Broaster VF3iXP, VF-2XP Installation & Operation Manual

“An American Tradition Since 1954!”

MODEL VF-2XP & VF3iXP

BROASTER

®

VENTLESS FRYER

INSTALLATION & OPERATION MANUAL

Be sure ALL installers read, understand, and have access to this manual at all times.

Broaster®,,Broasted®, Broaster Chicken®, Broaster Foods®, and Broasterie® are registered trademarks.

Usage is available only to licensed operators with written authorization from The Broaster Company.

2855 Cranston Road, Beloit, WI 53511-3991

Design Certified By:

Printed in U.S.A.

ETL (US & CAN), ETL Sanitation

The Broaster Company

608/365-0193 www.broaster.com

16887 4/09

Copyright 2006 The Broaster Company

FOR YOUR SAFETY

Do not use or store gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

WARNING: Improper installation, adjustments, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

For the sake of safety and clarity, the following words used in this manual are defined as follows:

DANGER: Indicates an imminently hazardous situation which, if not avoided, could result

in serious injury or death.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result

in serious injury or death.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, could result in

minor injury, property damage or both.

All adjustments and repairs shall be made

by an authorized Broaster Company representative.

If there is a power failure, turn power switch

OFF. DO NOT attempt to operate unit during a power failure.

WARNING: Failure to read and

understand this manual completely

could result in serious injury or death. Be

sure ALL operators read, understand and

have access to this manual at all times.

WARNING: Rags or papers containing

cooking oil can catch fire if exposed to

heat. Laundering will not remove the oil. Dispose of all oil-soiled papers and rags in a trash

container that is in a ventilated area away from

all cooking equipment or other heat sources

such as direct sunlight.

DANGER: DO NOT clean this fryer with

a water jet. Use of this cleaning method

could result in serious injury or death.

Manual #16887 5/08

NEW OWNER OR RELOCATION NOTIFICATION

If you are a new owner of a used unit or

®

have relocated your Broaster

VF-2 or VF3i

Fryer, please take a minute to fill out one of

the cards below. It is NOT a warranty registration.

PLEASE PRINT: 2

Business Name:

This card enables The Broaster Company to

better serve you and keep you informed of

changes in equipment, condiments, or service bulletins.

Address:

City: State: Zip Code:

Owner’s Name:

County:

Phone:

Model:

Serial Number:

PLEASE PRINT: 1

Business Name:

Address:

City: State: Zip Code:

Owner’s Name:

County:

Phone:

Model:

Serial Number:

Manual #16887 5/08

The Broaster Company

2855 Cranston Road

Beloit, WI 53511

The Broaster Company

2855 Cranston Road

Beloit, WI 53511

Manual #16887 5/08

TABLE OF CONTENTS

1 - OWNER RESPONSIBILITY ..........................................................................................1 - 1

2 - INSTALLATION .............................................................................................................2 - 1

LOCATION..................................................................................................................2 - 1

CLEARANCES............................................................................................................2 - 1

GENERAL REQUIREMENTS.....................................................................................2 - 1

UNPACKAGING..........................................................................................................2 - 2

FIRE SUPPRESSION ACTIVATION...........................................................................2 - 2

ELECTRICAL CHARACTERISTICS...........................................................................2 - 3

ELECTRICAL CONNECTIONS ..................................................................................2 - 3

ELECTRICAL AMPERGE RATING.............................................................................2 - 3

WIRING DIAGRAM

VF-2 EXPORT & CE...........................................................................................2 - 4

VF3i EXPORT & CE............................................................................................2 - 5

INITIAL START-UP......................................................................................................2 - 6

2 - GETTING TO KNOW YOUR BROASTER® VF-2 or VF-3i FRYER..............................2 - 1

4 - PRE-COOKING PREPARATION...................................................................................4 - 1

START-UP...................................................................................................................4 - 1

COOKING OIL ............................................................................................................4 - 1

FOOD AND CONDIMENTS........................................................................................4 - 1

5 - CONTROL PANEL ........................................................................................................5 - 1

DUAL DISPLAY FAMILIARIZATION ...........................................................................5 - 1

OPERATIONAL LOCKOUT ........................................................................................5 - 2

CONTROLLER BASIC PROGRAMMING...................................................................5 - 2

Normal Operating Mode......................................................................................5 - 2

Preset Cook Mode ..............................................................................................5 - 3

Programming Procedure.....................................................................................5 - 3

Manual #16887 5/08

6 - FIRE SUPPRESSION SYSTEMS..................................................................................6 - 1

GENERAL DESCRIPTION .........................................................................................6 - 1

AUTOMATIC OPERATION .........................................................................................6 - 1

MANUAL OPERATION ...............................................................................................6 - 1

INSPECTION & MAINTENANCE................................................................................6 - 1

Gaining Access...................................................................................................6 - 1

Monthly Inspection..............................................................................................6 - 2

Semi-Annually.....................................................................................................6 - 2

T welve Year.........................................................................................................6 - 3

SEMI-ANNUAL INSPECTION & MAINTENANCE LOG .............................................6 - 3

7 - VENTILATION SYSTEM................................................................................................7 - 1

8 - PRODUCT PREPARATION AND COOKING................................................................8 - 1

COOKING...................................................................................................................8 - 1

9 - COOKING OIL CARE....................................................................................................9 - 1

10 - CLEANING ................................................................................................................10 - 1

COOKING UTENSILS...............................................................................................10 - 1

HAND CLEANING METHOD....................................................................................10 - 1

DISHWASHER METHOD.........................................................................................10 - 1

CLEANER NEUTRALIZATION..................................................................................10 - 1

UNIT SURFACES .....................................................................................................10 - 1

DISHWASHER SAFE COMPONENTS.....................................................................10 - 1

MINIMUM PREVENTATIVE MAINTENANCE REQUIR EMENTS.............................10 - 1

11 - NIGHTLY SHUTDOWN/SEASON SHUTDOWN .......................................................11 - 1

NIGHTLY SHUTDOWN.............................................................................................11 - 1

SEASON SHUTDOWN.............................................................................................11 - 1

12 - TROUBLESHOOTING...............................................................................................12 - 1

ELECTRICAL TIPS...................................................................................................12 - 1

INDICATOR LIGHTS.................................................................................................12 - 2

SOLID STATE CONTROLLER TIPS.........................................................................12 - 3

FROZEN IQF PRODUCT..........................................................................................12 - 3

Manual #16887 5/08 rev 4/09

1 - OWNERS RESPONSIBILITY

It is the owner’s responsibility to:

• Insure the Broaster® VF-2, VF-3i Fryer

is properly maintained.

• Allow only properly trained personnel to

operate, clean and maintain a Broaster®

VF-2, VF-3i Fryer.

• Schedule and maintain documentation

that the appropriate inspection and

maintenance of the Fire Suppression

system has been completed.

• Retain this manual for future reference.

• Insure main power supply is discon-

nected before the unit is serviced.

• Ensure that all safety devices are intact

and the operation manual is included

with the unit when you sell, trade, dispose of, or give away your Broaster®

VF-2, VF-3i Fryer.

If you need replacement manuals, contact

an authorized Broaster Company representative or The Broaster Company at 608/365-

0193.

The Customer Service Department at The

Broaster Company should be contacted at

the time of sale or disposal of the Broaster®

VF-2, VF-3i Fryer so records may be

updated.

• Insure a proper surface is provided for

the Broaster® VF-2, VF-3i Fryer to sit

on.

• Keep the louvres in both the front and

the rear of unit free from obstructions.

• Ensure that access is not obstructed to

the fire suppression system. Fire suppression status can be monitored by

viewing through the right side panel

access hole.

Manual #16887 5/08

1 - 1

2 - INSTALLATION

As you progress through the set-up of your VF-2, VF-3i fryer, refer to Chapter 4, GETTING TO

KNOW YOUR BROASTER® VF-2, VF-3i FRYER for part descriptions and locations.

LOCATION

For convenience and speed, location of the

unit should be given careful consideration.

If possible, locate the unit so the flow of

cooked product is in a straight line from storage, in and out of the unit and to the customer. Landing tables should be provided

on at least one side of the unit.

• A flat, level, stable surface capable of

supporting an additional weight of 200

lbs is required for the safe operation of

this unit.

• To avoid splashing of hot liquid, unit

must be restrained to prevent tipping.

• Provision must be made to eliminate

movement of the unit which might cause

strain on electrical connections.

• DO NOT install unit where traffic areas

are on either side or in back of unit.

• DO NOT install unit where the louvres in

either the front or the rear are blocked or

void of ventilation.

• DO NOT install unit where access to fire

suppression system is blocked. Fire

suppression activation is located on front

panel. Fire suppression status can be

monitored by viewing through the right

side panel access hole.

CLEARANCES

Recommended clearances are:

Left Side: 0”

Rear: 2”

Right Side: 0” Note: You must be able to

access the right side panel periodically for

inspection and service.

GENERAL REQUIREMENTS

• When installing or servicing the unit,

always check the dataplates, located

toward the rear of the unit. This will

make certain proper parts are used and

the correct service rendered. DO NOT

apply a voltage to this unit other than

that shown on the dataplate. If in doubt,

consult your local power company.

• A remote circuit breaker or fuse should

be installed in main power supply

located in a path of exit and clearly identified.

• The VF-2 is 19 in. wide by 24.25 in. tall

by 20.12 in. deep.

• The VF-3i is 23 in. wide by 27 in. tall by

24.5 in. deep.

• Installation must conform to local codes

or in their absence with National codes

UL 197, UL 197SB, NFPA 70 for electrical, NFPA 96 for ventilation, NFPA 17A

for Wet Chemical Extinguishing Systems, also Canadian Electrical CSA

22.2.

• Unit to be sealed to countertop (ie. silicone) or elevate on legs with optional

platform.

2 - 1

Manual #16887 5/08

UNPACKING

FIRE SUPPRESSION ACTIVATION

1. Remove external cardboard packaging.

CAUTION: DO NOT cut cardboard

with utility knife. Damage to unit could

result.

2. Open Access Door by lifting Access

Door Latch and turning counter-clockwise. Remove Cooking Pot cardboard

retainer.

3. Remove Cooking Basket, Basket Platform, and cardboard/styrofoam seperator from Cooking Pot.

4. Remove tape from Air and Grease Filters.

5. Raise the Element by placing Element

Arm above Element Retainer and

remove the Cooking Pot.

6. Follow cleaning instructions as outlined

in CLEANING, Section 10 of this manual.

DANGER: DO NOT apply power to

unit until completing this procedure.

Failure to do so would leave the unit without

Fire Suppression capability.

7. To gain access to the Fire Suppression

system remove Electrical Control

Access Panel. Remove retaining

screw, slide the panel up, then pull the

bottom toward the outside of the unit.

8. Inside the cooking area, verify that

there is tension on the cable connected

to the Fusible Link.

CAUTION: If there is no tension on

the link, removing the Fire Suppression Arming Pin will activate the Fire Suppression System. Contact authorized

Broaster Company representative.

9. Verify the Fire Extinguisher gauge registers in the green.

DANGER: If the gauge does not regi-

ester green, DO NOT operate the unit.

The Fire Suppression System will not function to a satisfactory level. Contact authorized Broaster Company representative.

10. Inside the Electrical Control area,

11. Remove Fire Suppression Arming Pin

12. Replace the Electrical Control Access

2 - 2

Manual #16887 5/08

locate strap securing Fire Suppression

Arming Pin. Cut and remove the strap.

and let hang from connected chain.

The Fire Suppression System is now

active.

Panel and retaining screw.

ELECTRICAL CHARACTERISTICS

ELECTRICAL CONNECTIONS

The unit is available for 120/240 VAC or

120/208 VAC applied voltage, 30 amp,

60Hz, 1 phase electrical connection in the

USA and Canada. (4 wire with neutral and

ground)

• When installed, the unit is to be field

wired and must be electrically grounded

in accordance with local codes, or in the

absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, or the

Canadian Electrical Code, CSA C22.2,

as applicable.

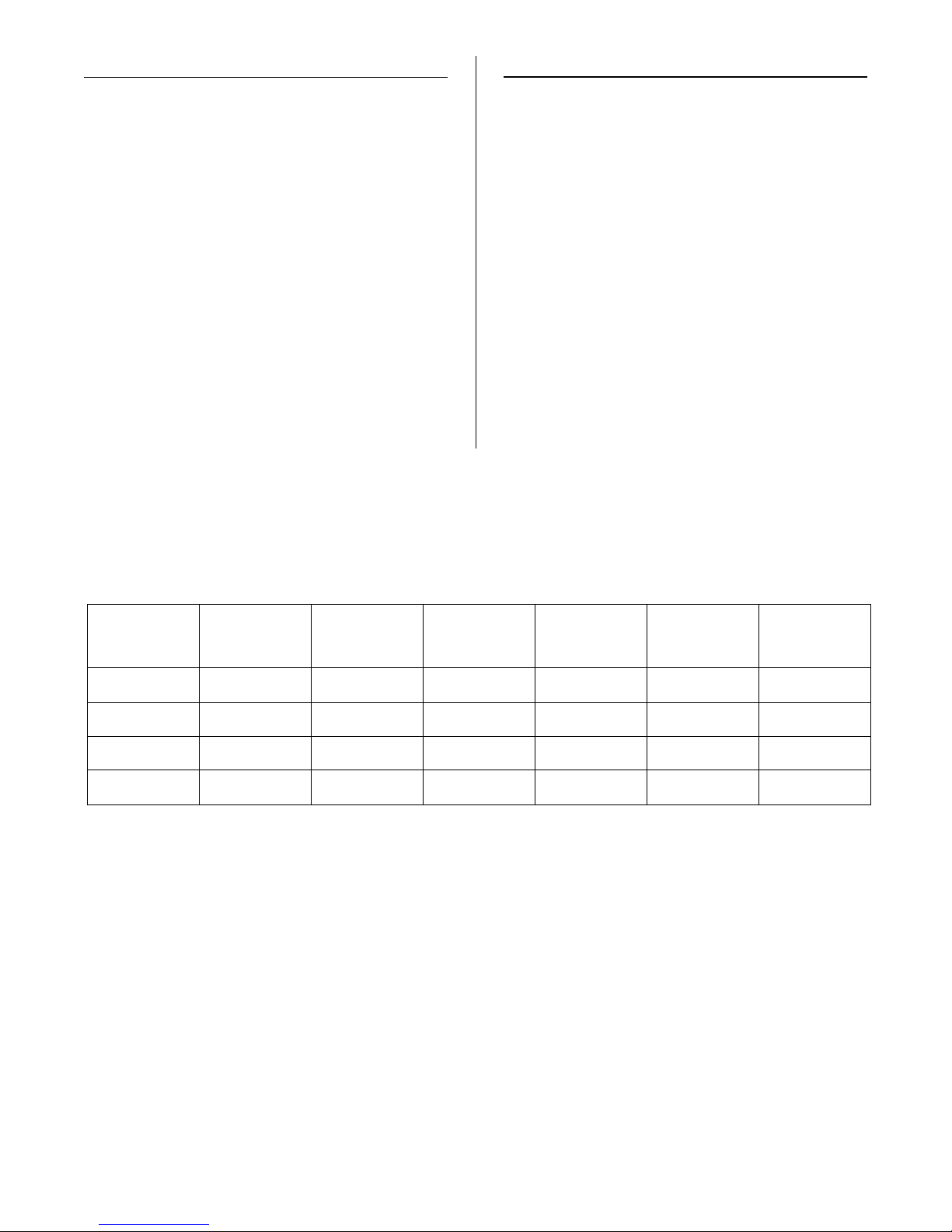

ELECTRICAL AMPERAGE RATING

Applied voltage should match dataplate

listed voltage.

The electrical schematics can be found on

pages 4 thru 7 of this section.

Input

Voltage

120/240 23 23 --- --- --- --120/208 27 27 --- --- --- ---

220 --- --- 21 28 --- --230 --- --- --- --- 22 29

VF2

Domestic

VF3i

Domestic

VF2

Export

VF3i

Export

VF2

CE

VF3i

CE

2 - 3

Manual #16887 5/08

Loading...

Loading...