Broaster 2400XP Installation Manual

“An American Tradition Since 1954!”

MODEL 2400XP & 2400CE

BROASTER

®

PRESSURE FRYER

OPERATION MANUAL

Be sure ALL installers read, understand, and have access to this manual at all times.

Printed in U.S.A.

Broaster®, Broasted®, Broasted Chicken®, Broaster Foods®. and Broasterie® are registered trademarks.

Usage is available only to licensed opertors with written authorization from The Broaster Comany.

The Broaster Company

2855 Cranston Road, Beloit, WI 53511-3991

608/365-0193 www.broaster.com

Manual #16285 Rev 5/10

Copyright 2005 The Broaster Company

FOR YOUR SAFETY

Do not use or store gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

WARNING: Improper installation, adjustments, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

For the sake of safety and clarity, the following words used in this manual are defined as follows:

DANGER: Indicates an imminently hazardous situation which, if not avoided, could result

in serious injury or death.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result

in serious injury or death.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, could result in

minor injury, property damage or both.

All adjustments and repairs shall be made

by an authorized Broaster Company representative.

If there is a power failure, turn cook/filter

switch OFF. On the Model 2400GH, also

slide switch on gas valve OFF. DO NOT

attempt to operate unit during a power failure.

2400GH: Post, in prominent locations,

instructions to be followed in the event that

the user smells gas. This information can

be obtained from your local gas supplier.

WARNING: Failure to read and

understand this manual completely

could result in serious injury or death. Be

sure ALL operators read, understand and

have access to this manual at all times.

WARNING: Rags or papers containing

cooking oil can catch fire if exposed to

heat. Laundering will not remove the oil. Dispose of all oil-soiled papers and rags in a trash

container that is in a ventilated area away from

all cooking equipment or other heat sources

such as direct sunlight.

WARNING: DO NOT operate unit without

filter pan and filter pan cover in its proper

position. Filter pan cover must be wiped clean

after each filtering cycle.

Manual #16285 8/05 Rev 5/10

NEW OWNER OR RELOCATION NOTIFICATION

If you are a new owner of a used unit or

have relocated your Model 2400 Broaster

Pressure Fryer, please take a minute to fill

out one of the cards below. It is NOT a warranty registration.

PLEASE PRINT: 2

Business Name:

®

This card enables The Broaster Company to

better serve you and keep you informed of

changes in equipment, condiments, or service bulletins.

Address:

City: State: Zip Code:

Owner’s Name:

County:

Phone:

Model:

Serial Number:

PLEASE PRINT: 1

Business Name:

Address:

City: State: Zip Code:

Owner’s Name:

County:

Phone:

Model:

Serial Number:

Manual #16285 8/05 Rev 9/05

The Broaster Company

2855 Cranston Road

Beloit, WI 53511

The Broaster Company

2855 Cranston Road

Beloit, WI 53511

See Stan for correct

layout and contents.

See Stan for correct

layout and contents.

Manual #16285 8/05

TABLE OF CONTENTS

1 - OWNER’S RESPONSIBILITY ....................................................................................1 - 1

2 - INSTALLATION INSPECTION....................................................................................2 - 1

GAS CONVERSION.................................................................................................2 - 1

USA & Canada.................................................................................................2 - 1

European Union ...............................................................................................2 - 1

3 - GETTING TO KNOW YOUR BROASTER® PRESSURE FRYER.............................3 - 1

4 - PRE-COOKING PREPARATIONS..............................................................................4 - 1

O-RING LUBRICATION............................................................................................4 - 1

COVER CHECK.......................................................................................................4 - 1

COOKING OIL..........................................................................................................4 - 1

Liquid Oil ..........................................................................................................4 - 1

Solid Shortening...............................................................................................4 - 1

OIL LEVEL................................................................................................................4 - 2

FOOD AND CONDIMENTS .....................................................................................4 - 2

2400GH LIGHTING INSTRUCTIONS......................................................................4 - 3

Start Up ............................................................................................................4 - 3

Shut Down........................................................................................................4 - 3

5 - SOLID STATE CONTROL PANEL .............................................................................5 - 1

DUAL DISPLAY FAMILIARIZATION.........................................................................5 - 1

CONTROLLER BASIC PROGRAMMING................................................................5 - 2

Normal Operating Mode

Set Temperature...............................................................................................5 - 2

Set Time...........................................................................................................5 - 2

Set AUTO COMP (Automatic Time Compensation).........................................5 - 2

Read Actual Temperature.................................................................................5 - 2

Reset Cycle Counter........................................................................................5 - 2

Multi-Program Feature

Preset Cook Mode............................................................................................5 - 3

Chose Preset Cook Cycle................................................................................5 - 3

Programming Procedure (Preset Mode) ..........................................................5 - 3

Change Cook Time...........................................................................................5 - 3

Change Cook Temperature ..............................................................................5 - 3

Activate/Deactivate Auto Comp........................................................................5 - 3

Advance To Next Preset ..................................................................................5 - 3

6 - COOKING WEIGHT, TEMPERATURE AND TIME.....................................................6 - 1

FRESH PRODUCTS................................................................................................6 - 1

FROZEN IQF CHICKEN...........................................................................................6 - 2

Manual #16285 8/05 Rev 9/05

7 - PRODUCT PREPARATION AND COOKING.............................................................7 - 1

PREPARING GENUINE BROASTER CHICKEN®...................................................7 - 1

COOKING.................................................................................................................7 - 1

MSG FREE CONDIMENT LIST FOR FRESH PRODUCT.......................................7 - 2

Broaster® Marinades........................................................................................7 - 2

Broaster® Coatings and Batters.......................................................................7 - 2

Other Broaster Foods® Recipes ......................................................................7 - 3

8 - COOKING OIL CARE AND FILTERING.....................................................................8 - 1

OIL CARE..............................................................................................................8 - 1

Oil Quality.................................................................................................8 - 1

Temperature.............................................................................................8 - 1

Volume .....................................................................................................8 - 1

Type of Coating and Seasoning Used......................................................8 - 1

Amount of Care and Filtering Oil Receives..............................................8 - 1

FILTERING ............................................................................................................8 - 1

FILTERING HINTS ................................................................................................8 - 3

9 - CLEANING..................................................................................................................9 - 1

COOKING WELL...................................................................................................9 - 1

FOOD BASKET.....................................................................................................9 - 2

UNIT SURFACES..................................................................................................9 - 2

CONDENSATE PAN..............................................................................................9 - 2

SLIDE RODS.........................................................................................................9 - 2

COVER..................................................................................................................9 - 2

SPLASH SHIELD...................................................................................................9 - 2

GAS SPRING COVER...........................................................................................9 - 3

PROBE GUARD....................................................................................................9 - 4

MINIMUM PREVENTIVE MAINTENANCE REQUIREMENTS..............................9 - 5

10 - NIGHTLY SHUTDOWN...........................................................................................10 - 1

11 - SEASONAL SHUTDOWN ......................................................................................11 - 1

12 - TROUBLESHOOTING............................................................................................12 - 1

ELECTRICAL TIPS..............................................................................................12 - 1

SOLID STATE CONTROLLER TIPS ...................................................................12 - 2

GAS TIPS............................................................................................................12 - 3

COVER, YOKE, AND LIFT TIPS.........................................................................12 - 4

PRESSURE SYSTEM TIPS................................................................................12 - 4

PRODUCT TIPS..................................................................................................12 - 5

Fresh Chicken..............................................................................................12 - 5

Frozen IQF Chicken.....................................................................................12 - 6

FILTERING TIPS .................................................................................................12 - 7

Manual #16285 8/05 Rev 11/08

1 - OWNERS RESPONSIBILITY

It is the owner’s responsibility to:

• Insure the Broaster® Pressure Fryer is

properly maintained.

• Insure all safety devices and warning

signs are in their original location and

are legible.

• Allow only properly trained personnel to

operate, clean and maintain a Broaster®

Pressure Fryer.

• Retain this manual for future reference.

• Insure main power supply is disconnected before the unit is serviced.

• When you sell, trade, dispose of or give

away your Broaster® Pressure Fryer,

you must make sure that all safety

devices and warning signs are intact and

legible and the operation manual is

included with the unit.

If you need replacement warning signs or

manuals, contact an authorized Broaster

Company representative or The Broaster

Company at 608/365-0193.

The Customer Service Department at The

Broaster Company should be contacted at

the time of sale or disposal of the Broaster®

Pressure Fryer so records may be updated.

• 2400GH: Keep burner area free and

clear of all combustible materials.

• 2400GH: DO NOT obstruct exhaust flue

or open area around bottom of unit at the

front, back and sides which would

restrict the flow of combustion and ventilation air .

Manual #16285 8/05 Rev 9/05

1 - 1

2 - INSTALLATION INSPECTION

Before operating unit, be sure installation

meets all requirements in the Installation

Manual provided with your unit.

CAUTION: Follow cleaning instruc-

tions as outlined in this manual before

operating the first time. See section 10 CLEANING.

• A remote circuit breaker or fuse should

be installed in the main power supply

located in a path of exit and clearly identified.

• To avoid splashing of hot liquid, unit

must be restrained to prevent tipping.

This can be done by installing the unit in

a battery of appliances, in an alcove or

with adequate ties.

• See Safety Relief Valve under GET-

TING TO KNOW YOUR BROASTER®

PRESSURE FRYER. DO NOT install

unit where traffic areas are on either side

or in back of unit.

2400GH:

WARNING: Electrical Grounding

Instructions - The Model 2400GH is

equipped with a three-prong (grounding)

plug for your protection against shock hazard and should be plugged directly into a

properly grounded three-prong receptacle.

DO NOT cut or remove grounding prong

from this plug.

• A gas shutoff valve, installed in gas sup-

ply line, should be located in a path of

exit and clearly identified.

Gas Conversion

USA & Canada

• Contact your local Broaster Company

representative for converting from one

type of gas to another.

European Union

• Units manufactured for use in the Euro-

pean Union are not convertible from one

type of gas to another.

2 - 1

Manual #16285 8/05 Rev 9/05

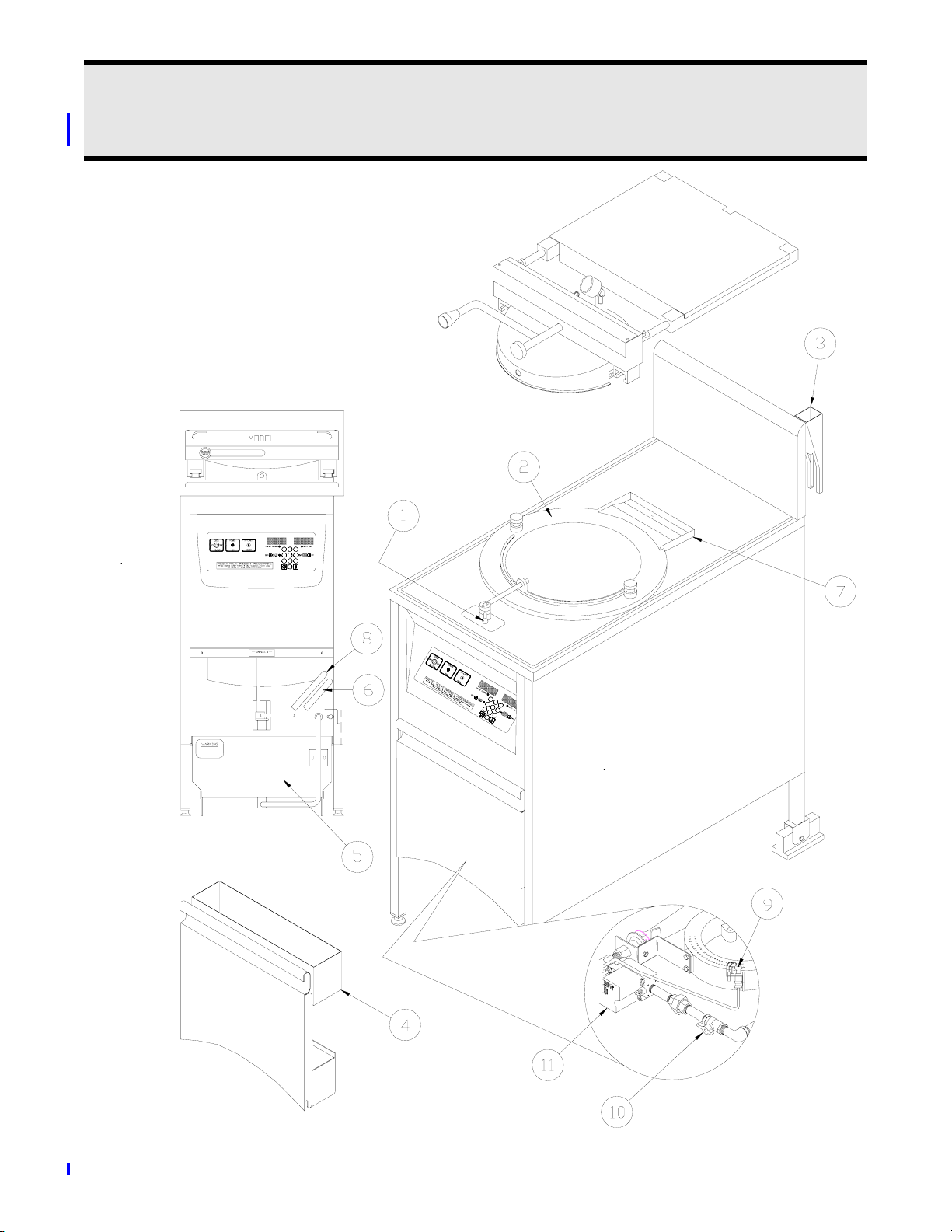

3 - GETTING TO KNOW YOUR

®

BROASTER

PRESSURE FRYER

BEFORE OPERATINGCHECK OIL LEVELCAUTION!

2

63415

987

0

C

A

U

T

I

O

N

!

C

H

E

C

K

O

I

L

L

E

V

E

L

B

E

F

O

R

E

O

P

E

R

A

T

I

N

G

1

2

4

3

5

7

6

8

9

0

For Gas

Models Only

3 - 1

Manual #16285 8/05 Rev 9/05

1. Pressure Regulating Valve: Opens

and closes pressure regulating valve.

When cover and valve are CLOSED,

this valve seals the cooking well allowing pressure to build up. Valve is preset to maintain pressure at 12 - 15 PSI

during a cooking cycle. When OPEN,

all pressure is exhausted and timer

stops timing.

2. Cooking Well: Holds cooking oil.

3. Basket Lifter Holder: Holds basket

lifter when not in use.

4. Condensate Pan: Holds condensation

drained from exhaust tank. Check liquid level several times daily. Empty as

needed.

WARNING: Water and hot oil DO

NOT mix. DO NOT pour contents of

condensate pan into cooking well or filter

pan. Hot oil could splash causing serious

burns.

top liquid toward Condensate Pan.

9. Pilot Burner: A small flame used to

ignite the main burner.

10. Manual Gas Shut Off Valve: Shuts off

gas flow to the gas valve. Gas will flow

when handle is in line with pipe. Turning handle crosswise to the pipe will

stop gas flow.

1 1. Gas V alve: Regulates gas supply. The

valve has a two position switch: OFF

to stop all gas flow and ON allows gas

flow to pilot and main burner as

needed.

5. Filter Pan: Holds filter components

and filtering compound used to filter

hot oil. Pan and Cover must be in

place during normal operation.

CAUTION: HOT Surfaces!

WARNING: Hot shortening! DO NOT

use this container to transport hot

shortening. Hot shortening could splash

causing serious burns.

6. Exhaust Drain Tube: Directs condensation from the exhaust tank into condensate pan.

7. Countertop Drip Pan: Collects condensate from the open cooking well and

directs it to the Drip Pan Drain Line.

Drip Pan is removable for cleaning.

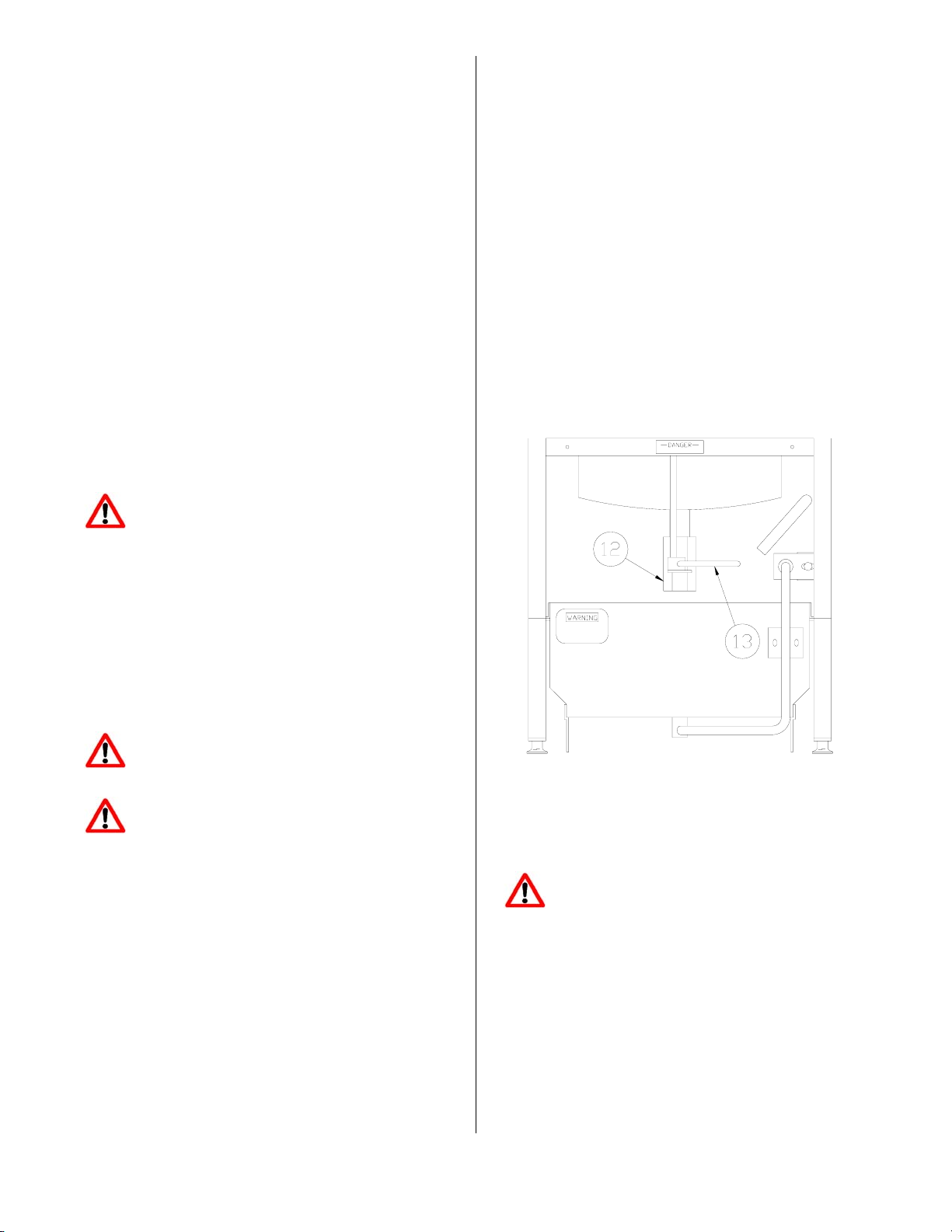

12. Drain Valve: Used to drain cooking oil

from cooking well into filter pan or container made for handling hot oil.

DANGER: Never drain oil unless

cook/filter switch is OFF and pressure

regulating valve is OPEN. Hot oil could

spray out under pressure causing serious

burns.

13. Drain V alve Handle: Opens and closes

drain valve. When handle is horizontal, valve is closed. When vertical,

valve is open.

8. Drip Pan Drain Line: Directs counter-

Manual #16285 8/05

3 - 2

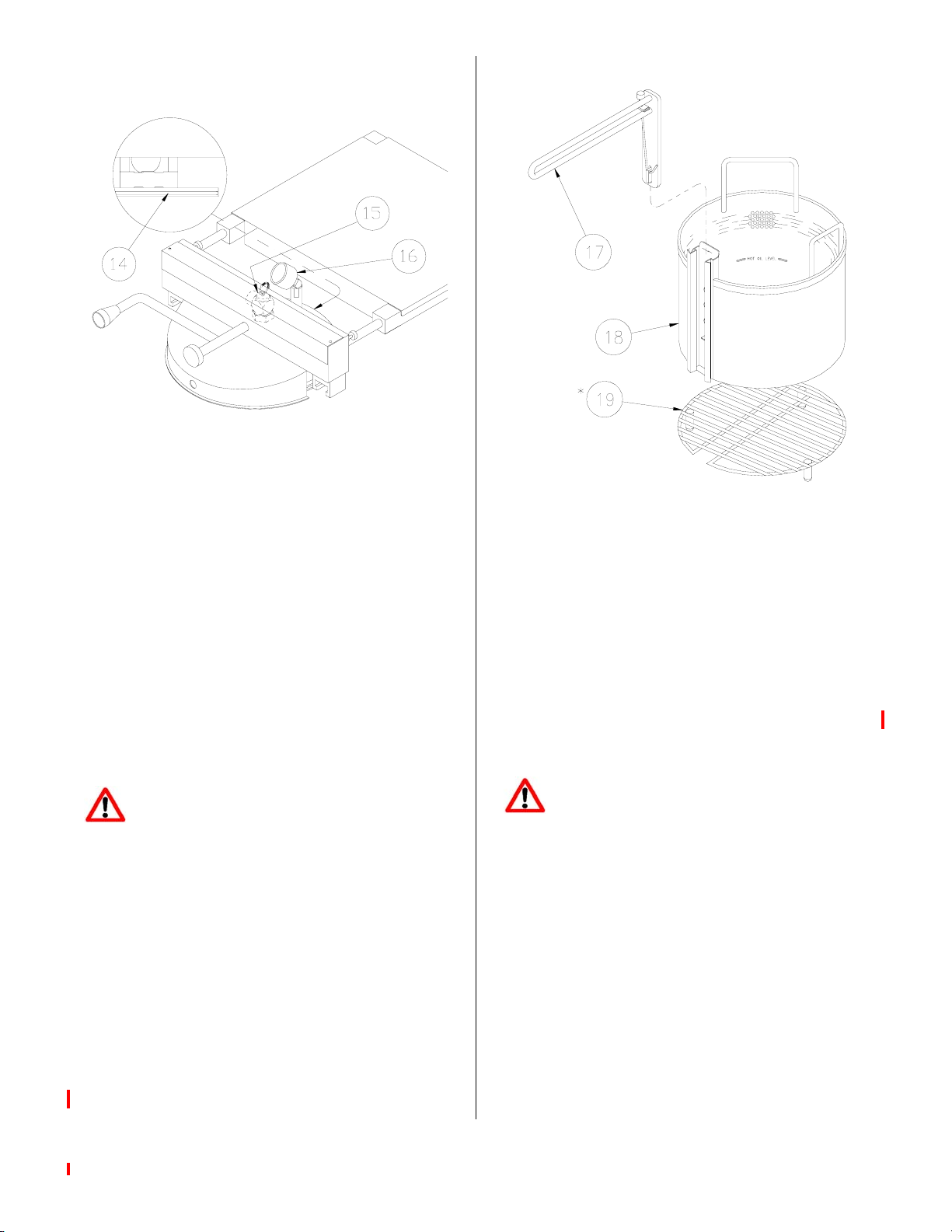

14. Cover O-Ring: Forms a seal when

cover is lowered into the cooking well.

15. Safety Relief Valve: This valve will

open in the event pressure in the cooking well meets relief pressure of valve.

A properly installed valve has the outlet

facing toward rear corner of the countertop. DO NOT use valve to release

pressure at the end of a cooking cycle.

If valve leaks during normal operation,

DO NOT operate your unit until valve is

replaced by an authorized Broaster

Company representative.

WARNING: Keep away from safety

relief valve opening without heat and

steam protective apparel. Escaping steam

could cause serious burns.

Test valve once a month. Also test

before and after an extended period of

non-service. Using a hot mitt, lift valve

handle during a cook cycle until pressure is released from cooking well.

Allow valve to snap closed.

17. Basket Lifter: Used to raise and lower

food basket into the cooking well.

18. Food Basket: Holds product for cooking. Indicates proper level of oil at

operating temperature.

19. Model 2400GH Basket Support Grate:

Used in the bottom of the cooking well

to support the basket w/o feet at the

proper height.

WARNING: Basket, lifting handle and

basket support grate are hot, use

gloves when handling. Hot surfaces could

cause serious burns.

16. Pressure Gauge: Indicates pressure

within the cooking well. Normal operating pressure is 12-14 PSI.

Manual #16285 8/05 Rev 9/08

* Used on 2400GH only

3 - 3

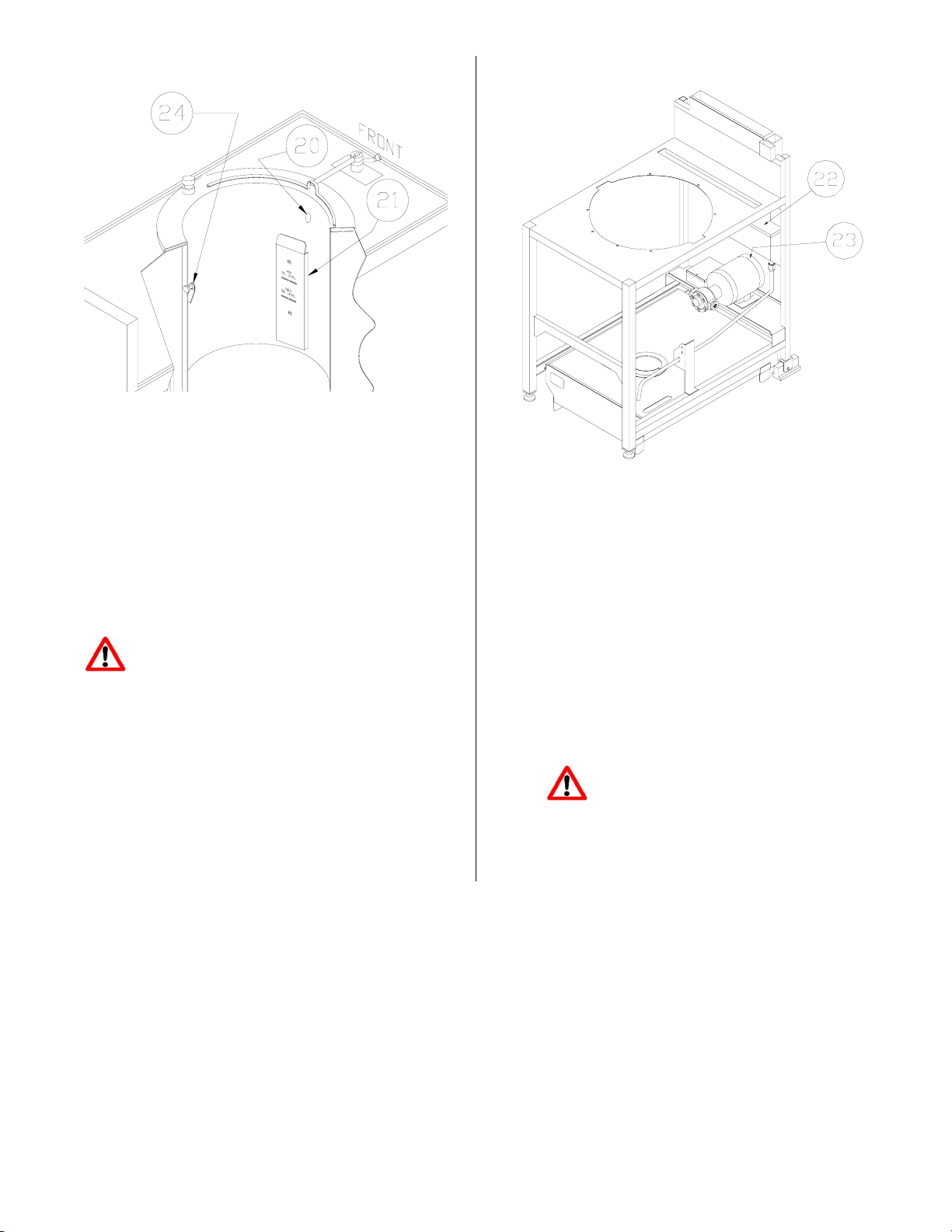

20. Pressure Port: When cover is

CLOSED while cooking, all steam

passes through this port into the pressure regulating valve.

21. Capillary Guard: This guard protects

temperature sensor probe, hi-limit bulb

and capillary from damage. Includes

hot and cold oil level indicator.

CAUTION: Check oil level before

turning cook/filter switch to COOK.

22. Exhaust Tank: Steam and vapors are

exhausted through this tank.

23. Filter Pump and Motor: Used to return

oil to cooking well when filtering.

24. Basket Rest: Used to hold and tilt basket for draining when removing cooked

product from oil or loading product

before lowering into oil.

CAUTION: DO NOT rest basket

on top flange of cooking well.

Damage to area in contact with o-ring

can cause leaking under pressure or oring failure.

3 - 4

Manual #16285 8/05

Loading...

Loading...