Page 1

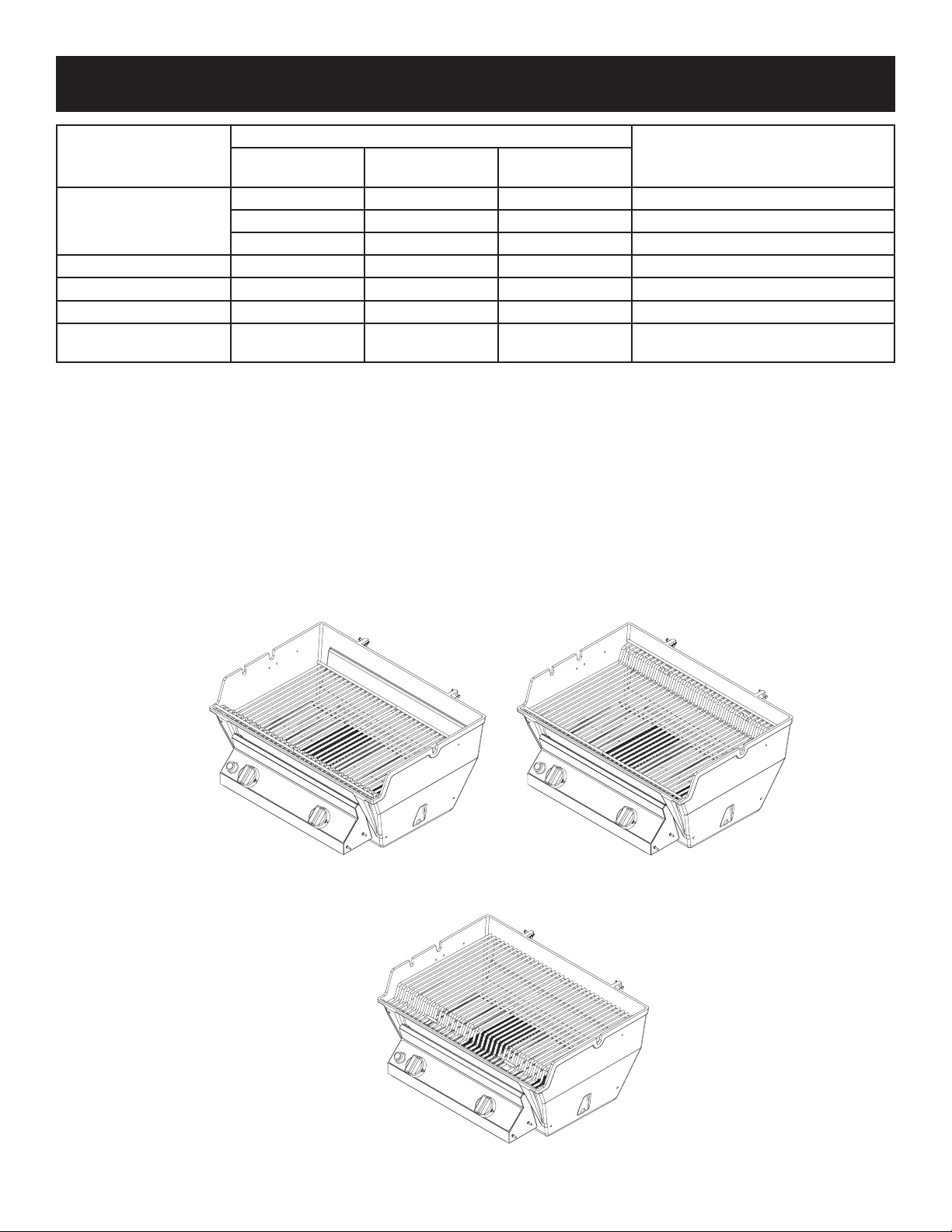

MODELS MODELS

H3X-1

H3XN-1

H3XPK-1 Series

MODELS MODELS

H4X-1

H4XN-1

H4PK-1 Series

P3X-1

P3SX-1

P3XF-1

P4X-1

P4XF-1

P3XN-1

P3SXN-1

P3XFN-1

P4XN-1

P4XFN-1

MODELS

R3-1 R3N-1

R3B-1 R3BN-1

GAS-FIRED

Page 1

Page 2

IMPORTANT

This manual should be read thoroughly by the person installing the grill and all persons

who will use and maintain the grill. The installer should be sure the manual is left in the

possession of the user. The user should retain this manual for future reference when using or cleaning the grill and to properly identify any repair parts that may be required.

WARNING

Reference this manual for proper installation and maintenance instructions. Improper

installation, adjustment, alteration, service or maintenance can cause personal injury or

property damage. For assistance or additional information consult a qualied installer,

service agency or the gas supplier.

DANGER: FOR YOUR SAFETY

IF YOU SMELL GAS:

1. Shut off gas to the appliance.

2. Extinguish any open ame.

3. Open the grill lid.

4. If odor continues, keep away from the appliance and imme-

diately call your gas supplier or your re department.

WARNING: FOR YOUR SAFETY

1. Do not store or use gasoline or other ammable vapors or liquids in the vicinity of

this or any other appliance.

2. An LP cylinder not connected for use shall not be stored in the vicinity of this or any

other appliance.

CAUTION:

Parts may have sharp edges. Wear leather work gloves and handle parts carefully during the unpacking, assembly and installation.

WARNING

Broilmaster® Gas Grills must ONLY use propane cylinders equipped with an Overll

Protection Device (OPD). Use only a reputable propane dealer when exchanging or

lling cylinders. An overlled or improperly lled propane cylinder can be dangerous.

B101623-5-1012Page 2

Page 3

Congratulations!

Welcome to the beauty, durability, and prestige of a Premium Gas Grill

by Broilmaster®. With award-winning excellence built into every feature

and durability that surpasses other Premium gas grills, Broilmaster has

manufactured the ultimate gas grill for discriminating outdoor chefs for

over 30 years.

At Broilmaster, we continually strive to enhance the performance and

quality of our products for your grilling enjoyment. Every effort will be

made to ensure that Broilmaster continues to be your choice as the

Premium grill of the future.

Whether you are at the lake or in the privacy of your own backyard, the

Broilmaster

®

Premium Gas Grill performs far beyond the ordinary and is

designed to provide your family with years of outdoor cooking pleasure.

Thank You!

Broilmaster® is a registered trademark of

Empire Comfort Systems, Inc.

918 Freeburg Ave.

Belleville, Illinois 62220

Telephone 800-851-3153

B101623-5-1012 Page 3

Page 4

TABLE OF CONTENTS

Congratulations!

You have chosen the nest grill for your outdoor cooking pleasure. Please take time to read this entire

manual before assembling your Premium Broilmaster® gas grill.

Master Parts Distributor List ........................................................................................................... 5

How To Order Repair Parts ............................................................................................................5

P3X Series Parts Diagram..............................................................................................................6

P3X Series Parts List......................................................................................................................7

P4X Series Parts Diagram..............................................................................................................8

P4X Series Parts List......................................................................................................................9

H3X Series Parts Diagram ...........................................................................................................10

H3X Series Parts List ................................................................................................................... 11

H4X Series Parts Diagram ...........................................................................................................12

H4X Series Parts List ...................................................................................................................13

R3 Series Parts Diagram ..............................................................................................................14

R3 Series Parts List ...................................................................................................................... 15

Grill Assembly ............................................................................................................................... 16

Warranty Terms .......................................................................................................................16-17

Propane Gas Grills ..................................................................................................................18-20

Natural Gas Grills .........................................................................................................................21

Owner’s Manual for P and H Series Grills ............................................................................... 22-34

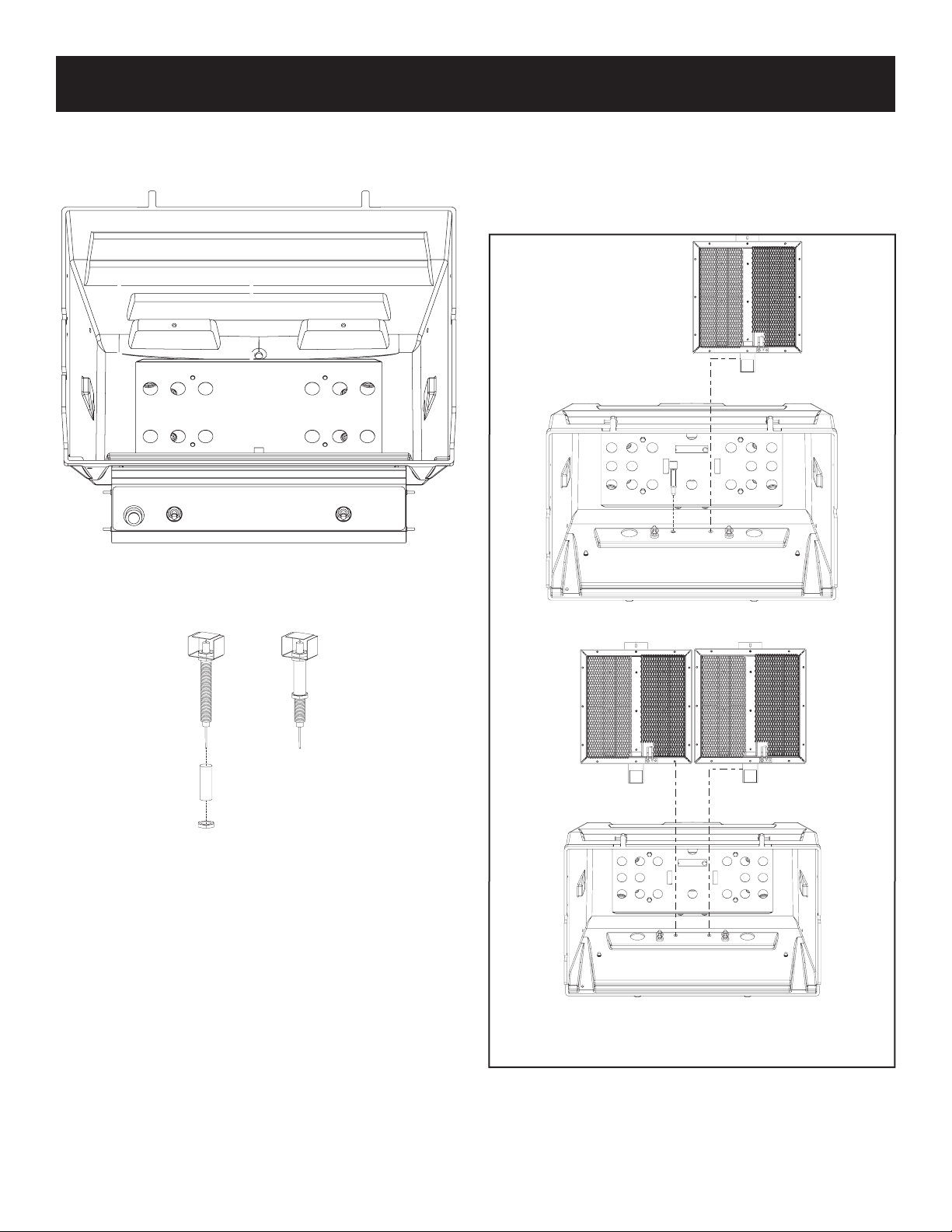

Hardware Pack ......................................................................................................................... 23

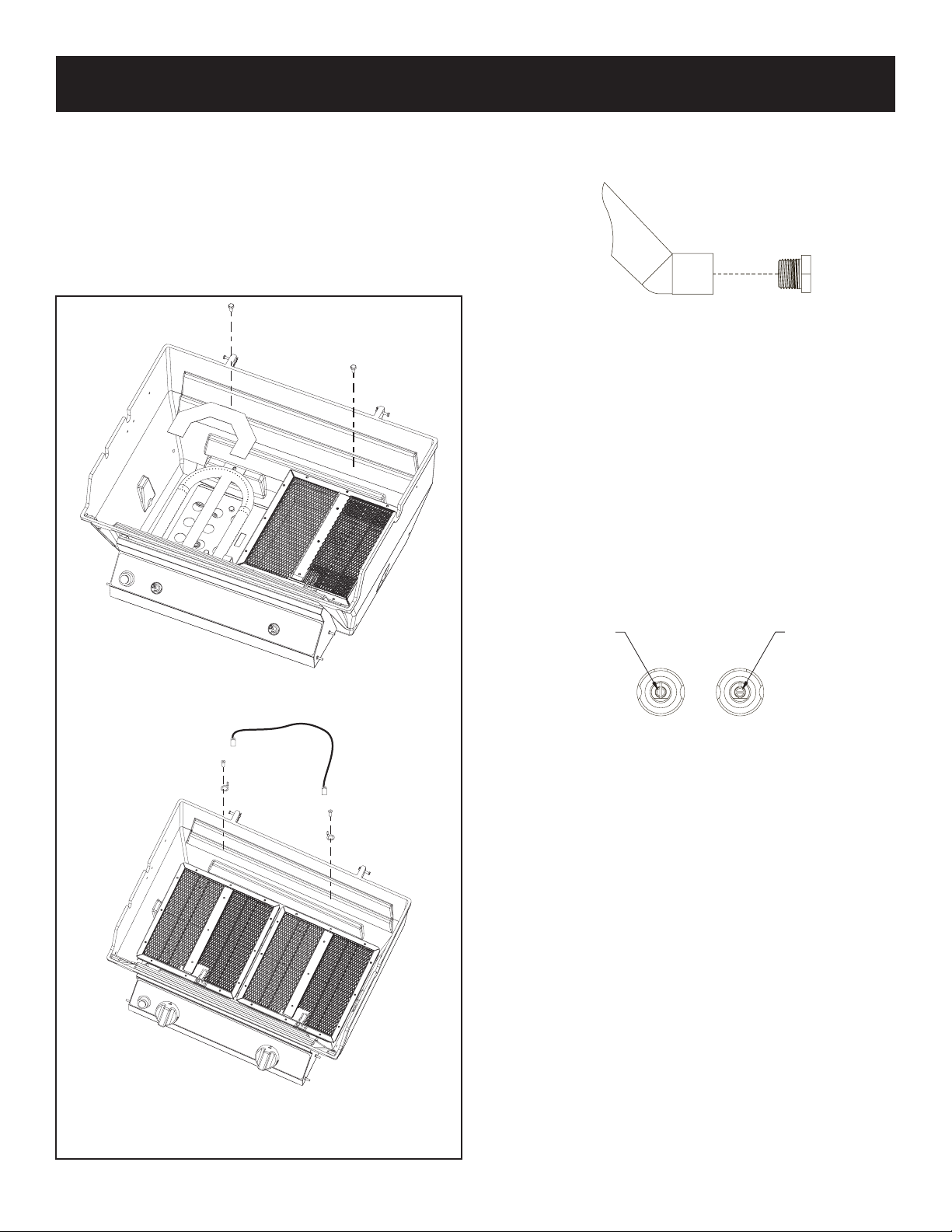

Grill Assembly ...................................................................................................................... 24-30

Operation - Propane & Natural Gas .........................................................................................31

Operation .................................................................................................................................. 32

Maintenance ............................................................................................................................. 33

Troubleshooting ........................................................................................................................ 34

Owner’s Manual for R Series Grills .........................................................................................35-52

Hardware Pack ......................................................................................................................... 36

Safety Precautions ...................................................................................................................37

Grill Assembly ...................................................................................................................... 38-41

Gas Conversion to Natural Gas...........................................................................................42-43

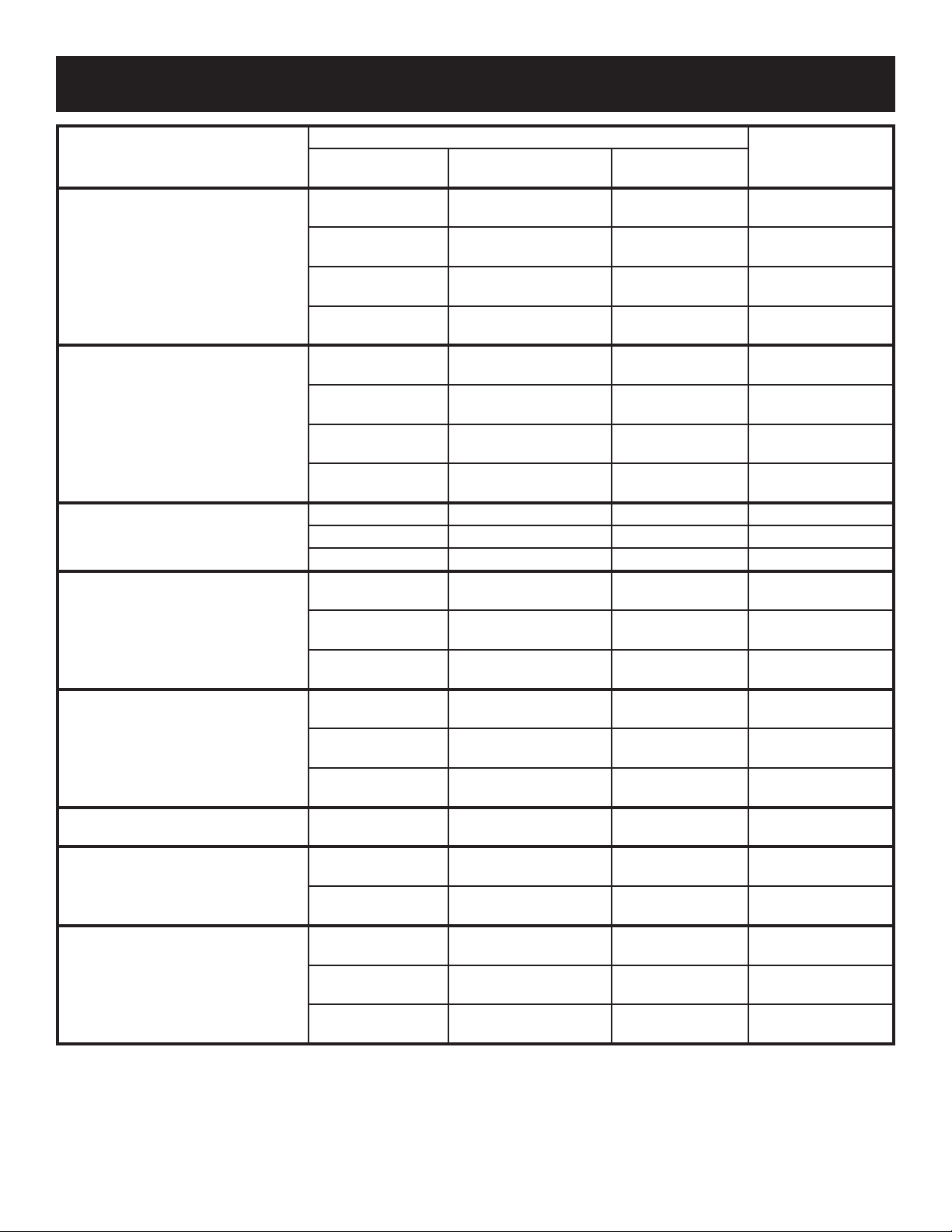

Infrared Cooking ..................................................................................................................44-46

Operation - Propane & Natural Gas Grills ...........................................................................47-48

Blue Flame Burner Maintenance .............................................................................................. 49

Infrared Burner Maintenance ............................................................................................... 50-51

Troubleshooting ........................................................................................................................ 52

Appliance Service History........................................................................................................23-55

B101623-5-1012Page 4

Page 5

MASTER PARTS DISTRIBUTOR LIST

To Order Parts Under Warranty, please contact your local Empire dealer. See the dealer locator at www.empirecomfort.com. To provide warranty service, your dealer will need your name and address, purchase date and serial number, and the nature of the problem with the unit.

To Order Parts After the Warranty Period, please contact your dealer or one of the Master Parts Distributors listed below. This list changes

from time to time. For the current list, please click on the Master Parts button at www.empirecomfort.com.

Please note: Master Parts Distributors are independent businesses that stock the most commonly ordered Original Equipment repair parts

for Heaters, Grills, and Fireplaces manufactured by Empire Comfort Systems Inc.

Dey Distributing

1401 Willow Lake Boulevard

Vadnais Heights, MN 55101

Phone: 651-490-9191

Toll Free: 800-397-1339

Website: www.deydistributing.com

Parts: Heater, Hearth and Grills

East Coast Energy Products

10 East Route 36

West Long Branch, NJ 07764

Phone: 732-870-8809

Toll Free: 800-755-8809

Fax: 732-870-8811

Website: www.eastcoastenergy.com

Parts: Heater, Hearth and Grills

Victor Division of F. W. Webb Company

200 Locust Street

Hartford, CT 06114

Phone: 860-722-2433

Toll Free: 800-243-9360

Fax: 860-293-0479

Toll Free Fax: 800-274-2004

Websites: www.fwwebb.com & www.victormfg.com

Parts: Heater, Hearth and Grills

HOW TO ORDER REPAIR PARTS

Parts Not Under Warranty

Parts can be ordered through your Service Person, Dealer, or a Master Parts Distributor. See this page for the Master Parts Distributors list. For best results, the service person or dealer should order parts through the distributor. Parts can be shipped directly to the

service person/dealer.

Warranty Parts

Warranty parts will need a proof of purchase and can be ordered by your Service Person or Dealer. Proof of purchase is required for

warranty parts.

All parts listed in the Parts List have a Part Number. When ordering parts, rst obtain the Model Number and Serial Number from the

name plate on your equipment. Then determine the Part Number (not the Index Number) and the Description of each part from the following illustration and part list. Be sure to give all this information . . .

Appliance Model Number Part Description

Appliance Serial Number Part Number

Type of Gas (Propane or Natural)

Do not order bolts, screws, washers or nuts. They are standard hardware items and can be purchased at any local hardware store.

Shipments contingent upon strikes, res and all causes beyond our control.

B101623-5-1012 Page 5

Page 6

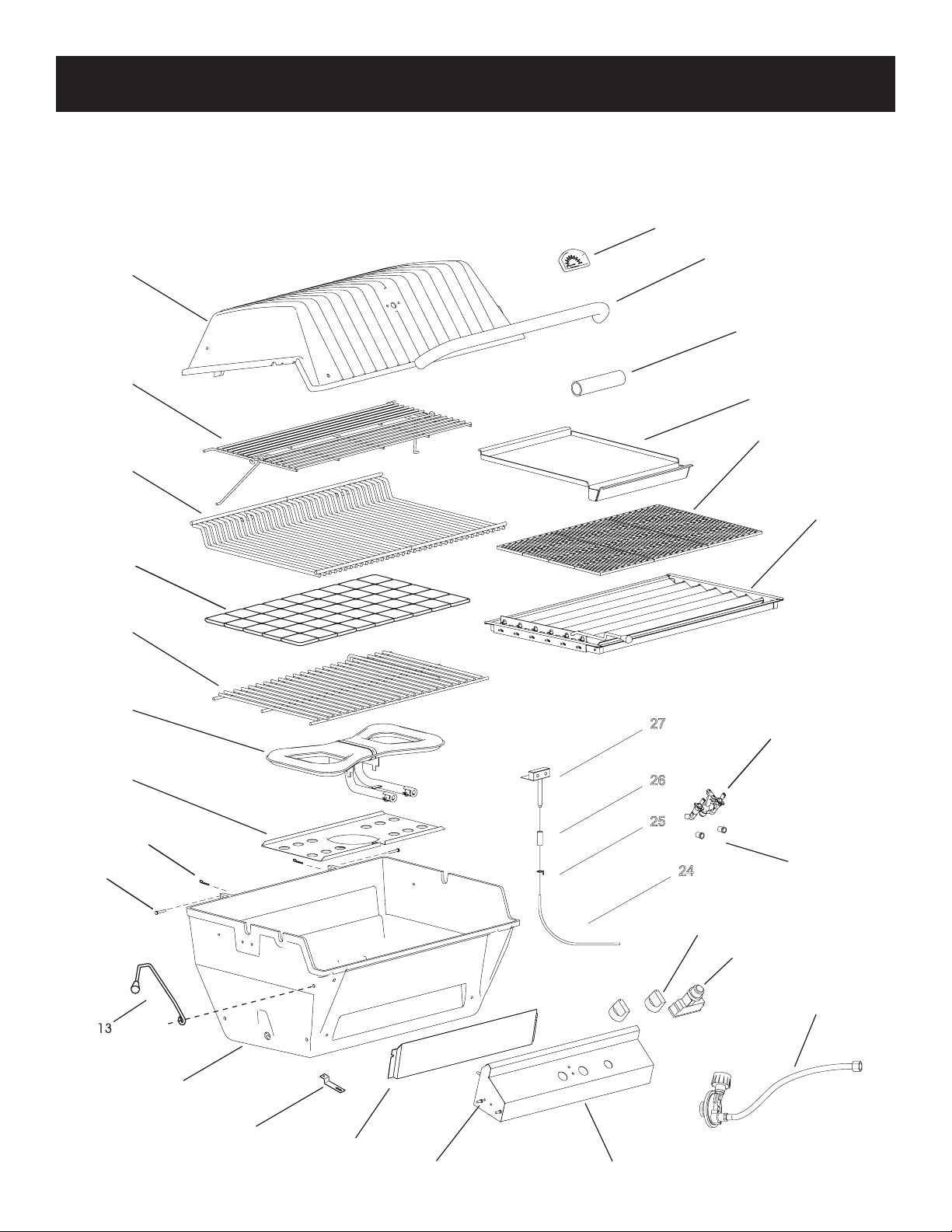

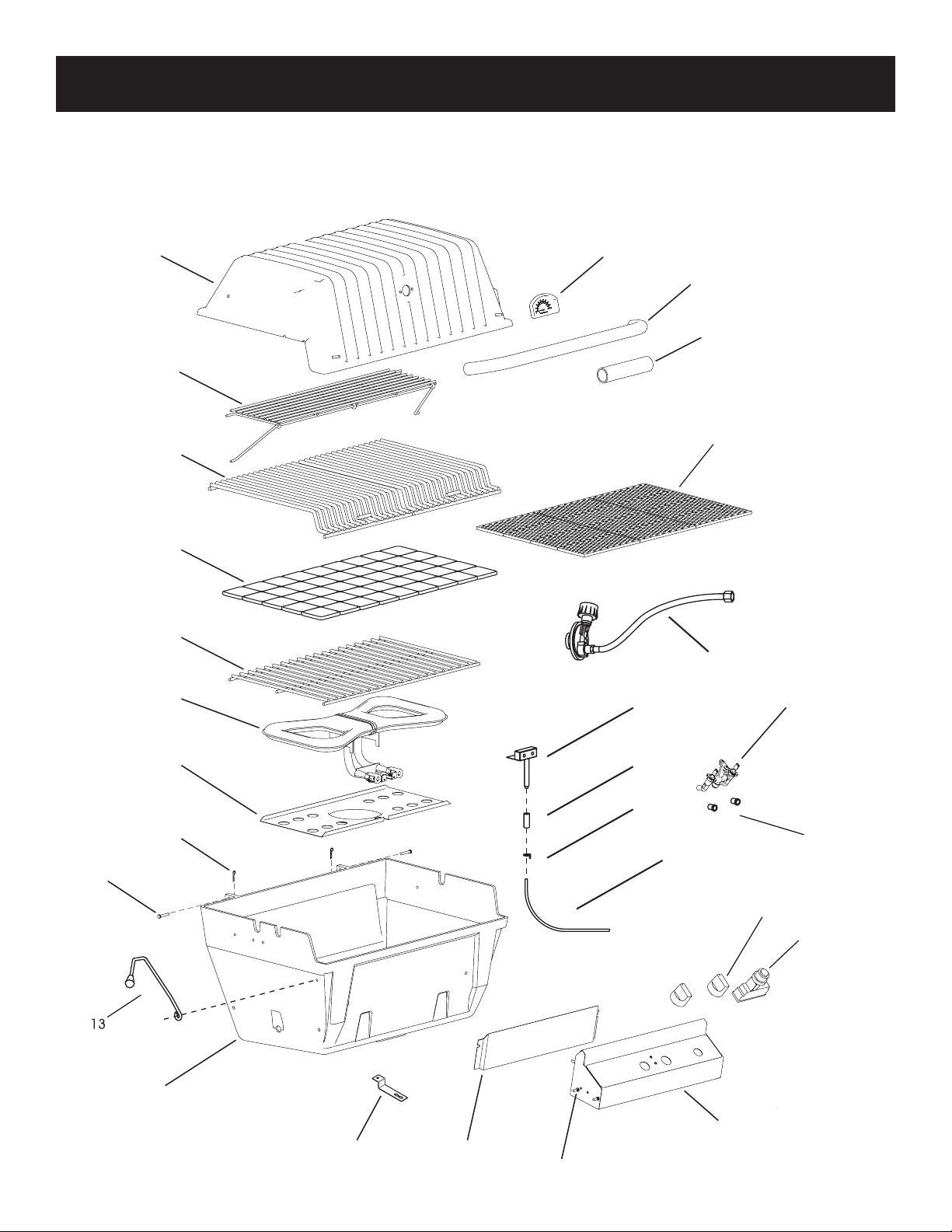

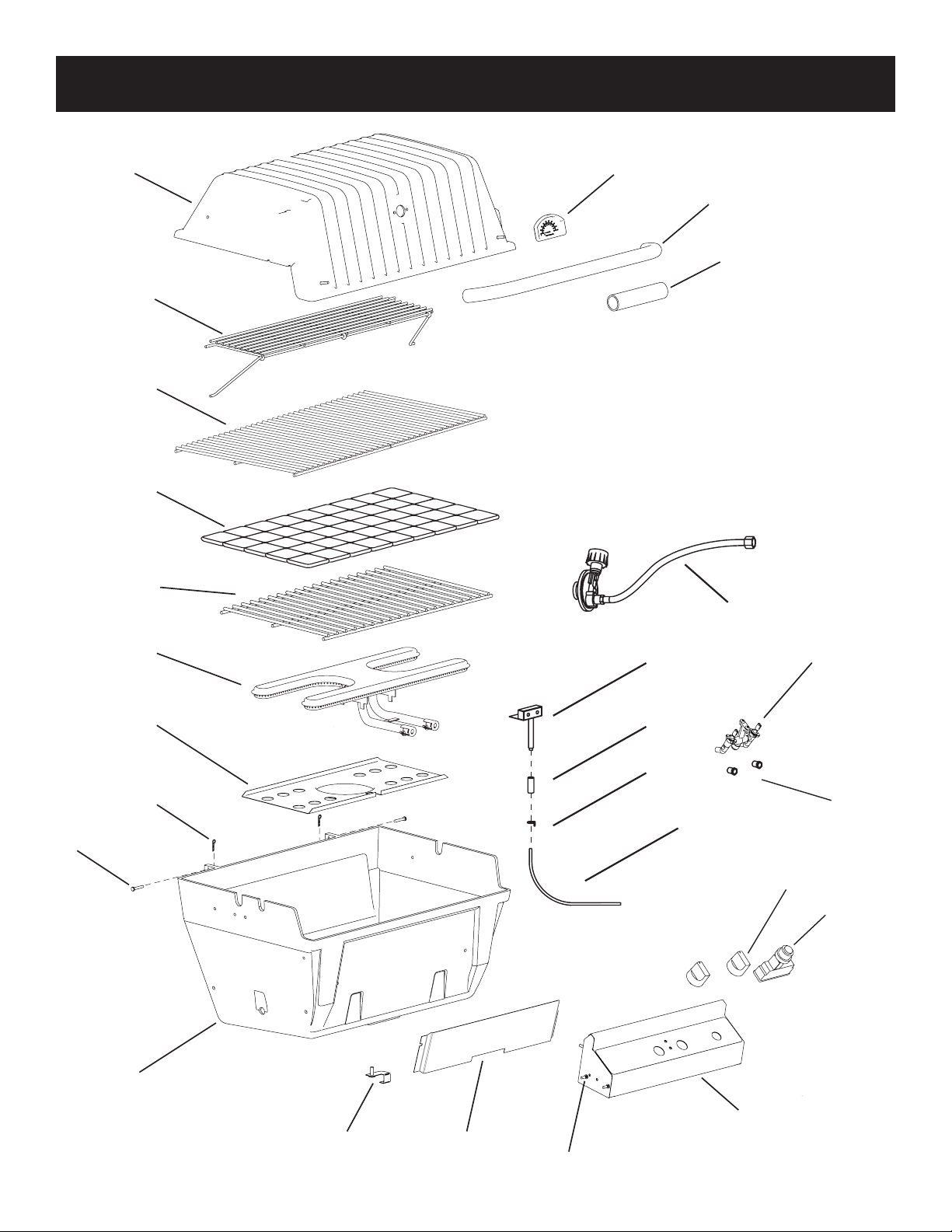

P3X SERIES PARTS DIAGRAM

All repair part orders should be placed through your local Broilmaster® dealer. To locate a dealer in your

area visit www.broilmaster.com. To ensure prompt and accurate service, please provide the following

information when placing a repair part order: Model Number, Serial Number, Part Name, Part Number,

and Quantity of parts needed.

2

3

1

4

12

10

5

6

7

8

9

27

26

25

11

24

34

28

29

17 or 18

14 or 15

22

35

23

19

21

16

32

20

B101623-5-1012Page 6

Page 7

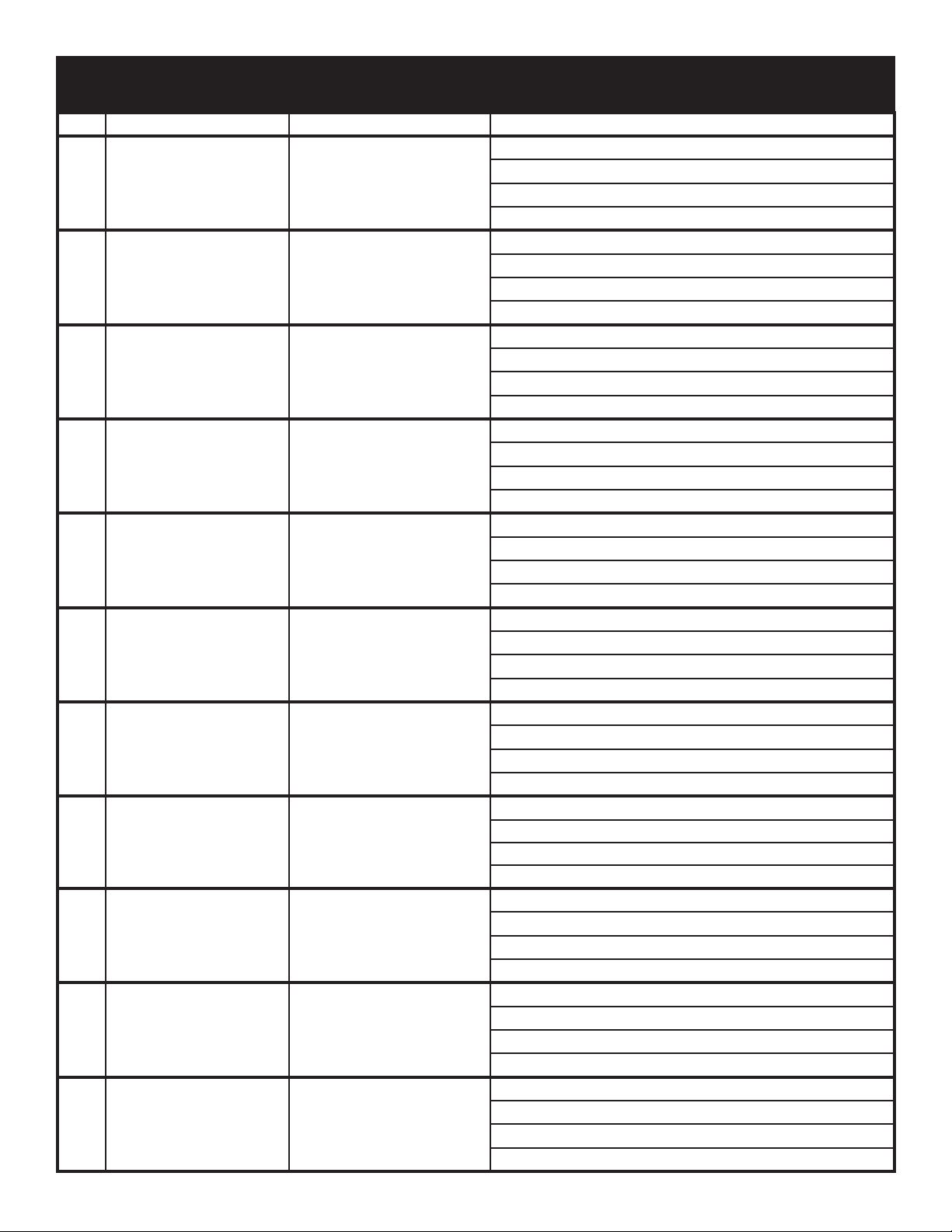

P3X SERIES PARTS LIST

Index

NS - Not Shown

*Valves are not convertible. To convert the unit to a different gas type, a new valve must be purchased.

Part Description

No.

1 Grill Body Top (with heat indicator, hinge, B100453 B100453 B100453 B100453 B100453 B100453

1 Grill Body Top (casting only) B100456 B100456 B100456 B100456 B100456 B100456

2 Heat Indicator (stainless) B101406 B101406 B101406 B101406 B101406 B101406

3 Lid Handle (stainless) B070486 B070486 B070486 B070486 B070486 B070486

4 Foam Grip B073097 B073097 B073097 B073097 B073097 B073097

5 Retract-A-Rack (stainless) B072695 B072695 B072695 B072695 B072695 B072695

6 Cooking Grid (2 piece Stainless Steel B101282 B101282 B101282 B101282 B101282 B101282

7 Briquette Bag N/A N/A B058122 B058122 N/A N/A

8 Briquette Rack B101061 B101061 B101061 B101061 B101061 B101061

9 Burner Assembly B101512 B101512 B101512 B101512 B101512 B101512

10 Wind Deector B063065 B063065 B063065 B063065 B063065 B063065

11 Bridge Pin B057805 B057805 B057805 B057805 B057805 B057805

12 Hinge Pin B057804 B057804 B057804 B057804 B057804 B057804

13 Lid Stop Kit DPA106 DPA106 DPA106 DPA106 DPA106 DPA106

14 Orice - LPG (#54 drill) P204 P204 P204 P204 P204 P204

15 Orice - NAT (#48 drill) P300 P300 P300 P300 P300 P300

16 Electric Ignitor B072218 B072218 B072218 B072218 B072218 B072218

17* Valve - LPG B101420 B101420 B101420 B101420 B101420 B101420

18* Valve - NAT B101421 B101421 B101421 B101421 B101421 B101421

19 Shelf Pin B073963 B073963 B073963 B073963 B073963 B073963

20 Control Panel Assembly (with label) B101514 B101514 B101514 B101514 B101514 B101514

20 Control Panel Label (not shown) B101517 B101517 B101517 B101517 B101517 B101517

21 Valve Knob - Black B070084 B070084 B070084 B070084 B070084 B070084

22 Grill Body Bottom (casting only) B101418 B101418 B101418 B101418 B101418 B101418

23 Control Panel Shield B101622 B101622 B101622 B101622 B101622 B101622

24 Ignitor Ground Wire B072684 B072684 B072684 B072684 B072684 B072684

25 Ignitor Grounding Lug B069747 B069747 B069747 B069747 B069747 B069747

26 Collector Box Spacer B069743 B069743 B069743 B069743 B069743 B069743

27 Collector Box B100446 B100446 B100446 B100446 B100446 B100446

28 Flare Busters Kit DPA116 DPA116 N/A N/A DPA116 DPA116

29 Smoker/Shutter (includes Actuator Arm & Knob DPA100 DPA100 N/A N/A N/A N/A

32 Hose & LPS Regulator B069756 B069756 B069756 B069756 B069756 B069756

33 Hardware Package B101655 B101655 B101655 B101655 B101655 B101655

34 Griddle, Stainless Steel B101400 B101400 N/A N/A N/A N/A

35 Burner Bracket B101648 B101648 B101648 B101648 B101648 B101648

NS Actuator Arm - Smoker/Shutter B100408 B100408 N/A N/A N/A N/A

NS Knob - Smoker/Shutter Knob B100098 B100098 N/A N/A N/A N/A

P3SX P3SXN P3X P3XN P3XF P3XFN

Part Number

B101623-5-1012 Page 7

Page 8

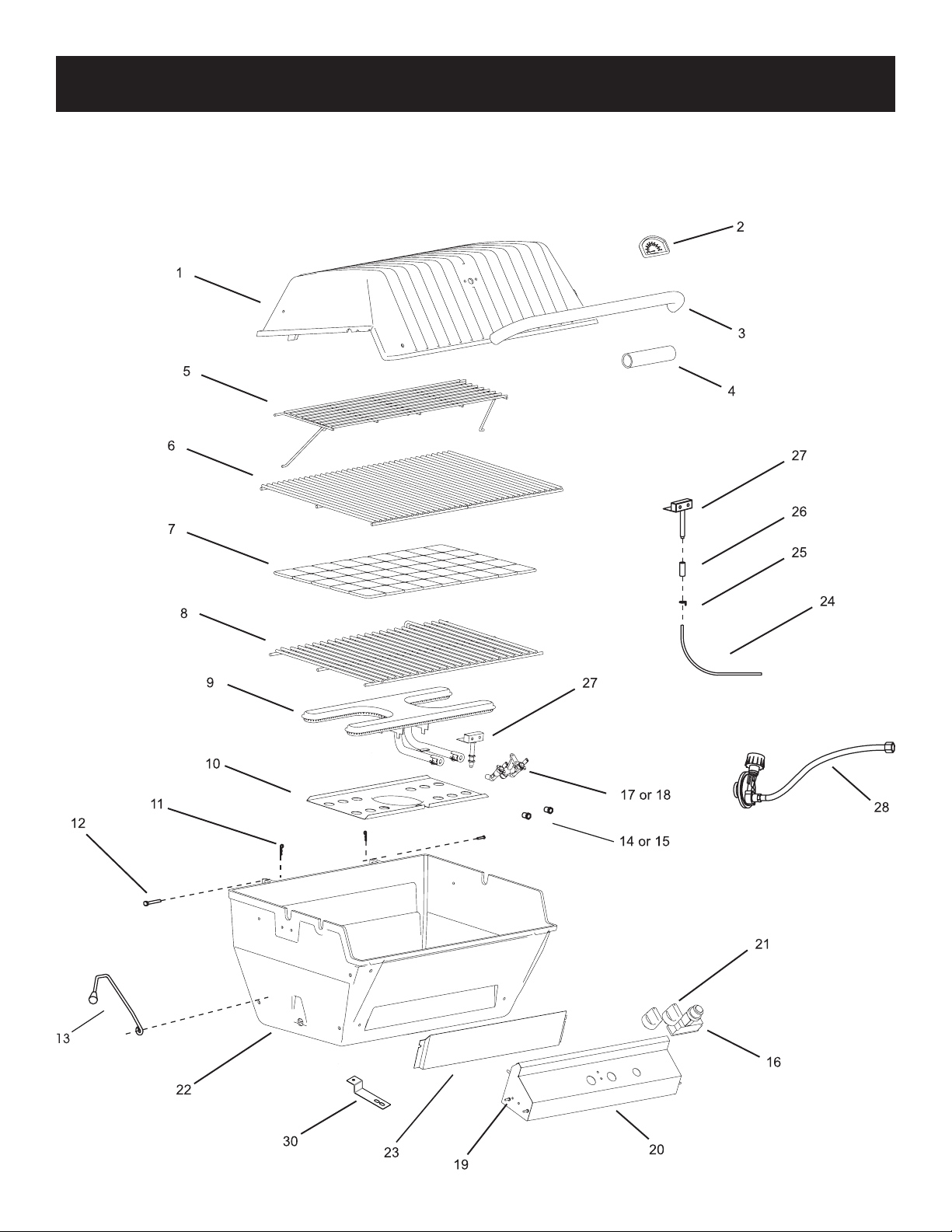

P4X SERIES PARTS DIAGRAM

All repair part orders should be placed through your local Broilmaster® dealer. To locate a dealer in your

area visit www.broilmaster.com. To ensure prompt and accurate service, please provide the following

information when placing a repair part order: Model Number, Serial Number, Part Name, Part Number,

and Quantity of parts needed.

1

5

6

7

8

9

2

3

4

28

32

27

17 or 18

12

22

10

11

26

25

14 or 15

24

21

16

20

34 23

19

B101623-5-1012Page 8

Page 9

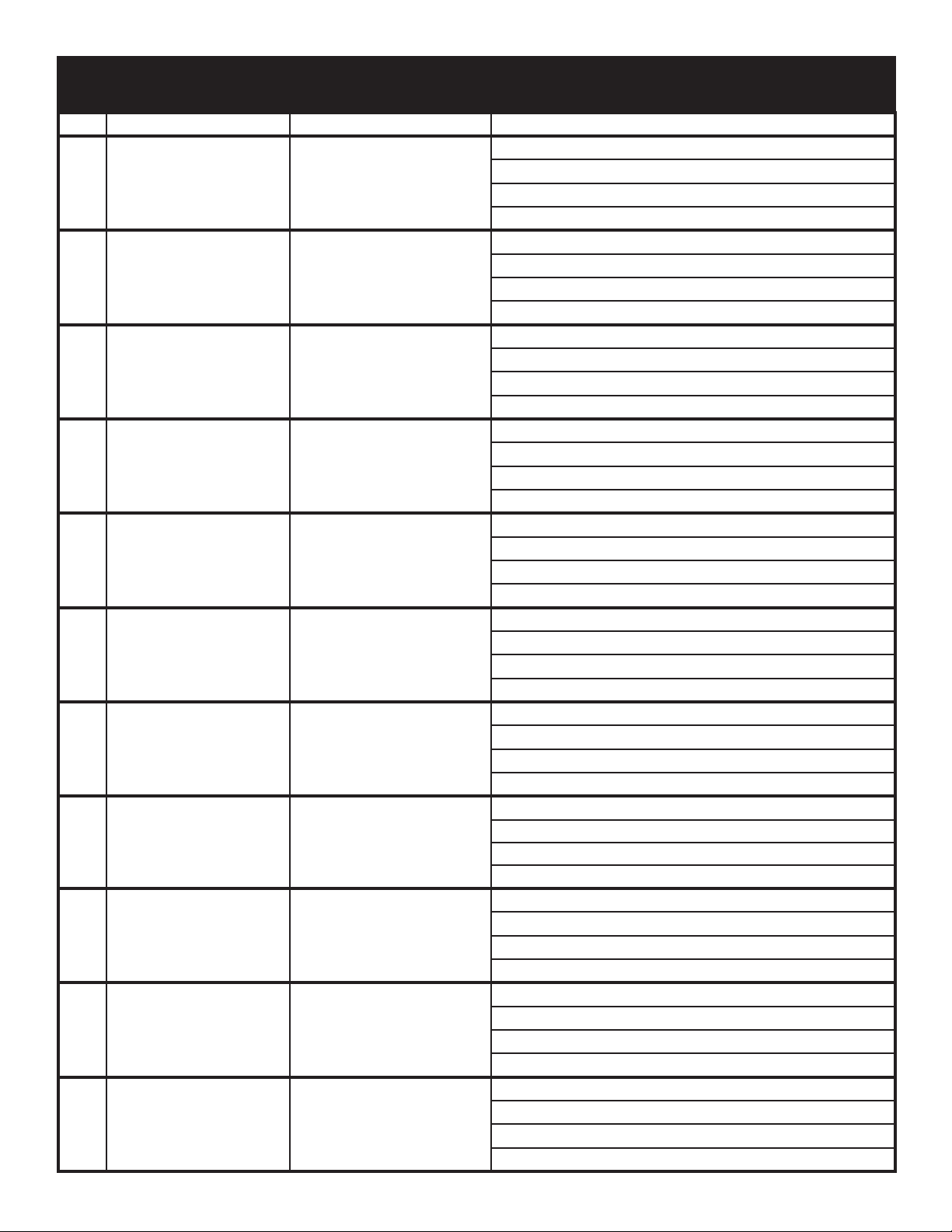

P4X SERIES PARTS LIST

Index

*Valves are not convertible. To convert the unit to a different gas type, a new valve must be purchased.

Part Description

No.

1 Grill Body Top (with heat indicator, hinge, B073286 B073286 B073286 B073286

1 Grill Body Top (casting only) B076621 B076621 B076621 B076621

2 Heat Indicator (stainless) B101406 B101406 B101406 B101406

3 Lid Handle (stainless) B070486 B070486 B070486 B070486

4 Foam Grip B073097 B073097 B073097 B073097

5 Warming Rack (stainless) B072696 B072696 B072696 B072696

6 Cooking Grid (2 piece Stainless Steel B101321 B101321 B101321 B101321

7 Briquette Bag B058122 B058122 N/A N/A

8 Briquette Rack B067449 B067449 B067449 B067449

9 Burner Assembly B101513 B101513 B101513 B101513

10 Wind Deector B063065 B063065 B063065 B063065

11 Bridge Pin B057805 B057805 B057805 B057805

12 Hinge Pin B057804 B057804 B057804 B057804

13 Lid Stop Kit DPA106 DPA106 DPA106 DPA106

14 Orice - LPG (#55 drill) P182 P182 P182 P182

15 Orice - NAT (#49 drill) P265 P265 P265 P265

16 Electric Ignitor B072218 B072218 B072218 B072218

17* Valve - LPG B101420 B101420 B101420 B101420

18* Valve - NAT B101421 B101421 B101421 B101421

19 Shelf Pin B073963 B073963 B073963 B073963

20 Control Panel Assembly (with label) B101515 B101515 B101515 B101015

20 Control Panel Label (not shown) B101518 B101518 B101518 B101518

21 Valve Knob - Black B070084 B070084 B070084 B070084

22 Grill Body Bottom (casting only) B101443 B101443 B101443 B101443

23 Control Panel Shield B101621 B101621 B101621 B101621

24 Ignitor Ground Wire B072684 B072684 B072684 B072684

25 Ignitor Grounding Lug B069747 B069747 B069747 B069747

26 Collector Box Spacer B069743 B069743 B069743 B069743

27 Collector Box B100446 B100446 B100446 B100446

28 Flare Busters Kit N/A N/A DPA117 DPA117

32 Hose & LPS Regulator B069756 B069756 B069756 B069756

33 Hardware Package - LPG & NAT B01655 B101655 B101655 B101655

34 Burner Bracket B101648 B101648 B101648 B101648

P4X P4XN P4XF P4XFN

Part Number

B101623-5-1012 Page 9

Page 10

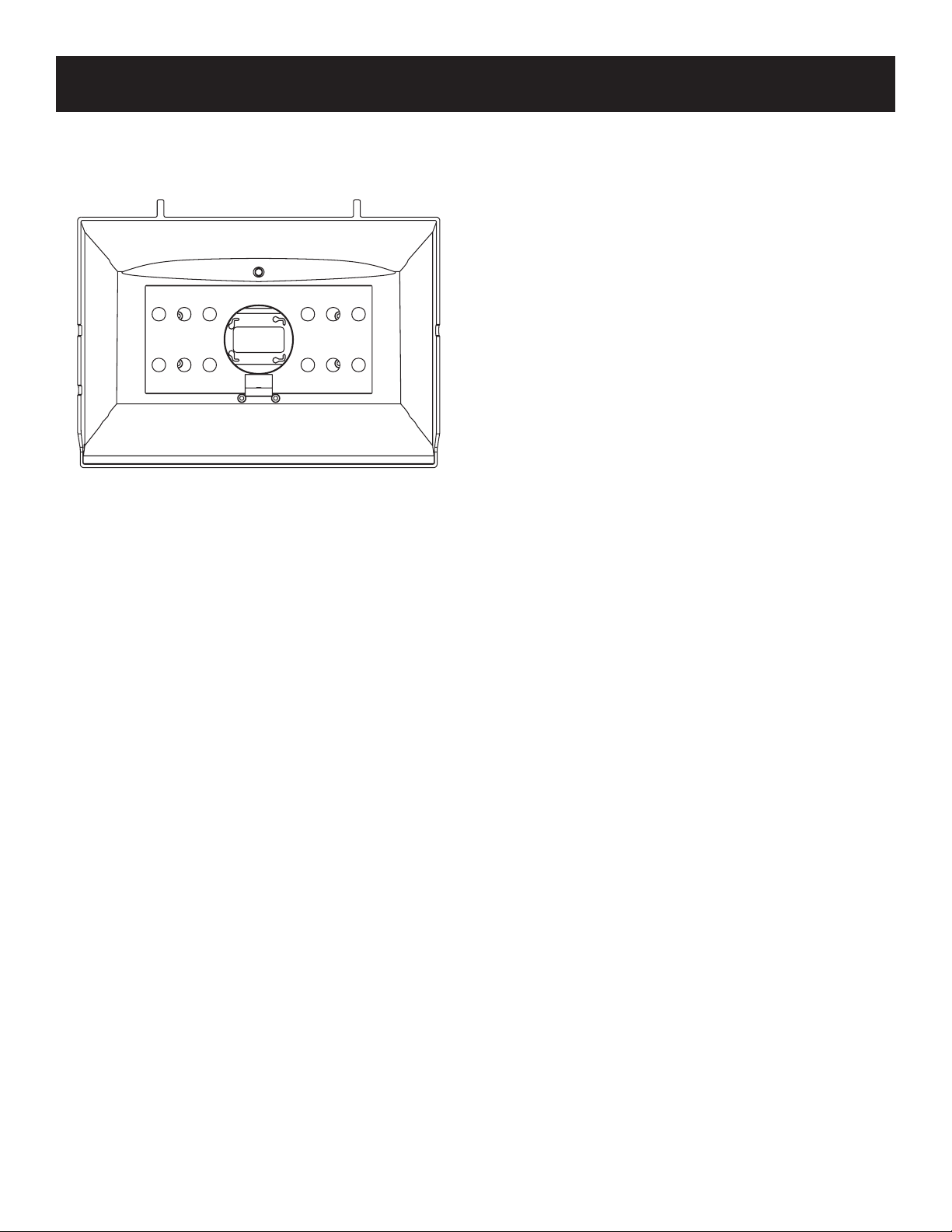

H3X SERIES PARTS DIAGRAM

All repair part orders should be placed through your local Broilmaster® dealer. To locate a dealer in your

area visit www.broilmaster.com. To ensure prompt and accurate service, please provide the following

information when placing a repair part order: Model Number, Serial Number, Part Name, Part Number,

and Quantity of parts needed.

B101623-5-1012Page 10

Page 11

H3X SERIES PARTS LIST

Index No. Part Description

1 Grill Body Top (with heat indicator, hinge, B100453 B100453

1 Grill Body Top (casting only) B100456 B100456

2 Heat Indicator (stainless) B101406 B101406

3 Lid Handle (stainless) B070486 B070486

4 Foam Grip B073097 B073097

5 Warming Rack (Chrome) B100594 B100594

6 Cooking Grid (2 piece Stainless Steel) B101397 B101397

7 Briquette Bag B058122 B058122

8 Briquette Rack B101061 B101061

9 Burner Assembly B101436 B101436

10 Wind Deector B063065 B063065

11 Bridge Pin B057805 B057805

12 Hinge Pin B057804 B057804

13** Lid Stop Kit DPA106 DPA106

14 Orice - LPG (#55 drill) P182 P182

15 Orice - NAT (#49 drill) P265 P265

16 Electric Ignitor B072218 B072218

17* Valve - LPG B101420 B101420

18* Valve - NAT B101421 B101421

19 Shelf Pin B073963 B073963

20 Control Panel Assembly (with label) B101563 B101563

20 Control Panel Label (not shown) B101517 B101517

21 Valve Knob - Black B070084 B070084

22 Grill Body Bottom (casting only) B101418 B101418

23 Control Panel Shield B101622 B101622

24 Ignitor Ground Wire B072684 B072684

25 Ignitor Grounding Lug B069747 B069747

26 Collector Box Spacer B069743 B069743

27 Collector Box B100446 B100446

28 Hose & LPS Regulator B069756 B069756

29 Hardware Package B101656 B101656

30 Burner Bracket B101648 B101648

*Valves are not convertible. To convert the unit to a different gas type, a new valve must be purchased.

** Note: H3 Series grills do not come with a Lid Stop Kit. The Lid Stop Kit must be purchased separately.

H3X H3XN

Part Number

B101623-5-1012 Page 11

Page 12

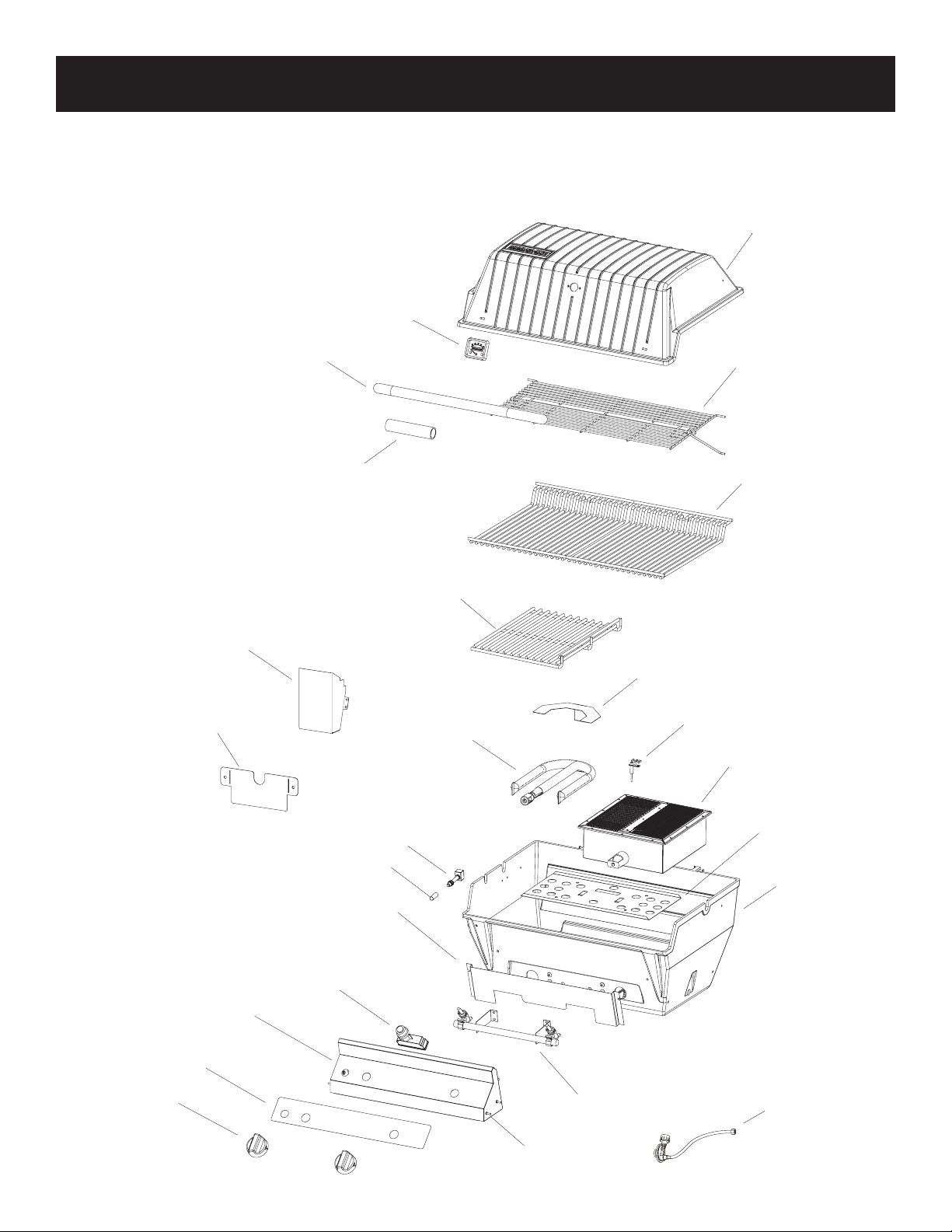

H4X SERIES PARTS DIAGRAM

1

5

6

7

8

2

3

4

32

12

22

10

11

9

27

26

25

24

17 or 18

14 or 15

21

16

34 23

20

19

B101623-5-1012Page 12

Page 13

H4X SERIES PARTS LIST

Index

13** Lid Stop Kit DPA106 DPA106

*Valves are not convertible. To convert the unit to a different gas type, a new valve must be purchased.

** Note: H4 Series grills do not come with a Lid Stop Kit. The Lid Stop Kit must be purchased separately.

Part Description

No.

1 Grill Body Top (with heat indicator, hinge, B073286 B073286

1 Grill Body Top (casting only) B076621 B076621

2 Heat Indicator (stainless) B101406 B101406

3 Lid Handle (stainless) B070486 B070486

4 Foam Grip B073097 B073097

5 Warming Rack (stainless) B072696 B072696

6 Cooking Grid B101492 B101492

7 Briquette Bag B058122 B058122

8 Briquette Rack B067449 B067449

9 Burner Assembly B101618 B101618

10 Wind Deector B063065 B063065

11 Bridge Pin B057805 B057805

12 Hinge Pin B057804 B057804

14 Orice - LPG (#122 mm) P312 P312

15 Orice - NAT (#50 drill) P245 P245

16 Electric Ignitor B072218 B072218

17* Valve - LPG B101420 B101420

18* Valve - NAT B101421 B101421

19 Shelf Pin B073963 B073963

20 Control Panel Assembly (with label) B101515 B101515

20 Control Panel Label (not shown) B101518 B101518

21 Valve Knob - Black B070084 B070084

22 Grill Body Bottom (casting only) B101443 B101443

23 Control Panel Shield B101621 B101621

24 Ignitor Ground Wire B072684 B072684

25 Ignitor Grounding Lug B069747 B069747

26 Collector Box Spacer B069743 B069743

27 Collector Box B100446 B100446

32 Hose & LPS Regulator B069756 B069756

33 Hardware Package - LPG & NAT B101656 B101656

34 Burner Bracket B101648 B101648

Part Number

H4X H4XN

B101623-5-1012 Page 13

Page 14

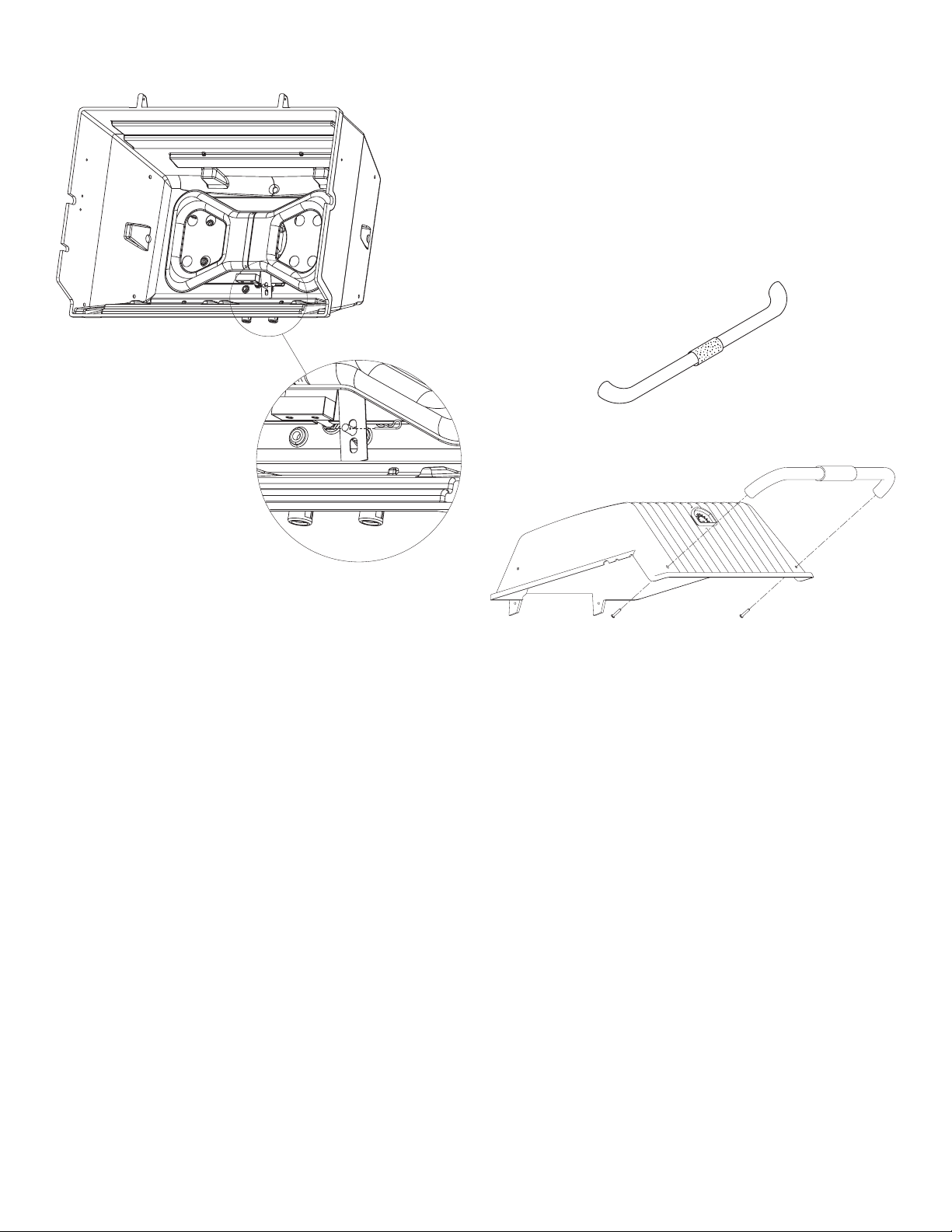

R3 SERIES PARTS DIAGRAM

All repair part orders should be placed through your local Broilmaster dealer. To locate a dealer in your

area, visit www.Broilmaster.com. To ensure prompt and accurate service, please provide the following

information when placing a repair part order: Model Number, Serial Number, Part Name, Part Number,

and Quantity of parts needed.

1

2

25

24

3

4

7

9

15

8

5

6

12

22

21

20

19

10

11

16

18

17

13

14

23

B101623-5-1012Page 14

Page 15

R3 SERIES PARTS LIST

Index

No.

10 Collector Box Assembly N/A N/A B101212 B101212

11 Ignitor Spacer N/A N/A B101082 B101082

12 Infrared Burner (1 required) N/A N/A B101269 B101269

12 Infrared Burner (2 required) B101269 B101269 N/A N/A

13 Wind Deector B101045 B101045 B101045 B101045

14 Grill Body Bottom - Black B101313 B101313 B101313 B101313

15 Infrared Ignitor (1 Required) N/A N/A B101271 B101271

15 Infrared Ignitor (2 Required) B101271 B101271 N/A N/A

16 Control Panel Shield B101046 B101046 B101046 B101046

17 Pin, Shelf B073963 B073963 B073963 B073963

18 Manifold And Valve Assembly B101356 B101316 B101314 B101317

19 Electronic Ignitor B072218 B072218 B072218 B072218

20 Control Panel Assembly B101033 B101033 B101033 B101033

21 Control Panel Label B101272 B101272 B101272 B101272

22 Valve Knob R3918 R3918 R3918 R3918

23 Hose And LP Regulator B069756 N/A B069756 N/A

24* Control Housing - Stainless Steel B101121 B101121 B101121 B101121

25** Cover Plate - Black B101596 B101596 B101596 B101596

25a** Cover Plate - Black B101767 B101767 B101767 B101767

25** Cover Plate - Stainless Steel B101597 B101597 B101597 B101597

25b** Cover Plate - Stainless Steel B101768 B101768 B101768 B101768

N/S Char-Master Briquets N/A N/A B101323 B101323

N/S Hardware Pack B101274 B101275 B101309 B101310

N/S Bridge Pin B057805 B057805 B057805 B057805

N/S Hinge Pin B057804 B057804 B057804 B057804

N/S Natural Gas Conversion Kit BCK1004 N/A BCK1004 N/A

N/S Ground Lug (2 Required) B069747 B069747 N/A N/A

N/S Ground Wire B072684 B072684 N/A N/A

N/S Hardware Pack, Adjustable Lid Stop B101097 B101097 B101097 B101097

N/S - NOT SHOWN

*Control Housing is used only when installing grill head onto cart. See the instructions that come with the cart for Control Housing

installation instructions.

** Cover Plate is used only when installing grill head onto post. See the instructions that come with the post for Cover Plate installation

instructions.

Description

1 Grill Body Top - Black B100456 B100456 B100456 B100456

2 Heat Indicator (Stainless) B101118 B101118 B101118 B101118

3 Lid Handle (Stainless) B070486 B070486 B070486 B070486

4 Foam Grip B073097 B073097 B073097 B073097

5 Stainless Steel Retract-A-Rack B072695 B072695 B072695 B072695

6 Stainless Steel Rod Cooking Grid B101282 B101282 B101282 B101282

7 Briquet Rack N/A N/A B101369 B101369

8 Burner N/A N/A B101030 B101030

9 Burner Shield N/A N/A B101154 B101154

R3 R3N R3B R3BN

Part Number

B101623-5-1012 Page 15

Page 16

GRILL ASSEMBLY

Before You Begin

All Broilmaster grills require some assembly and installation. Follow

all instructions unless noted to apply only to other specic models.

If you purchased an accessory with your Broilmaster, follow

the instructions provided with the accessory for assembly and

installation. If an instruction refers to a step that is not required for

your grill model, please continue to the next step.

Compare the parts found in the shipping container to the parts list

provided. If any parts are missing contact your Broilmaster® dealer

before beginning assembly.

CAUTION: FOR YOUR SAFETY

Parts may have sharp edges. Wear leather work gloves and

handle parts carefully during the unpacking, assembly and

installation.

Recommended Tools

These items are recommended for the assembly of your grill:

Do NOT use power tools.

• Phillips screwdriver

• Adjustable wrench set

• Socket set

• Soapy water solution (to test for leaks)

• Liquid soap (for foam grip)

Grill Mountings

Assemble your base option before assembling your Broilmaster® grill head.

Refer to the Broilmaster® Cart, Base, and Post instructions

provided with each accessory for assembly, installation, and

mounting procedures.

WARRANTY TERMS

Empire Comfort Systems Inc. warranties this Broilmaster premium gas grill to be free from defects at the time of purchase and for the

periods specied below. Broilmaster Premium Gas Grills must be installed by a qualied technician and must be maintained and operated safely, in accordance with the instructions in the owner’s manual. This warranty applies to the original purchaser only and is not

transferable. All warranty repairs must be accomplished by a qualied gas appliance technician.

Limited Lifetime Parts Warranty – Against Rust-Through

If the items listed below fail because of defective workmanship or material, Empire will repair or replace at Empire’s option.

• Aluminum Grill Housing (except paint)

• Stainless Steel Rod Cooking Grids and Stainless Steel Griddles

• Select Stainless Steel Components – Cart, Mounting, Bowtie Burner, Side Burner (DPSBSS), Side Burner Housing, and

Warming Rack

• Stainless Steel Built-In Components – Built-In Kits for 3-Series Grill Heads, Door Kit, Tilt-Out LP Tank Door, and Vent Register

Kit

Limited Ten-Year Parts Warranty – Against Rust-Through

If the items listed below fail because of defective workmanship or material, Empire will repair or replace at Empire’s option.

• H-Series and R3B Stainless Steel Burners

• Side Burner (DPASBC), Side Burner Housing (BSA)

B101623-5-1012Page 16

Page 17

WARRANTY TERMS

Limited Five-Year Parts Warranty – Against Rust-Through

If the items listed below fail because of defective workmanship or material, Empire will repair or replace at Empire’s option.

• Infrared Burners on R3 or R3B

• Flare Buster™ Ceramic Flavor Enhancers

• Painted Electro-Galvanized Steel Components

• Stainless Steel Smoker Shutter

Limited Two-Year Parts Warranty – Against Rust-Through

If the items listed below fail because of defective workmanship or material, Empire will repair or replace at Empire’s option.

• Porcelain Coated Steel Briquette Racks

• Chrome-Plated Warming Rack

• Stainless Steel Flavor Screen

• Stainless Steel Heat Shield

Limited One-Year Parts Warranty

If the items listed below fail because of defective workmanship or material, Empire will repair or replace at Empire’s option.

• Valves, knobs, ignitors, labels, hoses, ttings and all other parts and accessories – including those made from stainless steel –

unless specied above

• Paint on Aluminum Grill Head

Duties Of The Owner

The appliance must be installed by a qualied installer and operated in accordance with the instructions furnished with the appliance.

A bill of sale, cancelled check, or payment record should be kept to verify purchase date and establish warranty period.

Ready access to the appliance for service.

What Is Not Covered

Damages that might result from the use, misuse, or improper installation or storage of this appliance.

Travel, diagnostic costs and freight charges on warranted parts to and from the factory.

Claims that do not involve defective workmanship or materials.

Unauthorized service or parts replacements.

Removal and reinstallation cost.

Inoperable due to improper or lack of maintenance.

The costs of a service call to diagnose a problem and labor for replacement or repairs.

How To Get Service

To make a claim under this warranty, please have your receipt available and contact your installing dealer. Provide the dealer

with the model number, serial number, type of gas, and purchase verication. The installing dealer is responsible for providing service

and will contact the factory to initiate any warranted parts replacements. Empire will make replacement parts available at the factory.

Shipping expenses are not covered.

If, after contacting your Empire dealer, service received has not been satisfactory, contact: Consumer Relations Department,

Empire Comfort Systems Inc., PO Box 529, Belleville, Illinois 62222, or send an e-mail to info@empirecomfort.com with “Consumer

Relations” in the subject line.

Your Rights Under State Law

This warranty gives your specic legal rights, and you may also have other rights, which vary from state to state.

Broilmaster is a Division of Empire Comfort Systems, Inc.

B101623-5-1012 Page 17

Page 18

PROPANE GAS GRILLS

Grill Location

When choosing the ideal location for your Broilmaster® Premium

Gas Grill, remember this grill is designed for outdoor use ONLY.

You should never install or operate your grill in any building, garage,

or other enclosed area.

For your safety, this grill should not be installed or operated under

any combustible materials, such as carports, covered porches,

awnings, or overhangs.

Never install or operate your grill in or on any recreational vehicle

or boat.

CAUTION: The installation and operation of this grill at clear-

ances less than specied below may lead to the possibility of

re, property damage, or personal injury.

A minimum clearance of sixteen inches (16") is required from the

sides of the grill to any combustible material.

A minimum clearance of eighteen inches (18") is required from the

back of the grill to any combustible material.

Some examples of combustible materials are a wall, a fence, patio

furniture, or the wall of your home.

The area surrounding the grill should be clear to ensure proper

ventilation. Do not obstruct the ow of combustion and ventilation

air in any way. The ventilation openings on the propane cylinder

enclosure must also remain free and clear of debris.

The maximum height allowable for a replacement cylinder is approximately twelve (12") inches (30.5 centimeters)

The propane gas cylinder used must be:

1. Constructed and marked in accordance with the specications

for LP gas cylinder of the U.S. Department of Transportation

(D.O.T.) or the National Standard of Canada, CAN/CSA-B339,

Cylinders, Spheres, and Tubes for Transportation of Dangerous

Goods; and Commission as applicable.

2. Provided with a listed overlling protection device (OPD).

3. Provided with a listed safety device having direct access with

the vapor space of the cylinder and the cylinder supply system

must be arranged for vapor removal.

4. Provided with a shutoff valve terminating in a valve outlet as

specied in the Standard for Compressed Gas Cylinder Outlet

and Inlet Connections, ANSICGA-V-1.

5. Provided with a plug to effectively seal off the cylinder outlet

when the cylinder is being stored or transported.

6. Provided with a collar to protect the cylinder valve.

Caution: Do not use a propane gas cylinder which has a

capacity greater than twenty (20) pounds with this grill and

side burner.

.

Portable grills should be level and positioned away from direct wind

prior to each use.

WARNING: Do not install or operate this grill where gaso-

line or other ammable materials are used or stored. Failure

to comply with this warning could result in explosion or re

causing property damage or personal injury.

Cylinder Requirements

Your Broilmaster® Premium Gas Grill requires a standard twenty

(20) pound propane gas cylinder.

B101623-5-1012Page 18

Page 19

PROPANE GAS GRILLS

Propane Cylinder Safety

Liquid Propane (LP) gas has a long history of safe use when the

safety precautions provided in this manual are followed.

Failure to follow these safety precautions could result in a

re or explosion causing property damage or personal injury.

Propane gas cylinders should always be handled, stored, and

transported with extreme caution in a secured upright position.

Never attempt to use or repair a propane gas cylinder that has been

damaged. Never attempt to use or repair a cylinder with a faulty or

damaged valve outlet. A cylinder that has been dropped, dented,

or otherwise damaged must be replaced.

A propane gas cylinder should never be transported in the passenger area of a vehicle.

Keep cylinders out of direct sunlight and never apply any other

source of direct heat to them.

When relling your cylinder, always insist on a reputable, qualied

gas dealer. Your propane gas cylinder is lled by weight, and should

never exceed eighty percent (80%) of its weight limit. If the cylinder is not completely empty, the gas dealer must make necessary

adjustments to ensure it is not overlled. Never use an overlled

Propane gas cylinder.

installation shall be in accordance with CAN/CGA-B149.2 Propane

Installation Code, or CAN/CGA-B149.1 Natural Gas Installation

Code, and local codes where applicable. Consult your local gas

supplier or propane gas dealer for code regulations and recommended procedures.

Warning: Broilmaster® Premium Gas Grills require Liquid

Propane (LP) cylinders equipped with an Overll Protection

Device (OPD). An overlled or improperly lled Propane cyl-

inder can be dangerous.

Always use the pressure regulator and hose assembly supplied

with your Propane gas grill.

Note: Not all valve and cylinder combinations are compatible.

Check warning tag on valve and cylinder as well as external tting

threads.

All Broilmaster® pressure regulators and hose assemblies require

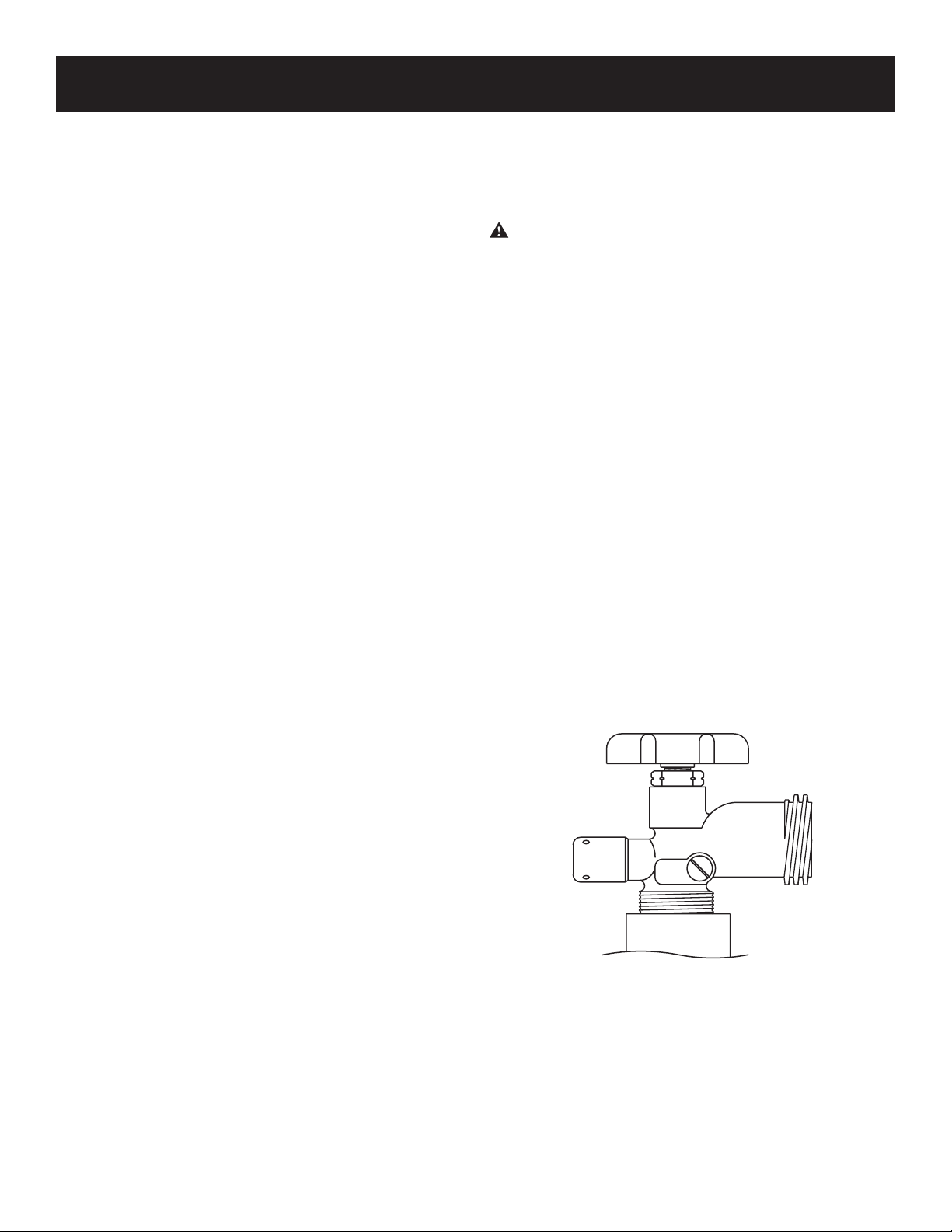

Propane cylinders with a Type 1 connection device as illustrated.

See Figure 1.

Cylinder Storage

Your grill must be stored outdoors in a well ventilated area if the

cylinder is attached to it.

Disconnected cylinders must have a threaded valve plug tightly

installed and must not be stored in any building, garage, or other

enclosed area.

Flammable materials (gasoline, grill covers, etc.) must not be stored

in the cylinder enclosure.

Always store Propane cylinders in a secured upright position, out

of the reach of children.

Connection Requirements

Caution: Never use Liquid Propane (LP) gas in a grill designed

for Natural gas, or Natural gas in a grill designed for Liquid

Propane gas. Questions regarding different types of gases

should be directed to your local gas supplier.

Installation must conform to local codes or, in the absence of local

codes, with the National Fuel Gas Code, ANSI Z223.1. In Canada,

Figure 1

B101623-5-1012 Page 19

Page 20

PROPANE GAS GRILLS

Pressure Regulator and Hose Assembly

The pressure regulator has an outlet pressure of not more than eleven (11") inches water column. It must be connected to the Propane

gas cylinder’s female valve outlet before the grill can be operated.

Caution: Operation of a Propane gas grill without the pressure regulator and hose assembly will cause gas leaks which could

lead to re or explosion, resulting in property damage or personal injury.

The pressure regulator’s tting must remain clean and free of nicks and scratches. A dirty, nicked or scratched tting can cause a gas

leak, resulting in an explosion or re. Use only genuine Broilmaster® replacement parts unless otherwise specied by the manufacturer.

Connecting to Propane Gas / Cylinder Retention Means

ATTENTION: Propane gas cylinders that are acceptable for use with this grill must comply with Cylinder Requirements, Page 18,

and Connection Requirements, Page 19.

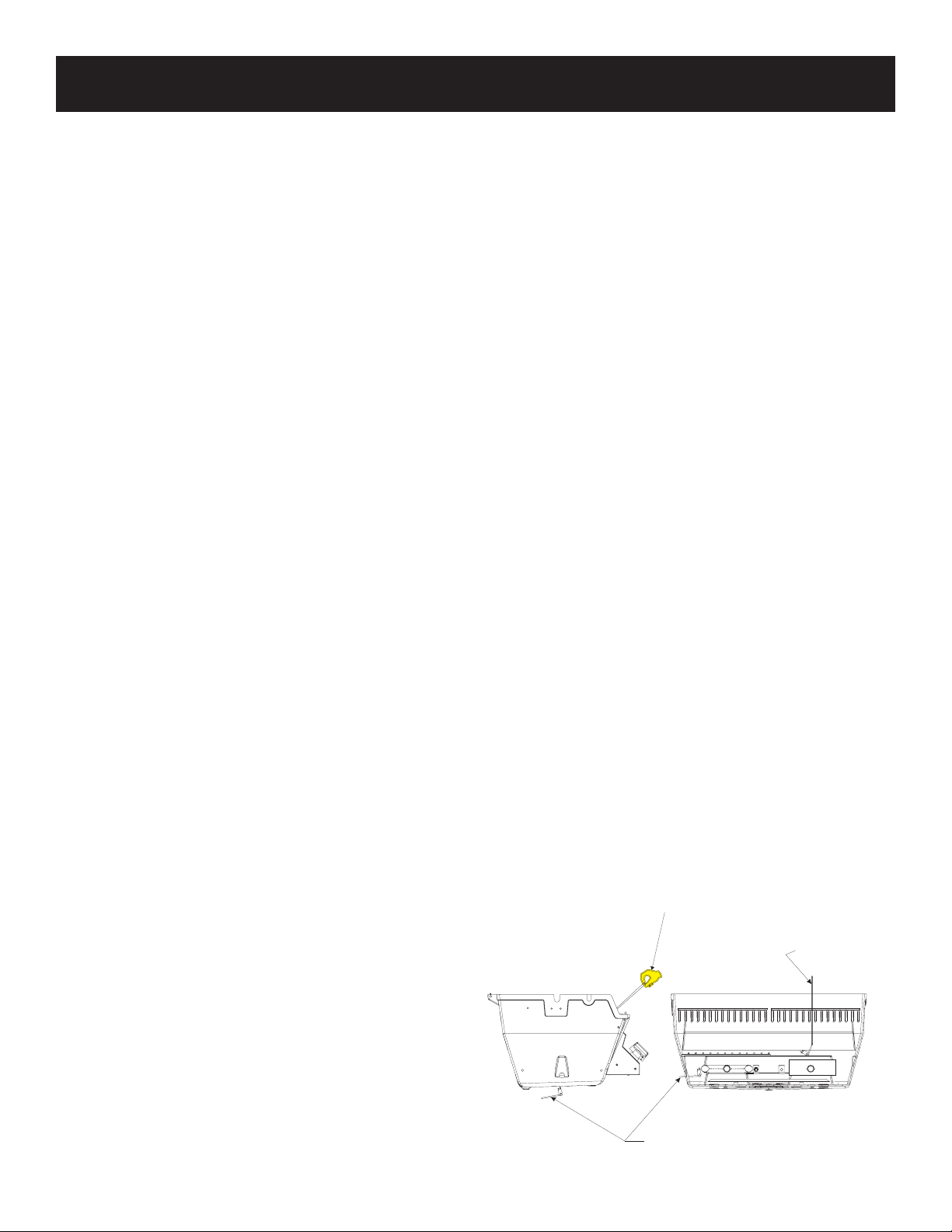

Position the cylinder in the opening in the bottom of the cart and secure with the cylinder retaining bracket. See Figure 2.

Figure 2

Attach the pressure regulator to the Propane gas cylinder’s valve

using the plastic handwheel. Tighten in a clockwise motion to

achieve a gas tight seal. See Figure 3.

Caution: Do not use a wrench or any other tool to tighten. Use

of a wrench or other tool will damage the plastic handwheel.

To disconnect the Propane gas cylinder, turn OFF the cylinder’s

valve and the grill’s control valve. Remove the regulator by turning

the plastic handwheel counterclockwise.

Caution: Assure hose does not touch the casting or mounting

components.

CLOCKWISE

Figure 3

B101623-5-1012Page 20

Page 21

NATURAL GAS GRILLS

Grill Location

When choosing the ideal location for your Broilmaster Premium

Gas Grill, remember this grill is designed for outdoor use ONLY.

You should never install or operate your grill in any building, garage,

or other enclosed area.

For your safety, this grill should not be installed or operated under

any combustible materials, such as carports, covered porches,

awnings, or overhangs.

Never install or operate your grill in or on any recreational vehicle

or boat.

CAUTION: The installation and operation of this grill at clear-

ances less than specied below may lead to the possibility of

re, property damage, or personal injury.

A minimum clearance of sixteen (16") inches is required from the

sides of the grill to any combustible material.

A minimum clearance of eighteen (18") inches is required from the

back of the grill to any combustible material.

Some examples of combustible materials are a wall, a fence, patio

furniture, or the wall of your home.

The area surrounding the grill should be clear to ensure proper

ventilation. Do not obstruct the ow of combustion and ventilation

air in any way. The ventilation openings on the propane cylinder

enclosure must also remain free and clear of debris.

Portable grills should be level and positioned away from direct wind

prior to each use.

Connection Requirements

Broilmaster grills are not equipped with pressure regulators. Your

gas grill operates at a manifold pressure of seven (7") inches water

column.

Connect cart mounted Natural gas grills to a pre-installed gas sup-

ply line using the twelve (12’) foot exible hose and quick disconnect

kit which can be purchased from your local dealer.

Hazardous Locations and Conditions

• The LP gas cylinder must be arranged upright for vapor withdrawal.

• Do not obstruct the ow of combustion and ventilation air.

• This grill should only be used outdoors in a well-ventilated space

must not be used in a building, garage, or any other enclosed

area.

• Keep all ammable substances away from the grill. These

include most aerosols and aerosol containers, gasoline and

similar liquids, paper and paper products, containers of grease,

paint, etc.

• Never store ammable materials or objects such as those

described above in the pedestal base.

• Never leave grill unattended while in operation.

• Never use any liquid in an attempt to control are-up.

• It may be necessary to adjust your grill away from the direction

of prevailing wind.

• Avoid wearing ammable and/or loose clothing such as long-

sleeves, neckties, scarves, aprons, etc., while the grill is in

operation.

• Avoid contact of hair to heat and ames.

Caution: The grill and its individual shutoff valve must be

disconnected from the gas supply piping system during any

system pressure testing at test pressures in excess of 1/2 PSIG.

WARNING: Do not install or operate this grill where gaso-

line or other ammable materials are used or stored. Failure

to comply with this warning could result in explosion or re

causing property damage or personal injury.

Gas Type

The type gas required for your grill can be determined from the

product identication label located on the grill’s control panel.

Questions regarding different types of gases should be directed to

your local gas supplier.

Caution: Never use Liquid Propane (LP) gas in a grill designed

for Natural gas, or Natural gas in a grill designed for Liquid

Propane gas. Questions regarding different types of gases

should be directed to your local gas company.

Caution: The grill must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 PSIG.

B101623-5-1012 Page 21

Page 22

Owner’s Manual For Models

P3X-1 P4X-1 H3X-1 H4X-1

P3SX-1 P4XF-1 H3XN-1 H4XN-1

P3XF-1 P4XN-1

P3XN-1 P4XF-1

P3SXN-1

P3XF-1

GAS-FIRED

B101623-5-1012Page 22

Page 23

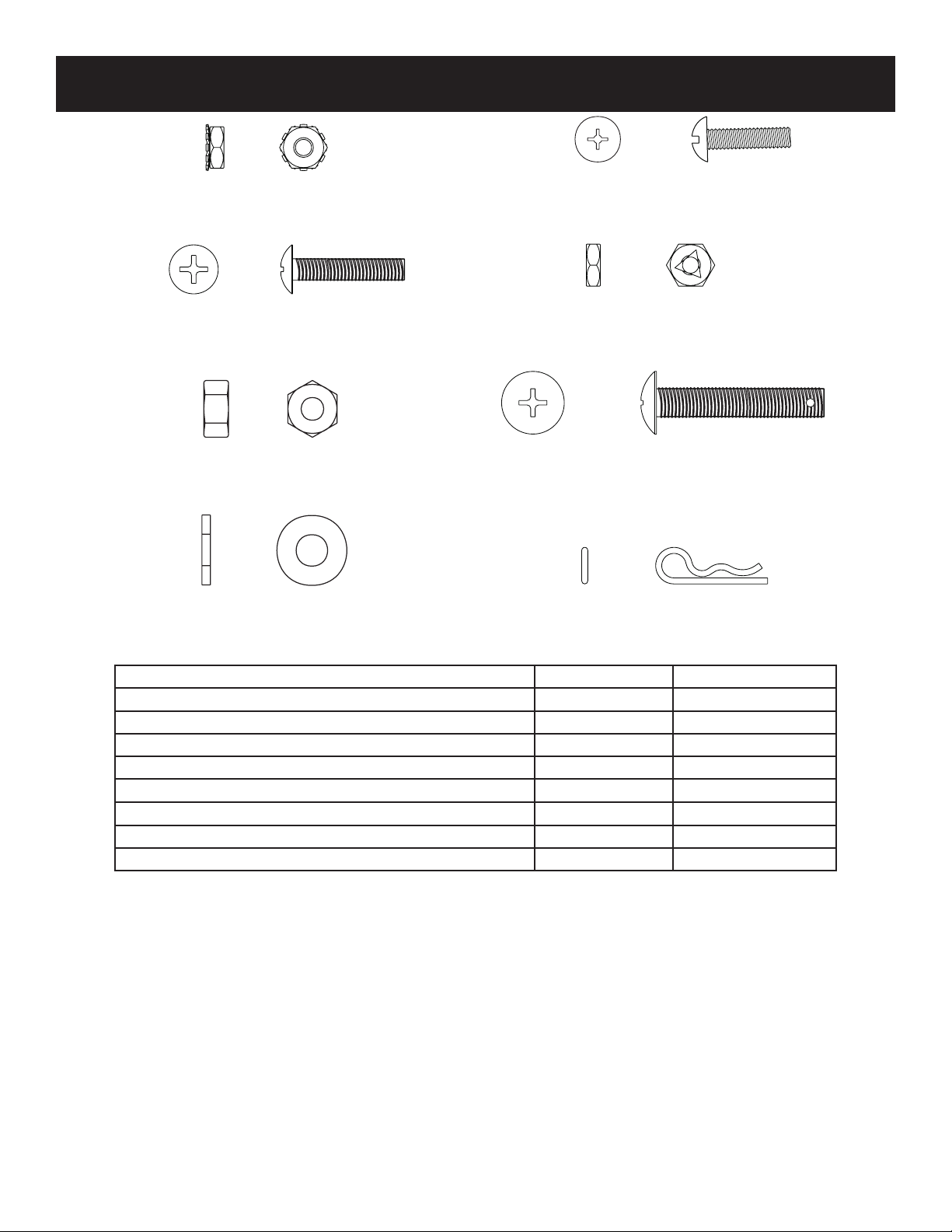

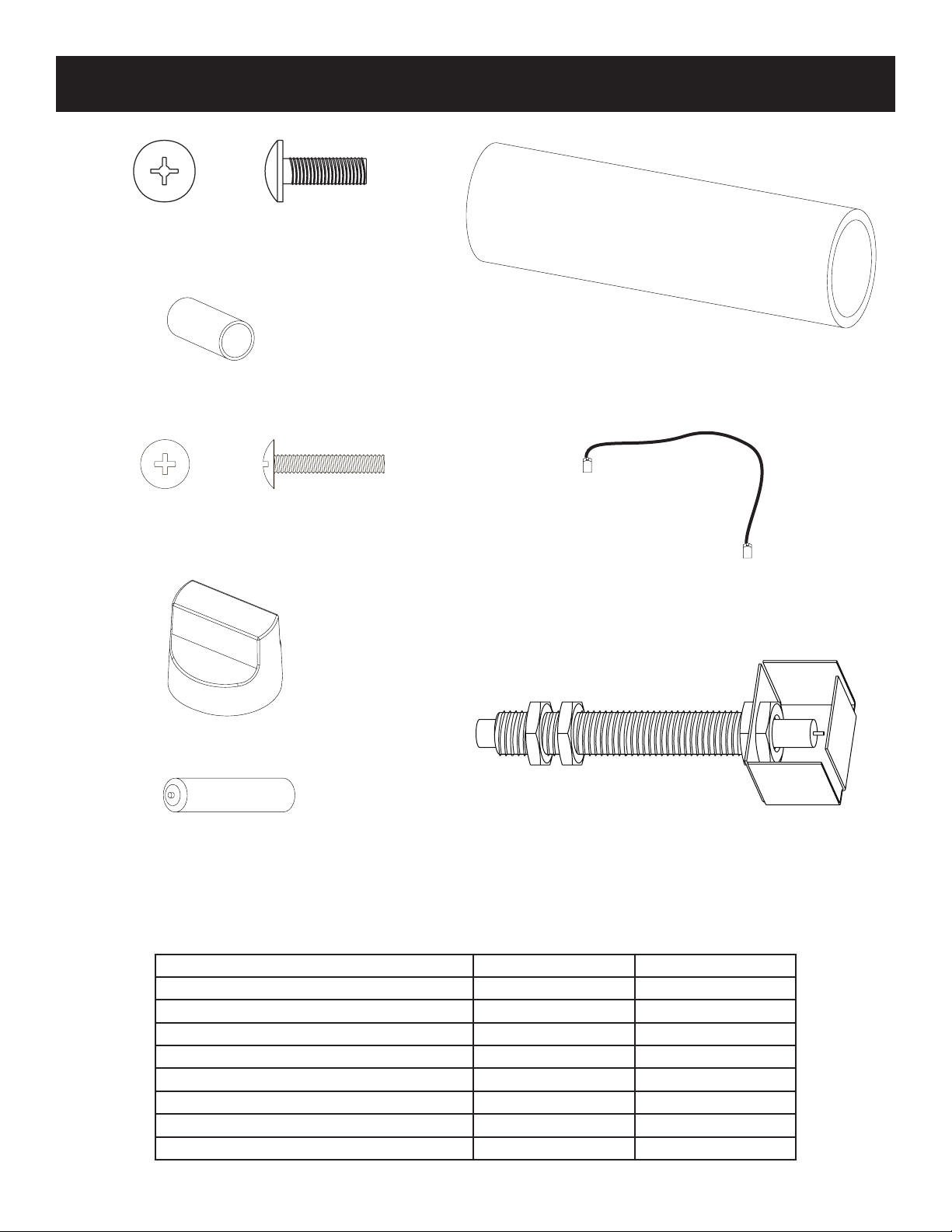

HARDWARE PACK

1/4 ID X 5/8 OD FLAT WASHER

PHILLIPS TRUSS HEAD SCREW 1/4-20 X 1 1/2

BRIDGE PIN

10-24 KEPS NUT

PHILLIPS TRUSS HEAD SCREW 10-24 X 1

1/4-20 HEX NUT

PHILLIPS TRUSS HEAD SCREW 10-24 X 3/4

10-24 HEX NUT, LOCK

DESCRIPTION PART NUMBER QUANTITY SUPPLIED

10-24 KEPS NUT B073967 2

PHILLIPS TRUSS HEAD SCREW 10-24 X 1 B073978 2

1/4-20 HEX NUT B076331 1

1/4 ID X 5/8 OD FLAT WASHER B076332 2

PHILLIPS TRUSS HEAD SCREW 10-24 X 3/4 B662325 1

10-24 HEX NUT, LOCK R4021 1

PHILLIPS TRUSS HEAD SCREW 1/4-20 X 1 1/2 B101649 1

BRIDGE PIN B057805 1

B101623-5-1012 Page 23

Page 24

GRILL ASSEMBLY

Installing the Hose and Regulator

To ease assembly, remove grill top before assembling. Remove the

2 pins and clips at the rear of the grill top and set aside. See Figure 4.

Installing Control Panel Shield

Attach shield by inserting the shield over the studs. See Figure 6.

Figure 6

Figure 4

LP Models: Attach the hose and regulator supplied with the unit as

shown in Figure 5.

Installing Control Panel

Attach control panel assembly to grill bottom with two 10-24 keps

nuts. See Figure 7.

Figure 5

Figure 7

B101623-5-1012Page 24

Page 25

GRILL ASSEMBLY

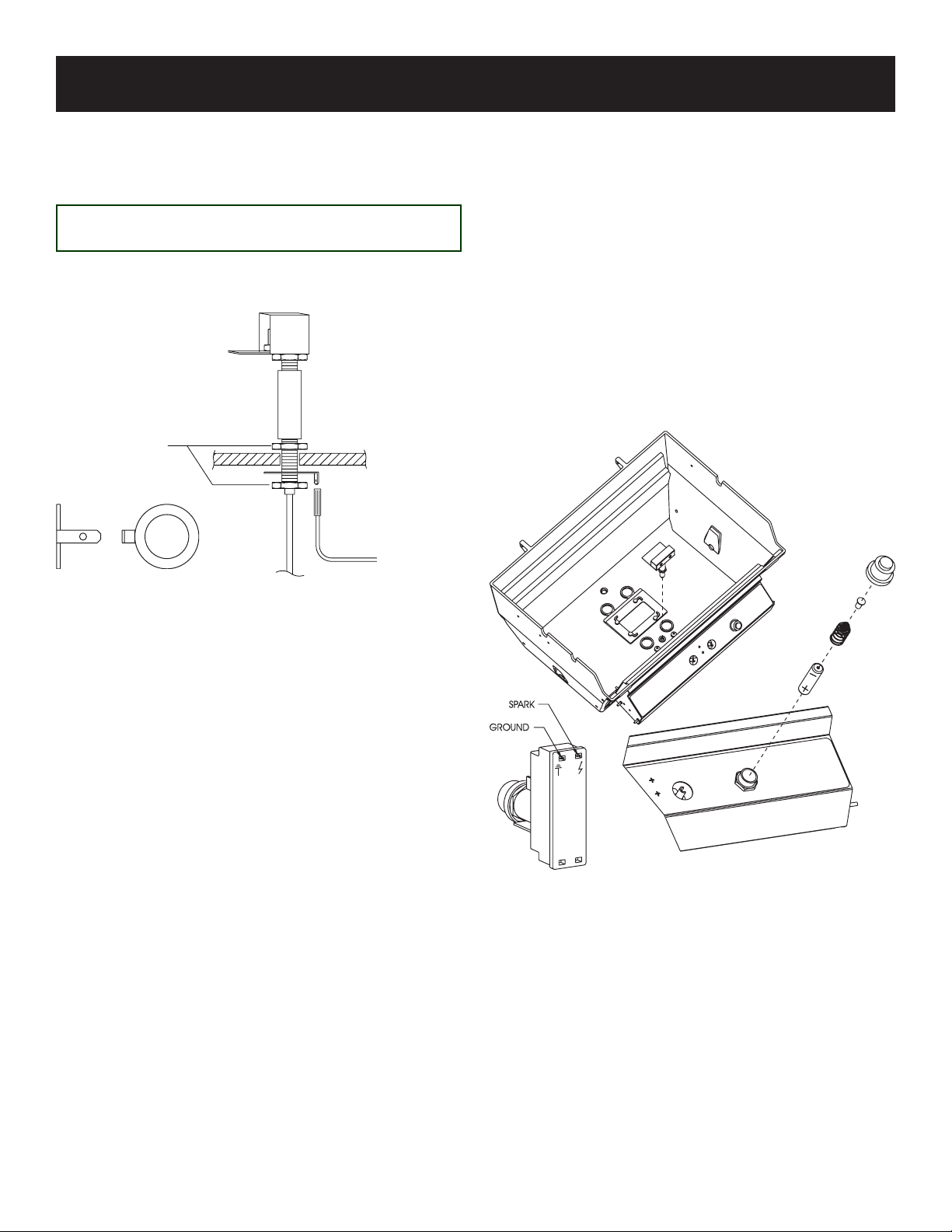

Ignitor Assembly

Slide the collector box spacer and nut (provided on assembly) onto

the collector box shaft and tighten. See Figure 8.

Note: Peel protective lm from control panel label before

installing ignitor.

Nut

Installing the Ignitor

Caution: Do not cut or damage ignitor wire.

Carefully thread the end of the ignitor wire through the center hole

in the grill bottom. Slide the ground lug over the ignitor wire and

fasten with nut provided.

Attach one end of the ground wire to the terminal on the rear of

the electronic ignitor. Attach the remaining end to the ground lug.

See Figures 8 and 9.

Attach ignitor wire to the spark terminal on the rear of the electronic

ignitor.

Figure 8

Figure 9

Installing Control Knobs

Place control knobs onto valve stems. The knobs will only t onto

the stems one way.

B101623-5-1012 Page 25

Page 26

GRILL ASSEMBLY

Wind Deector

Place the wind deector in the grill bottom.

See Figure 10.

Figure 10

B101623-5-1012Page 26

Page 27

6. The burner bracket should be at a slight angle as shown in

Figure 12. Once the proper angle is achieved, tighten the screw

securing the burner bracket to the venturi assembly and burner

body.

11°

C

L

“H” Series Burner Shown

Figure 12

7. Insert the 1/4-20 x 1 1/2 Phillips Truss Head Screw from the

underside of the grill and secure with the 1/4-20 Hex Nut. See

Figure 13.

Installing the Burner

1. Insert the burner assembly into the grill bottom with the venturi

tubes facing the front of the grill. See Figure 14.

Figure 14

Note: If the Grill Head is installed on a PCB1 or DCB1, make sure

the cart shield is not installed until the burner bracket is mounted.

2. Slide the venturi on to the valve assembly.

3. Raise the unsecured end of the burner bracket and slip it over

the 1/4-20 x 1 1/2 Phillips Truss Head Screw as shown in Figure

15. The screw will t into the hole on the burner bracket.

Figure 13

“P” Series Shown

Figure 15

B101623-5-1012 Page 27

Page 28

4. Slide the bridge pin through the hole in the 1/4-20 x 1 1/2 Phil-

lips Truss Head Screw as shown in Figure 16.

Handle

For your added comfort a foam grip has been provided. See

Figure 17.

Tip: For ease of installation, slightly lubricate the front handle with

liquid soap before pushing the foam grip into place.

Fasten the front handle to the grill lid with two #10-24 x 1" screws.

See Figure 18.

Figure 17

Figure 16

Figure 18

Install side shelves or side burner to side of grill at this time.

Reinstall grill top to grill bottom with 2 pins and clips removed in

Figure 4.

B101623-5-1012Page 28

Page 29

GRILL ASSEMBLY

Lid Stop

Attach the lid stop assembly to the grill bottom as shown.

See Figure 19.

Note: H3X/H4X Series grills do not come with a Lid Stop Kit. The

Lid Stop Kit is available as an accessory.

Figure 19

Installing Flare Busters

Place the briquet rack in the grill.

Position the are busters as shown in Figures 20a and 20b.

P3X

Figure 20a

P4X

Figure 20b

B101623-5-1012 Page 29

Page 30

GRILL ASSEMBLY

Installing Racks

Place the briquet rack or on the burner assembly.

Position the are busters on the briquette rack or the ceramic

briquets evenly on the briquette rack without overlapping. See

Figures 20a and 20b.

For Smoker Shutter installation see DPA100 manual included with

your P3SX grill.

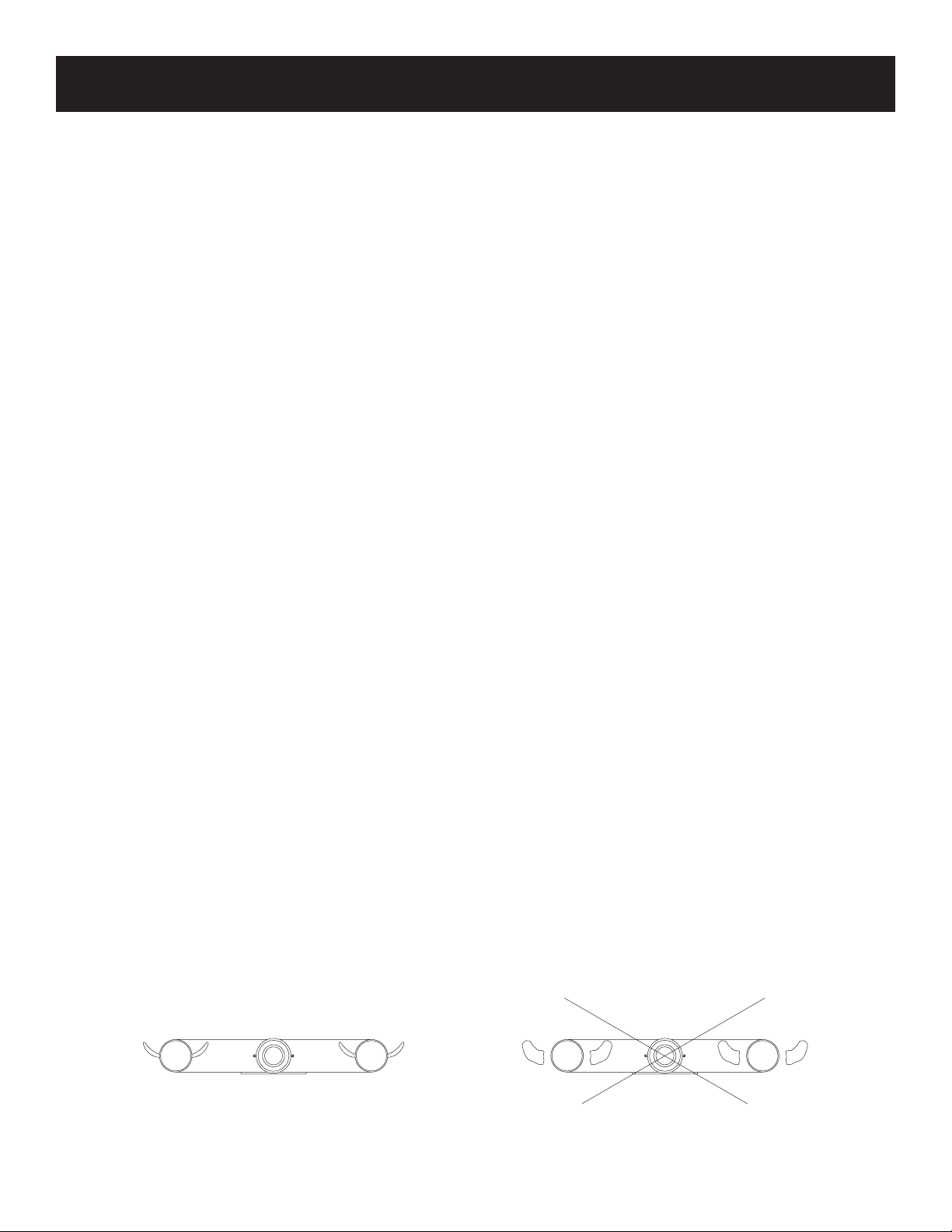

Set the multilevel cooking grids. See Figures 21a and 21b.

Installing Char-Master Briquets

Individually place the ‘Char-Master’ briquets in a single layer evenly

on your grill’s briquet rack; DO NOT dump them onto the briquet

rack. A single layer of ‘Char-Master’ briquets is all that’s needed.

DO NOT overlap or stack the briquets.

See Figure 21b.

Figure 21a

After properly placing the ‘Char-Master’ briquets on your grill’s

briquet rack, there may be some briquets left over. Save them for

future use.

Before cooking, always preheat the grill as directed by the grill’s

operating instructions. Hot briquets cause better, quicker cooking

and better avor.

Cleaning

Routine preheating and routine burn-off (also called post-heating)

of a grill will clean the ‘Char-Master’ briquets. Periodically turn the

briquets over while they are cool.

Note for H3 Package Owners: The side shelf must be installed

before installing the Briquets and Briquet Rack.

Figure 21b

B101623-5-1012Page 30

Page 31

OPERATION - PROPANE & NATURAL GAS GRILLS

Checking for Gas Leaks

Check for gas leaks every time you connect your Broilmaster® propane gas grill to a Propane gas cylinder, when a connected cylinder

has not been used recently, or when either a natural or propane grill

is being used for the rst time.

Caution: Do not use an open ame when checking for leaks.

Checking for leaks with an open ame may lead to a re or

explosion, resulting in property damage or personal injury.

To check for gas leaks:

1. Use dish washing liquid and a little water to make a soapy solution.

2. Turn OFF the knob on the control panel.

3. Turn ON the gas at the supply or cylinder. A hissing sound

indicates a leak. Turn OFF the gas and repair the leak.

4. Apply the soapy water solution to all gas connections.

5. Look for bubbles. Bubbles indicate a leak.

6. If there are bubbles turn OFF the gas and repair the leak.

7. Turn the gas back ON and repeat the above procedures until

all leaks are repaired.

Air Shutter Adjustment

The venturi air shutter(s) are preset at the factory so that after ve

minutes the burner ames are blue with well dened cones. If,

after ve minutes the ame is yellow, or there is a gap between

the burner and the ame, adjust the venturi air shutter as follows:

1. Turn gas OFF and let the burner cool.

2. Loosen shutter set screw

3. Close the air shutter to the minimum opening.

4. Light the burner, wait ve minutes and then carefully open the

air shutter until the ame is blue and well dened.

5. Retighten the set screw.

Operating Instructions

Using the Ignitor

Caution: If a burner fails to light after 5 seconds, turn the burner

OFF for 5 minutes, to allow the gas to clear, then try again.

1. Turn knob on the grill CLOCKWISE to the OFF position.

2. Turn ON gas at the source.

3. With the grill lid open, push and turn the burner control knob

COUNTERCLOCKWISE to Hi.

4. Push and hold the ignitor button until the burner lights (approximately 5 seconds).

5. If a burner does not light, turn OFF all gas and refer to the

Troubleshooting section of this manual.

Operating Instructions

Using Matches

Caution: If a burner fails to light after 5 seconds, turn the burner

OFF for 5 minutes, to allow the gas to clear, then try again.

1. Turn knob on the grill CLOCKWISE to the OFF position.

2. Turn ON gas at the source.

3. Open the grill lid.

4. Insert a burning long wooden match through the lighter hole on

either side of the grill. See Figure 21.

5. Turn the burner control knob COUNTERCLOCKWISE to HI.

6. If a burner does not light, turn OFF all gas and refer to the

Troubleshooting section of this manual.

Figure 22

B101623-5-1012 Page 31

Page 32

OPERATION

Before Cooking

Before cooking on a grill for the rst time, it should be broken in to

burn off any oil residue from the manufacturing process.

1. Raise the grill lid.

2. Light grill burner.

3. Burn on HI for ten minutes.

4. Close the lid and burn on HI for an additional ten minutes.

5. Turn OFF gas. The grill is now ready for use.

Preheating

Before cooking on a gas grill, allow the grill to preheat on HI for 5

minutes with the lid closed.

This uses very little fuel and provides better avor.

Electrical Accessories

If an electrical accessory (e.g. rotisserie) is used on your grill, the

accessory must be electrically grounded in accordance with local

codes or, in the absence of local codes, with the National Electric

Code, ANSI/NFPA 70. In Canada, the electrical accessory must

be electrically grounded in accordance with the applicable section

of the current Canadian Electrical Code, CSA C22.1.

Any electrical accessory should be equipped with a three-prong

(grounding) plug, and plugged into a properly grounded three-prong

receptacle or wall outlet. Do not cut or remove the grounding prong

from the plug.

If an extension cord is required, use only a three-prong cord and

plug into a properly grounded receptacle as described above.

Do not expose an electrical accessory to water. Avoid using any

electrical accessory in wet weather as it may present a shock

hazard.

Keep any electrical cord and fuel supply hose away from all heated

surfaces.

B101623-5-1012Page 32

Page 33

MAINTENANCE

Cleaning the Grill

Caution: To prevent injury, use care when cleaning a hot grill.

Note: Do not use a commercial cleaner on the cooking grid.

Do not brush grids while they are hot. Do not scrape grids.

For baked on residue use a brass (NOT STEEL) brush on the

cooking grid and other components.

Burn Off

This process is much like that used in self-cleaning ovens and is

most efcient when completed after each use of the grill.

Caution: Do not open the grill during the burn off process.

Opening the grill during the burn off process may cause a

sudden grease re are up that could burn your face and arms.

Wait until the grill has cooled before opening.

1. Turn gas knob to HI. Close lid and allow the grill to burn for ten

minutes, or until no smoke is present. Do not allow the grill to

burn for more than 30 minutes.

2. Turn gas knob and supply to OFF and allow the grill to cool.

3. Wipe COOL grill with a damp cloth to remove soot.

Venturi Tubes

The venturi tubes allow air and gas to mix prior to burning, thus

ensuring an efcient ame. Spiders or other small insects may

build webs or nests inside the tubes obstructing air ow. Fire, or

ashback, can occur, in and/or around obstructed venturi tubes

and can cause damage to components beneath the grill or an

unsafe condition. To reduce risk, inspections and cleaning should

be performed at least twice monthly when spiders are active. If the

grill has been unused for an extended period of time inspect the

tubes before using the grill.

Clean venturi tubes as follows:

1. Remove the cooking grids and briquette rack.

2. Remove the burner from the grill.

3. Lay the burner face down and remove the four retaining screws

from the venturi tube plate and the burner. See Figure 23.

4. Use a small exible brush to remove any debris for the tube(s).

5. Flush with water.

6. Allow the tube(s) to dry before reinstalling.

7. Reinstall the venturi tubes and burner.

Grill Bottom

Periodically remove cooking grids and are guard to clean the

interior of the grill. Scrape off baked on residue with a putty knife

or brass brush and rinse with water. Clean the bottom air holes

with a small knife.

Burner Maintenance

Stainless steel burners often turn reddish brown after use. This does

not effect the performance of the grill. When cleaning the interior of

the grill, remove the burners and clean with a brass brush. Wash

with water and a mild detergent.

Grease Cup

Empty periodically.

Figure 23

Note: Bowtie burner is shown. Follow the same steps for the

H burner assembly.

Exterior

Clean regularly with a solution of mild detergent and hot water.

Touch-up paint is available from your dealer. Broilmaster® protective covers are recommended. Stainless steel components can

be easily cleaned with a spray-on stainless steel cleaner found in

most hardware stores.

Briquettes

If the briquettes did not come clean during burn off, after cooling turn

them over. The residue will burn off during warm-up for the next use.

B101623-5-1012 Page 33

Page 34

TROUBLESHOOTING

Although the manufacturer has attempted to ensure that your grill will operate properly and satisfactorily,

sometimes problems do arise. The following troubleshooting guide lists several possible problems and

their probable cause and solution.

Problem Cause Solution

Burner will not light. Gas injector not inserted in venturi

tube.

Clogged gas injector. Remove gas injector from gas con-

Obstruction in gas line. For propane models, ensure gas

Spider webs in venturi tubes. Clean venturi tubes. See Mainte-

Misalignment of collector box and

burner.

Out of gas Rell LP gas cylinder. If natural

Dead battery. Replace with AA Alkaline battery.

Inadequate grill temperature.

Poor combustion. Adjust air shutter.

Misalignment of venturi tube and

gas injector.

Inadequate gas pressure. Contact gas supplier for assistance.

Realign/engage gas injector with

the venturi tube.

trol assembly and clean.

valve on cylinder is OFF. Remove

exible hose and blow out any

debris.

nance Section.

Position electrode properly. Clean

collector box.

model, turn on gas at source.

Realign/engage gas injector with

the venturi tube.

Incorrect orice/valve setting. Refer to gas conversion instructions

in this manual.

Flames blow out. Cold grill. Preheat grill at least 5 minutes on

HI with the grill lid closed.

Misalignment of burner tube and

gas injector.

Poor combustion. Adjust air shutter.

Extreme wind. Turn or shield grill.

Yellow ames. Air shutter improperly set. Open air shutter

Spider webs in venturi tubes. Clean venturi tubes. See Mainte-

Seasoning salts on burner. Clean by washing burner with mild

Oil lm on burner. Allow burner to operate on HI for

Realign/engage gas injector with

the burner tube.

nance Section.

detergent.

10-15 minutes.

B101623-5-1012Page 34

Page 35

Owner’s Manual For Models

R3-1, R3N-1 ,R3B-1, R3BN-1

GAS-FIRED

B101623-5-1012 Page 35

Page 36

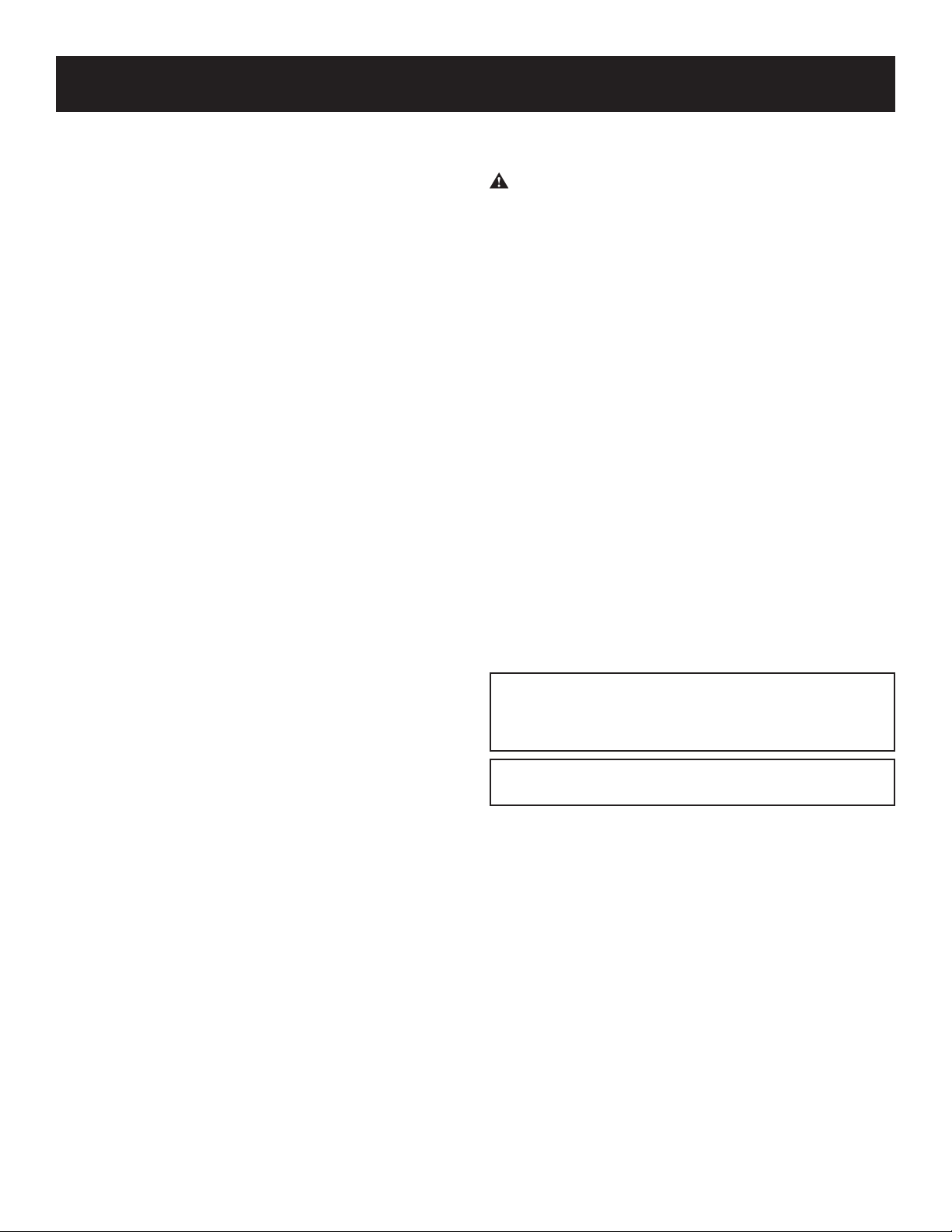

HARDWARE PACK

SCREW 1/4-20 X 3/4 PH TRUSS HEAD SS

SPACER, IGNITOR

R3B ONLY

SCREW #10-24 X 1 PHILLIPS TRUSS STAINLESS

FOAM GRIP

GROUND WIRE

R3 ONLY

KNOB

COLLECTOR BOX ASSEMBLY

BATTERY, AA

DESCRIPTION PART NUMBER QUANTIT SUPPLIED

Screw 1/4-20 x 3/4 PH Truss Head SS B063096 6

Spacer, Ignitor (R3B Only) B101082 1

Screw #10-24 x 1 Phillips Truss Stainless B073978 2

Knob R3918 2

Battery, AA N/A 1

Foam Grip B073097 1

Ground Wire (R3 Only) B072684 1

Collector Box Assembly (R3B Only) B101212 1

R3B ONLY

B101623-5-1012Page 36

Page 37

SAFETY PRECAUTIONS

Safety Practices to Avoid

Personal Injury

When properly cared for your Broilmaster Infrared Grill will give

safe, reliable service for many years. However, extreme care must

be used since the grill produces intense heat, which can increase

accident potential. When using this appliance, basic safety practices must be followed, including the following:

Read this Installation Instructions and Owner's Manual carefully and completely before using your grill to reduce the risk

of re, burn hazard or other injury.

Begin by ensuring proper assembly.

Do not repair or replace any part of the grill unless specically

recommended in this manual. All other service should be referred

to a qualied technician.

For personal safety, wear proper apparel. Loose tting garments

or sleeves should never be worn while using this appliance. Some

synthetic fabrics are highly ammable and should not be worn

while cooking. Never let clothing, pot holders or other ammable

materials come in contact with or too close to any grate, burner

or hot surface until it has cooled. Fabric may ignite and result in

personal injury.

Use only dry pot holders: moist or damp pot holders on hot surfaces may cause burns from steam. Do not use a towel or bulky

cloth in place of pot holders. Do not let pot holders touch hot portions of the grilling grids.

Only certain types of glass, heat-proof glass ceramic, earthenware, or other glazed utensils are suitable for grill use. Use of these

types of materials may break with sudden temperature changes.

Grease is ammable. Let hot grease cool before attempting to

handle it. Avoid letting grease deposits collect in the bottom of the

grill. Clean often.

Do not use aluminum foil to line the grilling grids or grill bottom.

This can severely upset combustion airow or trap excessive heat

in the control area. The result of this can be melted knobs, igniters

and increased chance of personal injury. The drip tray accessory

may be lined with aluminum foil.

Children should not be left alone or unattended in an area where

the grill is being used. Never allow them to sit, stand or play on or

around the grill at any time. Do not store items of interest to children around or below the grill or in the cart. Never allow children

to crawl inside of a cart.

Do not heat unopened food containers as a build-up of pressure

may cause the container to burst.

Use a covered hand when opening the grill lid. Never lean over

an open grill.

When lighting a burner, always pay close attention to what you

are doing. Be certain you are depressing the igniter button. When

using the grill: do not touch the grilling grids, burner, warming rack

or immediate surrounding area as these areas become extremely

hot and could cause burns.

For proper lighting and performance of the burners keep the ports

clean. The burners will only operate in one position and must be

mounted correctly for safe operation.

Clean the grill with caution. Avoid steam burns; do not use a wet

sponge or cloth to clean the grill while it is hot. Some cleaners

produce noxious fumes or can ignite if applied to a hot surface.

Insect Warning - Spiders and insects can nest in the burners

of this and any other grill, and cause the gas to ow from the front

of the burner. This is a very dangerous condition, which can cause

a re to occur behind the valve panel, thereby damaging the grill

and making it unsafe to operate. Inspect the grill at least twice per

year.

Be sure all grill controls are turned off and the grill is cool before

using any type of aerosol cleaner on or around the grill. The chemical that produces the spraying action could, in the presence of

heat, ignite or cause metal parts to corrode. Do not operate the

grill under unprotected combustible construction. Use only in well

ventilated areas. Do not use in buildings, garages, sheds, breezeways or any enclosed areas.

Keep the area surrounding the grill free from combustible materi-

als, trash, or combustible uids and vapors such as gasoline or

charcoal lighter uid. Do not obstruct the ow of combustion and

ventilation air. Keep the back of the cart free and clear from debris.

If the unit is stored indoors ensure that it is cool. If propane is used,

the cylinder must be unhooked and the propane cylinder stored

outside in a well-ventilated area, out of reach of children.

Never use the grill in windy conditions. If located in a consistently

windy area (oceanfront, mountain top, etc) a windbreak will be re-

quired. Always adhere to the specied clearance.

Keep any electrical supply cord, or the optional rotisserie motor

cord away from the heated areas of the grill. Do not use the grill

for cooking excessively fatty meats or products, which promote

are-ups.

OUTDOOR USE ONLY

Your Broilmaster Infrared Grill is designed for outdoor use

only and must not be installed in or on recreational vehicles

and/or boats.

NEVER USE A DENTED OR RUSTY PROPANE TANK.

SHUT OFF TANK WHEN NOT IN USE.

B101623-5-1012 Page 37

Page 38

GRILL ASSEMBLY

1. Mount grill onto cart, post or base per the mounting instructions.

2. Place wind deector (ange side up) onto four raised bosses

located on the interior bottom of the grill. See Figure 24.

Figure 24

4. R3B model only: Insert collector box assembly into hole adjacent to burner. The opening of the collector box should be

facing the burner. The infrared ignitor wire slides through the

empty hole next to the burner. See Figure 26.

3. R3B model only: Slide ignitor spacer onto collector box as-

sembly and secure with nuts. See Figure 25.

Figure 25

Attention: Do not cut or damage ignitor wires.

R3B

R3

Figure 26

B101623-5-1012Page 38

Page 39

GRILL ASSEMBLY

5. Place blue ame burner on the left and infrared on the right

into grill and insert burner tubes over orice ttings on valve.

Secure each burner and burner shield with one (1) 1/4-20 x

3/4 phillips screw and nut. See Figures 27, 28, and 29. R3

model only: Use lugs to attach ground wire before screwing

the two infrared burners on. See Figure 28. Tuck ground wire

underneath the burners to prevent damage.

R3B

Figure 28

R3

Figure 27

B101623-5-1012 Page 39

Page 40

GRILL ASSEMBLY

6. Remove ignitor from the control panel by unscrewing the ignitor button and nut. Attach ignitor wires to terminals on the

ignitor. See Figure 30.

Figure 30

R3B

7. Re-attach the ignitor to the control panel, then tighten nut and

insert AA battery, positive side down, and replace ignitor button. See Figure 31.

Figure 31

8. Install foam grip on lid handle. See Figure 32.

Tip: For ease of installation, slightly lubricate the lid handle

with liquid soap before pushing the foam grip into place.

R3

Figure 29

Figure 32

B101623-5-1012Page 40

Page 41

GRILL

GRILL ASSEMBLY

9. Fasten the lid handle to the grill body top with two #10-24 x 1"

screws. See Figure 33.

Figure 33

10. R3B models only: Place the briquet rack over the blue ame

burner only. See Figure 31.

11. R3B models only: Position the Char-Master briquet evenly on

the briquet rack without overlapping. See Figure 34.

°

90 ANGLE ON BRIQUETTE

RACK TO CENTER OF

Lid Stop

Attach the lid stop assembly to the grill bottom as shown in Figure 32.

Lid stop assembly hardware

Figure 33

12. Set the cooking grids.

13. Push valve knobs on to valves.

Note: Control Housing is used only when installing grill head

onto cart. See the instructions that come with the cart for Control

Housing installation instructions.

B101623-5-1012 Page 41

Figure 35

Page 42

LPG

NAT

ADJUSTMENT SCREW

ADJUSTMENT SCREW

GAS CONVERSION TO NATURAL GAS

1. R3B Grills: Remove cooking grids, briquets and briquet rack

from grill.

2. Blue Flame Burner: Remove blue ame burner shield and

blue ame burner from grill (one (1) 1/4-20 x 3/4 phillips screw

for burner). See Figure 36. Infrared Burner: Remove ignitor

wire, lugs and infrared burner from grill (one (1) 1/4-20 x 3/4

phillips screw for each burner). See Figure 36.

3. Remove LP burner orices marked 1.25 mm for R3B. Re-

move LP burner orice marked 1.3 mm for R3. See Figure

37.

Figure 37

4. Install natural gas burner orice marked 49 into each orice

tting. Apply pipe compound to threads on orices prior to in-

stallation.

5. Blue Flame Burner: Place burner shield and burners into

grill and insert burner tubes over orice ttings. Secure

each burner with one (1) 1/4-20 x 3/4 phillips screw from

Step 2.

Infrared Burner: Place infrared burners, ignitor, and lugs into

grill and insert burner tubes over orice ttings. Secure each

burner with one (1) 1/4-20 x 3/4 phillips screw from step 2.

6. Grasp valve knobs and remove from valves.

7. The low input adjustment screws are located inside the two

valve stems. Use a small screwdriver to turn each adjustment

screw clockwise 1/4 turn (90 degrees). When valves are in

the "OFF" position, the slot in the adjustment screw should be

vertical. See Figure 38.

R3B

R3

Figure 36

Figure 38

8. Remove the hose and regulator from the gas connection on

grill with adjustable wrench.

9. Connect the grill to the natural gas supply.

Attention: Before lighting your grill check all gas connections including the adjustment screws in valve stems

for gas leaks with a soapy water mixture.

Caution: Do not use the grill if a gas leak is detected until gas

leak is corrected. If a gas leak can not be stopped, do not use

grill. You must contact a qualied repair person.

10. Push valve knobs onto valves.

11. Apply the completed conversion label adjacent to the rating

plate label on the grill.

B101623-5-1012Page 42

Page 43

GAS CONVERSION TO NATURAL GAS

12. The natural gas inlet pressure at the grill is to be set at 7.0" of

inlet pressure.

13. Ignite burner on grill and observe ame pattern. If ame is yellow in color or ame is lifting off burner, the air shutter on blue

ame burners only will require adjustment.

14. Beneath the control panel you can access the air shutter

which is located on the end of the burner tube.

15. Loosen phillips screw at air shutter, open air shutter for a yel-

low ame or close air shutter for a lifting ame. Tighten phillips

screw at air shutter.

16. Ignite burners on grill to verify burner ame characteristics.

17. Replace briquet rack and briquets and reinstall cooking grids.

Installation must conform to local codes or in the absence of local

codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54,

Natural Gas and Propane Installation Code, CSA B149.1, or Propane Storage and Handling Code, B149.2.

Caution: The grill and its individual shutoff valve must be disconnected from the gas supply piping system during any system pressure testing at test pressures in excess of 1/2 PSIG.

Caution: The grill must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 PSIG.

B101623-5-1012 Page 43

Page 44

INFRARED COOKING

General Overview

Broilmaster Infrared gas grills make it possible for you to enjoy

cooking outdoors quickly and effortlessly. In minutes, you can en-

joy steaks, hamburgers, poultry, pork chops, sh and other foods.

You can also cook more slowly if you wish. Broilmaster's optional

accessories are designed to enhance your grill's versatility.

Infrared Searing Method

Searing is a process that seals juices in food by cooking with intense heat for a short period of time. The juices stay in the food

where they belong and the outside gets coated with avorful

smoke. For best results, follow these procedures when cooking.

Searing Method

1. Follow the Burner Ignition procedures and operate the grill for

5 minutes or until the burners glow uniformly.

2. Set the Burner Output Knob to HIGH and place the food on

the cooking grid for 1 - 2 minutes, or until food lifts without

sticking.

3. Turn the food and repeat Step 2.

4. Depending upon your taste, continue cooking on HIGH, turning the food frequently, or adjust the Burner Output Knob to

a setting between LOW and "medium" and continue cooking

until the food is cooked to your satisfaction. Turn as necessary (generally every one to three minutes).

During the searing period, ashing might occur when juices vaporize on contact with the cooking grid and burner surfaces. The

ashes and smoke greatly enhance the avor of food.

The intense infrared energy generated by your Broilmaster Grill has

other advantages. For example, food is evenly cooked throughout.

Also, upon contact with the cooking grids and burners, drippings

vaporize into avorful smoke that cooks back into the food.

not recommend cooking portion meats from a frozen state.

3. Start slowly. Infrared grilling is unlike other outdoor cooking

methods. It may take time to get used to the fast cooking process. As a benchmark, foods which generally cook in 20 minutes or less on conventional grills cook in about one-half the

conventional time on a Broilmaster infrared grill. Please refer

to the Infrared Cooking Sample Times on pages 43 and 44.

Indirect Cooking with a Broilmaster Infrared Grill

Indirect cooking is a slower process used to prepare large main

dishes - roasts, hams, turkeys, etc. Foods are placed on one side

of the grill and the other side is lighted to produce heat.

To protect the infrared burner from damage, place a heavy-duty disposable aluminum pan over the burner to catch drippings.

Note: Make sure the aluminum pan is the same size or larger than

the infrared burner. Any liquids that land on the burner while it is

not burning may cause it to break when ignited.

The pan may be lled part-way with liquid (water, marinade, etc.)

to enhance the moisture content of the meat, but take special care

not to spill anything onto the burner when adding liquids or when

removing the pan after cooking.

Flare-Up Control

NOTICE: NEVER DOUSE A FLARE-UP WITH

LIQUID. IT WILL DAMAGE THE BURNER AND VOID THE WARRANTY!

To minimize ame are-ups:

• Trim excess fat from meat.

• Reduce heat and reposition foods away from are-ups when

the occur.

• Prevent excess grease build up by periodically cleaning cooking grids.

Helpful Hints

1. Use the proper tools. Long handled tongs, spatula, knife, and

mitts or a hot pad for handling hot items. When turning or

moving foods, use tongs or a spatula, instead of a fork. Pierc-

ing the food with a fork allows the natural juices and avor to

escape.

2. Monitor meat temperature. Bring large cuts of meat, roasts,

or fowl to room temperature before cooking. Smaller meat

cuts such as hamburgers, hot dogs, or small steaks may be

cooked directly from the refrigerator. Note: Broilmaster does

B101623-5-1012Page 44

Page 45

INFRARED COOKING SAMPLE TIMES & GRID POSITIONS

FOOD "DONENESS"

FOOD

Steak Pieces- 1" Thick

Steak - 1" Thick

Pork Chops

Hot Dogs

Shrimp - 20 to 30 count

Beef Kabob - 1 1/2" Meat Cubes Not Recommended Done Not Recommended

Hamburger - 1" Thick

Hamburger - 1/2" Thick

COOKING GRID

POSITION 1

Medium Rare Medium/Medium Rare Rare

Medium Medium Rare Medium Rare

Well Medium Well Medium

Not Recommended Not Recommended Well

Rare Medium Rare Rare

Medium Well Medium Well Medium

Well Well Medium Well

Not Recommended Not Recommended Well

Well Medium Well Medium Well 6 Minutes per Side

Not Recommended Well Medium Well 7 Minutes per Side

Not Recommended Not Recommended Well 8 Minutes per Side

Done Not Recommended Not Recommended

Not Recommended Done Not Recommended

Not Recommended Not Recommended Done

Done Not Recommended Not Recommended

Not Recommended Done Not Recommended

Not Recommended Not Recommended Done

Not Recommended Done Not Recommended

Not Recommended Not Recommended Done

Medium Well Medium/Medium Well Medium

Well Well Medium Well

Not Recommended Not Recommended Well

COOKING GRID

POSITION 2

COOKING GRID

POSITION 3

APPROXIMATE

COOKING TIME

WITH INFRARED

4 Minutes, 2 minutes

per Side

6 Minutes, Turn

every 2 minutes

8 Minutes, Turn

every 2 minutes

10 Minutes, Turn

every 2 minutes

4 Minutes, 2 minutes

per Side

8 Minutes, Turn

every 2 minutes

10 Minutes, Turn

every 2 minutes

12 Minutes, Turn

every 2 minutes

3 Minutes, Turn as

Needed

4 Minutes, Turn as

Needed