING!!

STEP

NOTE:

COMPLETELY

AND

AND

THE

DOWEL

THE

FOR

USE

4

MOUNT

WITH

LATER

WHEN

ALONG

ALL

THE

THE

DRILLS

TEMPLATE.

THE

1\B''

ADJUSTMENTS

CUTIER

PROVIDED

PINS

USING

PILOT

DIA. {30-2376-08),

VERTICAL

(3)

'----JJ-3708-06

~33-0206-05

~

THE

WITH

IS

WORKING

TO

THE

USE

DRILL

HOLES

FIRST,

cuTTER

AND

As

A coMPLETE ASSEMBLY.

AROUND

r

TO

SUPPLY

SHEAR

SCREWS

33-3708-06

DOWEL

33-3106-08

SCREW S.H.C.S.

t0-1517-01

rACE

ASSEMBLY

33-3108-08

SCREW

DOWEL

u..rSCREW P.H .M.S.

MACHINE'S

FOOT

CUTIER

THE

DRILL

FACE

IS

STATIONARY

HAVE

BEEN

PERFECTLY, USE

HOLES

PLATE

//33

(30-1

3/16"

SAME

BETWEEN

THE

ADJUSTMENTS

PREVENT

BEFORE

CUTTER

33-3210-10.

PIN

PLATE

S.H.C.S.

PIN

INSTALLED

BLADE

MADE

FOR

THE

HOLES

070-01)

DEEP. THEN

DEPTH

AS

3/1

MACHINE

SERIOUS

fi.

DRILL GUIDE HOLES

fOR DRILL

START

BY

WALL

AND

MAKING

STEP

33-1516-01

HEX

NUT

D2-0244-01

BLADE SUPPORT

SHOULDER

SCREWED

TIGHT.

TO

LOCK IN THE ADJUSTED CONDITION.

PLACING

BAR

"A"

INJURY,

ANY

5

ADJUSTING

SCREW

INTO

THE

N0.21.

THE

un

ARM

AS

SHOWN

DISCONNECT

ADJUSTMENTS

33-4220-08

THE

HEX NUT

BLADE SUPPORT,

33-1516-01

IN

AND woRKING

THE

MOVABLE

02-0275-01

MOVABLE

02-2647-01

DRILL

FIXTURE

THE

AIR

.

10-1517-01

FACE

ASSEMBLY

.33-4220-08

SCREW

BLADE

SHOULD

FINGER

IS

USED

BLADE

PLATE

S.H.S.S.

BE

Page 3

ML

117VS-7-3A

STEP

IF

THE

BLADES

THE

(2)

JACK

ADJUSTMENT

ADJUST

RADIAL

THE

BLADE

SHEARING

GET

SCREWS

SCREWS

THE

ADJUSThAENT

(2)

SCREWS

SLOWLY

ACTION.

EXACTLY

02-0264-01-----;

AIR

02-02~9-01---l

CLEVIS

02-0252-01

F'IXED

33-2210-0.3

SET

02-0252-0~

FIXED

3.3-.3210-08

SCREW

33-2210-03

SET

FILTER,

6

.AOJUsnNG

ARE

NOT

33-3210-08. THIS

33-2210-0:S

.

(2)

SCREWS

OF

33-3210-08. TRY

(WITHOUT

IT

YOUR

MAY

CUTTING

CYLINDER

BLADE

SCREWS

SCREW

OILER,

-'----~

BLADE

REGULATOR,

THE

TOUCHING

TO

BE

33-2210-03

THE FIXED

THE

AIR BEI

REQUIRE

NEEDS

80-0181-01

80-0181-10

STATIONARY

EACH

OTHER,

WILL

ALLOW

TURNED

BLADE

ON

AS

TO

THE

LOWERING

NG

ON)

SEVERAL

.

FOR

ADJUSTMENTS

33-1616-02

HEX

02-0287-01

SPACER

02-0276

f

ix

(

with rodiol

adjustment)

.

OQJ/.006

SI

Sl.ADE

AOJUSTWENT

F

UKE

.

l-3-321

mounting

screw

.......

-r---

02-0276-01

STATIONARY

BLADE

GAUGE

ASSEMBLY

BLADE

LOOSEN

THE

MAKE

RIGHT

SHOWN. RETIGHTEN

THE

TESTING

NUT

THE

(2)

TOP

UP

ANY

F'OR

THE

MOVABLE

THE

TO

- 01

ed

blade

support

FAR

DE

Of

fiXED

'S

RADIAL

OR A SCISSOR

CUT

.

0-08

MACHINE

HORN

SUPPORT

INS-570

- JD

KNEE

SWITCH

YELLOW

4

WAY

AIR

CIRCUIT

loiOOEL

..OOEL 117'15

REO

YELLOW

FlLTER, OILER

REGULATOR

GAUGE

AIR

VAL.VE,

80-0185-01

DIAGRAM

117'15 KS

F'

.O.R.C.

c!c

KNEE

-KS

OPERATED

CUTTER

CYLINDER

117VS

1~-1119-IA

J0-0282-01

CAUCE

*

NOTE:

SEE

INS-DRAWINGS

2100-2

FOR

J0-10<t8-01

QUICK

F'EioiAL£

2100-1

S~ARE

DISCONNECT

~ARTS

AND

33-3712-16

DOWEL

~IN

J0

- 27.37-2

FITTING

01-4410-01

BUTTON

J0-0802-01

SPRING

01-1539-01

SU~I"'ft'T

JJ-2010-16

SCREW-P .H.S.

J0-0886-01

AIR

VALVE

l0-2738-250

ELBOW

JJ-0106-

SCREW-P.H.M.S.

01-4412-01

RoO

l0-0228-01

KNEE

J0-0902-01

KNEE

Ioi

20

PlATE

PAD

(J)

.S.

Page 4

ML

117VS-7-4

01-3061-11

SCREW

01-1509-61

BUSHING

02-0254-01

LEVER

33-3210-04

SCREW

02-0287-01

SPACER

(LONG)

{LONG)

S.H

.C.

S.

CUTIER

MODEL

BROTHER

80-0539-05

ASSEMBLY

117VS

8925

02-0256-01

ARM-RIBBON

RACK

01-3061-51

SCREW

01-1509-31

BUSHING

02-0247-01

LIFT

10-1517-01

FACE

ASSEMBLY

33-3708-06

DOWEL

33-321

SCREW

33-4220-08

SCREW

33-3210-04

SCREW

{SHORT)

{SHORT)

ARM

PLATE

PIN

0-04

S.H.C.S.

S.H.S.S

S.H.C.S

30-1509-01

RUBBER

*

*

.

*

.

PLUG

33-1716-02

FLAT

WASHER

02-0262-01

BEARING

33-1516-01

HEX

NUT

02-0244-01

BLADE

02-0275-01

MOVABLE

33-1616-02

HEX

02-0249-01

CLEVIS

02-0286-01

SCREW

02-0287-01

SPACER

33-1805-01

LOCK

33-3105-0

SCREW

02-0252-01

STATIONARY

33-3210-08

SCREW

SUPPORT

BLADE

NUT

S.H.

WASHER

S.H

.C.S.

S.H.C.

S.S.

4

-~

BLADE

S.

--.NOT

--PART

OF

80-0539-05

'L

~

02-0245-01

PRESSER

EXTENSION

FOOT

33-2210-03

SCREW

02-0276-01

STATIONARY

SUPPORT

S.S.

02-0657-01

NUT

PLATE

~\...----33-3210-09

S.

BLADE

SCREW

02-0255-01

FOLDER

01-3849-10

SPACER

33-3108-0B

SCREW

33-3708-06

DOWEL

33-0108-04

SCREW

33-1708-01

FLAT

33-0305-04

SCREW

S.H.C.S.

BRACKET

S.H.C.S.

PIN

P.H.M.S.

WASHER

F.H.M.S.

*

*

*

*

Loading...

Loading...