Page 1

Built-in Kit Owner’s Manual

BHa-1, BHaX-1, BBa-1, Bsa-1, BDa-1 anD BrB-1 Kits

OutDOOr Grill MOuntinGs

FOr use witH P3, r3, H3 Or t3 series BrOilMaster PreMiuM Gas

Grills

instructiOns Must Be leFt witH tHe Owner FOr Future reFerence aFter installatiOn.

retain Owner’s Manual FOr Future reFerence.

nOte: ul certiFicatiOn eXtenDs Only tO tHe PrODuct, nOt tHe installatiOn OF tHe PrODuct.

GAS-FIRED

Page 1

Page 2

THIS GAS APPLIANCE IS DESIGNED FOR OUTDOOR USE ONLY.

iMPOrtant

we aDvise yOu tO careFully reaD anD FOllOw tHe instructiOns in tHis Owner’s Manual BeFOre

installinG Or usinG yOur new BrOilMaster

yOur Built-in Kit will OFFer years OF cOOKinG satisFactiOn. tHe installer sHOulD Present yOu witH

tHis Manual. Please retain it FOr Future reFerence.

warninG

reFerence tHis Manual FOr PrOPer installatiOn anD Maintenance instructiOns. iMPrOPer

installatiOn, aDjustMent, alteratiOn, service Or Maintenance can cause PersOnal injury Or

PrOPerty DaMaGe. FOr assistance Or aDDitiOnal inFOrMatiOn cOnsult a qualiFieD installer, service

aGency Or tHe Gas suPPlier.

FOr yOur saFety

iF yOu sMell Gas:

1. sHut OFF Gas tO tHe aPPliance.

2. eXtinGuisH any OPen FlaMe.

3. OPen tHe Grill liD.

4. iF ODOr cOntinues, iMMeDiately call yOur Gas suPPlier Or Fire DePartMent.

5. DO nOt tOucH electrical switcHes.

®

Built-in Kit. wHen installeD anD useD as recOMMenDeD,

FOr yOur saFety

1. DO nOt stOre Or use GasOline Or OtHer FlaMMaBle vaPOrs anD liquiDs in tHe vicinity OF tHis Or

any OtHer aPPliance.

2. an lP cylinDer nOt cOnnecteD FOr use sHall nOt Be stOreD in tHe vicinity OF tHis Or any OtHer

aPPliance.

FOr yOur saFety

Be careFul wHen HanDlinG Parts DurinG asseMBly anD use as tHey May cOntain sHarP eDGes.

wOrK GlOves are HiGHly recOMMenDeD tO HelP Prevent POssiBle injury.

All repair part orders should be placed through your local Broilmaster® dealer. To locate a dealer in your

area, contact Broilmaster® Customer Service at 800-851-3153 • WWW.broilmaster.com. To ensure prompt

and accurate service, please provide the following information when placing a repair part order: Model

number of your Single Door, Part Name, Part Number, and Quantity of parts needed.

Page 2 B101502-3-1012

Page 3

taBle OF cOntents

Congratulations!

You have chosen the nest Built-In Kit for your outdoor cooking pleasure. Please take time to read this

entire manual before assembling your premium Broilmaster Built-In Kit.

Location, Connections, and Safety ................................................................................................ 3 - 4

Enclosure Construction Guidelines .................................................................................................... 5

BHA & BHAX Grill Surround ........................................................................................................ 6 - 10

BBA Tank Caddy ........................................................................................................................ 11 - 14

BSA Side Burner Surround ........................................................................................................ 15 - 17

BDA Single Door........................................................................................................................ 18 - 21

BRB Vent Register Kit ...............................................................................................................22 - 23

Warranty ........................................................................................................................................... 24

Your Broilmaster® accessory is identied by model number, serial number, and gas type.

This information is provided on a product identication label located on the accessory. The

grill’s model number, serial number, and gas type must also be provided when contacting

your Broilmaster® dealer. For your convenience, complete this section for future reference

when contacting your dealer.

Model No. Dealer

Serial No. Dealer Phone No.

Gas Type: Propane Natural Date of Purchase

Page 3B101502-3-1012

Page 4

lOcatiOn, cOnnectiOns, anD saFety

Built-In Kit Location

Built-In Kits are designed for outdoor use ONLY.

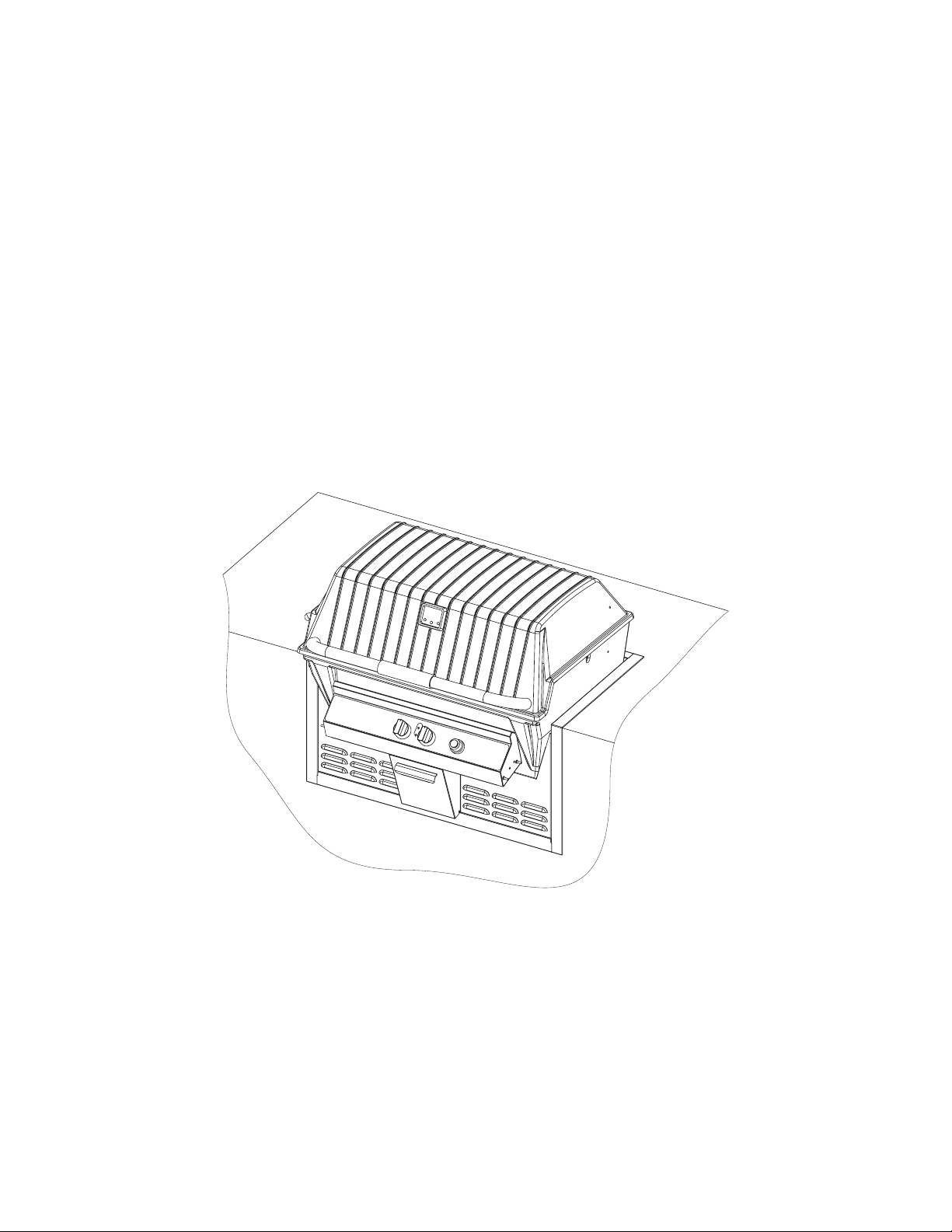

This Built-In Kit is designed for use with all P3 and T3 Model

Broilmaster® gas grills and cannot be used with any other

grill or in any other capacity.

Never install or operate your Built-In Kit in any building,

garage, or other enclosed area.

For your safety, the Built-In Kit should not be installed or

operated under any combustible materials, such as carports,

covered porches, awnings, or overhangs.

Never install or use your Built-In Kit in or on any recreational

vehicle or boat.

CAUTION: THE INSTALLATION AND OPERATION OF

THIS BUILT-IN KIT AT CLEARANCES LESS THAN

SPECIFIED BELOW MAY LEAD TO THE POSSIBILITY OF

FIRE, PROPERTY DAMAGE, OR PERSONAL INJURY.

A minimum clearance of twenty-four (24”) inches is required

from all sides of the island to any combustible material.

Examples of combustible materials are patio furniture,

fences, or the outside of your home.

The area surrounding the built-in kit should be clear to ensure

proper ventilation. Do not obstruct the ow of combustion

and ventilation air in any way. The ventilation openings on

the enclosure must also remain free and clear of debris.

WARNING: DO NOT INSTALL OR OPERATE THIS BUILTIN KIT WHERE GASOLINE OR OTHER FLAMMABLE

MATERIALS ARE USED OR STORED. FAILURE TO

COMPLY WITH THIS WARNING COULD RESULT IN

EXPLOSION OR FIRE CAUSING PROPERTY DAMAGE

OR PERSONAL INJURY.

CAUTION: THE GRILL AND ITS INDIVIDUAL SHUTOFF

VALVE MUST BE DISCONNECTED FROM THE GAS

SUPPLY PIPING SYSTEM DURING ANY SYSTEM

PRESSURE TESTING AT TEST PRESSURES IN EXCESS

OF 1/2 PSIG.

Checking for Gas Leaks

CAUTION: DO NOT USE AN OPEN FLAME TO CHECK

FOR LEAKS. CHECKING FOR LEAKS WITH AN

OPEN FLAME MAY LEAD TO A FIRE OR EXPLOSION,

RESULTING IN PROPERTY DAMAGE OR PERSONAL

INJURY.

Using the following steps, check for gas leaks during initial

use and each time your Broilmaster® gas grill or side burner

is connected to gas or is connected to a cylinder that has

not been used recently

1. Using dish washing detergent and water, make a soapy

solution.

2. Turn OFF the knob on both the grill and side burner’s

control panel.

3. Turn ON the gas at the supply. A hissing sound indicates

a leak. Turn OFF the gas and repair all leaks.

4. If no hissing occurs, apply the soapy solution to all gas

connections.

5. Look for bubbles. Bubbles indicate a leak.

6. If there are bubbles, turn OFF the gas and repair all

leaks.

7. Turn the gas ON and repeat the above procedure until

all leaks are repaired.

Connection Requirements

CAUTION: NEVER USE LIQUID PROPANE GAS IN A

GRILL DESIGNED FOR NATURAL GAS, OR NATURAL

GAS IN A GRILL DESIGNED FOR LIQUID PROPANE

GAS. QUESTIONS REGARDING DIFFERENT TYPES OF

GASES SHOULD BE DIRECTED TO YOUR LOCAL GAS

COMPANY.

Installation must conform to local codes or, in the absence

of local codes, with the National Fuel Gas Code, ANSI

Z223.1. In Canada, installation shall be in accordance with

CAN/CGA-B149.2 Propane Installation Code, or CAN/

CGA-B149.1 Natural Gas Installation Code, and local

codes where applicable. Consult your local gas company or

Propane gas dealer for code regulations and recommended

procedures.

Broilmaster® gas grills and side burners are NOT equipped

with pressure regulators. Your Nat. gas grill operates at a

manifold pressure of seven (7”) inches water column.

Page 4 B101502-3-1012

Page 5

enclOsure cOnstructiOn GuiDelines

Enclosure must be construction from non-combustible material.

If tile is used on the top surface of your enclosure, it may be necessary to enlarge openings at the top edges to allow the

frame pieces of the BHA and BSA to mount ush against the enclosure.

Screws for enclosure mounting have been supplied. Installer must measure for thickness and use appropriate hardware for

installation. If the enclosure is constructed from masonry materials, it may be necessary to substitute appropriate screws

and fasteners.

This diagram is only a basic plan for constructing an enclosure for your built-in kit. All construction and installation should

comply with all local building codes and requirements.

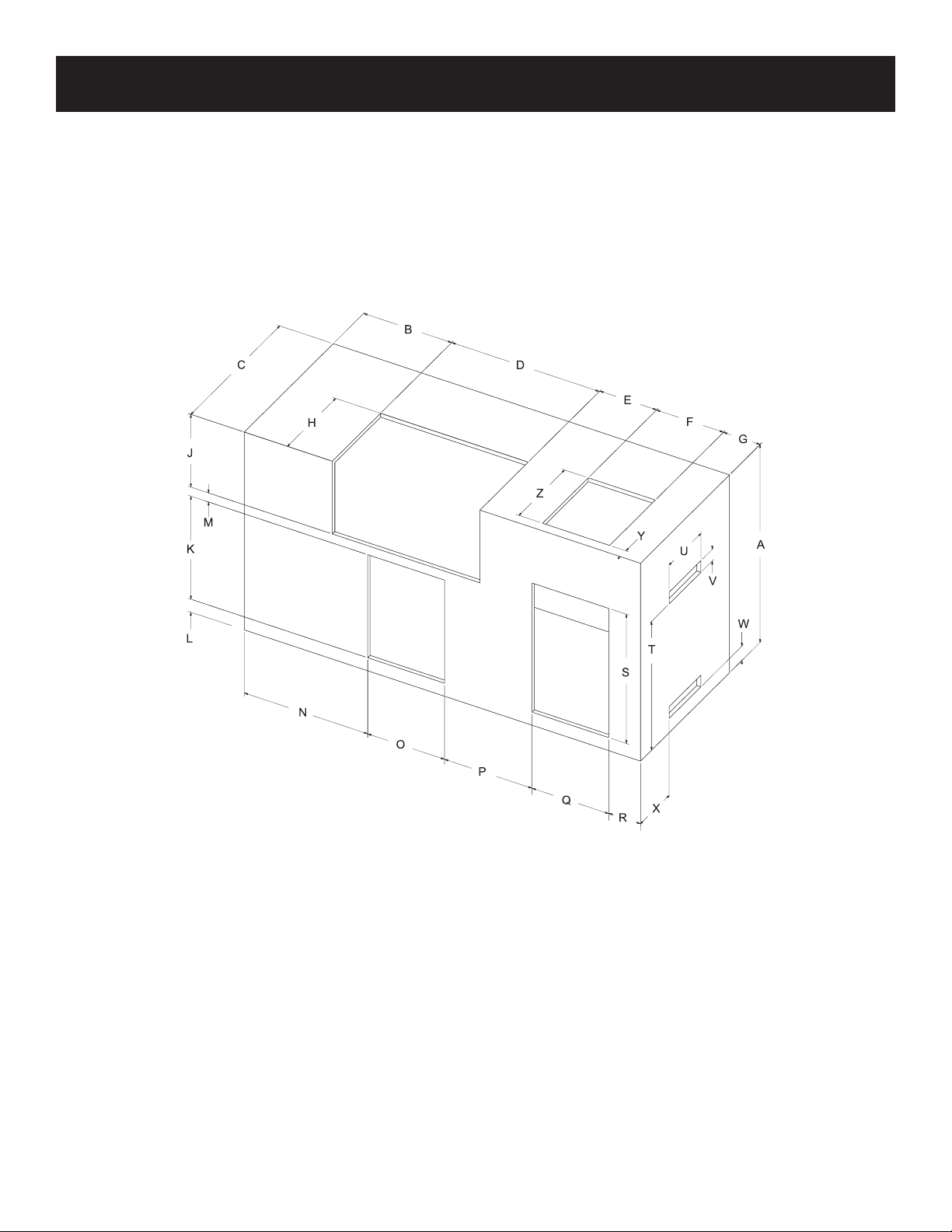

MINIMUM REQUIREMENTS

Key Dimension in Inches Key Dimension in Inches

A 38” (Minimum) O 14” (Single) - 27 1/2” (Double)

B 16” (Minimum) P 15 7/8” (Single) - 9 1/8” (Double)

C 28” (Minimum) Q 13 15/16”

D 26 13/16” R 5” (Minimum)

E 10 11/32” S 24 13/16”

F 12 3/16” T 24 3/4”

G 6” (Minimum) U 10”

H 15 3/8” V 2 1/4”

J 14” W 2 3/4”

K 19 13/16” X 9”

L 2 1/2” Y 1 13/16”

M 1 11/16” Z 14 3/8”

N 22 3/8” (Single) - 15 5/8” (Double)

Page 5B101502-3-1012

Page 6

BHa-1 & BHaX-1 Grill surrOunD Kits

installatiOn instructiOns

nOtice: reFer tO tHe Built-in Kit enclOsure cOnstructiOn GuiDe On PaGe 5 FOr PrOPer

DiMensiOns OF tHe OPeninG FOr tHe BHa-1 Grill surrOunD Kit

Page 6 B101502-3-1012

Page 7

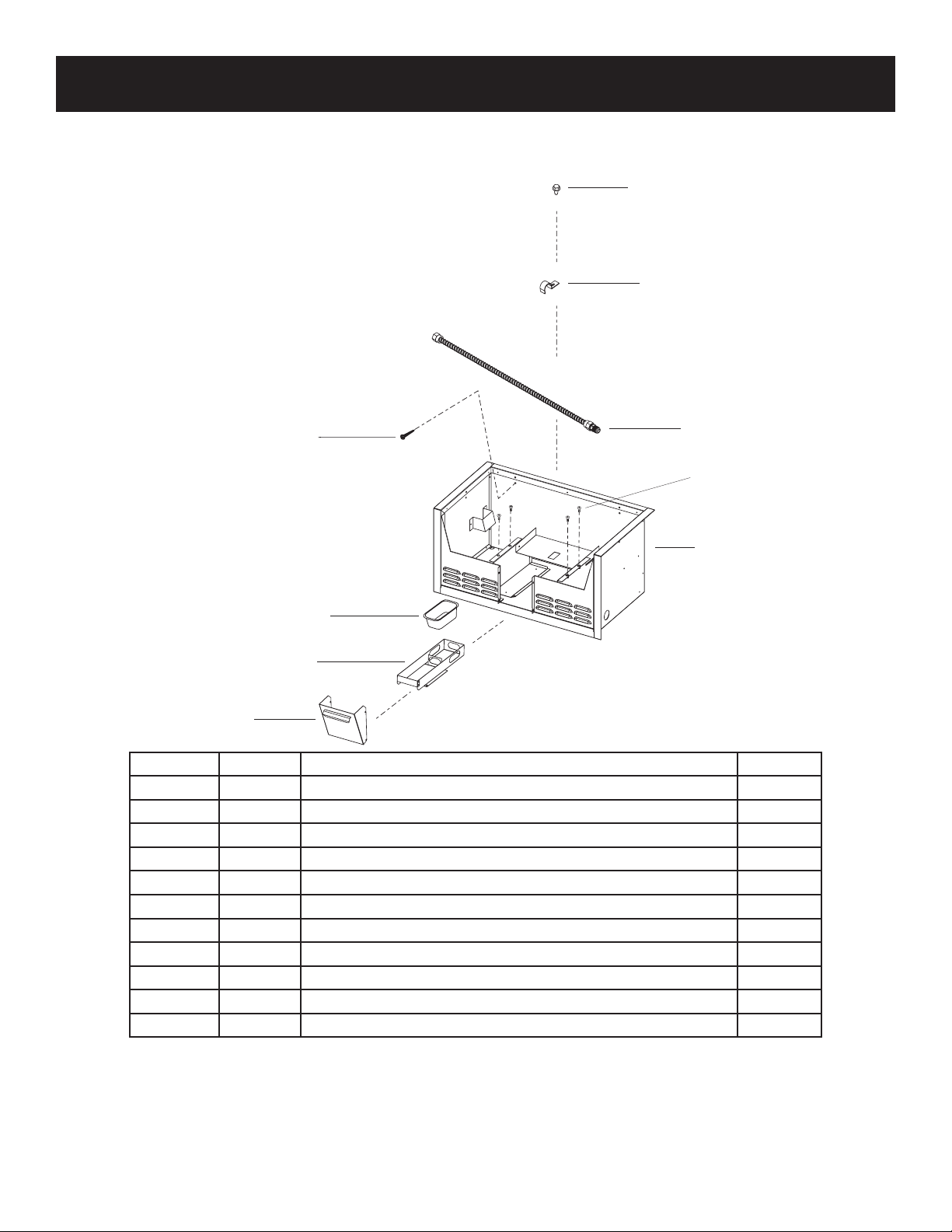

BHa-1 & BHaX-1 Grill surrOunD eXPlODeD view & Parts list

All repair part orders should be placed through your local Broilmaster

®

dealer. To locate a dealer in your area, contact

Broilmaster Customer Service at 800-851-3153 • www.broilmaster.com. To ensure prompt and accurate service, please

provide the following information when placing a repair part order: Model Number, Part Name, Part Number, and Quantity

of parts needed.

5

1

2

3

8

4

9

6

7

Index No. Part No. Description Quantity

1 R2737 10 x 1/2 Phillips Head Screw 1

2 B101206 Flexline Bracket 1

3 B101205 Flexline 1

4 B101200 BHA Assembly 1

4 B101529 BHAX Assembly 1

5 B101022 8 x 3/4” Hex Head Screw 8

6 B101178 Grease Tray 1

7 B101204 Control Housing Assembly - BHA 1

7 B101530 Control Housing Assembly - BHAX 1

8 B100113 1/4 - 20 x 1 1/4 Screw (use only with T3/P3 Sereis grill heads) 4

9 B060337 Grease Cup 2

Verify that all parts listed on the exploded view of this manual have been included in this

Built-In Kit before beginning installation.

Caution: Use caution when handling parts, as they may contain sharp edges.

Work gloves are recommended to prevent injury.

Tools Required: Phillips Head Screw Driver (An electric screw driver or drill is recommended to ease installation)

Page 7B101502-3-1012

Page 8

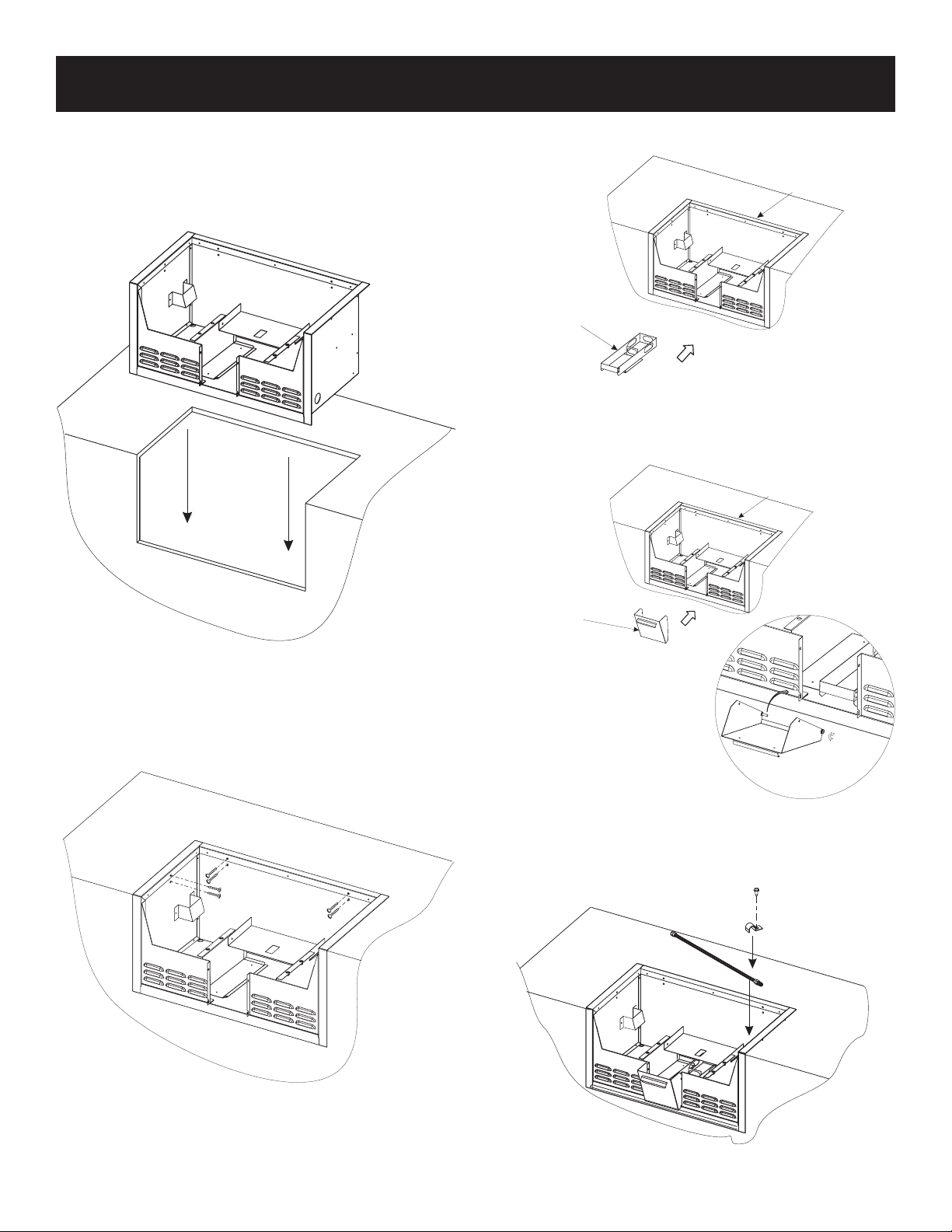

BHa & BHaX asseMBly

Attention: If applicable, remove protective lm from parts

before installation.

1. Remove the surround from the shipping box and place

the BHA surround into position in the constructed

enclosure. See Figure 1.

3. Place the grease tray into BHA surround by sliding it

under the bracket. See Figure 3.

BHA ASSEMBLY

GREASE TRAY

Figure 3

4. Place the control housing assembly into BHA surround

and secure it to the BHA surround. See Figure 4.

BHA ASSEMBLY

Figure 1

2. Secure the BHA surround to the enclosure using eight

(8) 8 x 3/4” Hex Head Screw screws. See Figure 2.

Note: If you have a masonry structure you may need to

substitute for the appropriate masonry fasteners.

CONTROL HOUSING

ASSEMBLY

Figure 4

5. Attach the ex line to the bottom of the BHA surround

using the ex line bracket and screw. See Figure 5.

Figure 2

Figure 5

Page 8 B101502-3-1012

Page 9

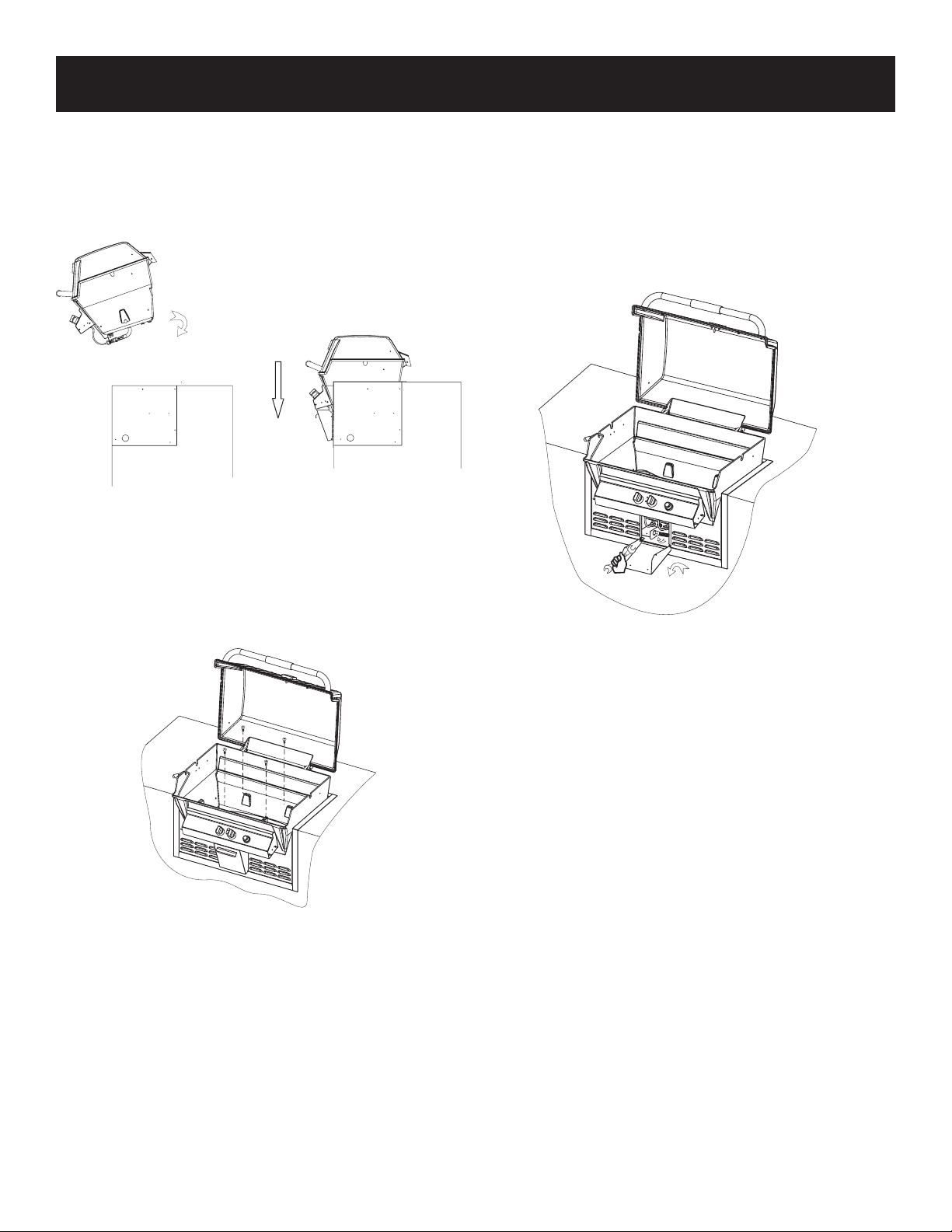

BHa & BHaX asseMBly

6. After insuring that all the contents are removed from the

inside of the grill, install the grill in the BHA surround by

slightly tilting the grill forward and placing it on the top

of the support bracket. See Figure 6.

Figure 6

7. Mount the grill to the BHA surround using four 1/4-20 x

1 1/4” screws. See Figure 7.

8. Check for gas leaks as discussed in the “Checking for

Gas Leaks” Section of this manual on page 4.

9. Open control housing and connect ex line to the main

valve, then close the control housing door. Figure 8.

Figure 7

Figure 8

Refer to your Grill Head Installation Instructions to complete installation of your Broilmaster grill.

Page 9B101502-3-1012

Page 10

BHa & BHaX asseMBly

10. Install each of the four vent covers (BRB Vent Register

Kit) into the Built-In Kit Enclosure using two #8 x 3/4”

screws. See Figure 9.

Alternate Match Lighting Instructions

1. Turn the burner control knobs clockwise to the OFF

position.

2. Turn ON gas at the source.

3. Open the grill lid.

4. Open the BHA access door. Locate the Ignitor Rod,

which is permanently attached to the inside of the

Bottom Shelf.

5. Insert an unlit match into the coiled end of the ignitor

rod. Light the match.

6. Insert the ignitor rod inside the access door and through

the front left air hole located on the bottom of the grill.

Position the match near the rear left corner of the burner.

See Figure 10.

7. Turn the left burner control knob counterclockwise to

HI.

8. If the burner fails to light after 5 seconds, turn the

burner control knob OFF for ve minutes then repeat

the procedure.

9. If the burner continues not to light, turn OFF all gas and

refer to the troubleshooting section of your grill Owner’s

Manual.

Figure 9

Figure 10

Page 10 B101502-3-1012

Page 11

BBA-1 TANK CADDY

INSTALLATION INSTRUCTIONS

nOtice: reFer tO tHe Built-in Kit enclOsure cOnstructiOn GuiDe FOr PrOPer DiMensiOns

OF tHe OPeninG FOr tHe BBa-1 tanK caDDy.

T

HE BBA TANK CADDY IS DESIGNED TO BE USED AS EITHER AN ENCLOSURE FOR A PORTABLE

PROPANE TANK OR A GARBAGE RECEPTACLE. PLEASE REFER TO THE APPROPRIATE SECTIONS OF THIS

MANUAL FOR PROPANE TANK REQUIREMENTS, CONNECTIONS, AND SAFETY.

Page 11B101502-3-1012

Page 12

BBa tanK caDDy eXPlODeD view anD Parts list

All repair part orders should be placed through your local Broilmaster

contact Broilmaster® Customer Service at 800-851-3153 • WWW.broilmaster.com. To ensure prompt and accurate

service, please provide the following information when placing a repair part order: Model number of your Single

Door, Part Name, Part Number, and Quantity of parts needed.

3

®

dealer. To locate a dealer in your area,

1

2

PARTS LIST

Index No. Part No. Description Quantity

1 B101180 BBA Frame Assembly 1

2 B101181 BBA Door Assembly 1

3 B101022

VERIFY THAT ALL PARTS LISTED IN THE EXPLODED VIEW ON THIS PAGE HAVE BEEN INCLUDED IN

THIS BUILT-IN KIT BEFORE BEGINNING THIS INSTALLATION.

CAUTION: USE CAUTION WHEN HANDLING PARTS, AS THEY MAY CONTAIN SHARP EDGES.

WORK GLOVES ARE RECOMMENDED TO PREVENT INJURY.

8 x 3/4” Hex Head Screw

8

Page 12 B101502-3-1012

Page 13

BBA TANK CADDY INSTALLATION

Recommended Tools: Phillips Screw Driver or an

electric screw driver.

1

Make sure BBA Tank Caddy opening dimensions match

those in FIGURE 1. Place the BBA Frame Assembly in

the Built-In Enclosure.

Secure the BBA Frame to the Enclosure with eight (8)

8 x 3/4” Hex Head screws as shown in FIGURE 1

Note: The hinge pins on the BBA Frame will be

located near the bottom of the Built-In Enclosure when

properly installed. Also See the proper dimensions of

the opening in FIGURE 1

13 15/16”

2

While positioned on its side, place the BBA Door

Assembly into the BBA Frame opening. FIGURE 2.

BBA FRAME ASSEMBLY

BBA DOOR ASSEMBLY

FIGURE 2

2413/16”

BBA FRAME

ASSEMBLY

SCREWS (8)

BUILD IN

ENCLOSURE

3

Once located inside the BBA Frame, rotate the BBA

Door to the upright position.

FIGURE 3.

FIGURE 1

FIGURE 3

Page 13B101502-3-1012

Page 14

BBA TANK CADDY INSTALLATION

4

Lower the BBA Door Assembly onto the two hinge pins

inside the lower left and right sides of the BBA Frame.

FIGURE 4 .

HINGE

PIN

FIGURE 4

ENCLOSURE REQUIREMENTS

The enclosure design must be constructed to allow

only storage of the LP cylinder in use thus preventing

storage of a second cylinder. Tank caddy must be

provided for use in the enclosure when employing the

propane self-contained system so as to prevent the

lateral movement of the propane tank cylinder from its

enclosure.

An enclosure for a LP gas cylinder shall be ventilated

by openings at the level of the cylinder valve and at oor

level. The effectiveness of openings(s) for purposes of

ventilation shall be determined with the LP gas supply

cylinder in place. This shall be accompanied by one

of the following: enclosure with one side completely

open; or enclosure having four sides, a top and a

bottom. Refer to the Built-In Kit enclosure construction

guide for proper dimensions of the opening for the

BBA-1 Tank Caddy.

less than a total free area of 10 square inches

(64.5 cm

2

).

2. Ventilation opening(s) shall be provided at oor

level and shall have a total free area of not less

than 1/2 square inch per pound (7.1 cm

2

/kg) of

stored fuel capacity and not less than a total free

area of 10 square inches (64.5 cm

2

). If ventilation

openings at oor level are in a side wall, there

shall be at least two openings. The bottom of the

openings shall be at oor level and the upper edge

no more than 5 inches (127 mm) above the oor.

The openings shall be equally sized, spaced at

180 degrees (3.14 rad) and unobstructed.

3. Every opening shall have minimum dimensions so

as to permit the entrance of an 1/8 inch (3.2 mm)

diameter rod.

The cylinder valve shall be readily accessible for hand

operation. A door on the enclosure to gain access to

the cylinder valves is acceptable, provided it is nonlocking and can be opened without the use of tools.

The enclosure for the LP gas cylinder shall isolate

the cylinder from the burner compartment to provide

shielding from radiant heat, a ame barrier, and

protection from foreign material, such as hot drippings.

There shall be a minimum clearance of 2 inches

(50.8 mm) between the oor of the LP gas cylinder

enclosure and the ground.

The design of the outdoor cooking gas appliance shall

be such that the LP gas cylinder can be connected,

disconnected and the connections inspected and

tested outside the cylinder enclosure; and those

connections which could be disturbed when installing

the cylinder in the enclosure can be leak tested inside

the enclosure.

1. At least two ventilation openings at cylinder valve

level shall be provided in the side wall, equally

sized, spaced at 180 degrees (3.14 rad), and

unobstructed. Each opening shall have a total free

area of not less than 1/2 square inch per pound

2

(7.1 cm

Page 14 B101502-3-1012

/kg) of stored fuel capacity and not

Page 15

BSA-1 SIDE BURNEr surrOunD Kit

INSTALLATION INSTRUCTIONS

nOtice: reFer tO tHe Built-in Kit enclOsure cOnstructiOn GuiDe FOr PrOPer DiMensiOns

OF tHe OPeninG FOr tHe Bsa-1 siDe Burner surrOunD

THE BSA SIDE BURNER SURROUND IS DESIGNED TO BE USED WITH THE DPASBC NATURAL and

PROPANE GAS SIDE BURNER ONLY. DO NOT USE ANY OTHER SIDE BURNER WITH THE BSA SIDE

BURNER SURROUND.

Page 15B101502-3-1012

Page 16

Bsa siDe Burner surrOunD eXPlODeD view anD Parts list

1

2

3

All repair part orders should be placed through your local Broilmaster® dealer. To locate a dealer in your area,

contact Broilmaster® Customer Service at 800-851-3153 • www.broilmaster.com. To ensure prompt and accurate

service, please provide the following information when placing a repair part order: Model number of your Side

Burner, Part Name, Part Number, and Quantity of parts needed.

PARTS LIST

Index No. Part No. Description Quantity

1 B101164 Side Burner Liner 1

2 B100130 10-24 x 3/8 Phillips Head Screw

(for use only with DPASBC Side Burner)

3 B101022

8 x 3/4” Hex Head Screw

2

4

VERIFY THAT ALL PARTS LISTED IN THE EXPLODED VIEW ON THIS PAGE HAVE BEEN INCLUDED IN

THIS BUILT-IN KIT BEFORE BEGINNING THIS INSTALLATION.

CAUTION: USE CAUTION WHEN HANDLING PARTS, AS THEY MAY CONTAIN SHARP EDGES.

WORK GLOVES ARE RECOMMENDED TO PREVENT INJURY.

Page 16 B101502-3-1012

Page 17

Bsa installatiOn

Recommended Tools: Phillips Screw Driver or an

electric screw driver.

1

Make sure BSA Side Burner Surround opening

dimensions match those in FIGURE 1. Place the BSA

Liner into the Enclosure and check for proper hole

alignment. Secure the BSA Liner to the Enclosure with

four (4) 8 x 3/4” Hex Head screws. You should use the

inside holes located on the inside of the BSA Liner.

FIGURE 2.

2

Attach one end of the Side Burner Hose to your

Broilmaster® DPASBC Side Burner. The remaining

end of the hose should be routed down through the

bottom of the BSA Liner. Place the side burner into

the BSA Liner and slide it completely to the rear of the

Liner. FIGURE 3.

ENCLOSURE

14 3/8”

(4)SCREWS

12 3/16”

FIGURE 1

BSA LINER

IGURE 3

F

3

Secure the DPASBC Side Burner to the BSA Liner

with two 10-24 x 3/8 PH PN screws to the inside holes

located on the side of the Side Burner. FIGURE 4.

Note: If you have already routed your Side Burner

Hose make sure it is projecting up through the bottom

of the BSA Liner.

#10-24x3/8 PH PN

SCREWS (2)

FIGURE 2

IGURE 4

F

Page 17B101502-3-1012

Page 18

BDa-1 sinGle/DOuBle DOOr Kit

INSTALLATION INSTRUCTIONS

nOtice: reFer tO tHe Built-in Kit enclOsure cOnstructiOn GuiDe FOr PrOPer DiMensiOns

OF tHe OPeninG FOr tHe BDa-1 sinGle/DOuBle DOOr Kit

THE BDA SINGLE DOOR KIT IS DESIGNED TO BE USED IN AN ISLAND OR OTHER APPLICATION.

Page 18 B101502-3-1012

Page 19

BDa sinGle DOOr eXPlODeD view anD Parts list

1

3

4

2

All repair part orders should be placed through your local Broilmaster® dealer. To locate a dealer in your area,

contact Broilmaster® Customer Service at 800-851-3153 • www.broilmaster.com. To ensure prompt and accurate

service, please provide the following information when placing a repair part order: Model number of your Single

Door, Part Name, Part Number, and Quantity of parts needed.

PARTS LIST

Index No. Part No. Description Quantity

1 B101191 BDA Door Frame 1

2 B101022 8 x 3/4” Hex Head Screw 8

3 B101192 BDA Door 1

4 B101153 BDA Door Bracket (used on double door installation

only)

VERIFY THAT ALL PARTS LISTED IN THE EXPLODED VIEW ON THIS PAGE HAVE BEEN INCLUDED IN

THIS BUILT-IN KIT BEFORE BEGINNING THIS INSTALLATION.

1

CAUTION: USE CAUTION WHEN HANDLING PARTS, AS THEY MAY CONTAIN SHARP EDGES.

WORK GLOVES ARE RECOMMENDED TO PREVENT INJURY.

Page 19B101502-3-1012

Page 20

BDa sinGle DOOr installatiOn

Attention: If Applicable, remove protective lm from parts before installation.

Recommended Tools: Phillips Screw Driver or an

electric screw driver.

1

The BDA Single Door will be fully assembled when it is

shipped out. Remove door from frame by depressing

one of the spring loaded pins and set aside.

FIGURE 1.

SCREW (8)

FIGURE 3

FIGURE 1

2

Make sure BDA Single Door opening dimensions

match those in FIGURE 2. Place the Frame into the

opening and check for proper hole alignment. Secure

the Frame to the grill enclosure with eight (8)

Hex Head Screw screws. FIGURE 3.

14”

19 13/16”

8 x 3/4”

3

Secure the BDA Door to the door frame by inserting the

spring loaded pin in the bottom frame hole. Locate the

upper hole in the frame then push on the spring loaded

pin on the door and insert the door in the frame.

Figure 4.

Make sure the Door is Aligned and Secured properly by opening and closing door

FIGURE 2

Page 20 B101502-3-1012

FIGURE 4

Page 21

BDA DOUBLE DOOR INSTALLATION

NOTE: You will need two BDA door kits for this installation.

3

1

Remove doors from frames by depressing one of the

spring loaded pins on each door and set them aside.

Disassemble frame by removing the two screws and

door pin from both door frames as shown in FIGURE

5.

FIGURE 5

Make sure BDA Double Door opening dimensions

match those in FIGURE 7. Place the Frame into

the opening and check for proper hole alignment.

Secure the Frame to the enclosure with 2 screws.

FIGURE 7.

Secure the Doors to the door frame by inserting the

spring loaded pins in the bottom frame holes. Locate

the upper hole in the BDA frame and push on the spring

loaded pin on the door and insert it into the frame.

Figure 4.

Make sure the Door is Aligned and Secured properly by opening and closing door.

27 ½”

19 13/16”

2

Use the door brackets included in the hardware

packages to combine the frames. Use the screws from

the single door to attach the bracket, and place the

door pin in position. FIGURE 6

FIGURE 7

FIGURE 6

Page 21B101502-3-1012

Page 22

BRB-1 VENT REGISTER KIT

INSTALLATION INSTRUCTIONS

nOtice: reFer tO tHe Built-in Kit enclOsure cOnstructiOn GuiDe FOr PrOPer DiMensiOns

OF tHe OPeninG FOr tHe BrB-1 vent reGister Kit

The BRB Vent Register Kit is designed to be used with any enclosure that has an

LP tank.

Page 22 B101502-3-1012

Page 23

BrB vent reGister cOver Kit eXPlODeD view anD Parts list

All repair part orders should be placed through your local Broilmaster® dealer. To locate a dealer in your area,

contact Broilmaster

service, please provide the following information when placing a repair part order: Model number of your Side

Burner, Part Name, Part Number, and Quantity of parts needed.

®

Customer Service at 800-851-3153 • www.broilmaster.com. To ensure prompt and accurate

1

2

PARTS LIST

Index

No.

1 B071712 Vent Register 2

2 B101022 8 x 3/4” Hex Head Screw 4

Two BRB Vent Register kits are needed for proper installation.

Part No. Description Quantity

Install two vent registers into each side of the Built-In Kit Enclosure using two screws per vent register.

Page 23B101502-3-1012

Page 24

LIMITED WARRANTY

Manufactured in U.S.A. by Broilmaster, a Division of Empire Comfort Systems, Inc.,

P.O. Box 529, Belleville, Illinois 62222.

WHAT IS COVERED AND FOR HOW LONG

From the date these kits are purchased for use, Broilmaster will make available, at our

factory, a free replacement for any defective part covered by this warranty on the following basis:

LIMITED LIFETIME WARRANTY

Stainless Components for Built-In Series (BHA, BBA, BSA, BDA, & BRB)

Page 24 B101502-3-1012

Page 25

nOtes

Page 25B101502-3-1012

Page 26

nOtes

Page 26 B101502-3-1012

Page 27

nOtes

Page 27B101502-3-1012

Page 28

THE MOST DURABLE GRILL

KNOWN TO MAN

BROILMASTER®

A Division of Empire Comfort Systems, Inc.

918 Freeburg Ave.

Belleville, Illinois 62220

Phone: 1-800-851-3153

FAX: 1-800-443-8648

VISIT OUR WEB SITE AT WWW.broilmaster.com

Page 28 B101502-3-1012

Loading...

Loading...